Page 1

GB

BU 0000

NORD CON

Manual for NORD CON

Page 2

NORD CON Manual

1 Introduction

...................................................................................................................................... 6

.......................................................................................................................................61.1 About NORD CON

.......................................................................................................................................61.2 How to use NORD CON

2 Graphic user interface

...................................................................................................................................... 8

.......................................................................................................................................82.1 Structure of the program interface

.......................................................................................................................................92.2 Main menu

..............................................................................................................................................102.2.1 Category "File"

..............................................................................................................................................112.2.2 Category "Edit"

..............................................................................................................................................122.2.3 Category "Device"

..............................................................................................................................................132.2.4 Category "View"

..............................................................................................................................................142.2.5 Category "Extras"

..............................................................................................................................................152.2.6 Category "Help"

.......................................................................................................................................152.3 Toolbars

..............................................................................................................................................162.3.1 Standard

..............................................................................................................................................172.3.2 Device

..............................................................................................................................................172.3.3 Start

.......................................................................................................................................182.4 View "Project"

..............................................................................................................................................192.4.1 Structure of popup menu

.......................................................................................................................................202.5 View "Messages"

.......................................................................................................................................212.6 View "Remote"

.......................................................................................................................................212.7 Docking and Undocking

3 Communication

...................................................................................................................................... 27

.......................................................................................................................................273.1 Overview

.......................................................................................................................................273.2 USS

..............................................................................................................................................273.2.1 General settings

..............................................................................................................................................283.2.2 Bus scan

4 Parameterization

...................................................................................................................................... 30

.......................................................................................................................................304.1 Overview

.......................................................................................................................................304.2 Parameter Viewing

.......................................................................................................................................314.3 How to manipulate parameters

.......................................................................................................................................324.4 Selective parameterization

© NORD DRIVESYSTEMS 2012BU 0000 GB

2

Page 3

.......................................................................................................................................334.5 Off-line Parameterization

.......................................................................................................................................334.6 How to compare parameters

.......................................................................................................................................344.7 Parameter upload from device

.......................................................................................................................................344.8 Parameter download to device

Table of Contents

5 Control

..............................................................................................................................................375.3.1 Overview

..............................................................................................................................................385.3.2 Control

..............................................................................................................................................395.3.3 Management of setting values and actual values

..............................................................................................................................................395.3.4 Formatting of Setpoint and/or actual value

..............................................................................................................................................405.3.5 Control word

..............................................................................................................................................415.3.6 Status word

6 Remote

...................................................................................................................................... 35

.......................................................................................................................................355.1 Overview

.......................................................................................................................................365.2 Standard control

.......................................................................................................................................375.3 Detailed control

...................................................................................................................................... 42

.......................................................................................................................................426.1 Overview

.......................................................................................................................................436.2 Standard

.......................................................................................................................................436.3 NORDAC SK200E

.......................................................................................................................................446.4 NORDAC SK 700/500/300 E

.......................................................................................................................................466.5 NORDAC vector mc

.......................................................................................................................................476.6 NORDAC vector ct

7 Oscilloscope

...................................................................................................................................... 47

.......................................................................................................................................477.1 Overview

.......................................................................................................................................487.2 Display

.......................................................................................................................................497.3 Handling

.......................................................................................................................................517.4 Measurement

.......................................................................................................................................517.5 Save and Print

8 Macro editor

...................................................................................................................................... 52

.......................................................................................................................................528.1 Graphic user interface

..............................................................................................................................................528.1.1 Window "Variables"

..............................................................................................................................................538.1.2 Window "Properties"

..............................................................................................................................................558.1.3 Window "Log"

.......................................................................................................................................568.2 Working with macros

© NORD DRIVESYSTEMS 2012BU 0000 GB

3

Page 4

NORD CON Manual

..............................................................................................................................................568.2.1 Create a new macro

..............................................................................................................................................568.2.2 Open a macro

..............................................................................................................................................568.2.3 Save a macro

..............................................................................................................................................568.2.4 Copy from instruction

..............................................................................................................................................568.2.5 Cut from instruction

..............................................................................................................................................568.2.6 Paste from instruction

..............................................................................................................................................578.2.7 Delete from instruction

..............................................................................................................................................578.2.8 Search and replace

..............................................................................................................................................578.2.9 Shift up a instruction

..............................................................................................................................................578.2.10 Shift down a instruction

..............................................................................................................................................578.2.11 Generate new instructions

.......................................................................................................................................598.3 Scheduler

..............................................................................................................................................598.3.1 Run a macro

..............................................................................................................................................598.3.2 Cancel a macro

..............................................................................................................................................598.3.3 Execute next instruction

9 Settings

...................................................................................................................................... 60

.......................................................................................................................................609.1 Overview

.......................................................................................................................................619.2 Interface

.......................................................................................................................................619.3 Device report

.......................................................................................................................................629.4 Control

.......................................................................................................................................639.5 Project

.......................................................................................................................................649.6 Directories

.......................................................................................................................................659.7 Macro editor

.......................................................................................................................................659.8 Parameter

10 Messages

...................................................................................................................................... 66

.......................................................................................................................................6610.1 Errors and informations

11 Getriebebau Nord

...................................................................................................................................... 69

.......................................................................................................................................6911.1 NORD In Short

.......................................................................................................................................7011.2 NORD corporate history

.......................................................................................................................................7211.3 Frequency Inverters

..............................................................................................................................................7211.3.1 General

..............................................................................................................................................7211.3.2 NORDAC SK 200 E

..............................................................................................................................................7311.3.3 NORDAC SK 300 E

© NORD DRIVESYSTEMS 2012BU 0000 GB

4

Page 5

Table of Contents

..............................................................................................................................................7611.3.4 NORDAC SK 500 E

..............................................................................................................................................7811.3.5 NORDAC SK 700 E

Index

........................................................................................................................................................83

© NORD DRIVESYSTEMS 2012BU 0000 GB

5

Page 6

NORD CON Manual

Attention

For the parameterization and controlling of the devices with NORD CON, your PC requires a

serial interface.

1 Introduction

1.1 About NORD CON

NORD CON is a PC program intended to control and parameterizes the NORDAC vector

Frequenzumrichter inverters produced by Getriebebau NORD and option modules.

With NORD CON, up to 31 frequency inverters can be controlled simultaneously via the

integrated RS485 interface. Communication with the frequency inverters is handled by the PC's

serial interface.

To enable trial runs or system start-ups, the connected frequency inverters can be controlled

via the PC. The program also provides for continuous monitoring of the current status of the

frequency inverter while these activities are going on. Complete process sequences can be

developed using macros.

With NORD CON, you can perform, document, and save the parameter settings of a frequency

inverter which will be read out by the inverter or transmitted to it respectively. Parameter

databases can be created or manipulated off-line - i.e. without a frequency inverter being

connected.

The program further provides for remote control of the connected frequency inverters. For the

frequency inverter to be remote-controlled the operating unit of the type in question is simulated

on the PC. This is a convenient way of operating devices which are either difficult to access or

haven't got an operating unit themselves.

1.2 How to use NORD CON

1. Installation

Please start the installation program of NORD CON on the enclosed CD or load the installation

program from the Internet ("http://www2.nord.com/cms/de/documentation/software/softwareoverview.jsp"). Enter all necessary information and install NORD CON into the standard

directory.

2. Connect

If the frequency inverter is equipped with an RS232 optional interface, it can be directly

connected to the PC with a serial 1-1 cable. In this case, only one frequency inverter can be

connected. Each NORDAC vector Frequenzumrichter frequency inverter features an

integrated RS485 interface which can be activated via the control terminals. This interface

allows for configuration of a master/slave bus system with up to 31 devices max. For NORD

BU 0000 GB

6

Page 7

Introduction

Attention

If several devices are operated simultaneously, make absolutely sure that a unique USS

address is assigned to each of the devices connected, and that all of them have the same baud

rate setting (see also Operating Instructions of the frequency inverter type involved).

CON to be connected to such a bus, an RS232 - RS485 converter will be required.

3. Run NORD CON

In order to start NORD CON, you use the shortcut "NORD CON start" or "Start->Program-

>Nord->NORD CON 2.1->NORD CON".

4. Setup of the communication module

In order to set the communication parameters, one must select the appropriate module in the

project view. Over the menu entry "Device-> Parameterize" the parameter dialog of the module

can be opened. In the edit field "Port" must be insert the correct COM port number. After that

you have to push the button "Apply". Additional settings are not necessary for the first

application and the window can be closed.

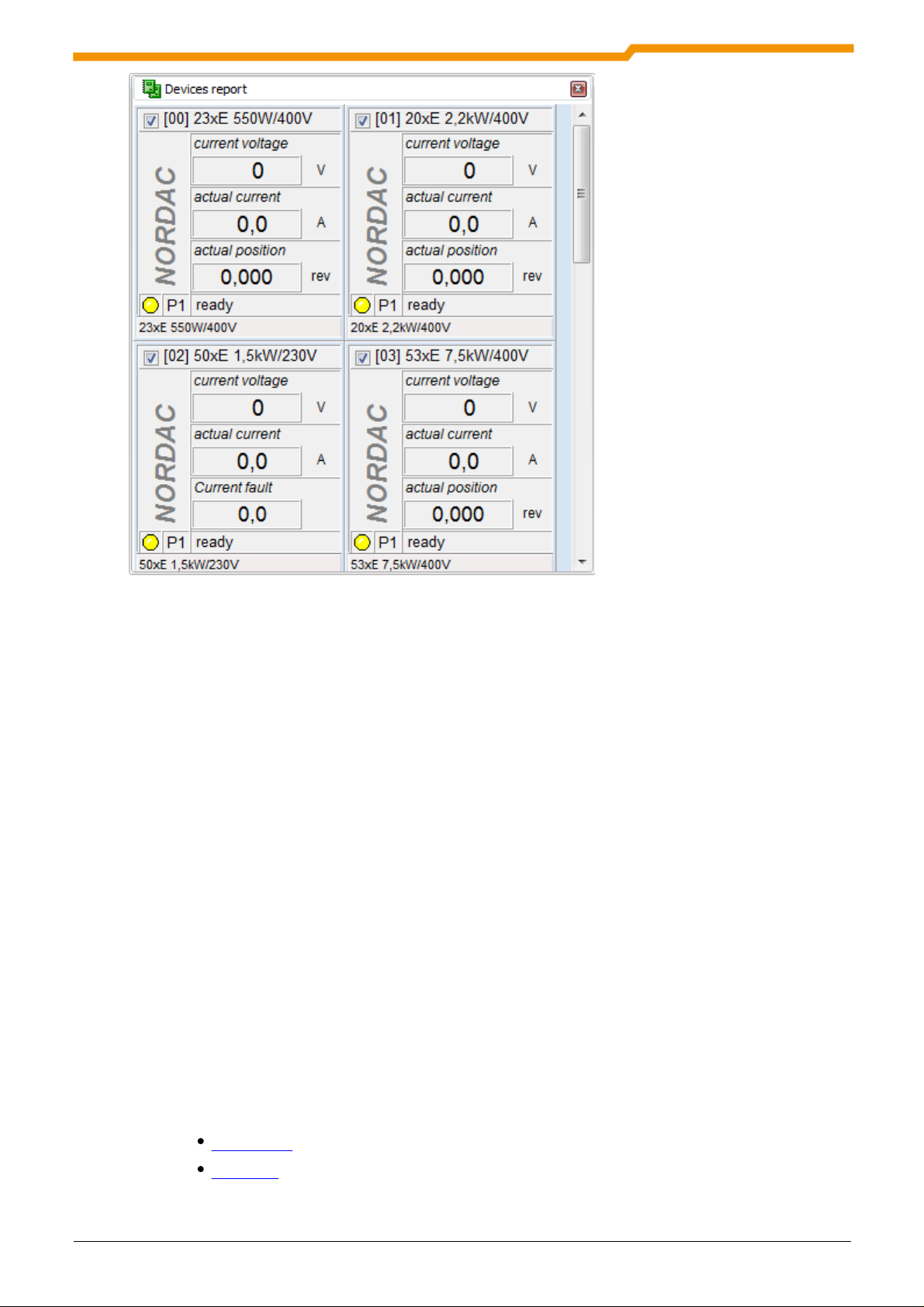

5. Bus scan

After the start of bus scan, all ready and connected devices are searched for. All found devices

are represented in the project tree and in the equipment overview. Subsequently, the first device

in the list is marked and the users can use all device-specific functions.

BU 0000 GB

7

Page 8

NORD CON Manual

Main Menu

Toolbars

6. Work with the devices

The user can now select the device by clicking the device in the device overview or in the

project tree. Functions, like control or parametrizes, are available in the popup menu of the

project tree, the tool bar or the main menu.

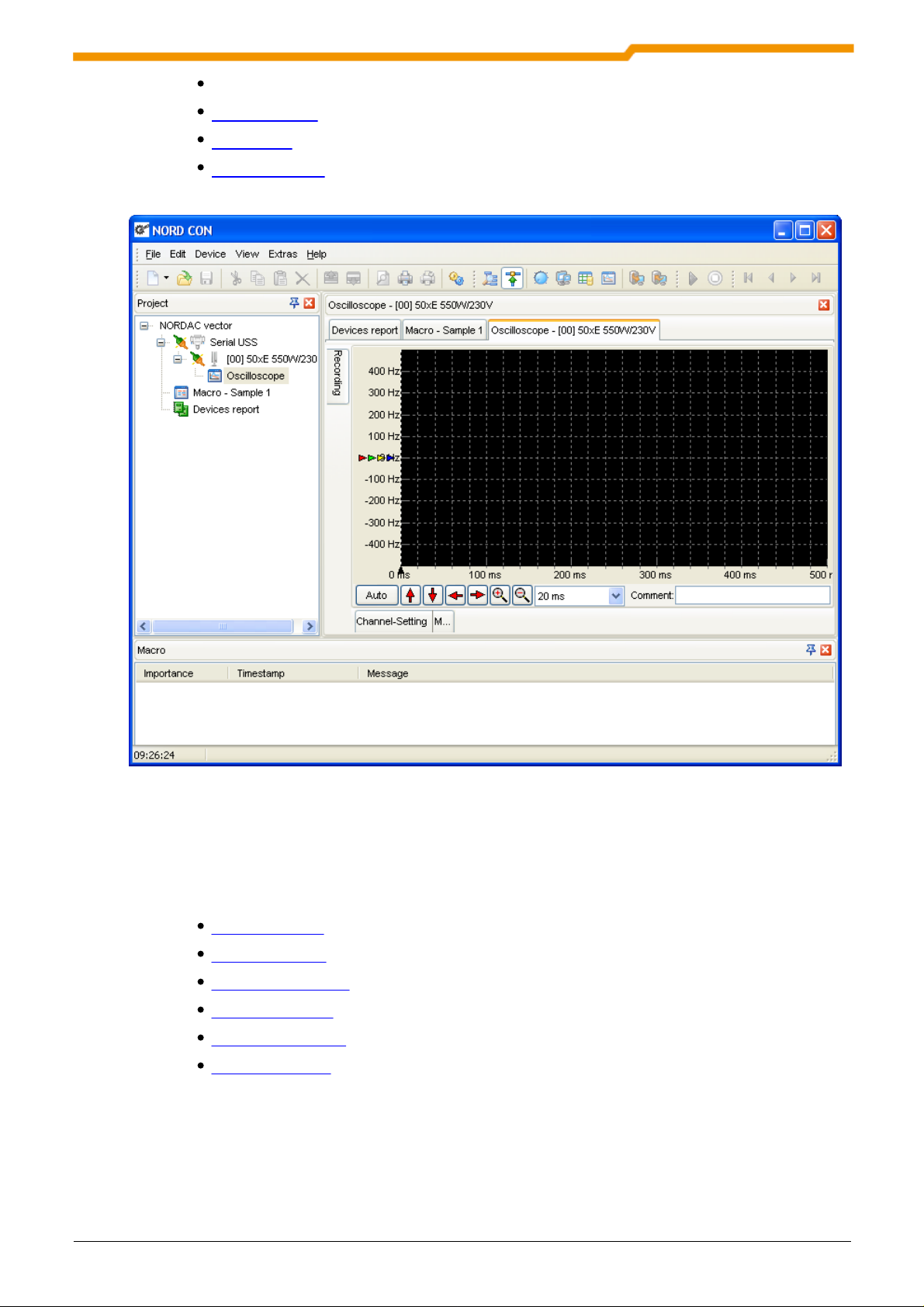

2 Graphic user interface

2.1 Structure of the program interface

If you run "NORD CON" for the first time, the window shown down is opened. The window

consists of main menu, toolbars, work area, and the different views. In the work area the

different editor windows like parameter windows or macros are shown. The windows can be

positioned freely or be docked at the sides of the work area. In order to change the position of a

docked window, click on the header bar of the window and keep the mouse button pressed.

