ProcessMate 100 Vacuum Pick-Up System

Operating Manual

™

Electronic pdf files of Nordson EFD

manuals are also available at

www.nordsonefd.com

ProcessMate 100 Vacuum Pick-Up System

You have selected a reliable, high quality ProcessMate™ 100 vacuum pick-up system from Nordson

EFD, the world leader in fluid dispensing. The ProcessMate100 vacuum pick-up system was designed

specifically for industrial dispensing, and will provide you with years of trouble-free, productive service.

This manual will help you maximize the usefulness of your ProcessMate100 vacuum pickup system.

Please spend a few minutes to become familiar with the controls and features. Follow our recommended

testing procedures. Review the helpful information we have included, which is based on more than

50years of industrial dispensing experience.

Most questions you will have are answered in this manual. However, if you need assistance, please do

not hesitate to contact EFD or your authorized EFD distributor. Detailed contact information is provided

on the last page of this document.

The Nordson EFD Pledge

Thank You!

You have just purchased the world’s finest precision dispensing equipment.

I want you to know that all of us at Nordson EFD value your business and will do everything in our power

to make you a satisfied customer.

If at any time you are not fully satisfied with our equipment or the support provided by your Nordson

EFD Product Application Specialist, please contact me personally at 800.556.3484 (US), 401.431.7000

(outside US), or Tara.Tereso@nordsonefd.com.

I guarantee that we will resolve any problems to your satisfaction.

Thanks again for choosing Nordson EFD.

Tara

Tara Tereso, Vice President

2 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Contents

Contents ..........................................................................................................................................................................3

Introduction .....................................................................................................................................................................4

Nordson EFD Product Safety Statement ........................................................................................................................5

Halogenated Hydrocarbon Solvent Hazards ...............................................................................................................6

High Pressure Fluids ....................................................................................................................................................6

Qualified Personnel ......................................................................................................................................................6

Intended Use ...............................................................................................................................................................7

Regulations and Approvals ..........................................................................................................................................7

Personal Safety ............................................................................................................................................................7

Fire Safety ....................................................................................................................................................................8

Preventive Maintenance ..............................................................................................................................................8

Important Disposable Component Safety Information ................................................................................................9

Action in the Event of a Malfunction ............................................................................................................................9

Disposal .......................................................................................................................................................................9

Specifications ................................................................................................................................................................10

Operating Features ........................................................................................................................................................11

Installation .....................................................................................................................................................................12

Unpack the Unit .........................................................................................................................................................12

Connect Air Supply ....................................................................................................................................................13

Connect Power ..........................................................................................................................................................13

Connect Foot Pedal ...................................................................................................................................................13

Attach Vacuum Pickup Pen / Wand Assembly ..........................................................................................................14

Attach Tip & Suitable Vacuum Cup ...........................................................................................................................14

Turn On Power to Unit ...............................................................................................................................................14

Operation .......................................................................................................................................................................15

Part Numbers ................................................................................................................................................................16

Accessories ...................................................................................................................................................................16

Replacement Parts ........................................................................................................................................................18

Troubleshooting ............................................................................................................................................................19

3www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Introduction

This manual provides safety, installation, operation, service,

and parts information for the ProcessMate100 vacuum pickup

system.

The ProcessMate100 Vacuum Pickup System provides a

simple, efficient way to lift and position small or delicate

components in benchtop assembly processes.

To lift the component, the operator simply places the pickup pen

on the component and presses an electric foot pedal to apply

vacuum. When the component has been positioned, releasing

the foot pedal stops the vacuum and releases the component.

4 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Nordson EFD Product Safety Statement

WARNING

The safety message that follows has a WARNING level hazard.

Failure to comply could result in death or serious injury.

ELECTRIC SHOCK

Risk of electric shock. Disconnect power before removing covers and / or disconnect, lock out, and

tag switches before servicing electrical equipment. If you receive even a slight electrical shock, shut

down all equipment immediately. Do not restart the equipment until the problem has been identified

and corrected.

CAUTION

The safety messages that follow have a CAUTION level hazard.

Failure to comply may result in minor or moderate injury.

READ MANUAL

Read manual for proper use of this equipment. Follow all safety instructions. Task- and equipmentspecific warnings, cautions, and instructions are included in equipment documentation where

appropriate. Make sure these instructions and all other equipment documents are accessible to

persons operating or servicing equipment.

