Page 1

GB

BU 0530

Functional Safety

Supplementary instructions for frequency inverter SK 500E

Functional Safety

Functional Safety

Page 2

Functional safety with NORD SK 500E frequency inverters Safety information

NORD frequency inverters

Safety and operating instructions for drive power converters

(as per: Low Voltage Directive 2006/95/EEC)

1.General

During operation, drive power converters may, depending on their protection class, have live, bare, moving or rotating parts or hot surfaces.

Unauthorised removal of covers, improper use, incorrect installation or

operation causes a risk of serious personal injury or material damage.

Further information can be found in this documentation.

All transportation, installation commissioning and maintenance work

must be carried out by qualified personnel (compliant with IEC 364 or.

CENELEC HD 384 or DIN VDE 0100 and IEC 664 or DIN VDE 0110

and national accident prevention regulations).

For the purposes of these basic safety instructions, qualified personnel

are persons who are familiar with the assembly, installation, commissioning and operation of this product and who have the relevant qualifications for their work.

2. Proper use in Europe

Drive power converters are components intended for installation in electrical systems or machines.

When installed in machines, the drive power converter must not be

commissioned (i.e. commencement of the proper use) until it has been

ensured that the machine meets the provisions of the EC Directive

2006/42/EEC (Machinery Directive); EN 60204 must also be complied

with.

Commissioning (i.e. implementation of the proper use) is only permitted

if the EMC directive (2004/108/EEC) is complied with.

Drive power converters with a CE label meet the requirements of the

Low Voltage Directive 2006/95/EEC. The stated harmonized standards

for drive current inverters are used in the declaration of conformity.

Technical data and information for connection conditions can be found

on the rating plate and in the documentation, and must be complied

with.

The drive power converters may only be used for safety functions which

are described and explicitly approved.

3. Transport, storage

Information regarding transport, storage and correct handling must be

complied with.

4. Installation

The installation and cooling of the equipment must be implemented according to the regulations in the corresponding documentation.

The drive power converter must be protected against impermissible loads. Especially during transport and handling, components must not be deformed and/or insulation distances must

not be changed. Touching of electronic components and contacts must be avoided.

Drive power converters have electrostatically sensitive components, which can be easily damaged by incorrect handling. Electrical components must not be mechanically damaged or destroyed (this may cause a health hazard!).

5. Electrical connection

When working on live drive power converters, the applicable national accident prevention regulations must be complied with

(e.g. BGV A3, formerly VBG 4).

The electrical installation must be implemented according to the

applicable regulations (e.g. cable cross-section, fuses, earth

lead connections). Further instructions can be found in the documentation.

Information regarding EMC-compliant installation – such as

shielding, earthing, location of filters and installation of cables –

can be found in the drive power converter documentation. These instructions must be complied with even with CE marked

drive power converters. Compliance with the limit values specified in the EMC regulations is the responsibility of the manufacturer of the system or machine.

6. Operation

Systems in which drive power converters are installed must be

equipped, where necessary, with additional monitoring and protective equipment as per the applicable safety requirements,

e.g. legislation concerning technical equipment, accident prevention regulations, etc.

The parameterisation and configuration of the drive power converter must be selected so that no hazards can occur.

All covers must be kept closed during operation.

7. Maintenance and repairs

After the drive power converter is disconnected from the power

supply, live equipment components and power connections

should not be touched immediately, because of possible

charged capacitors. Observe the applicable information signs

located on the drive power converter.

Further information can be found in this documentation.

These safety instructions must be kept in a safe place!

2 BU 0530 GB-3712

Page 3

Functional safety with NORD SK 500E frequency inverters About this document

Designation of

previous issues

Software

Version

Comments

BU 0530 GB, November 2007

Part. No. 607 5302 / 4707

First issue

BU 0530 GB, July 2010

Part. No. 607 5302 / 2710

V1.8 R2

and above

Supplement to SK 511E and sizes 5 - 6

Updating of references to standards

Inclusion of new certifications

BU 0530 DE, September 2012

Part. No. 607 5302 / 3712

V2.0 R2

and above

Supplement to SK 511E and sizes 7 - 9

Updating of references to standards

Inclusion of new certifications

NOTE

This supplementary operating manual is only valid in conjunction with the operating manual

supplied for the respective frequency inverter.

Documentation

Designation: BU 0530 GB

Part No.: 607 53 02

Device series: SK 510E, SK 511E, SK 515E, SK 530E, SK 535E, SK 540E and SK 545E

Version list

Publisher

Getriebebau NORD GmbH & Co. KG

Rudolf-Diesel-Str. 1 D-22941 Bargteheide http://www.nord.com/

Tel.: +49 (0) 45 32 / 289-0 Fax +49 (0) 45 32 / 289-2555

BU 0530 GB-3712 3

Page 4

Functional safety with NORD SK 500E frequency inverters About this document

Intended use of the frequency inverter

Compliance with the operating instructions is necessary for fault-free operation and the

acceptance of any warranty claims. These operating instructions must be read before

working with the device!

These operating instructions contain important information about servicing. They must

therefore be kept close to the device.

SK 500E series frequency inverters are devices for industrial and commercial systems used

for the operation of three-phase asynchronous motors with squirrel-cage rotors and

Permanent Magnet Synchronous Motors - PMSM (SK 54xE and above). These motors must

be suitable for operation with frequency inverters, other loads must not be connected to the

devices.

SK 500E frequency inverters are devices for stationary installation in control cabinets. All

details regarding technical data and permissible conditions at the installation site must be

complied with.

Commissioning (implementation of the intended use) is not permitted until it has been

ensured that the machine complies with the EMC directive 2004/108/EEC and that the

conformity of the end product meets the machine directive 2006/42/EEC (note EN 60204).

