Page 1

GB

B 1091-1

Motors in fi operation for Category 3D

Planning guideline for B 1091

Page 2

Motors in fi operation for Category 3D – Planning guideline for B 1091

Pos: 2 /Anleitungen/Motoren/B1091-1 Projektieru ngsleitfaden zur B1091/0. Prolog/0.2 Bestimmungs ge mäße Verwendung der Drehstrom-Asynchronmotoren im Frequ enzumrichterbetrieb[B1091-1] @ 2\mod_1358777562 957_388.docx @ 54047 @ @ 1

Proper use of three-phase asynchronous motors in frequency

inverter operation

Compliance with the planning guide for the operating and installation instructions B1091, and the

operating instructions for the frequency inverter is essential for correct operation and the fulfilment

of any warranty claims. Read the operating and installation instructions before starting work with

the motors and frequency inverters.

These operating instructions contain important information about servicing. They must therefore be

kept close to the motor.

The asynchronous motors and frequency inverters are intended for industrial and commercial systems

for the movement of various drive components and applications.

All details regarding technical data and permissible conditions at the installation site must be complied

with.

Commissioning (commencement of the intended use) is not permitted until it has been ensured that

the machine complies with the EMC Directive 2004/108/EEC and that the conformity of the end

product meets the Machinery Directive 2006/42/EEC (observe EN 60204).

Getriebebau NORD GmbH & Co. KG, 2013

Pos: 3 /---------- Seitenumbruch ---------- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

2 B 1091-1 GB-3213

Page 3

Documentation

Pos: 4 /Anleitungen/Motoren/B1091-1 Projektieru ngsleitfaden zur B1091/0. Prolog/0.3 Dokumentatio n - Versionsliste [B1091-1] @ 2\mod_1358777563534 _38 8.docx @ 54072 @ @ 1

Documentation

Designation: B1091-1

Part No.: 605 21 02

Series: Three-phase asynchronous

Frequency inverter

series:

Motor series: Standard, ATEX

Motor types:

Version list

motors in frequency inverter

operation

SK 2xxE, SK 5xxE

IE1, IE2

single phase

Size 63S/4 … 132MA/4

Planning Guideline

Name of previous issues Remarks

B1091-1 GB, February 2013

Part No. 605 2102 / 0613

B1091-1 GB, August 2013

Part No. 605 2102 / 3213

First issue, based on B1091-1 DE / January 2013

Revision of layout and correction of errors

Table 1: Version list

Pos: 5 /Anleitungen/Motoren/B1091-1 Projektieru ngsleitfaden zur B1091/0. Prolog/0.35 Gültigkei t [ B 1091- 1] @ 2\mod_1359975192650_388.docx @ 54951 @ @ 1

G

Validity

This Planning Guideline for the operation and instructions B 1091 describes the planning requirements

for NORD three-phase asynchronous motors supplied by frequency inverters for Zone 22.

Pos: 6 /Anleitungen/Elektronik/FU und Starter/ 0. Prolog/0.4 Herausgeber @ 0\mod_1325779078002_388.doc x @ 5270 @ @ 1

Publisher

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 1 D-22941 Bargteheide http://www.nord.com/

Tel.: +49 (0) 45 32 / 289-0 Fax +49 (0) 45 32 / 289-2555

=== Ende der Liste für Textmarke Copyright ===

B 1091-1 GB-3213 3

Page 4

Motors in fi operation for Category 3D – Planning guideline for B 1091

4 B 1091-1 GB-3213

Page 5

Table of Contents

Pos: 8 /Anleitungen/Steuermodule/Inhaltsverzei chnis @ 0\mod_1317978518480_388.docx @ 4078 @ @ 1

Table of Contents

=== Ende der Liste für Textmarke Inhaltsverzeichnis == =

1. Technical explanations ............................................................................................................................... 8

1.1 General .............................................................................................................................................. 8

1.2 Overview ............................................................................................................................................ 8

1.3 Wiring: ................................................................................................................................................ 9

1.4 Commissioning .................................................................................................................................. 9

1.5 Assignment of the frequency inverter and selection of the operating mode ..................................... 10

1.6 Examples ......................................................................................................................................... 11

1.6.1 1. Example: motor 100L/4 .................................................................................................. 11

1.6.2 2. Example: motor 100L/4 .................................................................................................. 14

1.7 Motor data for parameterisation of the frequency inverter ................................................................ 15

1.7.1 Parameterisation data for the 50 Hz characteristic curve, IE1 and IE2 motors ................... 15

1.7.2 Parameterisation data for the 87 Hz characteristic curve, IE1 and IE2 motors ................... 16

1.7.3 Parameterisation data for the 100 Hz characteristic curve, IE1 and IE2 motors ................. 17

2. Technical Data ........................................................................................................................................... 18

2.1 Motors .............................................................................................................................................. 18

2.1.1 Motors, 50 Hz nominal point ............................................................................................... 19

2.1.2 Motors, 87 Hz nominal point ............................................................................................... 20

2.1.3 Motors, 100 Hz nominal po int ............................................................................................. 21

2.2 Motors with external fan ................................................................................................................... 22

2.2.1 Motors with external fan, 50 Hz nominal point .................................................................... 23

2.2.2 Motors with external fan, 87 Hz nominal point .................................................................... 24

2.2.3 Motors with external fan, 100 Hz nominal point .................................................................. 25

3. Appendix .................................................................................................................................................... 26

3.1 Abbreviations ................................................................................................................................... 26

3.2 Legend / Formula symbols ............................................................................................................... 26

B 1091-1 GB-3213 5

Page 6

Motors in fi operation for Category 3D – Planning guideline for B 1091

Pos: 10 /Anleitungen/Steuermodule/Abbildungs ver zeichnis @ 0\mod_1317978515699_388.docx @ 3917 @ @ 1

List of illustrations

=== Ende der Liste für Textmarke Abbildungsverzeichni s ===

Figure 1: Selection of V/f characteristic curves ...................................................................................................... 10

Figure 2: Motor 100L/4, 50 Hz characteristic curve ............................................................................................... 11

Figure 3: Motor 100L/4, 100 Hz characteristic curve ............................................................................................. 12

Figure 4: Motor 100L/4, 87 Hz characteristic curve ............................................................................................... 13

6 B 1091-1 GB-3213

Page 7

List of tables

Pos: 12 /Anleitungen/Steuermodule/Tabellen verz eichnis @ 0\mod_1317978519199_388.docx @ 4124 @ @ 1

List of tables

=== Ende der Liste für Textmarke Tabellenverzeichnis = = =

Table 1: Version list ................................................................................................................................................. 3

Tabelle 2: Parameterisation data for the 50 Hz characteristic curve, IE1 motors .................................................. 15

Tabelle 3: Parameterisation data for the 50 Hz characteristic curve, IE2 motors .................................................. 15

Tabelle 4: Parameterisation data for the 87 Hz characteristic curve, IE1 motors .................................................. 16

Tabelle 5: Parameterisation data for the 87 Hz characteristic curve, IE2 motors .................................................. 16

Table 6: Parameterisation data for the 100 Hz characteristic curve, IE1 motors ................................................... 17

Table 7: Parameterisation data for the 100 Hz characteristic curve, IE2 motors ................................................... 17

Table 8: IE1 and IE2 motors, 50 Hz nominal point ................................................................................................ 19

Table 9: IE1 and IE2 motors, 87 Hz nominal point ................................................................................................ 20

Table 10: IE1 and IE2 motors, 100 Hz nominal point ............................................................................................ 21

Table 11: IE1 and IE2 motors with external fan, 50 Hz nominal point ................................................................... 23

Table 12: IE1 and IE2 motors with external fan, 87 Hz nominal point ................................................................... 24

Table 13: IE1 and IE2 motors with external fan, 100 Hz nominal point ................................................................. 25

Pos: 14 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1. Technische Erläuterungen [B1091-1] @ 2\mod_135841 6035402_388.docx @ 53660 @ 1 @ 1

B 1091-1 GB-3213 7

Page 8

Motors in fi operation for Category 3D – Planning guideline for B 1091

1. Technical explanations

Pos: 15 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.1 Allgemeines [B1091-1] @ 2\mod_1358235620867_ 388.docx @ 53281 @ 2 @ 1

1.1 General

The Category 3D motors supplied by NORD DRIVESYSTEMS comply with standard EN 50281-1-1

(electrical equipment for use in areas with inflammable dust) and EN 50014 (Electrical equipment for

explosion hazard areas). Category 3D motors with efficiency class IE2 comply with the standards

EN 60079-0 and EN 60079-31. In both versions the insulation of the windings is generally designed for

operation with frequency inverters. For operation with frequency inverters, the motors are always

equipped with triple thermistors as per DIN 44082.

