Liquidyn P-Dot Series Jet Valves

Operating Manual

™

WATCH VIDEOS

www.nordsonefd.com/LQMaintVideos

Electronic pdf files of Nordson EFD

manuals are also available at

www.nordsonefd.com

Liquidyn P-Dot Series Jet Valves

You have selected a reliable, high-quality dispensing system from Nordson EFD, the world leader in fluid

dispensing. The Liquidyn® P-Dot Series jet valve was designed specifically for industrial dispensing and

will provide you with years of trouble-free, productive service.

This manual will help you maximize the usefulness of your Liquidyn P-Dot valve

Please spend a few minutes to become familiar with the controls and features. Follow our recommended

testing procedures. Review the helpful information we have included, which is based on more than

50years of industrial dispensing experience.

Most questions you will have are answered in this manual. However, if you need assistance, please do

not hesitate to contact EFD or your authorized EFD distributor. Detailed contact information is provided

on the last page of this document.

The Nordson EFD Pledge

Thank You!

You have just purchased the world’s finest precision dispensing equipment.

I want you to know that all of us at Nordson EFD value your business and will do everything in our power

to make you a satisfied customer.

If at any time you are not fully satisfied with our equipment or the support provided by your Nordson

EFD Product Application Specialist, please contact me personally at 800.556.3484 (US), 401.431.7000

(outside US), or Tara.Tereso@nordsonefd.com.

I guarantee that we will resolve any problems to your satisfaction.

Thanks again for choosing Nordson EFD.

Tara

Tara Tereso, Vice President

2 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Contents

Contents ..........................................................................................................................................................................3

Introduction .....................................................................................................................................................................5

How the Valve Operates ..............................................................................................................................................5

How the Valve is Controlled.........................................................................................................................................5

Nordson EFD Product Safety Statement ........................................................................................................................6

Halogenated Hydrocarbon Solvent Hazards ...............................................................................................................7

High Pressure Fluids ....................................................................................................................................................7

Qualified Personnel ......................................................................................................................................................7

Intended Use ...............................................................................................................................................................8

Regulations and Approvals ..........................................................................................................................................8

Personal Safety ............................................................................................................................................................8

Fire Safety ....................................................................................................................................................................9

Preventive Maintenance ..............................................................................................................................................9

Important Disposable Component Safety Information ..............................................................................................10

Action in the Event of a Malfunction ..........................................................................................................................10

Disposal .....................................................................................................................................................................10

Equipment-Specific Safety Information .....................................................................................................................11

Specifications ................................................................................................................................................................12

Operating Features ........................................................................................................................................................13

Installation .....................................................................................................................................................................14

Unpack the System Components ..............................................................................................................................14

Assemble the Valve (Initial Assembly)........................................................................................................................15

Install a Nozzle Heater (Optional) ...............................................................................................................................17

Mount the Valve .........................................................................................................................................................18

Connect Cables .........................................................................................................................................................19

Connect the Air Supply ..............................................................................................................................................20

Installation Example ...................................................................................................................................................21

Initial Startup ..............................................................................................................................................................22

Parameter Settings ....................................................................................................................................................23

Recommended Setup Adjustments ...........................................................................................................................24

Tappet Adjustment ....................................................................................................................................................25

Adjusting the Force Screw .....................................................................................................................................25

Returning the Force Screw to the Factory Setting .................................................................................................27

Manually Setting the Force Screw for Multiple Valves ...........................................................................................28

Service ...........................................................................................................................................................................30

Recommended Maintenance Schedule.....................................................................................................................30

Valve Cleaning ...........................................................................................................................................................30

Shut Down the System ..........................................................................................................................................31

Disassemble the Valve ...........................................................................................................................................31

Clean the Valve Components .................................................................................................................................33

Assemble the Valve (After Cleaning) ......................................................................................................................34

Tappet Replacement .................................................................................................................................................36

Continued on next page

3www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Contents (continued)

Part Number ..................................................................................................................................................................38

Replacement Parts ........................................................................................................................................................38

Valve Components ....................................................................................................................................................38

Nozzles and Nozzle Retaining Nuts ...........................................................................................................................39

Syringe Barrels and Accessories ...............................................................................................................................40

Material Supply Tubing Components ........................................................................................................................41

Steel Tubing Connectors .......................................................................................................................................41

Tubing ....................................................................................................................................................................41

Accessories ...................................................................................................................................................................41

Quick-Release Valve Mounting Components ............................................................................................................41

Precision Pressure Regulator ....................................................................................................................................41

Nozzle Heaters ...........................................................................................................................................................42

Nozzle Heater Kits ..................................................................................................................................................43

Nozzle Heater Cables .............................................................................................................................................43

Nozzle Heater O-Rings...........................................................................................................................................43

Heater Key .............................................................................................................................................................43

Tools and Supplies ....................................................................................................................................................44

Technical Data ...............................................................................................................................................................45

Dimensions ................................................................................................................................................................45

M8 Valve Cable Pin Positions ....................................................................................................................................45

Appendix A, About Non-Contact Dispensing................................................................................................................46

Appendix B, P-Dot Valve Interface Overview ................................................................................................................47

Electrical Control .......................................................................................................................................................47

Optional Nozzle Heater Control .................................................................................................................................48

Pneumatic Control .....................................................................................................................................................49

Valve Configuration Options ......................................................................................................................................49

4 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Introduction

The Liquidyn P-Dot is a high performance jet valve designed for the

non-contact micro-dispensing of medium- to high-viscosity fluids,

including oils, greases, adhesives, silicones, lacquers, fluxes, and

medical and chemical substances.

Valve Speed and Deposit Size

The valve can produce micro-deposits ranging in size from 0.3–5.0mm

at dispensing frequencies of up to 150Hz, for a faster production

process. The distance between the valve and the substrate is usually

between 2 and 10 mm.

Modular, Exchangeable Components

Because the material-carrying components are separate from the

actuator, dispensing nozzles can be quickly and easily exchanged. The

exchangeable design makes material-type change-out and component

replacement fast and easy.

The Liquidyn P-Dot valve is configurable. Several choices for the

material supply components and sealing options are available, and an

optional nozzle heater can be installed to warm material at the nozzle.

