Page 1

GB

BU 0135

Motor Starter Manual

SK 105E…175E

Page 2

SK 105E…175E Motor Starter Manual Safety information

NORD Motor Starters

(Starters, Sort Starters, Reverse Starters)

Safety and operating instructions

for motor starters

1. General

During operation, motor starters may, depending on their protection

class, have live, bare, moving or rotating parts or hot surfaces.

Unauthorised removal of covers, improper use, incorrect inst allation

or operation causes a risk of serious personal injury or material

damage.

Further information can be found in this documentation.

All transportation, installation, initialisation and maintenance work

must be carried out by qualified personnel (compliant with IEC

364, CENELEC HD 384, DIN VDE 0100, IEC 664 or DIN VDE 0110,

and national accident prevention regulations).

For the purposes of these basic safety instructions, qualified personnel are persons who are familiar with the ass embly, installation,

commissioning and operation of this product and who have the relevant qualifications for their work.

2. Proper use in Europe

Motor starters are components intended for ins tallation in electrical

systems or machines.

When installed in machines, the drive power convert er must not be

commissioned (i.e. commencement of the proper use) until it has

been ensured that the machine m eets the provisions of the EC Directive 2006/42/EEC (Machinery Directive); EN 60204 must also be

complied with.

Commissioning (i.e. implementation of t he proper use) is only permitted if the EMC directive (2004/108/EEC) is complied with.

CE-labelled m otor starters meet the requirements of the Low Voltage Directive 2006/95/EEC. The harmonized standards stated in the

Declaration of Conformity are used for the drive power converters.

Technical data and information for connection conditions can be

found on the rating plate and in the documentation, and must be

complied with.

The motor starters may only be used for safety functions which are

described and explicitly approved.

3. Transport, storage

Information regarding transport, storage and correct handling must

be complied with.

4. Installation

The installation and cooling of the equipment must be implemented

according to the regulations in the corresponding documentation.

(as per: Low Voltage Directive 2006/95/EEC)

The motor starter must be protected against impermissible

loads. Especially during transport and handling, components must not be deformed and/or insulation distances

must not be changed. Touching of electronic components

and contacts must be avoided.

Motor starters have electrostatically sensit ive components,

which can be easily damaged by incorrect handling. Electrical components must not be mechanically damaged or destroyed (this may cause a health hazard!).

5. Electrical connections

When working on live drive components, the applicable national accident prevention regulations must be complied with

(e.g. BGV A3, formerly VBG 4).

The electrical installation must be im plement ed according t o

the applicable regulations (e.g. cable cross-section, fuses,

earth lead connections). Further instruct i ons can be found in

the documentation.

Information about EMC-compliant installation – such as

shielding, earthing, location of filters and installation of cables can be found in the drive power converter docum entation. These instructions must be complied with even with CE

marked motor starters. Compliance with the limiti ng values

specified in the EMC regulations is the responsibility of t he

manufacturer of the system or machine.

6. Operation

Systems in which motor starters are installed must be

equipped, where necessary, with addi tional monitoring and

protective equipment as per the applicable safety requirements, e.g. legislation concerning technical equipment, accident prevention regulations, etc.

The parameterisation and configuration of the m otor starter

must be selected so that no hazards can occur.

All covers must be kept closed during operation.

7. Maintenance and repairs

After the motor starter is disconnect ed from the power supply, live equipment components and power connections

should not be touched immediately, because of possible

charged capacitors. Observe the relevant information signs

located on the drive power converter.

Further information can be found in this documentation.

These safety instructions must be kept in a safe place!

2 BU 0135 GB-2713

Page 3

SK 105E…175E Motor Starter Manual Concerning this document

Documentation

Designation: BU 0135 GB

Part No.: 607 1302

Device series: SK 105E, SK 115E, SK 125E, SK 135E, SK 145E, SK 155E, SK 165E, SK 175E

Device types: SK 1x5E-301-340-A, SK 1x5E-751-340-A, 0.25 - 7.5kW, 3~ 200-500V

Version list

Designation of

previous issues

BU 0135 GB, July 2013

Part No. 607 1302 / 2713

Software

Version

V 1.0 R0 First version based on BU 0200 DE / 2011

Publisher

Getriebebau NORD GmbH & Co. KG

Rudolf-Diesel-Str. 1 • D-22941 Bargteheide • http://www.nord.com/

Tel.: +49 (0) 45 32 / 289-0 • Fax +49 (0) 45 32 / 289-2555

Intended use of the motor starter:

Compliance with the operating instructions is essential for fault-free operation and the

acceptance of any warranty claims. These operating instructions must be read before

working with the device!

These operating instructions contain important information about servicing. They must

therefore be kept close to the device.

SK 1x5E motor starters are devices for industrial and commercial plants for operating

three-phase asynchronous motors with squirrel-cage rotors.

SK 1x5E motor star ters are devices f or fixed installati on on motors or in the vicinit y of the

motors to be operate d. All details regarding technical data and permissible conditions

at the installation site must be complied with.

Commissioning (commencement of the intended use) is not permitted until it has be en e ns ured

that the machine com plies with the EMC Directive 2004/108/EEC and that th e conformity of

the end product meets the Machiner y Direct iv e 2006/42/EEC (observe EN 60204).

Comments

Getriebebau NORD GmbH & Co. KG, 2013

BU 0135 GB-2713 3

Page 4

SK 105E…175E Motor Starter Manual

1 GENERAL INFORMATION ...................................................................................................... 6

1.1 Overview .............................................................................................................. 7

1.2 Delivery ................................................................................................................ 7

1.3 Scope of supply ................................................................................................... 8

1.4 Safety and installation information ...................................................................... 9

1.5 Certifications ...................................................................................................... 10

1.6 Nomenclature / type codes ................................................................................ 12

1.7 Version with protection class IP55 / IP66 .......................................................... 15

2 ASSEMBLY AND INSTALLATION ....................................................................................... 16

2.1 Installation and assembly .................................................................................. 16

2.2 Dimensions of the motor starter ........................................................................ 20

2.3 Wiring guidelines ............................................................................................... 23

2.4 Electrical Connection ......................................................................................... 24

2.5 Electrical connection of the power unit .............................................................. 25

2.6 Electrical connection of SK 1x5E control unit .................................................... 28

2.7 Plug connectors ................................................................................................. 32

2.8 ATEX Zone 22 for SK 1x5E (in preparation) ..................................................... 35

2.9 Outdoor installation ............................................................................................ 40

1.5.1 European EMC Directive ........................................................................................ 10

1.5.2 UL and cUL approval(in preparation) ...................................................................... 10

1.5.3 C-Tick labelling ....................................................................................................... 11

1.5.4 RoHS compliance ................................................................................................... 11

1.6.1 Type code for basic unit .......................................................................................... 13

1.6.2 Type codes / Adapter unit - Technology Unit .......................................................... 13

1.6.3 Type codes / Optional modules .............................................................................. 13

2.1.1 Mounting the hous ing bo x ....................................................................................... 17

2.1.2 Adapters for different motors .................................................................................. 18

2.1.3 Installation of the motor starter ............................................................................... 19

2.1.4 Option locations in the device ................................................................................. 20

2.2.1 Power rating / Motor size ........................................................................................ 20

2.2.2 SK 1x5E mounted on motor .................................................................................... 21

2.2.3 SK 1x5E for wall-mounting...................................................................................... 22

2.5.1 Mains connections (L1, L2, L3, PE) ........................................................................ 26

2.5.2 Motor cable (U, V, W, PE)....................................................................................... 26

2.5.3 Electro-mechanical brake ....................................................................................... 27

2.6.1 SK 1x5E control terminal versions .......................................................................... 29

2.6.2 Details of the SK 1x5E control connections ............................................................ 30

2.6.3 Control connections for SK 1x5E communication ................................................... 31

2.7.1 Plug connectors for power connections .................................................................. 32

2.7.2 Plug connectors for control connection ................................................................... 33

2.8.1 Modified SK 1x5E for compliance with Category 3D ............................................... 36

2.8.2 Options for ATEX Zone 22 3D ................................................................................ 36

2.8.3 Commissioning information..................................................................................... 38

2.8.4 EC Declaration of Conformity (in preparation) ........................................................ 39

3 DISPLAY AND CONTROL .................................................................................................... 41

3.1 Diagnostic LEDs on the motor starter ............................................................... 42

3.2 Overview of external control devices ................................................................. 43

4 COMMISSIONING .................................................................................................................. 44

4.1 Factory settings ................................................................................................. 44

4.2 Commissioning the motor starter....................................................................... 44

4.2.1 Connection.............................................................................................................. 44

