794-TC Series Auger Valve

Operating Manual

™

Electronic pdf files of Nordson EFD

manuals are also available at

www.nordsonefd.com

794-TC Series Auger Valve

You have selected a reliable, high-quality dispensing system from Nordson EFD, the world leader in fluid

dispensing. The 794-TC auger valve was designed specifically for industrial dispensing and will provide

you with years of trouble-free, productive service.

This manual will help you maximize the usefulness of your 794-TC auger valve.

Please spend a few minutes to become familiar with the controls and features. Follow our recommended

testing procedures. Review the helpful information we have included, which is based on more than

50years of industrial dispensing experience.

Most questions you will have are answered in this manual. However, if you need assistance, please do

not hesitate to contact EFD or your authorized EFD distributor. Detailed contact information is provided

on the last page of this document.

The Nordson EFD Pledge

Thank You!

You have just purchased the world’s finest precision dispensing equipment.

I want you to know that all of us at Nordson EFD value your business and will do everything in our power

to make you a satisfied customer.

If at any time you are not fully satisfied with our equipment or the support provided by your Nordson

EFD Product Application Specialist, please contact me personally at 800.556.3484 (US), 401.431.7000

(outside US), or Srini.Subramanian@nordsonefd.com.

I guarantee that we will resolve any problems to your satisfaction.

Thanks again for choosing Nordson EFD.

Srini Subramanian

Srini Subramanian, General Manager

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

2

794-TC Series Auger Valve

Contents

Contents ..........................................................................................................................................................................3

Introduction .....................................................................................................................................................................4

Auger Assembly Sizes .................................................................................................................................................4

How the 794-TC Valve Operates .................................................................................................................................4

How to Control the 794-TC Valve ................................................................................................................................5

Safety ..............................................................................................................................................................................5

Specifications ..................................................................................................................................................................6

Operating Features ..........................................................................................................................................................7

Installation .......................................................................................................................................................................8

Unpack the System Components ................................................................................................................................8

Install the Valve ............................................................................................................................................................9

Set the Dispense Gap ................................................................................................................................................10

Make System Adjustments ........................................................................................................................................11

Changing Tips ...............................................................................................................................................................11

Changing the Auger Assembly ......................................................................................................................................12

Service ...........................................................................................................................................................................12

Purging ......................................................................................................................................................................12

Cleaning the Fluid Cartridge Assembly .....................................................................................................................13

Part Numbers ................................................................................................................................................................14

Thermal Interface Materials ...........................................................................................................................................14

Accessories ...................................................................................................................................................................14

Replacement Parts ........................................................................................................................................................15

Troubleshooting ............................................................................................................................................................16

Motor Voltage vs. Velocity .............................................................................................................................................19

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

3

794-TC Series Auger Valve

Introduction

The 794-TC Series auger valve system is designed to make

precise, repeatable deposits of TIM (thermal interface materials) or

other highly abrasive pastes. Its robust tungsten carbide (TC) auger

screw and fluid body liner resist wear from highly abrasive pastes

to ensure long valve life. By combining screw-feed principles with

precise time, pressure, and dispensing control, the 794-TC valve

is able to provide accurate, repeatable deposits without damaging

the metal particles of the solder.

The 794-TC valve is available in a variety of auger gap sizes. The

auger gap size is selected based on the presence and size of

particles in the dispensing material. The TC auger assembly can be

easily replaced to change the gap size as needed.

794-TC Series auger valves are designed for use with ValveMate™

7194 controllers and EFD’s automated dispensing systems.

