Page 1

Service Manual

Compressor Refrigerators

English

!

!

!

!

ATTENTION

ATTENTION

ATTENTION

ATTENTION

DANGER

WARNING

AVERTISSEMENT

ADVERTENCIA

Improper installation,

adjustment, alteration,

service or maintenance

can cause personal

injury or property

damage. Refer to this

manual. For assistance

or additional information, contact a qualifi ed installer, service

agency, or the gas

supplier.

!

ATTENTION

DANGER

Une installation, un

ajustement, une

modifi cation, une

réparation ou un entretien

incorrect peut causer

des blessures ou des

dommages matériels.

Consultez ce manuel.

Pour obtenir de l’aide ou

d’autres renseignements,

contactez un installateur

qualifi é, un service

de réparation ou le

fournisseur de gaz.

N10DCX

!

!

!

!

ATTENTION

ATTENTION

ATTENTION

ATTENTION

PELIGRO

WARNING

AVERTISSEMENT

ADVERTENCIA

Une installation, un

ajustement, une

modifi cation, une

réparation ou un

entretien incorrect peut

causer des blessures

ou des dommages

matériels. Consultez ce

manuel. Pour obtenir

de l’aide ou d’autres

renseignements,

contactez un installateur

qualifi é, un service

de réparation ou le

fournisseur de gaz.

Questions? / Des questions? / ¿Preguntas? 1-800-543-1219

© 2019 NORCOLD, INC. All rights reserved.

Part No. 640083 Rev. B 07.01.2019

Page 2

CONTENTS

SAFETY .......................................................................................2

INTRODUCTION ..........................................................................3

About this Manual ...........................................................................................3

Certifi cation and Code Requirements .............................................................3

About Installation .............................................................................................3

Replacement Parts ..........................................................................................3

T echnical Assistance .......................................................................................3

SPECIFICATIONS ........................................................................4

Refrigerator Model Number .............................................................................4

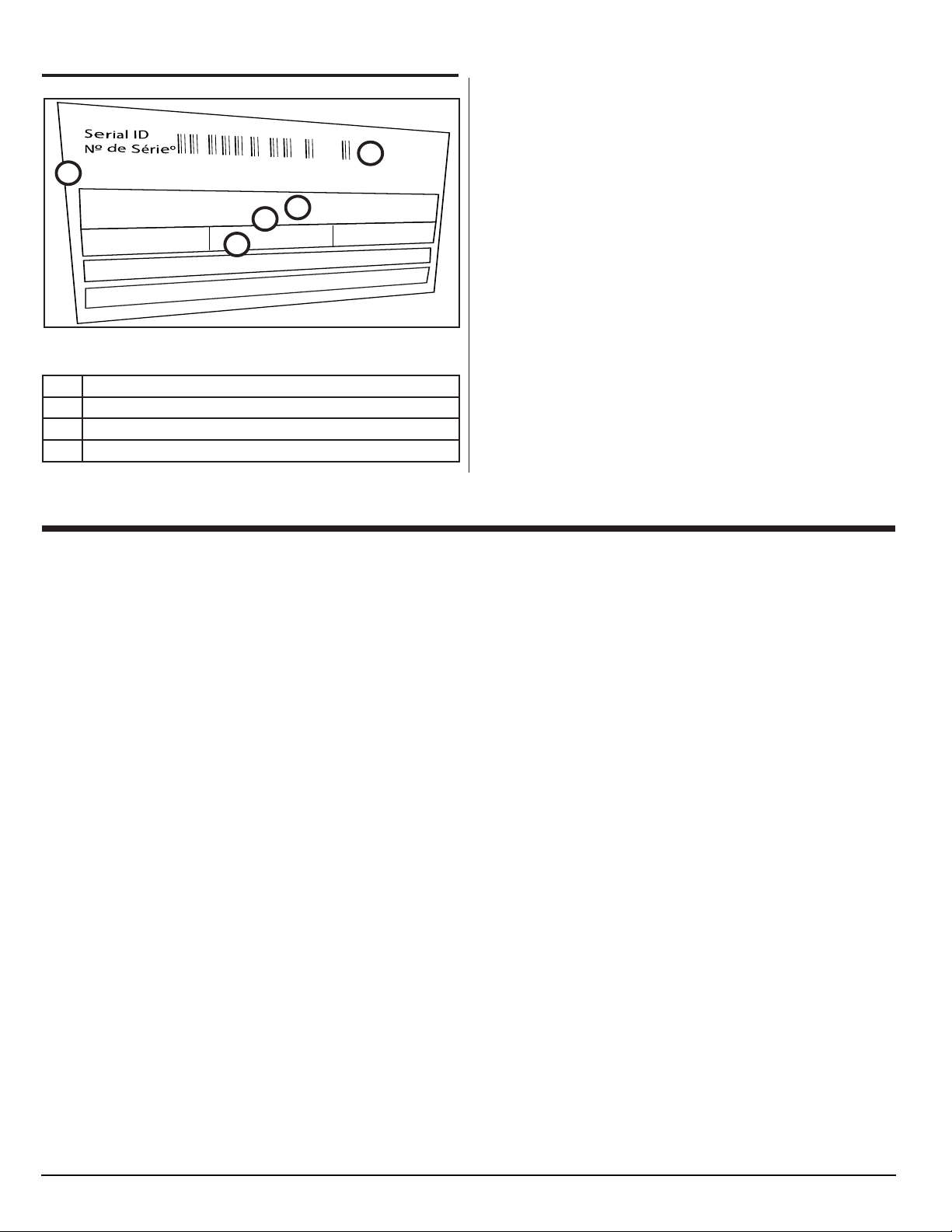

Exploded Views ...............................................................................................5

FIGURES

Fig. 1 - Refrigerator information label location ...............................................4

Fig. 2 - Front view ...........................................................................................5

Fig. 3 - Rear view ............................................................................................6

Fig. 4.1 - LED ..................................................................................................9

Fig. 4.2 - Female connectors ..........................................................................9

Fig. 4.3 - 12 VDC ...........................................................................................9

Fig. 4.4 - Adapter ...........................................................................................10

Fig. 4.5 - LED ................................................................................................10

Fig. 4.6 - 12VDC ...........................................................................................10

Fig. 5 - Mode Button will display Electronic Controls Fault Codes ................24

Fig. 6 - Wiring diagram ..................................................................................27

GENERAL INFORMATION ..........................................................7

Installation .......................................................................................................7

Ventilation .......................................................................................................7

Overview .....................................................................................................7

12 Volts DC Electrical Connection ..................................................................7

Polarity ........................................................................................................7

