RPC-600/610

Industrial Chassis

USER' Manual

Headquarters (China):86-0755-27331166

Shenzhen:86-0755-27331166

Beijing:86-010-82671166

Shanghai:86-021-61212088

Chengdu:86-028-85259319

Shenyang:86-024-23960846

Xi’an:86-029-88338386

Wuhan:86-027-87858983

TianJin:86-022-23727100

Singapore:65-68530809

Website:www.norco.com.cn

RPC-600/610

Industrial Chassis

USER' Manual

Shenzhen NORCO Intelligent Technology CO.,LTD.

RPC-600/610 Industrial Chassis

Equipment Classification:

Trade Name:Shenzhen NORCO Intelligent Technology CO., LTD..

Model Name:RPC-600/610

Responsible Party:

Type of Product:Industrial Chassis

Manufacturer:

Shenzhen NORCO Intelligent Technology CO.,LTD.

FCC Class B Subassembly

Shenzhen NORCO Intelligent Technology CO.,LTD.

Content

Chapter 1 Product Introduction......................................................................................1

1.1 Overview ....................................................................................................................1

1.2 Specification ..............................................................................................................1

1.3 Backplane information..............................................................................................2

1.4 Power optional...........................................................................................................2

1.5 Ordering Information ................................................................................................3

Chapter 2 Installation Guide............................................................................................4

2.1 Structure view............................................................................................................4

2.1.1 Outline Dimensions ...............................................................................................4

2.1.2 Front Panel Diagram .............................................................................................5

2.1.3 Back Panel Diagram .............................................................................................7

2.1.4 Internal Structure Diagram ...................................................................................8

2.2 System Setup ............................................................................................................9

2.2.1 Removing the cover ..............................................................................................9

2.2.2 Install HDD .............................................................................................................9

2.4 Replacing the filter ..................................................................................................12

2.5 Back window FAN Install(optional)..................................................................13

Appendix............................................................................................................................15

Appendix A: Backplanes ..............................................................................................15

Appendix B: Safety Instructions ..................................................................................22

Packing List

Thank you very much for choosing our products, completely check your

package as the following item checklist first, if you find any component missing or

damaged, please contact your retailer.

■ RPC-600/610

■ Key

■ Power cable (BS)

■ 5’ to 3 tray

■ Air Filter

■ Screw

■ Flexible adjust card clamp

■ Manual

1pcs

1set

1pcs

1set

1bag

1pcs

4pcs

1pcs

Chapter 1

Product Introduction

RPC-600/610

Industrial chassis

Chapter 1 Product Introduction

1.1 Overview

RPC-600/610 is an improved 4U 19’ rackmount chassis, It is fully compatible

with P3/P4 commercial mainboard; embedded industrial backplane; the Drive Disk

Enclosure contains 1x3.5’ drive bays and 3x5.25’ driver bay. Front panel with

dual-USB port. Built-in high-speed air-intake fan supports abundant cooling and

streamline ventilation. It is easy to clean. The bracket bay features anti-vibration

capability. Can be widely applied to many fields, such as industrial control, CTI, DVR

etc.

1.2 Specification

Physics

Construction: high strength 1.2mm carbon structural steel, meet FCC and CE Class

B spec

Technics: surface machining of spray-paint, high temperature firing

Color: White/Black (Optional)

Dimension: 488mm×471mm×177mm (W×D×H)

Chassis

Configuration:4U,RackMount,meet the EIARS-310C standards

Drive bay: 1x3.5’ drive bays, 3x5.25’ driver bay

Cooling FAN: 1x8025 fan with air filter on front panel

Control: Front reset button, power switch and keyboard-lock

Port: 2xUSB port

Backplane support: Industrial Backplane or ATX PC board

Indicators: LEDs for power On/Off and HDD

Power: AT/ATX (Optional)

Vibration: 1 Grms (5 ~ 500 Hz)

Shock: 10G (with 11 ms duration, half sine wave)

Applications: industrial control, CTI, DVR etc.

