Norcold N611V, N811V Service Manual

Service Manual

!

Gas / Electric Refrigerators

MODELS

N611v Series

N811v Series

WARNING

DO NOT install this refrigerator in below deck marine applications. Do not

install this refrigerator in fi xed indoor cabin or other dwelling applications. This

refrigerator must use only NORCOLD designed and approved outside air intake

and exhaust ventilation for correct and safe operation. Any other ventilation

could cause lethal combustion exhaust fumes and/or explosive propane gas

fumes to be in the living area and/or below deck.

Questions?/Des questions?/¿Preguntas? 1-800-444-7210

© 2013 NORCOLD, INC. All rights reserved.

Publication No. 636355 A (15-01-2014)

CONTENTS

Introduction ..................................................................................................3

About this Manual ...................................................................................3

Model Identification .................................................................................3

Information Label ....................................................................................3

Certification and Code Requirements .....................................................3

About Installation ....................................................................................3

Replacement Parts .................................................................................3

T echnical Assistance ...............................................................................3

Model Identifi cation .....................................................................................4

Cooling Unit Serial Number ....................................................................4

Safety Awareness ........................................................................................5

Safety Notice ...........................................................................................5

Attention Statements ...............................................................................5

Safety Statements ...................................................................................5

Specifi cations ..............................................................................................6

Theory of Operation ....................................................................................7

Overview .................................................................................................7

Cooling Unit ............................................................................................7

Leveled Operation ...................................................................................7

Gradual Decrease in Cooling Efficiency .................................................7

Gas Absorption System .......................................................................... 8

Electronic Controls ..................................................................................9

Theory of Operation - Auto Modes ........................................................9

Background Operations ........................................................................10

Fault Codes ............................................................................................... 12

Diagnostic Prechecks ...........................................................................13

Fault Code Flash Patterns ....................................................................13

Solid Red Indicator Light ................................................................13

Fault / Flash Pattern 2 Service Error ..............................................14

Fault / Flash Pattern 3 Open High Limit .........................................14

Fault / Flash Pattern 4 AC Relay Error ........................................... 14

Fault / Flash Pattern 5 Flame On, Should Not Be On ....................14

Fault / Flash Pattern 8 LOW DC (1) Error ......................................15

Fault / Flash Pattern 9 LOW DC (2) Error ......................................15

Thermister Fault .............................................................................15

Door Fault .......................................................................................15

Blank Display ..................................................................................16

LP Gas System .........................................................................................18

Pressure Requirements ........................................................................18

Testing for LP Gas Leaks ......................................................................18

Components ..........................................................................................19

Flame Appearance ................................................................................ 20

Burner Cleaning Procedure ..................................................................21

Gas Lockout ..........................................................................................23

Reset a Gas Lockout Condition - All Models ......................................... 23

Gas Safety Valve Test ........................................................................... 23

Electrical Requirements and Components ................................................ 24

DC Voltage Requirements and Polarity ................................................24

DC Power Wiring Requirements ........................................................... 24

AC/DC Converter as Power Source ......................................................24

12VDC Ventilation Fan .......................................................................... 24

Cooling Unit ...............................................................................................26

Cooling System Monitoring ................................................................... 26

Troubleshooting Cooling Faults ............................................................26

Refrigerant Leakage .............................................................................26

Disposal of Cooling Unit ........................................................................26

Cooling System Diagnostic Flowchart ..................................................27

Wiring Pictorial ..................................................................................... 29

Modes Of Operation .................................................................................. 30

Refrigerator Start-Up .............................................................................30

Refrigerator Shut-Down ........................................................................30

Effects of High Altitude on Propane Gas Operation ..............................30

Effects of Freezing Temperatures on Refrigerator Operation ...............30

Figures

Fig. 1 - Refrigerator Information Label Location .............................. 4

Fig. 2 - Cooling Unit Bar Code Label Location. ................................4

Fig. 3 - Gas Absorption System ........................................................8

Fig. 4 - Flash Patterns ....................................................................13

Fig. 5A - Thermistor .......................................................................16

Fig. 5B - Thermistor in Ice ..............................................................16

Fig. 6 - Continuous 12-Volt ............................................................17

Fig. 7 - Switch 12-Volt ....................................................................17

Fig. 8 - LP Gas System Components. ............................................ 18

Fig. 9 - Solenoid Gas Valve. ...........................................................19

Fig. 10 - LP15 Orifice Assemblies ..................................................19

Fig. 11 - Burner ...............................................................................19

Fig. 12 - Burner Tube ......................................................................19

Fig. 13 - Flue and Components ...................................................... 20

Fig. 14 - Flue Baffle ........................................................................20

Fig. 15 - Flame Appearance ........................................................... 20

Fig. 16 - Drip Cup and Burner Box Cover .......................................22

Fig. 17 - Burner and Components .................................................22