MAXIMUM AIR PRESSURE

Unless otherwise noted in the product manual, the maximum air input pressure is 7.0 bar (100

psi). Excessive air input pressure may damage the equipment. Air input pressure is intended to be

applied through an external air pressure regulator rated for 0 to 7.0 bar (0 to 100 psi).

RELEASE PRESSURE

Release hydraulic and pneumatic pressure before opening, adjusting, or servicing pressurized

systems or components.

BURNS

Hot surfaces! Avoid contact with the hot metal surfaces of heated components. If contact can not be

avoided, wear heat-protective gloves and clothing when working around heated equipment. Failure

to avoid contact with hot metal surfaces can result in personal injury.

5www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Nordson EFD Product Safety Statement (continued)

Halogenated Hydrocarbon Solvent Hazards

Do not use halogenated hydrocarbon solvents in a pressurized system that contains aluminum components.

Under pressure, these solvents can react with aluminum and explode, causing injury, death, or property damage.

Halogenated hydrocarbon solvents contain one or more of the following elements.

Element Symbol Prefix

Fluorine F “Fluoro-”

Chlorine Cl “Chloro-”

Bromine Br “Bromo-”

Iodine I “Iodo-”

Check the Safety Data Sheet (SDS) or contact your material supplier for more information. If you must use

halogenated hydrocarbon solvents, contact your EFD representative for compatible EFD components.

High Pressure Fluids

High pressure fluids, unless they are safely contained, are extremely hazardous. Always release fluid pressure before

adjusting or servicing high pressure equipment. A jet of high pressure fluid can cut like a knife and cause serious

bodily injury, amputation, or death. Fluids penetrating the skin can also cause toxic poisoning.

WARNING

Any injury caused by high pressure liquid can be serious. If you are injured or even suspect an injury:

• Go to an emergency room immediately.

• Tell the doctor that you suspect an injection injury.

• Show the doctor the following note.

• Tell the doctor what kind of material you were dispensing.

Medical Alert — Airless Spray Wounds: Note to Physician

Injection in the skin is a serious traumatic injury. It is important to treat the injury surgically as soon as possible. Do

not delay treatment to research toxicity. Toxicity is a concern with some exotic coatings injected directly into the

bloodstream.

Qualified Personnel

Equipment owners are responsible for making sure that EFD equipment is installed, operated, and serviced by

qualified personnel. Qualified personnel are those employees or contractors who are trained to safely perform

their assigned tasks. They are familiar with all relevant safety rules and regulations and are physically capable of

performing their assigned tasks.

6 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Nordson EFD Product Safety Statement (continued)

Intended Use

Use of EFD equipment in ways other than those described in the documentation supplied with the equipment may

result in injury to persons or damage to property. Some examples of unintended use of equipment include:

• Using incompatible materials.

• Making unauthorized modifications.

• Removing or bypassing safety guards or interlocks.

• Using incompatible or damaged parts.

• Using unapproved auxiliary equipment.

• Operating equipment in excess of maximum ratings.

• Operating equipment in an explosive atmosphere.

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which it is used. Any approvals obtained for

Nordson EFD equipment will be voided if instructions for installation, operation, and service are not followed. If the

equipment is used in a manner not specified by Nordson EFD, the protection provided by the equipment may be

impaired.

Personal Safety

To prevent injury, follow these instructions:

• Do not operate or service equipment unless you are qualified.

• Do not operate equipment unless safety guards, doors, and covers are intact and automatic interlocks are

operating properly. Do not bypass or disarm any safety devices.

• Keep clear of moving equipment. Before adjusting or servicing moving equipment, shut off the power supply

and wait until the equipment comes to a complete stop. Lock out power and secure the equipment to prevent

unexpected movement.

• Make sure spray areas and other work areas are adequately ventilated.

• When using a syringe barrel, always keep the dispensing end of the tip pointing towards the work and away

from the body or face. Store syringe barrels with the tip pointing down when they are not in use.

• Obtain and read the Safety Data Sheet (SDS) for all materials used. Follow the manufacturer’s instructions for

safe handling and use of materials and use recommended personal protection devices.

• Be aware of less-obvious dangers in the workplace that often cannot be completely eliminated, such as hot

surfaces, sharp edges, energized electrical circuits, and moving parts that cannot be enclosed or otherwise

guarded for practical reasons.

• Know where emergency stop buttons, shutoff valves, and fire extinguishers are located.

