Page 1

Intelligent Drivesystems, Worldwide Services

GB

B2000

Operating and Installation Instructions for

Explosion Protected Gear Units and Geared Motors

Page 2

Page 3

1 Notes ...................................................................................................................... 4

1.1 General information ............................................................................................... 4

1.2 Safety and information symbols ............................................................................. 4

1.3 Correct use ............................................................................................................ 4

1.4 Safety information .................................................................................................. 5

1.5 Disposal ................................................................................................................. 5

2 Description of gear units ........................................................................................ 7

2.1 Type designations and gear unit types .................................................................. 7

3 Storage, preparation, installation ......................................................................... 12

3.1 Storing the gear unit ............................................................................................ 12

3.2 Long-term storage................................................................................................ 12

3.3 Inspecting the drive unit ....................................................................................... 13

3.4 Checking the rating plate data ............................................................................. 13

3.5 Checking the configuration .................................................................................. 15

3.6 Preparing for installation ...................................................................................... 15

3.7 Installing the gear unit .......................................................................................... 16

3.8 Fitting hubs on the gear shafts ............................................................................ 17

3.9 Fitting push-on gear units .................................................................................... 18

3.10 Fitting shrink discs ............................................................................................... 21

3.11 Fitting the covers .................................................................................................. 22

3.12 Fitting a standard motor ....................................................................................... 23

3.13 Subsequent paintwork ......................................................................................... 25

3.14 Temperature sticker ............................................................................................. 25

3.15 Fitting the cooling coil to the cooling system ....................................................... 25

Contents

4 Commissioning .................................................................................................... 27

4.1 Check the oil level ................................................................................................ 27

4.2 Activating the Automatic Lubricant Dispenser ..................................................... 28

4.3 Temperature measurement ................................................................................. 29

4.4 Operation with lubricant cooling ........................................................................... 30

4.5 Checking the gear unit ......................................................................................... 31

4.6 Checklist .............................................................................................................. 31

4.7 Operation of the gear unit in explosive areas ...................................................... 32

5 Service and maintenance .................................................................................... 33

5.1 Service and Maintenance Intervals ...................................................................... 33

5.2 Service and Maintenance Work ........................................................................... 33

6 Appendix .............................................................................................................. 41

6.1 Versions and maintenance .................................................................................. 41

6.2 Lubricants ............................................................................................................ 54

6.3 Torque values ...................................................................................................... 55

6.4 Troubleshooting ................................................................................................... 55

6.5 Declaration of Conformity .................................................................................... 56

www.nord.com B2000-GB-0413 -3-

Page 4

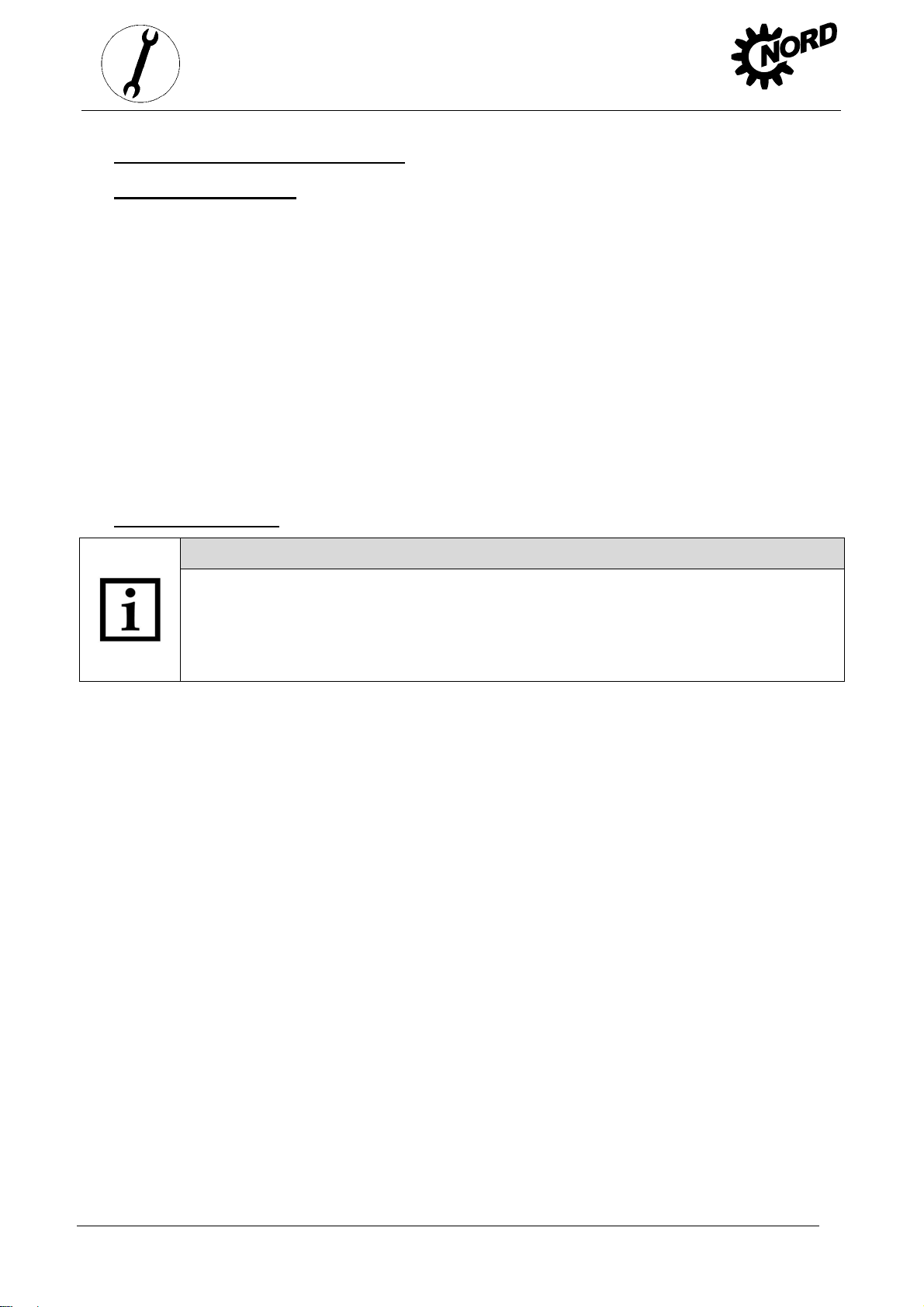

1 Notes

1.1 General information

Read the Operating Manual carefully prior to performing any work on or putting the gear unit into

operation. Strict compliance with the instructions in this Operating Manual is essential. This

Operating Manual and all associated special documentation must be kept in the immediate

vicinity of the gear unit. If geared motors are used, compliance with the Motor Operating Manual

is also necessary.

If additional components are attached to or installed in the gear unit (e.g. motor, cooling

system, pressure sensor etc.), or components (e.g. cooling system) are supplied with the

order, the operating instructions for these components must be observed.

If you do not understand the contents of this Operating Manual or additional operating

instructions, please consult Getriebebau NORD!

1.2 Safety and information symbols

Please always observe the following safety and information symbols!

Danger!

1. Notes

Risk of fatalities and injury

Attention!

Machine may be damaged

Note!

Useful information

Danger!

Important information about explosion protection

1.3 Correct use

These gear units generate a rotational movement and are intended for use in commercial

systems. They fulfil the explosion protection requirements of Directive 94/9EU (ATEX100a) for

the category stated on the rating plate. No mixture from categories IID and IIG may be present

during operation. The ATEX approval is void in case of a hybrid mixture.

Strict compliance with the technical data on the rating plate is essential. The

documentation must be observed. Appropriate safety measures must be taken for

applications where failure of a gear unit or geared motor may result in injury.

-4- B2000-GB-0413 www.nord.com

Page 5

1.4 Safety information

Danger!

No explosive atmosphere may be present during any work e.g. transportation, storage,

electrical connection, maintenance or repair.

All work including transportation, storage, installation, electrical connection, commissioning,

servicing, maintenance and repair must be performed only by qualified specialist personnel.

It is recommended that repairs to NORD Products are carried out by the NORD Service department.

Danger!

Installation and maintenance work must only be performed when gear units are at a standstill.

The drive must be isolated and secured to prevent accidental start-up.

Tighten the drive elements or secure the parallel key before switching on.

Danger!

1. Notes

Observe all safety information, including that provided in the individual sections of this

Operating Manual. All national and other regulations on safety and accident prevention must

also be observed.

1.5 Disposal

Observe the current local regulations. In particular, lubricants must be collected and disposed of

correctly.

The ringbolts which are screwed to the gear unit must be used for transport. No

additional load may be attached to the gear unit during transport. If geared motors have

an additional eyebolt attached to the motor, this must also be used. Avoid pulling the

eyebolts at an angle. Transportation aids and lifting gear must have an adequate loadbearing capacity.

Danger!

Serious physical and property damage may result from inappropriate installation, non-

designated use, incorrect operation, non-compliance with safety information, unauthorised

removal of housing components or safety covers and structural modifications to the gear unit.

Gear unit components: Material:

Toothed wheels, shafts, rolling bearings,

parallel keys, locking rings, …

Gear unit housing, housing components, … Grey cast iron

Light alloy gear unit housing,

light alloy gear unit housing components, …

Worm gears, bushes, ... Bronze

Radial seals, sealing caps, rubber components,… Elastomers with steel

www.nord.com B2000-GB-0413 -5-

Steel

Aluminium

Page 6

Coupling components Plastic with steel

Flat seals Asbestos-free sealing material

Gear oil Additive mineral oil

Synthetic gear oil (Rating plate labelling: CLP PG) Polyglycol-based lubricants

1. Notes

Cooling spiral, embedding material of the cooling spiral,

screw fittings

Copper, epoxy, yellow brass

-6- B2000-GB-0413 www.nord.com

Page 7

2. Description of gear units

2 Description of gear units

2.1 Type designations and gear unit types

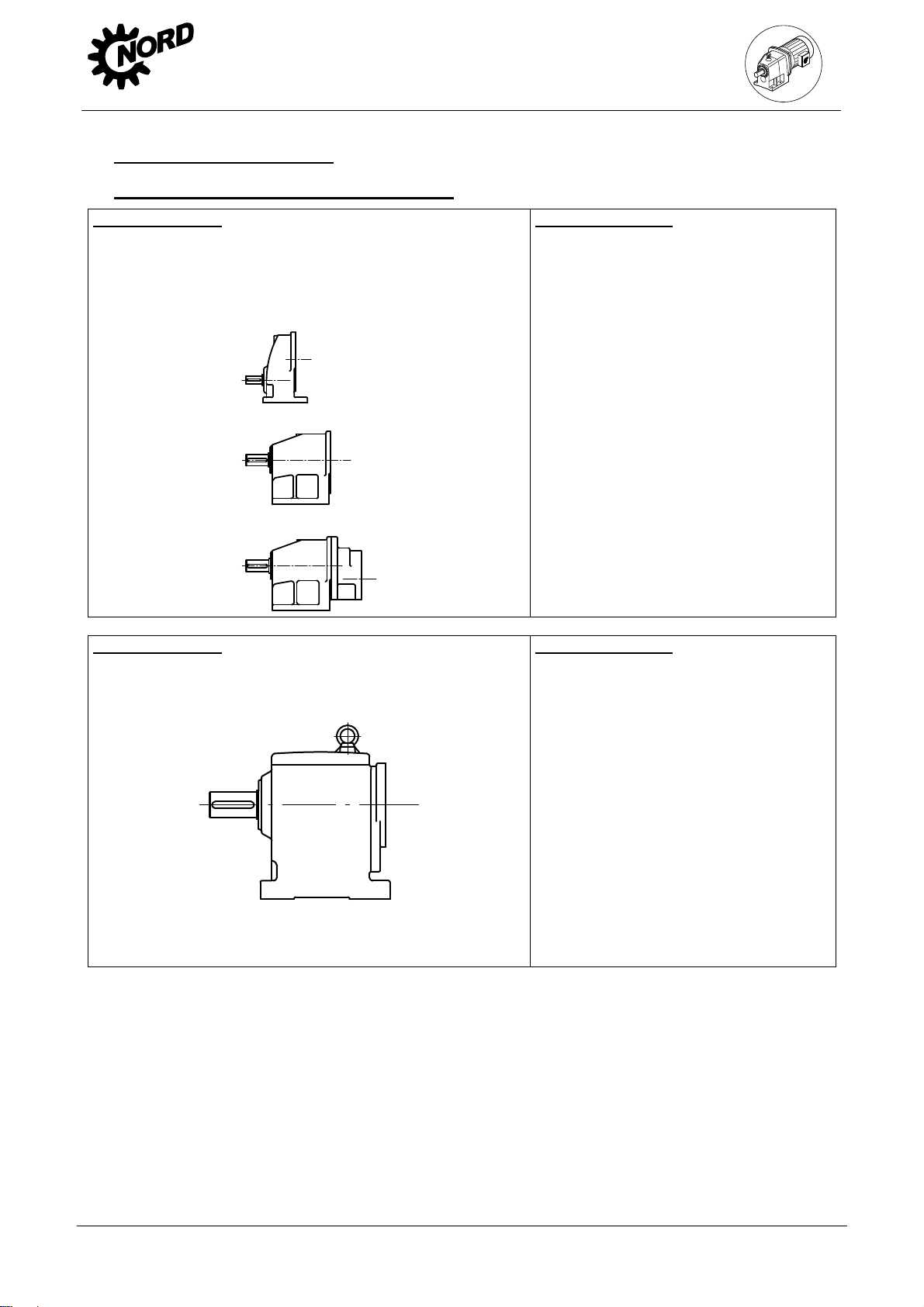

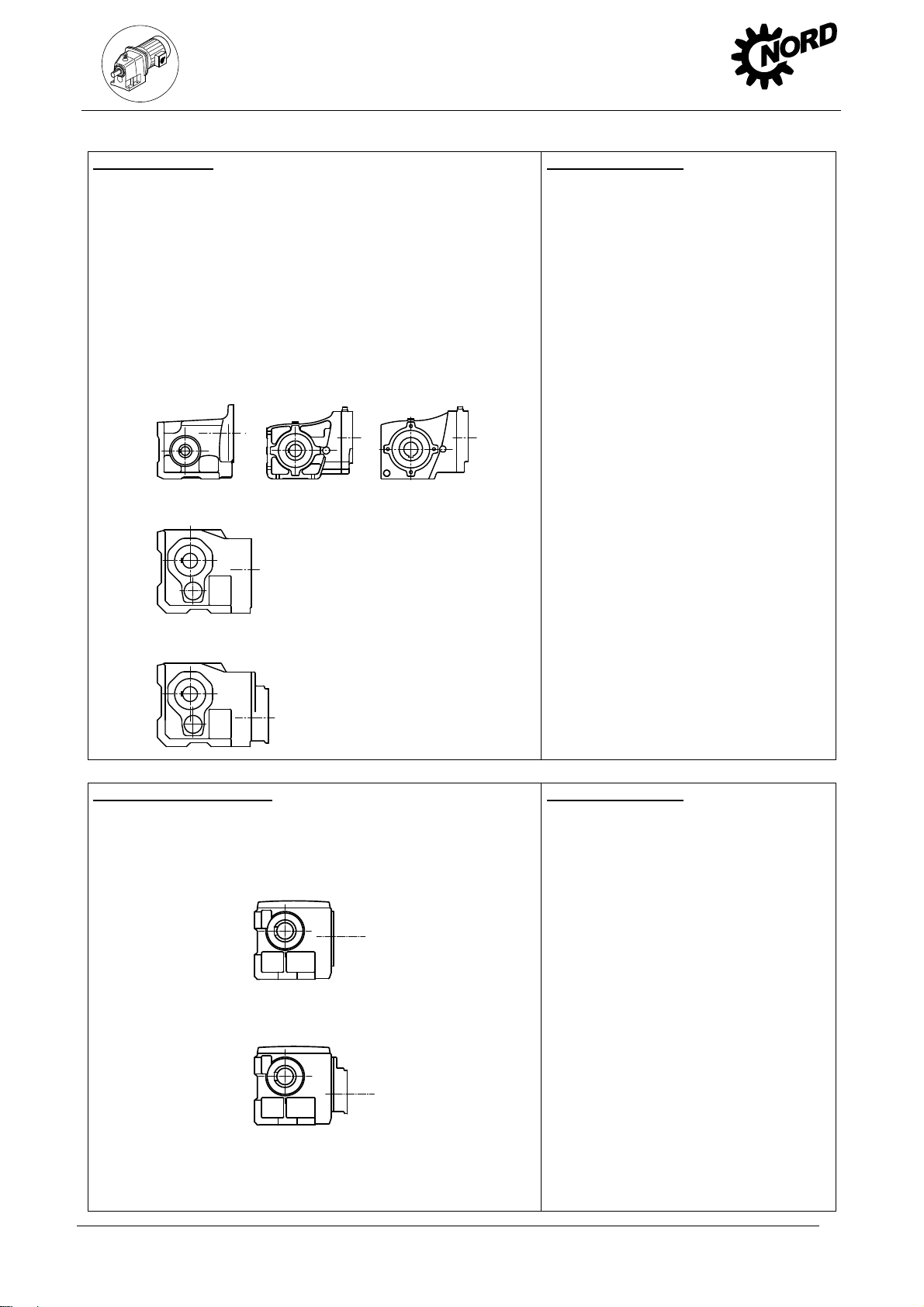

Helical gear units

Type designations:

SK 11E, SK 21E, ..... SK 51E (single-stage)

SK 02, SK 12, ........ SK 52, SK 62N (2-stage)

SK 03, SK 13, SK 23, SK 33N, SK 43, SK 53 (3-stage)

Helical gear units

Type designations:

SK 62, SK 72, SK 82, SK 92, SK 102 (2-stage)

SK 63, SK 73, SK 83, SK 93, SK 103 (3-stage)

Versions / Options

- Foot-mounted version

F Output flange B5

XZ Base and output flange B14

XF Base and output flange B5

VL Reinforced bearings

AL Reinforced axial bearings

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

OA Oil expansion vessel

SO1 Synthetic oil ISO VG 220

Versions / Options

- Foot-mounted version

F Output flange B5

XZ Base and output flange B14

XF Base and output flange B5

VL Reinforced bearings

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

OA Oil expansion vessel

SO1 Synthetic oil ISO VG 220

www.nord.com B2000-GB-0413 -7-

Page 8

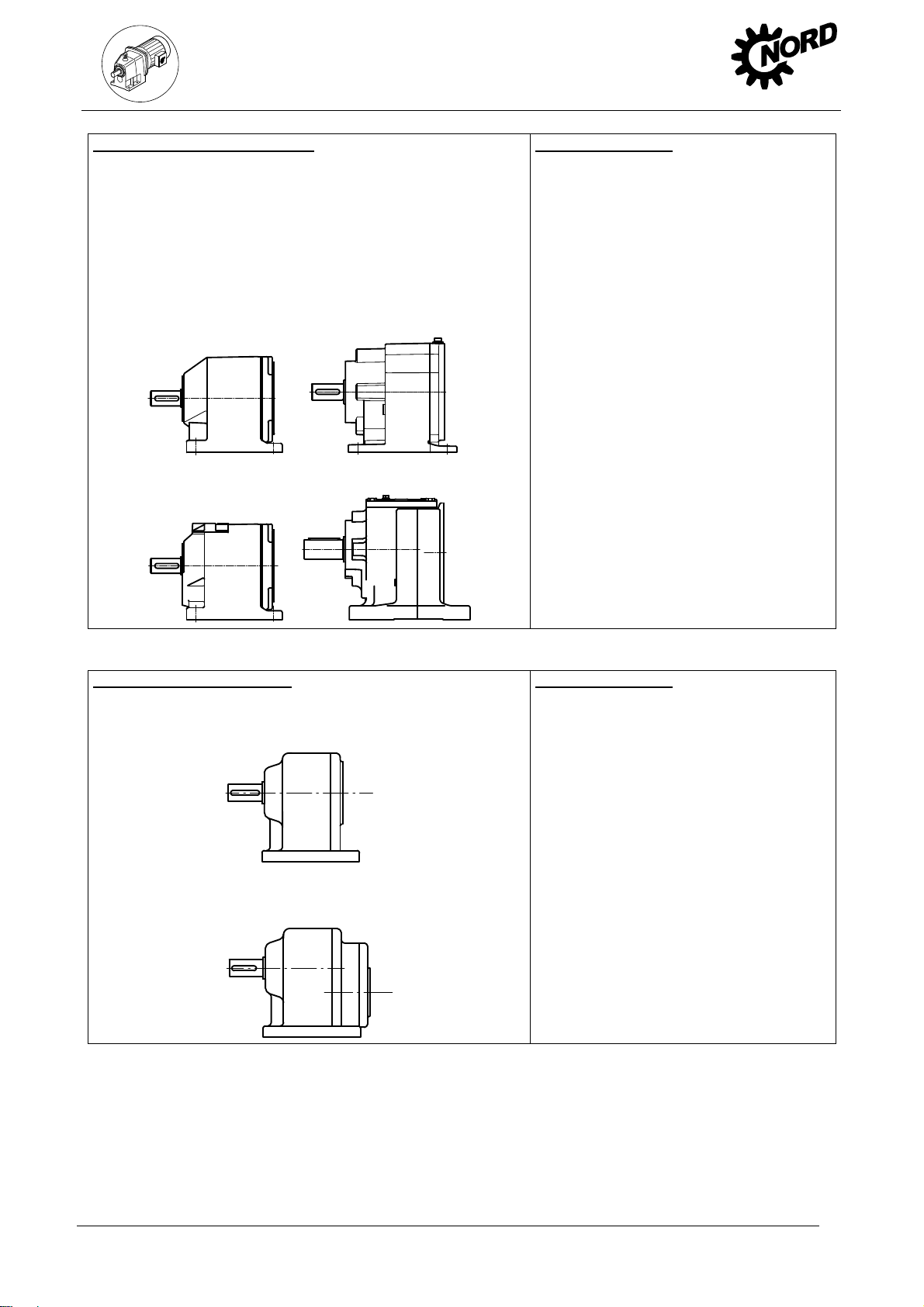

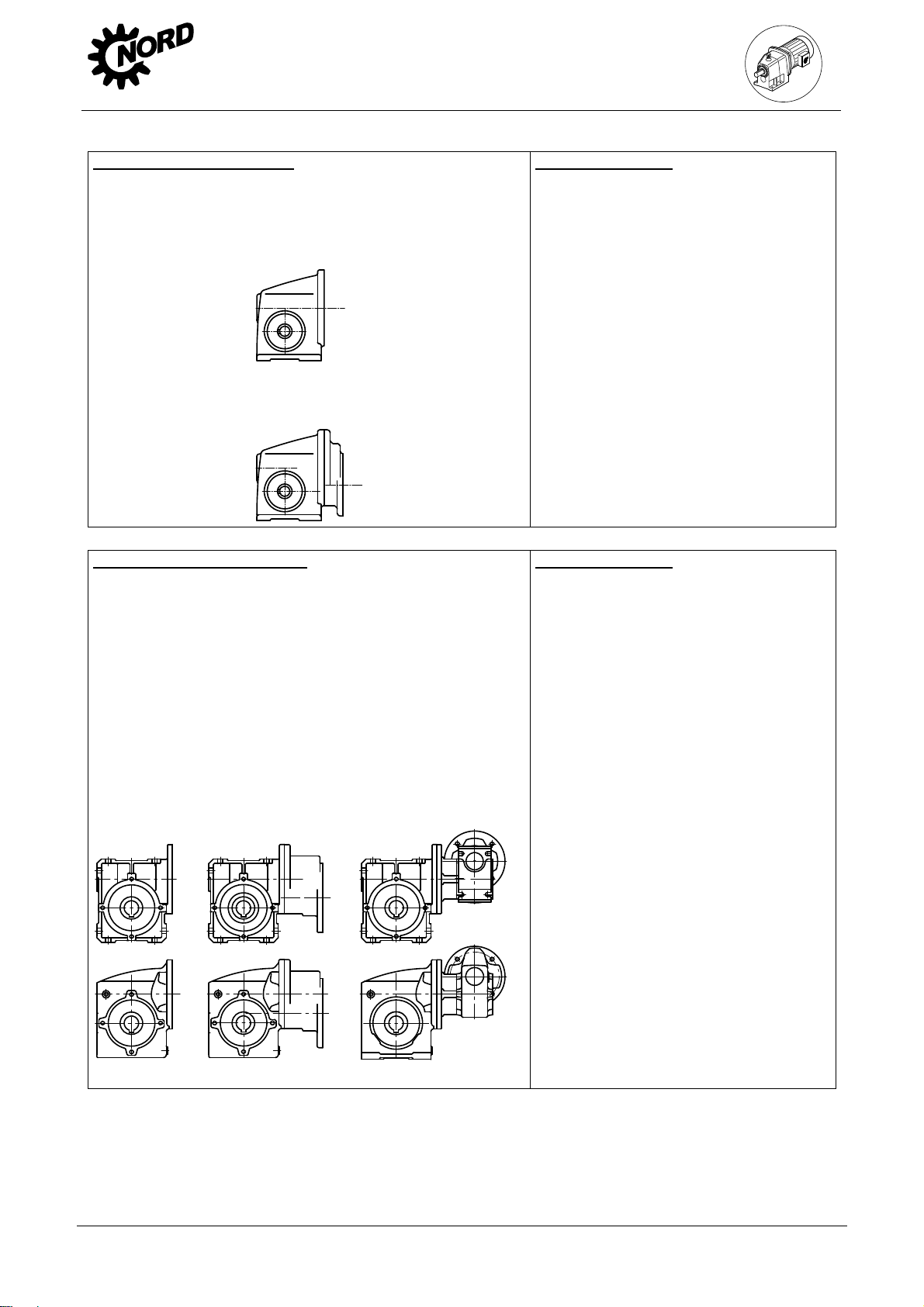

NORDBLOC helical gear units

Type designations:

SK 320, SK 172, SK 272, ..... SK 972 (2-stage)

SK 273, SK 373, ..... SK 973 (3-stage)

SK 072.1, SK 172.1 (2-stage)

SK 372.1, …. SK 672.1 (2-stage)

SK 373.1, …. SK 673.1 (3-stage)

SK 772.1, SK 872.1, SK 972.1 (2-stage)

SK 773.1, SK 873.1, SK 973.1 (3-stage)

2. Description of gear units

Versions / Options

- Foot-mounted version

F Output flange B5

XZ Base and output flange B14

XF Base and output flange B5

VL Reinforced radial bearings

AL Reinforced axial bearings

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

OA Oil expansion vessel

SO1 Synthetic oil ISO VG 220

Standard helical gear units

Type designations:

SK 0, SK 01, SK 20, SK 25, SK 30, SK 33 (2-stage)

SK 000, SK 010, SK 200, SK 250, SK 300, SK 330 (3-stage)

Versions / Options

- Foot-mounted version

Z Output flange B14

XZ Base and output flange B14

XF Base and output flange B5

F Output flange B5

5 Reinforced output shaft

V Reinforced drive

AL Reinforced axial bearings

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

SO1 Synthetic oil ISO VG 220

-8- B2000-GB-0413 www.nord.com

Page 9

Parallel shaft gear units

Type designations:

SK 0182NB, SK 0282NB, SK 1282, ..... SK 9282, SK 10282, SK

11282

(2-stage)

SK 1382NB, SK 2382, ….. SK 9382, SK 10382, SK 11382, SK 12382

(3-stage)

2. Description of gear units

Versions / Options

A Hollow shaft version

V Solid shaft version

Z Output flange B14

F Output flange B5

X Foot mounting

S Shrink disc

VS Reinforced shrink disc

EA Hollow shaft with internal spline

G Rubber buffer

VG Reinforced rubber buffer

B Fixing element

H Covering cap as contact guard

H66 Covering cap IP66

VL Reinforced bearings

VLII Agitator design

VLIII Drywell agitator de sign

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

OA Oil expansion vessel

SO1 Synthetic oil ISO VG 220

CC Casing cover with cooling spiral

OT Oil level tank

www.nord.com B2000-GB-0413 -9-

Page 10

Bevel gear units

Type designations:

SK 92072, SK 92172, SK 92372, SK 92672, SK 92772

SK 92072.1, SK 92172.1, SK 92372.1, SK 92672.1, SK 92772.1,

SK 93072.1, SK 93172.1, SK 93372.1, SK 93672.1, SK 93772.1

(2-stage)

SK 9012.1, SK 9016.1, SK 9022.1, SK 9032.1, SK 9042.1,

SK 9052.1, SK 9062.1, SK 9072.1, SK 9082.1, SK 9086.1,

SK 9092.1, SK 9096.1 (3-stage)

SK 9013.1, SK 9017.1, SK 9023.1, SK 9033.1, SK 9043.1,

SK 9053.1 (4-stage)

Contrate worm gear unit

Type designations:

SK 02040, SK 02050, SK 12063, SK 12080, SK 32100, SK 42125

(2-stage)

SK 13050, SK 13063, SK 13080, SK 33100, SK 43125

(3-stage)

2. Description of gear units

Versions / Options

- Foot mounting with solid shaft

A Hollow shaft version

V Solid shaft version

L Solid shaft both sides

Z Output flange B14

F Output flange B5

X Foot mounting

D Torque support

K Torque console

S Shrink disc

VS Reinforced shrink disc

EA Hollow shaft with internal spline

R Back stop

B Fixing element

H Covering cap as contact guard

H66 Covering cap IP66

VL Reinforced bearings

VLII Agitator design

VLIII Drywell agitator de sign

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

OA Oil expansion vessel

SO1 Synthetic oil ISO VG 220

CC Casing cover with cooling spiral

Versions / Options

- Foot mounting with solid shaft

A Hollow shaft version

V Solid shaft version

L Solid shaft both sides

X Foot mounting

Z Output flange B14

F Output flange B5

D Torque support

S Shrink disc

B Fixing element

H Covering cap as contact guard

H66 Covering cap IP66

VL Reinforced bearings

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

OA Oil expansion vessel

-10- B2000-GB-0413 www.nord.com

Page 11

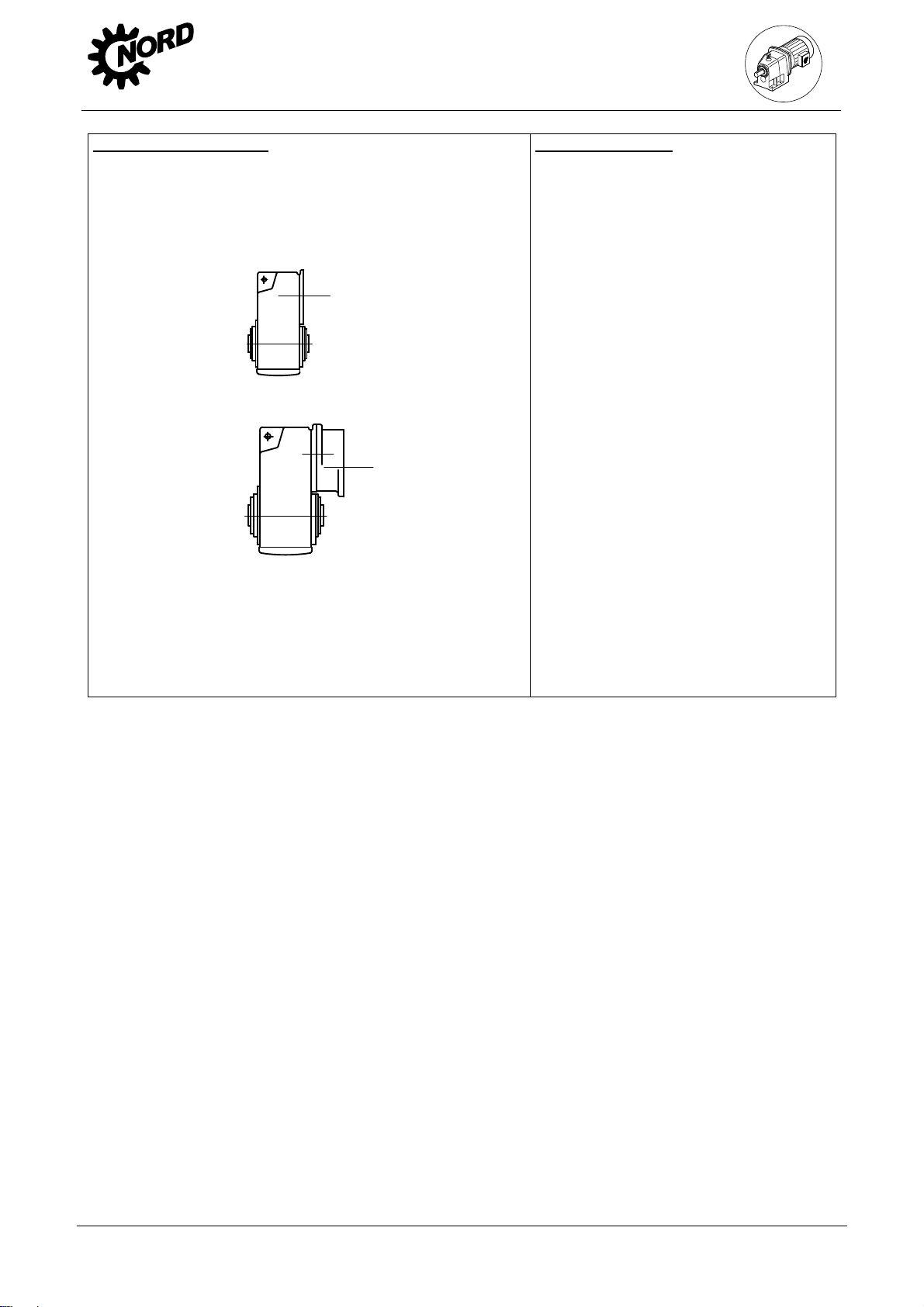

MINIBLOC worm gear units

Type designations:

SK 1S 32, SK 1S 40, SK 1S 50, SK 1S 63, SK 1SU... ,

SK 1SM 31, SK 1SM 40, SK 1SM 50, SK 1SM 63, (1-stage)

SK 2S32NB, SK 2S40NB, SK 2S50NB, SK 2S63NB,

SK 2SU…, SK 2SM40, SK 2SM50, SK 2SM63 (2-stage)

UNIVERSAL worm gear units

Type designations:

SK 1SI31, SK 1SI40, SK 1SI50, SK 1SI63, SK 1SI75,

SK 1SID31, SK 1SID40, SK 1SID50, SK 1SID63, SK 1SID75

SK 1SIS31,…, SK 1SIS75,

SK 1SD31, SK 1SD40, SK 1SD50, SK 1 SD63,

SK 1SIS-D31,…, SK 1SIS-D63

SK 1SMI31, SK 1SMI40, SK 1SMI50, SK 1SMI63, SK 1SMI75

SK 1SMID31,…, SK 1SMID63 (1-stage)

SK 2SD40, SK 2SD50, SK 2SD63, SK 1SI…/31, SK

1SI…/H10,

SK 2SID40,…, SK 2SID63

SK 2SIS-D40,…, SK 2SIS-D63

SK 2SMI40, SK 2SMI50, SK 2SMI63

SK 2SMID40, SK 2SMID50, SK 2SMID 63 (2-stage)

2. Description of gear units

Versions / Options

- Foot mounting with solid shaft

A Hollow shaft version

V Solid shaft version

L Solid shaft both sides

Z Output flange B14

F Output flange B5

D Torque support

X Foot mounting

B Fixing element

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

Versions / Options

V Solid shaft or plug-in shaft

A Hollow shaft version

L Solid shaft both sides

X Feet on three sides

Z Output flange B14

F Output flange B5

D Torque support

H Covering cap

H10 Modular contrate pre-stage

/31 Worm pre-stage

/40 Worm pre-stage

IEC Standard IEC motor attachment

NEMA Standard NEMA motor attachment

W With free drive shaft

VI Viton radial seals

Double gear units consist of two single gear units. They are to be treated as per the instructions

in this Manual, i.e. as two individual gear units.

Type designation of double gear units: e.g. SK 73/22 (consisting of single gears SK 73 and

SK 22)

www.nord.com B2000-GB-0413 -11-

Page 12

3. Storage, preparation,

installation

3 Storage, preparation, installation

3.1 Storing the gear unit

The following must be observed for storage:

Store in the fitting position (see Section 3.4 and 3.5) and secure gear units against falling

Lightly grease bare metal housing surfaces and shafts

Store in dry rooms

Temperature must not fluctuate beyond the range of –5

Relative humidity less than 60%

No direct exposure to sunlight or UV light

No aggressive, corrosive substances (contaminated air, ozone, gases, solvents, acids,

alkalis, salts, radioactivity etc.) in the immediate vicinity

No vibration or oscillation

3.2 Long-term storage

o

C to +50 oC

Note!

