Page 1

Gate Valve

Maintenance

& Adjustment

Procedures

1

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 2

Table of Contents

I. GATE AND BONNET O-RING 1.5” - 21” GATE VALVES ................................................................................3

II. BELLOWS, PNEUMATIC STANDARD 1.5” - 21” GATE VALVES ...................................................................5

III. ACTUATOR O-RING 1.5” - 21” GATE VALVES .............................................................................................8

IV. SEAL PLATE ASSEMBLY/ PINS BEARING 1.5” - 21” GATE VALVES ..........................................................10

Vl. VALVE ADJUSTMENT 1.5” - 21” GATE VALVES .........................................................................................14

VlI. VALVE ADJUSTMENT CHART 1.5” - 21” GATE VALVES ............................................................................15

Figures, Tables and Drawings

Figure 1 BONNET ACTUATOR CARRIAGE ASSEMBLY. SEPARATED FROM VALVE BODY ........................................ 3

Figure 2 GATE O-RING AND BONNET PLATE O-RING .............................................................................................. 4

Figure 3 BELLOWS AND PISTON SHOWN WITH ACTUATOR HOUSING REMOVED .................................................5

Figure 4 PISTON CLOSE-UP FOR SPANNER WRENCH POSITIONING ......................................................................5

Figure 5 BELLOWS AND ACTUATOR ASSEMBLIES DRAWING .................................................................................7

Figure 6 DRIVE SHAFT O-RING .................................................................................................................................8

Figure 7 ACTUATOR O-RING .....................................................................................................................................9

Figure 8 LINKAGE REMOVAL ..................................................................................................................................10

Figure 9 PIN AND LINKAGE CLOSE-UP ...................................................................................................................11

Figure 10 GATE AND STRONG-BACK ASSEMBLIES OPENED ...................................................................................11

Figure 11 PIN, WASHERS AND R-RING REMOVAL DRAWING .................................................................................12

Figure 12 GATE AND STRONGBACK ASSEMBLIES AFTER REASSEMBLY ................................................................13

Figure 13 STRONGBACK AND GATE ASSEMBLIES DRAWING ..................................................................................13

Figure 14 VALVE ADJUSTMENT TABLE .....................................................................................................................15

Figure 15 DIMENSIONS ............................................................................................................................................15

Figure 16 PNEUMATIC ACTUATOR ASSEMBLY .........................................................................................................16

