Page 1

INSTALLATION & OPERATOR’S GUIDE

MODEL 1082

FREE-STANDING

REFRIGERATOR

WARNING

Improper installation, adjustment,

alteration, service, or maintenance

can cause injury or property damage.

Refer to this manual. For assistance

or additional information consult a

qualified installer, service agency, or

the gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquid in the vicinity of this or any other appliance.

Part No.: 617149 C (96 -1 0)

FOR YOUR SAFETY

If you smell gas:

1. Extinguish any open flames, pilot

lights, and all smoking material.

2. Do not touch any electrical

switches.

3. Shut off the gas supply at the tank

valve(s) or gas supply connection.

4. Open doors and other ventilating

openings.

5. Leave the area until gas odor

clears.

6. Have the gas system checked and

leakage source corrected.

Page 2

NOTICE: THIS APPLIANCE IS NOT APPROVED FOR USE IN R.V. OR MARINE APPLICATIONS.

THIS REFRIGERATOR IS EQUIPPED FOR LP GAS AND CANNOT BE CONVERTED TO

ANY OTHER FUELS (NATURAL GAS, BUTANE, ETC.).

Safety Awareness

Read this manual carefully and become thoroughly acquainted with its contents before installing and

operating the refrigerator.

Be alert to a potential Safety Hazard when the S afety Al ert Symbol appears on your refrigerator or in this

manual.

A signal word (i.e., Danger, Warning, Caution) accompanying the Safety Alert Symbol identifies the seriousness

of the Safety Hazard. Review the safety symbols and signal words below. Carefully read their descriptions to

understand their meaning. They are for your safety.

DANGER indicates the presence of a hazard that will cause severe personal injury, death, or substantial

property damage if ignored.

WARNING indicates the presence of a hazard that can cause severe personal injury, death, or substantial

property damage if ignored.

CAUTION indicates the presence of a hazard that will or can cause a minor personal injury or substantial

property damage if ignored.

WARNING

Always apply the following precautions when operating this refrigerator. Failure to heed thes e precautions

can result in substantial property damage, severe personal injury, or death.

• Carbon Monoxide can be hazardous to your to health and can result in death. A gas appliance can emit

Safety Information

excessive Carbon Monoxide gas if the refrigerator’s burner and flue system is not regularly cleaned. See pages

10 & 11 in this manual for instructions.

• Unauthorized or improper servicing of this refrigerator can cause severe personal injury, property damage, or

both. All required service and maintenance must be performed by your dealer, your propane gas supplier, or

by a Norcold authorized service center.

• This refrigerator must be used in the manner for which it was designed. Refer to this manual for installation

and operating procedures.

• Keep the refrigerator and the surrounding area clean. Never store combustible materials near the refrigerator.

Storing combustible materials near the r efrigerator not only creates a safety hazard, but als o inhibits the air

flow to the cooling system thereby reducing cooling efficiency.

• Propane gas can cause an explosion that can result in property damage, personal injury, or death. Use extreme

care when working with or near a propane gas system. Do not smoke or create sparks. Do not use an open

flame to check supply piping and fittings for leaks.

• Ground the 120 volt AC circuit in compliance with any applicable local, state, or national codes. Never cut or

remove the round grounding prong from the refrigerator’s AC power cord. Do not use a two-prong adapter. Do

not use an extension cord.

• Always replace a blown fuse with a fuse of the same ampere rating. A circuit overload can result in an electrical

fire if undersized wires or improperly sized fuses are used. To prevent a possible electrical fire, follow Norcold’s

fuse size requirements (page 5) and any applicable state and local codes.

1

Page 3

• Protect all wiring from physical damage, vibration, and excessive heat.

• Always disconnect the AC power source from the refrigerator when performing routine maintenance. All

servicing of this refrigerator must be performed by a qualified service technician.

• Keep liquids away from electrical connections. Many liquids are electrically conductive and could cause serious

arching damage and fires.

• Never bend, drop, drill, weld, manipul ate, or impact the cooling system. Doi ng so can cause the system to

rupture, releasing corrosive chemicals that can cause severe damage to the eyes and skin.

• Never attempt to repair or recharge the cooling system. A defective cooling system must be replaced by a

qualified appliance repair technician.

• After the refrigerator is in operation, do not touch the cold surfaces of the freezer, particularly with damp or wet

hands. Skin may adhere to the cold surfaces.

• To prevent child entrapment, limit access to the refrigerator and insure all wire shelves are securely fastened.

Always remove the door(s) before disposing of any refrigerator.

• This refrigerator has sharp edges and corners at the rear. Use care when working on this refri gerator. To

prevent cuts or abrasions, wear cut resistant gloves.

• Surfaces at the rear of the refrigerator are extremely hot. Contact with these surfaces can result in minor burns.

Turn the refrigerator off for several hours before attempting to move the refrigerator.

Refrigerator Specifications

LP Gas Operation - 11.0 Inches Water Column Propane

Safety Information Specifications

AC Operation - 120 Volts AC (132 Volts Max.; 108 Volts Min.); 60 Hertz Grounded Circuit

Operation where these specifications are exceeded may cause refrigerator damage and will void the refrigerator

warranty.

Introduction

You are now the owner of a Norcold Model 1082 Free-Standing Refrigerator. When used properly, this product

gives years of trouble free operation. Please read this manual c arefully; it is designed to help you keep your

refrigerator running efficiently and to answer any questions that may arise concerning your refrigerator.

