Page 1

Adaptive Pressure Controller

Tel: 800-824-4166

or 530-842-4457

Fax: 530-842-9130

www.n-c.com

1967 So. Oregon

Yreka, CA 96097 USA

Nor-Cal Products, Inc.

IQ+ OP-LIT 9/08

Page 2

IntellIsys AdAptIve pressure Controllers

Table of Contents

1.0

............Introduction ..............................................................................................................................................

2.0

............Device Specification ..................................................................................................................................

............Unpacking and Installation ........................................................................................................................

3.0

3.1

....... Master Buried Box Controllers ...................................................................................................................

3.2

....... Slave Buried Box Controllers ......................................................................................................................8

3.3

....... Master On-Board Controllers ....................................................................................................................9

3.4

....... Slave On-Board Controller ......................................................................................................................

4.0

...........Theory of Operation ................................................................................................................................

5.0

............IQ+ Controller Module Interfaces ............................................................................................................

6.0 ..............

6.1

7.0

............DeviceNet Interface .................................................................................................................................

7.1

7.2

8.0

............DeviceNet Device Profile ..........................................................................................................................

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

8.11

8.12

8.13

9.0

............Battery Back-Up ......................................................................................................................................

10.0

Appendix I

Appendix II - Warranty and Intellectual Property Coverage

RS-232 Serial Interface and Commands ..................................................................................................

....... How to Configure IQ+ for Your System ...................................................................................................

....... Overview and Setup ................................................................................................................................

....... DeviceNet Communications ...................................................................................................................

....... Identity Object ........................................................................................................................................

....... Message Router Object ...........................................................................................................................

....... DeviceNet Object ....................................................................................................................................

....... Assembly Object .....................................................................................................................................

....... I/O Assembly Instances ............................................................................................................................

....... Connection Object..................................................................................................................................

....... Discrete Input Point Object ......................................................................................................................

....... S-Device Supervisor Object ......................................................................................................................

....... S-Analog Sensor Object ..........................................................................................................................

...... S-Analog Actuator Object .......................................................................................................................

...... S-Single Stage Controller Object .............................................................................................................

...... Selection Object ......................................................................................................................................

...... Master / Slave Object ..............................................................................................................................

..........Product Support......................................................................................................................................

- Spare Parts and Ordering Information ..................................................................................................

.............................................................................................

4

5

6

7

10

11

12

13

16

18

18

20

22

23

23

23

23

24

25

25

25

27

28

28

30

31

32

33

35

36

IQ+ OP-LIT 9/08

22

Visit our Web Site www.n-c.com

Page 3

IntellIsys AdAptIve pressure Controllers

List of Tables

2.1

......IQ+ Controller General Equipment Specification .............

2.2

.....IQ+ Controller Analog TTL I/O .........................................

2.3

......IQ+ Controller RS-232 Serial I/O ......................................

2.4

......IQ+ Controller Performance ............................................

2.5

......IQ+ Controller Reliability .................................................

3.1

......Buried Box Controllers (Master) .......................................7

3.2

......Buried Box Controllers (Slave) ..........................................8

3.3

......Master On-Board Controllers ..........................................9

3.4

......Slave On-Board Controllers .......................................... 10

5.1

......Dip Switch Configuration ............................................. 12

6.1

.....RS-232 Serial ICommands .............................................

......RS-232 Serial Requests and Responses ..........................

6.2

6.3

......Values for xx for use with Dual Range Mode ..................

..... DeviceNet Commands ............................................................17

6.4 .

6.5 ...... RS-232 Serial Commands .......................................................17

6.6 .....RS-232 Serial Requests and Responses ......................... 17

7.1

......DeviceNet Module LED Status .......................................

7.2

......DeviceNet Network LED Status ......................................

7.3

......DeviceNet Explicit Messaging ........................................

7.4

......Output Assembly Formats .............................................

7.5

......Input Assembly Formats ................................................

8.1.1

... Identity Object Attributes and services ...........................

8.1.2 ..Identity Object Status Bit Map .......................................

8.3.1

... DeviceNet Object Attributes and Services ......................

8.4.1

... Assembly Object Attributes ...........................................

8.5.1

... Output Assembly Instances ...........................................

8.5.2

... Input Assembly Instances ..............................................

8.6.1

... Connection Object Attributes .......................................

8.7.1

... Discrete Input Point Object Attribute; Instance ID 1........

8.7.2

... Discrete Input Point Object Attribute; Instance ID 2....... 25

8.8.1

... S-Device Supervisor Object Attributes and Services ........

8.8.2

... S-Device Supervisor Object Device Status Value ............

8.8.3

... S-Device Supervisor Object Exception Status Bit Map.... 25

8.8.4

..S-Device Supervisor Opject Exception Detail ................. 26

8.9.0

... S-Analog Sensor Object Class Attributes: Instance 0 ..... 27

8.9.1

... S-Analog Sensor Object Attributes; Instance 1,2 .......... 27

8.9.2

... S-Analog Sensor Object Attributes; Instance 3.............. 27

8.9.3

... S-Analog Sensor Object Status Bit Map .........................

13

13

15

18

18

20

21

21

23

23

23

23

24

24

25

25

25

25

27

8.10.1

5

5

5

5

5

.S-Analog Actuator Object Attibutes ..............................

8.10.2

.S-Analog Actuator Exception Status Bit Map .................

.S-Analog Actuator Object Override Value ......................

8.10.3

8.10.4

.S-Analog Actuator Object Safe State Value ...................

8.11.1

.S-Single Stage Controller Object Attributes; Instance 1 ..

8.11.2

.S-Single Stage Controller Object Attributes; Instance 2 ..

8.11.3 . S-Stage Controller Object Control Mode Value .

8.11.4 . S-Single Stage Controller Object Status Bit Map ......................29

8.11.5 . S-Single Stage Controller Object Safe State Value....................29

8.12.1 . Selection Object Attributes; Instance 1 ....................................29

8.12.2 . Selection Object Attributes; Instance 2 ....................................30

8.13.1 . Master/Slave Object Attributes ...............................................31

8.13.2 . Master/Slave Object Individual Valve Control (Action) Valve .....31

8.13.3 . Master/Slave Object Device Status Value .................................31

8.13.4 . Master/Slave Object Cluster Information Bit Map ....................31

8.13.5 . Slave Network LED Status .......................................................32

10.1 .... Possible Failure Modes and Recommended Actions ................33

10.2 .... Valid Status LED Combinations ...............................................34

......................29

List of Figures

3.1

......Buried Box Controller (Master) ........................................7

3.2

......Buried Box Controller (Slave) ...........................................

3.3 ...... On-Board Controller (Master) ...................................................9

3.4

......On-Board Controller (Slave) ...........................................

4.1 ...... Typical Installation and Configuration of a Buried Box IQ+ ..........

............ Pressure Control System .........................................................11

4.2 .....Typical Installation and Configuration of an IQ+ Pressure ..

...........Control Valve ............................................................... 11

6.1 .....Volume Too Low Slow Oscillations at set point .............. 16

6.2 .....Volume Too High Undershoot ...................................... 16

6.2.1 ..Volume Too High Slow Valve Movement, Slow ............ 16

6.3 .....Delay Too Low Overshoot and Pressure Oscillation........ 16

6.4 .....Speed Too High Low Speed Oscillations ........................ 17

6.5 .....Speed Too Low Undershoot, slow valve movement ...... 17

7.1 .....DeviceNet Connector Pin Assignment .......................... 18

7.2 .....DeviceNet Baud Rate Selection Switch ..........................

7.4

......Typical DeviceNet Hardware Installation ........................

8.1

......Object Model for the Process Control Valve Device ........

8.2

......Object State Transition Diagram ....................................

28

28

28

28

28

29

8

10

18

19

22

27

Information in this manual is subject to change without notice.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

Contact Nor-Cal Products

Intellisys Customer Support

at 800-824-4166 ext. 186

or visit our website

at www.n-c.com

IQ+ OP-LIT 9/08

3

Page 4

IntellIsys AdAptIve pressure Controllers

1.0 - Introduction

Thank you for purchasing the new Intellisys™ IQ+ downstream adaptive pressure controller from Nor-Cal Products. Before installing and operating the product,

please read this manual thoroughly as it contains critical correction, interface and operating tips. If you encounter any problems, or if you have any questions,

please contact our Intellisys Customer Service Support at 800-824-4166, ext. 186 or visit our web site at www.n-c.com.

Nor-Cal Products’ IQ+ pressure controllers are designed for downstream pressure control over a wide range of vacuum control applications. The IQ+ controller

is a self-contained unit that incorporates all control electronics and associated pressure control software. IQ+ controllers are available in Analog, DeviceNet and

Ethernet communication protocols. Buried box versions connect to the valve via a valve cable, while QPA, QPD and QPE controllers are mounted directly on the

valve. Any IQ+ controller, regardless of type, accepts the inputs from one or two pressure gauges as well as communications to the host controller, thus making

it the heart of a pressure control loop.

All models have local open/close switches, LED status lights and RS232 communication.

Important Personnel Safety and Product Protection Information

Throughout this manual, information that is of particular importance to the installation, the safety of operating personnel and the protection of equipment are highlighted by the following three symbols.

The WARNING symbol is also used on the equipment wherever necessary.

NOTE: Calls attention to helpful tips about proper

installation, maintenance or use of the controller.

CAUTION: Highlights areas of concern that, if overlooked, could

result in damage to the controller or surrounding equipment.

WARNING : Alerts the installation, operating or maintenance

personnel of hazardous aspects of the controller, which, if

ignored could result in serious personal injury or death.