Parallel Battery ...........................................................................................7

DIAGNOSTICS .............................................................................8

Diagnostic Pre-Checks ....................................................................................8

Self-Test Diagnostics .......................................................................................9

Table of LED References ............................................................................9

Conducting the LED Evaluation ..................................................................9

Prepare to Connect the LED .......................................................................9

Connect the LED ........................................................................................9

Self-Test Diagnostic Chart .............................................................................10

Diagnostic Symptom Chart ...........................................................................10

Electronic Controls Fault Code Chart ............................................................10

TROUBLESHOOTING ...............................................................11

Troubleshoot Compressor Control Module ...................................................11

Test A, Battery Protection Cut-Out ............................................................11

Test B, Fan Over Current Cut-Out ............................................................13

Test C, Motor Start Error ...........................................................................14

Test D, Minimum Motor Speed Error ........................................................15

Test E, Thermal Cut-Out of Electronic Unit ..............................................16

Troubleshoot Symptoms ...............................................................................17

Test F, Not Cooling, Not Turning On .........................................................17

Test G, Refrigerator Gets Too Cold ...........................................................19

Test H, Refrigerator Builds Frost Inside ...................................................20

Test I, Runs But Does Not Cool Properly ..................................................21

Test J, Will Not Run On DC Power ...........................................................22

Test K, Voltage Within Cutout Range but Refrigerator Cuts Out ..............23

Troubleshoot Electronic Controls Fault Codes ..............................................24

Fault Code - "E1" ..........................................................................................24

Fault Code - "E2" ..........................................................................................25

Fault Code - "E3" ..........................................................................................26

Fault Code - "E4" ..........................................................................................26

WIRING DIAGRAM ....................................................................27

REFRIGERATOR ENCLOSURE ...............................................28

Remove Refrigerator ....................................................................................28

Replace Refrigerator ....................................................................................28

La version française commence à la page 29.

La versión en español comienza en la página 57.

SAFETY

It is not possible to anticipate all of the conceivable ways or

conditions under which the refrigerator may be serviced or to

provide cautions as to all of the possible hazards that may result.

Standard and accepted safety precautions and equipment should

be used when working on electrical circuits and handling toxic or

fl ammable materials. Safety goggles and other required protection

should be used during any process that can cause material

removal, such as when removing a leaking cooling unit and

cleaning components.

Read this manual carefully and understand the contents before

working on the refrigerator. Be aware of possible safety hazards

when you see the safety alert symbol on the refrigerator and in this

manual. A signal word follows the safety alert symbol and identifi es

the danger of the hazard. Carefully read the descriptions of these

signal words to fully know their meanings. They are for your safety.

This signal word means a hazard, which

!

CAUTION

!

ATTENTION

WARNING

!

ATTENTION

WARNING

if ignored, can cause small personal

injury or much property damage.

This signal word means a hazard, which

if ignored, can cause dangerous personal

injury, death.

The storage of fl ammable materials

behind or around the refrigerator creates

a fi re hazard. Do not use the area

behind the refrigerator to store anything,

especially fl ammable materials (gasoline,

cleaning supplies, etc.).

A circuit overload can result in an

electrical fi re if the wires and/or fuses

are not the correct size. Use only the

wire and fuse sizes as written in the

“Installation Manual.”

Incorrect installation, adjustment, change

to, or maintenance of this refrigerator can

cause personal injury, property damage,

or both. Have service and maintenance

work done by your dealer or by an

authorized Norcold Service Center.

N10DCX

2

www.norcold.com

Page 3

Safety, cont’d.

!

ATTENTION

WARNING

Disconnect the DC power sources before

doing any maintenance work on the

refrigerator.

Do not bypass or change the

refrigerator’s electrical components or

features.

Do not spray liquids near electrical

outlets, connections, or the refrigerator

components. Many liquids are electrically

conductive and can cause a shock

hazard, electrical shorts, and in some

cases fi re.

Do not touch the evaporator or other

metal parts inside the refrigerator cabinet

with wet hands because they can freeze

to the refrigerator.

The rear of the refrigerator has sharp

edges and corners. To prevent cuts

or abrasions when working on the

refrigerator, be careful and wear cut

resistant gloves.refrigerator, be careful

and wear cut resistant gloves.

INTRODUCTION

About this Manual

This service manual provides maintenance, diagnostic, and repair

information for NORCOLD

a reference tool designed for technicians who are knowledgeable

in the theory and operation of AC/DC electrical systems as installed

in a variety of recreational vehicles (RV).

All information, illustrations, and specifi cations contained in this

publication are based on the latest product information available

at the time of publication. NORCOLD

changes at any time without notice.

®

N10DCX compressor refrigerators. It is

®

reserves the right to make

Certifi cation and Code Requirements

NORCOLD

edition of UL 60335-1 standards.

Electrical components are compliant.

®

compressor refrigerators are certifi ed under the latest

About Installation

Replacement Parts

Use only authorized NORCOLD

parts do not meet NORCOLD

and performance. The use of unauthorized aftermarket or generic

replacement parts voids the refrigerator’s limited warranty

coverage.

®

replacement parts. Generic

®

specifi cations for safety, reliability,

T echnical Assistance

If unable to resolve technical issues using the information provided

in this manual, technical support is available through NORCOLD

Customer Service Center:

Telephone: 1-800-444-7210

Fax: 1-734-769-2332

email info@thetford.com

World Wide Web: www.norcold.com

®

Refrigerator installation must conform with the N10DCX Series

Installation Manual for the NORCOLD

effect. Installation must also comply with applicable local codes and

standards set by the relevant certifi cation agency.

www.norcold.com

®

limited warranty to be in

The following information is required to process technical support

requests:

■ Refrigerator Model Number

■ Refrigerator Serial Number

■ Recreational Vehicle (RV) Make/Model/Year

SERVICE MANUAL

3

Page 4

Refrigerator Model Number

A

e

lum

o

V

Net

Nominale

n

o

i

274L

B

Mo

Input voltage /

Tot al I nput /

Rated

Gr

efr

R

Climate cl

Compress

del / Modé

Entrée du courant 12V DC

i

Pu

C

rrent/

cu

e

Volum

oss

Engorigene

/

gerant

i

a

or re

lass Clim

/ C

s

s

iger

r

f

le

N10DC

e total

ssanc

ourant nominal

ator

76L

2

:

/

290

R

atique: ST

SE288VDW00006

Volume

i

s

e

D

HIO

O

,

E

g

n Pr

4

D

essure

5373

Freezer

C

50g

RCOLD INC.

