Page 1

GB

BU 0750

NORDAC SK 750E

Manual for Frequency inverters

Page 2

NORDAC SK 750E Manual Safety information

SK 750E Frequency Inverter

Safety and operating instructions for

drive power converters

(as per: Low Voltage Directive 2006/95/EEC )

1. General

During operation, drive power converters may, depending on their

protection class, have live, bare, moving or rotating parts or hot

surfaces.

Unauthorised removal of covers, improper use, incorrect installation

or operation causes a risk of serious personal injury or material

damage.

Further information can be found in this documentation.

All transportation, installation, initialisation and maintenance work

must be carried out by qualified personnel (compliant with

IEC 364, CENELEC HD 384, DIN VDE 0100, IEC 664 or DIN

VDE 0110, and national accident prevention regulations).

For the purposes of these basic safety instructions, qualified

personnel are persons who are familiar with the assembly,

installation, commissioning and operation of this product and who

have the relevant qualifications for their work.

2. Proper use in Europe

Drive power converters are components intended for installation in

electrical systems or machines.

When installed in machines, the drive power converter cannot be

commissioned (i.e. commencement of the proper use) until it has

been ensured that the machine meets the provisions of the

EC Directive 2006/42/EEC (Machine Directive); EN 60204 must also

be complied with.

Commissioning (i.e. implementation of the proper use) is only

permitted if the EMC Directive (2004/108/EEC) is complied with.

Drive power converters with the CE mark meet the requirements of

the Low Voltage Directive 2006/95/EEC. The harmonized standards

stated in the Declaration of Conformity are used for the drive power

converters.

Technical data and information for connection conditions can be

found on the name plate and in the documentation, and must be

complied with.

The drive power converters may only be used for the safety

functions which are described and for which they have been

explicitly approved.

3. Transport, storage

Information regarding transport, storage and correct handling must

be complied with.

4. Installation

The installation and cooling of the equipment must be implemented

according to the regulations in the corresponding documentation.

The drive power converters must be protected against

impermissible loads. Especially during transport and

handling, components must not be deformed and/or

insulation distances must not be changed. Touching of

electronic components and contacts must be avoided.

Drive power converters have electrostatically sensitive

components, which can be easily damaged by incorrect

handling. Electrical components must not be mechanically

damaged or destroyed (this may cause a health hazard!).

5. Electrical connections

When working on live drive power converters, the applicable

national accident prevention regulations must be complied

with (e.g. VBG A3, formerly VBG 4).

The electrical installation must be implemented according to

the applicable regulations (e.g. cable cross-section, fuses,

ground lead connections). Further information is contained

in the documentation.

Information about EMC-compliant installation – such as

shielding, earthing, location of filters and installation of

cables can be found in the drive power converter

documentation. These instructions must be complied with

even with CE marked drive power converters. Compliance

with the limiting values specified in the EMC regulations is

the responsibility of the manufacturer of the system or

machine.

6. Operation

Where necessary, systems where drive power converters

are installed must be equipped with additional monitoring

and protective equipment according to the applicable safety

requirements, e.g. legislation concerning technical

equipment, accident prevention regulations, etc.

The parameterisation and configuration of the drive power

converter must be selected so that no hazards can occur.

All covers must be kept closed during operation.

7. Maintenance and repairs

After the drive power converter is disconnected from the

power supply, live equipment components and power

connections should not be touched immediately, because of

possible charged capacitors. Observe the relevant

information signs located on the drive power converter.

Further information can be found in this documentation.

These safety instructions must be kept in a safe place!

2 BU 0750 GB-3311

Page 3

NORDAC SK 750E Manual Concerning this document

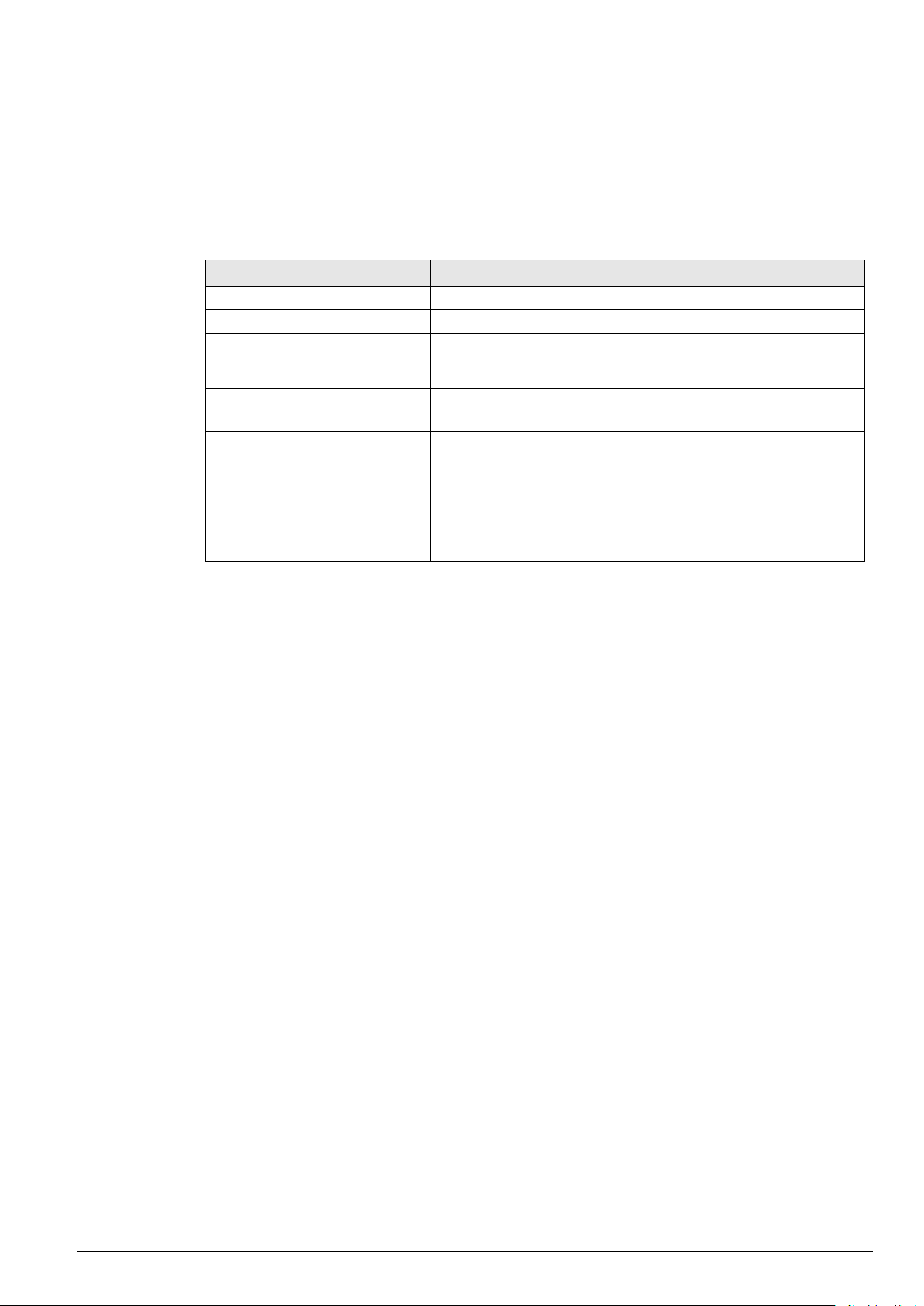

Designation of previous issues

SW status

Comments

BU 0750 GB, December 2004

V 3.1 R1

First issue based on BU 0700 DE

BU 0750 GB, December 2005

V 3.1 R2

Revision, supplementation and correction

BU 0750 GB, April 2006

V 3.2 R0

Revision, wall-mounting kit, motor mounting,

differentiation of the options for IP54 and IP65

version, cable glands

BU 0750 GB, March 2007

Part No.: 6077502 / 1207

V 3.2 R0

Data backup via P550 only right hand slot, Section 3.2

right / left slot

BU 0750 GB, March 2008

Part No.: 6077502 / 1208

V3.4 R4

Control for electromagnetic motor brakes, P217,

P426, P533, P535

BU 0750 GB, August 2011

Part No.: 6077502 / 3311

V3.5 R1

Addition of UL-relevant details; revision of Sections

2.6, 3.3.3, 3.3.4; revision of parameter P208, P215;

P216, function of digital inputs: 47/48;

addition of environmental classes, long-term storage

and min. brake resistances (Section 9)

Documentation

Designation: BU 0750 EN

Part No.: 607 75 01

Device series: SK 750E

Version list

Publisher

Getriebebau NORD GmbH & Co. KG

Rudolf-Diesel-Str. 1 D-22941 Bargteheide http://www.nord.com/

Tel.: +49 (0) 45 32 / 401-0 Fax +49 (0) 45 32 / 401-555

Intended use of the

frequency inverter

Compliance with the operating instructions is necessary for fault-free operation and the

acceptance of any warranty claims. These operating instructions must be read before

working with the device!

These operating instructions contain important information about servicing. They must

therefore be kept near to the device .

SK 750E frequency inverters are devices for industrial and commercial plants for operating

three-phase asynchronous motors with squirrel-cage rotors. These motors must be suitable for

operation with frequency inverters, other loads must not be connected to the devices.

SK 750E frequency inverters are devices for fixed installation in control cabinets. All details

regarding technical data and permissible conditions at the installation site must be complied

with.

Commissioning (commencement of the intended use) is prohibited until it has been ensured that

the machine complies with the EMC Directive 2004/108/EEC and that the conformity of the end

product meets the Machinery Directive 2006/42/EEC (observe EN 60204).

Getriebebau NORD GmbH & Co. KG, 2011

BU 0750 GB-3311 3

Page 4

NORDAC SK 750E Manual

1 GENERAL INFORMATION .......................................................................................................... 6

2 ASSEMBLY AND INSTALLATION ............................................................................................ 13

1.1 Overview ................................................................................................................... 6

1.2 Delivery ..................................................................................................................... 6

1.3 Scope of supply ........................................................................................................ 7

1.4 Safety and installationinformation ............................................................................ 8

1.5 Certifications ............................................................................................................. 9

1.5.1 UL and cUL certification ................................................................................... 9

1.5.2 European EMC Directive ................................................................................ 10

1.6 Nomenclature / Type code ..................................................................................... 11

1.7 Version with protection class IP54 / IP65 ............................................................... 12

2.1 Motor-integrated and close to motor layouts .......................................................... 13

2.2 Installation .............................................................................................................. 14

2.3 Dimensions of the SK 750E ................................................................................... 15

2.4 Attachment accessories for the SK 750E ............................................................... 16

2.5 SK 750E wall mounting kit ...................................................................................... 16

2.5.1 Dimensions of the SK 750E with wall mounting kit ........................................ 17

2.6 Mounting of the SK750E directly on a motor .......................................................... 18

2.7 Wiring guidelines .................................................................................................... 19

2.8 Electrical Connection .............................................................................................. 20

2.9 Electrical connection of power unit ......................................................................... 20

2.9.1 Mains supply (PE, L1, L2, L3) ........................................................................ 22

2.9.2 Electromagnetic brake (+Br, -Br, PE) ............................................................. 22

2.9.3 Brake resistor (+B, -B, PE) ............................................................................. 22

2.9.4 Motor cable (U, V, W, PE) .............................................................................. 22

2.9.5 Temperature sensor (T1, T2) ......................................................................... 23

2.9.6 PowerConnection Terminals .......................................................................... 23

2.9.7 Control connections (optional) ....................................................................... 24

2.9.8 Cable connections .......................................................................................... 25

3 OPTIONS .................................................................................................................................... 26

3.1 Modular options ...................................................................................................... 26

3.2 Overview of Technology Units ................................................................................ 27

3.2.1 Installing the Technology Unit ........................................................................ 29

3.2.2 ControlBox SK TU2-CTR ............................................................................... 30

3.2.3 PotentiometerBox SK TU2-POT .................................................................... 35

3.2.4 DeviceNet Module SK TU2-DEV .................................................................... 35

3.2.5 Profibus Module SK TU2-PBR ....................................................................... 36

3.2.6 CANopen BUS Module SK TU2-CAO ............................................................ 36

3.2.7 InterBus Module SK TU2-IBS ........................................................................ 37

3.2.8 AS interface SK TU2-AS1 .............................................................................. 37

3.2.9 Retrofit kit, SK TU2 cover ............................................................................... 38

3.3 Customer unit overview .......................................................................................... 39

3.3.1 Installation of customer units .......................................................................... 40

3.3.2 Removal of Customer Units ........................................................................... 41

3.3.3 Customer unit Basic I/O ................................................................................. 42

3.3.4 Customer unit Standard I/O............................................................................ 43

3.3.5 Multi I/O Customer Unit .................................................................................. 44

3.3.6 Multi I/O 20mA Customer Unit........................................................................ 45

3.3.7 BUS Customer Units, SK CU1-CAN-RJ, SK CU1-PBR ................................. 46

3.4 Overview of Special Extensions ............................................................................. 47

3.4.1 Installation of the special extension units ....................................................... 48

3.4.2 Removal of Special Extensions ...................................................................... 49

3.4.3 Special Extension Encoder I/O ...................................................................... 50

3.4.4 Special Extension PosiCon I/O ...................................................................... 51

3.5 Control Terminals of Customer I/Os ....................................................................... 52

3.6 Colour and contact assignments for the incremental encoders ............................. 54

4 BU 0750 GB-3311

Page 5

Table of Contents

4 OPERATION AND DISPLAY ...................................................................................................... 55

4.1 Control element connection variants ...................................................................... 56

4.2 ParameterBox, Handheld Version, SK PAR-2H ..................................................... 57

4.3 ParameterBox Installation Version, SK PAR-2E .................................................... 58

4.3.1 Electrical connection ...................................................................................... 59

4.4 Functions of the ParameterBox .............................................................................. 60

4.5 Parameters of the ParameterBox ........................................................................... 67

4.6 ParameterBox error messages .............................................................................. 70

4.7 Data transfer with NORD CON ............................................................................... 73

5 NORD CON SOFTWARE ........................................................................................................... 74

5.1 General Information ................................................................................................ 74

6 COMMISSIONING ....................................................................................................................... 76

6.1 Basic settings ......................................................................................................... 76

6.2 Basic operation - Quick start guide ........................................................................ 77

6.3 Minimum configuration of control connections ....................................................... 78

7 PARAMETERISATION ............................................................................................................... 79

7.1 Array parameter display ......................................................................................... 80

7.2 Operating displays .................................................................................................. 81

7.3 Basic parameters .................................................................................................... 82

7.4 Motor data / characteristic curve parameters ......................................................... 87

7.5 Speed control ......................................................................................................... 90

7.6 Control clamps ........................................................................................................ 94

7.7 Extra functions ...................................................................................................... 109

7.8 PosiCon ................................................................................................................ 119

7.9 Information ............................................................................................................ 120

7.10 Parameter overview, User settings .................................................................... 126

8 ERROR MESSAGES ................................................................................................................ 133

8.1 ControlBox display ................................................................................................ 133

9 TECHNICAL DATA ................................................................................................................... 139

9.1 General Data ........................................................................................................ 139

9.2 Electrical Data 230V ............................................................................................. 140

9.3 Electrical data 400V .............................................................................................. 140

9.4 Electrical data for UL/cUL certification ................................................................. 141

10 ADDITIONAL INFORMATION ................................................................................................ 142

10.1 Setpoint processing in the SK 750E ................................................................... 142

10.2 PID controller for the SK 750E ........................................................................... 144

10.3 Process controller ............................................................................................... 146

10.3.1 Process controller application example ...................................................... 146

10.3.2 Process controller parameter settings ........................................................ 147

10.4 Electromagnetic compatibility (EMC) ................................................................. 148

10.5 EMC limit value classes...................................................................................... 148

10.6 Maintenance and servicing information .............................................................. 150

10.6.1 Maintenance Instructions ........................................................................... 150

10.6.2 Repair information ...................................................................................... 151

11 KEYWORD INDEX .................................................................................................................. 152

BU 0750 GB-3311 5

Page 6

NORDAC SK 750E Manual

1 General information

The NORDAC SK 750E series is based on the proven SK 700E series. However, it is designed for use in

harsher ambient conditions (up to 60°C, at least IP54). These devices are characterised by the high modularity

and excellent control characteristics.

