Page 1

Intelligent Drivesystems, Worldwide Services

GB

B1092

Operating and Assembly Instructions for

1 MA-7 Three-phase Motors for operation with

Frequency Inverters BG 63 - 160

Page 2

1. General Information................................................................................................................3

2. Description ..............................................................................................................................3

2.1 Field of application....................................................................................................................3

2.2 Cooling .....................................................................................................................................3

3. Information on the correct handling of electric motors .....................................................3

3.1 Transport and storage...............................................................................................................3

3.2 Installation.................................................................................................................................4

3.3 Terminal box .............................................................................................................................4

3.4 Balancing, driving elements......................................................................................................4

3.5 Elekctrical connection ...............................................................................................................4

3.6 Checking the insulation resistance ...........................................................................................5

3.7 ICommissioning.........................................................................................................................5

4. Maintenance ............................................................................................................................6

5. Motors with increased ignition protection, type “e” Ex e 1MA..........................................8

5.1 Additional information for operation with a frequency inverter..................................................9

6. Drawing and list of replacement parts................................................................................11

6.1 Drawing and list of replacement parts.....................................................................................11

6.2 Tightening torques ..................................................................................................................15

6.3 Cross sections which may be connected................................................................................16

6.4 Changing the bearings............................................................................................................16

7. Data Sheets............................................................................................................................17

7.1 BG 63 M..................................................................................................................................17

7.2 BG 71 M..................................................................................................................................20

7.3 BG 80 M..................................................................................................................................23

7.4 BG 90 L ...................................................................................................................................26

7.5 BG 100 L.................................................................................................................................29

7.6 BG 100 L (increased performance).........................................................................................32

7.7 BG 112M.................................................................................................................................35

7.8 BG 132 M................................................................................................................................38

7.9 BG 160 M................................................................................................................................41

7.10 BG 160 L.................................................................................................................................44

8.

Type Plates ............................................................................................................................47

9. Declaration of Conformity....................................................................................................48

10. Addresses..............................................................................................................................49

Contents

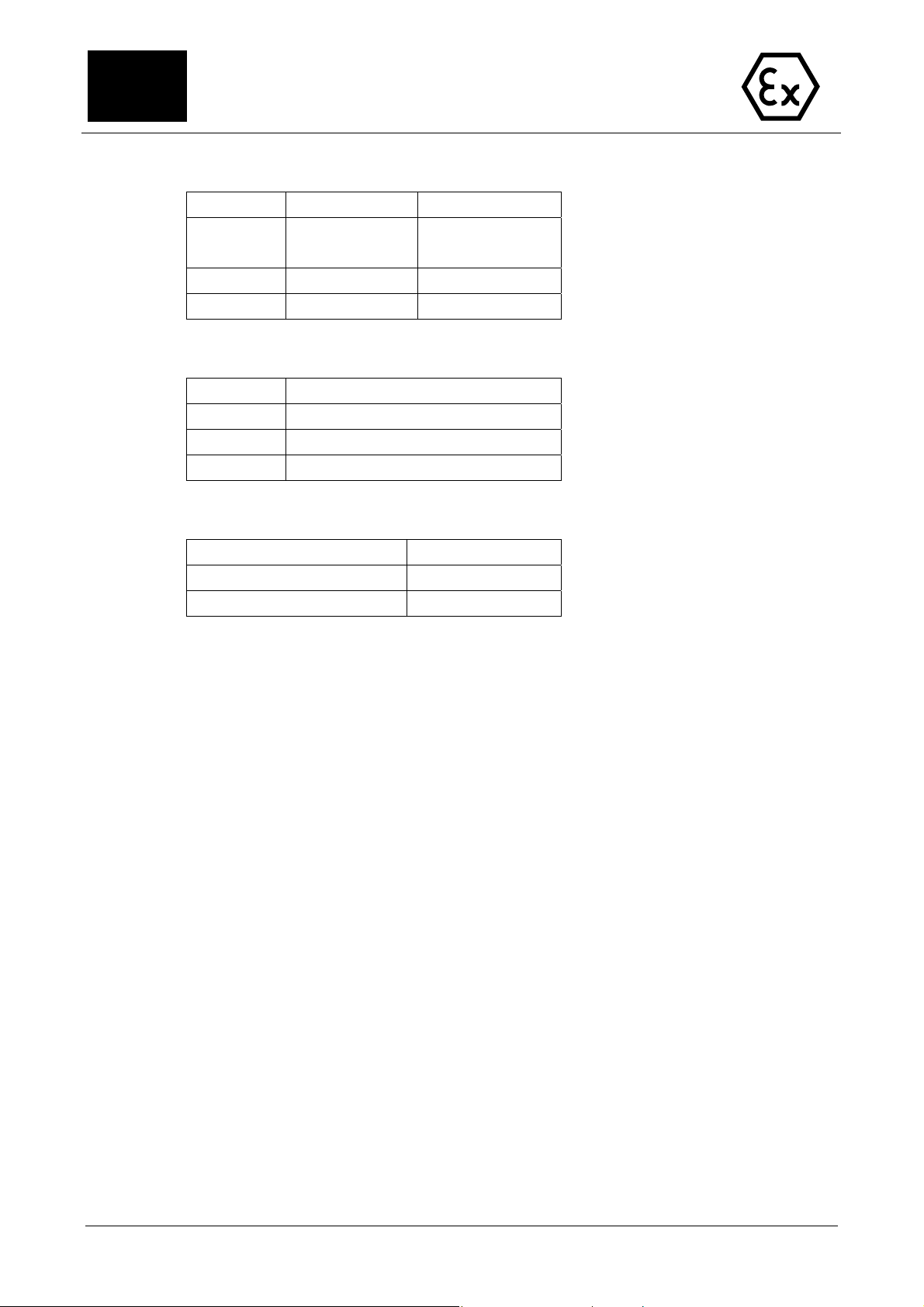

Safety and information symbols

Please always observe the following safety and information symbols!

Danger

Danger of death or injury

to persons

Danger

Important information

regarding explosion

protection

-2- B1092-GB www.nord.com

Attention!

Damage to the machine possible

Note!

Page 3

1. General information

2. Description

1. General information

The applicable national, local and plant-specific regulations and requirements must be

observed.

Technical details may vary for special designs and constructions. In case of doubt it is

urgently recommended that the manufacturer is contacted, giving details of the type and serial

number (No. …. see rating plate), or have the maintenance work carried out by a service

centre.

2.1 Field of Application

Intended use of the motors:

The motors are constructed in protection class IP55 (protection class: see rating plate). They

may be installed in dusty or damp environments. For use outdoors an additional covering is

recommended to avoid the tong-term influence of direct intense sunlight, rain, snow, ice or

dust. If necessary, consultation/technical coordination is advisable.

Ambient temperature: ......... -20°C to +40°C

Installation altitude: .............

In case of differing ambient conditions, these must be indicated on the rating plate. The details

on the rating plate then apply.

2.2 Cooling

1MA motors are self-cooling (with fan).

3. Information on the correct handling of electric motors

3.1 Transport and storage

When transporting the motor, all available lifting lugs must be used.

When transporting sets of machinery (e.g. gearbox, fan, pumps etc.) only use the attached

lifting lugs. Sets of machinery must not be lifted by hanging on the motor lifting lugs.

With long periods of storage the period of use of the bearing grease is reduced. For storage of

longer than 12 months the condition of the grease must be checked. If the check reveals

contamination of the grease (ingress of condensation causes a change in consistency of the

grease) the grease must be replaced.

The roller bearings should be replaced if the time from delivery to commissioning of the motor

exceeds 4 years.

The probable life-span of the bearing system reduces with increasing storage time.

Machined surfaces (flange surfaces, shaft ends, etc.) should be protected with corrosion

protection agents.

If necessary, the insulating resistance of the windings must be checked, see Sect ion 3.6.

≤ 1000 m

All work must be carried out only when the system is in an electrically voltage-free state.

www.nord.com B1092-GB -3-

Page 4

3.2 Installation

For vertical configuration, all available lifting lugs and if necessary lifting straps (DIN EN 14921:2000) and/or tie-down straps (DIN EN 12195-2:2001) must be used to stabilise the position.

