Nordyne Q5RD, Q5RD024K, Q5RD030K, Q5RD036K, Q5RD042K Installation Manual

...

Q5RD SERIES

13 SEER

USER’s MANUAL & INSTALLATION INSTRUCTIONS

Single Package Heat Pump - Single Stage, R-410A

Please read this information thoroughly and become familiar with the capabilities

and use of your appliance before attempting to operate or maintain this unit.

Keep this literature where you have easy access to it in the future. If a problem

occurs, check the instructions and follow recommendations given. If these

suggestions don’t eliminate your problem, call your servicing contractor.

These instructions are primarily intended to assist qualifi ed individuals

experienced in the proper installation of this appliance. Some local codes

require licensed installation/service personnel for this type of equipment.

Read all instructions carefully before starting the installation.

DO NOT DESTROY. PLEASE READ CAREFULLY AND

KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

IMPORTANT

USER INFORMATION

About the Heat Pump ................................... 3

Operating Instructions ................................ 3

Cooling Operation .................................... 3

Heating Operation ....................................3

Emergency Heat ......................................3

Defrost .....................................................3

System Shutdown .................................... 3

INSTALLER INFORMATION

Important Safety Information ......................4

General Information .....................................4

Before You Install this Unit ..........................4

Locating the Heat pump ............................ 4

Minimum Clearances .................................5

Service Access Clearance ......................5

Clearances to Combustibles ...................5

Air Duct System .........................................5

Heat Pump Installation .................................5

Unpacking the Unit ....................................5

Installing Return & Supply Air Collars ........5

Supply Duct ............................................5

Return Duct .............................................6

Connecting Return & Supply Air

Flexible Ducts .............................................6

Locating & Installing the Return Air

Assembly .................................................... 6

Locating & Installing the Supply

Dampers ..................................................... 7

Condensate Drainage .................................7

Electrical Connections .................................8

Pre - Electrical Checklist.............................8

Line Voltage ................................................8

Overcurrent Protection ............................... 9

Blower Speed ............................................9

2 - Speed Outdoor Fan Motor ..................9

Defrost Cycle Control .................................9

Ambient Sensor Mounting 10

Thermostat Connections ..........................10

Electric Heat Package ..............................11

Grounding .................................................11

Startup & Adjustments...............................11

Pre - Start Checklist .................................11

Start - Up Procedure ................................11

Air Circulation ........................................11

System Heating .....................................11

System Cooling ......................................11

IMPORTANT SAFETY INFORMATION

Safety markings are used frequently throughout

this manual to designate a degree or level

of seriousness and should not be ignored.

WARNING indicates a potentially hazardous

situation that if not avoided, could result in

personal injury or death. CAUTION indicates

a potentially hazardous situation that if not

avoided, may result in minor or moderate injury

or property damage.

Short Cycle Protection ...........................12

Emergency Heat ....................................12

Defrost Test Procedure .............................12

Anti Short Cycle Timer Test ......................12

Heating Mode ........................................12

Cooling Mode .........................................12

Adjustment of Refrigerant Charge ............12

Charging an R-410A Unit in AC Mode

with Outdoor Temp above 65° F ...............12

Charging R-410A Unit in Heat Mode .......13

Component Functions ...............................13

Low Pressure Switch ................................13

High Pressure Switch ...............................13

Unit Maintenance ........................................13

Figures & Tables .........................................13

Figure 9. - Unit Dimensions ....................13

Table 4. - Q5RD Physical Data ...............13

Charging Tables - Cooling Mode ..............14

Table 5. - Q5RD-X24K (2 Ton Units) .......14

Table 6. - Q5RD-X30K (2.5 Ton Units) ....14

Table 7. - Q5RD-X36K (3 Ton Units) .......15

Table 8. - Q5RD-X42K (3.5 Ton Units) ....15

Table 9. - Q5RD-X48K (4 Ton Units) .......16

Table 10. - Q5RD-X60K (5 Ton Units) .....16

Charging Tables - Heating Mode ..............17

Table 11. - Q5RD-X24K (2 Ton Units) .....17

Table 12. - Q5RD-X30K (2.5 Ton Units) ..17

Table 13. - Q5RD-X36K (3 Ton Units) .....18

Table 14. - Q5RD-X42K (3.5 Ton Units) ..18

Table 15. - Q5RD-X48K (4 Ton Units) .....19

Table 16. - Q5RD-X60K (5 Ton Units) .....19

Wiring Diagrams .......................................20

Figure 10. - 2 & 2.5 Ton Units .................20

Figure 11. - 3,4, & 5 Ton Units ................21

Figure 12. - Thermostat Connections .....22

Installation / Performance Checklist .........24

2

USER INFORMATION

ABOUT THE HEAT PUMP

Your heat pump is a unique, all weather comfortcontrol appliance that will heat and cool your