Subsequently, the new position can be specified with the pointer of mouse. A colored rectangle

shows the current position and dock condition. After releasing the left mouse button, the actual

action is implemented. In addition, the user can dock or undock the window by clicking on the

header bar. The layout is stored when closing application and resumed with the restart.

BU 0000 GB

The interface is divided into the following areas:

8

Page 9

Graphic user interface

Working Area

View "Project"

View "Log"

View "Remote"

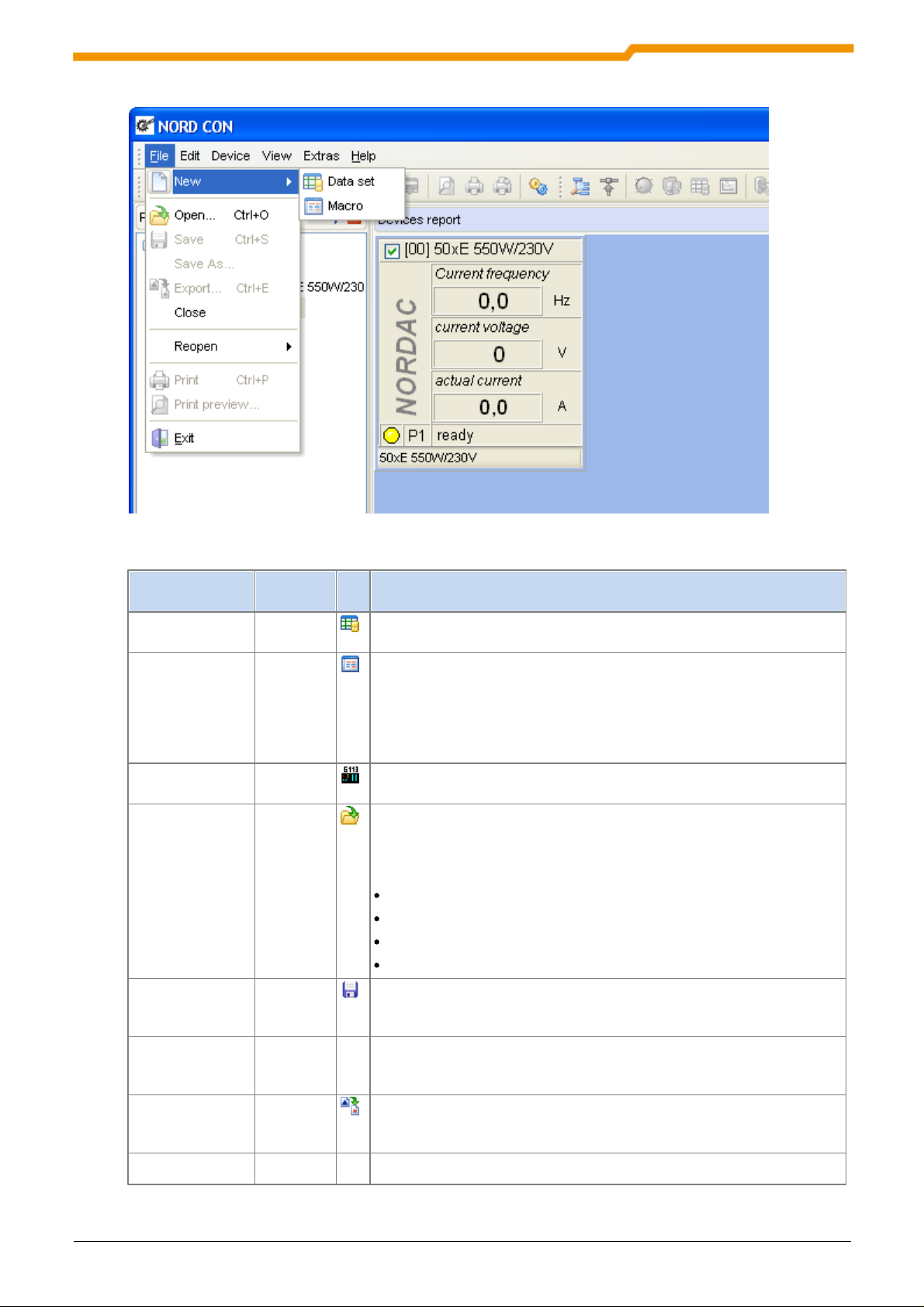

Category "File"

Category "Edit"

Category "Device"

Category "View"

Category "Extras"

Category "Help"

2.2 Main menu

The main menu is the central place for all actions of application. All editor windows register their

window-specific actions there. The actions are divided in categories.

BU 0000 GB

9

Page 10

NORD CON Manual

Name of action

Combinatio

n of keys

Icon

Description

New dataset

The action opens the parameter window for a new device. The user must

select the desired device in a previous window.

New macro

The action opens the macro editor with a new document. If the macro

window is already opened, the user can store the current document.

Attention:

In the current version, only one macro window can be opened!

PLC program

The action opens the PLC editor with an empty document. If a PLC

program is already opened, the user can store the current document.

Open

Ctrl + O

The action opens the file choice dialog in order to open a stored

document. The user selects a document type with the file filter, and selects

the file afterwards. The following types are supported:

Parameter files (*.ndbx, *.db (V1.27))

Scope files (*.scox, *.sco (V1.27))

Macro files (*.ncmx, *.ncm (V1.27))

PLC files (*.awlx, *.awl, *.nstx)

Save

Ctrl + S

The action stores the current document. The action is passed on to the

active editor window and implemented there. Depending upon the type of

editor, different operations can be implemented.

Save as...

The action stores the current document with a new name. The action is

passed on to the active editor window and implemented there. Depending

upon the type of editor, different operations can be implemented.

Export

Ctrl + E

The action exports the data active editor windows into a file. The action is

passed on to the active editor window and implemented there. Depending

upon the type of editor, different operations can be implemented.

Reopen

The action contains a submenu in which the opened last documents are

2.2.1 Category "File"

BU 0000 GB

10

Page 11

Name of action

Combinatio

n of keys

Icon

Description

listed. History is limited to 5. When clicking on one of the files, it is opened

again.

Print

Ctrl + P

The action is passed on to the active editor window and implemented

there. Depending upon the type of editor, different operations can be

implemented. This action is deactivated if no editor window is opened or

the editor does not support the action.

Print preview...

The action opens a print preview for the active editor. Depending upon

editor, the printing preview can be differently developed. This action is

deactivated if no editor window is opened or the editor does not support

the action.

Quit

The action closes application.

Note:

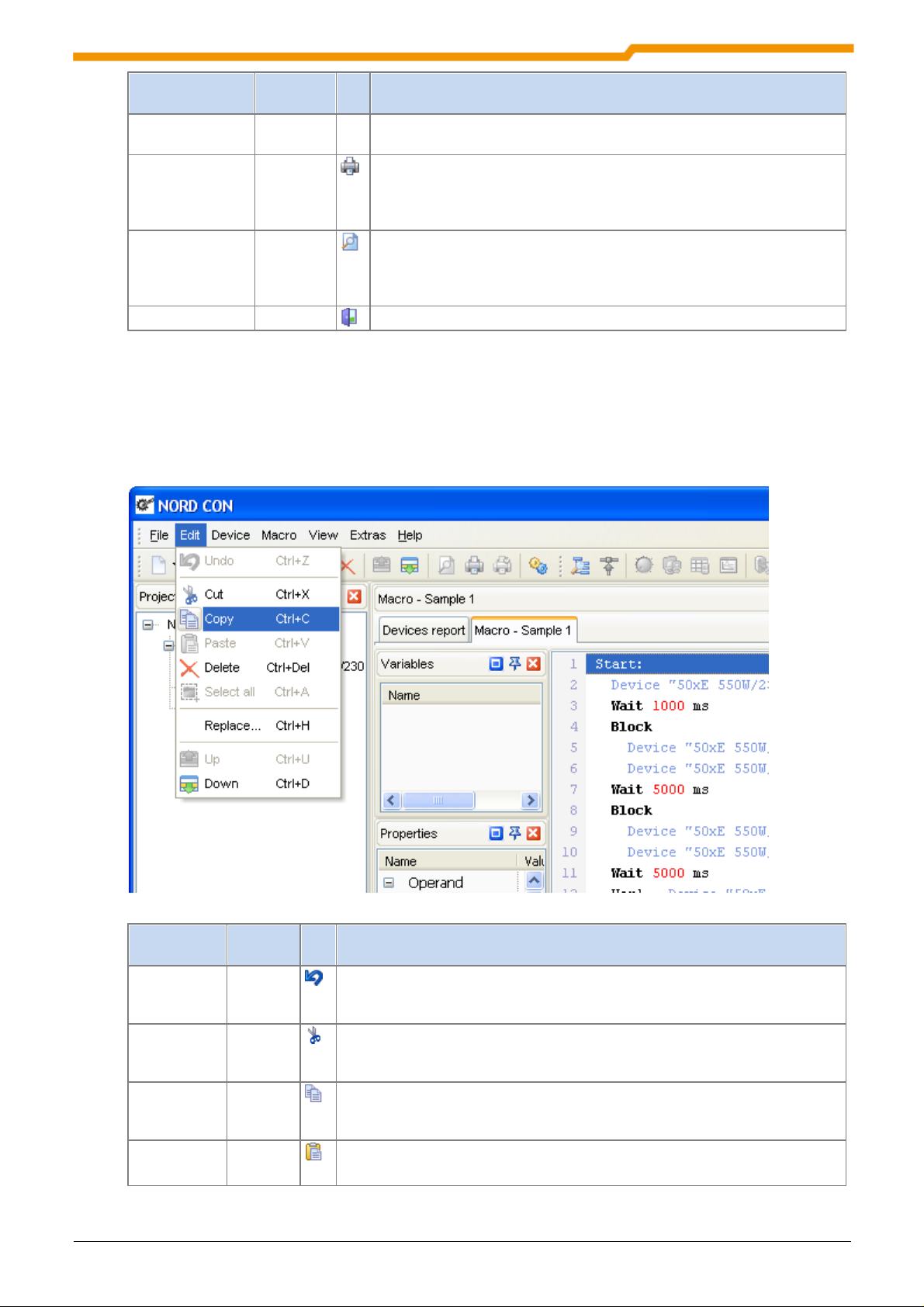

Name of

action

Combinati

on of keys

Icon

Description

Undo

Ctrl+Z

The action undoes the last action. The action is passed on to the active editor

window and implemented there. Depending upon the type of editor, different

operations can be implemented.

Cut

Ctrl+X

The action cuts the selected object and copies it into the clipboard. The action is

passed on to the active control member and implemented there. Depending

upon the type of editor, different operations can be implemented.

Copy

Ctrl + C

The action copies the selected object into the clipboard. The action is passed

on to the active control member and implemented there. Depending upon the

type of editor, different operations can be implemented.

Paste

Ctrl + V

The action copies contents of the clipboard to the selected position. The action

is passed on to the active control member and implemented there. Depending

A action is deactivated if no editor window is opened or if the editor does not support the action.

2.2.2 Category "Edit"

Graphic user interface

BU 0000 GB

11

Page 12

NORD CON Manual

Name of

action

Combinati

on of keys

Icon

Description

upon the type of editor, different operations can be implemented.

Note:

The action is deactivated if the current control element does not support this

action or the contents of the clipboard cannot be inserted.

Delete

Ctrl + Del

The action deletes the selected object. The action is passed on to the active

control and implemented there. Depending upon the type of editor, different

operations can be implemented.

Select all

Ctrl + A

The action selects all objects of the active control.

Replace...

Ctrl + H

The action searches for the indicated text and replaces these then by other text.

In a dialog, the appropriate option can be adjusted.

Up

Ctrl + U

The action shifts the delected object one position upward.

Down

Ctrl + D

The action entry shifts the delected object one position downward.