• Wear hearing protection to protect against hearing loss that can be caused by exposure to vacuum exhaust

port noise over long periods of time.

7www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Nordson EFD Product Safety Statement (continued)

Fire Safety

To prevent a fire or explosion, follow these instructions:

• Shut down all equipment immediately if you notice static sparking or arcing. Do not restart the equipment until

the cause has been identified and corrected.

• Do not smoke, weld, grind, or use open flames where flammable materials are being used or stored.

• Do not heat materials to temperatures above those recommended by the manufacturer. Make sure heat

monitoring and limiting devices are working properly.

• Provide adequate ventilation to prevent dangerous concentrations of volatile particles or vapors. Refer to local

codes or the SDS for guidance.

• Do not disconnect live electrical circuits when working with flammable materials. Shut off power at a disconnect

switch first to prevent sparking.

• Know where emergency stop buttons, shutoff valves, and fire extinguishers are located.

Preventive Maintenance

As part of maintaining continuous trouble-free use of this product, Nordson EFD recommends the following simple

preventive maintenance checks:

• Periodically inspect tube-to-fitting connections for proper fit. Secure as necessary.

• Check tubing for cracks and contamination. Replace tubing as necessary.

• Check all wiring connections for looseness. Tighten as necessary.

• Clean: If a front panel requires cleaning, use a clean, soft, damp rag with a mild detergent cleaner. DO NOT

USE strong solvents (MEK, acetone, THF, etc.) as they will damage the front panel material.

• Maintain: Use only a clean, dry air supply to the unit. The equipment does not require any other regular

maintenance.

• Test: Verify the operation of features and the performance of equipment using the appropriate sections of this

manual. Return faulty or defective units to Nordson EFD for replacement.

• Use only replacement parts that are designed for use with the original equipment. Contact your Nordson EFD

representative for information and advice.

8 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Nordson EFD Product Safety Statement (continued)

Important Disposable Component Safety Information

All Nordson EFD disposable components, including syringe barrels, cartridges, pistons, tip caps, end caps,

and dispense tips, are precision engineered for one-time use. Attempting to clean and re-use components will

compromise dispensing accuracy and may increase the risk of personal injury.

Always wear appropriate protective equipment and clothing suitable for your dispensing application and adhere to

the following guidelines:

• Do not heat syringe barrels or cartridges to a temperature greater than 38° C (100° F).

• Dispose of components according to local regulations after one-time use.

• Do not clean components with strong solvents (MEK, acetone, THF, etc.).

• Clean cartridge retainer systems and barrel loaders with mild detergents only.

• To prevent fluid waste, use Nordson EFD SmoothFlow™ pistons.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system immediately and perform the following

steps:

1. Disconnect and lock out system electrical power. If using hydraulic and pneumatic shutoff valves, close and

relieve pressure.

2. For Nordson EFD air-powered dispensers, remove the syringe barrel from the adapter assembly. For Nordson

EFD electro-mechanical dispensers, slowly unscrew the barrel retainer and remove the barrel from the actuator.

3. Identify the reason for the malfunction and correct it before restarting the system.

Disposal

Dispose of equipment and materials used in operation and servicing according to local codes.

9www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Specifications

NOTE: Specifications and technical details are subject to change without prior notification.

Item Specification

Cabinet size 18.3

Weight 1.0 kg (2.2 lb)

Cycle rate Up to 600 cycles per minute

Input AC (to power supply) Universal Multi Voltage, 100/240 VAC, 50/60 Hz

Output DC (from power supply) 24 VDC, 1.04 Amp maximum

Power requirements 24 VDC, 0.83 Amp maximum

Internal voltage 24 VDC

Foot pedal Voltage: 24 VDC

Cycle initiate Foot pedal, finger switch

Input air pressure 7.0 bar (100 psi) maximum

Air output 0–110 inH

Vacuum output 0–110 inH

Ambient operating conditions Temperature: 5–45° C (41–113° F)

Product classification Installation category II

Approvals CE, TÜV, RoHS, WEEE, China RoHS

W x 5.1H x 8.6D cm (7.22W x 2.00H x 3.38D")

Current: 20 mA

0 dependent on user setting

2

0 dependent on user setting

2

Humidity: 85% RH at 30° C non-condensing

Height above sea level: 2,000 m maximum (6,562 ft)

