Norcold 1200, 120-IM Service Manual

INC.

Service Manual

Gas/Electric Refrigerators

MODELS

1200XX

120X-IMXX

WARNING

!

DO NOT install this refrigerator in below deck marine applications. Do not

install this refrigerator in fixed indoor cabin or other dwelling applications. This

refrigerator must use only NORCOLD designed and approved outside air intake and exhaust ventilation for correct and safe operation. Any other ventilation could cause lethal combustion exhaust fumes and or/explosive propane

gas fumes to be in the living area and/or below deck.

© 2005 THETFORD CORP ., NORCOLD, INC. All rights reserved.

Publication No. 618968B (02-18-05)

TABLE OF CONTENTS

Introduction ------------------------------------------------------ 1

About this Manual ................................................................. 1

Model Identification .............................................................. 1

Information Label ................................................................. 1

Cooling Unit Serial Number ................................................1

Certification and Code Requirements ................................ 1

About Installation .................................................................1

Replacement Parts .............................................................. 1

Technical Assistance ........................................................... 1

Safety Awareness---------------------------------------------- 3

Safety Notice......................................................................... 3

Attention Statements ............................................................ 3

Safety Statements ................................................................ 3

Specifications --------------------------------------------------- 4

1200XX/120X-IMXX Models ..................................................4

Troubleshooting – Quick Reference Guide------------ 5

Displayed Fault Codesr -------------------------------------- 6

Troubleshooting Flowchart s-------------------------------- 8

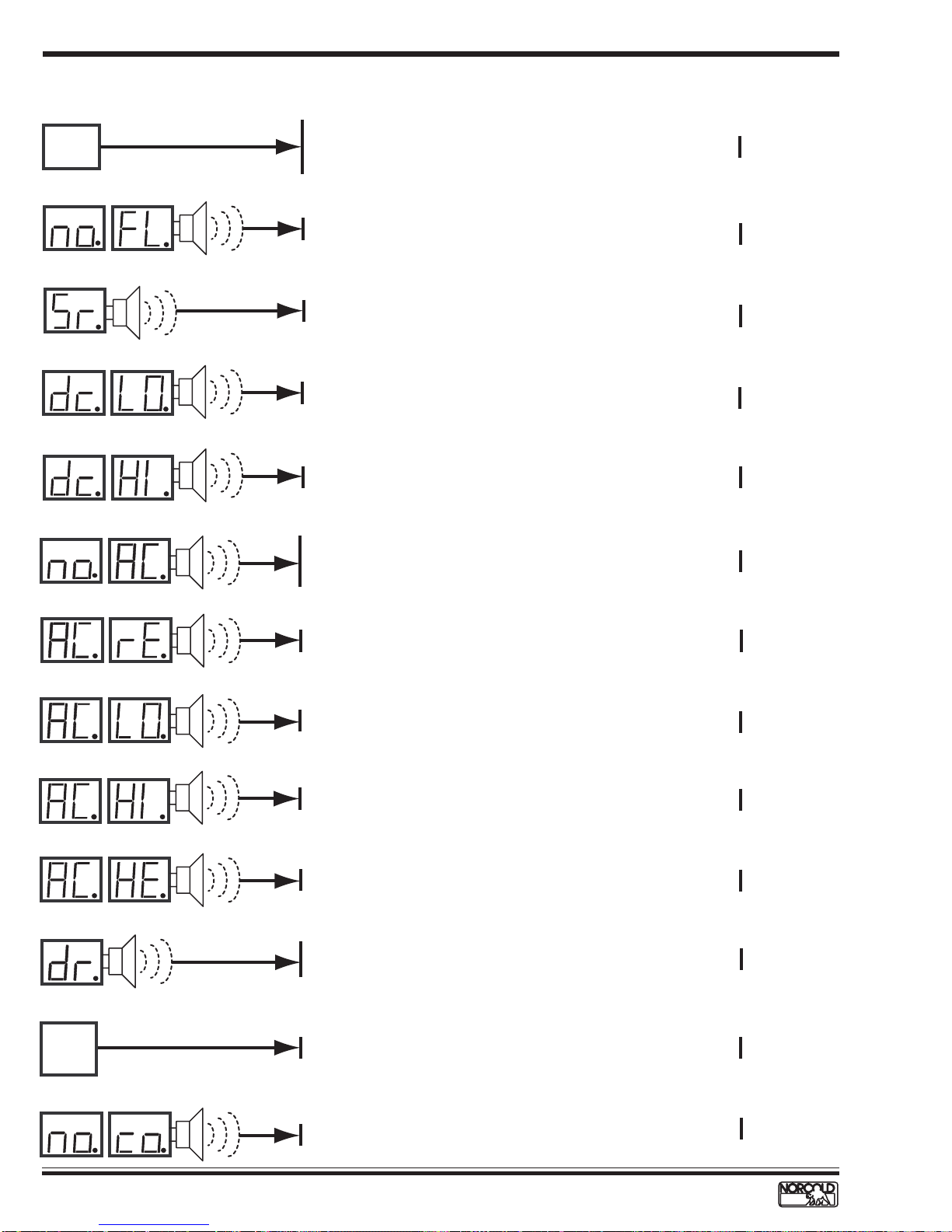

Blank Display – Refrigerator does not turn on .................... 8

no LP - no FL Fault Code – Burner failed to ignite or

reignite.................................................................................. 9

dc LO Fault Code – Low dc voltage................................... 10

Sr FS - Sr Fault Code – Flame sense circuit failure ......... 10

dc HI Fault Code – DC voltage high .................................. 11

Sr CL - AC rE Fault Code – AC relay stuck closed............ 11

no AC Fault Code – No AC power available...................... 12

AC LO Fault Code – AC voltage low ..................................13

AC HI Fault Code – AC voltage high.................................. 13

AC HE Fault Code – AC heater failed open ...................... 14

Food Compartment Lamp Switch .....................................15

Lamp Switch Operation.................................................... 15

dr Fault Code – Door open for more than 2 minutes .......15

Lamp Switch Testing Procedure ......................................15

Thermistor Failure Fault – Controls in Backup Operating

System mode ..................................................................... 16

Backup Operating System (BOS) ......................................16

1200XX/120X-IMXX Backup Operation .......................... 16

Power Board Resetting Procedure ................................... 17

no co Fault Code – No cooling detected by the controls - S/

N 832171 and higher .........................................................17

Ventilation-------------------------------------------------------18

Roof Exhaust Venting......................................................... 18

Air Intake Vent .....................................................................18

Roof Exhaust Vent.............................................................. 18

Baffles.................................................................................19

Vertical Angled Baffles .....................................................19

Double Sidewall Venting ....................................................20

Air Intake Vent ..................................................................20

Sidewall Exhaust Vent ...................................................... 20

LP Gas System------------------------------------------------- 2 3

Pressure Requirements ....................................................23

Components ...................................................................... 24

Testing for LP Gas Leaks ..................................................24

Solenoid Gas Valve .........................................................24

Solenoid Gas Valve Connections ....................................24

Replacing Old Style Gas Valve .......................................24

Orifice................................................................................25

Burner ............................................................................... 25

Burner Tube ...................................................................... 25

Flue ................................................................................... 26

Flue Cap ........................................................................... 26

Flue Baffle......................................................................... 26

Flame Appearance .............................................................26

Burner Cleaning Procedure ...............................................27

Electrical Requirements and Components ----------- 2 8

DC Voltage Requirements and Polarity ............................28

Power Board DC Fuse......................................................28

DC Power Wiring Requirements .......................................28

AC/DC Converter as Power Source .................................. 28

Lamp Assembly ...............................................................28

Divider Heater ..................................................................28

AC Power Requirements ................................................... 29

AC Heaters ....................................................................... 29

AC Heater Circuit Fuse .................................................... 29

Power Board AC Power Cord........................................... 29

Ice Maker AC Power Cord................................................30

12 Vdc Ventilation Fans ...................................................... 30

Cooling Unit-----------------------------------------------------31

Description .........................................................................31

Heat Absorption ...............................................................31

Leveled Operation ............................................................31

Gradual Decrease in Cooling Efficiency ...........................31

Cooling Performance Monitoring Control .........................31

Units with Serial Numbers 832171 and Higher Only ..... 31

Cooling Unit Monitoring Control Operation .....................32

First "no co" Fault Code.................................................... 32

Refrigerant Leakage ..........................................................32

Disposal of Cooling Unit ...................................................32

Cooling System Diagnostic Flowchart .............................. 33

Removing the Refrigerator and Cooling Unit ................. 35

Replacing the Cooling Unit ................................................35

Removing Cooling Unit ...................................................36

Installation of Replacement Cooling Unit ......................36

Reinstallation of Refrigerator into Enclosure .................. 38

Electronic Components -------------------------------------39

Power Board .......................................................................39

Removal–Power Board .................................................... 39

Installation–Power Board ................................................. 39

Controls----------------------------------------------------------- 40

Optical Control Assembly ...................................................40

Replacing Optical Control Assembly ..............................40

AUTO AC Operation .........................................................41

Modes of Operation, S/N 832170 and Lower ................... 41

AUTO................................................................................. 41

AUTO LP Operation .........................................................41

Shift from AUTO LP GAS to AUTO AC............................. 41

No AC Power and No Flame............................................ 41

Troubleshooting No Flame and No AC Faults ................ 41

AC Manual Mode ................................................................ 42

No AC Power or Loss of AC Power.................................. 42

AC Power Restored.......................................................... 42

Troubleshooting "no AC" Fault ........................................ 42

LP Manual Mode.................................................................42

Flame Fails to Ignite or Flame Goes Out ........................ 42

AUTO AC Operation .........................................................43

AUTO LP Operation .........................................................43

Modes of Operation, S/N 832171 and Higher ..................43

AUTO................................................................................. 43

Shift from AUTO LP GAS to AUTO AC............................. 43

No AC Power and No Flame............................................ 43

Troubleshooting No Flame and No AC Faults ................ 43

AC Manual Mode ................................................................ 44

No AC Power or Loss of AC Power.................................. 44

AC Power Restored.......................................................... 44

Troubleshooting "no AC" Fault ........................................ 44

LP Manual Mode.................................................................44

Flame Fails to Ignite or Flame Goes Out ........................ 44

Diagnostic Mode - S/N 832170 and Lower ------------45

Diagnostic Mode ................................................................ 45

Refrigerator Service Manual

www.norcold.com/cda

1200XX/120X-IMXX Models

i

Accessing the Diagnostic Mode ....................................... 45

Changing Screens ............................................................45

Exiting the Diagnostic Mode.............................................45

Screens and Diagnostic LEDS Information, Units with S/N

832170 and Lower .............................................................46

Diagnostic Mode - Units S/N 832171 and Higher---- 4 8

Diagnostic Mode ................................................................ 48

Accessing the Diagnostic Mode ....................................... 48

Changing Screens ............................................................48

Exiting the Diagnostic Mode.............................................48

Screens and Diagnostic Segments Information ..............49

Wiring Pictorials and Diagrams-------------------------- 51

Ice Maker Components and Service -------------------54

Specifications .....................................................................54

Wire Harness .....................................................................54

Water Fill Tube ................................................................... 55

Water Fill Line.....................................................................55

12 Vdc Water Line Heater ..................................................55

Water V alve......................................................................... 56

Water Valve Replacement Procedure ............................. 56

To install replacement solenoid water valve: ..................56

Ice Maker Troubleshooting Chart ......................................57

Water Valve Service............................................................ 57

Replacing Ice Maker .......................................................... 58

Cycle Testing Ice Maker ..................................................... 59

Checking Water Valve Operation....................................... 59

Water Fill Adjustment ......................................................... 60

Checking Water Valve Solenoid Resistance ....................60

Checking Mold Heater Resistance ................................... 61

Checking Voltage to Motor .................................................61

Winterization .......................................................................61

ii

1200XX/120X-IMXX Models

www.norcold.com/cda

Refrigerator Service Manual

INTRODUCTION

About this Manual

This service manual provides maintenance, diagnostic,

and repair information for NORCOLD, INC.® model

1200XX/120X-IMXX gas absorption refrigerators. It is a

reference tool designed for technicians who are

knowledgeable in the theory and operation of gas/

electric absorption refrigerators, liquefied petroleum

(LP) gas–propane–systems, and AC/DC electrical

systems as installed in a variety of recreational

vehicles (RV).

