Page 1

Supplementary Operating Instructions

NORDAC SK 700E Frequency Inverter

With Positioning Card (Special Extension Module)

SK XU1-POS

SK 700E with optional parameter box

T. Nr. 0603 7182

Getriebebau NORD

GmbH & Co. KG

... NORD Gear

BU 0710 GB

Last Update: February 2002

Page 2

2 BU 0710 GB

Page 3

NORDAC SK 700E Frequency Inverter

Instructions for the safety and use of

variable frequency converters

(as provided in the 73/23/EEC low-voltage directive)

1. General

Depending on their type of enclosure, variable frequency

inverter may have live, bare, in some cases even moving or

rotating parts as well as hot surfaces during operation.

Inadmissibly removing the required covers, improper use,

incorrect installation or handling can be dangerous and may

lead to serious damage to persons or to property.

See the documentation for more detailed information.

Any transport, installation, starting-up or maintenance work

shall be performed by properly qualified, skilled and

competent personnel (IEC 364 or CENELEC HD 384

respectively or DIN VDE 0100 and IEC 664 or DIN VDE

0110 and national accident prevention regulations to be

observed).

Qualified, skilled personnel as mentioned in these basic

safety instructions is understood to refer to persons who are

familiar with the installation, assembly, setting-up and

operation of the product and who have the qualifications

required for the job of which they are in charge.

2. Intended use

Variable frequency inverter are components designed to be

integrated into electrical installations or machinery.

If the converters are installed in machines, they must not be

put into operation (in other words, operation as intended by

the manufacturer must not begin) until it has been

established that the machine in question actually meets the

requirements mentioned in the EC directive 89/392/EEC

(Directive For Machines); EN 60204 is to be observed.

The device must not be put into operation (i.e. operation as

intended by the manufacturer must not be started) unless

the stipulations of the EMC directive (89/336/EEC) are

fulfilled.

Variable frequency inverter meet the requirements stated in

the low-voltage directive 73/23/EEC. Likewise the accorded

standards of the series prEN 50178/DIN VDE 0160 in

conjunction with EN 60439-1/ VDE 0660 Part 500 and EN

60146/ VDE 0558 are applied to the variable frequency

inverter.

Refer to the rating plate and the documentation for details

on technical data and connecting requirements and do not

fail to observe them and to follow instructions.

3. Transport, storage

Follow the instructions for transport, storage, and proper

handling.

Ensure climatic conditions as specified in prEN 50178.

4. Installation

The devices must be installed and cooled as directed in the

relevant documentation.

The variable frequency inverter must be protected against

inadmissible stress. Special care should be taken not to bend

components or to change the spacing of insulation during transport

and handling. Do not touch electronic components and contacts.

Variable frequency inverter contain electrostatically sensitive

components which are easily damaged through improper handling.

Electrical components must not be damaged or destroyed

mechanically (potential health risks!).

5. Electrical connection

Follow the applicable national accident prevention rules (e.g. VBG

4) when working on variable frequency inverter while they are live.

Electrical installation is to be performed in accordance with

applicable rules and regulations (e.g. regarding conductor cross

sections, fusing, PE connection). Apart from these, more

instructions may be mentioned in the documentation.

Recommendations for meeting EMC standards in installation - for

instance with regard to screening, earthing, filter arrangement and

the routing of lines - are found in the converter documentation. CEmarked variable frequency inverter are always subject to such

instructions as well. It is the responsibility of the machine or plant

manufacturer to ensure that the limit values stipulated by EMC

legislation are duly met.

6. Operation

It may be necessary to provide facilities in which variable

frequency inverter are installed with additional monitoring and

protecting devices to satisfy the applicable safety regulations, e.g.

the law on technical working materials, accident prevention

regulations etc. Modifications of the variable frequency inverter by

means of the operating software are allowed.

Do not touch live parts of the device or power terminals right after

the converter has been disconnected from the supply voltage as

capacitors may still be charged. The information plates on the

driving current converter will give you precise details on the

subject.

Keep all covers closed during operation.

7. Service and maintenance

As described in the manufacturer’s documentation.

Do keep these Safety Instructions for future reference!

Please note: Validity of these Supplementary Operating Instructions is contingent on the com-

plementary use of the basic Operating Instructions for the NORDAC SK 700E frequency inverter which are also enclosed with the unit delivered.

Page 4

4 BU 0710 GB

Page 5

Table of contents

1 GENERAL ............................................................................................................................ 6

2 INSTALLATION PROCEDURE ........................................................................................... 7

2.1 Safety and installation instructions ......................................................................................................7

2.1.1 How to install Posicon special extension modules ............................................................................................... 9

2.2 Posicon I/O connection ........................................................................................................................11

2.3 Incremental encoder connection ........................................................................................................12

2.4 Absolute encoder connection .............................................................................................................12

3 FUNCTIONAL CHARACTERISTICS................................................................................. 13

3.1 Introduction ...........................................................................................................................................13

3.2 Actual position recognition .................................................................................................................13

3.2.1 Position recognition with an incremental encoder .............................................................................................. 13

3.2.2 Position recognition with an absolute value encoder.......................................................................................... 15

3.2.3 Encoder monitoring ............................................................................................................................................ 15

3.2.4 Positioning with single-turn absolute value encoders and incremental shaft encoders used in absolute mode . 16

3.3 Setpoint setting.....................................................................................................................................17

3.3.1 Position array – Absolute setpoint position via digital inputs .............................................................................. 17

3.3.2 Position increment array – Relative setpoint position via digital inputs .............................................................. 17

3.3.3 16-bit bus mode ................................................................................................................................................. 17

3.3.4 32-bit bus mode ................................................................................................................................................. 17

3.3.5 Position array – Bus transmission of absolute setpoint position......................................................................... 17

3.3.6 Position increment array – Bus transmission of absolute setpoint position ........................................................ 18

3.4 Teach-in programming.........................................................................................................................18

3.5 Modes of position control (P600) ........................................................................................................18

3.6 Position control.....................................................................................................................................19

3.7 Relay signals .........................................................................................................................................20

4 POSITIONING PARAMETERS.......................................................................................... 21

5 SYSTEM START-UP.......................................................................................................... 26

6 FAULT CLEARANCE ........................................................................................................ 27

6.1 Error messages.....................................................................................................................................27

6.2 Table of errors and possible causes ..................................................................................................28

7 BUSINESS ESTABLISHMENTS & SALES OFFICES IN GERMANY ............................. 30

BU 0710 GB 5

Page 6

NORDAC SK 700E manual Posicon special extension

1 General

NORDAC vector frequency inverters are voltage source d.c. link inverters with microprocessor electronics

designed to control the speed of three-phase motors.

Providing an incremental encoder on the motor and/or an absolute encoder on the output shaft along with

using the optional SK_XU1_POS Posicon positioning card will enhance the standard components so as to

constitute a drive system capable of performing positioning tasks in a highly precise manner.

• 252 positions can be programmed to be approached by the unit controlled

• Position control in the destination window; the unit controlled will retain the desired position

even with substantial fluctuations of the load.

• Distance calculation ensures that the driven assembly is moved into the destination position

accurately and within the shortest possible time

• Control options not only provide for setting positions but also for pre-setting the step widths

required for moving from one position to the next (position increments)

• Also possible: transmission of setpoint positions via a field bus interface.

Designed to be plugged into the control board, the add-on positioning card fits into the standard housing of the

frequency inverter so that the overall size of the device is not increased.

The positioning card is equipped with a processor of its own which will determine the speed setpoint the

inverter will have to ensure.

The parameters which are required for distance calculation are inserted into the existing inverter menu

structure as an additional menu group.

The position setpoints can be applied to the digital inputs which are additionally provided on the positioning

card, or transmitted via the USS protocol or another field bus system respectively.

