Nordstrom 7119745C User Manual

MiniCuret

Customer Product Manual

Part 7119745C

Issued 08/07

global UV solutions

NORDSON UV LTD • SLOUGH, BERKSHIRE • UK

Nordson Corporation welcomes requests for information, comments, and inquiries about its products. General information

about Nordson can be found on the Internet using the following address: http://www.nordson.com.

Address all correspondence to:

Nordson UV Limited

Attn: Customer Service

816 Leigh Road

Slough, Berkshire SL1 4BD

Notice

This is a Nordson Corporation publication which is protected by copyright. Original copyright date 2006.

No part of this document may be photocopied, reproduced, or translated to another language without the prior written

consent of Nordson Corporation. The information contained in this publication is subject to change without notice.

© 2007 All rights reserved.

Trademarks

AccuJet, AeroCharge, AquaGuard, Asymtek, Automove, Autotech, Baitgun, Blue Box, CF, CanWorks, Century,

Clean Coat, CleanSleeve, CleanSpray, Control Coat, Cross-Cut, Cyclo-Kinetic, Dispensejet, DispenseMate, Durafiber,

Durasystem, Easy Coat, Easymove Plus, Econo-Coat, EFD, ETI, Excel 2000, Flex-O-Coat, FlexiCoat, Flexi-Spray,

Flow Sentry, Fluidmove, FoamMelt, FoamMix, Helix, Horizon, Hot Shot, Isocoil, Isocore, Iso-Flo, JR, KB30, Kinetix,

Little Squirt, Magnastatic, MEG, Meltex, Microcoat, MicroSet, Millennium, Mini Squirt, Moist-Cure, Mountaingate,

MultiScan, Nordson, OmniScan, OptiMix, Package of Values, Patternview, PluraFoam, Porous Coat, PowderGrid,

Powderware, Prism, Pro-Flo, ProLink, Pro-Meter, Pro-Stream, PRX, RBX, Rhino, S. design stylized, Saturn, SC5,

Seal Sentry, Select Charge, Select Coat, Select Cure, Slautterback, Smart-Coat, Solder Plus, Spectrum, Spray Squirt,

Spraymelt, Super Squirt, Sure Coat, Tela-Therm, Trends, Tribomatic, UniScan, UpTime, Veritec, Versa-Coat,

Versa-Screen, Versa-Spray, Walcom, Watermark, and When you expect more

.

are registered trademarks of Nordson Corporation.

ATS, Auto-Flo, AutoScan, BetterBook, Chameleon, CanNeck, Check Mate, Colormax, Control Weave,

Controlled Fiberization, CoolWave, CPX, Dura-Coat, Dry Cure, E-Nordson, EasyClean, Eclipse, Equi=Bead, Fill Sentry,

Fillmaster, Gluie, Heli-flow, Ink-Dot, Iso-Flex, Lacquer Cure, Maxima, MicroFin, MicroMax, Minimeter, Multifil, Origin,

PermaFlo, PluraMix, Powder Pilot, Powercure, Primarc, Process Sentry, PurTech, Pulse Spray, Ready Coat, Select Series,

Sensomatic, Shaftshield, SheetAire, Spectral, Spectronic, Speedking, Spray Works, Summit, Sure Brand, Sure Clean,

Sure Max, Swirl Coat, Tempus, Tracking Plus, Trade Plus, Universal, Vista, Web Cure, and 2 Rings (Design)

are trademarks of Nordson Corporation.

Part 7119745C

MiniCure 08-07

E 2007 Nordson Corporation

Introduction

O-1

Congratulations on the Purchase of

Your Nordson Product

Nordson equipment is engineered and manufactured in accordance with

strict specifications, using high quality components and state-of-the-art

technologies that assure reliable, long-term performance. Your product was

thoroughly tested for proper operation prior to shipment.

Before unpacking and installing your new equipment, please read this

manual. It is your guide to safe installation, productive operation and

effective maintenance. We recommend that you keep the manual available

for future reference.

Your Safety is Important to Nordson

Carefully read the Safety section. Your product is designed for safe

operation when used according to the published instructions. Potential

hazards exist when operating instructions are not followed.

Manufacturer of Equipment

Nordson UV Ltd.