IQ+ OP-LIT 9/08

44

Visit our Web Site www.n-c.com

Page 5

IntellIsys AdAptIve pressure Controllers

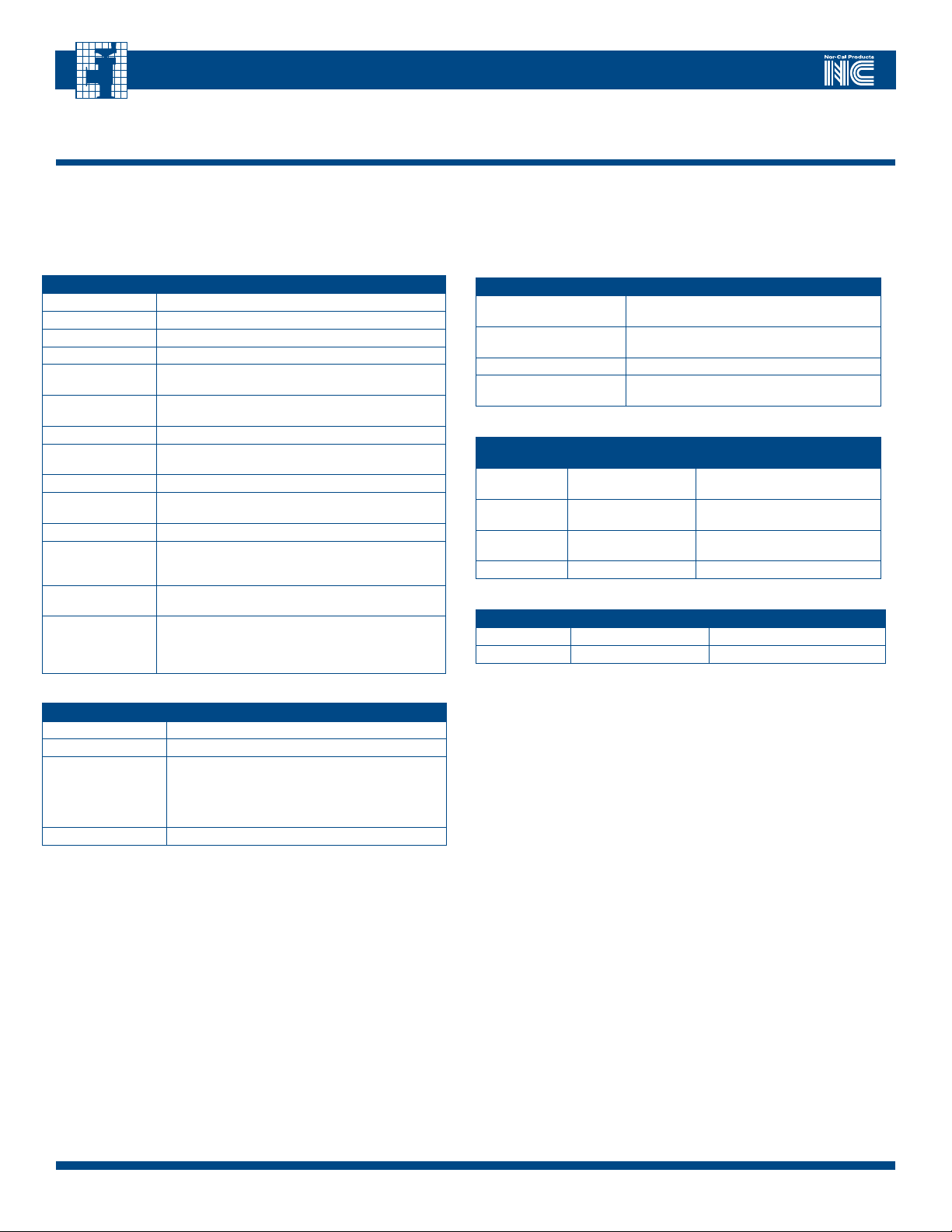

2.0 - Device Specification

The following tables summarize specifications essential to the installation and hook-up of the IQ+ product. Please note that the information herein is limited to

the IQ+ controller. For valve installation instructions and guidelines, please refer to the appropriate Valve Operating Manual.

TABLE 2.1 – IQ+ CONTROLLER GENERAL EQUIPMENT SPECIFICATIONS

FEATURE SPECIFICATION

Dimensions Please refer to the diagram specific to sections 3.1 to 3.5

Weight, in lbs (kg) 1.1 lb (0.5 kg)

Rated Input Voltage 24 VDC ±10%

Rated Current 5.0 A @ 24 VDC max, 1.5 A @ 24 VDC average

Rated Input

Protection

Gauge Power Supply

(Optional)

Protection Class I

Degree of Protection

(IP)

Laser Class 1 (LED’s)

Certifications/EU

Directives

Maximum Altitude 6562 ft (2000 m)

Allowable Ambient

Operating

Temperature

Allowable Ambient

Humidity

Installation Clearance

FEATURE SPECIFICATION

Analog (Gauge) Input 0 to 10V differential

Analog Output 0 to 10V unipolar @ 35 mA, short circuit protected

TTL Input

TTL Output Open collector, optically isolated, 25V @ 10 mA max

29 Volts max, reverse and current limited

± 15 VDC @ 1400 mA

X0

CE Standard for Process Equipment including EMC Directive

89/336/EC for D/C powered models..

32ºF to 113ºF (0ºC to 45ºC)

0 to 95% non-condensing

3” (75 mm) on all perforated sides. A minimum of 3½”

(90 mm) is needed to allow for connectors. If access and

line of sight is required for LED’s and switches a minimum

of 6” (150mm) is required on those sides.

TABLE 2.2 – IQ+ CONTROLLER ANALOG TTL I/O

Diode protected at –0.4 VDC, compatible with open

collector relay closure or standard logic signals, 25V max.

Maximum low input voltage is 0.6V and minimum sink

current is 1 mA. Minimum high input voltage is 2.5V, or

open.

TABLE 2.3 –IQ+ CONTROLLER RS-232 SERIAL I/O

FEATURE SPECIFICATION

Communications Settings

Connections

Communications Protocol See Section 6.0 in this manual

End of line delimiter

TABLE 2.4 – IQ+ CONTROLLER PERFORMANCE

FEATURE

Valve speed

(open to closed)

Control range

Accuracy

Repeatability 0.12% of reading 0.12% of reading

FEATURE BUTTERFLY VALVES PENDULUM VALVE

Electronics MTBF >10,000 hours >10,000 hours

Warranty 1 year 1 year

BUTTERFLY

VALVES

125 to 250 msec,

depending on valve size

0.5% to 100% of

gauge

0.25% of reading (5mV

min)

TABLE 2.5 – IQ+ CONTROLLER RELIABILITY

Factory configured at 9600 baud, 1 stop bit,

no parity, 8-bit character

Rxd Data, Txd data and Common.

No handshake connections.

Carriage return (ASCII 0x0D) or Line Feed (ASCII

0x0A) or carriage return then line feed in that order

GATE & PENDULUM VALVES

2 to 5 sec, depending on valve size

0.5% to 100% of gauge

0.25% of reading (5mV min)

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

IQ+ OP-LIT 9/08

5

Page 6

IntellIsys AdAptIve pressure Controllers

3.0 - Unpacking and Installation

Inspect the shipping box before unpacking. Any damage should be reported to Nor-Cal Products or directly to the transportation carrier. Carefully remove

the product from the box and visually inspect it for damage. If return of the product to Nor-Cal Products should become necessary, please contact Intellisys

Customer Service to obtain a Return Materials Authorization (RMA) Number.

NOTE: Do not discard the packing materials until the product has been inspected to your satisfaction.

Pre-Installation Functionality Check

Nor-Cal Products carefully ensures that every product shipped is in perfect working condition. However, it is still a good idea to

quickly check the functionality of the unit prior to installation into the vacuum system. To do so, for buried box IQ+ controllers,

connect the controller to the valve and then to an appropriate +24DC, 4A power source. For all valve IQ+ controllers simply

apply the +24DC, 4A power source. The butterfly valves will complete a 30 second valve initialization sequence ... the valve will

stop in the open positoin. For soft shut (TSS) valves and pendulum (TPV) valves press the open and close buttons at the same

time. The valves will begin the valve initialization sequence like the butterfly valve. The length of time to complete this sequence

will vary from 40-60 seconds depending upon the type and size of valve. The valve will complete a 30-second initialization

sequence during which the valve plate will cycle back-and-forth a few times while the OPEN/CLOSE LEDs blink in an alternating pattern. The valve will eventually stop in the open position. Further verification of the system can be done by toggling the

“OPEN / CLOSE” switch (if available) on the controller front panel. If the valve does not operate as described please contact NorCal Technical Support.

avoid putting bodily parts in or near the valve gate mechanism or other moving parts. These may move

WARNING : When working with or troubleshooting Nor-Cal APC products extreme care must be taken to

suddenly and unexpectedly, and many of them are driven with sufficient force so as to cause significant harm

and possibly even dismemberment. Nor-Cal Products recommends that a lock-out and tag-out procedure be

strictly followed whenever human physical intervention is required on all of its control valves.

Installation

To allow for proper ventilation, make sure that at least 3 inches of unobstructed space is available adjacent to all perforated

sides of the IQ+ controller. Then, complete all cable connections as required referring to the figures and pin assignment

tables in Sections 3.1 – 3.3 of this manual. A list of pre-manufactured cable assemblies available from Nor-Cal Products

can be found in Appendix I.

CAUTION: The optional +15V and –15V power supply pins of the IQ+ gauge connector are power sources

that are intended to power the optional system pressure gauge(s). It can supply a maximum of 1500 mA. Do

not use for any other purpose and do not connect to the tool main 15V supply as the two supplies would

interfere with each other.

NOTE: Low voltage controller models do not have a power on/off switch. Consider installing an external

power on/off switch between the DC power supply and the controller to allow for de-energizing the unit

without having to disconnect the cable.

