Page 1

Testing Wearable Electronics

Application Note

The Importance of Testing

Mechanical and Electrical

Performance Simultaneously

Introduction

Wearable electronics present exciting new opportunities for

technology such as health monitoring, fashion and sports

performance evaluation. Sensors, antennae and batteries

can all be incorporated into textiles, making clothing an

integrated circuit that is capable of tirelessly monitoring vital

human body functions, and the environment of the wearer.

One of the main challenges in developing this technology

into consumer products is in understanding how they will

perform in dierent conditions and how they will deteriorate

through their intended life.

Conductive fabrics have been developed to provide

connections between electronic components distributed

around a garment, allowing an array of sensors to connect

back to a central processing unit.

The integrity of these connections is crucial if the end

product is to perform reliably. Even a small change

in voltage drop across a connection can result in

a corrupted signal.

Here we show how the integrity of conductive fiber

connections can be qualified over a range of

dierent conditions.

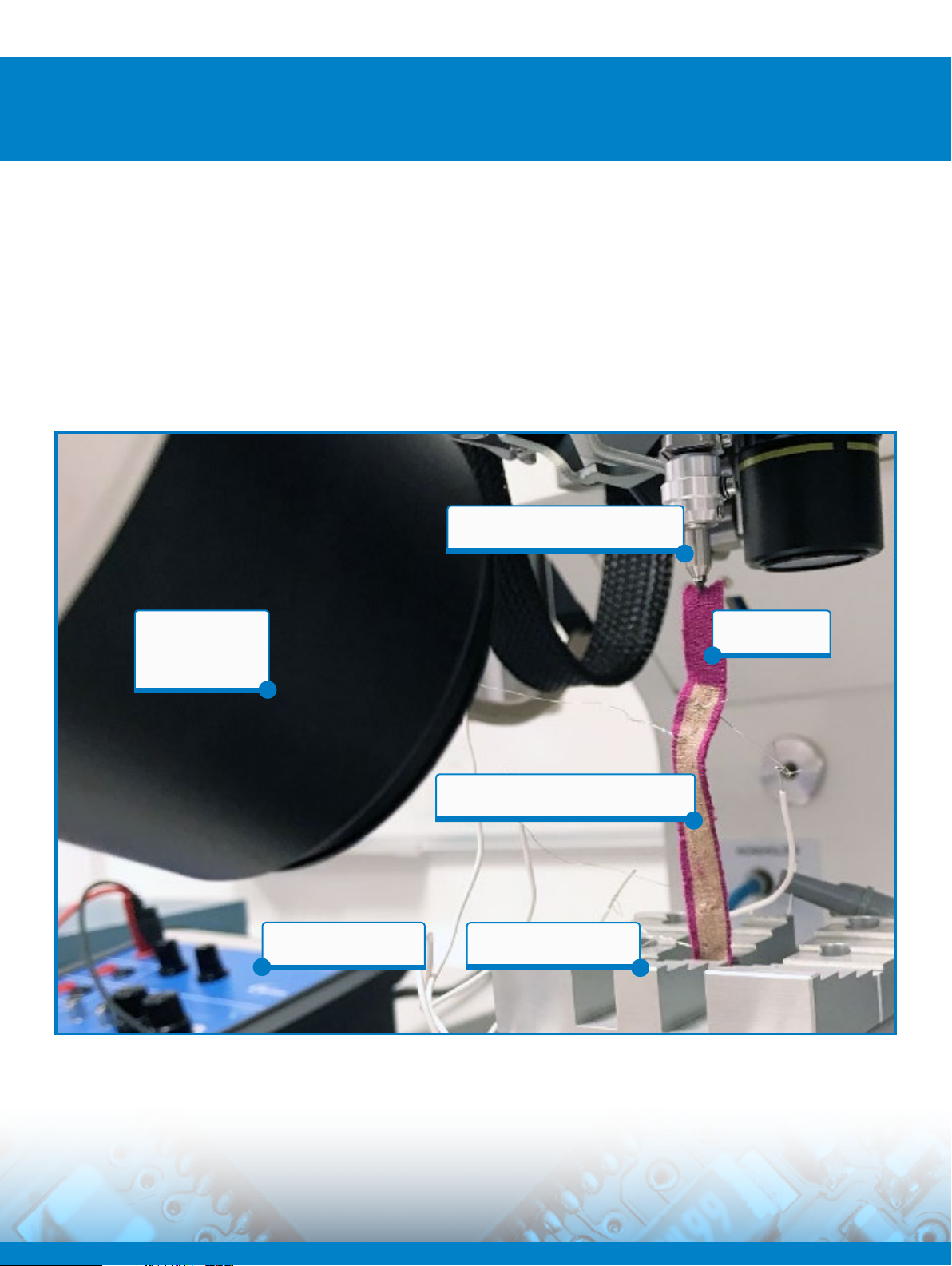

Figure 1. Metalized fibers form a conductive track through an electrically

voltage drop across fabric (purple); the metal wire transfers signal back to

the Prospector.