Getriebebau NORD GmbH & Co. KG, 2012

4 BU 0530 GB-3712

Page 5

Functional safety with NORD SK 500E frequency inverters About this document

Item Item Item

Item

Item 5

SK

510

E-

250 - 323 - 511 370 -CP -KAR

515 550 -ERS

530 750 -XXX

535 111

540 151

545 221

301 401

551

751

112

152 182

SK

510

E-

550 - 340 -

511 750 350 -CP -KAR

515 111 -ERS

530 151 -XXX

535 221

540 301

545 401

551

751

112 152 182 222

302

372 452 552 752

902

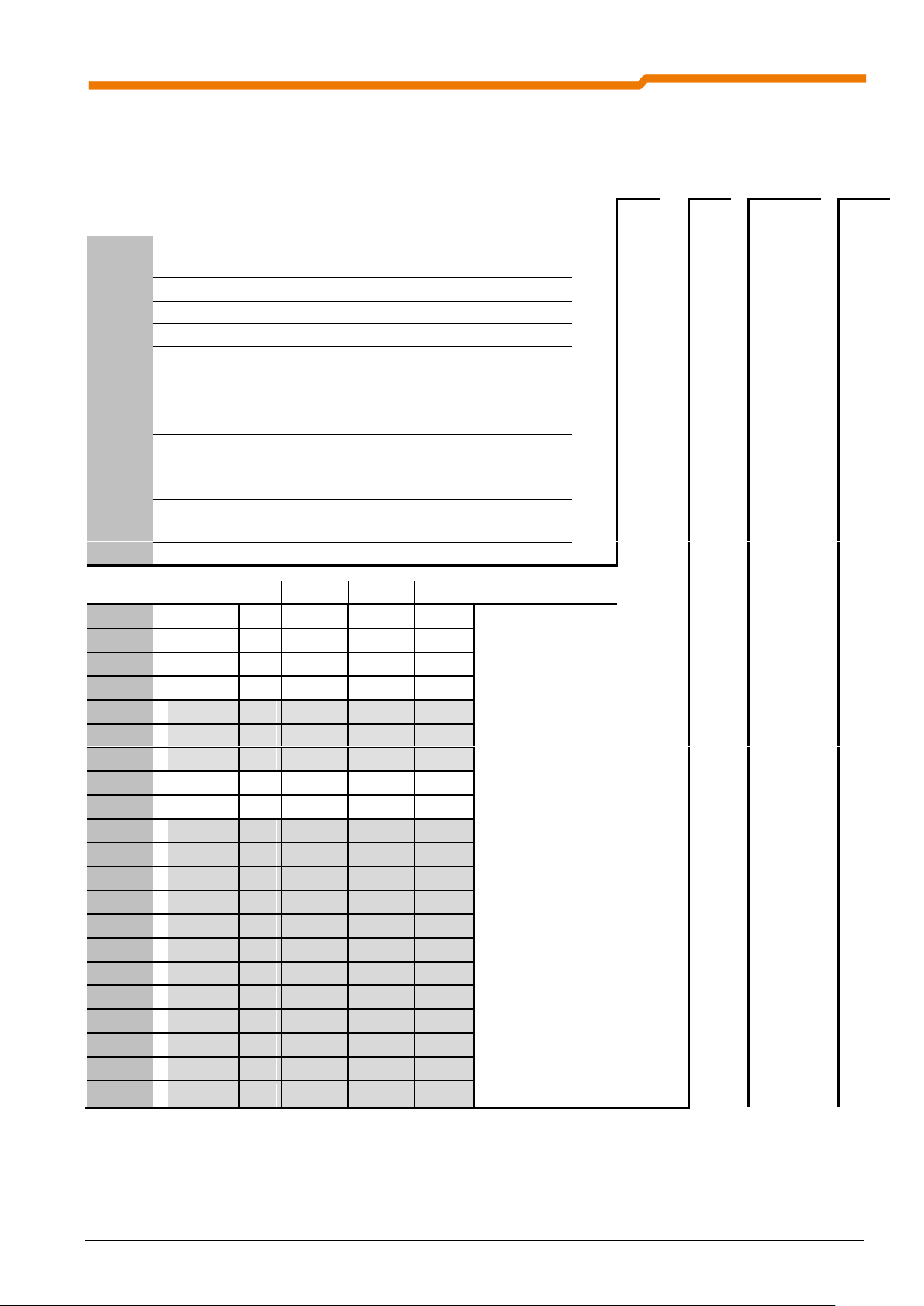

Scope of Application

These instructions are only applicable to devices whose type can be derived from the following key:

Item 1.: Configuration

510: as for 500 (standard I/O) + "Safe pulse block"

511: as for 510, however with additional 2 x CANbus/CANopen

515: as for 510, however with 24V control supply, 2 x CANbus/CANopen

520: as for 500, however with additional 2x CANbus/CANopen, 2x dig. IN, 2x dig. OUT, incremental

encoder input

530: as for 520 (extended I/O) + "Safe pulse block"

535: as for 530, however with 24V control supply

540: as for 530, however additionally with PLC functionality and multi-encoder interface

545: as for 540, however with 24V control supply

Item 2.: Power in encoded form: abc

2 significant places, 3rd place multiplier: P=(10*a+b)*10

(c+1)

in W

BU 0530 GB-3712 5

Page 6

Functional safety with NORD SK 500E frequency inverters About this document

Item 3.: Mains in encoded form: abc

a: Number of mains phases

bc: Mains voltage (Nominal voltage/10) in two significant places

230 V devices up to 2.2 kW are also suitable for single phase operation.

The suffix A after the mains voltage stands for an integrated mains filter (Class A)

Item 4.: Heat sink (blank: standard; CP: Cold Plate)

Item 5.: Custom versions (e.g. KAR, ERS; XXX stands for further versions in general)

The customised versions are only variants which differ in the areas of the I/O, bus system, or connectors

and terminals. These versions have no effect on the "Safe pulse block".

6 BU 0530 GB-3712

Page 7

1 General

SAFETY AND OPERATING INSTRUCTIONS FOR DRIVE POWER CONVERTERS .............. 2

1 GENERAL ................................................................................................................................. 9

1.1 Safety and installationinformation ........................................................................ 9

1.2 Approvals and certificates .................................................................................. 10

1.2.1 Certifications for the function STO .......................................................................... 11

1.2.2 Certifications for the function SS1 ................................................................ ........... 13

1.2.3 Certificate for the sole use of the digital inputs ........................................................ 15

1.3 Identification system ........................................................................................... 17

2 FUNCTION DESCRIPTION .................................................................................................... 19

2.1 Safe shut-down method ..................................................................................... 21

2.1.1 Safe pulse block ...................................................................................................... 21

2.1.2 Digital inputs ........................................................................................................... 21

2.2 Safety functions .................................................................................................. 22

2.2.1 Safe torque off, STO ............................................................................................... 22

2.2.2 Safe stop 1, SS1 ..................................................................................................... 22

2.3 Examples / Implementation ................................................................................ 23

2.3.1 STO function ........................................................................................................... 23

2.3.2 SS1 Function .......................................................................................................... 25

2.3.3 Simple restart block................................................................................................. 26

2.3.4 Example without safe shut-down method................................................................ 27

2.3.5 Ruling out wiring faults ............................................................................................ 28

3 ASSEMBLY AND INSTALLATION ........................................................................................ 29

3.1 Installation and assembly ................................................................................... 29

3.2 Wiring guidelines ................................................................................................ 29

3.3 Mains supply (X1-PE, L1, L2/N, L3) ................................................................... 29

3.4 Connecting the control cables ............................................................................ 29

3.4.1 Connecting the safe pulse block (X8 – VIS 24V, VIS 0V) ....................................... 30

3.4.2 Connection terminals .............................................................................................. 31

3.4.3 Details of the "Safe pulse block" control connections.............................................. 33

3.4.4 Details of the "Digital inputs" control connections ................................................... 34

3.4.5 Details of the "Digital outputs" control connections ................................................. 38

4 PARAMETERISATION ........................................................................................................... 40

5 PROTECTIVE SWITCHING DEVICES ................................................................................... 44

5.1 Output voltage .................................................................................................... 44

5.2 Switching capacity and current load ................................................................... 44

5.3 OSSD outputs, test pulse ................................................................................... 44

6 SAFETY CATEGORIES ......................................................................................................... 45

6.1 IEC 60204-1:2005 .............................................................................................. 45

6.2 IEC 61800-5-2:2007 ........................................................................................... 45

6.3 IEC 61508 ........................................................................................................... 45

6.4 ISO 13849-1:2006 .............................................................................................. 46

7 COMMISSIONING................................................................................................................... 47

8 DIAGNOSIS AND FAULTS .................................................................................................... 49

8.1 Diagnosis ............................................................................................................ 49

8.2 Faults .................................................................................................................. 49

8.2.1 Table of possible error messages ........................................................................... 49

8.2.2 Error display ............................................................................................................ 49

8.2.3 Error memory .......................................................................................................... 49

9 TECHNICAL DATA ................................................................................................................. 50

9.1 Environmental data............................................................................................. 50

9.2 Control terminal data .......................................................................................... 50

9.3 Data for the digital inputs .................................................................................... 51

9.4 Data for the safe pulse block .............................................................................. 52

BU 0530 GB-3712 7

Page 8

Functional safety with NORD SK 500E frequency inverters

10 ADDITIONAL INFORMATION ............................................................................................. 53

10.1 Maintenance and servicing information ........................................................... 53

10.2 Abbreviations in this manual ............................................................................ 53

11 KEYWORD INDEX ............................................................................................................... 54

8 BU 0530 GB-3712

Page 9

1 General

This manual BU 0530 ES describes the aspects that are directly related to the functional safety of the

equipment. All standard functions and parameters of the inverter are contained in the manual (BU 0500 GB).

1.1 Safety and installationinformation

SK 500E frequency inverters are equipment for use in industrial high voltage systems and are operated at

voltages that could lead to severe injuries or death if they are touched.

Installation and other work may only be carried out by qualified electricians and with the device

disconnected. The operating instructions must always be available to these persons and must

be strictly observed by them.

Local regulations for the installation of electrical equipment and accident prevention must be

complied with.

The equipment continues to carry hazardous voltages for up to 5 minutes after being switched

off at the mains. The equipment may only be opened or the cover or control element removed 5

minutes after the equipment has been disconnected from the power supply. All covers must be

put back in place before the mains voltage is switched back on again.

For single phase operation (115/230 V) the mains impedance must be at least 100H for each

conductor. If this is not the case, a mains choke must be installed.

1 General

For safe isolation from the mains, all poles of the supply cable to the frequency inverter must be

able to be disconnected.

Even during motor standstill (e.g. caused by an electronic block, blocked drive or output terminal

short circuit), the line connection terminals, motor terminals and braking resistor terminals may

still conduct hazardous voltages. A motor standstill is not identical to electrical isolation from the

mains.

Parts of the control board, and especially the connector socket for the removable technology

units also carry hazardous voltages. The control terminals are mains voltage free.

Note: with certain settings, the frequency inverter can start up automatically after the mains are

switched on.

The circuit boards contain highly-sensitive MOS semiconductor components that are particularly

sensitive to static electricity. Avoid touching circuit tracks and components with the hand or

metallic objects. Only the terminal strip screws may be touched with insulated screwdrivers when

connecting the cables.

The frequency inverter is only intended for permanent connection and may not be operated

without effective earthing connections which comply with the local regulations for large leakage

currents

(> 3.5 mA). VDE 0160 stipulates the installation of a second earthing conductor or an earthing

conductor cross-section of at least 10 mm2.

