Page 1

GB

BU 0180

SK 180E…190E

Manual for Frequency inverters

BU 0180 GB-0914 1

Page 2

SK 180E Manual for frequency inverters About this document

NORD frequency inverters

Safety and operating instructions for

drive power converters

(as per: Low Voltage Directive 2006/95/EEC)

1.General

During operation, drive power converters may, depending on their

protection class, have live, bare, moving or rotating parts or hot

surfaces.

Unauthorised removal of covers, improper use, incorrect installation

or operation causes a risk of serious personal injury or material

damage.

Further information can be found in this documentation.

All transportation, installation, initialisation and maintenance work

must be carried out by qualified personnel (compliant with IEC

364, CENELEC HD 384, DIN VDE 0100, IEC 664 or DIN VDE 0110,

and national accident prevention regulations).

For the purposes of these basic safety instructions, qualified

personnel are persons who are familiar with the assembly,

installation, commissioning and operation of this product and who

have the relevant qualifications for their work.

2. Proper use in Europe

Drive power converters are components intended for installation in

electrical systems or machines.

When installed in machines, the drive power converter cannot be

commissioned (i.e. commencement of the proper use) until it has

been ensured that the machine meets the provisions of the EC

Directive 2006/42/EEC (Machine Directive); EN 60204 must also be

complied with.

Commissioning (i.e. implementation of the proper use) is only

permitted if the EMC directive (2004/108/EEC) is complied with.

Drive power converters with a CE label meet the requirements of the

Low Voltage Directive 2006/95/EEC. The stated harmonized

standards for drive current inverters are used in the declaration of

conformity.

Technical data and information for connection conditions can be

found on the rating plate and in the documentation, and must be

complied with.

The drive power converters may only be used for safety functions

which are described and explicitly approved.

3. Transport, storage

Information regarding transport, storage and correct handling must

be complied with.

4. Installation

The installation and cooling of the equipment must be implemented

according to the regulations in the corresponding documentation.

The drive power converters must be protected against

impermissible loads. Especially during transport and

handling, components must not be deformed and/or

insulation distances must not be changed. Touching of

electronic components and contacts must be avoided.

Drive power converters have electrostatically sensitive

components, which can be easily damaged by incorrect

handling. Electrical components must not be mechanically

damaged or destroyed (this may cause a health hazard!).

5. Electrical connection

When working on live drive power converters, the applicable

national accident prevention regulations must be complied

with (e.g. BGV A3, formerly VBG 4).

The electrical installation must be implemented according to

the applicable regulations (e.g. cable cross-section, fuses,

earth lead connections). Further instructions can be found in

the documentation.

Information regarding EMC-compliant installation – such as

shielding, earthing, location of filters and installation of

cables – can be found in the drive power converter

documentation. These instructions must be complied with

even with CE marked drive power converters. Compliance

with the limit values specified in the EMC regulations is the

responsibility of the manufacturer of the system or machine.

6. Operation

Systems in which drive power converters are installed must

be equipped, where necessary, with additional monitoring

and protective equipment as per the applicable safety

requirements, e.g. legislation concerning technical

equipment, accident prevention regulations, etc.

The parameterisation and configuration of the drive power

converter must be selected so that no hazards can occur.

All covers must be kept closed during operation.

7. Maintenance and repairs

After the drive power converter is disconnected from the

power supply, live equipment components and power

connections should not be touched immediately, because of

possible charged capacitors. Observe the applicable

information signs located on the drive power converter.

Further information can be found in this documentation.

These safety instructions must be kept in a safe place!

2 BU 0180 GB-0914

Page 3

SK 180E Manual for frequency inverters About this document

Designation of

previous issues

Software

Version

Comments

BU 0180 DE, June 2013

Part. No.607 1801 / 2313

V 1.0 R0

First version based on BU 0200 DE / 2011

BU 0180 EN, February 2014

Part No. 607 1801 / 0914

V 1.0 R1

Bus options supplemented (Section 3),

Amendment of individual technical data (Section 8)

1.5 kW, 3~ 230V device added (Section 8.2.2)

Revision of EMC section, incl. supplement to EC Declaration

of Conformity (Section 9.3)

Various other corrections

Documentation

Designation: BU 0180 GB

Part No.: 607 1801

Device series: SK 180E, SK 190E

Device types: SK 1x0E-250-112-O ... SK 1x0E-750 -112-O, 0.25 - 0.75 kW, 1~ 100-120 V, Output. 230 V

SK 1x0E-250-323 -B ... SK 1x0E-111-323-B, 0.25 - 1.1 kW, 1/3~ 220-240 V

SK 1x0E-151-323 -B, 1.5 kW, 3~ 220-240 V

SK 1x0E-250-340 -B ... SK 1x0E-221-340-B, 0.25 – 2.20 kW, 3~ 380-480 V

Version list

Publisher

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Str. 1 D-22941 Bargteheide http://www.nord.com/

Tel.: +49 (0) 45 32 / 289-0 Fax +49 (0) 45 32 / 289-2389

BU 0180 GB-0914 3

Page 4

SK 180E Manual for frequency inverters About this document

Intended use of the frequency inverter

Compliance with the operating instructions is essential for fault-free operation and the

acceptance of any warranty claims. These operating instructions must be read before

working with the device!

These operating instructions contain important information about servicing. They must

therefore be kept close to the device.

Frequency inverters are devices for industrial and commercial plants for operating threephase asynchronous motors with squirrel-cage rotors. These motors must be suitable for

operation with frequency inverters, other loads must not be connected to the devices.

Frequency inverters are devices for fixed installation on motors or in systems in the vicinity

of the motors to be operated. All details regarding technical data and permissible

conditions at the installation site must be complied with.

Commissioning (commencement of the intended use) is not permitted until it has been ensured

that the machine complies with the EMC Directive 2004/108/EEC and that the conformity of

the end product meets the Machinery Directive 2006/42/EEC (observe EN 60204).

Getriebebau NORD GmbH & Co. KG, 2014

4 BU 0180 GB-0914

Page 5

Table of Contents

1 GENERAL ................................................................................................................................. 8

1.1 Overview ............................................................................................................... 9

1.2 Delivery ................................................................................................................. 9

1.3 Scope of supply .................................................................................................... 9

1.4 Safety and installation information ..................................................................... 11

1.5 Certifications ....................................................................................................... 13

1.5.1 European EMC Directive ......................................................................................... 13

1.5.2 UL and cUL approval (in preparation) ..................................................................... 13

1.5.3 C-Tick labeling ........................................................................................................ 14

1.5.4 RoHS compliance ................................................................................................... 14

1.6 Nomenclature / type codes ................................................................................. 15

1.6.1 Type code / Frequency inverter - Basic device ....................................................... 16

1.6.2 Type codes / Adapter unit - Technology Unit .......................................................... 16

1.6.3 Type codes / Optional modules ............................................................................... 16

1.7 Version with protection class IP55 / IP66 ........................................................... 17

2 ASSEMBLY AND INSTALLATION ........................................................................................ 18

2.1 Installation and assembly ................................................................................... 18

2.1.1 Mounting the housing box ................................ ................................ ....................... 19

2.1.2 Adapters for different motors ................................................................................... 20

2.1.3 Installation of the frequency inverter ....................................................................... 21

2.1.4 Option slots in the device ................................................................ ........................ 22

2.2 Dimensions of the frequency inverter ................................................................. 23

2.2.1 Power rating / Motor size ........................................................................................ 23

2.2.2 Motor-mounted frequency inverter .......................................................................... 23

2.2.3 Wall-mounted frequency inverter ............................................................................ 24

2.3 Brake resistor (BR) (only size 2) ........................................................................ 25

2.3.1 Internal brake resistor SK BRI4-… .......................................................................... 25

2.3.2 External brake resistor SK BRE4-... ........................................................................ 26

2.3.3 External brake resistor dimensions ......................................................................... 26

2.3.4 Electrical data BR ................................................................................................... 27

2.4 Overvoltage filter SK CIF .................................................................................... 28

2.5 Wiring guidelines ................................................................................................ 29

2.6 Electrical connection........................................................................................... 30

2.7 Electrical connection of power unit ..................................................................... 31

2.7.1 Mains supply (L1, L2, L3, PE) ................................................................................. 32

2.7.2 Motor cable (U, V, W, PE) ....................................................................................... 32

2.7.3 Brake resistor connection (-B, +B) (only size 2) ...................................................... 33

2.7.4 Mains supply jumpers ............................................................................................. 33

2.8 Electrical connection of the control unit .............................................................. 34

2.8.1 Control terminals ..................................................................................................... 35

2.8.2 Control connection details ....................................................................................... 36

2.8.3 Control connections, communication ...................................................................... 38

2.9 Plug connectors .................................................................................................. 39

2.9.1 Plug connectors for power connections .................................................................. 39

2.9.2 Plug connectors for control connection ................................................................... 41

2.10 ATEX Zone 22 for frequency inverters (in preparation) ................................... 43

2.10.1 Modified frequency inverter for compliance with Category 3D .............................. 44

2.10.2 Options for ATEX Zone 22 3D .............................................................................. 44

2.10.3 Maximum output voltage and torque reduction ..................................................... 47

2.10.4 Commissioning information ................................................................................... 48

2.11 Outdoor installation........................................................................................... 48

BU 0180 GB-0914 5

Page 6

SK 180E Manual for frequency inverters

3 OPTIONS................................................................................................................................ 49

3.1 Overview of optional modules ........................................................................... 50

3.2 Mounting of optional module ............................................................................. 53

3.3 Details of internal Customer Units SK CU4-… .................................................. 54

3.4 Details of external Technology Units SK TU4-… .............................................. 60

4 DISPLAYS AND CONTROL .................................................................................................. 63

4.1 Diagnostic LEDs on the Frequency Inverter ...................................................... 63

4.2 Overview of external control devices ................................................................. 64

5 COMMISSIONING .................................................................................................................. 65

5.1 Factory settings ................................................................................................. 65