4.2.2 Configuration .......................................................................................................... 45

4.3 AS Interface ....................................................................................................... 49

4.3.1 The bus system ...................................................................................................... 49

4 BU 0135 GB-2713

Page 5

Table of Contents

4.3.2 Features .................................................................................................................. 50

4.3.3 Bus structure and technology .................................................................................. 50

4.3.4 Commissioning of the AS Interface ......................................................................... 52

4.3.5 Technical data for AS interface ............................................................................... 55

4.3.6 Functions of the ASI I/O bits ................................................................................... 55

4.4 PROFIBUS ................................................... Fehler! Textmarke nicht definiert.

4.4.1 Features .................................................................................................................. 56

4.4.2 Connection .............................................................................................................. 56

4.4.3 Addressing .............................................................................................................. 57

4.4.4 Displays .................................................................................................................. 58

4.4.5 Process data ........................................................................................................... 59

5 PARAMETERISATION ........................................................................................................... 60

5.1 Parameter ........................................................................................................... 61

5.1.1 Operating displays .................................................................................................. 62

5.1.2 Basic parameters .................................................................................................... 63

5.1.3 Motor and characteristic curve parameters ............................................................. 66

5.1.4 Control terminals ..................................................................................................... 67

5.1.5 Additional parameters ............................................................................................. 69

5.1.6 Information .............................................................................................................. 72

6 OPERATING STATUS MESSAGES ...................................................................................... 77

6.1 SimpleBox display .............................................................................................. 77

6.2 Table of possible error messages ...................................................................... 78

6.3 Table of possible warning messages ................................................................. 79

6.4 Table of possible reasons for the operating status "switch-on disabled" ........... 79

7 TECHNICAL DATA ................................................................................................................. 80

7.1 General data forSK 1x5E motor starter series ................................................... 80

7.2 Motor starter electrical data ................................................................................ 81

7.3 Electromagnetic compatibility ............................................................................. 82

7.4 EMC limit value classes ..................................................................................... 83

7.5 Operation with FI circuit breakers ....................................................................... 83

8 ADDITIONAL INFORMATION ................................................................................................ 84

8.1 Maintenance and servicing information .............................................................. 84

8.1.1 Maintenance Instructions ........................................................................................ 84

8.1.2 Repair information ................................................................................................... 84

8.2 Abbreviations in this manual .............................................................................. 85

9 KEYWORD INDEX .................................................................................................................. 86

BU 0135 GB-2713 5

Page 6

SK 105E…175E Motor Starter Manual

1 General information

The SK 1x5E series is based on the tried and tested NORD platform. These devices feature a compact

design with optimum characteristics.

Due to dual phase control, not onl y a pure motor start, but also a soft start is possible. T he phase control

process was selected s o that the res ulting harm onic torques are k ept as low as possible. A c omprehensiv e

spectrum of monitoring functions rounds off the range.

This series of devices can be adapted to individual requirements by means of extension modules.

Due to the numerous setting options, these inverters are capable of operating all three-phase motors.

The power range is from 0.25kW to 7.5kW. The device is equipped with an integrated mains filter.

This manual is based on the device sof tware V1.0 R0 (see P707) of the motor s tarter. If the motor star ter

uses a different software version, this may cause differences. If necessary, the latest manual should be

downloaded from the Internet (www.nord.com

For the various versions of the device series SK 105E…SK 175E there are differences in functions, the

integrated AS interface or the integrated PROFIBUS interface.

Typically, this series of devices is installed directly on a three-phase asynchronous motor. Alternatively,

optional accessories are available for m ounting the devices close to the motor, e.g. on the wall or on a

machine frame.

In the simplest config uration, ev en without a PC or contr ol box, all of the mos t important par ameter s can be

set using up to four potent iometers and the four DIP switches . LEDs are pr ovided for the diagnostics of the

operating status. The use of a control module is therefore not absolutely necessary.

In order to gain access to all parameters, the internal RS232 PC interface (RJ12) can be used, or an

optional SimpleBox or Param eterBox may be used. I n this case, t he parameter settings which are changed

by the user are saved in the flash memory of the device.

A permanent connection via the RS 232 interface is not intended for normal operation.

).

6 Pre-series version BU 0135 GB-2713

Page 7

1.1 Overview

x x x

x

This manual describes al l of the possib le f unctions and equ ipm ent. T he equipm ent and f unctions are limited

according to the t ype of device (SK 105 E…175E). T ype SK 175E d evices have t he maxim um configuration

level.

Basic features of the SK 1x5E:

• 2 digital inputs

• 2 digital outputs

• Temperature sensor input (TF+/TF-)

• Control and connection of an electromechanical brake

2

• Motor overload protection (I

• Mains and motor phase failure monitoring

• Flux monitoring (monitoring of minimum current)

• Automatic phase sequence detection

• Can be installed directly on, or near to the motor

• Permissible ambient temperature -25°C to 50°C (please refer to the technical data)

• Integrated EMC line filter for limit curve category C1

• 4x DIP switches and up to four potentiometers for configuration

• LEDs for diagnostics

• RS232 interface via RJ12 plug

Additional features:

Differences between the in dividual versions (SK 10 5E / … SK 175E) are summ arised in the following table

and will be described in this manual.

Additional features

Feature 105E 115E 125E 135E 145E- 155E- 165E- 175E-

Soft start function

Reversing function

Two additional digital inputs

AS interface (4I / 4O)

PROFIBUS-DP (4I / 4O)1

SK 145E … SK 175E devic es ar e avail abl e as ( -ASI) versions with an integra ted AS i nterf ac e and as ( -PBR)

versions with integrated PROFIBUS DP. The version with integrated PROFIBUS DP is only available on

request.

t triggering characteristic according to EN 60947)

x x x x

x x x x

ASI ASI ASI ASI

PBR PBR PBR PBR

1 General

1.2 Delivery

Check the equipment immediately after delivery/unpacking for transport damage such as deformation or

loose parts.

If there is any damage, contact the carrier immediately and carry out a thorough assessment.

Important! This also applies even if the packaging is undamaged.

1

Only available on request and as an alternative to the ASI interface.

BU 0135 GB-2713 Pre-series version 7

Page 8

SK 105E…175E Motor Starter Manual

1.3 Scope of supply

Standard version: IP55 (optionally IP66)

Operating instructions as PDF file on CD-ROM

including NORD CON (PC parameterising software)

Available accessories: Matching RJ12 to SUB-D9 adapter cable to connection to a PC

(Selection) RS485-RS232 conversion for connecting control boxes

SK CSX-3H, SimpleBox, 4-digit 7-segment LED display

SK PAR-3H, ParameterBox, plain text LCD display

Expansion module:

internal SK CU4-24V-123-B, internal 24V mains unit 1~ 230V

SK CU4-24V-140-B, internal 24V mains unit 1~ 400V

SK CU4-REL, internal setpoint converter with 2 relays

SK TIE4-SWT, direction selector switch module

<

2

2

2

2

2

2

2

External SK TU4-PBR, external PROFIBUS® module

SK TU4-CAO, external CANopen® module

SK TU4-DEV, external DeviceNet™ module

SK TU4-ECT, external EtherCAT® module

SK TU4-PNT, external PROFInet® module

SK TU4-POL, external POWERLINK® module

SK TU4-EIP, external Ethernet/IP™ module

SK TU4-24V-123-B, external 24V mains unit 1~ 230V

SK TU4-24V-140-B, external 24V mains unit 1~ 400V

SK TI4-TU-BUS or NET or MSW, connection unit TU4

SK TIE4-WMK-TU, wall-mounting kit TU4

SK TU4 MSW, external maintenance switch

NOTE: Details for the use o f t he relev ant b u s sy ste ms c an be found in the applicable su pple men ta ry bu s manual .

> www.nord.com

2

External bus modules can be used to control the motor starter via their additional digital inputs and outputs.

Parameterisation via the field bus module s is not possible!

8 Pre-series version BU 0135 GB-2713

Page 9

1.4 Safety and installation information

t be maintained.

ages for up to 1

minute after being switched off at the mains. Starter terminals, motor cables and motor

Touching open or free terminals, cables and equipment components can lead to severe injury

with the electrical supply

ufacturer.

Unauthorised modifications and the use of spare parts and additional equipment which has

not been purchased from or recommended by the manufacturer of the device may cause fire,

This product is intended for use in an industrial environment and is subject to sales

cause high frequency interference, in which case the user may be required to take

SK 1x5E motor starters are equipment for use in industrial high voltage systems and are operated at

voltages that could lead to severe injuries or death if they are touched.