By switching from one parameter set to another, the operator may quit speed control in order to access

distance calculation or position control, or vice versa.

6 BU 0710 GB

Page 7

2 Installation procedure

2 Installation procedure

2.1 Safety and installation instructions

NORDAC SK 700E frequency inverters are operational equipment for use in industrial power plant. That is

why touching them may cause, due to the voltages at which they are operated, serious injuries or even

death.

• Only skilled personnel qualified in electrotechnical professions is allowed to perform

installation or any other work on the devices provided that these have been previously

disconnected from supply. The personnel involved must have access to the operating

instructions any time and observe them conscientiously without exception.

• Local regulations governing the installation of electric plant as well as any regulations for

accident prevention have to be followed.

• The device continues to be dangerously live for up to 5 minutes after its disconnection from

the mains. Accordingly the device must not be opened or either the covers or the control

panel be detached until 5 minutes after it has been disconnected from supply. Reattach all

covers before switching the mains voltage on again.

• Even when the motor has stopped (e.g. following electronic disable, jamming of the drive, or

a short circuit of the output terminals), the supply terminals, the motor terminals, and the

terminals for the braking resistor can be dangerously live. Even if the motor is not running it

can by no means be assumed that it is also electrically isolated from the mains.

• Caution, parts of the control board and especially the female connector for the detachable

equipment boxes are dangerously live, too. No mains potential is applied to the control

terminals, however.

• Caution, certain setting configurations may cause the inverter to start up automatically when

it is connected to the mains.

• The printed circuit boards carry highly sensitive MOS semiconductor components for which

static electricity can be particularly harmful. That is why you should avoid to touch the

conductive tracks or electronic components with your hands or with metallic objects. When

connecting the cables, use insulated screw drivers to manipulate the screws of the terminal

strips.

• The inverter is intended for permanent connection only and must not be operated without

having been effectively earthed as stipulated by the local regulations for high leakage

currents (> 3.5 mA). German VDE 0160 demands that either a second earth conductor be

laid or that the earth conductor cross section be 10 mm

• If to conform with local regulations the leakage current must not contain any proportion of

direct current at all, conventional fault-current circuit breakers alone will not afford

sufficient protection where three-phase frequency inverters are concerned. The construction

of standard fault-current circuit breakers is supposed to meet the new VDE 0664

requirements.

• NORDAC SK 700E frequency inverters are maintenance-free provided that they are

operated according to instructions. In a dusty environment the cooling surfaces must be

cleaned with compressed air at regular intervals.

CAUTION! DANGER!

The power section may still be live up to 5 minutes after disconnection from the mains.

2

minimum.

Inverter terminals, motor supply cables, and motor terminals may be live, too!

Touching exposed or unconnected terminals, cables, or parts of the device may lead to

serious injuries or even death!

BU 0710 GB 7

Page 8

NORDAC SK 700E manual Posicon special extension

CAUTION

• Ensure that neither children nor the general public will have access to the device or a

chance to manipulate it!

• The device must not be used for any purpose other than the one intended by the

manufacturer. Unauthorized modifications and the use of replacement parts and

attachments which are not sold or recommended by the manufacturer, may cause fire,

electric shock, and injuries.

• Keep this Manual where it will be accessible to any person involved in using the device

or hand it to him/her on your own accord!

8 BU 0710 GB

Page 9

2.1.1 How to install Posicon special extension modules

IMPORTANT

Only properly qualified personnel who can be assumed to be aware of and adhere to the

safety and warning instructions both generally applicable and contained in this document

should be allowed to perform installation work.

2 Installation procedure

1. Switch off mains voltage, wait a few

minutes as directed.

2. Loosen the 2 screws by which the

cover grille is fixed to the connection

area, remove it, and wedge the device

cover out of its slots or simply pull it

off.

3. Move the locking pin to position

"open“.

4. Push the Posicon special extension

board into the lower guide rail exerting

a little pressure until it snaps in. This

may be easier when you take out the

customer interface first and reinstall it

after you have fitted the Posicon

special extension.

5. Set the locking pin to its "closed"

position.

6. Release the connection plug and pull it

off. Make the connections as required.

Then fit the pins again, and make sure

that they lock.

Locking pin

Technical unit

Customer interface

Special extension

7. Reattach all covers.

OPEN

CLOSED

Locked

Released

BU 0710 GB 9

Page 10

NORDAC SK 700E manual Posicon special extension

How to remove the special extension

module :

1. Switch off the mains voltage, wait a few

minutes as directed.

2. Loosen the 2 screws which hold down the

cover grille of the connection area, remove

it, and wedge the device cover out of its

slots, or simply pull it off.

3. Set the locking pin to the "open" position.

4. Use a screwdriver to unlatch the special

extension module (as shown in the figure to

the right) and pull it out completely with your

hand. It may be more convenient to

temporarily remove the customer interface.

5. If you have done so, fit it back into the inverter again.

6. Set the locking pin to

the "closed" position.

7. Reattach all covers.

Customer interface

Special extension

Customer interface

Special extension

10 BU 0710 GB

Page 11

2.2 Posicon I/O connection

The Posicon I/O special extension module (also referred to as XU,

EXtension Unit) is a system of positioning control for integration

into the frequency inverter. The positions which have been

programmed in advance will be exactly and dynamically

appproached on the basis of distance calculation.

Positions are captured by means of an incremental encoder and/or

an absolute value encoder.

The encoders may be installed either on the motor or on the load.

Step-up or step-down ratios can be adjusted at discretion.

Maximum connection cross section of the control lines:

Connector Functions Maximum cross section

X10.1 Output relay 1.0 mm

X10.2 Digital inputs 1.0 mm

X10.3 SSI input 1.0 mm

X10.4 Incremental encoder input 1.0 mm

2

2

2

2

2 Installation procedure

Floating contact or PLC output:

7.5 ... 33V

Absolute value encoder input:

SSI, 24 bits

Incremental encoder input:

TTL, RS 422, 250kHz max.

500 – 5000 pulses/rev.

05 REL3.1

06 REL3.2

07 REL4.1

08 REL4.2

27 DIG IN 7

28 DIG IN 8

29 DIG IN 9

30 DIG IN 10

31 DIG IN 11

32 DIG IN 12

42 VO +15V

40 GND /0V

63 SSI1 CLK+

64 SSI1 CLK65 SSI1 DAT+

66 SSI1 DAT-

41 VO +5V

40 GND /0V

51 ENC1 A+

52 ENC1 A53 ENC1 B+

54 ENC1 B55 ENC1 N+

56 ENC1 N-

X10.1

X10.2

Digital inputs:

Voltage supply:

15V, ∑ 300mA max.

Output relay:

max. 2,0A

28V DC / 230V AC

DIG IN 7 to 12

for position setting

X10.3

X10.4

Voltage supply:

5V, ∑ 300mA max.

PLEASE NOTE: All of the control voltages are related to the same reference potential!

The total allowable current rating of all individual power sources put together will be = 300mA max.

BU 0710 GB 11

Page 12

NORDAC SK 700E manual Posicon special extension

2.3 Incremental encoder connection

Input for an incremental encoder with two tracks and a zero track, with TTL-compatible signals for drivers

according to EIA RS 422. Maximum current input to the incremental encoder must not exceed 250mA. Supply

voltage for the encoder is 5V.

The number of graduation marks per revolution may amount to between 500 and 5000 increments. It is set in

the "positioning" menu group which is accessed through parameter 606. If very long cables are used, or if the

motor speed exceeds 1500 1/min, the encoder should not have more than 2048 graduation lines per revolution.

With more than average cable lengths the cross sectional area must be large enough to ensure that voltage

won’t drop too much from one end of the cable to the other. This is especially important with regard to the

supply cables where the cross section can be enlarged for instance by connecting several wires in parallel.