A universal leakage current-sensitive circuit breaker (type B) according to EN 50178/VDE 0160

must be used.

SK 500E frequency inverters are maintenance free. The cooling surfaces must be regularly

cleaned with compressed air if the ambient air is dusty.

Installation of the frequency inverter in an IP54 switching cabinet is mandatory.

The clamp cover must be used!

BU 0530 GB-3712 9

Page 10

Functional safety with NORD SK 500E frequency inverters

CAUTION

The heat sink and all other metal components can heat up to temperatures above 70 ℃.

When mounting, sufficient distance from neighbouring components must be maintained.

When working on the components, allow sufficient cooling time beforehand

Protection against accidental contact may need to be provided.

ATTENTION

DANGER TO LIFE!

The power unit can continue to carry voltages for up to 5 minutes after being switched off at

the mains. Inverter terminals, motor cables and motor terminals may carry voltage!

Touching open or free terminals, cables and equipment components can lead to severe injury

or death!

Work may only be carried out by qualified specialist electricians and with the electrical supply

to the equipment disconnected!

CAUTION

Children and the general public must be kept away from the equipment!

The equipment may only be used for the purpose intended by the manufacturer.

Unauthorised modifications and the use of spare parts and additional equipment which has

not been purchased from or recommended by the manufacturer of the device may cause fire,

electric shock and injury.

Keep these operating instructions in an accessible location and give them to all operators!

WARNING

This product is intended for use in an industrial environment and is subject to sales

restrictions according to IEC 61800-3. In a domestic environment, this product can cause

high frequency interference, in which case the user may be required to take appropriate

measures.

An appropriate measure would be the inclusion of a recommended mains filter.

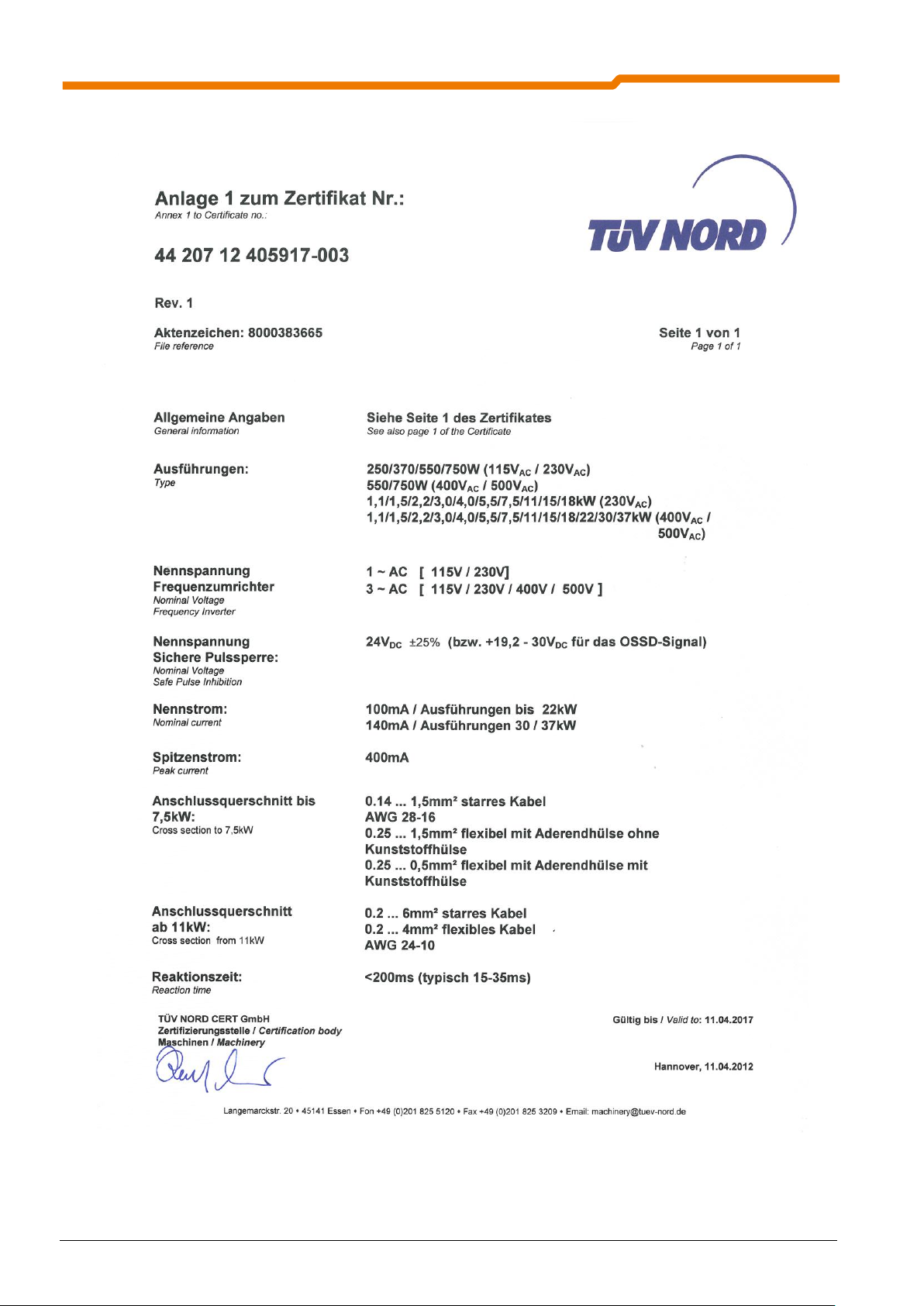

1.2 Approvals and certificates

The certificates listed below refer to functional safety. Certifications relating to the frequency inverter (EMC,

UL, etc.) are listed in the main manual (BU0500).

The certificates for size 8 and 9 frequency inverters (45 ... 90kW) were not available at the time of

publication, however, they will be provided towards the end of 2012.

10 BU 0530 GB-3712

Page 11

1.2.1 Certifications for the function STO

1 General

BU 0530 GB-3712 11

Page 12

Functional safety with NORD SK 500E frequency inverters

12 BU 0530 GB-3712

Page 13

1.2.2 Certifications for the function SS1

1 General

BU 0530 GB-3712 13

Page 14

Functional safety with NORD SK 500E frequency inverters

14 BU 0530 GB-3712

Page 15

1.2.3 Certificate for the sole use of the digital inputs

1 General

BU 0530 GB-3712 15

Page 16

Functional safety with NORD SK 500E frequency inverters

16 BU 0530 GB-3712

Page 17

Name for ordering SK 5xxE

Example:

SK

520

E-

751

-

340-A

-

XXX

Configuration

500

5x dig. IN, 2x analog IN, 2x relay OUT, 1x analog OUT,

RS232/485

505*

as for "500", however 24 V supply for the control unit

510*

as for "500", but with additional "safe pulse block"

511*

as "510", but additionally with 2x CANbus/CANopen

515*

as for "510", however 24 V supply for the control unit

520

as "500", but additionally with 2x CANbus/CANopen, 2x dig. IN,

2x dig. OUT, incremental encoder input

525*

as for "520", however 24 V supply for the control unit

530

as for "520", however with additional "safe pulse block" and

positioning control

535

as for "530", however 24 V supply for the control unit

540

as for 530, however additionally with PLC functionality and

multi-encoder interface

545

as for "540", however 24 V supply for the control unit

Power

Mains

112

323-A

340-A

350-A

250

250W

I I

Size S

370

370W

1 1

550

550W

1 1 1

1

750

750W

1 1 1

1

111

1.1kW

2 2

2

151

1.5kW

2 2

2

221

2.2kW

2 2

2

301

3.0kW

3 3

3

401

4.0kW

3 3

3

551

5.5kW

5 4

4

751

7.5kW

5 4

4

112

11kW

6 5

5

152

15kW

7 5

5

182

18.5kW

7 6

6

222

22kW

6

6

302

30kW

7

7

372

37kW

7

7

452

45kW

8

8

552

55kW

8

8

752

75kW

9

9

902

90kW

9

9

1.3 Identification system

1 General

BU 0530 GB-3712 17

Page 18

Functional safety with NORD SK 500E frequency inverters

Name for ordering SK 5xxE

Example:

SK

520

E-

751

-

340-A

-

XXX

Mains

112-O

Single phase, 115V, without filter, only devices without "Safe

pulse block" (SK 500E, 505E, 520E and 525E, SK 530E only

position control)

323-A

3-phase, 230 V, internal A-filter (1/3 phases up to 2.2 kW)

340-A

3-phase, 400 V, internal A-filter

350-A*

3-phase, 500V, internal A-filter

Option

No option

CP

Cold Plate

XXX

Further options possible

* only available on request!