For variable speed drives, the thermistor is the most important protective element for compliance with

the maximum surface temperature, which is stated in the type plate of the motor.

As the thermistor only provides an indirect temperature monitoring of some components of the

motor, e.g. the motor shaft, it is necessary to observe all the specifications stated in this

planning guideline.

The operating ranges stated in the Appendix have been checked in the course of extensive test runs

and only these ranges are approved. Compliance with the listed procedures is therefore a prerequisite

for the planning and commissioning of Device Group II regulated drive units in Zone 22 (nonconducting dust).

Pos: 16 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.2 Überblick [B1091-1] @ 2\mod_1358237172757_38 8.docx @ 53304 @ 25 @ 1

1.2 Overview

Necessary frequency inverter characteristics:

• Only frequency inverters with a vector regulation process which provides load-dependent terminal

voltage adjustment in the low speed range may be used.

• The maximum output voltage of the frequency inverter must not be less than 91% of the mains

voltage.

• The inverter must provide i²*t monitoring which is adjustable to the rated current for the motor.

• The pulse frequency of the output stage must be adjustable to 4 kHz or higher.

• If the inverter does not have an input for evaluation of the thermistor, the evaluation must be

carried out by a separate triggering device, which switches off the inverter. Operation without

evaluation of the thermistor is not permitted.

Pos: 17 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

8 B 1091-1 GB-3213

Page 9

1 Technical explanations

Pos: 18 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.3 Verdrahtung [B1091-1] @ 2\mod_1358237941880 _388.docx @ 53328 @ 2 @ 1

1.3 Wiring:

• No filters which come into the resonance range may be wired between the inverter and the motor

The resulting overvoltage could damage the insulation of the cable or the motor.

• Only filters which are prescribed or approved by the supplier of the frequency inverter may be

used.

• The wires used must have an insulation strength of at least 2,000 VDC.

• Additional mains or motor chokes reduce the output voltage of the frequency inverter and are not

considered in this planning guideline. Chokes shift the threshold of the field weakening range

downwards and the field weakening becomes greater.

Pos: 19 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.4 Inbetriebnahme [B1091-1] @ 2\mod_13582386088 76_388.docx @ 53352 @ 2 @ 1

1.4 Commissioning

• Set the pulse frequency of the output stage to 4 - 6 kHz. With NORD frequency inverters, 6 kHz

corresponds to the standard frequency of the frequency inverter.

• Parameterise the vector regulation to the motor used.

• The i²*t monitoring must be set to the rated current for the motor.

• The maximum frequency must be set according to the application and must not exceed 100 Hz.

• Activate the thermistor evaluation.

• Check the thermistor monitoring by interrupting the cable connection to the frequency inverter.

ATTENTION

The maximum permissible input speed of the gear unit must be observed.

Exceeding the permissible speed may cause overheating and dam age to the component s of the gear units, up to

the complete destruction of the gear unit.

For frequency inverter operation the speed of the motor must be limited according to the planning specificatio ns.

Gear unit damage - high speed

Pos: 20 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

B 1091-1 GB-3213 9

Page 10

Motors in fi operation for Category 3D – Planning guideline for B 1091

Pos: 21 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.5 Frequenzumrichterzuordnung und Auswahl der B etr i ebsart [B1091-1] @ 2\mod_1358240883977_388.docx @ 53380 @ 2 @ 1

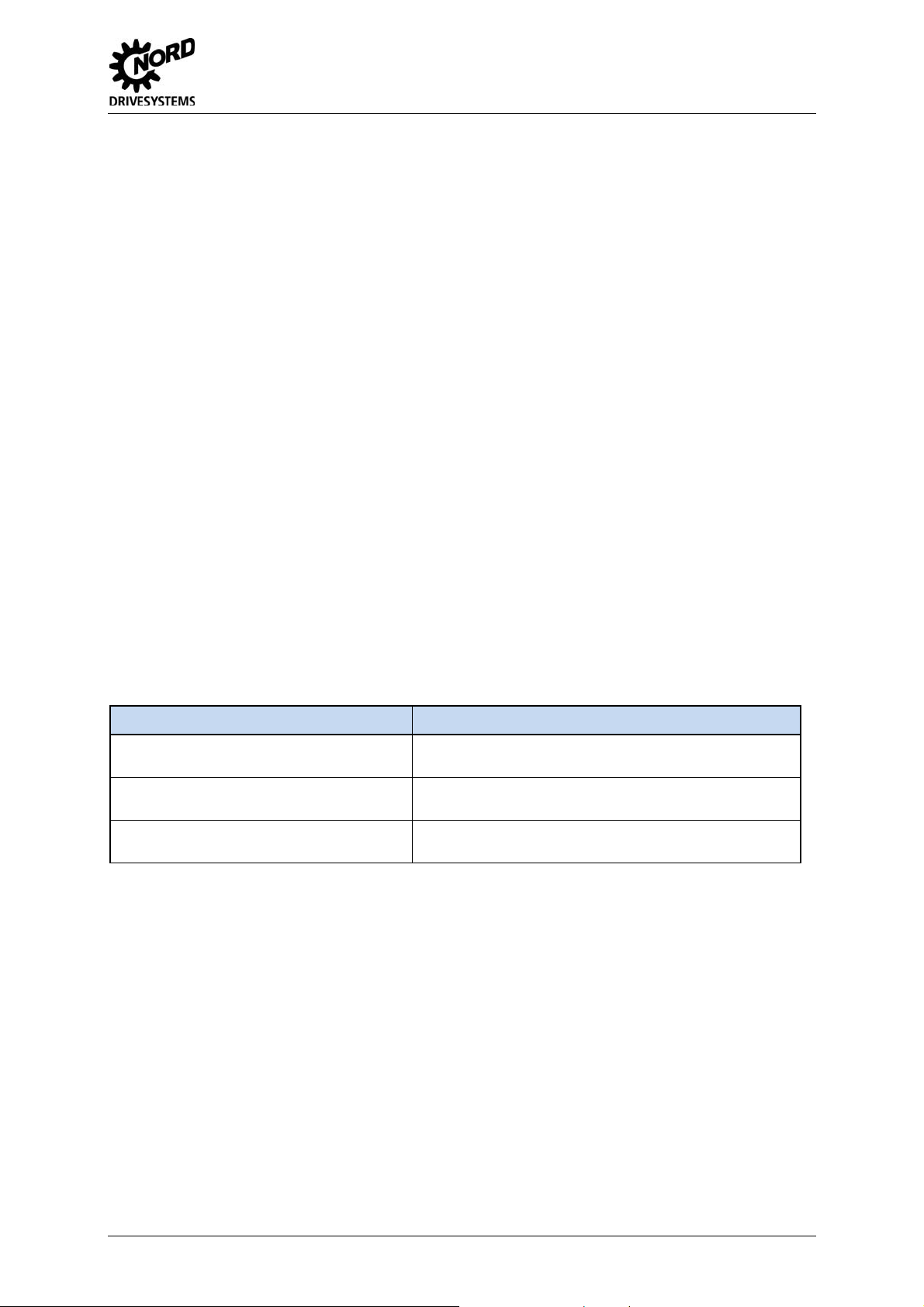

1.5 Assignment of the frequency inverter and selection of the operating mode

The rated current of the frequency inverter must match the rated current of the motor in order to

achieve an adequate accuracy of the current measurement. The rated current of the frequency

inverter must not exceed 2x the rated motor current.

According to this planning guideline, multiple-motor operation is not permitted, as selective i²*t

monitoring of a motor is then no longer possible.