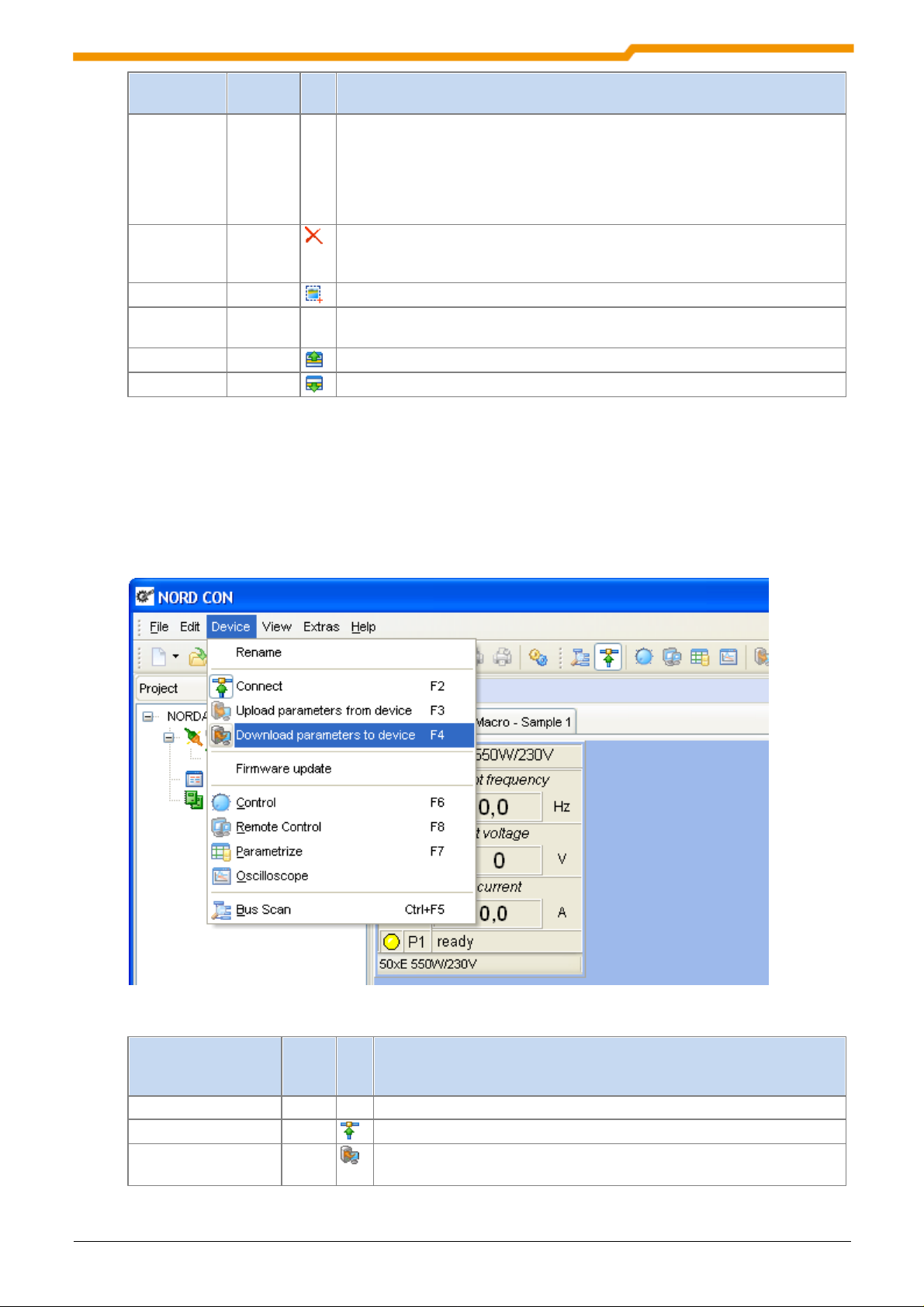

Name of action

Combin

ation of

keys

Icon

Description

Rename

With the action the user can change the name of the selected device.

Connect

F2

The action starts or stops the connection to the selected device.

Upload parameters

from device

F3

The action uploads the parameters from the device to the PC.

Note:

The action is deactivated if the current control element does not support this action.

2.2.3 Category "Device"

BU 0000 GB

12

Page 13

Graphic user interface

Name of action

Combin

ation of

keys

Icon

Description

Download parameters

to device

F4

The action downloads the parameters from the PC to the device.

Update firmware

The action starts the firmware upload program.

Control

F6

The action opens the "control" window of the selected device in the work

area. If the window was already opened, it is brought into the foreground.

Remote

F8

The action opens the "remote" window of the selected device. If the

window was already opened, it is brought into the foreground.

Parameterize

F7

The action opens the "Parameter" window of the selected device in the

work area. If the window was already opened, it is brought into the

foreground.

Oscilloscope

The action opens the "oscilloscope" of the selected device in the work

area. If the window was already opened, it is brought into the foreground.

PLC

The action entry opens the PLC editor of the selected device in the work

area. If the window was already opened, it is brought into the foreground.

Bus scan

Ctrl+F5

The action implements a network scan for the selected communication

module.

Note:

With a network scan, all devices are removed from the device list and all

device-specific windows are closed!

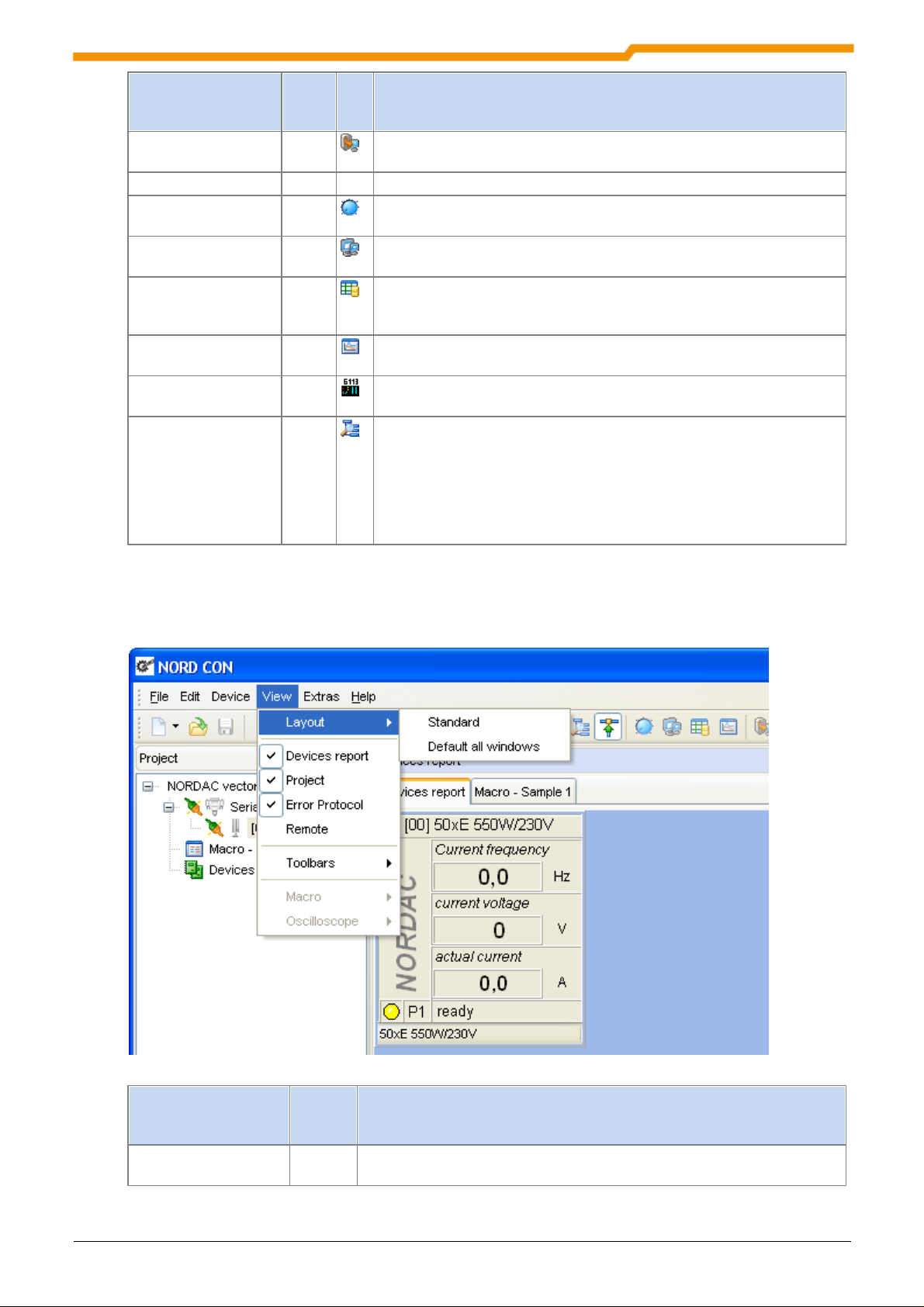

Name of action

Combinat

ion of

keys

Description

Layout -> Standard

The action build the standard - layout of application for all views. The

2.2.4 Category "View"

BU 0000 GB

13

Page 14

NORD CON Manual

Name of action

Combinat

ion of

keys

Description

position of the editor windows is not changed.

Layout -> Standard all

windows

The action build the standard layout of application for all windows including

the work area.

Device report

The action closes or opens the device report.

Project

The action closes or opens the view "project".

Log

The action closes or opens the view "log".

Remote

The action closes or opens the view "remote control".

Toolbar->Standard

The action closes or opens the toolbar "standard".

Toolbar->Device

The action closes or opens the toolbar "device".

Toolbar ->Start

The action closes or opens the toolbar "device".

Macro

The action opens a submenu. In this submenu, all special actions of the

macro editor are listed. The status as well as the execution of the actions is

incumbent on the active macro window. If no window is active, all actions are

deactivated.

Oscilloscope

The action opens a submenu. In this submenu, all special actions of the

oscilloscope are listed. The status, as well as the execution of the actions, is

incumbent on the active oscilloscope. If no window is active, all actions are

deactivated.

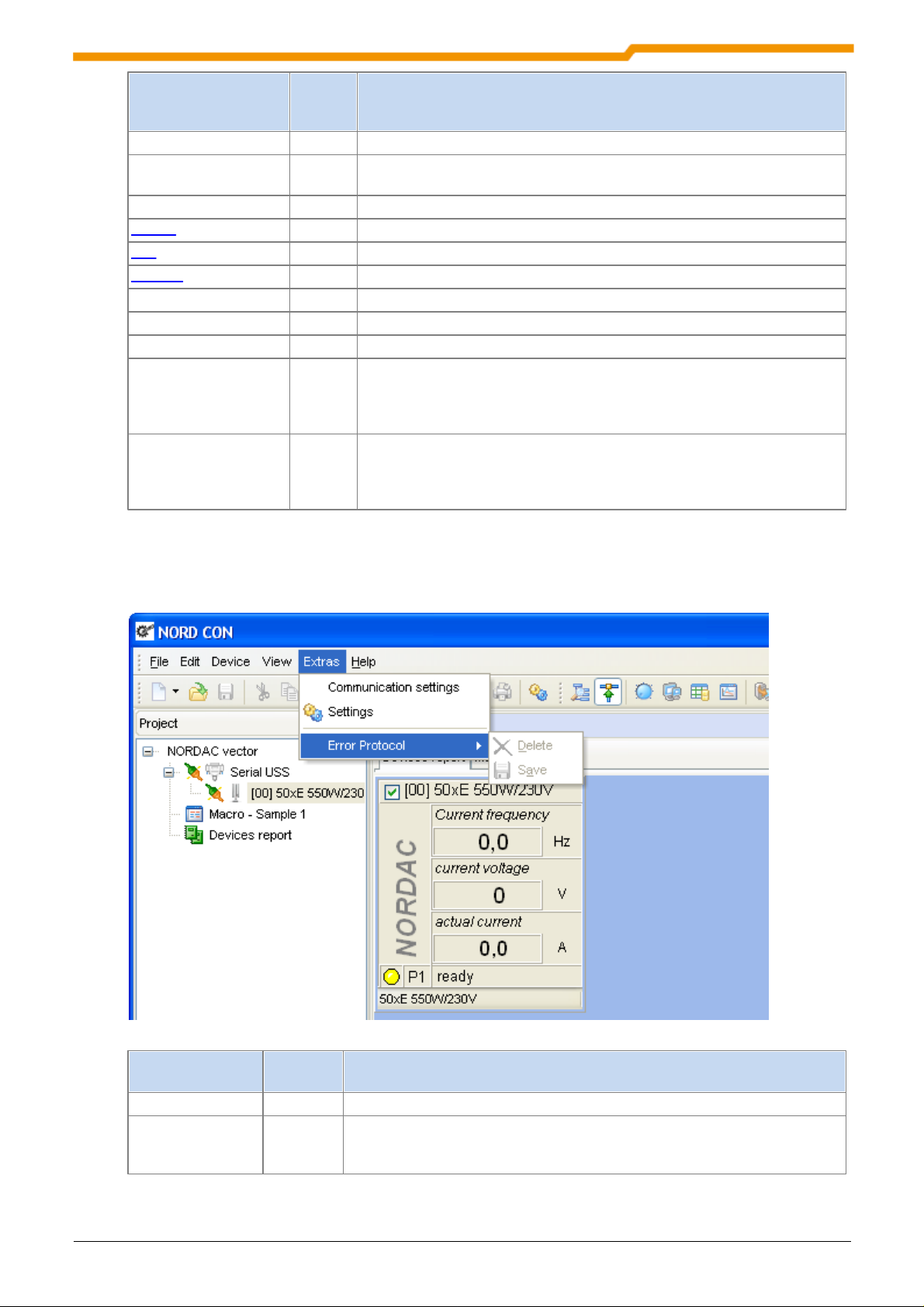

Name of action

Combinatio

n of keys

Description

Settings

The action opens a window to edit the global settings of the program.

Log

The action opens a submenu. In this submenu all special actions of the view

"log" are listed. The status, as well as the execution of the actions, is

incumbent on the view.

2.2.5 Category "Extras"

BU 0000 GB

14

Page 15

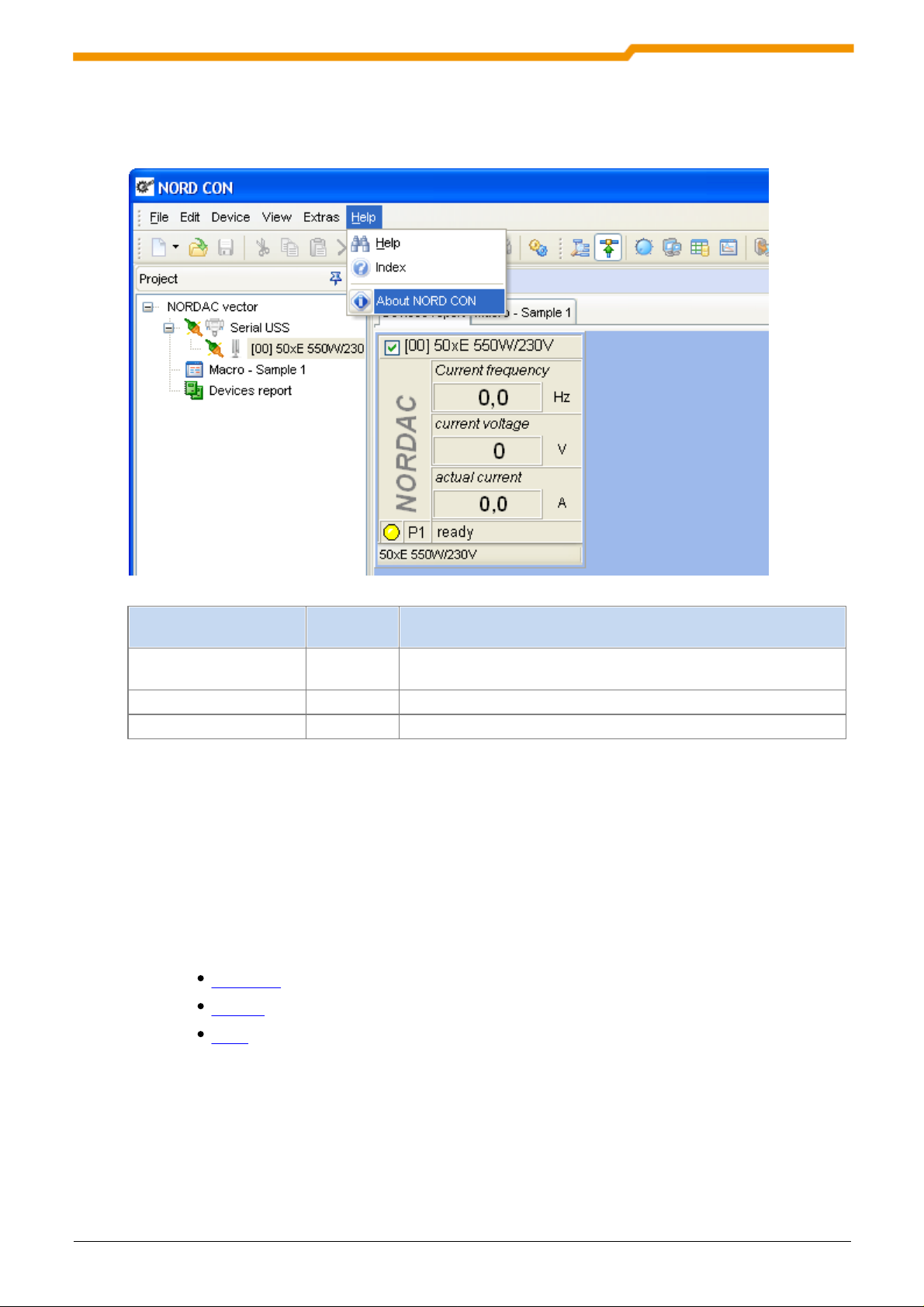

2.2.6 Category "Help"

Name of action

Combination

of keys

Description

HelpF1The action opens online help and selects the register map

"Contents".