816 Leigh Road,

Slough,

Berkshire

United Kingdom

SL1 4BD

Telephone: 0044 (0) 1753--558--000

Fax: 0044 (0) 1753--558--100

For a list of local Nordson organisations, see Nordson International.

E 2002 Nordson Corporation

UV_CONG_EN_B--0802

O-2

Introduction

UV_CONG_EN_B--0802

E 2002 Nordson Corporation

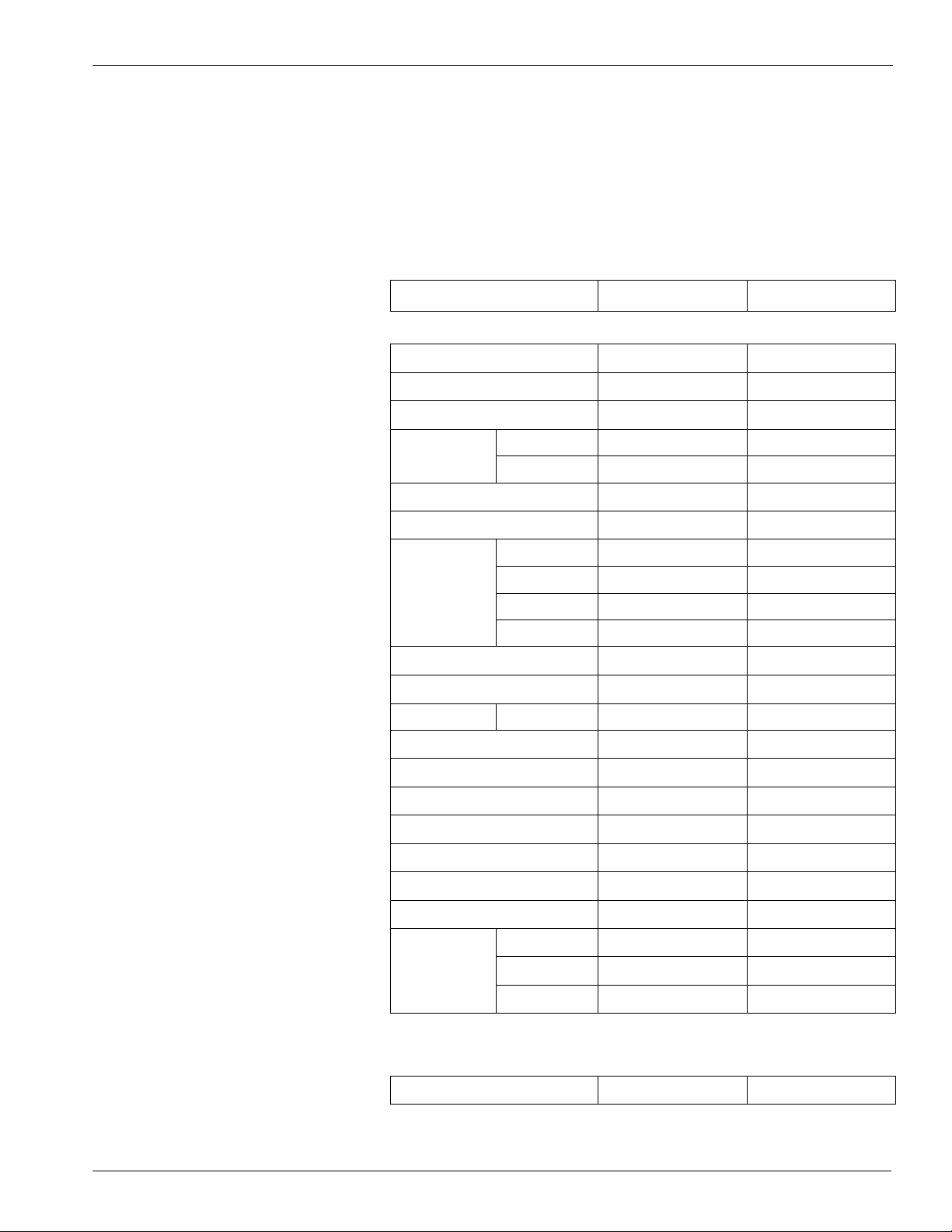

Nordson International

http://www.nordson.com/Directory

Country Phone Fax

Europe

Austria 43-1-707 5521 43-1-707 5517

Belgium 31-13-511 8700 31-13-511 3995

Czech Republic 4205-4159 2411 4205-4124 4971

Denmark Hot Melt 45-43-66 0123 45-43-64 1101

Finland 358-9-530 8080 358-9-530 80850

O-1Introduction

Finishing 45-43-200 300 45-43-430 359

France 33-1-6412 1400 33-1-6412 1401

Germany Erkrath 49-211-92050 49-211-254 658

Lüneburg 49-4131-8940 49-4131-894 149

Nordson UV 49-211-9205528 49-211-9252148

EFD 49-6238 920972 49-6238 920973

Italy 39-02-904 691 39-02-9078 2485

Netherlands 31-13-511 8700 31-13-511 3995

Norway Hot Melt 47-23 03 6160 47-23 68 3636

Poland 48-22-836 4495 48-22-836 7042

Portugal 351-22-961 9400 351-22-961 9409

Russia 7-812-718 62 63 7-812-718 62 63

Slovak Republic 4205-4159 2411 4205-4124 4971

Spain 34-96-313 2090 34-96-313 2244

Sweden 46-40--680 1700 46-40-932 882

Switzerland 41-61-411 3838 41-61-411 3818

United

Kingdom

Hot Melt 44-1844-26 4500 44-1844-21 5358

Finishing 44-161-495 4200 44-161-428 6716

Nordson UV 44-1753-558 000 44-1753-558 100

Distributors in Eastern & Southern Europe

DED, Germany 49-211-92050 49-211-254 658

E 2007 Nordson Corporation

All rights reserved

NI_EN_M-0307

O-2

Introduction

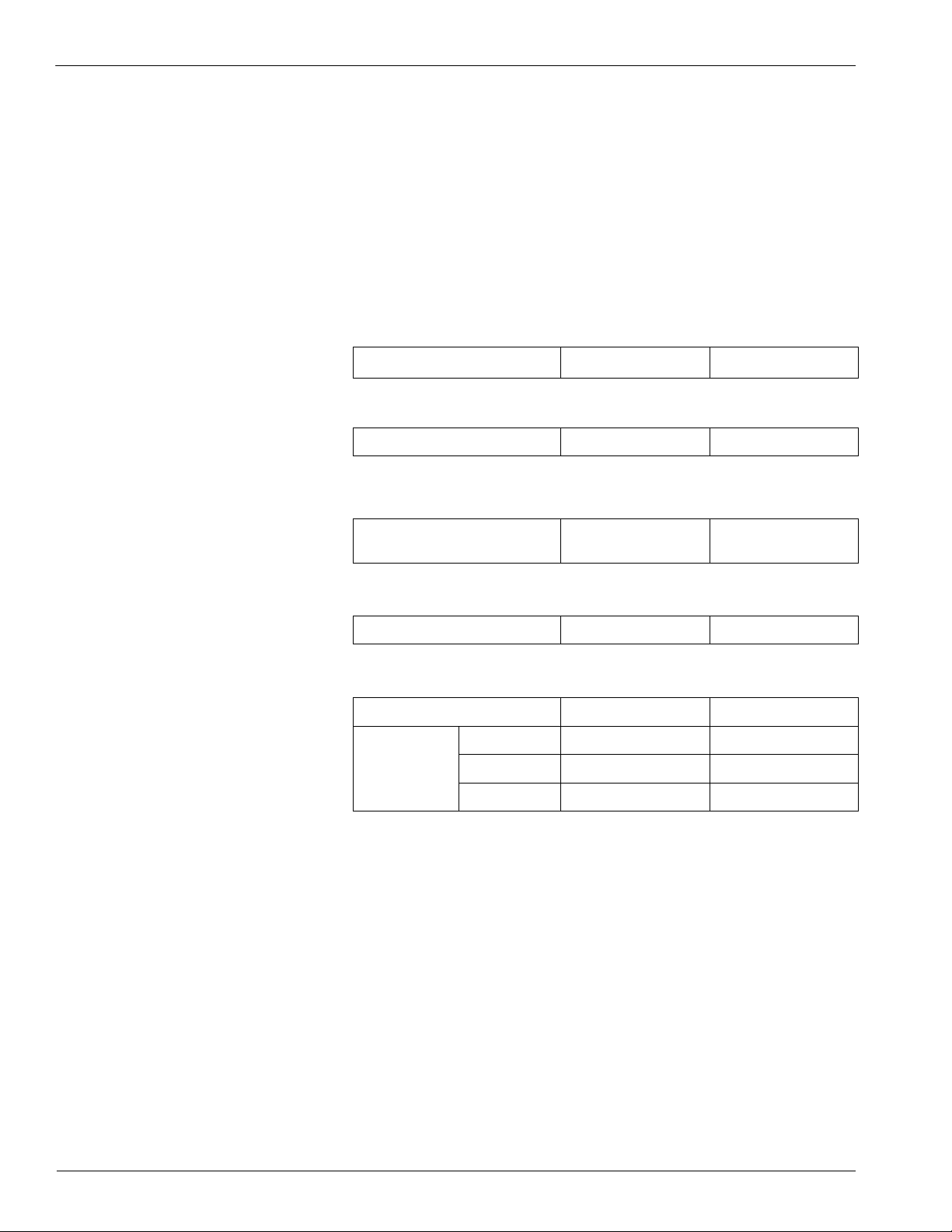

Outside Europe / Hors d’Europe / Fuera de Europa

S For your nearest Nordson office outside Europe, contact the Nordson

offices below for detailed information.

S Pour toutes informations sur représentations de Nordson dans votre

pays, veuillez contacter l’un de bureaux ci-dessous.

S Para obtener la dirección de la oficina correspondiente, por favor

