Page 1

Service Manual

Gas Electric Refrigerators

Improper installation, adjustment, alteration, service or maintenance can cause

personal injury or property damage. Refer

to this manual. For assistance or addition-

al information, contact a qualied installer,

service agency, or the gas supplier.

Polar 7 Series (N7V, N7X, N7LX) Models

Polar 8 Series (N8V, N8X, N8LX) Models

© 2017 NORCOLD, INC. All rights reserved.

Questions? 1-800-444-7210

Part No. 639410 Rev. A 04.17.2018

Page 2

CONTENTS

SAFETY .......................................................................................4

INTRODUCTION .......................................................................... 5

About this Manual ...........................................................................................5

Certification and Code Requirements .............................................................5

About Installation .............................................................................................5

Replacement Parts ..........................................................................................5

Technical Assistance ....................................................................................... 5

Model Identification .........................................................................................6

Cooling Unit Serial Number .............................................................................6

Refrigerator Model Number .............................................................................6

SPECIFICATIONS ........................................................................ 7

Exploded Views ...............................................................................................8

GENERAL INFORMATION ........................................................ 10

Ventilation .....................................................................................................10

Overview .....................................................................................................10

Enclosure ....................................................................................................10

Baffles .........................................................................................................10

Lower Intake Vent ......................................................................................10

Exhaust Vent ...............................................................................................10

Roof Cap .....................................................................................................10

Propane Gas Connections ............................................................................ 11

Leak Test-Detergent .................................................................................... 11

Electrical Connections ...................................................................................11

120 Volts AC Electrical Connection ............................................................. 11

12 Volts DC Electrical Connection ..............................................................11

Main Control Board (Power Board) Fuses ..................................................12

Electrical Components ..................................................................................12

Interior Light ................................................................................................12

Divider Heater ............................................................................................12

12 Volt DC Fan ............................................................................................12

Low Ambient Heater (optional) ....................................................................12

Temperature Control System ...................................................................... 13

Backup Operating System ..........................................................................13

PREVENTATIVE MAINTENANCE ............................................. 13

Gas Flame Appearance ................................................................................13

Clean the Openings of the Burner Tube ........................................................14

USER INTERFACE (CONTROLS) - N7V AND N8V MODELS . 15

Power ON / OFF Button ................................................................................15

Modes of Operation .......................................................................................15

Air in the Propane Gas Supply Lines ............................................................16

Refrigerator Temperature Settings ................................................................ 16

Diagnostic Prechecks ....................................................................................16

FAULT CODES - N7V AND N8V MODELS ..............................17

Fault Code Flash Patterns - N7V and N8V Models .......................................17

TROUBLESHOOTING FLOWCHARTS - N7V AND N8V MODELS

18

Fault - Code - Solid Red Indicator Light ........................................................18

Fault Code - Flash Pattern 1 .........................................................................20

Fault Code - Flash Pattern 2 .........................................................................21

Fault Code - Flash Pattern 3 .........................................................................21

Fault Code - Flash Pattern 4 .........................................................................21

Fault Code - Flash Pattern 5 .........................................................................22

Fault Code - Flash Pattern 8 .........................................................................22

Fault Code - Flash Pattern 9 .........................................................................22

Fault Code - Flash Pattern 10 .......................................................................23

Fault Code - Thermistor Fault .......................................................................24

Blank Display ................................................................................................25

USER INTERFACE (CONTROLS) - N7X AND N8X MODELS . 26

Power ON / OFF Button ................................................................................26

Mode Button ..................................................................................................26

Temperature Set Button ................................................................................ 26

Temperature Setting Indicators ..................................................................... 26

Gas Mode Operation .....................................................................................26

AC Mode Operation ......................................................................................26

Air in the Propane Gas Supply Lines ............................................................27

Diagnostic Prechecks ....................................................................................27

FAULT CODES - N7X AND N8X MODELS ..............................27

Fault Code Flash Patterns - N7X and N8X Models .......................................27

Fault Code - Flash Patterns ..........................................................................28

TROUBLESHOOTING FLOWCHARTS - N7X AND N8X MODELS

29

Fault Code - Solid Red Indicator Light ..........................................................29

Fault Code - Flash Pattern 1 .........................................................................31

Fault Code - Flash Pattern 2 .........................................................................32

Fault Code - Flash Pattern 3 .........................................................................32

Fault Code - Flash Pattern 4 .........................................................................32

Fault Code - Flash Pattern 5 .........................................................................33

Fault Code - Flash Pattern 8 .........................................................................33

Fault Code - Flash Pattern 9 .........................................................................33

Fault Code - Flash Pattern 10 .......................................................................34

Fault Code - Thermistor Fault .......................................................................35

Blank Display ................................................................................................36

USER INTERFACE (CONTROLS) - N7LX AND N8LX MODELS 37

Power ON / OFF Button ................................................................................37

Mode Button ..................................................................................................37

Temperature Set Button ................................................................................ 37

Gas Operation ...............................................................................................37

Gas Mode ......................................................................................................38

AC Mode .......................................................................................................38

DC Mode (3-way models only) ......................................................................38

Air in the Propane Gas Supply Lines ............................................................38

Diagnostic Pre checks ...................................................................................38

FAULT CODES - N7LX AND N8LX MODELS ........................39

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

2

www.norcold.com

Page 3

TROUBLESHOOTING FLOWCHARTS - N7LX AND N8LX

MODELS ....................................................................................40

Fault Code - “no” “FL” with audible alarm .....................................................40

Fault Code - “no” “AC” with audible alarm .....................................................42

Fault Code - “AC” “HE” with audible alarm ....................................................43

Fault Code - “dc” “HE” with audible alarm .....................................................44

Fault Code - “AC” “rE” with audible alarm .....................................................44

Fault Code - “dc” “rE” with audible alarm ......................................................44

Fault Code - “Lo” “dc” ....................................................................................45

Fault Code - “Lo” “dc” with audible alarm ......................................................45

Fault Code - “Lo” “dC” with audible alarm .....................................................45

Fault Code - “HI” “dc” with audible alarm ......................................................45

Fault Code - “no” “dt” with audible alarm .......................................................46

Fault Code - “Sr” with audible alarm .............................................................47

Fault Code - “oP” “LI” with audible alarm ......................................................47

Fault Code - “FL” “- -” with audible alarm ......................................................47

Fault Code - Flashing Temperature Setting ..................................................48

Blank Display ................................................................................................49

DIAGNOSTIC MODE - N7LX AND N8LX MODELS .................50

General Diagnostic Information .....................................................................50

Access Diagnostic Mode ...............................................................................50

Change Screens ...........................................................................................50

Exit Diagnostic Mode ....................................................................................50

Screens and Diagnostic Segments Information ............................................50

SCREEN 1: All Diagnostic Icons ON ..........................................................50

SCREEN 2: All Diagnostic Icons OFF .........................................................50

SCREEN 3: Fresh Food Fin Temperature ..................................................50

SCREEN 4: Stored Fault History ................................................................51

SCREEN 5. Stored Fault History ................................................................51

SCREEN 6. Erasing Fault History ...............................................................51

SCREEN 7. Power Board Inputs ................................................................51

SCREEN 8. Power Board Outputs ..............................................................52

SCREEN 9. Power Board DC Input Voltage Status ....................................52

SCREEN 0. Power Board AC Input Voltage Status .................................... 52

SCREEN A. .................................................................................................52

SCREEN B. .................................................................................................52

Cooling System Diagnostic Flowchart ...........................................................53

Figures

Fig. 1 - Double-wrenching gas fittings ...........................................................5

Fig. 2 - Cooling unit bar code label location. .................................................6

Fig. 3 - Refrigerator information label location .............................................6

Fig. 4 - Exploded front view .........................................................................8

Fig. 5 - Exploded rear view ..........................................................................9

Fig. 6 - Typical roof exhaust venting .........................................................11

Fig. 7 - Fuse locations .................................................................................12

Fig. 8 - Fan wiring .......................................................................................12

Fig. 9 - Burner tube location .......................................................................14

Fig. 10 - Openings of the burner tube .........................................................14

Fig. 11 - N7V and N8V user interface (control) locations ............................15

Fig. 12 - Change mode and temperature setting ........................................15

Fig. 13 - Example fault code flash pattern ..................................................17

Fig. 14 - N7X and N8X user interface (control) locations ............................26

Fig. 15 - N7LX and N8LX user interface (control locations .........................37

Fig. 16 - Wiring diagram .............................................................................55

Fig. 17 - Wiring pictorial ..............................................................................56

Fig. 18 - Fan only wiring ..............................................................................57

Fig. 19 - Cold weather heater only wiring ...................................................57

Fig. 20 - Fan and cold weather heater wiring ..............................................58

Fig. 21 - Ice maker only wiring ....................................................................58

Fig. 22 - Ice maker and fan wiring ...............................................................59

Fig. 23 - Ice maker, fan, and cold weather heater wiring ............................59

WIRING SCHEMATIC ................................................................ 55

ICE MAKER* ...............................................................................................55

WIRING PICTORIAL ..................................................................56

AUXILIARY WIRING CIRCUITS ................................................57

Fan Only ........................................................................................................57

Cold Weather Heater Only ............................................................................57

Fan and Cold Weather Heater ......................................................................58

Ice Maker Only ..............................................................................................58

Ice Maker and Fan ........................................................................................59

Ice Maker, Fan, and Cold Weather Heater ....................................................59

ICE MAKER ...............................................................................60

REMOVE / REPLACE THE REFRIGERATOR .......................... 60

Remove the Refrigerator ...............................................................................60

Replace the Refrigerator ...............................................................................60

Conduct Leak Test ........................................................................................60

www.norcold.com

3

SERVICE MANUAL

Page 4

CAUTION

WARNING

SAFETY

It is not possible to anticipate all of the conceivable ways or conditions under which the refrigerator may be serviced or to provide

cautions as to all of the possible hazards that may result. Standard

and accepted safety precautions and equipment should be used

when working on electrical circuits and handling toxic or ammable

materials. Safety goggles and other required protection should be

used during any process that can cause material removal, such as

when removing a leaking cooling unit and cleaning components.

Read this manual carefully and understand the contents before

working on the refrigerator. Be aware of possible safety hazards

when you see the safety alert symbol on the refrigerator and in this

manual. A signal word follows the safety alert symbol and identies

the danger of the hazard. Carefully read the descriptions of these

signal words to fully know their meanings. They are for your safety.

This signal word means a hazard, which if

!

!

ATTENTION

ignored, can cause small personal injury

or much property damage.

This signal word means a hazard, which

if ignored, can cause dangerous personal

injury, death.

Norcold refrigerators are designed and

equipped for the use of propane gas only.

Do not modify, alter, or equip the refrigerator to any other fuel (natural gas, butane,

etc.).

Incorrect installation, adjustment, alteration, or maintenance of the refrigerator

can cause personal injury, property damage, or both.

Do not smoke, light res, or create sparks

when working on propane gas system.

Propane gas is highly ammable and

explosive. Do not use an open ame for

leak testing any of propane gas system

components.

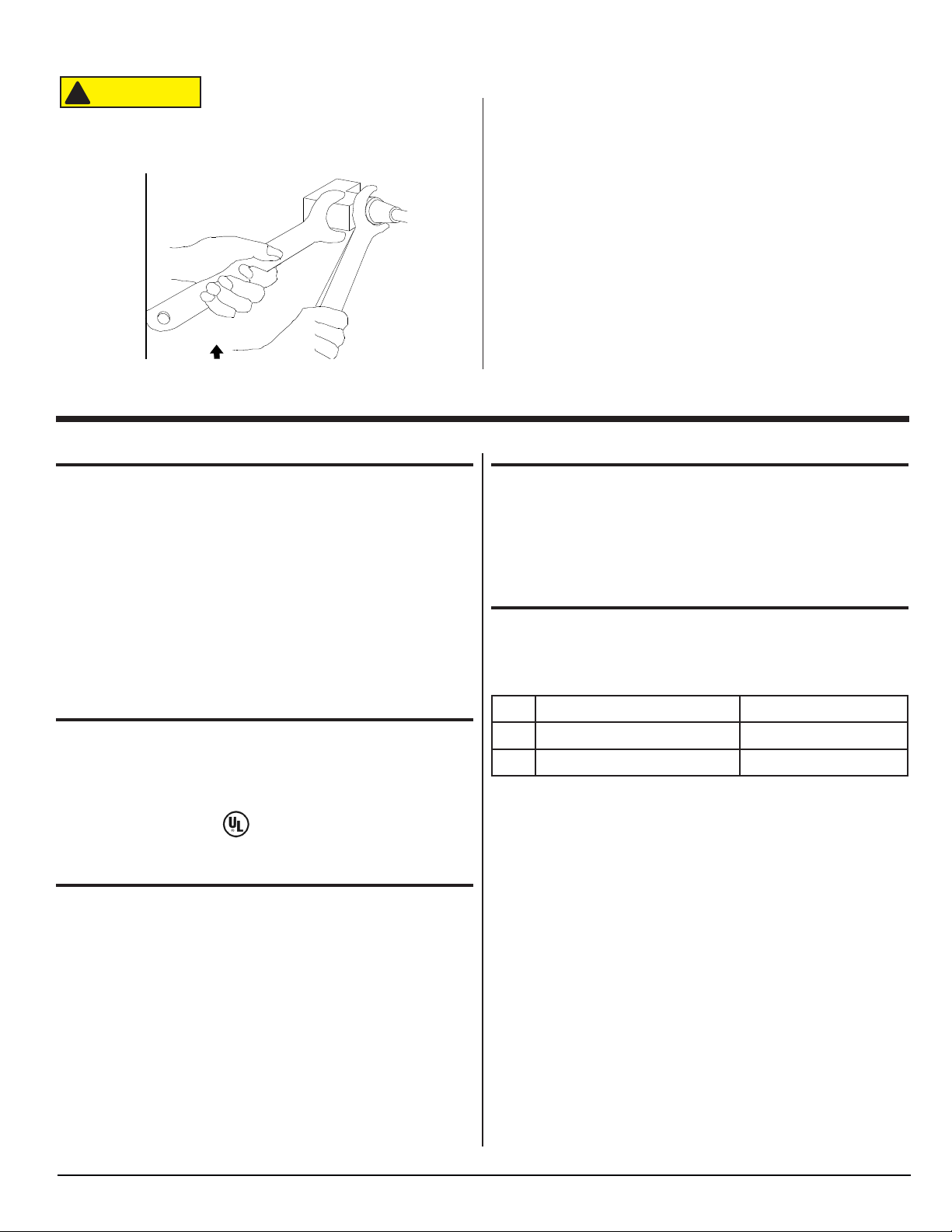

Always use two wrenches to tighten or

loosen propane gas connections. Damaged connections, piping, and components create the potential for gas leaks.