Attachments must not be used as lifting aids.

After installation, screwed-on lifting lugs must be tightened or removed.

For vertical installation with the shaft end pointing downwards, a protective cover for the fan

cover is recommended, to prevent the entry of foreign bodies.

On the other hand, in the case of shaft ends pointing upwards, the ingress of liquids along the

shaft must be prevented.

Smooth running: Precise alignment of the clutch and a well-balanced drive element (clutch,

pulleys, fan …) are prerequisites for smooth vibration-free running.

Complete balancing of the motor and the drive elements may be necessary.

3.3 Terminal box

Tightening torques for the screws of the terminal box: See Fig. 4.2.

3.4 Balancing, drive elements

3. Notes

The fitting and removal of drive elements (clutch, pulley, gear wheel,…) must be performed

with suitable equipment (see Fig.7).

As standard, the rotor is balanced with half parallel key.

When fitting the drive element, pay attention to the type of balancing!

The balancing condition is stated on the end face of the shaft or the type plate (H = half, F =

full parallel key balancing, N = balancing without parallel key).

The drive elements must be balanced according to ISO 1940:2003.

For balancing with half parallel key, the protruding visible portion of the parallel key T

be machined off (see Fig. 8).

The generally necessary measures for protection against touching the drive elements must be

observed.

3.5 Electrical connection

All work must only be carried out by qualified technicians on stationary low-voltage machines

which have been switched off and secured against switching on again. This also applies to the

auxiliary power circuits.

The terminal box must be sealed against dust and water.

The mains voltage and frequency must conform to the data on the rating plate. A voltage

deviation of ± 5% and/or a frequency deviation of ± 2% are permissible. The connection and

configuration of the jumpers must be performed according to the circuit diagram in the

terminal box. Connect the bonding conductor to this terminal

For connection terminals with terminal bridges (e.g. according to DIN 46282) the conductors

must be arranged so that approximately the same terminal heights result on both sides of the

bar. This type of connection therefore requires that individual conductors are bent to a Ushape or a fork terminal must be connected (see Fig. 5) This also applies to the bonding

connector and the external green/yellow earthing conductor.

.

must

p

-4- B1092-GB www.nord.com

Page 5

3. Notes

For tightening torques of screw connections of the electrical connections and terminal board

connections (except for the terminal bar) see Fig. 4.

3.6 Checking the insulation resistance

Prior to the initial commissioning of the motor after a long period of storage or standstill

(approx. 6 months) the insulation resistance of the windings must be checked.

During and immediately after the measurements, the terminals have voltages which can be

dangerous, and must not be touched.

Insulation resistance

The minimum insulation resistance of new, cleaned or repaired windings against earth

is 10 MΩ.

Initially, the critical insulation resistance R

multiplying the measured voltage U

R

= 0.69 kV x 0.5 MΩ /kV =0.345 MΩ

krit

, e.g. 0.69 kV AC, with the constant factor (0.5 MΩ /kV):

N

is calculated. The calculation is made by

krit

Measurement:

The minimum insulation resistance of the winding against earth is measured with 500 V DC.

The temperature of the windings should be 25°C ± 15°C.

The critical insulation resistance must be measured with the windings at operating

temperature using 500 V DC.

Testing:

If for new or cleaned windings or repaired motors, which have been stored or not used for

long periods, the minimum insulation resistance of the winding against earth is less than 10

MΩ, this may be caused by moisture. The windings must then be dried.

After long periods of operation the minimum insulation resistance may fall to the critical

insulation resistance. As long as the measured value does not fall below the calculated value

for the critical insulation resistance, operation of the motor may continue. If this value is fallen

below, the motor must be switched off immediately. The cause of this must be established

and if necessary the windings or parts of the windings must be repaired, cleaned or

dried.

3.7 Commissioning

NOTE: Electromagnetic compatibility

Production of interference: Great differences of torque (e.g. when driving a piston

compressor) induce a non-sine wave motor current, whose harmonics can cause an

impermissible effect on the mains and therefore impermissible production of interference.

With supply by frequency inverters, various strengths of interference are produced according

to the design of the frequency inverter (type, interference suppression, manufacturer). The

EMC information of the inverter manufacturer must be observed. If a shielded motor supply

cable is recommended, the shielding is most effective if a large area is electrically connected

to the metal terminal box of the motor (with metal screw connectors). With motors with

integrated sensors (e.g. thermistors) interference voltages due to the inverter may be

produced in the sensor cables.

Interference immunity: For motors with integrated sensors (e.g. thermistors) the operator

must ensure adequate immunity to interference by the selection of a suitable sensor cable

(possibly with screening, with connection as for the motor supply cable) and evaluation

device.

When operating motors with inverters at higher speeds than the nominal speed, the

mechanical limiting speed (Safe operating speed IEC 60034-1) must be observed (max. 3000

1

/

).

min

www.nord.com B1092-GB -5-

Page 6

Safety measures

Before starting any work on the motor or the device, but especially before opening the covers

of active components, the motor must be isolated according to regulations. In addition to the

main power circuits, any additional or auxiliary circuits must be taken into account.

The usual "5 Safety Rules" e.g. according to EN 50110-1 (DIN VDE 0105) are:

• Isolate,

• S ecure against switching on,

• Check for no voltage,

• Earth and short circuit,

• Cover or fence off neighbouring live components.

These measures may only be removed when the maintenance work is complete and the

motor has been completely assembled.

NOTE: If the motors are designed with closed condensation outlets, these must be opened

occasionally in order to allow any accumulated condensation to drain off. Condensation

outlets must always be located at the lowest point of the motor.

Changing bearings, grease packing

Bearing replacement period [h] under normal operating conditions, with horizontal installation

of the motor, cooling medium temperature or motor speed:

up to 1800 min-1 approx. 40000 h

up to 3000 min-1 approx. 20000 h

NOTE: The permissible axial and transverse forces must not be ex ceeded.

Independent of the hours of operation of a motor which is in use, the roller bearing should be

replaced approximately every 3 years due to the reduction of lubrication.

Under special operating conditions, e.g. vertical motor installation, heavy loads due to

vibration and shock, or operation with frequent reversing, the operating hours stated above

are significantly reduced.

The motors have groove ball bearings with cover plates (2ZC3 design). The material of the

plates should be temperature resistant from -30°C to +150°C, e.g. polyacrylic rubber (ACM).

Grease types for standard machines: UNIREX N3 (ESSO); Substitute greases must comply

with

DIN 51825-K3N:2004.

Special greases are indicated on the rating plate or on an additional plate.

Dismantle the motor to the necessary extent. Remove the roller bearing using suitable

equipment (see Fig. 6). Clean any contamination from the bearing seats.

Uniformly heat the roller bearings to approx. 80-100°C and fit. Hard blows (e.g. with a

hammer) must be avoided.

Any warn sealing elements (e.g. shaft seals) must also be renewed. If shaft sealing rings

without springs are installed, the replacement component must also be installed without

springs.

Centring edge seal

When assembling the motor, the bright fitting surfaces between the motor housing and the

bearing covers must be sealed with a suitable non-hardening sealing compound, e.g. Fluid-D.

Tightening torques for the screws on the bearing covers: see Fig. 4.2.

Regreasing device

For motors with regreasing devices, the details on the lubrication plate or the rating plate must

be observed. Regreasing should be performed with the motor running.

4. Maintenance

40°C

-6- B1092-GB www.nord.com

Page 7

4. Maintenance

General overhaul

A general overhaul of the motor must be carried out every 5 years.

For this the motor must be dismantled. The following work must be carried out:

• All components of the motor must be cleaned

• All components of the motor must be examined for damage

• All damaged components must be replaced

• All roller bearings must be replaced

• All seals and shaft sealing rings must be replaced

• Measure the insulation resistance

• Check the stationary voltage according to EN 60034-1

The general overhaul must be carried out by qualified personnel in a specialist workshop with

appropriate equipment. We strongly recommend that the general overhaul is carried out by

NORD-Service.

www.nord.com B1092-GB -7-

Page 8

5. Motors with increased ignition

protection, type "e" Ex e

5. Motors with increased ignition protection, type "e" Ex e 1MA

Identification: CE 0102 II G Ex e lI T3

Attention

Repairs must be carried out in or by authorised workshops. Repairs must be documented on

the motor (e.g. additional plate).