Fig. 18 - AC Power Cord. ................................................................25

Fig. 19 - Fan Mounted on Top of Absorber Coil. ............................. 25

Fig. 20 - Fan Thermostat. ............................................................... 25

Fig. 21 - Fan with Installed NORCOLD Fan Kit. ............................. 25

Fig. 22 - NORCOLD Fan Kit Wiring Pictorial. ................................ 25

Fig. 23 - Reset Pushbutton .............................................................26

Fig. 24 - Cooling System Diagnostics .............................................27

Fig. 25 - Wiring ..............................................................................29

Fig. 26 - Wiring ..............................................................................29

2

www.norcold.com/cda

Refrigerator Service ManualN611v, N811v Models

INTRODUCTION

About this Manual

This service manual provides maintenance, diagnostic, and

repair information for NORCOLD

gas absorption refrigerators. It is a reference tool designed

for technicians who are knowledgeable in the theory and

operation of gas/electric absorption refrigerators, liquefi ed

petroleum (LP) gas–propane–systems, and AC/DC electrical

systems as installed in a variety of recreational vehicles (RV).

All information, illustrations, and specifi cations contained in

this publication are based on the latest product information

available at the time of publication. NORCOLD

right to make changes at any time without notice.

®

models N611v, N811v

®

reserves the

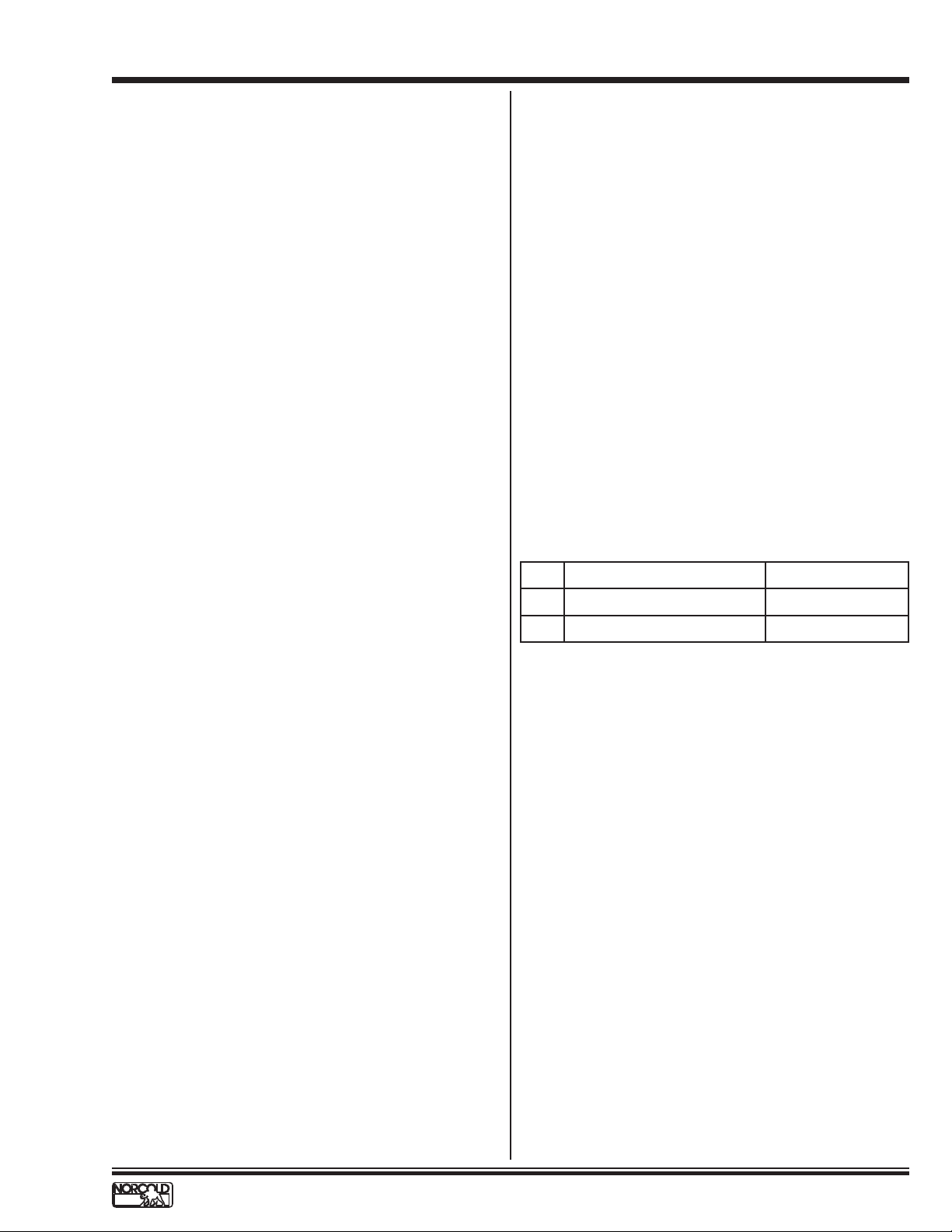

Model Identifi cation

Models N611v and N811v are 2-way refrigerators that operate

on AC power or LP gas.

