Page 1

NORDAC SK 200E Handbuch Sicherheitshinweise

y

GB

EtherCAT® Bus module

for NORD frequenc

BU 0570 GB-0312 Subject to technical amendments 1

inverters SK 5xxE

Page 2

EtherCAT bus module for NORD frequency inverters SK 5xxE Safety information

N O R D Frequency inverters

Safety and operating instructions for drive power converters

(as per: Low Voltage Directive 2006/95/EEC )

1. General

During operation, drive power converters may, depending on their

protection class, have live, bare, moving or rotating parts or hot

surfaces.

Unauthorised removal of covers, improper use, incorrect installation

or operation causes a risk of serious personal injury or material

damage.

Further information can be found in this documentation.

All transportation, installation, initialisation and maintenance work

must be carried out by qualified personnel (compliant with IEC

364, CENELEC HD 384, DIN VDE 0100, IEC 664 or DIN VDE 0110,

and national accident prevention regulations).

For the purposes of these basic safety instructions, qualified

personnel are persons who are familiar with the assembly,

installation, commissioning and operation of this product and who

have the relevant qualifications for their work.

2. Proper use in Europe

Drive power converters are components intended for installation in

electrical systems or machines.

When installed in machines, the drive power converter cannot be

commissioned (i.e. commencement of the proper use) until it has

been ensured that the machine meets the provisions of the EC

Directive 2006/42/EEC (machine directive); EN 60204 must also be

complied with.

Commissioning (i.e. implementation of the proper use) is only

permitted when the EMC directive (2004/108/EEC) is complied with.

CE-labelled drive power converters meet the requirements of the

Low Voltage Directive 2006/95/EEC. The harmonised standards for

drive power converters listed in the declaration of conformity are

used.

Technical data and information for connection conditions can be

found on the rating plate and in the documentation, and must be

complied with.

The drive power converters may only be used for safety functions

which are described and explicitly approved.

3. Transport, storage

Information regarding transport, storage and correct handling must

be complied with.

4. Installation

The installation and cooling of the equipment must be implemented

according to the regulations in the corresponding documentation.

The drive power converter must be protected against

impermissible loads. Especially during transport and

handling, components must not be deformed and/or

insulation distances must not be changed. Touching of

electronic components and contacts must be avoided.

Drive power converters have electrostatically sensitive

components, which can be easily damaged by incorrect

handling. Electrical components must not be mechanically

damaged or destroyed (this may cause a health hazard!).

5. Electrical connection

When working on live drive power converters, the applicable

national accident prevention regulations must be complied

with (e.g. VBG A3, formerly VBG 4).

The electrical installation must be implemented according to

the applicable regulations (e.g. cable cross-section, fuses,

ground lead connections). Further instructions can be found

in the documentation.

Information about EMC-compliant installation – such as

shielding, earthing, location of filters and installation of

cables can be found in the drive power converter

documentation. These instructions must be complied with

even with CE marked drive power converters. Compliance

with the limiting values specified in the EMC regulations is

the responsibility of the manufacturer of the system or

machine.

6. operation

Where necessary, systems where drive power converters

are installed must be equipped with additional monitoring

and protective equipment according to the applicable safety

requirements, e.g. legislation concerning technical

equipment, accident prevention regulations, etc.

The parameterisation and configuration of the drive power

converter must be selected so that no hazards can occur.

All covers must be kept closed during operation.

7. Maintenance and repairs

After the drive power converter is disconnected from the

power supply, live equipment components and power

connections should not be touched immediately, because of

possible charged capacitors. Observe the applicable

information signs located on the drive power converter.

Further information can be found in this documentation.

These safety instructions must be kept in a safe place!

2 Subject to technical amendments BU 0570 GB-0312

Page 3

EtherCAT bus module for NORD frequency inverters SK 5xxE About this document

Documentation

Designation: BU 0570 GB

Part No.: 607 57 02

Device series: SK TU3-ECT (EtherCAT® - Bus module) for SK 5xxE (entire series)

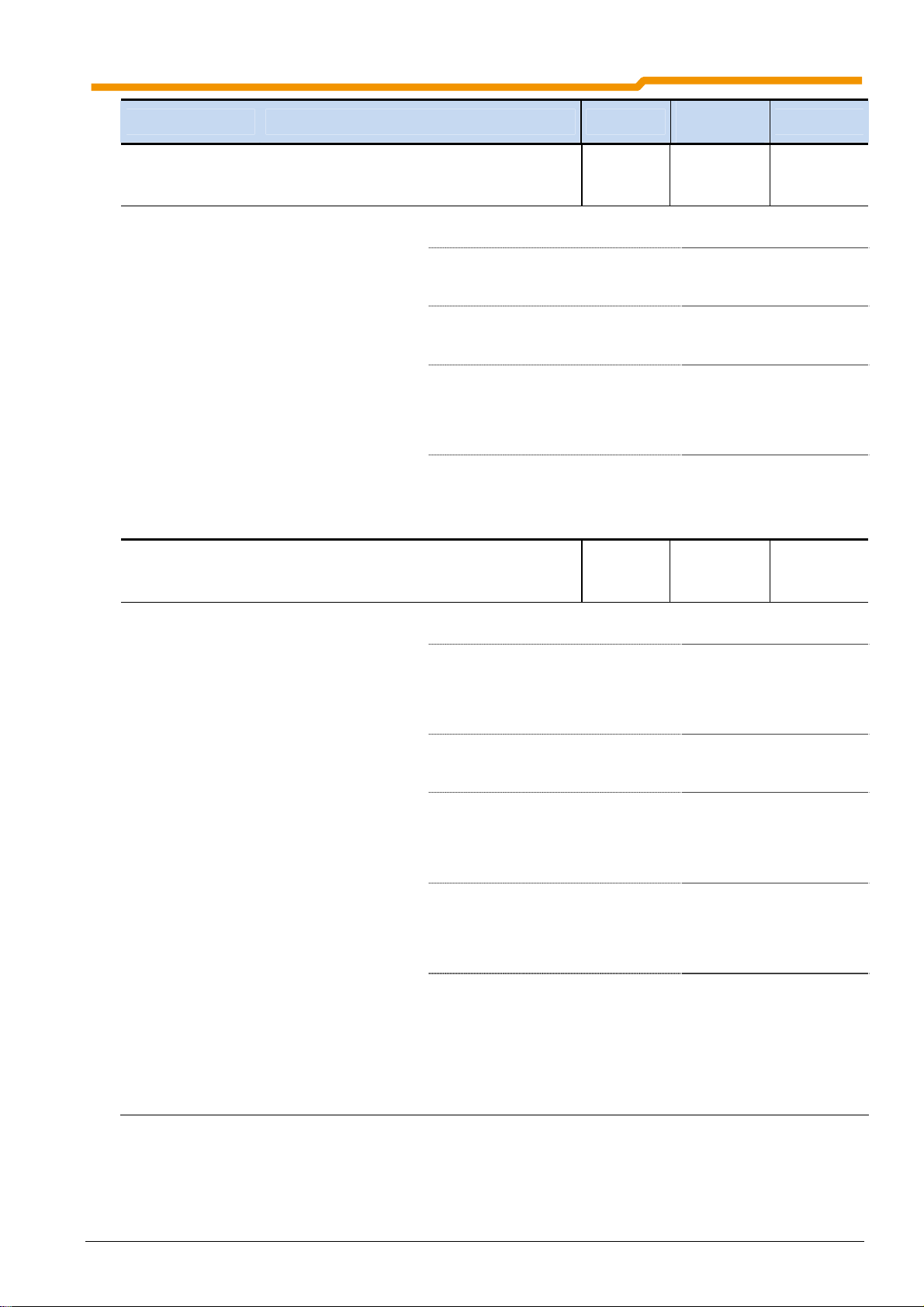

Version list

Designation of previous versions Software

BU 0570 GB, June 2009

Part No. 607 5701

BU 0570 GB, Jan 2010

Part No. 607 5701 / 0410

BU 0570 GB, April 2010

Part No. 607 5701 / 1710

BU 0570 GB, Jan 2012

Part No. 607 5701 / 0312

Publisher

NOTE

Remarks

Version

V 1.0 R0 First issue

V 1.0 R1 The trademark entry for the firm Beckhoff was amended in

the introduction

V 1.0 R1 Replacement of Fig. 3, correction of spelling errors in

parameter (P172).

V 1.4 R0 Extension to frequency inverter SK 54xE

Getriebebau NORD GmbH & Co. KG

Rudolf- Diesel- Str. 1 D-22941 Bargteheide Germany ### http://www.nord.com/

Tel.: +49 (0) 45 32 / 401-0 Fax +49 (0) 45 32 / 401-555

This supplementary operating manual is only valid in conjunction with the operating manual

supplied for the respective frequency inverter (Manual BU0500).