2

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 3

I. Viton Gate & Bonnet O-ring

STD AND MSB 1.5” - 21” GATE VALVES

A. Tools and Materials Required:

1. Allen Wrench for 1.5”—14” Gate Valves

2. 1/2” Box Wrench for 16”—21” Gate Valves

3. O-Ring Pick

4. Rubber Gloves

5. Grease – Apezion L O-Ring Type

6. IPA

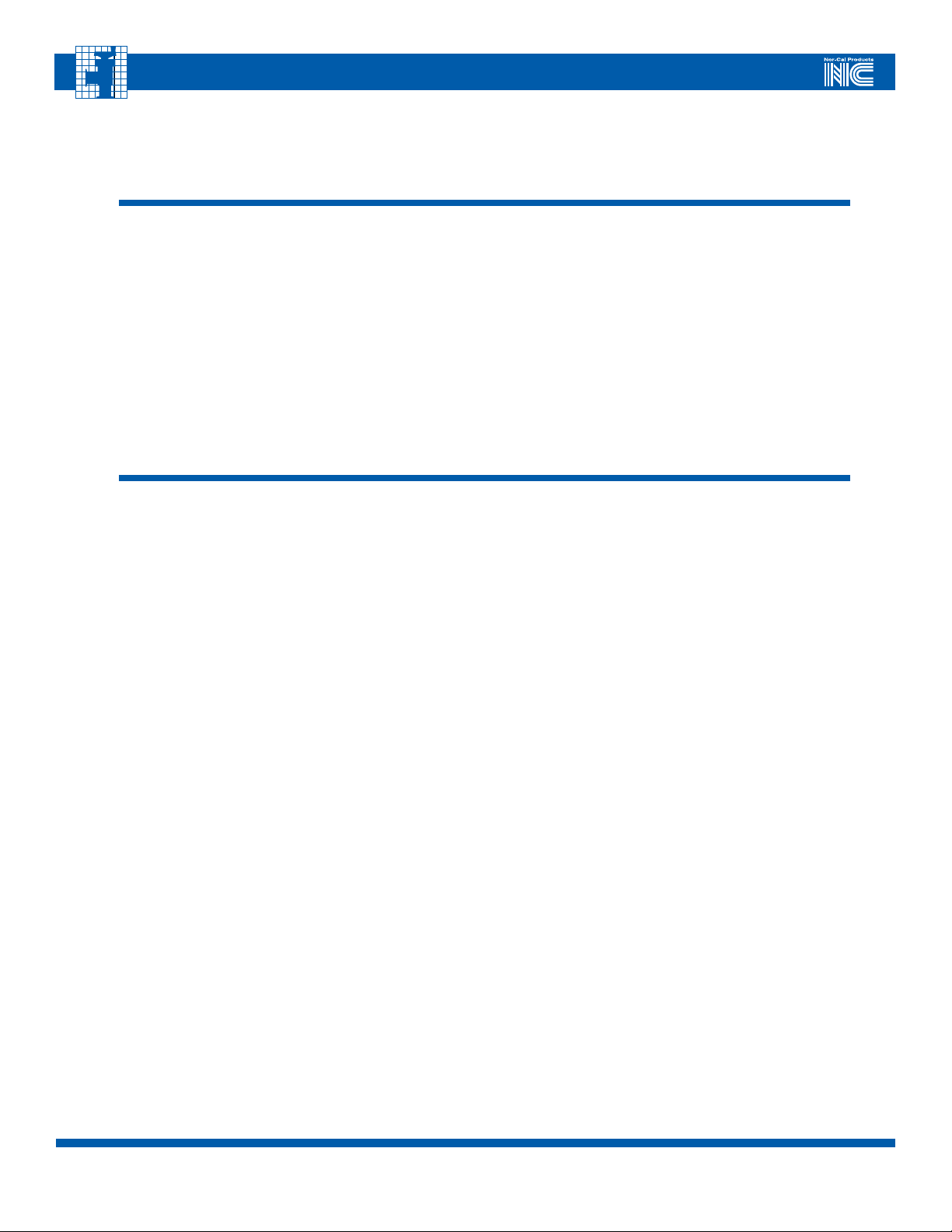

B. Procedure: Always wear Rubber Gloves when handling the Gate Valve

1. Vent station and pump corresponding to Gate Valve to atmosphere.

2. Actuate valve to Gate Open position.

3. For safety, remove air to actuator.

4. Remove bolts that hold Bonnet Actuator Assembly to body,

or for Quick-Clamp Bonnet, undo the clamp.

5. Pull out the Bonnet Actuator Carriage Assembly,

taking care not to move adjustment of linkage.

(Continued Next Page)

VALVE BODY

GATE ASSEMBLY &

STRONGBACK

LOWER AND UPPER LINKAGE

BONNET PLATE ASSEMBLY

ACTUATOR ASSEMBLY

ACTUATOR TOP WITH SENSORS

(OPENCLOSED)

Figure 1 - BONNET ACTUATOR CARRIAGE ASSEMBLY

SEPARATED FROM VALVE BODY

3

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 4

6. Remove O-Ring or Gasket from Bonnet Assembly and discard.

7. Remove Gate O-Ring with the plastic pick, taking care not to scratch the O-Ring groove.

Discard the O-Ring.

8. Clean O-Ring groove with IPA and dry out with Nitrogen or CDA.

9. Apply a light coat of Apezion L grease to the new Gate O-Ring. (It is very important

that gloves are worn for this step)

10. Install new O-Ring on gate, taking care to avoid twisting or deforming the O-Ring.

11. Apply a light coat of Apezion L grease to the new Bonnet assembly Viton O-Ring/

Copper Gasket. Install dry.

12. Install new O-Ring/Gasket on Bonnet assembly, taking care to avoid twisting

or deforming the O-Ring.

13. Replace Bonnet Actuator Assembly into valve body.

14. Install bolts and tighten. (For MSB, Copper gasket type, tighten side to side 20-25 ft-lb)

BONNET PLATE O-RING

Figure 2: GATE O-RING AND BONNET PLATE O-RING

GATE ASSEMBLY O-RING

NOTE:

1. BE CAREFUL NOT TO

SCRATCH O-RING

GROOVE

2. APPLY ONLY THIN

LAYER OF GREASE

3. AVOID TWISTING,

STRETCHING OR

DEFORMING THE

O-RING

4

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 5

II. Bellows, Pneumatic Standard Cycle Only

1.5” – 21” GATE VALVES

A. Tools and Materials Required:

1. Spanner Wrench

2. Allen Wrench Set

3. O-Ring Pick

4. Pick (for R-Ring removal)

5. Needle-Nose Pliers

6. Small Standard Screw Driver

7. Actuator O-Rings

8. Grease for Bellows O-Ring: Apezion L

9. Vacuum Grease

10. IPA

11. Heat Gun

12. Lock-Tite

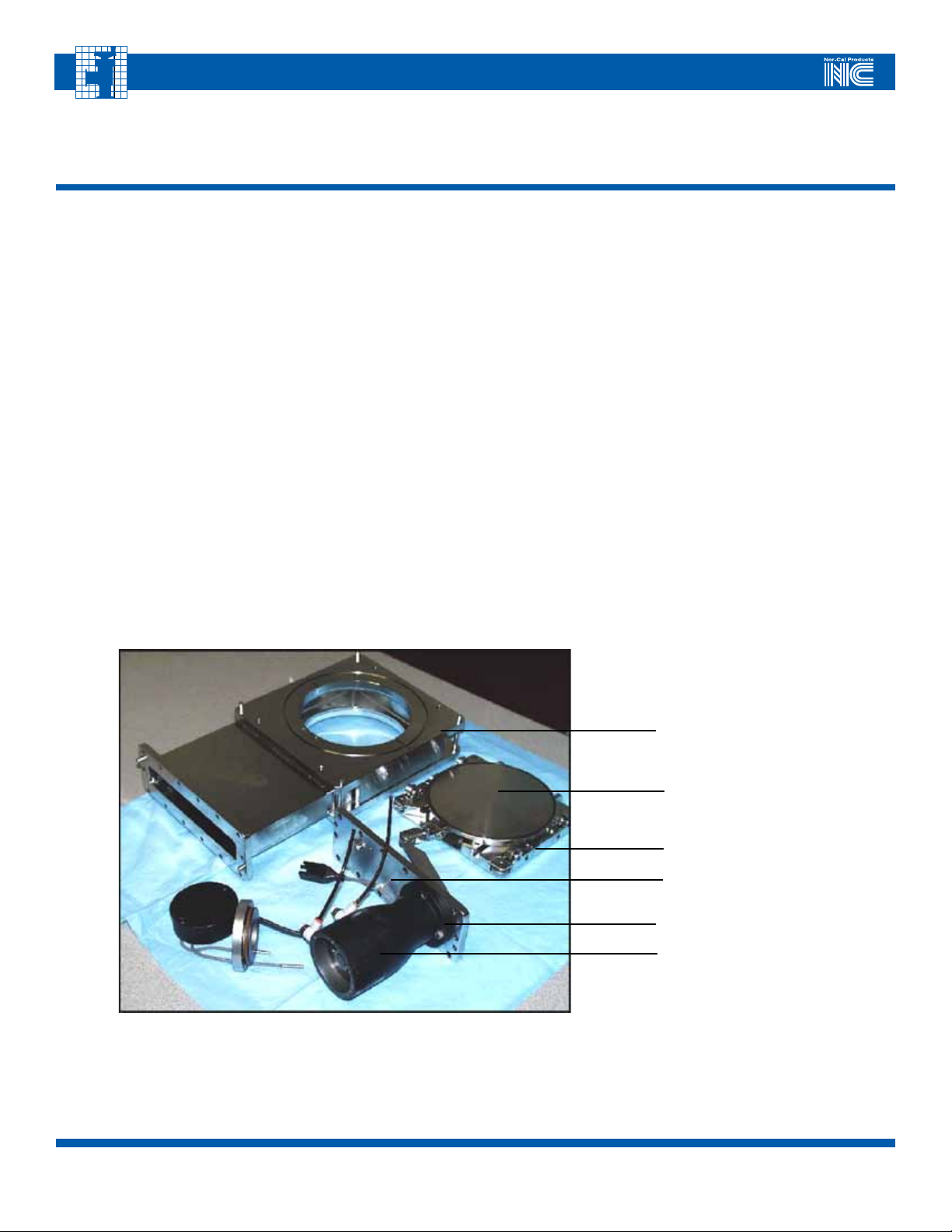

B. Procedure:

1. Vent station and pump corresponding to Gate Valve to atmosphere.

2. Actuate valve to Gate Open position.

3. For safety, remove air to actuator.

4. Remove Actuator Cover. ( 2 screws)

5. Remove Actuator Top. (6 screws)

6. Measure the distance between the top of the Piston and the top of the Drive Shaft.

(This will be helpful later during reassembly and adjustment)

7. Remove the Jam Nut from the Drive Shaft. (Heat gun may be needed to melt the

Lock-Tite on the thread)

(Continued Next Page)

Figure 3: BELLOWS AND PISTON

SHOWN WITH

ACTUATOR HOUSING

REMOVED

BELLOWS

PISTON

DIMENSION “A”

5

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 6

Figure 4 - PISTON CLOSE-UP FOR SPANNER WRENCH POSITIONING

8. Using a spanner wrench, turn Piston counterclockwise to remove from Actuator Housing.

9. Remove O-Ring from top of Drive Shaft.

10. Remove remaining screws holding the Actuator Housing to the Bonnet Plate. (2 screws)

11. Remove the Actuator Housing.

12. Remove R-Ring from Drive Shaft, using a pick. If a replacement is NOT available, use care to preserve the

R-Ring. Otherwise, pull out using the needle nose pliers and discard.