1

RPC-600/610

Environment

Temperature: -20℃-60℃ (-4-140F)

Humidity: 5%-95%@ 40°C, (no condensing)

Acoustic Noise: Less than 56 dB sound pressure at 5 ~ 28°C (41 ~ 82°F)

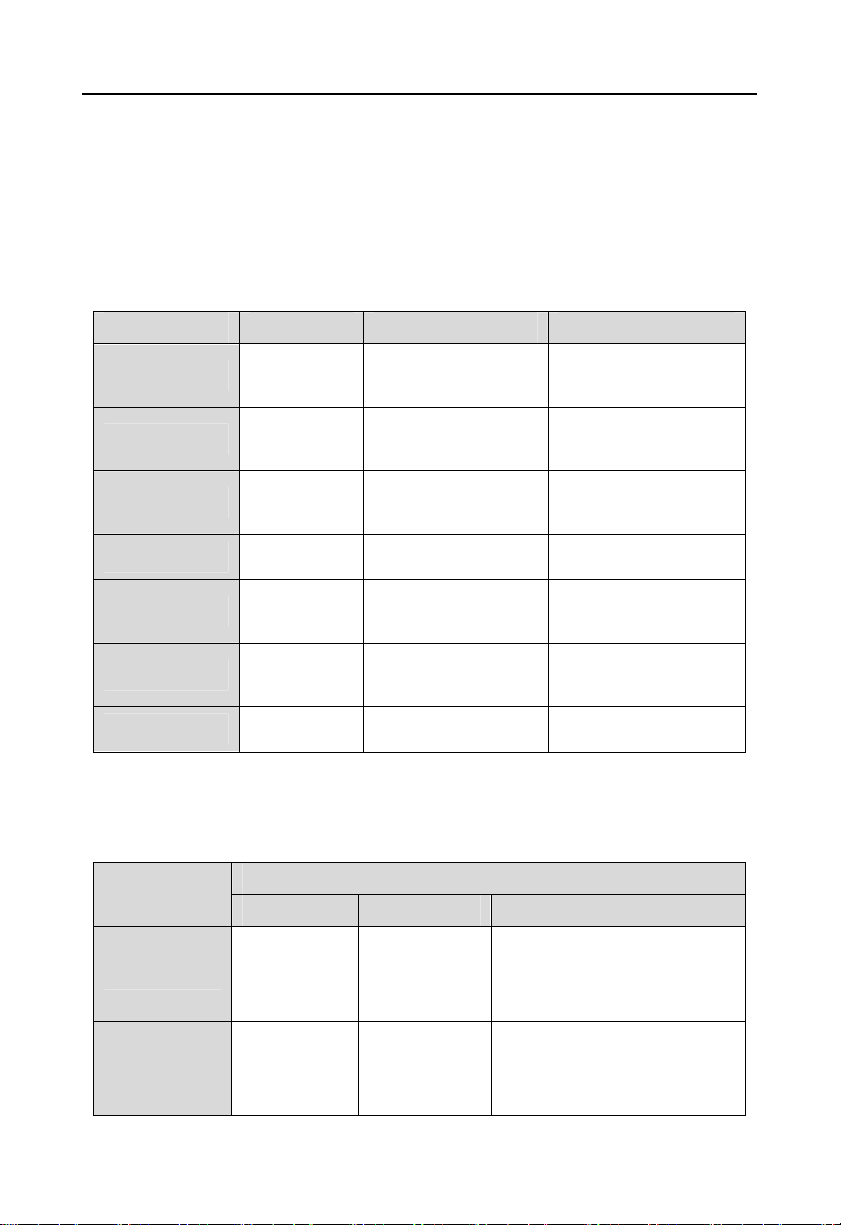

1.3 Backplane information

Industrial chassis

Model system slots

PBP-08P4

PBP-09P6

PBP-13L4

PBP-14I

PBP-14P4

PBP-15P7

PBP-15P12

single

single

single

single 14ISA 315.5×173.5

single

single

single 12PCI/3 PICMG 317×270

1.4 Power optional

Model

PWR-300

PWR-350

Power Input Output

300W

350W

4PCI/2 PICMG/2

ISA

6PCI/2 PICMG/1

ISA

4PCI/2 PICMG/7

ISA

4PCI/2 PICMG/8

ISA

7PCI/2 PICMG/6

ISA

Characters

180~

260VAC 47~

63Hz

180~

260VAC 47~

63Hz

Dimension(mm)