Intended use of the frequency inverter

The compliance with the operating instructions is necessary for fault-free operation and

the acceptance of possible warranty claims. These operating instructions must be read

before working with the device!

These operating instructions contain important information about servicing. They must

therefore be kept close to the device.

The Ethernet module can only be used for the defined frequency inverter series (SK500E).

The use of this module with other devices is not permitted and can lead to their destruction.

The Ethernet module and the associated frequency inverter are devices for fixed installation

in control cabinets. All details regarding technical data and permissible conditions at the

installation site must be complied with.

Commissioning (implementation of the intended use) is not permitted until it has been

ensured that the machine complies with the EMC directive 2004/108/EEC and that the

conformity of the end product meets the machine directive 2006/42/EEC (note EN 60204).

Getriebebau NORD GmbH & Co. KG, 2012

BU 0570 GB-0312 Subject to technical amendments 3

Page 4

EtherCAT bus module for NORD frequency inverters SK 5xxE

1 INTRODUCTION................................................................................................................. ..... 6

1.1 General information ............................................................................................. 6

1.2 The bus system ................................................................................................... 6

1.3 Delivery................................................................................................................ 7

1.4 Scope of supply ................................................................................................... 7

1.5 Certifications........................................................................................................ 7

1.5.1 European EMC Directive ..........................................................................................7

1.5.2 RoHS compliance ..................................................................................................... 7

1.6 Identification System ........................................................................................... 7

2 MODULES................................................................................................................................ 8

2.1 SK 5xxE frequency inverters ............................................................................... 8

2.2 EtherCAT - BUS Module ..................................................................................... 9

2.2.1 Mounting................................................................................................................... 9

2.2.2 Technical data ........................................................................................................ 10

2.2.3 Connections............................................................................................................ 10

2.2.4 Status display via LED............................................................................................ 11

3 COMMISSIONING.................................................................................................................. 13

3.1 Cabling............................................................................................................... 13

3.1.1 Topology................................................................................................................. 13

3.1.2 EMC........................................................................................................................ 13

3.2 Commissioning the bus module ........................................................................ 14

3.2.1 Connecting the bus module ....................................................................................14

3.2.2 Parameter settings of the frequency inverter .......................................................... 14

3.3 Configuration in the Bus system........................................................................ 15

3.3.1 Integration into TwinCAT System Manager (Example)........................................... 15

3.3.2 Addressing.............................................................................................................. 16

4 COMMUNICATION................................................................................................................ 17

4.1 NMT State Machine........................................................................................... 17

4.2 Process data...................................................................................................... 18

4.2.1 Process data structure............................................................................................ 18

4.2.2 Control word ...........................................................................................................19

4.2.3 Status word............................................................................................................. 20

4.2.4 FI Status Machine................................................................................................... 21

4.2.5 Setpoint and actual values...................................................................................... 23

4.2.6 Beispiel für FU das Ein- / Ausschalten des Frequenzumrichters ............................24

4.2.7 Timeout monitoring ................................................................................................. 24

4.3 Parameterübertragung EtherCAT ..................................................................... 25

4.3.1 Ablauf der Parameterübertragung .......................................................................... 25

4.3.2 Error codes for SDO parameter access.................................................................. 25

4.4 XML File............................................................................................................. 27

5 PARAMETER......................................................................................................................... 28

5.1 Parameterisation of the EtherCAT module SK TU3-ECT ................................. 28

5.1.1 EtherCAT parameters............................................................................................. 28

5.1.2 BUS module standard parameters (P15x) ..............................................................28

5.1.3 BUS module information parameters, general (P17x) ............................................ 29

5.1.4 BUS module information parameters, bus-specific (P18x) ..................................... 30

5.2 SK5xxE inverter parameters (selection)............................................................ 31

5.2.1 Extra functions........................................................................................................ 31

5.2.2 Information parameters........................................................................................... 34

4 Subject to technical amendments BU 0570 GB-0312

Page 5

Table of Contents

6 ERROR MONITORING AND ERROR MESSAGES...............................................................37

6.1 EtherCAT error monitoring .................................................................................37

6.2 Error messages in the EtherCAT module SK TU3-ECT ....................................38

6.3 Error messages in the SK 5xxE frequency inverter ...........................................38

7 LISTS / INDEX ........................................................................................................................39

7.1 Abbreviations......................................................................................................39

7.2 Keyword Index....................................................................................................39

7.3 Figures................................................................................................................40

7.4 Tabellen..............................................................................................................40

7.5 Keyword index....................................................................................................41

BU 0570 GB-0312 Subject to technical amendments 5

Page 6

EtherCAT bus module for NORD frequency inverters SK 5xxE

1 Introduction

1.1 General information

Modern field bus systems, microcontrollers and communication networks have had a great influence on

automation systems and have resulted in greater flexibility, availability and ultimately, also a reduction in

costs.

The widespread use of PC-based control only became possible with the availability of field bus systems.

With increasing control unit performance, the classic field bus ultimately became the limiting criterion for the

entire system. It was therefore an obvious step to adapt Ethernet technology, which provides high rates of

data transmission in IT applications, to the field of automation.

1.2 The bus system

In order to achieve real-time capability, EtherCAT uses a system which had already been used in a similar

form by Interbus. Ethernet packages are not first received, interpreted and then forwarded to participants by

each connected device, but rather each EtherCAT slave module extracts the data which is intended for it

whilst the telegram passes through the module. Output data is inserted into the telegram in the same way.

This results in delays of only nanoseconds.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Features of the SK TU3-ECT

Static 8 byte process data for input and output

Parameterisation via CoE (CAN over EtherCAT)

Error messages (emergency messages) compliant with CANopen DS301

EtherCAT addressing via DIP switches

Distributed Clocks are not supported

Performance

Via the SK TU3-ECT, up to 1000 frequency inverters can each update their process data (8 byte

input and output data) in a cycle of one millisecond.

An update interval for process data between the SK TU3 ECT and the SK 500E requires

approximately1.5 ms

Reading access to a parameter on the SK 500E requires about 25ms

Writing access and storage of a parameter in the EEPROM requires about 70 ms.

6 Subject to technical amendments BU 0570 GB-0312

Page 7

1 Introduction

1.3 Delivery

Check the equipment immediately after delivery/unpacking for transport damage such as deformation or

loose parts.

If there is any damage, contact the carrier immediately and carry out a thorough assessment.

Important! This also applies even if the packaging is undamaged.

1.4 Scope of supply

SK TU3-ECT* EtherCAT bus module for SK 5xxE frequency inverters IP20

*incl. screw for optional fixing to the FI

1.5 Certifications

1.5.1 European EMC Directive

If NORD frequency inverters or their options are installed according to the

recommendations in this instruction manual, it meets all EMC directive

requirements, as per the EMC product standard for motor-operated systems

EN 61800-3.

1.5.2 RoHS compliance

The bus options described here are designed to be RoHS compliant

according to Directive 2002/95/EEC

1.6 Identification System

SK TU3-ECT

Bus system: AS1 = AS-In terface, CAN = CAN, CAO = CANopen,

ECT = EtherCAT®, PNT = PROFINET®, etc.

Device series: SK TU1 / SK TU2 / SK TU3 / SK TU4

Fig. 1 Type Codes

BU 0570 GB-0312 Subject to technical amendments 7

Page 8

EtherCAT bus module for NORD frequency inverters SK 5xxE

2 Modules

2.1 SK 5xxE frequency inverters

By the use of various modules for display, control and parameterisation, the SK 5xxE can be easily adapted

to various requirements.

Alphanumerical display and operating modules can be used for simple commissioning. For more complex

tasks, various connections to a PC or an automation system can be selected.

The technology unit (Technology Unit, SK TU3-…) is connected externally to the front of the frequency

inverter and is therefore easy to access and replace at any time.

In the delivery condition (without technology unit) 2 LEDs (green/red) are visible externally. These indicate

the actual device status.

The green LED indicates that the mains voltage is present and operational, while a flashing code that

increases in speed shows the degree of overload at the frequency inverter output.

The red LED signals actual error by flashing with a frequency which corresponds to the number code of the

error (Manual BU 0500 Section 6).

LED

red/green

Fig. 2 Frequency inverters with SK TU3- optional modules (selection)

WARNING

Modules should not be inserted or removed unless the device is free of voltage. The slots may

only be used for the intended modules.

Installation of a technology unit separate from the frequency inverter is not possible. It must be

connected directly to the frequency inverter.

NOTE

8 Subject to technical amendments BU 0570 GB-0312

Page 9

2.2 EtherCAT - BUS Module

2.2.1 Mounting

The technology units must be installed as follows:

1. Switch off the mains voltage (frequency inverter), observe the waiting period.

2. Push the control terminals cover down slightly or remove.

3. Remove the blank cover by pressing the release on the lower edge and pulling off with an upward

turning movement. If necessary, the fixing screw next to the release must be removed.

