Nordson EFD 7860C-RS Installation Manual

7860C-RS Radial Spinner System

Installation Guide

Introduction

The 7860C-RS radial spinner system is a precision, air-actuated spinner

device that produces a narrow radial output band ideal for coating the

interior walls of cylindrical shaped parts. Air pressure is released to the

colleted air motor to spin the radial disc and shaft assembly. During this

radial spin cycle, fluid is dispensed onto the spinning disc, causing it to

be distributed in a narrow band-like pattern onto the side wall.

The spinner disc and shaft assembly have a shaft length of 70mm

(2.75"), with disc sizes ranging from 9mm (0.354"), 12mm (0.473"),

15mm(0.590"), and 19mm (0.745"). The radial spinner system is easy to

use and will operate for many millions of cycles without maintenance.

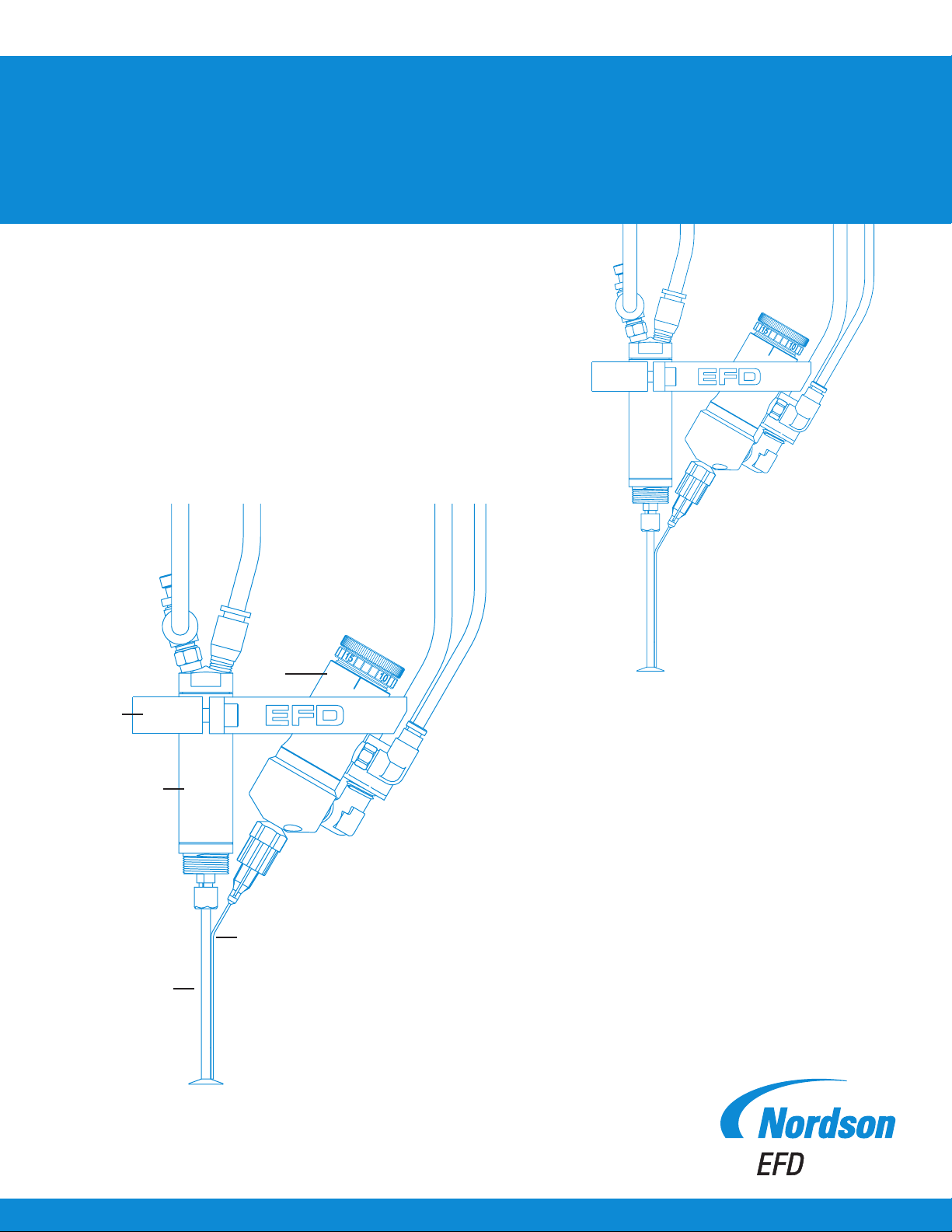

Bracket

752V-UHSS

valve

7860C

air motor

Tip

Shaft / disc

assembly

Electronic pdf files of Nordson EFD

manuals are also available at

www.nordsonefd.com

To exhaust

0.5 mm

(.020”)

2.5 mm

(.100”)

7860C-RS Radial Spinner System | Installation Guide

Installation

Prior to installing this

system, read the associated

reservoir and ValveMate™

7160RA controller operating

manuals to become familiar

with the operation of all

components of the radial

spinner system.

NOTE: Refer to the

ValveMate 7160RA

controller operating

manual for air connection

instructions.