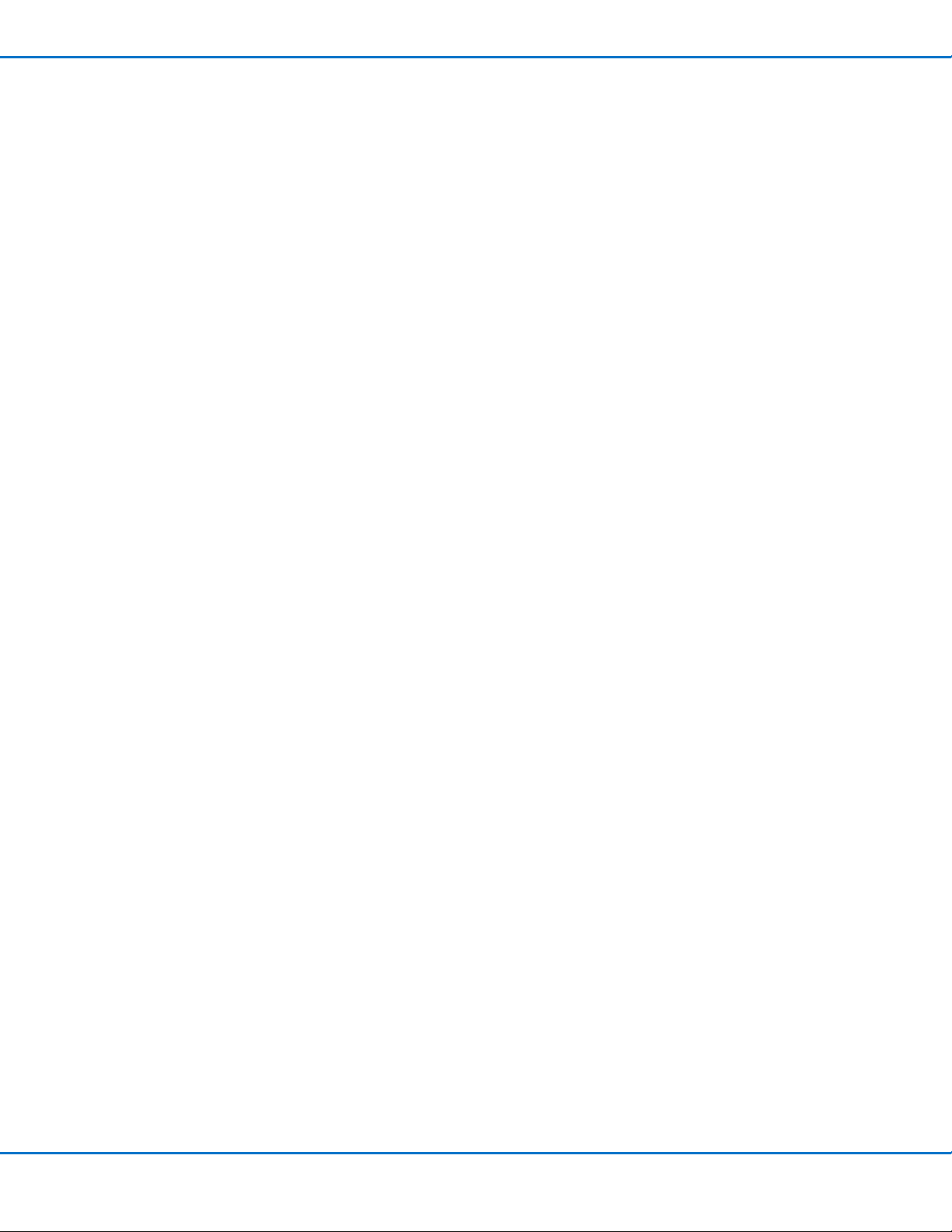

Auger Assembly Sizes

The following double-pitch auger assemblies are available:

• Standard (no gap) — for fluids without particles

• 0.05 mm (0.002") = 0.025 mm (0.001") around the auger —

recommended for fluids with a particle size <20 μm

• 0.10 mm (0.004") = 0.05 mm (0.002") around the auger —

recommended for fluids with a particle size <40 μm

• 0.15 mm (0.006") = 0.075 mm (0.003") around the auger —

recommended for fluids with a particle size <40 μm

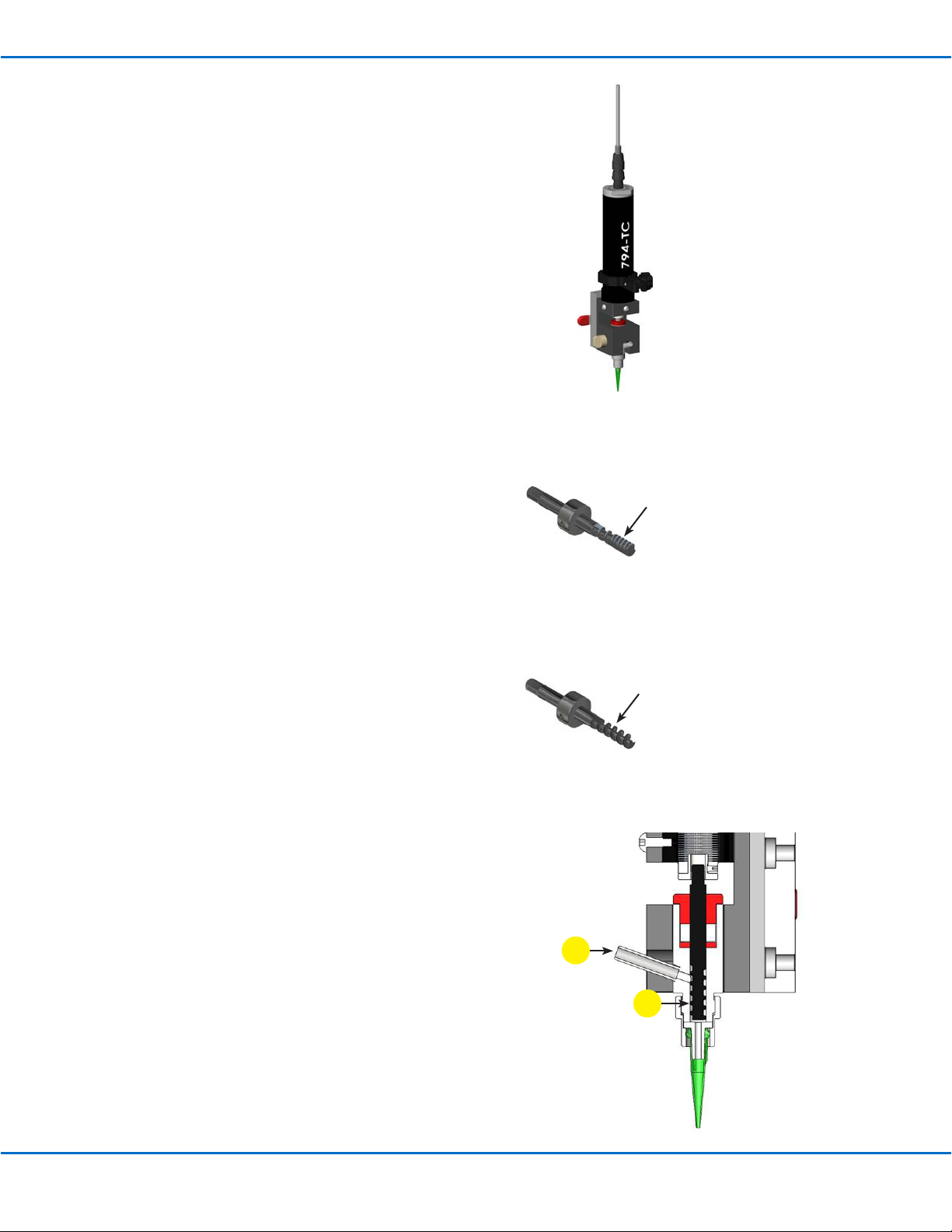

A single-pitch, ultra-high flow auger assembly is also available:

• 0.15 mm (0.006") = 0.075 mm (0.003") around the auger —

recommended for applications needing higher flow output for

thermal interface materials (TIM)