The increased hazard in areas endangered by explosions or fire damp requires particularly careful

observation of the general safety and start-up information.

Replacement parts - Only original replacement parts (see replacement parts list) may be used: this

particularly applies to seals and connection components. Exceptions are standard equivalent

commercially available components (e.g. roller bearings).

Explosion-protected electrical machines comply with standards:

EN 60034-1:2004 and all relevant parts, as well as EN 60079-0:2004, EN60079-7:2003.

They may only be used in explosion hazard areas according to the conditions stipulated by

the responsible supervisory authorities. They are responsible for the determination of the

explosion hazard (allocation of zones).

If the certification is supplemented with an "X" the special conditions in the EU prototype

certification must be observed.

The cable entries must be approved for explosion hazard areas and secured against

spontaneous loosening. Unused openings must be closed with approved stoppers. For the

assembly of the cable entries the instructions in the instruction manual of the cable entry

manufacturer must be observed. The number of threaded holes, the thread sizes and the type

of thread are given in Table 1. Special entries are indicated.

For vertical installation of the motor with the end of the shaft facing upwards or downwards,

e.g. types IMV3, IMV6, IMV19, for 1MA motors a cover must be arranged so that foreign

bodies cannot enter into the motor fan cover. Cooling of the motor must not be obstructed by

the cover. If nothing is stated to the contrary in the EU prototype certification or on the rating

plate with regard to type of operation and tolerances, electrical machines are designed for

continuous operation and normal infrequent starts, in which there is not significant start-up

warming.

The motors may only be used for the type of operation stated on the rating plate.

Range A in EN 60034-1:2004 - voltage ± 5%, frequency ± 2%, curve shape, symmetrical

mains - must be complied with in order that warming remains within the permissible limits.

Larger deviations from the rated values can cause a permissible warming of the electrical

machine and must be stated on the rating plate.

The temperature class of the motor stated on the rating plate must conform with the

temperature class of any escaping inflammable gases.

In addition, the safety device must be adjusted to the rated current. A triggering device

certified according to RL94/9/EU must be used.

Thermal protection of the machine by means of direct temperature monitoring of the windings

is permissible, if this is certified and stated on the rating plate.

An earthing tab is cast onto the housing for the connection of the external bonding cable. The

thread sizes for the screws of this external bonding cable are stated in Table 2.

-8- B1092-GB www.nord.com

Page 9

5. Motors with increased ignition

protection, type "e" Ex e

In the case of external sources of heat or cold, no additional measures are necessary if the

temperatures of the attached components do not exceed the permissible temperatures listed

in Table 3. The values in Table 3 apply for an ambient temperature of -20°C to +40°C with

self-ventilation. Special applications with external sources of heat and cold must be examined

by means of type testing with regard to the effect on the maximum surface and operating

temperatures and suitable measures taken if necessary.

For the installation of electrical equipment in explosion hazard areas in Germany, attention is

drawn to DIN EN 60079-14:2003 and the "Betriebssicherheitverordnung" [Operating Safety

Regulations]! In foreign countries the appropriate national regulations must be observed.

Operation with an inverter must be explicitly certified. The separate manufacturer's information

must be observed.

5.1 Additional information for operation with a frequency inverter

In addition to this information, the operating instructions of the frequency inverter and if

necessary the operating instructions of the gear unit and any other operating instructions must

be observed. Failure to observe these can cause material damage and personal injury.

Series 1 MA7 motors are produced in the ignition protection type "Increased Safety" and are

suitable for operation with a frequency inverter. The suitability can be identified by the

statement of the maximum frequency (e.g. f

Individual acceptance by a designated testing facility is not necessary.

It is essential that the supplied data sheet for the EU prototype certification (see

Section 7.) is complied with. This includes important information for operation and

commissioning.

Ex e motors suitable for use with frequency inverters are equipped with a triple PTC.

This must be evaluated by a certified triggering device with protection type labelling Ex II (2)

G.

The joint operation of several motors on one frequency inverter is not permissible.

Connecting cables must be dimensioned for a continuous thermal load of at least 80°C.

In addition, the frequency inverter used must be equipped with a speed-dependent current

limitation (Precision of measurement of effective current: 5%).

The current limitation is set to the maximum permissible nominal current of the

frequency inverter. A limitation of the output current of the frequency inverter to double the

rated current of the motor must be ensured.

Observation of the rev/f characteristic and the permissible torque depending on the

frequency is essential.

Voltage drops due to the use of long supply cables and/or sine wave filters between the

motor and the frequency inverter must be taken into account. The maximum

permissible length of cable is 30m. The frequency inverter also causes a drop in

voltage.

The motor terminal voltage can be influenced by increasing the input voltage of the frequency

inverter.

Voltages in excess of 1556 V (peak values) must not occur at the motor terminals.

Unfavourable cable lengths and short switching times of the frequency inverter can

cause impermissible overvoltages. The occurrence of such overvoltages must

be ruled out before starting up.

100 Hz) on the type plate.

max

www.nord.com B1092-GB -9-

Page 10

5. Motors with increased ignition

protection, type "e" Ex e

Shaft height Thread size Number

63 – 90 M16x1.5

M25x1.5

100 – 132 M32x1.5 4

160 M40x1.5 4

Table 1: Thread sizes in terminal box

Shaft height Thread of screw for bonding cable

63 – 90 M4

100 – 112 M5

132 – 160 M6

1

1

Table 2: Bonding cable screw threads

Number of pairs of poles 4-pole

Maximum shaft temperature 75°C

Maximum flange temperature 75°C

Table 3: Maximum permissible heat and cold sources

-10- B1092-GB www.nord.com

Page 11

replacement parts

6.1 List and drawings of replacement parts

Replacement parts which can be supplied ex works

Item no. Designation

1.00 AS bearing

.40 Bearing cover

.43 Shaft seal

.58 Spring washer

.60 Roller bearing

.61 Spring strip for bearing cover hub (not always present)

3.00 Rotor, complete

.88 Parallel key for fan

4.00 Stator, complete

.07 Housing foot, right

.08 Housing foot, left

.18 Rating plate

.19 Screw

.20 Cover

.30 Contact bracket

.31 Earthing bracket

5.00 Terminal box, complete

.03 Seal

.04 Seal

.10 Terminal board, complete

.11 Terminal bar

.44 Terminal box, upper section

.70 Retaining clip

.71 Retaining clip

.83 Seal

.84 Terminal box cover

.85 Seal

.90 Terminal box upper section, rotatable 4x90 degrees, complete (for retrofitting)

.92 Terminal box cover

.93 Seal

.95 Terminal box, upper section

.98 Seal

.99 Adapter plate

6.00 BS bearing

.10 Roller bearing

.11 Spring strip for bearing cover hub (not always present)

.20 Bearing cover

.23 Shaft sealing ring

7.00 Ventilation, complete

.04 Fan

6. Drawing and list of

.40 Fan hood

Fitting and removal tools for roller bearings, fan and drive elements can not be supplied!

www.nord.com B1092-GB -11-

Page 12

6. Drawing and list of

Standard components to be obtained commercially according to dimensions, materials and surfaces.

4.05 (see Fig. 3) DIN EN ISO 70897090

(DIN 125)

4.10

4.39

5.78

7.12 DIN 471

6.02 DIN 472

4.04 (see Fig. 3) DIN 580

1.49

4.11

4.39

5.19

5.49

5.79

5.89

5.91

5.94

6.29

7.49

3.38 DIN 6885

5.52

5.53

5.96

1.60

6.10

DIN 128

DIN EN ISO 4762

(DIN 912)

DIN EN ISO 4017

(DIN 933)

DIN EN ISO 4014

(DIN 931)

DIN EN ISO 7045

(DIN 7985)

DIN EN 50262

DIN 625 Bearing type

replacement parts

Replacement parts are to be ordered via the Sales departments of the particular producers.

