INSTALLATION- AND OPERATING INSTRUCTIONS

Steam air humidier

Nordmann ES4

2559439 EN 1310

NORDMANN

ENGINEERING

3

Contents

1 Introduction 4

1.1 To the very beginning 4

1.2 Notes on the installation and operating instructions 4

2 For your safety 6

3 Product Overview 8

3.1 Models overview 8

3.2 Identicationoftheunit 9

3.3 Steamhumidierconstruction 10

3.4 Functional description 11

3.5 Humidicationsystemoverview 13

3.6 Options 15

3.7 Accessories 16

3.7.1 Accessories overview 16

3.7.2 Accessory details 17

3.8 Standarddelivery 20

3.9 Storing/Transportation/Packaging 20

4 Notes for the planning engineer 21

4.1 Selecting the unit version 21

4.1.1 Calculating the maximum required steam capacity 21

4.1.2 Selecting the unit 22

4.2 Selecting the options an accessories 22

4.3 Selecting the control system 23

5 Mounting and installation work 25

5.1 Importantnotesformountingandinstallationwork 25

5.2 Installation overviews 26

5.3 Mounting the unit 28

5.3.1 Notes on locating the unit 28

5.3.2 Mountingthehumidier 30

5.3.3 Inspecting the installed unit 31

5.4 Steam installation 32

5.4.1 Overview steam installation 32

5.4.2 Positioningandmountingofthesteam

distribution pipes 33

5.4.3 Installing the steam distributors 37

5.4.4 PositioningandmountingofthefanunitsFAN4N... 38

5.4.5 Installingthesteamhose 39

5.4.6 Common steam and condensate line errors 43

5.4.7 Inspecting the steam installation 44

5.5 Water installation 45

5.5.1 Overview water installation 45

5.5.2 Notes on water installation 46

5.5.3 Inspecting the water installation 47

5.6 Electric installation 48

5.6.1 Wiring diagram Nordmann ES4 48

5.6.2 Notesonelectricinstallation 49

5.6.3 Unitconguration 52

5.6.4 Inspecting the electrical installation 53

6 Operation 54

6.1 Functionofthedisplayandoperatingelements 54

6.2 Commissioning 55

6.3 Notes on operation 56

6.3.1 FunctionoftheLED'sininfomode 56

6.3.2 Remoteoperatingandfaultindication 56

6.3.3 Inspections during operation 57

6.4 Carrying out manual draining 57

6.5 Takingtheunitoutofoperation 57

7 Maintenance 58

7.1 Important notes on maintenance 58

7.2 Maintenancelist 59

7.3 Removingandinstallingpartsformaintenance 60

7.3.1 Removalandinstallationofthesteamcylinder 60

7.3.2 Removalandinstallationofthedraincup 63

7.3.3 Removalandinstallationofthewatercup

and the water hoses 64

7.3.4 Removalandinstallationofthedrainvalve 65

7.3.5 Removalandinstallationoftheinletvalve 66

7.4 Notes on cleaning the unit components 67

7.5 Notes on cleaning agents 68

7.6 Resetting the maintenance indication 68

8 Fault elimination 69

8.1 Faultindication 69

8.2 Malfunctionlists 70

8.2.1 Systemfaults 70

8.2.2 Unitfaults 70

8.3 Notesonfaultelimination 72

8.4 Resettingtheerrorindication(redLEDlights) 72

9 Taking out of service/Disposal 73

9.1 Takingoutofservice 73

9.2 Disposal/Recycling 73

10 Productspecications 74

10.1 Technicaldata 74

10.2 Unitdimensions 75

4

1 Introduction

1.1 To the very beginning

We thank you for having purchased the steam humidier Nordmann ES4.

The steam humidier Nordmann ES4 incorporates the latest technical ad

van ces and meets all recognized safety standards. Nevertheless, improper

use of the Nordmann ES4 may result in danger to the user or third parties

and/or impairment of material assets.

To ensure a safe, proper, and economical operation of the steam humidier

Nordmann ES4, please observe and comply with all information and safety

instructions contained in the present installation and operating instructions

as well as the instructions given in the manuals for the components used

in the humidication system.

If you have questions, which are not or insufciently answered in this

documentation, please contact your Nordmann supplier. They will be glad

to assist you.

1.2 Notes on the installation and operating instructions

Limitation

The subject of these installation and operating instructions is the

steam humidier Nordmann ES4. The various accessories (e.g. steam

distributor, steam distribution system, etc.) are only described insofar as this

is necessary for proper operation of the equipment. Further information on

accessories can be obtained in the respective instructions.

These installation and operating instructions are restricted to the installa-

tion, commissioning, operation, servicing and trouble shooting of the

steam humidier Nordmann ES4 and is meant for well trained personnel

being sufciently qualied for their respective work.

These installation and operating instructions are supplemented by various

separate items of documentation (spare parts list, manuals for accessories,

etc.). Where necessary, appropriate crossreferences are made to these

publications in the present documentation.

5

Explanation of the symbols used in this manual

CAUTION!

The catchword “CAUTION” designates notes in this documentation that, if

neglected, may cause damage and/or malfunction of the unit or other

material assets.

WARNING!

The catchword “WARNING” used in conjunction with the general caution

symbol designates safety and danger notes in this documentation that, if

neglected, may cause to injury to persons.

DANGER!

The catchword “DANGER” used in conjunction with the general caution

symbol designates safety and danger notes in this documentation that, if

neglected, may lead to severe injury or even death of persons.

Safekeeping

Please safeguard these installation and operating instructions in a safe place,

where it can be immediately accessed. If the equipment changes hands,

the documentation should be passed on to the new operator.

If the documentation gets mislaid, please contact your Nordmann supplier.

Language versions

The present installation and operating instructions are available in various

languages. Please contact your Nordmann supplier for information.

Copyright protection

The present installation and operating instructions are protected under the

Copyright Act. Passingon and reproduction of the manual (or part thereof)

as well as exploitation and communication of the contents are prohibited

without written permission by the manufacturer. Violation of copyright terms

is subject to legal prosecution and arises liability for indemnication.

The manufacturer reserves the right to fully exploit commercial patent rights.

6

2 For your safety

General

Every person working with the Nordmann ES4 must have read and understood the present installation and operating instructions before carrying

out any work.

Knowing and understanding the contents of the installation and operating

instructions is a basic requirement for protecting the personnel against any

kind of danger, to prevent faulty operation, and to operate the unit safely

and correctly.

All ideograms, signs and markings applied to the unit must be observed

and kept in readable state.

Qualication of personnel

All actions described in the present Installation and operating instructions

(installation, operation, maintenance, etc.) must be carried out only by well

trained and sufciently qualied personnel authorised by the owner.

For safety and warranty reasons any action beyond the scope of this

manuals must be carried out only by qualied personnel authorised by the

manufacturer.

It is assumed that all persons working with the Nordmann ES4 are familiar

and comply with the appropriate regulations on work safety and the preven-

tion of accidents.

This unit may not be used by persons (including children) with reduced

physical, sensory or mental abilities or persons with lacking experience and/

or knowledge, unless they are supervised by a person responsible for their

safety or they received instructions on how to operate the unit.

Children must be supervised to make sure that they do not play with unit.

Intended use

The steam humidier Nordmann ES4 is intended exclusively for air humidication via a steam distributor or a fan unit approved by the

manufacturer within the specied operating conditions (see chapter 10

“Product specications”). Any other type of application without the express

written consent of the manufacturer is considered as not conforming with the

intended purpose and may lead to the Nordmann ES4 becoming dangerous.

Operation of the equipment in the intended manner requires that all the

information in these instructions is observed (in particular the safety

instructions).

7

Danger that may arise from the unit

DANGER!

Danger of electric hazard!

The Nordmann ES4 is mains powered. One may get in touch with live

parts when the unit is open. Touching live parts may cause severe

injury or danger to life.

Prevention: Before carrying out any work set the Nordmann ES4 out of

operation as described in chapter 6.5 (switch off the unit, disconnect it

from the mains and stop the water supply) and secure the unit against

inadvertent powerup.

WARNING!

Hot water vapour - Danger of scalding!

The Nordmann ES4 produces hot water vapour. There is danger of

scalding when getting in touch with hot water vapour.

Prevention: Do not carry out any work on the steam system during

operation (steam lines, steam distributor, etc.). If the steam system is

leaky set the Nordmann ES4 immediately out of operation as described

in chapter 6.5. Correctly seal the steam system before putting the unit

into operation again.

WARNING!

Danger of burning!

During operation the components of the steam system (steam cylinder,

steam distributor, etc.) get very hot (up to 100 °C). There is danger of

burning when touching the hot components.

Prevention: Before carrying out any work on the steam system set the

Nordmann ES4 out of operation as described in chapter 6.5, then wait

until the components have cooled down sufciently thus preventing danger of burning.

Behaviour in case of danger

If it is suspected that safe operation is no longer possible, then the

Nordmann ES4 should immediately be shut down and secured against

accidental power-up according to chapter 6.5. This can be the case

under the following circumstances:

– if the Nordmann ES4 is damaged

– if the electrical installations are damaged

– if the Nordmann ES4 is no longer operating correctly

– if connections and/or piping are not sealed

All persons working with the Nordmann ES4 must report any alterations to

the unit that may affect safety to the owner without delay.

Prohibited modications to the unit

No modications must be undertaken on the Nordmann ES4 without the

express written consent of the manufacturer.

For the replacement of defective components use exclusively original ac-

cessories and spare parts available from your Nordmann supplier.