All information, illustrations, and specifications

contained in this publication are based on the latest

product information available at the time of publication.

NORCOLD, INC.® reserves the right to make changes

at any time without notice.

Model Identification

Model 1200XX/120X-IMXX are 2-way refrigerators that

can operate on AC power or LP gas. The electronic

controls operate on 12 Vdc.

Letter(s) appended to the model number identify

factory installed accessories. For example, a 1200IMSS is a 2-way refrigerator equipped with an ice

maker and stainless steel doors.

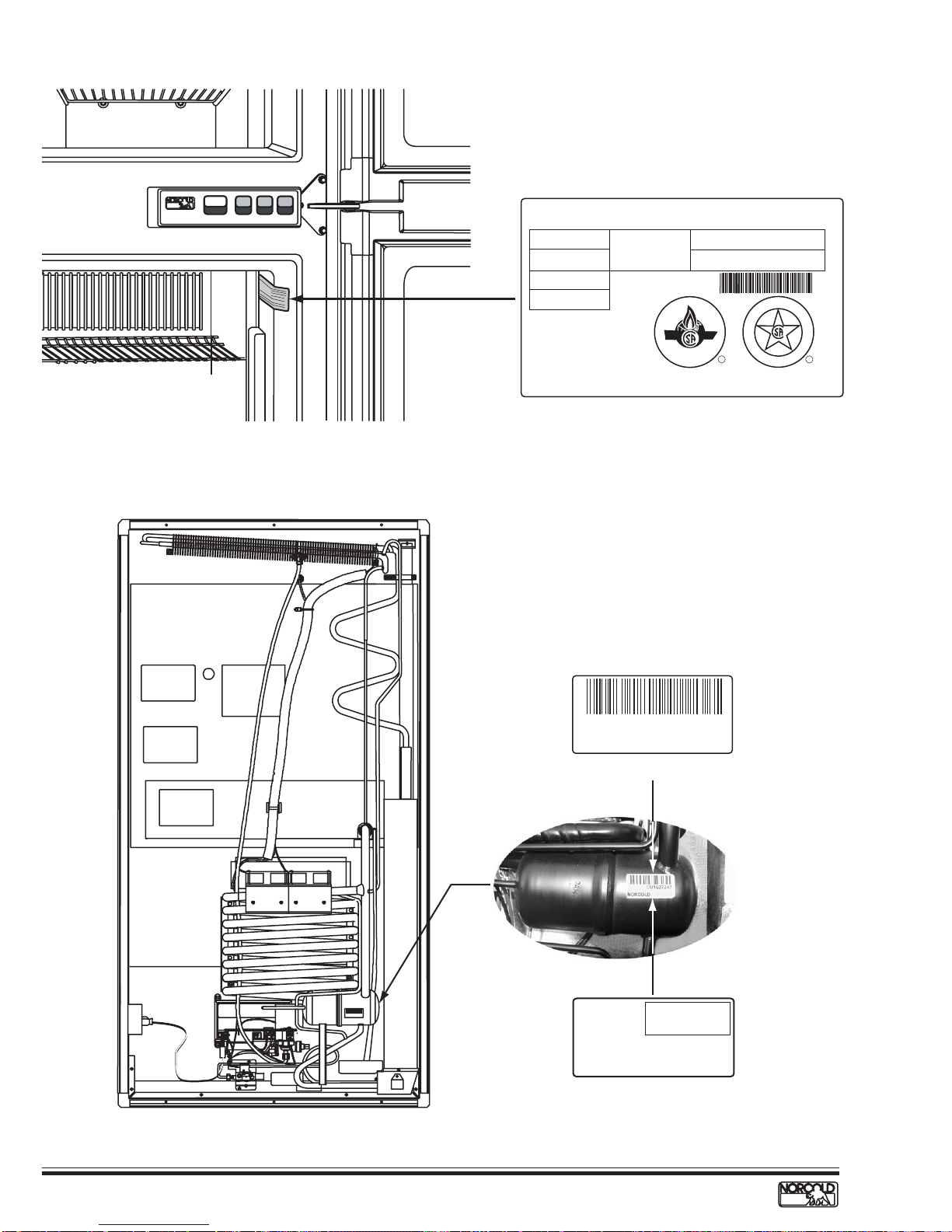

Information Label

The information label is located in the upper right

corner of the fresh food compartment just below the

divider. See Figure 1, p age 2. The label provides the

following information:

Serial number.

Model number.

LP gas (propane) pressure.

Btu/hr.

AC voltage and amperage.

DC voltage and amperage.

Design certification.

Vent kit requirement.

Cooling Unit Serial Number

The cooling unit has a separate serial number that

appears on the cooling unit bar code label. The label is

affixed to the surface of the cooling unit leveling

chamber. See Figure 2, p age 2.

Certification and Code Requirements

NORCOLD, INC.® 1200XX/120X-IMXX gas/electric

absorption refrigerators are certified under the latest

edition of ANSI Z21.19B standards for installation in

mobile homes or recreational vehicles. NORCOLD,

INC.® 1200XX/120X-IMXX gas/electric absorption

refrigerators are also certified with the Canadian

Standards Association, CAN/CGA-1.4-M94.

Electrical components are compliant.

About Installation

Refrigerator installation must conform with the

1200XX/120X-IMXX Installation Manual for the

NORCOLD, INC.® limited warranty to be in effect.

Installation must also comply with applicable local

codes and standards set by the applicable certification

agency.

Replacement Parts

Use only authorized NORCOLD, INC.® replacement

parts. Generic parts do not meet NORCOLD, INC.

specifications for safety , reliability , and performance.

The use of unauthorized aftermarket or generic

replacement parts voids the refrigerator's limited

warranty coverage.

®

T echnical Assistance

If unable to resolve technical issues using the

information provided in this manual, technical support

for service technicians is available through the

NORCOLD, INC.® Customer Service Center:

℡℡

℡ Telephone:.................................... 1-800-444-7210.

℡℡

Fax:.............................................. 1-937-497-3183.

World Wide Web: ............... www.norcold.com/cda.

The following information is required to process

technical support requests:

Model number.

Serial number.

Make, model, and year of recreational vehicle.

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

1

Figure 1. Refrigerator information label location

NORCOLD

Serial Number

700000

Made in USA

NORCOLD

XXXXXX

NORCOLD

Serial Number

XXXXXX

Made in USA

1 COLD-

9 COLDEST

ON

SET TEMP MODE ON/OFF

NORCOLD.

INC.

SIDNEY,

OHIO

pourle GPL, equipped por le propan

TESTED FOR LP GAS: EQUIPPED FOR PROPANE / Teste

3.8 Amps 456 Watts

SUPPLY

alimentati

11 "WC

10.5 "WC

BURNER

bruleur

120VAC

60Hz

12VDC

2.54 LBS

REFRIGERANT/frigorigene

R707

TEST PRESSURE /

D'ESSAI 800 PSI

1.90 Amps 23 Watts

SERIAL # / N de serie

XXXXXXX

MODEL # / N de modele

GROUP CODE / code de

INPUT / puissance

1200LRIM

For recreational vehicle installation

Min. Installation clearance 0" sides, top

bottom, back. Install only with Kit #3

See installation instructions.

Pour installation vehicule de plaisance

Degagement minimum pour I'installation

0" cotes, haut,bas, arriere, Installer

uniquement avec latrousse n_3

Voir les instructions d'installation.

618860

30916

2200 BTUH

CSA-1.10-2003

REFRIGERATORS

ANSI Z221.19-2003

REFRIGERATORS

D

E

S

I

G

N

C

R

E

T

I

F

I

E

D

CERTIFIED

R

R

Serial Number

700000

Made in USA

NORCOLD

Figure 2. Cooling unit bar code label location

NORCOLD

Serial Number

NORCOLD

Serial Number

XXXXXX

Bar code label

XXXXXX

Plain text label

Made in USA

Made in USA

2

1200XX/120X-IMXX Models

www.norcold.com/cda

Refrigerator Service Manual

Safety Notice

It is not possible to anticipate all of the conceivable

ways or conditions under which the refrigerator may be

serviced or to provide cautions as to all of the possible

hazards that may result. Standard and accepted safety

precautions and equipment should be used when

working on electrical circuits and handling toxic or

flammable materials. Safety goggles and other

required protection should be used during any process

that can cause material to become airborne, such as

removing a leaking cooling unit and cleaning

components.

Attention Statements

The safety alert symbol followed by the word

WARNING or CAUTION identifies potential safety

hazards or conditions.

!

Safety Statements

!

Do not modify, alter, or equip the refrigerator to the

use of any other fuel (natural gas, butane, etc.). 1200

refrigerators are designed and equipped for the use of

LP gas–propane gas–only.

!

Incorrect installation, adjustment, alteration, or

maintenance of the refrigerator can cause personal

injury, property damage, or both.

!

Do not smoke, light fires, or create sparks when

working on the propane gas system.

!

Do not use an open flame for leak testing any of the

propane gas system components. Propane gas is

highly flammable and explosive.

!

Always use two wrenches to tighten or loosen LP gas

connections. Damaged connections, piping, and

components create the potential for gas leaks.

!

All electrical connections and repairs to the refrigerator

must comply with all applicable codes. Refer to the

certification and code requirements section of the

1200XX/120X-IMXX Installation Manual for more

information.

!

Do not work on live electrical circuits. Turn off AC

power and DC power sources before attempting to

remove, service, or repair any of the refrigerator's

electrical or electronic components.

!

Do not modify, bypass, or eliminate any of the

refrigerator's electrical components, electronic circuits,

or propane gas system components.

!

Do not wet or spray liquids on or near electrical

connections or electronic components. Most liquids,

including leak detection solutions, are electrically

conductive and pose the potential for an electric shock

hazard, short electrical components, damage

electronic circuits, and/or ignite a fire.

SAFETY AW ARENESS

The safety alert symbol with the appropriate heading

appears on all safety labels posted on the refrigerator

and safety awareness notices presented throughout

this manual.

!

WARNING:

The above heading identifies hazards or conditions,

which if ignored can cause serious injury , death, and/

or extensive property damage.

!

CAUTION:

The above heading identifies hazards, which if ignored

can cause injury and/or property damage.

!

Do not use leak test solutions that contain ammonia

or chlorine. Ammonia and chlorine degrade copper and

brass components.

!

The cooling unit is a sealed system under

pressure! Do not try to repair or recharge the cooling

unit. Do not bend, drop, weld, drill, puncture, saw, or

strike the cooling unit.

!

Handle a leaking cooling unit with extreme

caution! The cooling unit contains ammonia,

hydrogen, and sodium chromate. Ammonia can cause

severe skin and eye burns. Hydrogen is highly

flammable, can ignite, and burns with an intense

flame. Certain chromium compounds, such as sodium

chromate, are carcinogenic.

!

Do not use extension cords. Do not remove the

grounding prong from the refrigerator AC power cord.

Do not use a two prong adapter to connect the

refrigerator to the AC outlet.

!

Do not over-fuse electrical circuits. Use specified

fuses and AWG wire sizes. The "Specifications"

section of this manual provides fuse size information.

Refer to the 1200XX/120X-IMXX Installation Manual

for the correct AWG wire size specifications.

!

Prevent child entrapment! Before disposing of the

refrigerator, remove all doors and fasten all shelves

with retainers.

!

Some of the refrigerator's metal components have

sharp corners and edges. Wear hand protection, such

as cut resistant gloves, and exercise extreme care

when handling the refrigerator.

!

Make sure all hardware, such as hinges and fasteners

(retaining screws, etc.), is properly fastened.

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

3

SPECIFICATIONS

1200XX/120X-IMXX Models

Storage volume

Freezer ----------------------------------------------------------------------------------------------------------------------- 1.3 ft.

3

each

Fresh food compartment -------------------------------------------------------------------------------------------------------- 8.0 ft.

Rough opening dimensions (H x W x D)

1200XX/120X-IMXX ---------------------------------------------------------------------------------- 63

1

/4 in. x 3211/16 in. x 24 in.

Decorative panels dimensions

Thickness--------------------------------------------------------------------------------------------------------------------------Freezer door (H x W) ----------------------------------------------------------------------- 17

Fresh food compartment door------------------------------------------------------------ 40

17

/32 in. x 1611/16 in. (each door)

11

/32 in. x 1613/64 in. (each door)

3

/16 in.