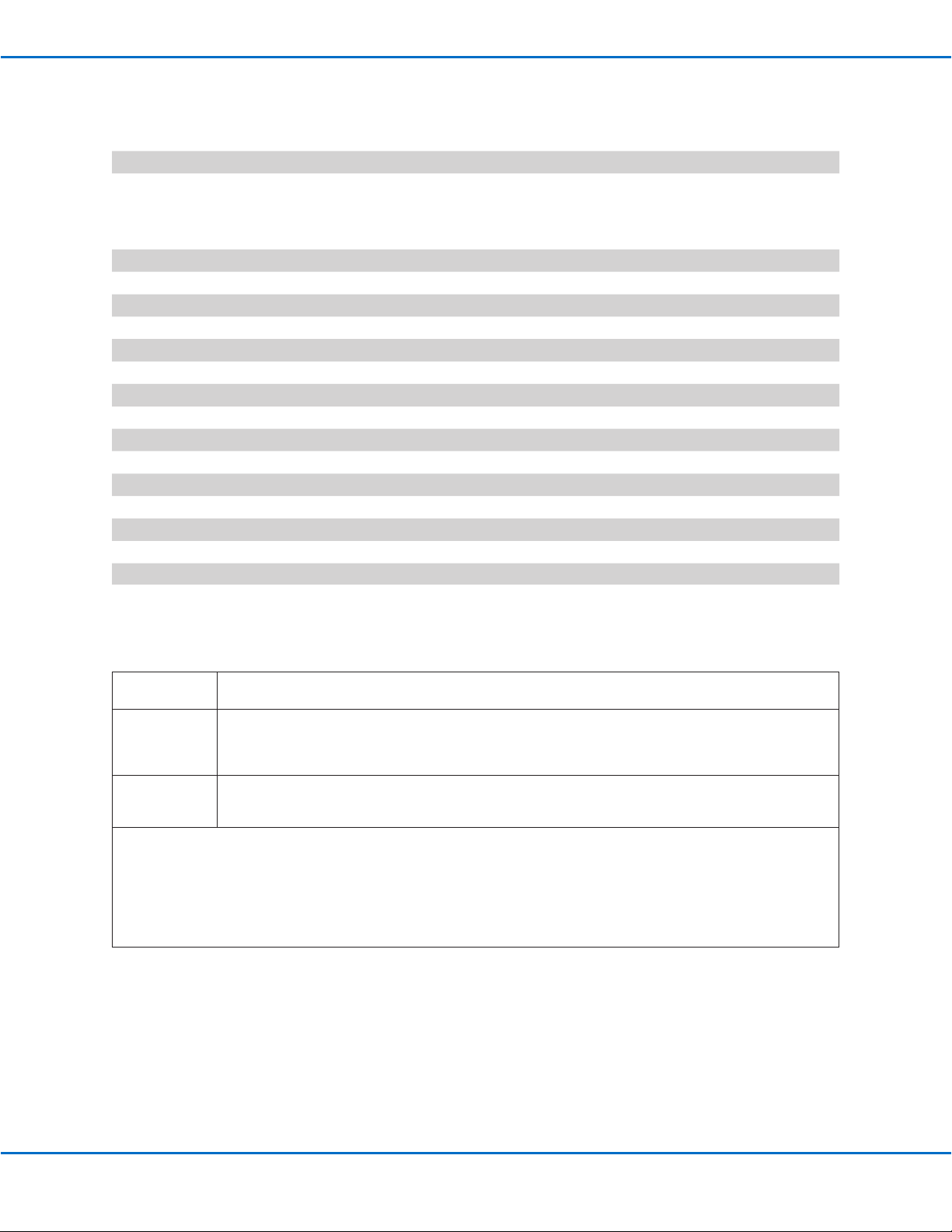

How the 794‑TC Valve Operates

Input air pressure at up to 2.1 bar (30 psi) is applied to the material

reservoir (1), forcing fluid into the path of the auger.

As the auger rotates, fluid moves along the auger flutes (2) and

is forced out through the dispense orifice. The valve controller

regulates the reservoir pressure, ensuring that there is enough

pressure to keep the valve primed with fluid without forcing it

past the auger. It is important to ensure that the reservoir fills

continuously.