Unlike a compressor driven refrigerator, the Norcold Model 1082 Refrigerator uses a gas absorption cooling

system. This cooling system uses an external energy source to heat the cooling solution, thereby evaporating the

solution and providing refrigerant circulation by means of percolation. The refrigerant travels to the freezer and

refrigerator areas, where it condenses and re-evaporates before returning to start the cycle again. This cooling

system contains no moving parts, and operates on either LP gas or AC electric input. This cooling system has

special requirements that do not apply to compressor driven refrigerators. These requirements include critical

leveling, ventilation concerns, and adequate gas an d electrical inputs, and are specifie d in later sections of t his manual.

If a problem occurs with your refrigerator, please refer to the trouble shooting section in the back of this manual.

The information provided in the trouble shooting section helps in solving minor problems.

The model and serial number of this refrigerator must be recorded. You will find these numbers on the serial tag

located in the interior of the refrigerator. These numbers should be used in any correspondence, either written or

verbal, concerning this refrigerator.

Introduction

Model: ______________________ Serial Number:_______________________

If a problem arises that is not addressed in the trouble shooting section of this manual, you will need to contact

an authorized Norcold Service Center. The service center booklet included in the information packet lists

authorized service centers in the United States and Canada.

2

Page 4

Locating and Installing the Refrigerator

Installation

This refrigerator must be installed in accordance with these Installation Instructions for the certifications and the

Norcold factory warranty to be in effect.

This appliance is design certified under the latest edition of ANSI Z21.19 Standards by the American Gas

Association and is approved by the Canadian Gas Association.

Install the refrigerator in accordance with local codes. In the absence of local codes, the installation must conform

with the following, as applicable:

In the United States:

• The National Fuel Gas Code, ANSI Z223.1.

InstallationLocation

• The manufactured Home Construction and Safety Standard, Title 24 CFR Part 3280.

When an external electrical source is utilized, the refrigerator, when installed, must be electricall y grounded in

accordance with local codes or, in the absence of local codes, the National Electrical Code, ANSI/NFPA 70.

In Canada:

• Any applicable code.

• Current Can 1-B 149.2 Installation Code for Propane Appliance and Equipment.

The refrigerator must be electrically grounded with the current Canadian Electrical Code C22.2 Parts 1 and 2.

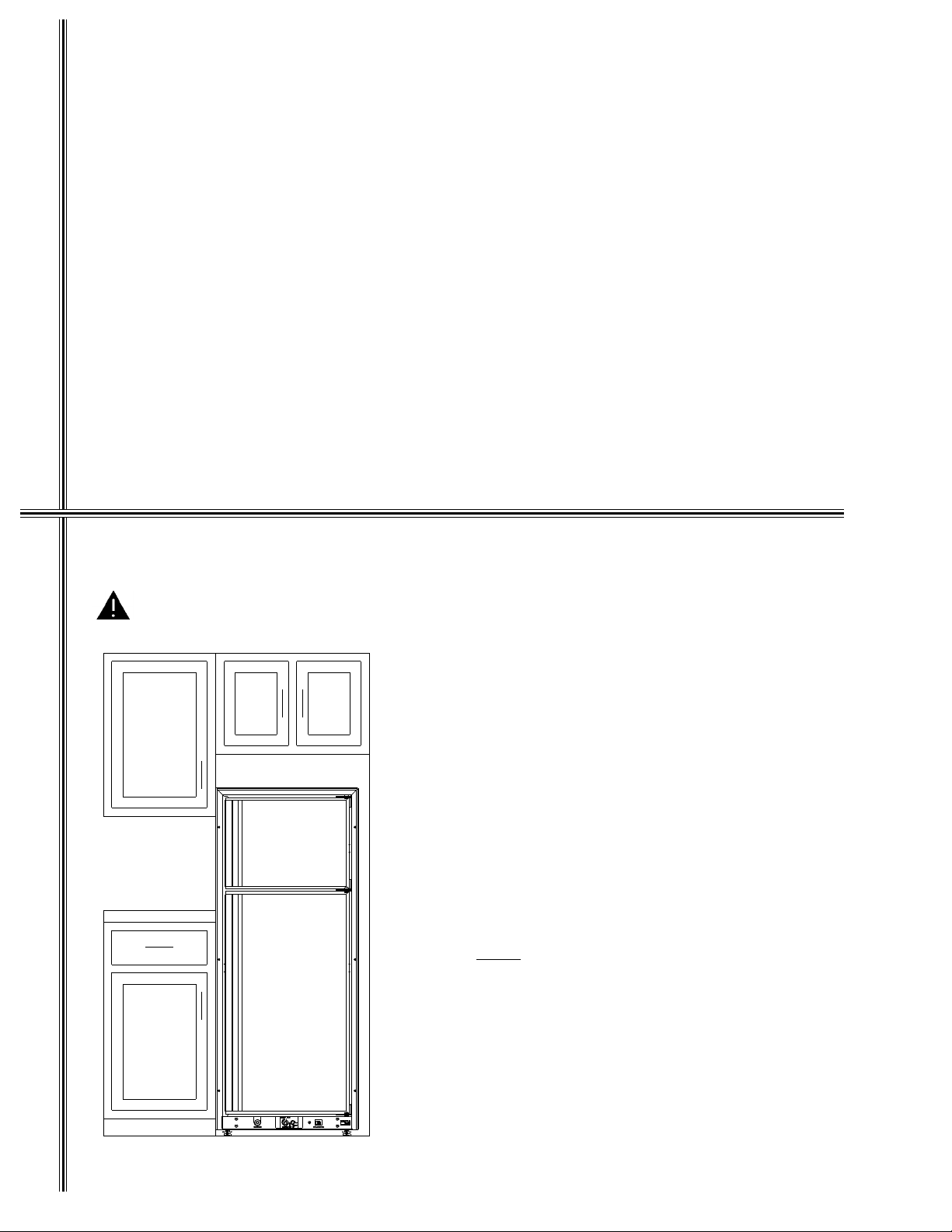

Locating the Refrigerator

WARNING

Improper location, installation, adjustments, or unauthorized modifications can

cause injury or property damage. Refer to this manual for proper instructions.