Please note the technical data in section 2

According to the application, the operating mode of the motor can be selected from one of the

following 3 characteristic curves:

•

50 Hz characteristic

curve:

•

87 Hz characteristic

curve:

•

100 Hz characteristic

curve:

Nominal point 400 V / 50 Hz, 0 – 50 Hz no field weakening and

50 – 100 Hz field weakening.

Nominal point 400 V / 87 Hz, 0 – 87 Hz no field weakening and

87 – 100 Hz field weakening.

Nominal point 400 V / 100 Hz, 0 – 100 Hz reduced constant torque with slight field

weakening.

V/f characteristic curves

Figure 1: Selection of V/f characteristic curves

Legend

50 Hz characteristic curve

87 Hz characteristic curve

100 Hz characteristic curve

Pos: 22 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

10 B 1091-1 GB-3213

Page 11

1 Technical explanations

Pos: 23 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.6 Beispiele [B1091-1] @ 2\mod_1358250027977_38 8. docx @ 53430 @ 2 @ 1

1.6 Examples

Pos: 24 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.6.1 Beispiel 1 Motor 100L/4 [B1091-1] @ 2\mod_135824 6005266_388.docx @ 53405 @ 35555 @ 1

1.6.1 1. Example: motor 100L/4

Motor type plate information:

Nominal voltage 230/400 V

Nominal frequency: 50 Hz

Nominal power: 2.2 kW

50 Hz characteristic curve

Motor in star circuit (400 V / 50 Hz), frequency inverter 2.2 kW

Figure 2: Motor 100L/4, 50 Hz characteristic curve

Legend

Motor output power in [kW]

Torque in [%]

B 1091-1 GB-3213 11

Page 12

Motors in fi operation for Category 3D – Planning guideline for B 1091

100 Hz characteristic curve

Motor in delta circuit (230 V / 50 Hz), frequency inverter 3.0 kW

Figure 3: Motor 100L/4, 100 Hz characteristic curve

Legend

Motor output power in [kW]

Torque in [%]

12 B 1091-1 GB-3213

Page 13

1 Technical explanations

87 Hz characteristic curve

Motor in delta circuit (230 V / 50 Hz), frequency inverter 4.0 kW

Figure 4: Motor 100L/4, 87 Hz characteristic curve

Legend

Motor output power in [kW]

Torque in [%]

Pos: 25 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

B 1091-1 GB-3213 13

Page 14

Motors in fi operation for Category 3D – Planning guideline for B 1091

Pos: 26 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.6.2 Beispiel 2 Motor 100L/4 [B1091-1] @ 2\mod_135825 0210775_388.docx @ 53455 @ 35 @ 1

1.6.2 2. Example: motor 100L/4

Motor type plate information:

Nominal voltage 400/690 V

Nominal frequency: 50 Hz

Nominal power: 2.2 kW

Due to the different design of the windings only the 50 Hz characteristic curve can be used with

the frequency inverter.

This type of winding is typically used for gentle starting with star/delta circuits. The motor is started in

the star circuit (690 V / 50 Hz) and switched to the delta circuit (400 V / 50 Hz) in operation.

Pos: 27 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

14 B 1091-1 GB-3213

Page 15

1 Technical explanations

Pos: 28 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.7 Motordaten für die Umrichterparametrier ung [B1091-1] @ 2\mod_1358252268103_388.docx @ 53480 @ 2 @ 1

1.7 Motor data for parameterisation of the frequency inverter

Motor types:

Category:

Pos: 29 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.7.1 Parametrierdaten 50 Hz- Kennlinie, IE1- und IE2- Motoren [B1091-1] @ 2\mod_1358254200428_388.doc x @ 53505 @ 3 @ 1

IE1 and IE2 motors

3D

1.7.1 Parameterisation data for the 50 Hz characteristic curve, IE1 and IE2 motors

Motor type

IE1

fN

[Hz]

63S/4 3D 50 1335 0.55 400 0.12 0.64 Y 68.0

63L/4 3D 50 1360 0.68 400 0.18 0.64 Y 47.37

71S/4 3D 50 1365 0.75 400 0.25 0.79 Y 39.9

71L/4 3D 50 1380 1.09 400 0.37 0.71 Y 22.85

80S/4 3D 50 1385 1.51 400 0.55 0.75 Y 15.79

80L/4 3D 50 1395 2.03 400 0.75 0.75 Y 10.49

90S/4 3D 50 1410 2.76 400 1.1 0.76 Y 6.41

90L/4 3D 50 1390 3.53 400 1.5 0.78 Y 3.99

100L/4 3D 50 1415 5.0 400 2.2 0.78 Y 2.78

100LA/4 3D 50 1415 6.8 400 3.0 0.78 ∆ 5.12

112M/4 3D 50 1430 8.24 400 4.0 0.83 ∆ 3.47

132S/4 3D 50 1450 11.6 400 5.5 0.8 ∆ 2.14

132M/4 3D 50 1450 15.5 400 7.5 0.79 ∆ 1.42

132MA/4 3D 50 1445 18.8 400 9.2 082 ∆ 1.16

nN

[rpm]

IN

[A]

UN

[V]

PN

[kW]

cos φ Circuit

RSt

[Ω]

Tabelle 2: Parameterisation data for the 50 Hz characteristic curve, IE1 motors

Motor type

IE2

fN

[Hz]

80SH/4 3D 50 1415 1.38 400 0.55 0.7 Y 9.34

80LH/4 3D 50 1410 1.8 400 0.75 0.75 Y 6.30

90SH/4 3D 50 1430 2.46 400 1.1 0.8 Y 4.96

90LH/4 3D 50 1420 3.38 400 1.5 0.79 Y 3.27

100LH/4 3D 50 1445 4.76 400 2.2 0.79 Y 1.73

100AH/4 3D 50 1420 6.4 400 3.0 0.77 ∆ 4.39

112MH/4 3D 50 1440 8.12 400 4.0 0.83 ∆ 2.96

132SH/4 3D 50 1455 10.82 400 5.5 0.83 ∆ 1.84

132MH/4 3D 50 1455 15.08 400 7.5 0.8 ∆ 1.29

160MH/4 3D 50 1465 20.5 400 11.0 0.85 ∆ 0.78

160LH/4 3D 50 1465 27.5 400 15.0 0.87 ∆ 0.53

180MH/4 3D 50 1475 34.9 400 18.5 0.84 ∆ 0.36

180LH/4 3D 50 1475 40.8 400 22.0 0.86 ∆ 0.31

Tabelle 3: Parameterisation data for the 50 Hz characteristic curve, IE2 motors

nN

[rpm]

IN

[A]

UN

[V]

PN

[kW]

cos φ Circuit

RSt

[Ω]

Legend

Nominal

f

N

frequency

nN

Nominal speed

Pos: 30 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

os: 31 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.7.2 Parametrierdaten 87 Hz- Kennlinie, IE1- und IE2- Motoren [B1091-1] @ 2\mod_1358256018431_388.doc x @ 53555 @ 3 @ 1

IN

Nominal current

UN

Nominal voltage

PN

cos φ

Nominal power

Power factor

Circuit

RSt

∆/Y circuit

Resistance on

line

B 1091-1 GB-3213 15

Page 16

Motors in fi operation for Category 3D – Planning guideline for B 1091

1.7.2 Parameterisation data for the 87 Hz characteristic curve, IE1 and IE2 motors

Motor type

IE1

fN

[Hz]

nN

[rpm]

IN

[A]

UN

[V]

PN

[kW]

cos φ Circuit

RSt

[Ω]