These devices are provided with sensorless vector current control system which in combination with

asynchronous three-phase motor types constantly ensures an optimised voltage-to-frequency ratio. This has

the following significance for the drive: Peak start-up and overload torques at constant speed.

Due to its modular construction, the variously combinable technology units, customer units and special

extension units, this device series is suitable for all possible applications.

Due to the wide range of setting options, these inverters are capable of controlling all three-phase motors. The

power range is from 5.5kW to 22kW (3~ 400V...480V) and 5.5 to 11kW (3~ 200…240V) with integrated line

filter. The overload capacity of these devices is 150% for 60 seconds and 200% for 3.5 seconds.

This manual is based on the device software V3.5R1 (P707) for the SK 750E. If the frequency inverter used

has a different version, this may lead to some differences. If necessary, you can download the current manual

from the Internet (http://www.nord.com/).

1.1 Overview

Properties of the basic device:

High starting torque and precise motor speed control setting with sensorless current vector control

Can be mounted next to each other without additional spacing

Permissible environmental temperature range: 0 to 50°C (or up to 60°C please refer to the technical

data)

Integrated EMC line filter for limit curve A as per EN55011

Automatic measurement of the stator resistance

Programmable direct current braking

Integrated brake chopper for 4 quadrant drive

Integrated RS485 interface on M12 socket

Four separate online switchable parameter sets

High protection class IP54 (air cooling), IP65 with water cooled version (special version)

NOTE: The characteristics of the basic device with an additional technology unit, customer unit or special

extension are described in Section 3 „Options„.

1.2 Delivery

Check the equipment immediately after delivery/unpacking for transport damage such as deformation or loose

parts.

If there is any damage, contact the carrier immediately and carry out a thorough assessment.

Important! This also applies even if the packaging is undamaged.

6 Subject to technical amendments BU 0750 GB-3311

Page 7

1. General information

NOTE:

Additional bus manuals are available –

BU 0020 … BU 0090..

>>> www.nord.com <<<

1.3 Scope of supply

Standard version: State the protection class, IP54 (air cooling) / (IP65 water cooling as special

version)

→ when ordering!

Integrated brake chopper

Integrated EMC line filter for limit curve A as per EN55011

Blank cover for the 1st and 2nd technology unit slots

Shield angle

Operating Instructions

Available accessories: Brake resistor with high protection class on request, otherwise as for SK 700E

(IP20)

Interface converter RS232 RS485 (additional description BU 0010)

NORD CON, PC parameterisation software > www.nord.com <

ParameterBox, external control panel with LCD plain text display, connection cable

(supplementary description BU 0040 DE)

Technology Unit:

SK TU2-CTR, ControlBox

detachable control panel, 4 figure 7 segment LED display, keyboard

SK TU2-POT, PotentiometerBox

Additional module with switch (R/L) and infinitely variable potentiometer

SK TU2-PBR, Profibus, additional module for Profibus communication (1.5MBaud)

SK TU2-PBR-24V, with external 24V supply (12MBaud)

SK TU2-PBR-KL, Connection to terminal bar with cover (1.5MBaud)

SK TU2-CAN, CANbus, additional module for CANbus communication

SK TU2-CAO, CANopen, bus switching

SK TU2-DEV, DeviceNet, bus switching

SK TU2-IBS, InterBus, bus switching

SK TU2-AS1, AS interface, bus switching

Customer interfaces:

SK CU1-BSC, basic I/O, limited scope for signal processing

SK CU1-BSC, standard I/O, moderate scope for signal processing

SK CU1-MLT, multi-I/O, high level of scope for signal processing

SK CU1-MLT-20mA, multi-I/O, high level of scope for signal processing

SK CU1-CAN, CANbus I/O, bus switching via the CANbus

SK CU1-PBR, Profibus I/O, bus switching via Profibus DP

Special extension units:

SK XU1-POS, PosiCon I/O, positioning module

(Supplementary instruction BU 0710 GB)

SK XU1-ENC, Encoder I/O, incremental encoder input for speed control

BU 0750 GB-3311 Subject to technical amendments 7

Page 8

NORDAC SK 750E Manual

CAUTION

The heat sink and all other metal components can heat up to temperatures above 70°C.

When mounting, sufficient distance from neighbouring components must be maintained.

When working on the components, allow sufficient cooling time before starting work.

ATTENTION

DANGER TO LIFE

The power unit can continue to carry voltages for up to 5 minutes after being switched off at

the mains. Inverter terminals, motor cables and motor terminals may carry voltage!

Touching open or free terminals, cables and equipment components can lead to severe injury

or death!

Work may only be carried out by qualified electricians and with the electrical supply to the

equipment disconnected.

1.4 Safety and installationinformation

NORDAC SK 750E frequency inverters are devices for use in industrial high voltage systems and are operated

at voltages which could lead to severe injuries or death if they are touched.

Installation and other work may only be carried out by qualified electricians and with the device

disconnected. The operating instructions must always be available to these persons and must be

strictly observed.

Local regulations for the installation of electrical equipment and accident prevention must be complied

with.

The equipment continues to carry hazardous voltages for up to 5 minutes after being switched off at

the mains. The equipment may only be opened or the cover or control element removed 5 minutes

after the equipment has been disconnected from the power supply. All covers must be put back in

place before the line voltage is switched back on again.

For safe isolation from the mains, all poles of the supply cable to the frequency inverter must be able

to be disconnected.

Even during motor standstill (e.g. caused by a release block, blocked drive or output terminal short

circuit), the line connection terminals, motor terminals and braking resistor terminals may still conduct

hazardous voltages. A motor standstill is not identical to electrical isolation from the mains.

Caution, even parts of the control card and, in particular, the connection plug for the removable

technology units can conduct hazardous voltages. The control terminals are mains voltage free.

Caution, with certain settings, the frequency inverter/motor can start up automatically after the mains

are switched on.

The circuit boards contain highly-sensitive MOS semiconductor components that are particularly

sensitive to static electricity. Avoid touching circuit tracks and components with the hand or metallic

objects. Only the terminal strip screws may be touched with insulated screwdrivers when connecting

the cables.

The frequency inverter is only intended for permanent connection and may not be operated without

effective earthing connections which comply with local regulations for large leakage currents

(> 3.5mA). VDE 0160 stipulates the installation of a second earthing conductor or an earthing

conductor cross-section of at least 10 mm2.

In case of three-phase frequency inverters, common ground-fault circuit interrupters are not suitable

only for protection if the local regulations do not permit possible DC components in the leakage

current. The standard FI circuit breaker must comply with the new design as per VDE 0664.

In normal use, NORDAC SK 750E frequency inverters are maintenance free. The cooling surfaces

must be regularly cleaned with compressed air if the ambient air is dusty.

8 Subject to technical amendments BU 0750 GB-3311

Page 9

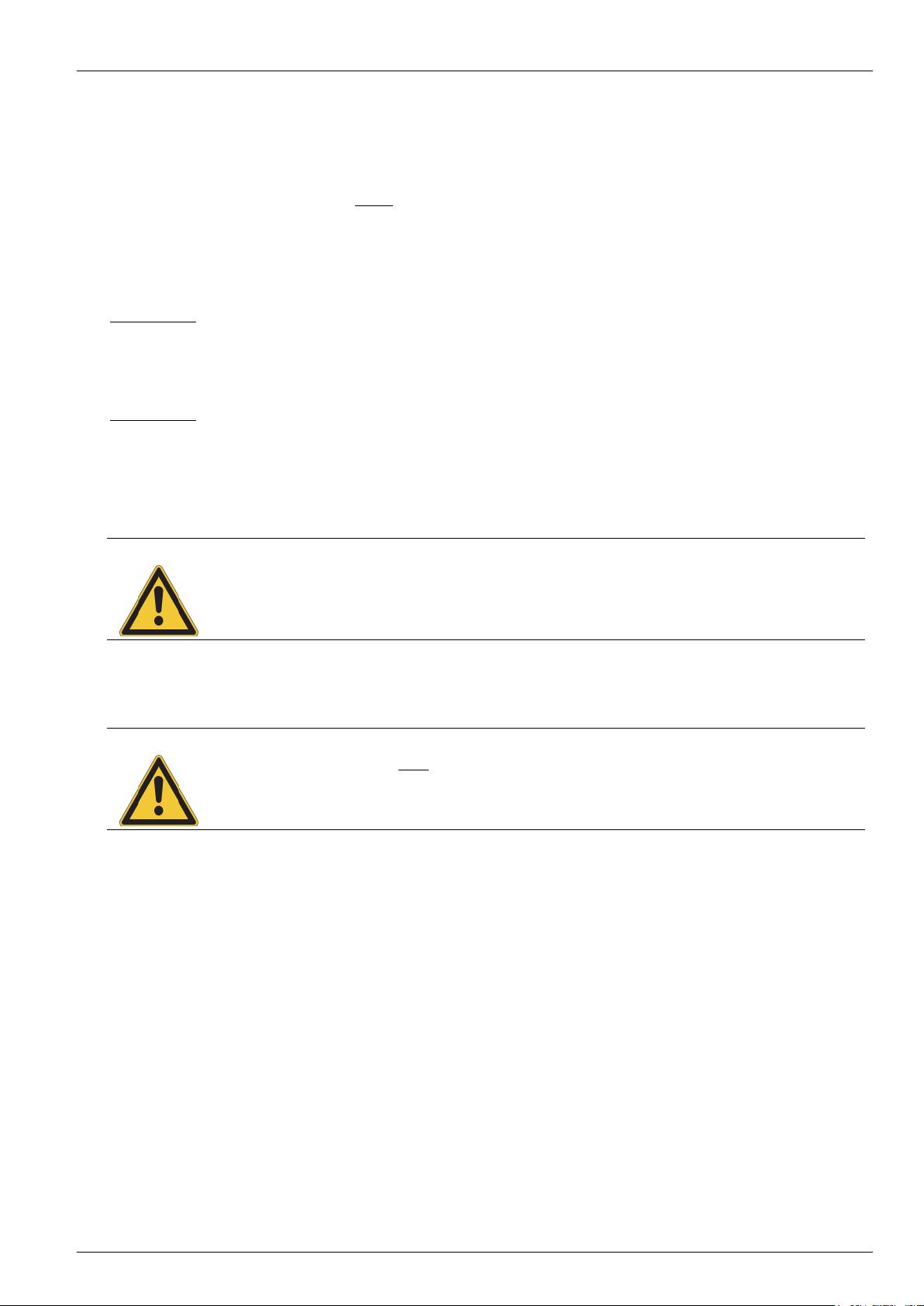

CAUTION

Children and the general public must be kept away from the equipment!

The equipment may only be used for the purpose intended by the manufacturer. Unauthorised

modifications and the use of spare parts and additional equipment which has not been

purchased from or recommended by the manufacturer of the device may cause fire, electric

shock and injury.

Keep these operating instructions in an accessible location and give them to all operators!

WARNING

This is a product with a restricted sale class as per IEC 61800-3. In a domestic environment this

product may cause high frequency interference, in which case the operator may be required to take

suitable measures.

An appropriate measure would be the inclusion of a recommended line filter.

UL File: E171342

1.5 Certifications

1.5.1 UL and cUL certification

(Use in North America)

“Suitable for use on a circuit capable of delivering not more than

5000 rms symmetrical amperes, 200…240 Volts or

380…480 Volts (three phase)” and “when protected by J class

fuses.” as indicated."

Suitable for use on a circuit capable of delivering not more than

5000A (symmetrical), 200...240V or 380...460 Volts (three

phase) and when protected by "J class fuses" as described in

Section 9.4.

NORDAC SK 750E frequency inverters have a motor overload

protection. Further technical details can be found in Section 9,

"Technical Data".

“Relays on extension units and customer interface units may

only be used at 230V ac maximum, same phase only.”

The relays of the extension units and customer interface units may only be used at max. 230V ac. The same

polarity must be used for all relays.

„Use 75°C Copper Conductor Only, Maximum Surrounding Air Temperature 50°C.”

"Copper cable with an insulation rating of at least 75°C must be used for connection. A maximum ambient

temperature of 50°C must be maintained.

Frequency inverter size1:

„The torque value for the field wiring terminals for mains circuit terminals and motor terminals must be 10.62 … 13.27 lb-in

(1.2 … 1.5Nm). The torque value for the supplemental terminal blocks, external brake resistor and thermal sensor must be

4.42 … 5.31 lb-in (0.5 … 0.6Nm).”

Frequency inverter size 1:

The tightening torque value for the terminals the mains and motor cables, must be between 10.62 … 13.27 lb-in

(1.2 … 1.5Nm). Control cable terminals, thermistor and PTC connections and connections to the brake resistor

must be tightened with 4.42 … 5.31 lb-in (0.5 … 0.6Nm).

Frequency inverter size2:

„The torque value for the field wiring terminals for mains circuit terminals and motor terminals must be 22.12 … 39.82 lb-in

(2.5 … 4.5Nm). The torque value for the supplemental terminal blocks and thermal sensor must be 4.42 … 5.31 lb-in

(0.5 … 0.6Nm). The torque value for the external brake resistor must be 10.62 … 13.27 lb-in (1.2 … 1.5Nm).”

Frequency inverter size 2:

The tightening torque value for the terminals the mains and motor cables, must be between 22.12 … 18.06 lb-in

(2.5 … 4.5Nm). Control terminal connections and thermistor/PTC connection must be tightened with

4.42 … 5.31 lb-in (0.5 … 0.6Nm).

BU 0750 GB-3311 Subject to technical amendments 9

1. General information

Page 10

NORDAC SK 750E Manual

1.5.2 European EMC Directive

If the NORDAC SK 750E is installed according to the recommendations in this

instruction manual, it meets all EMC directive requirements, as per the EMC product

standard for motor-operated systems EN 61800-3.

(See also Chapter 8.3 Electromagnetic compatibility [EMC].)

10 Subject to technical amendments BU 0750 GB-3311

Page 11

1. General information

NOTE

The nomenclature must always be provided in orders and for service and support cases!