4. Hook the technology unit onto the upper edge slots and press in lightly until engaged. Ensure full

contact with the connector strip and fasten with the screws if necessary (separate packet).

5. Close the control terminal cover again.

2 Modules

3

2 „press“

1

4

Similar to illustration

Fig. 3 Installation of the Technology Unit (optional module)

Further detailed information can be found in the device manual BU 0500.

- www.nord.com

–

BU 0570 GB-0312 Subject to technical amendments 9

Page 10

EtherCAT bus module for NORD frequency inverters SK 5xxE

2.2.2 Technical data

Specification

EtherCAT

Bus connection

Bus termination

Cable

Max. cable length

Supply voltage

Status display

Device address

PE

Shield

Table 1 Electrical specifications of the SK TU3-…

2.2.3 Connections

Max. baud rate 100 MBaud

Electrical isolation 500V

2 RJ45

Performed automatically by the SK TU3-… Technology Unit

Ethernet CAT-5 or better

100m between two Ethernet bus modules

24V 20%, current consumption ≈ 100mA

Reverse polarity protected

4 LEDs

via EtherCAT master or setting via 12-pole DIP switches on the rear of the

SK TU3-ECT

Connection via plug pins under the 24V supply

The shields of the two RJ sockets are connected together and connected to PE with a

high resistance and capacitance. If several technology units are adjacent to each

other, only one board needs to be connected to the PE.

eff

Name Name

45

46

Table 2 Power supply connections

+24V

GND

Signal Name RJ45 Pin

TX+

TXRX+

RX-

Table 3 RJ45 socket connections

Transmission Data + 1

Transmission Data - 2

Receive Data +

Receive Data -

SK TU3-…

24V

GND

PE

3

6

Pin 8

Pin 1

10 Subject to technical amendments BU 0570 GB-0312

Page 11

2.2.4 Status display via LED

DS DE

2 Modules

RUN

ERR

L / A*

*L / A = Link / Aktiv: auf jeder RJ45 Buchse vorhanden

Fig. 4 Location and designation of the LEDs

RUN

Green LED

Off

Flashing

Single Flash

On

Table 4 Description of the RUN LED (Ethernet Status)

Init No communication of process data and parameters

Pre-Operational

Save Operational

Operational

State Meaning

ERR

Red LED

Off

Flashing

Single Flash

Double Flash

No Error EtherCAT functioning normally on the Bus Module

Invalid Configuration

Unsolicited State

Change

Application Watchdog

Timeout

State Meaning

- Parameter communication active

- No process data communication

- Parameter communication active

- Limited process data communication

- No restrictions to actual values

- Setpoints not evaluated

- Parameter communication active

- Unrestricted process data communication

General EtherCAT configuration error, can be generated by a false

XML file.

SK TU3-ECT has changed the EtherCAT state without authorisation

EtherCAT or FI timeout (P513 in FI)

Table 5 Description of the ERR LED (Ethernet Status)

L/A

Green LED

Off

Flashing

ON

Table 6 Description of the Link / Activity LEDs

BU 0570 GB-0312 Subject to technical amendments 11

State

No Connection No connection via cable or the SK TU3-ECT has no power supply

Active Connected and active

Inactive Connected, but no bus activity

Meaning

Page 12

EtherCAT bus module for NORD frequency inverters SK 5xxE

DS

Green LED

Off Off

Off

Flashing

Cycle 0.50 sec

On

On Off

Table 7 Description of the DS and DE LEDs

DE

Red LED

Flashing 1...7x

Cycle 0.25sec

Pause 1s

Off

Flashing 1x

Cycle 0.25sec

Meaning

The technology unit does not have a power supply

The technology unit has a fatal system error

Technology unit OK but no FI (frequency inverter) detected

Causes The FI has no power supply or the technology unit is not

correctly plugged in

The FI is in an error condition

Technology unit OK and FI detected

12 Subject to technical amendments BU 0570 GB-0312

Page 13

3 Commissioning

3.1 Cabling

3.1.1 Topology

The TU3-ECT EtherCAT modules can only be interconnected in a linear structure.

EtherCAT

Master

TU3-ECT TU3-ECT TU3-ECT

3 Commissioning

Fig. 5 EtherCAT topology

The EtherCAT cable from the master must be connected to the RJ45 "IN" socket of the TU3-ECT. The

EtherCAT connection from the TU3-ECT must be made via the "OUT" socket. With the last device, the

"OUT" socket remains free, a cable termination is not necessary.

The integration of a normal Ethernet switch for the connection of normal EtherCAT devices must be made

between the EtherCAT master and the first EtherCAT module; see the following diagram.

EtherCAT

Master

Printer

Fig. 6 EtherCAT topology with integrated standard switch

Switch TU3-ECT TU3-ECT

TU3-ECT

3.1.2 EMC

If EMC measures are not in place, high-frequency interference which is mainly caused by switching

processes or lightning often causes electronic components in the bus participants to be faulty and error-free

operation can no longer be ensured.

Correct laying of the bus cable dampens the electrical influences which may occur in an industrial

environment. The following points must be observed:

Implement long connections between bus participants by the shortest possible distances.

Only use plugs with a metal housing.

For the production of bus cables lay the shielding on as wide an area of the plug as possible.

With the parallel installation of bus cables, a minimum distance of 20 cm should be maintained from

other cables carrying a voltage greater than 60V. In particular, this must be observed for cables to

motors or chopper resistors. This applies to lines laid both inside and outside of control cabinets.

The minimum distances for parallel installation may be reduced by shielding cables carrying voltage or

by means of earthed metal dividers in the cable ducts.

Connect SK TU3- Ethernet module to the PE (Connection via the plug pin next to the 24V supply).

BU 0570 GB-0312 Subject to technical amendments 13

Page 14

EtherCAT bus module for NORD frequency inverters SK 5xxE

3.2 Commissioning the bus module

3.2.1 Connecting the bus module

Connect the bus module to the PE via the plug pins

Connect the 24V supply via the plug-in terminal. Note the consumption of each module

(Technical Data)

Connect the Ethernet cable

Bus direction EtherCAT

Incoming cable

(from master /

controller)

Left RJ45 socket

Labelled "IN"

Outgoing cable

Table 8 Bus cable connections

Right RJ45 socket

Labelled "OUT"

If the bus module is the last participant, the RJ45 socket remains open in the outgoing direction. The

bus connection is performed automatically.

ATTENTION

Each bus module requires a separate PE connection via the plug pin. Otherwise,

interference-free operation of the bus module cannot be guaranteed.

3.2.2 Parameter settings of the frequency inverter

The following settings must be made on the frequency inverter (SK5xxE):

Control via Ethernet TU P509 = "8"

Setpoint via Ethernet TU P510 = "8" or "0" if P509 = "8"

Setting of setpoints via P546, P547 and P548 (SK 500E … SK 535E)

P546 [-01] … [-05] (SK 540E and above)

Setting of actual values via P543, P544 and P545 (SK 500E … SK 535E)

P543 [-01] … [-05] (SK 540E and above)

For a detailed description of the parameters, please refer to the frequency inverter operating manual

(BU 0500).

The parameters can be set with NORD parameterisation tools (e.g. NORD CON, SimpleBox) or via the bus

master / controller.

14 Subject to technical amendments BU 0570 GB-0312

Page 15

3 Commissioning

3.3 Configuration in the Bus system

3.3.1 Integration into TwinCAT System Manager (Example)

In the following, the integration of the SK TU3-ECT into the Beckhoff TwinCAT System Manager will be

explained. All modules must be connected and supplied with power.

Reboot of TwinCAT in config. mode via

or Shift + F4.

Scan the EtherCAT bus for connected units. See following diagram.

Fig. 7 Scanning the EtherCAT bus

The SK TU3-ECT modules which are found will be listed in the structural diagram

If an FI is to by parameterised with POSICIN or SERVO functionality via the System Manager, the

scanned type must be changed (Change to Alternative Type): see the following diagram. An

extended XML file containing the additional parameters will then be loaded. This step only needs to

be carried out once.

Fig. 8 Calling up the function "Change to Alternative Type"

With this, the SK TU3-ECT units are then integrated

BU 0570 GB-0312 Subject to technical amendments 15

Page 16

EtherCAT bus module for NORD frequency inverters SK 5xxE

3.3.2 Addressing

No settings need to be made on the SK TU3-ECT. Addressing of the bus participants is performed

automatically by the bus master according to their physical sequence on the bus.

Second Address

In modular applications, in which entire groups of bus participants are disconnected, the control unit would

have to continuously adapt its bus configuration.