-12- B1092-GB www.nord.com

Page 13

replacement parts

6. Drawing and list of

For aluminium bearing covers (1.40 AH 90) a spring strip (1.61) is inserted in the hub

(hook the bead into the groove).

certified screw connection (5.1)

Fig. 2 BG63…90L

www.nord.com B1092-GB -13-

Page 14

6. Drawing and list of

replacement parts

For aluminium bearing covers (1.40/6.20) a spring strip (1.61/6.11) is inserted in the hub

(hook the bead into the groove).

certified screw connection (5.1)

Fig. 2 BG 100…160L

-14- B1092-GB www.nord.com

Page 15

replacement parts

e.g. outlet for cables and wires - at bottom

Fig. 3, BD 100…160L, version with lateral configuration of upper section of terminal box (rotatable 4x90

degrees)

6. Drawing and list of

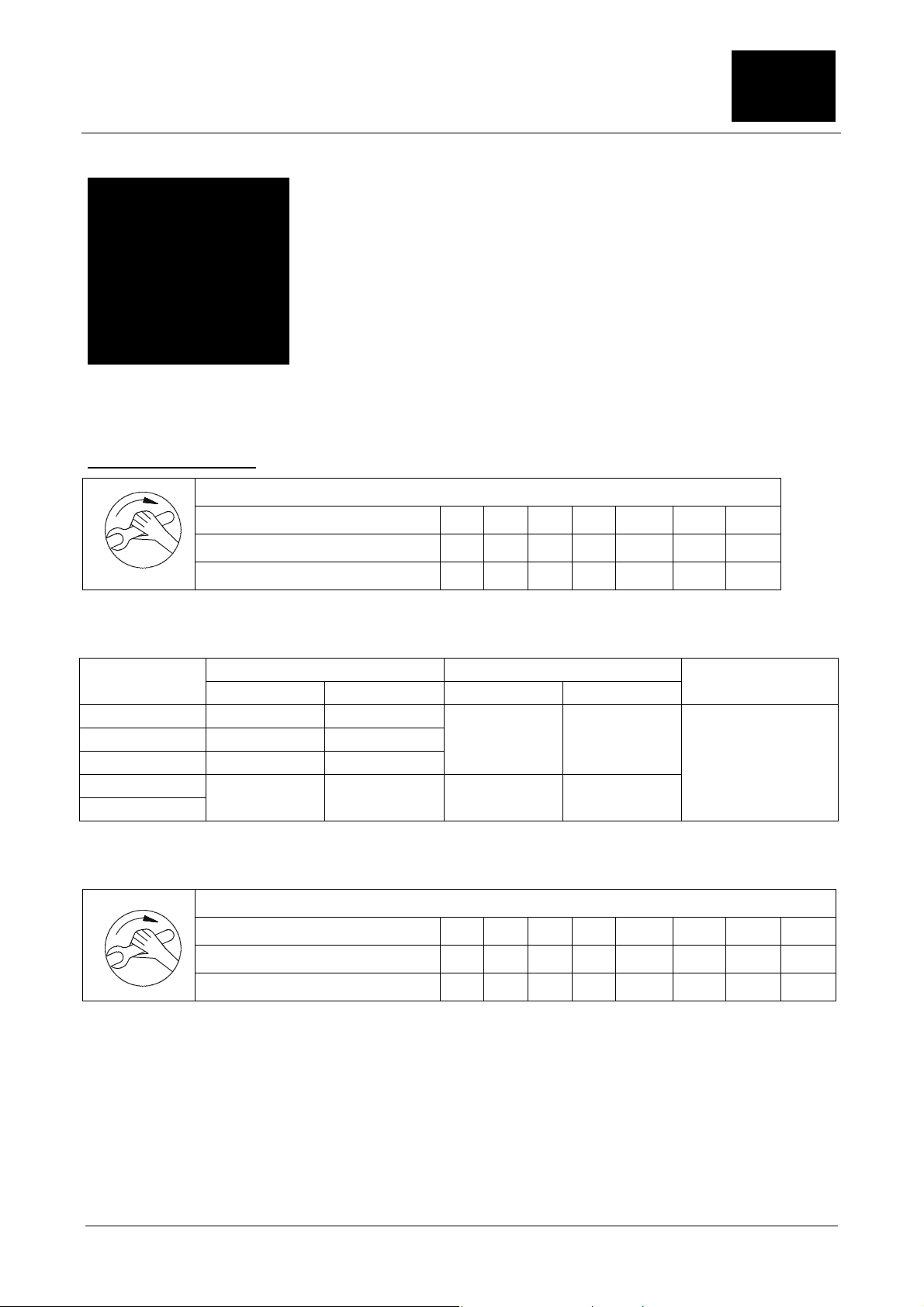

6.2 Tightening torques

Tightening torques for terminal board connections

Thread diameter M4 M5 M6 M8 M10 M12 M16

Tightening torque (Nm) min. 0.8 1.8 2.7 5.5 9.0 14.0 27.0

Tightening torque (Nm) max. 1.2 2.5 4.0 8.0 13.0 20.0 40.0

Fig. 4, Tightening torques of screw connections of the electrical connections and terminal board connections

(except for the terminal bar)

Nm min. Nm max. Nm min. Nm max.

M12x1.5 4 5

M16x1.5 5 7.5

M25x1.5 6 9

M32x1.5

M40x1.5

Fig 4.1, Tightening torques for cable connectors made from metal (*) and plastic 9**) for direct attachment to

motor. For other connectors (e.g. reducers) the corresponding torques according to the table should be used.

Tightening torque (Nm) max. 3 5 9 24 42 70 165 340

8 12 4 6

Thread diameter M4 M5 M6 M8 M10 M12 M16 M20

Tightening torque (Nm) min. 2 3.5

(*) (**)

2

Tightening torques on terminal box

6

3

16 28 46 110 225

O-ring thickness

mm

2

Fig. 4.2, tightening torques for screws on the electrical terminal box, on bearing covers and on screw

connectors for bonding cables

The above values apply unless other values are stated.

www.nord.com B1092-GB -15-

Page 16

6. Drawing and list of

6.3 Cross sections which may be connected

2

…25 mm

For connection with

a DIN fork terminal,

the fork terminal

must be angled

downwards.

Fig. 5, cross sections which may be connected according to the size of terminal (may be reduced due to the

size of the cable entries)

6.4 Changing the bearings

…10 mm2 …25 mm2 …10 mm2 …25 mm2

Connection of a

single conductor

with retaining clip.

replacement parts

Connection of two

conductors of

approximately the

same diameter with

retaining clip.

Connection of a

single conductor

under the external

earthing bracket.

For connection with

DIN fork terminal

under the external

earthing bracket.

Fig. 6, Intermediate plate (protection of centring in the end of the shaft)

Fig. 7, fitting and removal of drive elements (intermediate plate to protect the centring at the end of the shaft)

When fitting drive elements (clutch, gear wheel, pulley etc.) use the thread in the end of the shaft and as far

as possible heat the drive elements as necessary. Use suitable equipment for removal. When fitting or

removing, no blows (e.g. with a hammer or similar) or radial or axial forces in excess of those permissible

according to the catalogue may be transferred to the motor bearing via the end of the shaft.

Fig. 8, balancing with half parallel key

-16- B1092-GB www.nord.com

Page 17

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3046 X

for the three-phase motor, type 1MA7 063-4…

Rated values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 0.3 0.8 1.1 0.36 Nm

Power: 0.008 0.053 0.158 0.108 kW

Voltage: *) 80 200 400 400 V

Current: 0.33 0.48 0.58 0.34 A

Frequency: 10 25 50 100 Hz

Speed of rotation: 244 632 1370 2835 min

Operating mode: S1

Heat class F

-1

Delta connection

Torque: 0.3 0.8 1.1 1.1 Nm

Power: 0.008 0.053 0.295 0.334 kW

Voltage: *) 46 115 400 400 V

Current: 0.57 0.83 1.1 1,0 A

Frequency: 10 25 87 100 Hz

-1

Speed of rotation: 244 632 2485 2829 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter and

over the motor supply cable and may not fall below the rated value by more than 5% according to

IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter. This must be

taken into account for the design of the motor, the parameterisation of the inverter (e.g. rev/f

adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the rated voltage of the motor by means of the number of windings is permissible. The rated

current changes in inverse proportion to the rated voltage.