NO

NEY

D

SI

:

72L

Press

/

Fig. 1 - Refrigerator information label location

A Serial Number

B Model Number

C Amount of refrigerant in cooling system

D DC Voltage / Amperage

SPECIFICATIONS

N10DCX - Electronic

ON/OFF, Mode, Temperature Set

Multiple LED indicator lights

Five (5) Temperature Settings (Separate settings for freezer and fresh food compartments)

Night Mode

Rough Opening Dimensions ------------------59.88 - 60.01 high x 23.50 - 23.63 inched wide x 24.00 inches deep

Internal Capacity

Total capacity -------------------------------------------------------------------------------------------------------------- 9.7 cubic feet

DC (Direct Current) Specifi cations

Electronic Controls DC voltage input requirement ----------------------------------------------------------- 10.4 to 15.4 VDC

Minimum (cut-out) --------------------------------------------------------------------------------------------------------- 10.4 VDC

Restart (cut-in) -------------------------------------------------------------------------------------------------------------- 11.7 VDC

DC Fuse Requirements

DC Power Supply In-Line Fuse ----------------------------------------------------------------------------------------------- 15 A

DC Resistance / Amperage Ratings

Exterior Cooling Fan ----------------------------------------------------------------------------------------------------------- 0.18A

Interior Fan ------------------------------------------------------------------------------------------------------------------------- .09A

Interior Light ------------------------------------------------------------------------------------------------------------------------ .13A

Off-level Operating Limits

Side-to-side ------------------------------------------------------------------------------ 10 degrees maximum at refrigerator

Front-to-back ---------------------------------------------------------------------------- 10 degrees maximum at refrigerator

N10DCX

4

www.norcold.com

Page 5

Exploded Views

A

E

D

B

C

F

G

H

I

J

NOR000947A

Fig. 2 - Front view

No. Description

A Control Panel

B

C

D

E

F

G Light Housing

H Light

I Light Cover

J Door Light Switch

Control Panel Label

Control Board

Control Housing

Control Housing Bracket (3x)

Fan and Housing

www.norcold.com

5

SERVICE MANUAL

Page 6

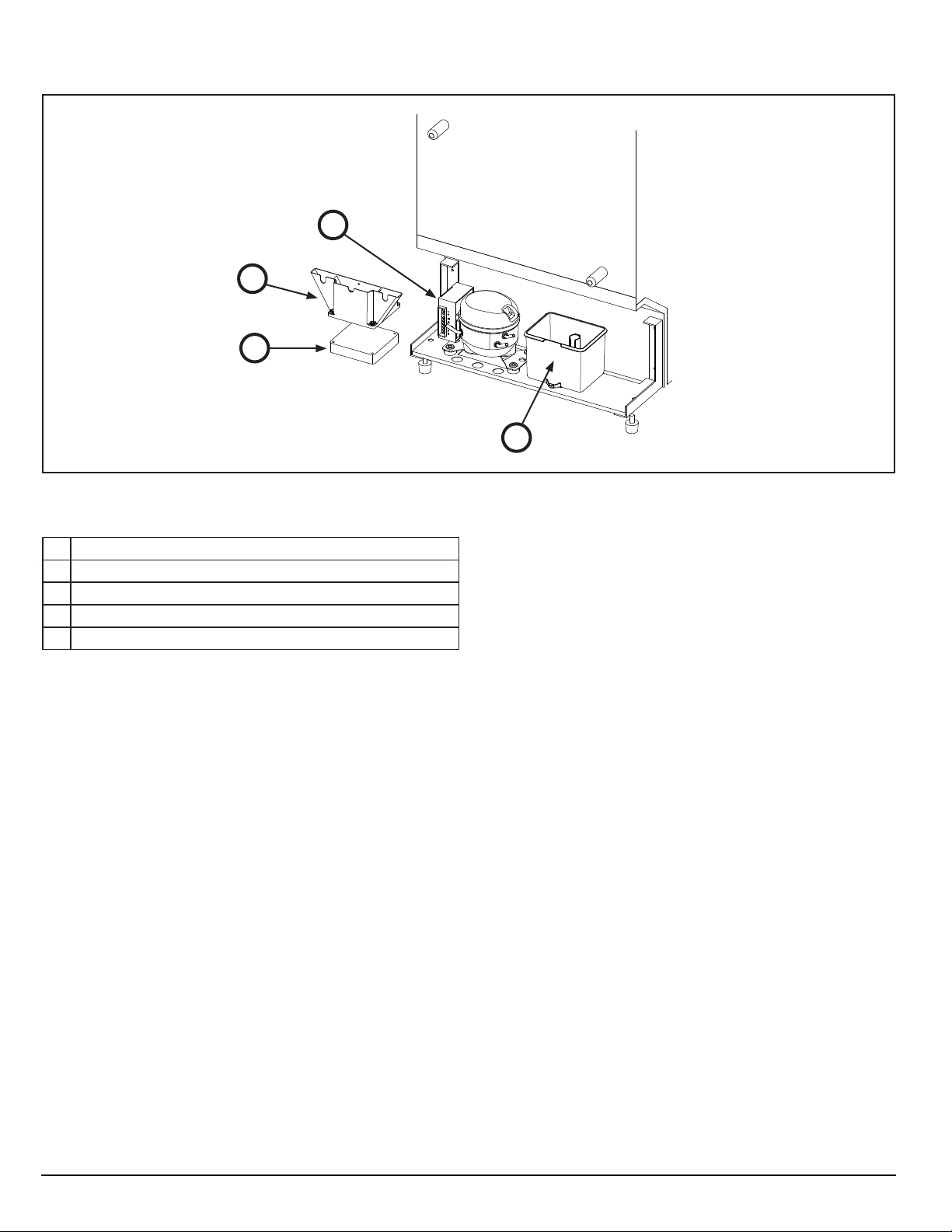

Exploded Views, cont’d.

Fig. 3 - Rear view

D

A

B

NOR000948A

C

No. Description

A Exterior Fan Vent

B Exterior Fan

C

Drip Cup

D

Control Module

N10DCX

6

www.norcold.com

Page 7

GENERAL INFORMATION

Installation

To confi rm that installation is adequate, make sure:

■ Ventilation is adequate. Refer to "Ventilation" section.

■ Electrical components are installed and operating in a safe

condition.

■ Refrigerator is installed on a solid and level fl oor (not on carpet)

and secured.

■ The fl oor is able to support the weight of the refrigerator and all

of its contents.