5.2 Commissioning of frequency inverters .............................................................. 65

5.3 KTY84-130 connection ...................................................................................... 68

5.4 AS interface (only SK 190E) .............................................................................. 70

3.1.1 Overview of internal customer units SK CU4-… ..................................................... 50

3.1.2 Overview of external technology units SK TU4-… .................................................. 51

3.2.1 Installation of internal customer units SK CU4-… ................................................... 53

3.2.2 Installation of external technology units SK TU4-… ................................................ 53

3.3.1 Potentiometer adapter, SK CU4-POT ..................................................................... 54

3.3.2 Electronic brake rectifier, SK CU4-MBR ................................................................. 55

3.3.3 Setpoint converter, SK CU4-REL ............................................................................ 57

3.3.4 Direction selection switch and potentiometer SK TIE4-SWT and SK TIE4-POT..... 59

3.4.1 Connection unit SK TI4-TU-BUS / -MSW ............................................................... 60

3.4.2 Maintenance switch, SK TU4-MSW-… ................................................................... 62

5.2.1 Connection.............................................................................................................. 66

5.2.2 Configuration .......................................................................................................... 66

5.2.3 Commissioning examples ....................................................................................... 68

5.4.1 The bus system ...................................................................................................... 70

5.4.2 Features ................................................................................................................. 70

5.4.3 Bus structure and topology ..................................................................................... 71

5.4.4 Commissioning of the AS Interface ......................................................................... 72

5.4.5 Technical data for AS interface ............................................................................... 74

6 PARAMETERISATION .......................................................................................................... 75

6.1 Frequency inverter parameterisation ................................................................. 76

6.1.1 Operating displays .................................................................................................. 79

6.1.2 Basic parameter (frequency inverter) ...................................................................... 80

6.1.3 Motor data / characteristic curve parameters .......................................................... 87

6.1.4 Control terminals ..................................................................................................... 92

6.1.5 Extra functions ...................................................................................................... 110

6.1.6 Information (Frequency inverter) ........................................................................... 127

6.2 Parameterisation of I/O - extension SK xU4-IOE-… ....................................... 136

6.2.1 Basic parameter (I/O - extension) ......................................................................... 136

6.2.2 Information (I/O - extension) ................................................................................. 138

7 OPERATING STATUS MESSAGES ................................................................................... 140

7.1 SimpleBox display ........................................................................................... 141

7.2 Table of possible error messages ................................................................... 141

7.2.1 Table of possible error messages in the frequency inverter ................................. 141

7.2.2 Table of possible error messages in the I/O extension module ............................ 147

7.3 Table of possible warning messages .............................................................. 148

7.4 Table of possible reasons for the operating status "switch-on disabled" ........ 150

6 BU 0180 GB-0914

Page 7

Table of Contents

8 TECHNICAL DATA ............................................................................................................... 151

8.1 General data for frequency inverter series SK 1x0E ........................................ 151

8.2 Electrical data for frequency inverter ................................................................ 152

8.2.1 Electrical data 1~115V .......................................................................................... 153

8.2.2 Electrical data 1/3~230V ....................................................................................... 154

8.2.3 Electrical data 3~400V .......................................................................................... 156

9 ADDITIONAL INFORMATION .............................................................................................. 158

9.1 Setpoint processing in the SK 1x0E ................................................................. 158

9.2 Process controller ............................................................................................. 159

9.2.1 Process controller application example ................................................................. 159

9.2.2 Process controller parameter settings ................................................................... 160

9.3 Electromagnetic compatibility (EMC) ............................................................... 161

9.3.1 General Provisions ................................................................................................ 161

9.3.2 Assessment of EMC.............................................................................................. 161

9.3.3 EMC of the frequency inverter .............................................................................. 162

9.3.4 EC Declaration of Conformity ................................................................................ 164

9.4 Reduced output power ..................................................................................... 165

9.4.1 Increased heat dissipation due to pulse frequency ............................................... 165

9.4.2 Reduced overcurrent due to time .......................................................................... 166

9.4.3 Reduced overcurrent due to output frequency ...................................................... 167

9.4.4 Reduced output current due to mains voltage ....................................................... 168

9.4.5 Reduced output current due to the heat sink temperature .................................... 168

9.5 Operation with FI circuit breakers ..................................................................... 169

9.6 System bus ....................................................................................................... 169

9.7 Energy Efficiency .............................................................................................. 171

9.8 Motor data - characteristic curves .................................................................... 172

9.8.1 50Hz characteristic curve ...................................................................................... 172

9.8.2 87Hz characteristic curve (only 400V devices) ..................................................... 174

9.8.3 100Hz characteristic curve (only 400V devices) ................................................... 175

9.9 Standardisation of setpoint / target values ....................................................... 176

9.10 Definition of setpoint and actual value processing (frequencies) ................... 177

9.11 Maintenance and servicing information .......................................................... 178

9.11.1 Maintenance Instructions .................................................................................... 178

9.11.2 Repair information ............................................................................................... 179

9.12 Abbreviations in this manual .......................................................................... 180

10 KEYWORD INDEX .............................................................................................................. 181

BU 0180 GB-0914 7

Page 8

SK 180E Manual for frequency inverters

1 General

The SK 1x0E series is based on the tried and tested NORD platform. These devices feature a compact

design with optimum control characteristics.

These devices are provided with sensorless vector current control system which in combination with

asynchronous three-phase motor types constantly ensures an optimised voltage-to-frequency ratio. This has

the following significance for the drive: Peak start-up and overload torques at constant speed.

This series of devices can be adapted to individual requirements by means of extension modules.

Due to the numerous setting options, these inverters are capable of controlling all three-phase motors.

The power range is from 0.25 kW to 2.2 kW. The device is equipped with an integrated mains filter.

This manual is based on the device software V1.0 R1 (see P707) of the frequeny inverter. If the frequency

inverter used has a different version, this may lead to some differences. If necessary, you can download the

current manual from the Internet (www.nord.com).

For the various versions SK 180E / 190E there are also supplementary descriptions for the integrated AS

interface (BU 0180, Section 5.4)

If a bus system is used for communication, a corresponding description (e.g. BU 0220 for PROFIBUS DP) is

provided, or this can be downloaded from the Internet (www.nord.com).

Typically, this series of devices is installed directly on a three-phase asynchronous motor. Alternatively,

optional accessories are available for mounting the devices near to the motor, e.g. on the wall or on a

machine frame.

In order to gain access to all parameters, the internal RS232 PC interface (RJ12) can be used, or an

optional SimpleBox or ParameterBox may be used. In this case, the parameter settings which are changed

by the operator are saved in the EEPROM which is integrated into the frequency inverter.

8 Pre-series version BU 0180 GB-0914

Page 9

1.1 Overview

Basic features of the SK 180E / SK 190E:

High starting torque and precise motor speed control setting with sensorless current vector control

Can be installed directly on, or near to the motor.

Permissible ambient temperature -25°C to 50°C (please refer to the technical data)

Integrated EMC line filter for limit curve category C1, motor-mounted (not for 115V devices)

Automatic measurement of the stator resistance or determination of the precise motor data

Programmable direct current braking

Only size 2: Built-in brake chopper for 4 quadrant operation, optional brake resistors (internal/external)

2 analog inputs (switchable between current and voltage operation), which can also be used as

digital inputs.

3 digital inputs

2 digital outputs

Temperature sensor input (TF+/TF-)

NORD system bus for connection of additional modules, with switchable termination resistor and

address which can be set with DIP switches.

Four separate online switchable parameter sets

Diagnostic LEDs

RS232/RS485 interface via RJ12 plug

Additional features of the SK 190E:

Integrated AS interface

1 General

1.2 Delivery

Check the equipment immediately after delivery/unpacking for transport damage such as deformation or

loose parts.

If there is any damage, contact the carrier immediately and carry out a thorough assessment.

Important! This also applies even if the packaging is undamaged.

1.3 Scope of supply

Standard version: IP55 (optionally IP66)

Operating instructions as PDF file on CD-ROM

incl. NORD CON (PC-based parameterisation software)

Available accessories:

NOTE: Only the options listed in this manual may be used with the frequency inverter. Options for other

series (e.g. SK CSX-0) may destroy the device and its options.

Only Size 2: Braking resistor, required for energy feedback, Section 2.3

Matching RJ12 to SUB-D9 adapter cable to connection to a PC

SK CSX-3H, SimpleBox, 4-digit 7-segment LED display

SK PAR-3H, ParameterBox, plain text LCD display

BU 0180 GB-0914 Pre-series version 9

Page 10

SK 180E Manual for frequency inverters

Extension modules:

internal SK CU4-IOE, internal I/O extension

SK CU4-PBR, internal PROFIBUS DP® module

SK CU4-CAO, internal CANopen® module

SK CU4-DEV, internal DeviceNet™ module

SK CU4-ECT, internal EtherCAT® module (Note: Derating)

SK CU4-PNT, internal PROFINET IO® module (Note: Derating)

SK CU4-POL, internal POWERLINK module (Note: Derating)

SK CU4-EIP, internal Ethernet/IP™ module (Note: Derating)

SK CU4-POT , Potentiometer adapter: internal potentiometer/switch module

SK CU4-REL, internal setpoint converter for bipolar analog signals, incl. 2 relays

SK CU4-MBR, internal brake rectifier for controlling electromechanical brakes

SK TIE4-POT, potentiometer module

SK TIE4-SWT, direction selector switch module

external SK TU4-IOE, external I/O extension

SK TU4-PBR, external PROFIBUS DP® module

SK TU4-CAO, external CANopen® module

SK TU4-DEV, external DeviceNet™ module

SK TU4-ECT, external EtherCAT® module

SK TU4-PNT, external PROFINET IO® module

SK TU4-POL, external POWERLINK module

SK TU4-EIP, external Ethernet/IP™ module

SK TI4-TU-BUS or NET or MSW, connection unit TU4

SK TIE4-WMK-TU, wall-mounting kit TU4

SK TU4 MSW, external maintenance switch

NOTE: Details for the use of the relevant bus systems can be found in the applicable supplementary bus

manual or in the data sheets for the individual modules.