home year round and provide energy saving

comfort. It’s an unknown fact that heat is always

in the air, even when the outside temperature is

below freezing. The heat pump uses this basic

law of physics to provide energy saving heat

during the winter months. For example, If the

outdoor temperature is 47° F (8° C), your heat

pump can deliver approximately 3.5 units of

heat energy per each unit of electrical energy

used, as compared to a maximum of only 1

unit of heat energy produced with conventional

heating systems.

In colder temperatures, the heat pump performs

like an air conditioner run in reverse. Available

heat energy outside the home is absorbed by

the refrigerant and exhausted inside the home.

This effi cient process means you only pay for

“moving” the heat from the outdoors to the indoor

area. You do not pay to generate the heat, as is

the case with more traditional furnace designs.

During summer, the heat pump reverses the fl ow

of the heat-absorbing refrigerant to become an

energy-effi cient, central air conditioner. Excess

heat energy inside the home is absorbed by the

refrigerant and exhausted outside the home.

Operating Instructions

Cooling Operation

1. Set the thermostat’s system mode to COOL

or AUTO and change the fan mode to AUTO.

See Figure 1.

2. Set the temperature selector to the

desired temperature level. The outdoor fan,

compressor, and blower motor will all cycle

on and off to maintain the indoor temperature

at the desired cooling level.

minutes following a previous operation or the

interruption of the main electrical power.

Emergency Heat

Some thermostats may include a system mode

called EM HT or AUX HT, etc. This is a backup heating mode that should only be used if a

problem is suspected. With the mode set to EM

HT, etc., the compressor and outdoor fan will

be locked off and supplemental heat (electric

resistance heating) will be used as a source

of heat (if installed). Sustained use of electric

resistance heat in place of the heat pump will

result in an increase in electric utility costs.

Defrost

During cold weather heating operation, the

outdoor unit will develop a coating of snow

and ice on the heat transfer coil. This is normal

and the unit will defrost itself. This unit features

Demand Defrost that monitors ambient and coil

temperatures to regulate the defrost function

accordingly.

At the beginning of the defrost cycle, both the

outdoor condenser fan and compressor will

turn off. After approximately 30 seconds, the

compressor will turn on and begin to heat the

outdoor coil causing the ice and snow to melt.

NOTE: While the ice and snow is melting, steam

may rise from the outdoor unit as the warm coil

causes the melting frost to evaporate. When

defrost is completed, the outdoor fan motor will

start, and the compressor will turn off again. In

approximately 30 seconds the compressor will

start up again and continue normal operation.

System Shutdown

Change the thermostat’s system mode to OFF

and the fan mode to AUTO (See Figure 1).

NOTE: The system will not operate, regardless

of the temperature selector setting.

Heating Operation

1. Set the thermostat’s system mode to HEAT

or AUTO and change the fan mode to AUTO.

See Figure 1.

2. Set the temperature selector to the desired

temperature level. The compressor, outdoor

fan, and blower motor will cycle on and off to

maintain the indoor temperature at the desired

heating level.

NOTE: If the temperature level is re-adjusted, or

the system mode is reset, the fan and compressor

in the outdoor unit may not start immediately. A

protective timer circuit holds the compressor

and the outdoor fan off for approximately three

Fan

Mode

Figure 1. Digital Thermostat

System

Mode

Temperature

Selector

3

INSTALLER INFORMATION

IMPORTANT SAFETY INFORMATION

WARNING:

The information listed below

must be followed during the

installation, service, and operation

of this unit. Unqualifi ed individuals

should not attempt to interpret

these instructions or install this

equipment. Failure to follow safety

recommendations could result in

possible damage to the equipment,

serious personal injury or de

• The installer must comply with all local

codes and regulations which govern the

installation of this type of equipment. Local

codes and regulations take precedence over

any recommendations contained in these

instructions. Consult local building codes

and the National Electrical Code (ANSI CI)

for special installation requirements.

• This equipment contains liquid and gaseous

refrigerant under high pressure. Installation or

servicing should only be performed by qualifi ed

trained personnel thoroughly familiar with this

type equipment.