For assistance or additional information consult a qualified install er, service

agency, or your gas supplier.

The Norcold refrigerator is to be located on a solid and

level floor that is strong enough to support the combined weight of the refrigerator and its contents. Keep

the refrigerator away from direct sunlight and other heat

generating sources.

The refrigerator must be installed with the following

clearances:

Top: 6 inches minimum

Right Side: 2 inches minimum

Left Side: 0 inch minimum

Bottom: 0 inch minimum

Rear: 0 inch minimum

Do not locate the refrigerator in an area where the flow

of combustion and ventilation air is obstructed.

Notice

: Never install the refrigerator directly on carpet-

ing or vinyl floor covering. Carpeting or vinyl

flooring must be protected by a metal or wood

panel beneath the refrigerator. The panel

should extend at least the full width and depth

of the refrigerator.

Figure 1

Keep the refrigerator and the surrounding area cl ear

and free of combustible materials, gasoline, and other

flammable vapors and liquids.

3

Page 5

Leveling the Refrigerator

The refrigerator has a moisture reduction device located in the divider panel. This device will inhibit moisture from accumulating on the divider panel between

the refrigerator and freezer doors. To insure proper

operation of the refrigerator and the moisture reduction

device, the refrigerator must be level.

The refrigerator is equipped with leveli ng feet. Using

a bubble level placed on the floor of the freezer, adjust

the leveling feet to obtain proper leveling. To raise the

refrigerator, turn screw of leveling feet clock wise. To

lower the refrigerator, turn screw of leveling feet counterclockwise. See Figure 2.

Leveling Screw

1 3/8" Wrench

Wrench fits on head

of leveling screw.

Figure 2

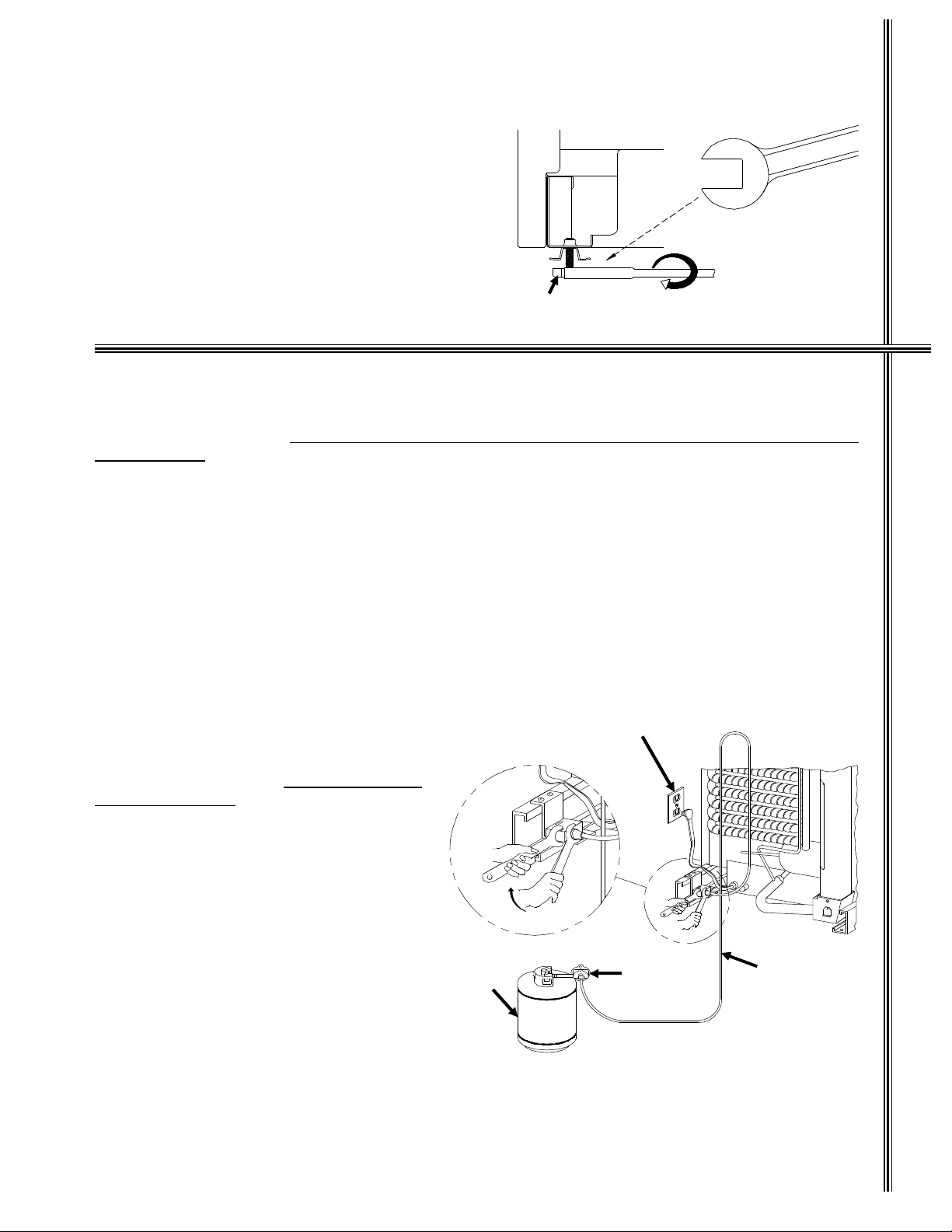

Gas Connection

Install a pressure regulator between the main gas supply tank and the refrigerator to maintain the supply pressure

of 11 inches water column.

regulator in line.