Ventilation

Overview

The refrigerator is made for a built-in installation. Correct ventilation

is necessary for the correct operation of the refrigerator and to

increase the life of the refrigerator cooling system.

Ventilation allows the natural fl ow of air that is necessary for good

ventilation. Cooler air comes in through the lower vent, goes

around the refrigerator coils where it removes the excess heat

from the refrigerator components , and goes out through the upper

vent / control cover. If this air fl ow is blocked or decreased, the

refrigerator will not cool correctly. Do not install the refrigerator in a

completely enclosed area such as a closet or a cabinet.

The refrigerator has built-in vents at

!

ATTENTION

WARNING

the top and the bottom. Make sure that

the air fl ow through these vents is not

blocked in any way. Blockage of the air

fl ow through these vents can:

12 Volts DC Electrical Connection

To reduce the risk of electrical interference from other DC

appliances and induction from voltage spikes:

■ The refrigerator must have an independent 12 volt supply and

not be on the same circuit as other DC appliances.

■ Route the DC power supply wires, including the fuses, directly

from the battery to the refrigerator.

The use of a battery in parallel and

!

CAUTION

■ Power converters or battery chargers used to supply DC power

are examples of installations that should have parallel battery

operation.

■ If an electrically fi ltered DC power converter is used as the sole

source of power, it must have a maximum DC ripple voltage of

less than or equal to 250mV.

Polarity

!

CAUTION

■ Connect the DC (positive) supply wire from the battery to the

red wire of the refrigerator.

■ Connect the DC (negative) supply wire from the battery to the

black wire of the refrigerator.

between the refrigerator and any

electrically fi ltered DC power converter or

battery charger used to supply DC power

to the refrigerator is recommended.

If the DC leads are installed incorrectly,

the refrigerator will not operate.

www.norcold.com

■ Shorten the life of the refrigerator cool-

ing system.

■ Cause poor cooling performance of the

refrigerator.

■ Cause continuous operation of the

refrigerator cooling system.

■ Cause fast battery discharge.

■ Void the refrigerator warranty.

SERVICE MANUAL

7

Page 8

DIAGNOSTICS

Diagnostic Pre-Checks

Diagnosing problems begins by starting with the basics. In many

cases, the problem can be solved by verifying the unit is operating

in acceptable conditions. Before performing detailed diagnostics

make sure:

■ The refrigerator is turned ON.

■ The door is closed and sealing correctly.

■ The refrigerator is correctly installed and the vents are not

blocked.

■ The vehicle fuse or circuit breaker is intact.

There may be more than one (1) over-

NOTICE

■ The ambient temperature is not unusually high (more than 110°

F. / 43° C.).

■ The air circulation inside the refrigerator is not decreased by

foods or by shelves that are covered with plastic, paper, etc.

■ The freezer is defrosted.

current device in the refrigerator supply

circuit. Be sure to check both the RV and

refrigerator.

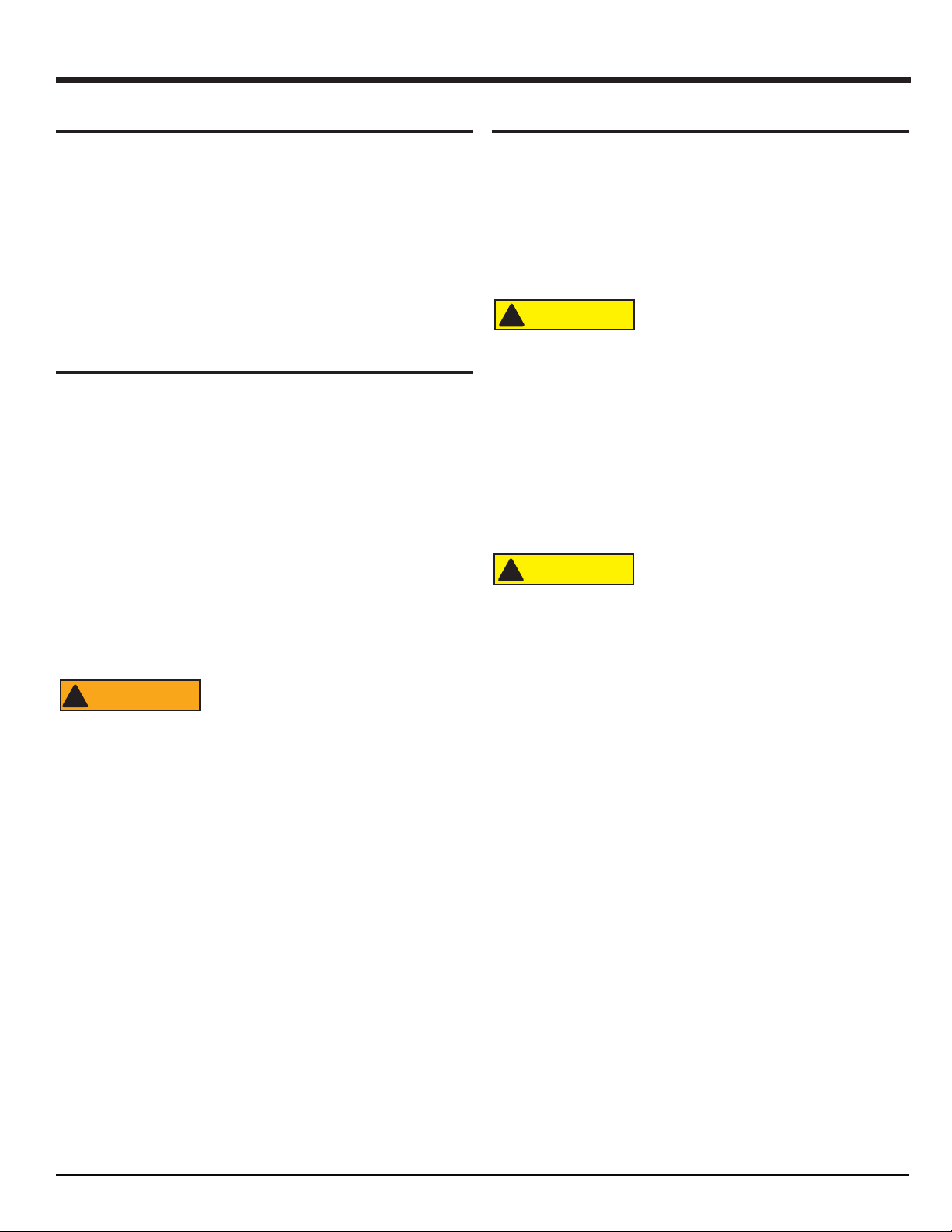

Then do the following procedure.