Page 2

Testing Wearable Electronics

Application Note

Setting up the Test

A conductive fabric sample was tested using the DAGE

ProspectorTM Micro Materials Tester. The fabric was cyclically

stretched under displacement control and the voltage drop

was measured over the length of the fabric using a fourpoint resistivity measurement set-up shown in Figure 2.

The electrical measurements were taken using Prospector’s

accessory sensor box, and were automatically plotted

Trinocular camera,

recording video of

the test

against the force and displacement measurements in real

time. It is important that the voltage drop is constant,

independent of fabric stretching.

A change in voltage drop across the conductive track will be

presented to the processor as a change in the signal from

the sensor.

DAGE 5 kg capacity tweezer cartridge

Insulating fabric

Electrical connection to conductive fabric

Accessory sensor box

Figure 2. A strip of conductive fabric with 4-point voltage drop across wires attached. External sensor box can be seen in the background.

Standard vice workholder

Page 3

Testing Wearable Electronics

Application Note

Test Findings

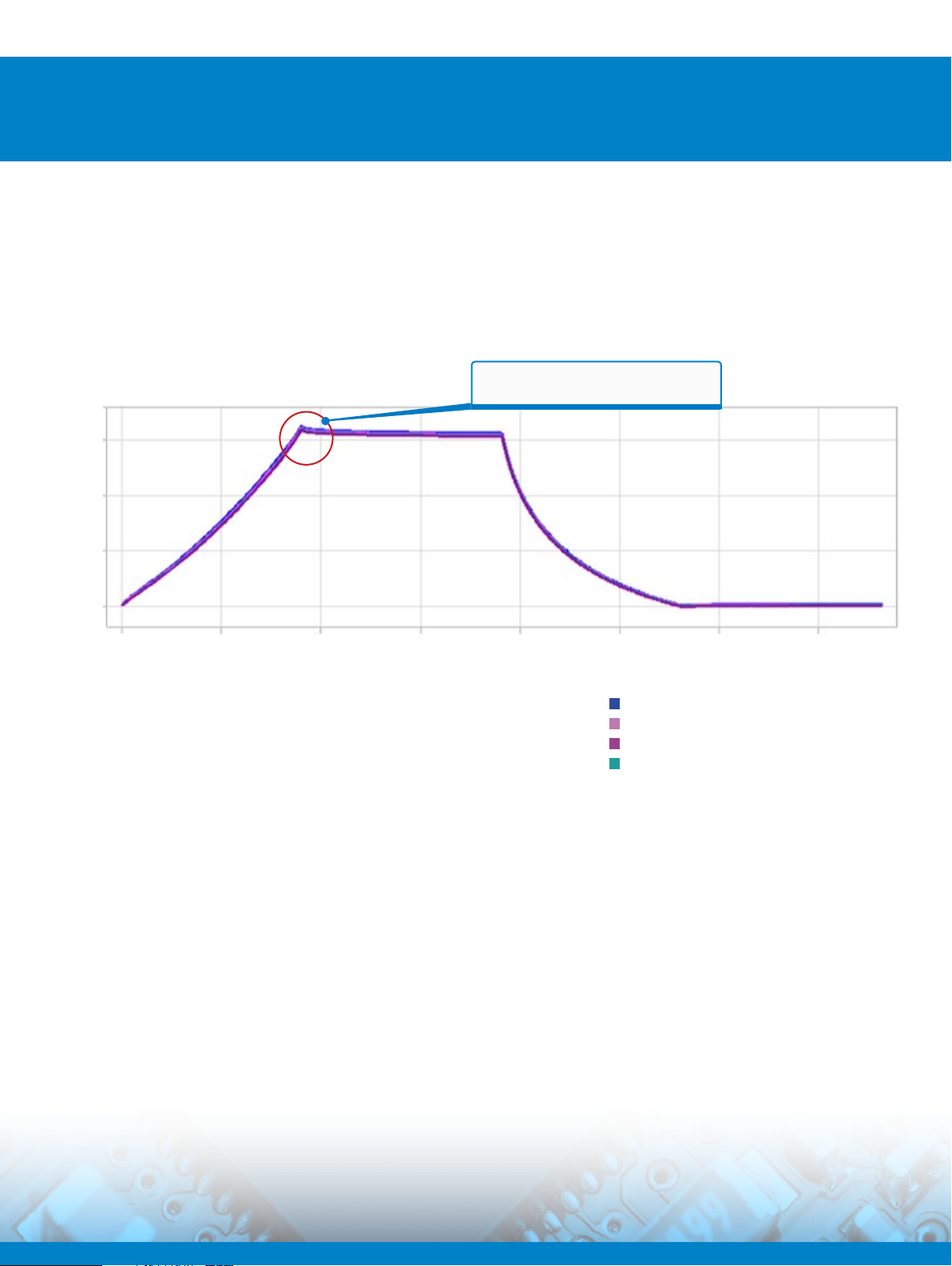

Figure 3 shows the force measured throughout a 30 second test cycle. The force versus time response is a consequence of the

position, time in the cycle and stress relaxation of the fabric.