18 BU 0530 GB-3712

Page 19

2 Description of function

Sizes 1 - 4

Sizes 5 - 7

I/O

Emergency stop

µC

T5

T6

T3

T4

T1

T2

U

V

W

L1

L2

L3

Frequency Inverter

=

=

=

=

Control voltage

VIS 0V (88)

VIS 24V (89)

=

=

=

=

Safe pulse block

VOS 0V (87)

VOS 24V (86)

Driver

Logic

T1 T3 T5

Gate supply

T2 T4 T6

M

Gate supply

Driver

Internal power supply

Frequency inverter

Safe pulse block

Mains

Motor

I/O

Control

µC

T5

T6

T3

T4

T1

T2

U V W

M

L1

L2

L3

Logic

VI_S +24V

2 Function description

To avoid danger to persons and to prevent damage to material, machines must be able to be switched off

safely. The frequency inverters SK 510E, SK 511E, SK 515E, SK 530E, SK 535E, SK 540 and SK 545E

provide a method for safe switch-off (Safe pulse block).

In order to understand the function of the shut-down methods, it is first of all necessary to consider the function

of the frequency inverter.

The mains voltages are rectified and the resulting DC voltage is reconverted to AC according to the

requirements of the operating status of the motor (frequency and voltage).

Internal structure of the safe pulse block:

BU 0530 GB-3712 19

Page 20

Functional safety with NORD SK 500E frequency inverters

Sizes 7 - 9

I/O

Emergency stop

Driver

µC

T5

T6

T3

T4

T1

T2

U

V

W

L1

L2

L3

Frequency Inverter

Logic

=

=

=

=

Control voltage

Gate supply

VIS 0V (88)

VIS 24V (89)

VOS 0V (87)

VOS 24V (86)

Primary power

=

=

=

=

PWM-IC

=

=

PWM-IC

=

=

PWM-IC

M

Safe pulse block

The semiconductor switches of the inverter (T1 to T6) are controlled by a highly complex pulse pattern. This

pulse pattern is generated by the microcontroller (µC) and amplified by the driver. The drivers convert the logic

signals on the control voltages of the semiconductor switch. The semiconductor switches are switched via the

control voltage and the pulse pattern is amplified and applied to the motor terminals. Due to the low-pass effect

of the motor, a three-phase pulse width modulated sine wave voltage - a three-phase system, results from the

pulsed voltage. The motor generates a torque.

20 BU 0530 GB-3712

Page 21

2 Description of function

NOTE

On triggering the safe shut-down method, a mechanical brake connected to the terminals 1

(K1.1) and 2 (K1.2) can be applied (see parameter 434 in the BU 0500 GB manual). If the

drive unit is not previously switched off, the brake must be designed as an operational brake.

1

DIN1 ...

GND

DIN4

Frequency inverter

Filter

for

OSSD

optional

21

40

24V

Safety output

Safety output

24V

Safety output

24V

GND SH

24V SH

Frequency inverter

88

89

Safety output

24V

or

Safety output

24V

or

Safety output

24V

2.1 Safe shut-down method

With the aid of a safe shut-down method the torque is now to be safely shut down. This corresponds to the

safety function STO (safe torque off).

In order to switch off the torque, the current to the motor must be interrupted. The pulse block is provided for

this.

2.1.1 Safe pulse block

Devices equipped with a "safe pulse block" have an additional DC/DC converter, which produces the supply

voltage for the driver from a 24V supply (24V_SH, GND_SH).

If the external 24 V voltage is switched off then the DC/DC converter does not transmit any power to the

drivers. As the drivers are now no longer supplied with power, no control pulses reach the relevant

semiconductor switches of the inverter. The flow of current in the semiconductor switches and the motor is

interrupted. I.e. after a certain reaction time of the electronics and the reduction time of the motor current, the

motor does not develop a driving torque.

The switch-off of the 24V supply (24V_SH, GND_SH) must be carried out by a fail-safe switching device. For

this, either the connection 24V_SH (Terminal 89) or the connection GND_SH (Terminal 88) may be

disconnected from the 24V source. For preference, the 24V_SH connection is disconnected.

2.1.2 Digital inputs

In order to implement a safety function, the digital inputs can be used as auxiliary inputs, e.g. for the triggering

of a braking process. It should be noted that the digital inputs only fulfil minimum safety requirements. A safe

shut-down method is always required!

The digital inputs, other I/Os and the 24V supply have a common earth. This means that a digital input may

only be switched off by disconnecting the associated connection (21 for DIN1 to 24 for DIN 4). Switch-off via

GND is not possible!

When operating with an OSSD1 a filter is only required for environments with strong interference.

If only low levels of functional safety are required, the safety function can also be implemented with the digital

inputs. It is recommended that this is only considered if the risk assessment has shown that slight (normally

temporary) injuries could result on failure of the safety function (see also Section 6 ). In case of doubt, a safe

shut-down method should always be used.

Output Signal Switching Device

BU 0530 GB-3712 21

Page 22

Functional safety with NORD SK 500E frequency inverters

NOTE

Control of a mechanical brake by means of the inverter is not fail-safe!

A mechanical brake connected to terminals 1 (K1.1) and 2 (K1.2) can be applied on triggering

of the STO function. This means that in this case, the brake must be designed as an operating

brake, as the drive unit and all of its rotating mass is stopped by the mechanical brake.

Slippage of lifting gear when triggering the STO function must be prevented by suitable brakes

where necessary!

NOTE

Controlled braking is triggered via a digital input and only complies with low safety requirements!

If controlled braking fails then the device switches over to STO.

If necessary, the braking process must be monitored.

NOTE

Control of a mechanical brake by means of the inverter is not fail-safe!

In case of failure of controlled braking, a mechanical brake connected to terminals 1 (K1.1) and

2 (K1.2) may be overloaded, as this brake is applied when the STO function is triggered.

If necessary, slippage of lifting gear must be prevented by the use of suitable brakes.

2.2 Safety functions

A stop function can be executed by means of a safe shut-down method. As this has priority over other control

functions this stop-function is suitable for stopping in emergencies. This ensures that the torque is shut down

by means of a safe shut-down method. This function is known as "safe torque off" or STO.

It is also possible to first stop the motor in a controlled manner and then to switch off the torque. This function

is referred to as "safe stop 1" or SS1.

2.2.1 Safe torque off, STO

With the STO function the drive torque is switched off as quickly as possible (see Technical Data Reaction

Time) and the drive until (motor and machine) run down to a standstill. This behaviour corresponds to Stop

Category 0 (uncontrolled braking) as per EN 60204-1. A certain time therefore elapses until the drive unit does

not perform any further dangerous movements and a safe state is achieved. Monitoring of whether or when the

drive unit has achieved a safe state is not integrated into the frequency inverter.

According to the switching equipment used and with the use of a safe shut-down method, an STO function with

Safety Category 4 as per DIN EN ISO 13849-1 can be implemented.

2.2.2 Safe stop 1, SS1

With the SS1 function, the motor is first stopped by the inverter and after standstill the device switches to the

STO function. This method is the same as stop category 1 (controlled stop) as per IEC60204-1. Switching to

the STO function can be monitored after reaching standstill or can be carried out via a fail-safe timing relay

(delayed output of a protective switching device).

22 BU 0530 GB-3712

Page 23

2 Description of function

NOTE

If the "Safe pulse block" triggers for an enabled frequency inverter, error E018 (18.0 safety

circuit) is triggered.

DIN1

GND

24V SH

21

40

88

89

24V

24V

24V

Frequency inverter

Use of the

"Safe pulse block"

Reset

Emergency stop button

Reset circuit

Safety output 1

Safety output 2

Supply voltage

Input circuit

with short-

circuit detection

Shielded cable to

eliminate errors as per

DIN EN ISO 13849-2

Filter

for

OSSD

optional

GND SH

24V SH

88

89

24V

-

24V

Frequency inverter

Use of the

"Safe pulse block"

Reset

Emergency stop button

Reset circuit

Shielded cable to eliminate

errors as per

DIN EN ISO 13849-2

Input circuit

with shortcircuit

detection

Supply

voltage

Safety output

2.3 Examples / Implementation

The following illustrates several examples of solutions for the safety functions STO and SS1.

2.3.1 STO function

Normally, a protective switching device is used to implement a safety function. The safety category of the

function is determined by the component with the lowest category.

In this example, Safety Category 4 as per DIN ISO 13849-1 can be achieved. The prerequisite for this is that

the emergency stop button, the protective switching device and the wiring fulfil the requirements for Category

4. For example, this can be achieved as follows:

Redundant protective switching device with self-monitoring

Dual-channel input circuit with short-circuit recognition (and appropriate emergency stop button)

Safety output with periodic switch-off tests (OSSD)

Elimination of errors as per DIN ISO 13849-2 for the wiring between the switching device and the input

terminals of the safe shut-down method used, by the use of a shielded cable and connection of the

shield at both ends.

