Page 1

DRIVESYSTEMS

NORDISC

™

ADJUSTABLE SPEED DRIVES

RETAIN FOR FUTURE USE

U21010 - 1 of 6

1. Basic operation and speed adjustment

The NORDISC™ Friction Drive will supply infi nite variable

speed adjustments over a fi xed speed range. The NORDISC™

Drive consists of a motor, dry traction drive, and main gear

drive. The motor is typically furnished as an integral mount

to the traction drive, however a NEMA C-face Input Adapter

(Flex-C-Input Adapter) is also available.

Attached to the output shaft of a constant speed motor, is

the driving disc portion of the traction drive. The driven disc

is angled approximately 2º, localizing the friction contact on

the disc pair. As the adjustment spindle is rotated, the input

side of the housing moves either up or down, changing the

effective pitch diameter of the driving disc. Speed is typically

adjusted by the handwheel.

STOP

Speed adjustments must be performed when the motor is

running to prevent possible damage to the traction drive

parts.

STOP

Initial adjustments of the speed stops located internal to

the traction drive are completed at the factory. Further

adjustments of the speed stops can cause damage to the

traction drive and/or main drive.

HARMFUL SITUATION

HARMFUL SITUATION

STOP

STOP

2. NORDISC™ Friction Drive

The variable speed drive requires only minimal maintenance.

However, the friction ring is a wear item.

STOP

The traction drive should be periodically operated through

its entire speed range, in order to prevent localized wear

patterns on the driving disc and/or possible damage to the

driving disc.

The friction drive does not require lubrication unless it is

disassembled for an overhaul. Units should be checked periodically for:

• Increased noise level.

• Increased operating temperatures.

• Increased vibration.

• Increased motor amperage draw.

• Increased or excessive shaft movement.

Every 10,000 hours of operation, it is suggested that the

bearings be cleaned and re-greased with a lithium-based

NLGI #2 Grease.

The adjustment wheel and speed adjustment shaft should

also be cleaned periodically and coated with molybdenumbased anti-seize compound.

HARMFUL SITUATION

STOP

3. Motor

WARNING

To prevent possible injury and/or damage to the electric

motor, the variable speed drive, or the driven equipment,

it is important to follow the motor manufacturer’s instructions pertaining to safe handling, installation, and maintenance of the electric motor.

Connect the motor in accordance with the wiring information supplied by the motor manufacturer and make sure the

motor nameplage voltage and frequency agree with the

available power supply. Use the proper protective motor

switches to help protect the motor windings from overload

and/or phase failure.

WARNING

Explosion proof motors should not be used on the friction

drive. The friction drive is not recommended for use in

explosion proof atmospheres.

