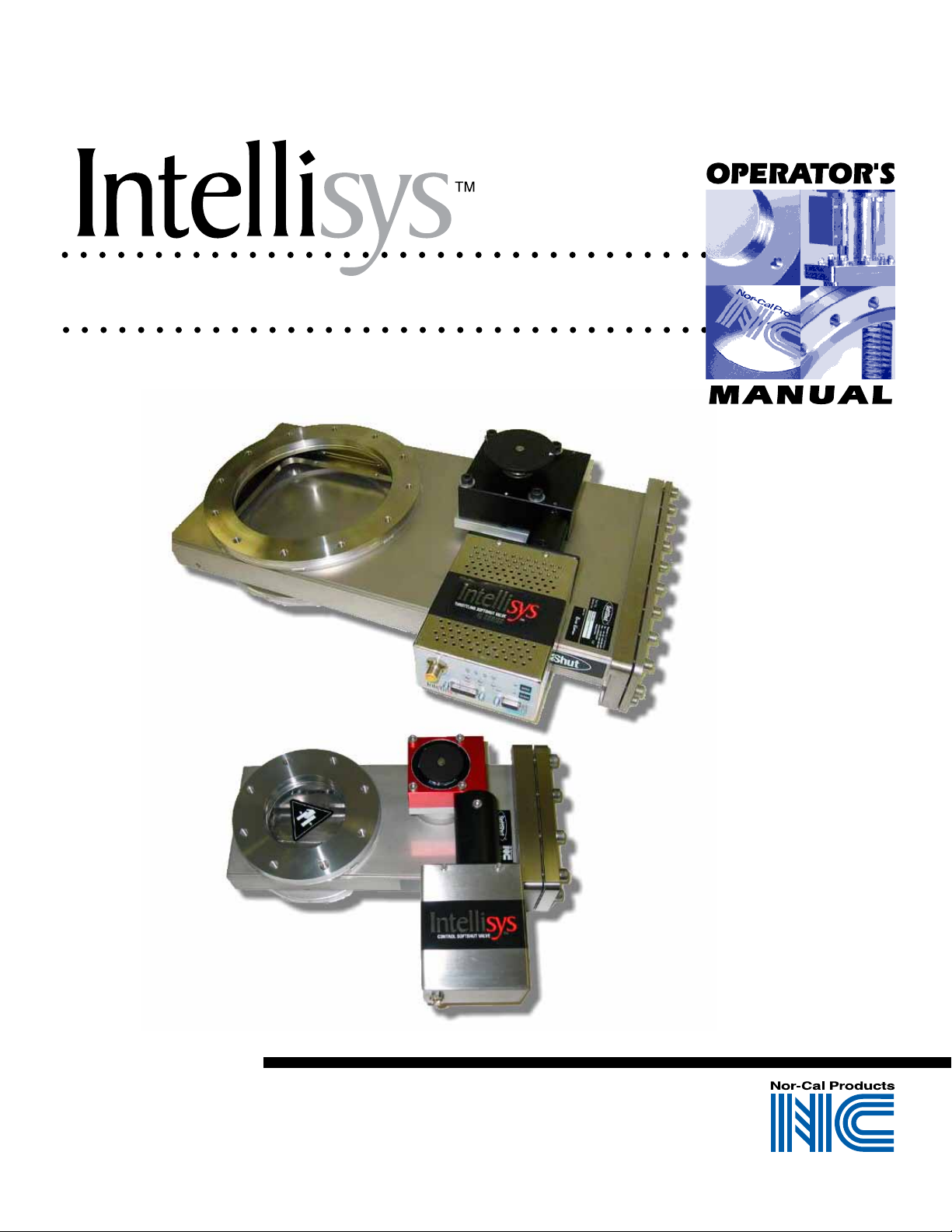

Page 1

TSS Owner’s Manual

Tel: 800-824-4166

or 530-842-4457

Fax: 530-842-9130

www.n-c.com

1967 So. Oregon

Yreka, CA 96097 USA

Nor-Cal Products, Inc.

SoftShutTM gate valve model TSS, TSS-IQA and TSS-IQD

TSS - 0P - LIT 08/11

Page 2

IntellIsys softshutTM Gate ValVe Models

Table of Contents

...................Introduction .......................................................................................................................................

1.0

2.0

...................Device Specification ...........................................................................................................................

3.0

...................Unpacking and Installation .................................................................................................................

4.0

...................Theory of Operation ...........................................................................................................................