13. Remove bellows by pulling and twisting slightly. Discard.

14. Remove O-Ring in the Bellows drive shaft area and discard.

15. Clean Drive Shaft groove and Bellows area with IPA.

16. Apply a thin coat of grease (Apezion L) on the O-Ring for the Drive Shaft in Bellows area.

17. Install O-Ring.

18. Apply a thin coat of grease (Apezion L) on the O-Ring for the Bellows base Flange.

19. Install O-Ring.

20. Replace Bellows assembly on the Drive Shaft, pushing and twisting slightly to go over the O-Ring.

21. Install R-Ring on the Drive Shaft, using a screw driver and a pick. Make sure it clicks into the groove next to

the top of the Bellows.

22. Apply a thin coat of Vacuum Grease to the Drive Shaft.

23. Install Actuator Housing on the Bonnet plate.

24. Apply a thin coating of Vacuum Grease to the O-Ring for the top of the Drive Shaft.

25. Install O-Ring on the top of the Drive Shaft.

26. Apply a thin coating of vacuum grease to the Piston area, if necessary.

(Continued Next Page)

INDENTATIONS ON THE

PISTON FOR SPANNER WRENCH

NOTE: GATE MUST BE IN OPEN

POSITION TO ACCESS THESE EASILY

JAM NUT

NOTE: May require use of the

heat gun to melt any LOCK-TITE

6

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 7

27. Install Piston on Drive Shaft; using a spanner wrench, turn clockwise

until the measurement in step # 5 is achieved.

28. Install Jam Nut, using Lock-Tite and tighten.

29. Install Actuator Top and tighten screws.

30. Install Actuator Cover and tighten screws.

31. Install air line and test operation of Valve and Actuator.

Figure 5: BELLOWS

AND ACTUATOR ASSEMBLIES

DRAWING

SCREW (6X)

ACTUATOR TOP

O-RING

JAM NUT

O-RING

PISTON

MAGNET

O-RING

ACTUATOR HOUSE

O-RING

R-RING

BELLOWS - BELLOWS

0-RING

END FLG

R-RING

REED SW DRIVE SHAFT

WASHER (3X)

R-RING

BEARING

PINS (2X)

STEM

O-RING

7

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 8

III. Actuator O-ring

1.5” – 21” GATE VALVES STD AND MSB

A. Tools and Materials Required:

1. Spanner Wrench

2. Allen Wrench Set

3. O-Ring Pick

4. Pick (for R-Ring removal)

5. Needle-Nose Pliers

6. Small Standard Screw Driver

7. Actuator O-Rings

8. Grease for Bellows O-Ring: Apezion L

9. Vacuum Grease

10. IPA

11. Heat Gun

12. Lock-Tite

B. Procedure:

1. Actuate valve to Gate Open position.

2. For safety, remove air to actuator.

3. Remove Actuator Cover. (2 screws)

4. Remove Actuator Top. (6 screws)

5. Measure the distance between the top of the Piston and the top of the Drive Shaft.

(This will be helpful later during reassembly and adjustment)

6. Remove the Jam Nut from the Drive Shaft. (Heat gun may be needed to melt the Lock-Tite on the thread)

7. Using a spanner wrench, turn Piston counterclockwise to remove from Actuator Housing.

8. Remove O-Ring from top of Drive Shaft.

(Continued Next Page)

DRIVE SHAFT O-RING

NOTE: REMOVE THIS

O-RING FIRST BEFORE

REMOVING THE

ACTUATOR HOUSING

FIGURE 6: DRIVE SHAFT O-RING

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

8

Page 9

9. Remove remaining screws holding the Actuator Housing to the Bonnet Plate. (2 screws)

10. Remove the Actuator Housing.

11. Remove O-Ring in Actuator Housing, using a pick and using care to not scratch the groove surface.

Figure 3: ACTUATOR O-RING

ACTUATOR O-RING

NOTE:

1. REMOVE THIS O-RING

BEFORE REMOVING

THE ACTUATOR HOUSING

2. BE CAREFUL NOT TO

SCRATCH THE O-RING

GROOVE

12. Apply a thin coat of vacuum grease on the new O-Ring.

13 Install O-Ring.

14. Inspect the drive shaft; clean and lubricate as necessary.

15. Install Actuator Housing on the Bonnet plate. Tighten screws.

16. Apply a thin coat of Vacuum grease on the O-Ring for the top of the Drive Shaft.

17. Install O-Ring.

18. Inspect actuator housing. Clean and lubricate as necessary.

19. Apply a thin coat of vacuum grease on the O-Ring for the Piston.

20. Install O-Ring on the Piston.

21. Install Piston on Drive Shaft, using a spanner wrench and turning clockwise until

the measurement in step # 5 is achieved.

22. Install Jam Nut, using Lock-Tite and tighten.

23. Apply a thin coat of vacuum grease to the O-Ring for the Actuator Top.

24. Install O-Ring on the Actuator Top.

25. Install Actuator Top and tighten screws.

26. Install Actuator Cover and tighten screws.

27. Install air line and test operation of Valve and Actuator.

9

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 10

IV. Seal Plate Assembly / Pins Bearing

1.5”—21”