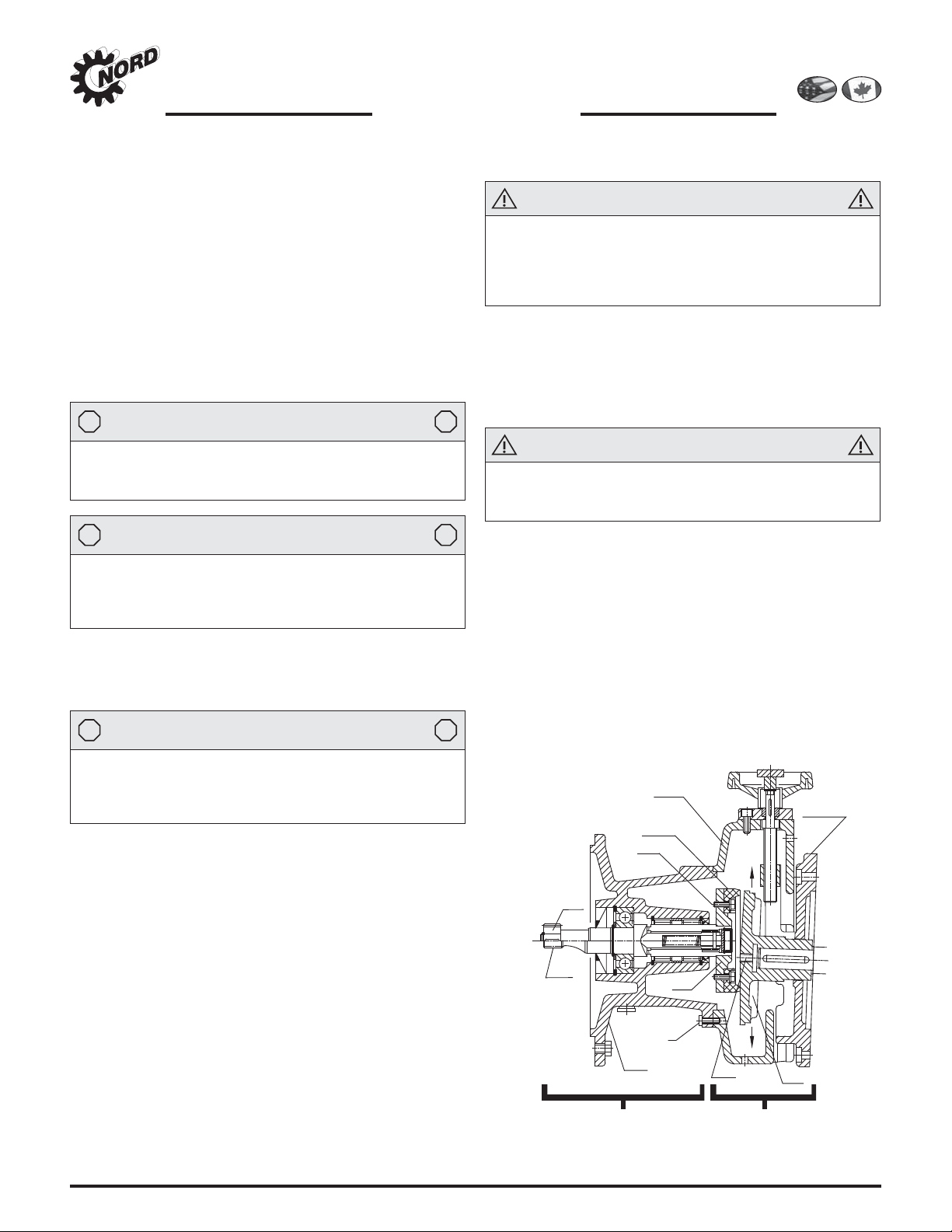

4. Seperating the driven disc assembly from the

driving disc assembly

A. Lockout the electric power to the motor and make sure

the wires are disconnected.

B. Support the intermediate housing (Item 447) and the

attached motor assembly.

C. Remove the four hex head screws that connect the

driving disc assembly (intermediate housing / Item 447)

to the driven disc assembly (output housing / Item 402).

D. Slide the intermediate housing (Item 447) away from the

output housing (Item 402).

447

472 (474)

409

410

424

425

Hex Head

Screws (4X)

402

407

493

489

NORD Gear Limited

Toll Free in Canada: 800.668.4378

DRIVE DISK ASSEMBLYDRIVEN DISK ASSEMBLY

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

www.nord.com/docs06.09.09

Page 2

DRIVESYSTEMS

NORDISC

™

ADJUSTABLE SPEED DRIVES

RETAIN FOR FUTURE USE

U21010 - 2 of 6

5. Friction disc replacement

A. Separate the driven disc assembly from the driving disc

assembly (See Separate Instructions).

B. Once the friction disc (Item 409), is exposed remove the

socket head cap screws (Item 410) that hold the friction

disc or friction ring (Item 409) to the friction disc carrier

(Item 407).

C. Clean the contact surface between the friction disc and

friction disc carrier.

D. Vacuum or brush out the NORDISC™ drive housing to

remove accumulated friction material dust. Be careful

not to ingest dust while cleaning.