5.0

...................Product Support ...............................................................................................................................

Appendix I

Appendix II

Appendix III

Appendix IV

List of Tables

2.1

...................General Equipment Specifications ......................................................................................................

2.2

...................TSS Reliability .....................................................................................................................................

2.3

...................Standard TSS-series Dimensions and Weight Specifications ................................................................

2.4

...................IQ-seriesTSS Dimensions and Weight Specifications ............................................................................

5.1

...................Recommended TSS-series Preventive Maintenance Actions and Intervals ............................................

5.2

...................Spare Parts and Kits Ordering Information ........................................................................................

5.2A

.................Spare Parts and Kits Ordering Information for valves made prior to May 2005 ...................................

5.3

...................Possible Failure Modes and Recommended Actions ..........................................................................

A-II.1

................Installation Hardware for ISO-flanged TSS to OF-style ISO flange .......................................................

A-II.2

................Installation Hardware for ISO-flanged TSS to N-style ISO flange.........................................................

A-II.3

................Installation Hardware for CF-flanged TSS to CF flange ......................................................................

A-III.1

...............TSS and APC Cable Assemblies and Accessories ...............................................................................

.......Summary Valve and Controller Connection Information ...................................................................

......Installation Hardware .......................................................................................................................

.....Valve, Accessories and Cable Assembly Ordering Information...........................................................

.....Warranty and Intellectual Property Coverage ....................................................................................

3

4

7

8

10

13

17

18

20

4

4

5

6

9

11

11

12

17

17

17

19

List of Figures

4.1

...................Typical Installation and Configuration of a TSS-series control valve ......................................................

5.1

...................Exploded View of Typical TSS value assembly ....................................................................................

A-I .....................Controller Connection Diagrams ....................................................................................................................... 13

A-1.2 .................Pin-out Wiring Diagrams ................................................................................................................................... 14

A-1.3 .................IQA Controller ................................................................................................................................................... 14

A-1.4 .................IQD Controller ................................................................................................................................................... 15

A-II.1

................Installation Diagram for ISO-flanged TSS to OF-style ISO flange .........................................................

A-II.2

................Installation Diagram for ISO-flanged TSS to N-style ISO flange ..........................................................

A-II.3

................Installation Diagram for CF-flanged TSS to CF flange ........................................................................

Contact Nor-Cal Products

Intellisys Customer Support

at 800-824-4166

or visit our website

at www.n-c.com

8

10

16

16

16

Global Sales and Service

Nor-Cal Products maintains sales and

service centers in over 30 countries worldwide.

Please visit our website at www.n-c.com to

find the center nearest you.

Information in this manual is subject to change without notice.

TSS-OP-LIT 08/11

22

Visit our Web Site www.n-c.com

Page 3

IntellIsys softshutTM Gate ValVe Models

1.0 - Introduction

Thank you for purchasing a new Intellisys™ Tss SoftShut™ throttling gate valve from Nor-Cal Products. Before installing and operating the product,

please read this manual thoroughly as it contains critical hook-up and operating tips. If you encounter any problems, or if you have any questions,

please contact our Intellisys Customer Service Support at (800) 824-4166 or visit our web site at www.n-c.com.

Nor-Cal Products’ TSS Softshut gate valves are designed for foreline isolation and downstream pressure control over a wide range of vacuum control applications

in conjunction with an APC-series buried box or IQ-series on-valve controller module. The TSS Valve cannot be operated by other manufacturers’ valve

controllers. All interface and communications connections are made directly to the controller module that, in turn, provides power and position signals to the

valve motor. Used with a controller module and the inputs from one or two pressure gauges the TSS-series gate valve forms an integral part of a complete

downstream pressure control system.

Important Personnel Safety and Product Protection Information

Throughout this manual, information that is of particular importance to the installation, the safety of

operating personnel and the protection of equipment are highlighted by the following three symbols.

The WARNING symbol is also used on the equipment wherever necessary.

NOTE: Calls attention to helpful tips about proper

installation, maintenance or use of the valve.

CAUTION: Highlights areas of concern that, if overlooked, could

result in damage to the valve or surrounding equipment.

WARNING : Alerts the installation, operating or maintenance

personnel of hazardous aspects of the valve, which, if

ignored could result in serious personal injury or death.

Call toll free 800-824-4166 or 530-842-4457 • FAX 530-842-9130

TTSS-OP-LIT 08/11

3

Page 4

IntellIsys softshutTM Gate ValVe Models

2.0 - Device Specification - General

The following figures and tables summarize specifications of the TSS-series product.