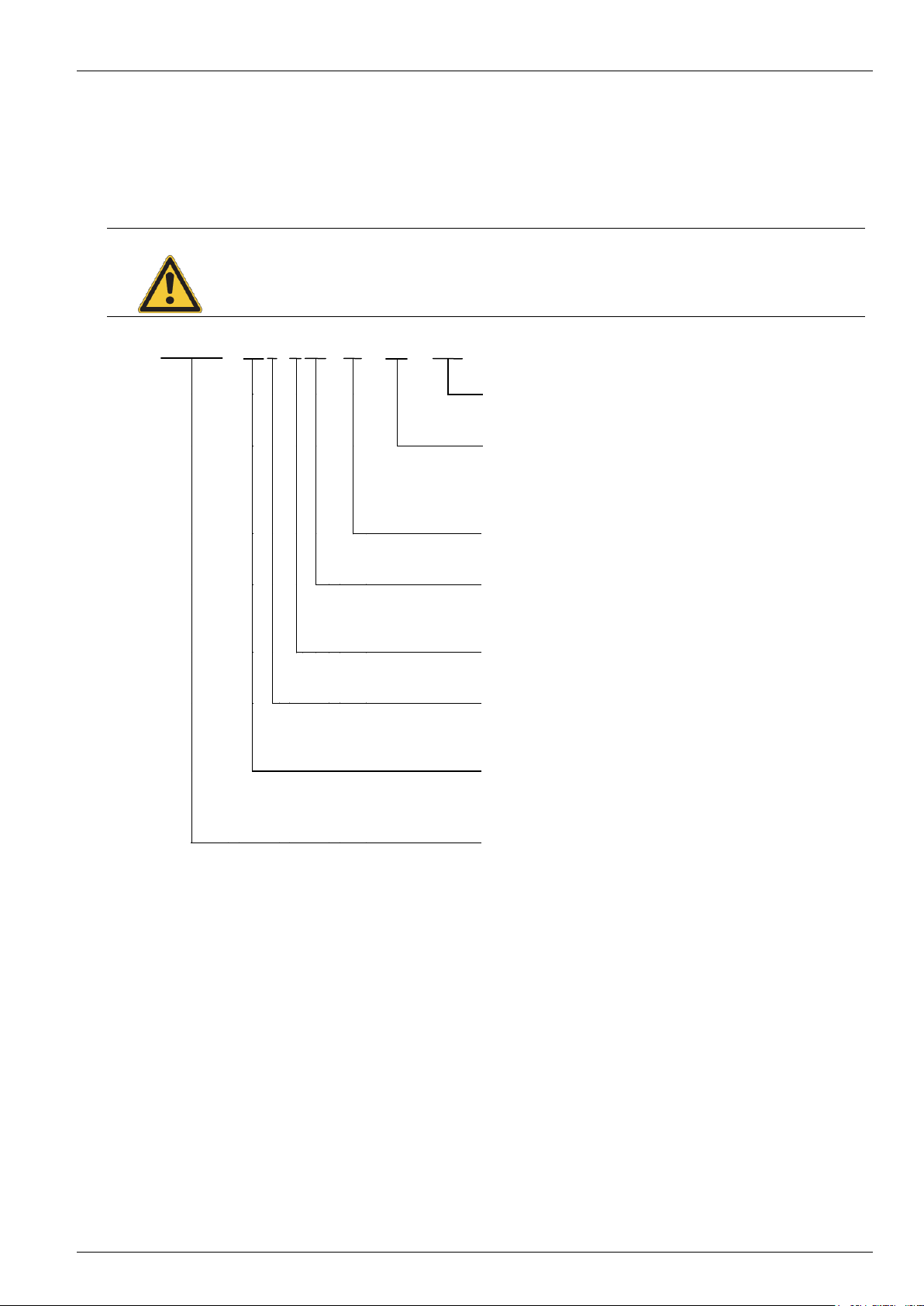

SK 750E

-

55 1 - 3 40 - A - W - ABC

Special device design

(3 letters)

IP protection class of frequency inverter:

space = IP54 version (air cooling)

W = IP65 version (Water cooling)

(incl. lacquered PCB cards)

Integrated noise suppression filter:

A = Class A

Mains voltage:

x23 = 230V

x40 = 400V

Number of mains phases:

3 = 3 phase

Digits before decimal point for power:

1 = 0x.x0

2 = xx.00

Device nominal power (xx):

55 = 5.50kW, …

22 = 22.00kW

Device series:

SK 750E

1.6 Nomenclature / Type code

The NORDAC SK 750E frequency inverter has a nomenclature with the same structure as for other NORDAC

frequency inverters. The information contained therein can be determined in the same way. The type

classification of the frequency inverter contains the device type, the nominal output, data on mains voltage, the

noise suppression filter, protection class and any special device designs.

BU 0750 GB-3311 Subject to technical amendments 11

Page 12

NORDAC SK 750E Manual

Note

The IP65 components and IP66 options (technology units) for the water cooled IP65 version have an

additional "-C" and are modified with the special measures listed below!

Note

With the the IP65 version it must be ensured that the cable lines and cable connections are carefully

matched so that no leaks occur in the SK 750E or any other problems occur that could affect the

maintenance of the IP65 protection class!

1.7 Version with protection class IP54 / IP65

TheNORDAC SK 750E frequency inverter can be ordered in any size and therefore any power stage with the

protection classes IP54 (air cooling) or IP65 (water cooling). These versions can be differentiated by the type

designation. The water cooled version has a "-W" (→ Water cooling) at the end of the type designation.

The protection classes IP54 or IP65 must always be stated when ordering!

The protection classes are determined by the type of cooling. With the air cooled device, the integrated fans

determine the protection class IP54; with the IP65 devices this is determined by the flange to the water cooling.

With the technology units, customer interfaces and special extensions there are no restrictions of functionality

between the IP54 and IP65 versions.

IP54 version:

The protection class IP54 applies for the air cooled SK 750E. Both versions (motor-integrated, close to motor)

are available. The standard modules of the SK 300E (SK TU2-…) and SK 700E (SK CU1-…, SK XU1-…) can

be inserted.

IP65 version:

The water cooled IP65 version has an additional "-W" (→ Water cooling). Both versions (motor-integrated,

close to motor) are also available. In addition, for IP65 devices the technology units (SK TU2-…-C) of the

SK 300E, have an additional "-C" (Coated → lacquered PCBs) in their type designation. As with the IP54

devices, the same standard modules of the SK 700E are inserted as customer interfaces (SK CU1-...) and

special extensions (SK XU1-...).

Special measures:

Coated circuit boards

12 Subject to technical amendments BU 0750 GB-3311

Page 13

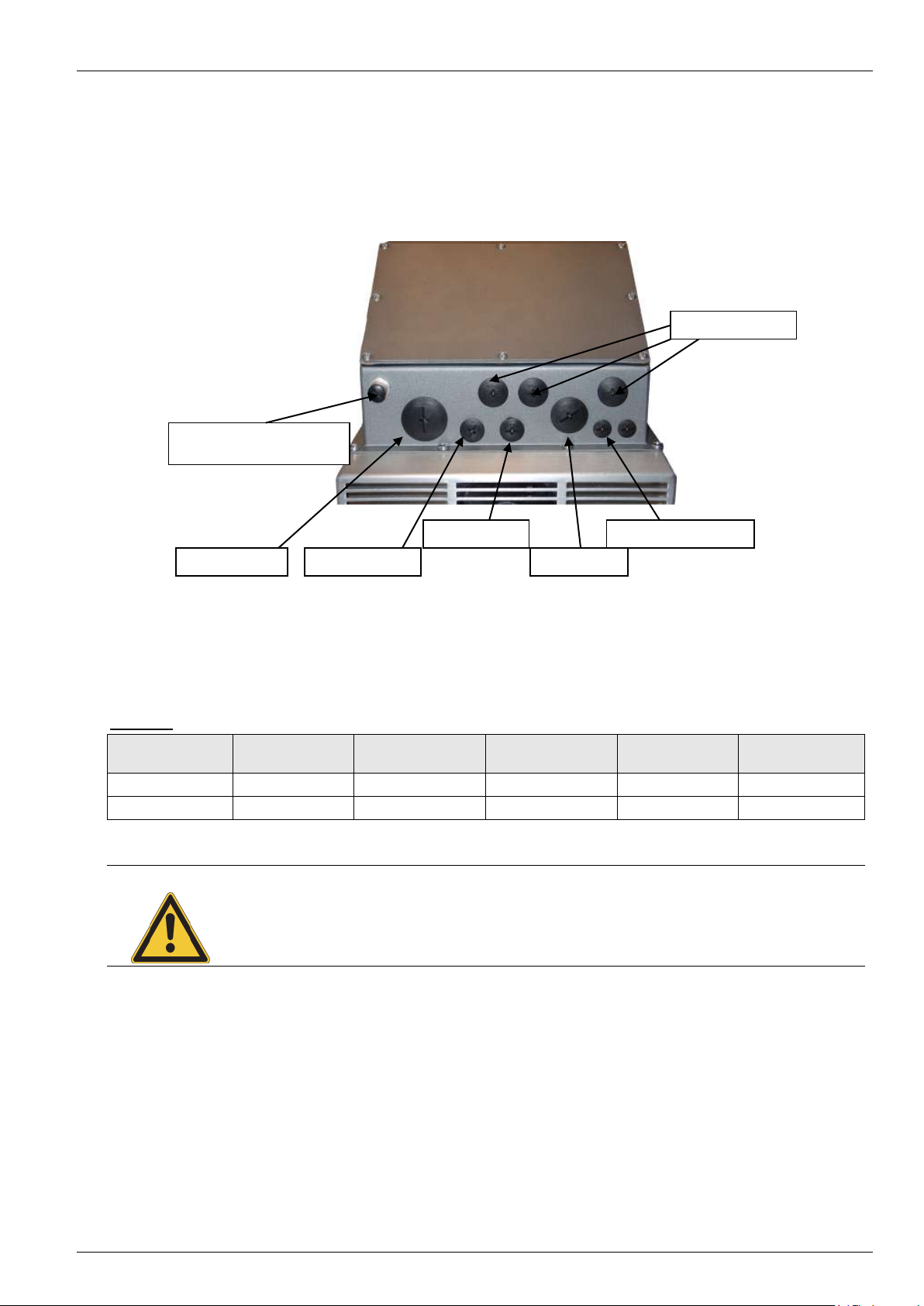

2 Assembly and installation

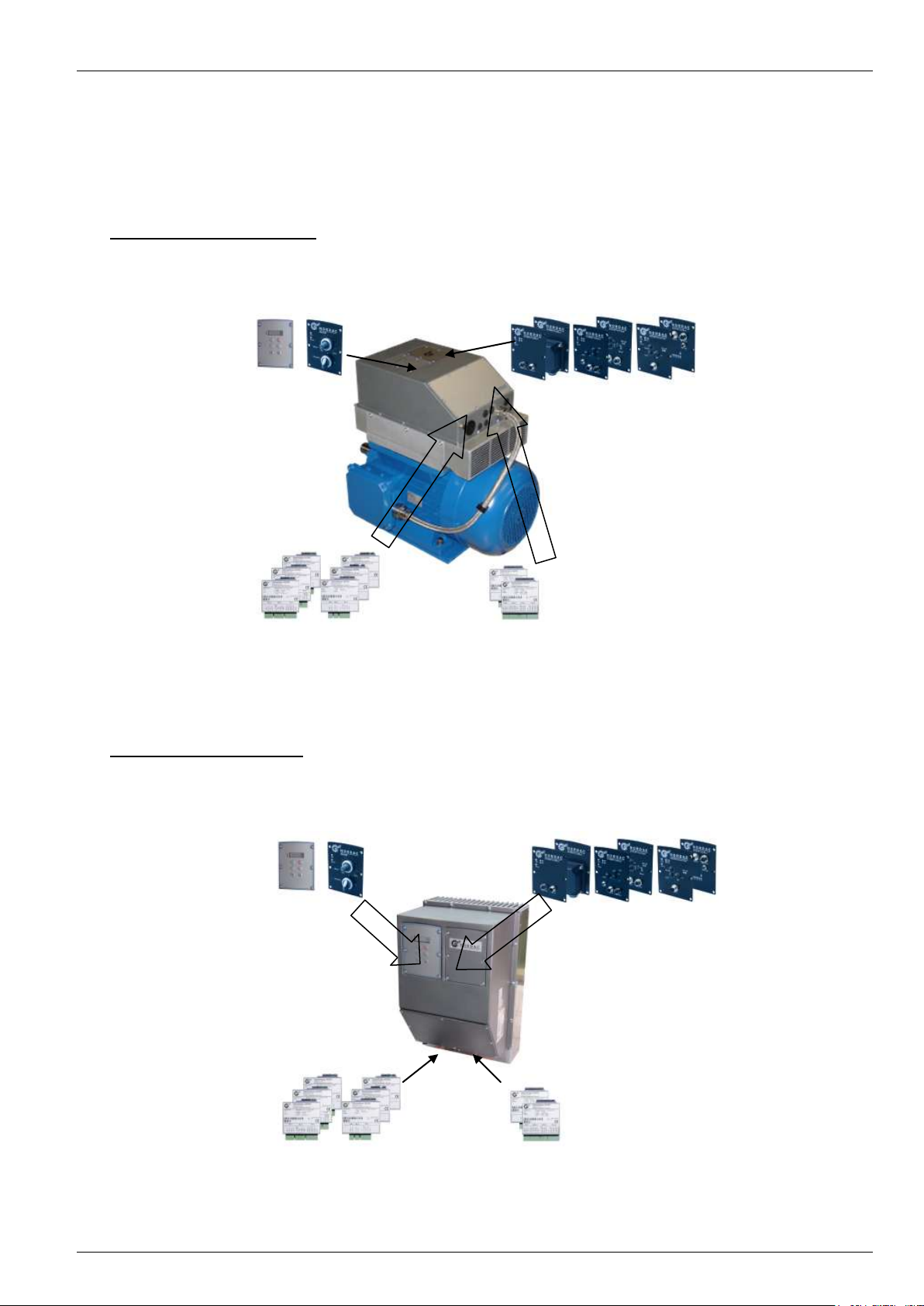

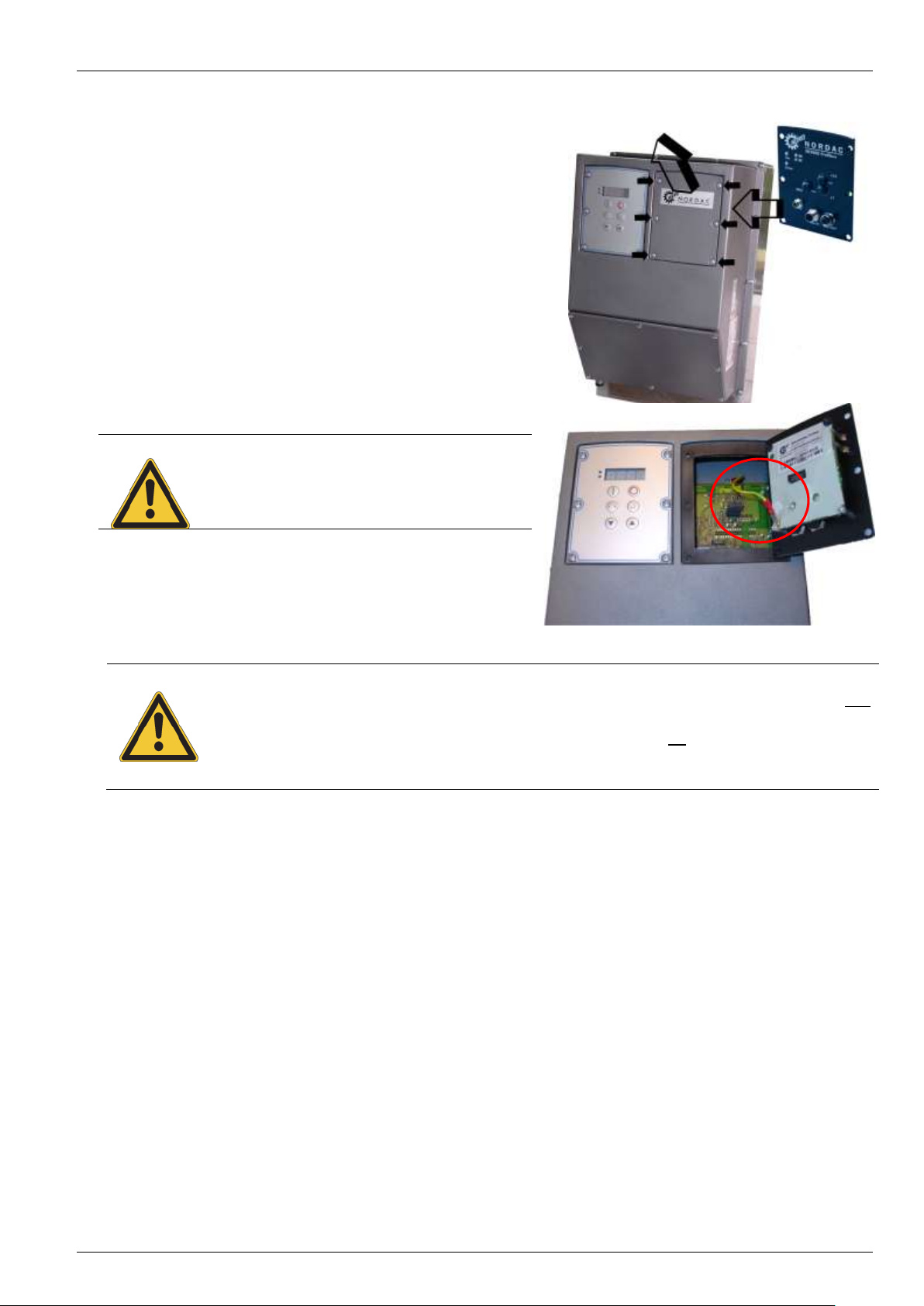

Motor-integrated version:

Fig.: SK 750E in IP54 version (air cooling)

Optional technology unit

SK TU2-CTR

SK TU2-POT

Optional technology unit

Bus modules

Optional customer unit

SK CU1-...

Optional special extension

SK XU1-...

Close-to-motor version:

Optional technology unit

SK TU2-CTR

SK TU2-POT

Optional technology unit

Bus modules

Optional customer unit

SK CU1-...

Optional special extension

SK XU1-...

Fig.: SK 750E in IP54 version (air cooling)

2 Assembly and installation

2.1 Motor-integrated and close to motor layouts

With the motor-integrated version the SK 750E frequency inverter is directly mounted on the motor by means

of an attachment frame and "mounting feet", which integrate it into the drive unit.

With the SK 750E close-to-motor version, the frequency inverter can be mounted close to the motor, i.e. on a

wall or a machine frame for example. A wall-mounting kit is required for this (see Section 2.5).

BU 0750 GB-3311 Subject to technical amendments 13

Page 14

NORDAC SK 750E Manual

100mm

100mm

2.2 Installation

NORDAC SK 750E frequency inverters are available in various sizes depending on their output. Attention must

be paid to a suitable position when installing.

The equipment requires sufficient ventilation to protect against overheating. For this the minimum guideline

distances from adjacent components above and below the frequency inverter, which could obstruct the air flow

apply. (above > 100 mm, below > 100 mm)

Mounting can be immediately next to each other. The installation position is normally vertical.

If several inverters are arranged above each other, it must be ensured that the upper air entry temperature limit

is not exceeded. (See also Section 9, Technical data). If this is the case, it is recommended that an "obstacle"

(e.g. a cable duct) is mounted between the inverters so that the direct air flow (rising warm air) is impeded.

Warm air must be vented above the device!

14 Subject to technical amendments BU 0750 GB-3311

Page 15

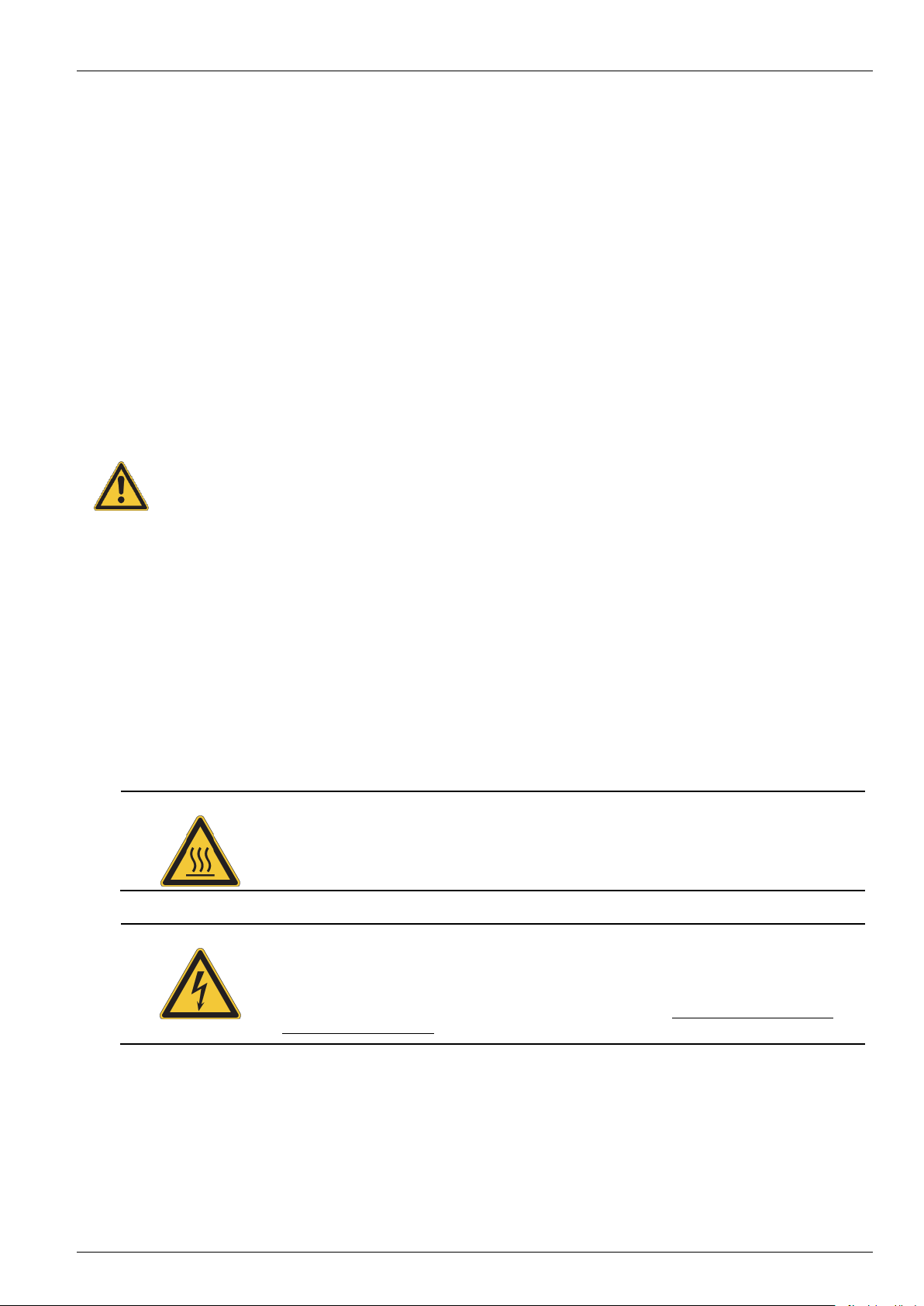

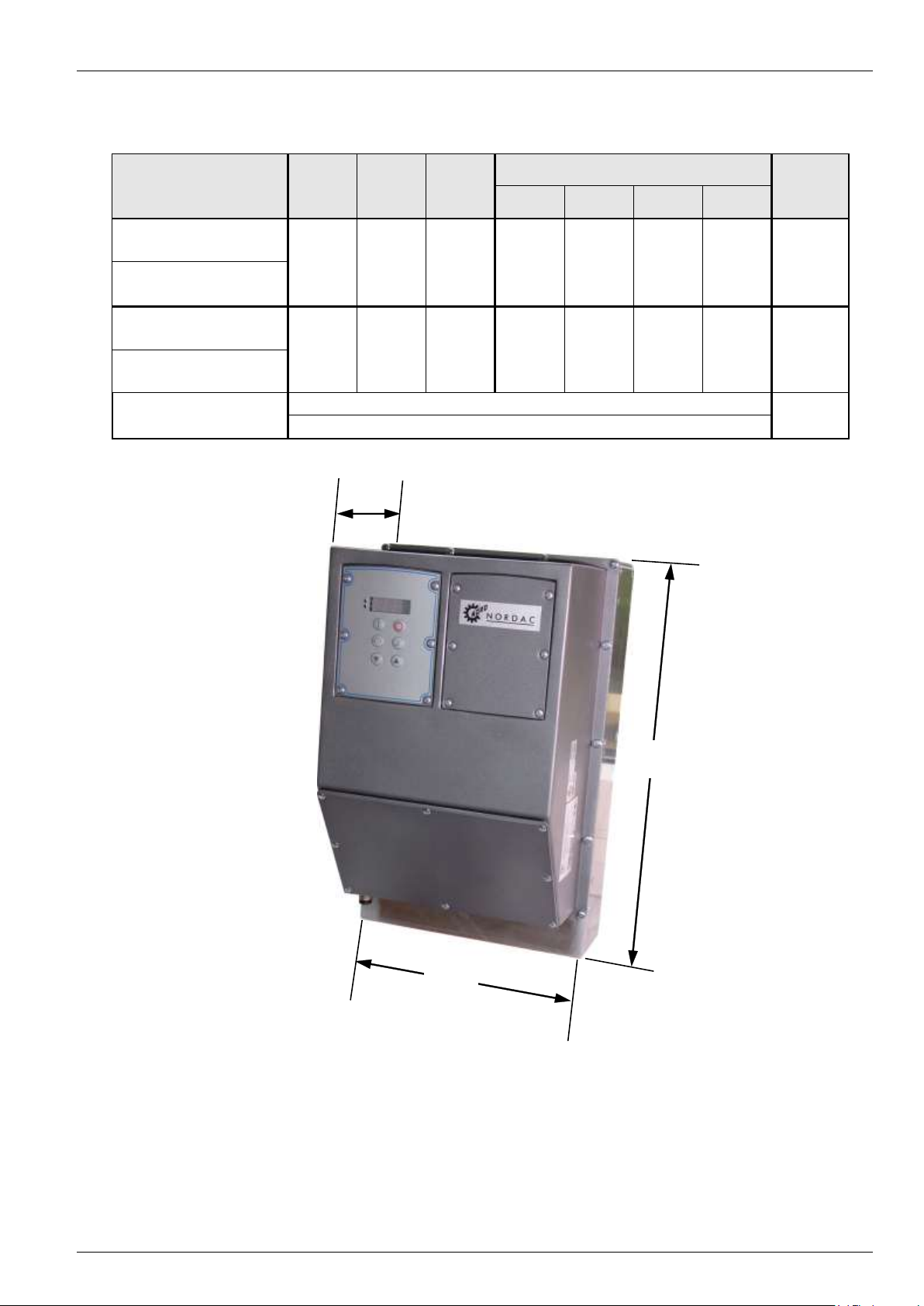

Frequency inverter type

L B D

Wall mounting kit (optional, Section 2.5)

Weight

L1

B1

L2

SK 750E-551-323-A …

SK 750E-751-323-A

414

372 *

255

237.5

165 *

443

401*

220.5

457.5

415.5*

6.5

18.0

SK 750E-551-340-A …

SK 750E-152-340-A

SK 750E-921-323-A …

SK 750E-112-323-A

472

430*

305

253

179 *

501

459*

270.5

516

474*

6.5

23.0

SK 750E-182-340-A …

SK 750E-222-340-A

All dimensions in [mm]

Approx.

[kg]

*) water cooled version

L

B

D

2.3 Dimensions of the SK 750E

2 Assembly and installation

BU 0750 GB-3311 Subject to technical amendments 15

Page 16

NORDAC SK 750E Manual

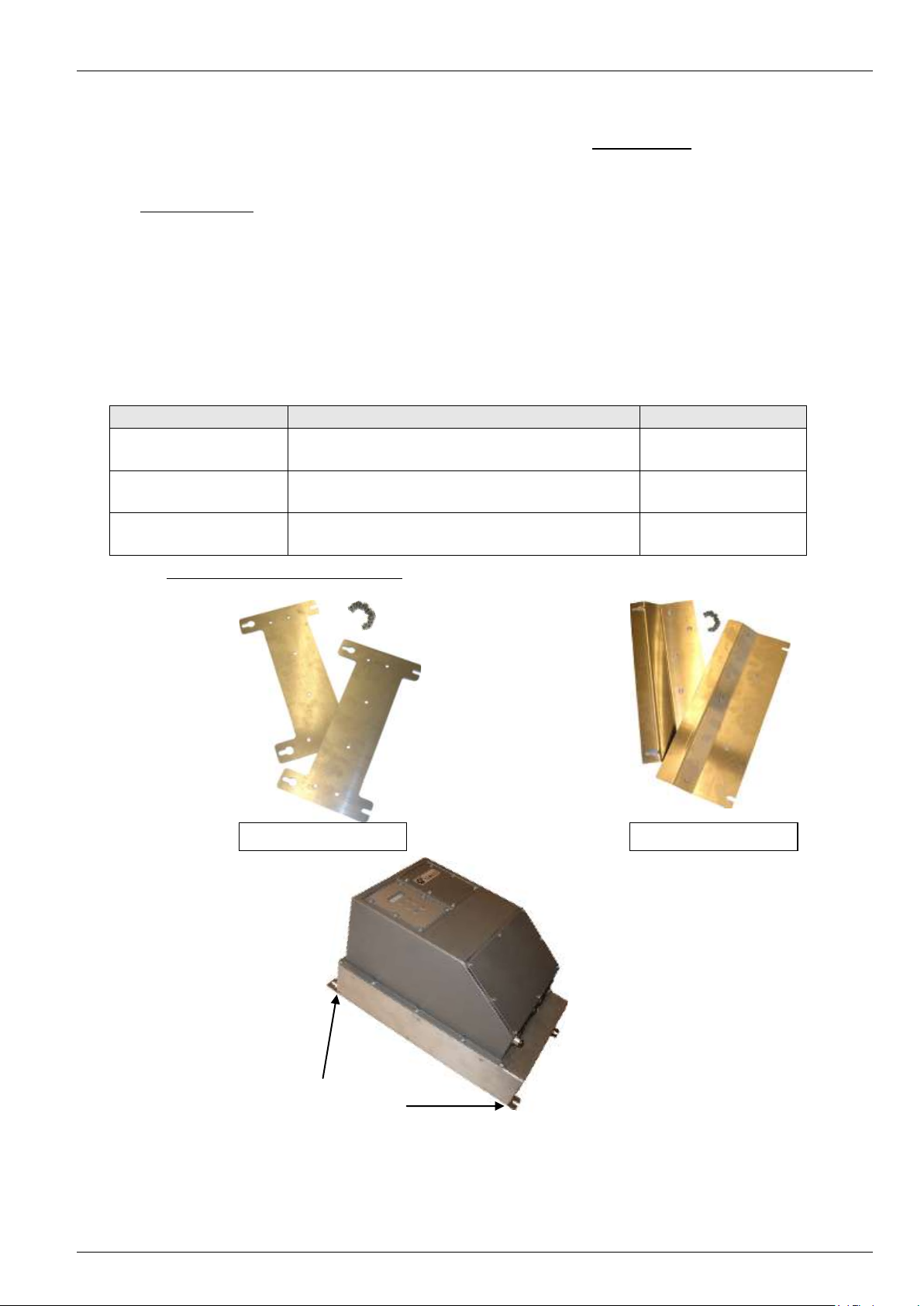

Type

for device

Part number

SK WMK-750E-Size 1

SK 750E-551-323-A (-W) ... SK 750E-751-323-A (-W)