Alternatively incremental encoders with a higher supply voltage requirement could be used. If the power

required to operate the incremental encoder does not exceed a range of 10 to 30 volts, the internal 15V

source will be sufficient (X10.2 terminal 42).

The screen of the encoder cable is connected to the screen angle using the PE clamps which are enclosed

with the basic unit.

Function Colour

(with incremental encoder ERN 420)

Input terminals Posicon

special extension

SK XU1-POS

5 V supply +5V brown / green

0 V supply DGND white / green

Track A A+ brown

Track A inverse A- green

Track B B+ grey

Track B inverse B- pink

Track 0 ZERO+ red

Track 0 inverse ZERO- black

X10.4.41 VO +5V

X10.3.40 GND /0V

X10.4.51 ENC1 A+

X10.4.52 ENC1 A-

X10.4.53 ENC1 B+

X10.4.54 ENC1 B-

X10.4.55 ENC1 N+

X10.4.56 ENC1 N-

2.4 Absolute encoder connection

Input for an absolute encoder with ‘Gray Code’ and SSI interface. Signals are TTL-compatible in accordance

with EIA RS 422. The inverter will provide the encoder with a supply voltage of 15V. The resolution per

revolution, the maximum number of revolutions or alternatively the length of the transmitted word (8 – 24 bits)

can be set in parameter P605.

The absolute encoder should be installed on the shaft so that the scale zero of the encoder is in the correct

position. The mark treated as zero point by the inverter can be set by defining an offset value.

Multiplication and reduction parameters allow for a transmission ratio to be ensured between motor and

absolute encoder.

The sense of rotation of motor and absolute encoder need not necessarily be the same. If the sense of

rotation is different, a negative transmission ratio must be set.

With the 100kHz clock frequency used, cable lengths of up to 80m are allowed. The cables should be twistedpair and screened.

Absolute encoders may include break-of-wire checking provided that an extra voltage monitoring bit has been

assigned for that purpose.

12 BU 0710 GB

Page 13

3 Functional characteristics

3 Functional characteristics

3.1 Introduction

The Posicon positioning card is extremely versatile in carrying out positioning and position controlling tasks.

To make it easier for you to decide which configuration will be most suitable for the application at hand, a

description of the various ways of setpoint setting and actual value recognition is provided below.

Setpoints can be fed to the control system as either absolute or relative position values. Absolute position

setpoints should be preferred in applications where the same positions are approached over and over again,

as e.g. with shifting trolleys, elevators, shelf operating equipment etc. Relative position setpoints are obviously

more suitable where axles operate in an intermittent fashion, especially endless ones driving turntables or

clock-controlled metering belts. Setpoints can also be transmitted over the bus (Profibus, CAN, Interbus, or

USS interface). In that case the position is translated into an encoded value or into a bit combination

representing the number of a position or a position increment.

If the operator wishes to quit the positioning mode and activate speed setting instead, he can do so by

switching parameter sets. While in one parameter set the position control parameter must be set to "On", an

"Off" setting will be required in the other. Switching between parameter sets is possible any time.

Position recognition can be handled using either an incremental or an absolute encoder. With rotary axles

turning in one direction most of the time, only an increment encoder can be used, since with absolute

encoders the range of values is limited to ±50000 revolutions. Using an incremental encoder implies that a

reference point will be needed.

3.2 Actual position recognition

3.2.1 Position recognition with an incremental encoder

The actual position is determined by the Posicon card processor. This calculation presupposes a reference

point which is used to define the zero position of the axle. The position recognition function will be active as

long as the frequency inverter is supplied with a voltage. The pulses generated by the incremental encoder are

counted in the inverter and added to the actual position value. When the inverter supply voltage is switched

on, the device will read out "0" as the actual position if the position saving option in parameter P606 has not

been activated, or else the value which was read out last before the inverter was switched off, if the position

saving option in P606 has been set to ON.

The position recognition function will work whether an enable signal has been fed to the inverter or not, and

also whether the P600 position control parameter has been set to ON or to OFF. The inverter will proceed with

actual position detection as long as it is supplied with a voltage.

Changes of position which take place while the frequency inverter is disconnected have no effect on actual

position indication. That is why a search for the reference point is usually required whenever the frequency

inverter is connected to the mains.

While generally the incremental encoder must be installed on the motor shaft, it may be accommodated

elsewhere if it is not possible to operate the inverter in the servo mode (P300). In that case the transmission

ratio between motor and incremental encoder needs to be parameterized. The inverter will convert the number

of revolutions determined by the incremental encoder into revolutions of the motor shaft proceeding from the

settings made in the multiplication and reduction parameters.

n

: number of motor shaft revolutions

M

n

= nG * Üb / Un n

M

: number of revolutions determined by increm. encoder

G:

Ü

: multiplication (P607

b

U

: reduction (P608

n

)

[1]

)

[1]

Example: The incremental encoder has been installed on the output side of the gearbox, the gearbox has got a

transmission ratio of i = 26.34. The following values should be set in the respective parameters:

multiplication: 2634; reduction: 100

On the software level an offset can be parameterized by which the starting point (zero) is transferred to a point

different from the one which is otherwise determined by the point of reference. After the value of incremental

encoder revolutions has been translated into a value representing the revolutions of the motor shaft, the offset

will be added to the actual position value. Accordingly a new offset value must be entered whenever the

multiplication or reduction setting has been changed.

BU 0710 GB 13

Page 14

NORDAC SK 700E manual Posicon special extension

3.2.1.1 Tracking the point of reference

Reference point tracking is started when one of the 6 digital inputs provided on the Posicon card or one of the

digital inputs of the customer interface is energized. Accordingly the digital input selected will have to be

programmed to execute this function (P618-P623, option 7; P420-P425 option 22). An enable left or enable

right signal is applied to define the direction in which the search for the reference point is to be performed. The

rate of reference point tracking depends on the current setpoint frequency. Reading in the point of reference is

ensured via one of the 6 digital inputs as well or else through one of the digital inputs of the customer

interface. For this to happen the digital input selected must have been assigned this function in the applicable

parameters (P618-P623, option 8; P420-P425 option 23).

The sequence of reference point tracking is as follows: When reference point tracking has been activated, the

the motor shaft will start turning in the direction the setpoint implies (enable right/left, setpoint sign +/-). The

direction of the motion is inverted by the signal received at the reference point input. When the axle has turned

so far as to trigger the reference point switch, the direction of motion is reversed. After the axle has moved out

of the operational range of the reference point switch again, reference point tracking continues until the

moment the next zero pulse is transmitted by the incremental encoder. If the position of the axle is such that

the switch responds the very moment reference point tracking is started, the axle will rotate in the inverse

sense right away. Likewise, after the axle has left the detection range of the switch, reference point tracking

will be completed when the next zero pulse of the incremental encoder is received.

This is when the current position is set to zero or to the value that has been set in the "offset" parameter. The

shaft remains in the new zero position until reference point tracking is terminated by the invalidation of the

"reference point tracking" signal. At the same time the setpoint position is set to zero in the "Position increment

array P610 = 1" position setpoint mode (relative positioning). When the frequency inverter has transferred the

reference point to memory, it will report that reference point tracking is complete through the action of multifunction relay 3 or 4, provided that one of these has been associated with the "reference point" function in the

relevant parameter.

If following a "reference point found" signal the incremental shaft encoder fails to supply a zero pulse before

the shaft has completed 1.5 revolutions, the inverter will signal a "reference point" error (E14/E142).

If the incremental encoder is used without at the same time activating the "Save position" function (see

parameter 606)), the inverter will indicate "0" to be the actual position when it is switched on again, whereas if

the inverter was instructed to save the position, it will read out the value that was stored last.

When the display is reading out a "reference point" signal triggered by the relay, this means that a valid point

of reference has been identified. The relay drops out when the search for a reference point begins and picks

up again when this search has been completed.