A. Tools and Materials Required:

1. Allen Wrench Set

2. Arbor Press

3. Punch

4. Hammer

5. Wrenches (Box or Open)

6. R-R Pliers

7. Vacuum Grease

8. IPA

9. Latex Gloves

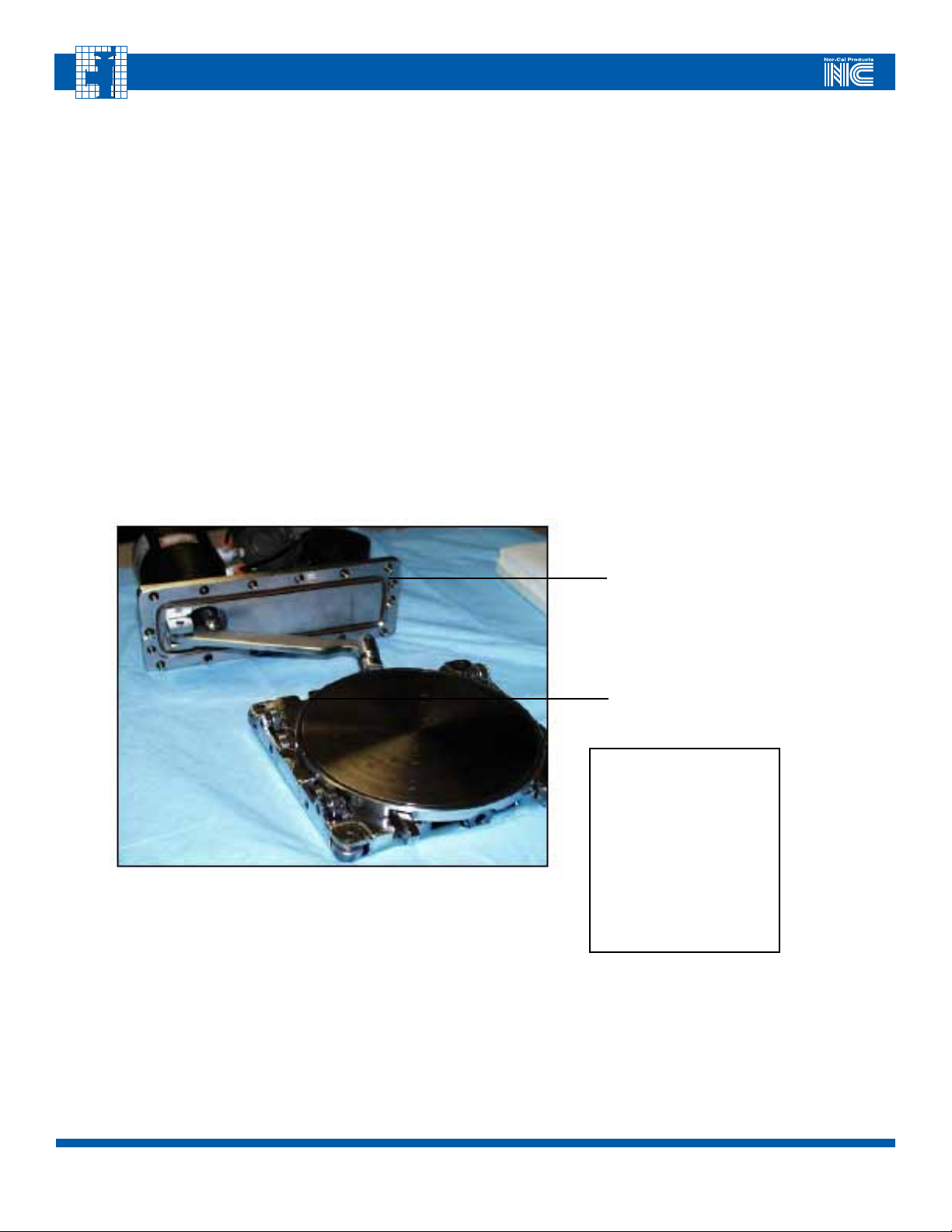

B. Procedure 4” – 21”

1. Actuate valve to gate Open position.

2. For safety, remove air to actuator.

3. Remove bolts that hold Bonnet Actuator Assembly to body. For Quick-Clamp

Bonnet, undo the clamp.

4. Pull out the Bonnet Actuator Carriage Assembly.

5. Using a punch and hammer, remove the pin that holds the Upper Linkage to the

Lower Linkage-Upper Linkage of Strongback. (Three washers and an R-Ring should be recovered)

Note: If the pin does not move, flip the assembly over and try from the other side.

Caution: Be careful not to bend the Upper Linkage; the use of a wooden

block for support is recommended)

(Continued Next Page)

HAMMER

WOODEN BLOCK

PUNCH

LOWER LINKAGE

UPPER LINKAGE

LOWER LINKAGE - STRONG-

BACK

FIGURE 8: LINKAGE REMOVAL

10

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 11

6. Separate the Bonnet Upper Linkage Assembly from the Carriage Assembly.

7. Measure the distance between the Strongback Lower Linkage and the Upper.

Linkage-Lower Linkage. (This will be helpful later during reassembly and valve adjustment)

Figure 5: PIN AND LINKAGE CLOSE-UP

PIN (HOLDS UPPER

AND LOWER LINKAGES

DIMENSION “C”