• All electrical wiring must be completed in

accordance with local, state and national

codes and regulations and with the National

Electric Code (ANSI/NFPA 70) or in Canada

the Canadian Electric Code Part 1 CSA C22.1.

• Follow all precautions in the literature, on tags,

and on labels provided with the equipment.

Read and thoroughly understand the

instructions provided with the equipment prior

to performing the installation and operational

checkout of the equipment.

GENERAL INFORMATION

Single packaged heat pumps are ready for easy

and immediate installation and can be readily

connected into the high static duct system of a

home. This unit is completely assembled, wired,

and run tested at the factory. This heat pump

is designed for outdoor installation only. The

only connections needed for installation are the

supply and return ducts, the line voltage, and

thermostat wiring. Use of components other than

those specifi ed may invalidate ARI Certifi cation,

Code Agency Listing, and limited warranty on

the air conditioner.

4

ath

Before You Install this Unit

The cooling load of the area to be conditioned

must be calculated and a system of the proper

capacity selected. It is recommended that the

area to be conditioned be completely insulated

and vapor sealed.

Check the electrical supply and verify the

power supply is adequate for unit operation.

If there is any question concerning the power

supply, contact the local power company.

All units are securely packed at the time of

shipment and upon arrival should be carefully

inspected for damage prior to installing the

equipment at the job site. Verify coil fi ns are

straight. If necessary, comb fi ns to remove

.

fl attened or bent fi ns. Claims for damage

should be fi led immediately with the carrier.

Please consult your dealer for maintenance

information and availability of maintenance

contracts. Please read all instructions before

installing the unit.

Locating the Heat Pump

• Survey the job site to determine the best

location for mounting the outdoor unit. Select

a solid, level position, preferably on a concrete

slab, slightly above the grade level, and parallel

to the home. If possible, select a site for the unit

that is as close as possible to the proposed

return grille location. DO NOT PLACE UNIT

UNDER THE HOME.

• The unit should be located with consideration of

minimizing the length of the supply and return

ducts. If practical, place the heat pump and

its ducts in an area where they will be shaded

from the afternoon sun, when the heat load is

greatest.

• The length of the supply and return ducts

should be kept to a minimum with no sharp

radius bends.

• Overhead obstructions, poorly ventilated

areas, and areas subject to accumulation of

debris should be avoided. The hot condenser

air must be discharged up and away from the

home, and if possible, in a direction with the

prevailing wind. Do not place the unit in a

confi ned space. See Figure 9 & Table 4 (page

13) for unit dimensions.

• Suffi cient clearance for unobstructed airfl ow

through the outdoor coil must be maintained

in order to achieve rated performance. See

Figure 2 (page 5) for minimum clearances to

obstructions.

• Consideration should also be given to

availability of electric power, service access,

noise, and shade.

Minimum Clearances

Minimum clearances MUST be maintained from

adjacent structures to provide room for proper

servicing and air circulation. DO NOT install unit

in a confi ned or recessed area that will allow

discharge air from the unit to re-circulate into the

condenser air inlet, through the coil. See Figure 2.

Service Access Clearance:

Blower access panel side ...........................24”

Electrical compartment access panel side .. . 1 2”

Clearance between overhang and top

of unit ..................................................... 72”

Clearance around condenser coil area to

wall or shrubs (excludes duct panel side) ...12”

Clearances to Combustibles:

Combustible base - wood or Class A, B, or C

roof covering material ................................. 0”

Supply & return air ducts ............................. 0”

Duct connection side ................................... 0”

• For highly resistive duct systems it may be

necessary to add an additional return air

duct and or supply to achieve maximum

performance and prevent coil icing and

refrigerant fl ood back.

• The heat pump system will not cool or

heat the home if air is lost to the outside

through leaks in the duct system. Ducts

that are collapsed or restricted by foreign

objects will also prevent adequate air fl ow.

• All duct work passing through unconditioned

space must be properly insulated to minimize

duct losses and prevent condensation.

Use insulation with an outer vapor barrier.

Refer to local codes for insulation material

requirements.

HEAT PUMP INSTALLATION

Unpacking the Unit

It is recommended that the unit be unpacked

at the installation site to minimize damage due

to handling.