Letter(s) appended to the model number identify factory

installed accessories. See Fig. 1.

Information Label

The information label is located in the upper right corner of the

fresh food compartment just below the divider. See Fig. 1. The

label provides the following information:

• Serial number.

• Model number.

• LP gas (propane) pressure.

• Btu/h.

• AC voltage and amperage.

• DC voltage and amperage.

• Design certifi cation.

• Vent kit requirement.

Certifi cation and Code Requirements

NORCOLD® N611v, N811v gas/electric absorption refrigerators

are certifi ed under the latest edition of ANSI Z21.19B

standards for installation in mobile homes or recreational

vehicles, and with the Canadian Standards Association CAN/

CGA-1.4-M94.

Electrical components are

compliant.

About Installation

Refrigerator installation must conform with the N611v, N811v

Installation Manual for the NORCOLD

in effect. Installation must also comply with applicable local

codes and standards set by the relevant certifi cation agency.

®

limited warranty to be

Replacement Parts

Use only authorized NORCOLD® replacement parts.

Generic parts do not meet NORCOLD

safety, reliability, and performance. The use of unauthorized

aftermarket or generic replacement parts voids the

refrigerator's limited warranty coverage.

®

specifi cations for

T echnical Assistance

If unable to resolve technical issues using the information

provided in this manual, technical support is available through

NORCOLD

The following information is required to process technical

support requests; refer to the following page:

• Refrigerator Model Number

• Refrigerator Serial Number

• Refrigerator Cooling Unit Serial Number

• Recreational Vehicle (RV) Make/Model/Year

®

Customer Service Center:

Telephone: 1-800-444-7210.

Fax: 1-734-769-2332

World Wide Web: www.norcold.com.

www.norcold.com/cda

N611v, N811v ModelsRefrigerator Service Manual

3

MODEL IDENTIFICATION

xxxxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxx

ORC

N

xxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

NORCOLD

A

Serial Number

Model Number

B

Group Code

C

Input Pressure

BTUH

xxxxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxx

xxxxxxxxxxxxxxx

OLD

G

I

N

S

E

D

xxxxx

xxxxxx

xxxx

SA

C

E

xxxxx

i

E

F

R

T

I

xxxxxxxxxxxxxxxxxxxxxxx

x

x

x

xx

x

x

x

x

x

x

x

x

xx

x

x

x

x

x

x

x

xx

x

x

x

D

xxxxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxx

E

Refrigerant

x.xx

LBS.

test pressure

xxx VOLTS - AC xx HZ

x.xx AMPS xxx Watts

xx VDC xx HZ

x.x AMPS xx xx Watts

SA

Certied

Serial Number / Model Number Location

Fig. 1 - Refrigerator Information Label Location

Explanation

N = Norcold

1

X = Sequence number indicating custom features

2

6 or 8 = Approximate storage volume in cubic feet

3

X = Sequence number indicating custom features

4

Models available. Blank = 2-Way operation

5

Icemaker unit. Blank = does not have ice maker, IM = has icemaker

6

Blank = Is not equipped for low ambient operation, C = Is equipped for low ambient operation

7

Door design: Blank: Insert panel doors, SS: Stainless steal wrapped, BK: Black wrapped, WH:

8

White wrapped, WPM: Pewter Royce wrapped

Fan: Blank: No fan, F = Equipped (1) Fan, F2 = Equipped (2) Fans, V = Equipped (1) High

9

Velocity Fan

Door swing: L = Left-hand door swing, R = Right-hand door swing

10

P=Black acrylic door panels

11

Packaging Type: Blank: Corrugated packaging, T = Returnable packaging tray, M6 = 6-unit

12

multi-pack

A. Serial Number

F

G

I

G

S

E

N

D

B. Model Number

C. Group Code

D. Btu/h

E. Amount of refrigerant in cooling

C

E

D

R

E

i

F

T

I

unit

F. AC Voltage/amperage

G. DC Voltage/amperage

NX610.3 IM C BK X R P T

Note: The actual refrigerator label specifi es the features applicable to that unit.

