Page 1

Nordson EFD Solutions:

Advanced Fluid Packaging Systems for Fluid Formulators

Page 2

Fluid Packaging Solutions

Contents

Introduction ......................................................................................................................................................... 1

Quality Standards .............................................................................................................................................. 2

Syringe Barrel Systems ..................................................................................................................................... 3

ESD-Safe Components ..................................................................................................................................... 9

Unity Components ........................................................................................................................................... 10

Optimum Class VI ............................................................................................................................................. 11

Optimum ECO ...................................................................................................................................................12

Cartridge Systems ............................................................................................................................................13

Two-Component (2K) Systems .........................................................................................................................18

Filling Systems .................................................................................................................................................. 19

Useful Resources ............................................................................................................................................. 21

Page 3

Fluid Packaging Solutions

Introduction

We understand the challenges facing

today’s uid formulators, especially in

advanced electronics, life science, and

automotive assembly markets.

Your high-tech, high-value assembly fluids

manufacture tomorrow’s innovative, high-value

products. That’s why Nordson EFD keeps improving

upon its already impeccable production and quality

control processes.

We designed our Optimum cartridge and syringe

barrel systems with unique elements that bring fluid

packaging and dispensing processes to a higher

level of precision, repeatability, and reliability.

We used Computational Fluid Dynamics software

to develop syringe barrels and cartridges that

fill quickly and smoothly without turbulence or

trapped air.

For you this means faster, more consistent

fills in packaging that emphasizes the quality

of your product. End users benefit from more

consistent, precise dispensing results with

virtually no fluid waste.

EFD delivers fluid packaging solutions for

tomorrow’s advanced manufacturing processes.

“ The quality of the packages that

we put our products in matters,

and that's why we use EFD

syringes and cartridges.”

- DYMAX CORPORATION

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

1

Page 4

Fluid Packaging Solutions

Optimum Quality

Standards

Nordson EFD adheres to highly controlled

manufacturing procedures, maintenance

schedules, and quality specifications in the

production of Optimum components. We also

maintain stringent quality control inspections

throughout the entire manufacturing process,

including incoming resin inspection before

production starts.

All components are produced in our own

silicone-free facilities in the USA. No silicone

mold-release agents are used in the precision

molding process or at any other time during

the production of our dispensing components.

Optimum components are also certified for

industrial use. They are rated to 100 psi

(6.9 bar) operating pressure and 100° F (38° C)

operating temperature.

All EFD dispensing components are stored

in anti-static bags to protect against

contamination. Package labels include lot

numbers for complete process control

and traceability.

Optimum components are always available

in conveniently packaged quantities. Syringe

barrels, cartridges, pistons, and caps can

be packaged separately, or pre-assembled

in any configuration that will help you

improve efficiency.

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

2

Page 5

Syringe Barrel Systems

Optimum Syringe Barrel Systems

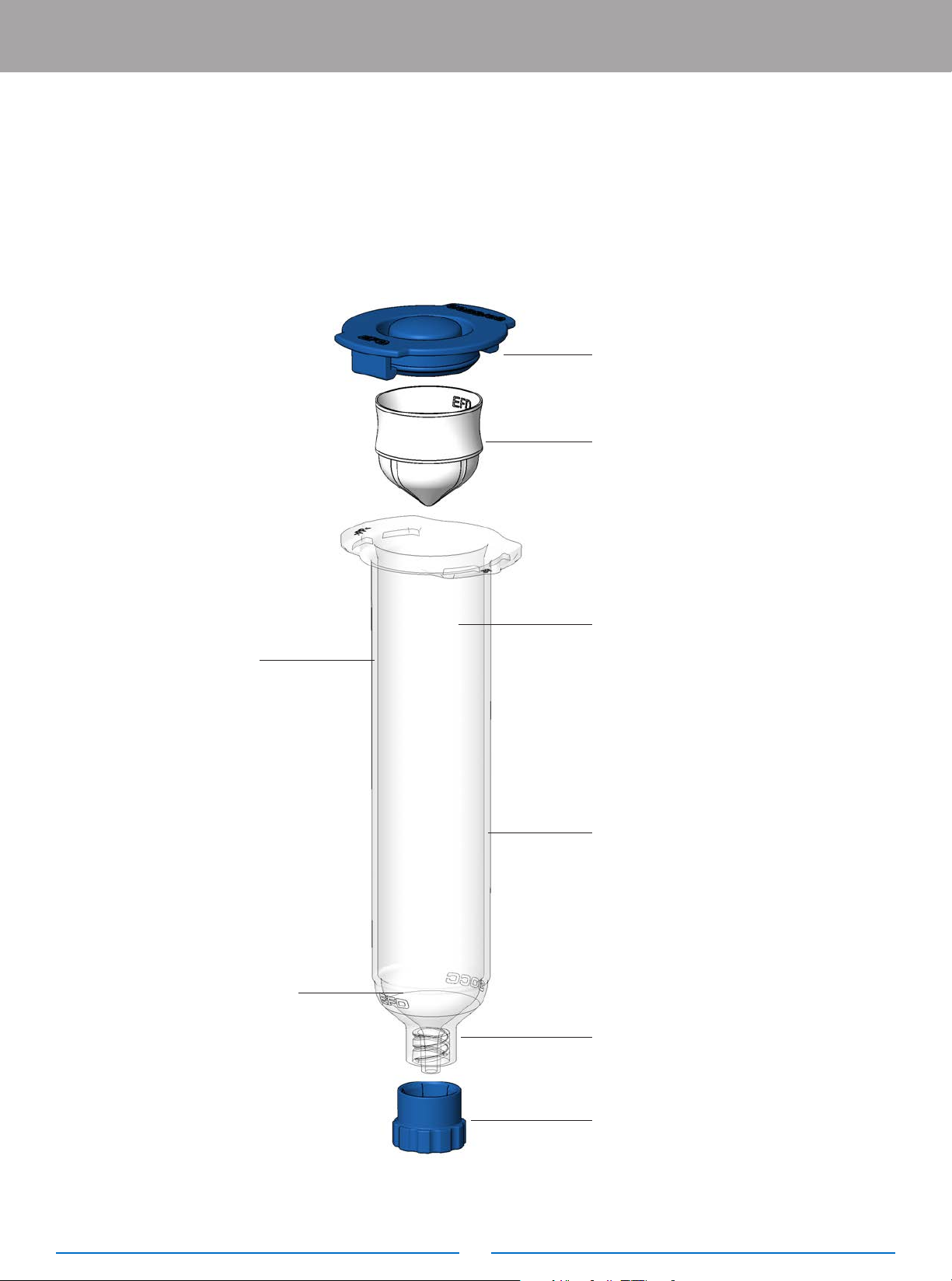

Optimum syringe barrel systems feature our patented, precision-molded Zero Draft™ syringe

barrels, SmoothFlow™ pistons, end caps, and tip caps. Each patented component has

been designed as part of a complete, integrated system that improves yields and reduces

costs by producing the most accurate, repeatable fluid deposits possible.