> www.nord.com <

10 Pre-series version BU 0180 GB-0914

Page 11

1.4 Safety and installation information

The frequency inverters are equipment for use in industrial high voltage systems and are operated at

voltages that could lead to severe injuries or death if they are touched.

Installation and other work may only be carried out by qualified electricians and with the

device disconnected. The operating instructions must always be available to these

persons and must be strictly observed.

Local regulations for the installation of electrical equipment and accident prevention

must be complied with.

The equipment continues to carry hazardous voltages for up to 5 minutes after being

switched off at the mains.

For single phase operation (115/230 V) the mains impedance must be at least 100 H

for each conductor. If this is not the case, a mains choke must be installed.

For safe isolation from the mains, all poles of the supply cable to the frequency inverter

must be able to be disconnected.

Even during motor standstill (e.g. caused by an electronic block, blocked drive or output

terminal short circuit), the line connection terminals, motor terminals and braking resistor

terminals may still conduct hazardous voltages. A motor standstill is not identical to

electrical isolation from the mains.

Warning, with certain settings, the frequency inverter/motor can start up automatically

after the mains are switched on.

The frequency inverter is primarily intended for permanent connection and may not be

operated without effective earthing connections that comply with local regulations for

large leakage currents (> 3.5 mA). VDE 0160 stipulates the installation of a second

earthing conductor or an earthing conductor cross-section of at least 10 mm2.

However, connection via a plug connector is also permissible if local regulations are

complied with.

A universal leakage current-sensitive circuit breaker (type B) compliant

with EN 50178/VDE 0160 must be used.

In normal use, frequency inverters are maintenance-free. The cooling surfaces must be

regularly cleaned with compressed air if the ambient air is dusty.

The frequency inverters are suitable for operation on TN or TT networks and with

observation of the measures described in Section 2.7.4, they are also suitable for IT

networks.

1 General

BU 0180 GB-0914 Pre-series version 11

Page 12

SK 180E Manual for frequency inverters

CAUTION

The heat sink and all other metal components can heat up to temperatures above 70°C.

When mounting, sufficient distance from neighboring components must be maintained. When

working on the components, allow sufficient cooling time beforehand

Protection against accidental contact may need to be provided.

ATTENTION

DANGER TO LIFE!

The power unit can continue to carry voltages for up to 5 minutes after being switched off at

the mains. Inverter terminals, motor cables and motor terminals may carry voltage!

Touching open or free terminals, cables and equipment components can lead to severe injury

or death!

Work may only be carried out by qualified specialist electricians and with the electrical supply

to the equipment disconnected!

CAUTION

Children and the general public must be kept away from the equipment!

The equipment may only be used for the purpose intended by the manufacturer.

Unauthorised modifications and the use of spare parts and additional equipment which has

not been purchased from or recommended by the manufacturer of the device may cause fire,

electric shock and injury.

Keep these operating instructions in an accessible location and give them to all operators!

WARNING

This product is intended for use in an industrial environment and is subject to sales

restrictions according to IEC 61800-3. Depending on the type of installation and the length of

the motor connection cable this product can cause high frequency interference in a domestic

environment, in which case the user may be required to take appropriate measures.

An appropriate measure would be the inclusion of a recommended mains filter.

12 Pre-series version BU 0180 GB-0914

Page 13

NOTE

"Integral solid state short circuit protection does not provide branch circuit protection. Branch

circuit protection must be provided in accordance with the National Electric Code and any

additional local codes."

The integral short-circuit protection does not provide branch circuit protection. Branch circuit

protection must be provided in accordance with the "National Electric Code" and all additional

local regulations.

NOTE

“The device has to be mounted according to the manufacturer instructions.”

"Installation must be carried out according to the manufacturer's instructions."

"Use 80°C Copper Conductors Only"

“Connection of copper cable with an insulation rating of at least 80°C“

(only refers to connection cables (mains and motor cables)

"These products are intended for use in a pollution degree 2 environment"

1.5 Certifications

1.5.1 European EMC Directive

If the frequency inverter is installed according to the recommendations in

this manual, it meets all EMC directive requirements, as per the EMC product standard for motor-operated systems EN 61800-3. (See also Section 9.3

Electromagnetic Compatibility [EMC].)

1.5.2 UL and cUL approval (in preparation)

The section applies for all devices of sizes 1 – 2. All frequency inverters are equipped with motor overload

protection. Further technical details can be found in Section 8.2.

1 General

UL Approval - File No. E171342

“Suitable For Use On A Circuit Capable Of Delivering Not More Than 100000 rms Symmetrical

Amperes, 120 Volts maximum (SK 1x0E-xxx-112), 240 Volts maximum (SK 1x0E-xxx-323) or

480 Volts maximum (SK 1x0E-xxx-340) and when protected by RK5 class or faster fuses as indicated in chapter 8.2.”

“Suitable For Use On A Circuit Capable Of Delivering Not More Than 10000 rms Symmetrical

Amperes, 120 Volts maximum (SK 1x0E-xxx-112), 240 Volts maximum (SK 1x0E-xxx-323) or 480 Volts maximum

(SK 1x0E-xxx-340) and when protected by Circuit Breaker (inverse time trip type) in accordance with UL 489”, current

and voltage ratings can be found in chapter 8.2.

„The torque value for the field wiring terminals for mains circuit terminals, motor terminals, break terminals and breaking

resistor terminals must be 11 … 15 lb-in (1.2 … 1.5Nm). The torque value for the field wiring terminals for control circuit

terminals must be 4.4 … 5.3 lb-in (0.5 … 0.6Nm).”

BU 0180 GB-0914 Pre-series version 13

Page 14

SK 180E Manual for frequency inverters

N 23134

cUL Approval - File No. E171342

“cUL only in combination with SK CIF-340-30 or SK CIF-340-60 for 380-480V models and

SK CIF-323-20 or SK CIF-323-40 for 3 phase 200-240V rated models”. The recognized transient surge suppression filter board has to be connected between supply and the input of the

drive according to the instruction manual.

Remarks:

cUL approval for 110-120V models provided without filter board

“Suitable For Use On A Circuit Capable Of Delivering Not More Than 5000 rms Symmetrical Amperes, 120 Volts maximum (SK 1x0E-xxx-112), 240 Volts maximum (SK 1x0E-xxx-323) or 480 Volts maximum (SK 1x0E-xxx-340) and when

protected by RK5 class or faster fuses according to instruction manual chapter 8.2.”

“Suitable For Use On A Circuit Capable Of Delivering Not More Than 5000 rms Symmetrical Amperes, 120 Volts maximum (SK 1x0E-xxx-112), 240 Volts maximum (SK 1x0E-xxx-323) or 480 Volts maximum (SK 1x0E-xxx-340) and when

protected by Circuit Breaker (inverse time trip type) in accordance with UL 489”, current and voltage ratings according to

instruction manual chapter 8.2.

1.5.3 C-Tick labeling

NORD frequency inverters fulfill all the relevant regulations in

Australia and New Zealand.

1.5.4 RoHS compliance

NORD frequency inverters are designed to be RoHS compliant according to Directive

2002/95/EEC.

14 Pre-series version BU 0180 GB-0914

Page 15

Group

Example of type code

Basic unit

SK 180E-370-340-A (-C)

Connection unit - Technology Unit

SK TI4-TU-MSW (-C-WMK-TU)

Optional modules

SK TU4-MSW (-C)

Extension modules

SK TIE4-M12-INI

Technology unit

SK TU4-xxx (-…)

Connection unit

Technology Unit

Frequency inverter

SK 1x0E

1.6 Nomenclature / type codes

Unique type codes have been defined for the individual modules and devices. These provide individual

details of the device type, its electrical data, protection class, fixing version and special versions.

A differentiation is made according to the following groups:

1 General

The type designation resulting from this type code can be obtained

from the name plate which is attached to or printed on the relevant

module.

BU 0180 GB-0914 Pre-series version 15

Page 16

SK 180E Manual for frequency inverters

SK 180E-370-323-B (-C)

IP protection class: Standard = IP55, C = “coated” = IP66

Radio interference filter: O = without, A = Class A1 (C2), B = Class B1 (C1)

Mains voltage: x12 = 115 V, x23 = 230 V, x40 = 400 V

Number of mains phases: 1xx = single phase, 3xx = 3-phase

(for 230V up to 1.1kW: 1~/3~)

Digits before decimal point for power: 0 = 0.xx, 1 = 0x.x0, 2 = 0xx.0

Device nominal power: 250 = 0.25 kW, 370 = 0.37 kW, ... 221 = 2.2 kW

Device series: SK 180E, SK 190E

(...) Options, only implemented if required.

SK TI4-TU-BUS (-C-WMK-TU)

Wall mounting kit: -1 = Size 1 + 2, -2 = Size 3

IP protection class: Standard = IP55, C = “coated” IP66

Suitable device types: NET = optional net module (e.g. TU4-24V-… )

MSW = maintenance switch (SK TU4-MSW)

BUS = optional bus module (z.B. CANopen: TU4-CAO)

Group: TU = Technology unit

Device series: SK TI4 = Adapter unit SK TI4

(...) Options, only implemented if required.

SK TU4-CAO (-C-M12)

M12 system connectors: only TU4, alternative to terminals

IP protection class: Standard = IP55, C = “coated” IP66

Option type: CAO = CANopen, PBR = Profibus, ECT = EtherCAT®

DEV = DeviceNet, IOE = I/O extension, .etc.

Option series: TU4 = external Technology Unit

CU4 = internal customer unit

(...) Options, only implemented if required.

1.6.1 Type code / Frequency inverter - Basic device

1.6.2 Type codes / Adapter unit - Technology Unit

1.6.3 Type codes / Optional modules

For bus module or I/O extension

16 Pre-series version BU 0180 GB-0914

Page 17

NOTE

The modules for the IP66 design are identified by an additional "-C" and are modified

according to the following special measures!

NOTE

For all versions, care must be taken that the cable and the cable gland are carefully

matched. Wherever possible, the cables should be inserted so that water is deflected away

from the device (if necessary use loops). This is essential to ensure that the required

protection class is maintained.