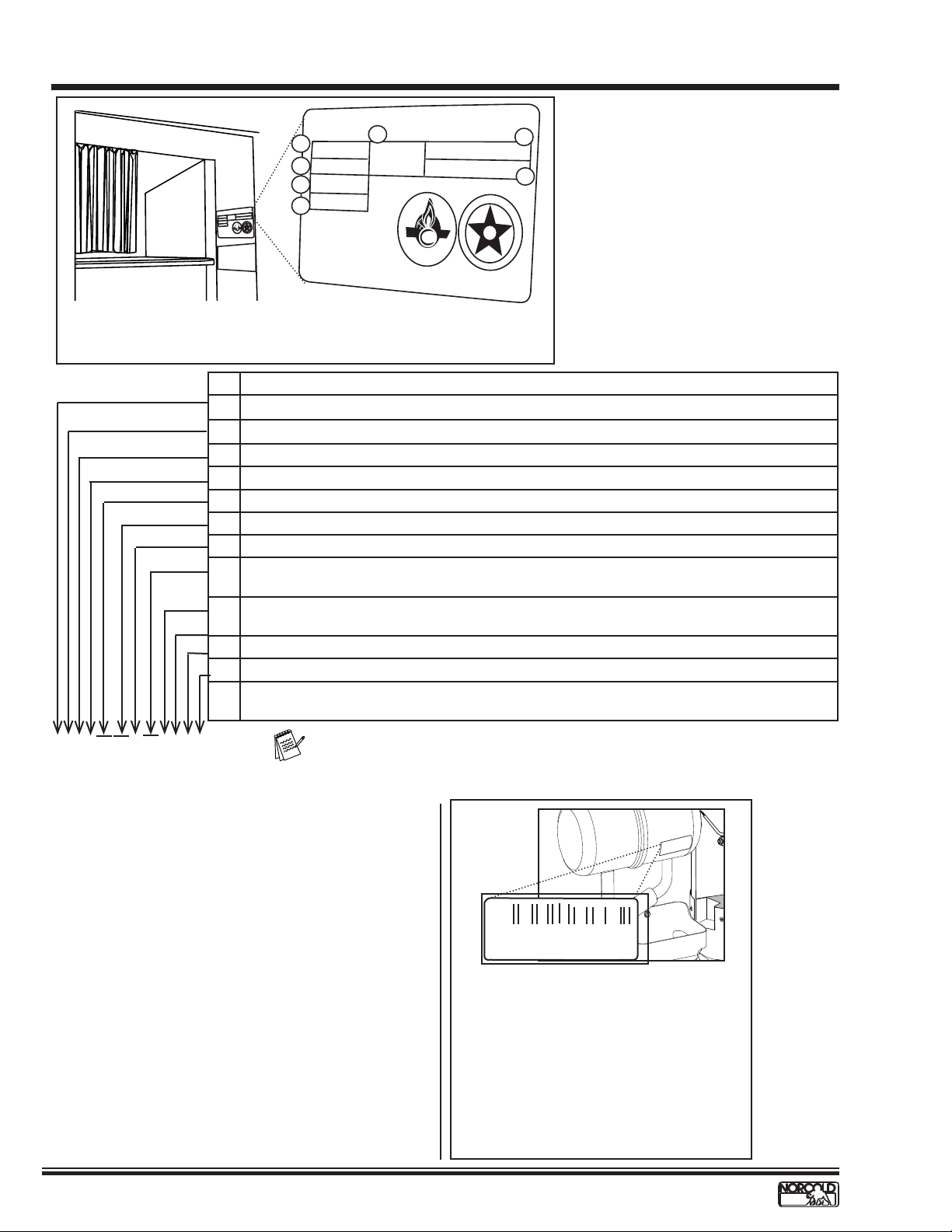

Cooling Unit Serial Number

The cooling unit serial number appears on the cooling unit bar

code label. The label is affi xed to the surface of the cooling

unit leveling chamber.

NORCOLD

1167359

Cooling Unit Bar Code Location

Be sure to have the cooling unit serial

number available if you need technical

support on this component.

Fig. 2 - Cooling Unit Bar Code

Label Location.

4

www.norcold.com/cda

Refrigerator Service ManualN611v, N811v Models

SAFETY AW ARENESS

Safety Notice

It is not possible to anticipate all of the conceivable ways

or conditions under which the refrigerator may be serviced

or to provide cautions as to all of the possible hazards that

may result. Standard and accepted safety precautions and

equipment should be used when working on electrical circuits

and handling toxic or fl ammable materials. Safety goggles and

other required protection should be used during any process

that can cause material removal, such as when removing a

leaking cooling unit and cleaning components.

!

WARNING:

The above heading identifi es hazards or conditions,

which if ignored can cause serious injury , death, and/

or extensive property damage.

Attention Statements

The safety alert symbol

CAUTION identifi es potential safety hazards or conditions.

The safety alert symbol with the appropriate heading appears on

all safety labels posted on the refrigerator and safety awareness

notices presented throughout this manual.

!

followed by the word WARNING or

Safety Statements

!

Do not modify, alter, or equip the refrigerator to the use

of any other fuel (natural gas, butane, etc.). N611v, N811v

refrigerators are designed and equipped for the use of LP

gas–propane gas–only.