diríjase a unas de las oficinas principales que siguen abajo.

Contact Nordson Phone Fax

Africa / Middle East

DED, Germany 49-211-92050 49-211-254 658

Asia / Australia / Latin America

Japan

North America

Pacific South Division,

USA

Japan 81-3-5762 2700 81-3-5762 2701

Canada 1-905-475 6730 1-905-475 8821

USA

Hot Melt 1-770-497 3400 1-770-497 3500

Finishing 1-880-433 9319 1-888-229 4580

Nordson UV 1-440-985 4592 1-440-985 4593

1-440-685-4797 --

NI_EN_M-0307

E 2007 Nordson Corporation

All rights reserved

Product Disposal Instructions

The symbol shown below and on the product means that the product is

classed as Electrical or Electronic Equipment and should not be disposed with

other commercial waste at the end of its working life.

The Waste of Electrical and Electronic Equipment (WEEE) Directive

(2002/96/EC) has been put in place to recycle products using best available

recovery and recycling techniques to minimise the impact on the environment,

treat any hazardous substances and avoid the increasing landfill.

Please contact Nordson UV at the end of the working life of this product for

advice on disposal. This product does contain non-RoHS compliant

components and should not be mixed with other commercial waste.

This page int entionally let blank

Table of Contents i

Table of Contents

Safety 1-1..................................................

Introduction 1-1.............................................

Qualified Personnel 1-1......................................

Intended Use 1-1............................................

Regulations and Approvals 1-2................................

Personal Safety 1-3.........................................

Fire Safety 1-4..............................................

Label Definitions 1-5.........................................

Refer to Manual 1-5......................................

Warning! UV Radiation 1-5.................................

Safety Glasses 1-5.......................................