End Cap (polyethylene)

Locks securely onto the syringe, airtight

seal ensures long material shelf life

Piston (inert polyethylene)

Channeled wiper piston eliminates

trapped air, waste, and dripping

0° taper barrel for smooth

top-to-bottom piston travel

External jog mates with piston to

ensure all contents are dispensed

Syringe Barrel (inert polypropylene)

Durable, heavy wall construction uniquely

molded silicone-free protects product

integrity

Exceptional clarity and chemical compatibility

SafetyLok™ thread design ensures

secure tip cap attachment

Tip Cap (polyethylene)

Airtight seal and vented to prevent air

entrapment during installation

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

3

Page 6

Syringe Barrel Systems

Optimum

➀

➁

➂

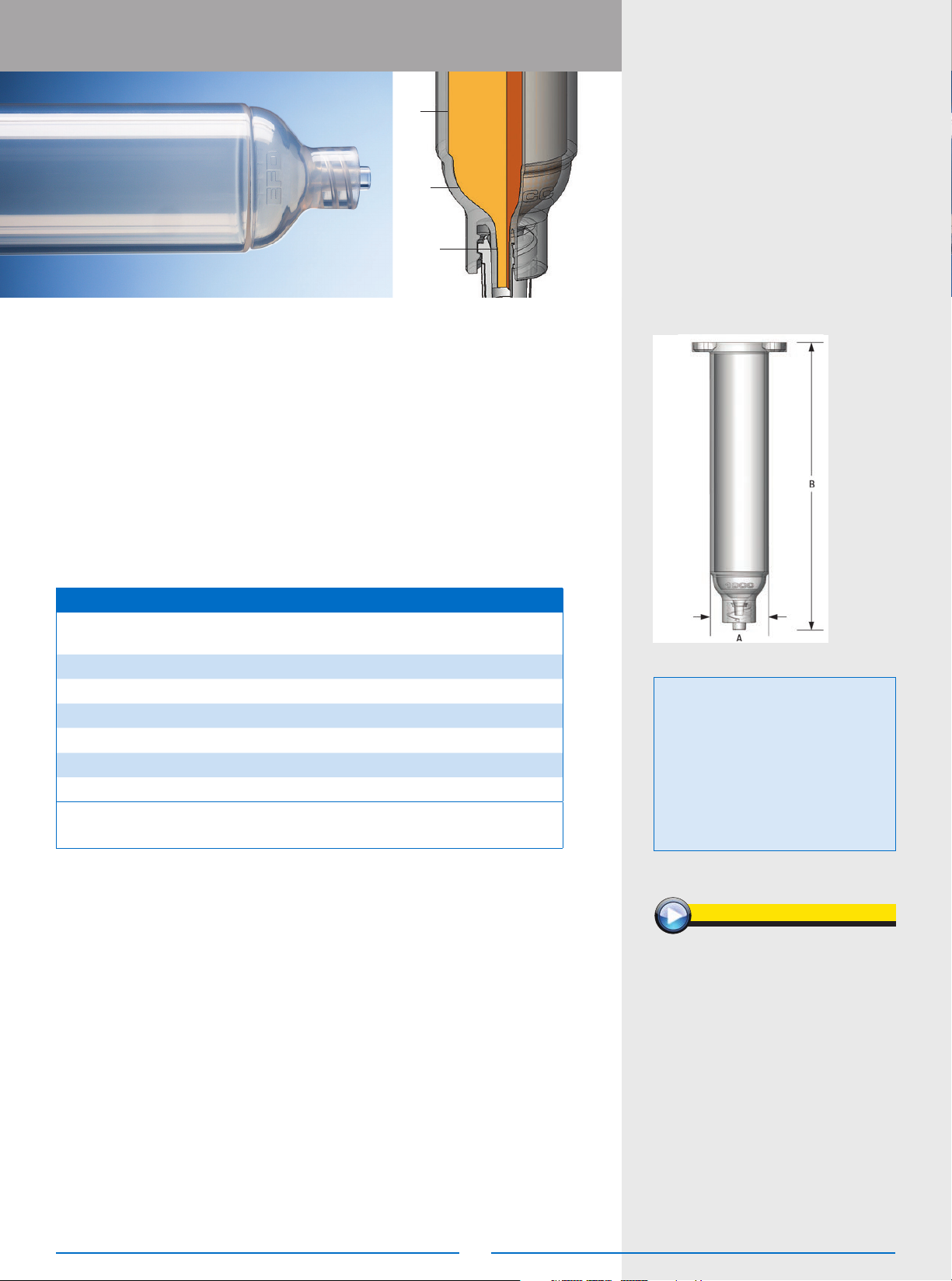

Optimum syringe barrels are molded from a proprietary polymer with

exceptional strength, clarity and chemical compatibility.

The internal profile ➀ ensures smooth, unimpeded laminar flow, without

turbulence or dead zones that could trap air. The thick dome area ➁ supports

drop strength. A tapered internal luer ➂ at the outlet minimizes fluid shear

during filling and dispensing.

Optimum syringe barrels are available in clear, UV-blocking amber, and lightblocking black configurations in 3cc, 5cc, 10cc, 30cc, and 55cc capacities.

The 70cc syringe barrels are our largest size. They allow production lines to run

longer with fewer fluid changeovers, reducing downtime. These barrels are ideal

for electronic applications such as underfill, potting, and conformal coating.