• Installation and other work may only be carried out by qualified electr icians and with the

device disconnected. The operating instructions must always be available to these

persons and must be strictly observed.

• Local regulations for the installation of electrical equipment and accident prevention

must be complied with.

• For safe isolation from the mains, all p oles of the sup ply cable to the m otor starter m ust

be disconnected.

• Even during motor standst ill (e.g. cause d by an electronic bl ock, block ed drive or output

terminal short circuit), t he li ne conn ection ter m inals, motor term inals an d brak ing res istor

terminals may still conduct hazardous voltages. A motor standstill is not identical to

electrical isolation from the mains.

• Warning, under certain s ettings the m otor s tarter can star t automatic ally after the mains

are switched on.

• The motor starter is onl y intended for permanent connection and m ay not be operated

without effective earthing connections that comply with local regulations for large

leakage currents (> 3.5m A). VDE 0160 stipulates the installation of a second earthing

conductor or an earthing conductor cross-section of at least 10 mm

• SK 1x5E motor starters are maintenanc e free in norm al operation. T he cooling surf aces

must be regularly cleaned with compressed air if the ambient air is dusty.

2

.

1 General

CAUTION

The heat sink and all other metal components can heat up to temperatures above 70°C.

When mounting, sufficient distance from neighbouring components mus

When working on the components, allow sufficient cooling time beforehand

Protection against accidental contact may need to be provided.

ATTENTION

DANGER TO LIFE!

Under certain circumstances, the motor starter can continue to carry volt

terminals may carry voltage!

or death!

Work may only be carried out by qualified specialist electricians and

to the equipment disconnected!

CAUTION

Children and the general public must be kept away from the equipment!

The equipment may only be used for the purpose intended by the man

electric shock and injury.

Keep these operating instructions in an accessible location and give them to all operators!

WARNING

restrictions according to IEC EN 60947-4-2. In a domestic environment, this product can

appropriate measures.

BU 0135 GB-2713 Pre-series version 9

An appropriate measure would be the inclusion of a recommended mains filter.

Page 10

SK 105E…175E Motor Starter Manual

1.5 Certifications

1.5.1 European EMC Directive

If the SK 1x5E is installed a c c ording to t he r ec om mendations in this m anual,

it meets all EMC d irective requirements, as per the EMC product st andard

for semiconductor m otor control devices EN 60947-4. (see als o Sectio n 7.3,

Electromagnetic Compatibility [EMC].)

1.5.2 UL and cUL approval (in preparation)

At present the approvals are in the process of preparation.

All SK 1x5E motor starters include motor overload protection. Further technical details can be found in

Section 7.2.

NOTE

"Integral solid state short circuit protection does not provide branch circuit protection. Branch

circuit protection must be provided in accordance with the National Electric Code and any

additional local codes."

NOTE

cUL Approval - File No. E171342

“Suitable For Use On A Circuit Capable Of Delivering Not More Than 100000 rms

Symmetrical Amperes, 500 Volt s maximum and when protected by RK5 class or faster

fuses as indicated in chapter 7.2.”

“Suitable For Use On A Circuit Capable Of Delivering Not More Than 10000 rms Symmetrical Amperes, 500 Volts

maximum and when protected by Circuit Breaker (inverse time trip type) in accordance with UL 489”, current and

voltage ratings according to instruction manual.

„The torque value for the field wiring terminals for mains circuit terminals, motor terminals, break terminals and breaking

resistor terminals must be 11 … 15 lb-in (1.2 … 1.5Nm). The torque value for the field wiring terminals for control circuit

terminals must be 4.4 … 5.3 lb-in (0.5 … 0.6Nm).”

“The device has to be mounted according to the manufacturer instructions.”

"Use 80°C Copper Conductors Only"

(only refers to connection cables (mains and motor cables but not control cables)

"These products are intended for use in a pollution degree 2 environment"

10 Pre-series version BU 0135 GB-2713

Page 11

1.5.3 C-Tick labelling

1 General

NORD SK 1x5E series motor starters fulfill all the relevant regulations in

Australia and New Zealand.

1.5.4 RoHS compliance

SK 1x5E series motor starters are designed to be RoHS compliant

according to Directi ve 2002 / 95/ EEC

N 23134

BU 0135 GB-2713 Pre-series version 11

Page 12

SK 105E…175E Motor Starter Manual

1.6 Nomenclatur e / type codes

Unique type codes have been defined for the individual modules and devices. These provide individual

details of the device type and its electrical data, protection class, fixing version and special versions.

A differentiation is made according to the following groups:

Group Example of type code

Basic unit SK 175E-751-340-A (-C)

Connection unit Technology Unit (optional terminal box module) SK TI4-TU-MSW (-C-WMK-TU)

Optional modules SK TU4-MSW (-C)

Extension modules SK TIE4-M12-INI

SK 1x5E

motor starter

Optional terminal

box module

Optional module

SK TU4-xxx (-…)

The type designation r es ult ing from this type code c an be o bta ine d f r om the name plate which is attached to

or printed on the relevant module.

12 Pre-series version BU 0135 GB-2713

Page 13

1.6.1 Type code for basic unit

SK 175E-751-340-B (-C)

IP protection class: Standard

= IP55, C =

“coated”

Radio interference filter: B = Class C1

Mains voltage: x40 = 200 - 500V

Number of mains phases: 3xx = 3-

phase

Digits before decimal point for power: 0 = 0.xx, 1 = 0x.x0, 2 = 0xx.0

Device nominal power: 301 = 3.0kW, 751 = 7.5kW

Device series: SK 105E, SK 115E, SK

125E,

SK 135E,

SK 145E, SK 155E, SK 165E, SK 175E

(...) Options, only implemented if required

.

SK TI4-TU-MSW (-C-WMK-TU)

Wall mounting kit: -1 = Size 1

+ 2

IP protection class: Standard = IP55, C = “coated” IP66

Suitable device types: NET = optional net module (e.g. TU4-24V-… )

MSW = maintenance switch

(SK TU4

-MSW

BUS = optional bus module (e.g. CANopen: TU4-CAO)

Group:

TU = Technology unit

Device series: SK TI4 = Adapter unit SK TI4

(...) Options, only implemented if required .

SK TU4-24V-123-B (-C)

IP protection class: Standard = IP55, C = “coated” IP66

Radio interference filter: B = Class C1

Mains connection: 123 = 1~ 230V*, 140 = 1~ 400V*

Option type: 24V = 24V power supply, FUSE

Option series: TU4 = external Technology Unit,

CU4 = = internal customer unit

*) The voltage depends on the motor starter used; please also refer to the technical data.

(...) Options, only implemented if required.

1 General

1.6.2 Type codes / Adapter unit - Technology Unit

1.6.3 Type codes / Optional modules

For optional modules

BU 0135 GB-2713 Pre-series version 13

Page 14

SK 105E…175E Motor Starter Manual

Optional external

Technology Unit, SK TU4-…

Optional internal

Customer Unit, SK CU4-…

14 Pre-series version BU 0135 GB-2713

Page 15

" and are modified

that the cable and the cable gland are carefully

from the device (if necessary use loops). This is the only way to ensure permanent

1.7 Version with protection class IP55 / IP66

The SK 1x5E motor starters and additio nal modules are availa ble in protection class es IP55 (standard) or

IP66 (optional).

Protection class IP66 must always be stated when ordering!

There are no restrictions or diff erences t o the scope of functions in either prot ection c lass. In or der to dif fer-

entiate the protection c lasses, m odules with prot ection c lass IP66 are g iven an ex tra “-C” (coated à coated

PCBs) in their type designation.

e.g. SK 175E-751-340-A-C

IP55 version:

The IP55 version of the SK 1x5E is t he standard version. Both vers ions (motor-mounted, m ounted on the

motor or wall-mounted on a wall brack et) are available. In additio n, all adapter units, tec hnology units and

customer units are available for this version.

IP66 version:

In contrast to the I P55 vers ion th e IP66 version is a m odified option. F or this version, bot h var iants (m otor-

integrated, close to motor) are also available. The modules available for the IP66 version (adapter units,

technology units and cus tomer units) have the same func tionalities as the corr esponding modules for the

IP55 version.

NOTE

1 General

Special measures:

Impregnated PCBs,

Powder coating RAL 9006 (white aluminium) for housing

Low pressure test

NOTE

The modules for the IP66 design are identified by an additional "-C

according to the following special measures listed below.

For all versions, care must be taken

matched. Wherever possible, the cables should be inserted so that water is deflected away

compliance with the required protection class.