E. Inspect main housing for damaged parts while

disassembled.

F. Attach the new friction disc to the carrier using the

socket head cap screws. Permissible tightening torques

are per the table below:

Type Screw

Size

RV10 M5 X 12 8.8 6 N-m / 53 lb-in

RV20 M5 X 16 8.8 6 N-m / 53 lb-in

RV30 M6 x 16 8.8 10 N-m / 88 lb-in

RV40 M6 x 20 8.8 10 N-m / 88 lb-in

G. Re-assemble intermediate housing or “RV” housing

(Item 447) to output bearing housing (Item 402). To

re-assemble, apply Steps 1-4 in reverse order. Use a

thread-locking compound to secure the hex head

screws.

Material

Grade

Tightening

Torque

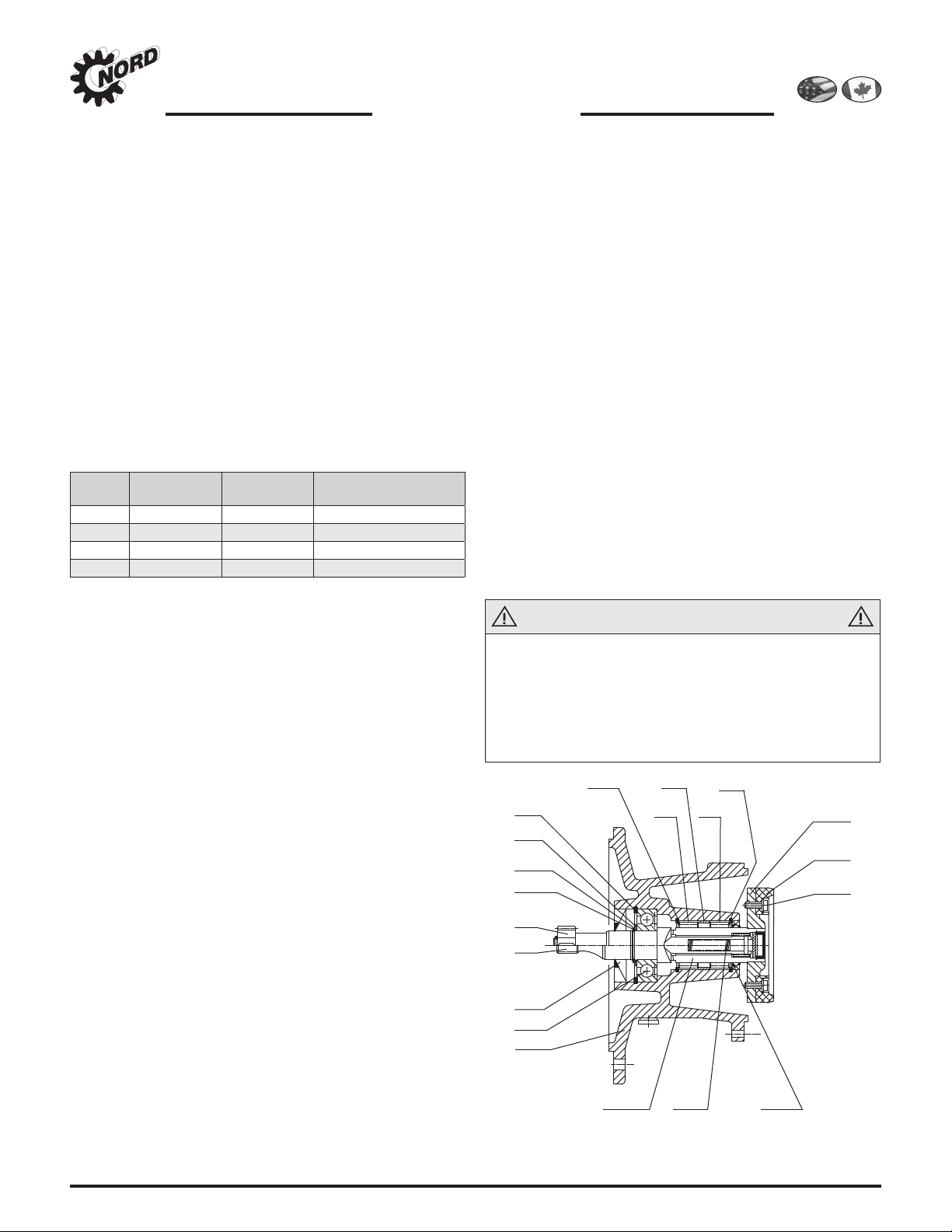

6.

Bearing and seal replacement - NORDISC™ output

A. Separate the driven disc assembly from the driving disc

assembly (See Separate Instructions).

B. Slide the intermediate housing (Item 447) away from

the output housing (Item 402) and remove the shaft oil

seal (Item 439).

C. Remove circlips/snap-rings (Item 437 and 438).

D. Remove shims and supporting disc (Items 434 & 436).

E. Slide the hollow shaft/friction disc carrier assembly

(Item 404) away from output housing (Item 402).

F. Press output gear-shaft (Item 424 or 425) and bearing

(Item 435) out of output housing. Shaft and bearing

come out on the output or gear-shaft side.

G. Remove oil seal (Item 421) from output housing.

H. Remove two circlips/snap-rings (Items 418) from output

housing and remove needle bearings and spacer (Items

419 and 420).

I. Re-assemble in the reverse order, replacing ball bearing,

needle bearings, and oil seals (Items 435, 419, 421 and

439). If required, also replace any shims, spacers, or

circlips (Items 434, 436, 420, 437, 438, and 418).

During assembly, repack bearings with a lithium-based

NLGI #2 grease. Needle bearing cavity should be

approximately 1/3 full after re-greasing.

WARNING

• The output shaft compression spring (Item 430) does

not require maintenance. If the spring fractures the