8

3 Product Overview

3.1 Models overview

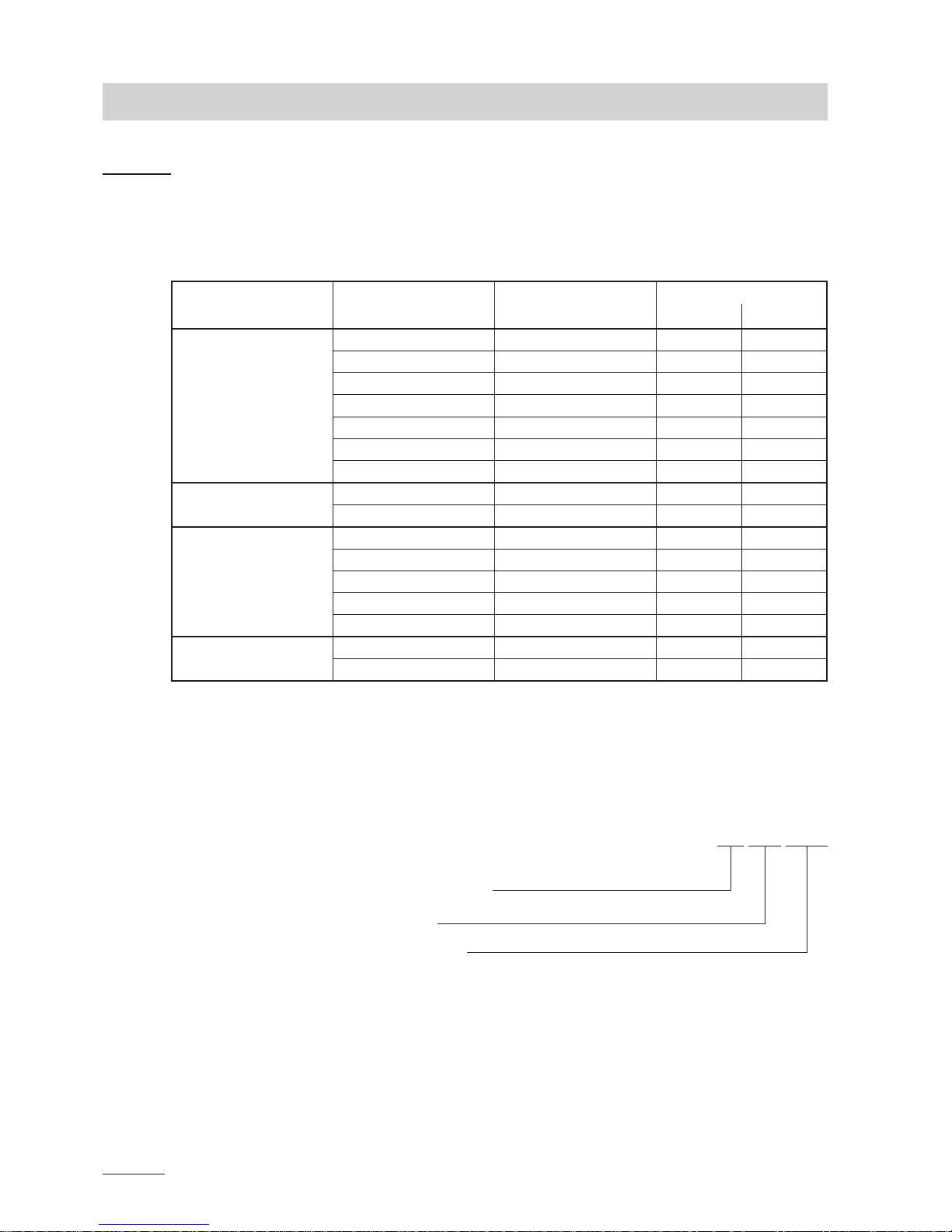

Steam air humidiers Nordmann ES4 are available with different heating

voltages and steam capacities ranging from 5 kg/h up to a max. of

65 kg/h.

Heating voltage ** Max. steam capacity

in kg/h

Model

Nordmann ES4

Unit size

Unit small Unit large

400V3

(400 V/3~/50...60 Hz)

5 534 1

8 834 1

15 1534 1

23 2364 1

32 3264 1

45 4564 1

65 6564 1

400V2

(400 V/2~/50...60 Hz)

5 524 1

8 824 1

230V3

(230 V/3~/50...60 Hz)

5 532 1

8 832 1

15 1532 1

23 2362 1

32 3262 1

230V1

(230 V/1~/50...60 Hz)

5 522 1

8 822 1

** Other heating voltages on request

Key model designation

Example:

Nordmann ES4 4564 400V3

Product designation:

Unit model:

Heating voltage:

400V/3~/50...60Hz: 400V3

400V/2~/50...60Hz: 400V2

230V/3~/50...60Hz: 230V3

230V/1~/50...60Hz: 230V1

9

3.2 Identicationoftheunit

The identication of the unit is found on the type plate:

Nordmann Engineering AG, CH-8808 Pfäfkon

Type: ES4 4564 Ser.Nr.: XXXXXXX 02.10

Heating voltage: 400V / 3~ / 50...60Hz Power: 33.8 kW

Steam capacity: 45.0 kg/h Ctrl. Voltage: 230V / 1~ / 50...60Hz

Water pressure: 1...10 bar

Made in Switzerland

Type designation Serial number (7 digits) Month/Year

Heating voltage

Maximum steam capacity per unit

Admissible water supply pressure

Power consumption

Control voltage

Field with certication symbols

10

3.3 Steamhumidierconstruction

1 Housing (small, large)

2 Cable openings, top side

3 SC pump (option)

4 Main contactor

5 Power board

6 Terminals heating voltage (option)

7 Remote operating and fault

indication board (option)

8 Control board with ES4 Card

9 Power supply unit 24 V (option)

10 Drain/info key

11 Operation status indicators

12 Unit switch

13 Water cup

14 Filling hose

15 Water supply hose

16 Overow hose

17 Drain valve

18 Inlet valve

19 Water supply connector

20 Drain connector

21 Cable openings, bottom side

22 Type plate

23 Steam cylinder

24 Level sensor

25 Electrode plug

26 Steam outlet

gure shows small unit

3

2

1

4

5

6

7

9

12

11

10

8

19

20

21

23

24

25

26

22

13

15

18

17

14

16

11

3.4 Functional description

The steam humidier Nordmann ES4 is a pressureless steam generator

that utilizes an electrode heating. The steam humidier Nordmann ES4 is

designed for air humidication via a steam distributor (steam distribution

pipe, fan unit or steam distribution system MultiPipe).

Steam distribution pipe

Condensate hose

with siphon

Steam hose

Water cup

Overow hose

Filling hose

Water supply hose

Inlet valve

Base tub

Drain valve

Steam cylinder

Electrodes

Level sensor

Control board

Power board

Unit switch

Main

contactor

Current sensor

Steam generation

Any time steam is requested, the electrodes are supplied with voltage via

main contactor. Simultaneously, the inlet valve opens and water enters the

steam cylinder from the bottom via water cup and supply line. As soon as the

electrodes come in contact with the water, current begins to ow between

the electrodes, eventually heating and evaporating the water. The more the

electrode surface is exposed to water, the higher is the current consumption

and thus the steam capacity.

12

Upon reaching the requested steam capacity, the inlet valve closes. If the

steam generation decreases below a certain percentage of the required

capacity, due to lowering of the water level (e.g. because of the evaporation process or drainage), the inlet valve opens until the required capacity

is available again.

If the required steam capacity is lower than the actual output, the inlet valve

is closed until the desired capacity is achieved by lowering of the water level

(evaporation process).

Level monitoring

A sensor provided in the steam cylinder cover detects when the water level

gets too high. The moment the sensor comes in contact with water, the

inlet valve closes.

Drainage

As a result of the evaporation process, the conductivity of the water increases

due to an escalating mineral concentration. Eventually, an inadmissibly high

current consumption would take place if this concentration process were

permitted to continue. To prevent this concentration from reaching a value,

unsuitably high for the operation, a certain amount of water is perio dically

drained from the cylinder and replaced by fresh water.

Control

The steam production can be controlled with an external 010V continuous

controller or an external humidistat (24 VDC On/Off control).