Gloves 1-6..............................................

Capacitor 1-6............................................

High Voltage 1-6.........................................

Hot Surfaces 1-7.........................................

Handle with Care 1-7.....................................

Equipment safety 1-8........................................

Introduction 1-8..........................................

High temperatures 1-8....................................

High voltage 1-8..........................................

Fire risk 1-9.............................................

Safety precautions while servicing 1-9.......................

Important Information 1-9...............................

Control System Cleaning 1-9............................

High Voltage Connections 1-10...........................

Lamphead Cleaning 1-10.................................

High Temperatures 1-10.................................

Safety UV curing 1-11......................................

U.V . Radiation 1-11......................................

Ozone Gas 1-12........................................

Mercury 1-13...........................................

U.V . Ink and Generated Products 1-14......................

System Checks 1-14....................................

U.V . Permissible Exposure Levels 1-15.......................

Action in the Event of a Malfunction 1-15........................

Disposal 1-15................................................

E 2007 Nordson Corporation

Description 2-1.............................................

Transport & Handling 3-1...................................

Weights & Dimensions 3-1....................................

Weight 3-1..............................................

Dimensions 3-1..........................................

Lifting 3-1..................................................

MiniCure 08-07

Part 7119745C

ii

Table of Contents

Installation 4-1.............................................