Index

The action opens online help and selects the register map "Index".

About NORD CON

The action opens a dialog with the program information.

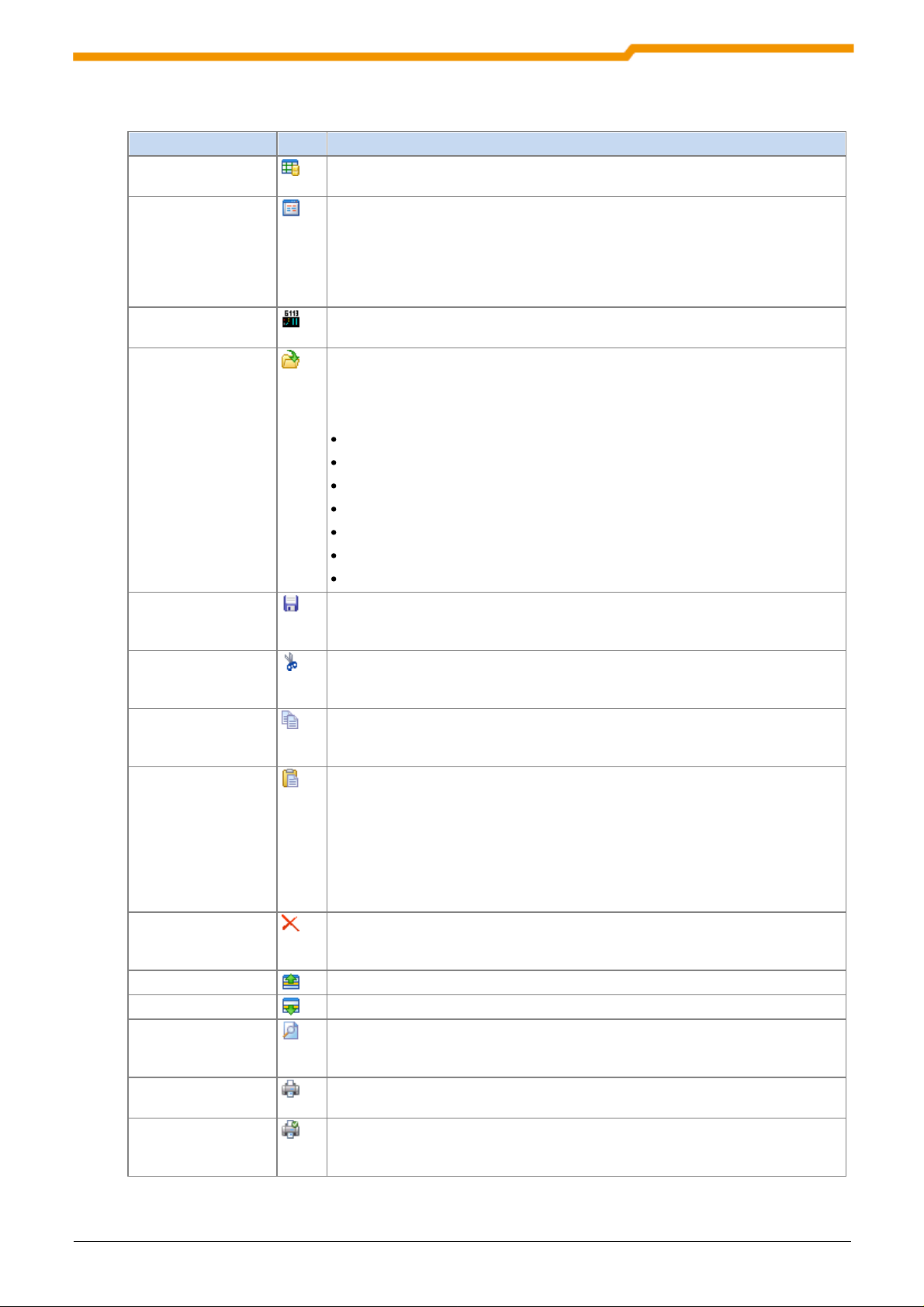

Standard

Device

Start

Graphic user interface

2.3 Toolbars

In the toolbars, the most common actions are available for fast access. By clicking the

appropriate symbol in the bar with the mouse, the desired action is specified.

The following toolbars are available:

BU 0000 GB

15

Page 16

NORD CON Manual

Name of action

Icon

Description

New data set

The action opens the parameter window for a new device. Before the user can

open the dialog, the device must be selected.

New Macro

The action opens the macro editor with an empty document. If a macro is already

open, the user can store the current document.

Attention:

In the current version, only one macro window can be opened!

New PLC program

The action opens the PLC editor with an empty document. If a program is already

opened, the user can store the current document.

Open

The action opens the file dialog in order to open a stored document. The user

selects a document type with the file filter and select the file afterwards. The

following types are supported:

Parameter dataset V1.27 (*.db)

Parameter dataset (*.ndbx)

Scope-File (*.sco)

Scope-File V2.1 (*.scox)

Macro (*.ncmx)

Macro V1.27 (*.ncm)

PLC Program (*.awlx)

Save

The action stores the current document. The action is passed on to the active

editor window and implemented there. Depending upon the type of editor,

different operations can be implemented.

Cut

The action cut the selected object and copies it into the clipboard. The action is

passed on to the active control element and implemented there. Depending upon

the type of editor, different operations can be implemented.

Copy

The action copies the selected object into the clipboard. The action is passed on

to the active control element and implemented there. Depending upon the type of

editor, different operations can be implemented.

Paste

The action copies contents of the clipboard to the selected position. The action is

passed on to the active control member and implemented there. Depending

upon the type of editor, different operations can be implemented.

Note:

The action is deactivated if the current control element does not support this

action or the contents of the clipboard cannot be inserted.

Delete

The action deletes the selected object. The action is passed on to the active

control member and implemented there. Depending upon the type of editor,

different operations can be implemented.

Up

The action shifts the selected object a position upward.

Down

The action shifts the selected object a position downward.

Preview

The action opens a print preview for the active editor. Depending upon editor, the

printing preview can be differently developed. This action is deactivated if no

editor window is opened or the editor does not support the action.

Print

The action print the content from the active editor. This action is deactivated if no

editor window is opened or the editor does not support the action.

Fast print

The action print the content from the active editor without the print dialog. This

action is deactivated if no editor window is opened or the editor does not support

the action.

2.3.1 Standard

BU 0000 GB

16

Page 17

Name of action

Icon

Description

Settings

The action opens a window to edits the global settings of the program.

2.3.2 Device

Name of action

Icon

Description

Bus scan

The action implements a network scan for the selected communication

module.

Note:

With a network scan, all devices are removed from the device list and all device-

specific windows are closed!

Connect

The action connects or disconnects the connection to the selected device.

Control

The action opens "control" window of the selected device in the work area. If the

window was already opened, it is brought into the foreground.

Remote

The action opens "remote" window of the selected device. If the window was

already opened, it is brought into the foreground.

Parameterize

The action opens the "parameter" window of the selected device in the work

area. If the window was already opened, it is brought into the foreground.

Oscilloscope

The action opens the "oscilloscope" of the selected device in the work area. If

the window was already opened, it is brought into the foreground.

Plc

The action opens the PLC editor of the selected device in the work area. If the

window was already opened, it is brought into the foreground.

Upload parameters from

device

The action uploads the parameters from the device to the PC.

Download parameters to

device

The action downloads the parameters from the PC to the device.

Name of

action

Combinati

on of

keys

Icon

Description

PLC settings

The action opens the settings of the PLC.

Compile

Shift + F7

The action starts the translation of a PLC program.

Programming

Shift F8

The action loads a PLC program to the Device.

RunF9The action runs a PLC program or a macro. The action is passed on to the

active editor window and implemented there. Depending upon the type of editor,

different operations can be implemented.

Cancel

F11

The action terminates running a PLC program or macro. The action is passed

on to the active editor window and implemented there. Depending upon the type

of editor, different operations can be implemented.

Next

F12

The action executes the next instruction. The action is passed on to the active

editor window and implemented there. Depending upon the type of editor,

different operations can be implemented.

Graphic user interface

2.3.3 Start

BU 0000 GB

17

Page 18

NORD CON Manual

Name of

action

Combinati

on of

keys

Icon

Description

Debug

Shift + F5

The action runs the PLC program with the debug mode.

The connection to the device is online

The connection to the device is offline

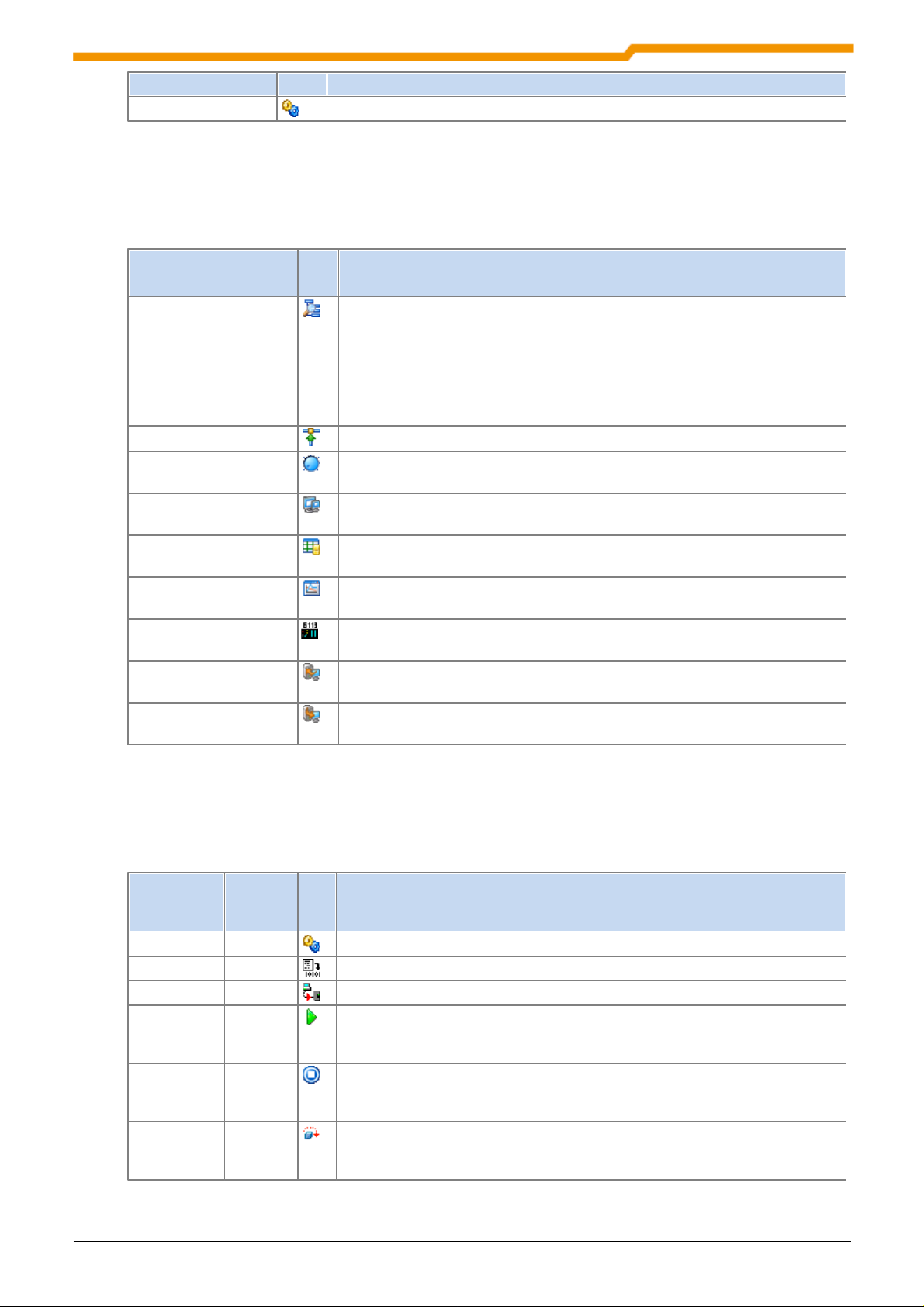

2.4 View "Project"

In View "Project", all devices of the project are shown in a tree structure. It can be closed or

opened with the main menu option "View->Project ". With the help of the mouse, you can

navigate between the individual devices. If the view possesses the input focus, you can

additionally select a device with the arrow keys "up" and "down ". If the pointer of mouse is over

a device entry, a reference about the type of device and fieldbus address is indicated. After the

selection of a device, the user can execute all actions with the tool bar as well as the popup

menu. If an action is shaded grey, the selected devices do not support. The popup menu is

opened by clicking the right mouse button in the view.