Pollution degree 2

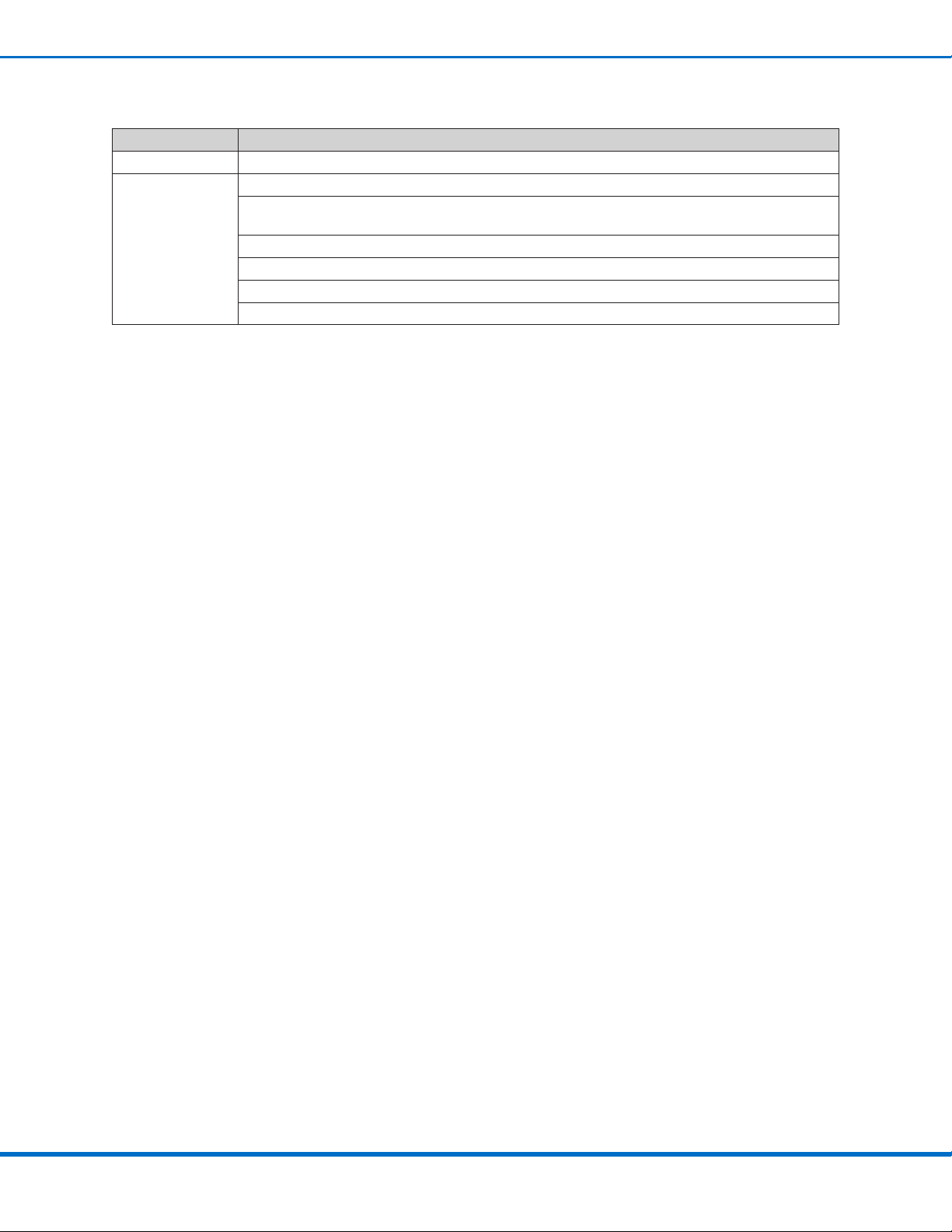

RoHS标准相关声明标准相关声明 (China RoHS Hazardous Material Declaration)

产品名称

Part Name

有害物质及元素

Toxic or Hazardous Substances and Elements

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr6)

多溴联苯

Polybrominated

Biphenyls

(PBB)

多溴联苯醚

Polybrominated

Diphenyl Ethers

(PBDE)

外部接口

External Electrical

Connectors

O: 表示该产品所含有的危险成分或有害物质含量依照EIP-A, EIP-B, EIP-C

的标准低于SJ/T11363-2006 限定要求。

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is below the

limit requirement in SJ/T11363-2006.

X: 表示该产品所含有的危险成分或有害物质含量依照EIP-A, EIP-B, EIP-C

的标准高于SJ/T11363-2006 限定要求.