NOTE: IF PIN

DOESN’T COME OUT

EASILY, FLIP OVER

AND HIT WITH

PUNCH ON THE

OTHER SIDE

8. Move Carriage assembly to a suitable work place for disassembly and the replacement

of Pins, Bearings and R-Rings

9. Remove Gate Spring by removing one set screw (Allen Wrench)

10. Remove four set screws( Allen-3/32”) that hold Gate and Strongback together

11. Separate Gate from Strongback.

12. Remove Set Screws, Links, Washers, Pins, and Carriage Bars; Discard Washers

Figure 6: GATE AND STRONGBACK ASSEMBLIES OPENED

WHEEL

LINK

LOWER LINKAGE-STRONGBACK

CARRIAGE BAR

GATE SPRING

11

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 12

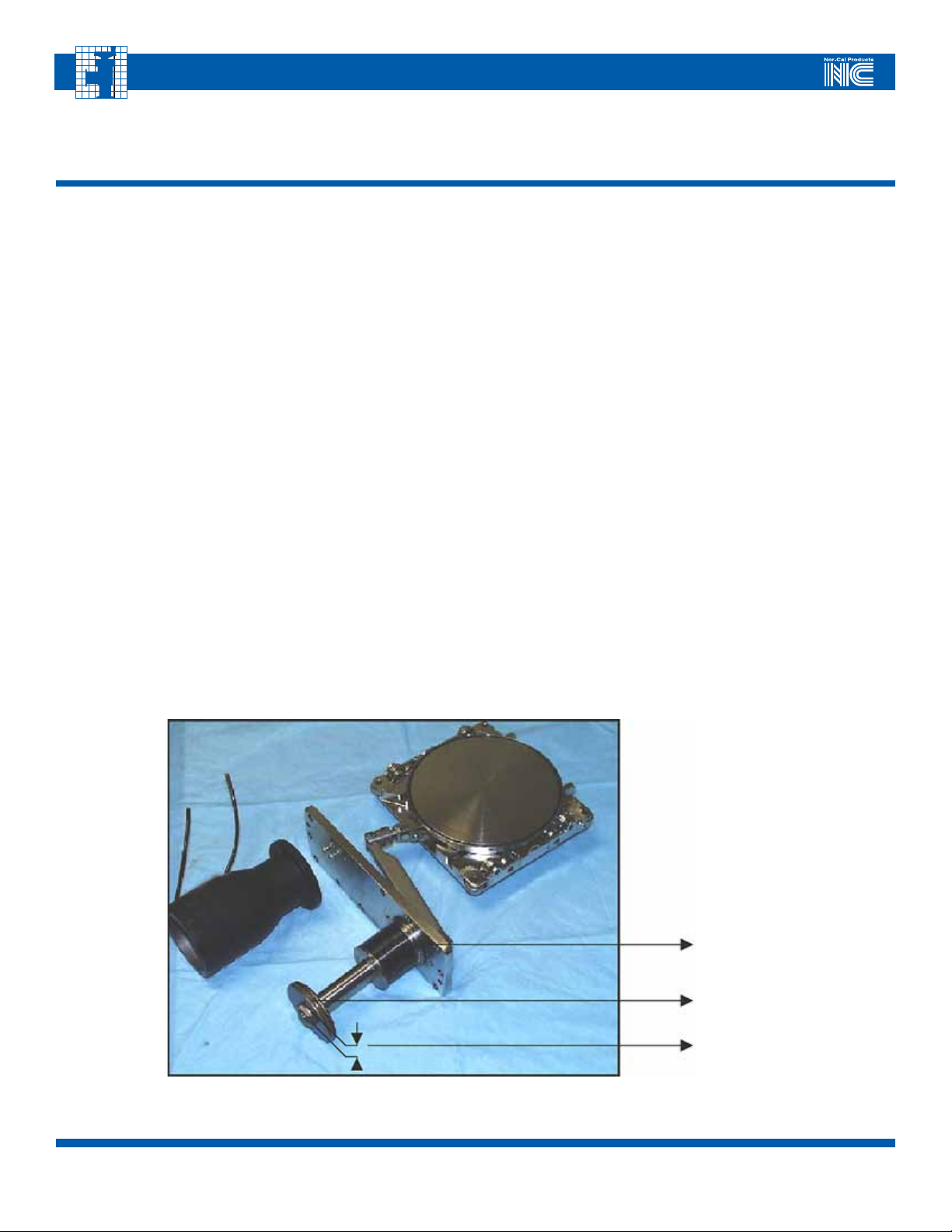

13. Using a punch and hammer, remove wheels from their pin.

Note: If the pin does not move, try from the other side.

14. Using an arbor press, remove the bearings from the links and wheels; Discard expendable parts;

15. Clean all reusable parts such as the gate, Strongback, Links, Carriage Bars, and Gate Spring with IPA;

16. Press new Bearings in using an arbor press; For Viton Bonnet sealing valves, ensure that the Bearings are properly lubricated with the appropriate vacuum grease( Micro Coat 601 recommended); For Copper sealing bonnet

valves run bearings dry

17. Verify that all bearings spin freely;

18. Install Washers, Pins and R-Rings into Strongback;

19. The recommended technique is as follows:

a) Slide long side of pin through hole first (the side without the groove);

b) Install R-Ring close to the end of the pin, not in the groove;

c) Add on the pin one Washer, then the Wheel, then the other two Washers;

d) Push Pin in until the R-Ring snaps into its groove;

20. Verify that all wheels spin freely

21. Set Strongback aside for later assembly

22. Install Links, Washers, and Pins into Gate Slots

23. Adjust Pins to correspond to Strongback Pin Pockets

24. Install Gate to Strongback; Verify that all Pins fit into Strongback pockets

25. Tighten the set screws loosened in step # 10

26. Verify that Gate moves freely up and down and is flush with the Strongback in the down position

27. Install Gate Spring

28. Install and tighten set screw removed in step # 9

29. Reattach Upper Linkage to Strongback Lower Linkage-Upper Linkage,

using the technique detailed in step # 19

30. Replace complete assembly into valve body

UPPER LINKAGE

WASHERS (3X)

R-RING

PIN

R-RING GROOVE

LOWER LINKAGE

NOTE: THE SAME TECHNIQUE IS USED TO REMOVE AND

REINSTALL THE WHEELS IN THE STRONGBACK ASSEMBLY

Figure 7: PIN, WASHERS AND R-RING REMOVAL DRAWING

12

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 13

31. Verify the measurement in step # 7, and adjust as necessary

32. Tighten bolts or install Quick-Clamp as appropriate

33. Test Valve operation

34. If necessary, refer to Valve Adjustment Procedure

Figure 12: GATE AND STRONGBACK

ASSEMBLY AFTER REASSEMBLY

AFTER REASSEMBLY, CHECK

THAT THE GATE ASSEMBLY

SITS FLUSH ON THE STRONGBACK AND MOVES FREELY UP

AND DOWN. DO THIS BEFORE

INSTALLING

THE GATE SPRING.