1.7 Version with protection class IP55 / IP66

The frequency inverters and additional modules are available in protection classes IP55 (standard) or

IP66 (optional). The protection class IP66 must always be stated when ordering!

There are no restrictions or differences to the scope of functions in either protection class. In order to differentiate the protection classes, modules with protection class IP66 are given an extra “-C” (coated coated

PCBs) in their type designation.

e.g. SK 180E-750-340-B-C

IP55 version:

The IP55 version of the external frequency inverter is the standard version. Both versions (motor-mounted,

installed on the motor or wall mounted on the wall bracket) are available. In addition, all adapter units,

technology units and customer units are available for this design.

IP66 version:

In contrast to the IP55 version the IP66 version is a modified option. Both versions (motor-integrated, close

to motor) are also available. The modules available to the IP66 design (adapter units, technology units and

customer units) have the same functionalities as the corresponding IP55 design modules.

1 General

Special measures:

impregnated PCBs,

Powder coating RAL 9006 (white aluminium) for housing

Low pressure test

BU 0180 GB-0914 Pre-series version 17

Page 18

SK 180E Manual for frequency inverters

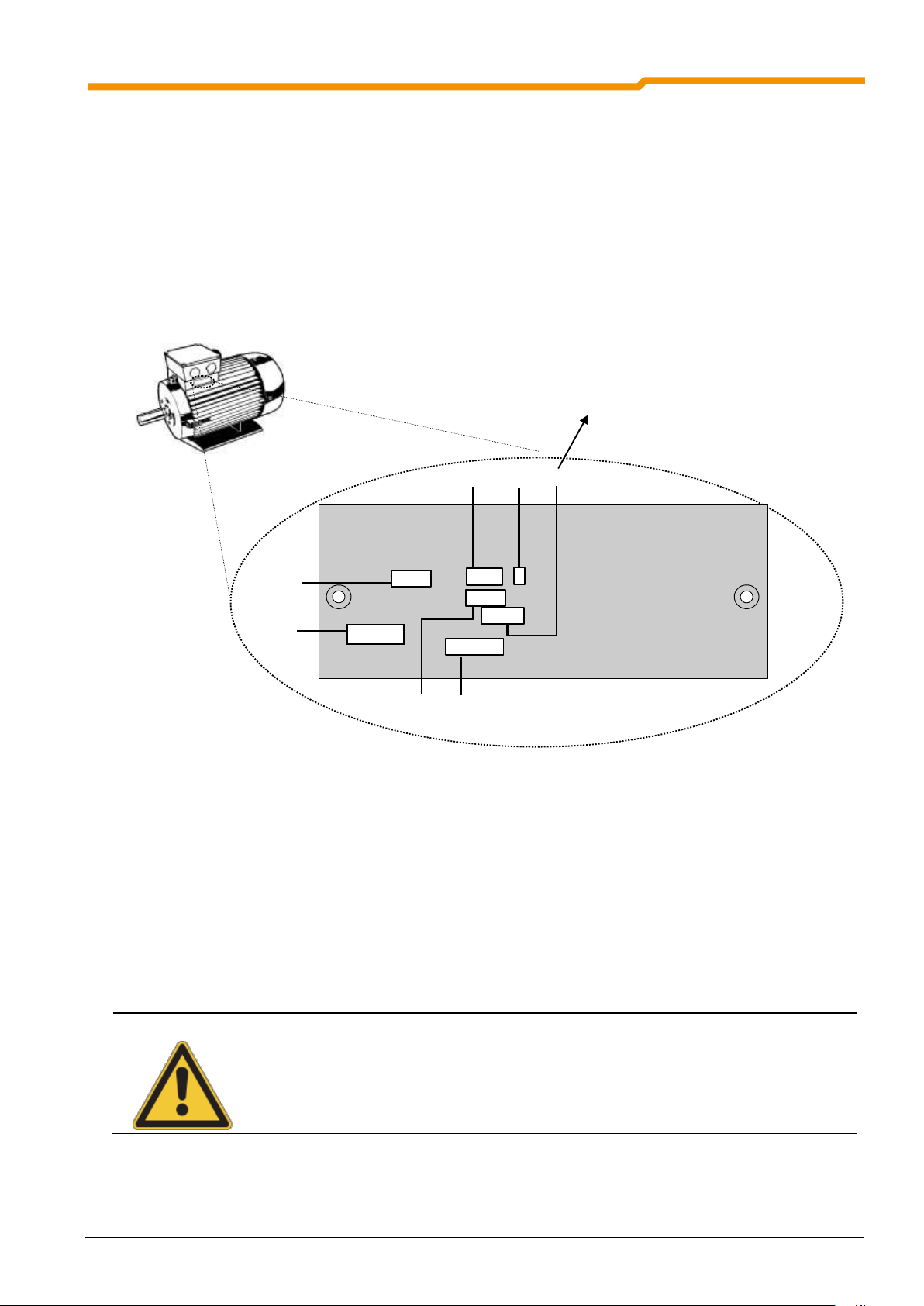

Motor-mounted version

Wall-mounted version

NOTE

The equipment requires sufficient ventilation to protect against overheating. Details of

power reductions and possible ambient temperatures as well as other details can be found

in the section 8 "Technical Data".

2 Assembly and installation

2.1 Installation and assembly

The frequency inverters are available in various sizes depending on their output. They can be mounted on

the terminal box of a motor or in its immediate vicinity.

18 Pre-series version BU 0180 GB-0914

Page 19

2 Assembly and installation

NOTE

Installation of an IP66-compliant frequency inverter must be carried out by NORD, as special

measures have to be implemented. IP66 components retrofitted on site cannot ensure that this

protection class is guaranteed.

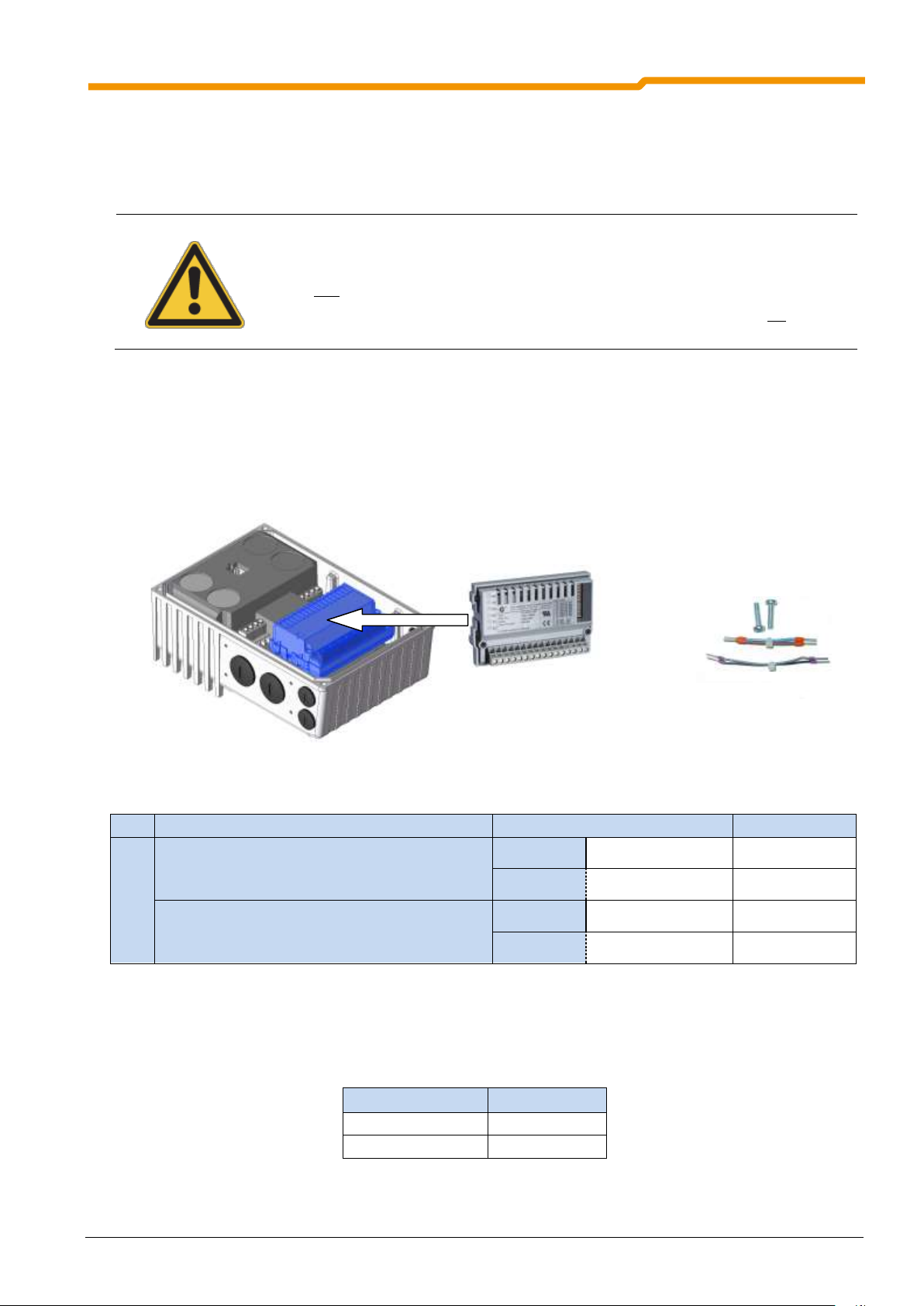

2.1.1 Mounting the housing box

On delivery of a complete drive unit (gear unit + motor + frequency inverter) the frequency inverter is always

fully installed and tested.

When delivered separately, the frequency inverter includes the following components:

Frequency inverters

Screws and contact washers for mounting the motor terminal box.

Pre-fabricated cable for motor and PTC connections

Procedures:

1. If necessary, remove the original terminal box from the NORD motor, so that only the base of the termi-

nal box and the terminal strip remain.