12"

24"

TO BE

TOP OF UNIT

UNOBSTRUCTED

0"

Figure 2. Minimum Unit Clearances

Air Duct System

Air ducts should be installed in accordance with

the standards of the National Fire Protection

Association “Standard for Installation of Air

Conditioning and Ventilation Systems” (NFPA

90A), “Standard for Installation of Residence

Type Warm Air Heating and Air Conditioning

Systems” (NFPA 90B), these instructions, and all

applicable codes. NFPA publications are available

by writing to: National Fire Protection Association,

Batterymarch Park, Quincy, ME 02269 or visit

www.NFPA.org on the web.

• Design the duct work according to methods

described by the Air Conditioning Contractors

of America (ACCA).

• The supply duct system, including the number

and type of registers, will have much more

effect on the performance of the system than

any other factor. The duct must be suffi ciently

large to conduct an adequate amount of air to

each register. See Figure 5 (page 7).

• Duct work should be attached directly to the

unit fl anges for horizontal applications.

12"

CAUTION:

Do not tip the unit on its side.

Oil may enter the compressor

cylinders and cause starting

trouble. If unit has been set on its

side, restore to upright position

and do not run for several hours.

Then run unit for a few seconds.

Do this three or four times with fi ve

minutes between runs.

1. Remove the bands from around the unit.

2. Unfold the top and bottom cap fl anges.

3. Carefully remove the top cap and tube.

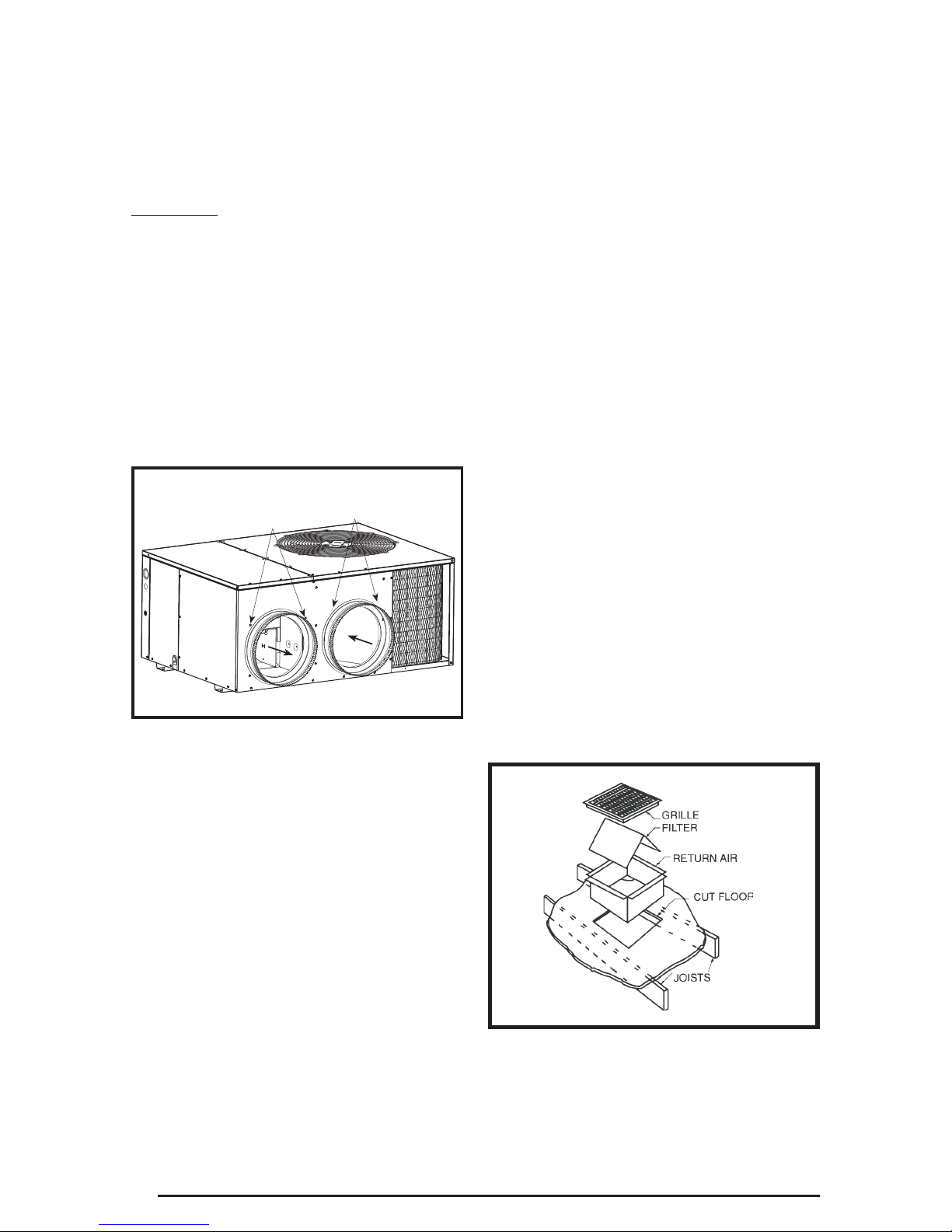

Installing Return & Supply Air Collars

If the supply and return collars are supplied

with the unit, they will be located in the supply

duct. They can be easily positioned over the unit

openings (Figure 3, page 6) and secured with

sheet metal screws.

• The diameter of the return duct collar is 14”.

NOTE: 2 ton units are designed with 12” returns.

• The diameter of the supply duct collar is 12”.

• Before permanently installing the collars,

it is recommended you pre-fi t them over

the openings fi rst to determine best fi t and

alignment.

Supply Duct

1. Assemble the collar by overlapping the two ends.

NOTE: One end of the collar is slotted and

the opposite end has two small holes. Position

the end with small screw holes underneath

the slotted end.

5

2. Fasten the collar ends with two self drilling

sheet metal screws.

3. Position the collar over the opening and align

the 4 holes in the collar with the 4 holes (or

dimples depending on model) in the rear panel.

4. Using self-drilling screws (10-16x.5), secure

the collar to the rear panel.

Return Duct

1. Assemble the collar by overlapping the two ends.

NOTE: One end of the collar is slotted and

the opposite end has two small holes. Position

the end with small screw holes underneath