Operation 5-1..............................................

Turning on the system power 5-1.............................

Starting the conveyor 5-2....................................

Operation 5-3..............................................

Stopping conveyor & system shutdown 5-3.....................

Emergency stop 5-4.........................................

Maintenance 6-1...........................................

Ultra--violet lamps 6-1.......................................

Lamp installation & removal 6-2...............................

Conveyor belt replacement & adjustment 6-3...................

Fuses & electrical equipment 6-5.............................

Panel lamp replacement 6-7..................................

Other service operations 6-7.................................

Parts 7-1...................................................

Introduction 7-1.............................................

Using the Illustrated Parts List 7-1..........................

Specifications 8-1..........................................

Introduction 8-1.............................................

Declaration of Conformity 8-3...............................

System Specification 8-5.....................................

Input Voltages 8-5........................................

Current Consumption 8-5..................................

Max. Working Temp. 8-5..................................

Max. Working Humidity 8-5................................

Ultraviolet Light Source 8-5................................

Effective Curing Width 8-5.................................

Reflector 8-5.............................................

Conveyor 8-5............................................

Cooling 8-5..............................................

Additional Features 8-6...................................

Drawings 9-1...............................................

Circuit Diagrams (50Hz) 9-1..................................

Circuit Diagrams (60Hz) 9-2..................................

Part 7119745C

MiniCure 08-07

E 2007 Nordson Corporation

Introduction

Safety 1-1

Section 1

Safety

Read and follow these safety instructions. Task- and equipment-specific

warnings, cautions, and instructions are included in equipment

documentation where appropriate.

Make sure all equipment documentation, including these instructions, is

accessible to all persons operating or servicing equipment.

Qualified Personnel

Equipment owners are responsible for making sure that Nordson equipment

is installed, operated, and serviced by qualified personnel. Qualified

personnel are those employees or contractors who are trained to safely

perform their assigned tasks. They are familiar with all relevant safety rules

and regulations and are physically capable of performing their assigned

tasks. Work on electrical parts and assemblies is only to be executed by a

qualified competent electrical engineer.

Intended Use

Use of Nordson equipment in ways other than those described in the

documentation supplied with the equipment may result in injury to persons

or damage to property.

Some examples of unintended use of equipment include, but not limited to:

S using incompatible materials

S making unauthorized modifications

S removing or bypassing safety guards or interlocks

S using incompatible or damaged parts

S using unapproved auxiliary equipment

S operating equipment in excess of maximum ratings

E 2007 Nordson Corporation

MiniCure 08-07

Part 7119745C

1-2

Safety

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which

it is used. Any approvals obtained for Nordson equipment will be voided if

instructions for installation, operation, and service are not followed.

All phases of equipment installation must comply with all federal, state, and

local codes.

The MiniCure has been designed and manufactured using the following

transposed harmonized European standards:

S EN12100 Parts 1&2:2003 Safety of machinery -- Basic concepts,

general principles for design

S EN60950 Part 1:2002 Information Technology Equipment -- Safety --

Part 1: General requirements

S EN61000--6--2:2005 Electromagnetic compatibility (EMC) -- Generic

standards -- Immunity standard for industrial environments

S EN61000--6--4:2001 Electromagnetic compatibility (EMC) -- Generic

standards -- Emission standard for industrial environments

Part 7119745C

MiniCure 08-07

E 2007 Nordson Corporation

Personal Safety

Safety 1-3

To prevent injury follow these instructions.

S On a daily basis the Earth Leakage Circuit Breaker and the combined

Isolator (at the connection box) should be tested.

S This is carried out by pressing the ’Test’ button while the

system is switched on -- the Isolator should switch off instantly.

WARNING: If the isolator or any indicator remains on, then it could indicate

that a SERIOUS fault is present on your system. Inform your electrician or

contact Nordson UV for advice immediately.

NOTE: To protect the Earth Leakage Sensor, this test function will only

work while the lamps are switched off.

WARNING: NEVER LOOK AT A LIGHTED LAMP

S ULTRA--VIOLET RADIATION IS HARMFUL TO EYES AND CAN

BE HARMFUL TO SKIN. ALWAYS WEAR SUITABLE

PROTECTION WHEN USING THIS SYSTEM.