Liquidyn P-Dot Series Jet Valves

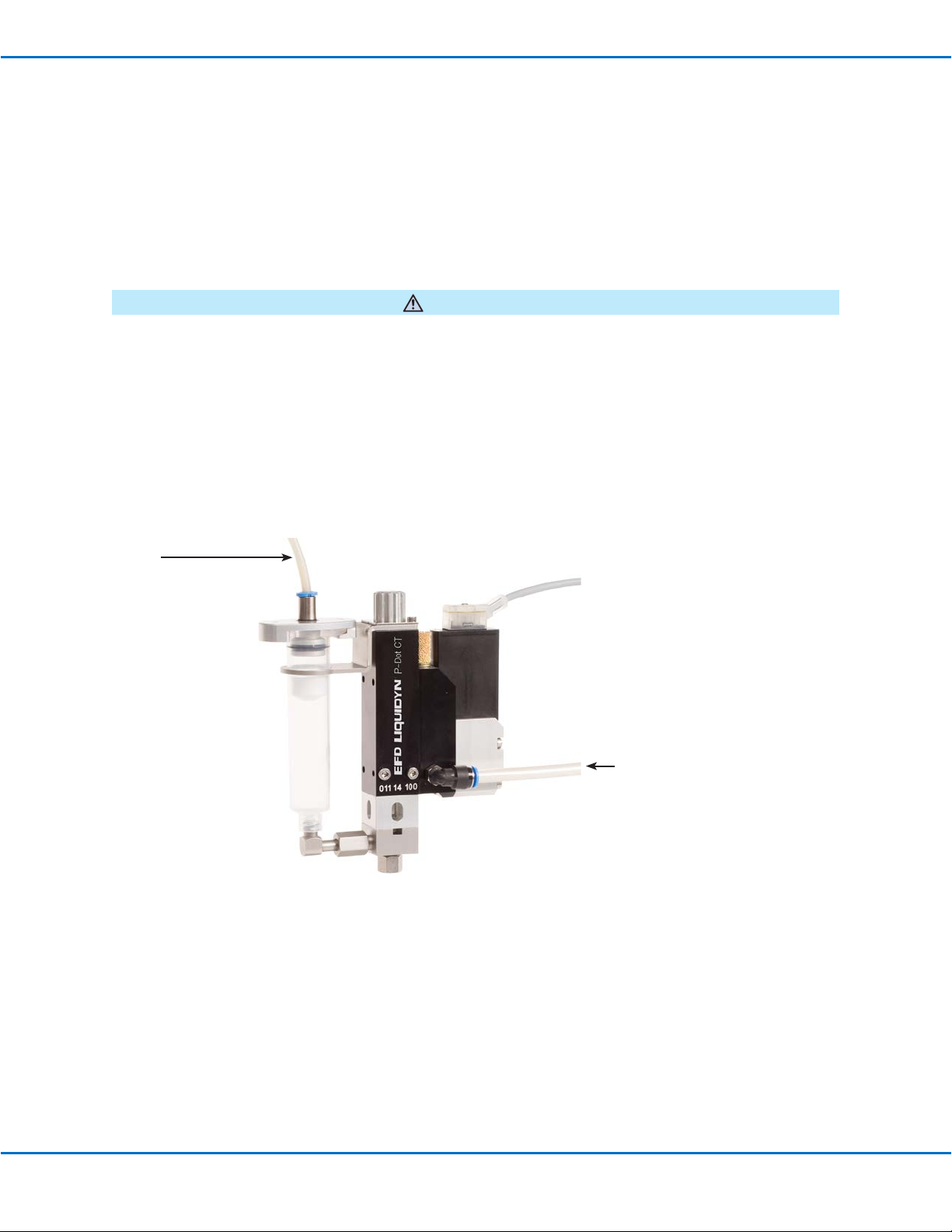

Liquidyn P-Dot micro-dispensing valve with

a syringe barrel material supply

How the Valve Operates

The Liquidyn P-Dot valve is electro-pneumatically operated by a low

voltage, 2 ms pulse signal. The dispensing tappet remains open until

the trigger signal ends. The valve is normally closed (NC) when idle,

thus reducing the possibility of unintended fluid release upon power off.

How the Valve is Controlled

The valve can be operated using a Nordson EFD Liquidyn controller

or directly by the customer via a 24V input using a customer-supplied

controller or a programmable logic controller (PLC).

The Liquidyn V200 controller can be used

to control the operation of the Liquidyn

P-Dot valve

5www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Nordson EFD Product Safety Statement

WARNING

The safety message that follows has a WARNING level hazard.

Failure to comply could result in death or serious injury.

ELECTRIC SHOCK

Risk of electric shock. Disconnect power before removing covers and / or disconnect, lock out, and

tag switches before servicing electrical equipment. If you receive even a slight electrical shock, shut

down all equipment immediately. Do not restart the equipment until the problem has been identified

and corrected.

CAUTION

The safety messages that follow have a CAUTION level hazard.

Failure to comply may result in minor or moderate injury.

READ MANUAL

Read manual for proper use of this equipment. Follow all safety instructions. Task- and equipmentspecific warnings, cautions, and instructions are included in equipment documentation where

appropriate. Make sure these instructions and all other equipment documents are accessible to

persons operating or servicing equipment.

MAXIMUM AIR PRESSURE

Unless otherwise noted in the product manual, the maximum air input pressure is 7.0 bar (100

psi). Excessive air input pressure may damage the equipment. Air input pressure is intended to be

applied through an external air pressure regulator rated for 0 to 7.0 bar (0 to 100 psi).

RELEASE PRESSURE

Release hydraulic and pneumatic pressure before opening, adjusting, or servicing pressurized

systems or components.

BURNS

Hot surfaces! Avoid contact with the hot metal surfaces of heated components. If contact can not be

avoided, wear heat-protective gloves and clothing when working around heated equipment. Failure

to avoid contact with hot metal surfaces can result in personal injury.

6 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Nordson EFD Product Safety Statement (continued)

Halogenated Hydrocarbon Solvent Hazards

Do not use halogenated hydrocarbon solvents in a pressurized system that contains aluminum components.

Under pressure, these solvents can react with aluminum and explode, causing injury, death, or property damage.

Halogenated hydrocarbon solvents contain one or more of the following elements.

Element Symbol Prefix

Fluorine F “Fluoro-”

Chlorine Cl “Chloro-”

Bromine Br “Bromo-”

Iodine I “Iodo-”

Check the Safety Data Sheet (SDS) or contact your material supplier for more information. If you must use

halogenated hydrocarbon solvents, contact your EFD representative for compatible EFD components.

High Pressure Fluids

High pressure fluids, unless they are safely contained, are extremely hazardous. Always release fluid pressure before

adjusting or servicing high pressure equipment. A jet of high pressure fluid can cut like a knife and cause serious

bodily injury, amputation, or death. Fluids penetrating the skin can also cause toxic poisoning.

WARNING

Any injury caused by high pressure liquid can be serious. If you are injured or even suspect an injury:

• Go to an emergency room immediately.

• Tell the doctor that you suspect an injection injury.

• Show the doctor the following note.

• Tell the doctor what kind of material you were dispensing.

Medical Alert — Airless Spray Wounds: Note to Physician

Injection in the skin is a serious traumatic injury. It is important to treat the injury surgically as soon as possible. Do

not delay treatment to research toxicity. Toxicity is a concern with some exotic coatings injected directly into the

bloodstream.

Qualified Personnel

Equipment owners are responsible for making sure that EFD equipment is installed, operated, and serviced by

qualified personnel. Qualified personnel are those employees or contractors who are trained to safely perform

their assigned tasks. They are familiar with all relevant safety rules and regulations and are physically capable of

performing their assigned tasks.

7www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Nordson EFD Product Safety Statement (continued)

Intended Use

Use of EFD equipment in ways other than those described in the documentation supplied with the equipment may

result in injury to persons or damage to property. Some examples of unintended use of equipment include:

• Using incompatible materials.

• Making unauthorized modifications.

• Removing or bypassing safety guards or interlocks.

• Using incompatible or damaged parts.

• Using unapproved auxiliary equipment.

• Operating equipment in excess of maximum ratings.

• Operating equipment in an explosive atmosphere.

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which it is used. Any approvals obtained for

Nordson EFD equipment will be voided if instructions for installation, operation, and service are not followed. If the

equipment is used in a manner not specified by Nordson EFD, the protection provided by the equipment may be

impaired.

Personal Safety

To prevent injury, follow these instructions:

• Do not operate or service equipment unless you are qualified.

• Do not operate equipment unless safety guards, doors, and covers are intact and automatic interlocks are

operating properly. Do not bypass or disarm any safety devices.

• Keep clear of moving equipment. Before adjusting or servicing moving equipment, shut off the power supply

and wait until the equipment comes to a complete stop. Lock out power and secure the equipment to prevent

unexpected movement.

• Make sure spray areas and other work areas are adequately ventilated.

• When using a syringe barrel, always keep the dispensing end of the tip pointing towards the work and away

from the body or face. Store syringe barrels with the tip pointing down when they are not in use.

• Obtain and read the Safety Data Sheet (SDS) for all materials used. Follow the manufacturer’s instructions for

safe handling and use of materials and use recommended personal protection devices.

• Be aware of less-obvious dangers in the workplace that often cannot be completely eliminated, such as hot

surfaces, sharp edges, energized electrical circuits, and moving parts that cannot be enclosed or otherwise

guarded for practical reasons.

• Know where emergency stop buttons, shutoff valves, and fire extinguishers are located.

• Wear hearing protection to protect against hearing loss that can be caused by exposure to vacuum exhaust

port noise over long periods of time.

8 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Nordson EFD Product Safety Statement (continued)

Fire Safety

To prevent a fire or explosion, follow these instructions:

• Shut down all equipment immediately if you notice static sparking or arcing. Do not restart the equipment until

the cause has been identified and corrected.

• Do not smoke, weld, grind, or use open flames where flammable materials are being used or stored.

• Do not heat materials to temperatures above those recommended by the manufacturer. Make sure heat

monitoring and limiting devices are working properly.

• Provide adequate ventilation to prevent dangerous concentrations of volatile particles or vapors. Refer to local

codes or the SDS for guidance.