BU 0135 GB-2713 Pre-series version 15

Page 16

SK 105E…175E Motor Starter Manual

2 Assembly and installation

2.1 Assembly

The motor starters are availa ble in various sizes depending on th eir output. They only differ with regar d to

their possibilities for adaption to the matching motors. The external dimensions of both sizes are

identical. Size 1 is matched to motor size 80-100. Size 2 is matched to motor size 132.

Motor-mounted version Wall-mounted version

16 Pre-series version BU 0135 GB-2713

Page 17

2 Assembly and installation

1x5E must be carried out by NORD as special measures

have to be implemented. IP66 components retrofitted on site cannot ensure that this protection

2.1.1 Mounting the housing box

On delivery of a complete drive unit (gear unit + motor + fr equency inverter) SK 1x5E motor star ters are

always fully installed and tested.

NOTE

Mounting of an IP66-compliant SK

class is guaranteed.

When delivered separately, the motor starter includes the following components:

• Motor starters

• Screws and contact washers for mounting the motor terminal box.

• Pre-fabricated cable for motor and PTC connections

Procedures:

1. If necessary, remove the original terminal box from the NORD motor, so that only the base of the

terminal box and the terminal strip remain.

2. Set the bridges for the correc t motor circuit and connect the pre-fabric ated cables for motor and PTC

connections to the respective connection points on the motor.

3. Mount the cast housing on the terminal box base of the NO RD m otor us ing the exis ting scre ws and s eal

as well as the enclos ed toothed / contact w ashers. Position the cas t housing with the d ome facing the

A-side of the motor (looking towards the A bearing cover). Check the adaptability for different motor

manufacturers.

If necessary, the plas tic cover (1) for the electronics m ust be carefully removed in order to m ake the

screw fastenings to the base of the terminal box.

4. Connect the motor cables U, V, W to the power terminal block and t he PT C cable TF+, TF- to the control

terminal block 38, 39.

BU 0135 GB-2713 Pre-series version 17

Page 18

SK 105E…175E Motor Starter Manual

Adapter plate

Seal

Motor Size 71

Motor starter SK 1x5E BGI

Example

2.1.2 Adapters for different motors

In some cases, the term inal box attachments are diff erent for different sizes of m otor. Therefore it may be

necessary to use an adapter to mount a motor starter.

In order to guarantee t he max imum protec tion class I P55 / I P66 of the e ntire un it, the pr otec tion cl ass of the

motor starter must also correspond to this value.

NORD motor

sizes

Size 63 – 71

Size 80 – 112

Size 132 not possible Direct mounting

Overview of adapter kits

Name Add-on SK 1x5E Part No.

Adapter kit size 63-71 to KK80-112

(Adapter kit I)

SK TI4-3 adapter kit_80-112

(Adapter kit II)

Add-on

SK 1x5E Size 1

with adapter kit I

Direct mounting

Adapter plate, terminal box frame seal and screws

Adapter plate, terminal box frame seal and screws

Add-on

SK 1x5E Size 2

not possible

with adapter kit II

275119050

275274321

NOTE

18 Pre-series version BU 0135 GB-2713

The adaptability of motors from other manufacturers must be checked individually!

Information for the conversion of controlled drive units to the SK 1x5E can be found in BU0320.

Page 19

2 Assembly and installation

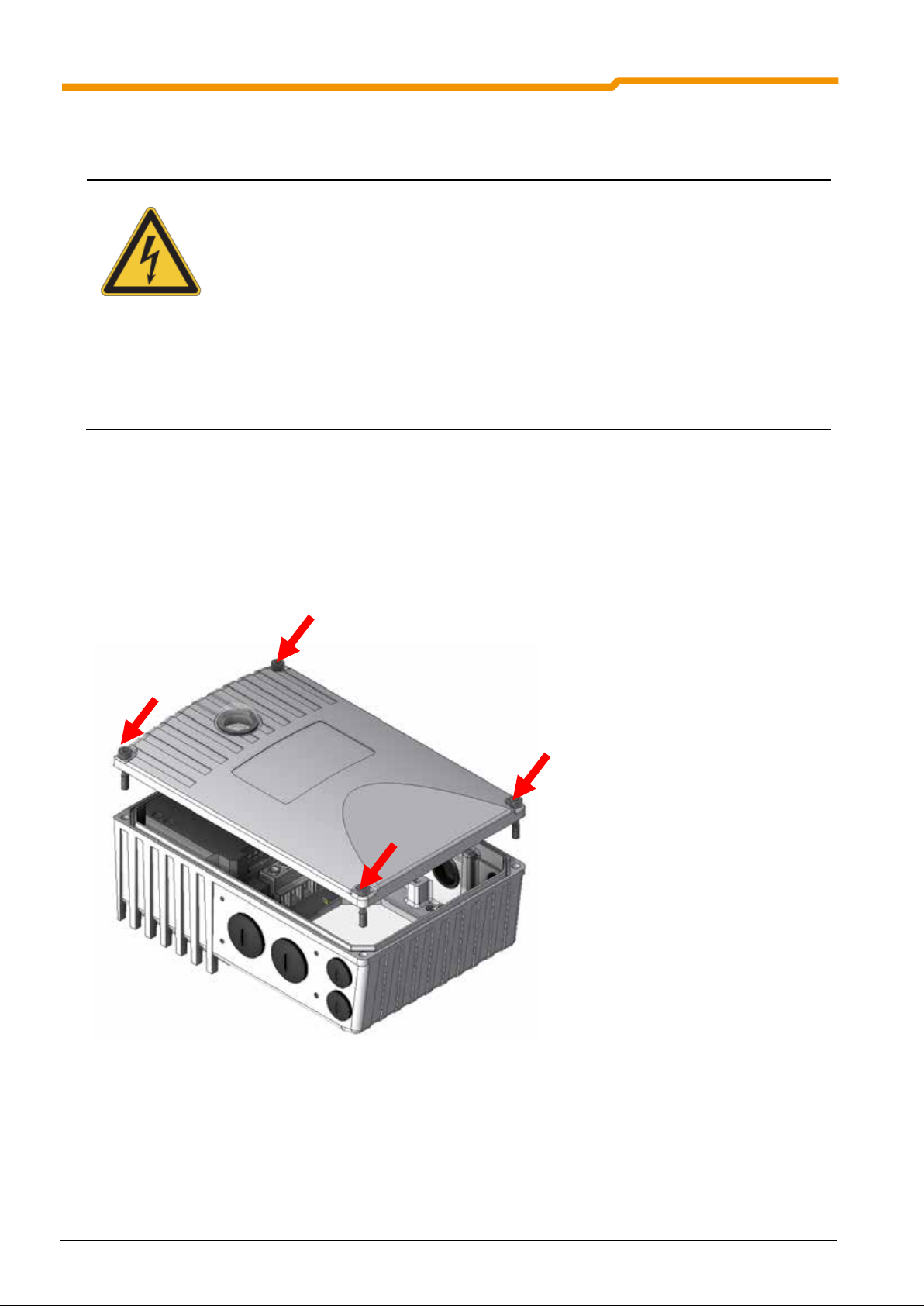

2.1.3 Installation of the motor starter

The housing cover must f irst be rem oved in or der to m ake the elect rical co nnections t o the SK 1x5E. T o do

this, unscrew the 4 fastening screws, so that the housing cover can be removed upwards.

After the electrical connections of the supply cables have been made, the housing cover can be replaced.

To achieve the maxim um protection c lass IP 55/IP6 6, care m us t be tak en that all t he fas tening sc re ws of the

housing cover are tightened diagonally, step-by-step and with the torques stated in the table below.

For the cable gland of the connecting cable , appropriate scr ewed connections f or cable cross-s ection must

be used.

Motor starter size Screw size Tightening torque

Size I M5 x 25 3.5Nm ± 20%

Size II M5 x 25 3.5Nm ± 20%

BU 0135 GB-2713 Pre-series version 19

Page 20

SK 105E…175E Motor Starter Manual

2.1.4 Option locations in the device

The drawing above shows the various mounting locations for the optional modules. Option location 1 is used

for the mounting of an internal bus module or internal mains unit. External bus modules, 24 V power

supplies can be implemented at option locations 3L or 3R. Option locations 4 and 5 are used for the

installation of M12 sockets or plug connectors or for cable glands. Of course, only one option can be

mounted at a single option location.

Option

location

1 Internal Mounting location for customer units SK CU4-…

3* on side Mounting location for

3 A/B* on side Cable gland M25 Not available if location

4 *,

5 *

* R and L (right and left side)

Position Meaning Size

Sizes 1 - 2

• External technology units SK TU4-…

• HARTING plug connectors

on side Cable gland M16 Not available if

Comments

3 is occupied or

SK TU4-… is fitted.