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is above the

limit requirement in SJ/T11363-2006.

X 0 0 0 0 0

WEEE Directive

This equipment is regulated by the European Union under WEEE Directive (2012/19/EU). Refer to

www.nordsonefd.com/WEEE for information about how to properly dispose of this equipment.

10 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Operating Features

ProcessMate 100 Vacuum Pick-Up System

1

2

1. Vacuum air regulator adjustment knob — Controls vacuum level

2. Output quick connector — Vacuum pickup pen / wand connection

3. Power switch — Main DC power control switch

4

3

5

6

7

4. Foot pedal / finger switch connector — Connection for actuating device

5. Power input jack — DC power input

6. Vacuum exhaust port — vacuum air exit

7. Air input push-in fitting — Main filtered air supply input

11www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Installation

Unpack the Unit

Unpack the contents of the package and lay them out on a clean

workbench. The following items should be included with your

ProcessMate100 vacuum pickup system:

1

a. Vacuum unit

b. Foot pedal assembly

c. Power supply

d. Vacuum pickup pen / wand assembly

e. Muffler

a

d

e

c

b

12 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Installation (continued)

Connect Air Supply

NOTE: Clean, dry filtered factory air is required to meet

warranty. If your air supply is not filtered, order the EFD

5-micron filter / regulator (#7016547).

2

a. Turn the air regulator adjustment knob to zero before

connecting the main air input to the ProcessMate100.

b. Push one end of the 6 mm air input hose into the AIR IN

input fitting on the back of the ProcessMate100.

c. Connect the other end of the hose to your plant air

supply.

d. Set the plant air supply from 5.5–6.9 bar (80–100 psi).

ProcessMate 100 Vacuum Pick-Up System

3

4

Connect Power

a. Locate the DC input connection on the back of your

ProcessMate100 vacuum pickup system.

b. Insert the DC Plug securely into the input connection.

c. Select the proper adapter from the power supply plug kit

and then connect the power supply to a grounded power

source.

NOTE: The power supply is multi-voltage, therefore no

external adjustments are required.

Connect Foot Pedal

The ProcessMate100 comes equipped with a foot pedal

cycle actuation device.

• Connect the foot pedal to the back of the

ProcessMate100.

NOTE: If you prefer, you can also operate the

ProcessMate100 with an optional finger switch (#7016718).

13www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Installation (continued)

Attach Vacuum Pickup Pen / Wand Assembly

a. Locate the air output quick connector located on the

front face of the ProcessMate100.

5

b. Attach the male quick connector on the vacuum pickup

pen / wand assembly to the output quick connector by

pushing and twisting.

Attach Tip & Suitable Vacuum Cup

6

7

• Twist on the appropriate pickup tip and select a cup to fit

the application need.

NOTE: A selection of pickup tips and cups was included

in the system package for your convenience. Please

contact an EFD Application Specialist should you need

assistance in selecting a special tip / cup to suit your

application needs.

Turn On Power to Unit

a. Locate the power switch on the front display panel of the

ProcessMate100.

b. To power the unit, simply switch the rocker switch to the

“red” position.

Your ProcessMate100 is now powered and ready to be

activated.

14 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Operation

The ProcessMate100 vacuum pickup system was designed for applications requiring the picking up and placing

of small, intricate items. The vacuum effect for each application is strictly dependent on the combination of all the

following items:

• Regulator pressure, vacuum pressure

• Dispensing tip size

• Pickup cup size

1. Make sure the power is on and the air supply to the unit is turned on.

2. Place the vacuum pickup cup over the item to be picked up.

3. Turn the regulator counterclockwise until it stops.

4. Depress the foot pedal and gradually and slowly increase the vacuum by turning the air regulator clockwise

while trying to pick up the item.

NOTE: The foot pedal must be depressed during the entire duration of pickup and place.

5. Upon successful pickup, place the item at the intended location and release the foot pedal. The vacuum will

stop immediately and the item will be released from the vacuum cup.

CAUTION

Excessive vacuum settings can damage delicate components. Always use the minimum required vacuum and verify

that components are not damaged by the pickup and place procedure.

6. Repeat this procedure a few times to verify sufficient vacuum setting for the application.

15www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Part Numbers

Item Part # Description

7012329 ProcessMate100 Vacuum Pickup System

Includes assorted anti-static tips and vacuum cups.