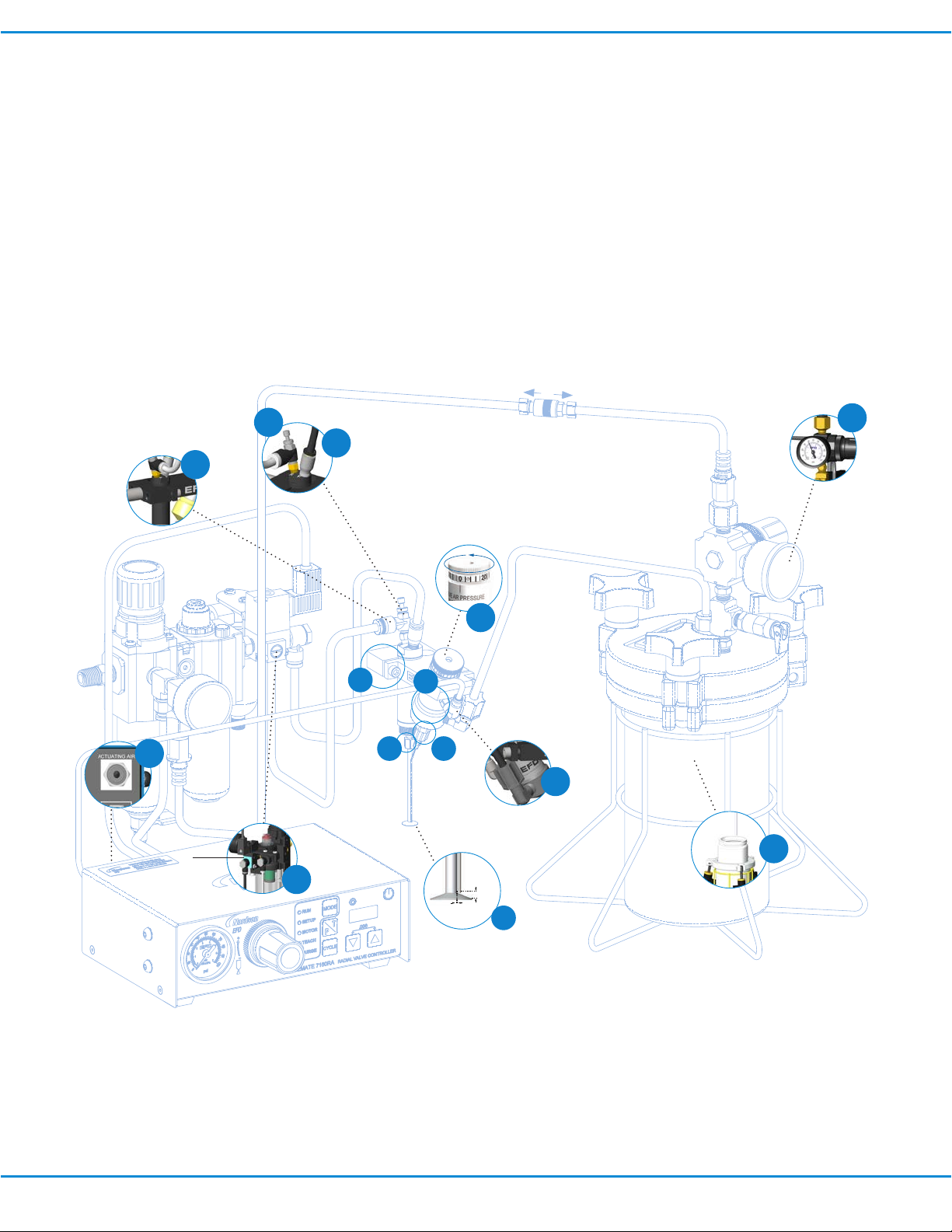

1. Mount the radial spinner bracket using

the rod provided or bolt it onto an

appropriate mounting fixture. Follow

these steps to install the radial spinner

valve:

a. Slide the valve up into the bracket

opening until it bottoms out at

the actuating air fitting. Secure in

place.

b. Install the special bent tip in the

rotating luer lock adapter. Make

sure the tip end is in the vertical

position.

c. Slide the air motor into the bracket

opening. Make sure the motor

collet does not make contact at

the bend of the dispense tip.

9

4

1

d. Insert the shaft into the collet.

Set the tip approximately

0.5mm (0.20") from the spinning

disc surface. Tip alignment

should be 2.5 mm (0.100") away

from the radial spinner shaft.

e. Realign the valve and motor

in the bracket as needed

to achieve recommended

clearances.

2. Connect the fluid feed hose to the

reservoir outlet and the valve inlet

port using the appropriate fittings

(supplied).

To pressurize

3. Connect the 4 mm diameter

air hose from the valve to

the 7160RA controller. The

white connector goes to the

ACTUATING AIR port. Make

sure the nozzle air is OFF and

set to 0 bar (0 psi).

NOTE: The NOZZLE AIR port

is not used for radial spinner

installations.

4. Connect the white and black

6mm diameter air hoses to

the air motor assembly: white

connects to the motor speed