IQ+ OP-LIT 9/08

66

Visit our Web Site www.n-c.com

Page 7

IntellIsys AdAptIve pressure Controllers

Net Ctrl

Fault

0

2

4

6

8

0

2

4

6

8

VALVE

GAUGE

P O W ER

POWER

SVC

PORT

2

5

P

1

RATE

SW1

C LOS E

O P EN

IQ+ SERIES

ADAPTIVE PRESSURE CONTROLLER

Mod

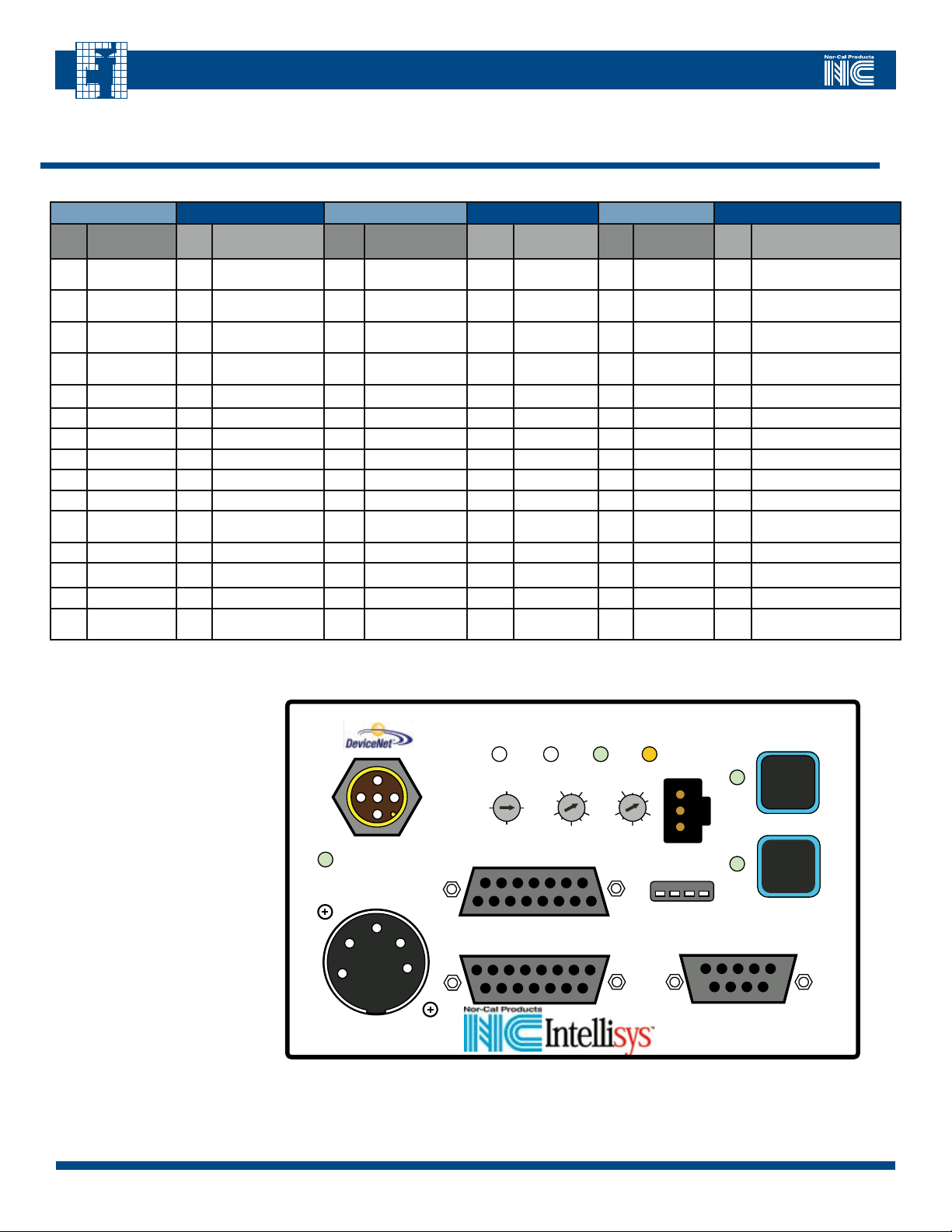

3.1 - Master Buried Box Controllers

TABLE 3.1 – BURIED BOX CONTROLLERS (MASTER)

POWER (XLR) SERVICE PORT VALVE AUXILIARY DEVICENET GAUGE

PIN FUNCTION PIN FUNCTION PIN SIGNAL

ASSIGNMENT

1 +24VDC

Power Input

2 Power Return 2 Authorized

3 Drain

4 N-C Net Hi

5 NC- Net Low

1

2

2

1 Authorized

Technicians Only

Technicians Only

3 Authorized

Technicians Only

1 Drive A + 1 Reserved 1 Drain 1 CDG1 +

2 Drive A- 2 RS232 TX 2 DNET Power

3 Drive B- 3 RS232 RX 3 DNET Power

4 Drive B + 4 Digital

5 Sense B - 5 Reserved 5 CAN L 5 CDG2 +

6 Sense B + 6 RS485 A 6 CDG2 -

7 Sense A - 7 Reserved 7 Reserved

8 Sense A + 8 RS485 B 8 CDG1 -

9 Reserved 9 TTL IN 0 9 CDG Power Ground

10 Reserved 10 TTL IN 1

11 Reserved 11 Digital

12 Reserved 12 TTL Com

13 Reserved 13 TTL Out 0

14 Reserved 14 TL Out 1

15 Reserved 15 Chassis

PIN FUNCTION PIN FUNCTION PIN FUNCTION

2 + 15VDC CDG Power

3 - 15VDC CDG Power

Ground

Ground

Ground

in +

in -

4 CAN H 4 Reserved

(Optional)

(Optional)

FIGURE 3.1 – BURIED BOX

CONTROLLER (MASTER)

1

Connect to Earth Ground at power supply

2

N-C Net is a proprietary communication protocol. Do not connect these pins to anything other than approved Nor-Cal items.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

IQ+ OP-LIT 9/08

7

Page 8

IntellIsys AdAptIve pressure Controllers

O P EN

C L OSE

Ctrl

Fault

1

3

5

7

9

SLAVE ID

POWER

Net

SVC

PORT

IQ+ SERIES

AADDAAPPTTIIVVEE PPRREESSSSUURREE CCOONNTTRROOLLLLEERR

P O W E R

VALVE

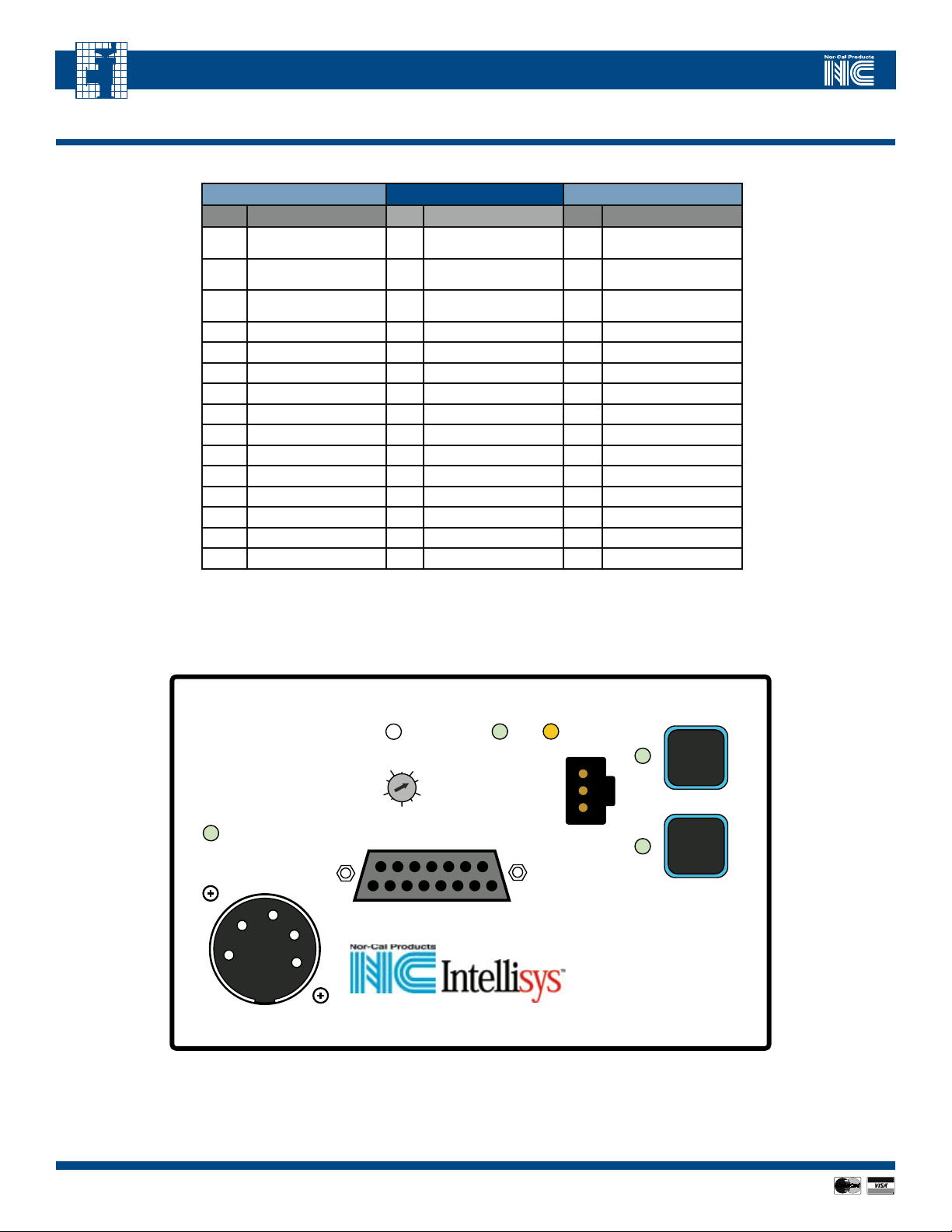

3.2 - Slave Buried Box Controllers

POWER (XLR) SERVICE PORT VALVE

PIN FUNCTION PIN FUNCTION PIN SIGNAL ASSIGNMENT

1 +240VDC Power Input 1 Authorized Technicians

2 Power Return 2 Authorized Technicians

3 Drain

4 N-C Net Hi

5 NC- Net Low

1

2

2

TABLE 3.2 – BURIED BOX CONTROLLERS (SLAVE)

Only

Only

3 Authorized Technicians

Only

1 Drive A +

2 Drive A -

3 Drive B -

4 Drive B +

5 Sense B -

6 Sense B +

7 Sense A -

8 Sense A +

9 Reserved

10 Reserved

11 Reserved

12 Reserved

13 Reserved

14 Reserved

15 Reserved

FIGURE 3.2 – BURIED BOX CONTROLLER (SLAVE)

1

Connect to Earth Ground at power supply

2

N-C Net is a proprietary communication protocol. Do not connect these pins to anything other than approved Nor-Cal items.

