Page 1

User's Information Manual

Residential Gas Furnaces

FOR Y OUR SAFETY

!

W ARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety precautions exactly could

result in serious injury, death or property damage.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor's phone. Follow

the gas supplier's instructions.

• If you cannot reach your gas

supplier, call the fire department.

• Extinguish any open flame.

— Installation and service must be

performed by a qualified installer,

service agency, or the gas supplier.

!

AVERTISSEMENT:

RISQUE D’INCENDIE OU

D’EXPLOSION

Le non-respect des consignes de sécurité pourrait

entraîner des blessures graves, la mort ou des

dommages matériels.

— Ne pas entreposer ni utiliser de

l’essence ni d’autres vapeurs ou

liquides inflammables dans le voisinage

de cet appareil, ni de tout autre appareil.

— QUE FAIRE S’UL Y A UNE ODEUR DE

GAZ

• Ne pas tenter d’allumer aucun appareil.

• Ne toucher à aucun interrupteur

électrique; n’utiliser aucun téléphone

dans le bâtiment.

• Appeler immédiatement le

fournisseur de gaz en employant le

téléphone d’un voisin. Respecter à

la lettre les instructions du

fournisseur de gaz.

• Si personne ne répond, appeler le

service des incendies.

— L’installation et l’entretien doivent être

effectués par un installateur qualifié,

un organisme de service ou le

fournisseur de gaz.

IMPORTANT

Read this owner information thoroughly

before attempting to operate or maintain this

furnace to become familiar with the

capabilities and use of your heating

appliance. Keep this with literature on other

appliances where you have easy access to it

in the future. If a problem occurs, check the

instructions and follow the recommendations

given. If the suggestions do not eliminate

your problem, call your NORDYNE Servicing

Contractor (Service PRO).

Any additions, changes, or conversions

required in order for the appliance to

satisfactorily meet the application needs

must be made by a qualified installer, service

agency, or the gas supplier using factory

specified and approved parts.

