Page 1

N-Series

Isolation Poppet Valves

NAP

NAP-075

NAP-100

NAP-150

NAP-200

NAIP

NAIP-075

NAIP-100

NAIP-150

NAIP-200

N-Series OP-LIT 10-2011

Nor-Cal Products, Inc.

1967 South Oregon Street

Yreka, CA 96097 USA

Tel: 800-824-4166

or 530-842-4457

Fax: 530-842-9130

www.n-c.com

Page 2

N-Series Isolation Poppet Valves

Table of Contents

1.0

Introduction .............................................................................................................................................................

Safety ...................................................................................................................................................................... 3

2.0

2.1

Symbols Used.............................................................................................................................................................3

2.2

Precautions ................................................................................................................................................................

Specifications ..........................................................................................................................................................

3.0

Description of N-Series Valves ................................................................................................................................................... 6

4.0

Overview .

4.1

Theory of Operation ................................................................................................................................................... 6

4.2

4.3 Valve & Options Nomenclature ..................................................................................................................................................... 7

5.0

Installation and Use ................................................................................................................................................7

5.1

Unpacking and Detrashing .........................................................................................................................................7

5.2 Valve Installation ........................................................................................................................................................ 8

5.3 Pneumatic Hook-Up ..................................................................................................................................................8

5.4 Solenoid Pilot Valve Connection ................................................................................................................................. 8

5.5 Position indicator Electrical Connection ..................................................................................................................... 9

6.0

Troubleshooting ......................................................................................................................................................9

6.1 Valve Will Not Close and Remains Fully or Partially Open ............................................................................................ 9

6.2 Valve Will Not Open All The Way or At All ................................................................................................................10

6.3 Valve Does Not Seal Adequately As Measured Between Inlet and Outlet Ports .........................................................10

6.4 Vacuum System Will Not Pump Down To Base Pressure ............................................................................................10

6.5 Position Sensors Are Not Sending Open / Close Signals ............................................................................................ 10

6.6 Valve Makes Noise ................................................................................................................................................... 11

6.7 Air Supply Pilot Valve Is Leaking or Makes Noise .......................................................................................................11

7.0

Spare Parts & Accessories ..................................................................................................................................... 11

7.1 O-ring Seal Kits with Work Instructions .................................................................................................................... 11

7.2 Valve Rebuild Kit with Work Instructions ..................................................................................................................13

7.3 Replacement or Add-On Solenoid Valve Kit with Work Instructions .......................................................................... 13

7.4 Replacement or Add-On Position indicator Kit with Work Instructions ..................................................................... 14

8.0 Product Support & Returns

Appendix - Limited Warranty and Intellectual Property ..................................................................................................17

................................................................................................................................................................................... 6

....................................................................................................................................... 15

3

3

4

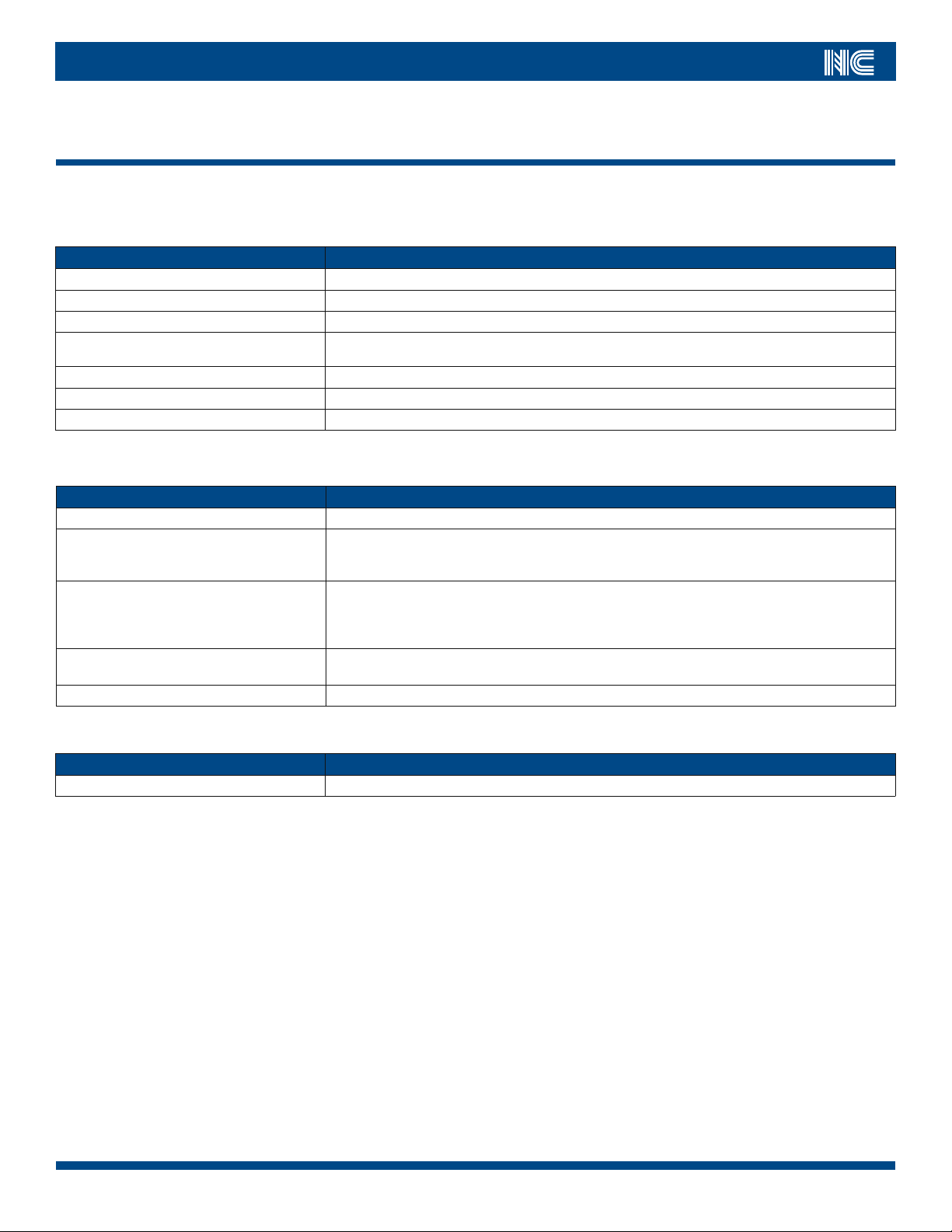

List of Tables

3.1 Environmental Specifications .......................................................................................................................................................... 4

Operational Specifications .......................................................................................................................................... 4

3.2

3.3 Certification

3.4

Pneumatic N-Series Angle Valve Dimensions ..............................................................................................................5

3.5

Pneumatic N-Series Angle In-Line Valve Dimensions ...................................................................................................5

.................................................................................................................................................................4

List of Figures

3.4.1

Valve Dimensions ....................................................................................................................................................