217×192

270×190.5

270×308

323×270

317×270

+3.3V@20A ,+5V@20A

+12V1@12A ,+12V2@12A,

-5V@0.5A,-12V@0.8A

+3.3V@28A ,+5V@25A

+12V1@15A ,+12V2@15A,

-5V@0.1A,-12V@0.8A

2

RPC-600/610

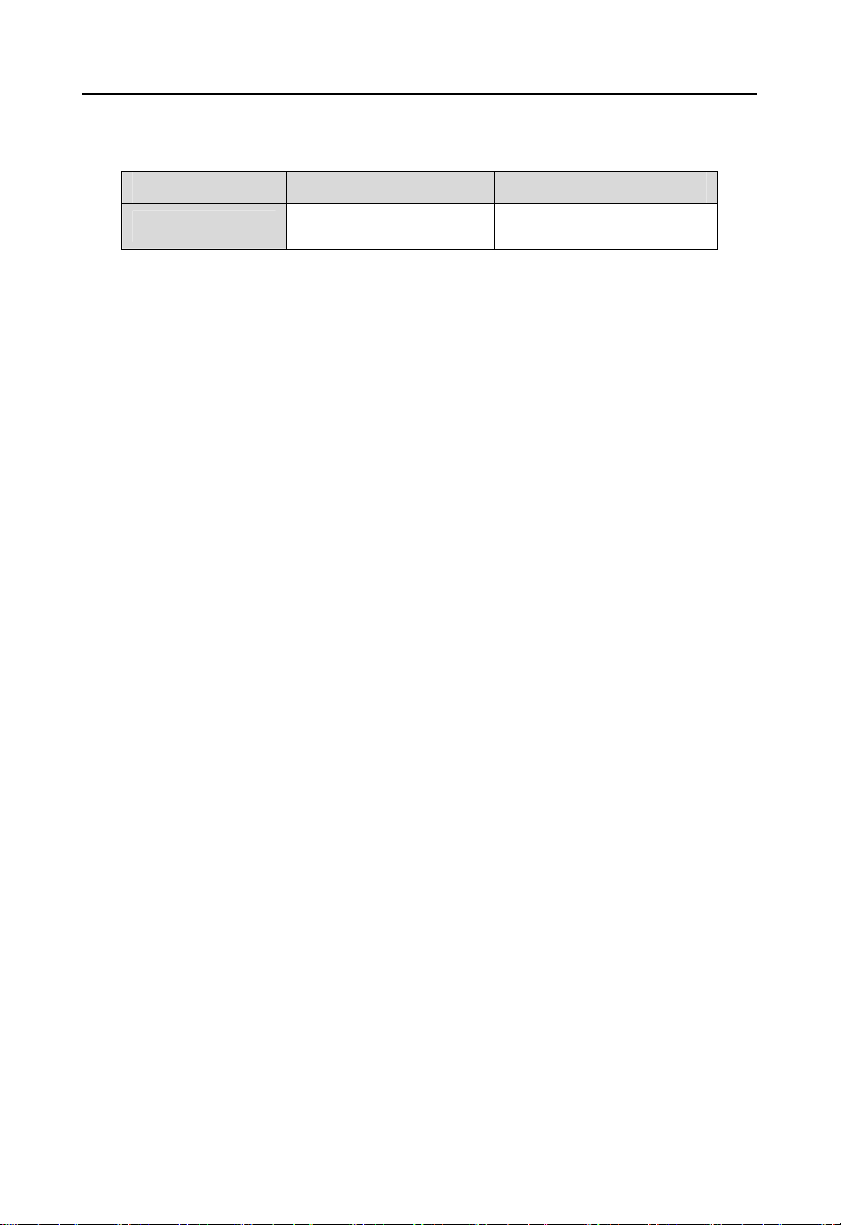

1.5 Ordering Information

Model Color Back Window

Industrial chassis

RPC-600/610

Black/White AT/ATX

3

Chapter2

Installation Guide

RPC-600/610

Industrial chassis

Chapter 2 Installation Guide

2.1 Structure view

2.1.1 Outline Dimensions

RPC-600 dimensions:

4

RPC-600/610

RPC-610 dimensions:

2.1.2 Front Panel Diagram

RPC-600 Exterior Front Panel:

Industrial chassis

1:

Chassis-lock

2: Power LED

3: HDD LED

5

RPC-600/610

RPC-610 Exterior Front Panel:

1: Chassis-lock

2: Power LED

3: HD LED

RPC600/610 Internal Front Panel:

Industrial chassis

1: Screw for open Air Filter

2: Power LED

3: HD LED

4: Drive bay

5: Power Button

6: Reset Button

7: Dual-USB Port

6

RPC-600/610

2.1.3 Back Panel Diagram

RPC-600/610 ATX Back Window(Configurable PC mainboard):

1: Screw for Top Cover

2: Cooling Hole

3: FAN Assemble (for 60mm FAN)

4: ATX I/O

RPC-600/610 Back Window (Configurable Industrial Backplane):

Industrial chassis

1: Screw for Top Cover

2: FAN Assemble position (for 60mm FAN)

3: Expansion (PCI/ISA/PICMG)

7

6

RPC-600/610

2.1.4 Internal Structure Diagram

RPC-600/610 Internal Structure:

1

Industrial chassis

4

2

3

1: FAN power connect cable

2: CPU card slot

3: Flexible adjust card clamp

4: Drive enclosure

5: Shock-resistant Screw

6:Hold-Down Clamp

5

8

RPC-600/610

Industrial chassis

2.2 System Setup

The following procedures are provided to assist you in installing drives, plug-in

cards and the hold-down clamp in to the RPC-600/610.

2.2.1 Removing the cover

Removing the chassis cover , place it in the flat surface, so as to avoid causing

scratches on the spraying surface of chassis cover.

1: Please use screwdrivers to twist both of host cover's sides of the screw by the

direction of anti-clockwise.

2: Seize the both sides of host cover, pull backwardly.

3: Take out the host cover and place it in a safe place to avoid scratches.

2.2.2 Install HDD

After removing host cover,You can easily install disk drivers。You should follow

these steps before installing disk drivers:

1: Twist off the screws on fixed Drive Disk Enclosure with screwdriver,

inside the container.

2: Take the Drive Disk Enclosure Out of chassis with gloves, put it in the smooth

platform, preferably where is foam pad avoid knocking and stumbling

FDD

Install:

Place FD into a 3.5-inch driver's location (At the bottom of driver), Fix FD with

screws on the both sides of Drive Disk Enclosure.

Place it

9

RPC-600/610

HD

Install:

Firstly fix hard disk and 5’ to 3‘tray, and then put it into a 5.25-inch driver's

location, Fix 5’ to 3 tray with screws on the both sides of Drive Disk Enclosure.

Industrial chassis

(optional)Firstly fix hard disk and HDD Shock-Resistant tray,and then put it into

a 5.25-inch driver's location,Fix HDD Shock-Resistant tray with screws on the both

sides of Drive Disk Enclosure.

10

RPC-600/610

CD-ROM Install:

Place CD-ROM into a 5.25-inch driver's location,

the both sides of Drive Disk Enclosure

5HD Expand

Install (optional):

Industrial chassis

Fix CD-ROM with screws on

1: Fix hard disk and HDD Shock-Resistant tray with Shock-Resistant Screw.

2: Fix the other 5 hard disks with trays and add them to Drive Disk Enclosure,

tighten the screws, and put them inside the chassis

2.2.3 Backplane and CPU Card Install

1: Open Hold-Down Clamp, Choose the proper backplane according to requirement,

and Fix the backplane inside the chassis.

2: Insert the CPU to be used into the chooses backplane (PC mainboard can be

straightly fixed inside the chassis)

3: Put down Hold-Down Clamp, adjust to the purpose height so as to held the

motherboard steady

11

RPC-600/610

Flexible adjust card clamp Can adjust from top to bottom.

Twist off the screw on flexible adjust card clamp, flexible adjust card clamp can

move back and forth.

Industrial chassis

2.2.4 Replacing the filter

Replacing the filter complied steps following:

1: Remove the screws located on the left side of the filter cover. Gently but firmly pull

the cover from the chassis.

12

RPC-600/610

2: Remove the filter and replace it with a new one.

3: Reinsert the filter and replace the cover onto the chassis.

Industrial chassis

Note: To avoid filter effect's declining, clean the filter per month.