Page 2

2

Page 3

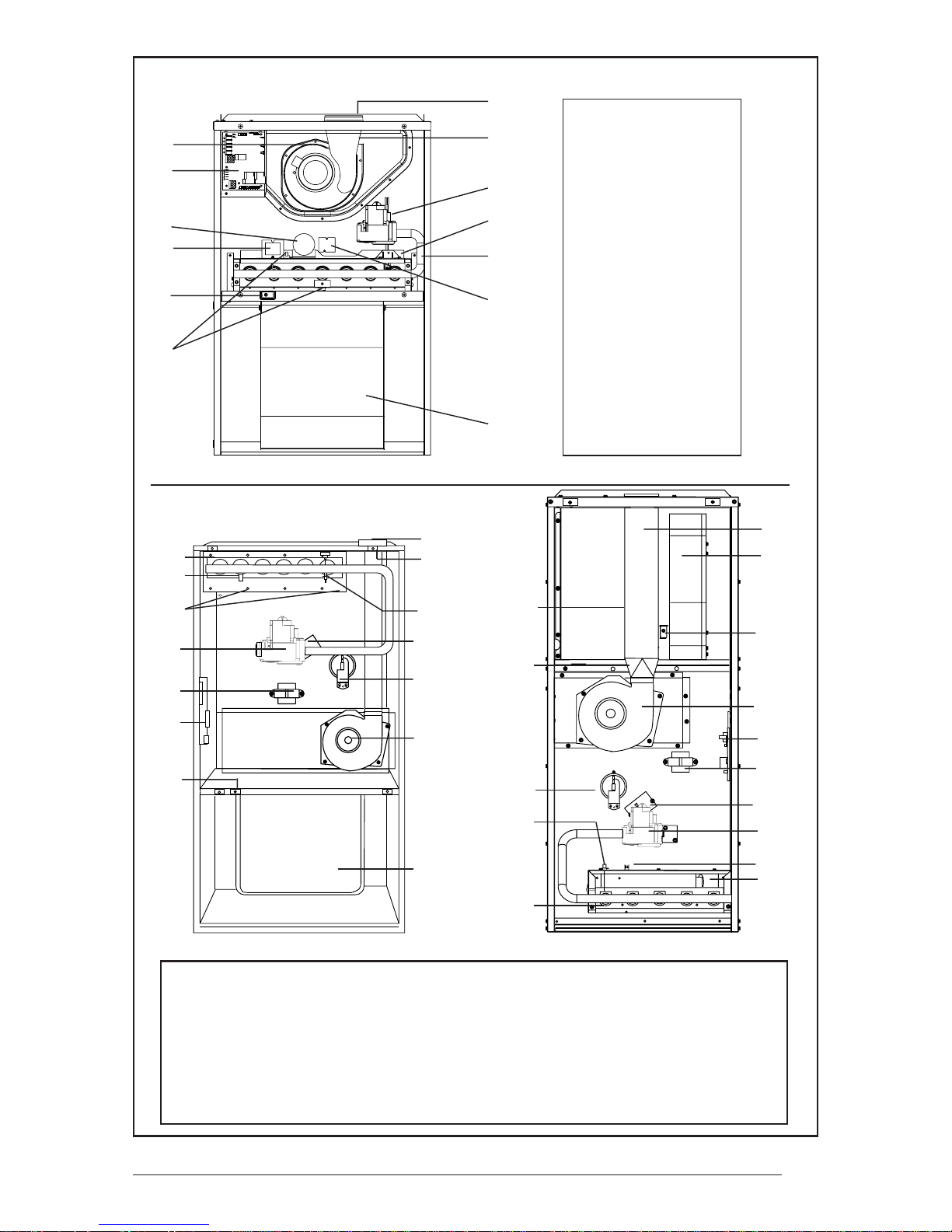

80+ AFUE

13

6

5

9

7

4

Upflow/Horizontal Furnace

80+ AFUE

11

1

8

14

3

1

10

11

12

8

9

1 Ignitor

2 Flame Sensor

(Not Shown)

3 Gas Valve

4 Flame Roll-out

Switch(s)

5 Pressure Switch

6 Control Board

7 Blower Door

Switch(s)

8 Exhaust Adapter

9 Low Voltage

Transformer

10 Burner Assembly

11 Supply Air Limit

Switch

12 Blower Assembly

13 Induced Draft

Blower

14 Vent Transition

15

13

4

3

10

6

7

Upflow/Horizontal Furnace

1 Ignitor

2 Flame Sensor

3 Gas Valve

4 Flame Roll-out

Switch(s)

5 Pressure Switch

6 Control Board

7 Blower Door

Switch

2

12

5

14

13

8 Vent Assembly

(Upflow Only)

9 Vent Switch

10 Low Voltage

Transformer

11 Burner Assembly

12 Supply Air Limit

Switch

13 Blower Assembly

16

11

9

7

14

6

10

5

12

2

3

4

1

Downflow Furnace

14 Induced Draft

Blower

15 Combustion Tube

w/insulation

(Downflow Only)

16 Vent Transition

Assembly

(Downflow Only)