If the "Save position" option (P606) has not been selected (which is usually the case), the relay drops out

when the inverter is switched on again.

If the "Save position" option has been selected though, the relay picks up immediately the moment the inverter

is switched on.

Reference point tracking can be interrupted by application of an "enable", a "quick stop", or a "cut off voltage"

command (without an error signal being activated).

3.2.1.2 Reset position function

As an alternative to reference point tracking as described above, one of the digital inputs provided on the

Posicon special extension can be assigned a position resetting function (P618 – P623, option 11). In that case

the input will be active all the time - whereas when executing the reference point tracking function it is

operative in an intermittent fashion - and will instantly set the actual position to zero or to the value selected in

the "offset" parameter as soon as the signal changes from 0 to 1, whether position control is ON or OFF. The

setpoint position in the digital mode 2 (position increments) is set to zero as well.

The repetition accuracy of referencing by means of the reset function falls short of the precision obtained by

reference point tracking as described above – it depends on the tolerance of the reference point switch and

the rate at which the operating threshold of the switch is approached. For many applications it is sufficient

though. Besides referencing can be carried out without interrupting position control.

14 BU 0710 GB

Page 15

3 Functional characteristics

3.2.2

Position recognition with an absolute value encoder

The absolute encoder transfers the actual position value to the frequency inverter via the serial SSI interface in

Gray code. As the complete position information is stored in the absolute encoder all the time, it is still

available even if the axle has been moved while the inverter was off. That is why in this case the program

need not search for the reference point again.

If an absolute encoder is connected, the "distance calculation" parameter (P604) must be set to "absolute".

If the absolute encoder is not mounted on the motor shaft, the transmission ratio between motor and absolute

encoder must be specified in the relevant parameter. The inverter will convert the absolute revolutions to

revolutions of the motor by means of the multiplication and demultiplication parameters.

n

: number of revolutions of motor

M

n

= nE * mul / dev nE:: number of revolutions of absolute encoder

M

mul: multiplication

dem: demultiplication

Example: The absolute encoder is installed on the output face of the gearbox, the gear ratio of the gearbox is i = 26.34.

The following values are parameterised: multiplication 2634; demultiplication: 100

The sense of rotation of the absolute value encoder must be identical to that of the motor. When the phase

sequence of the output frequency is positive (clockwise sense of rotation), the actual position value is

supposed to grow. If the sense of rotation is found not to be the same, this condition can be corrected by

setting a negative value in P608 (demultiplication).

The zero point (point of origin) of the axle can be corrected by providing an offset value in the relevant

parameter. This offset value is added to the value obtained after the absolute encoder revolutions have been

converted into revolutions of the motor shaft. That is why a new offset value must be entered any time the

multiplication or demultiplication ratio has been changed.

The maximum allowable position value depends on the encoder resolution and on the multiplication or

demultiplication factors. The range of +/- 50000 revolutions cannot be exceeded however. A complete turn is

not allowed. With continuous axles turning in one direction most of the time, incremental encoders must be

used for position sensing. The inverter will limit position setpoints to the maximum allowable range of values

internally.

3.2.3

Encoder monitoring

When an absolute value encoder is used for position recognition, monitoring is ensured by activating the

voltage monitoring bit in the "Position detection monitoring" parameter (P617). The absolute encoder must

feature the corresponding option. If the bit succeeding the last data bit is not equal to 0, the value will be

ignored. If no value has been read by the end of a 500 ms period, the inverter puts out the "error E14 (E143)".

When both an absolute and an incremental encoder are involved, Parameter 631 can be used to check

whether any discrepancy occurs regarding the position information supplied by either of the two. The

maximum allowable deviation between the positions as sensed by the absolute and the incremental encoder

depends on the value set in parameter 631. A "0" setting will inactivate the monitoring function. When the

actual deviation exceeds the maximum allowable value, the "E14 (E146)“ error signal is activated. The

absolute and the incremental encoder are allowed to have different multiplication factors and to be installed in

different places. The system allows for individual multiplication (P607), demultiplication (P608), and offset

factors (P609) to be set for each of the two encoders.

If no second redundant encoder has been installed for position control, parameter P630 provides for defining a

position-related synchronization error. This approach is based on a comparison of the current position with the

position variation calculated from the current speed. Each time a destination position has been reached, the

estimated position is aligned with the actual value transmitted by the encoder in order to prevent the

synchronization error from accumulating with time. If the position difference exceeds the value set in P630, the

"Error 14 (145)" fault signal is activated. Where longer displacement distances are involved, higher values

should accordingly be provided in P630. The required value is best determined experimenting. Setting the

option to "0" will inactivate the monitoring function.

BU 0710 GB 15

Page 16

NORDAC SK 700E manual Posicon special extension

With the "minimum position" (P616) and "maximum position" (P615) parameters, limits for the allowable

working range can be defined. When the actual position is found to have exceeded these limits, the "E147"

error message (actual position exceeding maximum position) or the "E148“ error message (actual position

below minimum position) will be generated.

Encoder monitoring is completely deactivated by setting the option to "0". Monitoring is not available either in

the "position increment array" position setpoint mode (displacement increments), nor in the mode for

incremental position recognition. If position setpoints are defined which are less than the set minimum or

greater than the set maximum positions, inverter control will take care of that by limiting them accordingly.

3.2.4 Positioning with single-turn absolute value encoders and incremental shaft

encoders used in absolute mode

With turntables where the individual positions to be approached are distributed along the circumference, there

is a certain problem : If a multi-turn absolute value encoder was fitted to the output end of the gearbox or an

incremental shaft encoder to the motor or to the output face of the gearbox, with the setpoint position to be

changed from – 0.375 to + 0.375 the drive would adopt the longer displacement route – "go the long way

round" (see fig. a) – while typically the displacement from one position to the next ought to be ensured via the

shortest possible, in other words the optimal, route.

This effect can be prevented if operation of a single-turn absolute value encoder or of an incremental shaft

encoder is governed by the "absolute 1 revolution" mode setting (P606 options 16-31). As a result the drive

will follow the shorter displacement route, and in doing so pass the "overflow point" of the shaft encoder type

used (as shown in fig. b).

0.5 /-0 .5

-0 .3750.375

-0 .5-0 .5

-0 .1250.125

0

0.5 /-0 .5

-0 .3750.375

-0 .5-0 .5

-0 .1250.125

0

a) Normal displacement route b) Displacement route with single-turn absolute encoder

The point of origin (zero) of a single-turn absolute value shaft encoder depends on the position in which it is

installed and can be varied by providing an offset value. If an incremental shaft encoder is mounted on the

output face of a gearbox and operated in the "absolute 1 revolution" mode, with this encoder, too, the point of

origin is determined by the zero track. With each zero pulse the count is automatically reset (cf. P606 settings

16-23). Thus the incremental shaft encoder is automatically referenced with every complete turn. Likewise the

location of zero can be varied by providing an offset value. Automatic referencing is not possible however

when the incremental encoder is mounted on the motor (P606 setting 24-31).

P605 setting P606 setting Automatic referen.

Absolute shaft

encoder on

gearbox output

Incremental shaft

encoder on

gearbox output

0…3

0: SSI Single-Turn 512 marks

1: SSI Single-Turn 1024 marks

2: SSI Single-Turn 2048 marks

3: SSI Single-Turn 4096 marks

---

---

16…23

16: 500 marks absolute 1 revolution

.....

23: 5000 marks absolute 1 revolution

yes

no

16 BU 0710 GB

Page 17

3 Functional characteristics

Incremental shaft

encoder on the

motor

---

24…31

24: 500 marks absolute 1 revol. mode 2

.....