All electrical connections and repairs to

the refrigerator must comply with all ap-

plicable codes. Refer to the “Certication

and Code Requirements” section of the

Installation Manual.

Turn off AC power and DC power sources

before attempting to remove, service, or

repair any of the refrigerator’s electrical

or electronic components. Do not work on

live electrical circuits.

Do not modify, bypass, or eliminate any of

the refrigerator’s electrical components,

electronic circuits, or propane gas system

components.

Do not wet or spray liquids on or near

electrical outlets, connections or components. Most liquids, including leak detection solutions, are electrically conductive

and pose the potential for an electric

shock hazard, short electrical components, damage electronic circuits, and/or

ignite a re.

Do not use leak test solutions that contain

ammonia or chlorine. Ammonia and chlorine degrade copper and brass components.

The cooling unit is a sealed system under

pressure! Do not try to repair or recharge

the cooling unit. Do not bend, drop, weld,

drill, puncture, saw, or strike the cooling

unit.

Handle a leaking cooling unit with extreme

caution! The cooling unit contains ammonia, hydrogen, and sodium chromate.

Ammonia can cause severe skin and eye

burns. Hydrogen is highly ammable, can

ignite and burns with an intense ame.

Certain chromium compounds, such as

sodium chromate, are carcinogenic.

Do not use extension cords. Do not remove the grounding prong from the refrigerator AC power cord. Do not use a two

prong adapter to connect the refrigerator

to the AC outlet.

Do not over-fuse electrical circuits. Use

specied fuses and AWG wire sizes. The

specication section of this manual pro-

vides fuse size information. Refer to the

Installation Manual for the correct AWG

wire size specications.

Prevent child entrapment! Before disposing of the refrigerator, remove all doors

and fasten all shelves with retainers.

Make sure all hardware such as hinges

and fasteners (retaining screws, etc.), are

properly fastened.

Obey the instructions in this manual with

regard to intake and exhaust venting

specications.

Do not install the refrigerator directly on

carpet. Put the refrigerator on a metal or

wood panel that extends the full width and

depth of the refrigerator.

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

4

www.norcold.com

Page 5

CAUTION

Safety, cont’d.

Some of the refrigerator’s metal com-

!

ponents have sharp corners and edges.

Wear hand protection, such as cut resistant gloves, and exercise extreme care

when handling the refrigerator.

Fig. 1 - Double-wrenching gas ttings

NOR000129A-1

INTRODUCTION

About this Manual

This service manual provides maintenance, diagnostic, and repair

information for NORCOLD® N7V, N7X, N7LX, N8V, N8X, and N8LX

Series gas absorption refrigerators. It is a reference tool designed

for technicians who are knowledgeable in the theory and operation

of gas/electric absorption refrigerators, liqueed petroleum (LP)

gas–propane–systems, and AC/DC electrical systems as installed

in a variety of recreational vehicles (RV).

All information, illustrations, and specications contained in this

publication are based on the latest product information available

at the time of publication. NORCOLD® reserves the right to make

changes at any time without notice.

Certication and Code Requirements

NORCOLD® gas/electric absorption refrigerators are certied

under the latest edition of ANSI Z21.19B standards for installation

in mobile homes or recreational vehicles, and with the Canadian

Standards Association CAN/CGA-1.4-M94.

Electrical components are compliant.

About Installation

Refrigerator installation must conform with the N7V, N7X,

N7LX, N8V, N8X, and N8LX Series Installation Manual for the

NORCOLD® limited warranty to be in effect. Installation must

also comply with applicable local codes and standards set by the

relevant certication agency.

Replacement Parts

Use only authorized NORCOLD® replacement parts. Generic parts

do not meet NORCOLD® specications for safety, reliability, and

performance. The use of unauthorized aftermarket or generic replacement parts voids the refrigerator’s limited warranty coverage.

Technical Assistance

If unable to resolve technical issues using the information provided

in this manual, technical support is available through NORCOLD®

Customer Service Center:

Telephone: 1-800-444-7210

(

Fax: 1-734-769-2332

3

World Wide Web: www.norcold.com.

8

The following information is required to process technical support

requests:

■ Refrigerator Model Number

■ Refrigerator Serial Number

■ Refrigerator Cooling Unit Serial Number

■ Recreational Vehicle (RV) Make/Model/Year

www.norcold.com

5

SERVICE MANUAL

Page 6

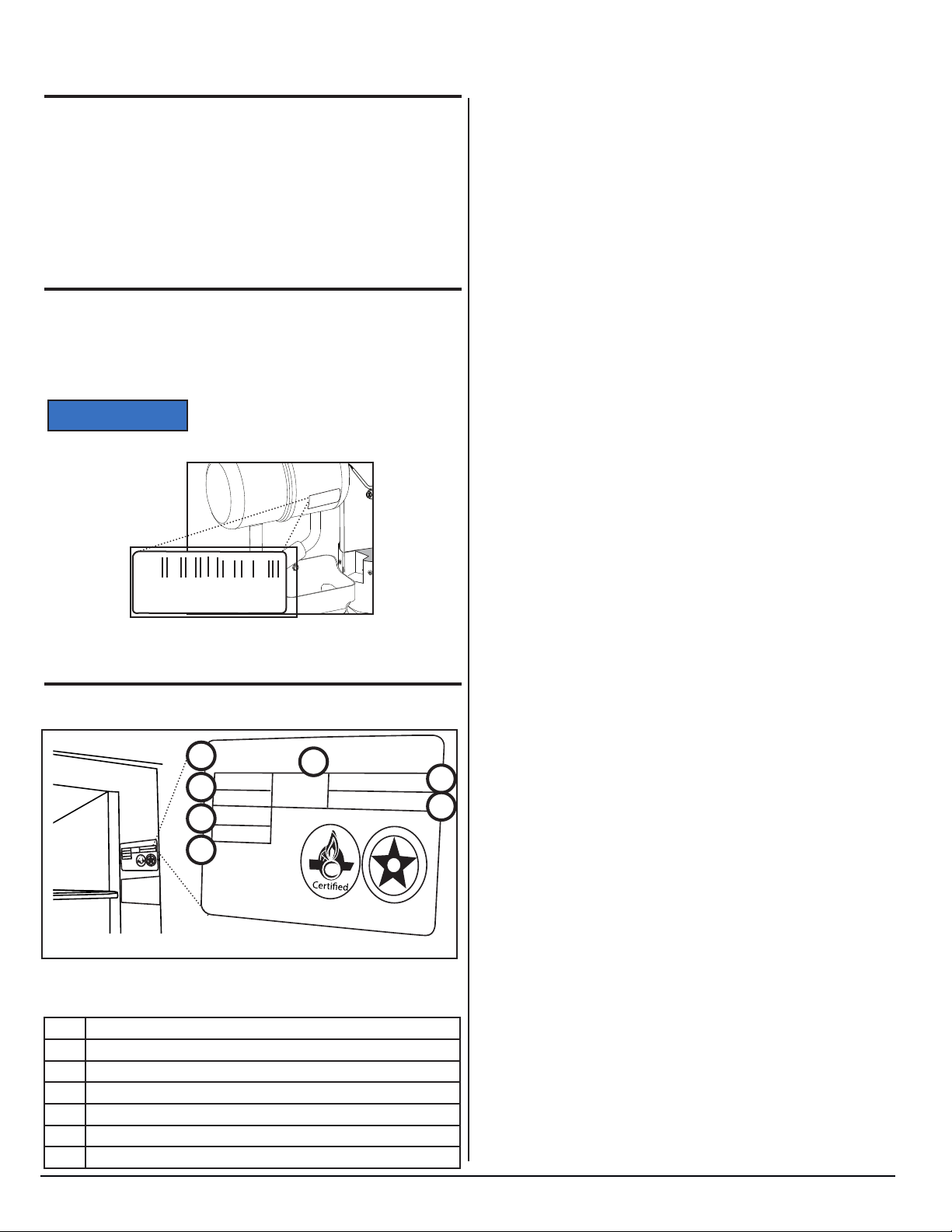

NOTICE

INTRODUCTION, cont’d.

xxxxxxxxxxxxxx

xxxxxxxxxxxxx

xxxxxxxxxxxxxxx

xxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxx xxxxx

xxxxxxxxxxxxxxxxxxxxx

xxxxxx

xxxxxxxxxxxxxxxxxxxxx xxxx

xxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxx

xxxxx

xxxxxxxxxxxxxxxxxxxxxxx xx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

D

E

S

I

G

N

C

E

R

T

I

F

i

E

SA

NORCOLD

x

x

x

x

xx

x

x

x

x

x

x

x

xx

x

x

x

x

x

x

x

x

x

x

x

x

Model Identication

Models which include .3 in the model number are 3-way

refrigerators that operate on AC power, propane gas, or DC power.

Models which DO NOT include .3 in the model number are 2-way

refrigerators that operate on AC power or propane gas.

Letter(s) appended to the model number identify factory installed

accessories.

Cooling Unit Serial Number

The cooling unit serial number appears on the cooling unit bar

code label. The label is afxed to the surface of the cooling unit

leveling chamber.

Be sure to have the cooling unit serial

number available if you need technical

support on this component

N000036A-1

1167359

NORCOLD

Fig. 2 - Cooling unit bar code label location.

Refrigerator Model Number

xxxxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxx

NORC OLD

A

Serial Number

B

Model Number

Group Code

C

Input Pressure

BTUH

xxxxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxx

D

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

Fig. 3 - Refrigerator information label location

Refrigerant

x.xx

LBS.

test pressure

E

E

xxx VOLTS - AC xx HZ

x.xx AMPS xxx Watts

xx VDC xx HZ

x.x AMPS xx xx Watts

SA

C

F

G

I

G

S

E

N

D

E

D

R

E

i

F

T

I

A Serial Number

B Model Number

C Group Code

D BTU / h

E Amount of refrigerant in cooling system

F AC Voltage / Amperage

G DC Voltage / Amperage

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

6

www.norcold.com

Page 7

SPECIFICATIONS

N7V, N8V Models - Electronic

• Capacitive Touch - ON/OFF

• Single LED Indicator Light (Multi-Color)

• Self-Diagnostic with Fault Indicators (LED Flash Pattern)

• 2-Way Automatic Operation

• Non-Settable Factory Preset Temperature Setting (With Backup Operating System)

N7X, N8X Models - Electronic

• Capacitive Touch - ON/OFF, Mode, and Temperature Set

• Multiple LED Indicator Lights

• Self-Diagnostic with Fault Indicators (LED Flash Pattern)

• 2-Way Automatic or Manual Operation

• Five (5) Separate Temperature Settings (With Backup Operating System Mode)

• Sleep Mode

N7LX, N8LX Models - Electronic

• Capacitive Touch - ON/OFF, Mode, and Temperature Set

• Backlit LCD Display with Icon, Numerical, and Text Indicators

• Self-Diagnostic with Fault Codes

• 2-Way Automatic or Manual Operation (Standard), 3-Way Automatic or Manual Operation (Optional)

• Nine (9) Separate Temperature Settings (With Backup Operating System Mode)

• Sleep Mode

• 12 Individual Diagnostic Screens

Rough Opening Dimensions (H x W x D)

N7V, N7X, N7LX models ----------------------------------------------------------------------- 52.88 - 53.01 in. x 23.50 - 23.63 x 24.00 - 24.13 in.