13

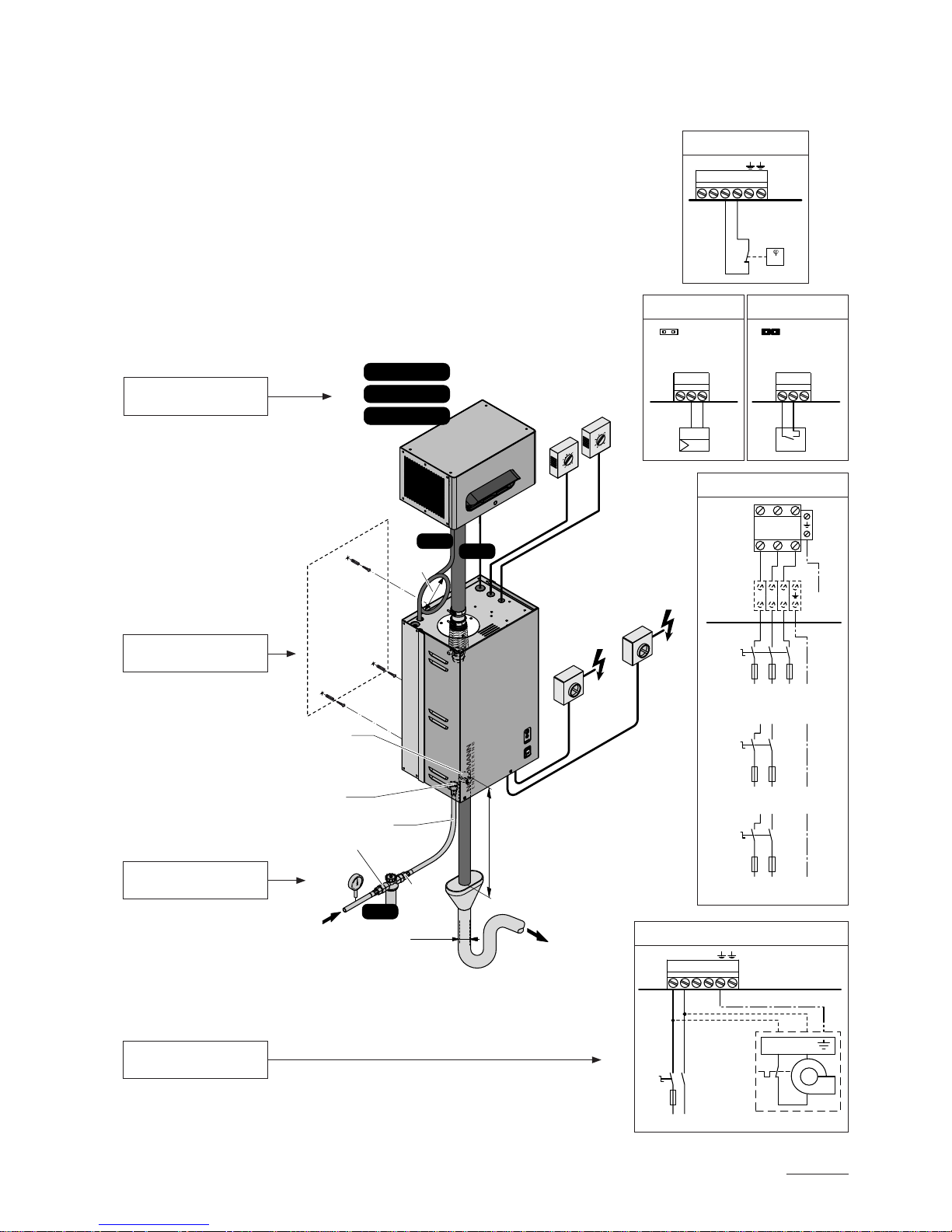

3.5 Humidicationsystemoverview

System overview duct humidication

1 Steamhumidier

2 Steamconnector

3 Waterdrainconnector

4 Watersupplyconnector

5 WaterconnectionhoseG3/4"-G3/8"

(includedinthedelivery)

6 Filtervalve(accessory“Z261”)

7 Manometer(installationrecommended)

8 Funnelwithsiphon(buildingside)

9 Waterdrainhose(includedinthedelivery)

10 Serviceswitchcontrolvoltagesupply(buildingside)

11 Serviceswitchheatingvoltagesupply(buildingside)

12 Steamhose(accessory“DS..”)

13 Condensatehose(accessory“KS10”)

14 Steamdistributionpipe(accessory“DV41-..”/“DV71-..”)

15 Steamdistributionsystem(accessory“MultiPipe”)

16 Humiditycontroller0-10VorHumidistat

17 Safetyhumidistat

125...1250µS/cm

1...10bar

1...40°C

16

15

ONOFF

1

2

3

4

5

6

7

DS35

DS22

Z261

ONOFF

12

13

17

KS10

11

10

14

DV41

DV71

MultiPipe

8

9

14

System overview room humidication

125...1250 µS/cm

1...10 bar

1...40 °C

1 Steam humidier

2 Steam connector

3 Water drain connector

4 Water supply connector

5 Water connection hose G 3/4"- G 3/8"

(included in the delivery)

6 Filter valve (accessory “Z261”)

7 Manometer (installation recommended)

8 Funnel with siphon (building side)

9 Water drain hose (included in the delivery)

10 Service switch control voltage supply (building side)

11 Service switch heating voltage supply (building side)

12 Steam hose (accessory “DS..”)

13 Condensate hose (accessory “KS10”)

14 Ventilation unit (accessory “FAN4 N...”)

15 Humidity controller 010V or Humidistat

16 Safety humidistat

ONOFF

ONOFF

10

11

15

16

1

3

4

5

6

7

Z261

DS80

KS10

13

12

FAN4 N S W

FAN4 N M W

FAN4 N L W

2

8

9

14

15

3.6 Options

Nordmann ES4...

522

524

532

534

822

824

832

834

1532

1534

2362

2364

3262

3264

4564 6564

Remote operating and fault indication

PCB with relay contacts for the connection of remote

displays for “Operation”, “Steam”, “Fault” and “Service”.

1xRFI

Overpressure set

Kit for mounting the water cup to the unit cover when

operating the steam humidi ers in systems with a duct

air pressure of up to 10 kPa.

1xOPS

Terminals heating voltage

Separate terminals for systems where direct connection

of heating voltage to main contactor (standard version)

is not permitted by local regulations.

1x

S-THV

1x

M-THV

1x

L-THV

Steam hose connector with condensate trap 1xCT22 1xCT35 2xCT35

Cable glands (with metric thread) CG

Internal control voltage 1x

S-CVI

1x

M-CVI

1x

L-CVI

Transformer (400V/230V) 1xM-Trafo 1xL-Trafo

SC pump (lime management system)

The SC pump keeps the solved minerals in the water of

the steam cylinder in motion, in order to discharge them

with the automatic drain cycles.

1xSC

24 VDC power supply

24 VDC power supply for the external humidity sensor

1x24VDC

Nordmann ES4... (400 V/3~/50...60 Hz)

534 834 1534 2364 3264 4564 6564

Steam cylinder for low water conductivity

from 80 to 125 µS/cm

1x

534A-L1x834A-L1x1534A-L1x2364A-L1x3264A-L1x4564A-L

___

16

3.7 Accessories

3.7.1 Accessories overview

Accessories for water installation

Nordmann ES4...

522

524

532

534

822

824

832

834

1532

1534

2362

2364

3262

3264

4564 6564

Filter valve Z261 (1 pcs. per system)

Accessories for steam installation

Nordmann ES4...

522

524

532

534

822

824

832

834

1532

1534

2362

2364

3262

3264

4564 6564

Steam distribution pipe

(details see chapter 3.7.2)

1xDV41-... 1xDV71-... 2xDV71-...

Steam distribution system MultiPipe

(details see chapter 3.7.2)

--- System 1 System 2

Fan unit

(details see chapter 3.7.2)

FAN4 N S W FAN4 N M W FAN4 N L W

Steam hose / meter 1xDS22 1xDS35 2xDS35

EcoTherm insulation hose / meter 1xECT22 1xECT60 2xECT60

Condensate hose / meter 1x KS10

Accessories for humidity control

Nordmann ES4...

522

524

532

534

822

824

832

834

1532

1534

2362

2364

3262

3264

4564 6564

Duct humidistat HBC (1 pcs. per system)

Room humidistat HSC (1 pcs. per system)

General accessories

Nordmann ES4...

522

524

532

534

822

824

832

834

1532

1534

2362

2364

3262

3264

4564 6564

All-weather protective housing Layout according to the separate data sheet

17

3.7.2 Accessory details

3.7.2.1 Steam distribution pipe DV41-.../DV71-...

The steam distribution pipes are selected on the basis of the duct width

(for horizontal installation) or the duct height (for vertical installation) and

the capacity of the steam humidier.

Important! Always select the longest possible steam distribution pipe (opti

mum humidication distance).

L

B

Steam distribution pipes for

Nordmann ES4

1)

Length (L) steam

distribution pipe

Duct width (B)

Type DV41-.. Type DV71-.. in mm

2)

in mm

41-200 200 210...400

41-350 71350 350 400...600

41-500 71500 500 550...750

41650 71650 650 700...900

41-800 71800 800 900...1100

41-1000 711000 1000 1100...1300

41-1200 711200 1200 1300...1600

711500 1500 1600...2000

711800 1800 2000...2400

712000 2000 2200...2600

712300 2300 2500...2900

712500 2500 2700...3100

1)

Material: CrNi steel

2)

special length on request

Note: If the humidication distance (see chapter 5.4.2) has to be reduced

for technical reasons, the amount of steam per basic unit must be divided

between two steam distribution pipes or the steam distribution system

MultiPipe must be used. If this is the case, contact your Nordmann supplier.

18

3.7.2.2 MultiPipe steam distribution system

H

B

The MultiPipe steam distribution system is used in ventilation ducts with a

short humidication distance (for the calculation of the humidication distance refer to chapter 5.4.2). When ordering an MultiPipe system the duct

dimension must be specied. Please consult the data in the following table.

MultiPipe Number of steam

connectors

Max. steam

capacity

in kg/h

1)

Duct dimensions

Width B

in mm

Height H

in mm

System 1 1 32 (23) 450-1500 4501650

System 2 2 65 (45) 450-2200 450-2200

1)

For duct widths <600 mm the value in brackets apply

19

3.8.2.3 Fan units FAN4 N...

The fan units FAN4 N... – in combination with the steam humidiers Nordmann ES4 – are used for direct room humidication. They are mounted

above the unit to the wall.

The type of fan unit is dependent on the steam capacity and on the type of

the humidier and can be gathered from the table in chapter 3.7.1.

Note: Further information on the fan units FAN4 N... can be found in the

separate manual supplied with the fan unit.

20

3.8 Standard delivery

The standard delivery includes:

– Steam humidier Nordmann ES4 with water drain hose and water con-

nection hose G 3/4" G 3/8" equipped with the options ordered according

to chapter 3.6, xing set and installation and operating instructions (this

document), packaged in cardboard box

– Unit small (WxHxD): 445 mm x 755 mm x 360 mm, shipping weight:

26 kg

– Unit large (WxHxD): 560 mm x 820 mm x 435 mm, shipping weight:

31 kg

– Ordered accessories with operating instructions according chapter 3.7,

packed separately

– Spare parts list

3.9 Storing/Transportation/Packaging

Storing

Store the unit in a protected area meeting the following requirements:

– Room temperature: 1 ... 40 °C

– Room humidity: 10 ... 75 %rh

Transportation

For optimum protection always transport the unit in the original packaging.