Use gas supply tubing and fittings that comply with local, state, and national codes. We recommend that the gas

be supplied by 3/8 inch diameter copper piping to prevent gas pressure loss to the refrigerator. The gas connection

at the rear of the refrigerator is a 3/8 inch SAE (UNF 5/8 inch-18) male flare connection.

The gas piping should be routed to limit the possibility of damage. It is recommended that the supply piping enter

directly at the rear of the refrigerator through the floor which supports the refrigerator. The hole through which the

gas piping enters should be of sufficient size (approximately 1/2" in diameter) to provide adequate clearance. Once

the gas piping is installed, apply a sealant around the piping at its point of entry to minimize abrasion and to serve

as a barrier from external moisture.

Provide an adequate length of gas supply tubing for connecting the refrigerator to the main gas supply tank.

Additional tubing is required at the rear of the refriger ator (Figure 3) to all ow the refriger ator to be pulled s everal

feet from the wall for cleaning, maintenance, and

burner flame inspection.

To prevent gas leaks and damage to the g as

supply tubing, use two wrenches when connecting gas fittings, as illustrated in Figure 3.

The propane gas supply tubing must be inspected and tested for leaks from the refrigerator

to the main gas supply tank.

with an open flame.

piping and measurement of input gas pressure

must be performed by a qualified installer, s ervice agency, or gas supplier.

Check gas pressure to the refrigerator without

other gas appliances operating. The pressure

should not exceed 11 inches water column. With

other gas appliances operating the pressure

should not be less than 10.5 inch es water column.

The refrigerator and its individual shutoff valve

must be disconnected from the main gas supply

during testing at pressures in excess of 1/2 psig

(14 inches water column).

The refrigerator must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any testing of the gas

supply piping system at tes t pressures equal to

or less than 1/2 psig (14 inches water column).

Testing of the gas supply

Do not connect the refrigerator directly to the main gas supply without a pressure

120 Volt AC

Receptacle

Do not test for leaks

Hold

Turn

Gas

Cylinder

Pressure

Regulator

To Refrigerator

3/8" Copper

Gas Supply Line

Figure 3

Leveling Gas Connection

4

Page 6

Gas Device Safety Test

After placing the refrigerator into operation, the gas safety device must be tested. The purpose of the gas safety

device is to prevent the escape of unburned gas from the burner if the burner flame is extinguished. While there

is a flame present at the burner, turn the refrigerator’s manual shutoff valve to "OFF". Wait 3 minutes and turn the

manual shutoff valve to "ON". Follow the Lighting Instructions ( do not push the control knob in) and try to ignite

Safety Test

the burner. The flame should not ignite. This test confirms that the safety valve is functioning properly.

Burner Flame

The efficiency of your refrigerator while operating in

the gas mode is dependent upon the correct burner

flame. The burner flame provides energy to the refrigerator’s cooling system.

The burner flame efficiency is a function of a) correct

input gas supply pressure, and, b) the burner and

burner orifice cleanliness.

After installation, the propane supply line from the

main tank to the refrigerator must be tested for leaks

All tests must be

Burner Flame InspectionAC Connection

Figure 4

and for the correct supply pressure.

performed by the propane gas supplier or a qualified

installer.

A visual inspection check of the burner flame should

be made regularly. The flame should be sharp blue with

a stable burning appearance (Figure 4). If there is a

constant yellow component observed or i f the flame

appears erratic or unstable, switch the refrigerator to

electric or turn the refrigerator "OFF", and contact a

qualified installer, service agency, or gas supplier.

120 Volts AC Connection

WARNING

3-Prong

Grounding Type

Wall Receptacle

Power Supply

Cord

This refrigerator is designed to operate on a 120 volts AC, 60 Hertz grounded

circuit. The refrigerator AC power cord is equipped with a three-prong grounding plug which must mate with a three-prong grounding receptacle to protect

against possible shock hazards. Operating the refrigerator without proper

ground can cause property damage, severe personal injury, or loss of life.

It is the owner/installer’s personal responsibility and obligation to provide a

properly grounded circuit to the refrigerator in accordance with local codes, or

in the absence of local codes , the National Electrical Code, ANSI/NFPA 70.

Do not cut or remove the grounding prong from the refrigerator’s AC power cord.

The refrigerator’s AC electrical circuit is protected by

a 5 amp fuse. The fuse is located at the rear of the

refrigerator to the right of the AC power cord.

3-Prong

Grounding

Plug

The free length of AC power cord is 72 inches. It is

recommended that the three-prong grounded receptacle be located within reach of the cord. The cord must

be routed so as not to come in contact with the burner,

flue pipe, or any other component that could cause

damage to the cord.

Figure 5

5

Page 7

Instructions for Reversing Door Swing

This refrigerator allows the owner to change the door swing if desired. The hinging of the doors can be changed

to the opposite side anytime you wish.