Status of device

BU 0000 GB

18

Page 19

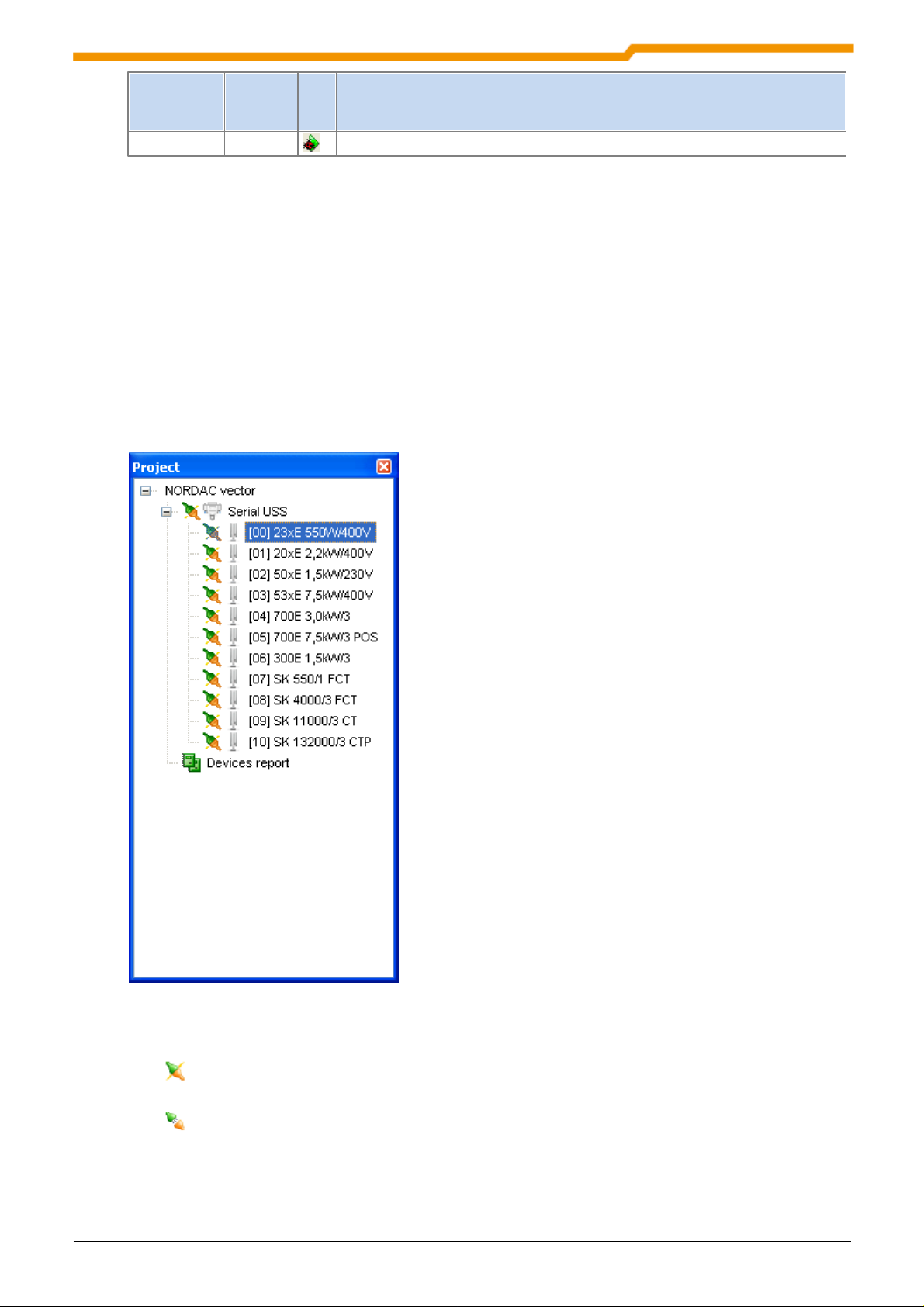

Used topics:

Name of action

Combination

of keys

Description

Rename

With the action the user can change the name of the selected device.

Upload parameters

from device

F3

The action uploads the parameters from the device to the PC.

Download parameters

to device

F4

The action downloads the parameters from the PC to the device.

Update firmware

The action starts the firmware upload program.

Control

F6

The action opens then "control" window of the selected device in the work

area. If the window was already opened, it is brought into the foreground.

Remote

F8

The action opens the „remote" window of the selected device. If the

window was already opened, it is brought into the foreground.

Parameterize

F7

The action opens the "parameter" window of the selected device in the

work area. If the window was already opened, it is brought into the

foreground.

Structure of popup menu, Structure of the program interface, Main menu, Toolbars, View "Log", View "Remote", Docking and Undocking

2.4.1 Structure of popup menu

The representation shows the popup menu of the project view. The menu always refers to the

selected nodes in the project tree.

Graphic user interface

BU 0000 GB

19

Page 20

NORD CON Manual

Name of action

Combination

of keys

Description

Oscilloscope

The action opens the „oscilloscope" of the selected device in the work

area. If the window was already opened, it is brought into the foreground.

PLC

The action opens the PLC editor of the selected device in the work area. If

the window was already opened, it is brought into the foreground.

Bus scan

Ctrl + F5

The action implements a network scan for the selected communication

module.

Note:

With a network scan, all devices are removed from the device list and all

device-specific windows are closed!

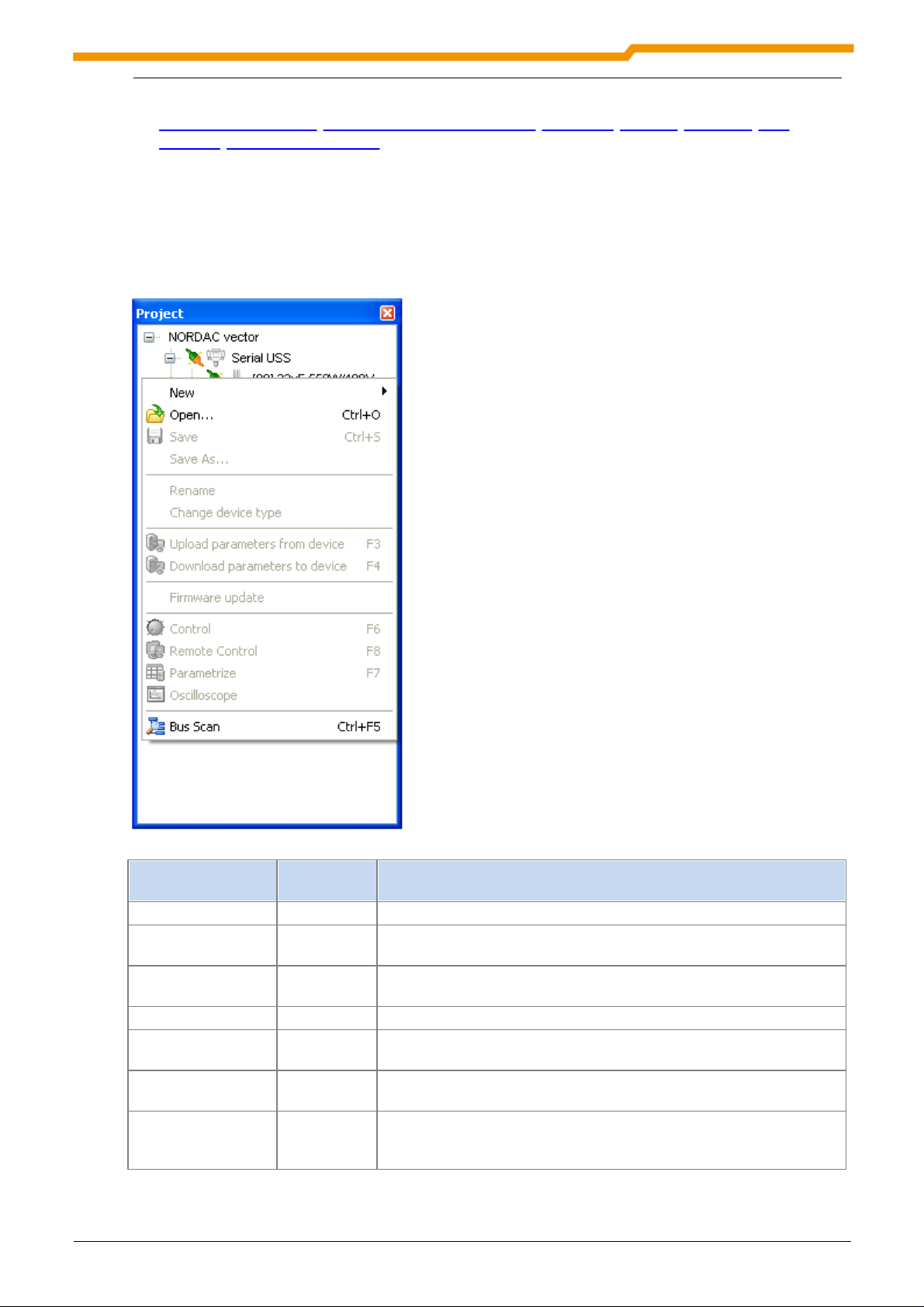

Filter

IconDescription

Error

This filter is enabled, displays all errors. In addition, it shows the number of errors in the caption

of the button.

Warning

This filter is enabled, all warnings are displayed. The number of warnings is displayed in the

caption of the button.

Informati

on

This filter is enabled, all information will be displayed. The number of information is displayed in

the caption of the button.

System

This filter is enabled, all messages of the "System" category are displayed.

Commun

ication

This filter is enabled, all messages of the "Communications" category are displayed.

PLC

This filter is enabled, all messages of the "PLC" category are displayed.

Macro

This filter is enabled, displays all messages in the "Macro" category.

Paramet

er

This filter is enabled, displays all messages in the "Parameter" category.

Name of action

Description

Delete

The action deletes the list.

2.5 View "Messages"

The view contains a list of all „NORD CON" messages. The entries are displayed by default

time ascending. The sortation can be adjusted by clicking on a column header. Following filters

available are for the filtering:

The messages can be saved or deleted via the popup menu (right mouse button). These

actions can be carried out via the main menu ("Extras/Messages").

BU 0000 GB

20

Page 21

Name of action

Description

Save

The action stores the entries into a file.

2.6 View "Remote"

Type of window

Rule

View of main window(e.g. Project, Logs,

Remote)

The views of the main window can be docked only to the left, right

and/or lower edge of the work area. Within these windows, there are

no rules and the user can select the position freely.

Editor window (e.g. Macro editor, Parameter

window, Oscilloscope)

The editor windows can only be docked into the work area. The

adjustment is fixed however on down and/or above, or as register

map.

Views of the Macro editor

The views of the macro editor can be docked only to the macro

window. The adjustment here is fixed on left, right or down. Within

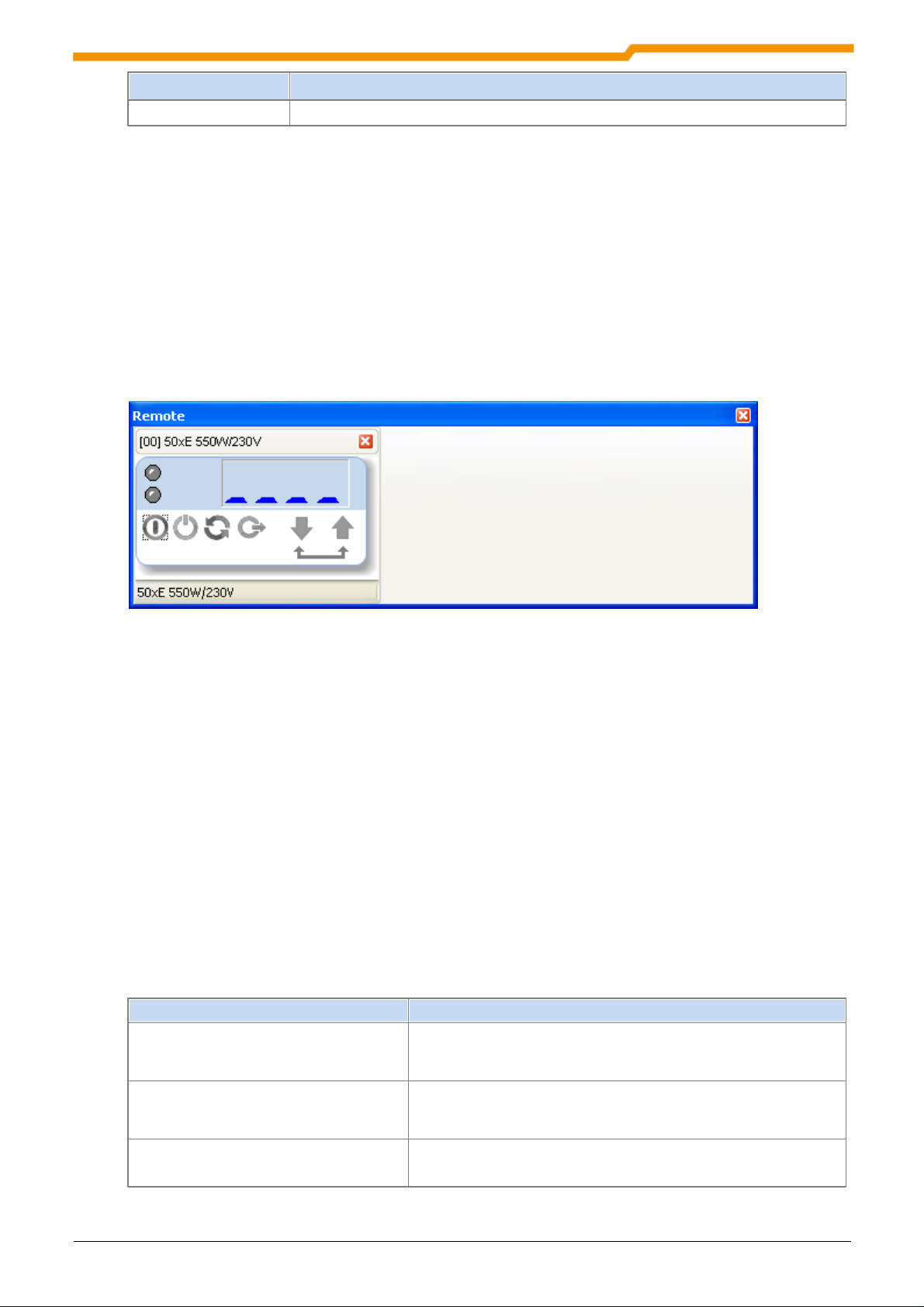

The view "remote" contains all windows of the function „Remote". The view opens automatically

when opening the first window and closes after closing the latest. The view can be docked or

undocked like all views to the work area. If the view was closed by the user, it can be opened by

the action "Remote" again. The new windows are always docked to the left side of the last

window. With the help of the mouse, it can be undocked or docked again. If the view is opened

for the first time with the menu "View->Remote", each device in the list the window "Remote" is

opened automatically.

Graphic user interface

Note:

Windows of type "Remote" can be docked only into the view "Remote".

2.7 Docking and Undocking

With the new design of NORD CON, the user has the possibility to adapt the layout of the

surface to their own requirements. In principle, you can undock each view and editor window

and position them freely on the screen. For this, the user must press the left mouse button over

the title border and pull the colored rectangle to the desired position. After releasing the mouse

button, the view or editor windows remains in those positions as independent windows. With

the editor windows, there is additionally the possibility - with the popup menu, which opens

when clicking with the right mouse button on the title border, to undock the windows. The

docking functions are similar to the undocking functions. The colored rectangle indicates in

each case the current docking position.

BU 0000 GB

21

Page 22

NORD CON Manual

Type of window

Rule

the views, no rules are defined.

Views of the oscilloscope

The views of the oscilloscope window can be docked only to the

oscilloscope window. The adjustment here is fixed on left, right or

down. Within the views no rules are defined.

„Remote" windows

"Remote" windows can only be docked to the view "Remote". Here

the adjustment is fixed on left.

Docking position left

BU 0000 GB

22

Page 23

Graphic user interface

Docking position right

BU 0000 GB

23

Page 24

NORD CON Manual

Docking position down

BU 0000 GB

24

Page 25

Graphic user interface

Docking position up

BU 0000 GB

25

Page 26

NORD CON Manual

Docking position tab

BU 0000 GB

26

Page 27

3 Communication

USS over serial interface

3.1 Overview

In order to start a connection to a device, you must insert the appropriate communication

module in the project. After the installation, a USS module is configured. With the action

"Parameterize" the user can modified the parameters of the module.