4.2.1

4.3.1

5.4.1 Solenoid Valve Connection .....................................................................................................................................8

5.5.1 Position indicator Electrical Connection ..................................................................................................................9

22

Cut-away Valve ...........................................................................................................................................................................7

Valve & Options Nomenclature ................................................................................................................................7

Information in this manual is subject to change without notice.

Visit our Web Site www.n-c.com

5

Page 3

N-Series Isolation Poppet Valves

1.0 - Introduction

Thank you for purchasing an N-Series isolation poppet valve from Nor-Cal Products. Before installing and operating the product, please read this manual

thoroughly as it contains critical hook-up and operating tips. In addition, this manual contains detailed information on spare parts, options and valve accessories.

If you encounter any problems, or if you have any questions, please contact Customer Service.

Nor-Cal Products, Inc.

1967 South Oregon Street

Yreka, CA 96097 USA

Phone: +1 (530) 842-4457

Toll Free: +1 (800) 824-4166

On-line: www.n-c.com

2.0 - Safety

2.1 Symbols Used

Throughout this manual, information that is of particular importance to the installation, the safety of operating personnel and the protection of equipment are

highlighted by the following three symbols. The WARNING symbol is also used on the equipment wherever necessary.

NOTE: Calls attention to helpful tips about proper

installation, maintenance or use of the controller.

CAUTION: Highlights areas of concern that, if overlooked, could

result in damage to the controller or surrounding equipment.

WARNING : Alerts the installation, operating or maintenance

personnel of hazardous aspects of the controller, which, if

ignored could result in serious personal injury or death.

2.2 Precautions

When installing, using or servicing this product please adhere to the following precautions.

WARNING:

WARNING:

REPAIR & MAINTENANCE: Use only Nor-Cal replacement parts for product maintenance and repair,

and adhere strictly to rework instructions outlined in this manual.

PRODUCT ALTERATION: Do not alter or modify the product without first consulting with Nor-Cal

Products’ product management or applications engineering staff.

CAUTION:

WARNING:

NOTE:

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

MATERIAL COMPATIBILITY: Make sure to understand the compatibility between hazardous and

reactive process chemicals and the product’s materials of constructions.

OPERATION: The product’s moving parts present a severe pinching hazard. Please keep fingers,

hands or other objects away from all ports and openings.

INSTALLATION: Use proper installation hardware and mating components. In particular, make sure

that electrical connectors and pneumatic supply fittings are selected in accordance with the instructions

in this manual.

3

Page 4

N-Series Isolation Poppet Valves

3.0 - Specifications

The following figures and tables summarize specifications of the N-Series vacuum valve.

TABLE 3.1 ENVIRONMENTAL SPECIFICATIONS

FEATURE SPECIFICATION

Installation Orientation Product may be installed in any orientation, with gas flow in either direction.

Ambient Operating Temperature Range 32

Allowable Ambient Humidity 0

Process Temperature Range 0

Heating Capabilities Body can be heated up to 302o F (150o C) with optional heater kits.

Maximum internal Pressure 20 psi (138 kPa).

Maximum delta-P across poppet 30 psi (206 kPa) in open direction. 35 psi (241 kPa) in closing direction.

FEATURE SPECIFICATION

Open / Close speed 0.5 seconds to open, 0.7 seconds to close at 80 psig.

Pneumatic Supply 60

Solenoid Electrical Specifications 120 VAC: 2.5 Watt (-S11 option code)

Position Indicators Optical: Standard NPN type (-0 option code)

Reliability 3 million cycles MTBF at 90% confidence factor, clean environment

o

– 122oF (0oC – 50oC)

– 95% non-condensing

o

F – 392o F (-18o C – 200o C). Process temperatures above 302o F (150o C), may require use of seal materials other than

Viton®.

TABLE 3.2 OPERATIONAL SPECIFICATIONS

– 100 psig (414 – 689 kPa) CDA or N2.

Standard connection accepts 5/32” [4MM] OD tubing.

Thread is 10-32 [M5].

24 VDC: 1.8 Watt (-S21 option code)

240 VAC: 4.0 Watt (-S31 option code)

24 VAC: 4.0 Watt (-S41 option code)

Optical: Optional PNP type (-02 option code)

TABLE 3.3 CERTIFICATION

FEATURE SPECIFICATION

Leak Rate 1 x 10-9 atm.scc/sec He (for valves with Viton® seals)