Figure 1. Furnace Parts Identified

3

Page 4

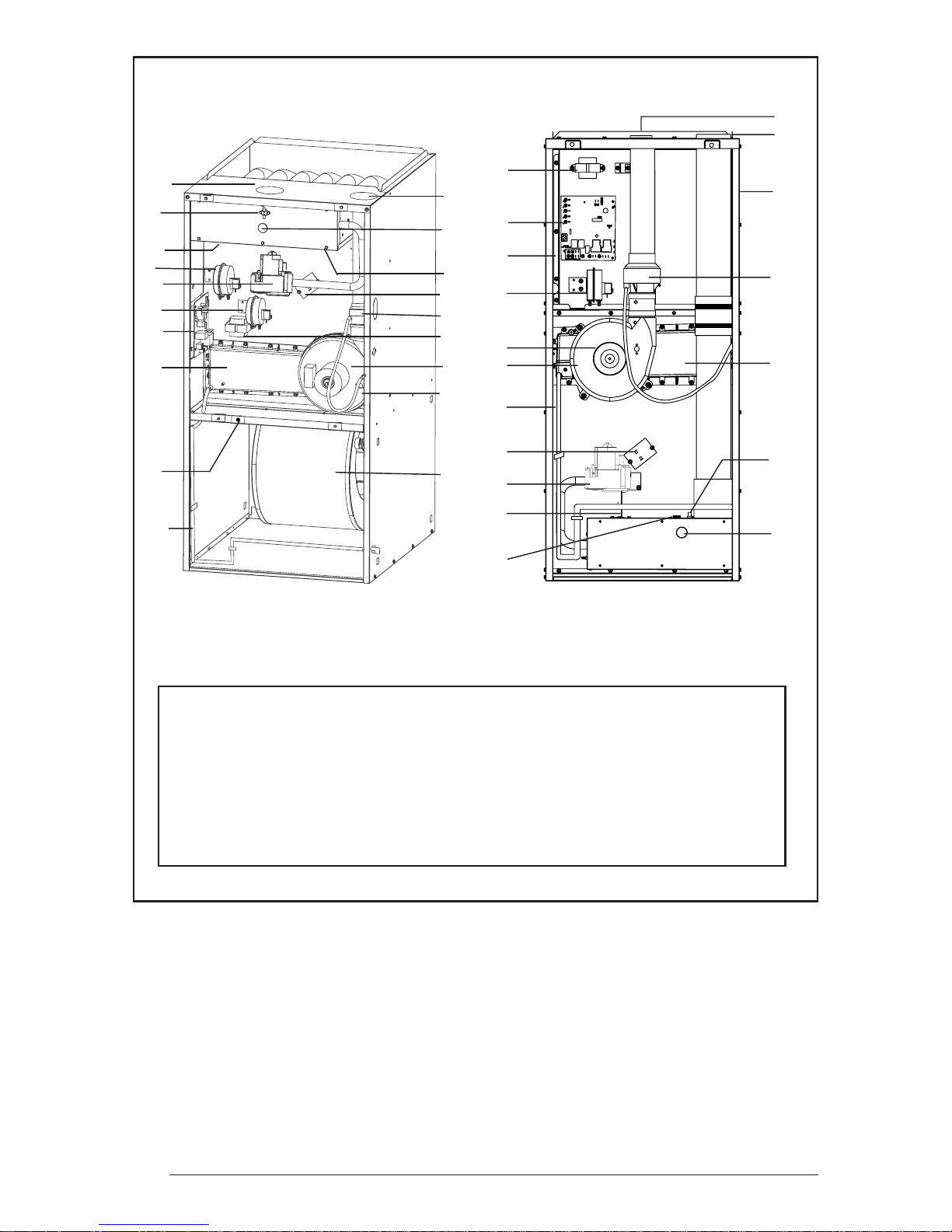

90+ AFUE

19

18

18

4

1

6

3

5

7

17

8

14

Upflow/Horizontal Condensing Furnaces

19

16

2

11

15

10

13

9

12

10

13

14

11

7

8

5

9

3

1

4

Downflow Condensing Furnace

12

15

17

2

16

1 Ignitor (Not Shown)

2 Flame Sensor (Not

Shown)

3 Gas Valve

4 Flame Roll-out

Switch(s)

5 Pressure Switch

6 Vent Pressure

Switch (93+ Only)

7 Control Board

8 Blower Door Switch

9 Vent Safety Switch

10 Low Voltage

Transformer

11 Supply AIr Limit

Switch

12 Circulating Air

Blower Assembly

13 Induced Draft

Blower

Figure 2. Furnace Parts Identified

14 Condensate Drain

15 In-Line Drain

16 Burner View Port

17 Front Header Box

18 Combustion Air

19 Exhaust Vent

Tube

Assembly

Intake

4

Page 5

90+ AFUE Two - Stage Models

20

20

19

5

7

3

6

8

11

18

9

13

15

Upflow/Horizontal Furnace Models

17

12

4

16

14

10

11

14

10

12

15

7

8

9

16

6

18

4

3

5

17

Downflow Furnace Models

1 Ignitor (Not Shown)

2 Flame Sensor (Not

Shown)

3 Primary Gas Valve

4 Secondary Gas Valve

5 Flame Roll-out Switch(s)

6 Pressure Switch

7 Vent Pressure Switch

8 Control Board

9 Blower Door Switch

Figure 3. Furnace Parts Identified

10 Vent Safety Switch

11 Low Voltage

Transformer

12 Supply Air Limit Switch

13 Circulating Air Blower

Assembly (Not Shown

on Downflow Model)

14 Induced Draft Blower

15 Condensate Drain

Tube

16 In-Line Drain

Assembly

17 Burner View Port

18 Front Header Box

19 Combustion Air

Intake (Not Shown

on Upflow Model))

20 Exhaust Vent

(Not Shown on

Downflow Model)

5

Page 6

80+ AFUE Tw o - Sta ge Models

10

1

4

3

6

9

7

2

5

11

8

13

12

1 Ignitor

2 Flame Sensor

3 Gas Valve

4 Flame Roll-out

Switch(s)

5 Pressure Switch

6 Control Board

Upflow/Horizontal Furnace

7 Blower Door

Switch

8 Vent Assembly

9 Low Voltage

Transformer

10 Burner Assembly

11 Supply Air Limit

12 Blower Assembly

13 Induced Draft

Figure 4. Furnace Parts Identified

Switch

Blower

6

Page 7

GENERAL INFORMATION

This furnace has been designed and built to

provide many years of safe and dependable

home comfort, providing it is properly installed

and maintained. With regular maintenance, this

furnace will operate satisfactorily year after year.