SK 750E-551-340-A (-W) ... SK 750E-152-340-A (-W)

275219000

SK WMK-750E-Size 2

SK 750E-921-323-A ... SK 750E-112-323-A

SK 750E-182-340-A ... SK 750E-222-340-A

275219010

SK WMK-750E-Size 2-W

(in preparation)

SK 750E-921-323-A -W... SK 750E-112-323-A-W

SK 750E-182-340-A -W... SK 750E-222-340-A-W

275219020

(in preparation)

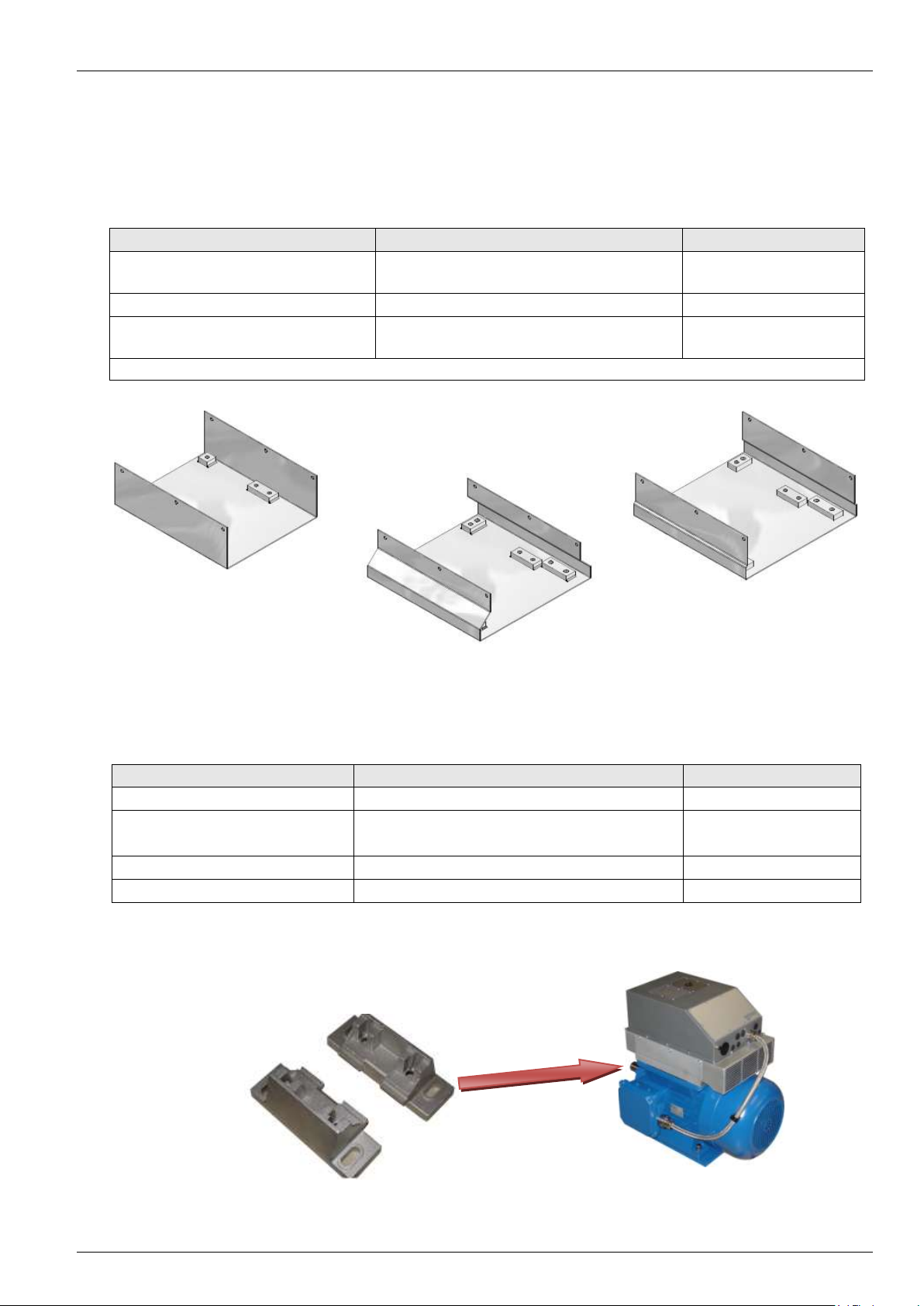

SK WMK-750E-Size 1

SK WMK-750E-Size 2

Components of the wall mounting kits:

Wall mounting kit:

SK WMK-750E-Size 1

2.4 Attachment accessories for the SK 750E

1. Wall mounting, SK WMK-750E Size 1 or. ...Size 2: For the close-to-motor version of the SK 750E

frequency inverter, attachment to a suitable mounting surface is by means of an optional mounting bracket.

2. Motor mounting: Alternatively, there is the possibility of direct mounting on NORD DS standard motors

(motor-integrated version). Additional mounting material is required for this.

2.5 SK 750E wall mounting kit

For use of the SK 750E frequency inverter close to the motor, the wall mounting kit enables the geared motor

and the frequency inverter to be installed separately. For wall mounting of the SK750E, 2 suitable brackets are

required, which can be ordered as accessories. These are screwed to the rear of the SK 750E with the

fastening material provided. Both of the wall mounting kits comply with protection classes IP54 or IP65. The

same wall mounting kit is required for Size 1 air cooled and water cooled versions. For Size 2, there are

differences in the wall mounting kits for the two versions.

16 Subject to technical amendments BU 0750 GB-3311

Page 17

Note

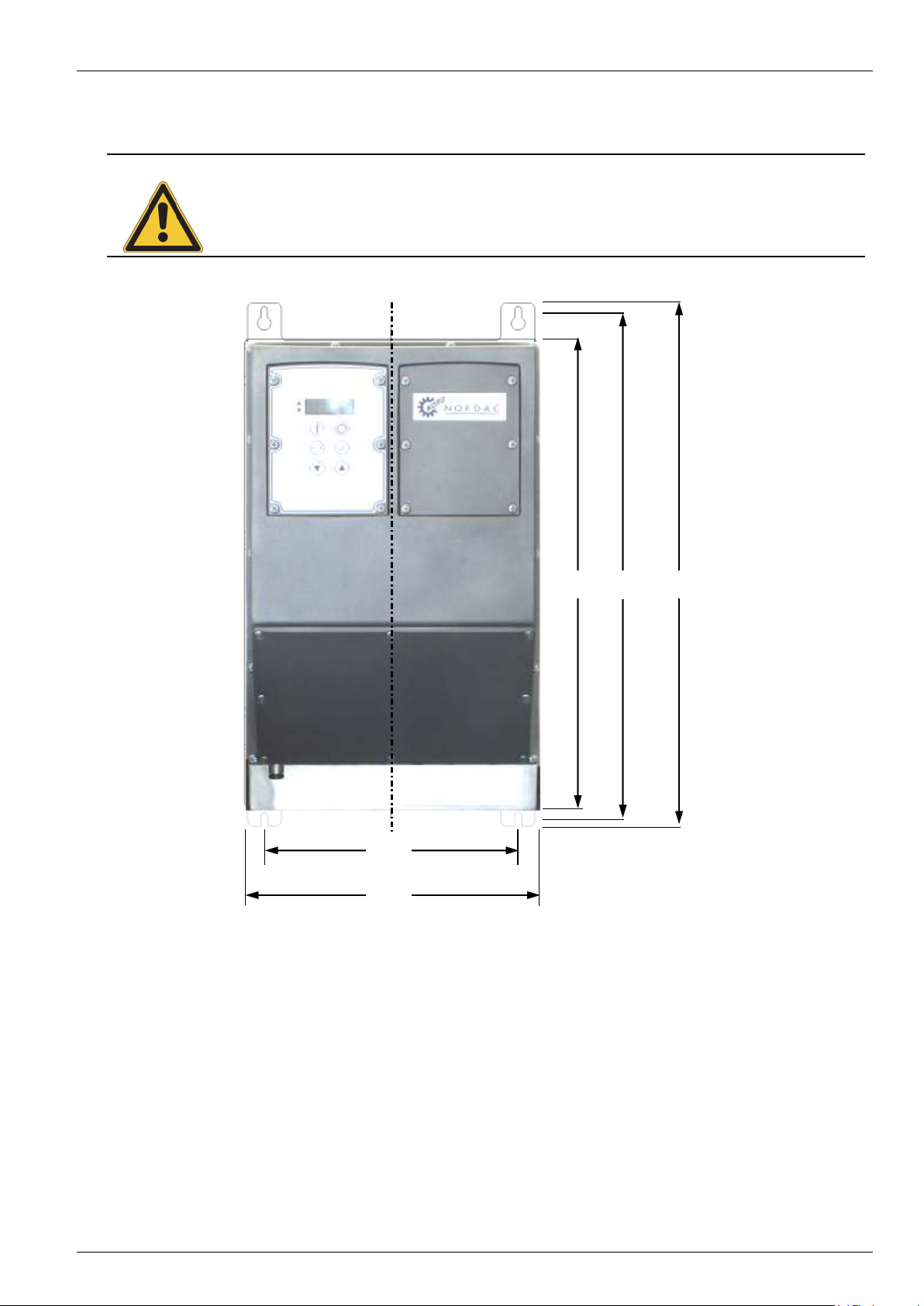

Please refer to the table in Section 2.2 for the dimensions.

B1

B

L

L2

L1

Fig.: SK 750E with SK WMK-750E-Size 1

2.5.1 Dimensions of the SK 750E with wall mounting kit

2 Assembly and installation

BU 0750 GB-3311 Subject to technical amendments 17

Page 18

NORDAC SK 750E Manual

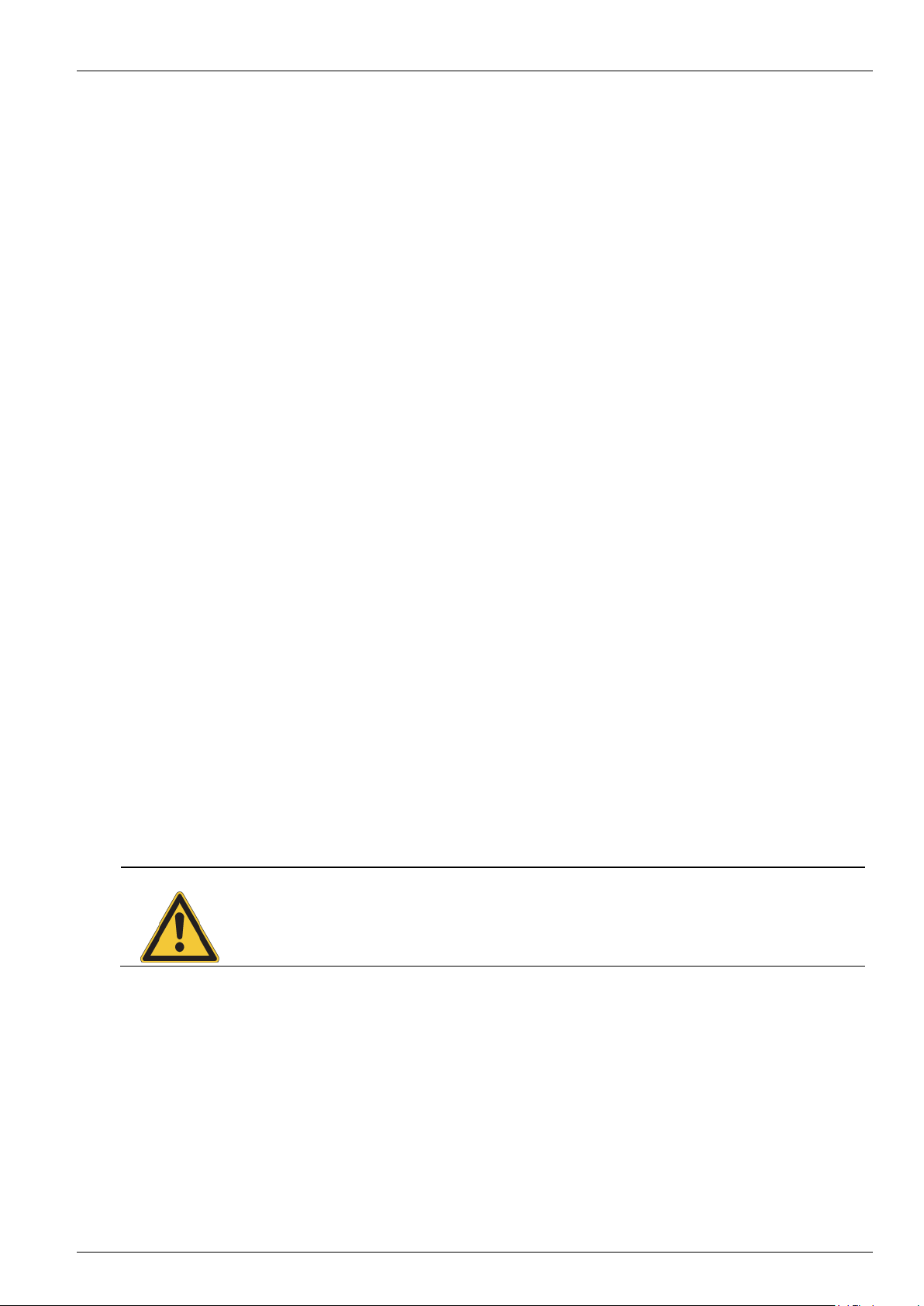

Attachment frame

for device

Part number

Attachment frame 750E-Size 1-IEC132

SK 750E-551-323-A ... SK 750E-751-323-A

SK 750E-551-340-A ... SK 750E-751-340-A

275218000

Attachment frame 750E-Size 1-IEC160*

SK 750E-112-340-A ... SK 750E-152-340-A

275217000

Attachment frame 750E-Size 2-IEC160*

SK 750E-921-323-A ... SK 750E-112-323-A

SK 750E-182-340-A ... SK 750E-222-340-A

275216000

*Also suitable for motor size IEC132

Attachment frame 750E-Size 1-IEC132

Attachment frame 750E-Size 1-IEC160

Attachment frame 750E-Size 2-IEC160

Part number

Motor size

Number per drive unit

16630900

132

2

17481000 ("Foot")

160, 180MX, 180LX (Siemens)

2

17181010 (Screw set)

4

17430900

160 L, 160 LH, 160 MH, 180MX, 180LX (NORD)

2

17130900

160M (NORD)

2

2.6 Mounting of the SK750E directly on a motor

For motor-mounted (motor-integrated) use of the SK 750E frequency inverter direct installation of the geared

motor and the frequency inverter is possible using the attachment frame and the additional "motor mounting

feet". Three different attachment frames are available for mounting on the various sizes of motor (132, 160,

180MX/LX).