For storage or standstill periods in excess of 9 months, Getriebebau NORD

recommends the long-term storage option. With the long-term storage option and the

use of the measures listed below, storage for up to 2 years is possible. As the actual

influences on the unit greatly depend on the local conditions, these times should only

be regarded as guide values.

Conditions of the gear unit and storage area for long-term storage prior to commissioning:

Store in the fitting position (see Section 3.4 and 3.5) and secure gear units against falling

Transportation damage to the external paint must be repaired. Check that a suitable rust

inhibitor is applied to the flange bearing surfaces. If necessary apply a suitable rust inhibitor

to the surfaces.

Gear units with the long-term storage option are completely filled with lubricant or have VCI

corrosion protection agents added to the gear oil. (See label on gear unit)

The sealing band in the vent plug must not be removed during storage. The gear unit must

remain sealed tight.

Store in a dry place.

In tropical regions, the drive unit must be protected against damage by insects

Temperature must not fluctuate beyond the range of –5

o

C to +40 oC

Relative humidity less than 60%

No direct exposure to sunlight or UV light

No aggressive, corrosive substances (contaminated air, ozone, gases, solvents, acids,

alkalis, salts, radioactivity etc.) in the immediate vicinity

No vibration or oscillation

Measures during storage or standstill periods

If the relative humidity is <50% the gear unit can be stored for up to 3 years.

-12- B2000-GB-0413 www.nord.com

Page 13

3. Storage, preparation,

Measures before commissioning

If the storage or standstill period exceeds 2 years or the temperature during short-term

storage greatly deviates from the standard range, the lubricant in the gear unit must be

replaced before commissioning (See Section 5.2).

If the gear unit is completely filled, the oil level must be reduced before commissioning (See

Section 3.5 and 6.1).

3.3 Inspecting the drive unit

Danger!

The drive unit must be inspected and may only be installed if:

No damage, e.g. due to storage or transport is apparent. In particular the shaft

sealing rings, the sealing caps and the covers must be inspected for damage.

No leakage or no oil loss is visible.

No corrosion or other indications of incorrect or damp storage is apparent.

The packaging material has been completely removed.

installation

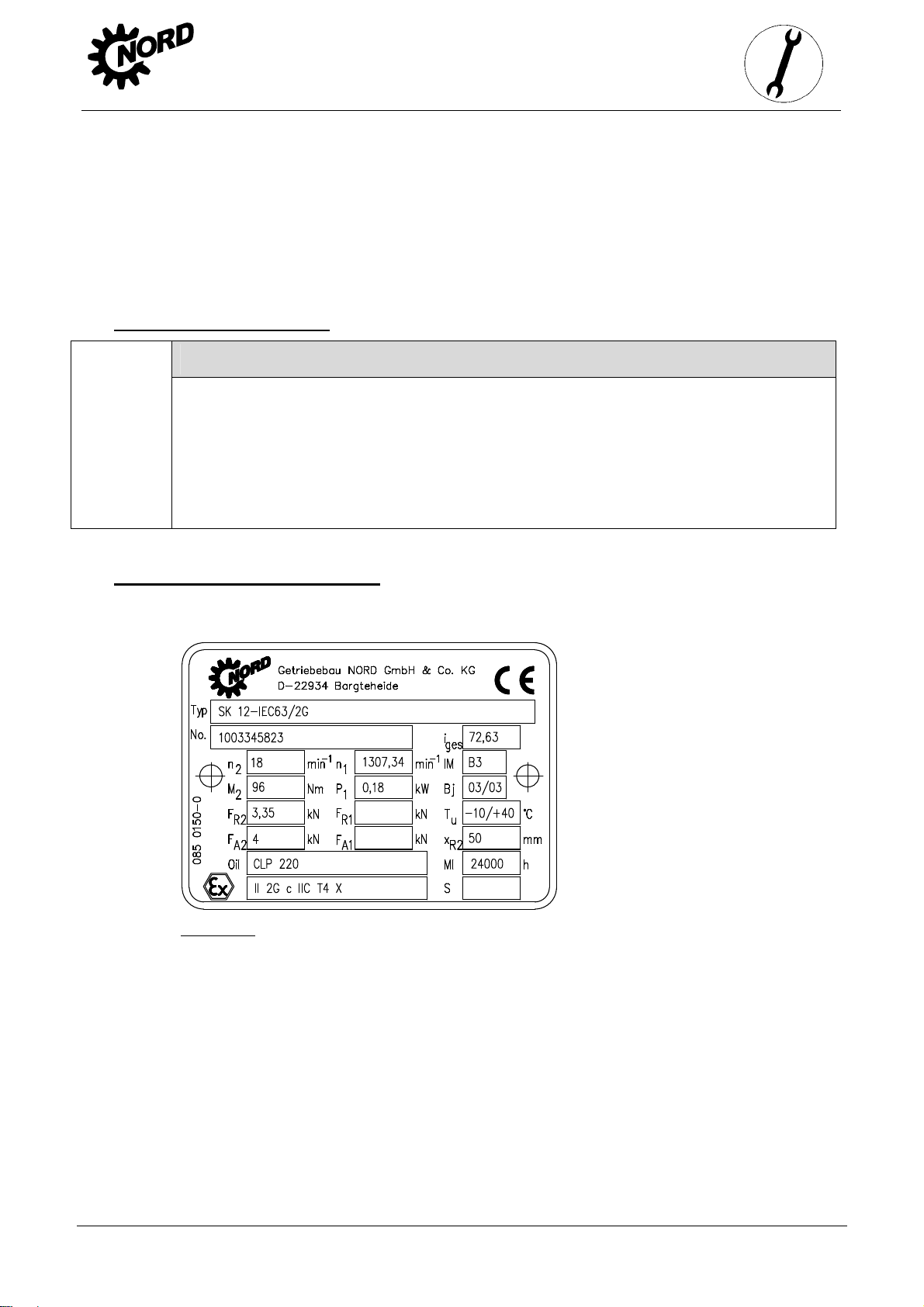

3.4 Checking the rating plate data

The rating plate must be firmly attached to the gear unit and must not be subjected to permanent

soiling. Please contact the NORD service department if the rating plate is illegible or damaged.

Figure 3-1: Rating plate (example)

www.nord.com B2000-GB-0413 -13-

Page 14

3. Storage, preparation,

g

1

1

A

A

Explanation of the Rating Plate

Abbreviation Unit Designation See

Typ - NORD gear unit type

No. - Serial number

i

- Overall gear unit ratio

es

n2 min

n1 min

IM - Configuration (installation orientation) Section 6.1

M2 Nm Max. permissible gear unit drive shaft torque

P1 kW Max. permissible drive power or motor power

Bj - Year of manufacture

FR2 kN Max. permissible transverse force on the gear unit driven shaft Section 3.8

FR1 kN Max. permissible transverse force on the gear unit drive shaft for option W Section 3.8

Tu °C Permissible ambient temperature for the gear unit

-

Rated speed of gear unit drive shaft*

-

Rated speed of the gear unit drive shaft or the drive motor*

installation

F

kN Max. permissible axial force on the gear unit driven shaft Section 3.8

2

F

kN Max. permissible axial force on the gear unit drive shaft for option W Section 3.8

1

MI h Interval between general overhauls of the gear unit in operating hours

or details of the non-dimensional maintenance class CM

xR2 mm Max. dimension for the point of application of the transverse force FR2 Section 3.8

Oil - Gear unit oil type (standard designation) Section 6.2

Last line

S - Number of the special documentation, consisting of serial no. / year

*The maximum permissible speeds are 10% above the rated speed, if the maximum permissible drive power

P1 is not exceeded.

If the fields FR1, FR2, FA1 und FA2 are empty, the forces are zero. If the field xR2 is empty, the point of

application of force F

-

Labelling as per ATEX (DIN EN 13463-1):

1. Group (always II, not for mines)

2. Category (2G, 3G for gas or 2D, 3D for dust)

3. Ignition protection type if fitted (c)

4. Explosion group if applicable (IIC, IIB)

5. Temperature class (T1-T3 or T4 for gas) or max. surface

temperature e.g. 125°C for dust)

6. Temperature measurement on commissioning (X)

is central on the drive shaft journal (See Figure 3-4).

R2

Section 5.2

Section 5.2

Section 4.3

Danger!

It must be checked and ensured that the gear unit type, all technical data and the ATEX

labelling conform to the planning of the plant or the machine.

It should be noted that with geared motors, the electric motor has its own rating plate with a

separate ATEX labelling. The motor labelling must also comply with data for the planning of the

plant or the machine. The lowest explosion protection of the gear unit and the motor

-14- B2000-GB-0413 www.nord.com

Page 15

3. Storage, preparation,

labelling applies for the geared motor unit. If the electric motor is driven with a frequency

inverter, the motor requires ATEX approval for inverter operation.

3.5 Checking the configuration

Danger!

The gear unit may only be operated in the stated configuration. The permissible

configuration is stated on the rating plate (IM ….). If an X is present in the field IM, the

special documentation, whose number is in field S, must be observed. Section 6.1, or

the special documentation, shows the configuration of the individual types of gear

units. It must be checked and ensured that the configuration as stated on the rating

plate complies with the installation orientation and that the installation orientation does

not change during operation.

The UNIVERSAL worm gear units type SK1SI... do not depend on the version, as with

these types of gear unit, the abbreviation UN is entered in the IM field of the type plate.

3.6 Preparing for installation

The drive unit must be inspected and may only be installed if no transportation damage or leaks

are visible. In particular the radial seals and the sealing caps must be inspected for damage.

All bare metal surfaces and shafts of the gear unit are protected against corrosion with oil,

grease or corrosion protection agents before shipping.

Thoroughly remove all oil, grease or corrosion protection agents and any dirt from the shafts and

flange surfaces before assembly.

installation

Danger!

Care must be taken that drive elements attached to the gear unit, such as clutches,

pulleys etc. and drive motors are also ATEX-compliant.

In applications where an incorrect rotational direction may result in damage or potential risk, the

correct rotational direction of the drive shaft is to be established by test running the drive when

uncoupled and guaranteeing such for subsequent operation.

Danger!

Gears with integrated return stops are marked with arrows on the driven/driving sides.

The arrows point in the rotation direction of the gear unit. It must be ensured, when

connecting the motor and during motor control, that the gear unit can only operate in

the rotation direction, e.g. by means of a rotary field test. Switching of the motor into

the blocked direction of rotation, i.e. the wrong direction of rotation may cause damage

to the gear unit.

Ensure that no aggressive or corrosive substances are present in the area surrounding the

installation site or are subsequently expected during operation, which attack metal, lubricants or

elastomers. In case of doubt, please contact Getriebebau NORD and take the recommended

action.

www.nord.com B2000-GB-0413 -15-

Page 16

3. Storage, preparation,

Oil expansion tanks (Option OA) must be fitted in accordance with works standard WN 0-530 04.

For M10x1 screw fixings, the attached works standard WN 0-521 35 must also be observed.

The pressure vent must be activated prior to commissioning. To activate, remove the transport

securing devices.

Double gear units consist of two single units and are equipped with 2 oil chambers and 2

pressure vents. Position of the vent plug: see Section 6.1.

Figure 3-2: Activation of the pressure vent

3.7 Installing the gear unit

installation

Danger!

The eyebolts screwed into the gear units must be used during installation. During

installation, no additional weights may be attached to the gear unit. If geared motors

have an additional eyebolt attached to the motor, this must also be used. Avoid pulling

the eyebolts at an angle.

Danger!

No explosive atmosphere must be present when installing the gear unit.

The base and/or flange to which the gear unit is fitted should be vibration-free, torsionally rigid

and flat (flatness error <0.2 mm). All contamination to the bolting surfaces of gear unit and base

and/or flange must be thoroughly removed.

The gear unit housing must always be earthed. With geared motors, earthing via the motor

connection must be ensured.

The gear unit must be installed in the correct configuration (See Section 3.5 and 6.1). All

gear unit feet and/or all flange bolts on each side must be used. Bolts must have a minimum

quality of 10.9. The bolts must be tightened to the correct torques (refer to Section 6.3 for torque

values). Tension-free bolting must be ensured, particularly for gear units with a foot and flange.

The oil inspection screws, oil drain screws and the vent valves must be accessible.

To ensure that the gearbox does not get too warm and to avoid injury to persons, observe

the following during installation:

Danger!