Abuse, improper use, and/or improper maintenance can shorten the life of the furnace and

create hazards for you. Please read this manual

carefully to familiarize yourself with operation,

maintenance, and safety procedures for this

furnace.

A regular service and maintenance schedule

should be established to insure efficient and

safe operation of the furnace. See Section 5 for

maintenance procedures and schedules.

Devices attached to the flue or vent for the

purpose of reducing heat loss up the chimney have not been tested and have not

been included in the design certification

of this furnace. We, the manufacturer, can

not and will not be responsible for injury

1. Safety Information

The furnace area and the vicinity of any other

gas appliance must be kept clear and free of

combustible materials, gasoline, and other

flammable vapors and liquids. Do not store or

use flammable items such as paint, varnish, or

strippers in the vicinity of the furnace.

Do not use the furnace closet or area next to the

furnace as a storage area. This area must be

kept clear, clean, and free of lint. The furnace

must also be kept clear of loose or exposed

insulation materials. Examine the furnace area

when the furnace is installed or when insulation

is added. Some insulation materials may be

combustible.

For proper and safe operation, the furnace

needs air for combustion and ventilation. Do not

block or obstruct air openings on the furnace, or

any air openings where the furnace may be

installed, including any surrounding spaces.

under water. A flood-damaged furnace is

extremely dangerous. Attemps to use the furnace

can result in fire or explosion. A qualified service

agency should be contacted to inspect the

furnace and to replace all gas controls, control

system parts, electrical parts that have been

wet or the furnace if deemed necessary.

Familiarize yourself with the controls that shut

off the gas and electrical power to the furnace.

If the furnace is to be shut down for an extended

period of time, turn off both the gas and electrical

power. For your safety always turn off both the

gas and electrical power before performing

service or maintenance on the furnace.

2. Combustion Air Supply

A furnace needs an adequate supply of

combustion and ventilation air for proper and

safe operation. Follow the installation

instructions included with the furnace to

properly vent air to the combustion air inlet

and exhaust the products of combustion to

the outside from the exhaust vent.

For 90+ and 93+ Models: If the furnace is

operated with a restricted combustion air supply,

the pressure switch will open, turning off the gas

supply to the burners. (See Figures 2 and 3).

DO NOT install a jumper wire across this switch

to defeat its function. If this switch must be

replaced, use only the replacement part specified

in the Replacement Parts List.

For 80+ Models: If the furnace is operated with

inadequate combustion air supply, the flame rollout control switch located above the burners may

open, turning off the gas supply to the burners.

The flame roll-out control is a manually resettable

device (See Figure 1 and 4). DO NOT install a

jumper wire across this switch to defeat its function.

DO NOT reset the control without identifying and

correcting the fault condition which caused the

control to trip. If this switch must be replaced, use

only the replacement part specified in the

Replacement Parts List.

Air openings in warm air registers, and return air

grilles must not be restricted.

Should the gas supply fail to shut off or if

overheating occurs, shut off gas valve to the

furnace before shutting off electrical supply.

Do not use this furnace if any part has been

!

CAUTION:

Combustion air must not be drawn

from a corrosive atmosphere.

7

Page 8

To maximize heat exchanger life, the combustion

air must be free of chemicals which form corrosive

acidic compounds in the combustion gases.

Some examples of these chemicals are chlorine,

fluorine, and sulphur. Some common sources of

these chemicals are detergents, bleaches,

aerosol sprays, cleaning solvents, and a wide

variety of commercial and household products.

be connected to any other heat producing device

such as a fireplace insert, stove, etc. Doing so

may result in fire, explosion, personal injury,

carbon monoxide poisoning, or property damage.

Use a type high velocity air filter in the return air

duct to maintain a clean heat exchanger.

3. Return Air Supply

In applications where the supply ducts carry

heated air to areas outside the space in which

the furnace is installed, the return air must be

delivered to the furnace by duct(s) sealed to the

furnace casing. These duct(s) must be full size

and without interruption in the spaces outside of

where the furnace is installed.

The return air duct connection(s) must be

physically sound and sealed to the furnace

casing to prevent products of combustion from

entering the living space.