The typical reaction time can be reduced by the additional use of a digital input (e.g.: DIN1), which must be

parameterised for the function "Block voltage":

Note: The optional filter on the digital input is only required in environments with heavy interference.

A second safety output is required to control the digital input.

BU 0530 GB-3712 23

Page 24

Functional safety with NORD SK 500E frequency inverters

NOTE

A separate shielded cable must be used for the "safe pulse block" or "switch-off of the 24V

supply". When using a protective switching device with short-circuit monitored OSSD-outputs,

the safety outputs can be combined in a single cable.

NOTE

Only the "safe pulse block" or "switch-off of the 24V" supply fulfil the requirements of Safety

Category 4. This does not apply to the digital input.

The frequency inverter can only fulfil safety category 1 during the period between activation of

the safe pulse block via a digital input and activation via terminals 88 and 89.

This solution is preferable, especially in cases where the switching device only checks its safety outputs in the

course of an enabling cycle, as is the case with some electro-mechanical switching devices. A suitable

checking interval must be specified according to the safety requirements.

24 BU 0530 GB-3712

Page 25

2 Description of function

NOTE

A separate shielded cable must be used for the "safe pulse block" or "switch-off of the 24V

supply". When using a protective switching device with short-circuit monitored OSSD-outputs,

the safety outputs can be combined in a single shielded cable.

NOTE

The requirements of Safety Category 4 / Performance Level e can only be fulfilled with a safer

shut-down method. Safety Category 1 (and PL c) can be achieved for the digital inputs and

therefore for controlled braking.

DIN1

GND

GND SH

24V SH

21

40

88

89

24V

Reset

24V

24V

Filter

for

optional

Frequency inverter

Use of the

"Safe pulse block"

Emergency stop

Supply voltage

Reset circuit

Input circuit

with shortcircuit

detection

Safety output 1

Safety output 2

Shielded cable to eliminate

errors as per

DIN EN ISO 13849-2

2.3.2 SS1 Function

A digital input is always required for the implementation of the SS1 function in order to initiate a braking

process performed by the inverter. For this, the digital input used is set to the function "fast stop" [11].

Note: The optional filter on the digital input is only required in environments with heavy interference.

When the safety function is requested, a controlled stopping procedure is first triggered via the digital input (in

this case DIN1). Here it must be ensured that the drive is brought to standstill within the parameterised fast

stop time (P426). After the elapse of a delay time which is controlled by the switching device, the safe shutdown method is triggered. The delay time must be dimensioned so that the delay is longer than the fast stop

time plus the DC follow-up time (P559). The delay time must be selected so as to be fail-safe.

Here it should be noted that controlled braking can fulfil the requirements for Safety Category 1. Safety

Category 4 as per DIN EN ISO 13849-1 can be achieved with final switch-off by the triggering of a safe shutdown method "safe pulse block" or "switch-off of the 24V supply". For this, the same conditions as described in

the examples for the STO function apply. If controlled braking fails then the device switches over to STO (after

the set delay).

BU 0530 GB-3712 25

Page 26

Functional safety with NORD SK 500E frequency inverters

NOTE

After triggering the "safe pulse block“, the inverter shows the acknowledgeable fault E018 (18.0

Safety circuit).

NOTE

In this example, there is no reset circuit as is the case with the protective switching devices. If

the result of risk analysis is that cancellation of the stop command must be acknowledged by

intended manual action then the resetting requirements can be fulfilled organisationally (e.g. by

an emergency-stop button with key releasing device and storage of the key away from the

machine).

NOTE

We recommend that the "automatic fault clearance“ (P506) and "automatic start-up" (P428)

functions are not used in combination with each other (See BU 0500 GB), as the drive would

otherwise immediately start up after unlocking the emergency-off button.

GND SH

24V SH

Frequency inverter

89

Emergency stop button

24V

Shielded cable to eliminate

errors as per

DIN EN ISO 13849-2

88

2.3.3 Simple restart block

Safety Category 4 as per DIN ISO 13849-1 can be achieved with a direct dual-channel triggering of the "safe

pulse block" with the aid of a safe switching element. The following illustration shows an example with an

emergency stop switch (guided contacts, Safety Category 4).

To achieve safety category 4, fault exclusion as per EN 13849-2 Sec. D.5 must be possible for the upstream

components (hard-wiring and dual-channel buttons with independent, positive-opening contacts). I.e., in this

example, the emergency-stop button and the wiring must be designed in such a way that short-circuiting at the

emergency-stop button and to other live systems can be ruled out.

26 BU 0530 GB-3712

Page 27

2 Description of function

NOTE

As a maximum, this example achieves Safety Category 1 or Performance Level c. This circuit

version is not SIL-capable

(See Section 6).

DIN1 ...

GND

DIN4

40

24

24V

Reset

24V

Frequency inverter

optional

Emergency stop button

Reset circuit

Safety output

Use of a

digital input

STO: P420[-01...-04]=10, "Disable voltage"

SS1: P420[-01...-04]=11, "Fast stop"

Filter

for

OSSD

Shielded cable to eliminate

errors as per

DIN EN ISO 13849-2

Supply voltage

Input circuit

with shortcircuit

detection

2.3.4 Example without safe shut-down method

It is possible to implement the safety functions STO or SS1 with a digital input and a protective switching

device. With this switching version, as a maximum, Safety Category 1 as per DIN EN ISO 13849-1 can be

achieved, if in addition to the digital inputs, all other components (protective switching device, emergency stop

button, wiring) fulfil the requirements for Category 1.

This switching version should only be considered if only low requirements for functional safety need to be

fulfilled and if the risk assessment has shown that failure of the safety function can only result in slight (usually

temporary) injuries (see also Section 6 ). In case of doubt, the "Safe pulse block" should always be used.

Note: The optional filter is only required in environments with heavy interference.

To implement the safety function STO, the digital input is parameterised to the function "Disable voltage".

With the safety function SS1 the digital input is assigned the function "Fast stop" (parameter P420[-01...-04])

and the fast stop time is set via parameter P426. It must be ensured that the drive is brought to standstill within

the parameterised fast stop time.

BU 0530 GB-3712 27

Page 28

Functional safety with NORD SK 500E frequency inverters

GND SH

24V SH

88

89

24V

Frequency inverter

Safety output 1

Safety output 2

Monitored outputs

DIN1

GND

21

40

24V

optional

Safety output 1

Filter

for

OSSD

24V SH

GND SH

89

88

24V

Safety output 2

Monitored outputs

without short-circuit detection

Frequency inverter

DIN1

GND

21

40

24V

optional

Safety output 1

Filter

for

OSSD

24V SH

GND SH

89

88

24V

Safety output 2

Monitored outputs

without short-circuit

Frequency inverter

2.3.5 Ruling out wiring faults

In the examples above, a separate shielded cable, whose shield is connected at both ends is used each of the

inputs used for the implementation of the safety function. This measures serves to rule out faults as per DIN

EN ISO 13849-1 in case of a short circuit between any of the conductors. This exclusion of faults is necessary

in order to fulfil the requirements of Safety Category 4 as per DIN EN ISO 13849-1. According to this, a single

detected fault or an accumulation of undetected faults must not lead to the loss of the safety function. A short

circuit from an external voltage, e.g. from a 24V control cable, to the 24V input of a safe shut-down method

could lead to the loss of a safety function. I.e. this fault must be prevented by means of suitable measures.

The use of a separate shielded cable for each input is not mandatory. For example, the cables for the digital

inputs and the safe shut-down method may be jointly laid in a shielded cable, if the monitored safety outputs of

the switching device is equipped with short-circuit detection (See Fig.). If necessary, the effectiveness of the

short-circuit detection must be demonstrated.

Other measures (separate cable duct, installation in armoured conduit) are possible. More precise details

result from the risk assessment and the FMEA for the specific application.

For the "safe pulse block" it is also conceivable that this is triggered via two safety outputs, one switching the

24V output and the other switching the GND output.

In this case a shielded cable is not strictly necessary if both safety outputs are monitored. If, for example, other

24V control cables are laid in the same cable duct and an error in the form of a short-circuit from 24V_SH to a

control cable (=24V) is assumed, this fault would be detected by the output monitoring of the switching device

and the "safe pulse block" would be triggered by the second safety output. More precise details result from the

FMEA for the specific application.