Controls

Type ------------------------------------------------------------------------------------ Electronic with built-in diagnostic function

ON/OFF/MODE/TEMP SET switches ----------------------------------------------------------------- Flush push-button style

Temperature settings ---------------------------------------------------------------------------------------------- 1=cold, 9=coldest

T emperature sensor ---------------------------------------------------------------------------------------- Thermistor, fin-mounted

Off-level operating limits

Side-to-side------------------------------------------------------------------------------------------------------- 3 degrees maximum

Front-to-back----------------------------------------------------------------------------------------------------- 6 degrees maximum

DC power

Controls operating voltage ----------------------------------------------------------------------------------------- 10.5 to 15.4 Vdc

DC fuse (F1 in power board)------------------------------------------------------------------------------------------------------------ Units with serial numbers 51660 and lower ----------------------------------3 A (violet color), automotive blade type

Units with serial numbers 51661 to 8321 171-------------------------- T wo, 3 A (violet color),automotive blade type

Units with serial numbers 8321 172 and higher -------------------------------- 5 A (tan color), automotive blade type

3

DC amp draws (at nominal 12 Vdc)

Automatic ignition----------------------------------------------------------------------------------------------------------------- 0.50 A

Moisture reduction heater and divider heater ------------------------------------------------------------------------------- 0.70 A

Fresh food compartment lamp ------------------------------------------------------------------------------------------------- 0.46 A

Gas valve--------------------------------------------------------------------------------------------------------------------------- 0.146 A

Fans (2) ------------------------------------------------------------------------------------------------------------------ 0.30 A (per fan)

AC power

AC heater operating voltage requirements -----------------------------------------------------------------------108 to 132 Vac

Fuse AC heater circuit (F3 in power board)------------------------------------ 5 A,

1

/4 in. x11/4 in. AGC type fast acting

AC heater rating ------------------------------------------------------------------------- 225 W @ 120 V ac (resist ance of 64 Ω)

LP gas (propane)

Operating pressure ---------------------------------------------------------------------------------------------- 10.5 to 11.5 in. w.c.

Heat input----------------------------------------------------------------------------------------------------2200 Btu/h @ 11 in. w.c.

Orifice, old style ----------------------------------------------------------------------------------------------------------0.190 jeweled

Orifice, new style-------------------------------------------------------------------------------------------------------------------- LP18

Gas ignition---------------------------------------------------------------------------------- Automatic with flame sensing circuit

Electrode tip-to-burner air gap -----------------------------------------------------------------------------------------

1

/8 to 3/16 in.

4

1200XX/120X-IMXX Models

www.norcold.com/cda

Refrigerator Service Manual

TROUBLESHOOTING – QUICK REFERENCE GUIDE

Problem Possible Cause Checks/Reference

The refrigerator does not turn ON.

The refrigerator does not cool on

AC power.

The refrigerator does not cool

efficiently on AC power.

The refrigerator does not operate

on LP gas.

The refrigerator does not

cool efficiently on LP gas.

No 12 Vdc power to refrigerator.

Faulty/loose 12 Vdc connections.

F1 fuse in power board open.

No AC power to refrigerator.

F3 fuse in power board open.

AC heater failed open.

Ventilation obstructed.

AC voltage low.

No LP gas.

Incorrect electrode-to-burner gap.

Faulty spark/sense electrode assembly.

Flame sensing circuit failure.

Ventilation obstructed.

Incorrect LP gas pressure.

Dirty burner.

Missing flue baffle.

Flue cap blocked.

See page 9.

Check 12 Vdc connections.

Check F1 fuse.

See page 13.

Check F3 fuse.

Check heaters' resistances.

Check enclosure for air flow obstructions.

Check AC voltage input.

Check LP gas supply and valves.

Set electrode to 1/8 to 3/16 in.

Replace spark/sense electrode.

Replace power board. See page 40.

Check enclosure for obstructed air flow.

Set gas pressure to 10.5 to 11.5 in. w.c.

Clean burner. See page 28.

Replace flue baffle. See page 27.

Clear flue cap. See page 27.

"No" "co" fault code.

Poor ventilation.

Off-level operation.

Dirty burner.

Low AC voltage.

Cooling fan inoperative (if present).

Improper installation.

Check enclosure for obstructed air flow.

Level unit. See page 32.

Clean burner. See page 28.

Check AC voltage input.

Test fan operation.

Check installation. See pages 19-23

and 1200 Installation Manual.

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

5

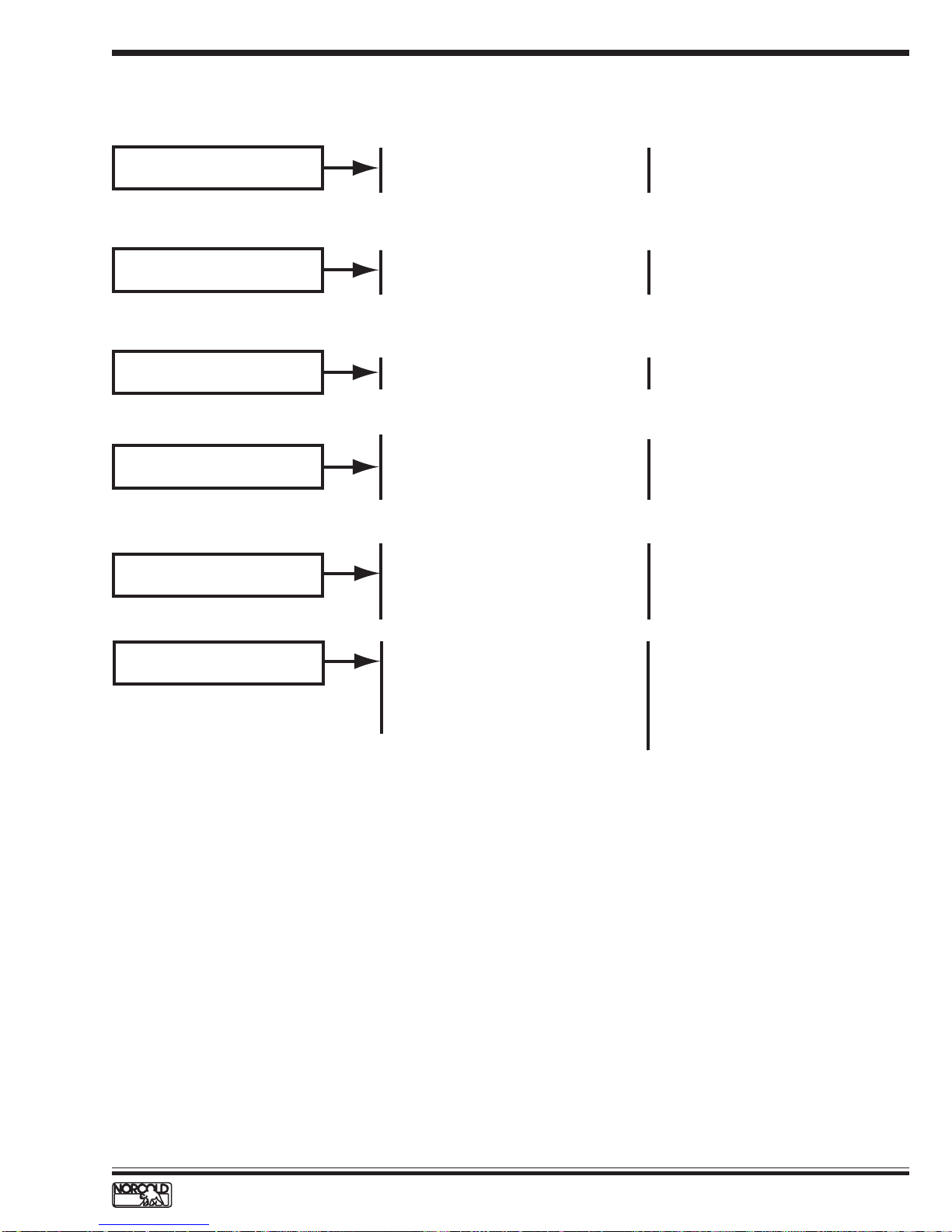

DISPLA YED FAULT CODES: S/N 832170 AND LOWER

Code

LEDs off

Cold

TEMP

ON

OFF

SET

MODE

AC LP GASAUTO

Mode LEDs off

"no" Flashing

Cold

TEMP

ON

OFF

SET

MODE

AC LP GASAUTO

"LP GAS" LED Flashing

"FS" and "Sr" Flashing

Cold

TEMP

ON

OFF

SET

MODE

AC LP GASAUTO

Coldest

Coldest

Coldest

Blank

Screen

Audible

Alarm

Audible

Alarm

Probable Cause

Refrigerator turned off.

No 12 Vdc to refrigerator

F1 fuse open.

The burner failed to ignite or reignite.

Flame sense circuit failure.

Reference

See page 9.

See page 10.

See page 11.

"LP GAS" LED Flashing

"dc" and "LO" Flashing

Cold

TEMP

ON

OFF

SET

MODE

AC LP GASAUTO

"dc" and "HI" Flashing

Cold

TEMP

ON

OFF

SET

MODE

AC LP GASAUTO

"no" Flashing

Cold

TEMP

ON

OFF

SET

MODE

AC LP GASAUTO

Coldest

Coldest

Coldest

Audible

Alarm

Audible

Alarm

Audible

Alarm

DC voltage high.

No AC power available to refrigerator.

AC cord not plugged into power board.

F3 fuse open.

See page 11.DC voltage low.

See page 12.

See page 13.

"AC" LED Flashing

6

1200XX/120X-IMXX Models

www.norcold.com/cda

Refrigerator Service Manual

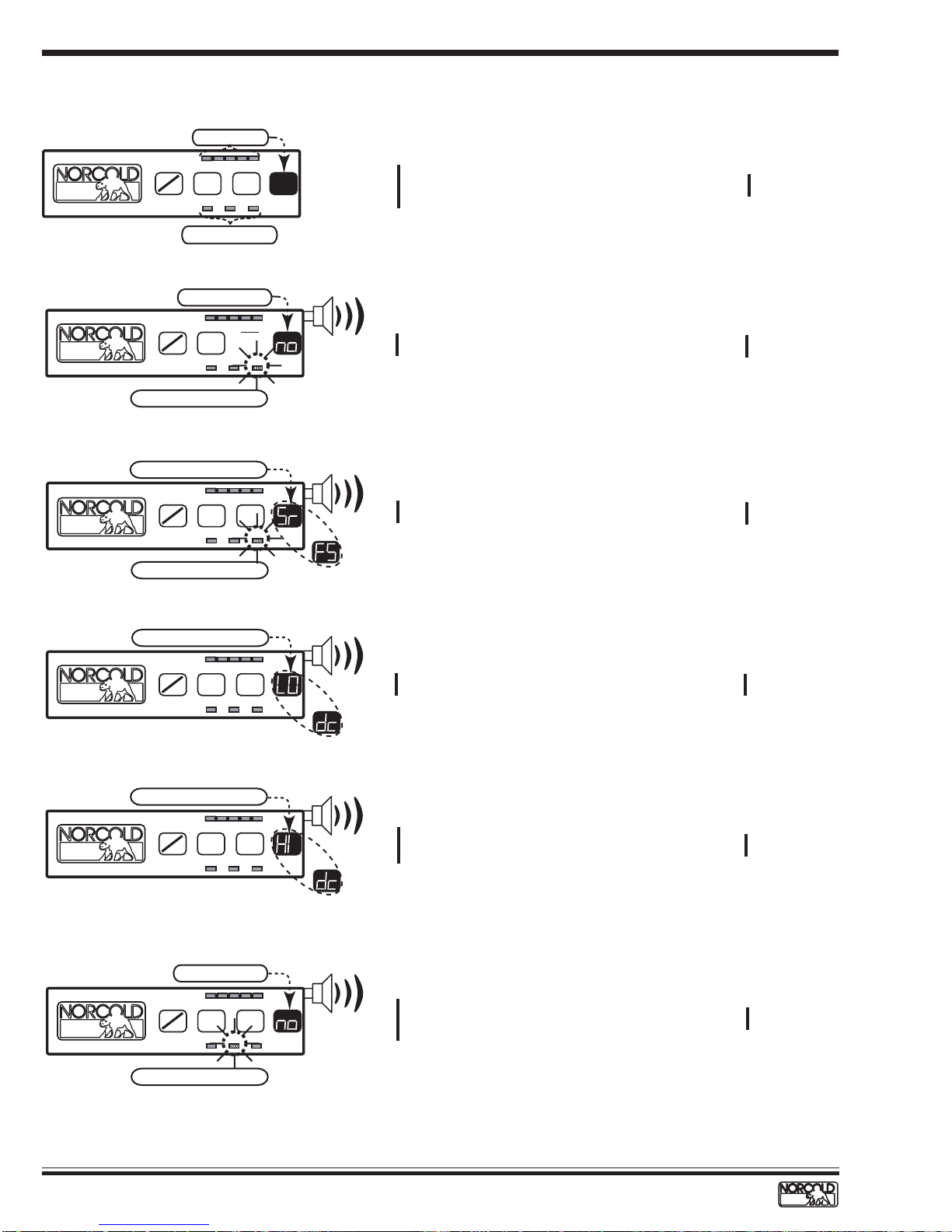

Code

Probable Cause

Reference

"Sr" and "CL" Flashing

Cold

TEMP

ON

SET

OFF

AC LP GASAUTO

"AC" LED Flashing

"LO" Flashing

Cold

TEMP

ON

SET

OFF

AC LP GASAUTO

"AC" LED Flashing

"HI" Flashing

Cold

TEMP

ON

SET

OFF

AC LP GASAUTO

"AC" LED Flashing

MODE

MODE

MODE

Coldest

Coldest

Coldest

Audible

Alarm

Audible

Alarm

Audible

Alarm

AC voltage low.