• Do not disconnect live electrical circuits when working with flammable materials. Shut off power at a disconnect

switch first to prevent sparking.

• Know where emergency stop buttons, shutoff valves, and fire extinguishers are located.

Preventive Maintenance

As part of maintaining continuous trouble-free use of this product, Nordson EFD recommends the following simple

preventive maintenance checks:

• Periodically inspect tube-to-fitting connections for proper fit. Secure as necessary.

• Check tubing for cracks and contamination. Replace tubing as necessary.

• Check all wiring connections for looseness. Tighten as necessary.

• Clean: If a front panel requires cleaning, use a clean, soft, damp rag with a mild detergent cleaner. DO NOT

USE strong solvents (MEK, acetone, THF, etc.) as they will damage the front panel material.

• Maintain: Use only a clean, dry air supply to the unit. The equipment does not require any other regular

maintenance.

• Test: Verify the operation of features and the performance of equipment using the appropriate sections of this

manual. Return faulty or defective units to Nordson EFD for replacement.

• Use only replacement parts that are designed for use with the original equipment. Contact your Nordson EFD

representative for information and advice.

9www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Nordson EFD Product Safety Statement (continued)

Important Disposable Component Safety Information

All Nordson EFD disposable components, including syringe barrels, cartridges, pistons, tip caps, end caps,

and dispense tips, are precision engineered for one-time use. Attempting to clean and re-use components will

compromise dispensing accuracy and may increase the risk of personal injury.

Always wear appropriate protective equipment and clothing suitable for your dispensing application and adhere to

the following guidelines:

• Do not heat syringe barrels or cartridges to a temperature greater than 38° C (100° F).

• Dispose of components according to local regulations after one-time use.

• Do not clean components with strong solvents (MEK, acetone, THF, etc.).

• Clean cartridge retainer systems and barrel loaders with mild detergents only.

• To prevent fluid waste, use Nordson EFD SmoothFlow™ pistons.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system immediately and perform the following

steps:

1. Disconnect and lock out system electrical power. If using hydraulic and pneumatic shutoff valves, close and

relieve pressure.

2. For Nordson EFD air-powered dispensers, remove the syringe barrel from the adapter assembly. For Nordson

EFD electro-mechanical dispensers, slowly unscrew the barrel retainer and remove the barrel from the actuator.

3. Identify the reason for the malfunction and correct it before restarting the system.

Disposal

Dispose of equipment and materials used in operation and servicing according to local codes.

10 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Nordson EFD Product Safety Statement (continued)

Equipment-Specific Safety Information

The following safety information is specific to the Liquidyn P-Dot valve.

CAUTION

Do not dry cycle the valve! The valve be damaged if it is operated without fluid, causing leakage and a poor seal.

Precise dispensing can no longer be guaranteed if this occurs.

General

• Before use, read the complete operating instructions and all safety instructions to ensure safe and correct usage.

• Observe all safety instructions.

Intended Use

• The micro-dispensing system is for indoor use only.

• Do not use the micro-dispensing system in an explosive atmosphere or with explosive materials.

Fluid Compatibility

• Use only for the micro-dispensing of medium- to high-viscosity fluids or pastes.

• Ensure that all fluid carrying parts and sealings are resistant to the dispensing material used.

Operating Conditions

• Operate heaters (optional) within the approved temperature range only. Refer to “Specifications” on page12.

• Use only heaters that are distributed by Nordson EFD specifically for this micro-dispensing valve.

• Adhere to the maintenance intervals specified under “Service” on page30.

• Do not subject the valve needle to force, knocks, or impact.

• Avoid long shutdown periods with the system switched on.

• Do not operate the valve in a dry condition (without dispensing material).

11www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Specifications

NOTE: Specifications and technical details are subject to change without prior notification.

Item Specification

Size Refer to “Dimensions” on page45.

Weight 270.0 g (9.5 oz)

Maximum fluid pressure 100 bar (1,450 psi)

Fluid inlet M8 x 1, flat sealing

Mounting M3 x 25

Maximum operating frequency 150Hz

Pulse time 2 ms

Input voltage 24 VDC, PLC compatible

Power consumption 0.5 Amp (peak 5.0 Amp)

Input air pressure 2.0–5.0 bar (29–73 psi)

Maximum valve temperature 40° C (104° F)

NOTE: Refer also to the manufacturer’s safety data sheet (SDS) for the

material to be dispensed for the required ambient operating conditions

Maximum nozzle heater temperature 90° C (194° F)

Humidity 10–80%

Storage temperature -5–40° C (23–104° F)

Dispensing volume 3–200 nL (1–6.8 oz) per cycle

Viscosity range 50–200,000 mPas (thixotropic)

Dispensing accuracy >99% (dispensing tolerance <1%)

Service life >100,000,000 cycles

Product classification IP65

Installation category II

Compressed air quality class Pollution degree DIN ISO 8573-1, class 5

Approvals CE, TÜV

12 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Operating Features

The Liquidyn P-Dot micro-dispensing valve is shipped with the components shown under “Unpack the System

Components” on page14, along with any additional configuration selections and accessories. The valve can be

uniquely configured to achieve the best dispensing result for your material and application.

Safety plate

Electrical input

(M8 valve cable)

Syringe barrel bracket

(ordered separately)

Sound absorber

Force screw

Actuator

Syringe barrel adapter

(fluid pressure)

(ordered separately)

Syringe barrel

(ordered separately)

Luer lock adapter

(ordered separately;

optional tube connector

not shown)

Air input (operating pressure)

Tappet

• Steel only

Tappet retaining nut

Drainage block

Rod sealing O-rings (2x)

• NBR (Buna-N)

• EPDM

• Perlast

• Viton

Mounting screws M3 x 14 (2x)

Fluid body

• Steel only

Mounting screws M3 x 14 (2x)

®

®

Nozzle retaining nut

(ordered separately;

optional nozzle heater

not shown)

Nozzle (ordered separately)

• Steel only

13www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Installation

Use this section in tandem with any other system component operating manuals to install all components of the

system.

Unpack the System Components

1

1 Liquidyn P-Dot valve equipped with the following parts:

• Actuator

• Safety plate

• Steel fluid body

• Drainage block

• 4 mounting screws

• 2 NBR O-rings (between the tappet rod and fluid body)

• Steel tappet with tappet nut

2

3

2 2.5 m (8.2 ft) M8 valve cable with 3-pin plug

3 Open-end wrench, size 3.5 mm

Open-end wrench, size 6 mm

(Not shown)

Optional components (ordered and shipped separately)

14 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Assemble the Valve (Initial Assembly)

Follow this procedure to assemble the valve before mounting it. You will need the following items:

• Open-end wrench, size 10 mm

• Hex wrench, size 2.5 mm

• Hex wrench, size 1.5 mm

• Nozzle

• Nozzle retaining nut

• Optional: Heater key (if installing a nozzle heater)

Refer to “Replacement Parts” on page38 for component part numbers.

NOTE: The steps provided in this manual are based on a valve with a syringe barrel.

1.

• Remove the protective covers.

2.

• Install the nozzle.

3.

• Secure the nozzle with the retaining nut.

• Optional: To heat the fluid at the nozzle, go to “Install a

Nozzle Heater (Optional)” on page17. Return here to

continue.

NOTE: The nozzle is only minimally secured by a nozzle

heater. The nozzle is fully secured by the retaining nut.

4.

(Syringe barrel installations only)

• By hand, thread the luer lock adapter loosely onto the

fluid body, positioning it at a 15-degree angle from its end

position.

• Tighten the nut with a wrench so that the adapter is

parallel to the straight axis of the valve.

Torque: 5 N•m (3.7 ft-lb) maximum

• Optional: Install a tube connector (for non-syringe barrel

installations).

~15°

Continued on next page

15www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Assemble the Valve (Initial Assembly) (continued)

5.

(Syringe barrel installations only)

• Remove the safety plate.

• Position the syringe barrel bracket on the valve and

reinstall the safety plate to secure it.

6.

• (Syringe barrel installations only) Install the syringe barrel

and syringe barrel adapter.

16 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Install a Nozzle Heater (Optional)

Install the optional nozzle heater as shown in the illustration below. A nozzle heater controls the temperature of

the material in the nozzle. The nozzle is secured minimally by the nozzle heater with an elastomer (heater O-ring)

between it and the valve. The nozzle is fully secured by the retaining nut.