This reconfiguration can be avoided by means of the so-called "Hot Connection Group" functionality and the

DIP address ("Second Address) of the SK TU3-ECT. With this functionality, the bus module is only

accessed via the DIP address ("Second Address"). The position of the module in the EtherCAT line is

irrelevant. Configured bus modules can still be removed or added at any time without the necessity for an

adaptation in the System Manager. Therefore various configurations of the EtherCAT bus can be operated

with a single SPS project. Assignment to the SPS variables is unique and always remains in effect.

For SK TU3-ECT which support the "Hot Connection Group" functionality, there is a 12-pole DIP switch on

the rear of the module for manual setting of the "Second Address". The address which is set there is

adopted when the bus module is switched on (Power On) and can therefore be used by the master. The

address which is set can be read out via the parameter P181.

12 11 10 9 8 7 6 5 4 3 2 1 Address

0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 1 1

0 0 0 0 0 0 0 0 0 0 1 0 2

- - - - - - - - - - - - -

1 1 1 1 1 1 1 1 1 1 1 1 4095

DIP switches

Table 9 Addressing via the DIP switch on the SK TU3-ECT module

The following steps are necessary for settings in the TwinCAT System Manager:

Highlight the SK TU3-ECT and select "Add to Hot Connection Groups" using the right-hand mouse

button.

In the dialogue which opens, select "2. Address" and enter the DIP address (P181).

Finish

ATTENTION

Devices without "Second Address" functionality must always be physically located at the

start of the bus. A device without this functionality may not follow a device with "Second

Address" functionality in the EtherCAT bus line.

16 Subject to technical amendments BU 0570 GB-0312

Page 17

4 Communication

4.1 NMT State Machine

The NMT State Machine defines various communication states of the SK TU3-ECT.

Init

Pre- Operational

Save- Operational

4 Communication

Operational

Fig. 9 NMT State Machine

State Explanation

Init No communication of process data and parameters

Pre-Operational - Communication of parameters

- No process data communication

Save Operational - Communication of parameters

- Restricted process data communication (only actual values are transmitted, setpoint are not evaluated)

Operational - Communication of parameters

- Unrestricted process data communication

Table 10 Explanation of NMT States

BU 0570 GB-0312 Subject to technical amendments 17

Page 18

EtherCAT bus module for NORD frequency inverters SK 5xxE

4.2 Process data

Control words and setpoints are transferred from the bus master to the SK TU3-…bus module as process

data and in return, the status word and actual values are sent to the bus master / controller from the FI.

Transfer is carried out cyclically. The bus master / controller can access these process values directly, as

they are stored in the I/O area.

For EtherCAT

the length and structure of the process data are fixed and are determined by the XML-File.

According to the SK TU3-ECT / FI combination, 4 or 6 process values are available.

The allocation of the values transferred in the setpoint/actual value area of the FI is made via the

parameters P543 to P548 or P543 [-01]…[-05].

4.2.1 Process data structure

The structure of the process data is defined by the XML file.

Direction of

transmission

1st word 2nd word 3rd word 4th word

... to SK TU3 Control word Setpoint 1 Setpoint 2 Setpoint 3

... from the SK TU3 Status word Actual

Table 11: Process data structure SK 500E to SK 535E

Transmitted data

( 8 Byte )

value 1

Actual

value 2

Actual

value 3

Direction of

transmission

1st word 2nd word 3rd word 4th word 5th word 6th word

... to SK TU3 Control word Setpoint 1 Setpoint 2 Setpoint 3 Setpoint 4 Setpoint 5

... from the SK TU3 Status word Actual

value 1

Table 12: Process data structure SK 540E to SK 545E

Transmitted data

( 12 Byte )

Actual

value 2

Actual

value 3

Actual

value 4

Actual value 5

18 Subject to technical amendments BU 0570 GB-0312

Page 19

4 Communication

4.2.2 Control word

Bit Value Meaning Remarks

0 0 OFF 1 Reverse with the brake ramp, with disconnection from supply at f=0Hz

1 ON Ready for operation

1 0 OFF 2

1 Operating condition OFF 2 is cancelled

2 0 OFF 3

1 Operating condition OFF 3 is cancelled

3 0 Disable operation

1 Enable operation The output voltage is enabled; ramp to the existing setpoint

4 0 Lock ramp generator

1 Operating condition Enable ramp generator

5 0 Stop ramp generator

1 Enable ramp generator Enable setpoint on ramp generator

6 0 Disable setpoint Selected setpoint value is set to zero on the ramp generator.

1 Enable setpoint Selected ramp generator setpoint is activated.

7 0 No acknowledgement With the switch from 0 to 1, errors which are no longer active are acknowledged.

1 Acknowledge

8 0

1 Bit 8 active

9 0

1 Bit 9 active

10 0 PZD invalid The transmitted process data is invalid.

1 PZD valid Valid process data is transferred from the master.

11 0

1

12 0

1

13 0/1 Reserved

14 0/1

15 0/1

Rotational direction:

right

Rotational direction:

left

Bit 0 to switch

parameter set

Bit 1 to switch

parameter set

Cut off voltage; the inverter output voltage is switched off; the FI enters a state

where switching on is disabled.

Quick stop with programmed quick stop time; with disconnection from supply at

f=0Hz; the FI switches to starting disabled condition.

Cut off voltage; the inverter output voltage is switched off; the FI enters a state

where switching on is enabled.

Ramp generator is set to zero; no disconnection from supply at f=0Hz; FI remains

in the operation enabled state.

The setpoint currently provided by the ramp generator is "frozen" (frequency is

maintained).

Note: When a digital input has been programmed for the "ack.fault" function, this

bit must not permanently be set to 1 via the bus (otherwise, edge evaluation

would be prevented).

Bus bit 8 from the control word is set. Only for SK 2xxE and SK 5xxE. For further

details of the function please refer to parameter (P480).

Bus bit 9 from the control word is set. Only for SK 2xxE and SK 5xxE. For further

details of the function please refer to parameter (P480).

Note: If setpoints only are transferred via the bus (setting: interface), this Bit must

be set so that the setpoint transferred is valid.

Rotation right (priority) is on.

Rotation left is on.

00 = Parameter set 1

01 = Parameter set 2

10 = Parameter set 3

11 = Parameter set 4

Table 13 Meaning of individual control word bits

BU 0570 GB-0312 Subject to technical amendments 19

Page 20

EtherCAT bus module for NORD frequency inverters SK 5xxE

4.2.3 Status word

Bit Value Meaning Remarks

0 0 Not ready to start

1 Ready to start Initialisation completed, charging relay ON, output voltage disabled

1 0 Not ready for operation

1 Ready for operation

2 0 Operation disabled

1 Operation enabled The output voltage is enabled; ramp to the existing setpoint

3 0 No fault

1 Fault

4 0 OFF 2 OFF2 command applied

1 No OFF 2

5 0 OFF 3 OFF3 command applied

1 No OFF 3

6 0 Starting not disabled

1 Starting disabled Switches first to OFF1, then to ready-to-start status

7 0 No warning

1 Warning Drive operation continues, no acknowledgement necessary

8 0 Actual value not O.K.

1 Actual value O.K. Actual value matches required setpoint (setpoint has been reached)

9 0 Local guidance Guidance on local device has been activated

1 Guidance requested The master has been requested to assume guidance.

10 0

1 Bit 10 active

11 0

1

12 0

1

13 0

1 Bit 13 active

14 0/1

15 0/1

Rotational direction:

right

Rotational direction:

left

Currently active

parameter set 0

Currently active

parameter set 1

Causes: No command has been activated, fault is signaled, OFF2 or OFF3

activated, starting disabled state activated

ON command activated, no faults present. The inverter can be started with the

command ENABLE OPERATION

Drive fault resulting in stoppage; this state is changed to starting disabled after

the fault has been successfully acknowledged

Actual value does not match the setpoint (with posicon: failure to reach setpoint

position)

(with posicon: setpoint has been reached)

Bus bit 10 from the status word is set. For further details of function, please refer

to parameter P481.

Inverter output voltage is turning right

Inverter output voltage is turning left

Bus bit 13 from the status word is set. For further details of function, please refer

to parameter P481.

00 = Parameter set 1

01 = Parameter set 2

10 = Parameter set 3

11 = Parameter set 4

Table 14 Meaning of individual status word bits

20 Subject to technical amendments BU 0570 GB-0312

Page 21

4 Communication

4.2.4 FI Status Machine

The frequency inverter passes through a status machine. The changes between various states are triggered

by the respective control commands in the process data control word. The actual status is returned in the

process data status word.

After switching on, the inverter is in switch-on disabled status. This status can only be ended by

transmitting the “Shut down (Off 1)” command.

The answer to a master telegram normally does not yet contain a reaction to the control command. The

controller has to check the answers from the slaves as to whether the control command has been carried

out.