S THIS SYSTEM IS DESIGNED TO BE USED FOR HAND FED

OPERATION, SPECIAL UV SAFETY GLASSES & GLOVES MUST

BE WORN.

Suitable glasses (Part No. 7350033) and gloves (Part No. 7350657) are

supplied with the unit, additional pairs are available from Nordson UV.

S Do not operate or service equipment unless you are qualified.

S Do not operate equipment unless safety guards, doors, or covers are

intact and automatic interlocks are operating properly. Do not bypass or

disarm any safety devices.

S Keep clear of moving equipment. Before adjusting or servicing any

moving equipment, shut off the power supply and wait until the

equipment comes to a complete stop. Lock out power and secure the

equipment to prevent unexpected movement. Wait 2 mins for the lamp

to cool down.

S If you receive even a slight electrical shock, shut down all electrical

equipment immediately. Do not restart the equipment until the problem

has been identified and corrected.

S Obtain and read Material Safety Data Sheets (MSDS) for all materials

used. Follow the manufacturer’s instructions for safe handling and use

of materials, and use recommended personal protection devices.

S To prevent injury, be aware of less-obvious dangers in the workplace

that often cannot be completely eliminated, such as hot surfaces, sharp

edges, energized electrical circuits, and moving parts that cannot be

enclosed or otherwise guarded for practical reasons.

E 2007 Nordson Corporation

MiniCure 08-07

Part 7119745C

1-4

Safety

Fire Safety

To avoid a fire or explosion, follow these instructions.

S Use only those inks and varnishes that cannot form explosive

atmospheres when heated by the lamp head (i.e. inks and varnishes

whose safety data sheets specify a flammable limit must not be used).

S Do not smoke, weld, grind, or use open flames where flammable

materials are being used or stored.

S Provide adequate ventilation to prevent dangerous concentrations of

volatile materials or vapors. Refer to local codes or your material MSDS

for guidance.

S Do not disconnect live electrical circuits while working with flammable

materials. Shut off power at a disconnect switch first to prevent

sparking.

S Shut down all equipment immediately if you notice sparking or arcing.

Do not restart the equipment until the cause has been identified and

corrected.

S Know where emergency stop buttons, shutoff valves, and fire

extinguishers are located. If a fire starts, immediately shut off the

system and exhaust fan.

S Clean, maintain, test, and repair equipment according to the instructions

in your equipment documentation.

S Only use replacement parts that are designed for use with original

equipment. Contact your Nordson representative for parts information

and advice or refer to the spares list in this manual.

Part 7119745C

MiniCure 08-07

E 2007 Nordson Corporation

Label Definitions

Refer to Manual

Warning! UV Radiation

Safety 1-5

Refer to the operating manual for further information.

Safety Glasses

Protective measures are necessary. Unprotected exposure to the UV light is

likely to have adverse effects on health. Gloves and eye protection must be

worn. Personnel in the vicinity of the device must be protected from

exposure by the use of suitable guarding.

UV protection safety glasses must be worn when operating this equipment.

Unprotected exposure to the UV light is likely to have adverse effects on

health.

E 2007 Nordson Corporation

MiniCure 08-07

Part 7119745C

1-6

Safety

Gloves

Capacitor

UV protection gloves must be worn when operating this equipment.

Unprotected exposure to the UV light is likely to have adverse effects on

health.

High Voltage

WARNING: Capacitor must be discharged to avoid electric shock.

WARNING: High voltage connections exposed on removal of cover.

Part 7119745C

MiniCure 08-07

E 2007 Nordson Corporation

Hot Surfaces

Handle with Care

Safety 1-7

WARNING: Potentially hot surafces. Allow to cool before touching.

WARNING: Handle with care. Do not break the quartz lamp; mercury

contained within.

E 2007 Nordson Corporation

MiniCure 08-07

Part 7119745C

1-8

Safety

Equipment safety

Introduction

All equipment is designed and manufactured to Internationally Recognized

Safety Standards to ensure that the health and safety of the operator is

protected at all times. This is conditional to equipment being installed

correctly by qualified personnel and operating instructions are strictly

adhered to.

Everyone who is required to work with the drying equipment in any way, i.e.

Installers, Operators, Service Engineers etc., must be made familiar with

these safety instructions.

The equipment is designed for the accelerated drying of UV inks and

coatings. No attempt should be made to dry alternative materials unless

these have been cleared by the supplier for this drying technique.