SK TU4-… is fitted.

2.2 Dimensions of the motor starter

2.2.1 Power rating / Motor size

Mains / Power category SK 1x5E

Size

3~ 200-240V 3~ 380-500V

Size I

Size II

20 Pre-series version BU 0135 GB-2713

0.12 ... 1.5kW 0.25 ... 3.0kW

2.2 ... 4.0kW 4.0 ... 7.5kW

Page 21

2 Assembly and installation

2.2.2 SK 1x5E mounted on motor

Size Housing dimensions SK 1x5E / Motor Weight of

FI

Motor

∅ g

g 1 n o p

SK 1x5E

without motor

Approx. [kg]

Size I

Size II

Size 71 * 145 177.5

Size 80 165 171.5 236

Size 90 S / L 183 176.5 251 / 276

Size 100 201 185.5 306

Size 80 ** 165 193.5

Size 90 S / L **

Size 100 ** 201 209.5 306

Size 112 ** 228 219.5 326

Size 132 S / M 266 216.5 373 / 411

183 198.5 251 / 276

All dimensions in [mm]

*) including additional adapter and seal (18mm) [275119050]

**) including additional adapter and seal (20mm) [275274321]

221

221

214

236

154 2.0

154 2.0

BU 0135 GB-2713 Pre-series version 21

Page 22

SK 105E…175E Motor Starter Manual

∅

2.2.3 SK 1x5E for wall-mounting

The SK 1x5E can be installed in the vicinity of the motor by means of an optional wall mounting kit.

Wall mounting

SK TIE4-WMK-1

total weight

Approx. [kg]

Device type

Size

Housing dimensions

g2 n p p2 d e

Size I à SK TIE4-WMK-1

Part No. 275 274 000

Size II à SK TIE4-WMK-2

Part No. 275 274 001

All dimensions in [mm]

113 221 154 205 64 180 5.5 2.6

115,5 221 154 235 64 180 5.5 2.6

All possible installation orientations are permissible for wall mounting.

22 Pre-series version BU 0135 GB-2713

Page 23

2 Assembly and installation

The control cables, mains cables and motor cables must be laid separately. In no

The test for high voltage insulations must not be used on cables which are connected to the

simultaneously connected to

the motor starter and the PC, as potential shifts may cause damage, especially to the PC.

2.3 Wiring guidelines

The motor starters have be en developed for use in an industr ial environm ent. In this environm ent, high le vels of electromagnetic interference can inf luence the motor starter. In genera l, correct installation ensures

safe and problem-f ree operation. To meet the limiting values of the EMC directives, the following i nstructions should be complied with.

(1) Ens ure that a ll equipm ent in th e control c abinet or field is s ecurel y earthed us ing shor t earthing c ables

which have large cross-sections a nd are connected to a comm on earthing point or earthing rail. It is

especially important th at all control dev ices connected to the motor star ter (e.g. an automat ion device)

are connected to the same earthing point as the motor starter itself, using a short cable with large

cross-section. Flat conductor s (e.g. metal clam ps) are preferable, as they have a lower impedance at

high frequencies.

(2) The bonding cable of the motor controlled by the motor starter should be connected directly to the

earthing terminal of the as sociated motor star ter. The presence of a c entral earthing bar in the contr ol

cabinet and the grouping together of all bonding conductors to this bar normally ensures safe

operation. (See also Section 7.3 / 7.4(EMC))

(3) W here possible, shielded cables should be used for control circuits. The shielding at the cable end

should be carefully sealed and it must be ensured that the wires are not laid over longer distances

without shielding.

(4) The control cables should be installed as far as possible from power cables, using separate cable

ducts, etc. Where cables cross, an angle of 90° should be ensured as far as possible.

(5) Ens ure that the contactors and brake chok es in the cabinet are interference protected , either by RC

circuits in the case of AC contactors, or by “free-wheeling” diodes for DC contactors, whereby the

interference protectors must be positioned on the contactor coils. Varistors for over-voltage

limitation are also effective.

In addition, an EMC-compliant cabling must be ensured. (See also Section 7.3 / 7.4 (EMC)).

The safety regulations must be complied with under all circumstances

when installing the motor starter!

ATTENTION

NOTE

circumstances should they be laid in the same protective pipes/installation ducts.

motor starter.

With the use of a ParameterBox SK PAR-3H this must never be

(See also Manual BU0040)

BU 0135 GB-2713 Pre-series version 23

Page 24

SK 105E…175E Motor Starter Manual

installed and commissioned by qualified personnel

In particular, the general and regional installation and safety regulations for work on high voltage

must the regulations concerning correct use of tools

Dangerous voltages can be present at the mains input and the motor connection terminals even

d screwdrivers on these terminal

Ensure that the input voltage source is not live before setting up or changing connections to the

2.4 Electrical Connection

WARNING

The housing cover must be removed from the SK 1x5E in order to make the electrical connections. Proceed

as follows:

1. Switch off the mains supply and if necessary check and observe the waiting period.

2. Loosen the 4 Allen screws (4mm).

3. Carefully lift the housing cover vertically from off the housing box.

4. The electrical connections and the option slots are now freely accessible.

THE DEVICES MUST BE EARTHED.

Safe operation of the devices requires that is

in compliance with the instructions provided in this Manual.

systems (e.g. VDE) must be complied with as

and the use of personal protection equipment.

when the motor starter is not in operation. Always use insulate

fields.

unit.

Ensure that the motor starter and motor are specified for the correct supply voltage.

5. Replace the cover

24 Pre-series version BU 0135 GB-2713

6. Evenly tighten the Allen screws in a cross-wise direction.

Page 25

2 Assembly and installation

2.5 Electrical con nect ion of the power unit

All connection terminals are located in the housing

box of the motor starter.

One terminal level is provided for the power

connections and one for the control connections.

The earthing connections (device earthing) are

located on the base in the cast housing.

Before and while the device is connected, the

following must be observed:

1. Ens ure that the m ains s uppl y provides the corr ect

voltage and is suitable for the current required

(see Section 7 Technical Data).

2. Ensure that suitable circuit breakers with the

specified nominal current range are inserted

between the voltage source and the inverter.

3. Connect the mains voltage directly to the

terminals L

4. T o connect the motor, three f lexible wires U-V-W

should be used when mounting the motor.

5. For wall-mounting a 4-conductor shielded motor

cable (recommended) to th e terminals U-V-W and

earth should be used.

NOTE: if certain wiring sleeves are used, the maximum connection cross-section can be reduced.

Screwdriver: Use a 0.6 x 3.5 mm slot-head screwdriver to connect the power unit.

NOTE: Only use copper cables with temperature class 80°C or equivalent for connection. Higher

temperature classes are permissible.

ATTENTION: This device produces high frequency int erference, whi ch may make additio nal suppression

and PE.

1-L2-L3

measures necessary in domestic environments. (Details in Section. 7.3 / 7.4 (EMC))

BU 0135 GB-2713 Pre-series version 25

Page 26

SK 105E…175E Motor Starter Manual

Main

2.5.1 Mains connections (L1, L2, L3, PE)

No special safety meas ures are required on the m ains input side of the m otor starter. It is advisable t o use

normal mains fuses (see technical data) and a main switch or circuit breaker.

400V devices are designed for three phase mains voltage 200...500V (L1/L2/L3).

For the exact specification, please refer to the technical data in Section 7.

Isolation from or c onnection to the mains must al ways be carried out for all the pol es and synchronously

(L1/L2/L3).

Connection to earth is made via screw terminals in the cast housing of the device.

Connection cross-section:

0.5...10mm

For looping of the mains voltage, up to a

cable cross-section of 2 x 4.0mm

wire end sleeves must be used.

Tightening torque:

1.2 ... 1.5Nm

2

rigid/ flexible cable AWG 20-6

2

double

PE

Main

PE

Main

2.5.2 Motor cable (U, V, W, PE)

Connection cross-section:

0.5 ... 10mm

AWG 20-6

Tightening torque:

1.2 ... 1.5Nm

2

rigid/ flexible cable

PE

Main

PE

26 Pre-series version BU 0135 GB-2713

Page 27

2 Assembly and installation

For the connection of a mechanical brake to the terminals of the motor starter, parameters

107 / P114 (brake application time / release time ) must be adjusted. In order to prevent

Brake connection terminal 79/80

2.5.3 Electro-mechanical brake

Connection of an electr omagnetic br ake is pos sible for all SK 1x5E devices . To control the brak e, an outp ut

voltage is generated to ter minals 79 / 80 (MB+ / MB-) by the motor starter to terminals 79 / 80 (MB+ / MB-)

(also refer to Sections 2.6.1 to 2.6.2). This depends on the supply voltage. The assignment is as follows:

Mains voltage / Alternating current (AC) Brake coil voltage (DC)

230 V ~ 105 V =

400 V ~ 180 V =

460 V ~ / 480 V ~ 205 V =

The allocation of the cor rect brak e or brak e coil volta ge m ust be taken into ac count in the design with reference to the mains voltage of the motor starter.