If a shielded cable is not used for the wiring of the safety function, the effects of electromagnetic fields may

need to be taken into account. Hence the use of a 1 m long cable (in a separate cable duct) in an environment

without strong electromagnetic fields is relatively safe, while the installation of a long cable in the direct vicinity

of a powerful transmitter or a medium voltage distributor may cause the failure of the safety function. Because

of this, the use of shielded cables is generally recommended.

28 BU 0530 GB-3712

Page 29

3 Assembly and installation

3 Assembly and installation

The installation instructions contained within this manual only deal with issues that are related to functional

safety. Additional information is contained in the manual (BU 0500 DE).

3.1 Installation and assembly

SK 5xxE series frequency inverters have protection class IP20 and may only be installed in an area with

protection class IP54 (or higher).

The installation instructions contained in BU0500 GB must be observed!

3.2 Wiring guidelines

With regard to this item, please observe the appropriate chapter of BU 0500 DE and the following chapters in

this manual.

3.3 Mains supply (X1-PE, L1, L2/N, L3)

devices with "safe pulse block“ may only be operated at TN networks, TT networks and grounded corner! The

equipment has not been designed for operation at IT networks.

3.4 Connecting the control cables

Detailed information regarding the connection of the control cables (terminal designation, terminal positions

etc) can be found in the main manual for the frequency inverter (BU0500).

BU 0530 GB-3712 29

Page 30

Functional safety with NORD SK 500E frequency inverters

q

l

R

CU

*

km

mm

CU

2

*19

5,0R

VAInumberRU

PeakINFUcable

14,0*5*5,0**

,

3.4.1 Connecting the safe pulse block (X8 – VIS 24V, VIS 0V)

SK 51xE SK 53xE and SK 54xE series frequency inverters are equipped with the option "Functional safety".

Connection of the corresponding control cables is made via terminal block X8. Up to and including size 4, this

terminal block and all other control connections are located under the front cover (See Section 3.4.2

"Connection terminals"). For sizes 5 to 7, the terminal block X8 is located on the underside of the frequency

inverter (motor output side).

A two-wire shielded cable must be used for the safe pulse block. The shield must be connected at on both

ends. For mechanical switching devices the line drop in the cable must not exceed ΔU

electronic protective switching devices it must not exceed ΔU

I

= 400 mA should be assumed.

IN,Peak

Operation at OSSD

The safe pulse block is specially designed for use with an OSSD.

The capacity between the wires (including the shielded capacities) must not exceed a value of 20nF for each

inverter connected.

Additional restrictions may apply here with regard to the protective switching device.

EMC

When the „safe pulse block“ has been wired correctly for EMC, the recommended EMC values (See BU 0500

GB) can be complied with up to a cable length of 20m between the safety switching device and the inverter.

Multi-device operation

When operating several inverters at one safety switching device, the switching capacity of the switching device

and the load rating of the 24V power-feeding supply must be observed.

The shield must be applied to all inverters.

The permissible line drops on the cable must be observed!

Example:

≤ 1 V. For the calculation, a peak current of

Cable

≤ 3 V and for

Cable

5x frequency inverter at an electronic safety switching device!

The 5x FIs are arranged next to each other in a switching cabinet

20m must be bridged between the FI and the switching device!

Shielded cable 2x1.5 mm2

with

Double the length of cable must be used because line drops occur in both wires.

=> OK!

30 BU 0530 GB-3712

Page 31

3.4.2 Connection terminals

Frequency inverter

Size 1 ... 4 and 8 ... 9

Rigid cable cross-section

0.14 … 1.5mm²

Flexible cable cross-section

0.14 … 1.5mm²

AWG standard

AWG 28-16

Flexible cable cross section with wire end sleeve, without plastic tube

0.25 … 1.5mm²

Flexible cable cross section with wire end sleeve, and with plastic tube

0.25 … 0.5mm²

Nominal ratings of safe pulse block

Terminal X8:86

(output - provision of +15V / +24V)

+24 V

(max. 300mA)

Terminal X8:87

GND

Terminal X8:88

GND

Terminal X8:89

(Input: “Safe pulse block”)

+24 V ± 25% or

+24 V -20% + 25% for operation with OSSD

2

100mA (AV) (Size 1 - 4)

50mA (AV) (Size 8 - 9)

400mA (peak) after switching-on or after

a test pulse from an OSSD

2

CAUTION: For this safe pulse block function,

the bridges must be removed!

As delivered, terminals 87-88 and 86-89 are

bridged in order to enable commissioning or

operation without the safety function (or ext. 24V).

X8: VIS 24V 24V

input of pulse block

NOTE:

15V output for commissioning

without safety switching device

or safety function.

NOTE:

For size V and above, the ter-

minal block X8 is located on the

motor output side of the fre-

quency inverter.

3 Assembly and installation

Connection terminals: Plug-in clip connectors can be released with a small screwdriver

Deviating position of terminal block X8 for sizes 5 to 7

Output Signal Switching Device

BU 0530 GB-3712 31

Page 32

Functional safety with NORD SK 500E frequency inverters

Frequency inverter

Sizes 5 ... 7

Rigid cable cross-section

0.2 … 6mm²

Flexible cable cross-section

0.2 … 4mm²

AWG standard

AWG 24-10

Tightening torque

for screw terminals

0.5 … 0.6Nm

Nominal ratings of safe pulse block

Terminal X8:86

(output - provision of +24V)

+24 V

(max. 300mA)

Terminal X8:87

GND

Terminal X8:89

(Input: “Safe pulse block”)

+24 V ± 25%

100mA (AV) (Size 5 - 6)

140mA (AV) (Size 7)

400mA (peak) after switching-on or after

a test pulse from an OSSD

Terminal X8:88

GND

In deviation from the illustration above, from size

5 and above, the position of terminal block X8 for

the connection of the safe pulse block is located

on the underside of the device (motor connection

side).

Connection data:

32 BU 0530 GB-3712

Page 33

3.4.3 Details of the "Safe pulse block" control connections

NOTE

As delivered, for commissioning without safety switching device, terminals 87-88 and 86-89 are

bridged. In order to be able to use the safety function, the bridges must be removed.

Relevance

SK 500E

SK 505E

SK 510E

SK 511E

SK 515E

SK 520E

SK 530E

SK 535E

SK 540E

SK 545E

√

√

√ √

Terminal X8:

86

87

88

89

VO_S 15V

VO_S 0V

VI_S 0V

VI_S 24V

Designation

Terminal

Function

[factory setting]

Data

Description / wiring suggestion

Parameter

up to SK

535E

SK 540E

and above

86

Supply voltage

15V 20%

When setting-up without using a

safety function, wire directly to V_IS

24V.

P420 et

seqq.

P420 [-…]

87

Reference potential

88

Reference potential

24V 25%, ≤140mA

See technical data in

BU0530!

Fail-safe input

89

Input,

safe pulse lock

Relevance

SK 500E

SK 505E

SK 510E

SK 511E

SK 515E

SK 520E

SK 530E

SK 535E

SK 540E

SK 545E

√

√

√

Terminal X8:

86

87

88

89

VO_S 24V

VO_S 0V

V_S 0V

VI_S 24V

Designation

Terminal

Function

[factory setting]

Data

Description / wiring suggestion

Parameter

up to SK

535E

SK 540E

and above

86

Supply voltage

18-30V, each to VI

24V

When setting-up without using a

safety function, wire directly to V_IS

24V.

P420 et

seqq.

P420 […]

87

Reference potential

88

Reference potential

24V 25%, ≤140mA

See technical data in

BU0530!

Fail-safe input

89

Input,

safe pulse lock

Terminal block X8 – Safe pulse lock (not with 115V devices)

3 Assembly and installation

BU 0530 GB-3712 33

Page 34

Functional safety with NORD SK 500E frequency inverters

NOTE

AGND and DGND are common reference potentials for analog or digital inputs.

5V / 15V can be collected by several terminals if required. The sum of collected currents must

not exceed 250mA / 150mA.

Relevance

SK 500E

SK 505E

SK 510E

SK 511E

SK 515E

SK 520E

SK 530E

SK 535E

SK 540E

SK 545E

√ √

√ √

√

Terminals X5:

21

22

23

24

25

42

40

41

DIN1

DIN2

DIN3

DIN4

DIN5

VO 15V

GND / 0V

VO 5V

Designation

Terminal

Function

[factory setting]

Data

Description / wiring suggestion

Parameter

up to

SK 535E

21

Digital input 1

[ON right]

7.5...30V, Ri=6.1k

Not suitable for

thermistor evaluation.

HTL encoders can only

be connected to DIN2

and DIN4

Limiting frequencies:

max. 10 kHz

min. 15 Hz

Each digital input has a reaction time

of ≤ 5ms.