Syringe Barrels

OPTIMUM SYRINGE BARRELS

Size

3cc 7012073 7012084 7012090 (1000)

5cc 7012095 7012102 7012108 (1000)

10cc 7012113 7012123 7012129 (1000)

30cc 7012135 7012144 7012148 (1000)

55cc 7012154 7012159 7012163 (500)

70cc 7365016 7364912 – (500)

Note: Sets are available in clear for most uids; transparent amber for UV- and light-sensitive materials

(*less than 12% visible light from 550 nm or less); and opaque black for complete light blockage.

MOST FLUIDS

Clear Barrels

UV/Light Block*

Amber Barrels

Opaque

Black

QTY

BARREL DIMENSIONS

Size A B

3cc 11.1 mm (0.44") 73.0 mm (2.88")

5cc 14.3 mm (0.56") 68.3 mm (2.69")

10cc 19.1 mm (0.75") 88.9 mm (3.50")

30cc 25.4 mm (1.0") 115.9 mm (4.56")

55cc 25.4 mm (1.0") 173.0 mm (6.81")

70cc 25.4 mm (1.0") 213.1 mm (8.39")

Note: This data is typical and does not constitute a specication.

www.nordsonefd.com/1kOptimum

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

44

Page 7

Syringe Barrel Systems

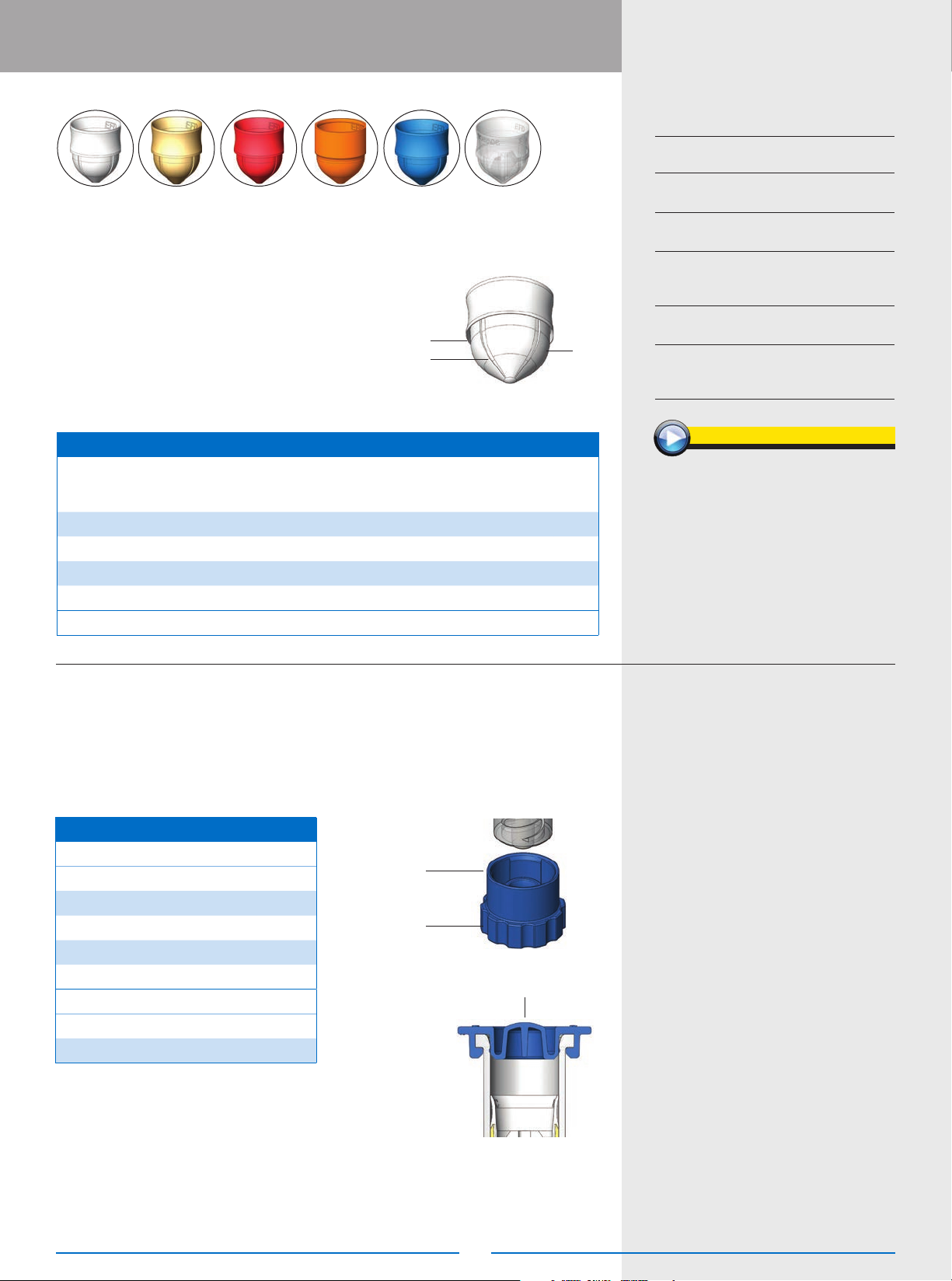

Molded from inert polyethylene, these patented SmoothFlow pistons are inserted

into syringe barrels to prevent air tunneling of viscous fluids and to provide easier,

safer handling of low viscosity liquids.

Unique pistons have precision molded channels ➀

that prevent air entrapment, along with a smooth

radius ➁ that reduces fluid shear during filling. The

precise geometry of the piston ➂ mates perfectly

with the precise geometry of the barrel to eliminate

material waste at the end of the dispense.

Note: Syringe barrels with pre-installed pistons are available for bottom lling.

OPTIMUM PISTONS

➁

➀

Optimum Pistons

Available in six styles:

White SmoothFlow wiper pistons are used with

most fluids.

Beige SmoothFlow pistons are loose-fitting and

used with air-entrapped fluids.

Red SmoothFlow pistons are tight-fitting and used

with mechanical dispensers.