63S/4 3D 50 1335 0.95 230 0.12 0.64 ∆ 68.00

63L/4 3D 50 1360 1.18 230 0.18 0.64 ∆ 47.37

71S/4 3D 50 1365 1.3 230 0.25 0.79 ∆ 39.9

71L/4 3D 50 1380 1.89 230 0.37 0.71 ∆ 22.85

80S/4 3D 50 1385 2.62 230 0.55 0.75 ∆ 15.79

80L/4 3D 50 1395 3.52 230 0.75 0.75 ∆ 10.49

90S/4 3D 50 1410 4.78 230 1.1 0.76 ∆ 6.41

90L/4 3D 50 1390 6.11 230 1.5 0.78 ∆ 3.99

100L/4 3D 50 1415 8.65 230 2.2 0.78 ∆ 2.78

100LA/4 3D 50 1415 11.76 230 3.0 0.78 ∆ 1.71

112M/4 3D 50 1430 14.2 230 4.0 0.83 ∆ 1.11

132S/4 3D 50 1450 20.0 230 5.5 0.8 ∆ 0.72

132M/4 3D 50 1450 26.8 230 7.5 0.79 ∆ 0.46

132MA/4 3D 50 1455 32.6 230 9.2 0.829 ∆ 0.39

Tabelle 4: Parameterisation data for the 87 Hz characteristic curve, IE1 motors

Motor type

IE2

fN

[Hz]

80SH/4 3D 50 1415 2.39 230 0.55 0.7 ∆ 9.34

80LH/4 3D 50 1410 3.12 230 0.75 0.75 ∆ 6.30

90SH/4 3D 50 1430 4.26 230 1.1 0.8 ∆ 4.96

90LH/4 3D 50 1420 5.85 230 1.5 0.79 ∆ 3.27

100LH/4 3D 50 1445 8.25 230 2.2 0.79 ∆ 1.73

100AH/4 3D 50 1420 11.1 230 3.0 0.77 ∆ 1.48

112MH/4 3D 50 1440 14.1 230 4.0 0.83 ∆ 1.00

132SH/4 3D 50 1455 18.8 230 5.5 0.83 ∆ 0.60

132MH/4 3D 50 1455 26.2 230 7.5 0.8 ∆ 0.42

160MH/4 3D 50 1465 35.5 230 11.0 0.85 ∆ 0.26

160LH/4 3D 50 1465 48.0 230 15.0 0.87 ∆ 0.17

180MH/4 3D 50 1475 60.8 230 18.5 0.84 ∆ 0.12

180LH/4 3D 50 1475 71.0 230 22.0 0.86 ∆ 0.10

nN

[rpm]

IN

[A]

UN

[V]

PN

[kW]

cos φ Circuit

RSt

[Ω]

Tabelle 5: Parameterisation data for the 87 Hz characteristic curve, IE2 motors

Legend

Nominal

f

N

frequency

nN

Nominal speed

IN

Nominal current

UN

Nominal voltage

PN

cos φ

Nominal power

Power factor

Circuit

RSt

∆/Y circuit

Resistance on

line

Pos: 32 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

16 B 1091-1 GB-3213

Page 17

1 Technical explanations

Pos: 33 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/1. Technische Erläuterunge n/1.7.3 Parametrierdaten 100 Hz- Kennlinie, IE1- und IE2- Motoren [B1091-1] @ 2\mod_1358264293717_388.doc x @ 53581 @ 3 @ 1

1.7.3 Parameterisation data for the 100 Hz characteristic curve, IE1 and IE2 motors

Motor type

IE1

fN

[Hz]

nN

[rpm]

IN

[A]

UN

[V]

PN

[kW]

cos φ Circuit

RSt

[Ω]

63S/4 3D 100 2850 0.84 400 0.18 0.59 ∆ 68.00

63L/4 3D 100 2880 0.95 400 0.25 0.63 ∆ 47.37

71S/4 3D 100 2895 1.07 400 0.37 0.71 ∆ 39.9

71L/4 3D 100 2900 1.59 400 0.55 0.72 ∆ 22.85

80S/4 3D 100 2910 2.0 400 0.75 0.72 ∆ 15.79

80L/4 3D 100 2910 2.8 400 1.1 0.74 ∆ 10.49

90S/4 3D 100 2925 3.75 400 1.5 0.76 ∆ 6.41

90L/4 3D 100 2920 4.96 400 2.2 0.82 ∆ 3.99

100L/4 3D 100 2930 6.95 400 3.0 0.78 ∆ 2.78

100LA/4 3D 100 2950 7.46 400 4.0 0.76 ∆ 1.71

112M/4 3D 100 2945 11.3 400 5.5 0.82 ∆ 1.11

132S/4 3D 100 2955 16.0 400 7.5 0.82 ∆ 0.72

132M/4 3D 100 2965 19.6 400 9.2 0.79 ∆ 0.46

132MA/4 3D 100 2960 23.0 400 11.0 0.8 ∆ 0.39

Table 6: Parameterisation data for the 100 Hz characteristic curve, IE1 moto rs

Motor type

IE2

80SH/4 3D 100 2930 1.9 400 0.75 0.7 ∆ 9.34

80LH/4 3D 100 2920 2.56 400 1.1 0.73 ∆ 6.3

90SH/4 3D 100 2930 3.53 400 1.5 0.79 ∆ 4.96

90LH/4 3D 100 2925 4.98 400 2.2 0.79 ∆ 3.27

100LH/4 3D 100 2955 6.47 400 3.0 0.78 ∆ 1.73

100AH/4 3D 100 2940 8.24 400 4.0 0.79 ∆ 1.48

112MH/4 3D 100 2950 11.13 400 5.5 0.82 ∆ 1.0

132SH/4 3D 100 2960 15.3 400 7.5 0.83 ∆ 0.6

132MH/4 3D 100 2965 19.5 400 9.2 0.79 ∆ 0.42

160MH/4 3D 100 2967 29.0 400 15.0 0.87 ∆ 0.256

160LH/4 3D 100 2975 35.7 400 18.5 0.86 ∆ 0.168

180MH/4 3D 100 2980 43.2 400 22 0.85 ∆ 0.115

180LH/4 3D 100 2980 55.5 400 30 0.88 ∆ 0.306

fN

[Hz]

nN

[rpm]

IN

[A]

UN

[V]

PN

[kW]

cos φ Circuit

RSt

[Ω]

Table 7: Parameterisation data for the 100 Hz characteristic curve, IE2 moto rs

Legend

Nominal

fN

frequency

nN

Nominal speed

IN

Nominal current

UN

Nominal voltage

PN

cos φ

Nominal power

Power factor

Circuit

RSt

∆/Y circuit

Resistance on

line

Pos: 34 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2. Techni sche Daten [B1091-1] @ 2\mod_1358415915517_388. docx @ 53636 @ 15 @ 1

B 1091-1 GB-3213 17

Page 18

Motors in fi operation for Category 3D – Planning guideline for B 1091

2. Technical Data

Data:

Motor type:

Mains voltage:

Surface temperature:

IE1 and IE2 *

400 V

T125 °C / T140 °C

Category:

Circuit: See tables

Ambient temperature Tu:

3D

max. 40 °C

* Values also apply for IE2 (Labelling xH), e.g. 80LH/4

Pos: 35 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2.1 Mo tor en/2.1 Motoren [B1091-1] @ 2\mod_1358759456932_388.d ocx @ 53819 @ 2 @ 1

2.1 Motors

Information

Operation is possible up to an ambient temperature of 60 °C. The stated torques must then be reduced to 72 %.

Information

A linear interpolation of the data between adjacent frequencies is permissible.

Pos: 36 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

Increased ambient temperature

Interpolation

18 B 1091-1 GB-3213

Page 19

2 Technical Data

Pos: 37 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2.1 Mo tor en/2.1.1 Motoren, 50 Hz Nennpunkt [B1091-1] @ 2\mod_13584 1775 2109_388.docx @ 53691 @ 3 @ 1

2.1.1 Motors, 50 Hz nominal point

Motor type Circuit see 1.7

Frequency inverter power and rated current

Motor power in [kW] at 50 Hz (upper value ) and 100 Hz (lower value)

3 102030405060708090100fs [Hz]

0,55 kW 0,11 0,4 0,6 0,8 0,9 0,9 0,8 0,7 0,6 0,6 0,5 0,4 M [Nm]

63S/4

63L/4

71S/4

71L/4

80S/4

80L/4

90S/4

90L/4

100L/4

100LA/4

T140°C 2,39 12 256 541 833 1.140 1.410 1.681 1.940 2.233 2.490 2.760

112M/4

132S/4

132M/4

1,6 A 516991101103948574655448M [%]

0,09 10 150 375 690 1.000 1.292 1.476 1.563 1.782 1.908 2.146

0,55 KW 0,17 0,6 0,9 1,1 1,3 1,3 1,3 1,1 0,9 0,8 0,7 0,6 M [Nm]