Status Bit 6

Switch-on

disable

Not ready to start 0 X X 0 0 0 0

Starting disabled 1 X X 0 0 0 0

Ready to start 0 1 1 0 0 0 1

Activated 0 1 1 0 0 1 1

Operation enabled 0 1 1 0 1 1 1

Fault 0 X X 1 0 0 0

Error active 0 X X 1 1 1 1

Emergency stop

active

0 0 1 0 1 1 1

Bit 5

Emergency

stop

Bit 4

Disable

voltage

Bit 3

Fault

Bit 2

Operation

enabled

Bit 1

Standby

Bit 0

Ready for

switch-on

Table 15 Codes for FI status

BU 0570 GB-0312 Subject to technical amendments 21

Page 22

EtherCAT bus module for NORD frequency inverters SK 5xxE

Internal status machi ne

1

Not on standby

34568

Sw itching on the inverter

5

6

Emergency stop

active

Bit2 = 0: Emer gency stop

Bit1 = 0: Disable voltage

v Bit2 = 0: Emergency stop

2

Sw itch-on

45

Bit0 = 0: Shut dow n

3

Ready for

5

5

Bit 3 = 0: Disable operation Bit0 = 1: Sw itch on

3

2

23

sw itch-on

4

Ac tivated

Loading relay applied

disabled

Bit0 = 0: Shut dow n

& Bit1 = 1: Enable voltage

& Bit2 = 1: Enable pulses

(xxxx x1xx xxxx x110)

2

From any device status

7

Er ror reaction

active

8

Error

f = 0 reached

(emergency stop complete)

Er r o r

Er ror reaction complete

Bit3 = 1: Enable operation

&Bit0 = 1: Sw itch on

364

2

Control bits

0. Standby / Shut dow n

1. Dis able / enable voltage

2. Enable pulses / emergency s top

3. Dis able / enable operation

4. Betriebsbedingung / HLG s perren

5. Enable / stop RUE

6. Enable / disable setpoint

7. Er ror acknow ledgement (0

10. Control data valid / invalid

11. Direction of rotation clockwise

12. Direction of rotation anticlockwise

14. Parameter set Bit 0

15. Parameter set Bit 1

1)

Fig. 10 Diagram of the FI Status Machine

Bit3 = 1: Enable operation

5

Operation

enabled

Priority of control commands:

1. Dis able / enable voltage

2. Emergency stop

3. Shut dow n

4. Enable operation

5. Sw itch on

6. Dis able operation

7. Reset error

Bit4 = 0: Move dow n emergenc y s top ramp and

Bit5 = 0: Hold frequenc y

Bit6 = 0: Setpoint = 0%

2

remain in 'Operation enabled'

Coding of status:

1: Bit 0 = 0

2: Bit 6 = 1

3: Bit 0 = 1

4: Bit 1 = 1

5: Bit 2 = 1

6: Bit 5 = 0

7: Bit 2 & Bit 3 = 1

8: Bit 3 = 1

Bit7 01

Er ror acknow ledgement

22 Subject to technical amendments BU 0570 GB-0312

Page 23

4 Communication

4.2.5 Setpoint and actual values

The meanings of setpoints are defined via the FI parameters P546 to P548 (SK 540E and above:

P546[-01] … [-05]). For the actual values, this determination is made via the FI parameters P543 to P545

(SK 540E and above: P543[-01] … [-05]).

The transfer of setpoint and actual values is carried out by three different methods, which will be explained

below.

Percentage transfer

The process value is transferred as a whole number with a value range of -32768 to 32767 (8000 hex to

7FFF hex). The value 16384 (4000 hex) is equal to 100%. The value -16384 (C000 hex) is equal to -100%.

For frequencies, the 100% value corresponds to the FI parameter "Maximum Frequency" (P105) and for

currents, this is the FI parameter "Torque Current Limit" (P112) Frequencies and currents result from the

following formulae.

105PValue

Frequency

Value = the 16Bit actual or setpoint value transmitted via Ethernet

16384

Current

16384

112PValue

Formula 1 Formation of 16Bit setpoint/actual value

Binary transmission

Inputs and outputs as well as Digital In bits and Bus Out bits are evaluated for each bit.

Transmission of positions

In the FI, positions have a value range of +/- 50000,000 rotations. A motor rotation can be divided into a

maximum of 1000 steps. This scaling is independent of the encoder which is used.

The 32Bit value range is divided into a Low and a High word, so that 2 setpoint/actual values are required

for transmission.

Direction of

transmission

1. word 2. word 3. word 4. word

... to SK TU3- Control word 32Bit setpoint Setpoint 3

... from the SK TU3- Status word Actual value 1 32Bit actual value

Table 16 Depiction of 32Bit setpoint/actual values

It is also possible to only transmit the Low component of the position. This results in a limited value range

from +32,767 to -32,768 rotations. This value range can be extended with the aid of the gear ratio factor

(P607 & P608). However, it must be noted that there is an according reduction in the resolution.

Transmitted data (8 Byte)

BU 0570 GB-0312 Subject to technical amendments 23

Page 24

EtherCAT bus module for NORD frequency inverters SK 5xxE

4.2.6 Beispiel für FU das Ein- / Ausschalten des Frequenzumrichters

In this example, a FI will be operated with a setpoint (setpoint frequency) and an actual value (actual

frequency). The "Maximum Frequency" is 50Hz.

Parameter settings:

P105 = 500

P543 = 1

P546 = 1

Control

word

- - - - - - 0000h 0000h

- - - - - - xx40h 0000h The mains voltage is switched on at the FI

047Eh 0000h xx31h 0000h FI is set to "Standby" status

047Fh

The FI is enabled, the motor is supplied with current and rotates with a frequency of 25Hz.

0047Eh

The FI is disabled again and the motor is without current.

047Fh

The FI is enabled, the motor is supplied with current and rotates with a frequency of 12.5Hz.

Setpoint 1 Status word Actual

value 1

2000h xx37h 2000h

2000h xx31h 0000h

1000h xx37h 1000h

Explanation

FI is set to "Operation enabled" status and controlled with a

50% setpoint.

FI is set to "Standby" status, the motor runs up its

parameterised ramp to speed 0 and is switched off.

FI is set to "Operation enabled" status and controlled with a

25% setpoint.

Table 17 Example of setpoint specification

4.2.7 Timeout monitoring

Data traffic on the EtherCAT side is monitored by EtherCAT watchdogs. Monitoring via the FI parameter

P513 is also possible.

P513 monitoring is triggered if the process data contact is interrupted or the process data is transferred with

an invalid control word (Bit10 in control word = 0). This function is activated when the first valid process data

telegram is received.

24 Subject to technical amendments BU 0570 GB-0312

Page 25

4 Communication

4.3 Parameterübertragung EtherCAT

4.3.1 Ablauf der Parameterübertragung

The transfer of parameter data is carried out cyclically with low priority. Transfer is carried out in CoE (CAN

over Ether CAT) protocol via the SDO transfer. All parameters of the FI and the bus module can be

accessed.

The parameter numbers stated in the documentation must be converted into the numerical range specified

for EtherCAT. This is performed according to the following formula:

SK TU3-ECT parameter = NORD parameter number + 2000h

SK 5xxE parameter = NORD parameter number + 2800h

Example:

The FI parameter P102 is accessed via EtherCAT with the parameter number 2866h (10342dec).

For parameters with a sub-index, the first value is always on sub-index 1. Sub-index 0 contains the

maximum size of the array.

The processing of SDP parameter access is complex and will not be described here. In general, the

EtherCAT SPS provides functional modules for this purpose.

4.3.2 Error codes for SDO parameter access

In case of failure of parameter access, one of the error codes listed in the table below is sent.

Error code in hex Explanation

0x05 03 00 00 Toggle bit has not changed status

0x05 04 00 00 Timeout of the SDO response by the bus module

0x05 04 00 01 Unknown SDO command

0x05 04 00 05 Insufficient memory

0x06 01 00 00 Access not supported

0x06 01 00 01 Reading access to write-only parameter

0x06 01 00 02 Writing access to a read-only parameter

0x06 02 00 00 Access to a non-existent parameter

0x06 04 00 43 Incompatible parameter

0x06 04 00 47 Internal incompatibility in module

0x06 06 00 00 Hardware error

0x06 07 00 10 Invalid parameter type

0x06 07 00 12 Parameter access with excess data length

0x06 07 00 13 Parameter access with insufficient data length

0x06 09 00 11 Parameter sub-index does not exist

0x06 09 00 30 Parameter value range overflow

0x06 09 00 31 Parameter value too large

0x06 09 00 32 Parameter value too small

0x06 09 00 36 Maximum value smaller than the minimum value

0x08 00 00 00 General error

0x08 00 00 20 Parameters cannot be read or stored in the FI, as there is no connection

between the SK TU3-ECT and the FI

Table 18 Error codes for parameter access failure

BU 0570 GB-0312 Subject to technical amendments 25

Page 26

EtherCAT bus module for NORD frequency inverters SK 5xxE

26 Subject to technical amendments BU 0570 GB-0312

Page 27

4 Communication

4.4 XML File

The XML file contains a description of the device properties for the SK TU3-ECT and its parameters as well

as the parameters of the SK 500E frequency inverter. As error messages occur of parameters which do not

exist in the FI are called up via EtherCAT, several devices are stored in the XML file.