31: 5000 marks absolute 1 revol. mode 2

yes

The example shown above is based on a multiplication and demultiplication ratio of "1". The maximum position

value or the overflow point respectively is calculated as follows:

N

: max. value of motor shaft revolution

max

= ± 0.5 * Üb / Un Ü

±n

max

Example: The absolute value shaft encoder is mounted on the output face of a gearbox. The multiplication factor of the

gearbox is i = 26.34. The following values are parameterised: n

: multiplication (P607)

b

U

: demultiplication (P608)

n

max

= ± 13.17 Umdrehungen

3.3 Setpoint setting

Essentially four methods of setpoint setting are available. Setpoints can be fed to the system via digital inputs

as absolute or as relative position values, or they can be transmitted over a bus. The way the actual position is

ascertained is irrelevant for setpoint setting. Absolute, relative and bus setpoints can be defined whether an

absolute encoder or an incremental encoder is used to determine the actual position.

3.3.1

In the "position array" position setpoint mode, up to 63 positions per parameter set can be selected via the

digital inputs 1 through 6. The position numbers result from the binary value of the inputs. For each position

number one position setpoint can be parameterised. The position setpoint is either entered via the control

panel (of the control box or the parameter box) or the "NordCon" parameterisation software (by reading the

current position and saving it as the setpoint in the inverter's memory) or made permanent by "teach-in"

programming which implies that the operator will "demonstrate" to the system how to make the driven

assembly adopt the various positions.

Position array – Absolute setpoint position via digital inputs

3.3.2

Position increment array – Relative setpoint position via digital inputs

The "position increment array 2" position setpoint mode is especially suitable for rotary shafts. A value can be

assigned to each of the 6 digital inputs which will be added to the setpoint position when the signal changes

from 0 to 1 . As both positive and negative values can be used, control also allows for returning to the original

position. The addition is made with any positive signal edge whether the inverter is enabled or not. By applying

several pulses to one input, the multiple of the parameterised increment can be preset. The pulse width as

well as the width of the pulse intervals must be 10 ms minimum.

3.3.3

16-bit bus mode

The setpoint can be transmitted via any of the various field bus activation circuits available. The position is fed

to the system in terms of revolutions. The resolution is 1/1000 rev. For setpoints to be transmitted via the serial

interface, the applicable option must be enabled in the P509 "Interface" parameter included in the "Additional

Functions" menu group. Parameter P546 (Bus - setpoint 1) is accessed to define whether 16 or 32 bits are to

be used for setpoint transmission. For detailed information regarding bus setpoints see the relevant

supplementary operating instructions.

3.3.4

32-bit bus mode

Same as 3.3.3, the word length being 32 bits however. In this mode the setpoint exactly corresponds to the

value represented in P602 (one motor revolution = 1000 in P602 and 1000

3.3.5

Position array – Bus transmission of absolute setpoint position

if transmitted as a bus setpoint).

10

Basically as 3.3.1, except that the position numbers are defined using bits 0...6 of the serial interface. In this

mode, the setting "Posicon control terminals" will have to be selected for one of the bus setpoints (P546, P547,

and P548).

BU 0710 GB 17

Page 18

NORDAC SK 700E manual Posicon special extension

3.3.6

Position increment array – Bus transmission of absolute setpoint position

Basically as 3.3.2, except that bits 0..6 of the serial interface are used to define the position increments.

The other bits can be used to control point-of-reference tracking, teach-in programming, and the "reset

position" function.

Bit 0: position array / position increment array

Bit 1: position array / position increment array

Bit 2: position array / position increment array

Bit 3: position array / position increment array

Bit 4: position array / position increment array

Bit 5: position array / position increment array

Bit 6: point-of-reference tracking

Bit 7: point of reference

Bit 8: teach-in

Bit 9: quit teach-in

Bit 10: reset position

3.4

Teach-in programming

Apart from entering them directly in terms of a position array, the setpoint positions can also be parameterised

using the "teach-in" programming function.

"Teaching-in" via input terminals involves two inputs on the customer interface or the positioning board being

assigned. Of these inputs one is programmed to execute the "teach-in" function and the other to execute the

"quit teach-in" function. "Teaching-in" is started applying a "1" signal to the chosen input. This command

remains active until the signal is removed. With a change of the "quit teach-in" signal from 0 to 1, the current

position value is stored as a setpoint position in the inverter memory.

The position number is defined using the option for digital input position setting. If no input is activated

(position 0), the position number is generated by an internal counter. The count will be increased each time a

position has been transferred to memory. When the "teach-in" programming function is started with a position

setting of 0, the count will be 1. When the value is stored with the "quit teach-in" digital input being energized,

the count is increased. As soon as a position is addressed via the digital inputs, the counter is set to the

number of this position.

While the "teach-in" programming function is active, the frequency inverter can be controlled by feeding to it

enable signals and frequency setpoints (in the same way as with the position control parameter set to OFF).

"Teach-in" programming can also be ensured via a field bus system. In that case the "Posicon control

terminals" setting will have to be selected for one of the bus setpoint modes (P546, P547, or P548).

3.5

Modes of position control (P600)

Positioning can be performed in either of two modes. They are different with regard to the way in which the

constant rate of progression during the positioning process is ensured. In one mode it is the frequency

(maximum frequency) set in parameter P105 which determines the rate at which the controlled unit is moving

on all through the process.

In the other the rate of constant progression can be selected by defining a setpoint in the usual way which

means that position and rate of displacement can be set independently of each other.

18 BU 0710 GB

Page 19

3 Functional characteristics

3.6 Position control

Position control is configured as a P control loop. Setpoint and actual position are constantly compared. The

setpoint frequency is calculated by multiplication of the position error with the value set in the "Position

controller P" parameter. Afterwards a maximum limit is determined which the setpoint frequency must not

exceed.

If the distance calculation function is activated, a derivative with respect to distance is calculated based on the

programmed braking time and the current speed. With braking time not being taken into account by distance

calculation, the speed would very probably be reduced too late, and the position be overshot. However braking

time is not a factor considered with highly dynamical systems where acceleration and deceleration periods are

extremely short, or with systems for which only very small displacement increments are defined.

Another parameter allows for the provision of settings for a destination window. In the destination window the

setpoint frequency is limited to minimum frequency (P104). In applications with varying loads and without

speed control, this parameter can be used to program a distance to be covered in crawling motion.

The destination window parameter does not affect the "Final position" relay signal.

Synoptical position control diagram:

frequency

max.

min.

T_brake

N_act

P_set

accel.time

P102

max. frequency

P105

f_maxf_min

size target window

decel.time

P103

P position controller

traveling with min.

frequency

time

(*)

(*) time depending on

"size of destination window"

P612

N_set

P_act

P position controller

BU 0710 GB 19

Page 20

NORDAC SK 700E manual Posicon special extension

3.7 Relay signals

The Posicon positioning card is endowed with two multi-function relays, each of which can be assigned one

function in a parameter. It is not possible to establish AND or OR circuits between any of these functions. The

following functions are available on both relays:

- Reference point

The relay signals that a valid reference point has been established. The relay drops out when reference

point tracking is started. As soon as the reference point is found the relay pulls up. The state the relay will be

in when the inverter voltage is switched on depends on the setting made in P606 (if the "save position"

option has been selected the relay will have picked up when the inverter is switched on, otherwise it will

have dropped out).

- Final position

The inverter will use this function to indicate that the setpoint position has been reached. The relay picks up

when the amount by which the actual position deviates from the setpoint position is smaller than the value

set in the "Relay hyst." parameter and when the current frequency is smaller than the + 2Hz minimum

frequency (P104).

- Reference position

The relay will close the circuit when the actual position is greater than or equal to the value defined in the

"Relay position" parameter. The relay will be released again when the actual position value becomes less

than "Relay reference position" – "Relay hyst". The sign is taken into account.