NOR000832B

Do the tests in “Self - Test

Diagnostics” section.

Are any

error codes

found?

YES

NO

If necessary, remove the

refrigerator from the enclosure.

Refer to the “Refrigerator Enclosure”

section.

Refer to “Self - Test Diagnostic Chart.”

Refer to “Diagnostic Symptom Chart.”

N10DCX

8

www.norcold.com

Page 9

Self-Test Diagnostics

The unit’s control module is equipped with a "Self-Test Diagnostic"

function which can be read using light emitting diode (LED) and

terminal connectors.

T able of LED References

References for Figs. 4.1 - 4.6

No. Description

A 10 mA LED With Wire Leads

A1 Black LED Wire (with connector attached)

A2 Red LED Wire (with connector attached)

B 1/4 Inch Push-On Female Connector (2x)

C 1/4 Inch Adapter With One (1) Female and Two (2) Male Connections

D 12 VDC Input Wire

E Positive (+) Terminal “+” of Control Module

F Terminal “D” of Control Module

G Control Module

Prepare to Connect the LED

You will need the following to conduct self-diagnostics:

B

N000033A

B

Fig. 4.1 - LED

■ A 10 mA LED with wire leads (See Fig. 4.1, A).

■ Two (2) 1/4 inch push-on female connectors (See Fig. 4.1, B).

■ A 1/4 inch adapter with 1 female to 2 male connections. (See

Fig. 4.1, C)

Do not leave jumpers in place for normal

NOTICE

operation.

A

C

Conducting the LED Evaluation

Follow the steps below. If an error code is activated in the control

module (Fig. 4.3, G) and the LED (Fig. 4.1, A) is connected, it will

fl ash a number of times. The number of fl ashes will depend on

what error was recorded. Each fl ash will last 1/4 second and after

the code is fl ashed there will be a delay, then the code will repeat.

Write down all error codes; then refer to "Self-Test Diagnostic

Chart" in this section.

Connect the LED

Refer to Figs. 4.2- through 4.6

Step 1. Attach Female Connectors.

A

N000019A-1

Fig. 4.2 - Female connectors

Attach a female connector to each LED wire lead.

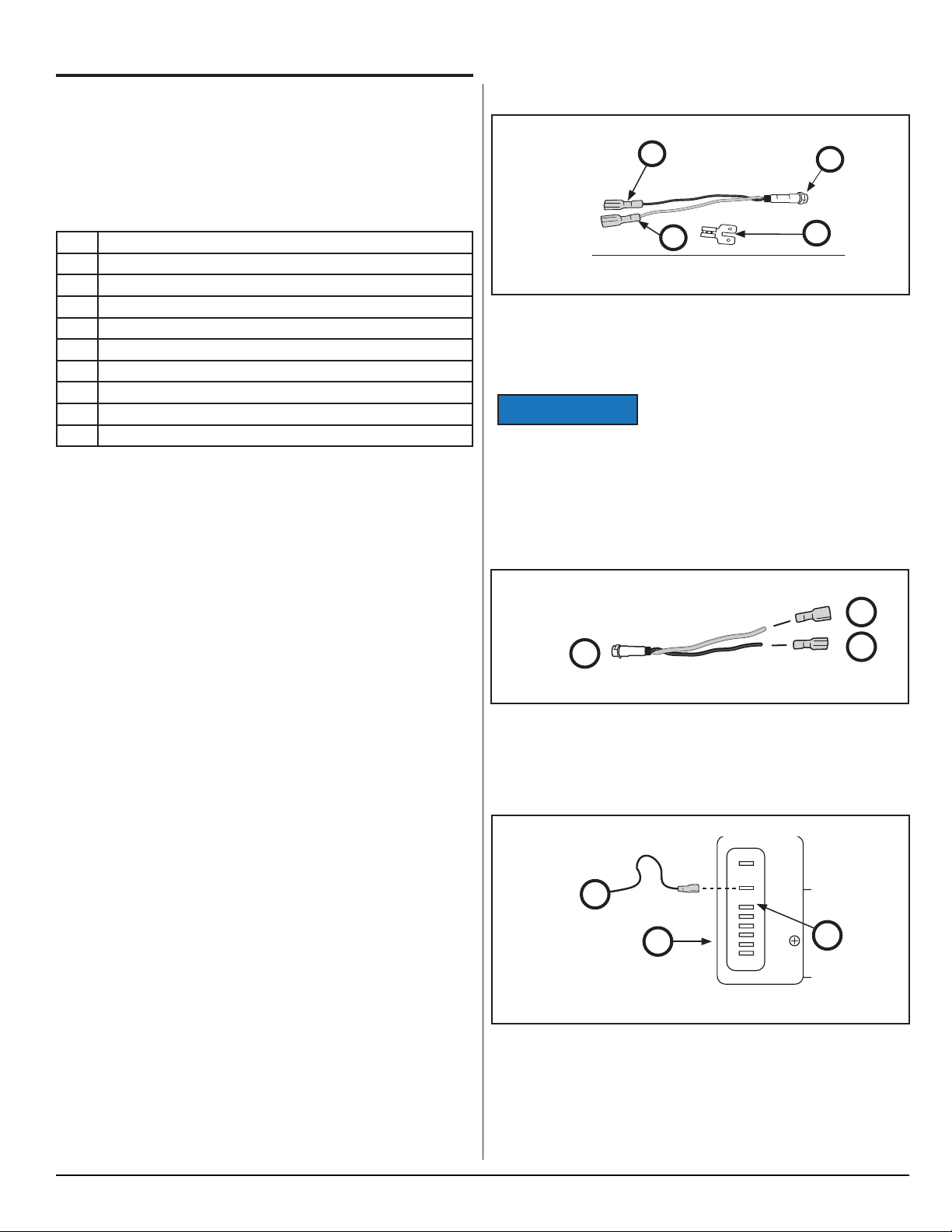

Step 2. Disconnect 12 VDC

D

G

NOOOO19A-2b

_

12/24 Vdc

+

+

F

D

C

P

T

B

B

E

www.norcold.com

Fig. 4.3 - 12 VDC

Disconnect the 12 VDC input wire from the positive terminal of the

control module.

SERVICE MANUAL

9

Page 10

Self -Test Diagnostics, cont’d.

Step 3. Connect Adapter

_

12/24 Vdc

NOOOO19A-3b

C

+

+

F

D

C

NOOOO19A-3b

P

T

E

Fig. 4.4 - Adapter

Connect the adapter to the positive terminal of the control module.