TABLE 2.1 –GENERAL EQUIPMENT SPECIFICATIONS

FEATURE SPECIFICATION

Dimensions Refer to Figures 2.1 and 2.2, as well as Tables 2.3 and 2.4

Weight, in lbs (kg) Refer to Tables 2.3 and 2.4

Rated Input

Actuation Speed 2 sec open to closed for 2.5” – 6” valves 4 sec open to closed for 8” and 10” valves

Position Resolution 1:6,144,000 steps for 2.5” – 6” valves. 1:12,288,000 steps for 8” and 10” valves.

Leak Rate 1x10-9 atm • scc/sec He (for valves with Viton® seals)

Allowable Gate Differential Pressure 15 psi (103.4 kPa)

Heating Capabilities Body can be heated up to 305ºF (150ºC) with optional heater kits.

Protection Class I

Degree of Protection (IP) X0

Laser Class 1 (LED’s)

Certifications CE Standard for Process Equipment including EMC Directive 89/336/EC and Machinery Directive 89/392/EEC

Maximum Altitude 6562 ft (2000 m)

Allowable Ambient Operating Temperature 32ºF – 122ºF (0ºC - 50ºC)

Allowable Ambient Humidity 0 – 95% non-condensing

Installation Clearance

2A, 2.25Ω

For IQ-series TSSs 3” (75 mm) is required on all perforated sides. Otherwise, a minimum of 3 ½” (90 mm) is

needed on top to allow for connector(s).

(only to be operated by Nor-Cal Products’ controller models)

SPECIFICATION COMMENTS

* MTBF > 2 million cycles or > 11,500 hours

* Warranty 1 year

TABLE 2.2 – TSS RELIABILITY

Processes with large amounts of effluent contamination or highly aggressive chemistries may reduce the MTBF

due to condensation on moving parts and/or O-ring degradation.

TSS-OP-LIT 08/11

44

Visit our Web Site www.n-c.com

Page 5

IntellIsys softshutTM Gate ValVe Models

2.1 - Dimension Call-outs for Standard and IQ-series TSS valves (cross-reference to Tables 2.3 and 2.4)

TABLE 2.3 – STANDARD TSS DIMENSION AND WEIGHT SPECIFICATIONS (REFER TO FIGURE 2.1)

TOTAL

VALVE

SIZE

DN-63 2

DN-80 3 10.7 (272) 6.30 (160) 12.56 (319) 5.04 (128) 12.1 (308) 16.3 (414) 27 (12.3)

DN-100 4 11.3 (287) 7.17 (182) 14.69 (373) 5.91 (150) 12.4 (316) 18.4 (468) 36 (16.3)

DN-160 6 12.6 (321) 10.08 (256) 19.06 (226) 8.78 (223) 14.7 (372) 21.6 (549) 61 (27.7)

DN-200 8 13.9 (352) 12.40 (315) 23.39 (284) 11.14 (283) 16.4 (415) 25.4 (645) 87 (39.5)

DN-250 10 14.9 (378) 14.41 (366) 27.14 (689) 13.11 (333) 17.3 (440) 28.0 (712) 114 (52)

NOM.

FLANGE

TYPE

DN-63 2

DN-80 3 2.68 (68) 3.15 (80) 5.71 (145) CALL 2.54 (65) 5.5 (140)

DN-100 4 2.87 (73) 4.02 (102) 6.93 (176) 5.94 (151) 2.76 (70) 5.7 (144)

DN-160 6 3.07 (78) 6.02 (153) 8.86 (225) 7.99 (203) 3.15 (80) 6.1 (155)

DN-200 8 3.27 (83) 8.39 (213) 11.34 (288) 10.74 (273) 3.15 (80) 6.5 (165)

DN-250 10 3.54 (90) 10.28 (261) 13.78 (350) 12.0 (305) 3.94 (100) 7.1 (179)

STANDARD

ID

1

/2 10.6 (269) 5.83 (148) 11.38 (289) 4.37 (111) 12 (306) 15.7 (398) 19 (8.6)

WIDTH

“A”

NOM.

THICKNESS

ID

1

/2 2.64 (67) 2.76 (70) 5.35 (136) 4.45 (113) 2.76 (70) 5.5 (140)

BONNET

“E”

BONNET

LENGTH

“B”

ACTUAL

I.D.

“F”

BODY

LENGTH

“C”

ISO

FLANGE

O.D.