The number and version of the attachment feet to be used depends on the type of motor and can be obtained

from the following table.

Example: "Attachment feet" for size 132 motor, Part No. 16630900:

18 Subject to technical amendments BU 0750 GB-3311

Page 19

2 Assembly and installation

NOTE

The control cables, line cables and motor cables must be laid separately. Under no circumstances

may they be laid in the same protective conduit or cable duct.

The test equipment for high voltage insulation must not be used for cable which are connected to

the frequency inverter.

2.7 Wiring guidelines

The frequency inverter has been developed for use in an industrial environment. In this environment, high

levels of electromagnetic interference can influence the frequency inverter. In general, correct installation

ensures safe and problem-free operation. To meet the limiting values of the EMC directives, the following

instructions should be complied with.

1) Ensure that all equipment in the control cabinet or field is securely earthed using short earthing cables

which have large cross-sections and are connected to a common earthing point or earthing rail. It is

especially important that every control device connected to the frequency inverters (e.g. an

automation device) is connected, using a short cable with large cross-section, to the same earthing

point as the inverter itself. Flat conductors (e.g. metal clamps are preferable, as they have a lower

impedance at high frequencies.

2) The PE lead of the motor controlled by the frequency inverter must be connected as directly as

possible to the earth connection of the cooling element, together with the PE of the corresponding

frequency inverter mains supply. The presence of a central earthing bar in the control cabinet and the

grouping together of all bonding conductors to this bar normally ensures safe operation. (See also

Chapter 8.3/8.4 EMC guidelines)

3) Where possible, shielded cables should be used for control circuits. The shielding at the cable end

should be carefully sealed and it must be ensured that the wires are not laid over longer distances

without shielding.

The shields of analog setpoint cables should only be earthed on one side on the frequency inverter.

4) The control cables should be installed as far as possible from power cables, using separate cable

ducts, etc. Where cables cross, an angle of 90° should be ensured as far as possible.

5) Ensure that the contactors in the cabinet are interference protected, either by RC circuits in the case

of AC contactors or by free-wheeling diodes for DC contactors, for which interference suppressors

must be connected to the contactor coils. Varistors for over-voltage limitation are also effective.

This interference suppression is particularly important when the contactors are controlled by the relay

in the frequency inverter.

6) Shielded or protected cables should be used for load connections (motor cable) and the

shielding/protection should be earthed at both ends, if possible directly to the frequency inverter

PE/EMC terminal.

In addition, EMC-compliant wiring must be ensured. (see also Section 8.3/8.4 EMC). If required, an

optional integrated motor filter is available.

7) Select the lowest possible switching frequency. This will reduce the intensity of the electromagnetic

interference produced by the frequency inverter.

The safety regulations must be complied with under all circumstances when

installing the frequency inverter!

BU 0750 GB-3311 Subject to technical amendments 19

Page 20

NORDAC SK 750E Manual

WARNING

NOTE

THESE DEVICES MUST BE EARTHED.

Safe operation of the devices requires that is installed and commissioned by qualified

personnel in compliance with the instructions provided in this Manual.

In particular, the general and regional installation and safety regulations for work on

high voltage systems (e.g. VDE) must be complied with as must the regulations

concerning correct use of tools and the use of personal protection equipment.

Dangerous voltages can be present at the motor connection terminals even when the

inverter is switched off. Always use insulated screwdrivers on these terminal fields.

Ensure that the input voltage source is not live before setting up or changing

connections to the unit.

Make sure that the inverter and motor have the correct supply voltage set.

Switching of the motor or brake resistor cable in not permitted when they are

connected to a voltage.

PE

L1

L2

L3

PE L1 L2 L3

+B -B PE

U V W PE

T1 T2

M

3 ~

Mains connection

a) 3 ~ 220-240V ~

b) 3 ~ 380-440V ~

c) 3 ~ 460/480V ~

Brake resistor

connection

R = 10-40Ω

for further

details see

Section

9.2/9.3

3~ motor

connection

Star/Delta

Temperature

sensor

(PTC)

+Br -Br PE

Electro-

magnetic

brake coil

a) 105V =

b) 180V =

c) 205V =

2.8 Electrical Connection

2.9 Electrical connection of power unit

The line, motor, brake resistor and control connections are located on the underside of the device. To gain

access to the terminals, the device covers (cover and terminal cover) must be removed. The connection

terminals are now accessible from the front or from above. The cables must be fed into the frequency inverter

via suitable screw fittings and pretected from tension. All covers must be put back in place before switching on

the supply voltage!

20 Subject to technical amendments BU 0750 GB-3311

Page 21

2 Assembly and installation

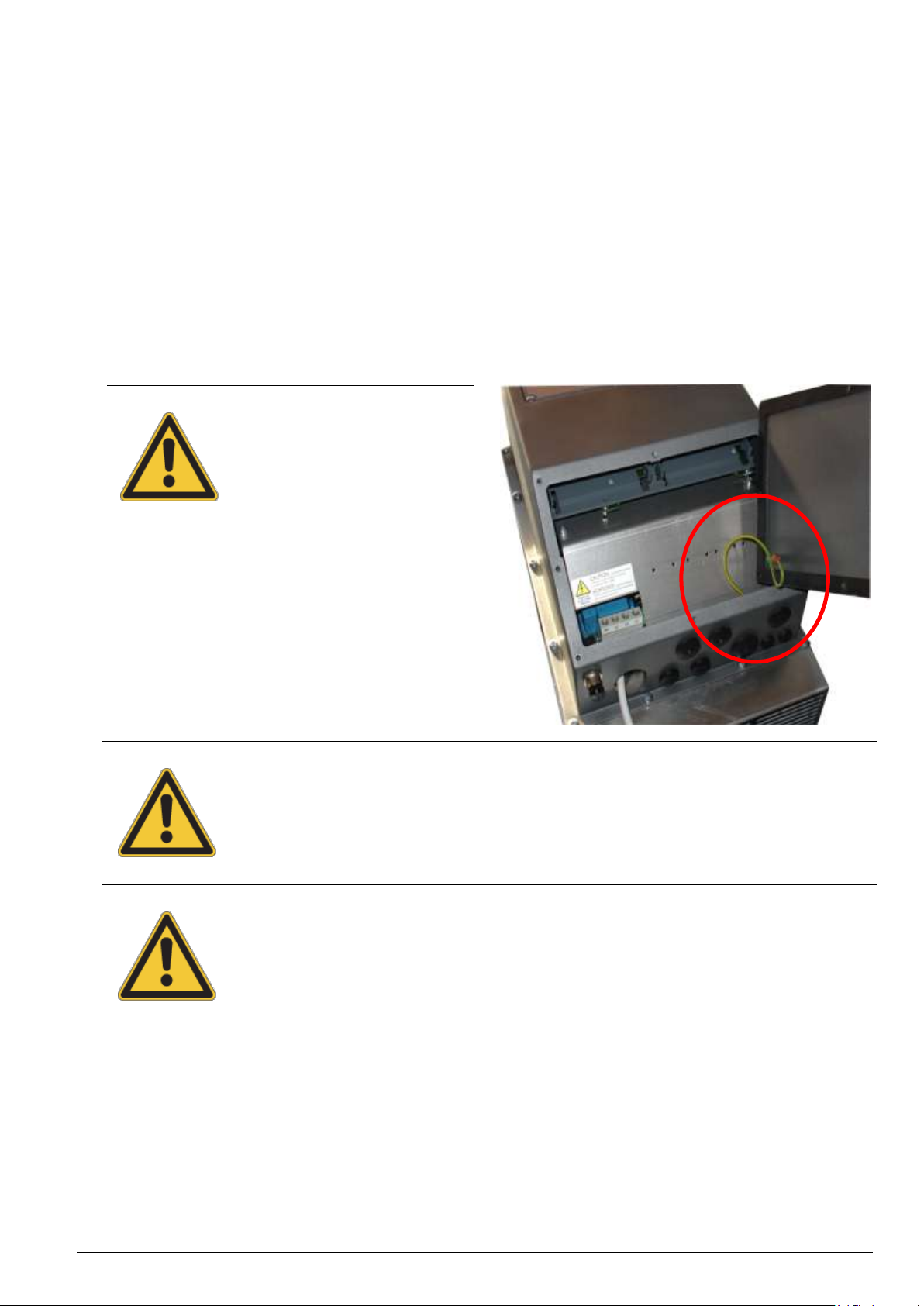

ATTENTION

Proper earthing must be ensured for

all metal covers. Otherwise the

frequency inverter must not be put

into operation (see illustration).

NOTE

If using certain wire end sleeves are used, the maximum cross-section which can be connected can

be reduced.

NOTE

If synchronous machines are connected or several motors are connected in parallel, the

frequency inverter must be operated with linear voltage/frequency characteristic curves,

P211 = 0 and P212 = 0.

Before connecting the device, the following must be observed:

1. Ensure that the voltage source provides the correct voltage and is suitable for the current required (see

Section 9 Technical data). In addition, care must be taken that suitable power switch with the specified

rated current range is installed between the voltage source and the frequency inverter.

2. Connect the mains voltage directly to the mains terminals L1 - L2 - L3 and connect the earth (PE).

3. A four-core cable must be used to connect the motor. The cable must be connected to the motor terminals

U - V - W and the PE.

4. If shielded motor cables are used (recommended), the cable shielding must also be connected to a large

area of the metal screw fittings.

Note: The use of shielded cables is essential in order to maintain the specified radio interference

suppression level. (See also Section 10.5 EMC limit value classes)

Usually, the line, motor and brake resistor cables are

connected first as their terminals are located on the

bottom circuit board. The various metric screw

fittings on the underside of the device are used as

cable glands (see 2.9.7 Cable Glands)

BU 0750 GB-3311 Subject to technical amendments 21

Page 22

NORDAC SK 750E Manual

Mains input voltage (AC)

Brake coil voltage (DC)

400V ~

180V =

460V ~ ... 480V ~

205V =

230V ~

105V =

2.9.1 Mains supply (PE, L1, L2, L3)

No special safety devices are required on the mains input side for the frequency

inverter, the use of the normal mains protection (see 9 Technical Data) and a

master switch or contactor is recommended.

Note: Use of this frequency inverter on an IT network is possible after minor

modifications. Please consult your supplier.

2.9.2 Electromagnetic brake (+Br, -Br, PE)

An output voltage is generated by the frequency inverter at the terminals

-Br/+Br to actuate an electromechanical motor brake (see Section 2.9,

Electrical connections to the power unit).

This depends on the supply voltage present in the frequency inverter. The

assignment is as follows:

Note: The allocation of the correct brake or brake coil voltage must be

taken into account in the design with reference to the mains

voltage of the frequency inverter.

2.9.3 Brake resistor (+B, -B, PE)

During dynamic braking (frequency reduction) of a three-phase motor,

electrical energy is returned to the inverter. In order to avoid overcurrent

switch-off of the frequency inverter, the integrated brake chopper can convert

the returned energy into heat by connection of an external braking resistor.

The connection for the frequency inverter → brake resistor should be

shielded and as short as possible.

Switching of this connection must only be made when no voltage is present!

Note: The possible generation of large amounts of heat in the braking

resistor must be taken into account.

2.9.4 Motor cable (U, V, W, PE)

The motor cable maximum length of 150m (Please note also Section 10.5 EMC

limit value classes). If a shielded motor cable is used, or the metallic cable duct is

well earthed, the maximum length of 50m should not be exceeded. For longer

cable lengths, the frequency inverter can be equipped with an optional internal

motor filter (at extra charge).

Switching (contactor or motor protection switch) at the output (U, V, W), is not

permitted while the frequency inverter is delivering current!

Note: For multiple motor operation the total cable length consists of the sum

of the individual cable lengths. If the sum of the cable lengths is too

large, an optional internal motor filter should also be ordered.

22 Subject to technical amendments BU 0750 GB-3311

Page 23

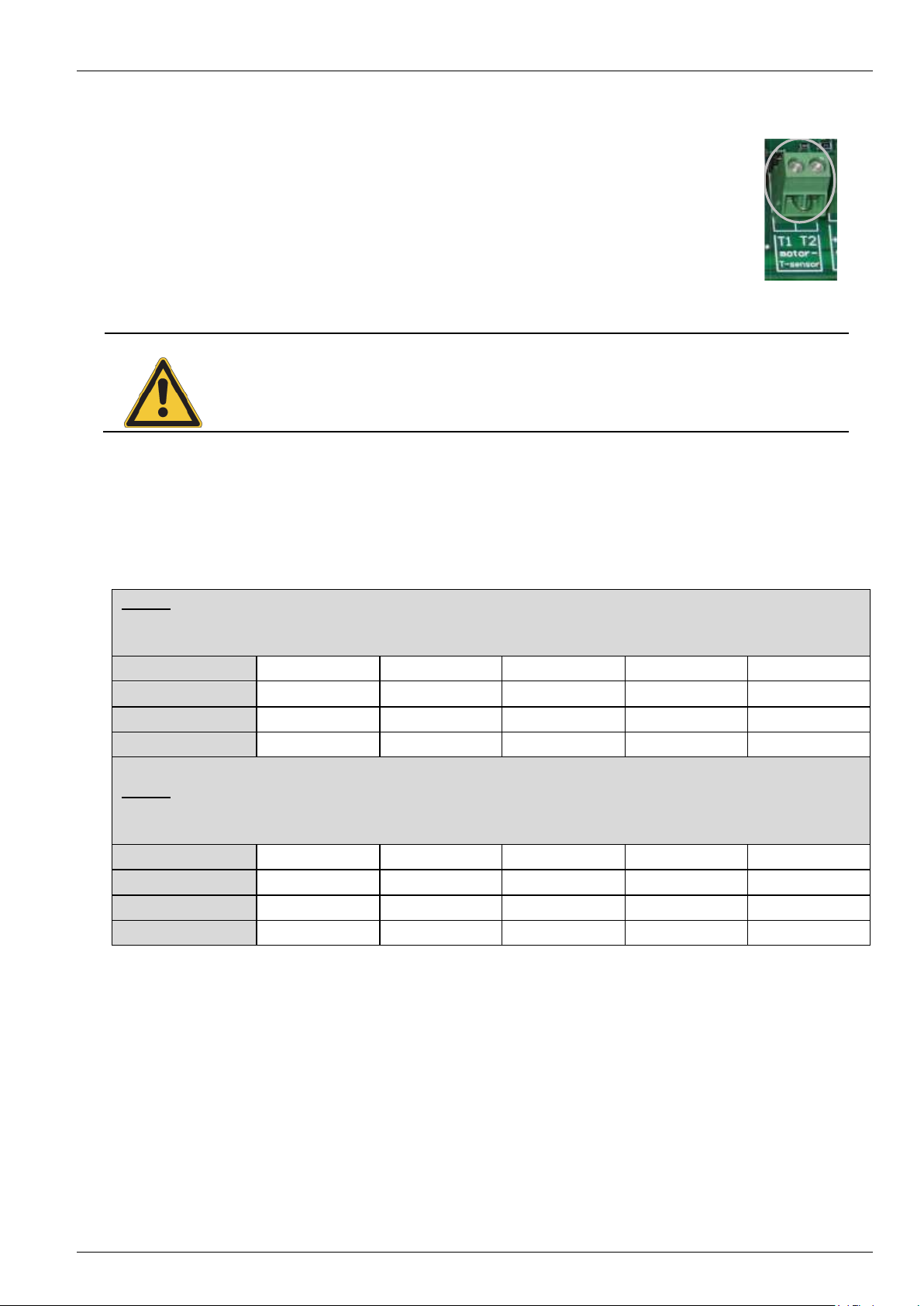

2 Assembly and installation

NOTE

The cable routing of the control cables or temperature sensor should always be separate from the

motor cable and be made with shielded cables.