!

Incorrect installation, adjustment, alteration, or maintenance

of the refrigerator can cause personal injury, property

damage, or both.

!

Do not smoke, light fi res, or create sparks when working on

the propane gas system.

!

Do not use an open fl ame for leak testing any of the

propane gas system components. Propane gas is highly

fl ammable and explosive.

!

Always use two wrenches to tighten or loosen LP

gas connections. Damaged connections, piping, and

components create the potential for gas leaks.

!

All electrical connections and repairs to the refrigerator

must comply with all applicable codes. Refer to the

certifi cation and code requirements section of the N611v,

N811v Installation Manual.

!

Do not work on live electrical circuits. Turn off AC power

and DC power sources before attempting to remove,

service, or repair any of the refrigerator's electrical or

electronic components.

!

Do not modify, bypass, or eliminate any of the refrigerator's

electrical components, electronic circuits, or propane gas

system components.

!

Do not wet or spray liquids on or near electrical

connections or electronic components. Most liquids,

including leak detection solutions, are electrically

conductive and pose the potential for an electric shock

hazard, short electrical components, damage electronic

circuits, and/or ignite a fi re.

!

CAUTION:

The above heading identifies hazards, which if

ignored can cause injury and/or property damage.

!

Do not use leak test solutions that contain ammonia or

chlorine. Ammonia and chlorine degrade copper and brass

components.

!

The cooling unit is a sealed system under pressure! Do

not try to repair or recharge the cooling unit. Do not bend,

drop, weld, drill, puncture, saw, or strike the cooling unit.

!

Handle a leaking cooling unit with extreme caution!

The cooling unit contains ammonia, hydrogen, and sodium

chromate. Ammonia can cause severe skin and eye burns.

Hydrogen is highly fl ammable, can ignite and burns with

an intense fl ame. Certain chromium compounds, such as

sodium chromate, are carcinogenic.

!

Do not use extension cords. Do not remove the grounding

prong from the refrigerator AC power cord. Do not use a

two prong adapter to connect the refrigerator to the AC

outlet.

!

Do not over-fuse electrical circuits. Use specifi ed fuses

and AWG wire sizes. The specifi cation section of this

manual provides fuse size information. Refer to the N611v,

N811v Installation Manual for the correct AWG wire size

specifi cations.

!

Prevent child entrapment! Before disposing of the

refrigerator, remove all doors and fasten all shelves with

retainers.

!

Some of the refrigerator's metal components have sharp

corners and edges. Wear hand protection, such as cut

resistant gloves, and exercise extreme care when handling

the refrigerator.

!

Make sure all hardware such as hinges and fasteners

(retaining screws, etc.), are properly fastened.

www.norcold.com/cda

N611v, N811v ModelsRefrigerator Service Manual

5

SPECIFICATIONS

N611v / N811v - Electronic

• Push Button - On/Off

• LED Indicator Lights

• Self-Diagnostic with Fault Indicators

• 2-Way Operation

Rough opening dimensions (H x W x D)

N611v ---------------------------------------------------------------------------------------------------- 52 7/8 in. x 23 1/2 in. x 24 in.

N811v ---------------------------------------------------------------------------------------------------- 59 7/8 in. x 23 1/2 in. x 24 in.

Decorative panels dimensions

Thickness -------------------------------------------------------------------------------------------------------------------------3/16 in.

Freezer door (H x W, both models) ----------------------------------------------------------------15 11/16 in. x 21 19/32 in.

Upper panel ---------------------------------------------------------------------------------------------- 15 11/16in. x 21 19/32in.

Fresh food compartment (H x W)

N611v --------------------------------------------------------------------------------------------------- 32 25/32 in. x 21 19/32 in.

N811v ---------------------------------------------------------------------------------------------------- 39 25/32 in. x 21 19/32 in.

DC power

DC input voltage requirements --------------------------------------------------------------------------- 10.5VDC to 15.4VDC

DC Fuse, F1 on Power Board --------------------------------------------------------Automotive Blade, Type APR-5A-Tan

Divider Heater ------------------------------------3.1W/12VDC, (43Ω to 50Ω), Current ≈ 240mA to 279mA @ 12VDC

Gas Valve ------------------------------- 1.75W/12VDC, (74Ω to 92Ω), Current ≈ 130mA to 162mA @ 12VDC

Interior Light -------------------------------------------------GE #214, Miniature Automotive Light Bulb, ½ A @ 13.5VDC

AC power

AC input voltage requirements ------------------------------------------------------------------------------108VAC to 132VAC

AC Fuse, F2 on Power Board ------------------------- AGC Series, 8A, Fast Acting, Glass Tube (1/4 in. x 1-1/4 in.)