The weight of the small and the large unit is more than 20 kg (weight without

packaging: small unit 23 kg, large unit 28 kg). Therefore, always transport

the unit with the help of another person or use a forklift or a crane. Always

place the unit on its back side.

Packaging

Keep the original packaging of the Nordmann ES4 for later use.

In case you wish to dispose of the packaging, observe the local regulations

on waste disposal. Never dispose of the packaging to the environment.

21

4.1 Selecting the unit version

To select the unit version the following planning steps are required:

1. Calculating the required maximum steam capacity according chapter

4.1.1

2. Selecting the unit version from the table in chapter 4.1.2

4.1.1 Calculating the maximum required steam capacity

The maximum required steam capacity must be calculated based on one

of the following formulas:

V • ρ

mD = • (x2 - x1)

1000

4 Notes for the planning engineer

mD: maximum steam demand in kg/h

V: volume of supply air portion per hour in m3/h (for indirect room humidi-

cation) or room volume to be humidied per hour in m3/h (for direct

room humidication)

ρ: specic gravity of air in kg/m

3

ε: specic volume of air in m3/kg

x2: desired absolute room air humidity in g/kg

x1: minimum absolute supply air humidity in g/kg

The values for ρ, ε, x

2

and x1 can be gathered from the h,x-diagram or

the Carrier-Diagram for moist air respectively.

Important notes:

– The required maximum steam capacity depends on the specic ap-

plication and the installation. The calculated steam capacity based on

the above formulas, the h,x diagram and the condition of the air to be

humidied does not consider any steam loss (e.g. due to condensation in the steam hoses and the steam distributors), any heat loss of

the unit as well as any absorption or release of humidity of materials

located in the room being humidi ed.

In addition, the calculated steam capacity does not consider any losses

caused by the draining rate depending on the water quality as well as

any losses occur if the steam humidier is operated on a mains circuit

with a ground fault circuit interrupter.

The total amount of losses depends on the entire system and must be

taken into consideration when calculating the required steam capacity. If you have any questions regarding the calculation of the steam

capacity please contact your Nordmann supplier.

– For systems where the max. required steam capacity varies extensively

(e.g. for test facilities or for systems with variable air volume ow, etc.),

please contact your Nordmann supplier.

or

V

m

D

= • (x2 - x1)

1000 • ε

22

4.1.2 Selecting the unit

Heating voltage ** Max. steam capacity

in kg/h

Model

Nordmann ES4 ..

Unit size

Unit small Unit large

400V3

(400 V/3~/50...60 Hz)

5 534 1

8 834 1

15 1534 1

23 2364 1

32 3264 1

45 4564 1

65 6564 1

400V2

(400 V/2~/50...60 Hz)

5 524 1

8 824 1

230V3

(230 V/3~/50...60 Hz)

5 532 1

8 832 1

15 1532 1

23 2362 1

32 3262 1

230V1

(230 V/1~/50...60 Hz)

5 522 1

8 822 1

** Other heating voltages on request

4.2 Selecting the options an accessories

For selecting the options and accessories see chapter 3.6 and 3.7.

Nordmann ES4 4564 400V3

23

4.3 Selecting the control system

The various control systems

– System 1: Room humidity control

System 1 is suited for direct room humidication and air condition-

ing systems with mainly recirculated air. The humidity sensor or

humidistat respectively is preferably located in the room itself or in the

exhaust air duct.

– System 2: Room humidity control with continuous limitation of the

supply air humidity

System 2 is suited for air conditioning systems with a large portion of

supply air, low supply air temperature, post-humidication, or vari-

able airow volume. If the supply air hum idity exceeds the preset value,

the continuous limitation is effected prior to the room hum idity control.

The humidity sensor (A1) is preferably located in the exhaust air duct

or in the room itself. The humidity sensor (A2) for the limitation of the

supply air humidity is located in the supply air duct after the steam distribution pipe. This control system requires a continuous controller with

the option to connect a second humidity sensor.

Attention! The continuous limitation of the supply air humidity is no

substitute for the safety humi distat.

A1 humidity sensor

B1 ventilation interlock

B2 airow monitor

B3 safety humidistat

B4 humidistat

PIE External continuous controller

(e.g. PI controller)

Y input signal from A1

A1/2 humidity sensor

B1 ventilation interlock

B2 airow monitor

B3 safety humidistat

PI

E

External continuous controller

(e.g. PI controller)

Y input signal from A1

Z input signal from A2

Nordmann

ES4

Nordmann

ES4

24

– System 3: Supply air humidity control with continuous output limi-

tation

Supply air humidity control (humidity sensor installed in supply

air duct) should be used only where room humidity control is

impracticable for technical reasons. Such systems always require

a PIcontroller.

The humidity sensor (A1) is located in the supply air duct after the steam

distribution pipe. The humidity sensor (A2) for the continuous output

limitation is located in the supply air duct before the steam distribution

pipe. Such a system requires a PIcontroller with the option to connect

a second humidity sensor.

A1/2 humidity sensor

B1 ventilation interlock

B2 airow monitor

B3 safety humidistat

PIE External PI controller

Y input signal from A1

Z input signal from A2

Which humidity control system for which application?

Application Location of the humidity sensor

room or exhaust air duct supply air duct

Air conditioning systems with:

– supply air portion up to 33% System 1 System 1

– supply air portion up to 66% System 1 or 2 System 2 or 3

– supply air portion up to 100% System 2 System 3

– supply air humidity control — System 3

Direct room humidication System 1 —

Please contact your Nordmann supplier, if your application meets the

following conditions:

– Humidication of small rooms up to 200 m

3

– Air conditioning systems with a high number of air exchanges

– Systems with variable air volume ow

– Test facilities with extreme control accuracy requirements

– Rooms with a high variation in max. steam capacity

– Systems with temperature uctuations

– Cold rooms and systems with dehumidication

Admissible input signals

– 0...10VDC (external continuous controller)

– 24 V On/Off (humidistat)

Nordmann

ES4

25

5 Mounting and installation work

5.1 Important notes for mounting and installation work

Qualication of personnel

All mounting and installation work must be carried out only by well qualied personnel authorised by the owner. It is the owner’s responsibility

to verify proper qualication of the personnel.

General note

Strictly observe and comply with all information given in the present installation and operating instructions regarding the location of the unit and the

installation of water, steam and electricity.

Observe and comply with all local regulations dealing with water, steam

and electrical installations.

Safety

Some installation work requires removal of the unit cover. Please note the

following:

DANGER!

Danger of electric hazard!

You may get in touch with live parts when the unit is open. The steam

humidier must be connected to the mains only after all mounting and

installation work has been completed and the cover has been relocated

properly.

CAUTION!

The electronic components inside the humidier are very sensitive to

electrostatic discharge. When the unit is open for installation work, appropriate measures must be taken to protect these components against

damage caused by electrostatic discharge (ESD protection).

26

≥ 40 mm

min. 50 cm

ONOFF

DS35

DS22

Z261

ONOFF

125...1250 µS/cm

1...10 bar

1...40 °C

ø14/7 mm

G 3/4"

G 1/2"

G 3/8"

Q2

Q3

B3

DV41

DV71

Pmin

1500 Pa

-800 Pa

Pmax

Rmin. 300 mm

Ømin.

200 mm

min. 300 mm

min. 300 mm

min. 20 %

–

KS10

min. 5 %

–

min. 20 %

+

X3

L1 N SC1 SC2

B3

max.

ES4

ext.

CONT.SIGN

V+ IN GND

X1

+ –

0-10V

A1

CONT.SIGN

V+ IN GND

X1

On/Off

A2

On/Off Mode

JP1

On/Off Mode

JP1

ES4

ext.

ES4

ext.

Q3

230V/1~/50...60Hz

L1 N

F3

X3

L1 N SC1 SC2

ES4

ext.

L1

Q2

K1

X0

F2

L1 L2 L3

L1 L2 L3

L1 L2 L3

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q2

F2

L1 N PE

PE

PE

230 V/1~/50..60 Hz

Q2

F2

L1 L2

400 V/2~/50..60 Hz

PE

ES4

ext.

A1 / A2

ø 30 mm

5.2 Installation overviews

Installation overview duct humidication

Water installation

see chapter 5.5

Steam installation

see chapter 5.4

Mounting the unit

see chapter 5.3

Control voltage

Heating voltage

On/Off-ControlContinuous control 0-10V

External safety chain

Electric installation

see chapter 5.6

27

X3

L1 N SC1 SC2

B3

max.

ES4

ext.

CONT.SIGN

V+ IN GND

X1

+ –

0-10V

A1

CONT.SIGN

V+ IN GND

X1

On/Off

A2

On/Off Mode

JP1

On/Off Mode

JP1

ES4

ext.

ES4

ext.

L1

Q2

K1

X0

F2

L1 L2 L3

L1 L2 L3

L1 L2 L3

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q2

F2

L1 N PE

PE

PE

230 V/1~/50..60 Hz

Q2

F2

L1 L2

400 V/2~/50..60 Hz

PE

ES4

ext.

X3

L1 N SC1 SC2

ES4

ext.

Q3

L1

N

F3

FAN4 N...

L1 N

ONOFF

ONOFF

FAN4 N S W

FAN4 N M W

FAN4 N L W

Q2

Q3

Z261

125...1250 µS/cm

1...10 bar

1...40 °C

ø14/7 mm

≥ 40 mm

G 3/4"

G 1/2"

G 3/8"

min. 50 cm

Ømin.