TU3-ECT Standard frequency inverter ( state as supplied )

TU3-ECT Encoder Standard with motor encoder interface

TU3-ECT Posicon Frequency inverter with PosiCon option

With the SK TU3-ECT in the status as supplied, the version "TU3-ECT" will always be detected with a bus

scan. The other versions can be set with the function "Change to Alternative Type" in the TwinCAT System

Manager (right mouse click on the appropriate unit). The newly set version is permanently stored in the

SK TU3-ECT.

BU 0570 GB-0312 Subject to technical amendments 27

Page 28

EtherCAT bus module for NORD frequency inverters SK 5xxE

5 Parameter

5.1 Parameterisation of the EtherCAT module SK TU3-ECT

The following parameters affect the bus modules.

5.1.1 EtherCAT parameters

These parameters are from the EtherCAT standard and are supported by the SK TU3-ECT.

Parameter

[Sub Index]

0x1000

[0]

Access Type Setting value / Description / Note

read only 32Bit Device type and functionality

0x1008

[0]

0x1009

[0]

0x100A

[0]

0x1018

[0] = 4

[1] = Vendor ID

[2] = Product code

[3] = Revision

[4] = Serial Number

0x1600

[0] – [4]

0x1A00

[0] – [4]

0x1C00

[0] – [4]

0x1C12

[0] – [1]

0x1C13

[0] – [1]

read only String Designation of module

read only String Hardware version

read only String Software Version

read only 32Bit Information for the module "Serial Number" is not supported.

read only 32Bit Mapping for the setpoint PDOs

read only 32Bit Mapping for the actual value PDOs

read only 8Bit Assignment and use of Sync channels

read only 16Bit Process data output

read only 16Bit Process data output

Table 19 EtherCAT parameters

5.1.2 BUS module standard parameters (P15x)

Access: Read/Write

Parameter

{Factory setting}

P152

0 ...1

{ 0 }

28 Subject to technical amendments BU 0570 GB-0312

Setting value / Description / Note Device

Factory setting

(Factory setting)

By selecting the appropriate value and confirming it with the ENTER key, the selected

parameter range is entered in the factory setting. Once the setting has been made, the value of

the parameter returns automatically to 0.

0 = No change: Does not change the parameterisation.

1 = Load factory settings: The complete parameterisation of the FI is reset to the factory

setting. All originally parameterised data are lost.

SK TU3-ECT 16 bit

Parameter

type

Page 29

5.1.3 BUS module information parameters, general (P17x)

Access: Read only

5 Parameter

Parameter Setting value / Description / Note Device

P170 ...

… [-02]

0 ... 5420

P171 … [-01]

…

… [-03]

0.0 ... 9999.9

P172

0 ... 2

Present error

(Present error)

Current errors in the EtherCAT module. The error message is reset when the supply voltage is

switched off.

Possible error codes:

- 1020 Bus Time Out via P151 (TU4-PNT) or P513 (TU3-PNT)

[-01] = Present module error [-02] = Present module error

Software-Version

(Software Version / Revision)

This parameter shows the software and revision numbers in the module. Array 03 provides

information about any special versions of the hardware or software A zero stands for the

standard version.

[-01] = Version

[-02] = Revision

Configuration

(Configuration level)

The version can be queried in this parameter.

Possible values:

0 = Internal module, (SK CU4)

1 = External module, (SK TU4)

2 = Module SK TU3-PNT

SK TU3-ECT 16 Bit

SK TU3-ECT 16 bit

[-03] = Special version

SK TU3-ECT 16 bit

Parameter

type

P173

0 ... 0xFFFF

BU 0570 GB-0312 Subject to technical amendments 29

Option status

(Module status)

Explanation of bits:

Bit 0 = Initialisation

Bit 1 = AR installed

Bit 2 = Reserved

Bit 3 = Timeout (P151 / P513)

Bit 4 = Reserved

Bit 5 = Ethernet connection

Bit 6 = Reserved

Bit 7 = Reserved

Bit 8 = Frequency inverter status

Bit 9 = Frequency inverter status

Explanation of frequency inverter status

Bit9 | Bit8

0 0 FI is offline

0 1 FI is not supported

1 0 FI is online

SK TU3-ECT 16 bit

Page 30

EtherCAT bus module for NORD frequency inverters SK 5xxE

Parameter Setting value / Description / Note Device

Parameter

type

P176 … [-01]

…

… [-27]

P177 … [-01]

…

… [-27]

-32768 ... 32767

PZD bus IN

(Process data bus IN)

Allocation of process data which have been received (data sent from PROFINET IO controller). -32768 ... 32767

[-01] = Bus module outputs

[-02] = Control word for FI1

[-03] = Setpoint 1 for FI1

[-04] = Setpoint 2 for FI1

PZD bus OUT

(Process data bus OUT)

Allocation of process data which have been transmitted (data sent to the PROFINET IO

controller).

[-01] = Bus module inputs

[-02] = Status word from FI1

[-03] = Actual value 1 from FI1

[-04] = Actual value 2 from FI1

5.1.4 BUS module information parameters, bus-specific (P18x)

SK TU3-ECT 16 bit

[-05] = Bus module outputs

[-06] = Control word for FI1

[-07] = Setpoint 1 for FI1

[-08] = Setpoint 2 for FI1

SK TU3-ECT 16 bit

[-05] = Bus module inputs

[-06] = Status word from FI1

[-07] = Actual value 1 from FI1

[-08] = Actual value 2 from FI1

Zugriff: Read only

Parameter Setting value / Description / Note Device

P181

0 ... 4095 Address set with the DIP switch.

P184

0 ... 0xFFFF

Second Address

(Second Address)

SPI error counter

(SPI error counter)

Counts transmission errors between the ASIC and the SK TU3-ECT processor. This value is set

to 1 as default.

SK TU3-ECT 16 bit

SK TU3-ECT 16 Bit

Parameter

type

30 Subject to technical amendments BU 0570 GB-0312

Page 31

5 Parameter

5.2 SK5xxE inverter parameters (selection)

The parameters listed below relate the the frequency inverter in combination with the EtherCAT bus module.

A complete list of inverter parameters can be found in the manual for the frequency inverter (BU0500)).

NOTE: The structure of individual parameters of the frequency inverter versions SK 500E to SK 535E

differs from the structure of the versions SK 540E and SK 545E. Because of this, the relevant

parameters descriptions are listed twice.

5.2.1 Extra functions

Access: Read/Write

Parameter

Setting value / Description / Note Device Supervisor Parameter set

{Factory setting}

P509

0 ... 10

{ 0 }

P510 [-01]

[-02]

0 ... 10

{ all 0 }

Source Control Word

(Source control word)

Selection of the interface via which the FI is controlled (for details see BU0500). Also note

parameter (P350).

Source setpoints

(Source setpoints)

Selection of the setpoints to be parameterised (For details see BU0500). Also note parameters

(P350) and (P351).

SK 5xxE

0 = Control terminals or keyboard

1 = Control terminals

2 = USS (or Modbus RTU: SK 540E and above)

3 = CAN

4 = Profibus

5 = InterBus

[-01] = Main setpoint source [-02] = Auxiliary setpoint source

0 = Automotive

1 = Control terminals

2 = USS (or Modbus RTU: SK 540E and above)

3 = CAN

4 = Profibus

5 = InterBus

6 = CANopen

7 = DeviceNet

8 = Ethernet TU

9 = CAN Broadcast

10 = CANopen Broadcast

SK 5xxE S

6 = CANopen

7 = DeviceNet

8 = Ethernet TU

9 = CAN Broadcast

10 = CANopen Broadcast

P513

-0.1 / 0.0 /

0.1 ... 100.0 sec

{ 0.0 }

BU 0570 GB-0312 Subject to technical amendments 31

Telegram time-out

(Telegram time out)

Monitoring function of the active bus interface. Following receipt of a valid telegram, the next

one must arrive within the set period. Otherwise the FI reports an error and switches off with the

error message E010 >Bus Time Out<.

0.0 = Off: Monitoring is switched off.

-0.1 = no error: Even if communication between BusBox and FI is interrupted (e.g. 24V error,

Box removed, etc.), the FI will continue to operate unchanged.