The surfaces of gear units or geared motors may become hot during or shortly after operation.

Attention: danger of burns! Protection against accidental contact may need to be installed.

-16- B2000-GB-0413 www.nord.com

Page 17

3. Storage, preparation,

installation

Danger!

The cooling air supplied to the gear unit/geared motor must be within the permissible

temperature range stated on the rating plate.

In case of direct sunlight falling onto the gear unit, the cooling air supplied to the gear

unit/geared motor must be at least 10°C below the highest permissible temperature of

the ambient temperature range Tu, which is stated on the rating plate.

Enable the free flow of air to all sides of the gear unit.

Ensure adequate space around the gear unit.

With geared motors, the cooling air of the motor fan must be able to flow unobstructed

onto the gear unit.

Do not enclose or encase the gear unit/geared motor.

Do not subject the gear unit to highly energetic radiation.

Do not direct warm exhaust air from other units onto the gear unit/geared motor.

The base or flange to which the gear unit is attached must not input any heat into the

gear unit during operation.

Do not pile up dust in the area of the gear unit

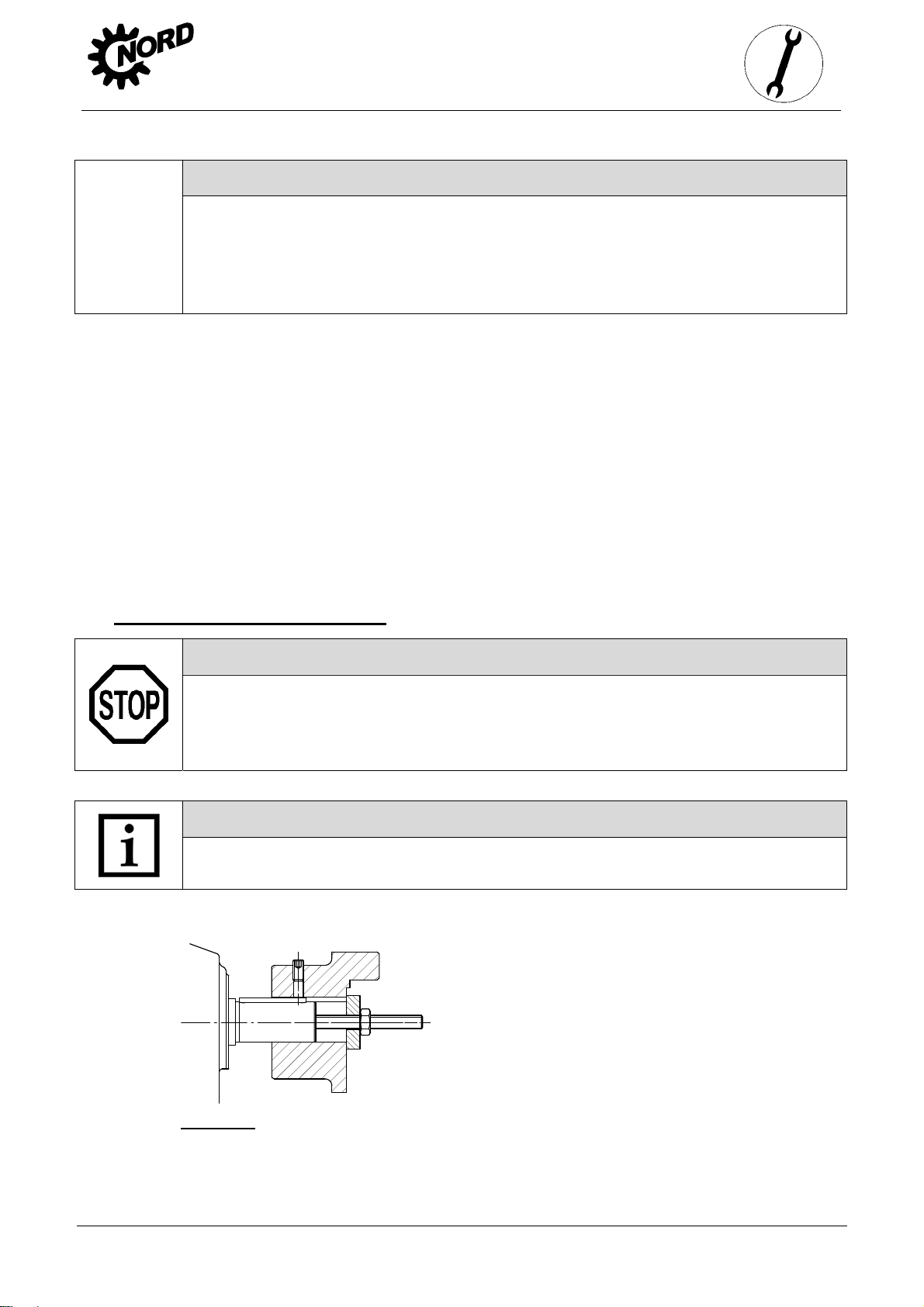

3.8 Fitting hubs on the gear shafts

Danger!

Drive and driven elements, e.g. coupling and chain-wheel hubs must be mounted onto

the drive and driven shaft of the gear unit using suitable pullers that will not apply

damaging axial forces onto the gear unit. In particular, do not hit the hubs with a

hammer.

Note!

Use the end thread of the shafts for pulling. Fitting can be aided by coating the hub

with lubricant or heating it up to approx. 100

o

C beforehand.

Figure 3-3: Example of a simple pulling device

www.nord.com B2000-GB-0413 -17-

Page 18

3. Storage, preparation,

installation

Danger!

Drive and driven elements, such as belt drives, chain drives and couplings must be

fitted with contact protection.

Danger!

Care must be taken that drive and driven elements attached to the gear unit must also

be ATEX-compliant.

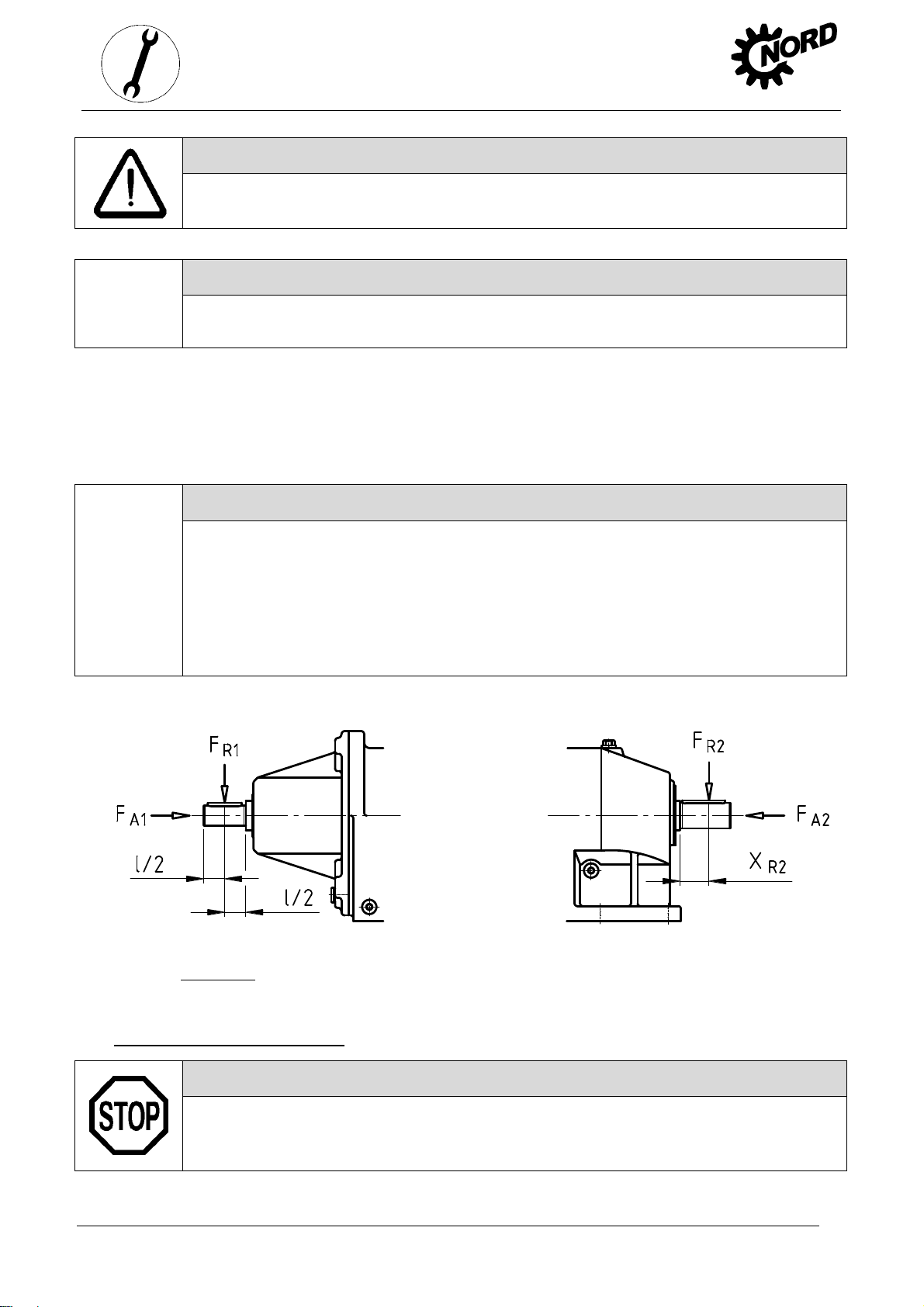

Drive and driven elements may only subject the drive units to the maximum radial forces

and FR and axial forces FA1 and FA as specified on the rating plate (See Section 3.4).

F

R1

Observe the correct tension, particularly on belts and chains. Additional loads due to unbalanced

hubs are not permitted.

Danger!

The radial force must be applied to the gear unit as closely as possible. For drive

shafts with free shaft ends – Option W – the maximum permissible transverse force

FR1 applies for the application of the transverse force to the centre of the free shaft

journal. For driven shafts, the application of the transverse force FR2 must not exceed

the dimension xR2 . If the transverse force F

rating plate, but no dimension xR2 is stated, the application of the force is assumed to

be to the centre of the shaft journal.

for the driven shaft is stated on the

R2

Free drive shaft (Option W) Driven shaft

Figure 3-4: Permissible application of force to drive and driven shafts

3.9 Fitting push-on gear units

Attention!

The push-on gear unit must be fitted onto the shaft using a suitable puller, which will

not exert damaging axial forces on the gear unit. In particular, do not hit the gear unit

with a hammer.

-18- B2000-GB-0413 www.nord.com

Page 19

3. Storage, preparation,

Assembly and subsequent dismantling is facilitated by applying an anti-corrosive lubricant to the

shaft before fitting (e.g. Nord Anti-Corrosion Art.-No. 089 00099). Excess grease or anticorrosion agent may escape after assembly and bay drip off. Clean these points on the output

shaft after a running-in time of approx. 24 hours. This escape of grease is not due to a leak in

the gear unit.

Figure 3-5: Applying lubricant to the shaft and the hub

installation

Note!

The gear unit can be fitted to shafts with and without a shoulder using the fastening

element (Option B). Tighten the bolt of the fastening element to the correct torque. (See

Chapter 6.3 for torque values.) For gear units with option H66, the factory-fitted closing

cap must be removed before fitting.

For shaft mounted gear units with option H66 and fastening element (Option B) the pressed-in

closing cap must be pushed out before fitting the gear unit. The pressed-in closing cap may be

destroyed during dismantling. As standard a second closing cap is supplied as a loose spare

part. After fitting the gear unit, fit the new / new condition closing cap as described in Section 3.11.

Figure 3-6: Removing the factory-fitted closing cap

Figure 3-7: Gear unit mounted to shaft with a shoulder using the fastening element

www.nord.com B2000-GB-0413 -19-

Page 20

3. Storage, preparation,

Figure 3-8: Gear unit mounted to shaft without a shoulder using the fastening element

A gear unit can be dismantled from a shaft with shoulder using the following device, for example.

Figure 3-9: Dismantling using dismantling device

installation

When mounting push-on gears with torque supports, the support must not be distorted. Tensionfree mounting is aided by the rubber buffer (Option G and/or VG).