You will need the following items:

• Nozzle

• Nozzle heater

• Nozzle heater O-ring (NBR or EPDM)

• Retaining nut

• Heater key

• Heater cable

Refer to “Replacement Parts” on page38 for component part numbers.

NOTES:

• The nozzle retaining nut predominantly secures and seals the nozzle in place. The heater remains in contact with

the retaining nut through pressure supplied by a heater O-ring, which creates a partial space between the heater

and the fluid body. This ensures thermal contact and allows the heater to rotate slightly even when the retaining

nut is fully tightened.

• The image below is based on a Liquidyn P-Dot valve with a standard nozzle heater. The mounting process is the

same for all valves.

Nozzle

Nozzle heater O-ring

Nozzle heater

Nozzle retaining nut

Heater key

Torque for a steel nozzle: 1.2 N•m (10.6 in.-lb)

NOTES:

• The electrical connection for the

heater is supplied through the

provided heater cable.

• To attach or release the heater

cable, loosen or tighten the knurled

nut by hand. Be sure to connect

the heater cable plug in the correct

orientation.

17www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Mount the Valve

Mount the valve using either of the following options.

Standard Mounting

Secure the valve using two M3 x 25 hex screws (customer-supplied).

Quick-Mounting

An optional quick-mounting bracket is available for faster valve removal

and installation. Once the valve is installed using the quick-mounting

components, it can be easily removed or installed using the quickrelease fastener. Refer to “Replacement Parts” on page38 for the

quick-mounting kit part number.

You will need the following items:

• Vibration decoupler

• Quick-release fastener

• 2 M4 hex screws (minimum length: 10 mm)

• Hex wrench, size 2.5

• Hex wrench, size 3.0

M3 mounting

hole locations

M3 x 30

mounting

screws

Example of the quick-release mounting option

Vibration decoupler

Hook (hooks into the

quick-release fastener)

Quick-release fastener

M4 x 10 mounting

screws

Lever (secures the hook)

M4 x 30 mounting

screws (for mounting

onto a socket; not

included)

18 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Connect Cables

Connect the M8 valve cable and other communication cables as applicable for your system to control the operation

of the valve. The diagram below shows some typical system control setups.

NOTE: The valve is triggered by a square-wave signal (24 VDC). Because the pulse time is set to 2 ms, the opening

time of the valve switches below 1 ms and automatically closes after each trigger signal. Most PLC systems make

use of high performance transistor outputs which are suitable to control the valve directly. The valve is electrically

connected to the control system via the supplied M8 valve cable.

V10 P-Dot

V200 P-Dot

PLC

PLC

V10

V200

V10

PLC

T10

PLC

Key:

T10 = Liquidyn T10 or T20 heater controller

V10 = Liquidyn V10, V10M, V10D, or M10D controller

V200 = Liquidyn V200 controller

PLC = Higher-level controller

P-Dot

NOTE: Direct actuation of the valve via PLC is possible. However, the trigger

times or cycle times, respectively, must be below 1 ms. For additional

information, contact your Nordson EFD application specialist or the PLC

manufacturer.

P-Dot

P-Dot

P-Dot

19www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Connect the Air Supply

To achieve consistent dispensing results, the process parameters must be kept constant. The valve has two air

pressure connections (operating pressure and fluid pressure) which must be continuously supplied with air pressure.

The level of pressure depends on the respective process. Each valve must be separately connected to a continuous

air supply adjustable through a precision pressure regulator. To keep the operating pressure stable and constant,

use a pneumatic accumulator (at least 0.4 liter volume).

For an air supply connection diagram, refer to “Installation Example” on page21.

CAUTION

Ensure that the pressure limit values for the syringe barrel and air pressure tubing are not exceeded.

1. For the operating pressure, connect 6 mm OD tubing to the plug-in connector on the side of the valve.

2. For the fluid pressure, connect 4 mm or 6 mm tubing to the syringe barrel adapter (syringe barrel installations

only).

NOTE: Nordson EFD recommends installing a precision pressure regulator with a maximum control tolerance of

0.2% and a pressure limit of 0–8 bar (0–116 psi).

Air input

(fluid pressure; syringe

barrel installation shown)

Air input (operating

pressure)

20 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Installation Example

Item Description

Pneumatic connections

Fluid connection

Electrical connections

Optional

• Compressed air tube, 6 mm OD

• Dry, filtered air pressure, oil-free

• Filter grade: 40 µm

• Regulated by a precision pressure regulator

• Operating pressure limit: 3–8 bar (44–116 psi)

• Using a syringe barrel supply: Syringe barrel accessories with compressed 4 mm

air tubing

• Using a tube supply: Tube connector with fluid tubing

• Fluid pressure limit: 100 bar (1450 psi)

• Supplied M8 valve cable from the valve to a valve controller or a higher-level

controller, such as a PLC

• Power supply: 24 VDC

• Power consumption: 0.5 Amp (peak 5.0 Amp)

• Nozzle heater (controlled by a temperature control unit)

• Process equipment (such as a laser light barrier for dot recognition or a cleaning

station for nozzles)

Liquidyn P-Dot Series Jet Valves

Tube connection

Syringe barrel

connection

Valve cable

Connection depends on material supply method

Fluid tubing

Higher-level controller

(e.g., PLC)

Fluid

reservoir

Fluid pressure

4 mm air supply tubing

Precision

pressure

regulator

Air pressure source

Liquidyn P-Dot valve connection diagram

Operating pressure

6 mm air supply tubing

Precision

pressure

regulator

Pressure

accumulator

(at least 0.4 liter)

21www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Initial Startup

This section provides recommendations for system startup and operation. System startup for the valve depends on

the control unit. If you are using a Nordson EFD Liquidyn controller, obtain the controller manual. If you are using

higher-level controller, the control is set up by the customer.

CAUTION

Before switching on the system, ensure that all electrical and pneumatic connections are connected correctly and

fully functioning.

1. Check electrical and pneumatic connections.

2. Switch on the control unit.

3. Turn on the air supplies.

4. Use the following actions to set up and test the valve operation using the control system manual or the

customer-supplied control system and documentation. Refer to “Parameter Settings” on page23 for

information and recommendations on system setup.

a. Trigger the valve until the material to be dispensed leaves the nozzle opening. Place a collecting container or

a paper sheet underneath the valve.

b. Clean the nozzle tip with a lint-free cloth.

c. Set the distance between the nozzle and the target (such as a sample product).

d. Initiate several dispense cycles to test the valve operation.

e. Evaluate the dispensing results and make adjustments until the desired dispensing performance is achieved.

Refer to “Parameter Settings” on page23 and to “Recommended Setup Adjustments” on page24 for

detailed information on system setup and adjustment.

5. To ensure optimal valve performance, maintain the system as described under “Service” on page30.

22 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Parameter Settings

The following table provides recommended settings for initial startup and testing of the valve operation. Detailed

information on each parameter is shown after the table.

Parameter Description Recommendation

Pulse Time The electrical trigger pulse of the valve. 2 ms only

Frequency The number of tappet movements per second. 5Hz starting value

Fluid pressure Sets the material supply to the valve for a consistent volume. 1.5 bar (22 psi)

starting value

Operating pressure Supplies the valve with energy for the tappet movement. 4 bar (58 psi) starting

value

Tappet setting The setting of the force screw, which changes the vertical

movement of the tappet.

Pulse Time

The Pulse Time corresponds to the electrical trigger pulse, or

opening time, of the valve. The Pulse Time for the Liquidyn

P-Dotvalve must be 2 ms. With the P-Dot valve, Pulse Time

adjustments do not affect the dispensing volume; instead,

they can cause poor dispensing results.

Do not adjust

Frequency

Frequency is the number of tappet movements per second.

A dispensing cycle consists of the Pulse Time and the pause

time.

Physical Quantity Formula Unit

Frequency (f) f = 1 / T 1Hz (hertz) = 1 / s

Dispensing cycle T = 1 / f 1 s (second) = 1 / Hz

ms = 0.001 s (second)

Higher-level controllers may not allow you to enter the exact frequency. If such cases, frequency is set using the

length of the pulse and the pause time.