“G”

BODY

WIDTH

“D”

CONFLAT

FLANGE

O.D.

“G”

TOTAL

L-POS.

WIDTH

“L”

FLANGETO-FLANGE

THICKNESS

“H”

TOTAL

T-POS.

HEIGHT

“T”

WEIGHT

LBS (KG)

TOTAL

VALVE

HEIGHT

“T”

TSS-OP-LIT 08/11

55

Visit our Web Site www.n-c.com

Page 6

IntellIsys softshutTM Gate ValVe Models

2.1 - Dimension Call-outs for Standard and IQ-series TSS valves (cross-reference to Tables 2.3 and 2.4)

TABLE 2.4 – IQ-SERIES TSS DIMENSION AND WEIGHT SPECIFICATIONS (REFER TO FIGURE 2.1)

VALVE

NOM.

SIZE

DN-63 2

TOTAL

STANDARD

ID

1

/2 13.4 (340) 5.83 (148) 11.38 (289) 4.37 (111) 13.3 (338) 17.7 (450) 20 (9.1)

WIDTH

“A

Q”

BONNET

LENGTH

“B”

BODY

LENGTH

“C”

BODY

WIDTH

“D”

TOTAL

L-POS.

WIDTH

“L

Q”

TOTAL

T-POS.

HEIGHT

“T

Q”

WEIGHT

LBS (KG)

DN-80 3 14.3 (364) 6.30 (160) 12.56 (319) 5.04 (128) 14.6 (371) 19.42 (493) 28 (12.8)

DN-100 4 13.9 (353) 7.17 (182) 14.69 (373) 5.91 (150) 14.4 (367) 20.5 (521) 37 (16.8)

DN-160 6 14.6 (373) 10.08 (256) 19.06 (226) 8.78 (223) 16.7 (423) 23.7 (603) 62 (28.2)

DN-200 8 15.8 (403) 12.40 (315) 23.39 (284) 11.14 (283) 18.4 (467) 27.4 (695) 88 (40)

DN-250 10 16.9 (428) 14.41 (366) 27.14 (689) 13.11 (333) 19.4 (492) 30.0 (762) 115 (52.5)

FLANGE

NOM.

TYPE

DN-63 2

BONNET

THICKNESS

ID

1

/2 2.64 (67) 2.76 (70) 5.35 (136) 4.45 (113) 2.76 (70) 5.7 (144)

“E”

ACTUAL

I.D.

“F”

ISO

FLANGE

O.D.

“G”

CONFLAT

FLANGE

O.D.

“G”

FLANGETO-FLANGE

THICKNESS

“H”

TOTAL

VALVE

HEIGHT

“IQ”

DN-80 3 2.68 (68) 3.15 (80) 5.71 (145) CALL 2.54 (64) 5.6 (142)

DN-100 4 2.87 (73) 4.02 (102) 6.93 (176) 5.94 (151) 2.76 (70) 5.9 (150)

DN-160 6 3.07 (78) 6.02 (153) 8.86 (225) 7.99 (203) 3.15 (80) 6.3 (160)

DN-200 8 3.27 (83) 8.39 (213) 11.34 (288) 10.74 (273) 3.15 (80) 6.7 (170)

DN-250 10 3.54 (90) 10.28 (261) 13.78 (350) 12.0 (305) 3.94 (100) 7.0 (178)

TSS-OP-LIT 08/11

66

Visit our Web Site www.n-c.com

Page 7

IntellIsys softshutTM Gate ValVe Models

3.0 - Unpacking and Installation

Unpacking: Inspect the shipping box before unpacking. Any damage should

be reported to Nor-Cal Products or directly to the transportation carrier.

Carefully remove the product from the box and visually inspect it for damage.

NOTE: Do not discard the packing materials until the

product has been inspected to your satisfaction.

If return of the product to Nor-Cal Products should become necessary, please

contact Intellisys Customer Service to obtain a Return Materials Authorization

(RMA) Number.

Pre-Installation Functionality Check: Nor-Cal Products carefully ensures

that every product shipped is in perfect working condition. However, it is still

a good idea to quickly check the functionality of the unit prior to installation

into the vacuum system. To do so, connect the TSS-series valve to a Nor-Cal

Products APC-series controller (or directly to an appropriate DC power source

in case of an IQA or IQD-series valve). On the controller, press OPEN-OPENCLOSE-CLOSE to start the valve homing sequence. The valve will complete

a 30-to-40-second initialization sequence during which the valve plate will

cycle back-and-forth a few times while the controller module OPEN/CLOSE

LEDs blink in an alternating pattern. The valve will eventually stop in the open

position.