Relaxation in load following initial peak

30

20

10

Force (gf)

0

0 5 10 15 20 25 30 35

Times (s)

Figure 3. Force versus time plot of several cycles of fabric stretching,

showing relaxation of load at constant displacement.

Fabric Connection 1_07 cycle30

Fabric Connection 1_07 cycle48

Fabric Connection 1_07 cycle64

Fabric Connection 1_07 cycle66

Page 4

Testing Wearable Electronics

Application Note

Force Peak and Relaxation

ProspectorTM is controlled by a fully featured soware

package called ParagonTM Materials. One of the key

advantages of Paragon Materials is the ability to analyze the

data without having to export it to post processing soware.

This allows users to quickly adapt their experiments on the

basis of early results.

Voltage recorded at maximum fabric stretch

position during cycle

1.9

1.8

1.7

1.6

1.5

1.4

1.3

One of the trends that is easily observed was a change in

the maximum and minimum voltage levels in each cycle,

shown in Figure 4. The voltage at the maximum pull force

was relatively constant throughout the testing, but the

minimum voltage dropped throughout the test. As the test

progresses, the individual fibers in the fabric shi position,

altering the voltage drop across of the fabric.

1.2

1.1

External (Volts)

1

0.9

0.8

0.7

0.6

0.5

10 20 30 40 50 60 70 80

Cycles

Figure 4. The maximum (blue) and minimum (pink) voltage for each cycle; all plots were produced using Paragon Materials.

Voltage recorded at minimum fabric stretch

position during cycle

Page 5

Testing Wearable Electronics

Application Note

Figure 5 shows the voltage drop at maximum load remains

fairly constant between cycles, but the minimum load

voltage drop reduces significantly with cyclic stretching,

as shown between the spread in curves from each cycle.

The plot also shows how the voltage drop increases slightly

when the fabric is held at maximum load, but the increase is

much greater when held at the minimum load.

2

1.5

1

0.5

External (Volts)

0

0 5 10 15 20 25 30 35

Prospector’s Omni-scope allows the trinocular camera

to be focused on specific points of interest at high

magnification. Video can be recorded throughout the test

so the movement of individual fibers can be monitored and

reviewed during the test investigation. This is especially

useful for wearable electronics samples where fiber position

determines the electrical properties.

The voltage drop changes between cycles

Times (s)

Figure 5. Electrical behavior of the fabric on four cycles spread over the test.

Fabric Connection 1_07 cycle4

Fabric Connection 1_07 cycle31

Fabric Connection 1_07 cycle58

Fabric Connection 1_07 cycle84

Page 6

Testing Wearable Electronics

Application Note

Figure 6. High magnification video image taken during the test, using the omni-scope mounted trinocular system; individual fibers can be seen in the weave.

External Sensor using the Break-out Box

These experiments used the ProspectorTM external sensor

break out box. The break out box easily allows the user

to connect a wide range of external sensors such as load

cells and strain gauges to the Prospector Micro Materials

Tester. It provides a variable voltage power supply (up to 10

V DC) and separate analogue inputs that can be adjusted

with manual oset and gain settings on the box. Paragon™

Materials digitizes the reading and converts it to grams or

microstrain before plotting the information against its own

load cell and position readings synchronously. The breakout box transforms the Prospector system from a flexible

micro-mechanical testing machine into a truly multifunctional experimental platform.

Page 7

Testing Wearable Electronics

Application Note

Conclusion

Conductive fabrics for wearable technology show complex electrical behaviour,

varying with force, hold time and between stretching cycles. Analogue signals would

suer from distortion and dri if they were transmitted through this particular fabric,

due to the constantly shiing electrical voltage drop across.

Studying behaviour in detail is of critical importance to make sure that the ‘smart’

garment is working as intended. These types of studies are ideally suited to the

powerful capabilities of the ProspectorTM Micro Materials Tester allowing the user

to easily carry complex experiments and analysis using one integrated system.

For more information,

speak with your Nordson

representative or contact

your Nordson regional oice

Americas

+ 1 760 930 3307

sales@nordsondage.com

Europe

+44 1296 317800

globalsales@nordsondage.com

China

+86 512 6665 2008

sales.ch@nordsondage.com

Germany

+49 89 2000 338 270

sales.de@nordsondage.com

Japan

+81 120 537 555

sales.jp@nordsondage.com

Korea

+82 31 462 9642

korea.at.cs@nordson.com

South East Asia

+65 6552 7533

sales.sg@nordsondage.com

Prospector Micro Materials Tester covers a wide range of test scenarios for the most

advanced product assessment applications.

Taiwan

+886 2 2902 1860

globalsales@nordsondage.com

United Kingdom

+44 1296 317800

globalsales@nordsondage.com

www.nordson.com

Loading...

Loading...