[Multifunction relay pulls up when p

act

> p

and drops out when p

ref

act

< p

ref

– p

hyst

]

- Absolute reference position

The function "absolute reference position" is basically similar to the function "reference position" except that

the actual position is processed as an absolute (unsigned) value. The relay is operated when the actual

position exceeds the parameterised value or drops below the value of the same but negative amount.

[Multifunction relay picks up when |p

act

| > |p

| and drops out when |p

ref

act

| < |p

ref

| – p

hyst

]

- Position array value

The relay picks up whenever any of the positions parameterised between 1 and 63 is either reached or

overshot. This function is available even if "position array" was not selected as position setpoint mode.

- Relay P541

Operation of the multifunction relay is defined in parameter P541. As a result unused relays can be

assigned other jobs via a field bus as required.

- Final reference position

The relay will close the circuit when the amount by which the actual position deviates from the reference

position is smaller than the value set in the "relay hyst." parameter.

[Multifunction relay picks up when |(p

- p

act

)| < p

ref

hyst

]

- Final absolute reference position

The relay closes the circuit when the absolute value of the amount by which the absolute actual position

deviates from the absolute reference position becomes smaller than the value set in the "relay hysteresis"

parameter.

[Multifunction relay pulls up when |(|p

vef

| - |p

act

|)| < p

hyst

]

All relay functions are available even if the system is not operated in the position control mode

(P600 = 0).

20 BU 0710 GB

Page 21

4 Positioning parameters

4 Positioning parameters

Parameter Setting / Description / Note Available with option

P600 (P) Position control ON / OFF

0...2

[ 0 ]

P601 Current actual position value

-50000...50000.000 rev. The current actual position value will be displayed.

P602 Current setpoint position value

-50000...50000.000 rev. The current setpoint position value will be displayed.

P603 Current position variance

-50000...50000.000 rev. The current deviation between actual and setpoint position will be displayed.

P604 Displacement measurement system

0...1

[ 1 ]

P605 Absolute value encoder

0...15

[ 15 ]

Activation of position control

0: OFF

1: Mode 1 ON (constant progression at maximum frequency)

2: Mode 2 ON (constant progression at setpoint frequency)

Way the actual position value is ascertained, in other words type of the shaft encoder being

used

0: Incremental value shaft encoder

1: Absolute value shaft encoder

The type of the absolute value shaft encoder is set here.

0: SSI single-turn 512 increments

1: SSI single-turn 1024 increments

2: SSI single-turn 2048 increments

3: SSI single-turn 4096 increments

4: SSI 16-revolution multi-turn 512 increments

5: SSI 16-revolution multi-turn 1024 increments

6: SSI 16-revolution multi-turn 2048 increments

7: SSI 16-revolution multi-turn 4096 increments

8: SSI 256-revolution multi-turn 512 increments

9: SSI 256-revolution multi-turn 1024 increments

10: SSI 256-revolution multi-turn 2048 increments

11: SSI 256-revolution multi-turn 4096 increments

12: SSI 4096-revolution multi-turn 512 increments

13: SSI 4096-revolution multi-turn 1024 increments

14: SSI 4096-revolution multi-turn 2048 increments

15: SSI 4096-revolution multi-turn 4096 increments

POS

POS

POS

POS

POS

POS

BU 0710 GB 21

Page 22

NORDAC SK 700E Manual Posicon special extension

Parameter Setting / Description / Note Available with option

P606 Incremental value shaft encoder

0...23

[ 6 ]

P607

-1000...1000

[ 1 ]

..-01 Æ incr.

..-02 Æ abs.

The type of incremental encoder is set here.

0: Incremental 500 increments

1: Incremental 512 increments

2: Incremental 1000 increments

3: Incremental 1024 increments

4: Incremental 2000 increments

5: Incremental 2048 increments

6: Incremental 4096 increments

7: Incremental 5000 increments

8: Incremental 500 increments with position storage

9: Incremental 512 increments with position storage

10: Incremental 1000 increments with position storage

11: Incremental 1024 increments with position storage

12: Incremental 2000 increments with position storage

13: Incremental 2048 increments with position storage

14: Incremental 4096 increments with position storage

15: Incremental 5000 increments with position storage

16: 500 increments absolute 1 revolution

17: 512 increments absolute 1 revolution

18: 1000 increments absolute 1 revolution

19: 1024 increments absolute 1 revolution

20: 2000 increments absolute 1 revolution

21: 2048 increments absolute 1 revolution

22: 4096 increments absolute 1 revolution

23: 5000 increments absolute 1 revolution

24: 500 increments absolute 1 revolution mode 2

25: 512 increments absolute 1 revolution mode 2

26: 1000 increments absolute 1 revolution mode 2

27: 1024 increments absolute 1 revolution mode 2

28: 2000 increments absolute 1 revolution mode 2

29: 2048 increments absolute 1 revolution mode 2

30: 4096 increments absolute 1 revolution mode 2

31: 5000 increments absolute 1 revolution mode 2

Multiplication

The multiplication factor for incremental and absolute value shaft encoders is set here.

nn

=

GM

tionmultiplica

ationdemultipic

POS

POS

P608

0...1000

[ 1 ]

P609

-50000...50000.000 rev.

[ 0 ]

P610 Position setpoint mode

0...1

[ 0 ]

P611 (P) P position controller

0,1...100,0 rev

[ 5 ]

..-01 Æ incr.

..-02 Æ abs.

..-01 Æ incr.

..-02 Æ abs.

Demultiplication

The demultiplication factor for incremental and absolute value shaft encoders is set here.

Position offset

In this parameter the position offset for absolute and incremental shaft encoders can be

defined separately depending on which of the two displacement measurement systems is

involved.

To set the desired position two different modes are available. The position can be defined as

either an absolute or a relative value.

0: Position array Æ an absolute position is defined

1: Position increment array Æ a relative position is defined

The P gain of position control can be varied. Too high a value will lead to overswinging,

whereas if it is too low, precision of positioning will be affected. The rigidity of the axle at

standstill increases with rising P values.

POS

POS

POS

POS

22 BU 0710 GB

Page 23

4 Positioning parameters

Parameter Setting / Description / Note Available with option

P612 (P) Size of destination window

0,1...100,0 rev

[ 0 ]

The destination window allows for ensuring a crawling motion towards the end of the

positioning operation. Inside the destination window the maximum rate of progression

depends on the setting made in parameter P104 (minimum frequency) rather than on the

maximum or setpoint frequency.

Important: If when setting up a destination window the minimum frequency set in

parameter P104 is 0Hz, the final position cannot be reached.

P613 (P)

..-01

…

-50000...50000.000 rev.

[ 0 ]

..-63

Position array element

Array for the 63 different setpoint positions which can be selected in the "position array"

setpoint mode via the digital inputs or via a field bus.

P614 (P)

-50000...50000.000 rev.

[ 0 ]

..-01

…

..-06

Position increment array element

Array for the 6 position increments which are selected in the "position increment array"

position setpoint mode via the digital inputs or via a field bus. With each change of signal from

"0" to "1" at the digital input involved, the value allocated to the digital input is added to the

position setpoint.

P615 (P) Maximum position

-50000...50000.000 rev.

[ 0 ]

Setpoints are limited to the value set here. When the actual position setpoint exceeds this

value, the error signal "E147" indicating that the maximum position was exceeded, becomes

active. When this parameter is set to 0, position monitoring is deactivated.

P616 (P) Minimum position

-50000...50000.000 rev.

[ 0 ]

Setpoints are limited to the value set here. When the actual position value drops below this

amount, the error signal "E148" indicating that the minimum position was exceeded, is

activated. Position monitoring is deactivated by setting this parameter to "0".

P617 Monitoring of position recognition

0...1

[ 0 ]

This type of monitoring can be used with absolute value shaft encoders where a voltage

monitoring bit is available.