IQ+ OP-LIT 9/08

88

Visit our Web Site www.n-c.com

Page 9

IntellIsys AdAptIve pressure Controllers

RATE

Net

Mod

Ctrl

Fault

0

2

4

6

8

0

2

4

6

8

MSD

LSD

AUXILIARY

GAUGE

POWER

SVC

PORT

IQ + SERIES

A DAP TIVE P R ES SU RE C ON TR OLL ER

C L O SE

O P E N

2

5

P

1

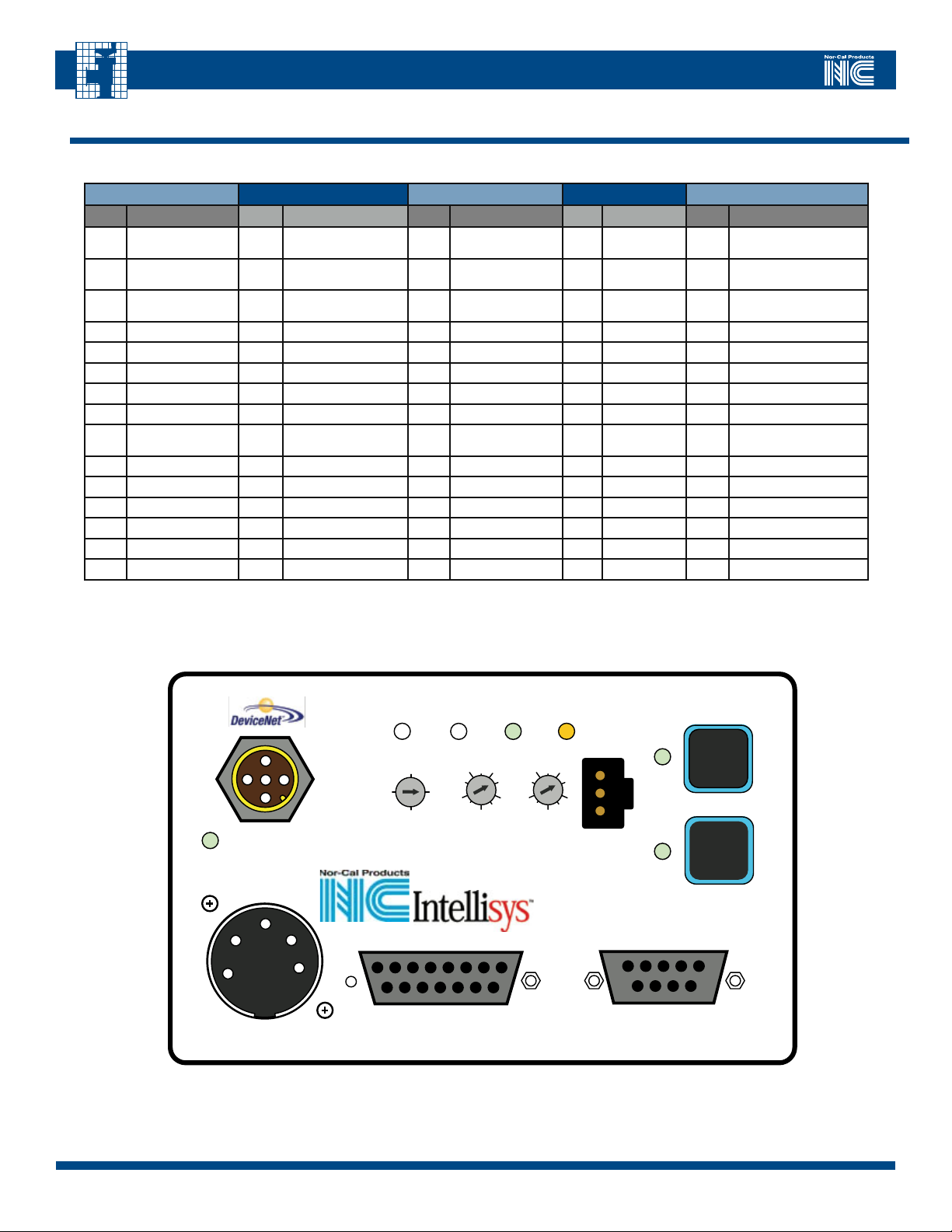

3.3 - Master On-Board Controllers

TABLE 3.3 – ON-BOARD CONTROLLER S(MASTER)

POWER (XLR) SERVICE PORT AUXILIARY DEVICENET GAUGE

PIN FUNCTION PIN FUNCTION PIN FUNCTION PIN FUNCTION PIN FUNCTION

1 +24VDC Power

Input

2 Power Return 2 Authorized

3 Drain

4 N-C Net Hi

5 NC- Net Low

1

2

2

1 Authorized

Technicians Only

Technicians Only

3 Authorized

Technicians Only

1 Reserved 1 Drain 1 CDG1 +

2 RS232 TX 2 DNET Power

3 RS232 RX 3 DNET Power

4 Digital Ground 4 CAN H 4 Reserved

5 Reserved 5 CAN L 5 CDG2 +

6 RS485 A 6 CDG2 -

7 Reserved 7 Reserved

8 RS485 B 8 CDG1 -

9 TTL IN 0 9 CDG Power Return

10 TTL IN 1

11 Digital Ground

12 TTL COM

13 TTL OUT 0

14 TL OUT 1

15 Chassis Ground

in +

In -

2 + 15VDC CDG Power

(Optional)

3 - 15VDC CDG Power

(Optional)

(Optional)

FIGURE 3.3 – ON-BOARD CONTROLLER (MASTER)

IQ+ OP-LIT 9/08

1

Connect to Earth Ground at power supply

2

N-C Net is a proprietary communication protocol. Do not connect these pins to anything other than approved Nor-Cal items.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

9

Page 10

IntellIsys AdAptIve pressure Controllers

O P EN

C LO S E

Ctrl

Fault

POWER

Net

1

3

5

7

9

SVC

PORT

IQ+ SERIES

AADDAAPPTTIIVVEE PPRREESSSSUURREE CCOONNTTRROOLLLLEERR

SLAVE ID

P O W ER

3.4 - Slave On-Board Controllers

POWER (XLR) SERVICE PORT

PIN FUNCTION PIN FUNCTION

1 +24VDC Power Input 1 Authorized Technicians Only

2 Power Return 2 Authorized Technicians Only

3 Drain

4 N-C Net Hi

5 NC- Net Low

TABLE 3.4 - ON-BOARD CONTROLLERS (SLAVE)

1

2

2

3 Authorized Technicians Only

FIGURE 3.4 – ON-BOARD CONTROLLER (SLAVE)

1

Connect to Earth Ground at power supply

2

N-C Net is a proprietary communication protocol. Do not connect these pins to anything other than approved Nor-Cal items.

1010

IQ+ OP-LIT 9/08

Visit our Web Site www.n-c.com

Page 11

IntellIsys AdAptIve pressure Controllers

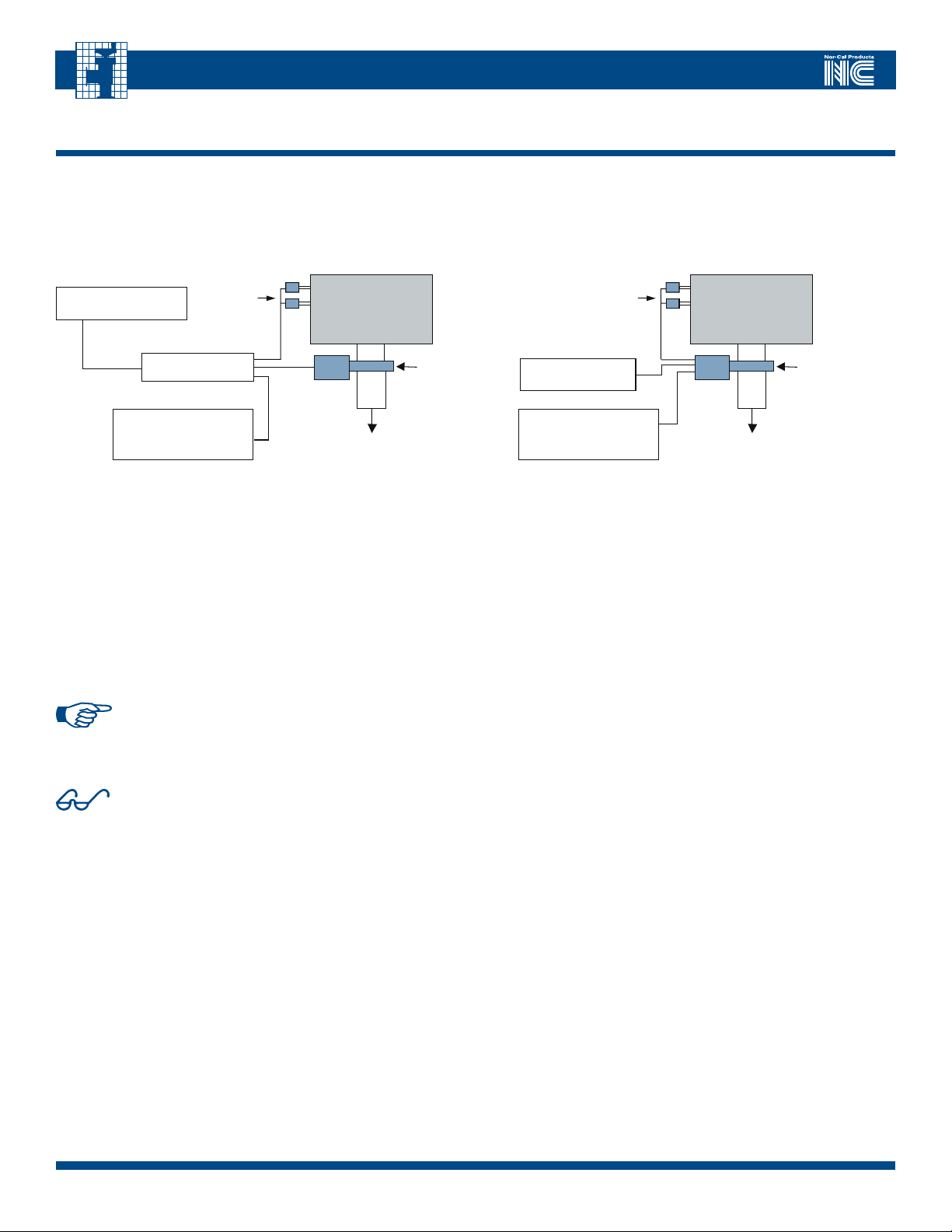

Vacuum Chamber

Pump

DC power supply

Host system with

RS232/485 or DeviceNet

communications

Nor-Cal

IQ+ Valve

Vacuum

gauge(s)

Vacuum Chamber

Pump

DC power supply

Host system with

RS232/485 or DeviceNet

communications

IQ+ Controller

Nor-Cal

throttle

valve

Vacuum

gauge(s)

4.0 - Theory of Operation

All IQ+ controllers are designed for downstream pressure control (see Fig 4.1 and 4.2). As such, it is one of several important components in a pressure

control system. Other essential components include a host system computer, a throttle valve and one or two vacuum gauges, such as a Capacitance Diaphragm

Gauge (CDG), and a pump system. Most manufacturers’ vacuum gauges can be used to provide the vacuum measurement signal, provided they have a voltage

output proportional to pressure. The IQ+ controller requires a pressure gauge signal output that is 0-10V linear and proportional to pressure.

FIGURE 4.1 – TYPICAL INSTALLATION AND CONFIGURATION OF A BURIED

BOX IQ+ PRESSURE CONTROL SYSTEM

Initialization Sequence

When first powered up, butterfly valves with the IQ+ controller will run the

valve through an initialization sequence that lasts for approximately 30

seconds. The primary purpose for this operation is for the controller to

determine the fully open and closed points, as well as for certain motor and

position calibration steps to occur. While the initialization sequence is active,

the amber FAULT light will be illuminated and the OPEN/CLOSE LEDs both will

be extinguished. Once the initialization sequence is complete, the valve will

move to the fully open position and the green OPEN LED will

illuminate.

NOTE: The controllers for TPV pendulum valves and TSS

gate valves contain a valve initialization safety lock function.