Self-Test Diagnostic Chart

Flashes Description Action

1 Battery Protection Cut-Out.

The voltage is outside the cut out setting.

2 Fan Over current Cut-Out.

The fan electrical load is more than 1.0 amp.

3 Motor Start Error.

The rotor is blocked or the differential pressure in the

refrigeration system is too high ( >5 bar).

4 Minimum Motor Speed Error.

The motor can not maintain minimum speed (1850 rpm).

5 Thermal Cutout of Electronic Unit.

The electronic unit is running too hot.

6 Controller Hardware Failure

Controller detects abnormal parameters

Perform

T est A.

Perform

Test B.

Perform

Test C.

Perform

Test D.

Perform

Test E.

Perform

Test K.

Step 4. Connect LED

_

12/24 Vdc

+

+

F

D

C

P

T

C

NOOOO19B-4b

A2

A1

F

Fig. 4.5 - LED

Connect the black LED wire to one side of the adapter; connect the

red LED wire to terminal “D” of the control module.

Step 5. Connect 12VDC

C

_

12/24 Vdc

+

+

F

NOOOO19A-5b

D

C

P

T

D

Fig. 4.6 - 12VDC

Connect the 12 VDC input wire to the other side of the adapter.

Diagnostic Symptom Chart

Problem Possible Cause Action

to Take

Not cooling, not

turning on.

Refrigerator gets

too cold.

Refrigerator

builds frost inside.

Runs, but does

not cool properly.

Will not run on

DC power.

Voltage within

range; refrigerator

cuts out.

- Faulty thermistor.

- No power to control module.

- Faulty wire from control module to compressor

- Faulty control module.

- Faulty Compressor.

- Bad capillary tube position.

- Faulty thermistor

- Faulty control module.

- Door not closed.

- Damaged door gasket.

- High ambient temperatures .

- Blocked air ventilation.

- Frost build up.

- Condenser coil restricted.

- Faulty condenser fan.

- Faulty cooling unit.

- Blown fuse in DC circuit.

- Undersized wiring to refrigerator, minimum #12

gauge wire required.

- Refer to Owner's Manual for recommended wire

size.

- Partially discharged battery, voltage below 11.3

VDC at compressor module.

- High resistance (voltage drop) in supply circuit.

- Parts can cause a + / - 10 VDC which can cause

refrigerator voltage to register within specifi cation,

but cutout because of part variance.

Perform

Test F.

Perform

Test G.

Perform

Test H.

Perform

Test I.

Perform

Test J.

Perform

Test K.

NOTICE

N10DCX

Do NOT leave jumpers in place for

normal operation.

Electronic Controls Fault Code Chart

Fault Code Fault Code Meaning Action to Take

E1

E2

The thermistor in the fresh food compartment is not cycling properly.

The thermistor in the freezer compartment

is not cycling properly.

E3 The voltage is outside the cut out setting.

E4

The fresh food compartment door has

been open for more than two (2) minutes.

Refer to "Fault Code "E1"" on page 24.

Refer to "Fault Code "E2"" on page 25.

Refer to "Fault Code "E3"" on page 26.

Refer to "Fault Code "E4"" on page 26.

www.norcold.com

10

Page 11

TROUBLESHOOTING

Troubleshoot Compressor Control Module

T est A, Battery Protection Cut-Out

Before starting this procedure make sure the DC supply voltage to

the refrigerator is correct. The DC supply voltage must be:

■ More than 11.7 VDC to start.

■ Remain between 10.4 VDC to 15.4 VDC to continue operation.

Make sure that the DC supply voltage

is correct.

Remove refrigerator from enclosure,

but do not disconnect the DC supply.

Inspect the fuse on the positive DC

Supply that is connected to control

module terminal “+”.

NOR000950A

Is the fuse

intact?

NO

YES

With the refrigerator turned OFF,

measure voltage at the DC connector.

VDC

10.4 - 15.4?

NO

YES

With freezer and fresh food

compartments at temperature

setting “5”, measure voltage at DC

connector.

Replace the fuse. Test the refrigerator.

Repair DC supply voltage.

Test the refrigerator.

www.norcold.com

VDC

10.4 - 15.4?

YES

Continued on next page.

NO

Repair DC supply voltage.

Test the refrigerator.

SERVICE MANUAL

11

Page 12

Troubleshooting Compressor Control Module, cont’d.

Continued from previous page.

With freezer and fresh food

compartments at temperature

setting “5”, measure voltage at

terminal “+”.

YES

NOR000950A

VDC

10.4 - 15.4?

NO

Repair refrigerator power cord.

Test the refrigerator.

Replace control module.

Test refrigerator.

N10DCX

12

www.norcold.com

Page 13

Troubleshooting Compressor Control Module, cont’d.

T est B, Fan Over Current Cut-Out

Remove refrigerator from enclosure,

but keep DC power supply connected.

With freezer and fresh food

compartments at temperature

setting “5”, make sure that the

exterior cooling fan is operating.

Is the fan

operating?

NO

Measure DC voltage at control

module terminal “+”.

VDC

10.4 - 15.4?

NO

NOR000951A

YES

YES

Replace the refrigerator.

Fan has failed. Replace the fan.

Replace control module.

www.norcold.com

13

SERVICE MANUAL

Page 14

Troubleshooting Compressor Control Module, cont’d.

T est C, Motor Start Error

Complete the “Diagnostic Pre-Checks.”

Remove refrigerator from enclosure,

but keep DC power supply connected.

Turn refrigerator OFF for a minimum

of five (5) minutes to allow internal

system pressures to equalize.

Turn refrigerator back ON.

NOR000952A

Does code

3 return?

NO

YES

Replace the refrigerator.

Repair complete.

N10DCX

14

www.norcold.com

Page 15

Troubleshooting Compressor Control Module, cont’d.

T est D, Minimum Motor Speed Error

Complete the “Diagnostic Pre-Checks.”

Remove refrigerator from enclosure,

but keep DC power supply connected.

Make sure the:

- Upper and lower vents are not

blocked.

- The refrigerator is not overloaded

with hot items.

- The ambient operating temperature

is lower than 110°F (43° C).

NOR000953A

Is

VDC

10.4 - 15.4?

YES

Is

unit

overloaded?

NO

Is fan

operating,

coils clean/not

blocked?

NO

NO

YES

YES

Correct input voltage.

Reduce load on unit.

Replace the refrigerator.

Replace control module.

www.norcold.com

15

SERVICE MANUAL

Page 16

Troubleshooting Compressor Control Module, cont’d.