the slotted end.

2. Fasten the collar ends with two self drilling

sheet metal screws.

3. Position the collar over the opening. Align the

four holes in the collar with the four dimples or

holes (depending on unit model) in the panel.

4. Secure the collar to the rear panel using self

drilling screws (10-16x.5).

Duct

Transition

Duct Screws

Supply Air

Dimples

Return Air

Figure 3. Return & Supply Air Collars

Locating & Installing the Return Air Assembly

To simplify installation, locate and install the

return air assembly fi rst. If desired, the return

opening can be located inside a closet with

louvered doors that has an open area equal to

or greater than a 12” x 20” grille. The return air

grille can be placed in the wall of a closet and

the ducted into the fi lter box through a boxed-in

area at the closet fl oor level. Make sure the fi lter

is readily accessible.

NOTE: The return air box with grille and fi lter

(Figure 4) should not be located in heavy traffi c

areas like hallways or center of rooms. A good

spot is in a corner or under a table, if a minimum

two inch clearance is available.

1. Start the installation from under the home by

cutting a small hole in the sub-fl oor. Determine

how the fl oor joist location will affect cutting

the opening needed for the return air box.

NOTE: Floor joists are generally located on

16” centers, leaving 14-3/8” between joists.

2. After measuring the return air box

(approximately 12-1/4” x 20-1/4”), cut the

hole through the fl oor so that the box will fi t

between the fl oor joists. Care should be taken

when cutting through carpeting to avoid snags.

NOTE: In most installations it will be necessary

to cut a similar hole in the fi berboard directly

under the hole in the fl oor. However, if the fl oor

is more than ten inches deep, it will only be

necessary to cut a hole for the collar on the

return air box or for the insulated duct.

3. Set the box into the opening and fasten with

screws or nails.

4. Put the fi lter and return air grille in place.

Connecting Return & Supply Air Flexible

Ducts

• Flexible ducts may be cut to the required

length and spliced with sheet metal sleeves

and clamps. Keep all ducts as short and

straight as possible. Avoid sharp bends.

Please follow all instructions packed with duct.

• Flexible ducts can be secured to the

corresponding collars with the provided

clamps. After the inner duct is connected to

the collar, pull the insulation and plastic sleeve

over the connection and clamp. NOTE: To

prevent a loss in cooling capacity, make sure

all connections are tight.

• Homes with multiple supply ducts (or special

applications), a Y fi tting is available for dividing

the supply air to different areas of the home for

more effi cient cooling. NOTE: For maximum

performance, insulate the Y fi tting.