EXAMPLE:

Because the pulse time must be 2 ms, set the pause time to 18 ms to achieve 50Hz.

Dispensing cycle

Pulse time Pause time

23www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Parameter Settings (continued)

Fluid Pressure

The fluid pressure must be properly set to ensure that material is supplied at a consistent volume. Consider the

following when setting the fluid pressure:

• The fluid pressure must stay within the tubing pressure specifications.

• Fluid supply tubing must be resistant to chemicals.

• The fluid pressure must be high enough for the material to exit the nozzle opening.

• The required fluid pressure will vary depending on the material, its viscosity, and the ambient temperature.

• Decreasing the fluid pressure too much may, in extreme cases, prevent proper deposit separation from the

nozzle.

• Prevent pressure fluctuations. Note that pressure loss due to friction occurs as material flows through the

material delivery components.

Recommended Setup Adjustments

The following table provides recommended adjustments to help you quickly find optimum system settings

for your application. Because of the diversity of materials that can be dispensed, the effectiveness of these

recommendations can vary, but they serve to share our experience with you.

Goal Operating Pressure

Smaller dots Down Down Down Down Down

Bigger dots Up Up Up Up Up

Prevent satellites Down Up Down Down Up

Prevent residue at

the nozzle

Key:

Down = lower operating pressure or temperature / tighten screw / smaller diameter

Up = greater operating pressure or temperature / loosen screw / larger diameter

Up Down Down Up Not applicable

Tappet

Adjustment

Fluid Pressure

Heater

(Temperature)

Nozzle Orifice

Diameter

Recommended Action for Preventing Satellite Drop Formation

Simultaneously adjust the operating pressure and the force screw as shown below.

Goal Operating Pressure Force Screw

Prevent satellites Decrease by 0.1 bar (1.5 psi) Loosen by 0.1 turn (counterclockwise as

viewed from above)

Recommended Action for Preventing Residue Buildup at the Nozzle

Simultaneously adjust the operating pressure and the force screw as shown below.

Goal Operating Pressure Force Screw

Prevent residue at the

nozzle

Increase by 0.1 bar (1.5 psi) Tighten by 0.1 turn (counterclockwise as

viewed from above)

24 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Tappet Adjustment

The setting of the force screw affects the vertical movement of the tappet. The screw is factory-preset.

NOTES:

• An improper setting can cause the valve to stop dispensing.

• To return a force screw to the factory setting, refer to “Returning the Force Screw to the Factory Setting” on

page27.

• To set all valves in a multi-valve system to the same force screw setting (required for deposit integrity), refer to

“Manually Setting the Force Screw for Multiple Valves” on page28.

(2) (3)

Force screw

(1) Safety plate

(1) M2.5 x 10 hex screw

Adjusting the Force Screw

1. Use a 2.5 mm hex wrench to remove the safety plate (1).

2. Adjust the force screw. Refer to the following table for settings.

Settings

Loosen (2)

counterclockwise, as viewed from above

Tighten (3)

clockwise, as viewed from above

NOTE: The two end positions of the force screw are extreme positions:

• Fully open decreases the force to fullest extent possible.

• Fully closed stops deposit formation.

• Reduces the force of the tappet movement.

• Prevents the formation of satellites.

• Slightly increases the dispensing volume.

• Increases the force of the tappet movement.

• Improves deposit cut-off.

• Slightly decreases the dispensing volume.

In between these two extreme positions is the optimum setting, which should be determined one time only

using these instructions.

25www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Tappet Adjustment (continued)

Force Screw Setting Units

The force screw setting is indicated by clicks or turns.

• 12 clicks = 1 turn

Special Tools for Tappet Adjustment

NOTE: Refer to “Replacement Parts” on page38 for tool part numbers.

The scale head tool allows you to easily replicate force screw settings for multiple valves.

The tappet measuring system tool allows you to easily determine the current tappet setting and to

very precisely replicate the setting for multiple valves.

Tappet Adjustment Methods

If you use several valves with the same parameters, the following methods can help you ensure that all valves have

the same tappet setting.

Manual • No additional accessories required.

• Takes the most time.

Refer to “Manually Setting the Force Screw for Multiple Valves” on page28.

Scale head tool

Tappet measuring system

tool

• Easy adjustment.

• Economical.

• Accuracy of 1/100 (1 to 100).

• Purpose-built for this task.

26 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Tappet Adjustment (continued)

Returning the Force Screw to the Factory Setting

You will need the following items:

• Open-end wrench, size 10 mm

• Hex wrench, size 2 mm

• Optional: Heater key

1.

• Disconnect all cables and tubing from the valve.

• Remove the valve from the machine.

• Remove the safety plate.

• Remove the retaining nut (or heater element) from the

valve.

NOTE: If a nozzle heater is installed, use the heater key to

remove the retaining nut.

NOTE: The nozzle is held by the retaining nut, so be

careful not to lose the nozzle.

2.

Set the zero position of the nozzle:

• Put the nozzle on the tip of the tappet and push gently

with your finger against the nozzle.

• Between the nozzle and the fluid body thread should now

be a gap (“x”). If no gap occurs, tighten the force screw

until a gap occurs.

Liquidyn P-Dot Series Jet Valves

X

3.

• Loosen the force screw while pushing against the nozzle

until the nozzle touches the front of the fluid thread. The

zero position is now obtained.

4.

• Tighten the force screw (from the zero position)

0.5–0.75turns clockwise as viewed from above.

5.

• Reassemble the safety plate and the retaining nut (or

heater element) and reinstall the valve.

Push

gently.

0

27www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Tappet Adjustment (continued)

Manually Setting the Force Screw for Multiple Valves

You will need the following items:

• Open-end wrench, size 10 mm

• Hex wrench, size 2 mm

• Optional: Heater key

If your application requires that several valves in a multi-valve system produce the same dispensing

results, all dispensing parameters (fluid pressure, operating pressure, tappet setting, and, if applicable,

temperature) must be set to the same values.

The fluid pressure, operating pressure, and temperature (if applicable) can easily be set with the

Liquidyn V200 controller. However, the tappet setting varies from valve to valve due to unavoidable part

tolerances. The best way to set the tappet is to use the scale head tool, which allows you to make the

tappet setting the same for every valve. You can also manually set the tappet using this procedure.

Before manually setting the tappet on all the valves, you must determine the tappet setting of the valve

with which the desired dispensing results have been achieved.

NOTE: Refer to “Replacement Parts” on page38 for the scale head and measuring system tool part

numbers.

1.

• Disconnect all cables and tubing from the valve.

• Remove the valve from the machine.

• Remove the safety plate.

2.

• Mark the position of the set screw.

3.

• Remove the retaining nut (or heater element) from the

valve.

NOTE: If a nozzle heater is installed, use the heater key to

remove the retaining nut.

NOTE: The nozzle is held by the retaining nut, so be

careful not to lose the nozzle.

4.

Set the zero position of the nozzle:

• Put the nozzle on the tip of the tappet and push gently

with your finger against the nozzle.

• Between the nozzle and the fluid body thread should now

be a gap (“x”). If no gap occurs, tighten the force screw

until a gap occurs.

X

Push

gently.

Continued on next page

28 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Tappet Adjustment (continued)

Manually Setting the Force Screw for Multiple Valves (continued)

5.

• Loosen the force screw while pushing against the nozzle

until the nozzle touches the front of the fluid thread. The

zero position is now obtained.

0

6.

• Determine how many turns / clicks the knob was moved

from the marked position (step 2) and memorize the

number.

In this example: 5/8 turns or 7.5 clicks.

7.

• Tighten the force screw the identified number of turns /

clicks until you reach the marked position.

5

6

7

Liquidyn P-Dot Series Jet Valves

4

3

2

1

8.

• Reassemble the safety plate and the retaining nut (or

heater element) and reinstall the valve.

9.

• Repeat the identified number of turns / clicks for all

valves.

NOTE: Always set the zero position of the nozzle first

before tightening the set screw the identified number of

turns / clicks.

29www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Service

Regularly perform maintenance on your micro-dispensing valve. Regular maintenance will save you cost-intensive

repairs and is a requirement for long valve lifespan. Nordson EFD valves are designed to be maintained easily. All

the material-carrying parts can be removed, cleaned, and maintained by the customer.