Internal switching in the inverter prevents excessive voltage to the thermistor. Further details can be

found in Section 8, Error messages.

Size 1:

SK 750E-551-323-A ... SK 750E-751-323-A (5.5 / 7.5kW, 230V)

SK 750E-551-340-A ... SK 750E-152-340-A (5.5 … 15kW, 400V)

Terminal block

Mains input

Mech. Brake

Brake resistor

Motor output

Temp. Sensor

VDE rigid

0.5 - 16mm²

0.2 - 6mm2

0.2 - 6mm²

0.5 - 16mm²

0.14 - 2.5mm²

VDE flexible

0.5 - 10mm²

0.2 - 4mm2

0.2 - 4mm²

0.5 - 10mm²

0.14 - 2.5mm²

UL/cUL

AWG 20-6

AWG 24-10

AWG 24-10

AWG 20-6

AWG 26-14

Size 2:

SK 750E-921-323-A ... SK 750E-112-323-A (9.2 / 11kW, 230V)

SK 750E-182-340-A ... SK 750E-222-340-A (18.5 / 22kW, 400V)

Terminal block

Mains input

Mech. Brake

Brake resistor

Motor output

Temp. Sensor

VDE rigid

0.5 - 35mm²

0.2 - 6mm2

0.5 - 16mm²

0.5 - 35mm²

0.14 - 2.5mm²

VDE flexible

0.5 - 25mm²

0.2 - 4mm2

0.5 - 10mm²

0.5 - 25mm²

0.14 - 2.5mm²

UL/cUL

AWG 20-2

AWG 24-10

AWG 20-6

AWG 20-2

AWG 26-14

2.9.5 Temperature sensor (T1, T2)

This input can be used to evaluate a temperature sensor (thermistor or temperaturecontrolled switch) in order to prevent overheating.

If the thermistor has a high resistance or the temperature controlled switch opens, the

frequency inverter switches off and reports a motor overtemperature error (E001).

If no temperature sensor is used, terminals T1 and T2 must be bridged.

An error message can be acknowledged by switching the mains off and on again, or by

pressing the ENTER key on a control display (ControlBox or ParameterBox).

Evaluation of a temperature sensor is also possible by means of the optional customer units (SK CU1-...).

Further details can be found in Section 3.3, Overview of customer units.

2.9.6 PowerConnection Terminals

BU 0750 GB-3311 Subject to technical amendments 23

Page 24

NORDAC SK 750E Manual

NOTE

All control voltages refer to a common reference potential 0V / GND.

If necessary, 5 / 15V can be taken from several terminals. The sum the currents must not exceed

300mA.

2.9.7 Control connections (optional)

The manner and type of control unit connections are dependent on the options chosen (customer unit / special

extension unit). The possible variants are described in Section 3.3/3.4.

Here you will find general data and information on all customer units and special extension units.

Connection terminals: - Plug-in clip connectors can be released with a small screwdriver

Maximum

connection cross-section: - 1.5mm2 or 1.0mm2 (AWG 26-14 or 26-16), according to option

Cable: - laid separately from the mains/motor cables and shielded

Control voltages: - 5V, max. 300mA, for the supply of a ParameterBox SK PAR-2H

(Short-circuit proof) - 10V, max. 10mA, reference voltage for an external potentiometer

- 15V, max. 300mA, for the supply of digital inputs or an incremental or

absolute encoder

- analog output 0 - 10V, max. 5mA for an external display unit

24 Subject to technical amendments BU 0750 GB-3311

Page 25

2 Assembly and installation

Line input

Brake resistor

Motor output

RS485 interface

→ SK PAR-2H connection

Temperature sensor

Control level

Fig.: Air cooled SK 750E, Size 1

Mech. Brake

Size

Line input

Motor output

Control level

Brake resistor

Temperature

sensor

Size 1

M32

M25

3x M25

2x M16

2x M12

Size 2

M40

M32

3x M25

2x M16

2x M12

NOTE

For operation with an SK 750E, the motor should be equipped with a temperature sensor.

2.9.8 Cable connections

With the cable connections, a differentiation must be made between Size 1 and Size 2 of the SK 750E

frequency inverter. Both have different cable connections for the line input and the output from the frequency

inverter to the motor (see the table below). The cable connections for the control level, control of the brake

resistor and the temperature sensor input are the same for both sizes.

Available cable connections for Size 1 and 2:

BU 0750 GB-3311 Subject to technical amendments 25

Page 26

NORDAC SK 750E Manual

WARNING

Modules must not be inserted or removed unless the device is free of voltage. The slots must only

be used for the intended modules.

Installation of a technology unit separate from the frequency inverter is not possible. It must be connected

directly to the frequency inverter.

NOTE

3 Options

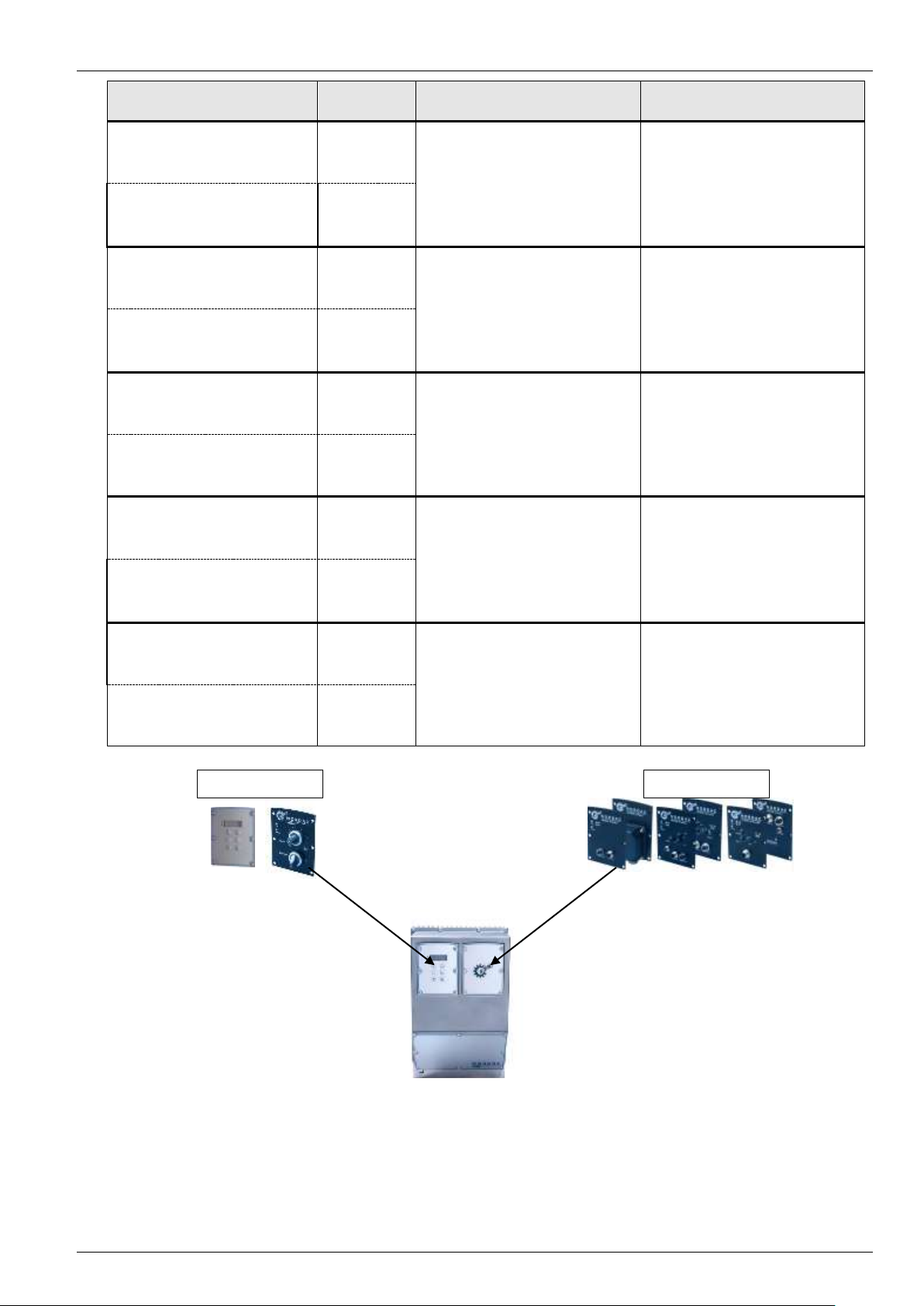

3.1 Modular options

By combining various modules for display, control and parameterisation, the NORDAC SK 750E can be easily

adapted to various requirements.

Modules are available for processing analog and digital signals and for all common Bus systems.

Alphanumerical display and operating modules can be used for simple commissioning. For more complex

tasks, various connections to a PC or an automation system can be selected.

Technology units (Technology Unit, SK TU2-...) are located on the frequency inverter and are accessible

from the outside for manual control or parameterisation, or to provide connection to field bus systems.

Customer interfaces (Customer Unit, SK CU1-...) are installed inside the frequency inverter. These allow

control with analog and digital signals or connection to the bus systems.

Special extension units (Extension Unit, SK XU1-...) include special functions such as speed control with

incremental encoders or position control with incremental or absolute encoders.

Further detailed information can be found in the Options manuals.

- www.nord.com –

26 Subject to technical amendments BU 0750 GB-3311

Page 27

3.2 Overview of Technology Units

ATTENTION

Left / right TU slot

When inserting the technology units, the left and right slots must be considered separately. The

left hand slot must only be used for the ControlBox or PotentiometerBox control unit. The right

hand slot can be used for all modules. Combined operation of the PotentiometerBox and the

ControlBox is not possible!

ATTENTION

The technology units SK TU2-… are available for protection class IP55 and technology units

SK TU2-…-C for IP66. It must be noted that the functionality and dimensions of the technology

units are identical for the IP55 and IP66 versions. However, with the IP66 version special

measures, such as coated PCBs are used in order to comply with the protection class.

Technology unit

SK TU2-...

Protection

class

Description

Data

ControlBox

SK TU2-CTR

Part. No. 275130130

IP55

Used for commissioning,

parameterisation, configuration

and control of the frequency

inverter.

4-digit, 7-segment LED display,

keyboard

ControlBox

SK TU2-CTR-C

Part. No. 275170130

IP66

PotentiometerBox

SK TU2-POT

Part. No. 275130060

IP55

For direct control of the

frequency inverter without

additional installation or setting

1 potentiometer 0...100 %

1 switch left-0-right

PotentiometerBox

SK TU2-POT-C

Part. No. 275170060

IP66

Profibus module (standard)

SK TU2-PBR

Part. No. 275130070

IP55

This interface enables control of

the NORDAC SK 750E via the

Profibus DP serial port.

Profibus interface

Baud rate: 1.5 MBit/s

2x 5 pin M12 system connectors

Profibus module (standard)

SK TU2-PBR-C

Part. No. 275170070

IP66

Profibus module (terminals)

SK TU2-PBR-KL

Part. No. 275130065

IP55

This interface enables control of

the NORDAC SK 750E via the

Profibus DP serial port.

Profibus interface

Baud rate: 1.5 MBit/s

8 pin terminal

Profibus module (terminals)

SK TU2-PBR-KL-C

Part. No. 275170065

IP66

3.2 Overview of Technology Units

Technology units are optional modules and are plugged onto the top of the frequency inverter. They are for the

control or parameterisation of the inverter and for the display of the actual operating values. The

PotentiometerBox and the ControlBox are available as technology units for simple control of the frequency

inverter and various bus modules are available for connection to a higher level control unit.

A differentiation is made between IP55 and IP66 technology units. Technology units with protection class

IP555 are used for the air cooled SK 750E and protection class IP66 is used for the water cooled SK 750E.

BU 0750 GB-3311 Subject to technical amendments 27

Page 28

NORDAC SK 750E Manual

Technology unit

SK TU2-...

Protection

class

Description

Data

Profibus module (ext. 24V)

SK TU2-PBR-24V

Part. No. 275130110

IP55

This interface enables control of

the NORDAC SK 750E via the

Profibus DP serial port.

Profibus interface

Baud rate: 12 MBit/s

2x 5 pin M12 system connectors

1 external 24 V power supply

Profibus module (ext. 24V)

SK TU2-PBR-24V-C

Part. No. 275170110

IP66

InterBus module

SK TU2-IBS

Part. No. 275130080

IP55

This interface enables control of

the NORDAC SK 750E via the

serial InterBus port.

InterBus interface

Baud rate: 500 KBit/s

2x 5 pin M12 system connectors

InterBus module

SK TU2-IBS-C

Part. No. 275170080

IP66

DeviceNet module

SK TU2-DEV

Part. No. 275130090

IP55

This option enables control of

the NORDAC SK 700E via the

DeviceNet serial port using the

DeviceNet protocol.

DeviceNet interface

Baud rate: 500 KBit/s

1x 5 pin M12 system connector

DeviceNet module

SK TU2-DEV-C

Part. No. 275170090

IP66

CANopen module

SK TU2-CAO

Part. No. 275130100

IP55

This option enables control of

the NORDAC SK 750E via the

CANbus serial port using the

CANopen protocol.