44

Visit our Web Site www.n-c.com

Page 5

N-Series Isolation Poppet Valves

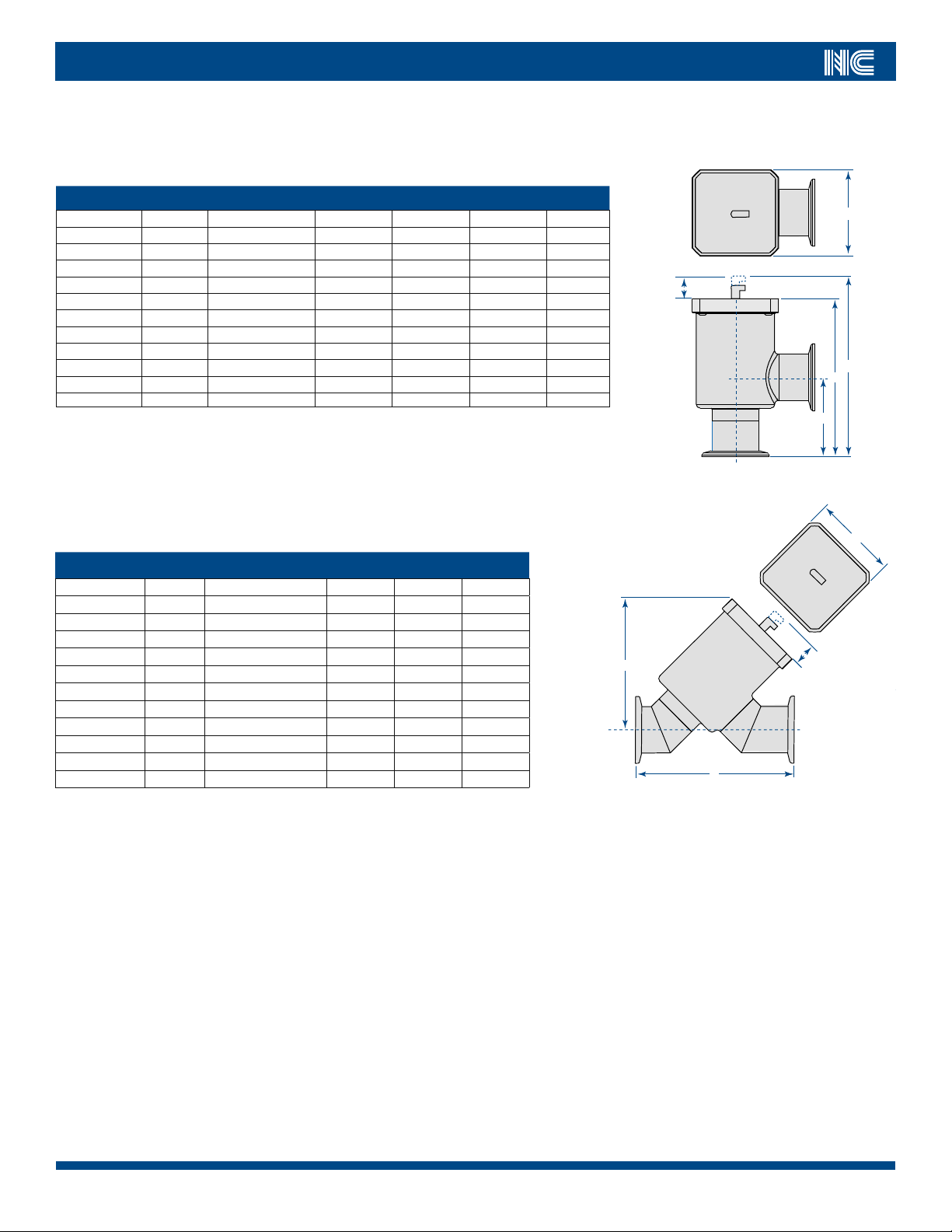

MODEL

NUMBER

NAP-075 0.75 No Flanges 1.42 (36) 3.95 (100) 4.90 (124) 1.6

NAP-075-NW 0.75 NW-16 1.57 (40) 4.10 (104) 5.05 (128) 1.7

NAP-075-CF 0.75 CF-133, Rotatable 1.91 (49) 4.73 (120) 5.68 (144) 1.9

NAP-100 1.0 No Flanges 1.82 (46) 4.35 (110) 5.30 (134) 1.6

NAP-100-NW 1.0 NW-25 1.97 (50) 4.50 (114) 5.45 (138) 1.7

NAP-100-CF 1.0 CF-212, Rotatable 2.28 (58) 4.81 (122) 5.76 (146) 1.9

NAP-150 1.5 No Flanges 2.41 (61) 4.94 (125) 5.89 (149) 1.6

NAP-150-NW 1.5 NW-40 2.56 (65) 5.09 (129) 6.04 (153) 1.7

NAP-150-CF 1.5 CF-275, Rotatable 2.62 (67) 5.15 (131) 6.09 (155) 1.9

NAP-200 1.5 No Flanges 2.61 (66) 5.14 (131) 6.09 (155) 1.6

NAP-200-NW 1.5 NW-50 2.76 (70) 5.29 (134) 6.24 (158) 1.7

NAP-200-CF 1.5 CF-338, Rotatable 2.84 (72) 5.37 (136) 6.32 (160) 1.9

TABLE 3.4 PNEUMATIC N-SERIES ANGLE VALVE DIMENSIONS TABLE

PORT OD DESCRIPTIO N

A B C

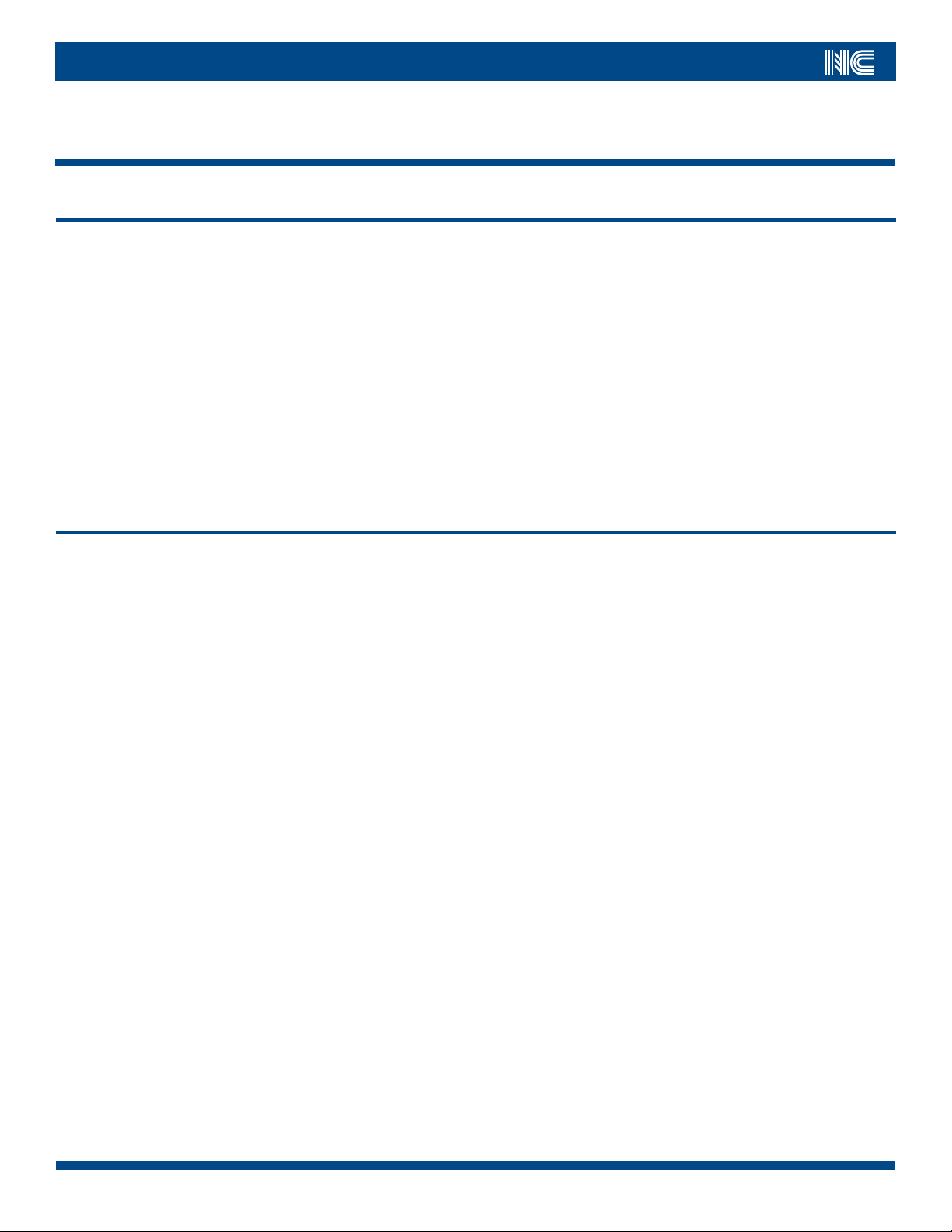

TABLE 3.5 PNEUMATIC N-SERIES ANGLE IN-LINE VALVE DIMENSIONS TABLE

MODEL

NUMBER

PORT OD DESCRIPTI ON

A B

NAIP-075 0.75 No Flanges 3.64 (92) 4.60 (117) 1.7

NAIP-075-NW 0.75 NW-16 3.94 (100) 4.60 (117) 1.8

NAIP-075-CF 0.75 CF-133, Rotatable 4.20 (107) 4.60 (117) 2.0

NAIP-100 1.0 No Flanges 3.64 (92) 4.00 (102) 1.7

NAIP-100-NW 1.0 NW-25 3.94 (100) 4.00 (102) 1.8

NAIP-100-CF 1.0 CF-212, Rotatable 4.75 (121) 4.00 (102) 2.0

NAIP-150 1.5 No Flanges 4.82 (122) 4.37 (111) 1.7

NAIP-150-NW 1.5 NW-40 5.12 (130) 4.37 (111) 1.8

NAIP-150-CF 1.5 CF-275, Rotatable 5.24 (133) 4.37 (111) 2.0

NAIP-200 1.5 No Flanges 5.21 (132) 4.37 (111) 1.7

NAIP-200-NW 1.5 NW-50 5.51 (140) 4.37 (111) 1.8

NAIP-200-CF 1.5 CF-338, Rotatable 5.66 (144) 4.37 (111) 2.0

WEIGHT

(Lb.)

WEIGHT

(Lb.)

FIGURE 3.4.1

B

0.95 (24)

2.77 (70)

C

B

A

2.77 (70)

0.95 (24)

A

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

5

Page 6

N-Series Isolation Poppet Valves

4.0 Description of N-Series Valve

4.1 Overview

Nor-Cal Products N-Series valves are pneumatically operated bellows sealed poppet valves, designed for light weight and compact size as well as robust operation and long life. The pneumatic valve is controlled by a pneumatic cylinder located inside the top of the valve body for extra low profile and envelope size. The

valve closes by use of an internal spring. Supplying compressed air to the pneumatic cylinder opens the valve. In the event of a power or pneumatic failure the