T est E, Thermal Cut-Out of Electronic Unit

The control module has a built in thermal

NOTICE

protection which stops the compressor

operation if the control module circuit

board temperature is higher than 203° F

(95° C). The refrigerator will not restart

until the control module circuit board

temperature is lower than 185° F (85° C).

Remove refrigerator from enclosure,

but keep DC power supply connected.

Make sure the:

- Upper and lower vents are not

blocked.

- Condenser coil is clean.

- Fan is operating.

- Ambient operating temperature

is lower than 110°F (43° C).

Test the unit.

NOR000954A

Does code

5 return?

NO

YES

Replace control module.

Repair complete.

N10DCX

16

www.norcold.com

Page 17

Troubleshoot Symptoms

T est F, Not Cooling, Not Turning On

Complete the “Diagnostic Pre-Checks.”

Remove refrigerator from enclosure,

but keep DC power supply connected.

Any wires

disconnected

from

terminals?

YES

NO

Turn refrigerator ON. The blue

“ON” indicator light should come on.

Does light

come on?

YES

NO

Is unit

connected to

DC power?

YES

Refer to “Wiring Diagram.” Connect wire.

Test unit.

Examine DC fuse. Replace if necessary.

NOR000955A

www.norcold.com

NO

With the refrigerator turned “OFF”,

use a DVOM to check input voltage.

The input voltage must be higher

than 11.7 VDC.

Is input

voltage

correct?

NO

YES

Continued on next page.

Correct input voltage. Test unit.

SERVICE MANUAL

17

Page 18

Troubleshooting Symptoms, cont’d.

Continued from previous page.

YES

Make sure the DC input is connected

correctly:

- Positive lead to “+” terminal.

- Negative lead to ”-” terminal.

Is input

connected

correctly

NO

YES

Remove control module and control

module base. Remove compressor

interface cover. Unplug compressor

wire harness at each end. Check

continuity of compressor wire harness.

Is

compressor

wire harness

OK?

NO

YES

With compressor harness unplugged

from the compressor, measure

resistance between all three (3) current

lead-in pins on the compressor.

Correct input connections. Test unit.

Replace compressor wire harness.

Test unit.

N10DCX

NOR000995A

Are

measured

values about

the same?

NO

YES

Replace the control module.

Replace the refrigerator.

www.norcold.com

18

Page 19

Troubleshooting Symptoms, cont’d.

T est G, Refrigerator Gets Too Cold

Complete the “Diagnostic

Pre-checks.”

Does the control

display show an E1

or E2 error?

YES

Are thermistors connected?

NO

Reconnect thermistors. Test unit.

YES

Remove refrigerator from enclosure,

but keep DC power supply connected.

Refer to the “Wiring Diagram” section.

Are the thermistors and magnet valve

connected the control board?

YES

Replace thermistor of compartment

that is too cold.

NOR000956B

NO

Reconnect thermistor and/or magnet

valve. Test unit.

YES

Did

unit stop

operating?

YES

NO

Disconnect wires at control module

terminals”C” and “T”.

Did unit stop operating?

NO

Is the magnet valve bad?

NO

Replace the thermistor.

YES

YES

Repair shorted wires between optical

display module and control module.

Test unit.

Replace the refrigerator.

www.norcold.com

Replace the control module. Test unit.

SERVICE MANUAL

19

Page 20

Troubleshooting Symptoms, cont’d.

T est H, Refrigerator Builds Frost Inside

These models are not frost free units

NOTICE

and the unit will have to be defrosted

at times. If the unit seems to have an

excessive amount of frost or it is building

quickly perform the following tests.

Check temperature setting of freezer

and fresh food compartments.

NOR000957B

Inspect door seal, hinges, and latch

for correct operation.

All

operating

correctly?

NO

Repair as needed. Test refrigerator.

N10DCX

20

www.norcold.com

Page 21

Troubleshooting Symptoms, cont’d.

T est I, Runs But Does Not Cool Properly

Check the temperature setting of

freezer and fresh food compartments.

Remove refrigerator from enclosure,

but keep DC power supply connected.

Inspect condenser coil for restriction.

Is it

restricted?

Check for 12 VDC at terminal (+) on

the control module.

Is voltage

correct?

NOR000958B

Replace control module.

NO

NO

YES

YES

Remove restriction. Clean as needed.

Fan has failed. Replace refrigerator.

www.norcold.com

21

SERVICE MANUAL

Page 22

Troubleshooting Symptoms, cont’d.

T est J, Will Not Run On DC Power

Check for blown fuse in DC circuit.

Is fuse

blown?

YES

NO

Check that the wiring to the refrigerator

is at least #12 gauge wire (required).

Is wiring at

least #12

gauge?

NO

YES

Check DC voltage at control module.

Is voltage

below 10.4

VDC?

NO

Replace fuse.

Refer to the Installation Manual for

the recommended wire size.

Correct high resistance (voltage drop) in

supply circuit.

N10DCX

YES

Recharge or replace battery.

NOR000959A

www.norcold.com

22

Page 23

Troubleshooting Symptoms, cont’d.

T est K, Voltage Within Cutout Range but Refrigerator

Cuts Out

Complete the “Diagnostic Pre-Checks.”

Remove refrigerator from enclosure,

but keep DC power supply connected.

Make sure:

- Upper and lower vents are not

blocked.

- The refrigerator is not overloaded

with hot items.

- The ambient operating temperature

is lower than 110°F (43° C).

Measure input voltage.

- 12 VDC nominal inout voltage is

10.4 - 15.4 VDC.

Is input

voltage

10.4 - 15.4

VDC?

NO

YES

NOR000960A

Is

unit

overloaded?

YES

NO

Disconnect thermistor wire from

terminal “C” on the cooling unit

control module. Test the refrigerator.

Does the refrigerator still cut out?

YES

Contact Customer Service.

Correct input voltage.

Reduce load on unit.

NO

Repair complete.

www.norcold.com

23

SERVICE MANUAL

Page 24

Troubleshoot Electronic Controls Fault Codes

Fig. 5 - Mode Button will display Electronic Controls Fault Codes

Fault Code - "E1"

Complete the “Diagnostic Pre-Checks.”

Make sure thermistor in the fresh food

compartment is connected.

Remove thermistor cover in fresh food

compartment and check connection of

thermistor wire to thermistor.

Is

thermistor

wire

connected?

NO

YES

Check connection of thermistor wire to

the refrigerator electronic controls.

Refer to the wiring diagram.

E1

Possible Cause:

The fresh food thermistor is not

cycling properly.

Correct connection.

N10DCX

NOR000978A

Is

thermistor

wire

connected?

YES

Replace Thermistor.