NOTE

P

damage to the brake control, a value ≠ 0 must be set in parameter (P107).

The following settings for (P107/P114) are recommended for NORD brakes:

BRE5, BRE10, BRE40 : 0.02s,

BRE20, BRE60, BRE100, BRE150: 0.03s,

BRE250: 0.04s,

Connection terminals: Screw terminals, 0.6 x 3.5 mm slot-head screwdriver

Connection cross-section: 0.2 ... 2.5mm

2

, AWG 24-14, rigid or flexible, without wire end sleeves

BU 0135 GB-2713 Pre-series version 27

Page 28

SK 105E…175E Motor Starter Manual

2.6 Electrical connection of SK 1x5E control unit

The control connections are located on the inside of the motor starter housing. The connections to the

terminal bar differ according to the version (SK 105E…175E).

Connection terminals: Spring-loaded terminal, 2.0 mm slot-head screwdriver

Connection cross-section: 0.2 ... 1.5mm

Control cable: Lay and shield separately from the mains/motor cables

Control voltages,

external: 18…30V, min. 25…100mA

the equipment and additional options. For the supply of the motor starter and

the connected options.

2

, AWG 24-16, rigid or flexible, without wire end sleeves

3

, the current load increases further according to

3

Maximum consumption by the basic device, without connected options and digital output loads (approx. 50mA for

SK 105E…135E and SK 145E…175E with optional AS interface, 100mA for SK145E…175E with optional

PROFIBUS)

28 Pre-series version BU 0135 GB-2713

Page 29

40 3 40

1 9 1

2.6.1 SK 1x5E control terminal versions

LABELLING, FUNCTION

2 Assembly and installation

SSF: Soft start function

REV: Reversing function

ASI: Integrated AS interface

PBR: Integrated PROFIBUS DP

24V: 24V power supply

DIN: Digital input

DOUT: Digital input

MB+/-: Electromagnetic brake control

(105V, 180V, 205V)

TF+/-: PTC connection of the motor

GND: Reference potential for digital signals

CONNECTIONS AND FUNCTIONS FOR SK 1X5E VERSIONS DEPENDING ON CONFIGURATION LEVEL

Terminal X4 (only SK 145E…175E):

SK 145E SK 155E SK 165E SK 175E Starter type SK 145E SK 155E SK 165E SK 175E

SSF

ASI

REV

ASI

SSF + REV

ASI

Labelling

SSF

PBR

REV

PBR

SSF + REV

PBR

Pin

GND, reference potential for digital signals

DIN4, digital input 4

(BUS-DIN2)

DIN3, digital input 3

(BUS-DIN1)

24V output max. 200mA

ASI-, AS interface

ASI+, AS interface

40

C2

C1

43

85

84

40

1

C2

2

C1

3

43

4

83

5

82

6

GND, reference potential for digital signals

DIN4, digital input 4

(BUS-DIN2)

DIN3, digital input 3

(BUS-DIN1)

24V output max. 200mA

PBR-A, PROFIBUS DP

PBR-B, PROFIBUS DP

Terminal X5:

SK 105E SK 115E SK 125E SK 135E Starter type SK 145E SK 155E SK 165E SK 175E

SSF REV SSF + REV

Labelling

Pin

SSF

ASI / PBR

REV

ASI / PBR

SSF + REV

ASI / PBR

24V, external 24V supply

24V, external 24V supply

GND, reference potential for digital signals

GND

24V, external 24V supply

DIN1 / digital input 1

DIN2, not used in

standard*

DIN2,

digital input 2

GND

DOUT1, digital output 1

DOUT2, digital output 2

GND

TF-, motor thermistor (PTC) connection

TF+, motor thermistor (PTC) connection

44

44

40

44

21

22

40

3

40

39

38

10

11

12

13

14

44

1

44

2

24V, external 24V supply

24V, external 24V supply

GND, reference potential for digital signals

40

4

44

5

21

6

22

7

40

8

DIN2, not used in

24V, external 24V supply

DIN1 / digital input 1

standard*

GND

DIN2,

digital input 2

GND

DOUT1, digital output 1

3

40

DOUT2, digital output 2

GND

39

38

TF-, motor thermistor (PTC) connection

TF+, motor thermistor (PTC) connection

*) In the state as delivered, this input is not used

BU 0135 GB-2713 Pre-series version 29

Page 30

SK 105E…175E Motor Starter Manual

2.6.2 Details of the SK 1x5E control connections

Control voltage 24V exter nal! Terminal 44. If the motor star ter is not equipped with an optiona l mains unit it

must be supplied with an external 24V voltage.

For devices with which the AS interface is used, the supply voltage can be taken from the AS interface cable

if the appropriate jumpers are set ("only yellow cable"). Otherwise the device can also have a separate

supply ("black and yellow cable"). In this case, the jumpers must not be set.

Terminal/

Name

SK 105E…SK175E

44 VI 24V 24V supply

40 GND / 0V Reference potential

21 DIN1 Digita l input 1

22 DIN2 Digita l input 2

1 DOUT1 Output 1

3 DOUT2 Output 1

38 TF+ PTC resistor input

39 TF- PTC resistor input

79 MB+ Brake control

80 MB- Brake control

Function

{Factory setting}

Input

for digital signals

{ON right}

{ON left}

{Error}

{Starter running}

Data Description /

wiring suggestion

24VDC ±25%

50mA (Starter without

accessories) ... 400mA

according to load on the

inputs and outputs or

equipment with options

Digital input as per

EN 61131-2, Type 1

Low: 0-5V (~ 9.5kΩ)

High: 15-30V

(~ 2.5-3.5kΩ)

Input capacitance: 10nF

Scanning time: 1ms

Reaction time: ≥ 4ms

Digital output

18-30V, each to VI 24V

max. 200mA

Devices with AS-I

(SK 145E or higher):

Total current 165 mA

max. 100k Ωload

-

Voltage:

Mains brake

230V 105V=

400V~ 180V=

460/480V~ 205V=

Current: max. 0.5A

Connection of the supply voltage

for the control unit and supply to

outputs DOUT1+2 as well as any

connected initiators

For control of the device from an

external control unit or switch.

For evaluation in a control system.

For monitoring the motor

temperature by PTC.

The motor starter generates an

output voltage on Terminals

MB+/MB- for control of an

electromagnetic brake. This

depends on the supply voltage to

the SK 1x5E.

It is essential to take the correct

brake coil voltage into account in

the selection.

Parameter

-

-

P420 [01]

P420 [02]

P434 [01]

P434 [02]

-

P107,

P114,

30 Pre-series version BU 0135 GB-2713

Page 31

RS485_A

RS485_B

GND

TXD

RXD

+5V

+24V

n.c.

n.c.

6: +24V

Additionally for SK 145E ... SK 175E

43 24V 24V supply

Output

40 GND / 0V Reference potential

for digital signals

C1 DIN3 Digital input 3

{ON right}

C2 DIN4 Digital input 4

{ON left}

84 ASI+

Actor Sensor

85 ASI-

82 PBR-B

Interface4

PROFIBUS DP

5

83 PBR-A

24VDC ±25%

165mA

Digital input as per

EN 61131-2, Type 1

Low: 0-5V (~ 9.5kΩ)

High: 15-30V

(~ 2.5-3.5kΩ)

Input capacitance: 10nF

Scanning time: 1ms

Reaction time: ≥ 4ms

26.5 – 31.6V,

max. 240mA

2 Assembly and installation

Connection of the supply voltage

for the control unit and supply to

outputs DOUT1+2 as well as any

connected initiators

Digital input for the evaluation of a

connected initiator. This input is

transferred to the control unit

directly via the AS interface or the

PROFIBUS. It is not evaluated by

the starter.

For control of the SK 1x5E via the

simple field bus level.

By means of jumpers it can be

selected whether only the "yellow

cable" is used, or "yellow" and

"black", i.e. supply with additional

auxiliary power.

For control of the SK 1x5E via

PROFIBUS DP.