NOTE: Customers should service only the material-carrying components. For any service not related to the materialcarrying components, contact your Nordson EFD support representative.

Recommended Maintenance Schedule

Cleaning and maintenance intervals vary based your operating conditions (dispensing frequency, frequency of use,

dispensing material, etc.). The following table provides recommendations only.

Variable Perform Weekly Valve Cleaning

Dispensing frequency Less than 20Hz Greater than 20Hz

Dispensing material

NOTE: The sealing effectiveness of the tappet O-rings can be compromised if the replacement intervals are too long

(causing worn or damaged O-rings). Worn or damaged O-rings can cause dispensing material to enter the drive

system, thus compromising valve operation.

• Oil

• Grease

• UV glue

Perform Daily Valve Cleaning (or at the end

of the pot life)

• Dispersions

• Reactive adhesives

• Epoxies

Valve Cleaning

You will need the following items:

• Protective clothing

• Open-end wrench, size 10 mm

• Hex wrench, size 2 mm

• Toothpick

• Cleaning material

• Container

• Compressed air

• Lint-free cloth

• Optional: Ultrasonic bath

• Optional: Microscope

WARNING

• Before any component change or service activity, relieve air pressure from the fluid reservoirs and switch off

heater control (if applicable).

• Disconnect the system from the power supply before beginning work on electrical or electronic system

components or opening the switchgear cabinet.

• Disconnect the mains power plug to isolate the system from the power supply. Check for safe isolation from the

power supply using suitable measuring instruments. Only perform maintenance work on a system that is safely

isolated from the power supply.

• Wear appropriate personal protective equipment, including, but not limited to, gloves, safety goggles, and

breathing protection.

• Switch off the compressed air supply before disconnecting the system from the pneumatic connections.

• Read and understand the SDS for the dispensing material and the risk of the associated health hazards so that

suitable safety measures can be taken for the correct handling of the dispensing material.

30 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Service (continued)

Shut Down the System

1. Shut off the air supply.

2. Switch off the power of every control unit, then switch off power to the valve.

3. Disconnect all tubing and cables.

4. Disconnect the material supply.

5. Continue with the procedures in this section to disassemble and clean the valve.

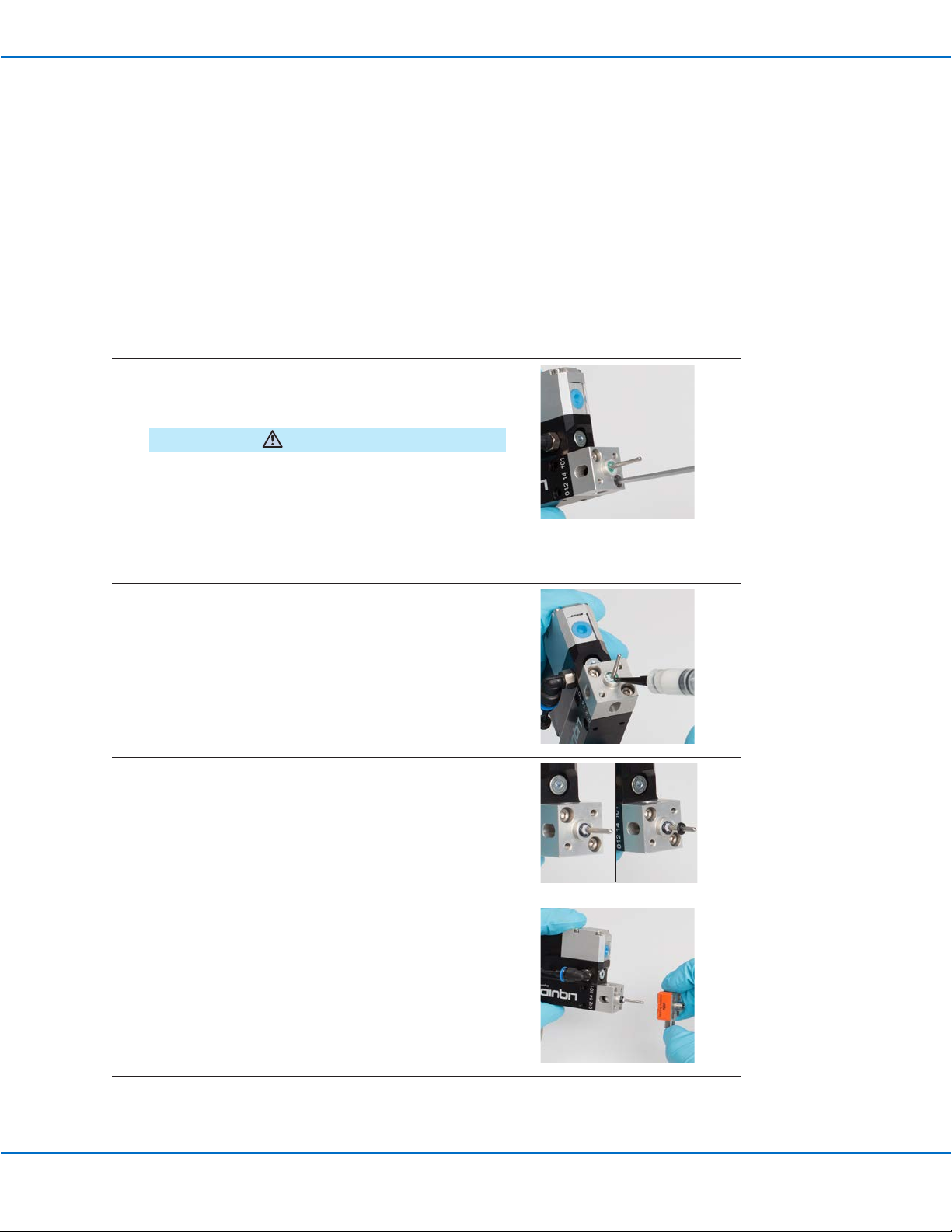

Disassemble the Valve

CAUTION

Do not open the color-sealed screws. Unauthorized modifications or the breaking of the sealed screws voids the

warranty and guarantee.

1.

• (Syringe barrel installations only) Remove the syringe

barrel from the valve.

2.

• (Syringe barrel installations only) Disconnect the luer

lock adapter from the fluid body.

• Optional: Remove the tube connector.

3.

• Unscrew the nozzle retaining nut.

• Optional: If you are using a heater, use the heater key

to remove the nozzle retaining nut.

4.

• Remove the nozzle from the fluid body.

Continued on next page

31www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Service (continued)

Disassemble the Valve (continued)

5.

• Unscrew and remove the four screws that secure the

fluid body.

• Carefully remove the fluid body without damaging the

tappet.

6.

• Use a toothpick to remove the O-ring from the fluid

body.

7.

• Remove the second O-ring from the tappet.

• Clean the tappet and annulus with lint-free paper.

8.

• Unscrew and remove the two screws that secure the

drainage block.

• Carefully remove the drainage block without damaging

the tappet.

32 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Service (continued)

Clean the Valve Components

CAUTION

Never use solvents or cleaning agents that contain halogenated hydrocarbons (such as trichlorethane, methyl

chloride, or dichloromethane). Halogenated hydrocarbons can dissociate, causing an explosion upon contact with

aluminum and galvanized surfaces. Before using a solvent or cleaning agent, check its ingredients.

1.

• Submerge all the components in a container filled with

cleaning fluid.

• After 3–5 minutes, remove the components from the

container and clean them with a lint-free cloth.

CAUTION

Do not damage the holes on the sealing faces of the

material carrying components.

• Optional: Use an ultrasonic bath to clean the

components.

2.

• Use the pipe cleaners from the cleaning kit to clean

the disassembled components (luer lock adapter,

nozzle retaining nut, nozzle, fluid body, and the tappet

if needed).

3.

• Use compressed air to clear any remaining cleaning

fluid from the parts.

CAUTION

Do not damage the holes on the sealing faces of the

material carrying components.

• Examine the cleaned components for any remaining

residue (especially the nozzle, which should be

examined under a microscope).

• If the parts are still contaminated, repeat the cleaning

process.