N8V, N8X, N8LX models ---------------------------------------------------------------------- 59.88 - 60.01 in. x 23.50 - 23.63 x 24.00 - 24.13 in.

DC (Direct Current) Specications

Electronic Controls DC input voltage requirement --------------------------------------------------------------------------- 10.5 VDC to 16.0 VDC

DC Fuse Requirements

Main Control Board (Power Board) F1-Control Circuit ----------------------------5-Amp, 32V, MINI ® Blade, Automotive Style Fuse

Main Control Board (Power Board) F2-Auxiliary Circuit ------------------------ 7.5-Amp, 32V, MINI ® Blade, Automotive Style Fuse

DC Heater Board F1 (Optional - N7LX, N8LX models only) ---------------- 30-Amp, 32V, ATO/ATC Blade, Automotive Style Fuse

DC Resistance / Amperage Ratings

Divider Heater ------------------------------------------------------------------------------------------43 Ω to 50 Ω, 240mA to 279mA @ 12 VDC

DC Heater (3-Way models only) --------------------------------------------------------------1 each, 6.7 Ω to 7.8 Ω, 16A to 18A @ 12 VDC

Cold Weather Heater (optional) ----------------------------------------------------------------------- 6.7 Ω to 7.8 Ω, 1.5A to 1.8A @ 12 VDC

Ice Maker Water Line Heater (IM models only) ---------------------------------------------------- 6.7 Ω to 7.8 Ω, 1.5A to 1.8A @ 12 VDC

External cooling fan ------------------------------------------------------------------------------------------------------------------430mA @ 12 VDC

Interior Light --------------------------------------------------------------------------------------------------------------------------------------- 180 mA

AC (Alternating Current) Specications

Electronic Controls AC input voltage requirement -------------------------------------------------------------------------- 108VAC to 132VAC

AC Fuse Requirements

Power Board F3 ---------------------------------------------------------------------------------- 8-Amp, 250V Glass FST 5 x 20mm GMA Type

AC Current Draw

AC Heater --------------------------------------------------------1 each, 300W @120VAC, (45.7 Ω to 50.5 Ω), 2.38A to 2.63A @ 120VAC

Ice Maker Water Valve (IM models only) -------------------------------------------------------------------------------------------10W @ 120VAC

Propane gas

Operating pressure ----------------------------------------------------------------------------------------------------------------------- 10.5 - 11.5 inch w.c.

Burner rating (Heat output) ------------------------------------------------------------------------------------------------------ 1750 Btu/h @ 11 in. W.C.

Burner orice size -------------------------------------------------------------------------------------------------------------------- LP18 (not replaceable)

Gas ignition --------------------------------------------------------------------------------------------------------------------- Electronic with ame sensing

Electrode tip-to-burner gap ------------------------------------------------------------------------------------------------------------------- 1/8 to 3/16 inch

Off-level operating limits

Side-to-side-------------------------------------------------------------------------------------------------------------------------------- 3 degrees-maximum

Front-to-back ------------------------------------------------------------------------------------------------------------------------------ 6 degrees-maximum

www.norcold.com

7

SERVICE MANUAL

Page 8

SPECIFICATIONS, cont’d.

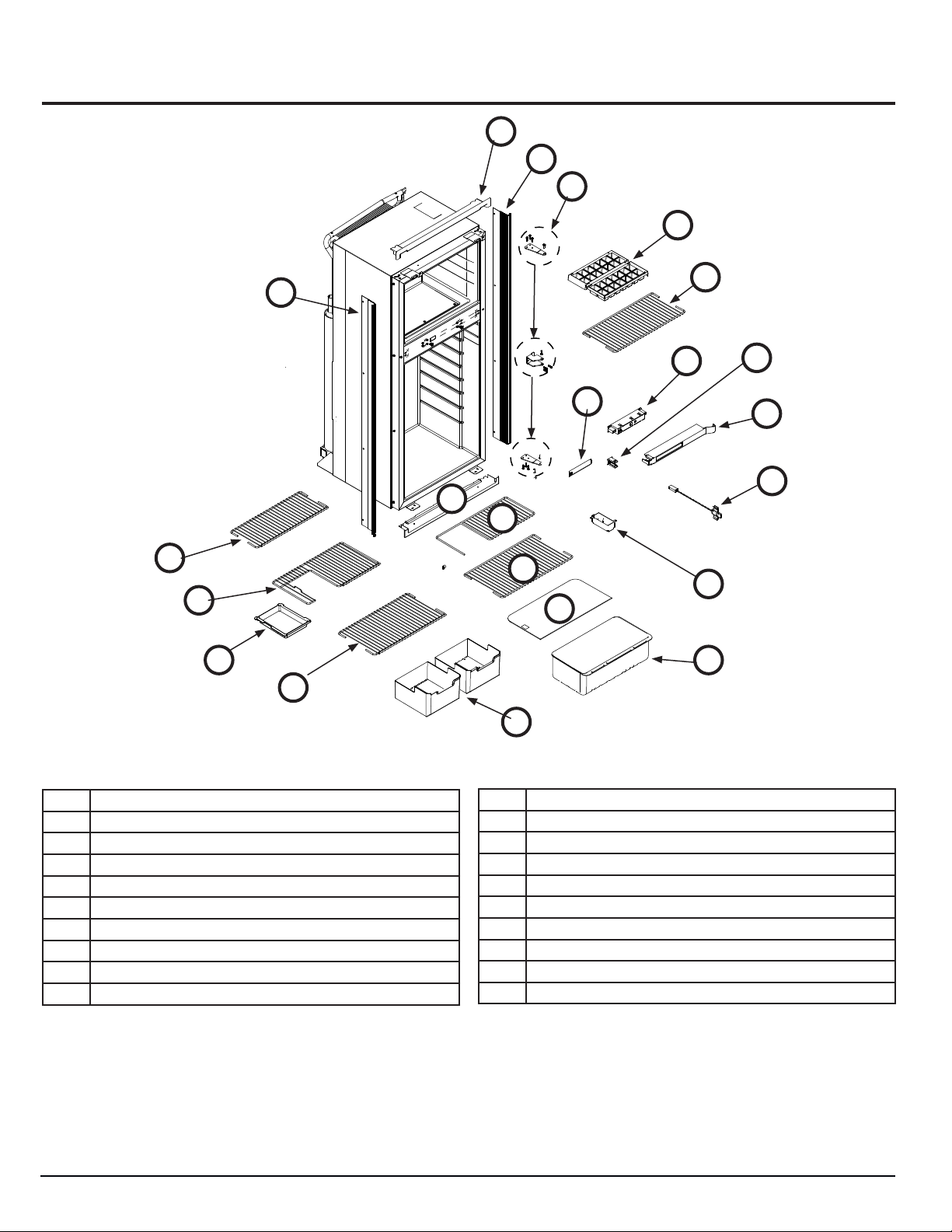

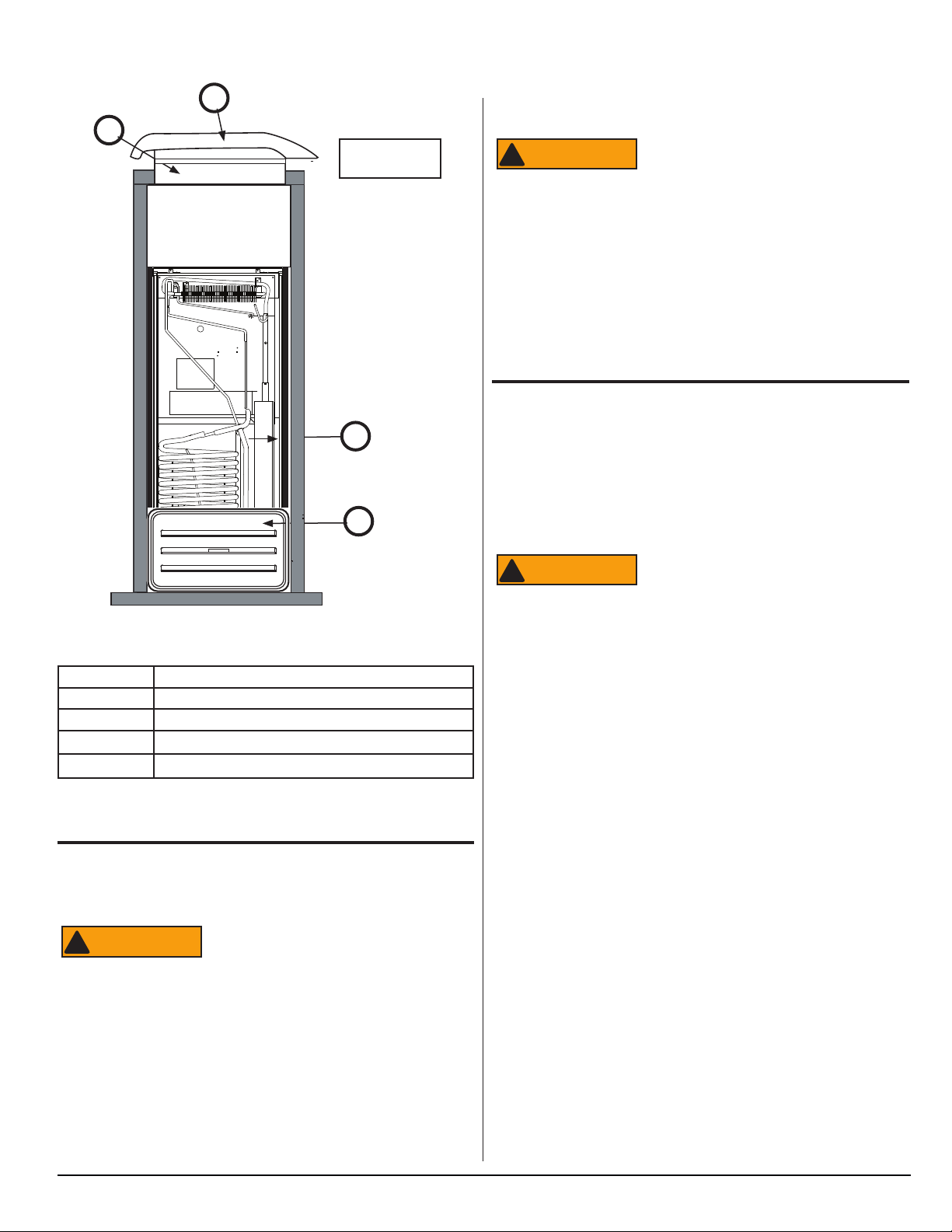

Exploded Views

R

B

A

C

G

I

J

Fig. 4 - Exploded front view

B

D

E

N

P

F

Q

S

I

H

O

K

K

L

H

M

NOR000724A

No. Description

A Hinges

B Trim Piece / Foam Tape Assembly

C Ice Cube Tray

D Freezer Wire Shelf

E User Interface Assembly (Control Assembly)

F User Interface Housing (Control Housing)

G Short Wire Shelf

H Full Wire Shelf

I Cut Out Wire Shelf

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

J Shelf Tray

K Crisper Cover / Glass Shelf

L Crisper

M Ice Bin

N Hinge Hole Cover

O LED Assembly

P Strike Plate

Q Thermistor

R Top Trim Piece

S Bottom Trim Piece

8

www.norcold.com

Page 9

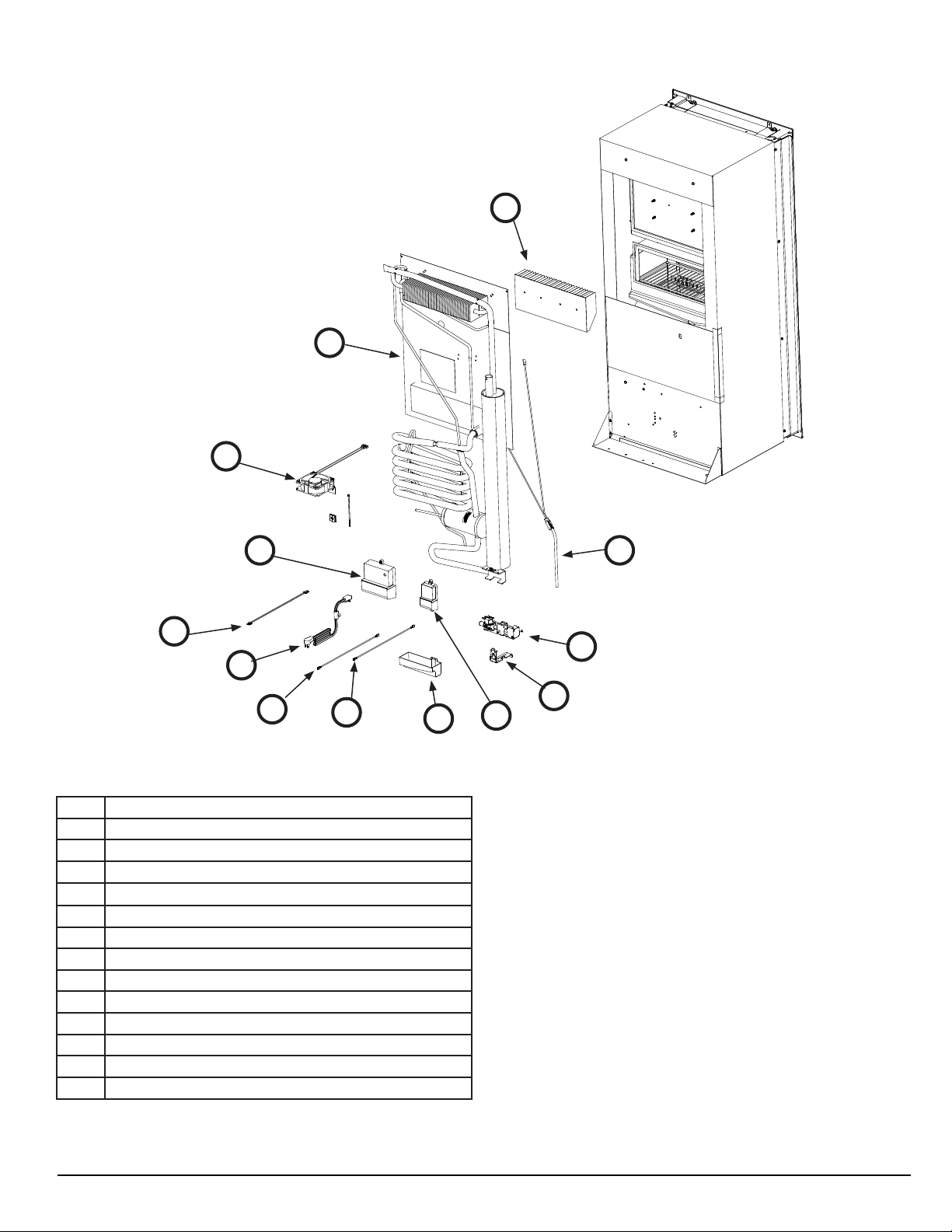

SPECIFICATIONS - Exploded Views, cont’d.