P618 Function digital input 7

0...11

[ 1 ]

"Bit 0 position array / position increment array“ is the default setting

P619 Function digital input 8

0...11

[ 2 ]

"Bit 1 position array / position increment array“ is the default setting

P620 Function digital input 9

0...11

[ 3 ]

"Bit 2 position array / position increment array“ is the default setting

P621 Function digital input 10

0...11

[ 4 ]

"Bit 3 position array / position increment array" is the default setting

P622 Function digital input 11

0...11

[ 7 ]

"Bit 4 position array / position increment array“ is the default setting

POS

POS

POS

POS

POS

POS

POS

POS

POS

POS

POS

BU 0710 GB 23

Page 24

NORDAC SK 700E Manual Posicon special extension

Parameter Setting / Description / Note Available with option

P623 Function digital input 12

0...11

[ 8]

"Bit 5 position array / position increment array“ is the default setting

0: No function

1: Bit 0 position array / position increment array

2: Bit 1 position array / position increment array

3: Bit 2 position array / position increment array

4: Bit 3 position array / position increment array

5: Bit 4 position array / position increment array

6: Bit 5 position array / position increment array

7: Reference point tracking

8: Reference point

9: Teach-in

10: Quit teach-In

11: Reset position

P624 (P) Function relay 3

0...8

[ 2 ]

"Final position reached“ is the default setting

0: No function

1: Point of reference

2: Final position reached

3: Reference position

4: Absolute value of reference position

5: Value of position array

6: Relay control via P541

7: Reference position reached

8: Absolute value of reference position ensured

P625 (P) Hysteresis relay 3

0,00...99,99 rev

[ 1 ]

Difference between operate point and release point which will prevent oscillation of the output

signal.

P626 (P) Reference position relay 3

-50000...50000,000 rev

[ 0 ]

Reference position for the settings 3, 4 and 7, 8 of relay 3

P627 (P) Function relay 4

0...8

[ 0 ]

Default setting is "no function"

0: No function

1: Reference point

2: Final position reached

3: Reference position

4: Absolute amount of reference position

5: Value of position array

6: Relay controlled via P541

7: Reference position reached

8: Absolute value of reference position ensured

P628 (P) Hysteresis relay 4

0,00...99,99 rev

[ 1 ]

Difference between operate and release point preventing oscillation of the output signal.

P629 (P) Reference position relay 4

-50000...50000,000 rev

[ 0 ]

Reference position for the settings 3, 4 and 7, 8 of relay 4

P630 (P) Pos. synchronization error

0,00...99,99 rev

[ 0 ]

The allowable deviation between estimated and actual position can be set. As soon as a

desired position is reached, the estimated position is set to the current actual position.

By adopting a "0" setting the synchronization error monitoring function can be deactivated.

POS

POS

POS

POS

POS

POS

POS

POS

24 BU 0710 GB

Page 25

4 Positioning parameters

Parameter Setting / Description / Note Available with option

P631 (P) Abs / inc synchronization error

0,00...99,99 rev

[ 0 ]

The allowable deviation between absolute value shaft encoder and incremental value shaft

encoder information can be set here.

Monitoring is deactivated with a "0" setting.

POS

BU 0710 GB 25

Page 26

NORDAC SK 700E Manual Posicon special extension

5 System start-up

When setting up Posicon control for an application it is advisable to carry out the individual steps in the order

described below. For errors that may occur during this stage see also Section 6, Fault clearance.

st

step: Putting the axle into operation without control

1

After all parameter settings have been entered as required, begin by putting the axle into operation without

position or speed control. Accordingly switch off position control in the "Positioning" parameter group, and the

servo mode in the "Control parameters" parameter group.

Important note: Make sure that emergency stop and safety circuits are operative!

With lifting gear applications take precautions before turning on the power for the first time to ensure that the

load will not suddenly drop or sag.

In speed-controlled lifting gear, set the speed controller before you optimise the moment the load is taken up

(setpoint delay parameter).

nd

2

step: Putting the speed controller into operation

If no speed control is desired or no incremental encoder provided, disregard this step, otherwise set the servo

mode to ON. For operation in the servo mode, enter the exact motor data and the correct number of encoder

graduation marks.

If after the servo mode has been activated the motor runs at low speed while the current input is high, this is

caused in all probability by a wiring error or by a parameterisation error concerning the connection of the

incremental encoder. Very often the above condition results from a discrepancy between the sense of rotation

of the motor and the counting direction of the encoder. Preferably the speed controller is not optimised until

the position controller is put into operation, because the behaviour of the position control loop can be

manipulated by varying the parameters relating to the speed controller.

rd

3

step: Putting the position controller into operation

When the parameters P604, P605/606 have been set, check first whether the actual position is recognized

correctly. The actual position is read out in the "Current position" parameter (P601). The value is supposed to

be stable, and to increase when the motor is activated with the "enable right" command. If the value does not

change when the axle is rotated, check on the parameter settings and the encoder connection. The same

checking should be performed if the actual position value read out is erratic although the shaft does not move.

After that a setpoint position should be parameterised next to the current position. If the axle moves away from

that position rather than towards it when the motor has been enabled, the sense of rotation of the motor does

not match the sense of rotation of the encoder. Exchange the sign of the multiplication factor to put things

right.

When actual position recognition is working correctly, the position controller can be optimised. As a rule the

axle will respond more "rigidly" as the P gain is increased, in other words there will be less deviation from the

setpoint position than with minor gain values.

The maximum P gain of the position controller that can reasonably be set depends on the dynamical

behaviour of the total system. As a rule the following principle is true: The greater the masses involved in the

system and the less the friction, the more it is prone to oscillation, and the less is the maximum allowable P

gain value. To determine the critical value, the gain is gradually increased until the drive oscillates around the

position (departing from it for an instant and returning to it again). After that set the gain to between 0.5 and

0.7 times the critical value.

As the default setting will probably not be adequate for positioning applications with cascaded controller (servo

mode) involving heavy loads, a different setting should be preferred, e.g. a value between 3% and 5% for the I

gain of the speed controller, and a value between 100% and 150% as the P gain.

26 BU 0710 GB

Page 27

6 Fault clearance

6 Fault clearance

6.1 Error messages

The majority of the frequency inverter functions and operational information is continuously monitored and

compared to limit values. Detecting a deviation the inverter will put out a warning or an error message.

For fundamental information on this subject kindly refer to the Operating Instructions for the basic unit.

The table below contains all of those faults which can be attributed to the Posicon function. It should be noted

that as far as the optional "Control Box" is concerned, only the error codes E14 or E15 will be shown however.

Access parameter P700 (current fault) or P701 (previous fault) for detailed information on the error that has

occurred.