Sheet 1/3

www.nord.com B1092-GB -17-

Page 18

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3046 X

for the three-phase motor, type 1MA7 063-4…

Monitoring devices

To prevent impermissible heating due to overload, the motors are monitored by connection to a device for

direct temperature monitoring in combination with defined setting data of the inverter.

Due to the special characteristics of motors supplied by inverters and the adapted monitoring device,

details of the relationship I

The type of device for direct temperature monitoring has been tested by the Physikalish-Technische

Bundesanstalt and consists of three DIN 44082 type M 110 PTCs installed in the windings and a functiontested triggering device according to Guideline 94/9/EU.

With a line current of 1.7 A and a blocked shaft, the PTC must trigger after 31.4 s (± 20 %) assuming a

cold condition (20 °C).

By means of the temperature monitoring device, temperature class T3 as per EN 60079-7 is complied

with.

Inverter setting data

In combination with the aforementioned monitoring device, the following inverter data must be set and

maintained during operation:

Minimum pulse frequency: 3 kHz

and the heating time tE are not required for motors operated by inverters.

A/IN

Short-term current limit: 1.5*I

N

Maximum overload time: 60 s

Minimum frequency f

Maximum frequency f

Permissible duration of operation at

:

f

min

: 10 Hz

min

max

:

100 Y / 100 Δ

Hz

60 s

The maximum overload time and the permissible duration of operation at f

refer to a time period of 10

min

min.

The relationship of the torque to the frequency results from the permissible continuous current limit.

Sheet 2/3

-18- B1092-GB www.nord.com

Page 19

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3046 X

The continuous current limit of the frequency inverter must be set dependent on the frequency according

to the following diagram:

1,2

1,1

0,9

I / In

0,8

0,7

Translated extract from Data Sheet 01

for the three-phase motor, type 1MA7 063-4…

Prohibited region

1

Permissible region

0,6

0,5

0,4

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Star connection

Delta connection

f / Hz

Setting parameters for the continuous current limit of

the frequency inverter between 10 Hz and 100 Hz

All other setting data should be selected according to the requirements of the drive unit.

Special conditions

Group operation of the motors is not permissible.

Motors of this type may only be operated with inverters which fulfil the requirements stated above under

"Inverter setting data".

The maximum rated current of the frequency inverter may correspond to double the rated current of the

motor.

The current monitoring of the frequency inverter must record the effective value of the machine current

with a tolerance of

± 5 % in relation to the rated current of the motor.

Before start-up it must be ensured that no overvoltages due to the inverter with a peak value in excess of

1556 V (2*

2

*550V) occur at the terminals of the electrical machine.

Test report

PTB Ex 07-37118

Certification Facility for Explosion Protection Braunschweig, 4 October 2007

pp

L.S.

Dr.-Ing. F. Lienesch

Senior Government Official Sheet 3/3

www.nord.com B1092-GB -19-

Page 20

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3047 X

for the three-phase motor, type 1MA7 073-4…

Design values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 0.5 2.0 2.6 0.8 Nm

Power: 0.005 0.128 0.356 0.224 kW

Voltage: *) 40 200 400 400 V

Current: 0.5 0.92 1.11 0.67 A

Frequency: 5 25 50 100 Hz

Speed of rotation: 102 610 1273 2586 min

Operating mode: S1

-1

Heat class F

Delta connection

Torque: 0.5 2.0 2.6 2.6 Nm

Power: 0.005 0.128 0.640 0.764 kW

Voltage: *) 23 115 400 400 V

Current: 0.86 1.59 1.97 1.98 A

Frequency: 5 25 87 100 Hz

-1

Speed of rotation: 102 610 2280 2796 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter and

over the motor supply cable and may not fall below the design value by more than 5% according to

IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter. This must be

taken into account for the design of the motor, the parameterisation of the inverter (e.g. rev/f

adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the design voltage of the motor by means of the number of windings is permissible. The

rated current changes in inverse proportion to the rated voltage.

Sheet 1/3

-20- B1092-GB www.nord.com

Page 21

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3047 X

Monitoring devices

To prevent impermissible heating due to overload, the motors are monitored by connection to a device

for direct temperature monitoring in combination with defined setting data of the inverter.

Due to the special characteristics of motors supplied by inverters and the adapted monitoring device,

details of the relationship I

The type of device for direct temperature monitoring has been tested by the Physikalish-Technische

Bundesanstalt and consists of three DIN 44082 type M 110 PTCs installed in the windings and a

function-tested triggering device according to Guideline 94/9/EU.

With a line current of 4.1 A and a blocked shaft, the PTC must trigger after 35 s (± 20 %) assuming a

cold condition (20 °C).

By means of the temperature monitoring device, temperature class T3 as per EN 60079-7 is complied

with.

Inverter setting data

In combination with the aforementioned monitoring device, the following inverter data must be set and

maintained during operation:

Minimum pulse frequency: 3 kHz

Translated extract from Data Sheet 01

for the three-phase motor, type 1MA7 073-4…

and the heating time tE are not required for motors operated by inverters.

A/IN

Short-term current limit: 1.5*I

N

Maximum overload time: 60 s

Minimum frequency f

Maximum frequency f

Permissible duration of operation

:

at f

min

: 5 Hz

min

max

:

100 Y / 100 Δ

Hz

60 s

The maximum overload time and the permissible duration of operation at f

refer to a time period of 10

min

min.

The relationship of the torque to the frequency results from the permissible continuous current limit.

Sheet 2/3

www.nord.com B1092-GB -21-

Page 22

A

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3047 X

Translated extract from Data Sheet 01

for the three-phase motor, type 1MA7 073-4…

The continuous current limit of the frequency inverter must be set dependent on the frequency according

to the following diagram:

1,1

Unacceptable Region

0,9

1

0,8

I / In

0,7

0,6

0,5

0,4

0 5 10 15 20

25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

cceptable Region

Star Connection

Delta Connection

f / Hz

Setting parameters for the continuous current limit of

the frequency inverter between 5 Hz and 100 Hz

All other setting data should be selected according to the requirements of the drive unit.

Special conditions

Group operation of the motors is not permissible.

Motors of this type may only be operated with inverters which fulfil the requirements stated above under

"Inverter setting data".

The maximum rated current of the frequency inverter may correspond to double the rated current of the

motor.

The current monitoring of the frequency inverter must record the effective value of the machine current

with a tolerance of

± 5 % in relation to the rated current of the motor.

Before start-up it must be ensured that no overvoltages due to the inverter with a peak value in excess of

1556 V (2*

2 *550V) occur at the terminals of the electrical machine.

Test report

PTB Ex 07-37119

Certification Facility for Explosion Protection Braunschweig, 4 October 2007

pp

L.S.

Dr.-Ing. F. Lienesch

Senior Government Official Sheet 3/3

-22- B1092-GB www.nord.com

Page 23

of the EU Prototype Test Certificate PTB 07 ATEX 3048 X

Translated extract from Data Sheet 01

7. Data Sheets

for the three-phase motor, type 1MA7 083-4…

Rated values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 1.4 4.5 5.2 1.8 Nm

Power: 0.015 0.295 0.75 0.531 kW

Voltage: *) 40 200 400 400 V

Current: 1.0 1.8 2.0 1.4 A

Frequency: 5 25 50 100 Hz

Speed of rotation: 101 627 1378 2819 min

Operating mode: S1

-1

Heat class F

Delta connection

Torque: 1.4 4.5 5.2 5.2 Nm

Power: 0.015 0.295 1.37 1.526 kW

Voltage: *) 23 115 400 400 V

Current: 1.7 3.1 3.6 3.5 A

Frequency: 5 25 87 100 Hz

-1

Speed of rotation: 101 627 2492 2836 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter and

over the motor supply cable and may not fall below the design value by more than 5% according to

IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter. This must be

taken into account for the design of the motor, the parameterisation of the inverter (e.g. rev/f

adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the design voltage of the motor by means of the number of windings is permissible. The

rated current changes in inverse proportion to the rated voltage.