2. Set the jumpers for the correct motor circuit and connect the pre-fabricated cables for motor and PTC

connections to the respective connection points on the motor.

3. Mount the cast housing on the terminal box base of the NORD motor using the existing screws and seal

as well as the enclosed lock washers. Position the cast housing with the cooling fins towards the fan end

of the motor. Check the adaptability for different motor manufacturers.

4. Connect the motor cables U, V, W to the power terminal block and the PTC cable TF+, TF- to the control

terminal block 38, 39.

BU 0180 GB-0914 Pre-series version 19

Page 20

SK 180E Manual for frequency inverters

NORD motor sizes

Add-on

SK 1x0E Size 1

Add-on

SK 1x0E Size 2

Size 63 – 71

with adapter kit I

with adapter kit I

Size 80 – 112

Direct mounting

Direct mounting

Designation

Add-on SK 1x0E

Part No.

Adapter kit size 63-71 to KK80-112

(Adapter kit I)

Adapter plate, terminal box frame seal and screws

275119050

Adapter plate

Seal

Motor Size 71

Inverter SK 1x0E

Example

NOTE

The adaptability of motors from other manufacturers must be checked individually!

Information for the conversion of inverter-controlled drive units to the SK 1xxE can be found in

BU0320.

2.1.2 Adapters for different motors

In some cases, the terminal box attachments are different for different sizes of motor. Therefore, it may be

necessary to use an adapter to mount the frequency inverter.

In order to guarantee the maximum protection class IP55 / IP66 of the entire unit, motor must also have a

corresponding protection class.

Overview of adapter kits

20 Pre-series version BU 0180 GB-0914

Page 21

2 Assembly and installation

Frequency inverter size

Screw size

Tightening torque

Size I

M5 x 25

3.5 Nm ± 20%

Size II

M5 x 25

3.5 Nm ± 20%

2.1.3 Installation of the frequency inverter

The housing cover must first be removed in order to make the electrical connections to the frequency

inverter. To do this, unscrew the 4 fastening screws, so that the housing cover can be removed upwards.

After the electrical connections of the supply cables have been made, the housing cover can be replaced.

To achieve the maximum protection class IP55/IP66, care must be taken that all the fastening screws of the

housing cover are tightened diagonally, step-by-step and with the torques stated in the table below.

For the cable gland of the connecting cable, appropriate screwed connections for cable cross-section must

be used.

BU 0180 GB-0914 Pre-series version 21

Page 22

SK 180E Manual for frequency inverters

Option

location

Position

Meaning

Size

Sizes 1 - 2

Comments

1

Internal

Mounting location for customer units SK CU4-…

2

Internal

Installation location for internal brake resistor

Only for size 2

3*

on side

Mounting location for

external technology units SK TU4-…

Power plug connector (e.g. HARTING)

3 A/B*

on side

Cable gland

M25

Not available if location 3 is occupied or

SK TU4-… is fitted.

4 *,

5 *

on side

Cable gland

M16

Not available if

SK TU4-… is fitted.

* R and L (right and left side) – for motor installation: viewed from the fan wheel toward the motor shaft

3BR

3AR

3R

4R

5R

4L

5L

3AL

3BL

3L

3BR

3AR

3R

4R

5R

4L

5L

3AL

3BL

3L

2

2

2.1.4 Option slots in the device

Size 1:

Size 2:

The above drawings indicates the different installation locations for optional modules. Option slot 1 is used

for the mounting of an internal customer interface (e.g. bus module). Option location 2 for installing an

internal brake resistor is only present in size 2. The brake resistor may only be installed at the factory

and must therefore be taken into account in the order. External bus modules, 24 V power supplies can

be implemented at option locations 3L or 3R. Option locations 4 and 5 are used for the installation of M12

sockets or plug connectors or for cable glands. Only one option per option location is possible.

22 Pre-series version BU 0180 GB-0914

Page 23

2.2 Dimensions of the frequency inverter

Size

Mains / Power category SK 1x0E

1~ 110-120 V

1~, 3~ 200-240 V

3~ 380-480 V

Size I

0.25 ... 0.75 kW

0.25 ... 0.55 kW

0.25 ... 1.1 kW

Size II

-

0.75 ... 1.5 kW

1.5 ... 2.2 kW

* 1.5 kW only 3~

Size

Housing dimensions SK 1x0E / Motor

Weight of SK 2xxE

without motor

Approx. [kg]

FI

Motor

g

g 1 n o

p

Size I

Size 71 *

145

177.5

221

214

154

2.0

Size 80

165

171.5

236

Size 90 S / L

183

176.5

251 / 276

Size II

Size 80

165

196.5

255

236

165

3.3

Size 90 S / L

183

201.5

251 / 276

Size 100

201

210.5

306

All dimensions in [mm]

*) including additional adapter and seal (18mm) [275119050]

2.2.1 Power rating / Motor size

2.2.2 Motor-mounted frequency inverter

2 Assembly and installation

BU 0180 GB-0914 Pre-series version 23

Page 24

SK 180E Manual for frequency inverters

Device type

Size

Housing dimensions

Wall-mounting

SK TIE4-WMK-L-1

total weight

Approx. [kg]

g2 n p

p2 d e

Size 1 SK TIE4-WMK-1

Part No. 275 274 000

113

221

154

205

64

180

5.5

2.6

Size 2 SK TIE4-WMK-1

Part No. 275 274 000

115,5

255

165

205

64

180

5.5

3.9

All dimensions in [mm]

2.2.3 Wall-mounted frequency inverter

The frequency inverter can be installed in the vicinity of the motor by means of an optional wall mounting kit.

All possible installation orientations are permissible for wall mounting. Please also note Section 8.

24 Pre-series version BU 0180 GB-0914

Page 25

2 Assembly and installation

CAUTION

The braking resistance and all other metal components can heat up to temperatures above 70°C.

When mounting, sufficient distance from neighbouring components must be maintained.

When working on the components, allow sufficient cooling time beforehand

NOTE

The internal brake resistor may only be installed at the factory and can not be retrofitted.

It is essential that this is taken into account for the configuration an ordering of the device.

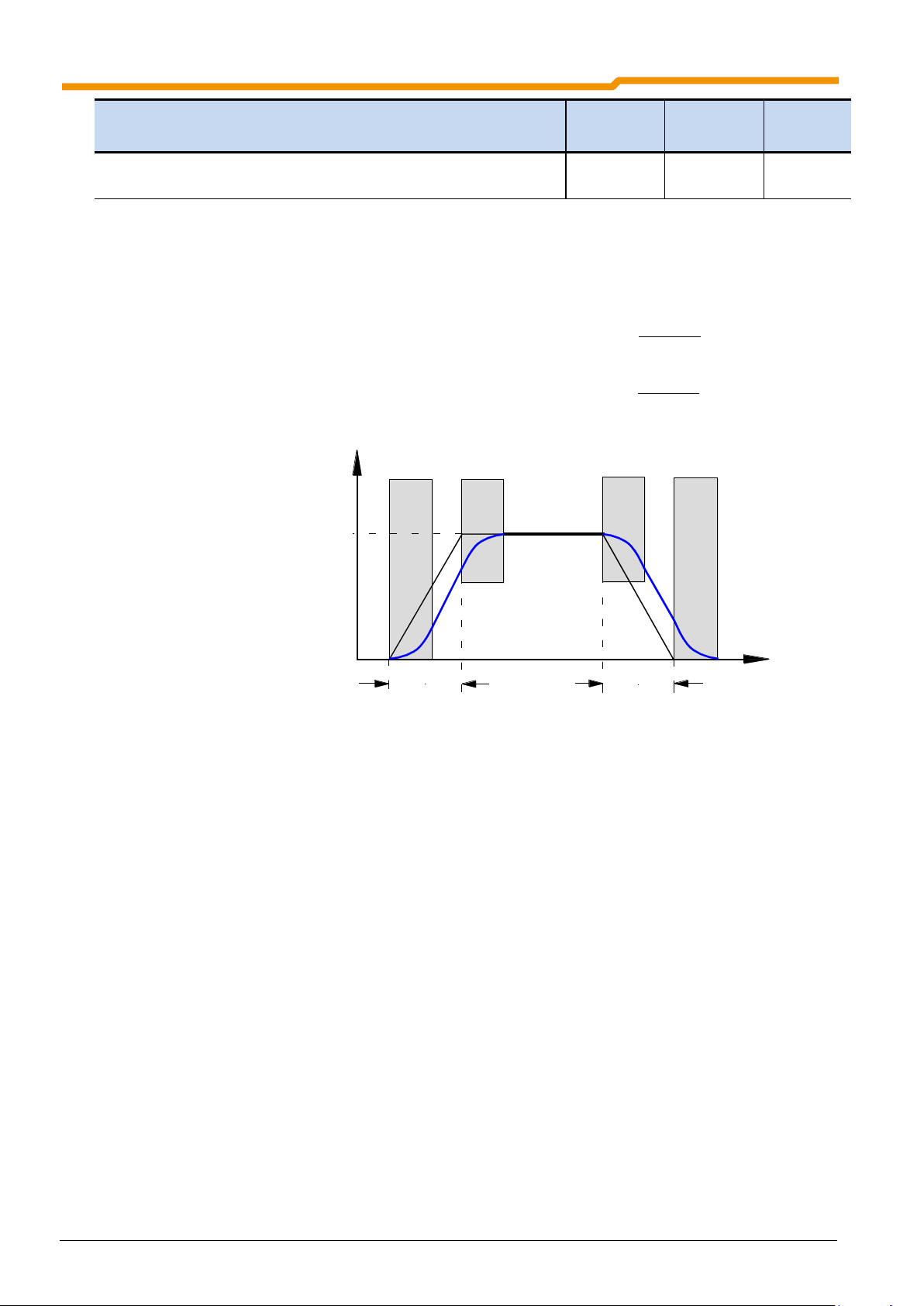

)²)/30(1(* tbrakesPnP

NOTE

If internal brake resistors are used, a suitable power limit must be set in P555, P556 and

P557. This is important in order to activate a peak and continuous power limit for the brake

resistor. Otherwise, the brake resistor may be damaged during operation.