valve closes automatically, and is therefore considered a “normally closed” or “fail close” design.

The electropolished 304 stainless steel valve body is available in a right angle or angle in-line configuration with a selection of flange types. Customer specific

flange arrangements and combinations are available upon request, as are a variety of O-ring seal types. Viton is the default elastomer material used.

Optional position indicators can be ordered with the valve, or they can easily be installed as a retrofit at the user’s site. The position indicators are mounted on a

small circuit board that resides in a molded slot in the valve top cover. No adjustment or bracket hardware is needed for the position indicator installation.

An air solenoid operated pneumatic valve may also be ordered with the valve. This valve allows electrical control of the N-Series valve while it is connected directly to the user’s pneumatic supply. The solenoid valves are available in 24 VDC as well as 24, 120 and 240 VAC varieties.

4.2 Theory of Operation

Figure 4.2.1 illustrates the components of the pneumatic N-Series valve. From its normally closed position, the valve is opened when compressed air is applied to

the pneumatic cylinder through the 10-32 [M5] female port (usually fitted with a 5.32” [4mm] quick disconnect fitting) in the valve stem). When the pneumatic

pressure in the cylinder reaches a level sufficient to overcome the force of the spring, the piston starts to rise, pulling the poppet off of the seat.

The actuator cylinder is vented to allow air from within the bellows to enter or escape as its volume changes. At the lower end of the stem, the poppet is permanently attached to the stem. The poppet includes an O-ring seal residing in a dovetail shaped O-ring groove, which contacts the seat to seal the valve port. The

bellows forms a flexible seal between the poppet and body valve housing.

As long as adequate pneumatic pressure is applied, the piston continues to travel upward, further compressing the spring, until the piston reaches the stop at the

full open position.

To close the valve, the cylinder is vented through the same 10-32 [M5] female port (usually fitted with a 5.32” [4mm] quick disconnect fitting). As the air pressure

falls below the value necessary to counter the spring force at the full open position, the piston and the poppet start to move towards the closed position. As venting continues, the poppet seat reaches the full close, sealed position.