AC voltage high.

See page 12.AC relay stuck closed.

See page 14.

See page 14.

"Sr" and "OP" Flashing

Cold

ON

OFF

"AC" LED Flashing

"dr" Flashing

Cold

ON

OFF

Temperature LED Flashing

Cold

ON

OFF

Selected Mode LED "ON"

TEMP

SET

Flashing "dr"

TEMP

SET

TEMP

SET

Audible

Coldest

MODE

AC LP GASAUTO

Alarm

See page 15.AC heater failed open.

Audible

Coldest

MODE

AC LP GASAUTO

Coldest

MODE

AC LP GASAUTO

Alarm

Fresh food compartment door open more than

2 minutes. Lamp switches faulty.

See page 16.

See page 17.Backup operating system in operation.

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

7

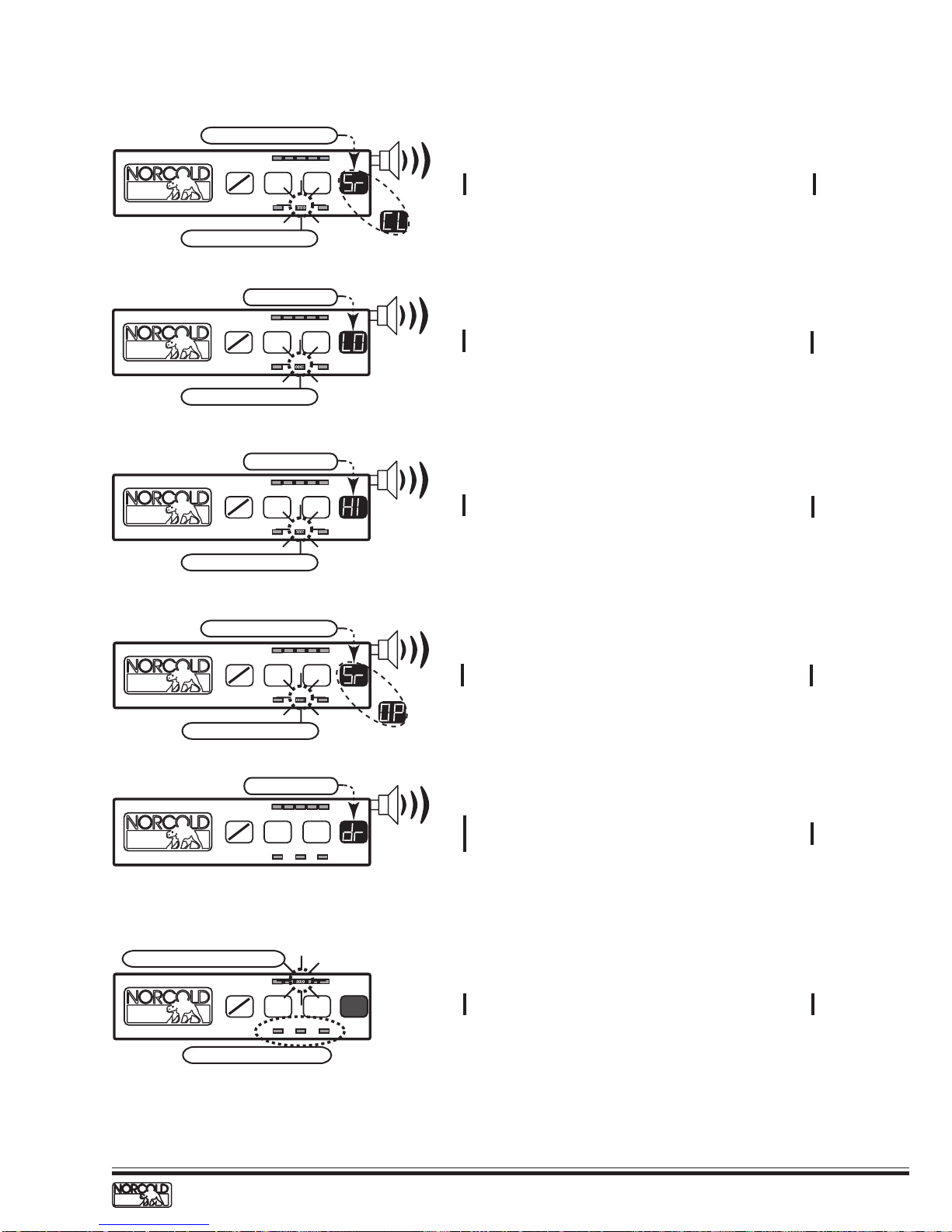

DISPLA YED FAULT CODES: S/N 832171 AND HIGHER

Code

Blank

Display

Screen

Probable Cause

Reference

Refrigerator turned off.

No 12 Vdc to refrigerator.

See page 9.

F1 fuse open.

a

t

i

n

n

r

g

e

t

l

A

y

D

a

l

i

s

p

Audible

Alarm

n

a

r

t

e

i

n

t

l

g

A

D

y

i

a

l

s

p

a

n

t

r

i

n

e

t

g

l

A

D

y

i

a

l

s

p

a

n

t

r

i

n

e

t

g

l

A

D

y

i

a

l

s

p

a

n

t

r

i

n

e

t

g

l

A

y

D

a

l

i

s

p

a

n

t

r

i

n

e

t

l

g

A

D

y

i

a

l

s

p

a

t

i

n

n

r

g

e

t

l

A

D

y

i

a

l

s

p

a

t

i

n

n

r

g

e

t

l

A

D

y

i

a

l

s

p

Audible

Alarm

Audible

Alarm

Audible

Alarm

Audible

Alarm

Audible

Alarm

Audible

Alarm

Audible

Alarm

Audible

Alarm

The burner failed to ignite or reignite.

Flame sense circuit failure.

DC voltage low.

DC voltage high.

No AC power available to refrigerator.

AC cord not plugged into power board.

F3 fuse open.

AC relay stuck closed.

AC voltage low.

AC voltage high.

AC heater failed open.

See page 10.

See page 11.

See page 11.

See page 12.

See page 13.

See page 12.

See page 14.

See page 14.

See page 15.

Audible

Fresh food compartment door open more than 2 minutes.

Lamp switches faulty.

Alarm

Flashing

Tem p

Setting

A

a

t

n

i

r

n

e

g

t

l

Audible

Backup operating system in operation.

No cooling detected by the controls.

D

y

i

a

l

s

p

8

1200XX/120X-IMXX Models

Alarm

www.norcold.com/cda

See page 16.

See page 17.

See pages 18

and 32-35.