2.3 Brake resistor (BR) (only size 2)

During dynamic braking (frequency reduction) of a three phase motor, electrical energy is returned to the

frequency inverter. From Size II or larger, an internal or external brake resistor may be used to prevent the

FI from shutting down in case of overvoltage. With this, the integrated brake chopper (electronic switch)

pulses the link circuit voltage (switching threshold approx. 420V/720V DC, according to the mains voltage)

into the braking resistor. The brake resistor ultimately converts the excess energy into heat.

For input voltages >460V the use of a brake resistor is generally recommended in order to compensate for

the reduced storage capacity of the link circuit due to the higher voltage.

2.3.1 Internal brake resistor SK BRI4-…

The internal brake resistor can be used if only slight, short braking phases are to be expected.

The output power of the SK BRI4 is limited (see also the following note field) and can be calculated as follows.

, however, P < P

(P=Brake power (W), Pn= Continuous brake power of resistor (W), Pmax. peak brake power, tbrakes = duration of braking process (s))

max

The permissible continuous brake power Pn must not be exceeded in the long-term average.

(For details of Pn and P

see Section 2.3.4)

max

BU 0180 GB-0914 Pre-series version 25

Page 26

SK 180E Manual for frequency inverters

The external brake resistor (available for SK 1x0E, Size 2) is

intended for energy feedback, e.g. in pulse drives or lifting

gear. Here, it may be necessary to plan for the exact brake

resistor required.

For installation, an M20 screw connection with an adapter for

M25 is supplied. The connecting wires for the brake resistor

are fed through this into the connection unit. Because of the

cable gland the brake resistor and an optional SK TU4technology unit must not be mounted on the same side of the

frequency inverter.

Resistor type

A B C

Fixing dimensions

d

e

SK BRE4-1-100-100

SK BRE4-1-200-100

150

178

61

83

32

4.3

All dimensions in mm

A

B

C

d

e

2.3.2 External brake resistor SK BRE4-...

The brake resistor is attached to the side of the connection unit using 4 suitable M4 x 10 screws. Installation

of an SK BRE4… is not possible in combination with the wall-mounting kit SK TIE4-WMK(-L).

2.3.3 External brake resistor dimensions

26 Pre-series version BU 0180 GB-0914

Page 27

2.3.4 Electrical data BR

Inverter ID

SK 1x0E-…

Resistor type

(IP54)

Resistance

Max. continuous

output / limit**

(Pn)

Energy

consumption*

(P

max

)

Connecting cable

or terminals

750…111-323-A

SK BRI4-1-200-100

Part. No. 275272008

200

100 W / 25%

1.0 kWs

Silicone

conductor

2x 0.75 mm

2

approx. 275 mm

151…221-340-A

SK BRI4-1-400-100

Part. No. 275272012

400

100 W / 25%

1.0 kWs

*) Maximum once within 10 s**

**) In order to prevent impermissible heating of the device, the continuous power is limited

to 1/4 of the rated power of the brake resistor.

This also has a limiting effect on the power consumption.

Inverter ID

SK 1x0E-…

Resistor type

(IP67)

Resistance

Max. continuous

power

(Pn)

Energy

consumption*

(P

max

)

Connecting cable

or terminals

750…111-323-A

SK BRE4-1-100-100

Part. No. 275273005

100

100 W

2.2 kWs

FEP flex

3x 1.9 mm2

AWG 14/19

approx. 350 mm

151…221-340-A

SK BRE4-1-200-100

Part. No. 275273008

200

100 W

2.2 kWs

*)Maximum once within 120 s

Internal

External

2 Assembly and installation

BU 0180 GB-0914 Pre-series version 27

Page 28

SK 180E Manual for frequency inverters

Inverter ID

Filter type

Data sheet

SK 1x0E-250-323-A… SK 1x0E-111-323-A*

SK CIF-323-20

(alternatively SK CIF-323-40)

TI 030 276997070

(TI 030 276997071)

SK 1x0E-250-340-A… SK 1x0E-221-340-A

SK CIF-340-30

(alternatively SK CIF-340-60)

TI 030 276997080

(TI 030 276997081)

* (only with suitable mains choke)

CAUTION!

Modules SK CIF-323-x0 may only be used in combination with a suitable mains choke

(L

min

= 3 x 0,73 mH) (see connection diagram).

For SK CIF-340-x0 modules the use of a mains input choke is not mandatory, but is recommended.

Note

With the use of a mains choke, the effective input currents of the 1~ 230V frequency inverter reduce

to approximately the values of the output currents. Several frequency inverters can be connected to

a choke - filter combination. In this case, the total input currents must not exceed the current rating

of the filter.

2.4 Overvoltage filter SK CIF

The use of a suitable ("CSA-") overvoltage filter is mandatory (see also Section 1.5) in order to comply with

cUL requirements. For 230V devices, operation of the frequency inverter with a suitable overvoltage filter is

only permissible if a mains choke is used in addition.

For further information about the overvoltage filter, please refer to the relevant data sheet. These data

sheets can be downloaded at www.nord.com.

Without an overvoltage filter, frequency inverters for 1~ 115V mains (SK1x0E-xxx-112-O) cannot be

approved according to cUL.

28 Pre-series version BU 0180 GB-0914

Page 29

2 Assembly and installation

NOTE

The control cables, line cables and motor cables must be laid separately. In no case should

they be laid in the same protective pipes/installation ducts.

The test for high voltage insulations must not be used on cables which are connected to the

frequency inverter.

ATTENTION

With the use of a ParameterBox SK PAR-3H this must never be simultaneously connected to

the frequency inverter and the PC, as potential shifts may cause damage, especially to the PC.

(See also Manual BU0040)

2.5 Wiring guidelines

The frequency inverter has been developed for use in an industrial environment. In this environment, high

levels of electromagnetic interference can influence the frequency inverter. In general, correct installation

ensures safe and problem-free operation. To meet the limiting values of the EMC directives, the following

instructions should be complied with.

(1) Ensure that all equipment in the control cabinet or field is securely earthed using short earthing cables

which have large cross-sections and are connected to a common earthing point or earthing rail. It is

especially important that all control devices connected to the frequency inverters (e.g. an automation

device) are connected to the same earthing point as the inverter itself, using a short cable with large

cross-section. Flat conductors (e.g. metal clamps) are preferable, as they have a lower impedance at

high frequencies.

(2) The bonding cable of the motor controlled by the frequency inverter should be connected directly to the

earthing terminal of the associated frequency inverter. The presence of a central earthing bar in the

control cabinet and the grouping together of all bonding conductors to this bar normally ensures safe

operation. (see also Section. 9.3 / 9.3.3 (EMC))

(3) Where possible, shielded cables should be used for control circuits. The shielding at the cable end

should be carefully sealed and it must be ensured that the wires are not laid over longer distances

without shielding.

The shields of analog setpoint cables should only be earthed on one side on the frequency inverter.

(4) The control cables should be installed as far as possible from power cables, using separate cable

ducts, etc. Where cables cross, an angle of 90° should be ensured as far as possible.

(5) Ensure that the contactors and brake chokes in the cabinet are interference protected, either by RC

circuits in the case of AC contactors, or by “free-wheeling” diodes for DC contactors, whereby the

interference protectors must be positioned on the contactor coils. Varistors for over-voltage

limitation are also effective. This interference suppression is particularly important when the contactors

are controlled by the relay in the frequency inverter.

(6) Use screened or armoured cable for the load connections (motor cable) and earth the

screening/armour at both ends, if possible to the frequency inverter bonding.

In addition, an EMC-compliant cabling must be ensured (see also Section. 9.3 / 9.3.3 (EMC)).

The safety regulations must be complied with under all circumstances

when installing the frequency inverter!

BU 0180 GB-0914 Pre-series version 29

Page 30

SK 180E Manual for frequency inverters

WARNING

THE DEVICES MUST BE EARTHED.

Safe operation of the devices requires that is installed and commissioned by qualified personnel

in compliance with the instructions provided in this Manual.

In particular, the general and regional installation and safety regulations for work on high voltage

systems (e.g. VDE) must be complied with, as must the regulations concerning correct use of

tools and the use of personal protection equipment.

Dangerous voltages can be present at the motor connection terminals even when the inverter is

switched off. Always use insulated screwdrivers on these terminal fields!

Ensure that the input voltage source is not live before setting up or changing connections to the

unit.

Make sure that the inverter and motor are specified for the correct supply voltage.

2.6 Electrical connection

NOTE: As with other signal cables, thermistor cables must be laid separately from the motor cables.

The housing cover must be removed from the SK 1x0E in order to make the electrical connections. Proceed

as follows:

1. Switch off the mains supply and if necessary check and observe the waiting period.

2. Loosen the 4 Allen screws (4 mm).

3. Carefully lift the housing cover vertically from off the housing box.

4. The electrical connections and the option slots are now freely accessible.

30 Pre-series version BU 0180 GB-0914

5. Replace the cover

6. Evenly tighten the Allen screws in a cross-wise direction (for tightening torques, please refer to

Section 2.1.3).

Page 31

2 Assembly and installation

L1 / L

L2 / N

L3 / PE

PE L3 L2 L1

M

3~

PE U V W +B -B

Internal or

external braking

resistor

2.7 Electrical connection of power unit

All connection terminals are located in the connection

unit of the frequency inverter.

Separate terminal bars are provided for the power

connections and the control connections, as well as a

further terminal bar for the connection of the

thermistor.

The PE connections (device earth) are located on the

power connections for the motor and the mains, as

well as on the base in the cast housing.

Before and while the device is connected, the

following must be observed:

1. Ensure that the mains supply provides the correct

voltage and is suitable for the current required

(see Section 8 Technical Data).

2. Ensure that suitable circuit breakers with the

specified nominal current range are installed

between the voltage source and the inverter.

3. Connect the mains voltage directly to the

terminals L1-L2/N-L3 und PE (according to the

device).

4. To connect the motor, three flexible wires U-V-W

should be used when mounting the motor.