This equipment is not designed for use in hazardous areas or hazardous

environments (i.e. it is not flameproof).

High temperatures

High voltage

UV reflector systems generally run at extremely high temperatures. It is

therefore necessary to check that any exposed parts which may be touched

by an operator or personnel are kept below a temperature of 60° C,

dependent on the material type.

If you find that any surface is above 60° C please contact the Nordson UV

service department.

The UV curing equipment works at high voltages. It is therefore essential

that should any fault develop, the operator is made aware that he should:

Switch the equipment off immediately, make no attempt to service the

equipment himself, but call a qualified electrician, trained to service this type

of equipment.

NOTE: This applies to the changing of lamps, where a possible lamp fault

has occurred.

Part 7119745C

MiniCure 08-07

E 2007 Nordson Corporation

Fire risk

With lamps running at up to 800 degrees Centigrade, there is always a risk

of fire should any paper or materials get jammed under or in the lamp

vicinity, or in the event of build-up of fluff, dirt or powder within the lamp

housing.

Should such a situation occur, the operator must:

WARNING: Switch off the equipment immediately. If a fire extinguisher is

to be used, make sure it is of a type which is suitable for use with electrical

equipment.

A suitable fire extinguisher should be available near the unit.

This equipment is fitted with high temperature lamps. It is not designed to

operate close to low flash point materials (solvents, etc.).

Safety precautions while servicing

Safety 1-9

Important Information

All electrical maintenance and servicing must be carried out by a qualified

engineer. It is preferable to call in Nordson UV for this servicing facility.

WARNING: This equipment operates at high voltage and is therefore

potentially dangerous. All precautions must be taken by the qualified

engineer in servicing this equipment. The equipment must be isolated at

the mains before opening any of the access covers.

In the event of your qualified engineer being unable to find fault with the

equipment, then Nordson UV Service should be called in.

Control S ystem Cleaning

It is essential that all contactors and relays are kept clean and free from dirt

and dust ingression. These should be checked regularly, particularly in

extremely dusty or powder-charged working rooms.

E 2007 Nordson Corporation

MiniCure 08-07

Part 7119745C

1-10

Safety

High Voltage C onnections

Careful checks should be kept on the lamp connections and high voltage

connections within the equipment to make sure that these do not become

dirty or coated with powder or other possible conducting material. They

should be cleaned regularly, at least whenever the lamp is changed,

possibly more often where a particularly heavily polluted atmosphere

occurs. Also, while changing the lamps, a careful check should be made of

the high voltage leads to make sure that no deterioration has occurred.

Dirty contacts may cause a potential hazard.

Lamphead Cleaning

The air inlets in the reflector head should be regularly checked, so that it is

ensured that they have not become blocked with dust or powder and that

the air passages are clear.

High Temperatures

It should be noted that the reflector head runs at very high temperatures

and the inside components become very hot during operation of the

machine and the equipment. Therefore, when maintaining the equipment, a

reasonable time should be allowed before access is attempted.

Alternatively, precautions should be taken.

Part 7119745C

MiniCure 08-07

E 2007 Nordson Corporation

Safety UV curing

Safety 1-11

NOTE: The subtrate collection tray on the outfeed of the unit forms part of

the UV shielding. If this tray is not fitted alternative shielding methods must

be provided for operator and bystander safety.

UV measurements in the infeed chamber at belt level are

2

20 Micro Watts/cm

. If gloves and glasses are not used, then exposure to

the UV should be limited to no more than 4 mins per day.

UV measurements in the delivery tray are between

0.8--1.0 Micro Watts/cm

2

.

U.V. Radiation

UV radiation is generated from UV lamps and can be harmful if operator

exposure exceeds recommended levels, (see U.V. Permissible Exposure

Levels in this section).

Radiation is in the wavelength bands A B and C. Exposure to UV radiation

can result in:

S Reddening of skin.

S Headaches

S Sore eyes

If any symptoms appear, investigations should be carried out.

Nordson UV can, on request, supply UV safety glasses -- Part No. 7350033

and gloves -- Part No. 7350657.

First Aid

On skin no treatment can immediately be made, however, soothing cream

can be applied to the affected area.

For exposure to eyes medical attention should be sought immediately.

E 2007 Nordson Corporation

MiniCure 08-07

Part 7119745C

Loading...

Loading...