Orange Flat-walled pistons have a looser fit to

prevent “bouncing” when dispensing stringy, airentrapped fluids.

Blue LV Barrier pistons are for cyanoacrylates and

very low viscosity fluids.

➂

Clear Flex pistons are flexible and reduce

“bouncing” in viscous fluids while maintaining

excellent wall-wiping.

www.nordsonefd.com/ClearFlex

Size

3cc 7012167 7012171 7012169 7012322 7014603 7362321 (1000)

5cc 7012173 7012177 7012175 7012324 – 7362318 (1000)

10cc 7012179 7012183 7012181 7012326 7014601 7029356 (1000)

30/55/70cc 7012185 7012189 7012187 7012328 7014599 7029552 (1000)

*Clear Flex pistons are molded from LDPE (low-density polyethylene).

White

SmoothFlow

Beige

SmoothFlow

Red

SmoothFlow

Orange

Flatwall

Blue

LV Barrier

Clear

Flex

QTY

Tip caps have a large knurled gripping surface ➀ for easy installation and removal,

and are vented ➁ to keep air from entering the fluid. End caps feature a convenient

pushbutton ➂ that produces a snug, air-tight seal.

Note: Syringe barrels with pre-installed tip caps are available for top lling.

OPTIMUM END AND TIP CAPS

Snap-on end caps provide tight seal.

Size Blue Green QTY

3cc 7012191 7013608 (1000)

5cc 7012193 7012769 (1000)

10cc 7012195 7012768 (1000)

30/55/70cc 7012197 7012767 (1000)

Twist-on tip cap seals syringe barrel.

Size Blue Green QTY

One size 7012199 7012201 (1000)

➁

➀

➂

Optimum

End and Tip Caps

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

55

Page 8

Syringe Barrel Systems

Optimum

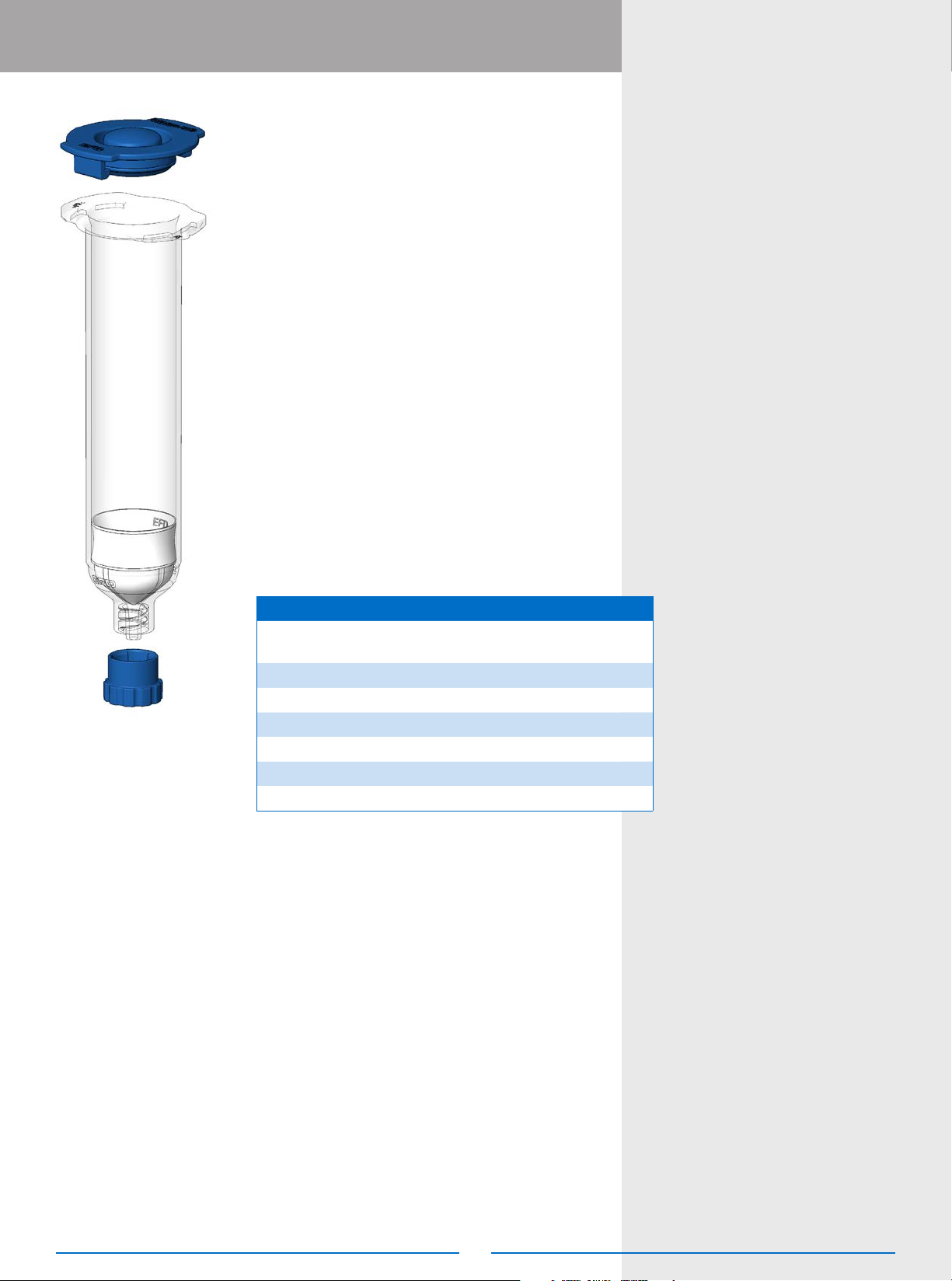

Nordson EFD syringe barrel kits provide the most

convenient and reliable way to package fluids.

Each kit contains 500 or 1,000 complete sets of

syringes, pistons, tip caps, and end caps. White

SmoothFlow wiper pistons and blue end and tip

caps are standard. Other colors are available.

The kit box is divided into four sections. Each

section contains 250 complete sets, packaged in

anti-static bags. Individual bags are sealed with

tamper-evident seals.