TOOLS REQUIRED

Phillips Screwdriver - Size #2

Two Slotted Screwdrivers

REMOVING THE DOORS

1. Turn ELEC-OFF-GAS switch, located on the control panel, to

OFF. Remove all items of food, juices, etc., from the doors.

Remove the juice rack and storage bins. Close both doors

before removing hinge pins.

2. Remove the top hinge pin using one of the slotted screwdrivers.

Remove the center hinge pin (both pieces) using the two slotted

screwdrivers; one on each end of the pin. Lastly, remove the

bottom hinge pin. Be sure to save the pins for reassembly later.

(See Figure 12)

3. Remove the upper door by opening the door slightly and pulling

the bottom of the door away from the refrigerator. Allow enough

room to slide the door down off of the upper hinge pin shoulder.

(See Figure 6)

4. Remove the lower door by opening it slightly and pulling the top

of the door away from the refrigerator. Allow enough room so

the door can be lifted up and off of the bottom hinge pin shoulder

(See Figure 7). Be sure to save the hinge plates along with the

spacer used in the middl e hinge br ack et, for r eass embly l ater.

(See Figures 12 - A, B, and C)

Figure 6

Reversing Door Swing

REMOVING AND RELOCATING THE HINGE BRACKETS

5. Remove the middle hinge bracket by using the #2 Phillips screwdriver and taking out the three screws holding

it in place. Next, remove the three sc rews on the opposite side corresponding to the c enter hinge location.

Relocate them in the holes just exposed by the removal of the hinge bracket. Attach the hinge bracket to the

refrigerator where the hole plugs previously were. Do not tighten screws completely. (See Figure 8)

6. Remove the top hinge bracket and reposition it in the opposite bottom corner. Use the same tec hnique as

outlined in Step #5.

7. Remove the bottom hinge bracket and reposition it in the opposite top corner. Use the same tec hnique as

outlined in Step #5.

Figure 7

Figure 8

6

Page 8

RELOCATING THE TRAVEL LATCHES

8. Remove both travel latches by taking out the two screws holding each to the refrigerator. Use the #2 Phillips

screwdriver. Remove the two screws from each of the corresponding holes on the opposite side of the

refrigerator. Relocate them in the two holes just exposed by the removal of the latches. Attach each latch in

the new position so the tab points towards the opposite side of the refrigerator. Do not tighten screws

completely. (See Figure 9)

9. Turn the door over so that the end previously at the bottom is now at the top. Relocate the bottom of the door

on the bottom hinge pin shoulder. Close door and align holes in top hinge brackets. The magnetic gasket will

hold the door in place. Before reinstalling the top door, check to insure that the spacer is in place. (See Figures

10 and 12 - C)

Figure 9

10. Reposition the upper door in a sim ilar ma nner as de scri bed in St ep #9, exc ept the top of the do or mus t

be engaged int o the hi nge pin sho uld er be fore s etti ng th e door in pla ce. (See Fi gur e 11)

11. Starting at the top, replace the hinge pins using the slotted screwdrivers as in the removal procedure. Tighten

all screws.

ALIGNMENT OF THE DOORS

12. Align the upper door with the lower so that there is a parallel gap between the door s and around the frame.

Adjust the doors to the cabinet so the gaskets seal but do not bind. Tighten the screws holding the hinge

brackets in place.

13. Door Seal: The door seal can be checked by closing the door on a long narrow strip of paper. A slight drag

Reversing Door Swing

should be noticed when the paper is pulled out from between the gasket and the cabinet. Repeat the process

around all four sides of the door. If the door does not seal properly, readjust the hinge brackets.

14. Position the travel latches so that they secure the doors when closed but do not prevent the doors from closing

properly. Tighten the two screws in each travel latch.

15. Replace the j uice r ack and storage bins into the door . Make sure that the mi lk bins (wi der storage bins) are

installed in the lowest door position.

A

Figure 10

B

Figure 11

C

D

Figure 12

7

Page 9

Lighting and Start Up Instructions

Lighting Instructions - Gas Operation

Hazardous Vapors. Holding the gas valve (C) in without flame ignition will

cause gas to build-up in the burner area and can result in severe personal

WARNING

injury, property damage, or death. Do not hold the gas valve in for more than

30 seconds. If the flame is not indicated within this time, turn the mode selector

knob to OFF, wait 2 minutes, and retry. If the flame still will not ignite, shut the

refrigerator off and contact a service repair technician.

Start Up Instructions

To light the refrigerator:

1. Turn on the gas supply to the refrigerator.

2. Set the thermostat (B) to it’s maximum setting.

3. Push and turn the "Elec-O ff-Gas" (C) knob counter-clockwise

to the "Gas" position.

4. Hold the control knob (C) in and push the igniter (A) repeatedly

until the gas is lit at the burner.

5. When the flame indicator (D) star ts to mov e, stop pushing the

igniter. Continue to hold the control knob in for approximately 5

seconds, then release. The flame indicator needle should remain in the green area indicating the flame is present at the

burner. If not, repeat steps 4 and 5.

The flame should ignite within 10 seconds. On initial refrigerator

Start-Up, it may take longer than 10 seconds to allow air to be

purged from the propane gas supply line.

6. Move the thermostat control (B) to desired setting.

Shutdown - All Modes

1. Push and turn the "Elec-Off-Gas" (C) control knob to the "Off"

position.