AC Heater--------------------------------------------- 300W/120VAC, (46Ω to 51Ω), Current ≈ 2.3A to 2.6A @ 120VAC

LP gas (propane)

Operating pressure (Input pressure to gas valve) -----------------------------------------------------10.5 to 11.5 in. W.C.

Burner rating (Heat output) ---------------------------------------------------------------------------1420 Btu/h @ 11 in. W.C.

Burner orifi ce size -----------------------------------------------------------------------------------------------------------------LP15

Gas ignition ------------------------------------------------------------------------------------------Electronic with fl ame sensing

Electrode tip-to-burner gap -------------------------------------------------------------------------------------------1/8 to 3/16 in.

Off-level operating limits

Side-to-side------------------------------------------------------------------------------------------------------3 degrees-maximum

Front-to-back ----------------------------------------------------------------------------------------------------6 degrees-maximum

Temperature Sensor ---------------------------------------- ---------- Thermistor, Fin mounted (10th fi n from the right)

6

www.norcold.com/cda

Refrigerator Service ManualN611v, N811v Models

THEORY OF OPERATION

Overview

The N611v, N811v MODEL gas absorption refrigerators are

comprised of two separate systems that together allow the

refrigerator to cool. When performing service it is important

to have a basic understanding of each system and their

interaction with one another and how this interaction provides

for cooling/refrigeration.

These two “systems” are the:

• Cooling Unit

• Refrigerator Controls (Electronic Controls)

Cooling Unit

The cooling unit is a self-contained gravity fl ow absorption

refrigeration system. The refrigerant charge is a solution of

water, ammonia, sodium hydroxide, and sodium chromate.

In order to produce cooling a precise heat must be applied to

the boiler area which in turn initiates a chemical reaction that

extracts heat from the freezer and fresh food compartments,

thus providing "cooling."

This precise heat is supplied to the cooling unit via heaters

and/or a LP gas burner which are controlled by the

refrigerators electronic controls. The refrigerant transfers the

heat from the freezer and fresh food cabinets to the absorber

coils. At the absorber coils the metal surface absorbs the heat

and air fl ow over the external surfaces of the coils carries

the heat away. A more detailed description of the absorption

process can be found under the heading “Cooling Unit

Detailed Description" on the following pages.

A thermal air current created by the rising hot air fl ows out of

the enclosure through either a roof exhaust vent or a sidewall

exhaust vent (depending on installation). The fl owing air

mass passes over the surface of the condenser fi ns where it

absorbs heat transferred from the ammonia vapors fl owing

through the condenser. The thermal airfl ow process creates

a "chimney effect" that creates a continuous draft of cooling

and combustion air. The fresh air drafted by the chimney effect

removes rejected heat, supports combustion, and expels

the exhaust gases produced by the combustion process.

Obstructions, restrictions, or modifi cations to vents or the

enclosure will affect the heat absorption cycle. Poor cooling

unit performance may be due to:

• Loose insulation interfering with the ventilation process

• Construction material or debris left in the enclosure

• Insect screen covering vents

• Plastic sheeting covering vents

• Items stored in the enclosure

• Modifi cations to vents or enclosure

• No roof or sidewall vent openings

Leveled Operation

The circulation of the refrigerant through the cooling unit is

accomplished by gravity fl ow; therefore, the refrigerator must

be operated leveled. Off-level operation affects the fl ow of the

refrigerant through the cooling system. The maximum off-level

operation limits are:

• 3° (Degrees) from side-to-side

• 6° (Degrees) from front-to-back

Exceeding the maximum off-level limits can permanently

damage the cooling unit. The cooling unit or its performance is

not affected when the vehicle is in motion.

Gradual Decrease in Cooling Effi ciency

A gradual decrease in cooling effi ciency is not a clear

indication of cooling system failure. Other factors that affect

cooling effi ciency include ventilation, the heat input, off-level

operation, lack of service and maintenance, inadequate

repairs, or unauthorized fi eld modifi cations. If any of these

factors exist and are not corrected, a replacement cooling

unit will also perform ineffi ciently or fail. Step-by-step

troubleshooting is the best approach when dealing with

a gradual decrease in cooling. It is important to consider

that, though not effi ciently, the cooling unit is working.

Troubleshooting should always begin by checking ventilation,

then thoroughly checking the cooling unit, and heat sources.

In the majority of reported cases, the problem is related to

the installation, which in turn hinders cooling unit ventilation.

Additionally, ambient air temperature plays a signifi cant role

if the unit is not installed correctly. Incorrect installation can

lead to poor ventilation, which in turn relates to poor cooling

performance.

The unit's service and maintenance history should be

considered when checking a cooling unit for poor cooling

performance. The service history and the scope of service

work performed may lead directly to cause and resolution

of a cooling problem. The cooling unit has to reach normal

operating temperatures before troubleshooting can take place.