• Simplify handling and control distribution to

filling stations

• Reduce waste and loss of individual

components — EFD kits are organized in

boxed sets

• Easily manage inventory and order placement

• Anti-static bags protect components from

dust and other contaminants

• Easily track parts by lot numbers that are

placed on each component bag

Syringe Barrel Kits

OPTIMUM SYRINGE BARREL KITS

Size

3cc 7012078 7012087 7012092 (1000)

5cc 7012100 7012105 7012110 (1000)

10cc 7012120 7012124 7012132 (1000)

30cc 7012141 7013612 7012151 (1000)

55cc 7012157 7012161 7013610 (500)

Customized kits are available upon requests. Contact EFD.

MOST FLUIDS

Clear Barrels

UV/Light Block

Amber Barrels

Opaque

Black Barrels

QTY

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

66

Page 9

Syringe Barrel Systems

Optimum

The option to purchase pre-installed pistons for

clear, amber, and black syringe barrels provides

considerable value. Pre-installed pistons save

labor and prevent dust or debris from entering

the syringe under the piston.

Each kit contains 500 or 1000 sets with the

piston pre-installed in the syringe all the way

to the bottom for added convenience. This

eliminates process time by allowing operators to

bottom-fill with less chance of air or contaminants

entering the fluid during packaging.

OPTIMUM SYRINGE BARREL / PISTON KITS

MOST FLUIDS

Size

3cc 7012080 7012088 7012093 (1000)

5cc 7013613 7012106 7012111 (1000)

10cc 7012121 7012125 7012133 (1000)

30cc 7012142 – 7012152 (1000)

55cc 7013611 7013792 7013791 (500)

White SmoothFlow wiper pistons are standard. Other colors are available.

Clear Barrels

/Piston Kits

UV/Light Block

Amber Barrels

/Piston Kits

Opaque

Black Barrels

/Piston Kits QTY

Syringe Barrels

with Pre-Installed

Pistons

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

7

Page 10

Syringe Barrel Systems

Optimum

The option to purchase pre-installed tip caps for

clear, amber, and black syringe barrels provides

considerable value for fluid formulators who top-fill.

With the tip cap pre-installed with the right amount

of torque, operators receive syringe barrels ready

to be filled. It eliminates a step.

OPTIMUM SYRINGE BARREL / TIP CAP KITS

MOST FLUIDS

Size

3cc 7013811 7361972 7361971 (1000)

5cc 7013810 7026760 7015971 (1000)

10cc 7013809 7015349 7015971 (1000)

30cc 7013808 7015350 7015348 (1000)

55cc 7013807 7360535 7360675 (500)

Blue tip caps are standard. Other colors are available.

Clear Barrels

/Tip Cap Kits

UV/Light Block

Amber Barrels

/Tip Cap Kits

Opaque

Black Barrels

/Tip Cap Kits QTY

Syringe Barrels

with Pre-Installed

Tip Caps

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

8

Page 11

Dispensing Components

Nordson EFD’s Optimum ESD-safe black dispensing components prevent

static buildup when dispensing adhesives, pastes, coatings, and other

assembly fluids used in manufacturing electronic products.

Features and Benefits

• Static decay rate less than 2.0 seconds

• High conductivity

• Meets industry standards that ensure static will not be transferred while

dispensing

• Molded from inert, non-carbon, non-surface-migratory material that’s safe,

even for sensitive fluids

Optimum ESD-Safe

Components

ESD-SAFE BLACK BARRELS

Size Part # Qty/Box

3cc 7362855 1000

5cc 7362857 1000

10cc 7362859 1000

30cc 7362861 1000

ESD-SAFE BLACK ADAPTER ASSEMBLY

Size

3cc 7016095 7016096 1

5cc 7027849 – 1

10cc 7016097 7016098 1

30cc/55cc 7362545 7362546 1

Adapter assemblies sold individually. Pistons sold separately; see pg 5.

0.9 m (3 ft)

Hose

1.8 m (6 ft)

Hose

Qty/Box

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

9

Page 12

Dispensing Components

Nordson EFD’s disposable Unity™ HiTemp™ syringe barrels provide

a cost-effective alternative to syringes commonly used in pneumatic

dispensing of hot melt adhesives. The barrels are compatible with

Nordson’s Unity IC Series and Unity PURJet™ 30 dispensing systems

and other standard industry hot melt dispensers.

Unity HiTemp

Components

Features and Benefits

• Proprietary materials maintain integrity at high temperatures for up

to eight hours

• Disposability reduces downtime and maintenance costs with better

cost of ownership compared to standard metal syringes

• Reliable, repeatable hot melt adhesive dispensing at up to 180° C

UNITY SYRINGE BARREL

Size

30cc 7360474 – 7363795 1000

30cc – 7360472 – 500

Size

30cc 7360317 7017987 7363886 1000

HiTemp

(125° C)

Tip Cap White

Extreme HiTemp

UNITY ADAPTER ASSEMBLY

Size

30cc 7362348 7362347 1

Adapter assemblies sold individually.

0.9 m (3 ft) Hose 1.8 m (6 ft) Hose Qty/Box

Extreme HiTemp

(180° C)

END AND TIP CAPS

Tip Cap Orange

Stemmed

HiTemp

Tapered

End Cap Blue

Unity

Qty/Box

Qty/Box

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

10

Page 13

Dispensing Components

Nordson EFD Optimum Class VI syringe barrels and dispensing components

are made from 100% United States Pharmacopeia (USP) Class VI virgin resin

to simplify process validation for medical manufacturers.

Note: These components are not manufactured in a clean room environment.

Optimum Class VI

Components

Features and Benefits

• Enhanced biocompatibility for medical use

• Ease of process validation for regulatory approvals

• Market-leading traceability for documentation requirements

• Ability to sterilize to ensure a bacteria-free product

CLASS VI COMPONENTS

Size

3cc 7364592 7364604 7364610 1000

5cc 7364593 7364605 7364611 1000

10cc 7362189 7362151 7364612 1000

30cc 7362190 7362152 7364613 1000

55cc 7362190 7362152 7364613 1000

– 7364591 – – 1000

Optimum Class VI pistons are designed for use with Class VI barrels only.

1,000 quantity part numbers come double-bagged to reduce the risk of contamination

in clean rooms.