WARNING : When working with or troubleshooting Nor-Cal

APC products extreme care must be taken to avoid putting bodily

parts in or near the valve gate mechanism or other moving parts.

These may move suddenly and unexpectedly, and many of them

are driven with sufficient force so as to cause significant harm and

possibly even dismemberment. Nor-Cal Products recommends

that a lock-out and tag-out procedure be strictly followed when

ever human physical intervention is required on all of its control

valves..

Further verification of the system can be done by toggling the “OPEN /

CLOSE” switch on the controller front/top panel. If the valve does not operate

as expected please contact Nor-Cal technical support.

Valve Installation: Install the TSS-series valve in your vacuum system using

the appropriate hardware and cables. To allow for proper ventilation and

access, make sure that at least 3” of unobstructed space is available adjacent

to all perforated sides when installing a IQA or IQD-series valve, and that at

least 3.5 inches of space is reserved above the top of the valve to allow for

cable connector hoods. A complete list of installation hardware and cables

assemblies available from Nor-Cal Products can be found in Appendices I

and II.

NOTE: Refer to the appropriate section of the Adaptive Pressure

Controller Operating Manual (APC-OP-LIT) for more details about

cable connections and pin-outs.

Once the valve is installed in the system, the approximate valve gate position

can be determined by referring to the black circular disk fastened to the rotary

shaft on the red gear box. The ut symbol represents an open valve,

whereas a closed valve is represented by the uIt symbol. Both symbols

are referenced to the small triangular mark on the gear box

Heating the Valves

Heating the Valves: Sometimes it is necessary to heat the TSS-series valve

to prevent process contamination from condensing on the internal valve surfaces. The valve can be ordered as a heated valve, in which case the heater is

laminated to the exterior of the valve and the entire valve body is encased in a

hard insulated shell. As an alternative, Nor-Cal can offer retrofit heater jackets

that can be installed in the field. These heater jackets are available in both PID

and Thermostatically controlled versions, custom fit for each size valve. Please

call Nor-Cal Intellisys Customer Support for heater jacket and related accessories ordering information.

77

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Page 8

IntellIsys softshutTM Gate ValVe Models

Nor-Cal TSS-series valve

4.0 - Theory of Operation

The TSS-series valve is designed for downstream pressure control. As such,

it is one of four important components in a pressure control system. The other

three essential components include a host system computer, a controller module (APC, IQA or IQD) and one or two vacuum gauges, such as a Capacitance

Diaphragm Gauge (CDG). Most manufacturers’ vacuum gauges can be used

to provide the vacuum measurement signal, provided they have a voltage output proportional to pressure. Please see Appedix I for summarized connection

information. More complete signal pin-out and communications information

can be found in Nor-Cal Adaptive Pressure Controller Operating Manual, part

# APC-OP-LIT

Vacuum gauge(s)

Vacuum

Chamber

APC Controller

Nor-Cal

TSS-series

Host system with RS-

232, Analog/TTL or

DeviceNet

communications

Pump

Valve

Normal Operation: After the initialization sequence is complete normal

operation of the TSS control valve is possible. There are two primary modes of

operation, a) position control mode and b) pressure control mode.

In Position control mode the valve will move to any position in its range based

on a position set-point command from the host. The valve will remain in that

position until instructed to do otherwise. Position control mode can be useful in certain cases where pre-determined amount of baffling or throttling is

necessary.

Pressure control mode, on the other hand, is used whenever control to a specific system pressure level is desired. The host provides the set-point value and

the throttle valve strives to achieve that set point as quickly as possible. During

pressure control mode, external perturbations such as flow changes and

plasma events will automatically be compensated for by the APC, IQA or IQD

controller module so that the pressure set-point is maintained.

Tuning: All Nor-Cal controller modules contain an Adaptive Pressure Control

Algorithm that has been designed to work over a wide range of flow- and

pressure-combinations. There are therefore no “learn modes” to execute, nor

does the user have to set PID parameters. In some instances, however, vacuum system design may affect the closed loop pressure control time constants.

As a result, pressure control performance may at times be affected. If satisfactory pressure control cannot be achieved with the Adaptive Pressure Control

Algorithm, please contact Nor-Cal Products Intellisys Customer Support.