Figure 3-10: Mounting the rubber buffer (Option G and/or VG) on parallel shaft gear units

To fit the rubber buffer, tighten the screw fastening until there is no play between the contact

surfaces when there is no load. Then turn the fastening nut (only applies for adjusting threads)

half a turn in order to pre-tension the rubber buffer. Greater pre-tension is not permissible.

Secure the screw fastening against coming loose, e.g. with Loctite 242 or a second nut.

-20- B2000-GB-0413 www.nord.com

Page 21

3. Storage, preparation,

Figure 3-11: Attaching the torque support on bevel gear and worm gear units

Tighten the bolts on the torque support to the correct torque (see Section 6.3 for tightening

torque values) and secure to prevent loosening. (e.g. Loctite 242, Loxeal 54-03)

installation

Always support torque support on both sides!

3.10 Fitting shrink discs

Shrink disc type, Mat. No.

and torque details for tensioning screws

Tensioning screws DIN 931 (933) -10.9

The shrink discs are supplied by the manufacturer

ready for fitting. They must not be dismantled prior to

fitting.

Figure 3-12: Hollow shaft with shrink disc

Attention!

Tensioning flanges

Solid shaft of machine

Hollow shaft of gear unit

Double half-slotted inner ring

Shaft and hollow shaft bore

GREASE FREE!

Do not tighten the tensioning screws if the shaft is not inserted!

Assembly sequence:

1. Remove any transport securing devices.

2. Loosen but do not remove tightening bolt and tighten gently by hand until there is no play

between the flanges and the inner ring.

www.nord.com B2000-GB-0413 -21-

Page 22

3. Storage, preparation,

3. Slide the shrink disc onto the hollow shaft until the outer clamping flange is flush with the

hollow shaft. The shrink disc is easier to slide on if the bore of the inner ring is lightly

greased.

4. Prior to mounting, grease the solid shaft only in the area which will later come into contact

with the bronze bush in the hollow shaft of the gear unit. Do not grease the bronze bush, in

order to prevent grease penetrating the area around the shrink connection.

5. The hollow shaft of the gear unit must be completely de-greased and completely

free of grease.

6. In the area of the shrink connection the solid shaft of the machine must be degreased and

completely free of grease.

7. Insert the solid shaft of the machine into the hollow shaft so as to completely fill the area

around the shrink connection.

8. Position the clamping flange by gently tightening the bolts.

9. Tighten the bolts successively in a clockwise direction by several turns – not crosswise –

with approx. ¼ rotation per turn. Tighten the bolts with a torque wrench to the torque

indicated on the shrink disc.

10. When the tensioning bolts have been tightened, there must be an even gap between the

clamping flanges. If this is not the case, the gear unit must be dismantled and the shrink disc

connection checked for correct fit.

11. The hollow shaft of the gear unit and the solid shaft of the machine should be marked with a

line (felt-tip pen) in order to detect any slippage under load.

installation

Danger!

Risk of injury from incorrect mounting and dismantling.

Dismantling sequence:

1. Loosen the bolts successively in a clockwise direction by several turns with approx. ¼

rotation per turn. Do not remove the bolts from their thread.

2. Loosen the clamping flanges from the cone of the inner ring.

3. Remove the gear unit from the solid shaft of the machine.

If a shrink disk has been in use for a long period or is dirty, it must be dismantled, cleaned and

the conical surfaces coated with Molykote G Rapid Plus or a similar lubricant before it is refitted.

The treads and head surfaces of the screws must be treated with grease without Molykote. In

case of damage or corrosion, damaged components must be replaced.

3.11 Fitting the covers

Danger!

Shrink disks require protection against contact. Covers (Option H) serve as contact

protection. These must always be used if contact protection is not provided by other

methods.

-22- B2000-GB-0413 www.nord.com

Page 23

3. Storage, preparation,

installation

Danger!

Covers must be inspected for transportation damage e.g. dents and warping before

they are fitted. Damaged covers must not be used, as they may cause rubbing.

All fixing screws must be used and coated prior to use with a securing lubricant e.g. Loctite 242,

Loxeal 54-03 and tightened to the correct torque. (See Section 6.3 for torque values) For covers

with option H66, press in the new / new condition closing cap by tapping it lightly with a hammer.

Figure 3-13: Fitting the covers, Option SH, Option H, and Option H66

3.12 Fitting a standard motor

Danger!

Only standard motors with an adequate ATEX Zone category according to the rating

plate may be used. In addition, for ATEX category 2D gear units (see the ATEX labelling

on the last line of the gear unit rating plate), the motor must have at least protection

class IP6x.

The maximum permitted motor weights indicated in the table below must not be exceeded:

Maximum permitted motor weights

IEC motor size 63 71 80 90 100 112 132 160 180 200 225 250 280 315

NEMA Motor size 56C 143T 145T 182T 184T 210T 250T 280T 324T 326T 365T

Max. motor weight [kg] 25 30 40 50 60 80 100 200 250 350 500 700 1000 1500

Assembly procedure to attach a standard motor to the IEC adapter (Option IEC)/NEMA adapter

1. Clean motor shaft and flange surfaces of motor and adapter and check for damage.

Mounting dimensions and tolerances of the motor must conform to DIN EN 50347/NEMA

MG1 Part 4.

2. Push the coupling sleeve onto the motor shaft so that the motor parallel key engages into

the groove in the sleeve on tightening.

3. Tighten the coupling sleeve on the motor shaft in accordance with the motor manufacturer’s

instructions until it touches the collar. With motor sizes 90, 160, 180 and 225, any spacer

bushes must be positioned between the coupling sleeve and the collar. With standard helical

gear units, dimension B between the coupling sleeve and the collar must be observed (see

Figure 3-14). Certain NEMA adapters require the adjustment of the coupling in accordance

with the specifications indicated on the adhesive plate.

www.nord.com B2000-GB-0413 -23-

Page 24

3. Storage, preparation,

installation

4. If the coupling half contains a threaded pin, the coupling must be secured axially on the

shaft. The threaded pin must be coated prior to use with a securing lubricant e.g. Loctite

242, Loxeal 54-03 and tightened to the correct torque. (See Chapter 6.3 for torque values)

5. The flange surfaces of motor and adapter must be completely coated with surface sealant

e.g. Loctite 574 or Loxeal 58-14 prior to mounting the motor, so that the flange seals after

mounting. (only necessary for category 2D gear units – see ATEX labelling on the last line of

the gear unit rating plate) Sealing of the flange surfaces is also recommended for installation

outdoors or in damp environments.

6. Mount the motor to the adapter. Do not forget to fit the gear rim or the sleeve.

(See Figure 3-14)

7. Tighten the adapter bolts to the correct torque. (See Chapter 6.3 for torque values)

Figure 3-14: Fitting the coupling onto the motor shaft - various types of coupling

I Gear coupling (BoWex), one-part

II Gear coupling (BoWex

III Gear coupling (BoWex

IV Claw coupling (ROTEX

V Claw coupling (ROTEX

), two-part

), two-part with spacer bush

), two-part

), two-part, observe dimension B:

Standard helical gear unit: SK0, SK01, SK20, SK25, SK30, SK33 (2-stage)

SK010, SK200, SK250, SK300, SK330 (3-stage)

IEC size 63 IEC size 71

Dimension B (Figure 3-12 V) B = 4.5mm B = 11.5 mm

VI Claw coupling (ROTEX), two-part with spacer bush

-24- B2000-GB-0413 www.nord.com

Page 25

3. Storage, preparation,

3.13 Subsequent paintwork

Attention!

For retrospective painting of the gear unit, the radial seals, rubber elements, pressure venting

valves, hoses, type plates, adhesive labels and motor coupling components must not come

into contact with paints, lacquers or solvents, as otherwise components may be damaged or

made illegible.

3.14 Temperature sticker

Danger!

With temperature class T4 gear units with a maximum surface temperature of less than

135°C the supplied self-adhesive temperature sticker (printed with value 121°C) must

be affixed to the gear unit housing. (Part No.:283 9050).

The temperature class or the maximum surface temperature can be seen from the ATEX

labelling in the last line of the rating plate.

Examples: II 2G c IIC T4 X or II 3D 125°C X

The temperature sticker must be affixed next to the oil level screw (See Section 6.1) towards the

motor. For gear units with an oil level vessel, the temperature sticker must be affixed in the same

position as for gear units without an oil level vessel. For gear units which are lubricated for life,

without oil maintenance, the temperature sticker should be affixed next to the rating plate.

installation

Figure 3-15: Position of the temperature sticker

3.15 Fitting the cooling coil to the cooling system

The cooling coil is recessed into the housing cover (See Item 2, Figure 3-16). Cutting ring screw

threads (see Item 1, Figs. 3-16) are located at the casing cover for the connection of a pipe with

an external diameter of 10 mm according to DIN 2353. Remove the drain plug from the screw

neck prior to assembly to avoid any contamination of the cooling system. The screw necks

should be connected with the coolant circuit, which must be provided by the operator. The flow

direction of the coolant is irrelevant.

www.nord.com B2000-GB-0413 -25-

Page 26

3. Storage, preparation,

Make sure not to twist the screw necks during or after assembly as the cooling coil may be

damaged (see Item 3, Figure 3-16). You must ensure that no external forces act on the cooling

coil.

1

2

Figure 3-16: Cooling cover

installation

3

Danger!

The pressure released from the cooling circuit before carrying out any work on the gear

unit.

-26- B2000-GB-0413 www.nord.com

Page 27

4 Commissioning

4.1 Check the oil level

Danger!

Before commissioning, the oil level must be checked with the supplied dipstick.

The installation must comply with the configuration on the rating plate. Section 6.1 describes the

versions and the corresponding oil level screws. With double gear units, the oil level must be

checked on both units. The pressure vent must be at the position marked in Section 6.1.

The oil level does not need to be checked on gear units without oil level screw (see Section 6.1).

Gear unit types that are not supplied full of oil must be filled before the oil level is checked.

(See Section 5.2)

Checking the oil level:

1. The oil level must only be checked when the gear unit is at a standstill and has cooled

down. The gear unit must be secured to prevent accidental switch-on.

2. Gear units with oil level screw:

4. Commissioning

Standard configuration M4 (V1 and V5) helical gear units have an angled pipe for checking

the oil level. This must point vertically upwards as shown in Figure 4-1 C. Before checking the

oil level, the pressure vent must be unscrewed.

The oil level screw corresponding to the version must be screwed out. (See Section 6.1)

The oil level in the gear unit should be checked with the supplied dipstick

(Part No.: 283 0050) as shown in Figure 4-1 A, C. To do this, the part of the dipstick which is

submerged in the oil must be held vertically.

The maximum oil level is the lower edge of the oil level hole.

The minimum oil level is approx. 4 mm below the lower edge of the oil level hole. The dipstick

then just dips into the oil.

If the oil level is not correct, it must be adjusted by draining off oil or topping up with the type

of oil stated on the rating plate.

If the screw lock coating in the thread of the oil drain screw or oil level screw is damaged, a

new oil level screw must be used or the thread cleaned and coated with securing adhesive,

e.g. Loctite 242, Loxeal 54-03 prior to insertion.

Check the sealing ring for damage. Replace with a new sealing ring in case of damage.

Fit the oil level screw together with the sealing ring and tighten to the correct torque. (See

Section 6.3 for torque values)

If the pressure vent has been unscrewed, reinsert it together with the sealing ring and tighten

to the correct torque. (See Section 6.3 for torque values)

3. Gear units with an oil level vessel:

The oil level must be checked in the oil level vessel with the aid of the dipstick plug (thread

G1 1/4). The oil level must be between the upper and lower marking when the dipstick is fully

screwed in (see Figure 4-1 B). These gearboxes may only be operated in the configuration

stated in Section 6.1.

www.nord.com B2000-GB-0413 -27-

Page 28

A

4. Gear units with oil inspection glass:

Check the oil level as described under 2. The oil level must be checked by means of its position

in the oil inspection glass.

5. Final check: Previously loosened screws must be correctly tightened.

4. Commissioning

Figure 4-1: Check the oil level with a dipstick

B

4.2 Activating the Automatic Lubricant Dispenser

Danger!

Some gear unit types with standard motor (Option IEC/NEMA) have an automatic

lubricant dispenser for the rolling bearings. This dispenser must be activated prior to

commissioning. The cartridge case cover has a red information sign for the activation

of the lubricant dispenser.