Class VI Clear

Barrels

Class VI Clear

Pistons

CLASS VI TIP CAPS

Class VI Clear

End Caps

Qty/

Box

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

11

Page 14

Dispensing Components

Optimum ECO

Components

Nordson EFD’s Optimum ECO dispensing components are manufactured

from sustainably-sourced polyethylene and feature a bio-based content rating

of 94% to 96%. This eco-friendly system helps meet corporate sustainability

initiatives by using raw resins derived from sugarcane stock versus

byproducts of the petrochemical industry.

Features and Benefits

• Eco-friendly components are made from renewable resources

• Minimize consumption and greenhouse gases, reducing carbon footprint

• Barrel transparency allows operator to see fluid level

• Superior freezing properties for premixed fluids compared to standard

polypropylene barrels

ECO COMPONENTS

Size ECO Natural Barrels ECO Natural Pistons ECO Natural End Caps

3cc 7364681 7364695 7364703 1000

5cc 7364682 7364696 7364704 1000

10cc 7364683 7364697 7364705 1000

30cc 7364684 7364698 7364706 1000

55cc 7364685 7364698 7364706 1000

*

ECO TIP CAPS

– 7364680 – – 1000

Qty/

Box

*Includes 500 syringe barrels.

Optimum ECO pistons are designed for use with ECO barrels only.

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

12

Page 15

Cartridge Systems

Optimum Cartridge Systems

Optimum cartridge systems feature our patented, precision-molded Zero Draft™ cartridges,

pistons, end caps, and outlet caps. Each component has been designed as part of a complete,

integrated system that improves yields and reduces costs by producing the most accurate,

repeatable fluid deposits possible.

End Cap (polyethylene)

Locks securely onto the cartridge, airtight

seal ensures long material shelf life

Cartridge Barrel (proprietary polymer)

0° taper barrel for

smooth top-to-bottom

piston travel

Exceptional clarity and

chemical compatibility

Durable, heavy wall construction

uniquely molded silicone-free protects

product integrity

Piston (high-density polyethylene)

Piston channels help dissipate air

during filling, dual wiping edges

eliminate waste and residue

Outlet Cap (polyethylene)

Airtight seal and vented to prevent

air entrapment during installation

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

13

Page 16

Cartridge Systems

Optimum

Optimum cartridges are molded from a strong, clear FDA- and RoHS-compliant

polymer, with ZeroDraft walls that maintain consistent internal diameters for

smooth piston travel.

Strong molded ribs ➀ around the cartridge outlet prevent splitting when installing

fittings or nozzles. Precision threads and a tapered counterbore ➁ at the ¼"

NPT outlet ensure a secure, leakproof seal during packaging and shipment. A

sturdy hex ➂ molded around the outlet fits into a matching orifice on the cartridge

retainer for fast, tool-free installation of fittings and nozzles.

Optimum cartridges are available in clear, UV-blocking amber, light-blocking

black, and white configurations. Capacities include 2.5 fl oz (75 ml), 6 fl oz (180

ml), 12 fl oz (360 ml), 20 fl oz (600 ml), and 32 fl oz (960 ml).

➀

➂

➁

Cartridges

OPTIMUM CARTRIDGES

Size Clear White Amber Black Green QTY

2.5 oz (75 ml) 7012392 – 7012393 7012394 7014168 250

6 oz (180 ml) 7012401 7026679 7012402 7012403 – 250

12 oz (360 ml) 7012410 7028389 7012411 7012412 7014174 250

20 oz (600 ml) 7012417 7028362 7012737 7013879 7014177 100

32 oz (960 ml) 7014092 7028393 7014093 7014095 – 100

Sets are available in clear for most uids; transparent amber for UV and light-sensitive materials (*less than 12%

visible light from 550 nm or less); opaque black for complete light blockage; and white for better frozen temperature

resistance.

CARTRIDGE DIMENSIONS

Size A B

2.5 oz (75 ml) 43.2 mm (1.70") 98.8 mm (3.89")

6 oz (180 ml) 43.2 mm (1.70") 181.5 mm (7.15")

12 oz (360 ml) 43.2 mm (1.70") 314.3 mm (12.38")

20 oz (600 ml) 68.3 mm (2.69") 249.7 mm (9.83")

32 oz (960 ml) 68.3 mm (2.69") 346.4 mm (13.69")

Note: This data is typical and does not constitute a specication.

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

14

Page 17

Cartridge Systems

Optimum

Optimum cartridge pistons are precision molded from high-density polyethylene.

Their consistent fit ➀ perfectly matches cartridge walls to prevent blow-by and

leakage during filling and shipment.

Unique dome shape and recessed channels ➁ on the bottom of the piston

help dissipate air during the filling process, reducing or eliminating the need to

centrifuge.

Note: Cartridges with pre-installed pistons are available for bottom lling.

➀

➁

OPTIMUM CARTRIDGE PISTONS

Part # Size Color QTY

7012420

7362086

7012422

2.5, 6, 12 oz

(75, 180, 360 ml)

2.5, 6, 12 oz

(75, 180, 360 ml)

20, 32 oz

(600, 960 ml)

White 250

Blue 250

White 100

Cartridge Pistons

Blue pistons have a smaller leading edge wiper. The looser t reduces dripping or stringing during the

dispensing of very thick uids and the color makes it easy to see the piston position inside the cartridge.

Threaded, self-venting outlet caps keep air from being introduced into

the fluid and have a hex recess ➀ for automated installation.

End caps have a flexible pushbutton ➁ that allows air to escape when

snapped onto the cartridge and ensures an air-tight seal to keep material

fresh and prevent leaks during shipment.

Note: Cartridges with pre-installed outlet caps are available for top lling.

➁

➀

Part # Size Color QTY

7012424

7012739

7012426

7014470

Optimum Cartridge

End/Outlet Caps

OPTIMUM CARTRIDGE END CAPS

2.5, 6, 12 oz

(75, 180, 360 ml)

2.5, 6, 12 oz

(75, 180, 360 ml)

20, 32 oz

(600, 960 ml)

20, 32 oz

(600, 960 ml)

Blue 250

Green 250

Blue 100

Green 100

OPTIMUM CARTRIDGE OUTLET CAPS

Part # Size Color QTY

7012428 All Blue 250

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

15

Page 18

Cartridge Systems

Optimum

The option to purchase pre-installed pistons provides

considerable value. Pre-installed pistons save labor

and prevent dust or debris from entering the cartridge

under the piston when bottom filling.