Figure 13:

STRONGBACK &

GATE ASSEMBLY

DRAWING

13

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 14

V. Valve Adjustment

COMPRESSION AND OVER-CENTER 1.5” – 21”

A. Tools and Materials required:

1. Allen Wrench Set

2. Wrench Set (Box and Open)

3. Air Regulator

4. Heat Gun

5. Latex Gloves

B. Procedure:

Steps 1 through 8 apply to 1.5” and 3” Gate Valves only.

1. Actuate Valve to Open Gate position.

2. For safety, remove air from Actuator.

3. Remove Actuator Cover (2 screws)

4. Remove Actuator Top (6 screws)

5. Loose Jam Nut on Drive Shaft. This may require the use of the heat gun to melt the Lock-Tite on the thread. ((Def

Pro #51574 for high temp applications or Lock-Tite 242-31 for standard applications recommended) 0

6. Check Dimension A on Chart for specific valve size. (This is only the starting adjustment)

7. Adjust and tighten Jam Nut. (Do not use Lock-Tite at this point, as adjustment may be needed later)

8. Install Actuator Top, using only 2 to 4 screws.

9. Remove bolts holding the Bonnet Actuator Assembly to valve body. For Quick-Clamp Bonnet, undo the clamp.

10. Pull out Actuator Bonnet Carriage Assembly from valve body.

11. Check Dimension C on Chart for specific valve size.

12. To adjust, loosen Jam Nut, then turn Lower Linkage-Upper Linkage counter clockwise to increase dimension

for more compression, or turn clockwise to decrease the dimension for less compression. (More compression

means more air pressure to lock valve. Less compression means less air pressure to lock valve)

13. After adjusting, tighten Jam Nut to 5 ft-lb torque.

14. Reassemble Bonnet Carriage Assembly on valve body.

15. Using an in-line air regulator, check the air pressure required to lock valve. Refer to chart on next page for Recommended Locking Air Pressure per size of gate valve.

16. Adjust Dimension C until the correct Locking Air Pressure is achieved.

Steps 17 through 20 apply to 4” through 12”Gate Valves Only

17. Check Dimension B on Chart for specific valve size, depending on Overcenter or No Overcenter requirement.

(Note: Proper Overcenter means that the Gate does not drop when air pressure is removed from the Actuator)

18. If necessary, loosen nut and adjust Dimension B by turning screw counter clockwise to increase dimension for

less Overcenter or turn clockwise to decrease dimension for more Overcenter. Less Overcenter means less travel

for the Linkage; more Overcenter means more travel.

19. Check for Overcenter adjustment: If gate drops after removal of air pressure for valves that require overcenter, go

back to Step # 18.

20. Tighten nut.

21. Intall all bolts and tighten.

22. Test valve operation.

14

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 15

Valve Adjustment Chart

INSTRUCTION FOR VALVE ADJUSTMENT

VALVE DIMENSION “A” DIMENSION “B” DIMENSION “B” DIMENSION “C” RECOMMENDED

SIZE PISTON ADJUST* OVERCENTER NO OVER- COMPRESSION LOCKING AIR

ADJUST CENTER ADJUST PRESSURE

ADJUST

1.50 .110 ** N/A N/A .210 20-30 PSI

2.00 .120 ** N/A N/A .360 35-50 PSI

2.50 .125 ** N/A N/A .190 35-55 PSI

3.00 .125 ** N/A N/A .390 60-65 PSI

4.00 N/A .278 .360 .420 20-35 PSI

6.00 N/A .085 .160 .350 35-45 PSI

8.00 N/A .365 .465 .260 55-65 PSI

10.00 N/A .770 .800 .720 25-35 PSI

10.75 N/A .635 1.035 .550 30-40 PSI

12.00 N/A .640 1.035 .550 30-40 PSI

14.00 N/A — — — 45-55 PSI

16.00 N/A .540 .760 .540 65-80 PSI

18.00 N/A — — — —

21.00 N/A — — — —

ALL DIMENSIONS IN INCHES

* = STARTING ADJUSTMENT

** = PISTON ADJUSTMENT CONTROLS

OVER- CENTER ADJUSTMENT

DIM “C”

DIM “B”

DIM “A”

PISTON ASSEMBLY AD-

JUSTMENT

LOWER LINK

ASSEMBLY

LOWER LINK

ASSEMBLY

ADJUSTMENT

Figure 14 - VALVE ADJUSTMENT TABLE

15

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Page 16

Figure 16

PNEUMATIC

ACTUATOR

ASSEMBLY

16

Nor-Cal Products, Inc., 1967 South Oregon St., Yreka, CA 96097 • Toll Free 800-824-4166 or 530-842-4457 • www.n-c.com Rev. 1-2013

Loading...

Loading...