Presently the following communication modules are supported:

3.2 USS

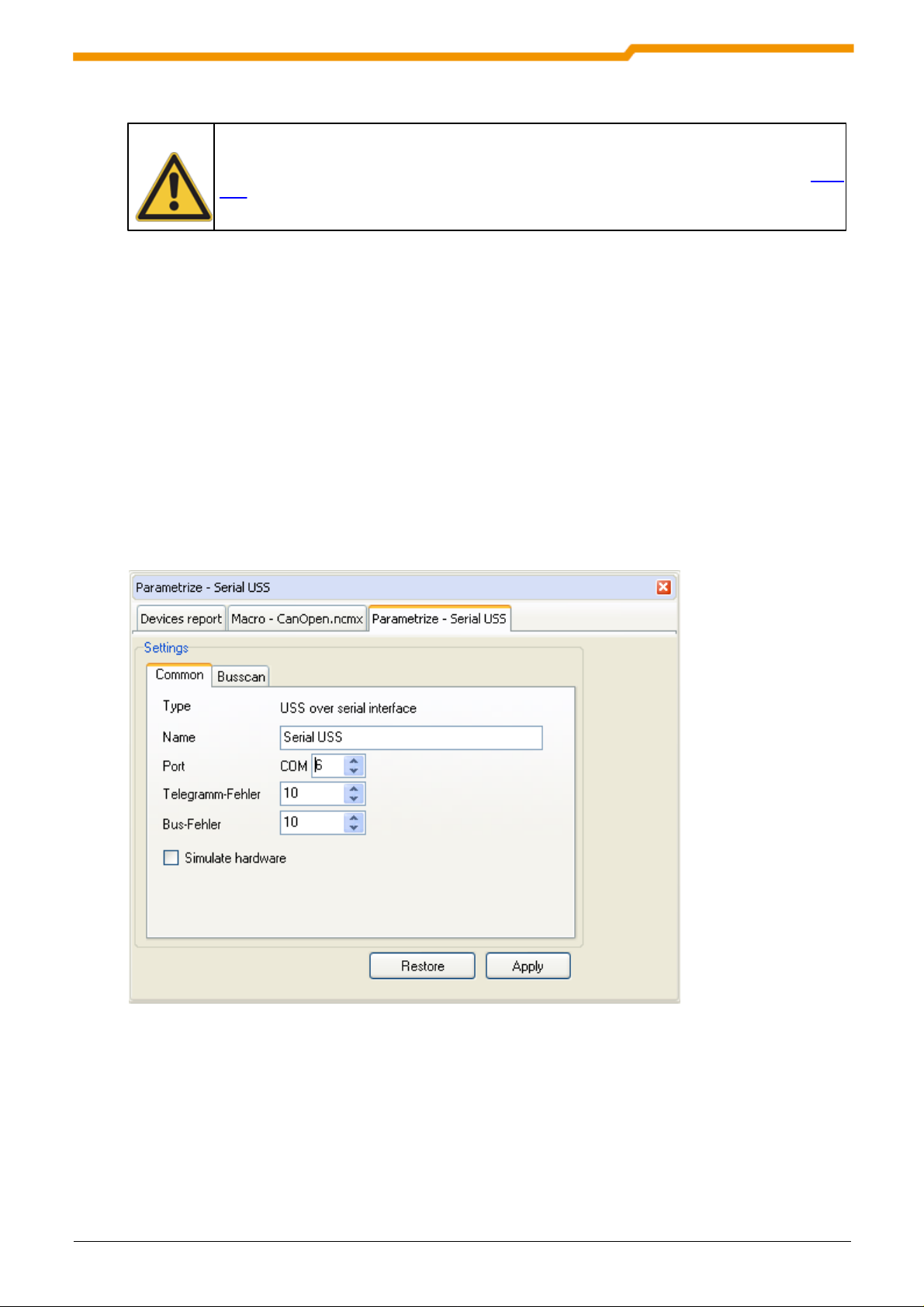

3.2.1 General settings

Name

Graphic user interface

In the edit field, the user can assign a name for the communication module.

Port

In the communication window, you can choose the COM-Ports of the computer where the

inverter is connected to.

Telegram error

The user defines the max number of allowed telegram errors.Telegram errors occur if the

content of a telegram is not correct. That means the answer does not fit to the parameter order.

Normally, each parameter order is answered after 2 telegrams. The number of allowable

telegram errors is the number of tries before the error message appears.

Bus error

The user defines the max number of acceptable bus errors. The bus error appears in the case

when the receiving telegram or the sending telegram was wrong. Incorrect telegrams are

ignored. Here you can program the max number of incorrect bus telegrams before the error

message is generated. In an installation with many interferring signals, the setting of acceptable

errors should be programmed to a higher number.

Simulation of Hardware

With this feature, the user activates or deactivates the simulation of the connected hardware.

BU 0000 GB

27

Page 28

NORD CON Manual

Attention

Older serial PC interfaces are sometimes not able to justify the accurate user specific Baud

rate. From this reason no connection can be made to the device.

Attention:

All changes are only available if the user push the button "apply". With the button "Restore" then

user can undo all changes.

3.2.2 Bus scan

Baud rate

In the selection box, the user can choose the communication speed of the serial interface. The

same value must be chosen on the frequency inverter. When using multiple frequency

inverters, the setting must be identical on all connected devices. The Baud rates over 115200

Bit/s are user specific Baud rates and not by all devices are supported.

Bus-Scan with all baud rates

With the action, the user activates or deactivates the bus scan with all baud rates. If the baud

rate of the connected device is unknown, the search with all baud rates can find the right one to

start communication.

Starting baud rate

In the selection box, the user can define the baud rate for start of the baud rate search.

BU 0000 GB

28

Page 29

Communication

Attention

All changes are only available if the user push the button "apply". With the button "Restore"

then user can undo all changes.

Starting address

In this field, the USS address can be defined, from where the search run of NORD CON starts

to find connected devices. All frequency inverters with lower address cannot be found by NORD

CON.

End address

In this field, the user can define the USS address for the ending of the search for connected

devices. All inverters with a higher address number cannot be found by NORD CON.

Stop all connected devices

With the action, the user can activate or deactivate the stopping (disable) of connected

devices. When this function is active, all enabled devices are stopped if the interface of the

device is programmed to "bus".

Automatic device search after start of program

With this action the user can activate or deactivate the automatic device search after start of

the program. When this function is active, NORD CON automatically starts the bus scan after

the program is started.

BU 0000 GB

29

Page 30

NORD CON Manual

Parameter Viewing

How to manipulate parameters

Selective parameterization

Off-line Parameterization

Comparison

Parameter upload from device

Parameter download to device

4 Parameterization

4.1 Overview

All parameters of the frequency inverter that can be changed can also be changed by NORD

CON. All of the parameters can be stored and retransmitted to the frequency inverter.

Parameters which have been read out can be printed out for documentation purposes.

4.2 Parameter Viewing

Each parameter has a parameter name and a unique parameter number by which it can

directly be accessed. The parameters are devided into menu groups.

Each parameter has a parameter value and parameter characteristics:

BU 0000 GB

30

Page 31

Parameterization

Note

The menu "Parameterize" is indicated only if a parameter window were marked.

Aktion

Place

Description

New

File -> New -> Dataset

The current database is re-initialized, in other words the

current and the new settings are deleted.

Open

File -> Open

Any database that was saved can be reopened.

Save

File -> Save

The current database is saved by the current name.

Save us...

File -> Save us...

The current database is saved with a new name.

Print preview...

File -> Print preview...

The current parameter settings are printed out.

Read all parameter or

Read all

Parameterize -> Read -> All

Parameter

All of the parameters of the frequency inverter are read out

and entered into the database.

Read actual menu

group

Parameterize -> Read ->

Actual menu group

The parameters of the selected menu group are read out

and entered into the database.

Send new settings

Parameterize -> Send -> new

Values

All parameters for which a new value was entered in the

'New settings' box are transmitted to the frequency inverter.

When a parameter has been selected, values of all parameter sets, if it can be set differently in

the sets, are displayed.

4.3 How to manipulate parameters

The selected parameter is read out and the value transferred to the 'Current Setting' box.

Management of the parameters of a frequency inverter is ensured by databases. These

databases can be stored, printed out or manipulated again at a later date.

NORD CON features two ways of parameter manipulation:

BU 0000 GB

31

Page 32

NORD CON Manual

Aktion

Place

Description

A selection is possible as to whether this operation is to be

performed on all parameters or only on those belonging to

the current menu group.

Send Factory settings

Parameterize -> Send ->

Reset values

The settings transmitted will be the default settings of all

parameters or of the parameters of the current menu group

respectively

Selection Enable

Parameterize -> Selection ->

Release

All of the parameters (or those included in the current

menu group respectively), are enabled.

Selection Disable

Parameterize -> Selection ->

no Release

None of the parameters (or of those belonging to the

current menu group), are enabled.

Standard

Button "Standard"

The default value is allocated to the currently selected

parameter.

Send

Button "Send"

The value "new setting" of the current parameter is

transferred to the inverter

Read

Button "Read"

The selected parameter is read out and the value

transferred to the 'Current Setting' box.

Note

When a filter has been activated, all operations are executed only on those parameters which

are displayed.

With the Auto-read option the selected parameter is read out automatically.

4.4 Selective parameterization

NORD CON allows for masking some parameters or other, a feature which may facilitate

manipulation or serve the purpose of restricting parameter readout or transmission to those

which remain unmasked or in other words have been filtered out.

Before any parameter can be masked the enable command must be inactivated. This can be

done using the checkbox preceding the parameter, or via the Selection menu. The Filter box

provides for the setting options mentioned below :

Selection only Only the enabled parameters are displayed (i.e. where the check box

preceding the parameter was clicked upon once).

No standard Only the parameters with a value that is different from the standard setting are

displayed.

Info parameters

Yes Information parameters are displayed.

No Information parameters are not displayed.

Only Information parameters are displayed exclusively.

BU 0000 GB

32

Page 33

4.5 Off-line Parameterization

Name

Description

New

A new database can be created. The new database is allocated to a frequency inverter

type which is set using a selection box.

Open

Any database that was read into memory can be opened and manipulated.

Attention

As reference for the parameters and the default values the configuration of the

equipment is used. A data record with the configuration of the equipment not

agrees selected, possibly non-existent parameters are empty represented and

marked as difference.

Attention

As reference for the parameters and the default values the configuration of the

opened parameter set is used. A data record with the configuration of the

equipment not agrees selected, possibly non-existent parameters are empty

represented and marked as difference.

Off-line parameterization implies that a database is manipulated which is not allocated to any

frequency inverter connected.

Off-line parameterization is started via the database menu in the main window.

4.6 How to compare parameters

The report shows the differences and/or thing in common of two data record. In principle only

data records of one device family can be compared. The parameters are represented in form of

a list. If two parameter values are different, the line with a grey bar is marked. Additionally it is

examined whether a value differs from the default value. In this case the value is red

represented.

Parameterization

Online / Offline compare

Connect the device with NORD CON. Afterwards the parameter window must be opened and it

be recommended to readout all parameters. With the parameter filters you can limit the

selection of the parameters. Over the menu option " Parameterize - > Compare" you can

generate a report. After the call of the function the user must select a stored data record. If the

selected parameters are to be used as backup, the user must store afterwards the current data

record. Thereupon the report is generated and showed.

Offline / Offline compare

For the comparison a stored or new data record must be opened. With the parameter filters you

can limit the selection of the parameters. Over the menu option " Parameterize - > Compare"

you can generate a report. After the call of the function the user must select a stored data

record.

BU 0000 GB

33

Page 34

NORD CON Manual

4.7 Parameter upload from device

The function loads the parameters of a device to the PC and then stores the values in a

parameter file. The action can be started through the tool bar "Device" or over the menu option

"Device/Parameter upload from device". After executing the function that opens following

window and the upload the parameter starts automatically. Communication errors occur during

the transfer, they displayed in the message window. At the end of the transfer the user prompts

one to enter a file name for the file. The user must confirm with "Save" to store the values.

4.8 Parameter download to device

The function opens a parameters file on the PC and sends all values to the device. The action

can be started via the tool bar "Device" or "Device/parameter download to the device" menu

item. After executing the function, the following window and a file dialog opens. In this dialog

selects the user the parameter file and confirm with "Open". The program checks whether the

parameter file to the selected device fits. In this case the download will start.