Each kit contains 250 or 100 sets with the piston preinstalled in the cartridge all the way to the bottom for

added convenience.

OPTIMUM CARTRIDGES / PISTON KITS

Size

2.5 oz (75 ml) 7012395 - 7012396 - 7014169 (250)

6 oz (180 ml) 7012404 7029561 7012405 7012406 - (250)

12 oz (360 ml) 7012413 7029689 7012414 7012415 7014175 (250)

20 oz (600 ml) 7012418 7029562 7012738 7013880 7014178 (250)

32 oz (960 ml) 7014096 7029500 7014097 - - (100)

White pistons are standard. Customized kits are available on request. Contact EFD.

Clear

/Piston

White

/Piston

Amber

/Piston

Black

/Piston

Green

/Piston

Cartridges with

Pre-Installed

Pistons

QTY

Nordson EFD also offers pre-installed outlet caps for our

20 fl. oz. (600 ml) clear cartridges (P/N 7015225), which

comes in a kit of 100 cartridge/outlet cap sets. Our

outlet caps are installed with the right amount of torque

to save labor and time when top filling cartridges.

Optimum

Cartridges with

Pre-Installed

Outlet Caps

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

16

Page 19

Cartridge Systems

Optimum Cartridge

Retainer Systems

Optimum cartridge retainers are molded from high-tensile, clarified resin that

permits easy visual monitoring of fluid levels. Large textured ribs provide an

ergonomic grip for cap installation.

Retainer caps feature locking tabs that snap securely into detents on the

retainer body with an audible click. A push-in air line connector on top of the

cap eliminates the need for bayonet connectors.

RETAINER SYSTEMS

Retainer Systems* Retainer Bodies

Part # Size Part # Size

7012430 2.5 oz (75 ml) 7013857 2.5 oz (75 ml)

7012433 6 oz (180 ml) 7013858 6 oz (180 ml)

7012436 12 oz (360 ml) 7013859 12 oz (360 ml)

7012439 20 oz (600 ml) 7013860 20 oz (600 ml)

7013899 32 oz (960 ml) 7013900 32 oz (960 ml)

Retainer Cap Assemblies

Part # Size

7012531 2.5, 6, 12 oz (75, 180, 360 ml)

7012532 20, 32 oz (600, 960 ml)

Retainer Cap O-ring Kits (2/pkg.)

Part # Material Size

7014373 Buna 2.5, 6, 12 oz (75, 180, 360 ml)

7026914 EPR 2.5, 6, 12 oz (75, 180, 360 ml)

7026915 Viton

7014372 Buna 20, 32 oz (600, 960 ml)

7026916 EPR 20, 32 oz (600, 960 ml)

7026917 Viton 20, 32 oz (600, 960 ml)

*Note: For retainer systems with 100 psi and 15 psi regulators, contact EFD. The retainer cap O-rings are available in

three different materials. Please select the one most compatible with your uid. Standard O-ring material is Buna.

®

2.5, 6, 12 oz (75, 180, 360 ml)

“EFD is our favorite vendor to deal with –

fast, professional, and top notch products.”

– Contract Packager

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

1717

Page 20

Fluid Packaging Solutions

Two-Component

(2K) Dispensing

Components

Nordson EFD’s 2K product line includes static mixers, cartridge systems, and

meter mix valves for reactive two-component adhesives & sealants such as

epoxies, urethanes, silicones, and acrylics.

Our ISO 9001:2015 certified mixing solutions include two mixer geometries:

Spiral and Square. Using proprietary flow simulation technology to improve the

material flow path design and element wedges, the square OptiMixer

480 delivers better mix quality in a 20% shorter length, without impacting other

performance factors.

Two-component cartridge systems range from 1.0 to 1500mL capacities. The

breakthrough, two-component u-TAH® Universal Cartridge looks identical to

standard caulking cartridges, yet delivers the most effective, highest-quality

dispensing in the industry.

It is the only cartridge system that maintains accurate ratio control and fits into

existing 1/10th gallon or 310mL caulking guns. The u-TAH Universal eliminates

the need for end users to purchase expensive special-purpose dispensing guns.

In addition, our collapsible film-based Film-

®

cartridges provide a highly-sustainable

Pak

option for packaging and dispensing

for two-component fluids. Seven fullycompressed Film-Pak cartridges replace

one rigid Side x Side cartridge in landfills —

reducing packaging waste volume by more

than 85%.

™

Series

Nordson EFD also offers disposable dual syringes and static mixers that provide

controlled mixing and placement of two-part epoxies, adhesives, sealants, gels,

pastes, and compounds used in a range of DIY home improvement, automotive,

health and beauty, and dental applications.

Contact EFD at 800-556-3484 or info@nordsonefd.com or visit our website at

nordsonefd.com/2Ksystems for more information. For part numbers visit our

2K Product Brochure.

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

18

Page 21

Filling Systems

Atlas Syringe

Filling Systems

EFD filling systems provide a fast, neat and easy way to transfer greases, silicones,

and other non-pourable fluids from cartridges and bulk containers into 3cc, 5cc, 10cc,

30cc, 55cc, and 70cc syringe barrels.

Manual filling systems are a cost-effective way to eliminate trips to the refilling station

and keep production lines running smoothly.

Barrel filling stations are available in sizes 2.5 fl oz, 6 fl oz, 12 fl oz, 20 fl oz, and

32 fl oz (75 ml, 180 ml, 360 ml, 600 ml, and 960 ml) cartridges.

Features and Benefits

• See-through design allows maximum amount of material usage per cartridge

• Fast and accurate filling

• Accommodates 3cc to 70cc syringes

• Small footprint allows easy positioning of multiple units

• Prefilling syringes increases productivity and reduces labor costs

1/10 Gallon Caulking Tube

Filling systems make it simple to transfer

silicones and other materials supplied in

1/10 gal cartridges to 3cc, 5cc, 10cc,

30cc, 55cc, or 70cc syringe barrels

without waste, mess or air bubbles.