This safety lock will prevent valve initialization to occur until

given a “clear-to-proceed” command. The RS-232 serial

command for this is T4.

CAUTION: Never attempt to initialize a throttle valve with

differential pressure across the sealing gate. Make sure the

pressure on both sides is equalized to ±20 Torr. Damage to

pumps and other equipment can occur otherwise.

FIGURE 4.2 – TYPICAL INSTALLATION AND CONFIGURATION

OF AN IQ+ PRESSURE CONTROL VALVE

Normal Operation

After the initialization sequence is complete normal operation of the valve is

possible. There are two primary modes of operation, a) position control mode

and b) pressure control mode.

In position control mode, the valve will move to any position in its range

based on a position set-point command from the host. The valve will remain

in that position until instructed to do otherwise. Position control mode can

be useful in certain cases where pre-determined amount of throttling is

necessary.

Pressure control mode, is used whenever control to a specific process

pressure level is desired. The host provides the set-point value to the

controller which, in turn, moves the valve to achieve that set point as quickly as

possible. During pressure control mode, external perturbations such as flow

changes and plasma events will automatically be compensated for by the

controller so that the pressure set-point is maintained. The value can be

changed by the host at any time.

Tuning

The IQ+ controller contains an Adaptive Pressure Control Algorithm that

has been designed to work over a wide range of flow and pressure combinations. In some cases 3 system parameters may have to be adjusted. These

include system volume, system delay and speed. See Section 6.1: How to

configure IQ+ for your system.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

IQ+ OP-LIT 9/08

11

Page 12

IntellIsys AdAptIve pressure Controllers

5.0 - IQ+ Controller Module Interfaces

IQ+ controllers have several interfaces available for communications and connectivity to peripheral devices, depending on model. These are described by function below. Please also refer to Figures 3.1 – 3.4 and their associated Tables for the specific connectors and their pin assignments.

Vacuum Gauge Interface

The pressure signal from one or two vacuum gauges can be interfaced to the

IQ+ controller module through the connector labeled GAUGE. In addition,

±15 VDC is available as an option to power such gauges from these ports.

NOTE: If the power requirement of the gauge(s) used

exceeds the rated power output, then a separate power

source must be used. ±15V@1500mA.

When only one gauge is used, then the pressure signal must be connected to

the CDG1+ and CDG1- signal pins. Use of two gauges requires adhering to

the following:

The full scale range of the two gauges used must be set prior to use. See section 6.0.

Serial interface

An RS-232 serial interface is available on all controller models. Please refer to

the Section 6.0 for a full description of the communications protocol and a

listing of all active serial commands. A three-wire connection completes the

communications consisting of Rxd (data from the IQ+), Txd (data to the IQ+)

and digital ground.

are neither needed nor available.

settings are 9600 Baud, 1 stop bit and no parity. These settings

Every serial input command sent by the HOST has an end-of-line delimiter, carriage return ASCII 0x0D [hex], or the line feed character ASCII 0x0A [hex], or

the carriage return and line feed character in that order. The IQ+ device endof-line delimiter is the carriage return and line feed characters.

NOTE: CTS, RTS and DSR connections

NOTE: The default factory RS-232 communications parameter

can only be changed on models with DIP switches, and changing

the setting requires cycling IQ+ input power off then back on.

DeviceNet Interface (not available on all models)

The five-pin circular DeviceNet port allows for complete remote control,

monitoring and power supply of the IQ+ controller in a cost effective and reliable way. In addition to the connector are two status LEDs labeled Mod and

Net, as well as three rotary switches labeled MSD, LSD and RATE. A complete

explanation of the DeviceNet physical and software interfaces can be found in

Sections 8 and 9.

Service Port

The Service Port is reserved for factory authorized service technicians

Indicating LEDs

There are a host of indicating LEDs on the IQ+ controller, depending on

model. In general, the green Power LED is illuminated whenever power is

applied to the device. The green Ctrl LED is illuminated whenever the IQ+ is

in set point control (pressure or position). The amber Fault LED is illuminated

briefly during the initialization sequence after power-up but primarily if the

IQ+ device enters a fault state. Two LEDs are located adjacent to the OPEN

and CLOSE switches, and are illuminated whenever the valve position is within

2% of either limit.

Switches

Some controller models have a bank of four DIP switches labeled SW1. These

switches are used to define valve size. Relative to the printed text on the overlay, switch 1 is on the left

switch in the “up’ position is OFF or “0”

A

A switch in the “down” position is ON or “1”

Refer to table 5.1 below for a complete listing of valid DIP switch settings.

Primarily intended for operation during installation or troubleshooting, the

IQ+ also features two push button switches on the face of the controller that

can be used to drive the valve fully open or closed. To prevent inadvertent

valve operation, these switches cannot be used if the IQ+ valve is in Control

Mode (green Ctrl LED on).

TABLE 5.1 – DIP SWITCH CONFIGURATION

SW1 SW2 SW3 SW4 VALVE SIZE

0 0 0 0 1 inch

0 0 0 1 1.5 inch

0 0 1 0 2 inch

0 0 1 1 2.5 inch

0 1 0 0 3 inch

0 1 0 1 4 inch

0 1 1 0 6 inch

0 1 1 1 8 inch

1 0 0 0 10 inch

1 0 0 1 12 inch

1 0 1 0 14 inch

1 0 1 1 16 inch

1 1 0 0 TBD

1 1 0 1 TBD

1 1 1 0 TBD

1 1 1 1 TBD

1212

IQ+ OP-LIT 9/08

Visit our Web Site www.n-c.com

Page 13

IntellIsys AdAptIve pressure Controllers

6.0 - RS-232 Serial Interface and Commands

Interface basics

All IQ+ controllers support RS-232 serial communications available though auxiliary port. A full description of the communications protocol and a listing of all

active serial commands follows in this section. A three-wire connection needs to be completed to provide the communications lines, with Rxd (data from the

IQ+), Txd (data to the IQ+) as well as signal common on. See Section 3.0 for details.

NOTE: Hardware handshaking is not available.

NOTE: The default factory RS-232 communications parameter settings are 9600 Baud, 1 stop bit, no parity and 8-bit character.

These settings can only be changed using a serial command.

Every serial input command sent by the HOST has an end-of-line delimiter, carriage return ASCII 0x0D [hex], or the line feed character ASCII 0x0A [hex],

or the carriage return and line feed character in that order. The IQ+ -device end-of-line delimiter is the carriage return and line feed characters.

Serial Commands Summary

Table 6.1 and 6.2 summarize the serial commands and responses available with the IQ+ controller. Additional commands

may be included to enable customer specific functions. Please contact Nor-Cal Products Intellisys Customer Support for more details.

TABLE 6.1 – RS-232 SERIAL COMMANDS

SERIAL

COMMAND DESCRIPTION

C Close the valve Same function as pressing the CLOSE button

O Open the valve Same function as pressing the OPEN button

H Hold the valve in the current position Stops active pressure control, if device is in that mode

T1x

S1xx.xx

D1 Activates set-point #1. Put the device in control mode, effectively making the setpoint active.

Vxx.xx Go to valve position xx.xx is 0 to 100% of full open

L0 Auto select CDG1 or CDG2 for best resolution Default two gauge configuration.

L1 Control to and report CDG1 values only Selects Gauge 1 for manitenance function.

L2 Control to and report CDG2 values only Selects Gauge 2 for manitenance function.

N1xx Sets the full scale range of CDG1 Values for xx can be found in Table 6.3

N2xx Sets the full scale range of CDG2 Values for xx can be found in Table 6.3

J4

Sets the type of set point #1. When x=0, the set-point type is position.

When x=1, the set-point type is pressure.

Used to program a value for set point xx.xx is any number between 0.00 and

100.00, representing the % of gauge full scale

Clears the “initialization safety lock feature” included on some TPV and TSS

controllers

RS-232 Commands Examples

The following section provides examples of the most commonly used commands and responses. The serial command protocol is not case sensitive, though all

the command examples in this section are listed in capital letters. Furthermore, whenever necessary the character Ø has been used to designate the number

zero, so as to not confuse it with the letter O.

TABLE 6.2 – RS-232 SERIAL REQUESTS AND RESPONSES

SERIAL

REQUEST DESCRIPTION

R1

R5

R6

R38

R26

GSN

RN1

RN2

RESET

Requests the set point value S1+xxxx, where xxxx is a number from 0.00 to 100.00

Requests the current pressure P+xxxx, where xxxx is a number from 0.00 to 100.00

Requests the current valve position V+xxxx, where xxxx is a number from 0.00 to 100.00

Requests the software version IQ+3-[version #] [version date] (text)

Report set point type

Get the serial number of the device SN: xxxxxxxx

Requests full scale range of CDG1 N1xx.xx, where xx.xx is the full scale range of CDG1 in Torr

Requests full scale range of CDG2 N2xx.xx, where xx.xx is the full scale range of CDG2 in Torr

Resets the device Same as cycling power

NOTES /

EXAMPLES

S150, for example, programs the value of 50% for the setpoint. When using

a 1 Torr gauge, this corresponds to 500 mTorr..

Initializes Valve

RESPONSE

T1x, When x=0, the set-point type is position. When x=1, the set-point type

is pressure.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

IQ+ OP-LIT 9/08

13

Page 14

IntellIsys AdAptIve pressure Controllers

6.0 - RS-232 Serial Interface and Commands (continued)

Modifying the Setpoint

The IQ+ controller normally has five programmable set point selectable

to be either pressure control or valve position control. Before using the set

point to control either pressure or valve position, the set point value must

be programmed. This is done by the following command:

S1xx.xx where xx.xx is a number from 0.00 to 100.00.

One or no decimal places may also be used i.e. x.x or x.

Reading the Setpoint

The set point can be read back to the Host

controller only through the serial port.

o verify the set point

R1 T

The IQ controller will respond with

S1+xx.xx where xx.xx is the set point value.

Selecting Valve Position Control or Pressure Control

The set point input value is common for both valve position and pressure

control. Therefore, it is necessary to program the IQ+ so that it controls

to the correct type. The factory default setting is pressure control.

Set set point type

T1x where X=0 g position control

T1x where X=1 g Pressure control (default)

Verifying the Control Mode

Before starting either pressure control or position control operations it

might be necessary to verify the setting of the set point type. This can

only be accomplished through the serial port with the command

R26

The IQ controller responds with:

here x is Ø for position control or 1 for pressure control (default).

T1x w

How to Control Valve Position

One of the two main functions of the IQ+ controller is Valve Position Control.

In this mode the IQ+ controller will simply move the throttle valve plate to a

prescribed position according to a set point. The set point is a value between

0% and 100%, where 0% is closed and 100% is open.

OPEN: The serial command is O.