1,6 A 45 65 83 96 101 96 87 73 65 55 43 M [%]

0,13 0 142 419 696 990 1.282 1.446 1.636 1.874 2.037 2.248

0,55 kW 0,23 0,9 1,2 1,4 1,6 1,7 1,6 1,4 1,2 1,0 0,8 0,7 M [Nm]

1,6 A 5271819299958172604842M [%]

0,19 10 150 437 733 1.032 1.319 1.549 1.780 2.015 2.245 2.466

0,55 kW 0,33 1,2 1,4 2,0 2,2 2,4 2,4 2,2 1,9 1,6 1,4 1,3 M [Nm]

1,6 A 4654778592928373625548M [%]

0,33 0 128 427 734 1.042 1.339 1.594 1.843 2.092 2.326 2.490

0,55 kW 0,48 1,6 2,0 2,9 3,4 3,8 3,5 3,2 2,7 2,3 2,0 1,6 M [Nm]

1,6 A 4252768999918271595242M [%]

0,43 30 150 463 765 1.061 1.314 1.604 1.837 2.073 2.296 2.529

0,75 kW 0,67 2,1 3,1 4,0 4,7 5,2 4,7 4,4 3,8 3,2 2,8 2,3 M [Nm]

2,2 A 40 60 77 90 100 90 85 73 62 54 45 M [%]

0,63 26 166 471 769 1.091 1.377 1.614 1.864 2.108 2.348 2.564

1,1 kW 1,01 3,5 5,4 6,6 7,3 7,6 7,0 6,4 5,6 5,1 4,3 3,9 M [Nm]

3,0 A 46 71 87 96 100 92 84 73 68 57 51 M [%]

1,06 10 207 503 800 1.032 1.379 1.626 1.875 2.096 2.372 2.606

1,5 kW 1,31 4,3 5,8 7,8 9,0 9,5 9,0 8,3 7,2 6,5 5,6 4,9 M [Nm]

3,7 A 4256768792878070635447M [%]

1,37 0 196 495 790 1.091 1.388 1.654 1.909 2.173 2.437 2.695

2,2 kW 1,92 5,5 9,5 12,1 13,6 14,3 13,1 12,2 10,8 9,9 8,3 7,4 M [Nm]

5,5 A 3866849599918475695851M [%]

2,17 0 207 488 805 1.106 1.408 1.715 2.010 2.234 2.523 2.807

3 kW 2,61 10,7 13,6 16,4 18,0 18,9 17,7 15,6 13,2 11,4 10,0 8,3 M [Nm]

7,0 A 5367818993877765564941M [%]

4 kW 3,52 13,2 18,1 21,9 24,0 25,5 23,8 21,1 18,0 15,9 14,0 12,1 M [Nm]

9,5 A 5069839197908068605346M [%]

3,51 17 237 529 824 1.120 1.414 1.689 1.963 2.236 2.506 2.775

5,5 kW 5,04 22,0 25,8 30,0 34,0 36,2 33,7 29,6 25,5 21,9 18,4 16,1 M [Nm]

12,5 A 61 71 83 94 100 93 82 71 60 51 45 M [%]

4,78 44 240 536 832 1.130 1.428 1.714 1.995 2.276 2.556 2.834

7,5 kW 6,66 30,0 35,0 41,0 47,1 49,5 44,5 39,3 32,2 27,7 23,8 20,5 M [Nm]

16,0 A 6070829499897964554841M [%]

6,06 62 241 538 837 1.133 1.431 1.713 1.967 2.268 2.551 2.828

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

Table 8: IE1 and IE2 motors, 50 Hz nominal point

Legend

FS

Stator frequency

[Hz]

in Hertz

M

[Nm]

Torque

in Newton metres

M

Torque

[%]

in % of rated torque

n

[rpm]

Speed

Speed in rpm

Pos: 38 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

B 1091-1 GB-3213 19

Page 20

Motors in fi operation for Category 3D – Planning guideline for B 1091

Pos: 39 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2.1 Mo tor en/2.1.2 Motoren, 87 Hz Nennpunkt [B1091-1] @ 2\mod_13587 6571 7448_388.docx @ 53868 @ 3 @ 1

2.1.2 Motors, 87 Hz nominal point

Motor type Delta circuit See below

Frequency inverter power and rated current

Motor power in [kW] at 50 Hz (upper), 87 Hz (middle) and 100 Hz (lower)

3 102030405060708090100

0,55 kW 0,12 0,5 0,6 0,7 0,8 0,9 0,9 0,9 0,9 0,8 0,8 0,8 M [Nm]

63S/4

1,6 A 0,20 58 70 85 95 100 100 100 100 96 92 90 M [%]

0,22 20 152 369 688 1.007 1.310 1.612 1.914 2.213 2.419 2.763

0,55 KW 0,18 0,6 0,8 1,0 1,2 1,3 1,3 1,3 1,3 1,3 1,2 1,2 M [Nm]

63L/4

1,6 A 0,28 46 63 77 91 99 101 103 101 96 91 89 M [%]

0,26 20 175 407 715 1.002 1.306 1.610 1.909 2.207 2.415 2.713

0,55 kW 0,24 0,9 1,1 1,3 1,6 1,6 1,7 1,7 1,7 1,7 1,6 1,5 M [Nm]

71S/4

1,6 A0,435264779095999999969089M [%]

0,44 100 146 442 734 1.031 1.327 1.623 1.925 2.224 2.434 2.772

0,75 kW 0,37 1,5 1,7 2,1 2,4 2,5 2,6 2,6 2,6 2,5 2,4 2,3 M [Nm]

71L/4

2,2 A 0,61 58 65 81 92 96 100 100 100 95 92 90 M [%]

0,69 0 188 488 782 1.077 1.350 1.633 1.941 2.245 2.457 2.79 7

1,1 kW 0,55 1,9 2,3 3,0 3,4 3,7 3, 9 3,9 3,9 3,8 3,6 3,5 M [Nm]

80S/4

3,0 A 0.93 50 60 79 89 97 102 102 102 99 94 92 M [%]

1,03 0 164 440 757 1.052 1.351 1.638 1.947 2.237 2.457 2.81 4

1,5 kW 0,78 2,9 3,3 4,2 4,7 5,0 5, 4 5,6 5,7 5,5 5,3 5,0 M [Nm]

80L/4

3,7 A 1,36 56 63 81 90 96 104 108 110 106 102 95 M [%]

1,46 0 207 493 792 1.086 1.377 1.668 1.970 2.256 2.439 2.81 3

2,2 kW 1,10 4,3 5,0 6,3 7,0 7,6 7, 7 7,6 7,6 7,4 7,0 6,8 M [Nm]

90S/4

5,5 A 1,83 57 66 83 92 100 101 100 100 98 92 90 M [%]

2,03 0 192 482 778 1.070 1.370 1.675 1.978 2.270 2.489 2.83 3

3 kW 1,39 4,1 5,4 7,3 8,5 9,3 9,6 9,9 9,9 9,8 9,1 8,6 M [Nm]

90L/4

7,0 A2,384052718390939696958883M [%]

2,56 73 179 487 789 1.085 1.387 1.684 1.988 2.284 2.497 2.863

4 kW 2,10 7,3 11,0 12,6 13,7 14,2 14,2 14,2 14,2 13,5 12,8 12,3 M [Nm]

100L/4

9,5 A3,375176889599999999948986M [%]

3,73 0 207 520 809 1.106 1.409 1.709 2.008 2.307 2.518 2.88 7

100LA/4

5,5 kW 2,98 11,3 14,1 17,2 18,6 19,6 19,8 20,2 20,0 18,8 18,0 17,6 M [Nm]

12,5 A4,725669859296979998938986M [%]

T140°C 5,27 7 229 524 819 1.116 1.413 1.713 2.014 2.304 2.505 2.869

7,5 kW 4,01 12,4 18,6 22,6 24,7 26,2 26,9 26,9 26,0 25,1 23,8 22,4 M [Nm]

112M/4

16,0 A6,50477186949910210298959085M [%]