Control with internal 15V:

21

22

23

24

25

42

40

41

15V

motor - PTC

Control with external 7.5-30V:

21

22

23

24

25

42

40

41

7.5 … 30V

motor - PTC

GND / 0V

P420

22

Digital input 2

[ON left]

P421

23

Digital input 3

[parameter set bit0]

P422

24

Digital input 4

[Fixed frequency 1,

P429]

P423

25

Digital input 5

[no function]

2.5...30V, Ri=2.2k

Not suitable for

evaluation of a safety

device.

Suitable for thermistor

evaluation with 5V.

NOTE: For the motor

thermistor P424 = 13

must be set.

P424

42

15V supply voltage

output

15V 20%

Supply voltage provided by the

frequency inverter for connection to

the digital inputs or the supply of a

10-30V encoder.

40

Reference potential

for digital signals

0V digital

Reference potential

41

5V supply voltage

output

5V 20%

Voltage supply for motor-PTC

3.4.4 Details of the "Digital inputs" control connections

Terminal block X5 – Digital In

34 BU 0530 GB-3712

Page 35

3 Assembly and installation

Relevance

SK 500E

SK 505E

SK 510E

SK 511E

SK 515E

SK 520E

SK 530E

SK 535E

SK 540E

SK 545E

√

√

√

Terminals X5:

21

22

23

24

25

44*

40

41

* Terminal 44:

up to Size 4: VI

Size 5 and above:

VO

DIN1

DIN2

DIN3

DIN4

DIN5

V…

24V

GND /

0V

VO 5V

Designation

Terminal

Function

[factory setting]

Data

Description / wiring suggestion

Parameter

up to

SK 535E

21

Digital input 1

[ON right]

7.5...30V, Ri=6.1k

Not suitable for

thermistor evaluation.

HTL encoders can

only be connected to

DIN2 and DIN4

Limiting frequencies:

max. 10 kHz

min. 15 Hz

Each digital input has a reaction

time of ≤ 5ms.

21

22

23

24

25

44

40

41

18 … 30V

motor - PTC

GND / 0V

P420

22

Digital input 2

[ON left]

P421

23

Digital input 3

[parameter set bit0]

P422

24

Digital input 4

[Fixed frequency 1,

P429]

P423

25

Digital input 5

[no function]

Only S1 – S4

2.5...30V, Ri=2.2k

Not suitable for

evaluation of a safety

device.

Suitable for thermistor

evaluation with 5V.

NOTE: For the motor

thermistor P424 = 13

must be set.

Above Size 5

Thermistor on

X13:T1/T2

P424

44

Size 1 to Size 4

VI 24V supply

voltage input

18…30V

at least 800mA (input)

Voltage supply for the FI control unit.

This is essential for the function of

the frequency inverter.

Size 5 and above

VO 24V supply

voltageoutput

24V ± 25%

max. 200mA (output)

Supply voltage provided by the

frequency inverter for connection to

the digital inputs or the supply of a

10-30V encoder.

The 24V control voltage is

generated by the FI, however it can

also be supplied via the terminals

X12:44/40. Supply via terminal

X5:44 is not possible.

40

Reference potential

for digital signals

0V digital

Reference potential

41

5V supply voltage

output

5V 20%

Voltage supply for motor-PTC

BU 0530 GB-3712 35

Page 36

Functional safety with NORD SK 500E frequency inverters

Relevance

SK 500E

SK 505E

SK 510E

SK 511E

SK 515E

SK 520E

SK 530E

SK 535E

SK 540E

SK 545E

√

Terminals X5:

21

22

23

24

39

38

42

40

DIN1

DIN2

DIN3

DIN4

TF-

TF+

VO 15V

GND / 0V

Designation

Terminal

Function

[factory setting]

Data

Description / wiring suggestion

Parameter

SK 540E

and above

21

Digital input 1

[ON right]

7.5...30V, Ri=6.1k

Not suitable for

thermistor evaluation.

HTL encoders can

only be connected to

DIN2 and DIN4

Limiting frequencies:

max. 10 kHz

min. 15 Hz

Each digital input has a reaction

time of ≤ 5ms.

Control with internal 15V:

21

22

23

24

39

38

42

40

motor - PTC

15V

Control with external 7.5-30V:

21

22

23

24

39

38

42

40

motor - PTC

GND / 0V

7.5 … 30V

P420 [-01]

22

Digital input 2

[ON left]

P420 [-02]

23

Digital input 3

[parameter set bit0]

P420 [-03]

24

Digital input 4

[Fixed frequency 1,

P429]

P420 [-04]

39

Thermistor input -

potential isolated

thermistor input, which

cannot be disabled,

for monitoring the

motor temperature

with a PTC

38

Thermistor input +

42

15V supply voltage

output

15V 20%

Supply voltage provided by the

frequency inverter for connection to

the digital inputs or the supply of a

10-30V encoder.

40

Reference potential

for digital signals

0V digital

Reference potential

36 BU 0530 GB-3712

Page 37

3 Assembly and installation

Relevance

SK 500E

SK 505E

SK 510E

SK 511E

SK 515E

SK 520E

SK 530E

SK 535E

SK 540E

SK 545E

√ Terminals X5:

21

22

23

24

39

38

44

40

DIN1

DIN2

DIN3

DIN4

TF-

TF+

VI 24V

GND / 0V

Designation

Terminal

Function

[factory setting]

Data

Description / wiring suggestion

Parameter

SK 540E

and above

21

Digital input 1

[ON right]

7.5...30V, Ri=6.1k

Not suitable for

thermistor evaluation.

HTL encoders can

only be connected to

DIN2 and DIN4

Limiting frequencies:

max. 10 kHz

min. 15 Hz

Each digital input has a reaction

time of ≤ 5ms.

21

22

23

24

39

38

44

40

motor - PTC

GND / 0V

18 … 30V

P420 [-01]

22

Digital input 2

[ON left]

P420 [-02]

23

Digital input 3

[parameter set bit0]

P420 [-03]

24

Digital input 4

[Fixed frequency 1,

P429]

P420 [-04]

39

Thermistor input -

potential isolated

thermistor input, which

cannot be disabled,

for monitoring the

motor temperature

with a PTC

38

Thermistor input +

44

24V supply voltage

input

18…30V

at least 800mA (input)

Voltage supply for the FI control unit.

This is essential for the function of

the frequency inverter.

40

Reference potential

for digital signals

0V digital

Reference potential

BU 0530 GB-3712 37

Page 38

Functional safety with NORD SK 500E frequency inverters

Relevance

SK 500E

SK 505E

SK 510E

SK 511E

SK 515E

SK 520E

SK 530E

SK 535E

SK 540E

SK 545E

√

√ √

Terminals X7:

73

74

26

27 5 7

42

40

RS485 +

RS485 -

DIN6

DIN7

DOUT1

DOUT2

VO 15V

GND / 0V

Designation

Terminal

Function

[factory setting]

Data

Description / wiring suggestion

Parameter

up to

SK 535E

SK 540E

and above

73

Data cable RS485

Baud rate

9600…38400Baud

Termination resistor

R=120

BUS connection parallel to RS485

on RJ12 plug

NOTE: The termination resistance of

DIP switch 1 (see RJ12/RJ45) can

also be used for terminal 73/74.

P503

P509

P503

P509

74

26

Digital input 6

[no function]

7.5...30V, Ri=3.3k

As described for terminal block X5,

DIN1 to DIN5.

Not suitable for the evaluation of a

motor thermistor.

P425

P420 [-06]

27

Digital input 7

[no function]

P470

P420 [-07]

Only SK 54xE

Alternatively:

Output 5 (DOUT3)

[no function]

Digital output

15V, max. 20mA

max. 100k load

With SK 54xE the digital input

(DIN7) can also be used as a digital

output (DOUT3).

If P434 [-05] and P420 [-07] are

parameterised with functions, a High

signal of the DOUT function results

in a High signal for the DIN function.

P434 [-05]

5

Output 3 (DOUT1)

[no function]

For evaluation in a control system.

The scope of functions corresponds

to that of the relay (P434).

P450

P434 [-03]

7

Output 4 (DOUT2)

[no function]

P455

P434 [-04]

Only SK 54xE

Alternatively:

Digital input 8

[no function]

7.5...30V, Ri=3.3k

With SK 54xE the digital output

(DOUT2) can also be used as a

digital input (DIN3).

If P434 [-04] and P420 [-10] are

parameterised with functions, a High

signal of the DOUT function results

in a High signal for the DIN function.

P420 [-10]

42

15V supply voltage

output

15V 20%

Voltage supply for connection to the

digital inputs or the supply of a 1030V encoder

40

Reference potential

for digital signals

0V digital

3.4.5 Details of the "Digital outputs" control connections

A digital output can be used to indicate the status of the "safe pulse block". It must be noted that this status

indication is not fail-safe.