6

Figure 4. Return Air Box

MULTIPLE DUCT APPLICATIONSINGLE DUCT APPLICATION

Figure 5. Typical Duct Applications

Locating & Installing the Supply Damper(s)

When locating the supply damper(s), carefully

check fl oor joists and frame members that could

interfere with the installation of the damper or

fl exible duct. Ideally, the damper (Figure 6) should

be located in the bottom of the main duct, forward

of center of the home, at least three feet from

the nearest register. The round supply opening

in the slanted side of the damper should face the

side of the home where the heat pump is located.

1. Locate the center of the heat duct by cutting

a small hole in the fi berboard below the duct

at the desired location.

2. Cut a hole approximately 3/4” larger than the

damper opening in the fi berboard.

3. Cut a 9-1/8” x 13-1/8” hole in the duct and

bend over all tabs fl at on the inside of the

heat duct.

4. Insert the damper into the duct and bend over

all tabs fl at on the inside of the heat duct.

5. Seal the opening between the fi berboard and

damper or fl exible duct.

Condensate Drainage

A 3/4” condensate fi tting extends out of the side

of the unit as shown in Figure 7. The drain trap,

shipped in the electrical compartment, must be

installed to prevent water from collecting inside

the unit.

1. Thread the elbow provided with the unit into

the drain connection until hand tight.

2. Connect the condensate tubing onto the fi tting,

forming a trap near the drain connection. See

Figure 7.

3. Route the condensate tube from the trap to

a suitable drain. NOTE: For proper drainage,

make sure the trap is level to the ground and

tubing outlet is below trap level.

Elbow

AUTOMATIC DAMPER IS CLOSED

Figure 6. Supply Damper

WHEN HEAT PUMP IS OFF

P-Trap

Figure 7. Drain Trap

7

ELECTRICAL CONNECTIONS

WARNING:

To avoid electric shock, personal

injury, or death, turn off the electric

power at the disconnect or the main

service panel before making any

electrical connections.

• Electrical connections must be in

compliance with all applicable local codes

and ordinances, and with the current

revision of the National Electric Code

(ANSI/NFPA 70).

• For Canadian installations the electrical

connections and grounding shall comply with

the current Canadian Electrical Code (CSA

C22.1 and/or local codes).

Pre-Electrical Checklist:

Verify that the voltage, frequency, and phase

of the supply source match the specifi cations

on the unit rating plate.

Verify that the service provided by the utility is

suffi cient to handle the additional load imposed

by this equipment. Refer to the unit wiring label

for proper high and low voltage wiring.

Verify factory wiring is in accordance with the

unit wiring diagram (Figures 10 & 11, pages

20 & 21). Inspect for loose connections.

Line Voltage

• It is recommended that the line voltage to the

unit be supplied from a dedicated branch circuit

containing the correct fuse or circuit breaker

for the unit.

• An electrical disconnect must be located

within sight of and readily accessible to the

unit. This switch shall be capable of electrically

de-energizing the outdoor unit. See unit data

label for proper incoming fi eld wiring. Any

other wiring methods must be acceptable to

authority having jurisdiction.

• Provide power supply for the unit in accordance

with the unit wiring diagram, and the unit rating

plate.

• Connect the line-voltage leads to the

terminals on the contactor inside the control

compartment. Extend leads through power

wiring hole (Figure 8). Connect L1 & L2 directly

to the contactor.

• Use only copper wire for the line voltage

power supply to this unit as listed in Table 1.

Use proper code agency listed conduit and a

conduit connector for connecting the supply

wires to the unit. Use of rain tight conduit is

recommended.

8

• See the unit wiring label for proper high and low

voltage wiring. Make all electrical connections

in accordance with all applicable codes and

ordinances. See Figures 10 & 11 (pages 20

& 21)

CAUTION:

Label all wires prior to

disconnection when servicing

controls. Wiring errors can

cause improper and dangerous

operation. Verify proper operation

after servicing.

• Units are shipped from the factory wired for 240

volt transfor mer operation. For 208V operation,

remove the lead from the transformer ter minal

marked 240V and connect it to the terminal

marked 208V.

COPPER WIRE SIZE — AWG

(1% Voltage Drop)

Supply Wire

Length (Feet)

200 150 100 50

6 8 10 14 15

46812 20

46810 25

44610 30

346 8 35

346 8 40

234 6 45

234 6 50

234 6 55

123 4 60

Wire Size based on N.E.C. for 60° type

copper conductors.

Table 1. Copper Wire Size

High Voltage

Low Voltage

Figure 8. Power Entry

Supply

Circuit

Ampacity

Loading...

Loading...