66

Visit our Web Site www.n-c.com

Page 7

N-Series Isolation Poppet Valves

Air Cylinder

Bonnet Seal O-ring

Position Sensor Ring

Closing Springs

Piston

Side Port

Actuator Cap

Bottom Port

Activation Air Inlet

Standard with 360

Bellows

Valve Body

Poppet O-Ring

o

Swivel

Poppet

Position Sensor Board

(Optional)

Air Solenoid

(Optional)

Activation Air Inlet

Piston Seal

FIGURE 4.2.1

4.3 Valve & Options Nomenclature

FIGURE 4.3.1

N-Series Options

Please use the following part numbering

tree to add the appropriate options to a

standard N-Series valve model number.

Valve

Model Number

Example: NAP-150-NW-O- O-K79-S11-SS

Right angle N-Series valve with 1.5 inch bore, NW-40 flanges, redundant optical

position indicators, Kalrez 4079 O-rings, 120VAC air solenoid and soft start option.

Position

Indicator 1

Position

Indicator 2

O-ring

Type

Air

Solenoid

Soft

Start

5.0 Installation and Use

5.1 Unpacking and Detrashing

Unless otherwise requested, the N-Series valve is bagged and labeled according to standard clean room protocol. Outer packaging varies depending on the

number and types of valves ordered.

Before unpacking, please inspect the box thoroughly to make sure it is undamaged. Report any obvious signs of damage or tampering to the freight carrier.

Leave plastic bag intact until the product is ready to be transferred to a clean area.

NOTE: HARD COPY DOCUMENTATION: Printed operating manuals are no longer supplied in the packaging with Nor-Cal valve products. All

product documentation is available on-line at http://www.n-c.com/productdocumentation.aspx.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

7

Page 8

N-Series Isolation Poppet Valves

5.2 Valve Installation

Every N-Series valve is packaged with plastic protective flange end-caps. Leave these caps in place until the product is ready to be installed in the piping manifold or vacuum system. Even the smallest scratch or nick on the flange sealing surface can significantly compromise the leak integrity of the vacuum system and

cause inadequate pump-down performance.

Be sure to always use the proper Nor-Cal flange connection hardware, including centering rings, O-rings, copper gaskets, clamps, nuts and bolts, etc.

CAUTION: BENDING MOMENTS: Improper installation of the N-Series valve may lead to failure of the valve to seal or permanent damage

to the valve housing body. Bending moments across the inlet and outlet flange connections should never exceed 50 ft-lb. Never

force two tube ends together with clamps or fastening hardware. Doing so will likely damage components in the line, such as a

valve. Instead, make use of flexible couplings to help join slightly misaligned sections of vacuum tubing.

5.3 Pneumatic Hook-Up

The standard N-Series valve comes equipped with a quick disconnect fitting. Use 5-32” [4mm] OD flexible tubing to supply compressed air to the valve.

Alternate tubing connections can be accommodated by replacing the quick disconnect fitting. The valve stem thread is 10-32 [M5].

5.4 Solenoid Valve Connection

Solenoid

Electrical Connection

Air Connection

(5/32”/4mm OD Tubing)

FIGURE 5.4.1

88

Visit our Web Site www.n-c.com

Page 9

N-Series Isolation Poppet Valves

5.5 Position indicator Electrical Connection

BLACK -Ground

GREEN - Closed

WHITE - Open

RED - +24 VDC

Input: +5 to +28 VDC

Output: NPN Standard

PNP Option available on request

FIGURE 5.5.1

6.0 Troubleshooting

Please refer to the following possible symptoms and root causes to troubleshoot your N-Series valve. Alternatively, you can contact Nor-Cal technical support at

800-824-4166. In many cases, the N-Series valve problem can be diagnosed and fixed in the field. Spare parts and kits can be found in Section 7 of this manual.

Should it be necessary to return a valve to Nor-Cal Products for service, then please refer to Section 8 for instructions.

CAUTION: FIELD SERVICE: Before attempting to diagnose or service a valve, please make sure that you have familiarized yourself with the

safe operation and maintenance of the valve (See Section 7). Compressed air and strong spring forces present potential hazards.

Make sure the valve is in a “safe state” before servicing by disconnecting the air supply line and /or the solenoid pilot valve power

supply.

CAUTION: FIELD SERVICE: While performing work on the N-Series valve, be certain to use only proper tools and any special fixtures or

assembly aids recommended or supplied by Nor-Cal Products.

6.1 Valve Will Not Close and Remains Fully or Partially Open

Observe the pneumatic connection on top of the valve to watch the valve stem rise and fall. A completely closed valve should show the valve stem / push-to-fitconnector interface flush with the top cap of the valve. If the valve does not appear to be closing completely, possible causes include:

• An obstruction inside the valve that prevents the poppet from seating all the way (ex. process debris).

• A broken or worn spring in the valve actuator.

• Degraded or inadequate lubrication in the pneumatic cylinder.

• A complete or partial blockage of the air vent from the pneumatic cylinder

• A faulty solenoid valve, whereby it does not cut off pneumatic supply to the valve or allow the pneumatic cylinder to vent.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

9

Page 10

N-Series Isolation Poppet Valves

6.2 Valve Will Not Open All The Way or At All

Observe the pneumatic connection on top of the valve to watch the valve stem rise and fall. A completely open valve should show the valve stem / push-to-fitconnector interface about 0.4” (10mm) above the top cap of the valve. If the valve does not appear to be opening completely, possible causes include:

• Inadequate air supply pressure. (Minimum pressure is 60 psig [414 kPa])

• A kink or blockage in the pneumatic supply line or inlet fitting.

• A faulty solenoid valve, whereby the pressurized air is not routed to the pneumatic cylinder

• Pneumatic air cylinder piston O-ring leak. (Listen for hissing and feel for air escaping between the stem and the top cap near the air inlet fitting.)

• Piston stem seal leak causing compressed air to enter inside of bellows. (Listen for hissing and feel for air escaping between the stem and the top cap

near the air inlet fitting.) This failure mode can also lead to overpressure and failure of the bellows, in which case compressed air would enter the

vacuum system.

6.3 Valve Does Not Seal Adequately As Measured Between Inlet and Outlet Ports

This failure is most often related to the poppet O-ring seal. Consider the following possibilities:

• Poppet seal O-ring is defective, such as being cracked, chipped, process hardened, etc.

• Poppet seal O-ring is contaminated with process debris.

• Poppet valve seat is contaminated with process debris.