100 mm

A1 / A2

B3

ø 30 mm

DS80

KS10

Installation overview room humidication

Water installation

see chapter 5.5

Steam installation

see chapter 5.4

Mounting the unit

see chapter 5.3

Control voltage

Heating voltage

On/Off-ControlContinuous control 0-10V

External safety chain

Electric installation

see chapter 5.6

28

5.3 Mounting the unit

5.3.1 Notes on locating the unit

Nordmann ES4 ...

522

524

532

534

822

824

832

834

1532

1534

2362

2364

3262

3264

4564 6564

Dimensions

Housing (XxYxZ) in mm 377x279x612 1 1 1

492x351x670 1 1 1 1

Weights

Net weight in kg 19 19 19 28 28 28 28

Operating weight in kg 24 24 30 65 65 65 65

min. 400 mm

min. 600 mm

min. 250 mm

min. 400 mm

min. 600 mm

60...70 °C

1 ... 40 °C

max. 75 %rh

IP20

Z

Y

X

29

The installation site of the steam humidier depends largely on the location

of the steam distributor (see chapter 5.4). To ensure proper functioning

of the steam humidier and to obtain an optimal efciency, the following

points must be considered and observed when choosing the location for

the steam humidier:

– Install the steam humidier so that the length of the steam hose is kept

as short as possible (max. 4 m) and that the minimum bend radius

(R= 300 mm) and up-slope (20 %) or down-slope (5 %) of the steam

hose is observed (see chapter 5.4.5).

– The steam humidiers Nordmann ES4 are designed for wallmount-

ing. Make sure that the construction (wall, pillar, oormounted console,

etc.) to which the humidiers are to be mounted, offers a sufciently

high load-bearing capacity (take notice of the weight information

found in the dimensions and weights table above), and is suitable for

the installation.

CAUTION!

Do not mount the steam humidier directly to the ventilation duct

(insufcient stability).

– The back panel of the Nordmann ES4 is retaining heat during operation

(max. surface temperature of the metal housing approx. 60 70 °C).

Make sure, therefore, that the construction (wall, pillar, etc.) to which

the units are to be mounted, does not consist of heatsensitive material.

– Install the steam humidier in such a manner that it is freely accessible

with sufcient space available for maintenance purposes (refer to the

above illustration for minimum distances).

– The Nordmann ES4 is protected according to IP20. Make sure the units

are installed in a dripproof location and the admissible ambient conditions are complied with.

– The steam humidier Nordmann ES4 may only be installed in rooms

with a oor drain.

CAUTION!

If for some reason the Nordmann ES4 must be installed in a location

without oor drain, it is mandatory to provide a leakage monitoring

device to safely interrupt the water supply in case of leakage.

– When xing the Nordmann ES4 use only the xing materials supplied

with the unit. If xing with the materials supplied is not possible in your

particular case, select a method of xing that is of similar stability.

– The Nordmann ES4 is designed for installation and operation within

buildings (admissible temperature range see chapter 10.1). For outdoor

operation the Nordmann ES4 must be placed in a weather protective

housing. If ambient temperatures near or below the freezing point have

to be expected, the protective housing must equipped with a thermostat

controlled heating of sufcient capacity. The water supply pipe must be

equipped with a traceheating and must be insulated up to the protective

housing.

30

5.3.2 Mountingthehumidier

Procedure

1. Mark the attachment point “A” on the wall.

2. Drill hole for attachment point “A” (diameter: 8 mm, depth: 40 mm).

3. Insert the supplied plastic plug, and tighten the screw until the distance

between the wall and the screw head is 4 mm.

4. Unlock the two screws xing the front panel to the unit, then remove the

front panel.

5. Hang up the unit onto the screw and adjust it horizontally and vertically

using a spirit level. Then, mark the xing points “B”.

6. Drill the holes for the xing points “B” (diameter: 8 mm, depth: 40 mm).

7. Insert the supplied plastic plugs, and tighten the screws until the distance

between the wall and the screw head is 4 mm.

8. Hang the unit up onto the screws. Before tightening the screws, readjust

the unit with the spirit level.

9. Reattach the front panel and secure it with the two screws.

Dimension Housing size

small large

a 189 mm 246 mm

b 61 mm 52 mm

c 490 mm 547 mm

d 120 mm 180 mm

e 120 mm 180 mm

d

e

b

c

a

A

B

B

31

5.3.3 Inspecting the installed unit

Check the following points:

Is the unit installed in the correct place (see chapter 5.3.1)?

Is the supporting surface stable enough?

Is the unit correctly aligned, vertically and horizontally?

Is the unit properly secured (see chapter 5.3.2)?

Has the front panel of the unit been relocated and correctly xed with

the two screws?

32

5.4 Steam installation

5.4.1 Overview steam installation

DS35

DS22

DV41

DV71

Pmin

1500 Pa

-800 Pa

Pmax

Rmin. 300 mm

Ømin.

200 mm

min. 300 mm

min. 300 mm

min. 20 %

–

KS10

min. 5 %

–

min. 20 %

+

Ømin.

100 mm

DS80

KS10

FAN4 N S W

FAN4 N M W

FAN4 N L W

min. 20 %

+

min. 20 %

–

33

The calculation of the humidication distance “BN” is dependent on several

factors. For a rough estimation of the humidication distance “BN”, the following table is useful. Recommended standard values listed in this table

are based on a supplyair temperature range of 15 °C to 30 °C. The values

given in bold type only apply to steam distribution pipes DV41-... and

DV71-..., the values in brackets apply to the MultiPipe steam distribution system.

Humidity at inlet

ϕ1 in %rh

Length of humidication distance BN in m

Humidity at outlet ϕ2 in %rh

40 50 60 70 80 90

5 0,9 (0,22) 1,1 (0,28) 1,4 (0,36) 1,8 (0,48) 2,3 (0,66) 3,5 (1,08)

10 0,8 (0,20) 1,0 (0,26) 1,3 (0,34) 1,7 (0,45) 2,2 (0,64) 3,4 (1,04)

20 0,7 (0,16) 0,9 (0,22) 1,2 (0,30) 1,5 (0,41) 2,1 (0,58) 3,2 (0,96)

30 0,5 (0,10) 0,8 (0,17) 1,0 (0,25) 1,4 (0,36) 1,9 (0,52) 2,9 (0,88)

40 – 0,5 (0,11) 0,8 (0,20) 1,2 (0,30) 1,7 (0,45) 2,7 (0,79)

50 – – 0,5 (0,13) 1,0 (0,24) 1,5 (0,38) 2,4 (0,69)

60 – – – 0,7 (0,16) 1,2 (0,30) 2,1 (0,58)

70 – – – – 0,8 (0,20) 1,7 (0,45)

φ1 in %rh: Relative supply air humidity prior to humidication at the lowest supply air tem-

perature

φ2 in %rh: Relative supply air humidity after the steam distribution pipe at maximum capac-

ity

For duct widths <600 mm the humidication distance for the MultiPipe system increases

by approx. 50%

5.4.2 Positioning and mounting of the steam distribution pipes

The location for the steam distribution pipes should be determined at the

time of dimensioning the air conditioning system. Please note the following

instructions to ensure proper humidication of the duct air.

Calculating the humidication distance

The water vapour, emitting from the steam distribution pipes, requires a

certain distance to be absorbed by the ambient air so that it is no longer

visible as steam. This distance is referred to as humidication distance

“B

N

” and serves as a basis for the determination of the minimum distances

from the upstream components in the system.

BN: Humidication distance B

N

E: Expansion and mixing zone

φ1: Supply air humidity before humidication

φ2: Supply air humidity after humidication

34

Example

given: ϕ1= 30 %rh, ϕ2= 70 %rh

humidication distance B

N

: 1,4 m

(0.36 m for steam distribution system MultiPipe)

Note: If the humidication distance has to be reduced for technical reasons,

the amount of steam per basic unit must be divided between two steam

distribution pipes or the steam distribution system MultiPipe must be

used. If this is the case, contact your Nordmann supplier.

Minimum distances to be observed

To prevent the water vapour, that is emitting from the steam distribution pipe,

from condensing on downstream system components, a minimum distance

to the steam distribution pipe must be observed (depends on the humidication distance “B

N

”).

0.5 x B

N

50 mm

after expansion

0.5 x B

N

1 x B

N

before bend

1 x B

N

before/after constriction

before branch

35

before diffuser

before/after lter/register before/after fan, zone exit

* 2,5 x B

N

before aerosol lter

before control sensor

+

1.5 x B

N *

50 mm

50 mm

1 x B

N

1 x B

N

Installation notes and dimensions

The steam distribution pipes are designed for either horizontal installation

(on the duct wall) or, with accessories, for vertical installation (in the duct

oor). The outlet orices should always point upwards and at right

angles to the airow.

If possible, the steam distribution pipes should be installed on the pressure

side of the duct (max. duct pressure 1500 Pa). If the steam distribution

pipes are installed on the suction side of the duct, the maximum vacuum

must not exceed 800 Pa.

Select a location for the installation, tailored to suit your duct (see the following illustrations) and position the steam distribution pipes in the duct so

that a uniform distribution of steam is achieved.

1 x B

N

5 x B

N

36

Positioning the steam distribution pipes in the duct

In positioning the steam distribution pipes, the following dimensions should

be observed:

Note: When locating the MultiPipe steam distribution system please note

the instructions in the separate documentation for this product.

Guidelines for dimensioning the ventilation ducts

– To facilitate the installation of the steam distribution pipes and for control

purposes, a sufciently sized control opening should be planned.

– Within the range of the humidication distance, the ventilation duct

should be waterproofed.