NO

Correct connection.

www.norcold.com

24

Page 25

Troubleshooting Electronic Control Fault Codes, cont’d.

Fault Code - "E2"

Complete the “Diagnostic Pre-Checks.”

Make sure thermistor in the freezer

compartment is connected.

Remove thermistor cover in freezer

compartment and check connection of

thermistor wire to thermistor.

Is

thermistor

wire

connected?

NO

YES

Check connection of thermistor wire to

the refrigerator electronic controls.

Refer to the wiring diagram.

E2

Possible Cause:

The freezer thermistor is not

cycling properly.

Correct connection.

NOR000979A

Is

thermistor

wire

connected?

YES

Replace Thermistor.

NO

Correct connection.

www.norcold.com

25

SERVICE MANUAL

Page 26

Troubleshooting Electronic Control Fault Codes, cont’d.

Fault Code - "E3"

Correct the DC input voltage to the refrigerator. Make sure the

input voltage is 12.0 VDC.

Fault Code - "E4"

Make sure:

■ the light switch closes when the door closes.

■ all of the connections to the refrigerator electronic controls are

intact.

E3

Possible Cause:

The voltage is outside the cut-out

setting.

E4

Possible Cause:

The door has be open for more

than two (2) minutes.

N10DCX

26

www.norcold.com

Page 27

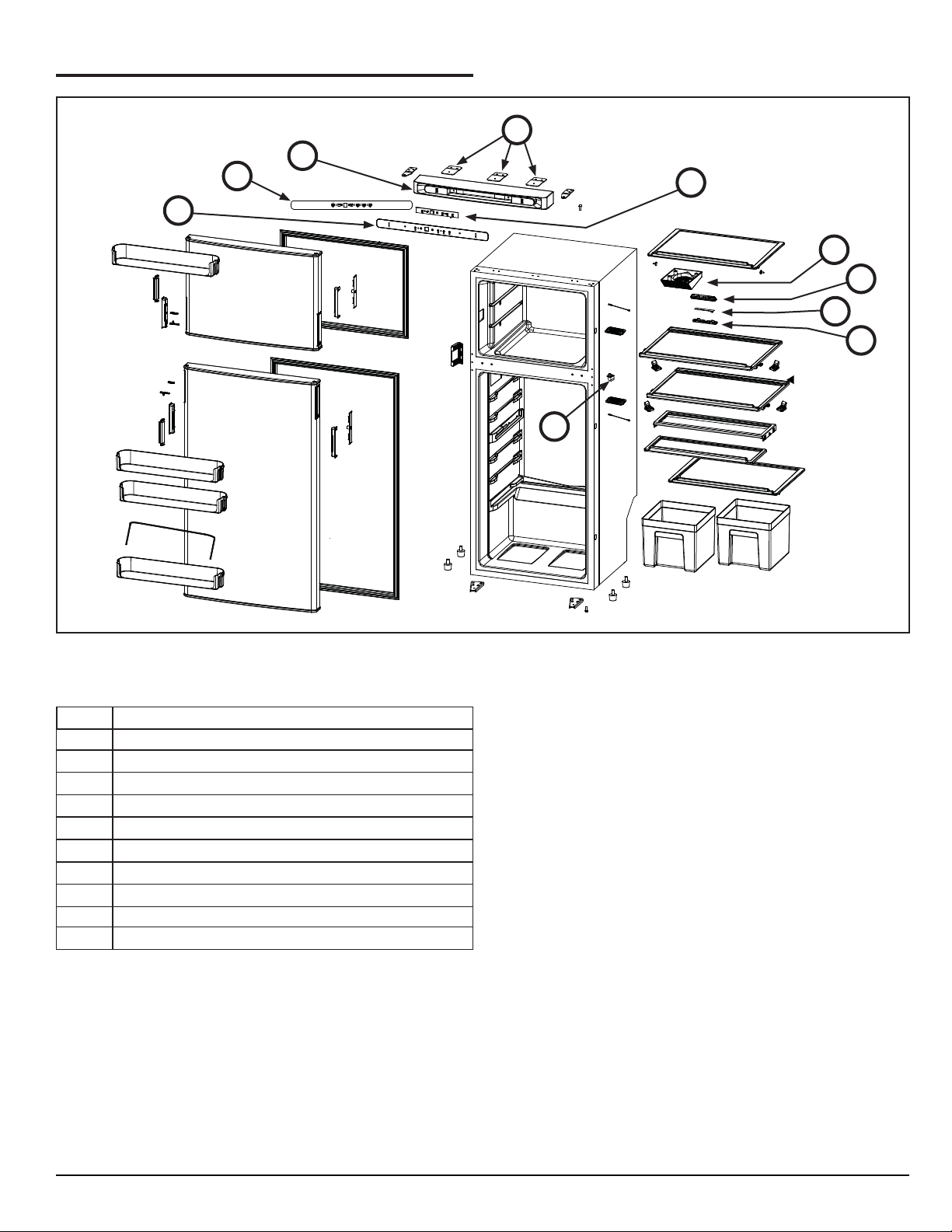

WIRING DIAGRAM

H

K

WH/BC

NOR000949A

BR/BN

+

-

B

Fig. 6 - Wiring diagram

Item Description

A Display Module

B 12 VDC Input

C 15A Fuse

D Main PCBA Cooling Unit

E Exterior Fan

F Freezer Compartment Thermistor

G Fresh Food Compartment Thermistor

H Interior Light

I Interior Fan

J Interior Light Switch

K Magnet Valve

I

BK/NR

DCFDCF

J

A

F

G

WH/BC

RD/RG

FUSE

WH/BC

C

+-+

F

T

P

D

C

D

WH/BC

WH/BC

WH/BC

BK/NR

BK/NR

RD/RG

BR/BN

BL/BL

BK/NR

GND

12V

FJ2

MK

LED

12V

CN5

GND

FJ1

T12V

12V

LD

LC

CN1

CN2

CN4

RD/RG

BL/BL

E

www.norcold.com

27

SERVICE MANUAL

Page 28

REFRIGERATOR ENCLOSURE

Remove Refrigerator

1. Disconnect all power supplies to the refrigerator.

Failure to disconnect the electrical

!

ATTENTION

WARNING

2. Remove the mounting screws from each mounting bracket. Pull

the refrigerator forward.

Replace Refrigerator

1. Push refrigerator fully into enclosure. Install screw into each

mounting bracket.

2. Connect all power supplies to the refrigerator.

sources can cause dangerous personal

injury or death.

N10DCX

28

www.norcold.com

Loading...

Loading...