5. For wall-mounting a 4-conductor shielded motor

cable (recommended) to the terminals U-V-W and

earth should be used. In this case the cable

shielding should be connected to a large area of

the metallic screw connector.

NOTE: if certain wire end sleeves are used, the maximum cross-section which can be connected may

be reduced.

Screwdriver: Use a 5.5mm slot-head screwdriver to connect the power unit.

NOTE: If synchronous machines or several motors are connected in parallel to a device, the fre-

quency inverter must be switched over to linear voltage/frequency characteristic curves,

P211 = 0 and P212 = 0.

NOTE: Only use copper cables with temperature class 80°C or equivalent for connection. Higher tem-

perature classes are permissible.

NOTE: The use of shielded cables is essential in order to maintain the specified radio interference

suppression level. (See also Section 9.3.3 (EMC))

CAUTION: This device produces high frequency interference, which may make additional suppression

measures necessary in domestic environments. (Details in Section 9.3 / 9.3.3 (EMC))

BU 0180 GB-0914 Pre-series version 31

Page 32

SK 180E Manual for frequency inverters

Mains

Motor

2.7.1 Mains supply (L1, L2, L3, PE)

No special safety measures are required on the mains input side of the frequency inverter. It is advisable to

use normal mains fuses (see technical data) and a main switch or circuit breaker.

115V devices may only be used with a 110…120V (L/N = L1/L2) single phase supply.

230V devices can optionally be used for single phase or three-phase operation.

400V devices are designed for three phase mains voltage 380...480V (L1/L2/L3).

For the exact specification, please refer to the technical data in Section 8.

Isolation from or connection to the mains must always be carried out for all the poles and synchronously

(L1/L2/L2 or L1/N).

Connection cross-section:

0.2 ... 4/6 mm 2 rigid/ flexible

cable AWG 24-10

For looping of the mains voltage,

up to a cable cross-section of

2 x 2.5mm2 double wire end

sleeves must be used.

Starting torque:

0.5 ... 0.6Nm

Operation in IT network

The use of this frequency inverter on an IT network is possible after modifications by means of jumpers for

size 2. Further details in Section 2.7.4. The prerequisite is a connected brake resistor, in order to prevent

impermissible charging of the inverter link circuit in case of a mains fault (short-circuit to earth).

2.7.2 Motor cable (U, V, W, PE)

The motor cable may have a total length of up to 50m if this is a standard cable. If a screened motor cable

is used, or if the cable is laid in a well earthed metal conduit, the total length should not exceed 20m.

In order to comply with interference suppression class C2, a total length of 5m must not be exceeded.

Connection cross-section:

0.2 ... 4/6 mm 2 rigid/ flexible

cable AWG 24-10

Starting torque:

0.5 ... 0.6 Nm

Note: Please note also Section 9.3.3

(EMC).

Note: For multiple motors operation

the total motor cable length consists of the sum of the individual cable lengths.

Note: The motor cable must not be switched as long as the inverter is providing power to the motor.

(The inverter must be on "Standby" or "Starting Disabled")

32 Pre-series version BU 0180 GB-0914

Page 33

2 Assembly and installation

B+,

B-

2.7.3 Brake resistor connection (-B, +B) (only size 2)

The terminals +B/ -B are intended for the connection of a suitable braking resistor (only size 2).

The connection should be as short as possible.

Connection cross-section:

0.2 ... 4/6mm 2 rigid/ flexible cable

AWG 24-10

Starting torque:

0.5 ... 0.6 Nm

Note: The great production of heat in

the braking resistor must be

taken into account.

2.7.4 Mains supply jumpers

These jumpers are used to adapt the

frequency inverter to various types of

networks (e.g. IT network). As delivered, the

jumpers are plugged in the "normal position"

(CY=ON) and are to be used in a network

which is earthed at the star point, with a

neutral conductor for single phase devices!

To adapt the frequency inverter to an IT

network (only size 2 in combination with a

brake resistor), the capacitors Cy must be

disconnected from the PE. This is carried out

by changing a jumper position as shown in

the diagram.

Here it must be noted that the specified degree of radio interference suppression changes. Further details

can be found in Section 9.3 EMC.

Jumper on the left side (CY capacitors, link circuit PE):

CY=OFF: CY=ON:

(default)

Jumper on the right side (CY capacitors, link circuit PE):

CY=OFF: CY=ON:

(default)

BU 0180 GB-0914 Pre-series version 33

Page 34

SK 180E Manual for frequency inverters

NOTE

GND is a common reference potential for analogue and digital inputs.

The labelling of the control terminal bar differs according to the inverter version.

X3

X4

X5

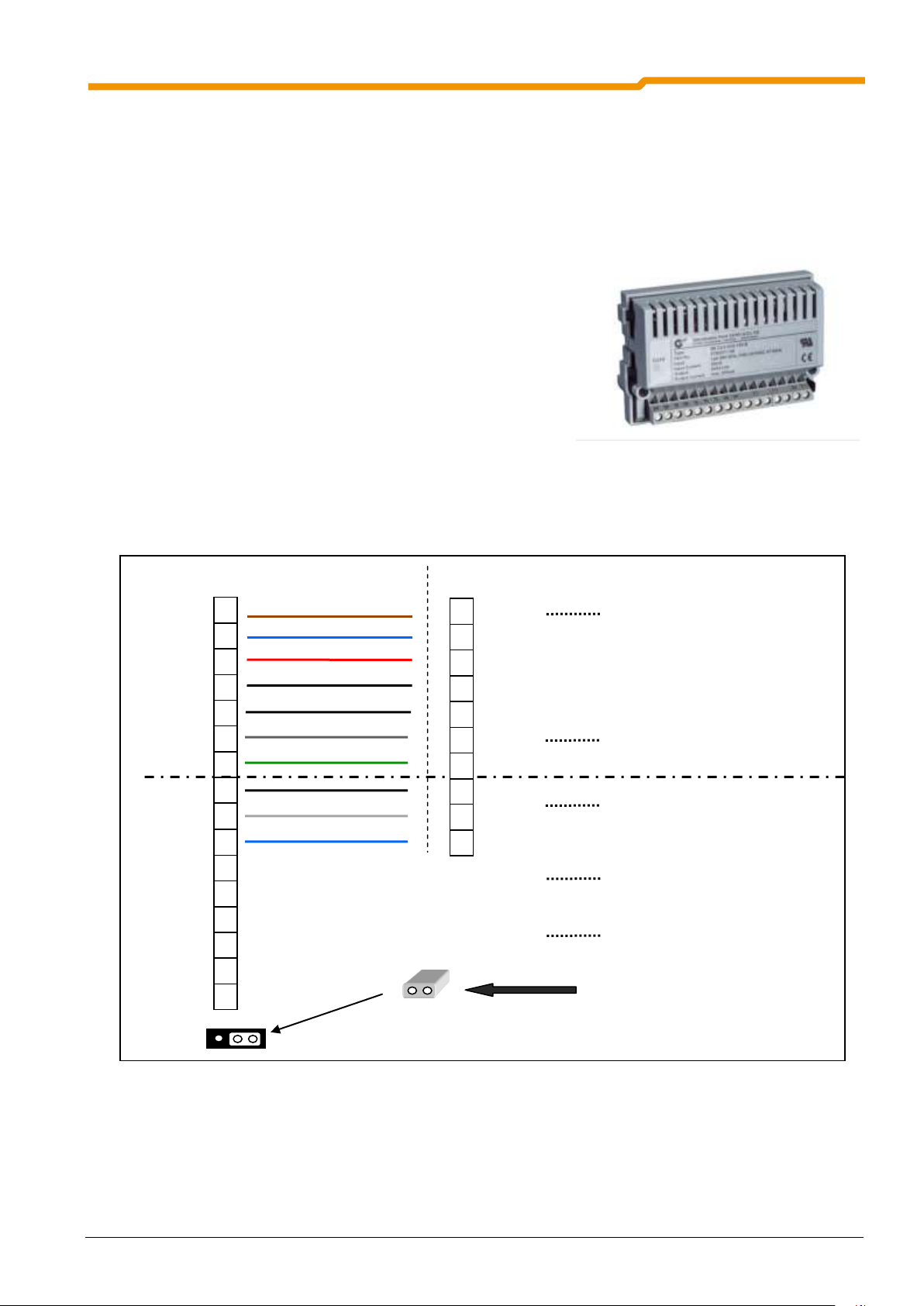

2.8 Electrical connection of the control unit

The control connections are located on the inside of the frequency inverter housing. The connections to the

terminal bar differ according to the version (SK 180E…190E).