6,79 34 244 535 830 1.126 1.425 1.725 2.024 2.325 2.609 2.890

11 kW 5,75 20,7 25,9 31,0 34,9 36,7 38,2 38,5 38,3 36,8 34,3 29,7 M [Nm]

132S/4

24,0 A 9,14 57 71 86 96 101 105 106 106 102 95 82 M [%]

9,06 49 241 541 839 1.139 1.437 1.737 2.037 2.335 2.544 2.918

15 kW 7,55 20,0 31,0 40,0 45,0 47,7 50,3 50,5 50,0 48,9 45,5 39,0 M [Nm]

132M/4

31,0 A 12,10 40 62 80 90 95 101 101 100 98 91 78 M [%]

11,91 18 244 541 837 1.137 1.434 1.734 2.034 2.332 2.540 2.916

for legend

f

s

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

[Hz]

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

-1

]

]

]

]

]

]

]

]

]

]

]

]

]

Table 9: IE1 and IE2 motors, 87 Hz nominal point

Legend

FS

Stator frequency

[Hz]

in Hertz

M

[Nm]

Torque

in Newton

metres

M

Torque

[%]

in % of rated torque

n

[rpm]

Speed

Speed in rpm

Pos: 40 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

Pos: 41 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2.1 Mo tor en/2.1.3 Motoren, 100 Hz Nennpunkt [B1091-1] @ 2\mod_1358 7704 24115_388.docx @ 53893 @ 3 @ 1

20 B 1091-1 GB-3213

Page 21

2 Technical Data

2.1.3 Motors, 100 Hz nominal point

Motor type Delta circuit

Frequency inverter power and rated current

Motor power in [kW] at 50 Hz (upper) and 100 Hz (lower)

3 102030405060708090100fs [Hz]

0,55 kW 0.09 0.5 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 M [Nm]

63S/4

63L/4

71S/4

71L/4

80S/4

80L/4

90S/4

90L/4

100L/4

100LA/4

T140°C 3.69 20 200 530 8 34 1,130 1,442 1,734 2,028 2,332 2,639 2,944

112M/4

132S/4

132M/4

1,6 A 5264737374747272717170M [%]

0.18 6 134 401 731 1,033 1,346 1,652 1,947 2,253 2,542 2,827

0,55 KW 0.12 0.7 0.8 0.8 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.8 M [Nm]

1,6 A 5459656567686870686760M [%]

0.23 30 185 422 7 50 1,057 1,351 1,648 1,944 2,256 2,548 2,851

0,55 kW 0.18 1.0 1.1 1.3 1.2 1.2 1.3 1.3 1.2 1.2 1.2 1.2 M [Nm]

1,6 A 5864727271727271716967M [%]

0.35 30 181 462 7 74 1,076 1,376 1,675 1,976 2,271 2,566 2,862

0,55 kW 0.27 1.4 1.6 1.8 1.9 1.9 1.8 1.8 1.7 1.6 1.5 1.4 M [Nm]

1,6 A 5462697373706966635854M [%]

0.42 0 152 475 788 1,090 1,398 1,700 1,992 2,283 2,587 2,891

0,75 kW 0.39 1.8 2.3 2.5 2.6 2.6 2.6 2.6 2.5 2.5 2.4 2.2 M [Nm]

2,2 A 4861646868686766666257M [%]

0.67 0 163 410 810 1,108 1,416 1,712 2,028 2,344 2,627 2,910

1,1 kW 0.53 3.0 3.3 3.6 3.6 3.6 3.6 3.6 3.6 3.5 3.4 3.2 M [Nm]

3,0 A 5863696969696969676662M [%]

0.99 0 196 505 812 1,116 1,414 1,715 2,015 2,313 2,611 2,908

1,5 kW 0.75 4.2 4.9 4.9 4.9 5.0 5.0 5.0 5.0 5.0 4.9 4.6 M [Nm]

3,7 A 5564646466666666666560M [%]

1.40 0 183 516 822 1,120 1,425 1,725 2,025 2,321 2,620 2,911

2,2 kW 1.06 4.0 5.6 7.2 7.2 7.2 7.2 7.2 7.2 7.1 6.9 6.6 M [Nm]

5,5 A 3954707070707070696764M [%]

2.00 20 192 484 7 99 1,098 1,406 1,707 2,008 2,309 2,606 2,905

3 kW 1.5 1 8.4 9.1 9.9 10.1 10.1 10.1 9.9 9.7 9.7 9.2 8.7 M [N m]

7,0 A 5863697070706967676461M [%]

2.68 25 205 524 8 29 1,132 1,429 1,736 2,036 2,335 2,631 2,927

4 kW 1.9 9 6.6 11.3 13.1 13.2 13.2 13.2 13.2 13.3 13.3 12.6 12.0 M [N m]

9,5 A 3256646565656565666259M [%]

5,5 kW 2.72 14. 4 17.0 18.0 18.0 18.0 18.0 18.0 18.0 18.0 17.3 16.3 M [Nm]

12,5 A 5464686868686868686562M [%]

5.02 36 233 539 8 40 1,142 1,442 1,742 2,042 2,341 2,640 2,933

7,5 kW 3.63 20. 6 22.0 24.3 24.3 24.3 24.3 24.3 24.3 24.3 24.3 24.3 M [Nm]

16,0 A 5761676767676767676767M [%]

7.42 36 227 530 8 28 1,124 1,425 1,724 2,023 2,324 2,623 2,918

11 kW 5.32 17. 2 28.9 35.7 35.7 35.7 35.7 35.7 35.7 35.7 35.7 35.7 M [N m]

24,0 A 3458717171717171717171M [%]

10.90 16 233 530 8 26 1,125 1,423 1,723 2,022 2,321 2,625 2,916

See below

for legend

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

]

]

]

]

]

]

]

]

]

]

]

]

]

Table 10: IE1 and IE2 motors, 100 Hz nominal point

Legend

F

Stator frequency

S

[Hz]

in Hertz

M

[Nm]

Torque

in Newton

metres

M

Torque

[%]

in % of rated torque

n

[rpm]

Speed

Speed in rpm

Pos: 42 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

Pos: 43 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2.2 Mo tor en mit Fremdlüfter/2.2 Motoren mit Fremdlüfter [ B1091- 1] @ 2\mod_1358758995864_388.docx @ 53745 @ 2 @ 1

B 1091-1 GB-3213 21

Page 22

Motors in fi operation for Category 3D – Planning guideline for B 1091

2.2 Motors with external fan

Information

Interpolation

A linear interpolation of the data between adjacent frequencies is permissible.

Pos: 44 /---------- Seitenumbruch -------- -- @ 1\mod_1329145698658_0.docx @ 15891 @ @ 1

22 B 1091-1 GB-3213

Page 23

2 Technical Data

Pos: 45 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2.2 Mo tor en mit Fremdlüfter/2.2.1 Motoren mit Fremdlüfter, 50 Hz Nennpunkt [B1091-1] @ 2\mod_1358771466655_388.doc x @ 53918 @ 3 @ 1

2.2.1 Motors with external fan, 50 Hz nominal point

Motor type For the circuit diagram see 1.7

Frequency inverter power and rated current

Motor power in [kW] at 50 Hz (upper) and 100 Hz (lower)

3 102030405060708090100fs [Hz]

0,55 kW 0.11 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.7 0.6 0.4 M [Nm]

63S/4

63L/4

71S/4

71L/4

80S/4

80L/4

90S/4

90L/4

100L/4

100LA/4

T140°C 2.59 11 172 488 804 1,105 1,406 1,673 1,940 2,214 2,488 2,753

112M/4

132S/4

132M/4

132MA/4

T140°C 7.52 18 238 539 840 1,140 1,435 1,720 2,008 2,298 2,580 2,866

1,6 A 9494949494949290826650M [%]

0.09 1 0 150 375 690 1,010 1,320 1,381 1,441 1,641 1,840 1,932

0,55 KW 0.17 1.3 1.3 1.3 1.3 1.3 1.3 1.2 1.2 1.1 0.9 0.8 M [Nm]

1,6 A 9696969696969391837361M [%]