2.2.5 Back window FAN Install(optional)

If the user chooses the RPC-600/610-ATX, 1 set of 60mm×60mm 6020 fan can

be installed at the back window,

any damage from high temperature.

1: Twist off the screw at the back cover of chassis,

put it in a safe place.

2:Put a complete set ( 2 fans, sharing a power connector ) of 60mm×60mm 6020 fan

so as to keep the chassis cool and clean, and avoid

2x6020 FAN location

remove the chassis cover and

13

RPC-600/610

into the position to be installed in the back window, fix the fan with screws in the rear

window

3: After installing fan,

Industrial chassis

please plug in the fan power connector

14

Appendix

RPC-600/610

Industrial chassis

Appendix

Appendix A: Backplanes

Model: PBP-08P4

Dimensions: 270.7mm×191.7mm

Description:

Slots

8

15

RPC-600/610

Industrial chassis

PCI

PICMG

ISA

Power supply

Model: PBP-09P6

Dimensions: 270mm×191mm

4

2

2

AT/AT X

Description:

Slots

16

AT

Power Connector

ATX Power Connector

PCI Slot

Standby Switch

Keyboard Port

Power Switch

ISA Slot

6Pin

Screw Hole

PICMG Slot

9

Power Connector

r

RPC-600/610

Industrial chassis

PCI

PICMG

ISA

Power supply

Model: PBP-13L4

Dimensions: 308mm×270mm

6

2

1

AT/AT X

Description:

Slots

17

13

Screw Hole

ISA Sl o t

AT Power Co nnec tor

PICMG Slot

6Pin

Po w e r C o n n e c t o

RPC-600/610

Industrial chassis

PCI

PICMG

ISA

Power supply

Model: PBP-14I

Dimensions: 315.22mm×173.35mm

4

2

7

AT/AT X

ISA Slot

Description:

Slots

ISA

Power supply

18

14

14

AT/AT X

Keyboard Port

Screw Hole

AT

ATX

Standby Switch

6Pin

Power Switch

Po w e r C o n n e c t o r

Power Connector

Power Co nnec tor

RPC-600/610

Model: PBP-14P4

Dimensions: 323mm×270mm

Industrial chassis

Description:

Slots

PCI

PICMG

ISA

Power supply

14

4

2

8

AT/AT X

19

RPC-600/610

Model: PBP-15P7

Dimensions: 317mm×270mm

Industrial chassis

Description:

Slots

PCI

PICMG

ISA

Power supply

15

7

2

6

AT/AT X

20

RPC-600/610

Model: PBP-15P12

Dimensions: 317mm×270mm

Industrial chassis

Description:

Slots

PCI

PICMG

Power supply

15

12

3

AT/AT X

21

RPC-600/610

Industrial chassis

Appendix B: Safety Instructions

1: Read these safety instructions carefully.

2. Keep this installation reference guide for later reference.

3. Disconnect this equipment from any AC outlet before cleaning. Do not use liquid

or spray detergents for cleaning. Use a damp cloth.

4. For pluggable equipment, the power outlet must be installed near the equipment

and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a reliable surface during installation. Dropping it or letting it

fall could cause damage.

7. The openings on the enclosure are for air convection. Protect the equipment from

overheating. Do not cover the openings.

8. Make sure the voltage of the power source is correct before connecting the

equipment to the power outlet.

9. Position the power cord so that people cannot step on it. Do not place anything

over the power cord.

10. All cautions and warnings on the equipment should be noted.

11. If the equipment is not used for a long time, disconnect it from the power source

to avoid damage by transient over-voltage.

12. Never pour any liquid into an opening. This could cause fire or electrical shock.

13. Never open the equipment. For safety reasons, the equipment should be opened

only by qualified service personnel.

14. If any of the following situations arises, get the equipment checked by service

personnel:

a. The power cord or plug is damaged.

b. Liquid has penetrated into the equipment.

c. The equipment has been exposed to moisture.

d. The equipment does not work well, or you cannot get it to work according to the

installation reference guide.

e. The equipment has been dropped and damaged.

f. The equipment has obvious signs of breakage.

15. Do not leave this equipment in an uncontrolled environment where the storage

22

Loading...

Loading...