It takes an average of four hours for the refrigerant to reach

normal operating temperatures. The time frame to reach

operating temperatures depends on ambient air temperature.

www.norcold.com/cda

N611v, N811v ModelsRefrigerator Service Manual

7

Theory of Operation - cont’d.

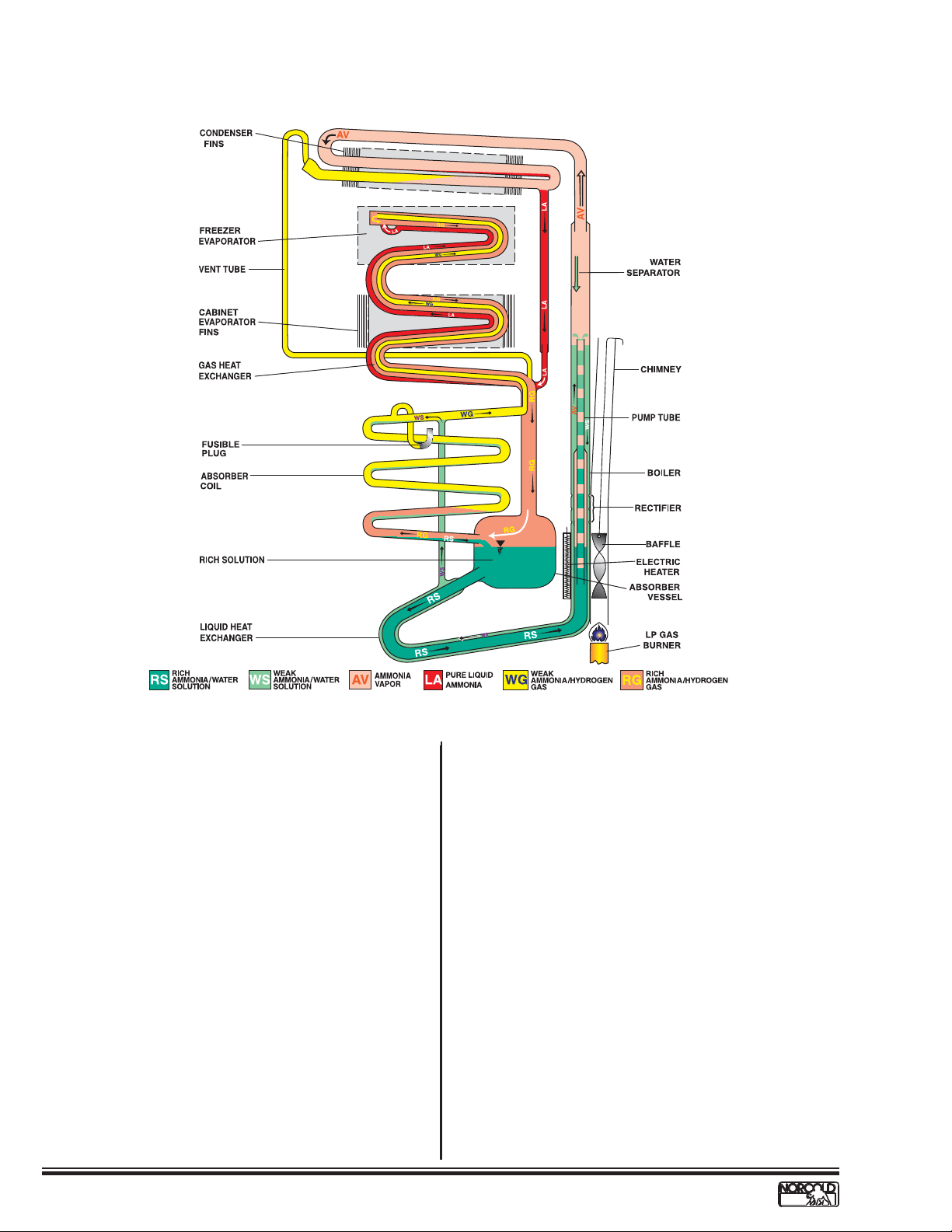

Gas Absorption System

Fig. 3 - Gas Absorption System

A rich solution (RS) leaves the absorber vessel and passes

through the liquid heat exchanger to the bottom of the pump

tube. Utilizing an AC cartridge heater or a LP gas burner, a

precise heat is applied to this area which in turn causes the

temperature of the solution to rise. This temperature increase

causes ammonia and some water vapor to be driven out of

the solution, forming vapor bubbles which push columns of

liquid up the pump tube.

As these columns of liquid exit the pump tube the liquid falls

downward through the rectifi er where the temperature is

increased causing additional ammonia vapor to be released.