• Valve is not closing fully (refer to Section 6.1)

6.4 Vacuum System Will Not Pump Down To Base Pressure

This usually indicates a leak in the vacuum system or a problem with the vacuum pump. There are naturally many different possible causes for this problem, and

some may have nothing to do with the N-Series valve at all. A basic pump operation and vacuum line integrity check should be performed first to narrow the

problem down. If, by process of elimination, it is suspected that a system leak is stemming from the N-Series valve please check the following:

• If available, use a He-leak detector to determine the exact location of the leak. Verify leak integrity at the inlet and outlet flanges as well as in and

around the top cap of the valve.

• Flange leaks can occur if the flanges or O-rings were damaged during installation.

• A valve body leak could occur if the valve was subjected to severe bending moments during installation. Look for signs of deformed port protrusions

and subsequent cracking.

• If the static top cap O-ring is compromised, then ambient air will leak in to the valve body cavity and on in to the vacuum system.

• If the valve bellows is cracked or broken, then ambient air will leak in to the vacuum system through the annulus between the stem and the top cap

near the air inlet fitting.

Seal and bellows kits are available to repair a defective valve in the field. Please refer to Section 7 for spare parts ordering details.

6.5 Position Indicators Are Not Sending Open / Close Signals

The position indicators are designed to provide remote indication when the N-Series valve is either fully open or fully closed. There is a reflective ring on the valve

stem that is used to trigger the optical detection circuit used in the position sensing. If open / close signals are not received by the customer, please consider

these causes:

• The valve is not closing fully, thereby not triggering the closed indicator. (see Section 6.1)

• The valve is not opening fully, thereby not triggering the open indicator. (see Section 6.2)

• The sensor cable is not connected properly or the connector pin-out is wrong. (Refer to Section 5.5 for proper position indicator connection.)

• The position indicator is broken and needs replacement.

The N-Series valve position indicators are mounted on a printed circuit board which, in turn, is located in a preformed slot in the valve actuator cap. It is held in

place by the label on top of the valve. This label must be removed in order to access the position indicator circuit board.

1010

Visit our Web Site www.n-c.com

Page 11

N-Series Isolation Poppet Valves

6.6 Valve Makes Noise

Under normal circumstances, the N-Series valve will make a very faint sound when actuated. This sound stems from the spring compressing and coming in intentional contact with the guides inside the pneumatic cylinder housing. If the valve starts making loud scraping or vibrational noises, then a more serious problem

has developed. Please contact Nor-Cal technical support at 1-800-824-4166.

6.7 Air Supply Solenoid Valve Is Leaking or Makes Noise

The air solenoid valve is controlled by a small electromagnetic solenoid coil, which typically lasts for millions of cycles. When operating normally, this part will

not make any sounds other than a light clicking when opened or closed. If compressed air starts to leak through the valve, or if it makes a buzzing sound, it is

possible that the valve is about to fail and replacement is necessary. A leading cause of premature failure is improper voltage. Check the power supplied to the

solenoid valve and make sure it meets the specifications.

7.0 Spare Parts & Accessories

This section contains ordering information as well as service and installation instructions for O-ring seal kits, replacement bellows and actuator assemblies, in

addition to solenoid valve and position indicator upgrade or replacement options.

CAUTION: FIELD SERVICE: Before attempting to diagnose or service a valve, please make sure that you have familiarized yourself with the

safe operation and maintenance of the valve (See Section 7). Compressed air and strong spring forces present potential hazards.

Make sure the valve is in a “safe state” before servicing by disconnecting the air supply line and /or the solenoid valve power

supply.

CAUTION: FIELD SERVICE: While performing work on the N-Series valve, be certain to use only proper tools and any special fixtures or

assembly aids recommended or supplied by Nor-Cal Products.

7.1 O-Ring Seal Kits

The N-Series valve contains two serviceable O-rings which include the main poppet seal and the bonnet seal (see Figure 4.2.1). N-Series valves sized from .75” to

2” use the same set of seals. The standard O-ring compound is Viton. Other compounds are available. [Aflas

etc…].

NOTE: ORDERING REPLACEMENT SEALS: Please make sure to have the part number or serial number of the valve available when ordering seal

replacements in the event you are not sure which seal compounds were originally installed.

Common replacement seal kits include:

®

NA-075-95: Viton

NA-075-95-K79: Kalrez

NA-075-95-C13: Chemraz

NOTE: Other seal materials are available. Call for details.

To replace the O-ring seals, please see the following instructions :

poppet and bonnet replacement O-rings

®

4079 poppet and bonnet replacement O-rings

®

513 poppet and bonnet replacement O-rings

®, Buna-N®, Chemraz®, Dupra®, Kalrez®, Perlast®,

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

11

Page 12

N-Series Isolation Poppet Valves

7.1 Replacing O-Ring Seal

1

Remove air fitting, if installed.

Install vented screw with large

flat washer [supplied in kit] until

screw stops.

Do NOT overtighten.

(This partially opens the valve

allowing the bellows /actuator

assembly to be removed.)

3

Grasp actuator top and lift

bellows /actuator assembly out

of body.

2

Remove the four button head

screws securing the bellows /

actuator assembly to the body

using a 3/32” hex key.

4

Remove and discard the old

bonnet and poppet O-rings.

Avoid scratching the seal

surfaces by using a plastic O-ring

pick to remove the O-rings.

5

Using an IPA soaked cleanroom

wipe thoroughly clean the

bonnet and poppet O-ring

grooves as shown.

7

Carefully install the sub assembly

into the body. Be sure that the

body O-ring is seated into the

groove.

6

Wipe O-rings with IPA and blow

dry with CDA. Evenly apply a

light sheen of Krytox to both

O-rings.

Install the O-rings. Wipe off any

excess Krytox with an IPA soaked

cleanroom wipe.

8

Place a small amount of anti-seize

onto the button head screws.

Insert the button head screws.

When all four screws are in place

tighten down and torque to 15 in.

lbs. using a cross pattern.

Now that the screws are torqued

in place it is safe to remove the

vented screw and flat washer

from the top cap. Thread the air

fitting into the stem to complete

the valve.