AF

U

T

AE

AC

AD

AA

AB

Fig. 5 - Exploded rear view

No. Description

T Cooling Unit

U Fins

V AC Heater

W Gas Train Assembly

X Gas Train Support Bracket / Burner Door Assembly

Y Drip Cup

Z DC Board Assembly (3-way models only)

AA Red Input Wire (3-way models only)

AB Black Input Wire (3-way models only)

AC Communication Harness (3-way models only)

AD AC Power Cord

AE Main Control Board Assembly (Power Board Assembly)

AF Fan

V

W

X

Y

Z

NOR000725A

www.norcold.com

9

SERVICE MANUAL

Page 10

WARNING

AVERTISSEMENT

ADVERTENCIA

DANGER

WARNING

GENERAL INFORMATION

To conrm that installation is adequate, check for:

■ Adequate ventilation - refer to "Ventilation Requirements" in the

refrigerator Installation Manual.

■ Both gas and electrical components installed and operating in a

safe condition.

■ Adequate seal between refrigerator mounting ange and cut-out

opening.

■ Installed on a solid oor (not on carpet) and secured.

This refrigerator is not intended to be

!

ATTENTION

operated as a free standing unit (i.e.

where the products of combustion are not

completely isolated from the living area) or

installed in such a way as to conict with

these installation instructions. Unapproved

installations could result in safety risks or

performance problems.

Ventilation

Overview

The installed unit must

!

!

!

!

ATTENTION

ATTENTION

ATTENTION

ATTENTION

Certied installation needs one lower intake vent and one upper

exhaust vent. Install the vents through the side wall of the vehicle

exactly as instructed in the Installation Manual. Any other installa-

tion method voids both the certication and the factory warranty of

the refrigerator.

The bottom of the opening for the lower intake vent, which is also

the service access door, must be even with or immediately below

the oor level. This allows any leaking propane gas to escape to

the outside and not to collect at oor level.

American Gas Association/Canadian Gas Association (AGA/CGA)

certication allows the refrigerator to have zero (0) inch minimum

clearance at the sides, rear, top, and bottom. While there are no

maximum clearances specied for certication, the following maxi-

mum clearances are necessary for correct refrigeration:

Bottom 0 inch min. 0 inch max.

Each Side 0 inch min. 1/4 inch max.

Top 0 inch min. 1/4 inch max.

Rear 0 inch min. 1 inch max.

isolated from the combustion system of the

refrigerator and it must have complete and

unrestricted ventilation of the ue exhaust

which, in gas mode, can produce carbon

monoxide. The breathing of carbon monoxide fumes can cause dizziness, nausea, or

in extreme cases, death.

be completely

Enclosure

The cabinet that encloses the refrigerator is built by the RV manufacturer. Depending on cabinet depth, height, and width certain

bafes may be present when cabinet clearances exceed installation guidelines and specications.

Bafes

Bafes prevent hot air buildup “pocketing” between the refrigerator

cabinet and the enclosure walls and/or ceiling. An enclosure may

be tted with:

■ An absorber bafe and a condenser bafe

■ Side bafes (Fig. 6, A)

■ Vertical top bafe (Fig. 6, B)

■ Vertical angled bafes

■ Box bafe

■ Or a combination of any of the above

For complete detail about any necessary bafe(s), refer to the

refrigerator Installation Manual.

Lower Intake Vent

Ventilation and combustion air ow through the lower intake vent

(Fig. 6, C), which also serves as the service access or door. The

lower intake vent needs be kept clear of obstructions that may

restrict the ow of fresh air into the enclosure.

Exhaust Vent

Warm air and combustion gases ow out of the enclosure through

the exhaust vent. The exhaust vent can be either a roof exhaust

vent (Fig. 6, D) or an upper sidewall exhaust vent.

The roof exhaust vent has a non-removable metal mesh screen

to prevent leaves, birds, rodents and/or debris from entering the

enclosure.

Roof Cap

The roof cap (Fig. 6, E) ts over exhaust vent. The sloped end

always faces the front of the RV. It is held in place by four (4) 2-1/2”

long Phillips head screws.

These clearances plus the lower and upper vents cause the natural

air draft that is necessary for good refrigeration.

Cooler air goes in through the lower intake vent, goes around the

refrigerator coils where it removes the excess heat from the refrigerator components, and goes out through the upper exhaust vent.

If this air ow is blocked or decreased, the refrigerator may not cool

correctly.

Each NORCOLD model is certied by AGA and CGA for correct

ventilation.

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

10

www.norcold.com

Page 11

WARNING

WARNING

WARNING

GENERAL INFORMATION - Roof Cap, cont’d.

E

D

B

Front of RV

■ To avoid possible propane gas leaks, always use two wrenches

to tighten or loosen the propane gas supply line connections.

■ Leaking propane gas can ignite or explode and result in danger-

ous personal injury or death.

Do not allow the leak detecting solution

!

ATTENTION

to touch the electrical components. Many

liquids are electrically conductive and can

cause a shock hazard, electrical shorts,

and in some cases re.

Leak Test-Detergent

Using a solution of liquid detergent and water:

■ Examine the propane gas supply system for leaks: make sure

the propane gas supply line and all gas connections have no

leaks. Do not use any liquid that contains ammonia.

Electrical Connections

A

C

NOR000843A

Fig. 6 - Typical roof exhaust venting

A Side Baffles

B Vertical Top Baffles

C Lower Inake Vent

D Roof Exhaust Vent

E Roof Cap

Propane Gas Connections

The refrigerator operates on propane gas at a pressure of 10.5

inches Water Column min. to 11.5 inches Water Column max.

!

ATTENTION

■ Do not smoke, or use an open ame near the propane gas

system.

■ Do not use an open ame to examine for leaks.

■ Do not connect the refrigerator to the propane gas tank without

a pressure regulator between them.

Be very careful when working on or near

the propane gas system.

120 Volts AC Electrical Connection

The refrigerator is equipped with a three-prong plug for protection

against shock hazard and must be connected into a recognized

three-prong attachment receptacle. The cord must be routed so as

not to come in contact with the burner cover, ue pipe or any other

component that could damage the cord insulation.

Do not remove (cut) grounding plug from

!

ATTENTION

■ Verify AC power cord is in a grounded three-prong receptacle.

■ Verify receptacle is within easy reach of the lower intake vent.

■ Verify power cord does not touch the burner cover, the ue

pipe, or any hot component that could damage the insulation of

the power cord.

the refrigerator AC power cord. Removal

of this prong can result in a severe electrical shock, as well as voiding the refrigera-

tor’s electrical certication and warranty.

12 Volts DC Electrical Connection

The refrigerator controls require 12 volt DC to operate. The minimum control voltage is 10.5 volts DC. The maximum control voltage is 16.0 volts DC.

Polarity

The correct polarity of the DC leads to the main control board

(power board) connections is:

■ The 12 volt DC (positive) supply wire from the battery must be

connected to the terminal marked “12 VDC” of the main control

board (power board). On 3-way models, this connection is made

to the DC control board terminal marked “12 VDC” .

■ The 12 volt DC (ground) supply wire from the battery must be

connected to the terminal marked “GND” of the main control

board (power board). On 3-way models, this connection is made

to the DC control board terminal marked “GND”.

www.norcold.com

11

SERVICE MANUAL

Page 12

GENERAL INFORMATION - Electrical Connections, cont’d.

NOTICE

12 Volt DC Fan

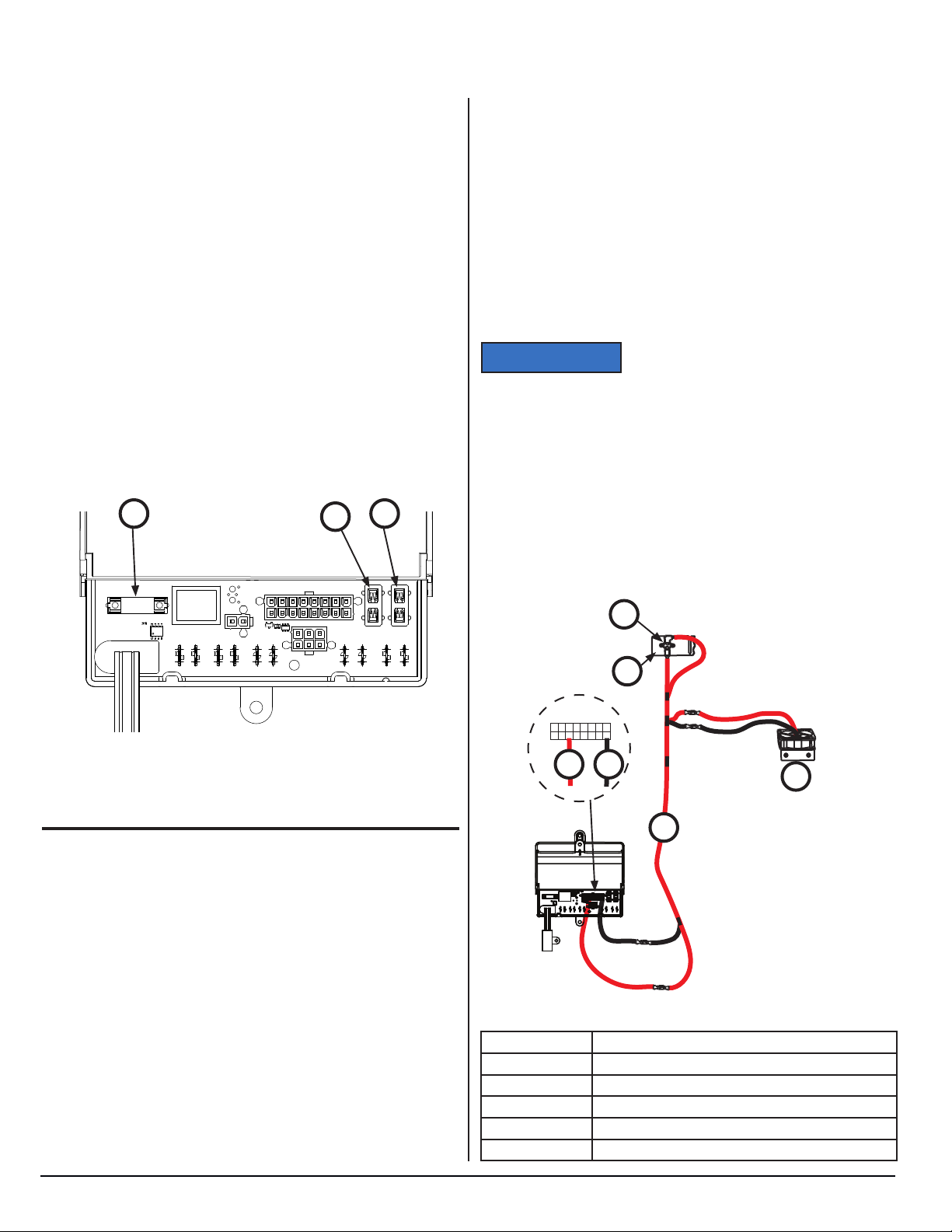

Main Control Board (Power Board) Fuses

There are three (3) fuses located on the main control board (power

board). Two (2) are MINI ® Blade, Automotive Style Fuses used to

protect DC voltage circuits (F1 and F2) and one (1) is a glass body

cartridge style fuse (F3) used to protect AC voltage circuits.