complete shaft should be replaced as a complete

assembly or returned to NORD Gear for repair.

• Special fi xtures are required to remove and install the

spring. Personal injury can result if this repair is

attempted in the fi eld.

NORD Gear Limited

Toll Free in Canada: 800.668.4378

419

420

430

419

418

407

409

410

421

438

436

434

437

424

425

439

435

402

418

404

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

www.nord.com/docs06.09.09

Page 3

DRIVESYSTEMS

NORDISC

™

ADJUSTABLE SPEED DRIVES

RETAIN FOR FUTURE USE

U21010 - 3 of 6

7. Driving disc dissassembly and reassembly

The driving disc (Item 489) is attached directly to either the

motor shaft or the shaft of the C-Face Input (Flex-C-Input)

Adapter. One must fi rst remove the driving disc from the

input-side of the NORDISC™ in order to:

• Replace the motor.

• Replace the bearings in the C-Face Adapter.

Driving Disc Removal

A. Separate the driven disc assembly from the driving disc

assembly (See Separate Instructions).

B. Slide the intermediate housing (Item 447) away from

the output housing (Item 402).

C. After removing the input side from the output side,

position the driving disc (Item 489) in the middle of the

housing by turning the speed adjusting hand wheel

(Item 462).

D. Remove the setscrew in the middle of the driving disc

(Item 493). Insert a hardened bolt in the hole that is in

the center of the driving disc (Item 489), and tighten

the bolt against the shaft to separate or remove the

driving disc from the shaft (see table).

Type Setscrew Size Bolt Size

RV10 1/4-20 1/4-20 x 2-1/4 in

RV20 5/16-18 5/16-8 x 2-3/4 in

RV30 1/2-13 1/2-13 x 3 in

RV40 5/8-11 5/8-11 x 4 in

Driving Disc Re-Assembly

A. Installation of the driving disc (Item 489) may require

heating the disc in an oven or on a hot plate, to allow

the disc to be positioned all the way on to the motor

shaft or C-Face Input shaft.