0.18 0 142 419 696 990 1,282 1,458 1,633 1,787 1,941 2,151

0,55 kW 0.23 1.7 1.7 1.7 1.7 1.7 1.6 1.5 1.4 1.2 1.1 0.9 M [Nm]

1,6 A 100 100 100 100 100 92 87 81 72 61 53 M [%]

0.23 1 0 150 437 733 1,032 1,364 1,537 1,710 1,939 2,168 2,388

0,55 kW 0.33 2.4 2.4 2.4 2.4 2.4 2.4 2.2 1.9 1.6 1.4 1.3 M [Nm]

1,6 A 9292929292928373625548M [%]

0.33 0 128 427 734 1,042 1,339 1,594 1,843 2,092 2,326 2,490

0,55 kW 0.48 3.5 3.5 3.5 3.5 3.5 3.5 3.2 2.7 2.3 2.0 1.6 M [Nm]

1,6 A 9191919191918271595242M [%]

0.43 3 0 150 463 765 1,061 1,314 1,604 1,837 2,073 2,296 2,529

0,75 kW 0.67 4.7 4.7 4.7 4.7 4.7 4.7 4.4 3.8 3.2 2.8 2.3 M [Nm]

2,2 A 9090909090908573625445M [%]

0.63 2 6 166 471 769 1,091 1,377 1,614 1,864 2,108 2,348 2,564

1,1 kW 1.01 7.0 7.0 7.0 7.0 7.0 7.0 6.4 5.6 5.1 4.3 3.9 M [Nm]

3,0 A 9292929292928473685751M [%]

1.06 1 0 207 503 800 1,032 1,379 1,626 1,875 2,096 2,372 2,606

1,5 kW 1.31 9.0 9.0 9.0 9.0 9.0 9.0 8.3 7.2 6.5 5.6 4.9 M [Nm]

3,7 A 8787878787878070635447M [%]

1.37 0 196 495 790 1,091 1,388 1,654 1,909 2,173 2,437 2,695

2,2 kW 1.92 13.1 13.1 13.1 13.1 13.1 13.1 12.2 10.8 9.9 8.3 7.4 M [N m]

5,5 A 9191919191918475695851M [%]

2.17 0 207 488 805 1,106 1,408 1,715 2,010 2,234 2,523 2,807

3 kW 2.68 20.3 20.3 20.3 20.3 20.3 18.2 16.1 13.9 12.1 10.1 9.0 M [ Nm]

7,0 A 100 100 100 100 100 90 79 69 59 50 44 M [%]

4 kW 3.57 26.4 26.4 26.4 26.4 26.4 24.0 21.2 18.6 16.0 13.8 12.1 M [N m]

9,5 A 100 100 100 100 100 91 80 70 61 52 46 M [%]

3.53 2 224 402 827 1,123 1,418 1,691 1,967 2,242 2,519 2,793

5,5 kW 4.88 35.2 36.4 36.4 36.4 35.8 32.3 28.3 23.4 19.5 17.3 14.2 M [Nm]

12,5 A 97 100 100 100 98 89 78 64 54 47 39 M [%]

4.28 2 6 250 551 851 1,153 1,444 1,725 2,010 2,299 2,585 2,876

7,5 kW 6.83 47.0 49.6 49.6 49.6 49.6 45.2 38.6 31.3 27.1 23.1 20.0 M [Nm]

16,0 A 95 100 100 100 100 91 78 63 55 47 40 M [%]

6.03 2 7 249 551 851 1,151 1,442 1,727 2,011 2,302 2,585 2,875

11 kW 8.19 57.2 60.8 60.8 60.8 60.8 54.5 46.8 38.8 32.9 28.9 25.1 M [Nm]

24,0 A 94 100 100 100 100 90 77 64 54 48 41 M [%]

See below

for legend

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

Table 11: IE1 and IE2 motors with external fan, 50 Hz nominal point

Legend

F

Stator frequency

S

[Hz]

in Hertz

M

[Nm]

Torque

in Newton

metres

M

Torque

[%]

in % of rated torque

n

[rpm]

Speed

Speed in rpm

B 1091-1 GB-3213 23

Page 24

Motors in fi operation for Category 3D – Planning guideline for B 1091

Pos: 46 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2.2 Mo tor en mit Fremdlüfter/2.2.2 Motoren mit Fremdlüfter, 87 Hz Nennpunkt [B1091-1] @ 2\mod_1358773222601_388.doc x @ 53968 @ 3 @ 1

2.2.2 Motors with external fan, 87 Hz nominal point

Motor type Delta circuit

Frequency inverter power and rated current

Motor power in [kW] at 50 Hz (upper), 87 Hz (middle) and 100 Hz (lower)

3 102030405060708090100

0,55 kW 0,12 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,9 0,8 0,8 0,8 M [Nm]

63S/4

1,6 A 0,20 100 100 100 100 100 100 100 100 96 92 90 M [%]

0,22 20 152 369 688 1.007 1.310 1.612 1.914 2.213 2.419 2.763

0,55 KW 0,18 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,3 1,2 1,2 M [Nm]

63L/4

1,6 A 0,30 100 100 100 100 100 100 100 100 96 92 90 M [%]

0,33 20 175 407 715 1.002 1.306 1.610 1.909 2.207 2.415 2.713

0,55 kW 0,25 1,7 1,7 1,7 1,7 1,7 1,7 1,7 1,7 1,7 1,6 1,6 M [Nm]

71S/4

1,6 A 0,41 100 100 100 100 100 100 100 100 97 92 92 M [%]

0,47 100 146 442 734 1.031 1.364 1.663 1.962 2.260 2.460 2.818

0,75 kW 0,35 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,4 2,3 M [Nm]

71L/4

2,2 A0,619595959595959595959290M [%]

0,69 0 188 488 782 1.077 1.350 1.633 1.941 2.245 2.457 2.797

1,1 kW 0,54 3,8 3,8 3,8 3,8 3,8 3,8 3,8 3 ,8 3,8 3,6 3,5 M [Nm]

80S/4

3,0 A0,939999999999999999999492M [%]

1,03 0 164 440 757 1.052 1.351 1.638 1.947 2.237 2.457 2.814

1,5 kW 0,79 5,5 5,5 5,5 5,5 5,5 5,5 5,5 5 ,5 5,5 5,3 5,0 M [Nm]

80L/4

3,7 A 1,36 106 106 106 106 106 106 106 106 106 102 95 M [%]

1,46 0 207 493 792 1.086 1.377 1.668 1.970 2.256 2.439 2.813

2,2 kW 1,07 7,4 7,4 7,4 7,4 7,4 7,4 7,4 7 ,4 7,4 7,0 6,8 M [Nm]

90S/4

5,5 A1,839898989898989898989290M [%]

2,03 0 192 482 778 1.070 1.370 1.675 1.978 2.270 2.489 2.833

3 kW 1,42 9,8 9,8 9,8 9,8 9,8 9,8 9,8 9,8 9,8 9,1 8,6 M [Nm]

90L/4

7,0 A2,389595959595959595958883M [%]

2,56 73 179 487 789 1.085 1.387 1.684 1.988 2.284 2.497 2.863

4 kW 1,99 13,5 13,5 13,5 13,5 13,5 13,5 13,5 13,5 13,5 12,8 12,3 M [Nm]

100L/4

9,5 A3,379494949494949494948986M [%]

3,73 0 207 520 809 1.106 1.409 1.709 2.008 2.307 2.518 2.887

100LA/4

5,5 kW 3,02 20,3 20,3 20,3 20,3 20,3 20,3 20,3 20,3 19,3 18,5 17,3 M [Nm]

12,5 A 4,87 100 100 100 100 100 100 100 100 95 91 85 M [%]

T140°C 5,21 51 211 516 820 1.120 1.419 1.718 2.016 2.263 2.510 2.877

7,5 kW 3,92 21,1 26,4 26,4 26,4 26,4 26,4 26,4 26,4 26,3 26,1 21,6 M [Nm]

112M/4

16,0 A 6,87 80 100 100 100 100 100 100 100 100 99 82 M [%]

6,54 15 213 518 820 1.119 1.419 1.719 2.016 2.312 2.517 2.896

11 kW 5,52 33,5 36,4 36,4 36,4 36,4 36,4 33,8 31,7 28,7 25,3 20,5 M [Nm]