Fuse F1

This is a DCV, 5-Amp, 32V, MINI ® Blade, Automotive Style Fuse.

It is used to protect the DC circuitry / componentry located on the

Main Control Board (Power Board).

Fuse F2

This is a DCV, 7.5-Amp, 32V, MINI ® Blade, Automotive Style

Fuse. It is used to protect DC “loads” connected to the auxiliary

output of the main control board (power board).

Examples of these loads are: External cooling fan, waterline heaters, etc.

Fuse F3

This is an ACV, 8-Amp, 250V, Glass Body Cartridge, FST 5x20mm,

Automotive Style Fuse. It is used to protect the AC circuitry / componentry located on the main control board (power board).

F3 F1

F2

A 12 volt DC fan (Fig. 8, A) increases ventilation of the cooling

system. The fan is located near the condenser on the rear of the

cooling system foam plug. Fan resistance through the fan motor

circuit is approximately 1.8 ohms.

The fan is unidirectional and is controlled by a thermostatic switch

(Fig. 8, B).

The thermostatic switch is located on the rst condenser n (Fig. 8,

C).

The switch turns the fan on and off. The fan comes on when the

temperature of the rst condenser n is about 130° F (54.4° C) and

turn off at about 115° F (46°C).

The DC power is supplied by an auxiliary wire harness (Fig. 8, D)

through to connector pins P1-1 (Fig. 8, E) and P1-6 (Fig. 8, F).

If the vehicle has a roof exhaust vent,

you may need to remove the refrigerator

from the enclosure to test the thermostatic switch. If the vehicle has an upper

side-wall exhaust vent, you can test the

thermostatic switch by removing the upper

sidewall vent.

Low Ambient Heater (optional)

Some models are factory equipped with a low ambient heater.

NOR000815A

Fig. 7 - Fuse locations

Electrical Components

Interior Light

The interior light is located in the top of fresh food compartment.

The light remains on at all times while the refrigerator is ON.

Divider Heater

This heater is controlled by a thermostat. The thermostat allows DC

voltage to the heater only while the refrigerator is turned ON and

only when the ambient temperature is low enough.

B

C

11 10 9

1213141516

P1

5438

1

6

7

2

F E

A

D

NOR000793A

The divider heater is permanently “foamed into” the divider between the freezer compartment and the fresh food compartment.

The divider heater warms this area to prevent condensation from

forming. Powering on the refrigerator automatically powers on the

divider heater. Power to the heater is continuously supplied by the

main control board (power board).

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

Fig. 8 - Fan wiring

A Fan

B Thermostatic Switch

C Condenser

D Auxiliary Wire Harness

E P1-1 Auxiliary 12 VDC (ground)

F P1-6 Auxiliary 12 VDC (positive)

12

www.norcold.com

Page 13

NOTICE

WARNING

GENERAL INFORMATION - Electrical Components, cont’d.

Temperature Control System

Although the refrigerator is not frost-free, it is made to limit frost on

the cooling ns. At regular intervals, the temperature control system

automatically melts most of the frost from the cooling ns. The water from the cooling ns drains into a collection cup attached to the

back of the refrigerator. The heat of the cooling system evaporates

the water from the collection cup.

Backup Operating System

This refrigerator has a backup operating system. The backup

operating system allows the refrigerator to continue to cool if the

thermistor of the refrigerator should fail.

If a failure occurs:

■ The refrigerator automatically changes to the backup operating

system.

■ N7V and N8V models:

• In Auto AC mode, the green power ON / indicator light will

ash OFF once every 20 seconds and repeat until the

thermistor is sensed to be operating correctly.

• In Auto Propane Gas mode, the amber power ON / indicator

light will ash OFF once every 20 seconds and repeat until

the thermistor is sensed to be operating correctly.

PREVENTATIVE MAINTENANCE

An annual maintenance check is strongly recommended:

■ Leak test the gas lines.

■ Check combustion seal; repair or replace, if necessary (visual

check without removing the refrigerator).

■ Inspect or clean the openings of the burner tube.

■ Check/adjust the spark electrode gap to 1/8 - 3/16 inch.

■ Make sure the spark electrode tip is clean and the spark elec-

trode is securely attached to the gas train assembly.

■ Check/adjust AC and DC voltages and propane gas supply

pressure.

■ Make sure that area around the burner and controls is free of

debris, oily rags, etc.

■ Inspect the controls, piping and wiring to insure that they are in

good condition.

THESE MAINTENANCE PROCEDURES

MUST BE PERFORMED BY A QUALIFIED SERVICE PERSON.

NORCOLD CANNOT ACCEPT RESPONSIBILITY FOR REPAIRS, ADJUSTMENT,

OR MAINTENANCE PERFORMED BY

OTHER THAN A QUALIFIED DEALER

OR SERVICE CENTER.

■ N7X and N8X models:

• In ANY mode, the temperature setting will ash ON and

OFF for 10 seconds when the control is “awake”.

■ N7LX and N8LX models:

• In ANY mode, the temperature setting will ash ON and

OFF for 10 seconds when the control is “awake”.

■ The backup operating system can over-freeze or thaw the con-

tents of the freezer and the fresh food compartment.

■ Make sure the temperatures of the freezer and the fresh

food compartment are satisfactory.

Gas Flame Appearance

While in propane gas operation, examine the appearance of the

gas ame:

1. Change the refrigerator controls to the coldest temperature

setting.

2. Open the lower intake vent.

!

ATTENTION

3. Open the burner door and look at the gas ame:

■ The ame should be a darker blue inside and a lighter blue

outside and should be a constant and steady shape.

■ The ame should not be yellow and should not have an er-

ratic and unstable shape.

■ Make sure the ame does not touch the inside of the ue

tube.

4. Close the burner door.

5. Clean the openings of the burner tube as part of routine

maintenance. Follow the instructions in the “Clean the

Openings of the Burner Tube’ section of these instructions.

If the ame is not at peak performance, after the openings of

the burner tube are cleaned, contact Customer Service.

The burner door can be hot. Wear gloves

to avoid burns.

www.norcold.com

13

SERVICE MANUAL

Page 14

WARNING

WARNING

WARNING

PREVENTIVE MAINTENANCE, cont’d.

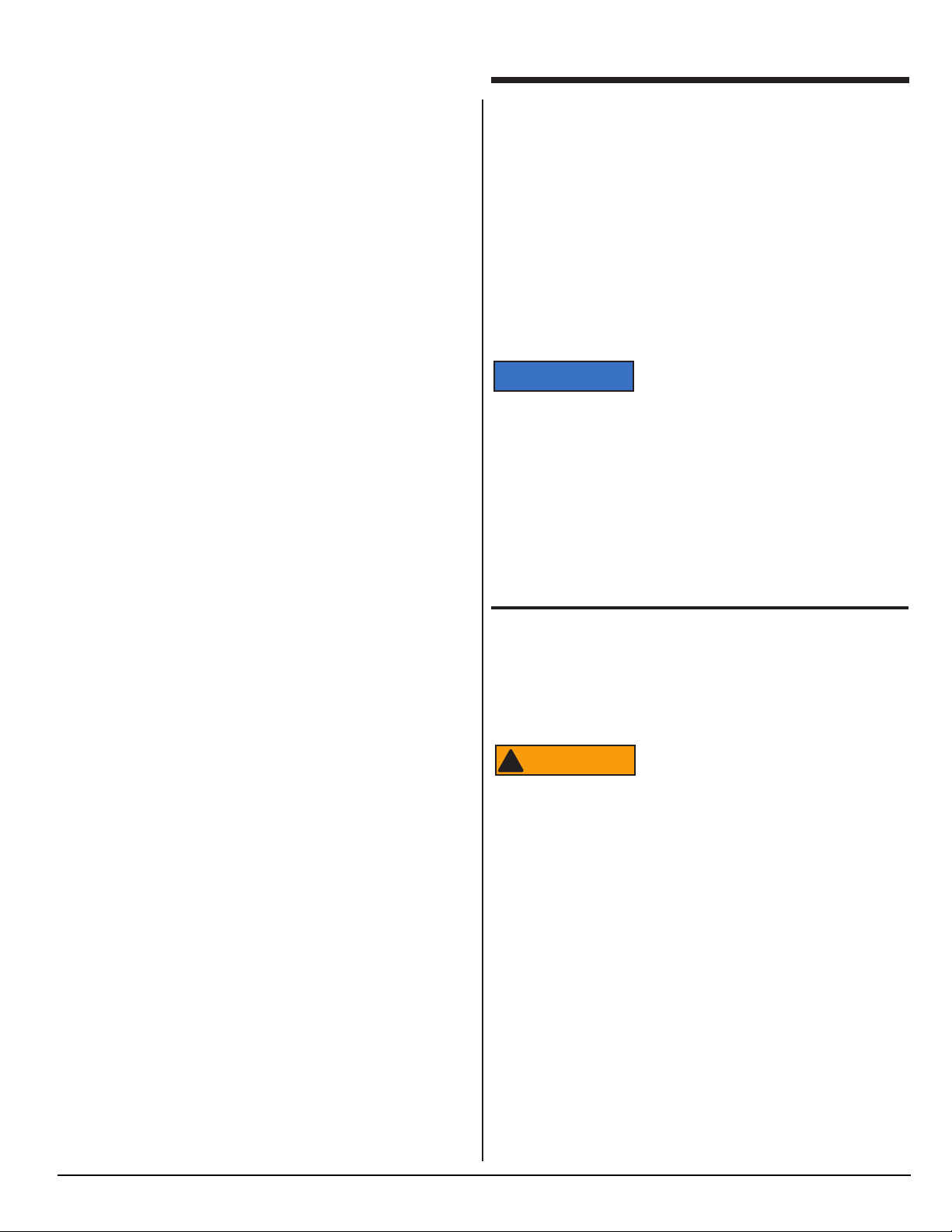

Clean the Openings of the Burner Tube

Clean the openings of the burner tube annually. To clean:

1. Close the valve at the vehicle propane gas tank(s).

2. Touch and hold the ON/OFF button ( ) for one (1) second

to turn the refrigerator off.

3. Open the lower intake vent.

4. Disconnect the two (2) white wires from the gas train assembly (Fig. 9, A).

!

ATTENTION

5. Disconnect the gas supply line from the gas train assembly.

6. Remove the two (2) screws (Fig. 9, B) that attach the gas

train support bracket/door assembly (Fig. 9, C) to the cooling unit.

!

ATTENTION

7. Remove the gas train assembly from the cooling unit.

To avoid possible propane gas leaks,

always use two (2) wrenches to loosen

and tighten the gas supply line at the gas

train assembly.

Never attempt to operate the gas train

when it is NOT installed in the cooling unit

because of the risk of electrical shock.

NOR000683A-1

B

C

Fig. 9 - Burner tube location

A Gas Train Assembly

B Screws

C Gas Train Support Bracket/Door Assembly

Air

A

When cleaning, do not try to remove

!

ATTENTION

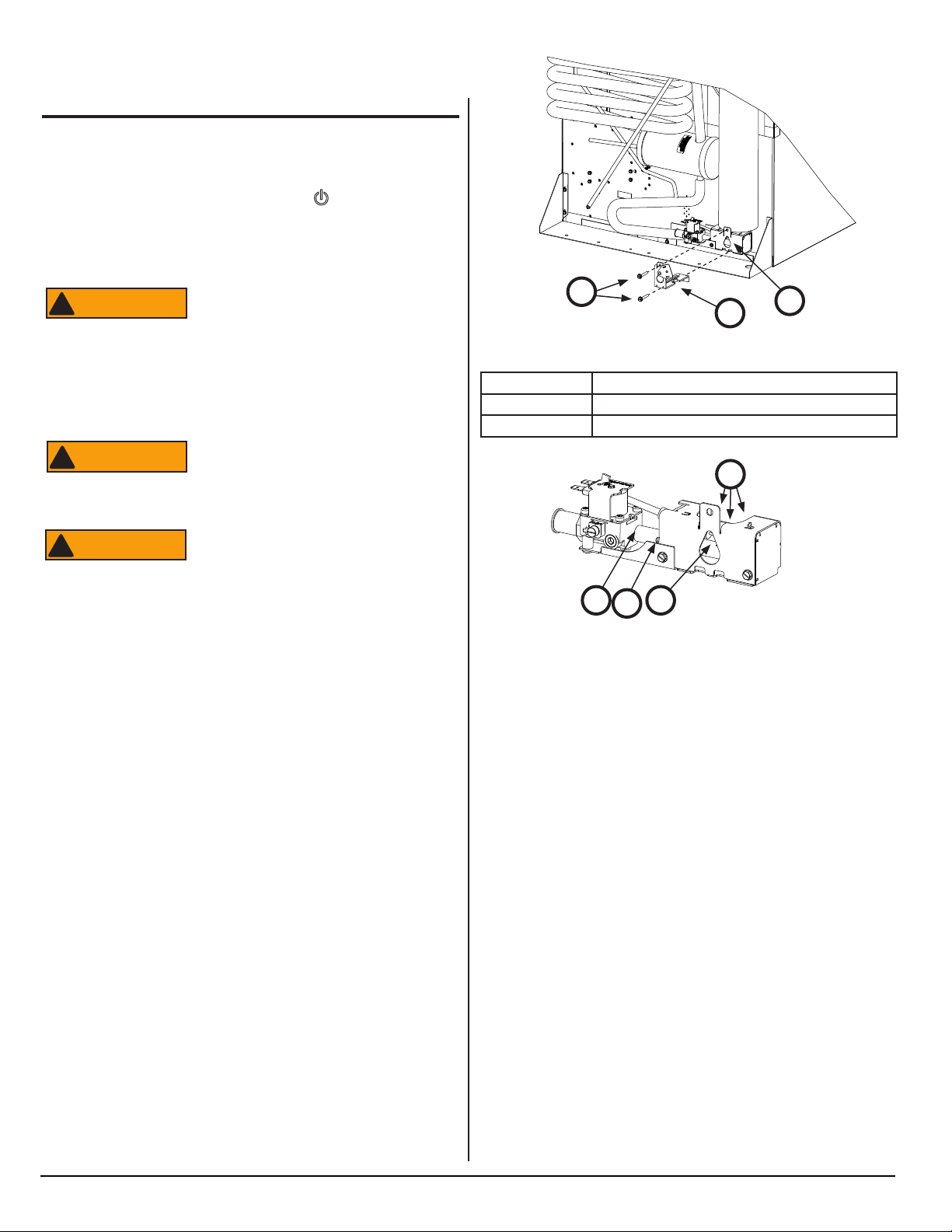

8. Clean the openings of the burner tube with compressed air

only. Blow air into the openings of the burner tube.