The controller will only respond by opening the valve.

CLOSE: The serial command is C.

The controller will only respond by closing the valve.

HOLD: The serial command is H. The controller will

only respond by stopping the valve at the current position.

lve Position: Vxx.xx where xx.xx is a number from

Any Va

0.00 to 100.00% of full open. One or no decimal places

may also be used i.e. x.x or x.

Similarly use the T1Ø command to set the set point type to position control.

Then follow the information outlined in the How To Modify the Setpoint and

How To Control System Pressure sections.

Reading the Valve Position

The valve position may also be obtained through the serial port.

The valve position is reported as a % of full open using the command:

R6

The Controller responds with the valve position using the format:

xxx.xx where xx.xx is a number from 0.00 to 100%

V+

of valve open position.

How to Control System Pressure

The principal function of the IQ+ controller is to control system pressure. To

accomplish this, the controller needs to be put in “pressure control mode”

while being supplied a pressure set point. The pressure set point is proportional to the vacuum gauge’s full scale range.

Controlling pressure using the serial port provides additional flexibility.

To activate a set point issue the command:

D1

The active set point must be set to the correct value before activating the

pressure control set point. The set point can be modified any time before, during, or after pressure control. Also a different set point can be activated

at any time.

Note: For pressure control mode, the setpoint type must = 1, i.e. T11

Reading System Pressure

Pressure, as output by the system gauge(s) to the IQ+ Controller,

can be read directly from the controller. Both the signals from

CDG1 and CDG2 can be read independently.

The IQ+ controller will report the pressure via

the serial port with the following command:

R5

The controller will respond with:

P+xx.xx where + indicates the polarity of

the value and xx.xx is the valuein % relative to CDG1 full scale.

The range of xx.xx is from 0.00 to 100.00 and represents the pressure as a

percentage of the full scale of the CDG1 pressure gauge. The value can be less

than 0 if the vacuum gauge electronics have drifted or greater than 100 but

limited to 110%. For example, it the system uses a 100 Torr gauge and the

pressure is actually 10 Torr, the controller response will be P+10.00. On the

other hand, if the pressure is 10 Torr but the system has a 20 Torr gauge, the

controller response will be P+50.00.

When two CDG’s are used, the IQ+ will always report the pressure as a

percentage of the high range gauge. For example, if the system has a 100 Torr

gauge attached to CDG1 and a 1 Torr gauge attached to CDG2 and the actual

system pressure is 0.1 Torr the response to the R5 command will be P+0.100.

IQ+ OP-LIT 9/08

1414

Visit our Web Site www.n-c.com

Page 15

IntellIsys AdAptIve pressure Controllers

6.0 - RS-232 Serial Interface and Commands (continued)

Activating Dual Pressure Sensor Configuration

When two pressure gauges are attached to the IQ+ controller, the controller

can operate in three distinct modes of operation.

Dedicated to the first gauge:

(This is the power-on default mode)

In that mode the controller only considers CDG1 for pressure control

as well as reporting. This mode is initiated by the L1 command

Dedicated to the second gauge:

In that mode the controller only considers CDG2 for pressure control.

as well as reporting. This mode is initiated by the L2 command. Pressure is still

reported as a % of full scale of CDG1.

The L1 and L2 commands particularly relevant to dual chamber

systems venting to one single downstream exhaust valve. In that situation

there are two distinct pressure gauges corresponding to each individual

vacuum chamber. The IQ+ controller is then used alternatively control

pressure in each chamber.

Dual range mode: (Default)

LØ activates this mode, in which the controller utilizes the two gauges to

optimize the pressure measurement. Two gauges are intended to be complementary in covering the dynamic pressure range. The high gauge is referred to

as the primary gauge. The low gauge is designed to be the secondary gauge

covering the low range measurements. In dual range mode gauges can be

switched. The gauge range needs to be predefined as illustrated in the next

section. The IQ+ controller will use the range information to determine the

pressure at which the controller will switch from reading one CDG to another.

The automatic switch over is at 90% of the full scale value of the lower range

gauge when the pressure is decreasing and greater than 99% of the full scale

value of the lower range gauge when the pressure is increasing. Please note

that in Dual Range Mode, all set point commands are with respect to the primary gauge range (CDG1).

L1 and L2 are normally used for maintenance purposes only. Restore the IQ+

to dual range made upon conpletion of maintenance usign the LØ serial com-

mand

TABLE 6.3 – VALUES TYPICAL OF

XX FOR USE WITH

DU

AL RANGE MODE

CDG1 OR

CDG2

FULL SCALE

(IN TORR)

0.1 0.1

0.2 0.2

0.5 0.5

1 1

2 2

5 5

10 10 (CDG1 default)

50 50

100 100

500 500

1000 1000

0

VALUE

OF

XX

Not connected

(CDG2 default)

NOTE: Any number can

be used for a

gauge full scale.

How to Configure Pressure Sensor Parameters

When two pressure gauges are used it is necessary to program the IQ+

with sufficient information so that it knows the full scale of each gauge

and, hence, the ratio of the full scale pressure ranges. The factory default

full-scale range for CDG1 is 10 Torr, and that for CDG2 is 0 Torr ( not connected).

NOTE: Programming the gauge full scale range is not necessary

when only one gauge is installed. First, program the full scale

range of CDG1 using:

N1xx where xx is the number found in Table 6.3 describing the

full scale range of CDG1. For example, enter N1100 if CDG 1 is a

100 Torr gauge or N10.25 if it is a 250 milltorr gauge.

Then, program the CDG2 full scale range with:

N2xx where the value for xx can

also be found in Table 6.3,

epresenting the CDG2 full scale.

r

he full scale of CDG1 must always

T

e greater than that of CDG2.

b

x N210 is a 10 Toor gauge 2.

E

Reading the Pressure Sensor Configuration

The full scale setting of the CDG’s can only be accessed through the serial

port. Once the full scale ranges for CDG1 and CDG2 have been entered,

the IQ+ controller will automatically calculate their ratio. A ratio of 1000:1

is the limit between the two pressure gauges.

Verify the CDG entries by querying the IQ+ controller

for a CDG range report with the following commands:

RN1

The controller will respond with:

N1xx.xx where xx.xx is the full scale range of CDG1.

To check the full scale range of CDG2 send the command:

RN2

The controller will respond with

N2xx.xx where xx.xx is the full scale range of CDG2.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

IQ+ OP-LIT 9/08

15

Page 16

IntellIsys AdAptIve pressure Controllers

6.1 - How to Configure IQ+ for Your System

System Configuration Parameters

There are three parameters to adjust that will affect how the valve will react

to changes in gas flow and pressure set points.

The parameters only need to be set once and will cover the full range of process pressure setpoints. The three parameters are:

lume

Vo

Delay

Speed

Volume

Volume is a Dependent phase multiplier and is based on the size of the pressure chamber and controls how fast the valve will react.

No specific relationship to physical chamber size (example: a setting of 50

does not equal a 50L chamber).

ume is 0. Range is 1-100.

The default setting for Vo

If the pressure signal over shoots the set point, increase the value of Vo

l

FIGURE 6.1 – VOLUME TOO LOW

ume.

l

FIGURE 6.2 .1– VOLUME TOO HIGH

Delay

Feedback delay compensates for the physical properties of the vacuum

system that cause delays in the pressure gauge readings when a pressure

change occurs.

Keep the Delay setting as low as possible.

The default value of Delay is 0. Range is 0-10.

If Delay is adjusted, it should be set as low as possible.

If the pressure signal oscillates at set point then increase Delay.

If the pressure signal under shoots the set point, decrease the value of

Volume.

FIGURE 6.2 – VOLUME TOO HIGH

FIGURE 6.3 – DELAY TOO LOW

Speed

The default setting for Speed is 100 (100%). Range is 1-100. Normally

this parameter does not require adjustment.

Reducing speed will help reduce low frequency oscilations. Speed

should be reduced only after any adjustments to Vo

have failed. When reducing Speed, set Delay to 0..

Maximum valve speed during pressure control does not affect the

Open-Close, or Close-Open valve speed. If Speed is set too high the

pressure will oscillate at set point (See Fig. 6.4). If Speed is set too low

the valve will move slowly (See Fig. 6.5).

lume and Delay

1616

IQ+ OP-LIT 9/08

Visit our Web Site www.n-c.com

Page 17

IntellIsys AdAptIve pressure Controllers

6.1 - How to Configure IQ+ for Your System (continued)

FIGURE 6.4 – SPEED TOO HIGH

System Configuration Commands

DeviceNet Commands

Class ID 33 hex

Instance ID 1 (Process Control)

Setting Volume, Delay and Speed

FIGURE 6.5 – SPEED TOO LOW

E 6.4 – DEVICENET COMMANDS

TABL

ATTRIBUTE ID HEX ACCESS CODE NAME FORMAT VALUE

64 OE (get) 10 (set) Volume INT 1-100, default = 0

65 OE (get) 10 (set) Delay INT 0-10, default = 0

66 OE (get) 10 (set) Speet INT 1-100, default = 100

TABLE 6.5 – RS-232 SERIAL COMMANDS

SERIAL COMMAND DESCRIPTION RESPONSE

SVxxx Set Volume where xxx is a number from 1 to 100 PID VOLUME: xxx

SDxxx Set Delay where xxx is a number from 1 to 10 PID DELAY: xxx

SSxxx Set Speed where xxx is a number from 1 to 100 PID SPEED: xxx

TABLE 6.6 – RS-232 SERIAL REQUESTS AND RESPONSES

SERIAL REQUEST DESCRIPTION RESPONSE

RV Requests Volume value PIC VOLUME: xxx

RD Requests Delay value PID DELAY: xxx

RS Requests Speed value PID SPEED: xxx

RPI Requests values of Volume, Delay and Speed SPEED: xxx

VOLUME: xxx

DELAY: xxx

A Record the current Volume, Delay, and Speed parameters.

or serial interface set the serial port speed 100ms or less. For Devicenet

F

B

set to 50ms. Or less.

C Start pressure control at a process critical set point, or a set point halfway

between the system maximum and minimum process pressure set points.

With the system GUI or a PC that can graph data observe the pressure and

valve movement.

D If the pressure parameters need adjusting stop pressure control and Open

the valve. Enter new value for pressure parameters.

Setting Volume, Delay and Speed (Example)

The system has a 1 Torr pressure gauge. The pressure control range is

20mTorr - 600 mTorr. The process critical range is 120mTorr.

A Record values of Volume, Delay, and Speed.

Start pressure control with a set point 120mTorr. Adjust the parameters if

B

necessary.

C Start pressure control with a set point of 20mTorr. Adjust parameters if

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

necessary. If any changes are made then re-check the 120mTorr set point.