132S/4

24,0 A 6,79 92 100 100 100 100 100 93 87 79 70 56 M [%]

6,27 15 240 545 848 1.150 1.450 1.755 2.057 2.357 2.566 2.921

15 kW 7,40 46,9 49,6 49,6 49,6 49,6 48,7 47,0 45,3 41,6 39,0 33,8 M [Nm]

132M/4

31,0 A 10,47 95 100 100 100 100 98 95 91 84 79 68 M [%]

10,43 19 244 547 849 1.151 1.452 1.757 2.054 2.356 2.562 2.944

132MA/4

18 kW 9,01 51,9 60,8 60,8 60,8 59,7 59,6 56,4 53,9 50,4 45,6 42,6 M [Nm]

38,0 A 12,20 85 100 100 100 98 98 93 89 83 75 70 M [%]

T140°C 13,09 17 234 540 840 1.143 1.443 1.746 2.049 2.349 2.556 2.934

See below

for legend

[Hz]

f

s

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

n [min

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

-1

]

Table 12: IE1 and IE2 motors with external fan, 87 Hz nominal point

Legend

F

Stator frequency

S

[Hz]

in Hertz

M

[Nm]

Torque

in Newton

metres

M

Torque

[%]

in % of rated torque

n

[rpm]

Speed

Speed in rpm

Pos: 47 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/2. Technische Daten/2.2 Mo tor en mit Fremdlüfter/2.2.3 Motoren mit Fremdlüfter, 100 Hz Nennpunkt [B1091-1] @ 2\mod_1358775573172_388.doc x @ 54021 @ 3 @ 1

24 B 1091-1 GB-3213

Page 25

2 Technical Data

2.2.3 Motors with external fan, 100 Hz nominal point

Motor type Delta circuit

F requency inverter power and rated current

Mo t or power i n [kW] at 50 H z ( upper) and 100 Hz (lower)

3 102030405060708090100fs [Hz]

0,55 kW 0.09 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 0.6 M [Nm]

63S/4

63L/4

71S/4

71L/4

80S/4

80L/4

90S/4

90L/4

100L/4

100LA/4

T140°C 3.61 20 210 520 830 1,131 1,431 1,731 2,031 2,330 2,629 2,924

112M/4

132S/4

132M/4

132MA/4

T140°C 12.73 15 238 536 837 1,138 1,439 1,731 2,029 2,329 2,633 2,930

1,6 A 7171717171717171717170M [%]

0.18 6 134 401 731 1,033 1,346 1,652 1,947 2,253 2,542 2,827

0,55 KW 0.13 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.8 M [Nm]

1,6 A 6868686868686868686764M [%]

0.25 30 185 422 750 1,057 1,351 1,648 1,944 2,256 2,548 2,851

0,55 kW 0.18 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.1 M [Nm]

1,6 A 7171717171717171716965M [%]

0.34 30 181 462 774 1,076 1,389 1,687 1,985 2,284 2,583 2,884

0,55 kW 0.24 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.6 1.5 1.4 M [Nm]

1,6 A 6363636363636363635854M [%]

0.42 0 152 475 788 1,090 1,398 1,700 1,992 2,283 2,587 2,891

0,75 kW 0.38 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.4 2.2 M [Nm]

2,2 A 6666666666666666666257M [%]

0.67 0 163 410 810 1,108 1,416 1,712 2,028 2,344 2,627 2,910

1,1 kW 0.52 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.5 3.4 3.2 M [Nm]

3,0 A 6767676767676767676662M [%]

0.99 0 196 505 812 1,116 1,414 1,715 2,015 2,313 2,611 2,908

1,5 kW 0.75 5.0 5.0 5.0 5.0 5.0 5.0 5.0 5.0 5.0 4.9 4.6 M [Nm]

3,7 A 6666666666666666666560M [%]

1.40 0 183 516 822 1,120 1,425 1,725 2,025 2,321 2,620 2,911

2,2 kW 1.05 7.1 7.1 7.1 7.1 7.1 7.1 7.1 7.1 7.1 6.9 6.6 M [Nm]

5,5 A 6969696969696969696764M [%]

2.00 20 192 484 799 1,098 1,406 1,707 2,008 2,309 2,606 2,905

3 kW 1.45 9.7 9.7 9.7 9.7 9.7 9.7 9.7 9.7 9.7 9.2 8.7 M [Nm]

7,0 A 6767676767676767676461M [%]

2.68 25 205 524 829 1,132 1,429 1,736 2,036 2,335 2,631 2,927

4 kW 1.96 13.1 13.1 13.1 13.1 13.1 13.1 13.1 13.1 13.1 12.4 11.8 M [Nm]

9,5 A 6565656565656565656158M [%]

5,5 kW 2.67 18.0 18.0 18.0 18.0 18.0 18.0 18.0 18.0 18.0 18.0 18.0 M [N m]

12,5 A 6868686868686868686868M [%]

5.46 5 220 520 820 1,120 1,420 1,720 2,020 2,320 2,599 2,898

7,5 kW 3.68 24.2 24.2 24.2 24.2 24.2 24.2 24.2 24.2 24.2 24.2 23.8 M [N m]

16,0 A 6767676767676767676766M [%]

7.36 15 240 550 850 1,150 1,450 1,750 2,050 2,350 2,650 2,950

11 kW 5.42 35.7 35.7 35.7 35.7 35.7 35.7 35.7 35.7 35.7 35.7 33.9 M [N m]

24,0 A 7272727272727272727268M [%]

10.46 15 240 550 850 1,150 1,450 1,750 2,050 2,350 2,650 2,950

15 kW 6.58 43.7 43.7 43.7 43.7 43.7 43.7 43.7 43.7 43.7 43.7 41.5 M [N m]

31,0 A 7272727272727272727268M [%]

See below

for legend

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

-1

n [min

]

]

]

]

]

]

]

]

]

]

]

]

]

]

Table 13: IE1 and IE2 motors with external fan, 100 Hz nominal point

Legend

F

Stator frequency

S

[Hz]

in Hertz

Pos: 48 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/3. Anhang [B1091-1]/3. A nhang [ B1091-1] @ 2\mod_1358783118545_388.docx @ 54169 @ 1 @ 1

M

[Nm]

Torque

in Newton

metres

M

Torque

[%]

in % of rated torque

n

[rpm]

Speed

Speed in rpm

B 1091-1 GB-3213 25

Page 26

Motors in fi operation for Category 3D – Planning guideline for B 1091

3. Appendix

Pos: 49 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/3. Anhang [B1091-1]/3.1 A bkür zungen [B1091-1] @ 2\mod_1358779308835_388.doc x @ 54121 @ 2 @ 1

3.1 Abbreviations

3D

Rare occurrence of thrown-up

dust in an explosive atmosphere

ATEX

DIN

EN

Atmospheres explosibles

German industrial standard

European standard

IE1

IE2

V/f

Motors with standard efficiency

Motors with high efficiency

Voltage/frequency characteristic

curve

Pos: 50 /Anleitungen/Motoren/B1091-1 Projektier ungsleitfaden zur B1091/3. Anhang [B1091-1]/3.2 Legen de / Formelzeichen [B1091-1] @ 2\mod_1358781997082_ 388. docx @ 54145 @ 2 @ 1

3.2 Legend / Formula symbols

cos φ

Tu

T125 / T140

f

s

Power factor

Ambient temperature [°C]

max. surface temperature [°C]

Stator frequency [Hz]

M

n

P

N

RSt

Torque [Nm] or [%]

Speed [min

Rated power [kW]

Resistance on line [Ω]

-1

] or [rpm]

f

N

I

N

Nominal frequency [Hz]

Nominal motor current [A]

=== Ende der Liste für Textmarke Inhalt ===

UN

Rated voltage [V]

26 B 1091-1 GB-3213

Page 27

Pos: 52 /Anleitungen/Steuermodule/Stichwortver zeichnis @ 0\mod_1317978518730_388.docx @ 4101 @ @ 1

=== Ende der Liste für Textmarke Stichwortverzeichni s ===

B 1091-1 GB-3213 27

Page 28

6052102 / 3213

Loading...

Loading...