9. Put the gas train assembly back onto the cooling unit.

10. Attach the gas train support bracket/door assembly to the

cooling unit.

11. Connect the gas supply line to the gas train assembly.

12. Connect the two (2) white wires to the gas valve of the gas

train assembly.

13. Open the valve at the vehicle propane gas tank(s).

14. Examine all of the gas connections for leaks. Refer to the

“Conduct Leak Test” procedure.

the burner. Removal may can cause a

propane gas leak. Leaking propane gas

can ignite or explode and result in dangerous personal injury or death. Do not try to

clean the burner with anything other than

compressed air.

NOR000683A

Air

Air

Air

Fig. 10 - Openings of the burner tube

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

14

www.norcold.com

Page 15

WARNING

USER INTERFACE (CONTROLS) - N7V AND N8V MODELS

change temp setting.

if red

check

NORCOLD

NOR000647A

A B

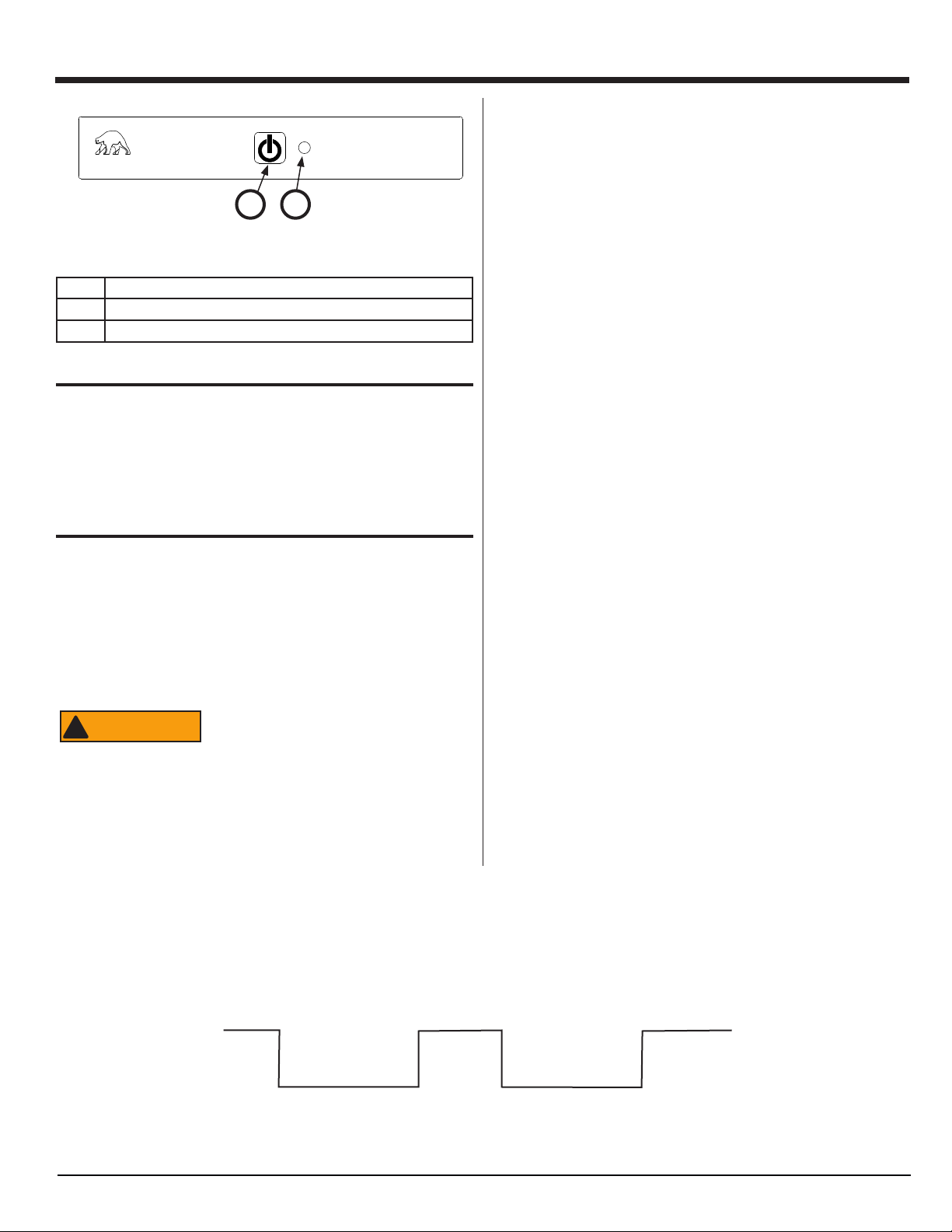

Fig. 11 - N7V and N8V user interface (control) locations

No. Description

A Power ON / OFF button

B Power ON / Indicator Light

Power ON / OFF Button

Touch the Power ON / OFF button (See Fig. 11, A) to turn on the

refrigerator.

Touch and hold the Power ON / OFF button for one (1) second to

turn off the refrigerator.

Modes of Operation

A precise heat is applied to the boiler area of the cooling unit causing a chemical reaction within the cooling unit that ultimately results

in the refrigerator cooling. The heat is applied by means of:

■ A 120 volt AC heater positioned in a heater well welded to the

surface of the boiler. AC operation requires 108 to 132 volts AC.

To replace the heater, the refrigerator must be removed from the

enclosure.

gas

These heat sources are turned on/off via a factory preset Auto

mode. The unit will attempt to operate the heat source requirements in the following order of priority:

■ 1st Priority Choice - Auto Mode

While in the Auto Mode, the AC cartridge heater is operated to

provide heat to the boiler area of the cooling unit and the power

ON / indicator light (See Fig. 11, B) is solid GREEN.

■ 2nd Priority Choice - Propane Gas Mode

While in the Propane Gas Mode, the propane gas burner is operated to provide heat to the boiler area of the cooling unit and

the power ON / indicator light is solid AMBER.

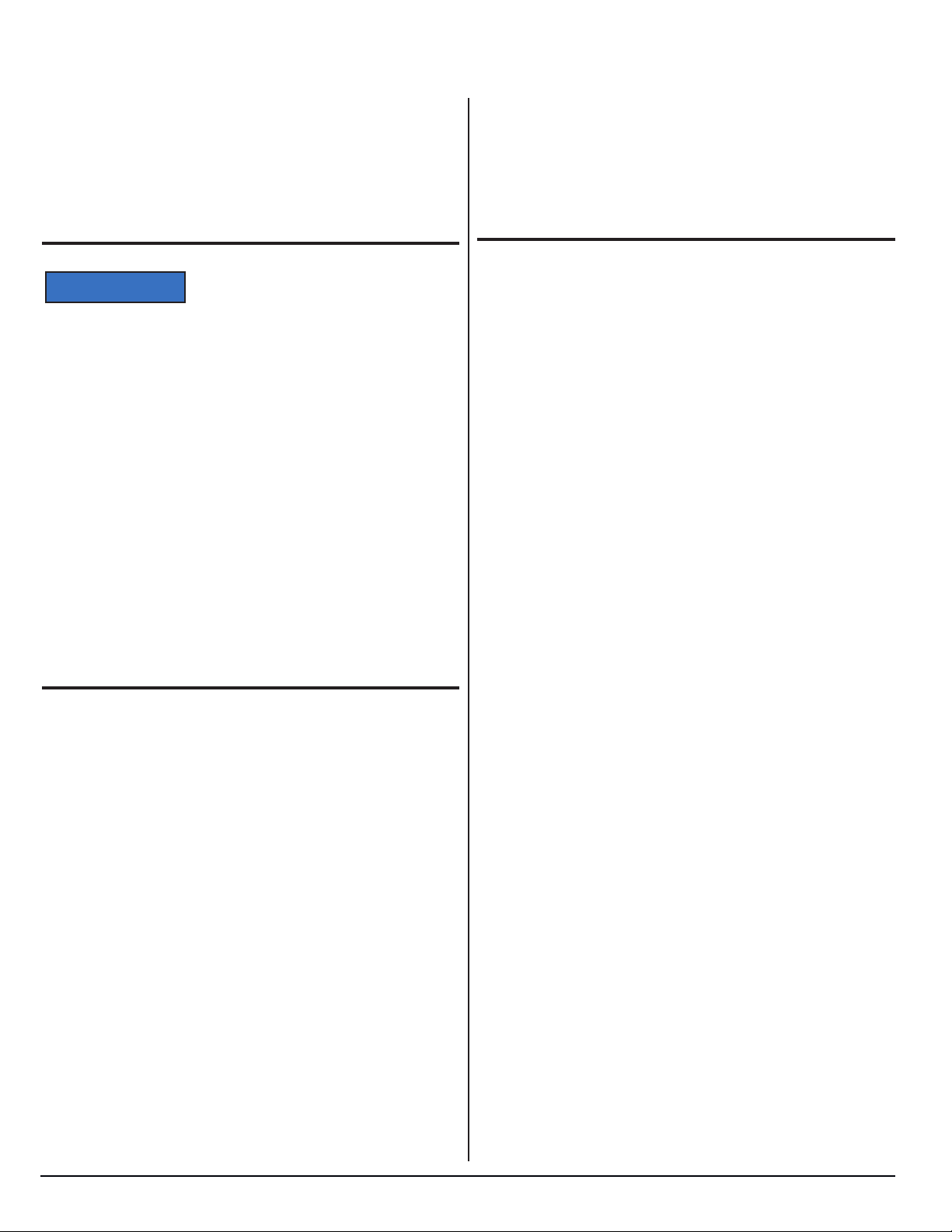

■ Touch and hold the Power ON / OFF button for between 20-23

seconds to change the mode between Auto Mode and Manual

Propane Gas Mode (See Fig. 12).

■ If the refrigerator is operating in Auto Mode, touch and hold

the ON / OFF button. The green power ON indicator light

will go out. Continue to hold the Power ON / OFF button

for between 20-23 seconds. When the power ON indicator

light comes on solid AMBER, release the Power ON / OFF

button. The refrigerator is now operating in Manual Propane

Gas Mode.

■ If the refrigerator is operating in Manual Propane Gas Mode,

touch and hold the ON / OFF button. The amber power ON

indicator light will go out. Continue to hold the Power ON /

OFF button for between 20-23 seconds. When the power

ON indicator light comes on solid GREEN, release the

Power ON / OFF button. The refrigerator is now operating in

Auto Mode.

■ If the power ON / indicator light is solid RED, there is a problem

and the refrigerator is not cooling. Refer to “Fault Codes N7V

and N8V Models” section.

Burn hazard! Allow canister and heaters

!

ATTENTION

■ A propane gas burner positioned below the boiler such that the

heat from the flame is directed across the surface of the boiler.

The controls energize the solenoid coil to open the gas valve.

Spring pressure closes the valve when the controls stop the flow

of current to the solenoid coil. The controls use an electronic

sparker to ignite the propane gas at the burner.

to cool before attempting to remove and

replace.

Touch and hold.

Green Amber Amber flashing

ON

OFF

Seconds 0 1 through 20 21 22 23 through

Fig. 12 - Change mode and temperature setting

Release here to

change mode.

Release here to

NOR000795A

30 31 32

www.norcold.com

15

SERVICE MANUAL

Page 16

NOTICE

USER INTERFACE (Controls) - N7V and N8V Models, cont’d.