Refrigerator Service Manual

TROUBLESHOOTING FLOWCHARTS

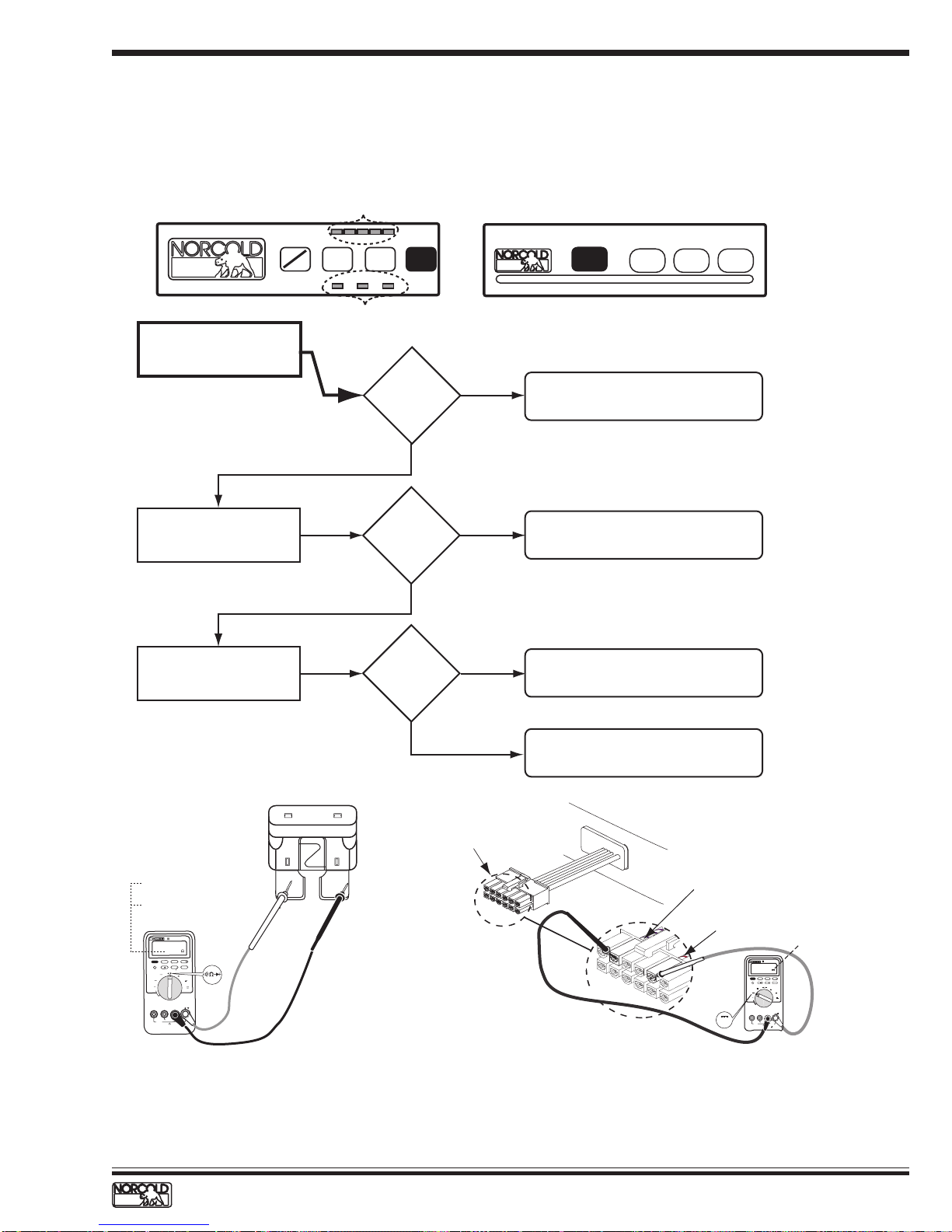

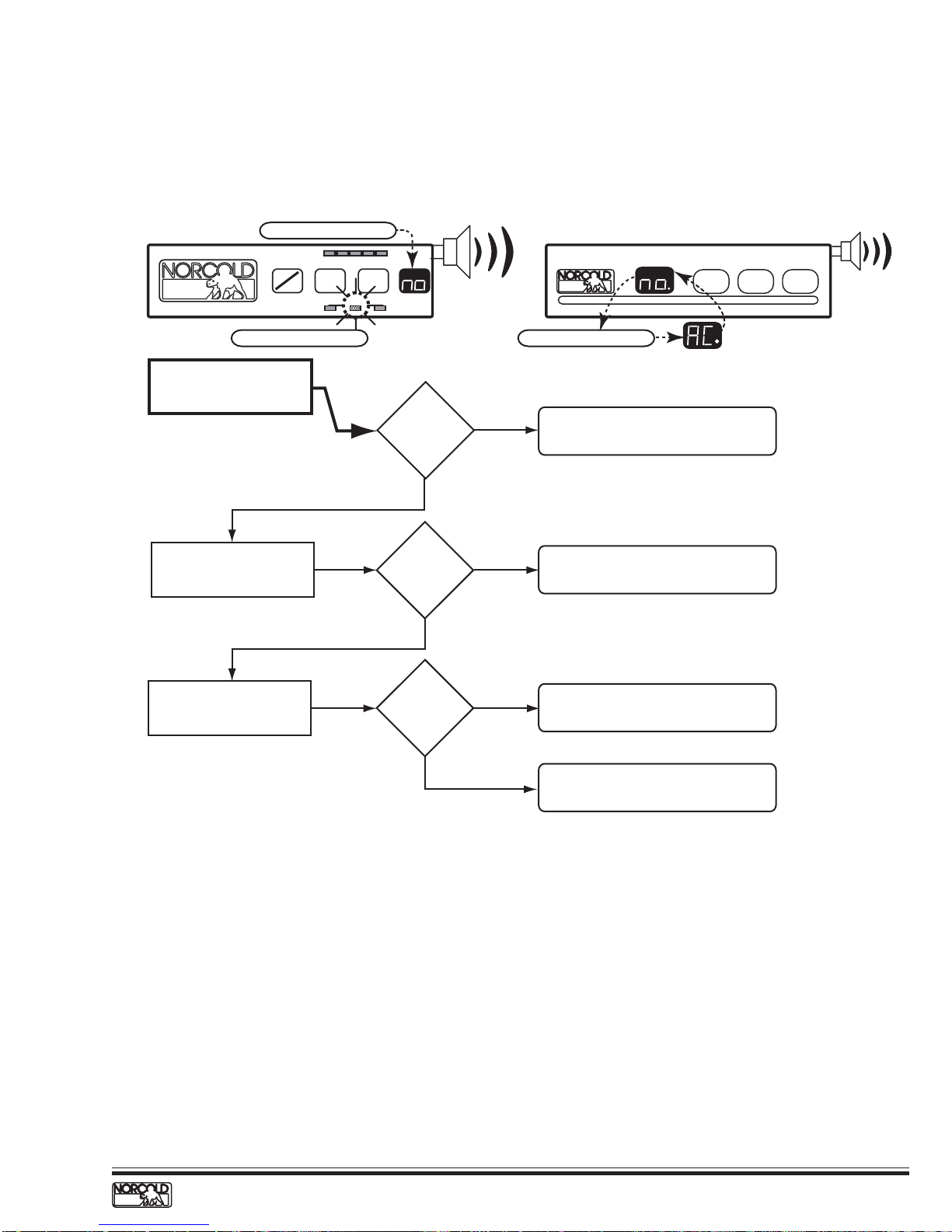

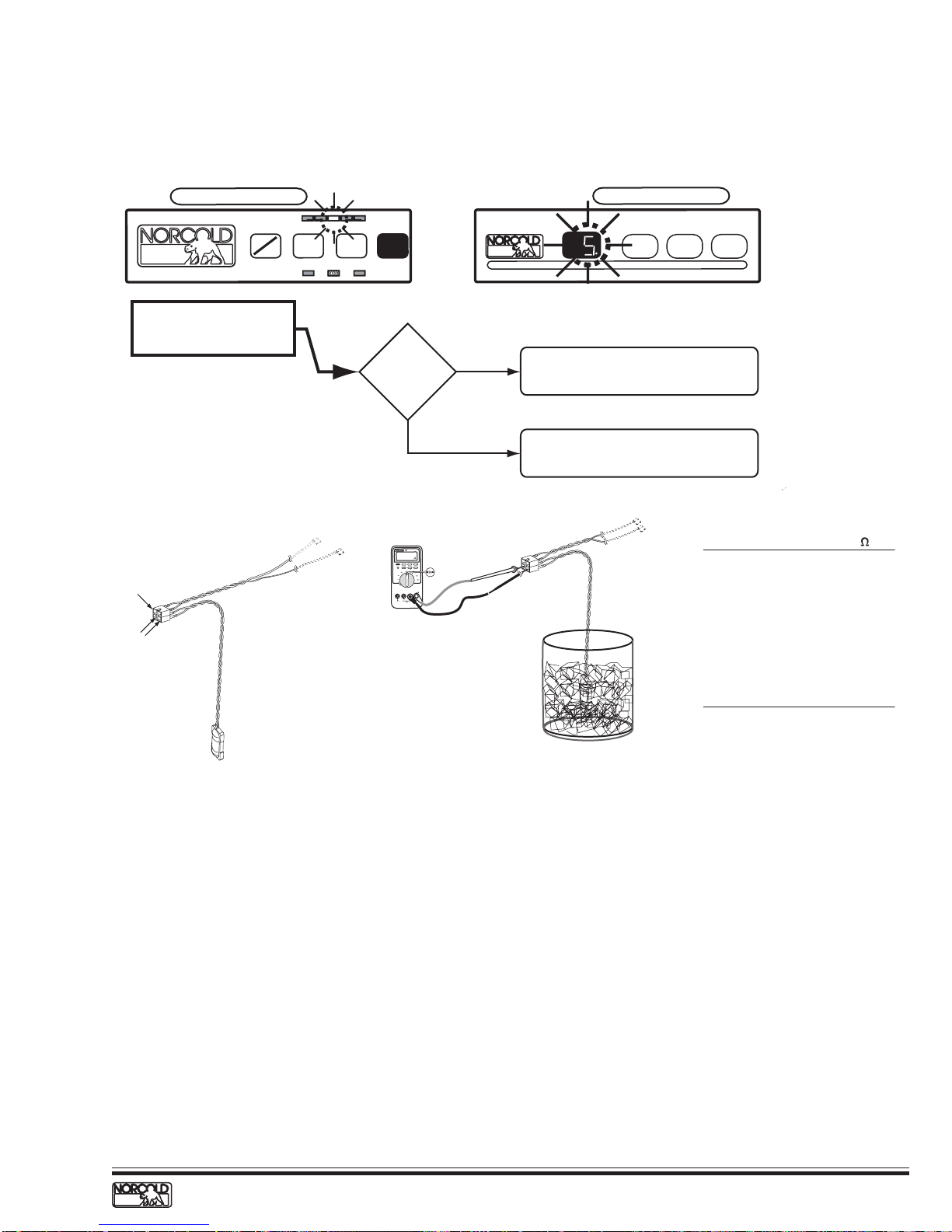

Blank Display – Refrigerator does not turn on

Before beginning this procedure make sure:

■

The RV DC power system is supplying 10.5 to 15.4 volts to the refrigerator.

■

No other RV appliances or lighting circuits are connected to the refrigerator DC circuit.

■

12 Vdc input to the power board is wired according to the 1200XX/120X-IMXX Installation Manual.

Fault indicator displayed:

ON

Measure voltage across

power board 12VDC and

GND1 connections

.

OFF

All LEDs off

Cold

TEMP

SET

AC LP GASAUTO

Mode LED off

MODE

15.4 Vdc?

YES

Coldest

10.5

Blank

Screen

to

NO

Blank

Screen

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

on

1. No DC power input from RV to unit.

2. Faulty wiring or connectors.

Check condition of F1 fuse

in power board. See Figure 3.

Measure voltage at optical

control harness. See

Figure 4.

Good= 00.0

Ohms

Bad = OL

ETER

ULTIM

TRUE RMS M

87

III

00.0

H

HOLD

RANGE

MIN MAX

Hz

REL

PEAK MIN MAX

4 1/2 DIGITS

1 Seconds

mV

mA

A

V

A

µ

V

OFF

V

M

O

C

A

µ

A

m

A

!

400mA MAX

II

T

A

C

FUSED

1000V MAX

10A MAX

FUSED

!

F1 Fuse

F1 fuse okay?

YES

Voltage

present?

YES

Wire harness optical

control display connector

NO

NO

Replace fuse. Refer to

Specifications on page 4.

Replace power board.

See page 40.

Replace optical control assembly.

See page 41.

White/violet wire

White/red wire

V

10.5 to 15.4 Vdc

TRUE RMS MULTI METER

87

III

V

H

MIN MAX RANGE HOLD

HzREL

PEAK MIN MAX

4 1/2 DIGITS

1 Seconds

mV

mA

V

A

µA

V

OFF

V

COM

A

mA µA

!

400mA MAX

CAT II

FUSED

1000V MAX

10A MAX

!

FUSED

Figure 3. Checking the DC fuse continuity

Figure 4. Measurement points for wire harness voltage

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

9

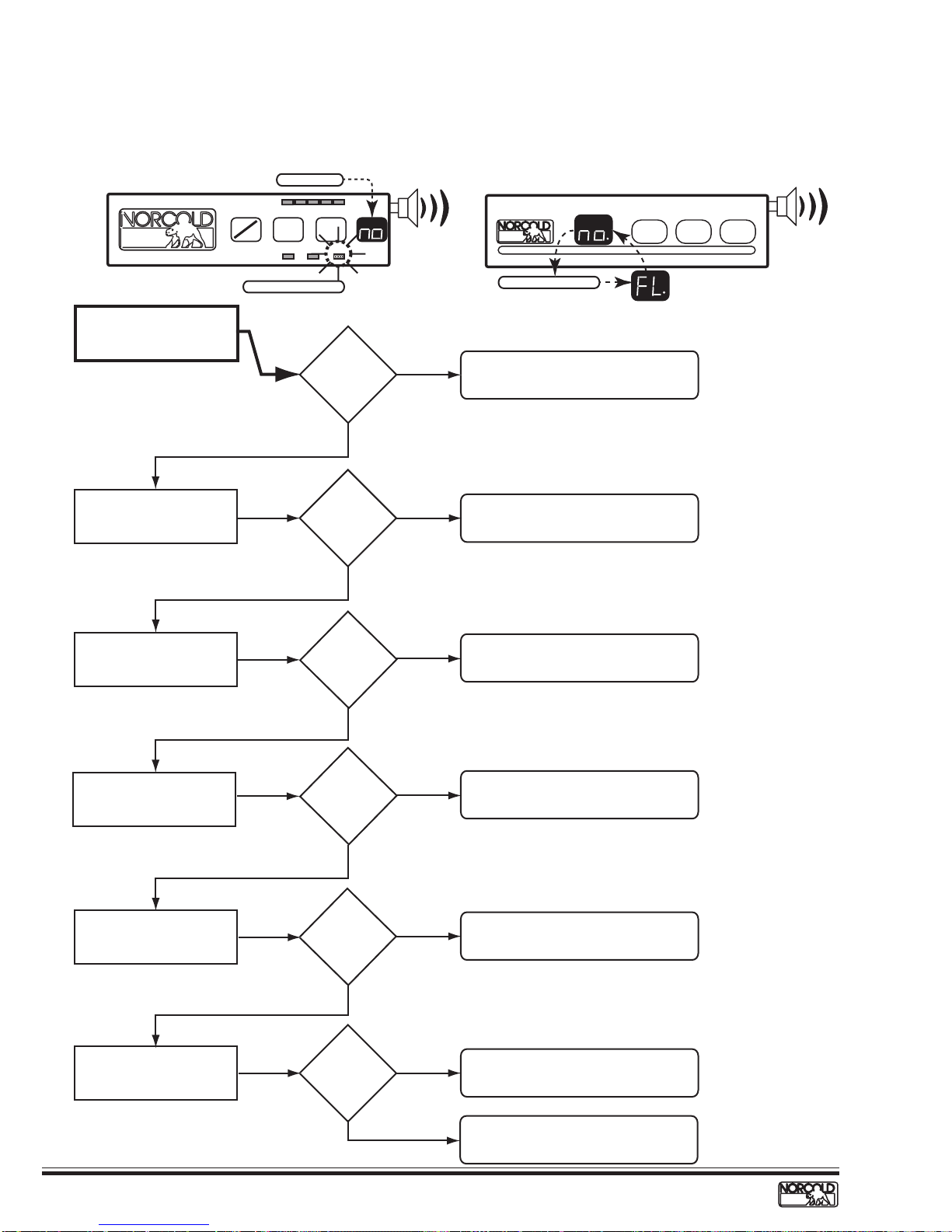

no LP - no FL Fault Code – Burner failed to ignite or reignite

Before beginning this procedure make sure:

■

RV LP gas tank valve is open.