BU 0000 GB

34

Page 35

Parameterization

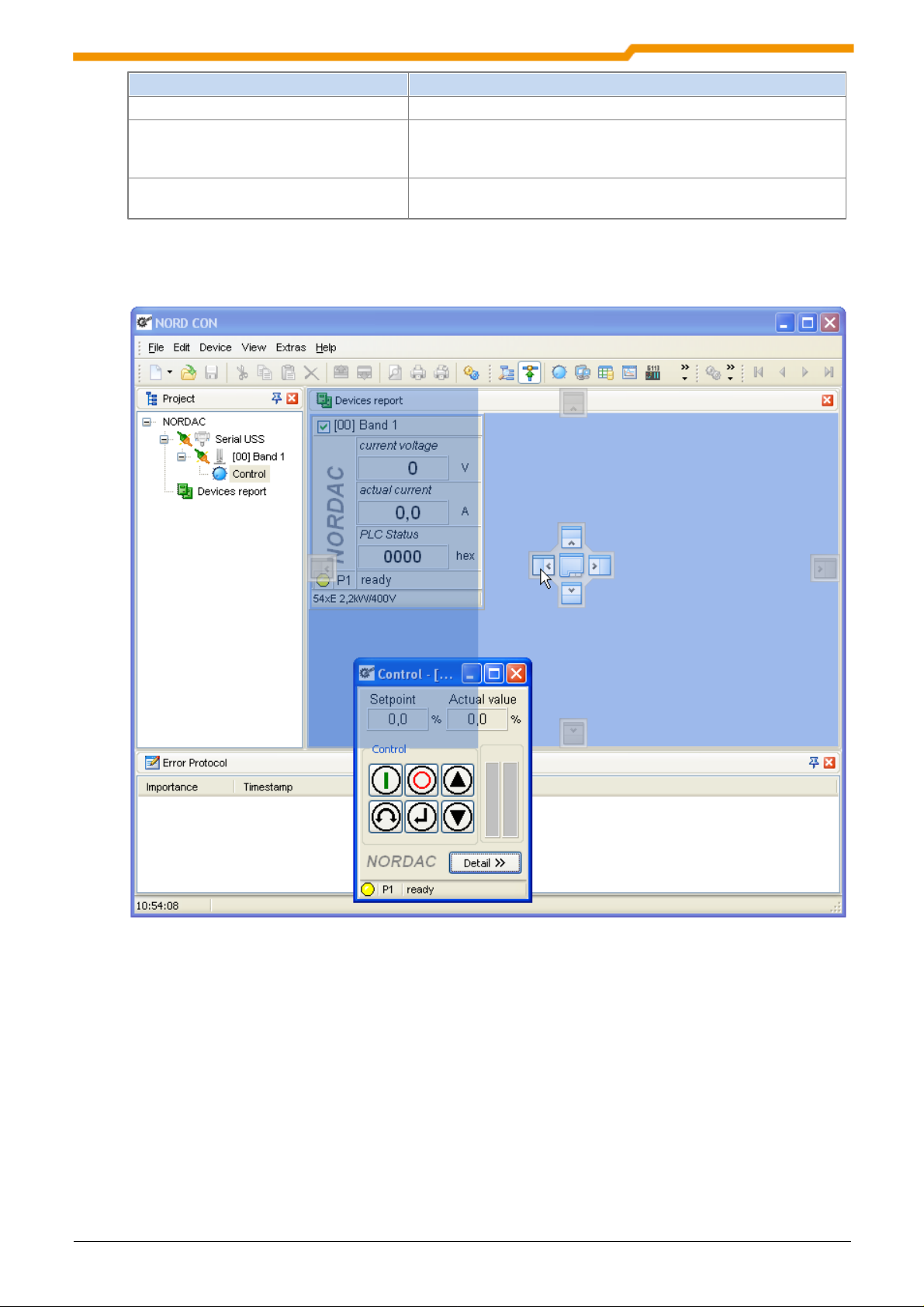

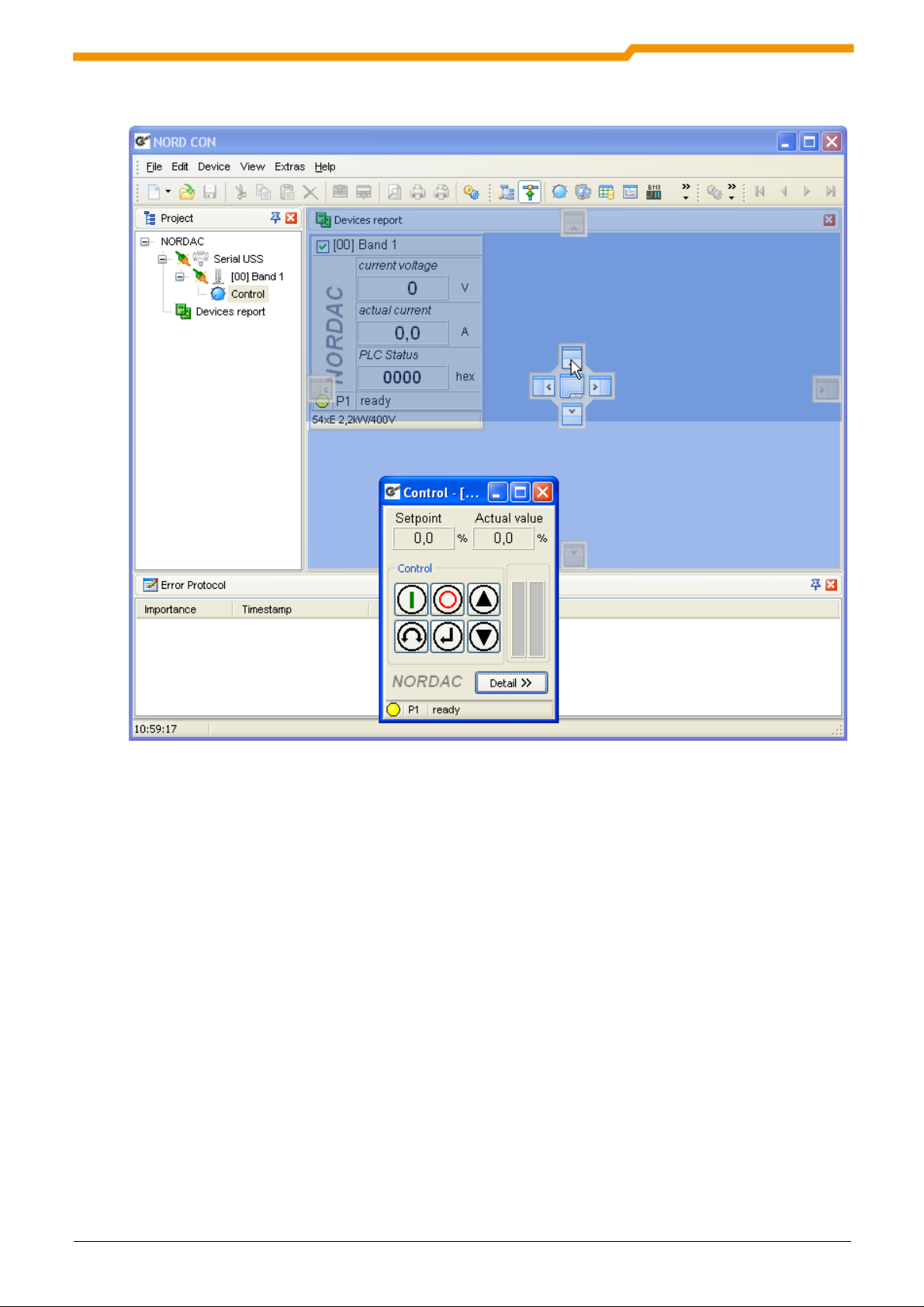

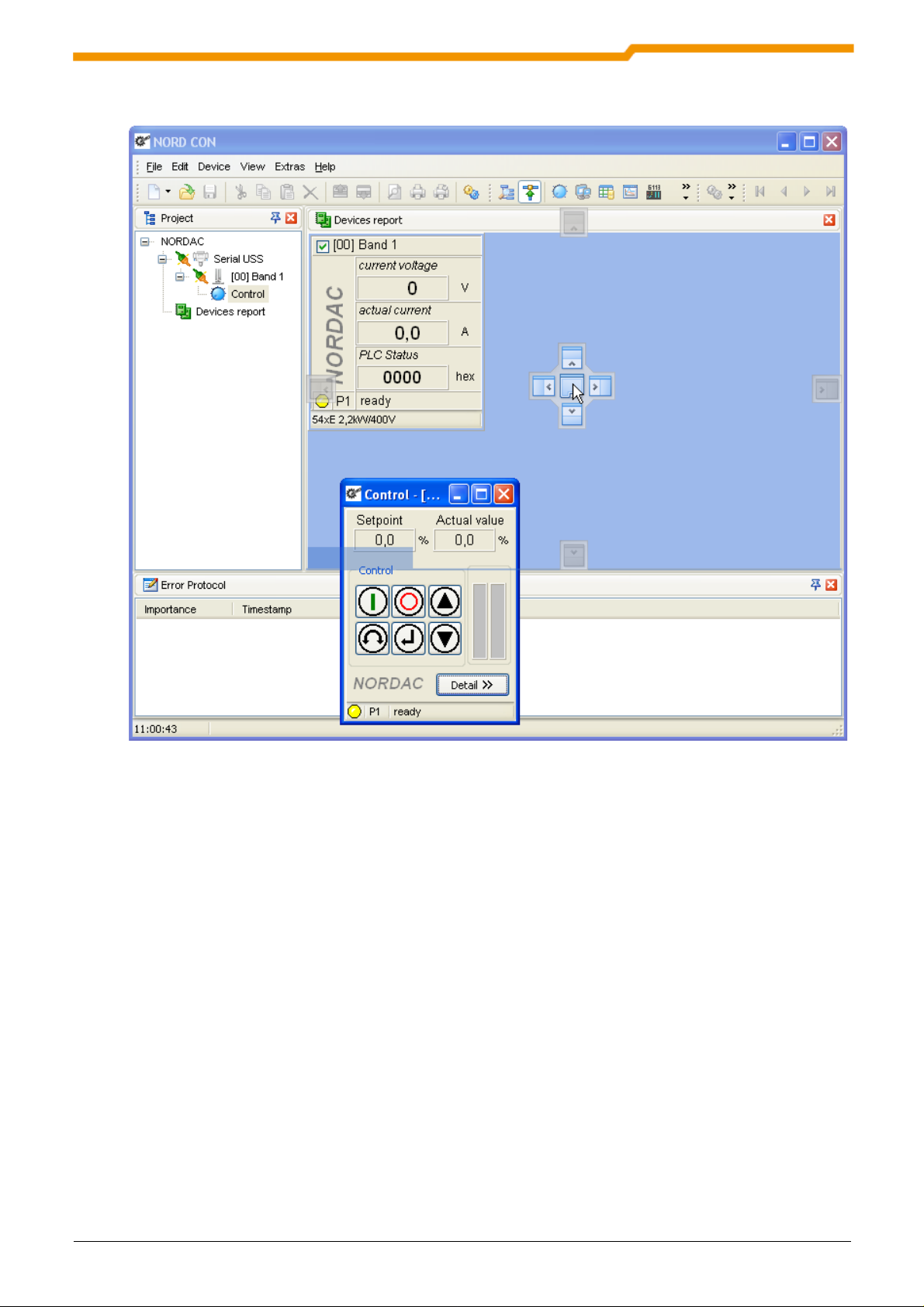

5 Control

5.1 Overview

The program NORD CON can be used to control NORDAC vector Frequenzumrichter. To

use this function the inverter must be parametriesed in the right way. Because of different

settings of different inverter types the user must check the manual to find the right settings.

Before the inverter can be controlled the Bus-scan must be done. After the scanning process

has finished all connected inverter are displayed in the main window. Now the inverter to be

controlled can be chosen by mouse click. The window „control" can be opened via "device/

control (F6) in the main menu or via pull-down menu (right mouse click).

BU 0000 GB

35

Page 36

NORD CON Manual

Standard

C

o

n

t

r

o

l

:

The frequency inverter can be released and the setting value can be

increased or decreased. Direction change and error acknowledge is

possible, too.

Detailed Control

:

Mit diesem Fenster können sämtliche Steuerungsmöglichkeiten

ausgenutzt werden.

Enable of the frequency inverter

Now the control configuration of the inverter is read and checked with the standard setting

(setting/control/control configuration check). If the "control" of inverter limited or impossible there

will be a warning note on the screen.

In the window „Control" there are two versions available:

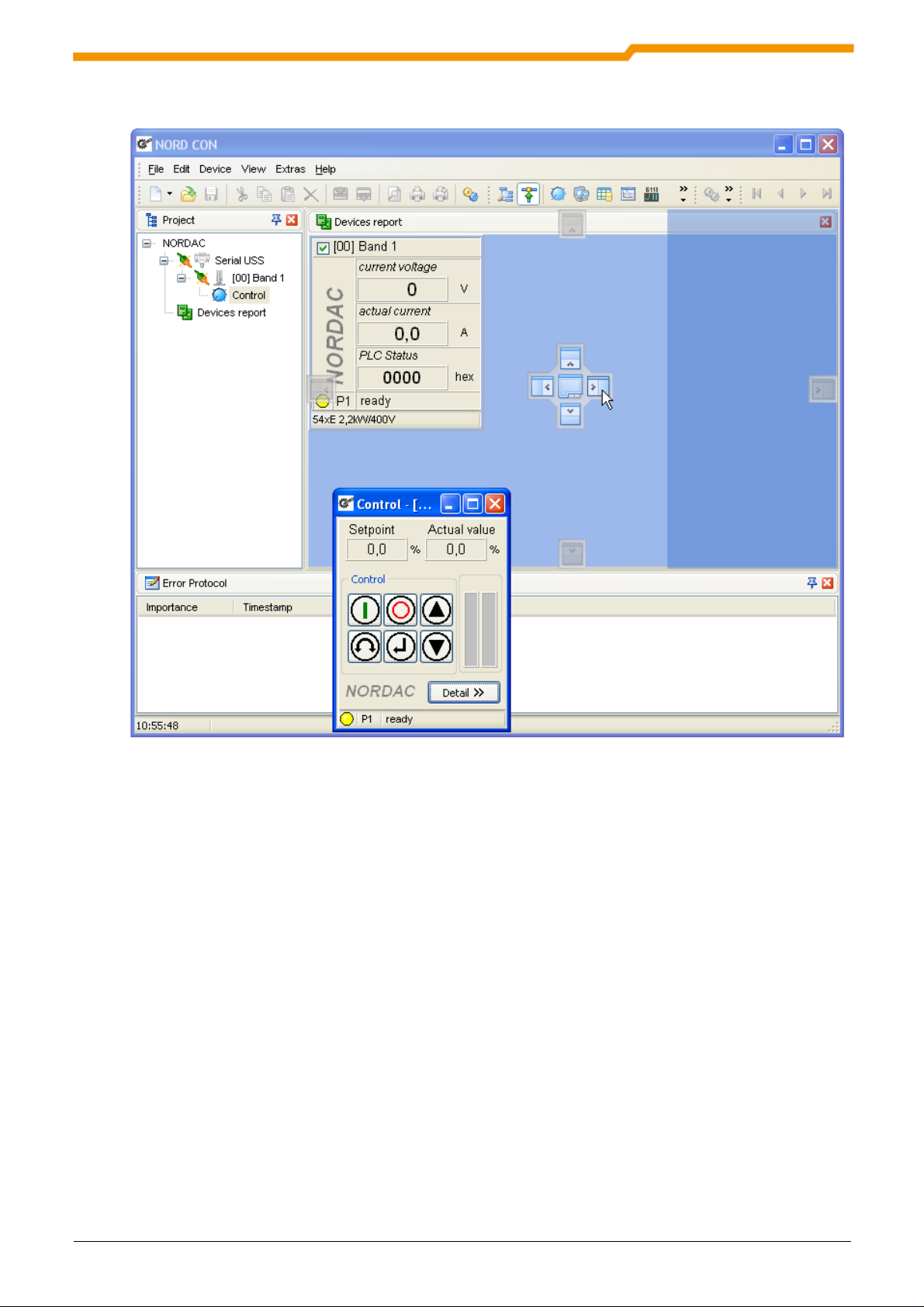

5.2 Standard control

Using the Standard Control the following functions are available:

BU 0000 GB

36

Page 37

Control

Increase or decrease of the setting value

Change of direction

Error Acknowledge

Setting of control word and display of status word

Management of setting values and actual values

Sending of broadcast telegramme

Choice of different parameter sets

Automatic sending of control word and setting values

To use this functionality, the inverter must be programmed for control via bus. You can find the

required parameter and settings in the manual available for each inverter type.

On the „Standard" display only the first setting value and first actual value are displayed. The

form of value is fixed for each configuration.

By pressing the button 'Detail' you can switch to the extended control function.