A thermistor is mounted on the n assembly located inside the

fresh food compartment. The thermistor acts as a temperature sensor, reporting the temperature sensed to main control board (power

board) which turns on/off the appropriate heat source accordingly.

The user interface (controls), main control board assembly (power

board assemlby), thermistor, and other components within the

refrigerator are interconnected via a wire harness.

While the Power On indicator light is ashing, touch and release

the Power ON button to change to each of the three (3)temperature

settings, one at a time.

When the desired temperature setting is shown, touch and hold

the Power On button for ten (10) seconds to exit the temperature

setting mode. The Power ON / indicator light will stop ashing and

return to the solid GREEN or AMBER.

Air in the Propane Gas Supply Lines

For safety reasons, the refrigerator electronic controls are designed so that while

operating in Propane Gas Mode, the trial

for ignition (the maximum time that the

gas valve and the igniter can be left on

without a ame present) is limited to 30

seconds. When starting the refrigerator for

the rst time, after storage, or after replac-

ing the propane gas tanks(s), the propane

gas supply lines can have air in them.

Due to the air in the gas supply lines, the

burner may not ignite within the 30 second

time limit. If this happens, the gas valve

and igniter outputs will be turned off, the

propane gas mode will be “locked out,”

and the appropriate fault code will show in

the display.

The gas lock out condition can be reset

by powering the refrigerator OFF and

back ON, at which time a new 30 second

trial for ignition will begin. You may need

to repeat this procedure several times to

remove all of the air from the gas supply

lines.

Refrigerator Temperature Settings

Diagnostic Prechecks

Diagnosing fault codes begins by starting with the basics. In many

cases, the problem can be solved by verifying the unit is operating

in acceptable conditions:

■ The refrigerator is plugged into a known working AC outlet

with a voltage between 108VAC and 132VAC

■ Extension cords are not being used to supply AC power to

the refrigerator

■ The refrigerator is connected to a known working DC power

supply and/or battery supplying between 10.5 and 16.0

VDC

■ Propane gas is available to the refrigerator and is regulated

between 10.5 and 11.5” WC (Inches of Water Column).

The user interface (controls) has three (3) temperature settings.

The temperature setting can be changed within the temperature set

mode of the user interface (controls). To enter the temperature set

mode (See Fig. 12):

■ Touch and hold the ON / OFF button. The power ON indica-

tor light will go out. Continue to hold the Power ON / OFF

button. The power ON indicator light will come on after 20

seconds and go off again after 23 seconds. Continue to

hold the Power ON / OFF button. The power ON indicator

light will come on again after 30 seconds. Release Power

ON / OFF button.

The color of the power ON indicator light shows the current temperature setting of the refrigerator:

■ Green shows the COLD temperature setting.

■ Amber shows the COLDER temperature setting.

■ Red shows the COLDEST temperature setting.

Touch and release the Power ON button and the Power ON / indi-

cator light will ash on and off, which indicates that the temperature

setting can be changed.

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

16

www.norcold.com

Page 17

FAULT CODES - N7V AND N8V MODELS

NOR000123A

NOTICE

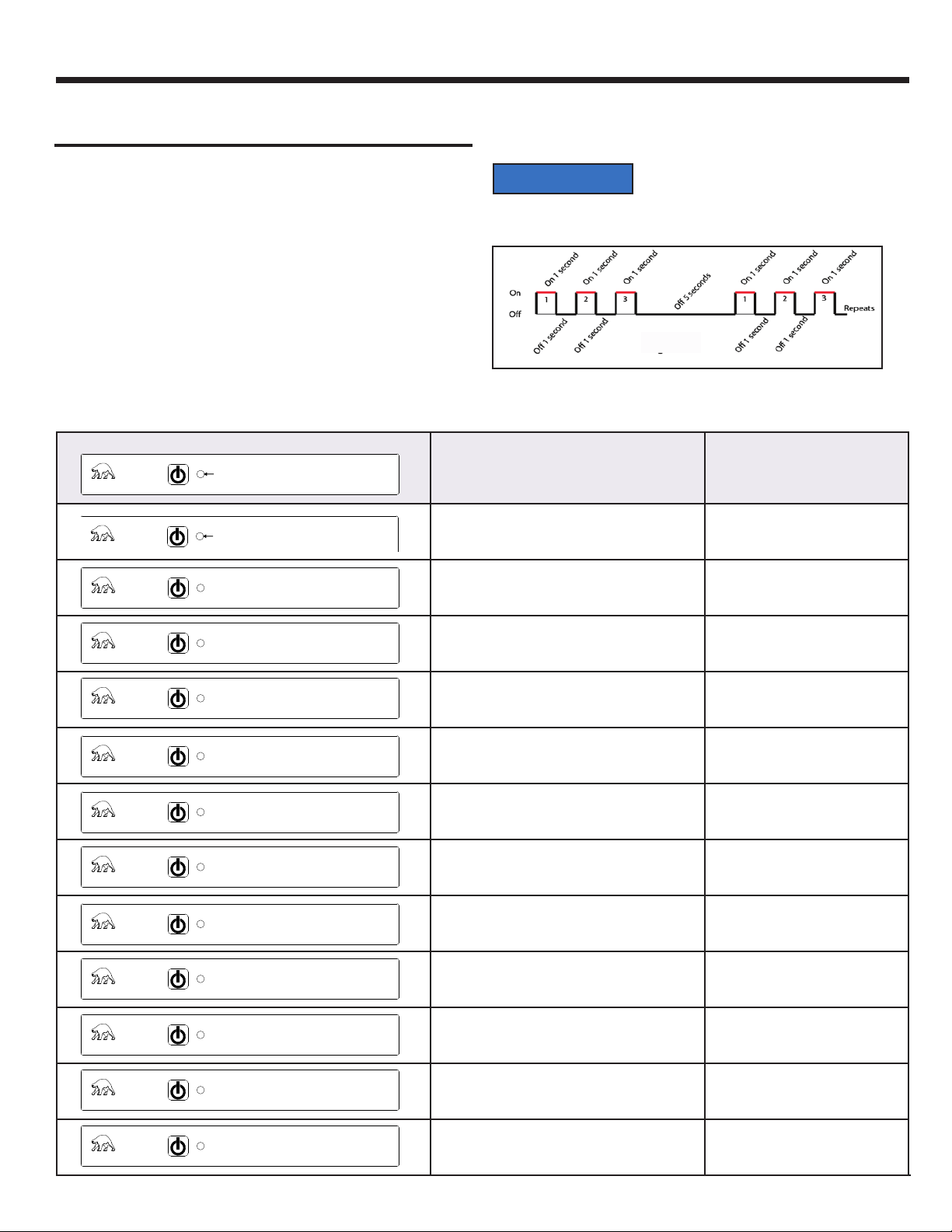

Fault Code Flash Patterns - N7V and N8V

Models

The user interface (controls) has the ability to recognize various

fault conditions and will display a unique error/fault code accordingly.

Should none of the heat source inputs be available, the power ON/

indicator light (See Fig. 12) will be solid RED.

ALL other fault codes will be displayed using ash patterns. The

term “ash pattern” means the power ON / indicator light is turned

ON and OFF to create a numeric pattern. These ash patterns di-

rectly correspond to particular fault codes. For example, fault code

3 will be indicated by ashing the power ON / indicator light RED

3-times, followed by a 5-second pause, and then repeated as long

as the fault condition is present (See Fig. 13).

Fault Code Flash Pattern Fault Code Meaning Action to Take

The refrigerator is not cooling if the power

ON / indicator light is either on solid RED

or ashes on RED.

NOROOO6123A

Fig. 13 - Example fault code ash pattern

NORCOLD

NORCOLD

NOR000647-

NORCOLD

NORCOLD

NORCOLD

NORCOLD

NORCOLD

NORCOLD

NORCOLD

Flash Pattern Appears Here

Red, on solid.

Red, flashes on one (1) time,

is off five (5) seconds, repeats.

Red, flashes on two (2) times,

is off five (5) seconds, repeats.

Red, flashes on three (3) times,

is off five (5) seconds, repeats.

Red, flashes on four (4) times,

is off five (5) seconds, repeats.

Red, flashes on five (5) times,

is off five (5) seconds, repeats.

Red, flashes on eight (8) times,

is off five (5) seconds, repeats.

Red, flashes on nine (9) times,

is off five (5) seconds, repeats.

The refrigerator tried to operate on the selected energy

source(s) with no success.

Refer to ”Fault - Code - Solid Red Indicator Light” on page 18.

AC heater fault. Refer to “Fault Code - Flash Pattern 1”

on page 20.

Internal control fault. Refer to “Fault Code - Flash Pattern 2”

on page 21.

Internal control fault. Refer to “Fault Code - Flash Pattern 3”

on page 21.

The AC heater relay stuck on. Refer to “Fault Code - Flash Pattern 4”

on page 21.

A flame is sensed at the burner when there should be

none present.

Refer to “Fault Code - Flash Pattern 5”

on page 22.

The DC input voltage to the refrigerator is too low. Refer to “Fault Code - Flash Pattern 8”

on page 22.

The DC input voltage to the refrigerator is too high. Refer to “Fault Code - Flash Pattern 9”

on page 22.

www.norcold.com

NORCOLD

NORCOLD

NORCOLD

NORCOLD

Red, flashes on ten (10) times,

is off five (5) seconds, repeats.

Green, flashes off once every

twenty seconds.

Amber, flashes off once every

twenty seconds.

Communications between the controls have been lost. Refer to “Fault Code - Flash Pattern 10”

on page 23.

The refrigerator is operating on AC electric power. The

thermistor has been sensed as inoperable, so the tem-

Refer to “Fault Code - Thermistor Fault”

on page 24

perature is being controlled via backup operating system.

The refrigerator is operating on propane gas. The thermistor has been sensed as inoperable, so the temperature

Refer to “Fault Code - Thermistor Fault”

on page 24.

is being controlled via a backup operating system.

The refrigerator is OFF. Refer to “Blank Display” on page 25.

17

SERVICE MANUAL

Page 18

TROUBLESHOOTING FLOWCHARTS - N7V AND N8V MODELS

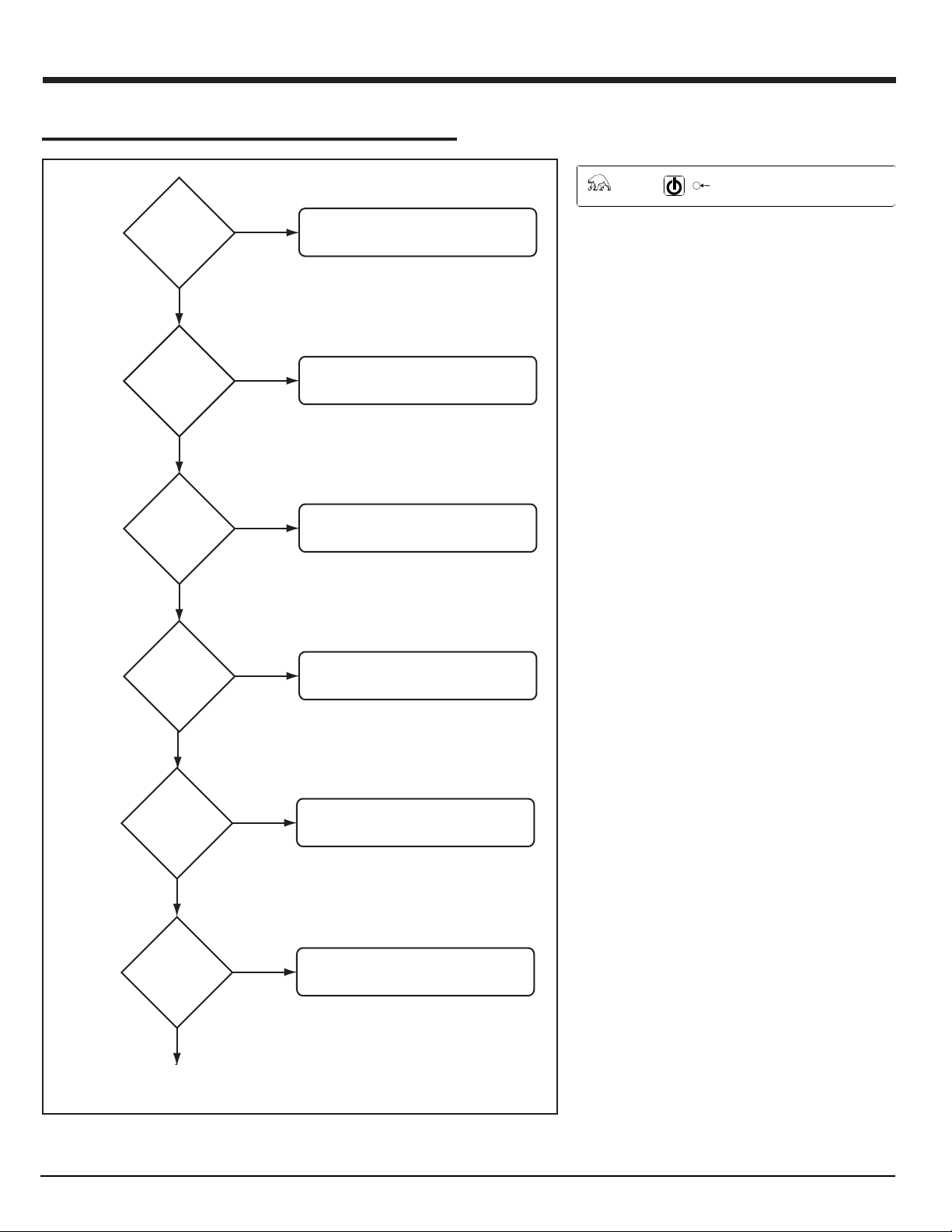

Fault - Code - Solid Red Indicator Light

Plugged

into working AC

outlet with min.