– Air ducts passing through cold rooms should be insulated to prevent

the humidied air from condensing along the duct wall.

– Poor airow conditions within the air duct (e.g. caused by obstacles,

tight bends, etc.) can lead to condensation of the humidied air.

– Steam distribution pipes must not be mounted to round ducts.

If you have questions relating to the dimensioning of ventilation ducts in

combination with steam humidiers Nordmann ES4, contact your Nordmann

supplier.

1/2

1/2

H

H

1/3

2/3

h

min

H

2/7

2/7

3/7

H

2/7

2/7

3/7

g

min

1/3

1/3

1/3

H

H

1/2

1/2

g min.= 100 mm

h min.= 85 mm

H min.= 250 mm H ≥400 mm H min.= 200 mm

H min.= 400 mm H min.= 350 mm H min.= 300 mm

37

5.4.3 Installing the steam distributors

Detailed information on the installation of steam distribution pipes DV41

.., DV71... and MultiPipe steam distribution system can be found in the

separate mounting instructions for these products.

38

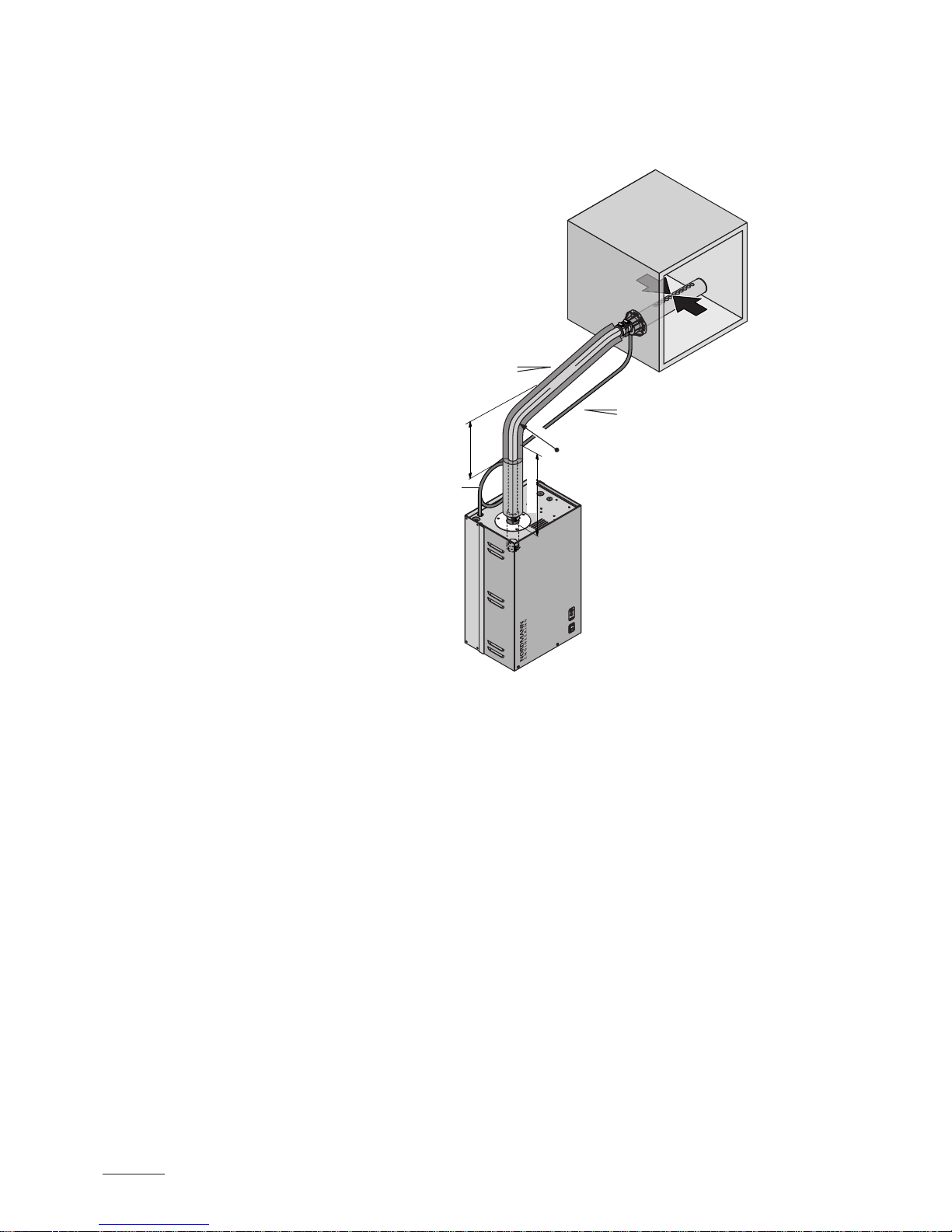

5.4.4 Positioning and mounting of the fan units FAN4 N...

The fan unit FAN4 N... is mounted on the wall separately above the unit.

To allow the steam coming from the fan unit to spread out evenly, without

condensing on obstacles (ceilings, joists, pillars, etc.), the following minimum

dimensions must be observed when selecting the location for the fan unit.

FAN4 N S W FAN4 N M W FAN4 N L W

m

D

max. 8 kg/h 15 kg/h 23 kg/h 45 kg/h

A min. 4.0 m 6.0 m 8.0 m 10.0 m

B min. 1.0 m 1.0 m 1.0 m 1.5 m

C approx. 2.2 m 2.2 m 2.2 m 2.2 m

D approx. 1.0 m 1.0 m 1.0 m 1.5 m

E min. 1.0 m

E max. (max. steam hose length) 4.0 m (recommended: 2.0 m)

Note: The minimum spaces in the table apply for a room atmosphere of

15 °C and max. 60 %rh. For lower temperatures and/or higher humidity the

values should be adjusted accordingly.

In order to achieve a uniform distribution of the humidity within the room,

additional factors such as the room size, the room height, etc., must be taken

into consideration besides observing the minimum distances for the fan units

FAN4 N.... If you have questions concerning the direct room humidication,

please contact your Nordmann supplier.

Further information is provided in the separate installation and operating

instructions for the fan unit.

A

C

B

E

D

D

39

5.4.5 Installing the steam hose

Important! Use original steam and condesate hose from your Nordmann

supplier exclusively. Other types of hoses can cause undesired operational

malfunctions.

Instructions for the hose layout

The hose layout depends on the position of the steam distribution pipe:

– Steam distribution pipe is mounted more than 500 mm above the top

edge of the humidier:

Initially, lead the steam hose with an upslope of at least 20% over

a minimum height of 300 mm, then lead the hose with a minimum

upslope of 20% and/or a minimum downslope of 5% to the steam

distribution pipe.

The condensate hose is led down to the humidier with a minimum slope

of 20 %, in the form of a siphon (min. hose bend diameter Ø200 mm),

and inserted into the specied opening until it comes to a stop.

Note: If your unit feeds a number of steam distribution pipes, the individual condensate hoses are to be led into a discharge funnel.

Important! Before putting the unit into operation, the siphon of the

condensate hose must be lled with water.

Rmin. 300 mm

min. 300 mm

max. 4 m

min. 300 mm

Rmin. 300 mm

min. 300 mm

max. 4 m

min. 300 mm

min. 20 %

–

min. 20 %

–

min. 20 %

+

min. 20 %

+

Ømin. 200 mm

Ømin. 200 mm

40

– Steam distribution pipe is mounted less than 500 mm above the top

edge of the humidier:

Rmin. 300 mm

Ømin.

200 mm

min. 300 mm

max. 4 m

min. 300 mm

min. 20 %

–

min. 5 %

–

min. 20 %

+

Rmin. 300 mm

Rmin. 300 mm

Ømin.

200 mm

Ømin.

200 mm

max. 4 m

min. 300 mm

min. 300 mm

min. 20 %

–

min. 20 %

–

min. 20 %

+

min. 5 %

–

min. 20 %

+

Obstacle

Install condensate drain (accessory)

at the lowest point

Initially, the steam hose is led with an upslope of at least 20 % over a

minimum height of 300 mm above the top edge of the humidier and

then down to the steam distribution pipe with a minimum slope of 5 %.

Condensate hose is led down with a minimum slope of 20 %, in the

form of a siphon (min. hose bend diameter Ø200 mm), directly into

a discharge funnel.

Important! Before putting the unit into operation, the siphon of the

condensate hose must be lled with water.

41

– The steam hose should be kept as short as possible (max. 4 m) while

observing the minimum bend radius of 300 mm. Important! Allowance

must be made for a pressure loss of 10 mm water column (approx.

100 Pa) per meter steam hose.

Note: If your particular installation exceeds the maximum steam hose

length of 4 m contact your Nordmann representative. In any case, steam

hoses longer than 4 m must be insulated in their entire length (e.g. with

insulation hose “EcoTherm”).

– Reductions in the cross section such as kinks should be avoided through-

out the entire length of the hose. The installation of a stop cock in the

steam hose is not permissible.

– Steam hoses must be prevented from sagging (condensate pockets); if

necessary, support with pipe clamps, trough, or wall brackets, or install

a condensate drain in the steam hose.

– Important! When deciding on the length and layout of the hose, it

should be noted that the steam hose may become somewhat shorter

with progressive ageing.

Securing the hose

The steam hose must be secured to the steam distribution pipe and humidi er

steam outlet by means of hose clamps.

Caution! Do not overtighten the hose clamp on the steam connector of the

steam humidier.

42

Steam line with xed piping

For steam lines with xed piping, the same instructions apply to the laying

of the piping as already described.

min. 300 mm

min. 300 mm

max. 4 m

Rmin. 5 x D

min. 20 %

–

min. 20 %

+

Ømin. 200 mm

The following additional notes should be observed:

– The minimum internal diameter of the steam line (diameter depend-

ent on the steam humidier) should be applied over the whole length of

the piping.