D Start pressure control at 600mTorr.. Adjust the parameters if neces-

sary. If any changes are made then re-check the 120mTorr and 20mTorr set

points.

E Record new values of Volume, Delay, and Speed.

l

Parameters are adjusted in this order: Vo

ume

Delay

Speed

(not normally adjusted)

E If the pressure response is satisfactory, input a set point at the system

minimum pressure or another process critical set point. Make adjustments

as necessary. If a change was made re-check pressure set point in step C.

F If the pressure response is satisfactory, input a set point at system maxi-

mum pressure. Adjust if necessary. If a change was made re-check set

points in steps C and D.

G Record new parameters for Volume, Delay, and Speed.

IQ+ OP-LIT 9/08

17

Page 18

IntellIsys AdAptIve pressure Controllers

250Kb

P

RATE

500Kb125Kb

1 Drain

4 CAN_H

3 V-

2 V+

5 CAN_L

MSD

LSD

4

6

2

8

2

4

6

P

ADDRESS

0

0

7.0 - DeviceNet Interface

7.1. Overview and setup

DeviceNet is a network communication protocol that provides a cost-effective

solution to low-level device networking for semiconductor equipment tools.

Process data and other information such as configuration parameters can

be communicated for up to 64 nodes per network at data rate up to 500K

baud. The DeviceNet pressure controller conforms to the ODVA & ControlNet

International, Ltd. Process Control Valve (PCV) device profile. This device

profile is available in the CIP Networks Library: Volume One, Edition 3.3 -- The

Common Industrial Protocol (CIP

Accordingly, the purpose of this manual is to provide an overview on the basic

use of the DeviceNet communication interface as it relates to the IQ+ pressure

controller, as well as report the different options supported by the controller software communication interface.

DeviceNet Connector:

The communication port is a sealed microstyle M12 male connector that conforms

to the DeviceNet specification. The

connector pin out is shown in Figure 7.1.

DeviceNet requires power input of 11-24

VDC provided through the DeviceNet connector. Separately, the controller unit

requires a 24 VDC +/- 10% power source, which is provided through the power

connector. See section 3.0.

TM

) of the official DeviceNet specification.

FIGURE 7.1 - DEVICENET

CONNECTOR PIN ASSIGNMENT

Mo

dule Status: A bicolor (red/green) Module status LED indicates the status

of the communication module according to the logic in Table 7.1.

TABLE 7.1 - DEVICENET MODULE LED STATUS

LED STATUS

Green Module OK

Red Fault condition

Flashing Red Lost DeviceNet power

OFF No DC power

Network Status:

A bicolor (red/green) Network status LED indicates the status of the communication link according to the logic in Table 7.2.

TABLE 7.2 - DEVICENET NETWORK LED STATUS

LED STATUS

Flashing Green Network OK device online

Green Network OK connection established

Flashing Red Recoverable fault

Red Unrecoverable fault

OFF No network detected

ud Rate Selection:

Ba

The baud rate selector as shown in Figure 7.2 is a 4

position rotary switch used to select the desired baud

FIGURE 7.2 -

DEVICENET BAUD RATE

SELECTION SWITCH

rate of the controller, respectively 125Kb, 250Kb,

500Kb and software programmable.

The factory default setting is 125Kb. The software

programmable baud rate is kept

in non-volatile memory and settable through

the DeviceNet object.

CID Selector:

MA

Two rotary switches are used to set the MACID of the device on the network

between 0 and 63 and software programmable. Note that MACID 0 is com-

monly reserved for the DeviceNet network

master and should not be used by any device.

The factory default setting is MACID 63.

Additionally, positions 64 to 99 correspond

to the software programmable setting. The

MACID programmed in non-volatile memory

will then be used.

The software programmable MACID is

FIGURE 8.3 - DEVICENET

ADDRESS SWITCHES

configurable via DeviceNet. However, note

that a change to the baud rate and MACID

switches only becomes effective once the

device is reset. This happens automatically

hen setting the MACID in programmable

w

mode.

No network detected:

This is an indication from the software that multiple attempts to publish a

message (typically a duplicate MACID check message) have been made but no

acknowledgement of that message has been received. It is the normal mode

of operation if the network connection is not used.

Network OK

device online:

If the device successfully detects a live bus it will transition to flashing green,

that is the standby mode, the device is ready for the master node to establish

a connection.

Network OK

connection established:

When the device has successfully been attributed a connection by the master

the network LED will transition to solid green.

Recoverable fault:

If the master unexpectedly drops the DeviceNet connection (lets the slave time

out) the LED will transition to flashing red, signaling the occurrence of a time

out fault. If the network master re-establishes the connection the device will

then recover to normal operating mode.

Unrecoverable fault:

A red Network LED signals the occurrence of a major network fault such as

two devices having the same MACID, an incompatible baud rate setting or a

short in the communication signal lines.

1818

Visit our Web Site www.n-c.com

IQ+ OP-LIT 9/08

Page 19

IntellIsys AdAptIve pressure Controllers

SSTechnology

interface card

SST 5136 DN

Tool

system

CAN_H

CAN_L

V+

V-

Drain

Interface

Card

Power

Supply

+24v

GND

IQ+ based

Controller 1

Controller 2

Controller 3

Other Devices

Cordset

InterlinkBT RSC572-*M

Drop Junction

InterlinkBT VB2-FKM FKM FSM 57

BUS

IQ+ based

IQ+ based

7.1. Overview and setup (continued)

Required Hardware:

A DeviceNet network is composed of a host controller, a bus and one or more

external devices such as IQ+. The master node or host controller is commonly

composed of a computer equipped with a DeviceNet interface card. The bus

is made of cable connectors and junctions generally arranged in trunklinedropline configuration as shown in Figure 7.4.

Interface and bus system part numbers are given as indication only.

The IQD Controllers come ready to plug into any qualified DeviceNet network.

Prior to power up, you must initially:

1. Select the appropriate baud rate.

All the devices on the network must operate

t the same baud rate.

a

2. Select an individual device MACID that is

not already in use by another device.

IQ+ controller devices can be plugged in and removed from the network live,

however, if an inappropriate baud rate setting is selected it will bring the IQ+

controller to a network fault and possibly bring other installed devices on the

bus to a fault. Upon connection the IQ+ controller will transmit a duplicate

MACID check to verify the uniqueness of its address. If another device with

the same MACID address is detected the IQ+ Controller transitions to a red

network LED status.

Power Supply System and Typical Configuration:

It is essential for the controller to have dedicated access to the pressure gauge.

Accordingly the preferred configuration is for the controller to host the gauge

through the analog signal link while the controller takes charge of reporting

the process parameter through the DeviceNet communication link.

The IQ+ controllers require external 24 VDC power for operation. This must

be applied to the XLR power port. The DeviceNet interface requires separate

power input via the DeviceNet cable connection. This DeviceNet link can be

powered from 11 to 24 VDC.

General Considerations for Valve Operation Using DeviceNet

DeviceNet is an object oriented communications protocol. The Process

Control Valve device type encompasses several objects from the

Hierarchy of Semiconductor Equipment Device Objects (see figure 9.1).

These objects are managed by the S-Device Supervisor Object, which

tasks include reporting device status. The interaction with the device can

be carried out in different ways. The Selection Object is a router object

which directs setpoint data to the desired destination – pressure control

or position control – via the S-Single Stage Controller Object. Instead of

setting a setpoint through the Selection Object, it can be set directly in

the S-Single Stage Controller Object. Process data is gathered from the

S-Analog Sensor Object, which provides pressure data from up to two

pressure gauges and valve position data. This document contains examples of how to set and get parameters through DeviceNet.

To be able to perform pressure or position control, the controller must

first be transitioned to the device Executing state. This can be done in

one of two ways; explicitly by means of executing a Start service request

or by sending valid polled I/O data to the controller. See the DeviceNet

Communications section for a more detailed description on how this is

done. See figure 9.2 for more details on device states.

Pressure control is performed based on the selected process variable

source. By default, the selection will be automatic based on the pressure range that each pressure gauge covers. Setting a setpoint using

automatic switching will be relative to the high gauge range, if multiple

gauges are used. The source can be forced to either the low or the high

range gauge. When the source used is set to “automatic”, the source

actually reporting the pressure data can be retrieved through the SAnalog Sensor Object.

Some Nor-Cal valves require initialization before they are ready for operation. Nor-Cal has an Initialize service designed solely for this purpose. See

S-Device Supervisor Object section for more information on which valve

models are affected.

FIGURE 7.4 - TYPICAL DEVICENET HARDWARE

INSTALLATION

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

IQ+ OP-LIT 9/08

19

Page 20

IntellIsys AdAptIve pressure Controllers

7.2 - DeviceNet Communications

This section describes how to communicate with and control the controller using the DeviceNet port. DeviceNet has two basic message types: Explicit and I/O

messaging

Explicit Me

Explicit messages are used to read or write an individual piece of information

in the device. They are mainly used for initial configuration. Explicit messages

include the path to locate the data of interest, this consists of the class ID,

attribute ID, and instance number. They also specify an action to be taken.

The table below lists some of the key information available through explicit

messaging. Please refer to Section 9 for the full device profile characteristic.

CLASS

ID

The most straightforward way of sending individual commands to the

controller is to use a node-commissioning software utility. These utilities

are part of the DeviceNet interface card package.

Explicit messaging connection examples:

• P

• L

• T

Note that in DeviceNet communications, data to and from the device is always

encoded least significant byte first as specified in the data management section of the DeviceNet protocol specification. For instance the value 12345678

hex is encoded as follow:

OCTET NUMBER

OU

How to get device identity information:

• S

• S

• S

• S

• T

or 612 dec, which is the vendor ID that has been attributed to

N

• C

• T

meaning 2B13A hex or 176442 dec, which is the serial number of the

d

(

ssaging:

TABLE 7.3 - DEVICENET EXPLICIT MESSAGING

INSTANCE

HEX

1 1 1

1 1 6

1 1 7

3 1 1

3 1 2

31 1 6

31 2 6

31 3 6

2E 1 5

2E 1 9

ID

HEX

ATTRIBUTE

ID

HEX

SERVICE ID

0E (get) Vendor ID

0E (get) Serial Number

0E (get) Product Name

0E (get) 10 (set) MACID

0E (get) 10 (set) Baud Rate

0E (get)

0E (get)

0E (get) Valve position

0E (get) 10 (set)

0E (get) 10 (set) Process setpoint

HEX

VARIABLE

NAME

Process input

(low range)

Process input

(high range)

Pressure control

and position

control

ower up the device, the network LED will transition to flashing green

et the master open an explicit connection with the device

he network LED will transition to solid green

1st 2nd 3rd 4th

TPUT DATA

78 56 34 12

elect the service code 0E (get attribute)

elect class ID 1 (select the identity object)

elect instance ID 1 (there is only instance supported)

elect attribute ID 1 (vendor ID attribute)

he device will respond with data bytes 64 02 meaning 264 hex

or-Cal Products Inc.

hange the attribute ID for 6 (serial number attribute)

he device will respond with data bytes on the form, 3A B1 02 00

evice.