85 VAC?

YES

AC power

cord in good

working

condition?

YES

Is

8A fuse on

main control

board assy

(pwr board)

intact?

YES

NO

NO

NO

Correct AC outlet.

Replace AC power cord.

Replace fuse.

NORCOLD

Red, on solid.

Possible Cause:

120 VAC power is not available. Refrigerator defaulted to propane gas opera-

tion, but did not establish a ame.(Gas

Lockout).

Turn the refrigerator OFF and then back

ON to reset.

Are all

propane gas

valves open and

supply free of

air?

NO

YES

Is burner clean?

NO

YES

Is burner/

electrode gap

1/8”-3/16”?

NO

YES

Continued on following page.

Correct.

Clean burner.

Correct gap.

NOR000707A

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

18

www.norcold.com

Page 19

YES

Replace fuse.

NO

Is

8A fuse on

main control

board assy

(pwr board)

intact?

YES

Correct.

NO

Are all

propane gas

valves open and

supply free of

air?

YES

Clean burner.

NO

Is burner clean?

Correct gap.

NO

Is burner/

electrode gap

1/8”-3/16”?

TROUBLESHOOTING FLOWCHARTS - N7V AND N8V MODELS -

Fault - Code - Solid Red Indicator Light, cont’d.

Continued from previous page.

valve connected

YES

Spark/sense

wire installed

correctly w/

continuity?

YES

Gas valve

solenoid coil

resistance

74-92 Ohms?

YES

Wires to gas

w/continuity?

YES

NO

NO

NO

Correct. Replace spark / sense

ignitor wire if needed.

Replace gas train assembly.

Correct. Replace wires if needed.

Does

main control

board (pwr board)

supply 12VDC to

gas train?

YES

Replace gas train.

NO

Replace main control board assembly

(power board assembly).

NOR000707A

www.norcold.com

19

SERVICE MANUAL

Page 20

TROUBLESHOOTING FLOWCHARTS - N7V AND N8V MODELS, cont’d.

Fault Code - Flash Pattern 1

Before starting this procedure:

■ Make sure that the AC voltage to the refrigerator is 108-132

VAC.

■ Make sure no other appliance or lighting circuit is connected to

the refrigerator AC circuit.

Check AC heater wires

for loose or damaged

connections

Heater

connections

okay?

YES

NO

NORCOLD

Repair or replace connectors. If

connectors cannot be repaired,

replace AC heater.

Red, flashes on one (1) time,

is off five (5) seconds, repeats.

The AC is off when it should be on. AC

heater “lockout”. Turn the refrigerator

OFF and then back ON to reset.

Possible Cause:

AC heater fault.

The AC heater is not plugged in.

The AC heater failed open.

Check AC heater resistance.

See figure, below.

Resistance

38-50 Ohms?

YES

NO

Replace AC heater.

Replace main control board assembly

(power board assembly).

NOR000715A

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

20

www.norcold.com

Page 21

TROUBLESHOOTING FLOWCHARTS - N7V AND N8V MODELS, cont’d.

Fault Code - Flash Pattern 2

valve wires

plugged in?

To reset fault, power

refrigerator OFF and

then back ON.

continue?

NOR000706A

Are gas

YES

Does

problem

NO

NO

YES

Correct.

Solved.

Replace main control board assembly

(power board assembly).

NORCOLD

Red, flashes on two (2) times,

is off five (5) seconds, repeats.

Possible Cause:

The main control board assembly (power board) detected an internal fault. This

fault can be displayed in any MODE.

Fault Code - Flash Pattern 3

On the main control board

assembly (power board),

the limit circuit is open.

NOR000804A

Fault Code - Flash Pattern 4

On the main control board

assembly (power board), the

AC heater relay is stuck closed.

NOR000708A

Replace the main control board

assembly (power board).

Replace main control board assembly

(power board).

NORCOLD

NORCOLD

Red, flashes on three (3) times,

is off five (5) seconds, repeats.

Possible Cause:

On the main control board assembly

(power board), the limit circuit is open.

Red, flashes on four (4) times,

is off five (5) seconds, repeats.

Possible Cause:

On the main control board assembly

(power board), the AC heater relay is

stuck closed.

www.norcold.com

21

SERVICE MANUAL

Page 22

TROUBLESHOOTING FLOWCHARTS - N7V AND N8V MODELS, cont’d.

Fault Code - Flash Pattern 5

The gas valve is

“mechanically” stuck open.

NOR000709A

Replace gas train assembly

Fault Code - Flash Pattern 8

Correct the DC input voltage to the regerator. Make sure the input

voltage is 12.0 VDC.

NORCOLD

NORCOLD

Red, flashes on five (5) times,

is off five (5) seconds, repeats.

A ame is sensed at the burner when

there should be none present.

Possible Cause:

The gas valve is “mechanically” stuck

open. Therefore, the main control board

senses a ame is present at the burner

when there should be none

Red, flashes on eight (8) times,

is off five (5) seconds, repeats.

Possible Cause:

The DC input voltage to the refrigerator

is too low.

Fault Code - Flash Pattern 9

Correct the DC input voltage to the regerator. Make sure the input

voltage is 12.0 VDC.

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

22

NORCOLD

Red, flashes on nine (9) times,

is off five (5) seconds, repeats.

Possible Cause:

The DC input voltage to the refrigerator

is too high.

www.norcold.com

Page 23

TROUBLESHOOTING FLOWCHARTS - N7V AND N8V MODELS, cont’d.

Fault Code - Flash Pattern 10

Check that the blue wire, within the main

wire harness, is fully plugged in; both at

P1-14 of main control board assembly

(power board) and P1-3 of user interface

(optical display).

NORCOLD

Red, flashes on ten (10) times,

is off five (5) seconds, repeats.

Possible Cause:

Fully

plugged

in?

NO

YES

With the wire harness unplugged from the

main control board assembly (power

board) and the user interface (optical

display), check continuity of the blue wire

to make sure the wire is not “open”.

Continuity?

YES

NO (OPEN)

Replace the refrigerator.

Correct connections.

Check that there is NO continuity

between the blue wire and ground.

YES

Continuity?

Communications between the user

interface (controls) and the main control

board assembly (power board) have

been lost.

Shorted to ground.

Replace the refrigerator.

NOR000796A

NO

Check that there is NO continuity

between the blue wire and any of the

other wires of the wire harness.

YES

Continuity?

NO

Reconnect the wire harness at main

control board assembly (power board)

and the user interface (optical display).

Replace the main control board assembly

(power board).

Shorted to another wire.

Replace the refrigerator.

www.norcold.com

23

SERVICE MANUAL

Page 24

TROUBLESHOOTING FLOWCHARTS - N7V AND N8V MODELS, cont’d.

Fault Code - Thermistor Fault

Is

thermistor

wire plugged

in?

NO

Plug in thermisor wire.

YES

Check thermistor wire

assembly and connctor

for broken/dirty connections.

Are

wires and

connector

good?

NOR000711A

Temperature* (°F) Resistance* (k Ω)

85 8.1 - 9.0

80 9.1 - 10.0

75 10.1 - 11.0

70 11.1 - 12.0

60 12.1 - 13.0

50 15.5 - 16.5

40 22.5 - 23.5

35 24.5 - 25.5

33 28.5 - 29.5

32 30.0 - 32.0

* Approximate values

NO

YES

Clean or repair as needed.

Check resistance at thermistor connector

with the thermistor packed in ice.

NORCOLD

NORCOLD

Green, flashes off once every

twenty seconds.

Possible Cause:

The refrigerator is operating on AC

electric power. The thermistor has been

sensed as inoperable, so temperature

is being controlled via backup operating

system.

Amber, flashes off once every

twenty seconds.

Possible Cause:

The refrigerator is operating on propane

gas. The thermistor has been sensed

as inoperable, so temperature is being

controlled via backup operating system.

Polar Series N7V, N7X, N7XL / N8V, N8X, N8XL

24

www.norcold.com

Page 25

Blank Display

Before starting this procedure verify:

■ Vehicle DC voltage to the refrigerator is 10.5 to 16.0 volts.

■ No other appliance or lighting circuit is connected to the refrig-

erator DC circuit.

■ DC input of the vehicle is wired into the main control board ac-

cording to the Refrigerator Installation Manual.

Touch Power ON button

to turn refrigerator on.

Refrigerator

turns ON?

YES

No problem.

NO

Measure DC input voltage to main

control board (power board)

at terminals 12VDC and GND.

10.5 to

16.0 VDC?

YES

NO

NORCOLD

Blank display.

Possible Cause:

The refrigerator will not turn ON.

Correct DC input

to refrigerator.

Check continuity of F1 fuse

located on main control board

(power board).

Measure voltage at main control

board (power board) between

P1-9 (white/violet) and P1-12 (green)

Measure voltage at user interface

(controls) wire harness between P1-1

(green) and P1-5 (white/violet).

YES

YES

YES

Is fuse intact

(zero ohms)?

10.5 to

16.0 VDC?

10.5 to

16.0 VDC?

NO

NO

NO

Replace fuse

(5-Amp MINI Blade

Automotive style)

Replace main

control board

(power board).

Check connection/continuity of

green wire between main control

board (power board) (P1-12) and

user interface (controls (P1-1).

Check connection/continuity of

white/violet wire between main

control board (power board) (P1-9)

and user interface (controls (P1-5).

NOR000803A

Replace user interface assembly.

www.norcold.com

25

Call Customer Service.

SERVICE MANUAL

Page 26

USER INTERFACE (CONTROLS) - N7X AND N8X MODELS

NORCOLD

NOR000648A

D E

A

MODE

HF

A B G C

Fig. 14 - N7X and N8X user interface (control) locations

No. Description

A Power ON / OFF Button

B Mode Button

C Temperature Set Button

D Power ON / Indicator Light

E Temperature Setting Indicators

F AUTO Mode Indicator

G AC Mode Indicator

H Gas Mode Indicator

Power ON / OFF Button

Touch the Power ON / OFF button (See Fig. 14, A) to turn on the

refrigerator.

Touch and hold the Power ON / OFF button for one (1) second to

turn off the refrigerator.

■ MANUAL AC mode: The refrigerator operates using only AC

electric as the power source and the AC mode indicator only

comes on.

■ MANUAL GAS mode: The refrigerator operates using only

propane gas as the power source and the propane gas mode

indicator only comes on.

Temperature Set Button

Touch and release the Temperature Set button (See Fig. 14, C) to

view the current temperature setting.

Then touch and release the Temperature Set button to change the

temperature settings, one at a time.

Or touch and hold the Temperature Set button to scroll through

temperature settings, one after the other. Release the Temperature Set button when the desired temperature setting appears.

There are ve (5) temperature settings.

Temperature Setting Indicators

There are ve (5) temperature setting indicators (See Fig. 14, E).

■ When only one (1) temperature setting indicator is on, the tem-

perature setting is the warmest.

■ When all five (5) temperature setting indicators are on, the tem-

perature setting is the coldest.

Gas Mode Operation

Mode Button

The mode button is manually operated and does not automatically

change the operating mode of the refrigerator.

Touch and hold the Mode button (See Fig. 14, B) to scroll through

the available modes of operation of the refrigerator, one after the

other. When the desired mode indicator(s) comes on, release the

Mode button.

Or touch and release the Mode button to change the available

modes of operation one at a time. There are one (1) Automatic and

two (2) Manual Modes of operation.

■ AUTO Mode: The AUTO Mode indicator (See Fig. 14, F) comes

on and the refrigerator controls automatically select the most

efficient energy source that is available.

■ If available, the refrigerator controls select AC electric as the

power choice and the AC mode indicator (See Fig. 14, G)

comes on also.

■ If AC electric is not available, the controls select gas as the

power choice and the gas mode indicator (See Fig. 14, H)

comes on also.

In AUTO GAS mode and MANUAL GAS mode, the controls energize the solenoid coil to open the gas valve. Spring pressure closes

the valve when the controls stop the ow of current to the solenoid

coil.

The propane gas burner will cycle in response to the n temperature to maintain cabinet temperature.

The controls use an electronic sparker to ignite the propane gas at

the burner.

When either AUTO or MANUAL GAS mode is selected, the refrigerator attempts to ignite the propane gas burner. If unable to ignite