About Your Refrigerator

Figure 6

D

A

Start-Up Instructions - AC Operation

1. Make certain 110 volts AC are available to the refrigerator.

2. Set thermostat to maximum setting.

3. Push and turn "Elec-Off-Gas" control

knob clockwise to "Elec". Upon release, the knob will move outward,

indicating the control is locked into

electric operation.

C

B

THIS APPLIANCE IS DESIGNED FOR STORAGE OF FRES H FOODS, STOR AGE OF FROZ EN FOODS, AND

MAKING ICE.

Storage Volume

The model 1082 Free-Standing refrigerator provides 7.5 cubic feet of usable storage volume.

Controls

The Norcold free-standing refrigerator utilizes a single combination control to determine and regulate the mode

of operation (Gas and Electric). The control is operated by two control knobs. The first knob selects the operating

mode and the second controls the thermostat setting. The control c onsists of a gas s hut-off valve, safety valve,

thermostat, and electric interlock. The interlock prevents the poss ibility of operating on gas and electric at the

same time.

During normal operating conditions, set the thermostat at a mid-range setting. When the refrigerator or freezer

door is opened frequently or the ambient temperature is higher than 90 degrees, set the ther mostat to a colder

position.

On initial start up, it is recommended that the refrigerator be empty until the desired temperature is obtained.

Cooling to the desired operating temperature will take from eight to twelve hours, depending upon ambient

temperatures.

8

About Your Refrigerator

Page 10

Periodic Refrigerator Use

The burner , burner orifice, and the flue tu be must be inspected prior to igniting the burner f lame after extend ed

shut-down (seasona l) pe r iod s. Th ese are as m ust be fr e e fr o m du st, sp ide r w eb s, or ot he r o bst ruction s which

would restrict the flow of exhaust air, resulting in unsatisfactory refrigeration and increased carbon

monoxide emissions

(See REFRIGERATOR MAINTENANCE).

Divider Moisture Reduction Device

This refrigerator is equipped with a moi sture reduction devic e located in the divider panel. This device inhibi ts

moisture from accumulating on the divider panel between the refrigerator doors.

The Freezer Compartment

This compartment is designed to retain food in a frozen state. It is not intended for quick freezing of food.

When making ice, place the ice trays on the bottom freezer surface. Set the thermostat to its coldest setting. Do

not place packages on top of or around the ice trays while making ice.

The freezer shelf can be adjusted for different heights or can be removed to increase freezer storage capacity.

The Fresh Food Compartment

This compartment is intended to store and cool fresh foods.

Notice: Refrigeration requires air circulation within the fresh food compartment. Restriction of air circulation

will cause inadequate refrigerator temperatures and possible food spoilage. DO NOT COVER THE

REFRIGERATOR SHELVES WITH PAPER OR PLASTIC.

To control food odors, store odor emitting foods in sealed containers. Cover vegetables to retain their crispness.

To reduce frost formation on the cooling fins, cover liquids and moist foods. Do not put hot foods into the

refrigerator or let the doors remain open longer than necessary.

Allow the refrigerator to operate for a minimum of eight hours or overnight before loading the refrigerator with

About Your RefrigeratorCleaning the Interior

foods. Loading a warm refrigerator with warm foods will result in a longer refrigerator cool down period.

Door Bins

This refrigerator comes equipped with convenient door bins. These bins allow y ou to store smaller items in the

door, where they are easier to reach. These bins can be moved by simply lifting them off their attachment clips

and pushing them down over their new attachment clips. The large bins , however , need to remain in the bottom

of the door.

Crispers

The crispers located in the bottom of the refrigerator are designed to provide a higher humidity region to maintain

vegetable crispness. It is r ecommend that v egetables wi th s trong odors be wrapped so that thei r odor and taste

will not be transmitted to other stored foods.

Refrigerator Care and Cleaning

Cleaning the Interior Surfaces of the Refrigerator

Notice: Do not use abrasive cleaners to c lean the interior of the refrigerator. Abr asive cleaner s can harm

the refrigerator’s interior surfaces. Do not wash r emovable plastic door bins, shelves, etc., in an

automatic dishwasher.

It is important to keep the refrigerator interior clean to minimize food odors. The best time to clean the refrigerator

interior is after defrosting. Add a small quantity of dish detergent to lukewarm water and wash the interior.

Rinsing the interior in a solution of baking soda and water (

freshen the cabinet and neutralize odors. Wipe with a soft dry cloth to prevent water spots.

The door gaskets can be cleaned in the same manner as the refrigerator interior. After cleaning, a thi n layer of

petroleum jelly may be applied to the gaskets on the hinge side to keep the gaskets soft, thereby insuring a proper

door seal.

a tablespoon of baking soda to a quart of water

) will

9

Page 11

Cleaning the Exterior Surfaces of the Refrigerator

Clean the outer surface of the refrigerator wi th a damp sponge or c loth. Remove stubborn s tains using a mi ld

solution of soap and warm water.

The area surrounding the refrigerator, particularly at the rear, needs to be cleaned often. Cleaning prevents dust

and other foreign materials from collecting in the burner and the flue tube. Collecti on of dust, spider webs, etc.,

on the refrigerator’s condenser and absorber coils (Figure 13) restricts air circulation and results in poor refrigerator

performance. Use a soft brush to clean the absorber and condenser coils.

Procedure for Cleaning Burner, Burner Orifice, and Flue

Carbon Monoxide can be hazardous to your health and life. Gas appliances

may emit excessive Carbon Monoxide if the burner, burner orifice, and the flue

WARNING

1. Turn off gas at the main tank supply.

2. Turn the mode selection knob to the OFF position.

3. Allow the refrigerator to sit for 2-3 hours to insure the components at the rear of the refrigerator are cool before

cleaning.