– Use exclusively copper pipe or stainless steel (min. DIN 1.4301).

– To minimize the condensate formation (=loss), the steam pipes must

be insulated.

– The minimum bend radius for solid pipes is 5 x internal diameter.

– Connection of the steam pipes to the steam distribution pipe and steam

humidier is effected by means of short lengths of steam hose secured

with hose clamps.

– Important! Allowance must be made for a pressure loss of 10 mm

water column (approx. 100 Pa) per meter length or per 90° bend.

43

5.4.6 Common steam and condensate line errors

1. Steam hose not led at least 300 mm perpendicularly upwards before

rst bend.

2. Minimum bend radius of steam hose of 300 mm not maintained (forming

of condesate).

3. Siphon of the condensate hose not at least 300 mm below the steam

distribution pipe.

4. No condensate drain installed at vertical transition.

5 . Steam hose not sloped (slope min. 20 %).

1.

2.

3.

4.

5.

44

5.4.7 Inspecting the steam installation

Use the following check list to ascertain that the steam installation was

performed correctly:

– Steam distribution pipe

Steam distributors (steam distribution pipe or MultiPipe steam distri-

bution system) correctly positioned and secured (screws tightened)?

Are the outlet orices at right angles to the air ow direction?

– Steam hose

Maximum length of 4 m?

Minimum bend radius of 300 mm (5 x internal diameter with xed

piping)?

Have the instructions for hose positioning been followed?

Steam hose: no sagging (condensate pocket) or condensate drain

with siphon (hose bend with a minimum diameter of 200 mm) installed

at the lowest point?

Rigid steam lines: properly insulated? Correct installation material

used? Minimum internal diameter maintained?

Steam hose(s) securely attached with clamps?

Heat expansion during operation and shortening of the hose with

ageing taken into consideration?

– Condensate hose

Downslope of at least 20 %?

Siphon (min. ø200 mm) existing and lled with water?

Condensate hose correctly xed and not kinked?

45

5.5 Water installation

5.5.1 Overview water installation

125...1250 µS/cm

1...10 bar

1...40 °C

ø 30 mm

ø14/7 mm

ø14/7 mm

Z261

G 3/4"

G 3/4"

G 1/2"

G 3/8"

G 3/8"

G 3/4"

ø 30 mm

ø 40/31 mm

≥ 40 mm

min. 50 cm

46

5.5.2 Notes on water installation

Water supply

The water supply is to be carried out according to the gure found in chapter

5.5.1 and the applicable local regulations for water installations. The indicated

connection specications must be observed.

– The installation of the lter valve (accessory “Z261”, alternatively a

shutoff valve and a 5 µm water lter can be used) should be made as

close as possible to the steam humidier.

– Admissible mains pressure 1.0 to 10.0 bar (hammer-free system)

For mains pressures >10 bar, the connection must be made via a pressure reducing valve (adjusted to 1.0 bar). For mains pressures <1.0 bar

please contact your Nordmann supplier.

– Notes on water quality:

– For the water supply of the Nordmann ES4, use exclusively untreated

drinking water.

– The use of additives such as corrosion inhibitors, disinfectants,

etc. is not allowed, since these additives may endanger health and

affect proper operation.

– If the Nordmann ES4 shall be operated with softened or partly sof-

tened water, please contact your Nordmann supplier.

– The connection material must be pressure-proof and certied for use

in drinking water systems.

– Important! Before connecting the water line, the line should be well

ushed out.

CAUTION!

The thread at the humidier connection is made of plastic. To avoid

overtightening, the union nut of the water pipe must be tightened by

hand only.

Water drain

The water drain is to be carried out according to the gure found in chapter

5.5.1 and the applicable local regulations for water installations. The indicated connection specications must be observed.

– Make sure that the drain pipe is correctly xed and easily accessible for

inspections and cleaning purposes.

– The draining temperature is: 80…90 °C. Use temperature-resistant

installation materials only!

47

5.5.3 Inspecting the water installation

Check the following topics:

– Water supply

Has lter valve (accessory “Z261”) or shutoff valve and 5 µm water

lter respectively been installed in supply line?

Have admissible water pressure (1 – 10 bar) and admissible tem-

perature (1 – 40 °C) been observed?

Does the supply capacity match the humidier and is the minimum

inside diameter of the supply pipe maintained throughout the entire

length?

Are all components and pipes properly secured and are all threaded

connections securely tightened?

Is the water system properly sealed?

Does the water supply installation meet the requirements of the local

regulations for water installations?

– Water drain

Is the minimum inside diameter of the drain pipe of 40 mm maintained

throughout the entire length?

Has drain pipe been installed with a downslope of at least 10 %?

Has the heat resistance of the material used been veried to be at

least 100 °C?

Is the drain hose properly secured (hose clamps at unit connection

tightened)?

Does the water drain installation meet the requirements of the local

regulations for water installations?

48

5.6 Electric installation

5.6.1 Wiring diagram Nordmann ES4

A1 Continuous controller (active 010V)

A2 On/Off controller (passive 24VDC), set jumper on JP1

A3 On/Off control (active 230VAC)

B1 Ventilation interlock

B2 Airow monitor

B3 Safety humidistat

F1 Internal fuse power board (6.3 A, slow acting)

F2 External fuse heating voltage supply

F3 External fuse control voltage supply

F4 External fuse 230V On/Off control

H1 Remote operating and fault indication (option “RFI”)

J Short circuited, if no external monitoring devices are connected

JP1 Jumper On/Off mode

K External safety chain (230V/5A)

K1 Main contactor (for connecting the heating voltage supply to the unit)

M Fan unit FAN4 N...

Q2 External service switch heating voltage supply

Q3 External service switch control voltage supply

S1 Rotary switch "Cylinder type”

S2 Potentiometer “Drain factor”

S3 Potentiometer “Power limitation”

S4 DIP switch “General unit settings”

X0 Connection terminal heating voltage (option THV)

X1 Connection terminal control signal

X2 Connection terminal On/Off control active

X3 Connection terminal control voltage

Control board Power board

ES4 Card

red yellow green

F1

(6.3 AT)

CONT.SIGN

V+ IN GND

X2 X3

VD

MAIN SUPPLY

L1 N SC1SC2

LEV.SENSOR

Driver board

CPU board

J1

X1

CURRENT SENSOR

CPU BOARD

1 2

On/Off

JP1 must be plugged

B3

K

B2

B1

J

Q3

230 V/1~/50..60 Hz

L1 N

F3

On/Off Mode

JP1

+ –

0-10V

A1

H1

A2

A3

F4

230V

L1’

1 2 3 4 5 6 7 8 9 10

Error Service Steam Unit On

Cylinder

Drain Factor

Power Limit

Manual Drain

Low Conduct.

Standby Drain

Force Drain

Cylinder A/D

GFCI-Mode

Offset

Settings

0

DriverRFI

ON

1 2 3 4 5 6

J8

J1

V+ IN GND

X5

X7

X8

X4

1 2 3 4

SWITCH

1 2 3 4

INLET

1 2

CONTACTORDRAIN

∆p

max.

M

L1 N

PE

S1

S2

S3

S4

L1

Q2

K1

X0

F2

L1 L2 L3

L1 L2 L3

L1 L2 L3

400 V/3~/50..60 Hz

230 V/3~/50..60 Hz

Q2

F2

L1 N PE

PE

PE

230 V/1~/50..60 Hz

Q2

F2

L1 L2

400 V/2~/50..60 Hz

PE

ES4

ext.

49

5.6.2 Notes on electric installation

Important notes

– The electric installation must be carried out according to the wiring dia-

gram in chapter 5.6.1, the notes on electric installation as well as the

applicable local regulations. All information given in the wiring diagram

must be followed and observed.

– All cables must be lead into the unit via the cable openings equipped with

cable glands (e.g. option “CGcable gland”). The cable for the heating

voltage supply must be lead into the unit from the bottom via the cable

opening equipped with the clamp strap. Fix the cable with the clamp

strap.

– Make sure the cables do not scrub on any components.

– Maximum cable length and required cross section per wire must be

observed.

– The supply voltages must match the respective voltages (heating and

control voltage) stated in the wiring diagram.

Heating voltage supply

CAUTION!

Before connecting, ensure that the mains voltage corresponds with the

heating voltage for the unit (see type plate).

The Nordmann ES4 is to be connected to the mains supply in accordance

with the wiring diagram, via a service switch “Q2” (disconnecting device

with a minimum contact opening of 3 mm is an essential requirement) and

an fuse group “F2” (essential requirement, fuses are to be as detailed in

the following table). The supply wiring is to be fed into the unit via a tension

relieving device (cable gland) and connected to the terminals of the main

contactor “K1”.

Heating voltage Max. steam

capacity

[kg/h]

Nordmann

ES4 ..

Nominal power

[kW]

Nominal

current

[A]

Main fuses F2

[A]

400V3

(400 V/3~/50...60 Hz)

5 534 3.8 5.4 3x 10

8 834 6.0 8.7 3x 16

15 1534 11.3 16.2 3x 25

23 2364 17.3 24.9 3x 35

32 3264 24.0 34.6 3x 50

45 4564 33.8 48.7 3x 80

65 6564 48.8 70.4 3x 100

400V2

(400 V/2~/50...60 Hz)

5 524 3.8 9.4 2x 16

8 824 6.0 15.1 2x 25

230V3

(230 V/3~/50...60 Hz)

5 532 3.8 9.4 3x 20

8 832 6.0 15.1 3x 25

15 1532 11.3 28.2 3x 40

23 2362 17.3 43.3 3x 63

32 3262 24.0 60.2 3x 100

230V1

(230V/1~/50...60Hz)

5 522 3.8 16.3 25

8 822 6.0 26.1 40

The crosssection of the mains cable must comply with the applicable local

regulations.