33www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Service (continued)

Assemble the Valve (After Cleaning)

Follow this procedure to assemble a valve after cleaning it. You will need the following items:

• Hex wrench, size 10

• Hex wrench, size 2.5

• Nozzle

• Nozzle retaining nut

• O-rings and barrier grease

• Wooden pick

• Optional: Heater key (if installing a nozzle heater)

NOTE: The steps provided in this manual are based on a valve with a syringe barrel.

1.

• Position the drainage block on the valve body in the

correct orientation.

CAUTION

Do not subject the valve tappet to lateral, or sideways,

force.

• Secure the drainage block with the two screws removed

previously.

• Ensure that the screw heads disappear within the screw

holes.

2.

• Using a wooden pick, apply a small amount of barrier

grease (Barriereta L55/2) at the base of the tappet and

distribute this around the annulus.

NOTE: When dispensing instant adhesive

(cyanoacrylates), Nordson EFD recommends petroleum

jelly for use as the barrier grease. Contact Nordson EFD

for assistance in dispensing cyanoacrylates.

3.

• Install a new O-ring (standard material: NBR) on the

tappet and press the O-ring down into the greased

annulus.

• Distribute the grease evenly so that the entire sealing

surface of the O-ring is covered.

• Install the second new (grease-free) O-ring on the tappet

on top of the initial O-ring.

4.

• Mount the fluid body precisely over the tappet without

tilting it.

Continued on next page

34 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Service (continued)

Assemble the Valve (After Cleaning) (continued)

5.

• Tighten the fluid body screws (2x) crosswise.

Torque: 0.8 N•m (5.9 ft-lb) maximum

6.

• Install the nozzle.

7.

• Secure the nozzle with the retaining nut.

Liquidyn P-Dot Series Jet Valves

NOTE: The nozzle is only minimally secured by a nozzle

heater. The nozzle is fully secured by the retaining nut.

8.

(Syringe barrel installations only)

• By hand, thread the luer lock adapter loosely onto the

fluid body.

• Position the luer lock adapter at a 15-degree angle to its

end position and then tighten the nut with a wrench so

that the adapter is level with the straight axis of the valve.

Torque: 5 N•m (3.7 ft-lb) maximum

• Optional: Install the tube connector.

9.

• (Syringe barrel installations only) Install the syringe barrel

and syringe barrel adapter.

• Mount the valve and restore the system to normal

operation.

~15°

35www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Service (continued)

Tappet Replacement

Follow this procedure to replace the tappet. You will need the following items:

• Replacement tappet

• Barrier grease

• Open-end wrench, size 3 mm (supplied)

• Open-end wrench, size 6 mm (supplied)

1.

• Go to “Disassemble the Valve” on page31 and perform

all the steps to disassemble the valve. Return here to

continue.

2.

• Remove the tappet from the housing by pulling the tappet

retaining nut just enough to allow you to position a 3.5

mm open-end wrench on the piston rod.

3.

• Hold the piston rod in place with the 3.5 mm open-end

wrench and loosen the retaining nut with the 6 mm openend wrench by turning it counterclockwise.

4.

• Remove the retaining nut (including the tappet) by hand.

5.

• Insert the new / cleaned tappet in the retaining nut.

6.

• If the valve is used to dispense adhesives, apply a small

amount of barrier grease to the piston rod threads to

prevent the retaining nut from adhering to the piston rod

during dispensing.

• Screw the retaining nut and tappet into the piston rod by

hand.

NOTE: When turning the piston rod, ensure that the

tappet is centrally aligned.

Continued on next page

36 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Service (continued)

Tappet Replacement (continued)

7.

• Hold the piston rod in place with the 3.5 mm open-end

wrench and secure the retaining nut with the 6 mm openend wrench by turning it clockwise.

Torque: 0.4–0.6 N•m (3.5–5.3 in.-lb).

8.

• Refer to “Assemble the Valve (After Cleaning)” on

page34 to reassemble the valve, then reinstall the valve

and restore the system to normal operation.

Liquidyn P-Dot Series Jet Valves

37www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Part Number

Part # Description

7825002 Liquidyn P-Dot CT actuator Suitable for medium- to high-viscosity fluids with cycle rates

of up to 150Hz

Replacement Parts

Valve Components

Refer to “Operating Features” on page13 for the location of the these components in the valve.

Part # Description Material Item

7825033* Tappet, P-Dot, 27L x 2.0D mm Steel

7825034 Tappet nut, P-Dot Steel

7826092* (5 pack)

7826093* (50 pack)

7826080 (5 pack)

7826081 (50 pack)

7826082 (5 pack)

7826083 (50 pack)

7826084 (5 pack)

7826085 (50 pack)

7825037* Steel fluid body 303 stainless steel

7825008 Drainage block 303 stainless steel

7825182 2.5 m (8.2 ft) M8 valve cable n/a

7825011 Safety plate

*Other selections are available. Contact your Nordson EFD application specialist for assistance.

O-ring, 2 x 1.5 mm (between the tappet and

fluid body)

NBR

EPDM

Perlast

Viton

n/a

38 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Replacement Parts (continued)

Nozzles and Nozzle Retaining Nuts

Liquidyn P-Dot Series Jet Valves

Nozzle

Type

Flat

Needle

*Many nozzle types and sizes are available. Contact your Nordson EFD application specialist for assistance.

The retaining nut secures the nozzle to the valve. The choice of retaining nut depends on the type of nozzle and

whether or not a nozzle heater is installed. Contact your Nordson EFD application specialist for assistance.

Nozzle

Type

Without

heater

With heater

Part # Description Material Item

7825063*

7825075*

Part # Description Material Compatibility Item

7825042*

7825051*

7825047*

Steel flat nozzle, 150 μm 303 stainless steel

Steel needle nozzle, 150 μm 303 stainless steel

Hexagon retaining

nut

Stainless-steel

retaining nut

Stainless-steel

retaining nut

Stainless steel

Stainless steel

Stainless steel

For all flat nozzles and steelneedle nozzles

For the standard nozzle heater

(compatible with all nozzle

types)

For the small nozzle heater

(compatible with all nozzle

types)

*Other selections are available. Contact your Nordson EFD application specialist for assistance.

39www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Replacement Parts (continued)

Syringe Barrels and Accessories

Many syringe barrel sizes and accessories are available. Contact your Nordson EFD application specialist for

assistance. For a complete list of Optimum components, see www.nordsonefd.com/Optimum.

5, 6

4

2, 3

1

Item Description Configuration Options

1

2

3

4

5

6

Luer lock adapter for 3cc to 70cc syringe barrels • Steel

• Normal

Syringe barrel

Piston

Syringe barrel holder

Syringe barrel adapter for 4 mm OD tube connection • Aluminum

O-ring (NBR) for syringe barrel adapter

• Light-proof

• UV-blocker

• Normal

• UV-blocker

Typical Luer Lock Fitting

Part # Description Material Item

7825120* Steel luer lock adapter for syringe barrels Stainless steel

*Other selections are available. Contact your Nordson EFD application specialist for assistance.

40 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Replacement Parts (continued)

Material Supply Tubing Components

The following material supply tubing and connectors are available from Nordson EFD. Additional selections may be

available. Contact your Nordson EFD application specialist for assistance.

Steel Tubing Connectors

Part # Description Material Item

7825137 4 mm OD tubing connector

7825138 6 mm OD tubing connector

7825139 8 mm OD tubing connector

Tubing

Part # Description Material

7826072 3.2 mm (1/8") PTFE tubing, 5 m (16.4 ft) PTFE

7826074 4 mm OD / 2.6 mm ID PTFE tubing, 5 m (16.4 ft) PTFE

7826075 6 mm OD / 4 mm ID PTFE tubing, 5 m (16.4 ft) PTFE

7826076 4 mm OD compressed air tubing, 5 m (16.4 ft) Polyurethane (PU)

7826077 6 mm OD compressed air tubing, 5 m (16.4 ft) Polyurethane (PU)

Stainless steel / aluminum

Accessories

Quick-Release Valve Mounting Components

When a valve is installed using these components, it can be quickly and easily removed and reinstalled. Refer to

“Quick-Mounting” on page18 for installation instructions.