4. Pull the refrigerator forward from its permanent location.

5. Unplug the refrigerator’s AC power cord.

CAUTION

tube are not regularly cleaned. To prevent Carbon Monoxide build-up, the

burner, burner orifice, and flue tube must be cleaned

after prolonged (seasonal) shut-down periods. Refer to the following cleaning

procedures, or conta ct a qualif ied insta ller, serv ice agency, or your gas sup plier.

Exercise care when servicing this refrigerator. The rear of this refrigerator is

extremely hot and has sharp edges. To prevent minor burns, turn the refrigerator off for several hours before accessing the rear of the refrigerator. Wear

cut resistant gloves to prevent cuts or abrasions while attempting to move the

refrigerator.

(Refer to Figure 13 on Page 11)

at least twice a year and

Cleaning the Flue

6. Remove the heat reflector cap from the flue.

7. Remove the spiral baffle assembly from the flue tube.

8. Using a stiff brush or fine emery cloth, clean spiral baffle of debris.

9. Clean the inside of the flue tube with a flue brush.

10. Re-install the spiral baffle.

cooling while operating in the gas mode.

Insure the baffle is securely in place. The spiral baffle is required for efficient

Cleaning the Exterior Surfaces

Cleaning the Burner and Burner Orifice

11. Remove the screws securing the burner cover and burner box to the refrigerator.

12. Review the illustration of the burner and orifice assembly (Figure 13 on page 11).

13. Loosen the gas tube connection fitting.

14. Carefully remove the gas tube from the burner.

15. Remove the orifice and orifice gasket and clean them with alcohol and air pressure.

with a pin, drill, or similar object.

16. Remove the screw securing the burner to the burner bracket. Remove the burner.

17. Use air pressure to remove du st, spider webs, etc. , from inside the burne r. Clean the ports o f the burner with a brush.

18. Clean and inspect the ignition electrode and the thermocouple. Replace if corroded.

19. Using air pressure, clean any debris from burner bracket of cooling system.

20. To reinstall, reverse the above procedures.

assembled as illustrated in Figure 13 on page 11.

Note

: If the copper gasket shows signs of wear or damage, dispose of it and contact your dealer for a

replacement.

21. Insure the burner slots are centered under the flue tube and the ignition electrode and thermocouple are

properly located (See Figure 13).

22. Leak test all fittings using a soapy water solution.

Make sure the orifice and orifice’s copper gasket are

Do not leak test fittings with an open flame.

Do not clean the orifice

10

Page 12

Condenser

Heat Deflector Cap

Flue Tube

Baffle Suspension

Wire

Absorber

Coils

Flue

Compression

Ring

Burner Box

Baffle

Burner Assembly

Orifice

Burner

Cleaning the Exterior SurfacesDoor SealsDefrosting

Connection

Fitting

Figure 13

Burner Tube

Checking Door Seals

The door gaskets must seal completely around the entire length of the door. This will insure cool ing efficiency

and prevent frost formation. Frequent frost formation or reduced cooling can be indications of air leaks.

To check for proper door seal, lay a long narrow strip of paper between the gasket and the refrigerator. Close

the door and withdraw the paper. A frictional drag should be observed. Repeat all around the doors. If the paper

does not have a noticeable drag, the gasket is not sealing. Contact your service agency for corrective procedures.

Orifice Copper

Gasket

Defrosting

After a period of operation, frost may accumulate on the freezer plate and the cooling fins, impairing cooling

efficiency. Refrigerator efficiency can be improved by periodically defrosting the refrigerator.

To defrost the refrigerator, set the "Elec-Off- Gas" control knob to "Off". E mpty the refrigerator, leav ing the drip

tray under the cooling fins and the doors open. To quicken the defrost cycle, fill a pan with hot water and place it

in the freezer. When the frost has melted, empty the drip tray and wipe it with a clean cloth. Replace the drip tray.

Replace all food and restart the refrigerator. Set the "Elec-Off-Gas" control knob to the desired mode of operation.

Set the thermostat to its maximum setting for several hours before returning it to a normal setting.

11

Page 13

Refrigerator Moving and Storage

Harmful gases. The gases in the cooling system are flammable and can be

WARNING

Before moving this refrigerator, it should be emptied, cleaned, and dried. It is imperative that the refrigerator

remain in an upright position while being moved. Failure to do so can result in a cooling system failure. Also, the

refrigerator must not be manipulated by grabbing the cooling system. This could result in a fracture of the cooling

system and the release of hazardous refrigerant.

If this refrigerator is going to be out of service for long periods of time, it should be emptied of all contents and

cleaned. Also, if possible, the doors should be left open to allow air to circulate in the refrigerator. This will prevent

the build up of odor in the refrigerator cabinet.

harmful to your health if inhaled. To prevent the release of these gases, never

place undue stresses on the cooling system. Do not manipulate the refrigerator

by grabbing the cooling system.