50

Control voltage supply

CAUTION!

– Before connecting, ensure that the mains voltage corresponds with

the control voltage of the unit (230 V/1 50…60 Hz).

– The humidier must only be connected to a mains supply with a

protective conductor.

The connection to the control voltage is made in accordance with the wir-

ing diagram, to the terminal “X3” on the power board. The customer is to

install a service switch Q3 in the supply line (all pole disconnecting device

with a minimum contact opening of 3 mm) and an F3 fuse (max. 10 A slow

acting) (these are both essential requirements).

The crosssection of the mains cable must comply with the applicable local

regulations (minimum of 1.5 mm

2

).

External safety circuit

To guarantee the safety of the humidication system, monitoring the operation by means of a safety circuit is an absolute requirement.

To accomplish this, the potential-free contacts (max. contact loading

250V/5A) of external moni t or ing devices (e.g. safety high limit humidistat,

airow monitor, ventilation interlock, etc.) are connected in series to the

contacts “SC1” and “SC2” of the terminal block “X3” in accordance

with the wiring diagram.

DANGER!

Danger of electric hazard!

The mains voltage is connected to terminal block “X3” (up to 240 V). The

steam humidier must therefore be isolated from the mains supply (heating and control voltage), before starting the connection work.

If, for whatever reason, no external monitoring devices are connected, a

connecting bridge “J” must be installed on the contacts “SC1” and “SC2” of

the terminal block “X3”.

Do not apply any extraneous voltage to the terminals.

The crosssection of the cable must comply with the applicable local regula-

tions (minimum of 1 mm

2

).

51

Remote operating and fault indication H1 (Option “RFI”)

The optional remote operating and fault indication PCB is to be connected

to the control board via the terminal “J1”. The optional remote operating

and fault indication PCB contains four potentialfree relay contacts for the

connection of the following operating and fault indications:

– “Error”: This relay is activated if an error is present.

– “Service”: This relay is activated when the set service interval has

expired.

– “Steam”: This relay closes as soon as the unit produces steam.

– “Unit On”: This relay closes as soon as the unit is switched on via the

main switch.

The maximum contact loading is 250V/5A.

Appropriate suppressor modules are to be used for the switching of relays

and miniature contactors.

Note: The minimum cross section of the supply cable must comply with the

local regulations.

Control signal

– External continuous humidity controller 0-10V (A1)

An external humidity continuous controller is to be connected to the

contacts “IN” (+) and “GND” (–) of the terminal block “X1”.

– 24 VDC On/Off humidistat (passive)

An 24 VDC On/Off humidistat is to be connected to the contacts “V+”

and “IN” of the terminal block “X1”.

Note: for the 24 VDC On/Off control a jumper must be set on “JP1”.

– 230V On/Off control (active)

The signal line of a 230V On/Off control is to be connected to the contact “VD” of the terminal block “X2” via external fuse “F4” (max. 10 A,

slowacting).

Connecting the fan unit FAN4 N...

Refer to the separate documentation of the corresponding fan unit.

52

5.6.3 Unitconguration

All setting components for the unit congration are located on the control

board:

– Rotary switch “Cylinder”: cylinder type

– Potentiometer “Drain Factor”: drain factor

– Potentiometer “Power Limit”: power limitation

– DIP switch “Settings”: general settings

Setting the steam cylinder type (“Cylinder”)

Use the rotary switch “Cylinder” to select the type of steam cylinder used:

Voltage/

Phase

200/1

230/1

400/2

200/3

230/3

400/3

200/3

230/3

400/3

200/3

230/3

400/3

200/3

230/3

400/3 400/3 400/3

Position 0 1 2 3 4 5 6 7 8 9 A B

Cylinder ype

522A

822A

524A

824A

532A

832A

534A

534A-L

834A

834A-L

1532A 1534A

1534A-L

2362A 2364A

2364A-L

3262A 3264A

3264A-L

4564A

4564A-L

6564A

Setting the drain factor

Use the potentiometer “Drain Factor” to set the drain factor (setting range:

0.5...2.0, factory setting: 1.0).

Setting the power limitation

Use the potentiometer “Power Limit” to set the power limitation in % of the

maximum capacity (setting range: 30...100%, factory setting: 100%).

General settings (“Settings”)

With the DIP switches “Settings” you can set different unit parameters. The

unit parameters are preset in the factory and may only be modied by the

client after consulting the Nordmann representative.

Switch Factory setting Description

1 OFF ON: low water conductivity <125 µS/cm

OFF: normal water conductivity ≥125 µS/cm

2 OFF ON: standby draining (72 hours) activated

OFF: standby draining (72 hours) deactivated

3 OFF ON: forced draining (72 hours) activated

OFF: forced draining (72 hours) deactivated

4 OFF ON: steam cylinder replacement interval 2500 h.

OFF: steam cylinder replacement interval 1500 h.

5 ON ON: the heating voltage is interrupted during draining

of the steam cylinder

OFF: the heating voltage is interrupted during draining

and relling of the steam cylinder

6 OFF ON: Offset control signal activated (2-10V)

OFF: Offset control signal deactivated (0-10V)

53

5.6.4 Inspecting the electrical installation

Check the following points:

Do the supply voltages for heating and control comply with the relevant

voltages given in the wiring diagram?

Is the correct ES4 Card inserted?

Are the voltage supplies (heating and control voltage) correctly fused?

Is the service switch “Q..” installed in the supply line for to the heating

and control voltage?

Are all components correctly connected according to the wiring diagram?

Are all connecting cables fastened?

Are the connecting cables free of tension (passed through cable glands?)

Does the electric installation meet the applicable local regulations for

electric installations?

Is the front panel mounted and correctly xed with the two screws?

54

6 Operation

6.1 Function of the display and operating elements

Drain/Info key

– press key shortly: Opens and closes the drain valve (manual drain-

ing).

Note: the drain valve is automatically closed after 10 minutes.

– press key for a extended period of time (>3 sec.): activating the

info mode

red LED “Error”

– in normal operating mode

– The LED lights in case of a malfunction of the unit. Further opera-

tion is no longer possible, the heating voltage is interrupted.

– The LED ashes alternately with the green LED if the external

safety chain (ventilation interlock, safety humidistat, etc.) is open.

– in info mode

LED ashes in intervals if a malfunction is present. The number of

“ashes” per interval indicates the left digit of the error code.

yellow LED “Warning and info indication”

– in normal operating mode

The LED lights if the cylinder maintenance is due (see chapter 7) or

the maintenance indication is not reset after the maintenance (see

chapter 7.6).

– in info mode

LED ashes in intervals if a malfunction is present. The number of

“ashes” per interval indicates the right digit of the error code.

green LED “Steam”

– in normal operating mode

– The LED lights if the unit produces steam.

– The LED ashes alternately with the red LED if the external safety

chain (ventilation interlock, safety humidistat, etc.) is open.

– in info mode

LED ashes in intervals. The number of “ashes” per interval multiplied

by 10 indicates the current steam output in %.

Unit switch

Switches the unit on and off. The switch is illuminated when the unit is

switched on.

55

6.2 Commissioning

Proceed as follows when putting the unit into operation:

1. Examine the steam humidier and installation for possible damage.

DANGER!

Damaged devices or devices with damaged installation may present

danger to human life or cause severe damage to material assets.

Damaged units and/or units with damaged or faulty installation

must not be operated.

2. Check whether the front panel is mounted and xed with the two screws.

3. Open the shutoff valve in the water supply line.

4. Verify the set humidity value at the humidity controller or at the humidistat,

and readjust as required.

5. Switch on the service switches for mains supplies (heating and control

voltage).

6. Actuate the unit switch of the steam humidier.

The steam humidier carries out a system test, during which all the LED’s

light up.

If, after the system test:

– the yellow LED lights permanently, the steam cylinder maintenance

is due (see chapter 7) or the maintenance indication has not been reset

(see chapter 7.6).

– the red LED lights permanently, a fatal malfunction has occurred (see

chapter 8).

After the system test the unit is in normal operation mode.

As soon as the humidity controller or the humidistat requires humidity, power

is switched on for heating. The inlet valve opens (slight delay) and the steam

cylinder lls with water. As soon as the submerged electrodes heat the water

up the green LED lights up and after a few minutes (approx. 5–10 minutes,

depending on the conductivity of the water) steam is produced.

Note: If the Nordmann ES4 is operated with water of low conductivity it may

happen that the maximum steam capacity is not reached in the rst few

hours of operation. This is normal. As soon as the conductivity has reached

a sufcient level (due to the vaporisation process) the humidier will reach

the maximum steam capacity.

56

6.3 Notes on operation

6.3.1 Function of the LED's in info mode

The info mode is activated by pressing the drain/info key for an extended

period of time (> 3 seconds). After activating the info mode:

– rst, the green LED ashes. The number of ashes indicates the current

steam output in % of the maximum steam capacity.

Green LED ashing ...

1x 2x 3x 4x 5x 6x 7x 8x 9x 10x

Steam output

in %

10 20 30 40 50 60 70 80 90 100

Note: if no steam production is in progress when the info mode is activated the green LED lights for 3 seconds, then it turns off again.

– then, if a malfunction is present (warning or error) the red and the yellow

LED ash successively. The number of ashes of the red LED indicates

the left digit of the error code while the number of ashes of the yellow

LED indicates the right digit of the error code.

Note: If the red LED lights when the info mode is activated the malfunction indicated is an error (E..) otherwise a warning (W..).