7024803 VacTweezer™ Pickup Tool

This kit includes the same assortment of silicone rubber vacuum cups and

tips, along with a small squeeze bulb with a luer fitting that attaches to the

tips to generate vacuum.

Accessories

Item Part # Description

7016547 5-micron filter regulator

Required for production areas where clean, dry filtered factory air is not available, or

to stabilize the plant air supply for more consistent deposits.

7016718 Finger switch

Replaces the foot pedal in applications where operators prefer to initiate the vacuum

cycle by hand.

16 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Accessories (continued)

Vacuum Pickup Pen

Part # Description

7016107 Vacuum pickup pen (complete)

Vacuum Straight Tips (does not include vacuum cups)

Part # Size Description Quantity

7018043 14 gauge Tips (olive) 50/box

7018233 21 gauge Tips (purple) 50/box

Vacuum Pickup Tips, 45º Angled (does not include vacuum cups)

Part # Size Description Quantity

7016906 14 gauge Tips (olive) 50/box

7016908 18 gauge Tips (green) 50/box

7016910 21 gauge Tips (purple) 50/box

ProcessMate 100 Vacuum Pick-Up System

Vacuum Cups

Part # Size Description Quantity

7016889 0.0938" diameter Vacuum cups 10/box

7016883 0.1250" diameter Vacuum cups 10/box

7016887 0.1875" diameter Vacuum cups 10/box

7016881 0.2500" diameter Vacuum cups 10/box

7016891 0.3750" diameter Vacuum cups 10/box

17www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Replacement Parts

Item Part # Description

1 7012274 Regulator knob, black

2 — Regulator bezel

3 7012277 Regulator assembly, 0–100 psi

4 7014752 Regulator replacement O-rings

5 — On / off rocker switch assembly

6 — Overlay, front, PM100

7 — Panel, rear, PM100

8 7022009 Case, pack of 2 (top / bottom)

9 7015199 Universal power supply, power supply plug kit

10 7014865 Foot pedal assembly

11 — Muffler, 6 mm push-in

10

8

3

2

1

5

4

6

9

9

11

7

18 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

ProcessMate 100 Vacuum Pick-Up System

Troubleshooting

Problem Solution

No power Check the power supply connection and DC power supply to the unit.

No vacuum Check the main air supply and primary regulator.

Check to make sure that the main air supply is connected to the back of the unit and has not

come loose.

Check to make sure that the regulator is not turned off (fully counterclockwise).

Check the vacuum pickup pen wand assembly for possible contamination or clogs.

Check that the vacuum exhaust is not blocked or covered.

For heavier and larger items, use larger tips and cups and increase vacuum.

19www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

NORDSON EFD ONE YEAR LIMITED WARRANTY

This NordsonEFD product is warranted for one year from the date of purchase to be free

from defects in material and workmanship (but not against damage caused by misuse,

abrasion, corrosion, negligence, accident, faulty installation, or by dispensing material

incompatible with equipment) when the equipment is installed and operated in accordance

with factory recommendations and instructions.

NordsonEFD will repair or replace free of charge any defective part upon authorized return

of the part prepaid to our factory during the warranty period. The only exceptions are those

parts which normally wear and must be replaced routinely, such as, but not limited to, valve

diaphragms, seals, valve heads, needles, and nozzles.

In no event shall any liability or obligation of NordsonEFD arising from this warranty exceed

the purchase price of the equipment.

Before operation, the user shall determine the suitability of this product for its intended use,

and the user assumes all risk and liability whatsoever in connection therewith. NordsonEFD

makes no warranty of merchantability or fitness for a particular purpose. In no event shall

NordsonEFD be liable for incidental or consequential damages.

This warranty is valid only when oil-free, clean, dry, filtered air is used, where applicable.

For Nordson EFD sales and service in over

40 countries, contact Nordson EFD or go to

www.nordsonefd.com.

Global

800-556-3484; +1-401-431-7000

info@nordsonefd.com

Europe

00800 7001 7001

infoefd.europe@nordsonefd.com

Asia

China: +86 (21) 3866 9006; china@nordsonefd.com

India: +91 80 4021 3600; india@nordsonefd.com

Japan: +81 03 5762 2760; japan@nordsonefd.com

Korea: +82-31-736-8321; korea@nordsonefd.com

SEAsia: +65 6796 9522; sin-mal@nordsonefd.com

The Wave Design is a trademark of Nordson Corporation.

©2021 Nordson Corporation 7016150 v041421

Loading...

Loading...