1212

Visit our Web Site www.n-c.com

Page 13

N-Series Isolation Poppet Valves

7.2 Valve Rebuild Kit

All N-Series valves port size 0.75” thru 2”, use the actuator rebuild kit. The rebuild kit consists of the pneumatic / spring actuator and the bellows assembly. The

rebuild kit does NOT include the poppet and bonnet O-rings, solenoid valves or position indicators. These parts should either be reused from the original parts,

or they need to be ordered separately (refer to Sections 7.1, 7.3 and 7.4 as applicable).

The valve rebuild kit can be ordered under part number:

NA-075-99: Rebuild kit fits sizes 0.75” – 2” N-Series valves.

To rebuild the N-Series valve, please follow the same instructions as outlined in section 7.1 for replacing the O-ring seal.

7.3 Replacement or Add-On Solenoid Valve Kit

The N-Series valve can be equipped with four different solenoid (air pilot) valves, including operating voltages of 24 VDC, 120 VAC, 240 VAC and 24 VAC.

NOTE: ORDERING SOLENOID VALVES: Please make sure to have the part number or serial number of the valve available when ordering the

solenoid valve replacements in the event you are not sure which solenoid type (operating voltage) was originally installed.

The solenoid replacement kits include:

N-S11-K: 120 VAC solenoid kit

N-S21-K: 24 VDC solenoid kit

N-S31-K: 240 VAC solenoid kit

N-S41-K: 24 VAC solenoid kit

To add or replace the N-Series solenoid valve, please see the following instructions :

1

Air Fittings

Install the two air fittings

and air filter onto the

solenoid as shown.

The straight air fitting

accepts a 5/64“ or 2mm

hex key internally for easy

fastening.

Filter

3

Attach the solenoid

assembly to the bracket

using the two 4-40 x

1/2” screws supplied.

2

Install solenoid bracket

using the two 4-40 x

1/4” thread forming

screws supplied.

4

Insert the poly tubing

into the air fitting of the

valve and the air fitting

of the solenoid.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

13

Page 14

N-Series Isolation Poppet Valves

5

Solenoid test:

Insert air supply line into the straight fitting on the solenoid.

Apply 60 to 100 psi air pressure.

Valve should not open until power is applied. Verify valve opens with power is applied and closes when

power is removed.

Alternately you can actuate the solenoid valve by pressing the manual actuation button.

Actuation

Button

7.4 Replacement or Add-On Position Indicator

The N-Series valve position indicators are mounted on a printed circuit board which, in turn, is located in a preformed slot in the top housing of the valve. It is

held in place by the label on top of the valve. This label must be removed in order to access the position indicator circuit board. As such, the position indicator

replacement or add-on kit includes a spare label to be used, since the original adhesive likely will not be adequate to be used a second time.

The position indicator kit can be ordered under part number N-O-K.

Position indicator kit includes the circuit board, connection cable and top label.

To add or replace the N-Series position indicator,

please see the following instructions :

1

Remove the air fitting if installed.

Remove the label to access the

position indicator card slot.

Replacement label is included in

the kit.

Install the sensor board with the

optics toward the stem, and the

electrical connector located at the

top of the valve facing away from

the stem.

Do Not wear latex gloves when

handling boards!!!

3

Connect position indicator cable

as shown.

Connect air line for normal valve

operation.

BLACK -Ground

GREEN - Closed

WHITE - Open

RED - +24 VDC

Input: +5 to +28 VDC

Output: NPN Standard

PNP Option available on request

2

Place label onto valve as shown

so the electrical connector is

accessible through the opening

in the label.

Reinstall the air fitting.

4

When the valve is in the open

position the “I” led should illuminate on the valve as shown.

When the valve is in the closed

position the “0” led should illuminate on the valve as shown

1414

Visit our Web Site www.n-c.com

Page 15

N-Series Isolation Poppet Valves

8.0 Product Support & Returns

Many product support documents are available for viewing and download on the Nor-Cal Products website (www.n-c.com). Look for Frequently Asked

Questions, Product Support, Operating and Service Manuals, 3D CAD models, and more. If you prefer, you may also reach Nor-Cal’s Sales and Technical Support

departments by phone at 800-824-4166.

To inquire about and schedule a product return, you may contact our RMA Coordinator directly by e-mail at RMA@n-c.com.

NOTE: RETURNING PRODUCT TO NOR-CAL: Do NOT return any parts to Nor-Cal Products without first being issued an RMA number. Any

such shipments will be returned to you immediately.

This process may also be completed on-line by accessing the necessary forms in the RMA section of the Nor-Cal website (http://www.n-c.

com/rma.aspx).

We are very concerned that we do not inadvertently expose our employees to hazardous materials as a result of handling components that

have been returned for rework or repair. In compliance with Federal OSHA Safety Standard 1910-1200, Hazard Communications “Right to

Know”, Nor-Cal Products requires that a signed RMA (Return Material Authorization) form be completed to preclude any potential health

risk or exposure to our employees that may occur during receiving, evaluating, disassembling/ assembling, cleaning, machining, welding or

handling potentially contaminated products. The RMA (Return Material Authorization) may be returned by fax, e-mail or mail prior to issuance

of an RMA (Returned Material Authorization) number.

If the products have been used, complete the PCDS (Product Contamination Data Sheet) section of the RMA form. Please provide specific

information regarding the type of process in which the parts were used, the process chemicals they were exposed to, and the residues that may

remain on the parts. Nor-Cal Products, Inc. is particularly concerned with compounds that outgas at room temperature and pressure. Strong

odors emanating from a part may significantly delay or even stop work on a returned part.

NOTE: The PCDS section of the form must be filled out completely, and signed by a person authorized to do so by the Customer.

After the PCDS has been reviewed and accepted by Nor-Cal Products, the RMA number will be issued and shipping instructions will be

forwarded to you.

Please use the following step-by-step guideline in completing this procedure:

1.

Fill out the RMA and fax or mail it to Nor-Cal Products. Use the fax number or mailing address on the header of the RMA form.

2.

Clean the part to meet DOT shipping and OSHA handling practices. If this cannot be done, contact Nor Cal Customer Service to determine a course of

action. Nor-Cal will not accept any contaminated product without written evidence of decontamination.

3.

Seal the part in a plastic bag.

4.

Package and ship the bagged part to Nor-Cal Products according to the RMA instructions.

5.

