Nordson EFD 784S-SS User Manual

784S-SS Aseptic MicroSpray™ Valve

Maintenance & Parts Guide

™

IMPORTANT!

Save this Sheet.

Forward to

Maintenance or

Tool Crib Supervisors

Electronic pdf files of Nordson EFD

manuals are also available at

www.nordsonefd.com

784S-SS Aseptic MicroSpray Valve | Maintenance & Parts Guide

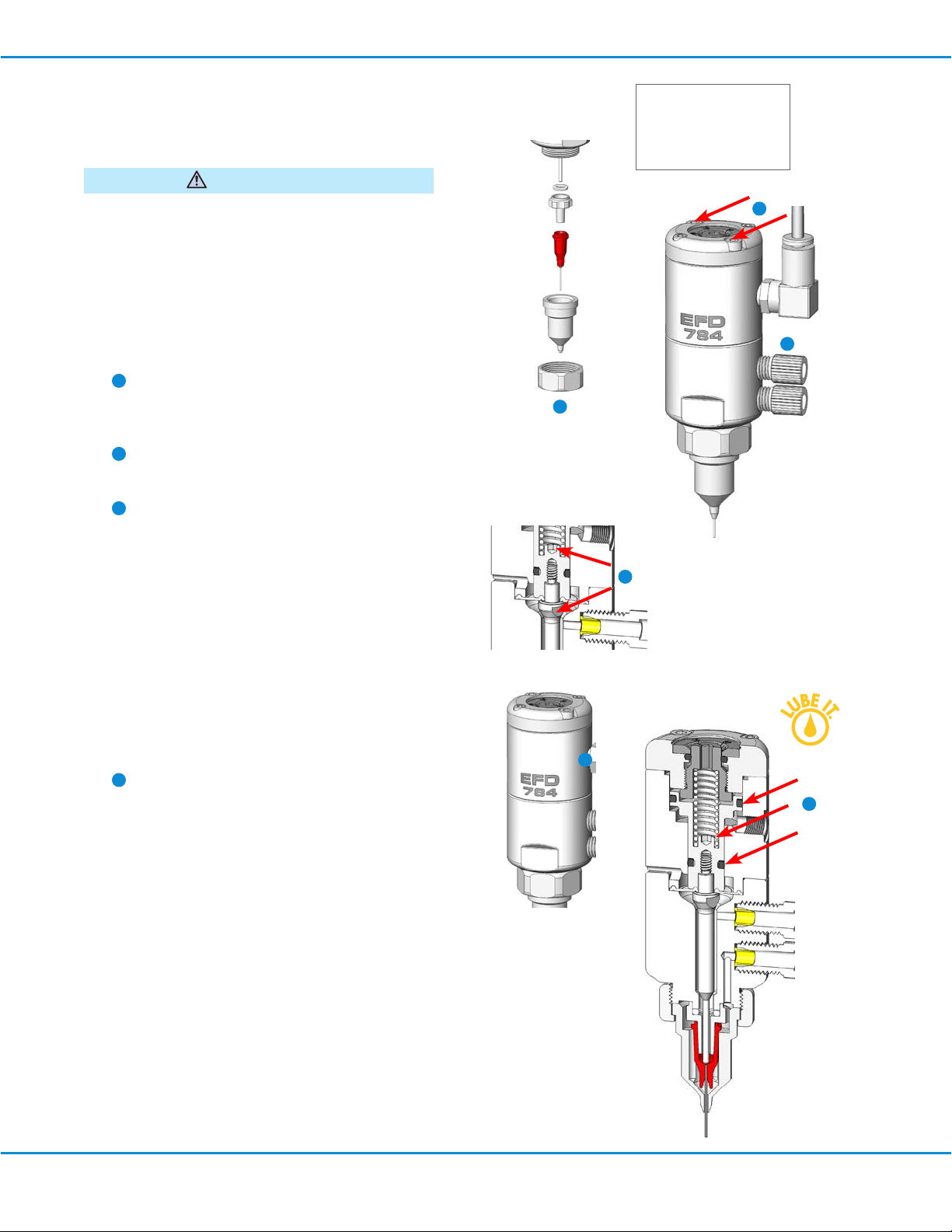

Valve Disassembly and

Reassembly Procedures

CAUTION

To prevent damage, the valve must be

disassembled starting at the fluid outlet end of the

valve.

Valve Maintenance: Fluid Body

To thoroughly clean the fluid body and replace

Diaphragm:

1. 1 Remove SS air cap retainer nut, air cap,

and microspray tip adapter from the fluid

body. Dispose of dispensing tip. Do not reuse.

2. 2 Remove the two retainer screws at the top

of the valve to release fluid body.

3. 3 Remove fluid inlet and nozzle air fittings.

4. To reinstall the fluid body, align fluid body

holes with air cylinder body holes and reinsert

retainer screws. Torque to 1.58 Nm (14 inch

pounds).

Tools required:

2.5 mm hex wrench

Adjustable wrench

2

3

1

4

Diaphragm

5. Back out stroke control two turns

counterclockwise from the closed position.

6. Remove fluid body.

7. 4 Insert Allen wrench (2.5 mm) through stroke

reference control and engage piston shaft.

8. Using the hex on the shaft, unthread shaft,

and remove shaft and diaphragm.

9. Install new diaphragm onto needle shaft.

10. With Allen wrench engaged into piston,

thread needle shaft / diaphragm onto piston

assembly.

11. Reinstall fluid body and torque retainer

screws to value specified in step 4.

12. Turn stroke control clockwise until closed,

and then reopen to desired stroke.

5

6

2 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Loading...

Loading...