■

Refrigerator solenoid gas valve manual shut-off is open.

■

LP gas pressure at the solenoid gas valve pressure tap is 10.5 to 11.5 in. w.c.

Fault indicator displayed:

Flashing "no"

Cold

TEMP

ON

SET

OFF

Coldest

MODE

AC LP GASAUTO

Audible

Alarm

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

on

Audible

Alarm

Check burner.

Check that electrode-toburner air gap is correct.

Check spark/sense electrode

assembly for continuity.

Blinking LP GAS LED

YES

Air gap

1/8 to 3/16

YES

Continuity?

YES

Burner

clean?

inch?

NO

NO

NO

Flashing "no" and "FL"

Clean and service burner.

See page 28.

Set electrode-to-burner air gap

1/8 to 3/16 inch.

Replace spark/sense electrode

assembly.

Check gas valve solenoid

resistance.

79 to 85 Ω?

YES

Check gas valve solenoid

wires for continuity.

Continuity?

YES

Check voltage across power

board terminals GV and

GV_GND.

YES

10

1200XX/120X-IMXX Models

NO

NO

Voltage

present?

www.norcold.com/cda

NO

Replace gas valve.

Replace gas valve wires.

Replace power board.

See page 40.

Faulty gas valve.

Replace gas valve.

Refrigerator Service Manual

Sr FS - Sr Fault Code – Flame sense circuit failure

Fault indicator displayed:

"Sr" and "FS" Flashing

Cold

TEMP

ON

OFF

"AC" LED Flashing

SET

MODE

AC LP GASAUTO

Coldest

Audible

Alarm

"Sr" Flashing

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

on

Audible

Alarm

Flame sense circuit failure.

Replace power board.

See page 40.

dc LO Fault Code – Low dc voltage

Before beginning this procedure:

■

Make sure RV DC voltage to refrigerator is 10.5 to 15.4 volts.

■

Determine if the "dc LO" fault code displays when the converter is the source of DC power.

■

Make sure no other appliance or lighting circuit is connected to the refrigerator DC circuit.

Fault indicator displayed:

"dc" and "LO" Flashing

ON

OFF

Check for DC voltage input

to power board terminals

12VDC and GND1.

Audible

AC LP GASAUTO

MODE

Coldest

Voltage

lower than

10.5 Vdc?

Alarm

YES

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

Check RV 12 Vdc power supply to

refrigerator.

Cold

TEMP

SET

"dc" and "LO" Flashing

on

Audible

Alarm

Electronic controls operate on 12 Vdc. When an AC/DC converter is used to

supply DC power, the refrigerator circuit must be connected to the appliance

output terminals of the converter (filtered side).

If the refrigerator circuit is connected to the unfiltered side, the AC ripple

generated by the converter may cause a "dc LO" fault code to display.

T o troubleshoot a "dc LO" fault, connect a charged 12 volt automotive battery

to the power board. If the "dc LO" code clears, the fault was caused by

unfiltered DC power.

If the "dc LO" code does not clear, replace the power board (see p age 40).

NO

See NOTE below to determine

and correct low "dc LO" fault.

NOTE

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

11

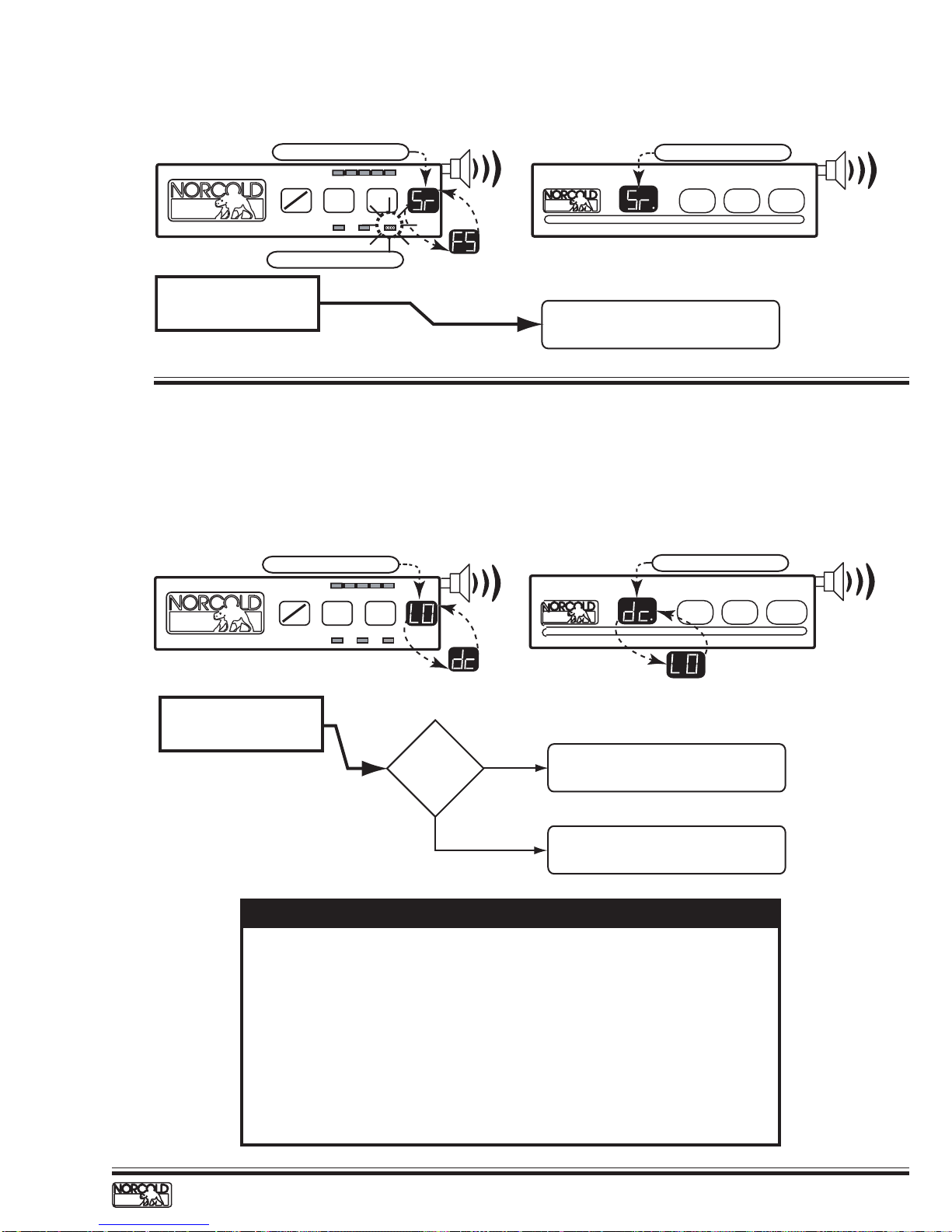

dc HI Fault Code – DC voltage high

Before beginning this procedure:

■

Make sure RV DC voltage to refrigerator is 10.5 to 15.4 volts.

■

Determine if the "dc HI" fault code displays when the converter is the source of DC power.

Fault indicator displayed:

Check for DC voltage input

to power board terminals

12VDC and GND1.

"dc" and "HI" Flashing

Cold

TEMP

ON

OFF

SET

AC LP GASAUTO

Voltage

higher than

15.4 Vdc?

MODE

Coldest

YES

Audible

Alarm

Check RV DC power distribution to

refrigerator.

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

"dc" and "HI" Flashing

on

Audible

Alarm

NO

See NOTE below to determine

and correct "dc HI" fault.

NOTE

Electronic controls operate on 12 Vdc. When an AC/DC converter is used to

supply DC power, the refrigerator circuit must be connected to the appliance

output terminals of the converter (filtered side).

If the refrigerator circuit is connected to the unfiltered side, the AC ripple

generated by the converter may cause a "dc HI" fault code to display .

T o troubleshoot a "dc HI" fault, connect a charged 12 volt automotive battery

to the power board. If the "dc HI" code clears, the fault was caused by

unfiltered DC power. If the "dc HI" code does not clear, replace the power

board (see page 40).

Sr CL - AC rE Fault Code – AC relay stuck closed

Fault indicator displayed:

"Sr" and "CL" Flashing

Cold

TEMP

ON

OFF

SET

MODE

AC LP GASAUTO

Coldest

Audible

Alarm

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

on

Audible

Alarm

"AC" LED Flashing

AC relay stuck closed.

12

1200XX/120X-IMXX Models

"AC" and "rE" Flashing

www.norcold.com/cda

Replace power board.

See page 40.

Refrigerator Service Manual

no AC Fault Code – No AC power available

Before beginning this procedure make sure:

■

No other problems exist with the RV AC power supply.

■

No other appliances or lighting circuits are connected to the refrigerator AC circuit.

■

Extension cords are not being used to supply AC power to the refrigerator.

Fault indicator displayed:

"no" Flashing

AC LP GASAUTO

MODE

Coldest

Audible

Alarm

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

Cold

TEMP

ON

OFF

SET

Audible

Alarm

on

"AC" LED Flashing

Measure voltage at power

board AC cord connection.

Check condition of F3 fuse

in power board.

Check that fuse holder clips

are making full contact with

fuse.

108

to

132 Vac?

YES

F3 fuse okay?

YES

Clips okay?

YES

"AC" and "no" Flashing

NO

NO

NO

1. Check AC power input from RV to unit.

2. Check AC power cord.

Replace fuse. See Specifications, page 4.

Adjust clips to ensure fuse contacts are

firm in clips and making full contact.

Replace power board.

See page 40.

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

13

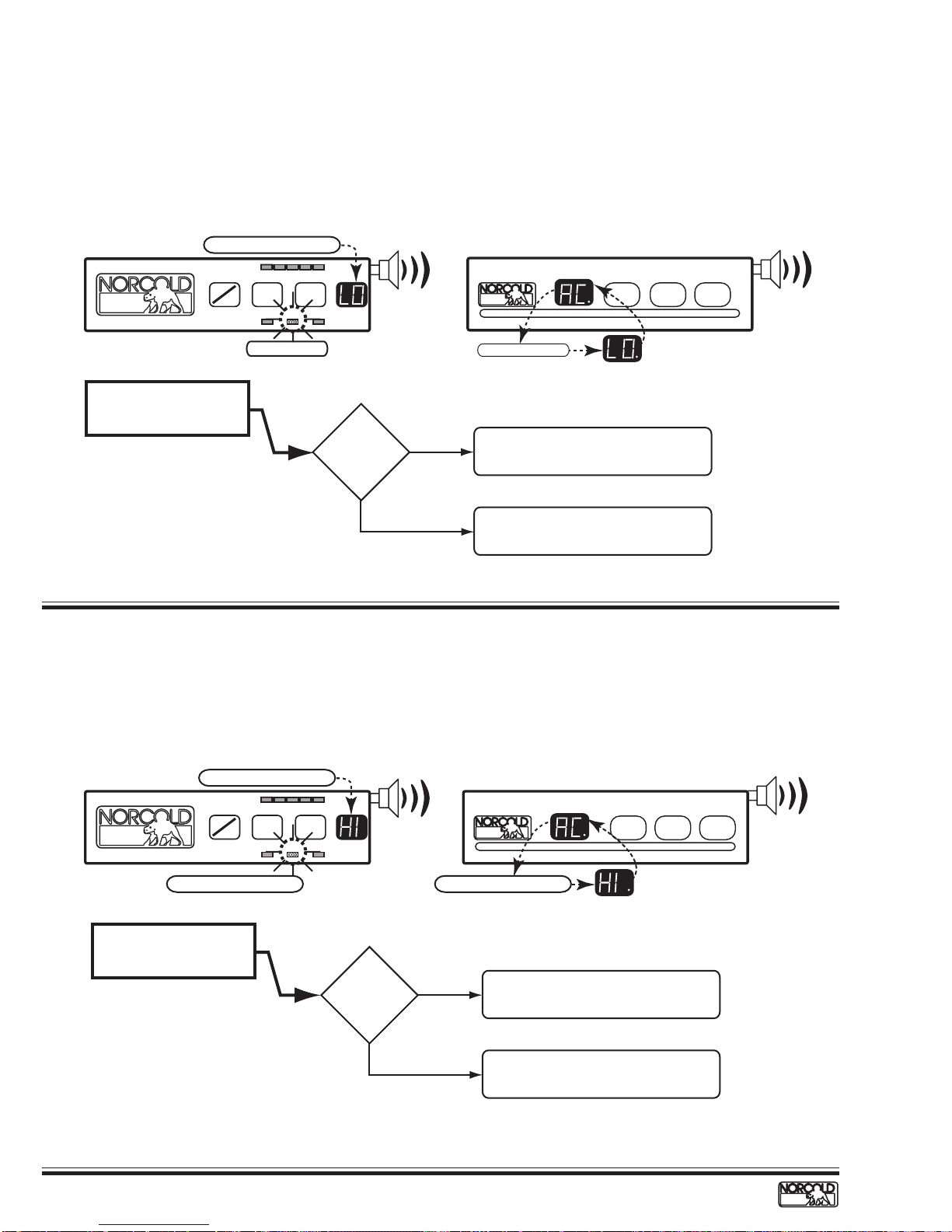

AC LO Fault Code – AC voltage low

Before beginning this procedure:

■

Determine if a certain AC power source sets the "AC LO" fault code (generator, shore power, inverter).