FIGURE 4.1 – TYPICAL INSTALLATION AND CONFIGURATION OF A

TSS-SERIES CONTROL VALVE (DASHED LINES REPRESENT TSS-IQA

OR IQD INSTALLATION)

Initialization Sequence: Before typical pressure or position control can

begin, the TSS-series valve needs to complete an initialization sequence that

lasts for approximately 30-40 seconds, depending on the size and starting position of the valve. The primary purpose for this operation is for the

controller to determine the fully open and closed points, as well as for certain

motor and position calibration steps to occur. When the valve controller is

first powered on, the amber FAULT light will be illuminated and the OPEN/

CLOSE LEDs will blink in an alternating fashion. To start the initialization

sequence, press OPEN-OPEN-CLOSE-CLOSE on the controller panel. Once

the initialization sequence is complete, the valve will move to the fully open

position and the green OPEN LED will illuminate.

TSS-OP-LIT 08/11

88

Visit our Web Site www.n-c.com

Page 9

IntellIsys softshutTM Gate ValVe Models

5.0 - Product Support

TSS Valve Service and Maintenance Intervals: The TSS valve was designed for long life and high reliability and, in clean environments, have been shown to

operate with a MTBF well in excess of a year of typical vacuum processing. Process chemistry, temperature and type of use do however affect the moving parts

of the valve and hence the necessary service interval. Therefore Nor-Cal Products recommends inspecting and servicing the valve on a regular basis to avoid

unexpected failures. Please refer to Table 5.1 for recommendations on TSS-series preventive maintenance and service.

TABLE 5.1 – RECOMMENDED TSS-SERIES PREVENTIVE MAINTENANCE ACTIONS AND INTERVALS

RECOMMENDED ACTION PURPOSE / WHAT TO LOOK FOR RECOMMENDED INTERVAL

With valve still installed in system and operating

normally, visually inspect the rotary indicator disk and

drive assembly.

Remove TSS control valve from system for visual inspection.

With controller power OFF, remove TSS motor drive

unit and inspect Oldham coupling disk (valve body can

remain installed in vacuum system)

Remove TSS control valve from system and perform leak

check across the seat and/or to atmosphere.

Disassemble valve body to access gate assembly, bearings and O-rings. Replace seals, re-lubricate and clean

as necessary

Rotary position indicator disk may give early indications of mechanism hang-ups, especially if observed

movement is more erratic than typical. The motor

drive assembly may move back-and-forth slightly if

too much friction is present in the valve assembly

– also an early indicator of mechanism hang-ups

Look for process build-up. Also, inspect for areas

showing scratches in or near gate tracks. The latter

can be a sign of gate misalignment or roller wear.

Inspect for Oldham coupling disk wear and fit. The

presence of a whitish powder indicates disk wear.

Also, the disk should fit snugly on each of the two

hubs, and remain on even when upside down.

Determine loss of seal integrity due to process

buildup or degradation due to chemical or thermal

attack. All new valves are tested to 1 10-9 atm•scc/

sec He (Viton® seals)

High vacuum grease used in bearings and seals can

gradually disappear due to evaporation or chemical

attack. The O-ring seals can wear or crack due to

contamination, chemical attack or excessive heat.

Process residue can accumulate in gate tracks and

rollers, either leading to increased particle generation or ultimate seizing of the assembly.

Weekly to monthly, initially, until a process specific service

interval has been determined for the valve.

Monthly, initially, until a process specific service interval has

been determined for the valve.

After 3 months of use, and then every 3 months, until a

process specific service interval has been determined.

Every 6 months, unless extremely high temperatures or

highly aggressive chemicals are used.

In heated or chemically aggressive applications :

after 6 months of continuous use.

In low temperature and inert applications: after 12

months of continuous use. Or, whenever a leak is found via

leak detection.

TSS-OP-LIT 08/11

99

Visit our Web Site www.n-c.com

Page 10

IntellIsys softshutTM Gate ValVe Models

5.1 - Product Support

TSS Spare Parts and Kits: User serviceable parts in a TSS valve assembly generally include the items listed in Table 5.2. Please refer to the exploded view draw-

ing for illustrative purposes and call-outs. Spare parts may be ordered by contacting Nor-Cal Sales at 800-824-4166, referencing the spare part numbers in

Table 5.2

NOTE: A pressure control system issue may not be related to the throttle valve itself. Please also refer to the Adaptive

Pressure Controller Operating Manual for related troubleshooting tips and actions.

NOTE: If an operational problem does occur with the TSS control valve, please refer to the basic troubleshooting

instructions below in Table 5.3, or contact Nor-Cal Products Intellisys Customer Support at 800-824- 4166 to obtain

additional instructions or a Return Materials Authorization number.

