Nordson EFD 725D-SS, 725D Maintenance Manual

725D-SS and 725D Piston Valves

Maintenance & Parts Guide

™

IMPORTANT!

Save this Sheet.

Forward to

Maintenance or

Tool Crib Supervisors

Electronic pdf files of Nordson EFD

manuals are also available at

www.nordsonefd.com

725D-SS and 725D Piston Valves | Maintenance & Parts Guide

Valve Disassembly and

Reassembly Procedures

CAUTION

To prevent damage, the valve must be disassembled

starting at the fluid outlet end of the valve.

1. Put threaded rod in mounting hole.

2. Remove body cap.

3. Remove sealing head.

4. With a wrench on the flats of the air cylinder

body, turn to loosen fluid body.

5. Remove fluid body.

6. Remove input air hose from push-in fitting on air

cap.

7. Insert 1/8" hex wrench through air inlet hole in

cap and back shaft locking screw out two

turns.

8. Using the hex on the shaft, un-thread shaft and

remove shaft and diaphragm.

9. Unscrew air cylinder cap from air cylinder

body.

10. Remove piston and spring.

NOTE: Before reassembling valve, clean

all parts, replace O-rings, sealing head and

diaphragm. Inspect for damaged threads, piston

pins for straightness and fluid body seat for

pitting.

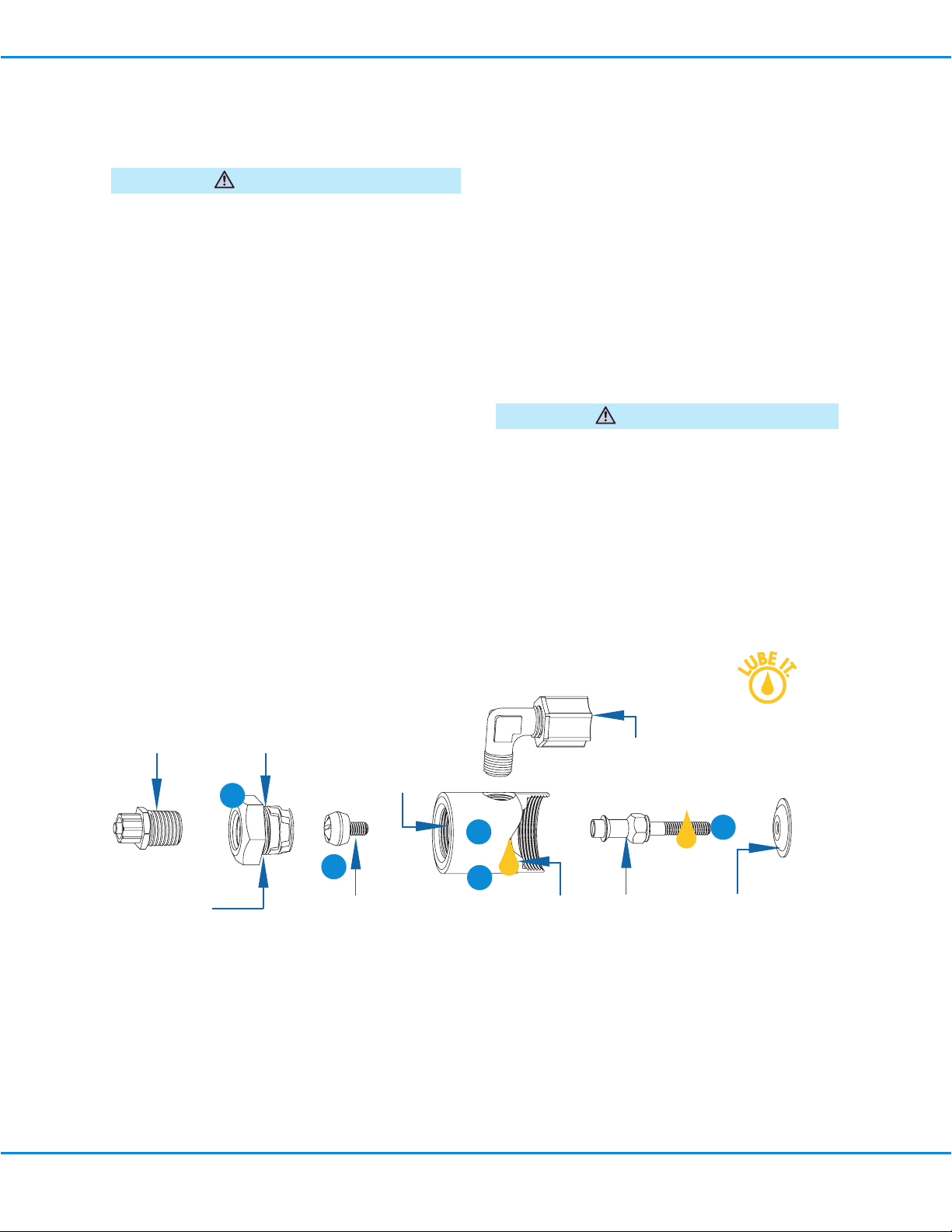

CAUTION

Do not thread fluid inlet fittings too far into the valve.

Doing so can obstruct the piston shaft, causing

leakage, poor dispensing performance, and damage

to the valve.

Reassemble the valve in reverse order of disassembly.

Lubricate parts indicated with Nye Lubricant #865

included in the General Maintenance Kit.

Tip adapter

#7016948

1/4 NPT

Body cap

with O-ring

#7020952

(stainless steel)

#7020949 (Viton)

O-ring

#7014863

(Viton*)

2

Fluid body

#7020932

(stainless steel)

#7020931

(hard-coated

aluminum)

3

Sealing thread

with screw

#7020935

Fluid

inlet fitting

#7021499

5

8

1

Shoulder

Shaft

#7020929

Diaphragm

#7020925

2 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Loading...

Loading...