Part # Description Item

7825018 Vibration decoupler

7825020 Quick-release fastener

— Two (2) M4 hex screws (minimum length: 10 mm) Customer supplied

Precision Pressure Regulator

Nordson EFD recommends a dry, oil-free, filtered air supply (40 µm filter grade).

Part # Description

7825268 Precision pressure regulator

41www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Accessories (continued)

Nozzle Heaters

Many materials can easily be dispensed without preheating. However, it is often advisable to preheat highly viscous

materials just before application to lower the viscosity. Doing so can prevent variations in viscosity. The use of

a nozzle heater guarantees a constant temperature of the material to be dispensed at the nozzle. Contact your

Nordson EFD application specialist for assistance.

A nozzle heater can be installed on the valve in place of the retaining nut. The heater can be controlled using a

separate temperature controller (such as the Liquidyn T10) or by the Liquidyn V200 controller.

NOTES:

• Nozzle heater O-rings are available in NBR or EPDM. Refer to “Nozzle Heater O-Rings” on page43 for part

numbers.

• A special heater key is required for installation. Refer to “Heater Key” on page43 for the part number.

• A nozzle retaining nut suitable for either a standard or small nozzle heater is required. Refer to “Nozzles and

Nozzle Retaining Nuts” on page39 for nozzle heater retaining nut part numbers.

Heater Type Heating Capability Nozzle Heater

Standard Up to 90° C (194° F)

Small (a small heater has a

low-profile height and is less

thick overall)

Up to 90° C (194° F)

42 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Accessories (continued)

Nozzle Heater Kits

These nozzle heaters include a flange suitable for mounting the Laser Light Barrier. Refer to “Nozzle Heater Cables”

on page43 for suitable cables.

Part # Description Material Item

7825149 Nozzle heater kit, standard, M5, straight plug n/a The kit includes the heater

7825150 Nozzle heater kit, standard, M5, 90-degree plug n/a

7825148 Nozzle heater element, standard, M5 Aluminum

7825152 Nozzle heater element, standard, M8 Aluminum

Nozzle heater element, large, M5

7825157

NOTE: This larger heater element heats the

material farther up into the supply tubing, allowing

more fluid to be heated before it is dispensed.

Aluminum

Nozzle Heater Cables

element, retaining nut, plug,

O-ring, and heater key.

Part # Description

7825182 2.5 m (8.2 ft) M8 valve cable

7825183 0.5 m (1.6 ft) M8 valve cable

7825176 3 m (10 ft) M5 valve cable, straight plug

7825177 3 m (10 ft) M5 valve cable, 90-degree plug

Nozzle Heater O-Rings

Two types of nozzle heater O-ring are available.

Part # Description Material

7826088 (pack of 5)

7826089 (pack of 50)

7825235 EPDM nozzle heater O-ring, 13 x 1.5 mm EPDM

NBR nozzle heater O-ring, 13 x 1.5 mm NBR

Heater Key

The heater key is required to install the heater retaining nuts.

Part # Description Item

7825209 Heater key

43www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Accessories (continued)

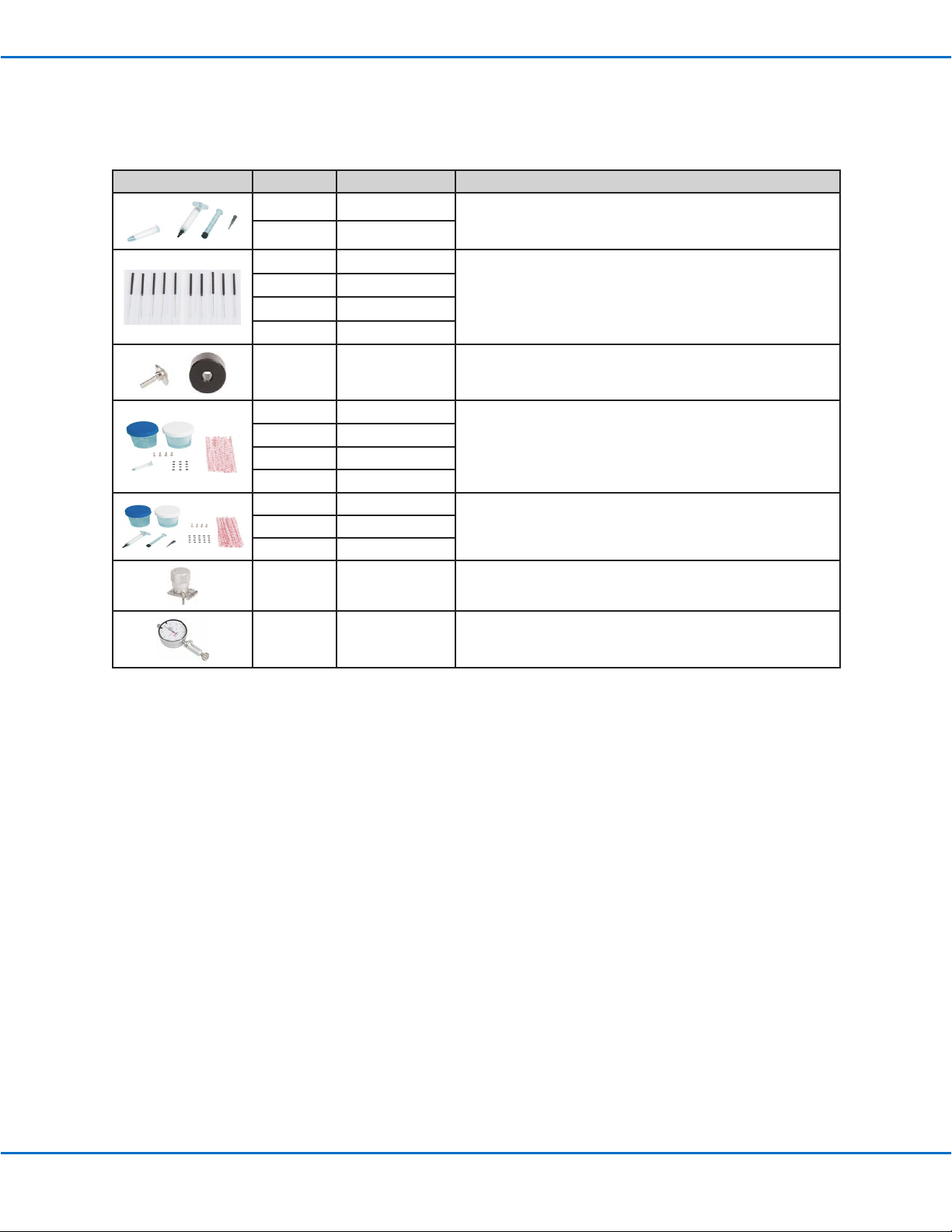

Tools and Supplies

Item Part # Size / Material Description

7825262 1.5 g

7825263 5.0 g

7825205 0.12 mm

7825206 0.16 mm

7825207 0.2 mm

7825208 0.25 mm

7825210 n/a Nozzle pinch tools

7825192 NBR

7825191 EPDM

7825194 Perlast

7825196 Viton

7825198 EPDM

7825197 Viton

Barrier grease for O-rings

Nozzle cleaning probes

Standard cleaning kit (order based on O-ring type)

Expanded cleaning kit (order based on O-ring type)7825195 Perlast

7825012 n/a Scale head tool for tappet force screw setting

7825215 n/a Measuring system tool for tappet force screw setting

44 www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Technical Data

Dimensions

Liquidyn P-Dot Series Jet Valves

M8 x 1

63 mm (2.5")

3.2

13 mm (0.5")

75 mm (3.0")

23 mm (0.9")

63 mm (2.5")

M3

127 mm (5.0")

32 mm (1.3")

13 mm (0.5")

3 H7

24 VDC

13 mm (0.5")

23 mm (0.9")

3 H7

19.8 mm ("0.77)

35.5 mm (1.4")

M8 Valve Cable Pin Positions

Pin Color Function

1 Brown None

2 Black Valve (+)

3 Blue Valve (-)

45www.nordsonefd.com info@nordsonefd.com +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Liquidyn P-Dot Series Jet Valves

Appendix A, About Non-Contact Dispensing

The way a micro-dispensing valve system works for the non-contact dispensing of micro-deposits of fluid is

comparable to the way an ink-jet system works. In both systems, a jetted deposit with a spherical head and a thin