SK 5xxE S

Page 32

EtherCAT bus module for NORD frequency inverters SK 5xxE

Parameter

Setting value / Description / Note Device Supervisor Parameter set

{Factory setting}

P543

0 ... 24

{ 1 }

Bus actual value 1

(Actual bus value 1)

The return value 1 can be selected for bus actuation in this parameter.

The possible analog functions can be found in the following table.

NOTE: For further details please refer to the manual BU0500 (P418, P543), the relevant

Bus actual value

P543 [-01]

...

[-05]

(Actual bus values)

0 ... 57

{ [-01] = 1 }

{ [-02] = 4 }

{ [-03] = 9 }

{ [-04] = 0 }

{ [-05] = 0 }

In this parameter the return value for bus actuation can be selected.

NOTE: The actual values 4 and 5 must be supported by the relevant bus module. For

[-01] = Actual bus value 1 [-02] = Actual bus value 2 [-03] = Actual bus value 3

[-04] = Actual bus value 4 [-05] = Actual bus value 5

0 = Off

1 = Actual frequency

2 = Actual speed

3 = Electricity

4 = Torque current (100% = P112)

5 = Digital IO status

6 = ... 7 Reserved

8 = Setpoint frequency

9 = Error number

10 = ... 11 Reserved

12 = BusIO Out Bits 0...7

13 = ... 16 Reserved

up to

SK 535E

BUS operating manual or the supplementary POSICON manual BU0510.

SK 540E and

above

further details please refer to the manual BU0500 (P418, P543), the relevant BUS

operating manual, the supplementary POSICON manual BU0510 or the

supplementary PLC manual BU0550.

17 = Value analog input 1

18 = Value analog input 2

19 = Setpoint frequency master value (P503)

20 = Set Freq. After Ramp "Setpoint frequency

master value after ramp"

1

21 = Act. Freq. w/o Slip "Actual frequency

without slip master value"

22 = Speed encoder

(only possible with SK 520E and encoder

feedback)

23 = Act. freq. with slip, "Actual frequency with

slip" (SW V2.0 and above)

24 = Lead.act.freq.+slip, "Master value, actual

frequency with slip" (SW V2.0 and above)

53 = ... 57 Reserved

S P

S P

P544

0 ... 24

{ 0 }

P545

0 ... 24

{ 0 }

Bus actual value 2

(Actual bus value 2)

This parameter is identical to P543.

Condition is PPO 2 or PPO 4 type (P507).

Bus actual value 3

(Actual bus value 3)

This parameter is identical to P543.

Condition is PPO 2 or PPO 4 type (P507).

up to

SK 535E

up to

SK 535E

S P

S P

1

The assignment of the digital inputs in P543/ 544/ 545 = 5

Bit 0 = DigIn 1 Bit 1 = DigIn 2 Bit 2 = DigIn 3 Bit 3 = DigIn 4

Bit 4 = DigIn 5 Bit 5 = DigIn 6 (SK 520E and above) Bit 6 = DigIn 7 (SK 520E and above) Bit 7 = Dig. func. AIN1

Bit 8 = Dig. func. AIN2 Bit 9 = DigIn 8 (SK 540E and above) Bit 10 = DigIn 1, 1st IOE (SK 540E and above) Bit 11 = DigIn 2, 1st IOE

(SK 540E and above)

Bit 12 = Out 1/ MFR1 Bit 13 = Out 2/ MFR2 Bit 14 = Out 3/ DOUT1 (SK 520E and above) Bit 15 = Out 4/ DOUT2

(SK 520E and above)

32 Subject to technical amendments BU 0570 GB-0312

Page 33

Parameter

{Factory setting}

5 Parameter

Setting value / Description / Note Device Supervisor Parameter set

P546

0 ... 55

{ 1 }

P546 [-01]

...

[-05]

0 ... 57

{ [-01] = 1 }

all other { 0 }

P547

0 ... 55

{ 0 }

Function Bus setpoint 1

(Function of bus - setpoint 1)

In this parameter, a function is allocated to the output setpoint 1 during bus actuation.

The possible analog functions can be found in the following table.

NOTE: For further details, please refer to manual BU0500 (P400, P546), the relevant BUS

Function Bus setpoint

(Function bus - setpoints)

In this parameter, during bus actuation a function is allocated to the setpoint provided.

NOTE: The setpoints 4 and 5 must be supported by the relevant bus module. For further

[-01] = Bus setpoint 1 [-02] = Bus setpoint 2 [-03] = Bus setpoint 3

[-04] = Bus setpoint 4 [-05] = Bus setpoint 5

0 = Off

1 = Setpoint frequency

2 = Torque current limit (P112)

3 = Actual frequency PID

4 = Frequency addition

5 = Frequency subtraction

6 = Current limit (P536)

7 = Maximum frequency (P105)

8 = Actual PID frequency limited

9 = Actual PID frequency monitored

10 = Torque servo mode (P300)

11 = Torque precontrol (P214)

12 = Reserved

13 = Multiplication

14 = Process controller actual value

15 = Process controller setpoint

16 = Process controller lead

Function Bus setpoint 2

(Function of bus - setpoint 2)

This parameter is identical to P546.

up to

SK 535E

operating manual or the supplementary POSICON manual BU0510.

SK 540E and

above

details, please refer to manual BU0500 (P400, P546), the relevant BUS operating

manual or the supplementary POSICON manual BU0510.

17 = BusIO In Bits 0...7

18 = Curve travel calculator

19 = Set relays, "Output status"

(P434/441/450/455=38)

20 = Set analog output (P418=31)

21 = …45 reserved from SK 530E and above

BU 0510

46 = Setval.torque p.reg., "Setpoint torque

process controller"

47 = reserved from SK 530E and above

BU 0510

48 = Motor temperature (SK 540E and above)

49 = reserved from SK 540E and above

BU 0510

53 = d-correction F process (SK 540E and above)

54 = d-correction Torque (SK 540E and above)

55 = d-correction F+torque (SK 540E and above)

56 = reserved from SK 540E and above

BU 0510

57 = reserved from SK 540E and above

BU 0510

up to

SK 535E

S P

S P

S P

P548

0 ... 55

{ 0 }

Function Bus setpoint 3

(Function of bus - setpoint 3)

This parameter is identical to P546.

up to

SK 535E

S P

BU 0570 GB-0312 Subject to technical amendments 33

Page 34

EtherCAT bus module for NORD frequency inverters SK 5xxE

5.2.2 Information parameters

Access: Read only

Parameter Setting value / Description / Note Device

P740 [-01]

...

[-13]

0000 ... FFFF (hex) This parameter informs

P740 [-01]

...

[-23]

0000 ... FFFF (hex) This parameter informs

PZD bus in

(Process data bus in)

about the actual control

word and the setpoints that

are transferred via the bus

systems.

For display, a BUS system

must be selected in P509

PZD bus in

(Process data bus in)

about the actual control

word and the setpoints that

are transferred via the bus

systems.

For display, a BUS system

must be selected in P509

[-01] = Control word

[-02] = Actual bus value 1

[-03] = Actual bus value 2

[-04] = Setpoint 3

[-05] = Bus I/O In Bits (P480)

[-06] = Parameter data In 1

[-07] = Parameter data In 2

[-08] = Parameter data In 3

[-09] = Parameter data In 4

[-10] = Parameter data In 5

[-11] = Setpoint 1

[-12] = Setpoint 2

[-13] = Setpoint 3

[-01] = Control word

[-02] = Actual bus value 1

[-03] = Actual bus value 2

[-04] = Setpoint 3

[-05] = Setpoint 4

[-06] = Setpoint 5

[-07] = Bus I/O In Bits (P480)

[-08] = Parameter data In 1

[-09] = Parameter data In 2

[-10] = Parameter data In 3

[-11] = Parameter data In 4

[-12] = Parameter data In 5

[-13] = Setpoint 1

[-14] = Setpoint 2

[-15] = Setpoint 3

[-16] = Setpoint 4

[-17] = Setpoint 5

[-18] = PLC control word

[-19] = Setpoint 1

[-20] = Setpoint 2

[-21] = Setpoint 3

[-22] = Setpoint 4

[-23] = Setpoint 5

up to

SK 535E

SK 540E

and above

Parameter

type

S

Control word, source from

P509.

Setpoint data from main

setpoint (P510 [-01]).

The displayed value depicts all

Bus In Bit sources linked with

or.

Data during parameter transfer:

Order label (AK),

Parameter number (PNU),

Index (IND), Parameter value

(PWE 1/2)

Setpoint data from the master

function value (Broadcast), if

P509 = 9/10

(P510 [-02])

S

Control word, source from

P509.

Setpoint data from main

setpoint (P510 [-01]).

The displayed value depicts all

Bus In Bit sources linked with

or.