Sheet 1/3

www.nord.com B1092-GB -23-

Page 24

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3048 X

for the three-phase motor, type 1MA7 083-4…

Monitoring devices

To prevent impermissible heating due to overload, the motors are monitored by connection to a device

for direct temperature monitoring in combination with defined setting data of the inverter.

Due to the special characteristics of motors supplied by inverters and the adapted monitoring device,

details of the relationship I

The type of device for direct temperature monitoring has been tested by the Physikalish-Technische

Bundesanstalt and consists of three DIN 44082 type M 110 PTCs installed in the windings and a

function-tested triggering device according to Guideline 94/9/EU.

With a line current of 9.8 A and a blocked shaft, the PTC must trigger after 21 s (± 20 %) assuming a

cold condition (20 °C).

By means of the temperature monitoring device, temperature class T3 as per EN 60079-7 is complied

with.

Inverter setting data

In combination with the aforementioned monitoring device, the following inverter data must be set and

maintained during operation:

Minimum pulse frequency: 3 kHz

and the heating time tE are not required for motors operated by inverters.

A/IN

Short-term current limit: 1.5*I

N

Maximum overload time: 60 s

Minimum frequency f

Maximum frequency f

Permissible duration of operation

:

at f

min

: 5 Hz

min

max

:

100 Y / 100 Δ

Hz

60 s

The maximum overload time and the permissible duration of operation at f

refer to a time period of 10

min

min.

The relationship of the torque to the frequency results from the permissible continuous current limit.

Sheet 2/3

-24- B1092-GB www.nord.com

Page 25

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3048 X

The continuous current limit of the frequency inverter must be set dependent on the frequency according

to the following diagram:

1,1

1

0,9

Translated extract from Data Sheet 01

for the three-phase motor, type 1MA7 083-4…

Prohibited region

0,8

I / In

0,7

0,6

0,5

0,4

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Permissible region

Star connection

Delta connection

f / Hz

Setting parameters for the continuous current limit of

the frequency inverter between 5 Hz and 100 Hz

All other setting data should be selected according to the requirements of the drive unit.

Special conditions

Group operation of the motors is not permissible.

Motors of this type may only be operated with inverters which fulfil the requirements stated above under

"Inverter setting data".

The maximum rated current of the frequency inverter may correspond to double the rated current of the

motor.

The current monitoring of the frequency inverter must record the effective value of the machine current

with a tolerance of

± 5 % in relation to the rated current of the motor.

Before start-up it must be ensured that no overvoltages due to the inverter with a peak value in excess of

1556 V (2*

2

*550V) occur at the terminals of the electrical machine.

Test report

PTB Ex 07-37120

Certification Facility for Explosion Protection Braunschweig, 4 October 2007

pp

L.S.

Dr.-Ing. F. Lienesch

Senior Government Official Sheet 3/3

www.nord.com B1092-GB -25-

Page 26

Translated extract from Data Sheet 01

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3049 X

for the three-phase motor, type 1MA7 096-4…

Rated values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 3.0 9.1 9.1 3.6 Nm

Power: 0.034 0.604 1.34 1.08 kW

Voltage: *) 40 200 400 400 V

Current: 1.6 3.1 3.1 2.3 A

Frequency: 5 25 50 100 Hz

Speed of rotation: 108 630 1407 2854 min

Operating mode: S1

-1

Heat class F

Delta connection

Torque: 3 9.1 9.1 9.1 Nm

Power: 0.034 0.604 2.41 2.73 kW

Voltage: *) 23 115 400 400 V

Current: 2.8 5.4 5.4 5.7 A

Frequency: 5 25 87 100 Hz

-1

Speed of rotation: 108 630 2518 2870 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter and

over the motor supply cable and may not fall below the design value by more than 5% according to

IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter. This must be

taken into account for the design of the motor, the parameterisation of the inverter (e.g. rev/f

adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the design voltage of the motor by means of the number of windings is permissible. The

rated current changes in inverse proportion to the rated voltage.

Sheet 1/3

-26- B1092-GB www.nord.com

Page 27

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3049 X

Monitoring devices

To prevent impermissible heating due to overload, the motors are monitored by connection to a device

for direct temperature monitoring in combination with defined setting data of the inverter.

Due to the special characteristics of motors supplied by inverters and the adapted monitoring device,

details of the relationship I

The type of device for direct temperature monitoring has been tested by the Physikalish-Technische

Bundesanstalt and consists of three DIN 44082 type M 110 PTCs installed in the windings and a

function-tested triggering device according to Guideline 94/9/EU.

With a line current of 17.4 A and a blocked shaft, the PTC must trigger after 17.5 s (± 20 %) assuming a

cold condition (20 °C).

By means of the temperature monitoring device, temperature class T3 as per EN 60079-7 is complied

with.

Inverter setting data

In combination with the aforementioned monitoring device, the following inverter data must be set and

maintained during operation:

Minimum pulse frequency: 3 kHz

Translated extract from Data Sheet 01

for the three-phase motor, type 1MA7 096-4…

and the heating time tE are not required for motors operated by inverters.

A/IN

Short-term current limit: 1.5*I

N

Maximum overload time: 60 s

Minimum frequency f

Maximum frequency f

Permissible duration of operation

:

at f

min

: 5 Hz

min

max

:

100 Y / 100 Δ

Hz

60 s

The maximum overload time and the permissible duration of operation at f

refer to a time period of 10

min

min.

The relationship of the torque to the frequency results from the permissible continuous current limit.

Sheet 2/3

www.nord.com B1092-GB -27-

Page 28

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3049 X

for the three-phase motor, type 1MA7 096-4…

The continuous current limit of the frequency inverter must be set dependent on the frequency according

to the following diagram:

1,2

1,1

1

Prohibited region

0,9

0,8

I / In

0,7

0,6

0,5

0,4

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

0

Permissible region

Star connection

Delta connection

f / Hz

Setting parameters for the continuous current limit of

the frequency inverter between 5 Hz and 100 Hz

All other setting data should be selected according to the requirements of the drive unit.

Special conditions

Group operation of the motors is not permissible.

Motors of this type may only be operated with inverters which fulfil the requirements stated above under

"Inverter setting data".

The maximum rated current of the frequency inverter may correspond to double the rated current of the

motor.

The current monitoring of the frequency inverter must record the effective value of the machine current

with a tolerance of

± 5 % in relation to the rated current of the motor.

Before start-up it must be ensured that no overvoltages due to the inverter with a peak value in excess of

1556 V (2*

2 *550V) occur at the terminals of the electrical machine.

Test report

PTB Ex 07-37121

Certification Facility for Explosion Protection Braunschweig, 4 October 2007

pp

L.S.

Dr.-Ing. F. Lienesch

Senior Government Official Sheet 3/3

-28- B1092-GB www.nord.com

Page 29

of the EU Prototype Test Certificate PTB 07 ATEX 3050 X

Translated extract from Data Sheet 01

7. Data Sheets

for the three-phase motor, type 1MA7 106-4…

Rated values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 5 13.5 13.5 5.5 Nm

Power: 0.061 0.937 2.0 1.67 kW

Voltage: *) 40 200 400 400 V

Current: 2.4 4.4 4.4 3.4 A

Frequency: 5 25 50 100 Hz

Speed of rotation: 114.2 662 1424 2872 min

Operating mode: S1

-1

Heat class F

Delta connection

Torque: 5 13.5 12.7 12.7 Nm

Power: 0.061 0.937 3.38 3.86 kW

Voltage: *) 23 115 400 400 V

Current: 4.15 7.6 7.6 7.8 A

Frequency: 5 25 87 100 Hz

-1

Speed of rotation: 114.2 662 2541 2896 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter

and over the motor supply cable and may not fall below the design value by more than 5%

according to IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter.

This must be taken into account for the design of the motor, the parameterisation of the inverter

(e.g. rev/f adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the design voltage of the motor by means of the number of windings is permissible. The

rated current changes in inverse proportion to the rated voltage.

Sheet 1/3

www.nord.com B1092-GB -29-

Page 30

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3050 X

for the three-phase motor, type 1MA7 106-4…

Monitoring devices

To prevent impermissible heating due to overload, the motors are monitored by connection to a device

for direct temperature monitoring in combination with defined setting data of the inverter.