The remaining liquid, now a weak ammonia-water solution

(WS), fl ows through the external shell of the liquid heat

exchanger where it transfers its residual heat to the rich

solution (RS) and enters the top of the absorber coil at a

reduced temperature. The ammonia-water vapor passes

through the water separator whose reduced temperature

causes any water vapor to condense and drop back down to

the boiler mixing with the existing weak solution (WS). The

ammonia vapor (AV) rises and enters the condenser where

it condenses (liquefi es) into pure liquid ammonia (LA). The

liquid ammonia, via gravity, drops into the tubular coil of the

freezer and cabinet evaporators and wets the internal surface

of the tubes.

The weak ammonia-hydrogen gas that was previously

released at the top of the absorber coil passes over the

wetted surfaces of the evaporator tubing causing the liquid

ammonia to evaporate into the hydrogen. The now rich

ammonia-hydrogen gas mixture (RG) draws heat from inside

the refrigerator. The weight of the hydrogen-ammonia gas

mixture (RG) is heavier than that of the weak gas (WG).

Consequently, it falls through the gas heat exchanger into the

top of the absorber vessel. From this point it enters the bottom

of the absorber coil.

The rich ammonia-hydrogen gas mixture (RG) travels up

through the absorber and makes contact with the weak

solution (WS) traveling down from the top of the absorber. As

the weak solution (WS) drops through the absorber it absorbs

the ammonia from the rich ammonia-hydrogen gas mixture

(RS). The relatively pure hydrogen (WG) exits the top of the

absorber coils to the evaporator and the rich solution falls to

the bottom of the absorber vessel where the cycle starts again.

8

www.norcold.com/cda

Refrigerator Service ManualN611v, N811v Models

Electronic Controls

A precise heat is applied to the boiler area of the cooling

unit causing a chemical reaction within the cooling unit that

ultimately results in the refrigerator cooling. The heat applied is

done so by means of:

• AC cartridge type heater positioned in heater wells

welded to the surface of the boiler

• LP Gas burner positioned below the boiler such

that the heat from the fl ame is directed across the

surface of the boiler

These heat sources are turned on/off via a factory preset

Auto mode. The unit will attempt to operate the heat source

requirements in the following order of priority:

• 1st Priority Choice - Auto AC Mode

While in the Auto AC Mode, the AC cartridge heater

is operated to provide heat to the boiler area of the

cooling unit.

• 2nd Priority Choice - LP Gas Mode

While in the Auto LP Gas Mode, the LP gas burner

is operated to provide heat to the boiler area of the

cooling unit.

Theory of Operation Auto Modes

AC voltage is applied to the power board via the AC power

cord at terminals L1 (Hot) and L2 (Neutral). This AC voltage

will pass through the AGC Series, 8A, Fast Acting, Glass Tube

Fuse (F2) where it is then measured. This measurement is

communicated to the optical display board which determines if

the applied voltage is below or above 85VAC. If the voltage is

above 85VAC the determination is that AC voltage is available

and the optical display board will request the power board to

operate via the Auto AC Mode. If the voltage is below 85VAC

the determination is that AC voltage is NOT available and the

optical display board will automatically default to the Auto LP

Gas Mode and request the power board to operate via the

Auto LP Gas Mode (see below). If the control is not able to

establish a fl ame while operating in the Auto LP Gas Mode the

optical display board will:

Automatically default back to the Auto AC mode and wait for

AC voltage to return, displaying the following fault code

• Solid RED power indicator light

A thermistor is mounted on the fi n assembly located inside the

fresh food compartment. The thermistor acts as a temperature

sensor, reporting the temperature sensed to the optical

display. The optical display then relays this information to

the power board that then turns on/off the appropriate heat

source accordingly. The optical display board, power board,

thermistor, and other components within the refrigerator are

interconnected via a wire harness.

Auto AC Mode

When operating in the Auto AC mode the power board

measures the thermistor value and communicates it to the

optical display board. The thermistor, a temperature device

whose internal resistance goes down as the temperature goes

up, is connected to the power board via terminals P2-1 and

P2-6. The optical display board compares the actual thermistor

value to preset cut-in and cut-out temperature values. Should

the thermistor value fall below the cut-in value it will request

the power board to turn ON the AC heater relay (K2). Should

the thermistor value go above the cut-out value it will request

the power board to turn OFF the AC heater relay.

Anytime relay K2 is turned ON, AC voltage is applied to

the AC heater via the now closed K2 contacts. Anytime AC

voltage is applied to the AC heater, AC current is produced.

This AC current is measured by the power board and its

value communicated to the optical display board. The optical

display board determines if the AC current is within specifi ed

limitations. If below the minimum specifi ed limit, the optical

display board will automatically default to the Auto LP Gas

Mode and request the power board to operate via the Auto

LP Gas Mode. AC related faults (Voltage or Current) are not

displayed while operating in the Auto Mode of operation.

www.norcold.com/cda

N611v, N811v ModelsRefrigerator Service Manual

9

Loading...

Loading...