WARNING

Exercise extreme caution when handling the hot driving

disc. Protective gloves are recommended.

B. After heating the disc, position it all the way onto the

shaft until it bottoms.

C. Using the table below, measure the “X” dimension

from the bottom edge of the friction drive housing

(Item 447) to the face of the driving disc (Item 489).

Type Setscrew Size “X” Dimension

RV10 1/4-20 0.837/0.867 in

RV20 5/16-18 0.975/1.005 in

RV30 1/2-13 1.133/1.163 in

RV40 5/8-11 1.311/1.341 in

D. Insert the setscrew (Item 493) into the hole in the center

of the driving disc, and tighten the setscrew snug to the

shaft of the motor or C-Face input assembly. Use a

thread-locking compound to help secure the setscrew.

447

472 (474)

489

493

MEASURING

DEVICE

"X"

NORD Gear Limited

Toll Free in Canada: 800.668.4378

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

www.nord.com/docs06.09.09

Page 4

DRIVESYSTEMS

NORDISC

™

ADJUSTABLE SPEED DRIVES

RETAIN FOR FUTURE USE

U21010 - 4 of 6

Removal and re-assembloy of motor or C-face input adapter

(Flex-C-Input)

A. Separate the driven disc assembly from the driving disc

assembly and remove the driving disc (See Separate

Instructions).

B. After removing the driving disc (Item 489), the mounting

bolts for the motor or C-Face adapter can be accessed.

To gain access to all four bolts requires the removal of

the two cam grooves (Item 477). The cam grooves can

be removed by fi rst removing the socket head screws

(Item 478). Then, the motor or adapter bolts ((Item 453)

can be removed.

C. Assembly is the reverse of disassembly.

465

462

472 (474)

477

478

479

MOTOR / C-FACE ADAPTER

MOTOR BOLTS (4X)

IMPORTANT NOTE

The cam grooves or tapered gibs (Item 477) need to be

adjusted during assembly.

Cam groove or tapered gib adjustment

The cam groove or tapered gib on the right side (Item 477)

is not adjustable. The cam groove on the left-hand side

is to be adjusted by the screws (Item 479) located next to

the slide bar (Item 477). The cam grooves are properly adjusted when the slide plate (Item 472 or 474) is allowed to

move freely through its complete range.

A. Remove the handwheel assembly nut (Item 465) and

handwheel (Item 462) before making adjustment.

B. Clean sliding surfaces of the slide plate and cam grooves,

and then re-apply a molybdenum-based anti-seize com

pound to these surfaces.

C. Assemble the motor and/or c-face adapter to the slide plate (Item 472/474) by re-installing the motor bolts.

Apply a thread-locking agent to the screw threads

during assembly.

D. Place the non-adjustable (right-side) cam groove onto

the slide plate and tighten the socket head setscrews

(Item 478). Apply a thread-locking agent to the screw

threads during assembly

E. Place the intermediate housing (Item 447) onto the

slide plate (Item 472 or 474) and then install the adjust able (Left-side) cam groove (Item 477).

F. Install the socket head screws (Item 478) and the adjust ment setscrews (Item 479). Apply a thread-locking

agent to the screw threads during assembly. Do not

completely tighten either set of screws – follow Steps 7

& 8!

G. Adjust the cam groove set screws (Item 479) so that

there is minimal side-play or side-movement and be

certain that the friction drive housing (Item 447) can

move freely.

H. Then, tighten the socket head setscrews (Item 478).

I. After completing the adjustment of the cam grooves

(Item 477) the handwheel (Item 462) and handwheel

assembly nut (Item 465) can be re-installed.

J. Re-assemble the driving disc and re-connect the driving

disc assembly and the driven disc assembly.