Due to the special characteristics of motors supplied by inverters and the adapted monitoring device,

details of the relationship I

The type of device for direct temperature monitoring has been tested by the Physikalish-Technische

Bundesanstalt and consists of three DIN 44082 type M 120 PTCs installed in the windings and a

function-tested triggering device according to Guideline 94/9/EU.

With a line current of 28.8 A and a blocked shaft, the PTC must trigger after 15 s (± 20 %) assuming a

cold condition (20 °C).

By means of the temperature monitoring device, temperature class T3 as per EN 60079-7 is complied

with.

Inverter setting data

In combination with the aforementioned monitoring device, the following inverter data must be set and

maintained during operation:

Minimum pulse frequency: 3 kHz

and the heating time tE are not required for motors operated by inverters.

A/IN

Short-term current limit: 1.5*I

N

Maximum overload time: 60 s

Minimum frequency f

Maximum frequency f

Permissible duration of operation

:

at f

min

: 5 Hz

min

max

:

100 Y / 100 Δ

Hz

60 s

The maximum overload time and the permissible duration of operation at f

refer to a time period of 10

min

min.

The relationship of the torque to the frequency results from the permissible continuous current limit.

Sheet 2/3

-30- B1092-GB www.nord.com

Page 31

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3050 X

The continuous current limit of the frequency inverter must be set dependent on the frequency according

to the following diagram:

1,2

1,1

1

Translated extract from Data Sheet 01

for the three-phase motor, type 1MA7 106-4…

Prohibited region

0,9

0,8

I / In

0,7

0,6

0,5

0,4

0

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Permissible region

Star connection

Delta connection

f / Hz

Setting parameters for the continuous current limit of the

frequency inverter between 5 Hz and 100 Hz

All other setting data should be selected according to the requirements of the drive unit.

Special conditions

Group operation of the motors is not permissible.

Motors of this type may only be operated with inverters which fulfil the requirements stated above under

"Inverter setting data".

The maximum rated current of the frequency inverter may correspond to double the rated current of the

motor.

The current monitoring of the frequency inverter must record the effective value of the machine current

with a tolerance of

± 5 % in relation to the rated current of the motor.

Before start-up it must be ensured that no overvoltages due to the inverter with a peak value in excess of

1556 V (2*

2

*550V) occur at the terminals of the electrical machine.

Test report

PTB Ex 07-37122

Certification Facility for Explosion Protection Braunschweig, 4 October 2007

pp

L.S.

Dr.-Ing. F. Lienesch

Senior Government Official Sheet 3/3

www.nord.com B1092-GB -31-

Page 32

Translated extract from Data Sheet 02

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3050 X

for the three-phase motor, type 1MA7 107-4…

Rated values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 5 14 16.8 7.5 Nm

Power: 0.065 0.99 2.5 2.2 kW

Voltage: *) 40 200 400 400 V

Current: 2.5 4.6 5.4 4.6 A

Frequency: 5 25 50 100 Hz

Speed of rotation: 124 679 1415 2831 min

Operating mode: S1

-1

Heat class F

Delta connection

Torque: 5 14 16.8 16 Nm

Power: 0.065 0.99 4.4 4.8 kW

Voltage: *) 23 115 400 400 V

Current: 4.3 8.0 9.4 9.6 A

Frequency: 5 25 87 100 Hz

-1

Speed of rotation: 124 679 2523 2885 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter

and over the motor supply cable and may not fall below the design value by more than 5%

according to IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter.

This must be taken into account for the design of the motor, the parameterisation of the inverter

(e.g. rev/f adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the design voltage of the motor by means of the number of windings is permissible. The

rated current changes in inverse proportion to the rated voltage.

Sheet 1/3

-32- B1092-GB www.nord.com

Page 33

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3050 X

Monitoring devices

To prevent impermissible heating due to overload, the motors are monitored by connection to a device

for direct temperature monitoring in combination with defined setting data of the inverter.

Due to the special characteristics of motors supplied by inverters and the adapted monitoring device,

details of the relationship I

The type of device for direct temperature monitoring has been tested by the Physikalish-Technische

Bundesanstalt and consists of three DIN 44082 type M 120 PTCs installed in the windings and a

function-tested triggering device according to Guideline 94/9/EU.

With a line current of 35.2 A and a blocked shaft, the PTC must trigger after 16 s (± 20 %) assuming a

cold condition (20 °C).

By means of the temperature monitoring device, temperature class T3 as per EN 60079-7 is complied with.

Inverter setting data

In combination with the aforementioned monitoring device, the following inverter data must be set and

maintained during operation:

Minimum pulse frequency: 3 kHz

Translated extract from Data Sheet 02

for the three-phase motor, type 1MA7 107-4…

and the heating time tE are not required for motors operated by inverters.

A/IN

Short-term current limit: 1.5*I

N

Maximum overload time: 60 s

Minimum frequency f

Maximum frequency f

Permissible duration of operation

:

at f

min

: 5 Hz

min

max

:

100 Y / 100 Δ

Hz

60 s

The maximum overload time and the permissible duration of operation at f

refer to a time period of 10

min

min.

The relationship of the torque to the frequency results from the permissible continuous current limit.

Sheet 2/3

www.nord.com B1092-GB -33-

Page 34

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3050 X

Translated extract from Data Sheet 02

for the three-phase motor, type 1MA7 107-4…

The continuous current limit of the frequency inverter must be set dependent on the frequency according

to the following diagram:

1,2

Prohibited region

Permisible region

I / In

1,1

0,9

0,8

1

0,7

0,6

0,5

0,4

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Star connection

Delta connection

f / Hz

Setting parameters for the continuous current limit of

the frequency inverter between 5 Hz and 100 Hz

All other setting data should be selected according to the requirements of the drive unit.

Special conditions

Group operation of the motors is not permissible.

Motors of this type may only be operated with inverters which fulfil the requirements stated above under

"Inverter setting data".

The maximum rated current of the frequency inverter may correspond to double the rated current of the

motor.

The current monitoring of the frequency inverter must record the effective value of the machine current

with a tolerance of

± 5 % in relation to the rated current of the motor.

Before start-up it must be ensured that no overvoltages due to the inverter with a peak value in excess of

1556 V (2*

2 *550V) occur at the terminals of the electrical machine.

Test report

PTB Ex 07-37427

Certification Facility for Explosion Protection Braunschweig, 4 October 2007

pp

L.S.

Dr.-Ing. F. Lienesch

Senior Government Official Sheet 3/3

-34- B1092-GB www.nord.com

Page 35

of the EU Prototype Test Certificate PTB 07 ATEX 3051 X

Translated extract from Data Sheet 01

7. Data Sheets

for the three-phase motor, type 1MA7 113-4…

Rated values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 10.1 19 23.9 11 Nm

Power: 0.123 1.38 3.57 3.23 kW

Voltage: *) 40 200 400 400 V

Current: 4.4 6.3 7.6 7.8 A

Frequency: 5 25 50 100 Hz

Speed of rotation: 116 699 1422 2788 min

Operating mode: S1

-1

Heat class F

Delta connection

Torque: 10.1 19 23.9 20.1 Nm

Power: 0.123 1.38 6.35 6.14 kW

Voltage: *) 23 115 400 400 V

Current: 7.6 10.9 13.4 12.8 A

Frequency: 5 25 87 100 Hz

-1

Speed of rotation: 116 699 2533 2910 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter and

over the motor supply cable and may not fall below the design value by more than 5% according to

IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter. This must be

taken into account for the design of the motor, the parameterisation of the inverter (e.g. rev/f

adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the design voltage of the motor by means of the number of windings is permissible. The

rated current changes in inverse proportion to the rated voltage.

Sheet 1/3

www.nord.com B1092-GB -35-

Page 36

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3051 X

for the three-phase motor, type 1MA7 113-4…

Monitoring devices

To prevent impermissible heating due to overload, the motors are monitored by connection to a device

for direct temperature monitoring in combination with defined setting data of the inverter.