Terminal block X/ – Digital I/O

38 BU 0530 GB-3712

Page 39

3 Assembly and installation

Relevance

SK 500E

SK 505E

SK 510E

SK 511E

SK 515E

SK 520E

SK 530E

SK 535E

SK 540E

SK 545E

√

√ Terminals X7:

73

74

26

27 5 7

44*

40

* Terminal 44:

up to Size 4: VI

Size 5 and above:

VO

485+

RS485 -

DIN6

DIN7

DOUT1

DOUT2

V… 24V

GND / 0V

Designation

Terminal

Function

[factory setting]

Data

Description / wiring suggestion

Parameter

up to

SK 535E

SK 540E

and above

73

Data cable RS485

Baud rate

9600…38400Baud

Termination resistor

R=120

BUS connection parallel to RS485

on RJ12 plug

NOTE: The termination resistance of

DIP switch 1 (see RJ12/RJ45) can

also be used for terminal 73/74.

P503

P509

P503

P509

74

26

Digital input 6

[no function]

7.5...30V, Ri=3.3k

As described for terminal block X5,

DIN1 to DIN5.

Not suitable for the evaluation of a

motor thermistor.

P425

P420 [-06]

27

Digital input 7

[no function]

P470

P420 [-07]

Only SK 54xE

Alternatively:

Output 5 (DOUT3)

[no function]

Digital output

S1 to S4

18-30V according to

VI 24V, max. 20mA,

max. 100k load

Above Size 5

DOUT1 and DOUT2:

24V, max. 200mA

max. 100k load

With SK 54xE the digital input

(DIN7) can also be used as a digital

output (DOUT3).

If P434 [-05] and P420 [-07] are

parameterised with functions, a High

signal of the DOUT function results

in a High signal for the DIN function.

P434 [-05]

5

Output 3 (DOUT1)

[no function]

For evaluation in a control system.

The scope of functions corresponds

to that of the relay (P434).

P450

P434 [-03]

7

Output 4 (DOUT2)

[no function]

P455

P434 [-04]

Only SK 54xE

Alternatively:

Digital input 8

[no function]

7.5...30V, Ri=3.3k

With SK 54xE the digital output

(DOUT2) can also be used as a

digital input (DIN3).

If P434 [-04] and P420 [-10] are

parameterised with functions, a High

signal of the DOUT function results

in a High signal for the DIN function.

P420 [-10]

44

Size 1 to Size 4

VI 24V supply

voltage input

18…30V

at least 800mA (input)

Voltage supply for the FI control unit.

This is essential for the function of

the frequency inverter.

Size 5 and above

VO 24V supply

voltageoutput

24V ± 25%

max. 200mA (output)

Supply voltage provided by the

frequency inverter for connection to

the digital inputs or the supply of a

10-30V encoder.

The 24V control voltage is

generated by the FI, however it can

also be supplied via the terminals

X12:44/40. Supply via terminal

X7:44 is not possible.

40

Reference potential

for digital signals

0V digital

BU 0530 GB-3712 39

Page 40

Functional safety with NORD SK 500E frequency inverters

ATTENTION

to implement the STO function, the "block voltage"function [10] must be assigned to the

appropriate parameter (P420 [-01]…[-04], depending on the digital input selected (DIN1 … DIN4).

For the SS1 function, the "fast stop" function [11] is assigned to the appropriate parameter. In

addition, the stopping time must be entered in parameter P426 and the DC run-on time must be

entered in parameter P559.

For function SS1, the fast stop time (P426) must be rated so that the drive is stopped within this

time. The DC follow-up time follows after the fast stop time (see above). The delay time of the

delayed output of the protective switching device must be rated so that it is longer than the fast

stop time plus the DC follow-up time.

Parameter

Setting value / Description / Note

Device

Supervisor

Parameter set

P420

Digital input 1

(Digital input 1)

up to

SK 535E

0 ... 74

{ 1 }

Enable right as factory setting, control terminal 21 (DIN1)

Various functions can be programmed. These can be seen in the following table.

P420 [-01]

...

[-10]

Digital inputs

(Digital input functions)

SK 540E and

above

0 ... 80

{ [-01] = 1 }

{ [-02] = 2 }

{ [-03] = 8 }

{ [-04] = 4 }

all other { 0 }

Up to 10 inputs which can be freely programmed with digital functions are available in the SK

54xE. Of these inputs, analog inputs 1 and 2 of the frequency inverter do not comply with

EN61131-2 (Type 1 digital inputs).

[-01] = Digital input 1 (DIN1): Enable right, (default), Terminal 21

[-02] = Digital input 2 (DIN2): Enable left, (default), Terminal 22

[-03] = Digital input 3 (DIN3): Parameter switching, (default), Terminal 23

[-04] = Digital input 4 (DIN4): Fixed frequency 1 (P429), (default), Terminal 24

[-05] = Digital input 5 (DIN5): No function, (default), Terminal 253

[-06] = Digital input 6 (DIN6): No function, (default), Terminal 26

[-07] = Digital input 7 (DIN7): No function, (default), Terminal 274

[-08] = Digital function Analog1 (AIN1), "Digital function of analog input 1": Terminal 145

[-09] = Digital function Analog2 (AIN2), "Digital function of analog input 2": Terminal 16c

[-10] = Digital input 8 (DIN8): No function, (default), Terminal 7b

P421

Digital input 2

(Digital input 2)

up to SK

535E

0 ... 74

{ 2 }

Enable left as factory setting, control terminal 22 (DIN2)

Various functions can be programmed. These can be seen in the following table.

P422

Digital input 3

(Digital input 3)

up to SK

535E

0 ... 74

{ 8 }

Parameter set switching Bit 0 as factory setting, control terminal 23 (DIN3)

Various functions can be programmed. These can be seen in the following table.

3

4

5

4 Parameterisation

In this manual, only those parameters and configurations are listed, which are of immediate significance to

functional safety. For additional information, please observe the instructions in manual BU 0500 GB.

Parameter list

Up to and including Size 4, digital input 5 is not available. In place of this a potential-free isolated thermistor input is implemented, whose function cannot be

disabled. If no thermistor is present the two terminals TF- and TF+ must be bridged. Parameterisation of this input does not have any effect.

Digital input 7 (DIN7) can also be used as digital output 3 (DOUT3 / Binary output 5). It is recommended that either an input function (P420 [-07] or an output

function (P434 [-05]) is parameterised. However, if and input function and an output function are parameterised, a High signal from the output function will result in the activation of the input function. This IO-exclusion is hence used as a kind of "flag". This also applies for digital input 8 (DIN8) and digital output 2

(DOUT2 / binary output 4).

The analog inputs 1 and 2 (AIN1 / 2) can also process digital functions. Care must be taken that either an analog function (P400 [-01]/[-02]) or a digital function (P420 [-08]/[-09]) is parameterised in order to prevent misinterpretation of the signals.

40 BU 0530 GB-3712

Page 41

4 Parameterisation

Parameter

Setting value / Description / Note

Device

Supervisor

Parameter set

P423

Digital input 4

(Digital input 4)

up to

SK 535E

0 ... 74

{ 4 }

Fixed frequency 1 (P429) as factory setting, control terminal 24 (DIN4)

Various functions can be programmed. These can be seen in the following table.

P425

Digital input 6

(Digital input 6)

From SK 520E

to SK 535E

0 ... 74

{ 0 }

No function as factory setting, control terminal 26 (DIN6)

Various functions can be programmed. These can be seen in the following table.

P426

Quick stop time

(Quick stop time)

P

0 ... 320.00 s

{ 0.10 }

Setting of the stop time for the fast stop function which can be triggered either via a digital input,

the bus control, the keyboard or automatically in case of a fault.

The emergency stop time is the time for the linear frequency decrease from the set maximum

frequency (P105) to 0Hz. If an actual setpoint <100% is being used, the emergency stop time is

reduced correspondingly.

P434

Relay 1 function

(Analog output 1 function (Relay 1– MFR1))

up to SK

535E

P

0 ... 39

{ 1 }

Control terminals 1/2:Settings 3 to 5 and 11 work with a 10% hysteresis, i.e. the relay contact

closes (Function 11 opens) when the limit value is reached and opens (function 11 closes) when a

10% smaller value is undershot. This behaviour can be inverted with a negative value in P435.

Various functions can be programmed. These can be seen in the following table.

BU 0530 GB-3712 41

Page 42

Functional safety with NORD SK 500E frequency inverters

Parameter

Setting value / Description / Note

Device

Supervisor

Parameter set

P434 [-01]

...

[-05]

Digital output function

(Digital output function)

SK 540E and

above

P

0 ... 39