Clearly write the RMA# on the outside of the box and, if possible, also write it on the bag or attach a copy of the RMA to the bagged part.

NOTE: The RMA number must be clearly visible on the outside of the package, or included on the shipping label and the packing

slip. It is also recommended that the RMA number or a copy of the RMA be attached to the bagged part inside the package.

Packages received without an RMA number clearly visible, will promptly be returned to the sender.

Nor-Cal Products, Inc. reserves the right to refuse delivery of parts for improper or inadequate cleaning, incomplete or

inadequate PCDS or RMA information, or for any other reason that may bring into question the safety of Nor-Cal employees.

Recommended Cleaning Facilities: For additional questions:

TMPI Phone: 530-841-9184

Phone: 510-786-0680 FAX: 866-640-9012

Chemetal E-mail:

rma@n-c.com

Phone: 510-783-5050

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

15

Page 16

N-Series Isolation Poppet Valves

RMA #

www.n-c.com

1967 South Oregon Street, Yreka, California 96097

800-824-4166

•

530-842-4457 • FAX: 530-842-9130

Return Material Authorization

It is mandatory to obtain an RMA from Nor-Cal Products before returning any parts, items or materials. Complete the requested information in the Sections

below and fax this form to Nor-Cal Products, attention RMA Coordinator at fax# 866- 640-9012 or 530-842-9130.

Section A Customer Contact Information

Company Name

Contact Name

Telephone e-mail address

Original P.O.# Sales Order #

Section B Item to be returned

*NOTE: If part is NEW (never been used) and still in the original Nor-Cal packaging, check the box in the New column, skip Section C PCDS, and sign and date

Section D. If part has been removed from the original packaging, do NOT check the NEW box; continue to Sections C and D.

Part Number Serial Number Quantity New? PCDS

Reason for Return

Do you need a replacement for this part? (Include replacement P/N, if known)

Section C Product Contamination Data Sheet

Type of process

Chemical exposure history

Cleaning performed

Describe any expected residues on returned part

*NOTE: IF TWO PARTS WITH OR WITHOUT THE SAME MODEL NUMBER HAVE BEEN EXPOSED TO DIFFERENT CHEMIC ALS THEY MUST BE LISTED ON SEPARATE

SHEETS. MAKE DUPLICATE COPIES OF THIS FORM AS NEEDED.

Section D Legally Binding Declaration

I represent that the information in this declaration is correct and complete to the best of my knowledge. I, the undersigned, have sufficient knowledge

regarding the condition of the product to complete this form. I am aware of the potential liabilities for damages and undertake to be responsible for such

damages to the extent that the damages are caused by incomplete or inaccurate information on this form. I certif y that I have provided accurate information

to Nor-Cal Products or its Representatives and understand that any discrepancy between the information that I have provided and the part returned under

the RMA may cause the RMA to be revoked and the part returned to me at my expense.

Signature Date

Section E TO BE COMPLETED BY NOR-CAL PRODUCTS

Your RMA is: Your shipment is authorized Shipper &

_ _______ ____ _______ ____ ___ ____ ____ ___ _ for freight collect (Y/N) ___ ____ ___ __ account: _____ ____ ___ ____ ____ ___ ____ ____ ___ _

Date reviewed

Determination

RMA # assigned

Welding Allowed? Yes

Cleaning Allowed? IPA

Signature MSDS Review

Signature

Please return goods to: Nor-Cal Products Inc., 1967 South Oregon Street, Yreka, CA 96097

Repair Technician

Rework/Repair Instructions

o

No o Eval.

o H2O Descale Chem Clean EP

Repair Date

I have reviewed the PCDS and corresponting MSDS’s.

AND

I understand how to safely handle these parts that may contain the

following contaminants

o

Signature

Date

1616

Visit our Web Site www.n-c.com

Page 17

N-Series Isolation Poppet Valves

Appendix

Limited Warranty

Products manufactured by Nor-Cal Products, Inc. (hereinafter referred to as “Nor-Cal”) are warranted against defects in material and workmanship for a

period of twelve (12) months from the date of shipment from Nor-Cal to the buyer. Any modification to the product by the buyer or their agent voids this warranty. Liability under this warranty is expressly, limited to replacement or repair (at Nor-Cal’s option) of defective parts. Nor-Cal may at any time discharge its

warranty as to any of it products by refunding the purchase price and taking back the products. This warranty applies only to parts manufactured, and labor

provided, by Nor-Cal under valid warranty claims received by Nor-Cal within the applicable warranty period and shall be subject to the terms and conditions

hereof. Expendable items such as tubes, heaters, sources, bellows, etc., by their nature may not function for one year; if such items fail to give reasonable service

for a reasonable period of time, as determined solely by Nor-Cal, they will be repaired or replaced by Nor-Cal at its election. All warranty replacement or repair

of parts shall be limited to equipment malfunctions which, in the sole opinion of Nor-Cal,are due or traceable to defects in original materials or workmanship.

Malfunctions caused by abuse or neglect of the equipment are expressly not covered by this warranty. Nor-Cal expressly disclaims responsibility for any loss or

damage caused by the use of its products other than in accordance with proper operating and safety procedures. Reasonable care must be taken by the user to

avoid hazards. In-warranty repaired or replacement parts are warranted only for the remaining unexpired portion of the original warranty period applicable to

the parts that have been repaired or replaced. After expiration of the applicable warranty period, the buyer shall be charged at Nor-Cal’s then current prices for

parts and labor plus transportation. Except as stated herein, Nor-Cal makes no warranty, expressed or implied (either in fact or by operation of law), statutory or

otherwise: and, except as stated herein, Nor-Cal shall have no liability for special or consequential damages of any kind or from any cause arising out of the sale,

installation, or use of any of its products. Statements made by any person, including representatives of Nor-Cal, which are inconsistent or in conflict with the

terms of this warranty shall not be binding upon Nor-Cal unless reduced to writing and approved by an officer of Nor-Cal. Merchandise may be returned at the

sole discretion of Nor-Cal Products, but not more than 60 days after shipment. A fee may be charged for restocking the item. An RMA number must be obtained

from Nor-Cal before returning any merchandise.

Intellectual Property

The products described in this manual are covered under U.S. Patents.

1717

Visit our Web Site www.n-c.com

Loading...

Loading...