■

Make sure no other appliance or lighting circuit is connected to the refrigerator AC circuit.

■

Make sure extension cords are not being used to supply AC power to the refrigerator.

Fault indicator displayed:

"LO" Flashing

Cold

TEMP

ON

OFF

SET

AC LED blinking

Coldest

MODE

AC LP GASAUTO

Measure voltage at power

board AC cord connection.

Voltage

lower than

108 Vac?

AC HI Fault Code – AC voltage high

Audible

Alarm

YES

NO

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

Flashing "AC" and "LO"

on

Fault related to RV AC power distribution

component or circuit supplying AC power

to refrigerator.

Replace power board.

See page 40.

Audible

Alarm

Before beginning this procedure:

■

Determine if a certain AC power source sets the "AC HI" fault code (generator, shore power, inverter).

Fault indicator displayed:

ON

OFF

"AC" LED Flashing

Measure voltage at power

board AC cord connection.

"HI" Flashing

Cold

TEMP

SET

AC LP GASAUTO

Coldest

MODE

Voltage

higher than

132 Vac?

Audible

Alarm

"Sr" and "FS" Flashing

YES

NO

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

on

Fault related to RV AC power distribution

component or circuit supplying AC power

to refrigerator.

Replace power board.

See page 40.

Audible

Alarm

14

1200XX/120X-IMXX Models

www.norcold.com/cda

Refrigerator Service Manual

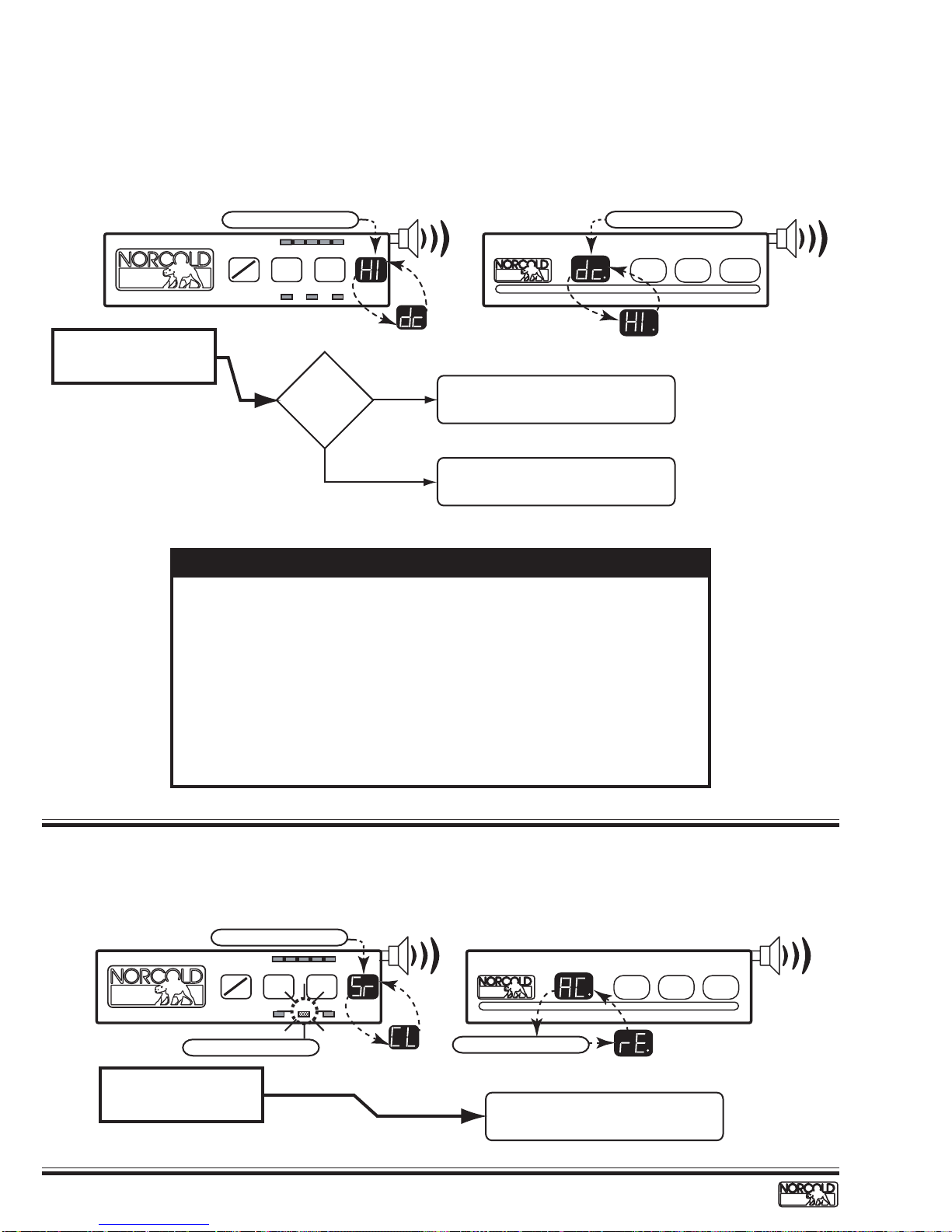

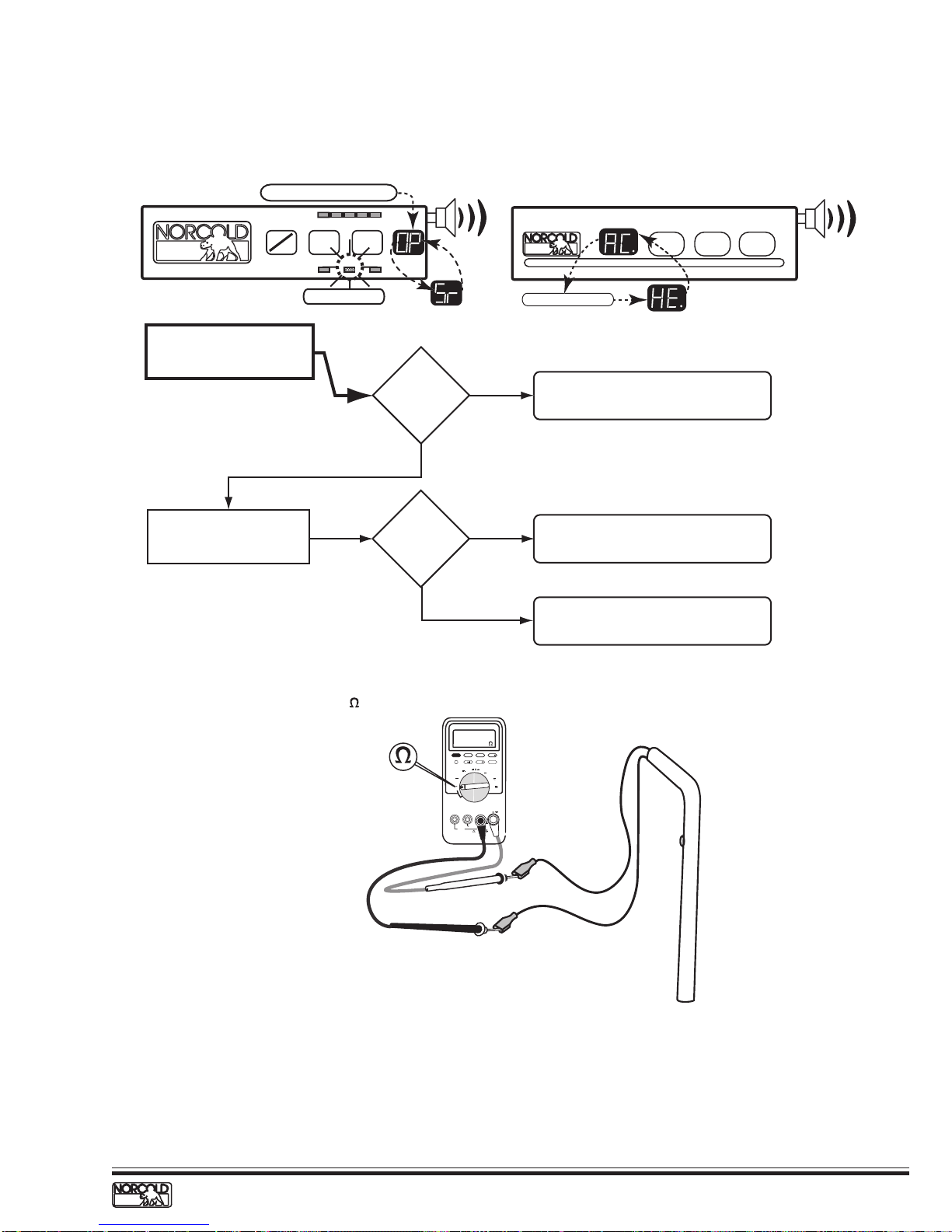

AC HE Fault Code – AC heater failed open

Before beginning this procedure make sure:

■

RV AC voltage to the refrigerator is 108 to 132 volts.

■

No other appliance or lighting circuit is connected to the refrigerator AC circuit.

Fault indicator displayed:

"OP and Sr" Flashing

ON

OFF

Check AC heater wires for

loose or damaged connection.

Check AC heater resistance.

See Figure 5.

Cold

TEMP

SET

AC LP GASAUTO

AC LED blinking

MODE

Coldest

Heater

connections

okay?

YES

Resistance

58 to 68 Ω?

YES

Audible

Alarm

NO

NO

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

on

Flashing "AC" and "HE"

Repair or replace connectors. If

connectors cannot be replaced,

replace heater.

Replace AC heater.

Replace power board.

See page 40.

Audible

Alarm

58 to 68

each heater

at room temperature

Figure 5. Checking AC heater resistance

4 1/2 DIGITS

1 Seconds

V

V

OFF

A

MIN MAX RANGE HOLD

PEAK MIN MAX

mV

mA µA

10A MAX

FUSED

H

HzREL

mA

A

µA

V

COM

!

400mA MAX

CAT II

FUSED

1000V MAX

!