1010

8, 8A, 8B & 8C

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Page 11

IntellIsys softshutTM Gate ValVe Models

5.2 - Spare Parts and Kits Ordering Information

TABLE 5.2 – SPARE PARTS AND KITS ORDERING INFORMATION

Re f .

Description DN-63 DN-80 DN-100 DN-160 DN-200 DN-250

No.

Bonnet bolt/washer set (one each of

1

M8x1.25x20 SHCS SS plus M8 Schnorr

lock washer)

2 Bonnet cover with Viton® o-ring TSS-63-911A TSS-80-911A TSS-100-911A TSS-160-911A TSS-200-911A TSS-250-911A

3 Oldham coupling center disk 54-310- 004 54-310-004 54-310- 004 54-310-004 54-310- 004 54-310-004

Oldham hub and key for mounting to

3A

gear box

Oldham hub and key for mounting

3B

to motor

Rotary disk indicator assembly (disk

4*

& screw)

5* Shaft Key TSS-63-962A TSS-80-962A TSS-100-962A TSS-160-962A TSS-200-962A TSS-250-962A

6* Shaft TSS-63-968A TSS-80-968A TSS-100-968A TSS-160-968A TSS-200-968A TSS-250-968A

7 Rotary Seal – Viton® TSS-63-961 TSS-80 -961 TSS-100-961 TSS-160-961 TSS-200-961 TSS-250 -961

Gate and carriage assembly with

8

bonded Viton® seal

Gate and carriage assembly with

8A

replaceable Viton® seal

Gate (only) with replaceable Viton

8B

seal

8C Gate O-ring Seal - Viton OR-2-232V OR-2-235V OR-2-241V OR-2-434V OR-2-444V OR-2-450V

9 Gear Box w /Oldham hub and key TSS-GB1 TSS-GB1 TSS-GB2 TSS-GB3 TSS-GB4 TSS- GB5

Motor Assembly w/Oldham hub and

10

motor mount (standard)

10A Motor Assembly w/Oldham hub (IQA) TSSIQA-001 TSSIQA-001 TSSIQA-001 TSSIQA- 001 TSSIQA-001 TSSIQA-001

10B Motor Assembly w/Oldham hub (IQD) TSSIQD-001 TSSIQD-001 TSSIQD-001 TSSIQD-001 TSSIQD- 001 TSSIQD-001

IQ-drive motor mount (used to

11

change standard valve to IQ-type)

Bearing kit (includes bearing and

12

replacement Circlip)

TSS-BBW

(Total of 10

needed for complete valve)

TSS-HK-GB TSS-HK-GB TSS-HK-GB TSS-HK-GB TSS-HK-GB TSS-HK-GB

TSS-HK-M TSS-HK-M TSS-HK-M TSS-HK-M TSS-HK-M TSS-HK-M

TSS-63-966A TSS-80-966A TSS-100-966A TSS-160-966A TSS-200-966A TSS-250-966A

TSS-63-925 TSS-80 -925 TSS-100-925 TSS-160-925 TSS-200-925 TSS-250 -925

TSS-63-925A TSS-80-925A TSS-100-925A TSS-160-925A TSS-200-925A TSS-250-925A

TSS-63-925B TSS-80-925B TSS-100-925B TSS-160-925B TSS-200-925B TSS-250-925B

TSS00-001 TSS00-001 TSS00- 001 TSS00-001 TSS00- 001 TSS00-001

TSS-XIQ-MM TSS-XIQ-MM TSS-XIQ-MM TSS-XIQ-MM TSS-XIQ-MM TSS-XIQ-MM

TSS-63-SB TSS-80-SB TSS-100-SB TSS-160-SB TSS-200-SB TSS-250-SB

TSS-BBW

(Total of 12

needed for complete valve)

TSS-BBW

(Total of 12

needed for complete valve)

TSS-BBW

(Total of 20

needed for complete valve)

TSS-BBW

(Total of 22

needed for complete valve)

TSS-BBW

(Total of 28

needed for complete valve)

Shaft assembly removal

N/A

remove the shaft and bearing during

*NOTE: Effective May 2005, the Rotary disc indicator, shaft and shaft key designs changed. TSS valves are serialized using a date code followed

by a three-digit sequential number. The serial number format are the letters SS followed by the digits YYMMxxx, where YY is the year, MM is

the month and xxx is the sequential number. Please refer to Table 5.2A below for replacement parts for valves manufactured before this date.