Faults Cause Remedy

E14 / E140-E141

E14 / E142

E14 / E143

E4 / E145

E14 / E146

E14 / E147

E14 / E148

E15 / E150

• EMC measures inadequate

• Posicon extension was not fitted

correctly

• Reference point tracking was

interrupted without a reference

point having been found

• Absolute encoder defective, or

communication fault

• Position recognition doesn't

work correctly, or there is an

open-circuit fault

• Position recognition doesn't

work correctly, or there is an

open-circuit fault

• Maximum position was

exceeded

• Minimum position was exceeded • Check controller and setpoint settings

• Software version is wrong • Software versions of the basic unit and

• Provide output choke, check

parameter settings

• Check on installation

• Check reference point switch and the

zero track of the incremental encoder,

check the selection circuit too

• Check the absolute encoder and cable

routing / connections

• Check position recognition function

• Check position recognition function

• Check controller and setpoint settings

the positioning extension are not

compatible

E15 / E151-E158

BU 0710 GB 27

• Internal program flow error • Check screening and earth

connection

Page 28

NORDAC SK 700E Manual Posicon special extension

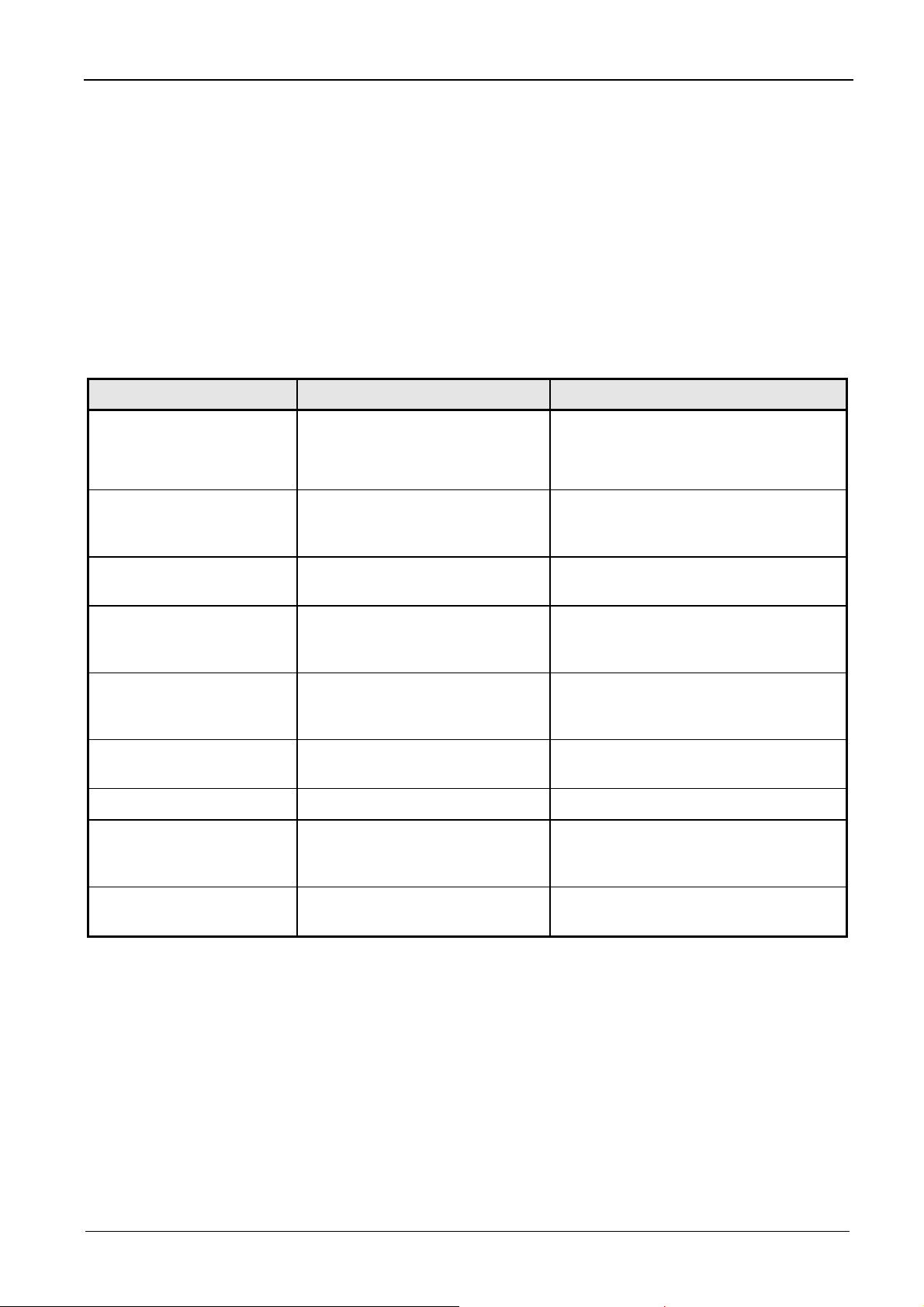

6.2 Table of errors and possible causes

In the table below the most frequent error sources are listed along with the characteristic symptoms. For

trouble shooting best proceed in the same order as when starting up the system, that is check first whether the

shaft runs correctly without being controlled, and only then go on to testing the speed and the position

controller.

1. Error sources while the system is operated in the servo mode (without position control)

Symptom Additional checking Possible cause

Motor speed very low, motor runs

jerkily

Motor speed is basically o.k.,

however there is some jerking at

lower speed

Overcurrent release at high speeds

Change sign in P301

Problems disappear when the

servo mode is switched off

• Motor sense of rotation and

incremental encoder counting

direction do not match

• Inappropriate incremental

encoder type (no RS422

outputs)

• Interruption of encoder cable

• No power is supplied to the

encoder

• The number of graduation

marks parameterised was

wrong

• Motor parameters are not

correct

• Encoder lacks one track

• Incremental encoder was not

installed correctly

• Encoder signals disturbed

Overcurrent tripping during

deceleration

2. General error sources

Symptom Additional checking Probable cause

Overshooting of position P gain value of position controller

Drive oscillates about position Too high a value set for P gain of

Drive moves into wrong direction

(away from setpoint position)

Load sagging after the enable

signal is invalidated (lifting gear)

Motor in field weakening range

• With field weakening operation

in the servo mode, the torque

limit must not exceed 200%

distinctly too high

Speed controller setting (servo

mode) inadequate (set I gain to

approx. 3%/ms, P gain to approx.

120%)

position controller

Sense of rotation of the absolute

encoder does not correspond to the

sense of rotation of the motor =>

set a negative multiplication value

in the relevant parameter

No setpoint delay was set (control

parameter); with the servo mode =

OFF the controller must be disabled immediately when the event

"final position reached" has

occurred

28 BU 0710 GB

Page 29

6 Fault clearance

3. Typical error sources in position control with incremental position recognition (without absolute

encoder)

Symptom Additional checking Possible cause

Reference point error

• Reference point tracking

completed but failed

• Encoder lacks zero track, or

encoder is defective

Drive drifts away from desired

position

• Encoder cable affected by

interference pulses

No repetitive accuracy when

moving into identical positions

Fault occurs even at low speed

(n < 1000 1/min))

• Encoder cable affected by

interference pulses

several times

Fault occurs at high speed only

(n > 1000 1/min)

• Number of graduation marks

too high considering the length

of encoder cable / the cable

type (pulse frequency too high)

4. Typical error sources in position control with absolute encoder

Symptom Additional checking Possible causes

The same actual position value is

signalled over and over again and

• Encoder connection is not

correct

remains steady afterwards

Current position is displayed as an

erratic ("jumping") value although

• Encoder cables are affected by

interference pulses

the shaft does not move

Recognition function supplies

varying information on the same

position; sometimes the axle

Is there any mechanical

irregularity?

• Axle is tight, getting jammed, or

does not move smoothly for

any other reason

seems to jump to and fro.

Position value is not in accordance

with amount of encoder rotation or

is erratic => shaft encoder is

defective

Check absolute encoder

(detach it, set multiplication and

demultiplication parameters to 1,

turn encoder by hand: the position

• Encoder defective

indicated must be in accordance

with the encoder revolutions)

BU 0710 GB 29

Page 30

NORDAC SK 700E Manual Posicon special extension

7 Business establishments & sales offices in Germany

G e tr i e b e b a u N O R D representative offices in Germany:

Niederlassung Nord

Getriebebau NORD GmbH & Co. KG

Rudolf-Diesel-Str. 1

22941 Bargteheide

Tel. 04532 / 401 - 0

Fax 04532 / 401 - 429

Niederlassung West

Getriebebau NORD GmbH & Co. KG

Großenbaumer Weg 10

40472 Düsseldorf

Tel. 0211 / 99 555 - 0

Fax 0211 / 99 555 - 45

Niederlassung Süd