L

N

O

O

C

R

Yellow

Black

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

15

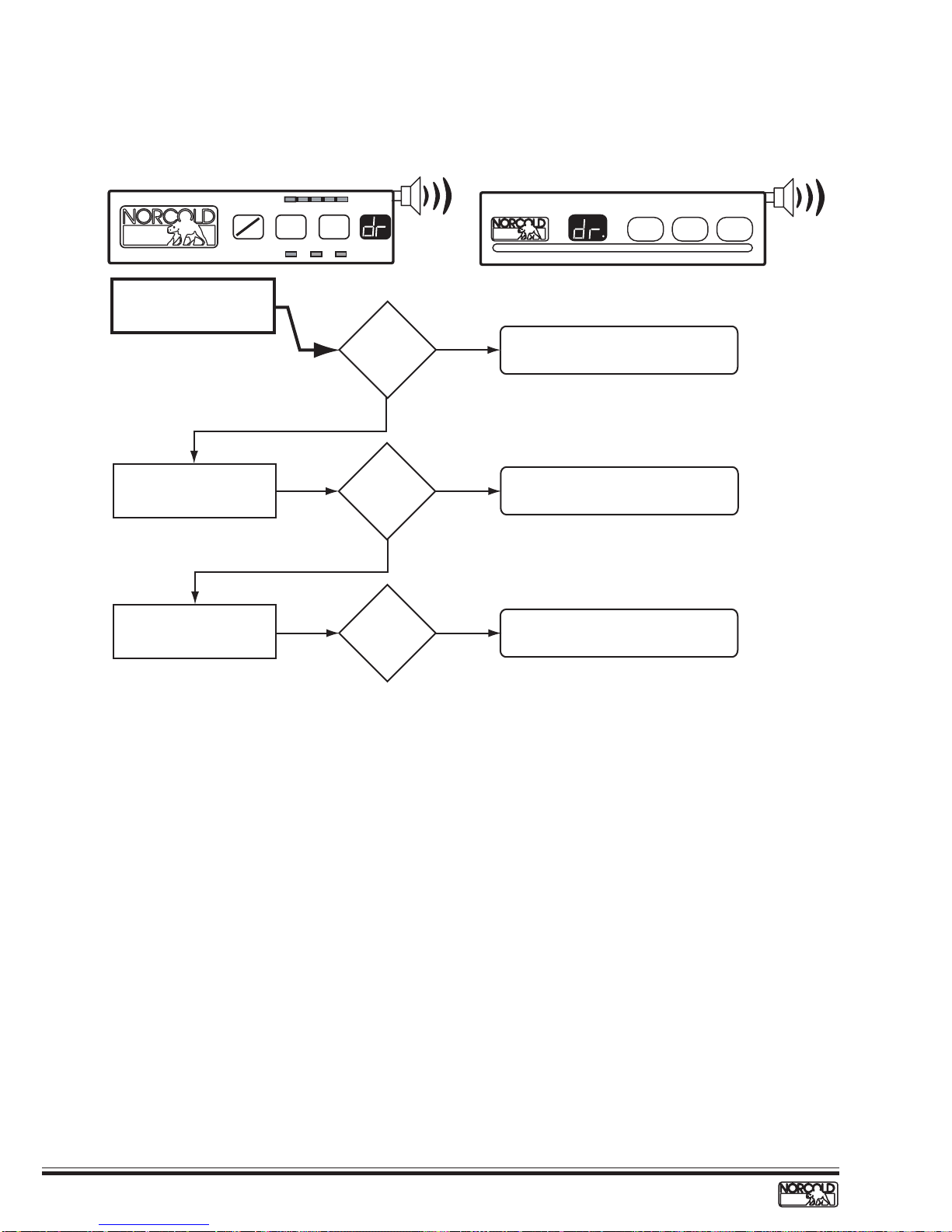

dr Fault Code – Door open for more than 2 minutes

Before beginning this procedure make sure:

■

Light/thermistor connector and wire harness connector are fully engaged and locked.

Fault indicator displayed:

Cold

ON

OFF

Check that the door latch

striker plate is adjusted

correctly.

TEMP

SET

Coldest

MODE

AC LP GASAUTO

Striker plate

okay?

YES

Audible

Alarm

NO

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

Adjust striker plate.

Audible

Alarm

on

Check fresh food

compartment door(s) for

vertical play.

Check operation of

light/door switches.

Door(s)

aligned

properly?

YES

Lights off

when switches

pressed?

NO

NO

Install Door Shim Kit, part number 625129.

Replace switch(es).

Magnetic tip screwdriver

16

1200XX/120X-IMXX Models

www.norcold.com/cda

Refrigerator Service Manual

Thermistor Failure Fault – Controls in Backup Operating System mode

Before beginning this procedure:

■

Make sure lamp/thermistor assembly is connected to the wire harness.

Fault indicator displayed:

Temp Setting Flashing

ON

OFF

Check lamp/thermistor wire

assembly and connector for

dirty/broken connections.

Cold

TEMP

SET

AUTO

MODE

AC LP GAS

Coldest

Wires and

connector

good?

NO

1 COLD - 9 COLDEST SET TEMP MODE

Clean/repair terminals or connector as

required. See Figure 6.

Temp Setting Flashing

on

ON / OFF

YES

R

E

T

E

IM

T

L

U

M

S

M

R

E

RU

T

87

I

II

H

D

L

O

H

E

G

N

A

R

X

A

M

N

I

M

z

H

L

E

R

X

A

M

IN

M

K

A

E

P

S

T

I

IG

D

2

/

1

4

s

d

n

o

c

e

S

1

V

m

mA

Lamp

Connection

Thermistor

Connections

A

V

A

µ

V

FF

O

V

M

O

C

A

µ

mA

A

!

X

A

M

A

m

0

0

4

CAT II

D

E

S

U

F

X

A

M

V

0

0

0

1

X

A

M

A

0

1

D

E

S

U

F

!

Thermistor

Figure 6. Thermistor terminals

Figure 7. Checking thermistor resistance

and connector

Backup Operating System (BOS)

The backup operating system (BOS) is an

electronically controlled duty cycle. It maintains the

refrigerator in operation if the thermistor is

disconnected or fails. The BOS maintains cooling by

controlling the heat source selected. When the

refrigerator is operating in BOS, the length of the

cooling cycle is regulated by time rather than

regulated by temperature.

To accomplish this, the BOS adjusts the length of the

cooling cycle according to the temperature setting

selected by the user; the higher the temperature

setting, the longer the cooling cycle. For example, if

the temperature setting is set to 5, raising the setting

to 6 will lengthen the cooling cycle, making the

cabinet colder.

Check thermistor resistance.

See Figure 7.

Temperature* Resistance*

(oF) (k )

85 8.1– 9.0

80 9.1–10.0

75 10.1–11.0

70 11.1–12.0

60 12.1–13.0

50 15.5–16.5

40 22.5–23.5

35 24.5–25.5

33 28.5–29.5

32 30.0–32.0

*

Approximate Values

Thermistor packed in ice bath

When a warmer temperature is desired, changing the

temperature setting to a lower number shortens the

cooling cycle. For example, if the temperature setting

is set to 6, lowering the setting to 5 will shorten the

cooling cycle.

1200XX/120X-IMXX Backup Operation, SN 832170

and Lower

When the 1200XX/120X-IMXX controls shift to BOS

operation, the temperature setting flashes until the

refrigerator is no longer in BOS.

1200XX/120X-IMXX Backup Operation, SN 832171

and Higher

When the 1200XX/120X-IMXX controls shift to BOS

operation, the temperature setting flashes for ten

seconds when the TEMP button is pressed. After ten

seconds, the "ON" LED displays.

www.norcold.com/cda 1200XX/120X-IMXX ModelsRefrigerator Service Manual

17

no co Fault Code* – No cooling detected by the controls - S/N 832171 and higher

Fault indicator displayed:

1 COLD - 9 COLDEST SET TEMP MODE ON / OFF

"no" and "co" Flashing

Check for cooling at fin

assembly.

Cooling

detected?

YES

Check for completion of

cooling cycle after resetting

power board.

"no" "co"

code shows

before cycle

end?

YES

* For more information on the "no co" fault code,

see pages 32-25.

on

NO

NO

Audible

Alarm

1. Check for ventilation obstructions

and leveled operation.

2. Reset power board as shown in

Figure 8 and described in procedure

below.

3. Allow unit to operate normally.

Cooling unit is good. Recheck for

ventilation obstructions and leveled

operation.

1. Replace cooling unit if "no co"

shows before completing a full

cooling cycle.

2. Reset power board as shown in

Figure 8 and described in procedure

below.

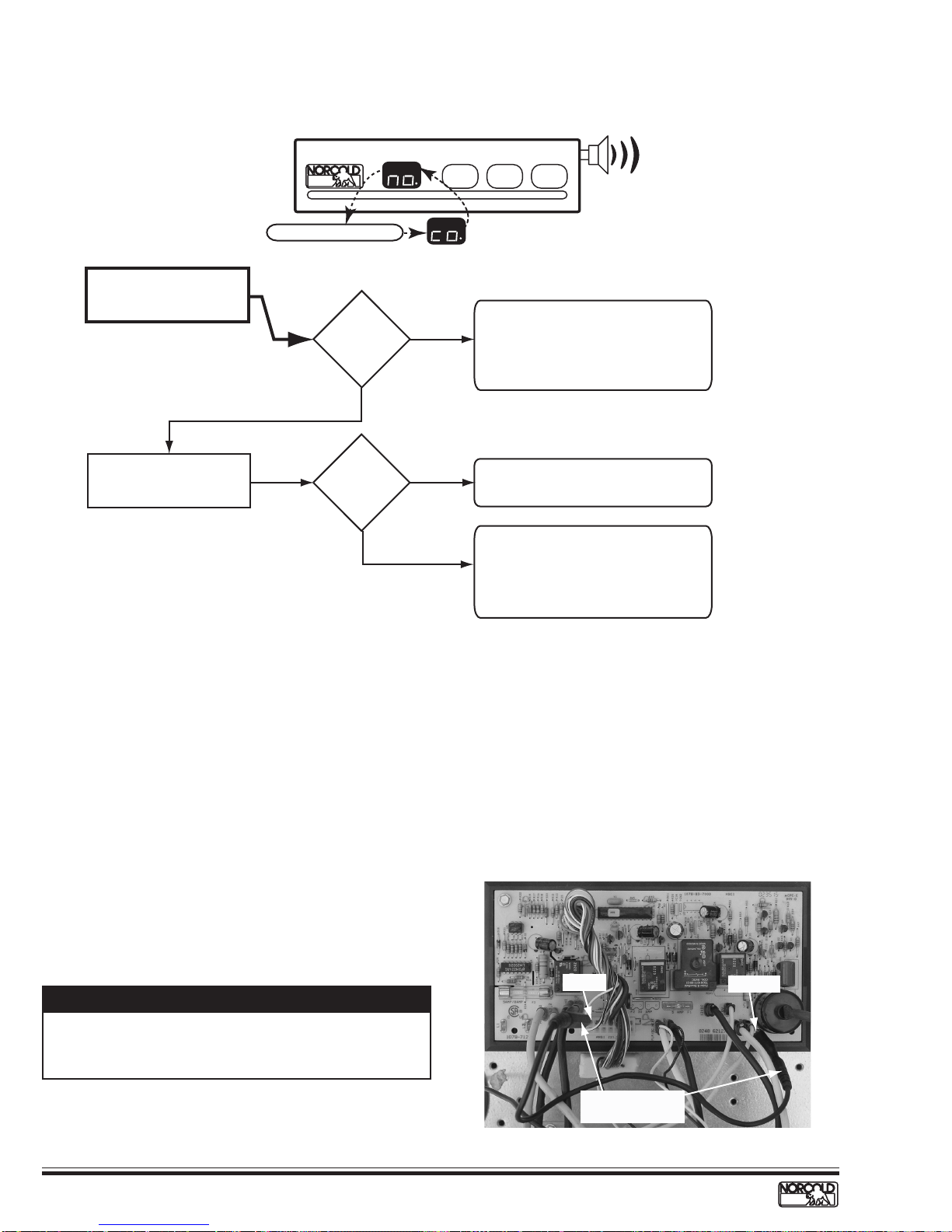

Power Board Resetting Procedure

1. Turn OFF the refrigerator .

2. Disconnect the following from power board:

a. 12 Vdc positive and negative wires.

b. AC power cord.

c. Solenoid gas valve wires.

d. Spark/sense electrode assembly wires.

3. Remove the power board cover.

4. Reconnect 12 Vdc positive and negative wire.

5. Turn ON the refrigerator .

6. Locate Pin 15 on 16 pin connector (P1). Pin

15 is the empty socket to the right of the

white/violet wire on the top row. See Figure 9.

7. Using an insulated jumper wire, short Pin 15

to the power board ground lug for 10 - 15

seconds. A click sound will indicate when the

controls are reset. See Figure 8.

NOTE

A jumper wire to short Pin 15 to ground can be made

from a six inch long insulated 22 A WG wire with a 1/2

inch of insulation stripped from each end.

10. Turn OFF the refrigerator .

1 1. Disconnect the 12 Vdc power positive and negative

wires from the power board.

12. Install the power board cover.

13. Reconnect the following to the power board:

a. Spark/sense electrode assembly wire.

b. Solenoid gas valve wires.

c. AC power cord.

d. 12 Vdc positive and negative wires from the

power board.

14. Place refrigerator in service.

Pin 15

Ground

8. Turn OFF the refrigerator .

9. Turn ON refrigerator . If "no co" code displays,

repeat steps 7 - 9.

18

1200XX/120X-IMXX Models

www.norcold.com/cda

Grounding probe

or jumper wire

Figure 8. Resetting the power board

Refrigerator Service Manual

Loading...

Loading...