7022446 922BL Filling System

2.5 fl oz (75 ml) cartridge. Comes complete with

0-100 psi (0-7.0 bar) regulator and gauge, retainer

and cap assembly with toggle switch, fittings,

stand, cartridge with plunger and 5cc, 10cc, and

30/55/70cc syringe barrel fill level plugs.

7022447 926BL Filling System

6 fl oz (180 ml) cartridge. Ships with the same parts

as the 922BL.

7022445 920BL Filling System

12 fl oz (360 ml) cartridge. Ships with the same

parts as the 922BL.

7013568 Filling System

20 fl oz (600 ml) cartridge. Ships with the same

parts as the 922BL.

7013901 Filling System

32 fl oz (960 ml) cartridge. Ships with the same

parts as the 922BL.

7022452 940BL 1/10 Gallon Caulking Tube

Comes complete with 0-60 psi (0-4.1 bar)

regulator and gauge, retainer and cap assembly

with toggle switch, fittings, stand, and 3cc, 5cc,

10cc, and 30/55/70cc size syringe barrel fill level

plugs.

Automatic Syringe Filling Systems

For extremely fast, consistent, and costeffective volumetric filling of pastes, gels,

and other non-pourable assembly fluids,

specify our automatic systems.

These systems rapidly fill syringe barrels

with ± 2% accuracy at the press of

a button. Syringes are bottom filled,

allowing air to escape for a consistent

7022064 8000BF-HF

Use with cartridges and tanks at pressures up to

100 psi (7.0 bar). System ships complete with

microprocessor controller, 5-micron filter/regulator,

fittings, and foot pedal.

7022068 8000BF-HPA

Use with very thick fluids at pressures up to

2500 psi (172 bar). System ships complete with

microprocessor controller, 5-micron filter/regulator,

fittings, and foot pedal.

volumetric fill. Accommodates 3cc, 5cc,

10cc, 30cc, and 55cc syringe barrels.

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

1919

Page 22

Filling Systems

Atlas Cartridge

Filling Systems

The Atlas™ Cartridge Filling System provides a simple, cost-effective way to fill

2.5 to 32 ounce cartridges with greater accuracy at lower cost, making it ideal for:

• Material suppliers

• Custom packagers

• Manufacturers who down-pack from larger containers

Easy to set up and operate, the Atlas Cartridge Filling System allows virtually any

operator to bottom-fill 2.5 ounce to 32 ounce cartridges with consistent amounts

of material.

Features and Benefits

• Accurate, repeatable filling

• Eliminates rework and overfills

• Fast, easy changeovers

• Handles viscosities from 2000 cps

and up

• Sensors work with all color cartridges

and pistons

REPLACEMENT PARTS

Part # Description

7022019 Power supply, 30 W

7013449 736HPA-NV valve

Specifications

Cabinet size: 52.3w x 71.1h x 22.9d cm

(21w x 28h x 9"d)

Max extended tower height: 100 cm (39.4")

Weight: 9.1 kg (20 lb)

Input AC (to power supply):

Universal Multi Voltage

100/240 VAC, 50/60Hz

Machine power requirement:

24 VDC, 0.5 Amp maximum

Max. input shop air pressure: 120 psi (8.3 bar)

An electrical fuse: 250 volt, 1 Amp, slow blow,

3AG cartridge

7014123 Atlas Cartridge Filling System

Includes tool kit, accessory kit, desktop power

supply with AC cord and Quick Start Guide.

Please assess the properties of your uid before trying the

Atlas Filling System. Fluids that are thick enough to have

minimal dripping or spill out when bottom-lled will work best

with the Atlas system.

“We are very pleased with the ease of

use. Any operator can use the Atlas Filling

System to achieve consistent fill weights.”

– Manufacturing Manager

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

2020

Page 23

Useful Resources

Choosing and implementing the best possible fluid packaging and dispensing solutions starts with access to the

best possible resources. Here are some to get you started:

Application Videos

Visit our Video Gallery to access 150+ application, how-to, and product videos.

See EFD solutions in action.

Watch Videos: videos.nordsonefd.com

What Our Customers Say

Find out how Nordson EFD helps manufacturers improve their processes every day —

see what our customers have to say.

Our Customers Know Best: www.nordsonefd.com/Testimonials

Expert Recommendations

Knowledgeable Nordson EFD fluid application specialists have, on average, more than

10 years of experience helping customers find the right solutions.

Request Expert Advice: www.nordsonefd.com/Advice

Follow our Blog: www.nordsonefd.com/Blog

Easy Part Number Search

It’s easy to search our digital catalog to find products by part number or keywords.

Plus, get links to product specs, videos, and more. With our app, you can even access

the catalog from your smartphone.

Find Part Numbers: www.nordsonefd.com/Digital-Catalog

Optimum Components Reference Guide

Full-color wall poster for easy reference. Includes helpful tips for selecting the best

components for specific dispensing applications.

Download Guide: www.nordsonefd.com/ComponentsGuide

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

2121

Page 24

Useful Resources

Request More Information

Nordson EFD’s worldwide network of experienced product application

specialists are available to discuss your needs and recommend a solution

that meets your uid packaging requirements and budget.

Call or email us for a consultation.

800-556-3484

info@nordsonefd.com

www.nordsonefd.com/samples

Connect with us

For Nordson EFD sales and service in over

40 countries, contact Nordson EFD or go to

www.nordsonefd.com.

Global

800-556-3484; +1-401-431-7000

info@nordsonefd.com

Europe

00800 7001 7001

infoefd.europe@nordsonefd.com

Asia

China: +86 (21) 3866 9006; china@nordsonefd.com

India: +91 80 4021 3600; india@nordsonefd.com

Japan: +81 3 5762 2760; japan@nordsonefd.com

Korea: +82-31-736-8321; korea@nordsonefd.com

SEAsia: +65 6796 9522; sin-mal@nordsonefd.com

Viton is a registered trademark of E.I. DuPont.

©2021 Nordson Corporation v042021

Loading...

Loading...