NORD Gear Limited

Toll Free in Canada: 800.668.4378

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

www.nord.com/docs06.09.09

Page 5

DRIVESYSTEMS

NORDISC

™

ADJUSTABLE SPEED DRIVES

RETAIN FOR FUTURE USE

U21010 - 5 of 6

Item 426 (Shaft assembly) and Item 405 (Friction ring

carrier assembly) are stocked as complete assemblies.

Item 409 (Friction disc) can be ordered separately per

the Table on page 6.

™

NORDISC

402 Housing

418 Snap Ring

419 Needle roller bearing

420 Spacer

421 Seal

434 Shim

435 Ball Bearing

436 Supporting disc

437 Snap ring

438 Snap ring

439 Seal

440 Key

441 Snap ring

443 Oil plug

444 Gasket

445 Flanged eye bolt

447 Intermediate housing

450 Set screw

451 Bore plug

452 Spindle cover

454 Socket head screw

455 Snap ring

Parts List

456 Adjusting spindle

460 Key

462 Hand wheel

464 Washer

465 Hex nut

468 Scale

469 Rivet / self-tapping screw

472 Slide-plate (NEMA)

474 Slide-plate (IEC)

477 Cam groove / taper gib

478 Socket head screw

479 Screw

481 Set screw

483 Spindle nut

484 Socket head screw

486 Indicator

487 Indicator screw

489 Driving disc

491 Supporting disc

492 V-ring seal

493 Set screw

426 Complete shaft assembly

424 Shaft, plain cut *

425 Shaft, gear cut *

430 Compression spring *

433 Dowel pin *

432 Spiral pin *

* Included with Item 426

405 Friction ring carrier assy

406 Hollow shaft **

407 Friction ring carrier **

409 Friction disc **

410 Socket head screw **

411 Washer **

413 Needle roller bearing **

414 Washer **

415 Snap ring **

416 Bore plug **

** Included with Item 405

NORD Gear Limited

Toll Free in Canada: 800.668.4378

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

www.nord.com/docs06.09.09

Page 6

™

NORDISC

DRIVESYSTEMS

8. NORDISC™ FRICTION DISC REPLACEMENT PART NUMBERS

NORDISC™ Type RV10 RV20 RV30 RV40

Item 409 - Friction Disc Part Number 79119000 79219000 79319000 79419000

9. TROUBLESHOOTING

Problem With Variable Speed Unit Possible Causes Suggested Remedy

Drive Slips. Friction Disc is worn. Friction Disc or

Drive heats up excessively. Load is too high. Check measured power and reduce

Drive appears noisy or too loud. Friction Disc is damaged:

Adjust rate is too low. Sluggish adjustment rate may be due to

ADJUSTABLE SPEED DRIVES

RETAIN FOR FUTURE USE

Drive Disc face is dirty or contaminated.

Load is too high.

• May be caused after a brief stalling

of the drive.

• May be caused by intermittent load ing of the drive.

corrosion between the slide plate and

the cam grooves that are internal to the

intermediate housing.

Replace Friction Disc (Page 3).

Clean Contaminated part:

• Friction Disc – use dry cloth or paper.

• Drive Disc – okay to use mild solvent

provided excess is removed or cleaned

with a dry cloth. Check measured

power and reduce operating load to

catalog values.

operating load to catalog values.

Determine cause of damage, and

replace friction disc (Page 3).

Re-establish low-friction conduction.

• Separate driven disc assembly from

driving disc assembly.

• Clean and re-lubricate slide plate

and cam grooves by applying a

molybdenum-based anti-seize com pound to these surfaces.

• In extreme instances it may be nec essary to remove the motor and

cam grooves in order to thoroughly

clean the cam grooves and slide

plate.

Reference instructions on Page 4, “Cam

Groove or Tapered Gib Adjustment”.

U21010 - 6 of 6

NORD Gear Limited

Toll Free in Canada: 800.668.4378

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

www.nord.com/docs06.09.09

Loading...

Loading...