CANopen interface

Baud rate: up to 1 MBit/s

2x 5 pin M12 system connectors

CANopen module

SK TU2-CAO-C

Part. No. 275170100

IP66

AS interface module

SK TU2-AS1

Part. No. 275130120

IP55

This interface enables the

control of sensors and

actuators. In addition, the NORD

SK 750E can be parameterised

via the AS interface

AS interface

2 x 2 M12 5 pin sockets /

connectors

AS interface module

SK TU2-AS1-C

Part. No. 275170120

IP66

Control units

Bus modules

28 Subject to technical amendments BU 0750 GB-3311

Page 29

WARNING

Modules must not be inserted or removed unless the device is free of voltage. The slots must only

be used for the intended modules.

Installation of a technology unit separate from the frequency inverter is not possible. It must be connected

directly to the frequency inverter.

NOTE

ATTENTION

Operation is not permitted if there is no secure

PE connection to the frequency inverter and to

the technology unit (see adjacent illustration)!

3.2.1 Installing the Technology Unit

Installation of the technology units must be carried out as

follows:

1. Switch off the mains voltage, observe the waiting

period.

2. Remove the blank cover by removing the 6 screws

and the PE cable.

3. Connect the technology unit to the PE cable and

push it in using slight pressure. Take care that the

connector strip makes proper contact.

4. Tighten the 6 fastening screws.

3.2 Overview of Technology Units

BU 0750 GB-3311 Subject to technical amendments 29

Page 30

NORDAC SK 750E Manual

NOTE

The digital frequency setpoint is factory set to 0Hz. To check whether the drive is working, a

frequency setpoint must be entered with the key or a jog frequency must be entered via the

relevant parameter >Jog frequency< (P113).

Settings should only be implemented by qualified personnel, strictly in accordance with the

warning and safety information.

ATTENTION:The drive may start immediately after pressing the START key !

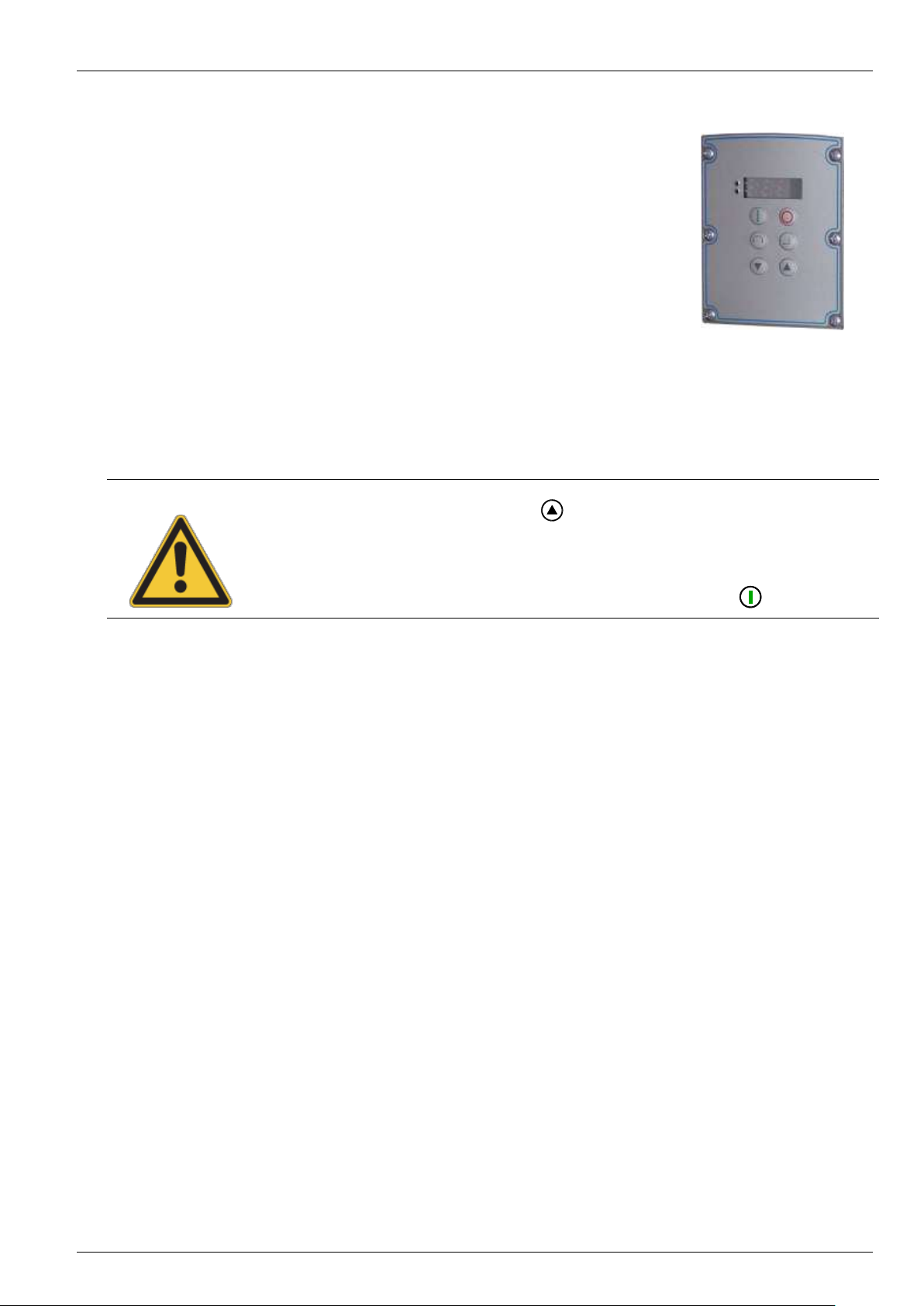

3.2.2 ControlBox SK TU2-CTR

(SK TU2-CTR, Part No.: 275130130)

(SK TU2-CTR-C, Part No.: 275170130)

This option is used as a simple parameterisation, display and control tool for the

frequency inverter SK 750E.

Features:

4-digit, 7-segment LED display

Direct control of a frequency inverter

Display of the active parameter set and operating values

After mounting the ControlBox and switching on the mains supply, horizontal dashes are displayed in the

4-digit, 7 segment display. This display signals the operational readiness of the frequency inverter.

If a jog frequency is preset in parameter P113, the display alternates between 0.0Hz and the value in P113.

If the frequency inverter is enabled, the display changes automatically to the operating value selected in

parameter >Selection Display value< P001(factory setting = actual frequency).

The actual parameter set is shown by the 2 LEDs next to the display on the left in binary code.

30 Subject to technical amendments BU 0750 GB-3311

Page 31

To switch on the frequency inverter. The frequency inverter is now enabled with the set jog frequency

(P113). A preset minimum frequency (P104) may at least be provided.

Parameter >Interface< P509 must = 0.

To switch off the frequency inverter. The output frequency is reduced to the absolute minimum

frequency (P505) and the frequency inverter shuts down.

7-segment

LED

display

Shows the actual operating value set during operation (selection in P001) or an error code. During

parameterisation, the parameter numbers or the parameter values are shown. When switched off, but in

standby mode, four dashes "_ _ _ _" are displayed.

LEDs

1

2

The LEDs indicate the actual operating parameter set in the display and the actual parameter set being

parameterised during parameterisation. In this case the display is coded in binary form.

1

2

= P1

2

1

= P2

1

2

= P3

2

1

= P4

The direction of rotation of the motor changes when this key is pressed. "Rotation to the left" is indicated

by a minus sign. Attention! Take care when operating pumps. screw conveyors, fans, etc. Block the

key with parameter P540.

Press key to increase the frequency. During parameterisation, the parameter number or parameter

value is increased

Press the key to reduce the frequency. During parameterisation, the parameter number or parameter

value is reduced.

Press "ENTER" to store a changed parameter value, or to switch between parameter number or

parameter value.

NOTE: If a changed value is not to be stored, the key can be used to exit from the parameter

without saving the change.

ControlBox functions:

3.2 Overview of Technology Units

BU 0750 GB-3311 Subject to technical amendments 31

Page 32

NORDAC SK 750E Manual

STOP

Store actual frequency as

jog frequency

(Enter key)

Set frequency = 0Hz

(press simultaneously)

Increase frequency

Change rotation direction

(Direction key)

Decrease frequency

START

Parameter set display

Emergency stop

(press simultaneously)

Controlling the frequency inverter with the ControlBox

The frequency inverter can only be controlled via the ControlBox, if it has not previously been enabled via the

control terminals or via a serial interface (P509 = 0).

If the START key is pressed, the frequency inverter switches to the operating display (selection P001). The

frequency inverter delivers 0Hz or a higher set minimum frequency (P104) or jog frequency (P113).

Parameter set display:

The LEDs indicate in the display the actual operating parameter set and during parameterisation ( P000) the

actual parameter set to be parameterised. In this case, the display appears in binary form.

The parameter set can also be changed during operation via the parameter P100 (control via ControlBox).

Frequency setpoint:

The actual frequency setpoint depends on the setting in the parameters jog frequency (P113) and minimum

frequency (P104). This value can be altered during keyboard operation with the value keys and

permanently stored as the jog frequency in P113 by pressing the ENTER key.

Emergency stop:

By simultaneously pressing the STOP key and the "Change direction key” , an emergency stop can be

initiated.

32 Subject to technical amendments BU 0750 GB-3311

Page 33

3.2 Overview of Technology Units

Simultaneous actuation:

Switching from control to

parameterisation while the

drive is running

(See Item 3)

Select menu group,

display parameter value

(Enter key)

One level each time back to

the operating value display

Next menu group or

parameter number

Previous menu group or

parameter number

Switching from

parameterisation to

control

(See Item 3)

Parameter set display

Parameterisation with the ControlBox

Parameterisation of the of the frequency inverter can be performed in the various operating states. All

parameters can always be changed online. Switching to the parameter mode is carried out in different ways

depending upon the operating states and the enabling source.

1. If there is noenable (if necessary press the STOP key ) via the ControlBox, the control terminals or

a serial interface, it is still possible to switch to parameterisation mode from the operating value display

by means of the value keys or . P 0 _ _ / P 7 _ _

2. If an enable is present via the control terminals or a serial interface and the frequency inverter is

producing an output frequency, it is also possible to switch to the parameterisation mode directly from

the operating value display using the value keys or . P 0 _ _ / P 7 _ _

3. If the frequency inverter is enabled via the ControlBox (START key ), the parameterisation mode

can be reached by pressing the START and ENTER keys ( + ) simultaneously.

4. Switching back to the control mode is achieved by pressing the START key .

Changing parameter values

To access the parameter section, one of the value keys or must be pressed. The display changes to

the menu group display P 0 _ _ ... P 7 _ _. After pressing the ENTER key access to the menu group is

obtained and the required parameter can be selected with the value keys.

All parameters are arranged in order in the individual menu groups in a continuous scroll pattern. It is therefore

possible to scroll forwards and backwards within this section.

Each parameter has a parameter number P x x x . The significance and description of the parameters starts

in Section 7 "Parameterisation".

BU 0750 GB-3311 Subject to technical amendments 33

Page 34

NORDAC SK 750E Manual

P0--

_ _ _ _

P1--

P2--

P4--

P5--

P6--

P7--

P001

P002

P100

P101

P114

P200

P201

P216

P400

P401

P460

Operating value display

(or operational)

following mains ON

P3--

P300

P301

P330

Accept changed value

Simultaneous actuation:

Value to factory setting

Accept changed value

Reduce value

Do not change value

(Direction key)

Parameter set display

Menu structure with the ControlBox

To change a parameter value, the ENTER key must be pressed when the relevant parameter number is

displayed.

Changes can then be made using the VALUE keys or and must be confirmed with to save them

and exit from the parameter.

As long as a changed value has not been confirmed by pressing ENTER, the value display will blink; this value

has not yet been stored in the frequency inverter.

During parameter changes, the display does not blink so that the display is more legible.

If a change is not to be saved, the "DIRECTION" key can be pressed to exit from the parameter.

34 Subject to technical amendments BU 0750 GB-3311

Page 35

LED

Description

Green LED [ON]

The green LED indicates that the mains voltage is present and operational, while

a flashing code that increases in speed shows the degree of overload at the

frequency inverter output.

Red LED [ERROR]

Indicates actual error by flashing with a frequency according to the number code

of the error.

DeviceNet status LEDs

MS (red/green)

Module status

MS (red/green)

Mains (bus) status

Module status LEDs

DS (green)

Module status

DE (red)

Module error

3.2.3 PotentiometerBox SK TU2-POT

(SK TU2-POT, Part No.: 275130060)

(SK TU2-POT-C, Part No.: 275170060)

The PotentiometerBox can be used as a control unit for various

functions. Selection can be carried out in parameter P549. An

infinitely variable potentiometer and a three-position switch for

selecting CW/CCW operation or Stop are integrated in the module for

operation. This is a control switch that can generate an enable signal.

The factory setting enables direct control of the output frequency in

the minimum (P104) and maximum frequency (P105) ranges.

Note: The frequency inverter can only be controlled via the

PotentiometerBox, if parameter P509 >Interface< is set to

"Control terminals or keyboard" (P509 = 0) and has not

previously been enabled via the control terminals

(customer unit).

3.2 Overview of Technology Units

3.2.4 DeviceNet Module SK TU2-DEV

(SK TU2-DEV, Part No.: 275130090)

(SK TU2-DEV-C, Part No.: 275170090)

DeviceNet is an open communications profile for distributed

industrial automation systems. It is based on the CANbus system.

Up to 64 participants can be linked to a single Bus system.

The transfer rate (125, 250, 500 kBit/s) and the Bus addresses are

set using rotary coding switches or the applicable parameters.

NOTE: Detailed information can be obtained from the operating instructions BU 0080 or contact the

supplier of the frequency inverter.

BU 0750 GB-3311 Subject to technical amendments 35

Page 36

NORDAC SK 750E Manual

Profibus status LEDs

BR (green)

BUS ready

BE (red)

BUS error

CANopen Status LEDs

CR (green)

CANopen RUN LED

CE (red)

CANopen ERROR LED

Module status LEDs

DR (green)

Module status

DE (red)

Module error

3.2.5 Profibus Module SK TU2-PBR

(SK TU2-PBR, Part No.: 275130070)

(SK TU2-PBR-24V, Part No.: 275130110)

(SK TU2-PBR-KL, Part No.: 275130065)

(SK TU2-PBR-C, Part No.: 275170070)

(SK TU2-PBR-24V-C, Part No.: 275170110)

(SK TU2-PBR-KL-C, Part No.: 275170065)

Profibus allows the exchange of data between a wise range of automation devices. PLC's, PC's, operating and

monitoring devices can all communicate via a uniform bus in serial bit mode.

PROFIBUS DP is primarily used for communication between sensor and actuator where system response

needs to be very fast. PROFIBUS DP is a suitable alternative to expensive 24-volt parallel signal transmission

and transmission of measured values. This type of PROFIBUS, which is optimised to speed, is used for

instance for operating frequency inverters on automation devices.

Data exchange is specified in DIN 19245 Part 1 and 2 and application-specific upgrades in Part 3 of this

standard. Within the European field bus standardisation process, PROFIBUS is integrated into the European

field bus standard pr EN 50170.

The termination resistor for the last bus participant is located in the Profibus standard plug.

NOTE: Detailed information can be obtained from the operating instructions BU 0020 or contact the

supplier of the frequency inverter.