-

-

-

-

-

-

2.6.3 Control connections for SK 1x5E communication

Terminal/

Designation

all SK 1x5E, connector block RJ12, RS232

3 GND

4 232 TXD

5 232 RXD

6 +24V 24V supply voltage

Function

{Factory setting}

Reference potential

for Bus signals

Data cable RS232

from the FI

Data Description / wiring suggestion Parameter

0V digital

Baud rate 38400Baud

Address 0

USS protocol

24V ± 20%

RJ12: Pin No. 1 … 6

1: n.c.

2: n.c.

3: GND

4: RS232_TxD

5: RS232_RxD

4

SK145E…SK175E with integrated AS interface

5

SK145E…SK175E with integrated PROFIBUS

BU 0135 GB-2713 Pre-series version 31

Page 32

SK 105E…175E Motor Starter Manual

nt load for the connection terminals, plugs and supply cables must be

E.g. SK1x5E with HAN 10E plug connector E.g. SK1x5E with plug connector 2 x Q4-2

2.7 Plug connectors

The use of optional ly available plug connectors f or the power and control con nections enables the risk of

installation errors when connecti ng the dev ice to be minimised. The most c ommon plug conn ector versio ns

are summarised below. The possible mounting locations on the housing box are listed in Section 2.1.4.

2.7.1 Plug connectors for power connections

Plug connectors for the motor or mains connection to the motor starter are available.

Connection of up to t wo power plug con nectors (HAN Q 4-2: up to 2 x 2 plu g connectors ) are only made on

the housing box. The following 3 connection versions are available:

Mounting version Meaning

… - LE Power input

… - LA Power output

… - MA Motor output

With this, the mains connec tion and the motor output can be implem ented with separate plug connec tors in

the case of wall-mounted motor starters.

For motor-mounted s tarters it is possible to m ount a mains output plug in p lace of the motor connection.

Via this, the mains voltage can be looped to the next device.

ATTENTION

The permissible curre

observed when looping the mains voltage.

32 Pre-series version BU 0135 GB-2713

Page 33

2 Assembly and installation

Disassembly of the

plug housing with

screws and contact

Make the electrical

Installation

Mounting of a plug connect or on the housing of the motor starter is usuall y only possible with a connec tion

adapter (connection ex te ns ion SK TIE4-HAN10E).

Plug connector* Part. No. Technical data plus

SK TIE4-HAN10E

(275274100)

HAN 10E LA 2BUE

(Power output)

HAN 10E LE 1BUE

(Power input)

HAN 10E LE 2BUE

(Power input)

HAN 10E MA 2BUE

(Motor output)

HQ8 LA

(Power output)

HQ8 LE

(Power input)

HQ8 MA

(Motor output)

Connection extension

HAN Q5

(Power input + motor

or power output)

* Further types available on request

275135010 Add-on housing with 2-clamp lock, socket insert 10-pin. +

PE, spring terminals, PE: Screw connection,

electrical data: 16A 500V

275135070 Add-on housing with 1-clamp lock, pin insert 10-pin. +

PE, spring terminals, PE: Screw connection,

electrical data: 16A 500V

275135000 Add-on housing with 2-clamp lock, pin insert 10-pin. +

PE, spring terminals, PE: Screw connection,

electrical data: 16A 500V

275135020 Add-on housing with 2-clamp lock, socket insert 10-pin. +

PE, spring terminals, PE: Screw connection,

electrical data: 16A 500V

275135040 Add-on housing, socket insert 8-pin. + PE, crimp connec-

tion,

electrical data: 16A 500V

275135030 Add-on housing, pin insert 8-pin. + PE, crimp connection,

electrical data: 16A 500V

275135050 Add-on housing, socket insert 8-pin. + PE, crimp connec-

tion,

electrical data: 16A 500V

275274110 2 x add-on housing on a connector frame, each with one

5-pin pin insert + PE and a 5-pin socket insert + PE,

crimp connection, PE: Screw connection,

electrical data: 16A, 230V/400V

X

X

X

X

X

X

X

Not required!

The connection extens ion

SK TIE4-HAN10E contains all t he additional elements required f or the HAN 10E

and HAN Q8 versions listed a bove. Install ation is rec ommended as follows. Ste ps 2 and 3 are not requir ed

for plug version HAN Q5.

Step 1 Step 2 Step 3 Step 4 Step 5

Put on seal Put on adapter plate Install the add-on

2 x M25 blank plug

connections

2.7.2 Plug connectors for control connection

Various M12 round plug co nnectors ar e avail able as f langed plugs or flanged s ock ets. The plug connec tors

are intended for instal lation in the housi ng box an d can be oriented as required . The pr otection class (IP67)

of the plug connector onl y applies in the sc rewed state. T he cover caps correspond t o the colour version as

does the plastic body of the plug connector.

BU 0135 GB-2713 Pre-series version 33

washers

Page 34

SK 105E…175E Motor Starter Manual

System

components

External voltage supply

SK TIE4-M12-POW

Part No. 275274507

Sensors and actuators

SK TIE4-M12-INI

Part No. 275274503

AS Interface

SK TIE4-M12-ASI

Part No. 275274502

Description Data

A-coded, 4-pin

PIN 1 +24V (brown)

PIN 2 n. c.

PIN 3 GND (blue)

PIN 4 n. c.

M12 flanged plug

to connect a 24V- supply

PIN 5 n. c.

Plastic body in black

A-coded, 4-pin

PIN 1 +24V (brown)

PIN 2 DI or DO (white)

PIN 3 GND (blue)

PIN 4 DI or DO (black)

M12 flanged plug

to connect sensors and actuators

PIN 5 n. c.

Plastic body in black

A-coded, 5-pin

PIN 1 AS-i+ (/+24V) (brown)

PIN 2 n. c.

PIN 3 AS-i- (/GND) (blue)

PIN 4 n. c.

M12 flanged plug

to connect an AS interface cable

PIN 5 n. c.

Plastic body in yellow

SK TIE4-M12-ASI-AUX

Part No. 275274513

M12 flange plug

for connection of an AS interface cable with additional 24V

supply ("Auxiliary Power")

PROFIBUS DP

SK TIE4-M12-PBR

Part No. 275274500

M12 flanged plug

to connect the incoming PROFIBUS DP cable

Kit consisting of M12

flanged plug and

flanged socket

M12 flanged plug

to connect the outgoing PROFIBUS DP cable

Pin designation of M12 plug

A-coded, 5-pin

PIN 1 AS-i+ (brown)

PIN 2 GND (white)

PIN 3 AS-i- (blue)

PIN 4 +24V (black)

PIN 5 n. c.

Plastic body in yellow

B-coded, 5-pin

PIN 1 +5V* (brown)

PIN 2 PBR-A (green)

PIN 3 G ND * (blue)

PIN 4 PBR-B (red)

PIN 5 n. c.

Plastic body in violet

*PIN 1 and PIN 3 areonly

assigned in the M12-flanged

socket

The pin designations of the

M12 socket are the

corresponding mirror image.

34 Pre-series version BU 0135 GB-2713

Page 35

2 Assembly and installation

If the motor starter is connected to a motor and a gear unit, the EX labelling of the motor and

Before opening the device for the connection of electric cables or other work, the mains

d the motor, which are higher than the

these impair the cooling of the

All cable glands which are not used, must be closed with blind screw plugs which are

2.8 ATEX Zone 22 for SK 1x5E (in preparation)

General information

The SK 1x5E can be used in explos ion ha zard areas with a suitable modif ication. For this it is im por tant that

all the safety inf ormation in the operating instructions is strictl y complied with f or the prev ention of pers onal

injury and material damage. This is essential to prevent injury and damage.

Qualified personnel

Qualified personnel must be used to carry out work involving the transport, assembly, installation,

commissioning and m aintenanc e. Qu alified p ersonne l ar e persons who due t o the ir train ing, exper ience a nd

instruction, and their knowledge of the relevant stand ards, accident prevention regulations and operating

conditions are authorised to carr y out the necess ary ac tivities f or c omm issioning t he m otor star ter. T his also

includes knowledge of first aid measures and the local emergency services.

ATTENTION

All work must only be carried out with the power to the system switched off.

the gear unit must also be observed.

Safety information

The increased danger in areas with inflamm able dust demands the strict obser vation of the general safet y

and commissioning inf ormation. The drive unit m ust comply with the specificati ons in Planning Guideline

No. 6052101. Explosive c oncentrations of dust may cause explos ions if ignited by hot or sparking obj ects.

Such explosions may cause serious or fatal injuries to persons or severe material damage.

It is essential tha t t he pers o n r es po nsib le f or t he us e of motors and m ot or s tart ers in explosion hazard are as

is trained in their correct use.

ATTENTION

voltage must always be switched off and secured against switching on again !