Connection terminals: Spring-loaded terminal (X4, X5), slot-head screwdriver, size 2.0 mm

PCB terminal with screw connection (X3), size 2.0 mm, 0.5...0.6 Nm

Connection cross-section: 0.2...1.5 mm2, AWG 24-16, rigid or flexible, with wire end sleeves without

plastic sleeves

Control cable: Lay and shield separately from the mains/motor cables

34 Pre-series version BU 0180 GB-0914

Page 35

FI type

SK 180E

SK 190E

Labelling

Pin

1

39

TF-, motor thermistor (PTC) connection

2

38

TF+, motor thermistor (PTC) connection

FI type

SK 180E

SK 190E

(ASI)

Labelling

Pin

1

11

10V, reference voltage output

2

14

AIN1, analog input 1 / DIN4, digital input 4

3

16

AIN2, analog input 2 / DIN5, digital input 5

4

12 / 40

AGND / 0 V, reference potential for analog signals*

GND / 0 V, reference potential for digital signals

5

43

24 V, power supply output

6

21

DIN1 / digital input 1

7

22

DIN2 / digital input 2

8

23

DIN3, digital input 3

9

1

DOUT1, digital output 1

10

40

GND / 0 V, reference potential for digital signals

11

3

DOUT2, digital output 2

12

40

GND / 0 V, reference potential for digital signals

13

77

SYS H, system bus +

14

78

SYS H, system bus-

FI type

SK 180E

SK 190E

(ASI)

Labelling

Pin 1

84

ASI+, AS interface+

2

85

ASI-, AS interface-

2.8.1 Control terminals

Terminal X3:

Terminal X4:

2 Assembly and installation

*) the analog and digital reference voltages are internally bridged and are therefore identical

Terminal X5 (only SK 190E):

BU 0180 GB-0914 Pre-series version 35

Page 36

SK 180E Manual for frequency inverters

Terminal/

Designation

Function

{Factory setting}

Data

Description / wiring suggestion

Parameter

43 VO/24V

24V supply

Output

24V DC ±25%

max. 150 mA1 (output)

Voltage supply provided by the FI

for control of the digital inputs

-

40 GND / 0V

Reference potential

for digital signals

-

21 DIN1

Digital input 1

{ON right}

Digital input as per

EN 61131-2 Type 1

Low: 0 -5 V

(~ 9.5 kΩ)

High: 15-30 V

(~ 2.5-3.5 kΩ)

Input capacitance:

Input 1…3 = 10 nF

Scan time: 1 ms

Reaction time: ≥ 4 ms

Input 1 reacts slowly

Inputs 2 + 3 react quickly

P420 [01]

22 DIN2

Digital input 2

{ON left}

P420 [02]

23 DIN3

Digital input 3

{fixed frequency 1,

(P465[-01])}

P420 [03]

1 DOUT1

Output 1

{Fault}

Digital output

24V DC, max. 20 mA

For inductive loads:

provide protection with a

free-wheeling diode.

For evaluation in a control system.

P434 [01]

3 DOUT2

Output 2

{Fault}

P434 [02]

14 AIN1 +

Analog input 1

{Setpoint frequency}

U=0…10 V, Ri=30 kΩ

Resolution 12Bit

I=0/4…20 mA,

burden resistor (250 Ω)

via DIP switch S1 can be

switched to AIN1/2

11

12

14

16

R=10k

Matching of the analog signals is

performed via P402 and P403.

P400 [01]

16 AIN2 +

Analog input 2

{No function}

P400 [02]

12 AGND / 0V

Reference potential

for analog signals

0 V analog

11 10V REF

+10 V

Reference voltage

+10 V, 5 mA

38 TF+

PTC resistor input

-

For monitoring motor temperature

with PTC

A shielded cable must be used for

separate mounting of the motor

and the FI (note the cable length).

39 TF-

PTC resistor input

1

2.8.2 Control connection details

The frequency inverter generates its own control voltage and provides this to Terminal 43.

The current which is drawn from the digital outputs must also be covered by this. Any control modules which are

connected to the RJ12 socket also place a load on the 24V supply. (150mA = I

36 Pre-series version BU 0180 GB-0914

+ I

+ I

DIG1

DIG2

OUT

+ I

CONTROL

)

Page 37

2 Assembly and installation

Terminal/

Designation

Function

{Factory setting}

Data

Description / wiring suggestion

Parameter

77 SYS H

System bus+

Up to four SK 1x0E or

SK 2xxE can be operated

on a single system bus.

Address = 32 / 34 / 36 / 38

Internal FI system bus for

communication with optional

modules and other frequency

inverters.

For further details see Section 9.6.

P509/510

P514/515

78 SYS L

System bus-

S1

Termination resistor

System bus

{OFF}

Additionally for SK 190E

84 ASI+

Actuator Sensor

Interface

26.5 – 31.6 V, max. 25 mA

For control of the SK 190E via the

simple field bus level.

In this case, only the yellow AS

interface cable can be used.

Additional supply via the black

cable is not possible.

P480

... P483

85 ASI-

S1

BU 0180 GB-0914 Pre-series version 37

Page 38

SK 180E Manual for frequency inverters

Terminal/

Designation

Function

{Factory setting}

Data

Description / wiring suggestion

Parameter

all devices, plug connector block RJ12, RS485/RS232

1 RS485 A +

Data cable RS485

(for connection to a

ParameterBox)

Baud rate

9600…38400 Baud

Termination resistor

R=1 k is fixed.

RS485_A

RS485_B

GN D

TXD

RXD

+ 5 V

+24V

RJ12: Pin No. 1 … 6

1: RS485_A

2: RS485_B

3: GND

4: RS232_TxD

5: RS232_RxD

6: +24V

P502

...P513

2 RS485 B -

3 GND

Reference potential

for Bus signals

0 V digital

4 232 TXD

Data cable RS232

(for connection to a

PC for NORDCON)

Baud rate

9600…38400 Baud

5 232 RXD

6 +24V

24 V voltage supply

from FI

24 V 20%

All devices, cable accessories

Optional

Adapter cable

RJ12 to SUB-D9

... for direct

connection to a PC

with NORD CON

software

Note: For connection

to a USB port on the

PC, a normal

interface converter

(RS232 (SUB-D9) /

USB 2.0) is required.

Length 3m

Assignment RS 232

(RxD, TxD, GND)

Part. No. 278910240

TxD

RxT

GND

+24V

n.c.

n.c.

Pin2: RS232_TxD

Pin3: RS232_RxD

Pin5: GND

RxD

GND

TxD

6

1 5 9

n.c.

2.8.3 Control connections, communication

38 Pre-series version BU 0180 GB-0914

Page 39

2 Assembly and installation

Mounting version

Meaning

… - LE

Power input

… - LA

Power output

… - MA

Motor output

ATTENTION

The permissible current load for the connection terminals, plugs and supply cables must be

observed when looping the mains voltage.

E.g. SK1x0E with HAN 10E plug connector E.g. SK1x0E with plug connector 2 x Q4-2

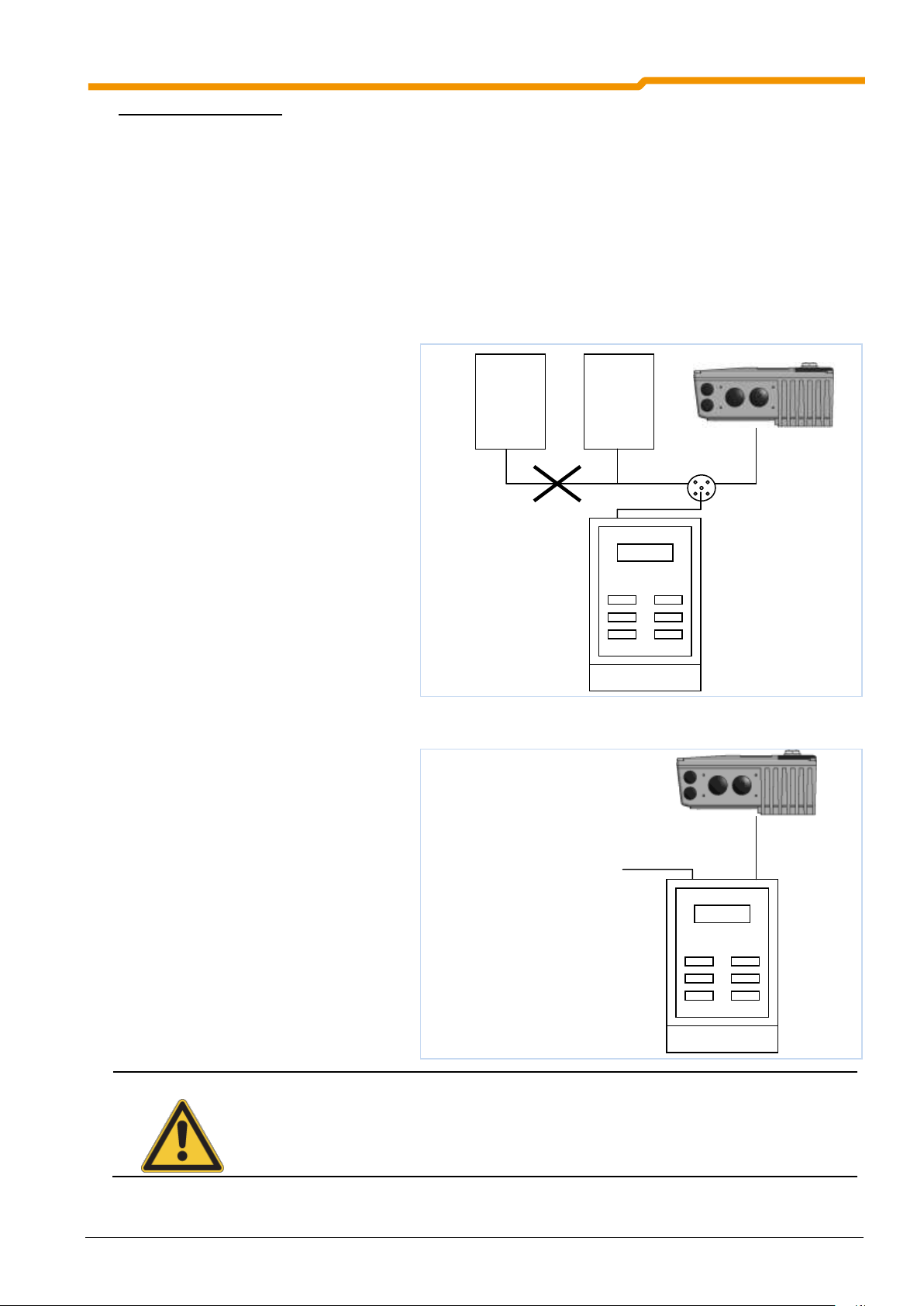

2.9 Plug connectors

The use of optionally available plug connectors for power and control connections not only makes it possible

to replace the drive unit more quickly in case of servicing, but also minimises the danger of installation

errors when connecting the device. The most common plug connector versions are summarized below.

The possible mounting locations on the housing box are listed in Section 2.1.4.

2.9.1 Plug connectors for power connections

Plug connectors for the motor or mains connection to the frequency inverter are available.

Connection of up to two power plug connectors (HAN Q4-2: up to 2 x 2 plug connectors) are made on the

housing of the frequency inverter. The following 3 connection versions are available:

With this, the mains connection and the motor output can be implemented with separate plug connectors in

the case of wall-mounted frequency inverters.