Nor-Cal device serial numbers are composed of at least 6 digits)

How initialize the valve (not required on all valve types):

elect the service code 32 (initialize service)

• S

• Select class ID 30 (select the s-device supervisor object)

elect instance ID 1

• S

How to transition the controller to the executing state:

To be able to perform pressure or position control by means of explicit

messaging, the controller has to be transitioned to the device Executing state.

elect the service code 6 (start service)

• S

elect class ID 30 (select the s-device supervisor object)

• S

elect instance ID 1

• S

How to control valve position:

elect the service code 10 (set attribute)

• S

elect class ID 2E (select the selection object)

• S

elect instance ID 1 (setpoint)

• S

elect attribute ID 0E (destination used) followed by the data 02 (position

• S

control)

hen

t

elect the service code 10 (set attribute)

• S

elect class ID 2E (select the selection object)

• S

elect instance ID 1 (setpoint)

• S

elect attribute ID 0F (source data value) followed by the setpoint 00 40

• S

he device will move the valve to 50% of its stroke

• T

elect attribute ID 0F (source data value) followed by the

• S

setpoint 00 00 The device will move the valve to 0% of its

troke or closed

s

How to control pressure:

• Select the service code 10 (set attribute)

elect class ID 2E (select the selection object)

• S

elect instance ID 1 (setpoint)

• S

elect attribute ID 0E (destination used) followed by 01 (pressure control)

• S

then

elect the service code 10 (set attribute)

• S

• Select class ID 2E (select the selection object)

elect instance ID 1 (setpoint)

• S

elect attribute ID 0F (source data value) followed by the setpoint 00 20

• S

pressure control)

(

he device will try to control pressure at 25% of full scale of the selected

• T

ressure source

p

elect attribute ID 0F (source data value) followed by the setpoint FF 7F

• S

he device will try to control pressure at 100% of full scale of the selected

T

ressure source

p

How to read the valve limit switch:

elect the service code 0E (get attribute)

• S

elect class ID 8 (select the discrete input point object)

• S

elect instance ID 1 (closed limit switch)

• S

elect attribute ID 3

• S

he device will respond with data bytes 01 meaning that

• T

the close limit switch is activated and the valve is closed

elect instance ID 2 (open limit switch)

• S

elect attribute ID 3

• S

he device will respond with data bytes 00 meaning that

• T

the open limit switch is not activated and the valve is not opened

Note: The examples above assume that default data

type (INT) and data units (Counts) is used.

IQ+ OP-LIT 9/08

2020

Visit our Web Site www.n-c.com

Page 21

IntellIsys AdAptIve pressure Controllers

7.2 - DeviceNet Communications (continued)

How to read system pressure and valve position:

elect the service code 0E (get attribute)

• S

• Select class ID 31 (select the s-analog sensor object)

elect instance ID 1 (process input low range)

• S

elect attribute ID 6 (value attribute)

• S

he device will respond with data bytes 00 00

• T

meaning that the measured pressure is 0

elect instance ID 3 (valve position)

• S

elect attribute ID 6 (value attribute). The device will respond

• S

with data bytes FF 7F meaning that the valve position is fully open.

OUTPUT ASSEMBLY FORMATS

INSTANCE HEX VARIABLES

7

(default)

17

97

(Master / Slave)

INSTANCE HEX VARIABLES

2

(default)

4

5

0B

12

1A

96

97

(Master / Slave)

TABLE 7.4

Control setpoint

Control instance

FP-Control setpoint

Control instance

Control mode

Pressure setpoint

Position setpoint

Control instance

Individual valve control (address)

Individual valve control (action)

INPUT ASSEMBLY FORMATS

TABLE 7.5

Exception status

Process variable

Exception status

Process variable

Control setpoint

Exception status

Process variable

Control setpoint

Valve position

Exception status

Process variable

Valve

Discrete

Input 2

Exception status

FP-Process variable

Exception status

FP - Process variable

FP - Valve

Discrete

Input 2

Exception status

Process variable input 1 (low range)

Process variable input 2 (high range)

Valve

Active process input instance

Discrete

Input 2

Control mode

Pressure setpoint

Position setpoint

Control instance

Individual valve control (address)

Individual valve control (action)

Discrete

Input 1

Discrete

Input 1

Discrete

Input 1

Input/Output Messaging:

I/O messaging is used to read and write data to the device on a periodic basis.

They are used for transmission of a continuous stream of data such as setpoint

or process pressure. I/O messages have limited overhead and rely on a

prearranged set of data called assemblies. The IQ+ controller handles input

assemblies and output assemblies in a poll connection. In an I/O poll

connection the tool DeviceNet controller periodically sends an output

assembly and the IQ+ responds with an input assembly. The IQ+ supports 3

output and 8 input assembly formats. For polled I /O connections, the device

will automatically transition to the device Executing state after the first valid

I/O data has been received.

Example of I/O messaging transactions:

The following is an example format of a typical poll connection, using

default settings.

After having opened the I/O connection the master sends the following data:

BYTE DESCRIPTION DATA RANGE

1

2

3

4

Setpoint (low byte)

Setpoint (high byte)

Setpoint destination

(low byte)

Setpoint destination

(high byte)

0 to 7FFFh

00 for no operation

01 for pressure control

02 for position control

Note: The setpoint is a number from 0000 hex to 7FFF hex covering the

range 0 to 100%. In other words, in pressure control mode, 7FFF hex

represent full scale of the selected pressure source. If the pressure gauge

used is 1 Torr then a set point of 4000 hex will control pressure to 0.5 Torr.

In valve position control mode, 7FFF hex represents full open stroke.

Respectively, 0000 hex setpoint corresponds to closing the valve and 7FFF hex

corresponds to fully opening the valve.

The controller response is formatted accordingly:

BYTE DESCRIPTION DATA RANGE

1

exception status See table 8.8.2 on page 12

2

pressure (low byte)

3

pressure (high byte)

0 to 6000h

Note: Data types and data units may be changed in application objects

handling pressure and position related attributes. Data type can only be

changed if no I/O connection has been established using a related attribute

and the device is in idle state. Data units can only be changed when the device

is in idle state. Changes to these attributes in application objects are

non-volatile (recorded in NVRAM).

IQ+ OP-LIT 9/08

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

21

Page 22

IntellIsys AdAptIve pressure Controllers

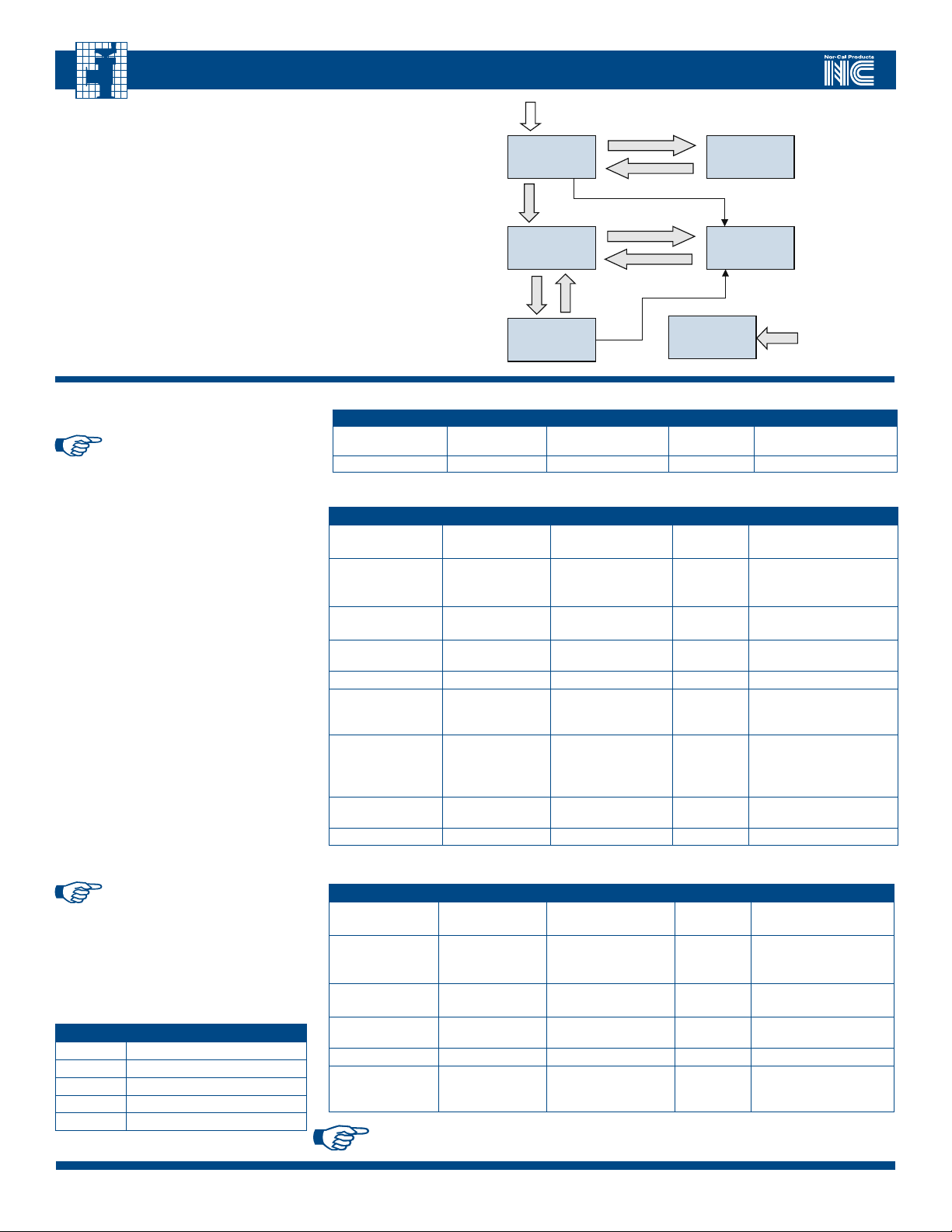

Discrete

Input Class

Connection

Class

I/O

I/O

I/O

Explicit

Message

Explicit

Message

Explicit

Message

Message

Router

Assembly

Assembly

Assembly

S-Device

Supervisor

DeviceNet

Identity

Hierarchy of

Semiconductor Equipment

Device Objects

Selection Class

S-Analog Sensor

Class

Process 1

Process 2

S-Single Stage