Moving and Storage Wiring Pictorial / Diagram

12

Page 14

Trouble Shooting

Unauthorized or improper servicing of this refrigerator can cause severe

personal injury, property damage, or both. All required service and mai nte-

must

nance

WARNING

Note: The refrigerator information packet supplied with your refrigerator includes a Norcold Service Center

location booklet.

center. Norcold will not accept respons ibility for improper instal lation, adjustment, alteration, service, or maintenance performed by anyone other than a

qualified dealer or a Norcold Service Center. Costs and consequential problems resulting from unauthorized or improper servicing of this refrigerator are

the refrigerator owner’s responsibility.

be performed by your dealer or a Norcold authorized service

Trouble Shooting

SYMPTOM

Refrigerator does not

operate in AC Mode

SYMPTOM

Refrigerator does not

operate in Gas Mode

Possible Causes

* Switch may be set to "OFF" or "GAS". See page 8

* Temperature Selector set too low. See page 8

* Refrigerator’s power cord may not be securely plugged in.

See page 5

* Circuit breaker or fuse may be tripped or blown ( AC

power source to refrigerator).

* Wall outlet may be inoperative. (This can be checked

by trying a different appliance in the same outlet.)

* If unit fails to operate after the above items have been

checked, unplug the unit and contact a service center.

Possible Causes

* Temperature Selector set too low. See page 8

* May be using gas other than LP gas.

AND CONTACT SERVICE CENTER.

* Gas not available to refrigerator (clogged gas supply

line, empty tanks, etc.). Contact gas supplier.

* Burner and orifice need cleaned. See pages 10 & 11

* Spark igniter needs replaced.

* If unit fails to operate after the above items have been

checked, unplug the unit and contact a service center.

TURN OFF GAS

SYMPTOM

Poor Performance,

Gas and Electric

Possible Causes

* Incorrect power supply. See pages 4 & 5

* Incorrect installation. See page 3

* Refrigerator off level. See page 4

* Unusually high ambient temperatures.

* Door opened frequently or for extended periods.

* Internal cabinet air circulation (wire shelves) blocked by

food items, paper, or plastic. See page 9

* Hot foods placed in refrigerator. See page 9

* Refrigerator needs defrosting. See page 11

* Temperature selector set too low. See page 8

13

Page 15

LIMITED WARRANTY

NORCOLD

P O BOX 4248

SIDNEY OH 45365-4 24 8

This Limited Warranty is given by NORCOLD ("Company") to the original consumer-purchaser of any new

refrigerating equipment ("Equipment") supplied by the Company, excluding glassware, electric light bulbs, replaceable fuses, and will be effecti ve for a period of one year from date of original purchase. The Company warrants,

provided that the Equipment shall at all times have been in possession of and used by the original consumer-purchaser, that:

A. The Company will provide free service and replacement of defective parts at no charge at all authorized

Norcold Service Centers for a period of one year from the date of original purchase. This Limited Warranty

covers labor costs incurred in removing a nd re-installing the refrigerator only when n ecessary to replace a defective

part. The Company will pay in boun d a nd ou tbou nd tra nsp ortat ion cost s of an y d efect ive pa rt, for a 1-ye ar pe riod

commencing with date of purchase. The origina l consumer-p urchaser must p ay all expenses incurred in making

the equipment available at one of the Norcold Service Centers. Any parts replaced under warranty (including

cooling units) will be warranted for the duration of the original warranty period.

B. The following procedure shall be followed by an original consumer-purchaser desiring to obtain performance

under the terms of this Limited Warranty. The refrigerator must be brought to any of the Norcold Service

Centers and the original consumer-purchaser must present evidence (1) to identify the original consumerpurchaser: and (2) that the item claimed to be defective is stil l within the warranty coverage. If the original

consumer-purchaser is unable to accomplish this task, written notice should be immediately directe d to Norcol d

and advice will be promptly given concerning the manner in wh ich warran ty service may be obtain ed. In ab lity to

physically bring the refrigerator to a Norcold Service Center will not void the warranty, but any additional costs

thereby incurred are solely for the account of the original consumer-purchaser.

C. The Company will not be liable under this Limited Warranty for any of the following:

(1) Defects which arise by reason of transit damage, misuse, neglect or accident.

(2) Manufacturing defects found at the time of purchase, or parts replaced under warranty, and associated

labor, which are not communicated to the Company within 30 days.

(3) Labor performed without need for parts replacements which is not communicated to the Company within

30 days.

(4) Defects in glassware, electric light bulbs, or replacement of fuses.

(5) Defects arising from improper installation or adjustment of the Equipment.

(6) The need for normal maintenance of this refrigerator according to the guidelines specified in the Installation

and Operating Instructions.

(7) Defects arising from the improper use of parts or parts not manufactured or supplied by the Company in

the course of repairs or replacements to the Equipment.

D. Employees and agents of the Company, and its authorized service representatives, have no authority to vary

the terms of the Limited Warranty, which applies only to Equipment purchased and i nstalled in the United

States of America and the Dominion of Canada. The Company reserves the right to make any improvements

or changes in parts or models without notice to any original consumer-purchaser.

E. The Company shall not be liable or in any way responsible for any loss or damage to person or property, or

lost profits or other similar loss or damage that may result or be claimed to have resulted from a defect in any

parts of the Equipment covered by this Limited Warranty. Some states do not allow the exclusion or limitations

of any incidental or consequential damages, so the above limitation or exclusion may not apply to you.

F. ANY IMPLIED WARRANTY OF MERCHANTABLITY OR FITNESS FOR A PARTICULAR PURPOSE:

(1) APPLICABLE TO A PART O R P ARTS OF THE REFRIGERATOR IS LIMITE D T O A PE RIOD O F ONE

YEAR FROM DATE OF PURCHASE.

(2) SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS.

THE ABOVE LIMITATIONS MAY N O T APPLY TO YOU.

G. This Warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

14

Loading...

Loading...