Due to the special characteristics of motors supplied by inverters and the adapted monitoring device,

details of the relationship I

The type of device for direct temperature monitoring has been tested by the Physikalish-Technische

Bundesanstalt and consists of three DIN 44082 type M 120 PTCs installed in the windings and a

function-tested triggering device according to Guideline 94/9/EU.

With a line current of 54 A and a blocked shaft, the PTC must trigger after 15 s (± 20 %) assuming a

cold condition (20 °C).

By means of the temperature monitoring device, temperature class T3 as per EN 60079-7 is complied

with.

Inverter setting data

In combination with the aforementioned monitoring device, the following inverter data must be set and

maintained during operation:

Minimum pulse frequency: 3 kHz

and the heating time tE are not required for motors operated by inverters.

A/IN

Short-term current limit: 1.5*I

N

Maximum overload time: 60 s

Minimum frequency f

Maximum frequency f

Permissible duration of operation

:

at f

min

: 5 Hz

min

max

:

100 Y / 100 Δ

Hz

60 s

The maximum overload time and the permissible duration of operation at f

refer to a time period of 10

min

min.

The relationship of the torque to the frequency results from the permissible continuous current limit.

Sheet 2/3

-36- B1092-GB www.nord.com

Page 37

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3051 X

The continuous current limit of the frequency inverter must be set dependent on the frequency according

to the following diagram:

1,2

1,1

1

0,9

0,8

I / In

0,7

Translated extract from Data Sheet 01

for the three-phase motor, type 1MA7 113-4…

Prohibited region

Permissible region

0,6

0,5

0,4

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Star connection

Delta connection

f / Hz

Setting parameters for the continuous current limit of

the frequency inverter between 5 Hz and 100 Hz

All other setting data should be selected according to the requirements of the drive unit.

Special conditions

Group operation of the motors is not permissible.

Motors of this type may only be operated with inverters which fulfil the requirements stated above under

"Inverter setting data".

The maximum rated current of the frequency inverter may correspond to double the rated current of the

motor.

The current monitoring of the frequency inverter must record the effective value of the machine current

with a tolerance of

± 5 % in relation to the rated current of the motor.

Before start-up it must be ensured that no overvoltages due to the inverter with a peak value in excess of

1556 V (2*

2 *550V) occur at the terminals of the electrical machine.

Test report

PTB Ex 07-37123

Certification Facility for Explosion Protection Braunschweig, 4 October 2007

pp

L.S.

Dr.-Ing. F. Lienesch

Senior Government Official Sheet 3/3

www.nord.com B1092-GB -37-

Page 38

Translated extract from Data Sheet 01

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3052 X

for the three-phase motor, type 1MA7 133-4…

Rated values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 15 44 44 20.2 Nm

Power: 0.218 3.28 6.83 6.18 kW

Voltage: *) 40 200 400 400 V

Current: 7.4 13.8 13.9 12.5 A

Frequency: 5 25 50 100 Hz

Speed of rotation: 139 711 1477 2926 min

Operating mode: S1

-1

Heat class F

Delta connection

Torque: 15 44 35 35 Nm

Power: 0.218 3.28 9.49 10.88 kW

Voltage: *) 23 115 400 400 V

Current: 12.8 23.9 21.3 21.9 A

Frequency: 5 25 87 100 Hz

Speed of rotation: 139 711 2582 2956 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter and

over the motor supply cable and may not fall below the design value by more than 5% according to

IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter. This must be

taken into account for the design of the motor, the parameterisation of the inverter (e.g. rev/f

adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the design voltage of the motor by means of the number of windings is permissible.

The rated current changes in inverse proportion to the rated voltage.

-1

Sheet 1/3

-38- B1092-GB www.nord.com

Page 39

7. Data Sheets

of the EU Prototype Test Certificate PTB 07 ATEX 3052 X

Monitoring devices

To prevent impermissible heating due to overload, the motors are monitored by connection to a device

for direct temperature monitoring in combination with defined setting data of the inverter.

Due to the special characteristics of motors supplied by inverters and the adapted monitoring device,

details of the relationship I

The type of device for direct temperature monitoring has been tested by the Physikalish-Technische

Bundesanstalt and consists of three DIN 44082 type M 110 PTCs installed in the windings and a

function-tested triggering device according to Guideline 94/9/EU.

With a line current of 108 A and a blocked shaft, the PTC must trigger after 13 s (± 20 %) assuming a

cold condition (20 °C).

By means of the temperature monitoring device, temperature class T3 as per EN 60079-7 is complied

with.

Inverter setting data

In combination with the aforementioned monitoring device, the following inverter data must be set and

maintained during operation:

Minimum pulse frequency: 3 kHz

Translated extract from Data Sheet 01

for the three-phase motor, type 1MA7 133-4…

and the heating time tE are not required for motors operated by inverters.

A/IN

Short-term current limit: 1.5*I

N

Maximum overload time: 60 s

Minimum frequency f

Maximum frequency f

Permissible duration of

operation at f

min

:

: 5 Hz

min

max

:

100 Y / 100 Δ

Hz

60 s

The maximum overload time and the permissible duration of operation at f

refer to a time period of 10

min

min.

The relationship of the torque to the frequency results from the permissible continuous current limit.

Sheet 2/3

www.nord.com B1092-GB -39-

Page 40

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3052 X

for the three-phase motor, type 1MA7 133-4…

The continuous current limit of the frequency inverter must be set dependent on the frequency according

to the following diagram:

1,1

0,9

1

Prohibited region

0,8

I / In

0,7

0,6

0,5

0,4

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Permissible region

Star connection

Delta connection

f / Hz

Setting parameters for the continuous current limit of

the frequency inverter between 5 Hz and 100 Hz

All other setting data should be selected according to the requirements of the drive unit.

Special conditions

Group operation of the motors is not permissible.

Motors of this type may only be operated with inverters which fulfil the requirements stated above under

"Inverter setting data".

The maximum rated current of the frequency inverter may correspond to double the rated current of the

motor.

The current monitoring of the frequency inverter must record the effective value of the machine current

with a tolerance of

± 5 % in relation to the rated current of the motor.

Before start-up it must be ensured that no overvoltages due to the inverter with a peak value in excess of

1556 V (2*

2 *550V) occur at the terminals of the electrical machine.

Test report

PTB Ex 07-37124

Certification Facility for Explosion Protection Braunschweig, 4 October 2007

pp

L.S.

Dr.-Ing. F. Lienesch

Senior Government Official Sheet 3/3

-40- B1092-GB www.nord.com

Page 41

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3053 X

for the three-phase motor, type 1MA7 163-4…

Rated values and data

This certificate applies for the following versions on condition that motors of this type only vary to an

insignificant extent from the tested sample with regard to the electrical and thermal load:

Star connection

Torque: 50 60 65.7 27 Nm

Power: 0.672 4.48 10 8.244 kW

Voltage: *) 53 200 400 400 V

Current: 14 17.6 18.9 17.6 A

Frequency: 5 25 50 100 Hz

Speed of rotation: 128 710 1455 2907 min

Operating mode: S1

-1

Heat class F

Delta connection

Torque: 50 60 65.7 56 Nm

Power: 0.672 4.48 17.663 17.3 kW

Voltage: *) 31 115 400 400 V

Current: 24.2 30.5 33.3 32.8 A

Frequency: 5 25 87 100 Hz

-1

Speed of rotation: 128 710 2563 2946 min

Operating mode: S1

Heat class F

*) Basic oscillation, measured at the motor terminals.

The voltage depends on the input voltage of the frequency inverter, the voltage drop at the filter

and over the motor supply cable and may not fall below the design value by more than 5%

according to IEC 60034 - 1 Range "A", even with minimum input voltage of the frequency inverter.

This must be taken into account for the design of the motor, the parameterisation of the inverter

(e.g. rev/f adaptation) and for the minimum input voltage of the inverter.

The maximum input voltage of the inverter is 500V.

Adaptation of the design voltage of the motor by means of the number of windings is permissible.

The rated current changes in inverse proportion to the rated voltage.

Sheet 1/3

www.nord.com B1092-GB -41-

Page 42

7. Data Sheets

Translated extract from Data Sheet 01

of the EU Prototype Test Certificate PTB 07 ATEX 3053 X