Temperatures may occur within the motor starter an

maximum permissible surface temperature of the housing. The device may therefore not be

opened or removed from the motor in an atmosphere of explosive dust!

Impermissibly heavy dust deposits must not be permitted, as

motor starter!

approved for explosion hazard areas.

Only the original seals may be used.

The protective film covering the diagnostic LEDs in TU4 modules must not be damaged.

Repairs may only be carried out by Getriebebau NORD.

BU 0135 GB-2713 Pre-series version 35

Page 36

SK 105E…175E Motor Starter Manual

Series SK 1x5E motor starters and the associated options are only designed for a degree

Device*

Kit designation

Part Number

2.8.1 Modified SK 1x5E for compliance with Category 3D

Only a modified motor starter is permissible for operati ng a n SK 1x 5 E in the AT E X Zone 22. This adaptatio n

is only made at the NORD f actory. In order to use the m otor starter in ATEX Z one 22, among other things,

the diagnostic caps are replaced with aluminium / glass versions.

II 3D Ex tD A22 IP55 T125 °C X

Categorisation:

§ Protection with "housing"

§ Procedure "A" Zone "22" Category 3D

§ Protection class IP55 / IP66 (according to the device)

§ Maximum surface temperature 125°C

§ Ambient temperature -20°C to +4 0°C

of mechanical hazard corresponding to a low impact energy of 7J.

The necessary adaptations are contained in the ATEX outdoor installation kits.

SK 1x5E

SK TU4-xxx

* One kit must be used for each device

SK 200E-ATEX-TU4 275274206

2.8.2 Options for ATEX Zone 22 3D

In order to ensure an AT EX-compliant m otor starter, the appr oval of optional m odules for explosio n hazard

areas must be observed. The f ollo win g lists the vari ou s options with regar d t o the i r approv al f or us e in AT EX

Zone 22 3D.

36 Pre-series version BU 0135 GB-2713

Page 37

2.8.2.1 Technology Units for ATEX Zone 22 3D

SK TI4-TU-BUS(-C)

275280000 / (275280500)

x

SK TI4-TU-NET(-C)

275280100 / (275280600)

x

SK TU4-PBR(-C)

275281100 / (275281150)

x

SK TU4-CAO(-C)

275281101 / (275281151)

x

SK TU4-DEV(-C)

275281102 / (275281152)

x

SK TU4-24V-123-B(-C)

275281108 / (275281158)

x

SK TU4-24V-140-B(-C)

275281109 / (275281159)

x

SK TU4-PBR-M12(-C)

275281200 / (275281250)

x

SK TU4-CAO-M12(-C)

275281201 / (275281251)

x

SK TU4-DEV-M12(-C)

275281202 / (275281252)

X

SK TU4-PNT(-C)

275281115 / (275281165)

x

SK TU4-ECT(-C)

275281117 / (275281167)

x

SK TU4-POL(-C)

275281118 / (275281168)

x

SK TU4-EIP(-C)

275281119 / (275281169)

x

SK CU4-24V-123-B

275271108

x

SK CU4-24V-140-B

275271109

x

SK CSX-3H

275281013

x

SK PAR-3H

275281014

x

be opened in an atmosphere containing

2 Assembly and installation

Name Part Number

2.8.2.2 Customer Units for ATEX Zone 22 3D

Name Part Number

Approved for

ATEX Zone 22 3D

Approved for

ATEX Zone 22 3D

Not approved for

ATEX Zone 22 3D

Not approved for

ATEX Zone 22 3D

2.8.2.3 Hand-held Technology Units for ATEX Zone 22 3D

All hand-held technology units are not approved for continuous use in the ATEX Zone 22 3D. The may

therefore only be used dur ing comm issioning or f or maintenanc e purposes, if it is ensured tha t no explosive

dust atmosphere exists.

Name Part Number

Approved for

ATEX Zone 22 3D

Not approved for

ATEX Zone 22 3D

ATTENTION

The diagnostic opening of the basic unit for the connection of a hand-held

technology unit or a PC must not

explosive dust.

BU 0135 GB-2713 Pre-series version 37

Page 38

SK 105E…175E Motor Starter Manual

SK TIE4-WMK-1

275274000

x

SK TIE4-WMK-2

275274001

x

SK TIE4-WMK-TU

275274002

x

SK TIE4-HAN10E

275274100

x

SK TIE4-HANQ5

275274110

x

SK TIE4-SWITCH

275274610

x

SK TIE4-M12-M16

275274510

x

SK TIE4-M12-PBR

275274500

x

SK TIE4-M12-AS1

275274502

x

SK TIE4-M12-AS1-AUX

275274513

x

SK TIE4-M12-INI

275274503

x

SK TIE4-M12-POW

275274507

x

2.8.2.4 Other options

M12 sockets and p lugs f or i nst allat ion in th e h ous i ng b ox of the bas ic de vice or in technology units may only

be used if they are approved for use in ATEX Zone 22 3D.

Name Part Number

Approved for

ATEX Zone 22 3D

Not approved for

ATEX Zone 22 3D

2.8.3 Commissioning information

For Zone 22 the cable glands must at least comply with protec tion class IP 55. Unused open ings must be

closed with blank screw caps suitable for ATEX Zone 22 3D (minimum protection class IP 55).

The motors are protected against overheating by means of the motor starter. This is carried out by the

evaluation of the motor PTC in the motor starter. In order to ensure this function, the PTC must be

connected to the intende d input (Terminal 38/39 control term inal plug connector) . In addition, care m ust be

taken that the nominal current of the motor is adjusted accordingly.

Overview of the necessary parameter settings:

Parameter Setting value Factory setting Description

P203

Motor data

P535

I²t motor

Data according to rating

plate

According to motor and

ventilation

[xxx]

[0]

If a 4-pole NORD motor is not used, the nominal

current on the rating plate must be entered here.

The I²t- monitoring of the motor must be switched

on. The set values depend on the type of

ventilation and the motor used. See

Planning Guideline No.: 605 2101

38 Pre-series version BU 0135 GB-2713

Page 39

2.8.4 EC Declaration of Conformity (in preparation)

2 Assembly and installation

BU 0135 GB-2713 Pre-series version 39

Page 40

SK 105E…175E Motor Starter Manual

tor starter)

2.9 Outdoor installation

Series SK 1x5E motor starters and technology units can be installed outdoors under the following

conditions:

• IP66 version (See Special Measures, Section 1.7)

• UV-resistant blind plugs and viewing window.

The UV-resistant bli nd plugs and ins pection glasses are p art of the ATEX k it for the SK 1x5 E. This means

that with the use of the ATEX option for IP66 (Sec tion 2.8) all of the c ond itions f or outdo or ins tallat ion of the

device are fulfilled.

It is recommended that the motor starter is provided with a roof.

NOTE

The diaphragm valve (b ag enclosed with the I P66 version of the m o

compensates for pressure differences between the interior of the device and the

environment and at the sa m e time prevents the entr y of m oistur e. If it is f itted i n

an M16 cable gland of the m otor starter , care m ust be tak en that the diaphra gm

valve does not come into contact with standing water.

40 Pre-series version BU 0135 GB-2713

Page 41

3 Display and control

Potentiometer P3

Potentiometer P2

Diagnostic connection

PROFIBUS address

LED for AS interface

Potentiometer P1

Status LED DS

Diagnostic interface

Potentiometer P4

3 Display and control

By the use of various m odules for displa y, control and parameterisation, the SK 1x 5E can be e asil y adapted

to various requirements.

No additional control units are required for simple commissioning. Alpha-numeric displays and control

modules can be used for the ada ptation of individu al parameters. For more complex tasks, c onnection to a

PC system and the use of NO RD CON parameterisation software is available. T he cover of the de vice m ust

be removed in order to access the diagnostic interface.

As supplied, without a dditional options, the diagnos tic LEDs are externally visib le. These signal the actual

device status. 4 potentiometers and 4 DIP switches are provided in order to set the most important

parameters. Of these, two potentiometers can also be accessed with the housing cover closed via the

diagnostic connection.

BU 0135 GB-2713 Pre-series version 41

Page 42

SK 105E…175E Motor Starter Manual

Name

Colour

Description

Signal status

Meaning

Master in

l is therefore always "green".

3.1 Diagnostic LEDs on the motor starter

The motor starter gen erates operating st atus messages. T hese messages ( warnings, errors, s witching statuses, measurem ent data) can be displayed w ith parameterisation tools (e. g. ParameterBox - see Section

3.2) (Parameter group P7xx).

To a limited extent, the messages are also indicated via the diagnostic and status LEDs.

Diagnostic LEDs

LED

DS dual

red/green

green on Starter is switched on (running)