Activating the Automatic Lubricant Dispenser:

1. Loosen and remove cylinder bolts M8x16 (1)

2. Lift off cartridge case cover (2)

3. Insert activation screw (3) into the lubricant dispenser (5) until the lug (4) breaks off at the

defined fracture point

4. The flange surfaces of the cartridge case cover (2) must be completely coated with

surface sealant e.g. Loctite 574 or Loxeal 58-14 prior to assembly, so that the cover seals

after it has been fitted. (Only necessary for Category 2D gear units – see ATEX labelling,

last line of the rating plate)

5. Refit cartridge case cover (2) and fasten using cylinder bolt (1). (See Chapter 6.3 fo r torque

values)

6. Mark activation date on the adhesive plate (6) indicating month/year

C

-28- B2000-GB-0413 www.nord.com

Page 29

Attention!

Screw in the activation screw until the lug breaks off

before commissioning the gear unit.

Dispensing time: 12 Months

Month Activation date Year

1 2 3 4 5 6 7 8 9 10 11 12 99 00 01 02 03

Figure 4-2: Activating the automatic lubricant dispenser with standard motor mounting

4.3 Temperature measurement

The details of the ATEX temperature class or the maximum surface temperature are based on

normal installation conditions (See Section 3.6). Even small changes to the installation

conditions can have a significant effect on the temperature of the gear unit.

4. Commissioning

Danger!

On commissioning, a surface temperature measurement of the gear unit must be made

under maximum load.

(This does not apply to gear units which are labelled as temperature class T1 – T3 or a

maximum surface temperature of 200°C in the last line of the rating plate.)

For the measurement, a normal temperature measuring device is required, with a measurement

range from 0°C to 130°C and a precision of at least ± 4°C and which enables the measurement

of the surface temperature and the temperature of the air. Temperature measurement

procedure:

1. Allow the gear unit to run at maximum speed under maximum load for approx. 4 hours.

2. After it has warmed up, measure the temperature of the surface of the gear unit housing

Tgm immediately next to the temperature label (See Section 3.14).

3. Measure the temperature of the air Tum in the immediate vicinity of the gear unit.

Danger!

The gear unit must be shut down and Getriebebau NORD must be consulted if any of

the following criteria do not apply:

The measured air temperature Tum is within the permissible range stated on the rating plate.

The measured temperature of the surface of the gear unit housing Tgm is below 121°C and

the temperature sticker has not turned black. (See Figure 4-3)

www.nord.com B2000-GB-0413 -29-

Page 30

g

g

The measured temperature of the surface of the gear unit housing plus the difference

between the highest permissible air temperature Tu stated on the rating plate and the

measured air temperature must be at least 15°C lower than the maximum permissible

surface temperature, i.e.:

4. Commissioning

ATEX labelling: II 2G c T4 / II 3G T4: T

ATEX labelling: II 2D c T

Tgm: measured temperature of the surface of the gear unit housing in °C

Tum: measured air temperature in °C

T

: maximum surfa ce tempe rature acco rding t o gear unit rating pl ate (ATEX la belling) in °C

max

Tu: upper value of the permissible ambient temperature range according to the rating plate in °C

max

/ II 3D T

Centre dot is white: Centre is black:

OK Temperature was too high

Figure 4-3: Temperature sticker

4.4 Operation with lubricant cooling

+ Tu – Tum < 135°C – 15°C

m

: T

max

+ Tu – Tum < T

m

max

– 15°C

The drive may only be commissioned after the cooling spiral has been connected to the cooling

circuit, and the cooling circuit has been put into operation.

The coolant must have a similar thermal capacity as water (specific thermal capacity at 20°C

c=4.18 kJ/kgK). Industrial water without any air bubbles or sediments is recommended as a

coolant. The water hardness must be between 1° dH and 15° dH, and the pH value must be

between pH 7.4 and pH 9.5. No aggressive liquids should be added to the coolant!

The coolant pressure must not exceed 8 bar. The required quantity of coolant is 10

litres/minute, and the coolant inlet temperature should not exceed 40°C; we recommend

10°C.

We also recommend fitting a pressure reducer at the coolant inlet to avoid any damage due to

excessive pressure.

If there is a danger of frost the operator should add a suitable anti-freeze solution to the cooling

water.

Danger!

The temperature of the cooling water and the cooling water flow rate must be

supervised and ensured by the operator.

The ATEX approval is void if these instructions are not observed!

-30- B2000-GB-0413 www.nord.com

Page 31

4.5 Checking the gear unit

During a test run under full load, the gear unit should be checked for:

Unusual noises, such as grinding, knocking or rubbing noises

Unusual vibrations, oscillations and movements

Production of steam or smoke

After the test run, the gear unit should be checked for:

Leaks

Slippage of the shrink disks. For this, the cover should be removed and a check carried out

whether the marking described in Section 3.10 shows a relative movement of the hollow shaft

of the gear unit and the machine shaft. Then the cover should be fitted as described in

Section 3.11.

Note!

Shaft sealing rings are rubbing seals and have sealing lips made from an elastomer

material. These sealing lips are lubricated with a special grease at the factory. This

reduces the wear due to their function and ensures a long service life. An oil film in the

region of the rubbing sealing lip is therefore normal and is not due to leakage.

4. Commissioning

Danger!

The drive must be shut down and Getriebebau Nord consulted if any irregularities are

observed during the checks described above.

4.6 Checklist

Checklist

Information –

Object of the check Checked on:

Is any transportation damage or damage apparent? Section 3.3

Does the labelling on the rating plate conform to the specifications? Section 3.4

Does the configuration on the rating plate conform to the actual installation? Section 0

Is the pressure vent screwed in? Section 3.6

Do all drive and driven elements have ATEX approval? Section

Are the external gear shaft forces within permitted limits (chain tension)? Section

Are contact guards fitted to rotating components? Section 0

Does the motor also have a relevant ATEX approval? Section 3.12

see Section

Is the temperature sticker affixed? Section 3.14

Has the correct oil level for the configuration been checked? Section 4.1

Is the automatic lubricant dispenser activated? Section 4.2

Has the temperature measurement been carried out? Section 4.3

Has the centre of the temperature sticker turned black? Section 4.3

www.nord.com B2000-GB-0413 -31-

Page 32

Is the cooling cover connected to the cooling circuit? Section 3.15/4.4

Has the gear unit been checked with a test run? Section 4.5

Has the shrink disk connection been checked for slippage? Section 4.5

4. Commissioning

4.7 Operation of the gear unit in explosive areas

Danger!

When operating the gear unit, the instructions in this operating manual must be

complied with.

The prescribed inspection and servicing intervals must be complied with.

It must be ensured that the power ratings stated on the rating plate are not exceeded. If,

e.g. for variable speed drive units, there are several operating points, the maximum

permissible drive power P1 or the maximum permissible torque on the driven shaft M2

or the maximum permissible speed must not be exceeded at any operating point.

Overload of the gear unit must be ruled out.

If the gear unit is equipped with a cooling coil, it may only be put into operation if the

cooling coil has been connected to the cooling circuit and the cooling circuit is in

operation. The temperature of the cooling fluid and the cooling fluid flow rate must be

monitored and ensured by the operator.

Gear units with an integrated back stop on the drive shaft may only be operated at

more than the minimum speed of the gear unit drive shaft, n

During operation, there must be no electrostatic charging effects on the surface of the

gear unit (e.g. friction on the surface of the housing).

During operation, if any of the irregularities described in Section 4.5 are detected, or

the temperature sticker has turned black, the gear unit must be shut down and

Getriebebau NORD must be consulted.

1min

= 900 min

-1

.

-32- B2000-GB-0413 www.nord.com

Page 33

5. Service and maintenance

5 Service and maintenance

5.1 Service and Maintenance Intervals

Service and Maintenance Intervals Service and Maintenance Work Information –

see Section

Weekly

or every 100 operating hours

Every 2500 operating hours,

at least every six months

Every 5000 operating hours,

at least every year

(Only for standard IEC/NEMA motor

attachment)

Every 10000 operating hours,

at least every 2 years

Every 25000 operating hours,

at least every 5 years

According to the interval specified in

field MI of the rating plate

at least every 10 years

(Only for Category 2G and 2D)

- Perform a visual inspection for leaks

- Check the gear unit for unusual running noises

and/or vibrations

- Only for gear units with cooling cover:

Visual inspection of temperature sticker

- Check oil level

- Visual inspection of rubber buffer

- Visual inspection of hose

- Visual inspection of temperature sticker

- Remove dust

(only for category 2D)

- Check coupling

(Only for category 2G and standard IEC/NEMA

motor attachment)

- Re-grease

(applicable only to free drive shaft / Option W

and for agitator bearings / Option VLII / VLIII)

- Clean or replace the pressure venting screw

- Replace the automatic lubricant dispenser 5.2 / 4.2

- Changing the oil

- Check the cooling coil for deposits

- Replace shaft sealing rings if worn

- Re-lubrication of the bearings in the gear unit

- General overhaul 5.2

5.2

5.2

5.2

4.1

5.2

5.2

5.2 / 4.3

5.2

5.2

5.2

5.2

5.2

5.2

5.2

5.2 Service and Maintenance Work

Danger!

No explosive atmosphere must be present during servicing and repair work. Servicing

and maintenance work must only be performed by qualified specialist personnel.

When cleaning the gear unit, do not use procedures or materials which may cause

electrostatic charging of the gear unit or adjacent non-conducting components.

www.nord.com B2000-GB-0413 -33-

Page 34

Danger!

Installation and maintenance work must only be performed when gear units are at a

standstill. The drive must be isolated and secured to prevent accidental start-up.

Visual inspection for leaks:

Danger!

The gear unit must be checked for leaks. Attention should be paid to escaping gear oil

and traces of oil on the exterior or underneath the gear unit. In particular, the radial

seals, cover caps, screw plugs, hoses and housing joints should be checked.

If leaks are suspected, the gear unit should be cleaned, the oil level checked (see Section 4.1)

and checked again for leaks after approx. 24 hours. If a leak is confirmed (dripped oil), the gear

unit must be repaired immediately. Please contact the NORD service department.

If the gear unit is equipped with a cooling coil in the housing cover, the connections and the

cooling coil must be checked for leaks. If there are any leaks, these must be repaired

immediately. Please contact the NORD service department.

5. Service and maintenance

Check for running noises

Danger!

If the gear unit produces unusual running noises and/or vibrations, this could indicate

damage to the gear unit In this case the gear should be shut down and a general

overhaul carried out.

Checking the oil level:

See Section 4.1

Visual inspection of the rubber buffer

Gear units with rubber buffers (Option G or VG) and gear units with torque supports are

equipped with rubber elements. If these show damage such as tears to the rubber surface, the

elements must be replaced. Please contact the NORD service department.

Visual inspection of hose

Gear units with an oil level vessel (Option OT) have rubber hoses. If damage to the external

surface of the hoses as far as where they are inserted occurs, e.g. due to abrasions, cuts or

tears, they must be replaced. Please contact the NORD service department.

Visual inspection of the temperature sticker

(Only necessary for temperature class T4 or max. surface temperature < 135°C)

-34- B2000-GB-0413 www.nord.com

Page 35

Remove dust

5. Service and maintenance

Danger!

The temperature sticker must be checked that it has not turned black (See Figure 4-3).

If the temperature sticker has turned black, the gear unit has become too hot.

The cause of overheating must be established. Please contact the NORD service department

immediately. The drive unit must not resume operation before the cause of overheating has

been remedied and renewed overheating can be ruled out. Before recommissioning, a new

temperature sticker must be affixed to the gear unit (See Section 3.14).

(Only necessary for Category 2D)

Danger!

Dust deposits on the gear unit housing must be removed if they are more than 5 mm

thick.

With gear units fitted with a covering cap (Option H) the covering cap must be removed. Dust

deposits in the covering cap, on the driven shaft and on the shrink disk must be removed. Then

the covering cap must be fitted (See Section 3.11). Note: Some covering caps can be completely

sealed with liquid sealing agent. In such cases, there is no need for regular cleaning of the

covering cap if it is completely sealed with a liquid sealing agent such as Loctite 574 or Loxeal

58-14.

Checking the coupling

(Only necessary for Category 2G and IEC/NEMA standard motor attachments)

The motor must be removed. Plastic or elastomer coupling components must be examined for

traces of wear. If the limiting values listed below for the particular coupling versions and sizes

are exceeded, the plastic or elastomer coupling components must be replaced. Caution: only

use replacement parts with the same colour!