The floor or platform on which the furnace is

mounted must provide sound physical support

of the furnace with no gaps, cracks, or sagging

between the furnace and floor or platform. The

return air and circulating air ductwork must not

MAINTENANCE ITEM BEG INNI NG O F END O F E ACH

EACH HEATING SE ASON HEATI NG SEAS ON MONTHLY

VERIFY F URNACE ARE A IS F RE E

OF CO MBUS TI BL E MAT ERI ALS

!

W ARNING:

Failure to prevent products of combustion from being circulated into the

living space can create potentially

hazardous conditions including carbon monoxide poisoning that could

result in personal injury or death.

4. Vent System

The furnace must always be connected to an

approved vent pipe to carry the furnace

combustion products outdoors. At the beginning

and end of each heating season, inspect the

outdoor vent terminal closely with a flashlight to

determine if any of the conditions listed under

the following warning exist.

FREQUENCY OF MAINTENANCE

XXX

VERIF Y COMBUSTI O N AND VENTIL AT I O N

AIR I S NOT RE S TRICTED

VERIFY NO SIGNS OF PHYSICAL

DETE RIO RATIO N OF THE F URNACE

VERIFY NO OBSTRUCTIONS OR

RESTRICTIONS IN VENT OR CHIMNEY

VERIFY NO HOL E S OR CRACKS I N VENT P IPE

VERIFY NO CORROSI ON I N VENT PI PE

VERIFY THAT HORI Z ONTAL VENT PIPES

SLO PE UPWARDS AWAY FROM FURNACE

VERIFY BURNER FLAME

CLEAN O R RE P LACE FILTER( S )

CLEAN BLOW ER COMPARTMENT

CLEAN BURNER ASSEMBLY

8

XXX

XXX

XX

XX

XX

XX

X

X

X

X

Table 1. Maintenance Table

Page 9

5. Maintenance

Proper maintenance is most important to achieve

the best performance from this furnace and

should be performed by a qualified service

technician. Follow the maintenance schedule

(see Table 1) and the following instructions for

years of safe, trouble free operation.

• Do not place combustible materials on

or against the furnace cabinet.

• Do not store gasoline or any other

flammable vapors and liquids in the

vicinity of the furnace.

• Annually inspect the furnace, ductwork,

and vent system for signs of physical

deterioration.

• Change or replace the air filters monthly

during any period when the circulating

blower is operating regularly.

• Always replace the doors on the furnace

after servicing or cleaning/changing the

filters. Do not operate the furnace

without all doors and covers in place,

except to check burner operation.

• Avoid operating the furnace when

windows and doors are open.

• Be sure that the thermostat is properly

installed and is not being affected by

drafts or heat from lamps or other

appliances.

air blower motors used in these furnaces are

pre-lubricated and sealed at the factory. No

further oiling of the bearings is required for the

life of the motor.

Blower Compartment — The blower

compartment should be cleaned monthly during

the heating and cooling seasons to remove any

dirt and lint that may have accumulated in the

compartment or on the blower and motor. Buildup of dirt and lint on the blower and motor can

create excessive loads on the motor resulting in

higher than normal operating temperatures and

possible shortened service life.

Burner Maintenance — Check the burner

flames at the start of every heating season. Set

the thermostat to a temperature setting above

the room temperature. Remove the top door

from the furnace and visually inspect the burner

through the view hole to make sure that the

flame is drawn into the center of the heat

exchanger tube (See Figure 5). In a properly

adjusted burner assembly, the flame bends

down and to the right at the end of the heat

exchanger tube, and the end of the flame will be

out of sight around the bend. The flame color

should be blue, however some light yellow streaks

may occur on the outer portions of the flame.

Air Filter(s) — Air filter(s) are not supplied with

the furnace as shipped from the factory. The

installer must provide a high velocity filter and

rack in the return air duct adjacent to the furnace,

or in a return air grille to the furnace. The filter(s)

must be removed and cleaned monthly during the

heating season to ensure proper furnace

operation. New or newly renovated homes may

require more frequent changing until the

construction dust has been removed.

!

WARNING:

Never operate the furnace without a

filter in place. Dust and lint in the

return air can build up on the internal

components, resulting in a loss of

efficiency, equipment damage, and

possible fire.

Always replace the door(s) on the furnace after

servicing or cleaning/changing the filters. Do not

operate the furnace without the door(s) in place.

Lubrication — The bearings in the circulating

!