The duration of the dispensing time is controlled by adjusting

the time control up or down until the required deposit size is

established, at which point it is repeated with each initiate cycle.

Double-pitch

auger thread

Single-pitch

UHF (ultra high

flow), deep-cut

auger thread

1

2

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

4

794-TC Series Auger Valve

How to Control the 794‑TC Valve

The ValveMate 7194 controller is recommended for use with the

794-TC auger valve. The ValveMate 7194 controller regulates

solder feed pressure, dispense time, and auger speed. It provides

motor startup acceleration limits and maximum current overload

protection for extended motor life. The precision air pressure

regulator ensures that consistent pressure is applied to the

material in the syringe barrel.

Safety

It is intended that the 794-TC auger valve be rigidly mounted to and positioned by a suitable factory automation

system and controlled by a suitable valve controller. Follow the procedures in this manual to select, install, and

configure the automation system and valve controller.

Prohibited Uses

The 794-TC auger valve should not be operated in the following ways:

• Hand-held

• In damp or wet conditions

• In explosive atmospheres

• Under conditions which violate limits set in the specifications section

• Without all system guards, interlocks and other safety features in place and operational

WARNING

It is the responsibility of the factory automation system designer, builder and / or installer to include safety features

sufficient to prevent personal injury or loss of life during operation.

Safety Precautions

The 794-TC auger valve should be installed, configured, and operated only by qualified personnel who have read

and understood all appropriate sections of this manual as well as the operating instructions supplied with the factory

automation system onto which it is installed. Protective eyewear should always be worn while operating, adjusting,

and servicing the valve. Additional personal protective equipment should be used as appropriate for the material

being dispensed. An SDS for all materials to be dispensed should be available at or near the operator’s station. The

factory automation system should be designed and installed so as to allow the operator to be positioned at a safe

distance while operating and adjusting the valve.

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

5

794-TC Series Auger Valve

Specifications

NOTE: Specifications and technical details are subject to engineering changes without prior notification.

Item Specification

Size 61.0

Weight 470.0 g (16.6 oz)

Auger speed (dry) 170–400 rpm based on voltage input

Auger pitch High flow (double pitch), ultra high flow (single pitch)

Input voltage 10–24 VDC (<10% ripple)

Maximum acceleration 2.0 g (0.07 oz)

Maximum continuous current 240 mA (time delay fuse recommended)

Maximum fluid pressure 2.0 bar (30 psi)

Fluid inlet 1/8" ID tubing supplied for connection

Mounting

Luer lock tip adapter assembly 303 stainless steel

Fluid inlet tube 303 stainless steel

Fluid cartridge liner Tungsten carbide

Auger Tungsten carbide

Approvals China RoHS

All stainless steel parts are passivated.

L x 32.0DIA mm (2.40L x 1.25DIA")

NOTE: The valve length varies based on which side the fluid body /

cartridge screw is installed; the measurement provided is the maximum

length.

10-32, low profile

RoHS标准相关声明标准相关声明 (China RoHS Hazardous Material Declaration)

产品名称

Part Name

有害物质及元素

Toxic or Hazardous Substances and Elements

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr6)

多溴联苯

Polybrominated

Biphenyls

(PBB)

多溴联苯醚

Polybrominated

Diphenyl Ethers

(PBDE)

外部接口

External Electrical

Connectors

O: 表示该产品所含有的危险成分或有害物质含量依照EIP-A, EIP-B, EIP-C

的标准低于SJ/T11363-2006 限定要求。

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is below the

limit requirement in SJ/T11363-2006.

X: 表示该产品所含有的危险成分或有害物质含量依照EIP-A, EIP-B, EIP-C

的标准高于SJ/T11363-2006 限定要求.

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is above the

limit requirement in SJ/T11363-2006.

X 0 0 0 0 0

www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

6

Loading...

Loading...