With claw couplings (ROTEX

as per Figure 5-1. B

Figure 5-1: Measurement of gear rim wear with ROTEX

For gear couplings, the limiting wear value is X = 0.8 mm, as per Figure 5-2.

) the tooth thickness of the elastomer gear rim must be measured

is the minimum permissible tooth thickness.

min

Limiting wear values for coupling gear rims

Type R14 R24 R38 R42 R48 R65 R90

B 9.7 8.6 13.3 15.7 17.7 22.2 32.3

Bmin 7.7 5.6 10.3 11.7 13.7 17.2 24.3

claw couplings

www.nord.com B2000-GB-0413 -35-

Page 36

5. Service and maintenance

SleeveSleeve

Regreasing

Hub Hub

New Wear limit X = 0.8mm

Figure 5-2: Measurement of gear sleeve wear for gear BoWex

couplings

Note!

If the examination only shows slight wear (25% of the limiting value), it is permissible to

extend the interval for examination of the coupling to twice the normal period, i.e. 5000

operating hours and at least every year.

Some gear unit designs (free drive shaft, Option W, agitator designs VLII and VLIII) are

equipped with a regreasing device.

For agitator versions VLII and VLIII, the vent screw located opposite to the grease nipple must

be unscrewed before regreasing. Grease should be injected until a quantity of 20-25g escapes

from the vent hole. After this, the vent plug must be reinserted and tightened.

For Option W and some IEC adapters, the outer roller bearing must be regreased with approx.

20-25g of grease via the grease nipple provided

Recommended grease: Petamo GHY 133N (see Section 6.4: Klüber Lubrication).

Cleaning or replacing the vent screw

Unscrew the pressure vent, thoroughly clean the vent screw (e.g. with compressed air) carry out

a function test and fit the vent screw in the same place. If necessary, use a new vent screw.

Replacing the automatic lubricant dispenser

Screw-off the cartridge case cover (2), (see Figure 4-2). The lubrication dispenser (5) is screwed

out and replaced with a new component (Part No. 283 0100). Then activate (see Chapter 4.2)!

Changing the oil

The figures in Section 6.1 show the oil drain screw, the oil level screw and the pressure vent

screw for various designs. Sequence:

1. Place the drip tray below the oil drain screw

2. Completely remove oil level screw, screwed sealing plug with dipstick if an oil level tank is

being used and oil drain screw.

-36- B2000-GB-0413 www.nord.com

Page 37

5. Service and maintenance

Danger!

Warning: Hot oil!

3. Drain all the oil from the gear unit.

4. If the screw lock coating of the oil drain screw or oil level screw is damaged in the thread, a

new oil level screw must be used or the thread cleaned and coated with securing lubricant,

e.g. Loctite 242, Loxeal 54-03 prior to inserting. Check the sealing ring for damage. Replace

with a new sealing ring in case of damage.

5. Support the seal ring, insert the oil drain screw into the hole and tighten to the correct

torque! (See Chapter 6.3 for torque values)

6. Using a suitable filling device, refill with new oil of the same type (see rating plate,

Sections 3.4and 6.2) through the oil level hole until oil emerges from the oil level hole. (The

oil can also be filled through the pressure vent screw or a sealing plug located higher than

the oil level). If an oil level vessel is used, fill the oil through the upper inlet (thread G1¼)

until the oil level is set as described in Section 4.1.

7. Wait at least 15 minutes, or at least 30 minutes if an oil level tank is used, and then check

the oil level. Proceed as described in Section 4.1.

Note!

The oil does not need to be changed on gear units without oil level screw (see Section

6.1). These gear units are lubricated for life.

Note!

Standard ATEX category 3G and 3D helical gear units (See rating plate, Section 3.4) do

not have an oil level screw. Here, the oil is topped up through the threaded pressure

vent bolt using the quantities listed in the table in the following table.

www.nord.com B2000-GB-0413 -37-

Page 38

5. Service and maintenance

[L] [L]

SK0 0,13 0,22 0,13 0,22 0,13 0,13 SK0 F 0,13 0,22 0,13 0,22 0,13 0,13

SK01 0,22 0,38 0,22 0,38 0,22 0,22 SK01 F 0,22 0,38 0,22 0,38 0,22 0,22

SK20 0,55 1,00 0,55 1,00 0,55 0,55 SK20 F 0,35 0,60 0,35 0,60 0,35 0,35

SK25 0,50 0,90 0,50 0,90 0,50 0,50 SK25 F 0,50 0,90 0,50 0,90 0,50 0,50

SK30

SK33 0,80 1,60 1,00 1,60 0,80 1,00 SK33 F 1,00 1,60 1,00 1,60 0,80 1,00

SK000 0,24 0,41 0,24 0,41 0,24 0,24 SK000 F 0,24 0,41 0,24 0,41 0,24 0,24

SK010

SK200 0,80 1,30 0,80 1,30 0,80 0,80 SK200 F 0,60 1,04 0,60 1,04 0,60 0,60

SK250 1,20 1,50 1,40 1,50 1,40 1,40 SK250 F 1,40 1,50 1,40 1,50 1,40 1,40

SK300 1,40 1,50 1,40 1,50 1,40 1,40 SK300 F 1,40 1,50 1,40 1,50 1,40 1,40

SK330 1,50 1,58 1,50 1,58 1,50 1,50 SK330 F 2,00 1,58 1,50 2,80 1,50 1,50

M1 M2 M3 M4 M5 M6

6.1

0,80 1,40

0,38 0,60

0,70 1,40 0,70 0,70

0,38 0,60 0,38 0,38

Check the cooling coil for deposits

The inner surface of the cooling coil must be checked for deposits, as in case of severe deposits

(fouling) the dissipation of heat is no longer guaranteed. In this case, the cooling coil must be

cleaned. If a chemical cleaner is used, it must be ensured that the cleaning agent does not

attack the material of the cooling coil (Cu pipe and yellow brass fittings)

Replacing the shaft sealing ring

Shaft sealing rings are rubbing seals made from an elastomer material and according to their

principle are subject to natural wear. The wearing life of shaft sealing rings depends on many

factors and cannot be calculated in advance. Once the shaft sealing ring has reached the end of

its service life, the oil film in the region of the sealing lip increases and a measurable leakage

with dripping oil occurs. The shaft sealing ring must then be replaced. To reduce the risk of

leaks due to worn shaft sealing rings we recommend that as a precaution, the shaft sealing rings

are replaced after every 25,000 operating hours or every 5 years. The space between the

sealing lip and the protective lip must be filled approximately 50% with grease on fitting

(recommended grease: PETAMO GHY 133N). Take care that after fitting, the new shaft sealing

ring does not run in the old wear track.

6.1

SK30 F

SK010 F

M1 M2 M3 M4 M5 M6

0,80 1,40 0,70 1,10 0,70 0,70

0,38 0,60 0,38 0,60 0,38 0,38

Re-lubricating bearings

For bearings which are not oil-lubricated and whose holes are completely above the oil level,

replace the roller bearing grease (recommended grease: PETAMO GHY 133N). Please contact

the NORD service department.

-38- B2000-GB-0413 www.nord.com

Page 39

General overhaul

With Category 2G and 2D gear units, a general overhaul is necessary after a specified longer

period of operation. The specification of the operating period in terms of operating hours, after

which a general overhaul must be carried out, can be seen from the rating plate data in field MI.

Alternatively, the maintenance class CM can be used to determine the operating period after

which a general overhaul must be carried out. The data in field MI of the rating plate is then e.g.:

MI CM=5.

The time for the general overhaul with the stated maintenance class CM is calculated as follows:

5. Service and maintenance

NA= C

M

f

kA

L

NA: Number of years since commissioning. With calculated values of NA which exceed 10

years, a general overhaul is due 10 years after commissioning.

CM: Maintenance class according to field MI of the rating plate

fL: Running time factor

fL= 10 Maximum running time 2 hours per day

fL= 6 Running time 2 to 4 hours per day

fL= 3 Running time 4 to 8 hours per day

fL= 1.5 Running time 8 to 16 hours per day

fL= 1 Running time 16 to 24 hours per day

kA: Utilisation factor

If the utilisation factor is unknown, KA=1.

If the actual power required by the application is known, longer maintenance intervals may

result. The utilisation factor may be calculated as follows:

k

A

3

P

1

P

tat

P1: Max. permissible drive power or motor power in kW according to the rating plate

P

: Actual drive power or motor power in kW which is required by the application at the rated

tat

speed. This is determined e.g. by measurements.

With variable loads with differing actual drive powers with rated speeds P

P

, … with known percentage times q1, q2, q3, …, the following equivalent average

tat3

tat1

, P

tat2

,

drive power applies:

q

3

3

PP

1

1

P

q

3

2

2

P

q

3

3

...

3

tattattattat

100100100

Danger!

The general overhaul must be carried out by qualified personnel in a specialist

workshop with appropriate equipment in observance of national regulations and laws.

We urgently recommend that the general overhaul is carried out by NORD Serv ice.

www.nord.com B2000-GB-0413 -39-

Page 40

If a general overhaul is due, the gear unit must be completely dismantled. The following work

must be carried out:

Clean all gear unit components

Examine all gear unit components for damage

All damaged components must be replaced

All roller bearings must be replaced

Replace back stops if fitted

Replace all seals, radial seals and Nilos rings

Replace plastic and elastomer components of the motor coupling

5. Service and maintenance

-40- B2000-GB-0413 www.nord.com

Page 41

6 Appendix

6.1 Versions and maintenance

For versions which are not listed, please refer to the special documentation drawing. (See rating

plate Section 3.4).

Explanation of symbols for the following version illustrations:

Standard helical gear units

Standard ATEX category 3G and 3D helical gear units do not have oil filling screws. (See rating

plate, Section 3.4)

Parallel shaft gear units

The following illustration applies for the version M4/H5 of gear unit types SK9282, SK9382,

SK10282, SK10382, SK11282, SK11382 and SK12382 with oil level vessel.

6. Appendix

Vent

Oil level

Oil drain

Figure 6-1: Parallel shaft gear units with oil level vessel

Oil level screws are not fitted to gear unit types SK 0182 NB, SK 0282 NB and SK 1382 NB in

the ATEX Categories 3G und 3D. (See rating plate, Section 3.4).

In Category 2G and 2D, types SK 0182 NB, SK 0282 NB and SK 1382 NB only have one oil

level screw. These gear unit types have checkable life-long lubrication

NORDBLOC helical gear units

Gear unit types SK 320, SK 172, SK 272, SK 372 and SK 273 and SK373 are not fitted with oil

level screws for ATEX Categories 3G and 3D. (See rating plate, Section 3.4).

In Category 2G and 2D, types SK 320, SK 172, SK 272, SK 372 and SK 273 and SK 373 only

have one oil level screw. These gear unit types have checkable life-long lubrication.

www.nord.com B2000-GB-0413 -41-

Page 42

NORDBLOC helical gear units SK072.1 and SK172.1

6. Appendix

Danger!

Oil level check in the M4 installation orientation for SK072.1 and SK172.1:

The oil level check for the M4 installation orientation must be carried out as follows in

the installation orientation M2:

1. Bring the gear unit into the M2 installation orientation and remove the oil level screw for the

M2 orientation.

Figure 6-2: Bring the gear unit into the M2 installation orientation

2. Determine the measurement X between the upper edge of the gear unit housing and the oil

level. If necessary, adapt the dipstick (see below).

Upper edge of housing

Figure 6-3: Measuring the oil level

3. Compare the determined measurement X with the corresponding measurement in the

following table. If necessary, adjust the oil level with the type of oil shown on the rating plate.

4. Screw in and tighten the oil level screw in the installation orientation M2 as per Section 4.1.

5. Bring the gear unit back into the installation orientation M4.

Gear unit type

SK 072.1 M8x1 22 ± 1mm

SK 172.1 M8x1 20 ± 1mm

Thread

size

Measurement

X [mm]

X

Oil level

-42- B2000-GB-0413 www.nord.com

Page 43

UNIVERSAL worm gear units

SK 1SI 31 – SK 1SI 75

SK 1SIS 31 – SK 1SIS 75

Figure 6-4: Orientation for oil level check.

For the oil level check, the gear unit or the geared motor must be brought into the orientation

shown above. To do this, it may be necessary to remove the gear unit or the geared motor.

NB: An adequate resting time of the warm gear unit in the position shown in Figure 6-4 must be

observed, in order to allow the oil to settle evenly.

The oil level can then be checked as described in Section 4.1.