Data during parameter transfer:

Order label (AK),

Parameter number (PNU),

Index (IND), Parameter value

(PWE 1/2)

Setpoint data from the master

function value (Broadcast), if

P509 = 9/10

(P510 [-02])

Control word, source PLC

Setpoint data from the PLC.

34 Subject to technical amendments BU 0570 GB-0312

Page 35

Parameter Setting value / Description / Note Device

Parameter

type

5 Parameter

P741 [-01]

...

[-13]

0000 ... FFFF (hex) This parameter provides

P741 [-01]

...

[-23]

0000 ... FFFF (hex) This parameter provides

PZD bus out

(Process data bus out)

information about the

actual status word and

the actual values that are

transferred via the bus

systems.

PZD bus out

(Process data bus out)

information about the

actual status word and

the actual values that are

transferred via the bus

systems.

up to

SK 535E

… [-01 ] = Status word

[-02] = Actual value 1 (P543)

[-03] = Actual value 2 (P544)

[-04] = Actual value 3 (P545)

[-05] = Bus I/O Out Bit (P481)

[-06 ] = Parameter data Out 1

[-07 ] = Parameter data Out 2

[-08] = Parameter data Out 3

[-09] = Parameter data Out 4

[-10] = Parameter data Out 5

[-11] = Actual value 1 master function

[-12] = Actual value 2 master function

[-13] = Actual value 3 master function

SK 540E

and above

… [-01 ] = Status word

[-02] = Actual value 1 (P543 [-01])

[-03] = Actual value 2 (P543 [-02])

[-04] = Actual value 3 (P543 [-03])

[-05] = Actual value 4 (P543 [-04])

[-06] = Actual value 5 (P543 [-05])

[-07] = Bus I/O Out Bit (P481)

[-08] = Parameter data Out 1

[-09] = Parameter data Out 2

[-10] = Parameter data Out 3

[-11] = Parameter data Out 4

[-12] = Parameter data Out 5

[-13] = Actual value 1 master function

[-14] = Actual value 2 master function

[-15] = Actual value 3 master function

[-16] = Actual value 4 master function

[-17] = Actual value 5 master function

[-18] = PLC status word

[-19] = Actual value 1 PLC

[-20] = Actual value 2 PLC

[-21] = Actual value 3 PLC

[-22] = Actual value 4 PLC

[-23] = Actual value 5 PLC

S

Status word, source from

P509.

The displayed value depicts

all Bus Out Bit sources

linked with or.

Data during parameter

transfer.

Actual value of master

function 502/P503.

S

Status word, source from

P509.

The displayed value depicts

all Bus Out Bit sources

linked with or.

Data during parameter

transfer.

Actual value of master

function 502/P503.

Status word via PLC

Actual value data via PLC

BU 0570 GB-0312 Subject to technical amendments 35

Page 36

EtherCAT bus module for NORD frequency inverters SK 5xxE

Parameter Setting value / Description / Note Device

Parameter

type

P745

0.0 ... 999.9 Version status (software version) of the technology unit (SK TU3-xxx), but only when own

P746

0000 ... FFFF (hex) Actual status (readiness, error, communication) of the technology unit (SK TU3-xxx), but only

Option version

(Module version)

processor is present, therefore not for SK TU3-CTR.

Have this data available if you have a technical query.

Option status

(Module status)

when own processor is present, therefore not for SK TU3-CTR.

Possible values:

Bit 0 = EtherCAT state "Pre- Operational"

Bit 1 = EtherCAT state "Save- Operational" or "Operational"

Bit 2 = Vacant

Bit 3 = Vacant

Bit 4 = Error 1

Bit 5 = Error 2

Bit 6 = Error 3

Bit 7 = Vacant

Bit 8 – Bit 15 = Module number (EtherCAT = 20)

Error table

Error 3 | Error 2 | Error 1 | Meaning

0 0 0 No error

0 0 1 EtherCAT ASIC cannot be accessed

0 1 0 EtherCAT watchdog timeout

0 1 1 P513 timeout

1 0 0 General EtherCAT configuration error

SK 5xxE

SK 5xxE S

NOTE

When activated, the functions block current, qu ick sto p , remote control and c ancel er ror

are available at the (local) control terminals. To operate the drive, a high signal must be

present on the digital inputs being used before the drive can be enabled.

36 Subject to technical amendments BU 0570 GB-0312

Page 37

6 Error monitoring and error messages

6 Error monitoring and error messages

According to the cause, frequency inverters and technology units generate appropriate messages if they

deviate from their normal operating status.

6.1 EtherCAT error monitoring

In case of FI errors, SK TU3-ECT sends an error message on the EtherCAT bus via Emergency Message

(CoE). The message is structured as follows.

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

Error code

Table 20 Structure of Emergency Message ( CoE )

Error

Register

FI-ID

FU ID = identifies the FI from which the error message has come FI1 = 1, FI2 = 2, etc. (for TU3-ECT = 1)

Error code Error register FI Error Code Explanation

0x0000 0 0 No error

0x1000 1 ? ? ? General error the FI error code cannot be assigned

0x2200 3 4.0 / 4.1

0x2310 3 3.0

0x2311 3 3.2

0x2312 3 3.3

0x3110 5 5.1

0x3120 5 6.1

0x3130 5 7.0

0x3210 5 5.0

0x3230 5 6.0

0x4210 9 1.1

0x4310 9 2.0 / 2.1 / 2.2

0x5000 1 10.8

0x5110 1 11.0

0x5300 1 17.0

0x5510 1 20.0

0x5520 1 20.8

0x5530 1 8.2

0x6000 1

0x7112 3 3.1

0x7120 1 16.0 / 16.1

0x7305 1 13.0

0x8100 17

20.1 to 20.7 /

21.3

10.0 / 10.1 /

10.2

Not used

BU 0570 GB-0312 Subject to technical amendments 37

Page 38

EtherCAT bus module for NORD frequency inverters SK 5xxE

Error code Error register FI Error Code Explanation

0x8111 17

0x8300 1 13.2

0x8400 1 13.1

0x9000 1 12.0

0xFF00 129 18.0

0xFF10 129 19.0

Table 21 Assignment of Emergency Error Codes to the FI Error Codes

10.3 / 10.4 /

10.5 / 10.6 /

10.7 / 10.9

6.2 Error messages in the EtherCAT module SK TU3-ECT

All SK TU3-ECT error messages are displayed in parameter (P170) of the bus module and trigger an error

in the connected FI. This is permanently stored in the FI error statistics. The error messages in the bus

module memory (P170) parameter are lost when the 24V supply voltage is switched off.

6.3 Error messages in the SK 5xxE frequency inverter

Errors cause the frequency inverters to switch off, in order to prevent a device fault.

The following options are available to reset a fault (acknowledge):

1. Switching the mains off and on again,

2. By an appropriately programmed digital input (P420 ... P425 / P470 = Function 12),

3. By switching of the “enable” on the frequency inverter (if no

acknowledgement),

4. By Bus acknowledgement or

5. By P506, the automatic error acknowledgement.

The following error messages are directly associated with the Bus module SK TU3-ECT.

FI Error Code Error register

0 No error

10.1

No communication with the EtherCAT- ASIC.

The ASIC error can only be reset by switching

off the 24V supply voltage of the TU3-ECT

10.2 Timeout EtherCAT Watchdog

10.3 Timeout via P513 monitoring

10.5 General EtherCAT configuration error

10.8 The connection between the FI and the SK TU3-ECT had a timeout

digital input is programmed for

Table 22 SK5xxE error messages associated with the SK TU3-ECT

For a complete overview of the error messages relating to the frequency inverter, please refer to the

frequency inverter manual BU0500.

38 Subject to technical amendments BU 0570 GB-0312

Page 39

7 Lists / Index

7.1 Abbreviations

AIN ....... Analog input

AOUT ... Analogue output

CoE....... CAN over EtherCAT

COB-ID . Communication Object Identifier

DI (DIN) Digital input

DO (DOUT) Digital output

I / O ....... Input /Output

EEPROM Non-volatile memory

EMC...... Electromagnetic compatibility

FI ……... Frequency inverters

HSW ..... Main setpoint

I/O ......... In / Out (Input / Output)

7 Lists / Index

ISD........ Field current (Current vector control)

LED....... Light-emitting diode

NSW...... Auxiliary setpoint

P-Box... ParameterBox

S ........... Supervisor Parameter, P003

SW ....... Software version, P707

STW...... Control word

TU ......... Technology Unit (technology module,

e.g.: EtherCAT Bus module)

ZSW...... Status word

7.2 Keyword Index

Baud rate

Binary code

Bit / Byte

Broadcast

Jitter

XML

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

………………………………………….

The transmission rate for serial interfaces in

bits per second

The designation for a code in which

messages are communicated by "0" and "1"

signals.

A bit (binary digit) is the smallest unit of

information in the binary system. A byte has

8 bits.