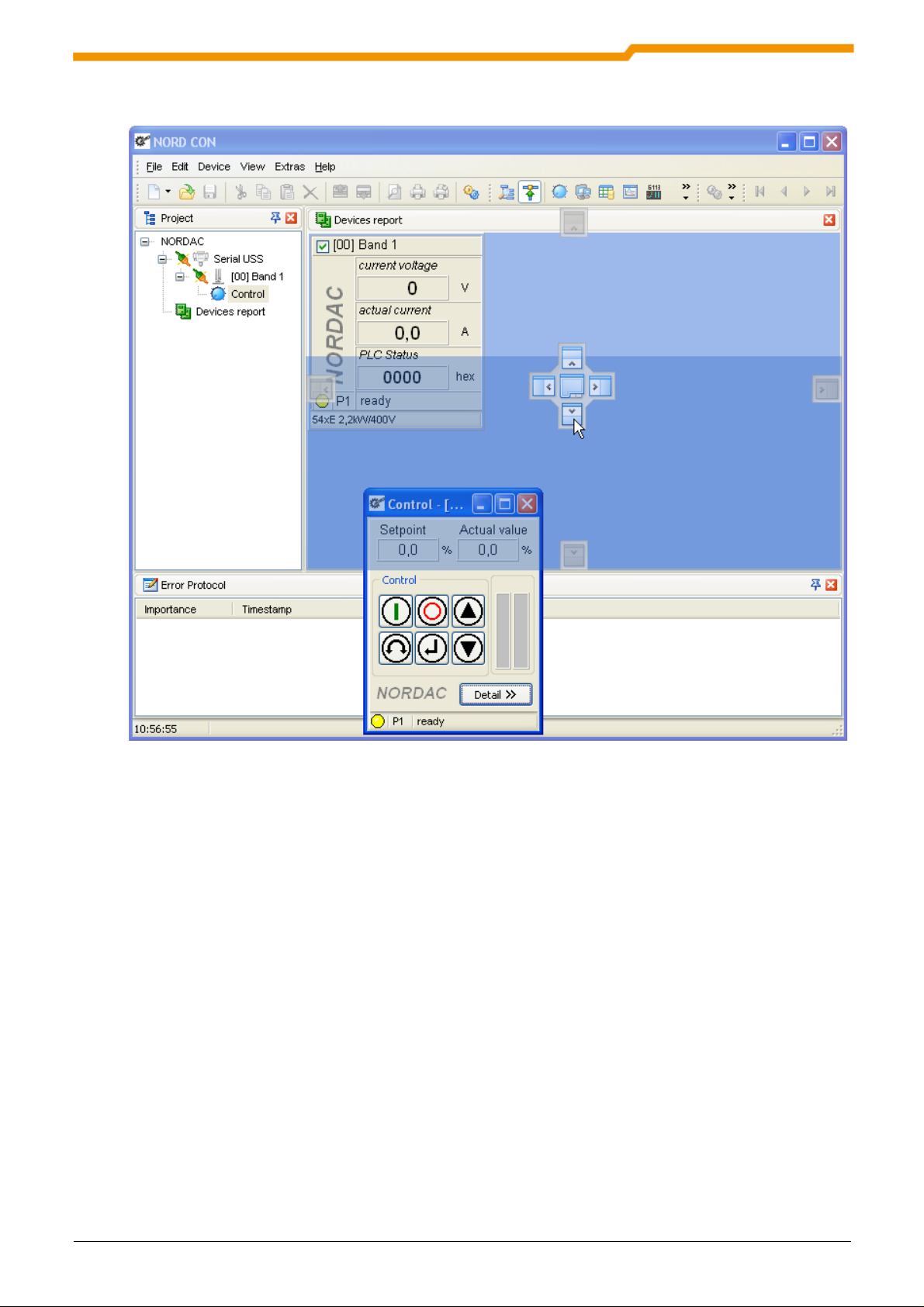

5.3 Detailed control

5.3.1 Overview

In the mode „Detailed Control" some extra functions are available:

BU 0000 GB

37

Page 38

NORD CON Manual

5.3.2 Control

The controlword is displayed as a hexadecimal value in the field „control word". By entering a

new value (hexadecimal) the user can change the control word. For a bit-coded setting of

control word the user can open up a new editorial window by pressing the button "control word

edit". In this window the control word is displayed in bits.

The status word is displayed hexadecimal in the screen „status word". To display the status

word in the bit resolution the button „bit orientated detail view" can be chosen. The status is

displayed in the status line of the status machine as clear text.

BU 0000 GB

38

Page 39

5.3.3 Management of setting values and actual values

Char

Name

Description

"%"

16 Bit standardised values

This standardisation transforms the setpoint/actual value to a 16

Bit standardised value. Standardisation means a scaling of

value range and is between -200% and 199% of a basic value

(e.g. nominal frequency).

"16"

16 Bit not standardised

By this formatting the setpoint and actual value are transformed

to 16 Bit value and transmitted to inverter and displayed without

any scaling.

"B"

DigInBits

By this Formatting the setpoint and actual value are transformed

to 8 Bit value. The bit status is displayed individual in check

boxes. In these check boxes each bit of setting value can be

changed.

"L"

32 Bit Low-Word

By this formatting the setpoint and actual value are taken as the

low word (16 Bit) of a 32 Bit word..If there is another setpoint or

actual value parametriesed with formatting "32 Bit High-Word",

then both values are combined in the top display. The setting

For controlling the inverter the user can define up to 3 different setpoints and actual values (see

user manual). The setpoints and actual values are displayed according to the formatting (Button

„formatting setting value x"). The input of setpoins can be done in same way.

With the option „setting/control/ parameter set individual management" the setting values and

actual values can be managed individually. So setting values can be set for each parameter set.

With activation of a parameter set its setting values are transmitted to the frequency inverter.

This is necessary because for each parameter set the setting values and actual values can be

defined individually. The active parameter set is marked with a star.

If the option „setting/control/configuration automatically checked" was not activated, the user

can transmit the new configuration by pressing the button „update".

Control

5.3.4 Formatting of Setpoint and/or actual value

BU 0000 GB

39

Page 40

NORD CON Manual

Char

Name

Description

value can be given as a 32 Bit value.

"H"

32 Bit High-Word

By this formatting the setpoint and actual value are taken as the

high word (16 Bit) of a 32 Bit word. (see "32 Bit Low-Word").

"P"

16 Bit Posicon Arr control clamps

(SK7xx, Vector CT with Posicon)

By this formatting the setpoint and actual value are taken as the

„Posicon position array". The meaning of each bit you can find in

the Posicon manual. This option is only available for inverter with

Posicon functionality.

"I"

16 Bit Posicon Inc control clamps

(SK7xx, Vector CT with Posicon)

By this formatting the setpoint and actual value are taken as

„Posicon position increment array". You can find the meaning of

each bit in the Posicon manual. This option is only available for

inverter with Posicon functionality.

"32"

32 Bit standardised (SK7xx, Vector

CT with Posicon)

By this formatting the setpoint and actual value is taken as an 32

Bit value without standadisation. This option is only available for

inverter with Posicon functionality.

LED

Importance

The Bit is set and/or the inverter is enabled.

An error is active or an enable signal is missing.

The Bit is not set.

5.3.5 Control word

The present status word is displayed with each bit in the window „status word". All bits are listed

in a table including bit number, name and status. According to bit value and function there is a

coloured LED shown.

Importance of LEDs:

With the standard setting the status word is read in cycles and the changes are displayed in the

window. For deactivating the cyclic reading switch off the function „automatic" in the menu (right

mouse click).

The window is docked left next to the „control" window. If the window should be free on desktop,

you should choose the popup menu "docking/no". To save space the window can be added as

an index card next to the index card „general". To do this the window must be moved (pressed

left mouse button) over the index card "general". After release of the button the window is

shown as an index card. With double click (left mouse button) on the index card you get back to

window mode.

BU 0000 GB

40

Page 41

Control

LED

Importance

The Bit is set and/or the inverter is enabled.

An error is active or an enable signal is missing.

The Bit is not set.

5.3.6 Status word

The present control word is displayed with each bit in the window „status word". All bits are

listed in a table including bit number, name and status. According to bit value and function there

is a coloured LED shown. If inverter is programmed to USS control then the bits can be set by

control buttons. Each change of control word is sent immediately to the inverter (see „automatic

sending").

Importance of LEDs:

With the standard setting the control word is read in cycles and the changes are displayed in

the window. For deactivating the cyclic reading switch off the function „automatic" in the menu

(right mouse click).

The window is docked left next to the „control" window. If the window should be free on desktop,

you should choose the popup menu "docking/no". To save space the window can be added as

an index card next to the index card „general". To do this the window must be moved (pressed

left mouse button) over the index card "general". After release of the button the window is

shown as an index card. With double click (left mouse button) on the index card you get back to

window mode.

BU 0000 GB

41

Page 42

NORD CON Manual

Remote Standard

Remote NORDAC SK2xxE

Remote NORDAC SK7xxE/SK5xxE/SK300E

Remote NORDAC vector mc

Remote NORDAC vector ct

Note

NORDAC vector Frequenzumrichter can be controlled via the keyboard (enable, setpoint +/-,

phase sequence etc.). As the timeout monitoring function is not active in this mode, any

breakdown of the connection between PC and frequency inverter will make further control

impossible.

6 Remote

6.1 Overview

NORD CON can simulate the control unit of the respective frequency inverter. For this purpose

the frequency inverter transfers the content of its display to NORD CON. The key functions are

simulated on the PC and transmitted to the frequency inverter.

The frequency inverter can only be controlled via the Remote, if it has not previously been

enabled via the control terminals or via a serial interface (P509 = 0 and P510 = 0). In addition,

for this the parameter “PotentiometerBox Function” (P549) must not be set to function {4}

“Frequency addition” or function {5} “Frequency subtraction”.

BU 0000 GB

42

Page 43

6.2 Standard

Name

Icon

Description

Enable

Switching on the frequency inverter. The frequency inverter is now enabled with the set jog

frequency (P113). A preset minimum frequency (P104) may at least be provided.

Parameter >Interface< P509 and P510 must = 0.

Disable

Switching off the frequency inverter. The output frequency is reduced to the absolute

minimum frequency (P505) and the frequency inverter shuts down.

Change dir

The motor rotation direction changes when this key is pressed. "Rotation to the left" is

indicated by a minus sign.

Attention:

Take care when operating pumps. screw conveyors, ventilators, etc. Block the key with

parameter P540.

Up

Press key to increase the frequency. During parameterisation, the parameter number or

parameter value is increased.

Down

Press the key to reduce the frequency. During parameterisation, the parameter number or

parameter value is reduced.

Enter

Press "ENTER" to store an altered parameter value, or to switch between parameter

number or parameter value.

Note:

If a changed value is not to be stored, the key can be used to exit the parameter without

storing the change.

Change Dir +

Stop

By simultaneously pressing the STOP key and the "Change direction key” , an quick

stop can be initiated.

Enter + Start

If the inverter is enabled via the "ON" key, the parameterisation mode can be

reached by pressing the ON and ENTER keys simultaneously.

The standard window for the function "Remote" is used for all Devices, if the option "Use

device-specific remote windows" were not activated.

Remote

All functions available with the operating unit (control box) of the frequency inverter can be

performed.

6.3 NORDAC SK200E

The window for remote control of the frequency inverters of the NORDAC SK 200 E series

looks like this:

BU 0000 GB

43

Page 44

NORD CON Manual

Name

Icon

Description

Enable

Switching on the frequency inverter. The frequency inverter is now enabled with the set jog

frequency (P113). A preset minimum frequency (P104) may at least be provided.

Parameter >Interface< P509 and P510 must = 0.

Disable

Switching off the frequency inverter. The output frequency is reduced to the absolute

minimum frequency (P505) and the frequency inverter shuts down.

Change dir

The motor rotation direction changes when this key is pressed. "Rotation to the left" is

indicated by a minus sign.

Attention:

Take care when operating pumps. screw conveyors, ventilators, etc. Block the key with

parameter P540.

Up

Press key to increase the frequency. During parameterisation, the parameter number or

parameter value is increased.

Down

Press the key to reduce the frequency. During parameterisation, the parameter number or

parameter value is reduced.

Enter

Press "ENTER" to store an altered parameter value, or to switch between parameter

number or parameter value.

Note:

If a changed value is not to be stored, the key can be used to exit the parameter without

storing the change.

Change Dir +

Stop

By simultaneously pressing the STOP key and the "Change direction key” , an quick

stop can be initiated.

Enter + On

If the inverter is enabled via the "ON" key, the parameterisation mode can be

reached by pressing the ON and ENTER keys simultaneously.

All functions available with the operating unit (control box) of the frequency inverter can be

performed.

6.4 NORDAC SK 700/500/300 E

The window for remote control of the frequency inverters of the NORDAC SK 700/500/300 E

series looks like this:

BU 0000 GB

44

Page 45

Remote

Name

Icon

Description

Enable

Switching on the frequency inverter. The frequency inverter is now enabled with the set jog

frequency (P113). A preset minimum frequency (P104) may at least be provided.

Parameter >Interface< P509 and P510 must = 0.

Disable

Switching off the frequency inverter. The output frequency is reduced to the absolute

minimum frequency (P505) and the frequency inverter shuts down.

Change dir

The motor rotation direction changes when this key is pressed. "Rotation to the left" is

indicated by a minus sign.

Attention:

Take care when operating pumps. screw conveyors, ventilators, etc. Block the key with

parameter P540.

Up

Press key to increase the frequency. During parameterisation, the parameter number or

parameter value is increased.

Down

Press the key to reduce the frequency. During parameterisation, the parameter number or

parameter value is reduced.

Enter

Press "ENTER" to store an altered parameter value, or to switch between parameter

number or parameter value.

Note:

If a changed value is not to be stored, the key can be used to exit the parameter without

storing the change.

Change Dir +

Stop

By simultaneously pressing the STOP key and the "Change direction key” , an quick

stop can be initiated.

Enter + On

If the inverter is enabled via the "ON" key, the parameterisation mode can be

reached by pressing the ON and ENTER keys simultaneously.

All functions available with the operating unit (control box) of the frequency inverter can be

performed.

BU 0000 GB

45

Page 46

NORD CON Manual

Name

Icon

Description

Enable

Switching on the frequency inverter. The frequency inverter is now enabled with the set jog

frequency (P113). A preset minimum frequency (P104) may at least be provided. Parameter

>Interface< P509 and P510 must = 0.

Disable

Switching off the frequency inverter. The output frequency is reduced to the absolute

minimum frequency (P505) and the frequency inverter shuts down.

Change dir

The motor rotation direction changes when this key is pressed. "Rotation to the left" is

indicated by a minus sign.

Attention:

Take care when operating pumps. screw conveyors, ventilators, etc. Block the key with

parameter P540.

Up

Press key to increase the frequency. During parameterisation, the parameter number or

parameter value is increased.

Down

Press the key to reduce the frequency. During parameterisation, the parameter number or

parameter value is reduced.

Enter

Press "ENTER" to store an altered parameter value, or to switch between parameter number

or parameter value.

Note:

If a changed value is not to be stored, the key can be used to exit the parameter without

storing the change.

Change

Dir + Stop

By simultaneously pressing the STOP key and the "Change direction key” , an quick

stop can be initiated.

Enter + On

If the inverter is enabled via the "ON" key, the parameterisation mode can be reached

by pressing the ON and ENTER keys simultaneously.

6.5 NORDAC vector mc

The window for remote control of the frequency inverters of the NORDAC vector mc series

looks like this:

BU 0000 GB

46

Page 47

All functions available with the operating unit (control box) of the frequency inverter can be

Monitoring of up to 4 channels

Many different ways of trigger

performed.

6.6 NORDAC vector ct

The following functions are available for remote control of the NORDAC vector CT series:

Remote

All functions available with the operating unit (control box) of the frequency inverter can be

performed.

7 Oscilloscope

7.1 Overview

The oscilloscope function integrated inNORD CON can show process data of an NORDAC

vector Frequenzumrichter as an arithmetic chart.

Note:

This option is not available in all types of NORDAC vector ct and NORDAC vector mc!

The features of oscilloscope-function are:

BU 0000 GB

47

Page 48

NORD CON Manual

Scaling of each measurement

Calculation of average values, effective value, etc.

Save, print and export of measurement data

Name

Description

Auto

Automatic Scaling of all measured data

Offset

Selection of display detail (displace of all data in x- or y-direction)

Zoom

Display size (Zoom of all data)

Note:

With the right mouse button you can choose between modi 'Move' and 'Measurement', if the

mouse pointer is on the display. In 'Move' mode you can choose the detail of display by mouse

pointer by pressing the left mouse button while moving over the display.

Auto scrolling