CAUTION:

Some components in the burner

vestibule are at high temperatures

while the burners are operating. Use

caution to avoid personal injury.

Burner

Manifold

Figure 5. Burner Inspection

Flame

9

Page 10

6. Operating Instructions

!

WARNING:

Do not operate your furnace if you

find any of the following conditions.

Such conditions may allow toxic

fumes to escape into your home:

• Obstructions or restrictions in

the vent pipe and/or chimney.

• Holes or cracks in the vent pipe.

• Visible corrosion in the vent pipe.

• Horizontal vent pipes that do not

slope upward.

If any of the above conditions are found

in the vent pipe, call a qualified service

technician to install new vent pipe.

For 80+ upflow and downflow models only:

Burner Maintenance (NOx), If the second or

eighth character of the model number is an “N”

the furnace has factory installed NOx reduction

inserts. The inserts reduce the NOx emissions

of the furnace. The NOx reduction inserts are

located in the first pass of the top portion of the

heat exchanger. When the burners are

operating, the flame should extend through the

center of the NOx reduction inserts. The flame

color should be blue, however some light yellow

streaks may occur on the outer portions of the

flame.

READ THE SAFETY INFORMATION ON

THE FOLLOWING PAGE BEFORE

OPERATING.

!

W ARNING:

Should overheating occur, or the gas

supply fail to shut off, shut off the

manual gas valve to the furnace

before shutting off the electrical

supply.

!

ADVERTISSEMENT:

En cas de température excessive, ou

s’il est impossible de couper

l’alimentation en gaz, fermer le robinet

manuel d’alimentation en gaz du

générateur d’air chaud avant de

couper l’alimentation électrique.

These furnaces are equipped with roll-out limit

switch(s), a vent safety switch, and a pressure

switch (See Figures 1, 2, 3 and 4). The pressure

switch verifies that the flame is receiving

combustion air. If the flame is not drawn into the

heat exchanger tube, the roll out limit switch or

flame sensor, will shut the furnace down.

Inspect the burners, mounting brackets, and all

other parts in the vestibule for signs of

deterioration. The burner vestibule should be

vacuumed clean and inspected annually.

!

CAUTION:

Do not strike any of the internal

electrical components while

vacuuming.

10

The vent safety switch shuts the furnace down

if the vent becomes blocked or restricted.

Furnace Fails To Operate — If the furnace

does not operate, check the following:

1) Is the thermostat operating properly?

2) Are the blower door(s) in place?

3) Is the furnace disconnect closed?

4) Has the circuit breaker tripped (or fuse

blown)?

5) Is the gas turned on?

6) Is the filter dirty or plugged?

Page 11

If the combustion and circulating air blowers are

operating, and items 1 through 6 have been

checked without identifying the cause of the

problem, press the red reset buttons on the vent

safety and the roll out limit switches. (See

Figures 1, 2, 3 and 4).

IMPORTANT: If the furnace operates after

depressing the reset button on the vent limit

or roll out limit, it is an indication of a

potentially serious problem in the installation.

Contact a qualified serviceman to identify

and repair the problem.

MANUFACTURER WARRANTY, OWNER RESPONSIBILITIES

It is the sole responsibility of the homeowner to make certain the gas furnace has been correctly

set up and adjusted to operate properly.

The Manufacturer warrants the furnace to be free from defects in material or workmanship for the

warranty period. However, the Manufacturer will not be responsible for any costs found necessary

to correct problems due to improper set-up, improper installation, furnace adjustments, improper

operating procedure on the part of the user, etc.

Some specific examples of service calls which cannot be included in warranty payments are:

1. Repairing duct work in the home found to be faulty.

2. Correcting wiring problems in the electrical circuit supplying the furnace.

3. Re-setting circuit breakers or other switches.

4. Correction of problems due to improper gas supply pressure to the furnace.

5. Providing instructional training on how to light and operate the furnace.

6. Furnace problems caused by installation of an air conditioner, heat pump, or other air comfort

devices.

7. Revising installation of the vent assembly.

8. Adjusting or calibrating of the thermostat.

Carefully review these responsibilities with your dealer, service company, or gas supplier so there

will be no misunderstanding at a later time.

Read Your Warranty

Please read your limited warranty completely. It contains valuable information about your furnace.

If you have any questions about the warranty information, contact your distributor.

11

Page 12

¢708222y¤

7082220

7082220 (Replaces 7081670)

Specifications and illustrations subject to change

without notice and without incurring obligations.

Printed in U.S.A. (01/03)

Loading...

Loading...