control and black connects to

the F fitting (actual markings on

air motor).

7

c

a

3

8

bd

2

Control valve

6

5

e

NOTE: Set the tip approximately 0.5mm (0.020")

from the spinning disc surface. Tip alignment should

be 2.5mm (0.100") away from the radial spinner

shaft.

5. Connect the white and black

6mm diameter hoses to the filterregulator-lubricator assembly.

White connects to the oil recovery

bowl and black connects to the

control valve.

6. Fill the fluid reservoir. After filling,

secure the cover and connect the

reservoir air pressure regulator to

2 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

the air tee using the flexible air

line (supplied). Attach the male

quick-connect in the air line to

the reservoir regulator and then

attach the white quick-connect

to the air tee. To pressurize the

system, slide the shut-off valve

in the air line toward the fluid

reservoir.

7. Set the reservoir pressure regulator

according to fluid viscosity: low for

thin fluids [0.07 to 0.2 bar (1 to

3 psi)] and higher for thicker fluids.

8. Set the 752V-UHSS valve (or other

appropriate valve model) stroke

control to achieve a desired flow

rate onto the spinning disc. Set the

flow to approximately one drop per

second.

9. Adjust the air motor RPM

using the speed control knob.

Turn the speed control knob

clockwise to reduce RPM and

counterclockwise to increase

RPM.

Loading...

Loading...