O-ring and valve maintenance

tool. Helps

SD-M0014 SD-M0014 SD-M0014 SD-M0014 SD-M0014 SD-M0014

TABLE 5.2A – SPARE PARTS AND KITS ORDERING INFORMATION FOR VALVES MADE PRIOR TO MAY 2005

Re f .

Description DN-63 DN-80 DN-100 DN-160 DN-200 DN-250

No.

Rotary disk indicator

4

assembly (disk, spacer &

screw)

5 Shaft Key TSS-63-962 TSS-80 -962 TSS-100-962 TSS-160-962 TSS-200-962 TSS-250-962

6 Shaft TSS-63-968 TSS-80-968 TSS-100-968 TSS-160-968 TSS-200-968 TSS-250-968

1111

TSS-63-966 TSS-80-966 TSS-100-966 TSS-160-966 TSS-200-966 TSS-250-966

Visit our Web Site www.n-c.com

TSS-OP-LIT 08/11

Page 12

IntellIsys softshutTM Gate ValVe Models

5.3 - Troubleshooting

Some basic troubleshooting can be done by the user referring to the instructions and suggestions below. Table 5.3 describes possible

symptoms and recommended actions.

TABLE 5.3 – POSSIBLE FAILURE MODES AND RECOMMENDED ACTIONS

Symptom Possible Causes Recommended Action

The TSS valve does not appear to turn on or operate.

The TSS appears to operate but pressure- or position control is inconsistent and poor

A whining or buzzing sound is heard from the TSS

motor drive

The motor and valve shaft rotate continuously in

one direction without stopping and without moving the valve gate

The TSS is not connected to the controller module

(standard TSS models only)

The controller-to-valve cable is faulty (standard

TSS models only)

The controller module is not on, or is faulty.

The Oldham coupling is broken

The valve gate is jammed or partially jammed in

the valve bore.

The Oldham coupling disk is worn or cracked

The Oldham coupling disk, or possibly hubs, is

loose or worn and a harmonic resonance point has

been excited

The controller motor control coefficients have

been corrupted.

The wrong controller is being used.

The square key between the rotary shaft and

gearbox is missing or broken.

The gate actuation arm is broken or otherwise

decoupled.

Check to make sure the controller-to-valve cable

is connected at both ends, using the correct connectors.

Try another TBV-CRD-XX cable.

Check controller module and refer to appropriate

controller Operating Manual

Turn off controller power. Remove motor drive to

inspect Oldham coupling

Turn off controller power and remove the motor

drive from the gearbox. Attempt to move

the gearbox input shaft by hand. If binding is

observed, remove valve from system to determine the root cause. Clean off process residue as

necessary using a non-abrasive method. If damaged parts are found, contact Nor-Cal Intellisys

Customer Support

Turn off controller power. Remove drive unit from

gearbox. Replace the Oldham coupling disk as

necessary.

Turn off controller power. Remove drive unit from

gearbox. Replace the Oldham coupling disk as

necessary. If problem persists, contact Nor-Cal

Intellisys Customer Support.

Turn off controller power. Turn back on and allow

initialization sequence to complete

Note model and serial number of valve and controller and contact Nor-Cal Intellisys Customer

Support

Remove the rotary indicator disk, spacer and

screw. Remove the four screws holding the gearbox to the valve. Slide off gearbox / motor assembly from rotary shaft and inspect key and shaft

keyway. Replace items as necessary.

Turn off vacuum system. Open the bonnet cover

by loosening the bolts on back plate. Look inside

to inspect short gate arm that links the rotary

shaft to the gate and carriage mechanism. NOTE:

It is impossible to move or turn the shaft with

the gearbox attached. If manual operation is

required, then removal of the gearbox is necessary (see step above).

Follow steps above to open bonnet cover AND

remove gear head. Remove the square and plates

found under the gearbox, and remove the short

The valve has developed a leak to atmosphere

along the valve shaft

O-ring damage and/or loss of vacuum grease can

cause this

gate arm attached to the shaft. Pull shaft out

from bearing and seal cavity (this may require a

tool (Please contact Nor-Cal Intellisys Customer

Support to obtain instructions). Visually inspect

the seal, relubricate or replace as necessary.

Global Sales and Service: Nor-Cal Products maintains sales and service centers in over 30 countries worldwide. Please visit our

website at

1212

http://www.n-c.com

to find the center nearest you.

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Page 13

IntellIsys softshutTM Gate ValVe Models

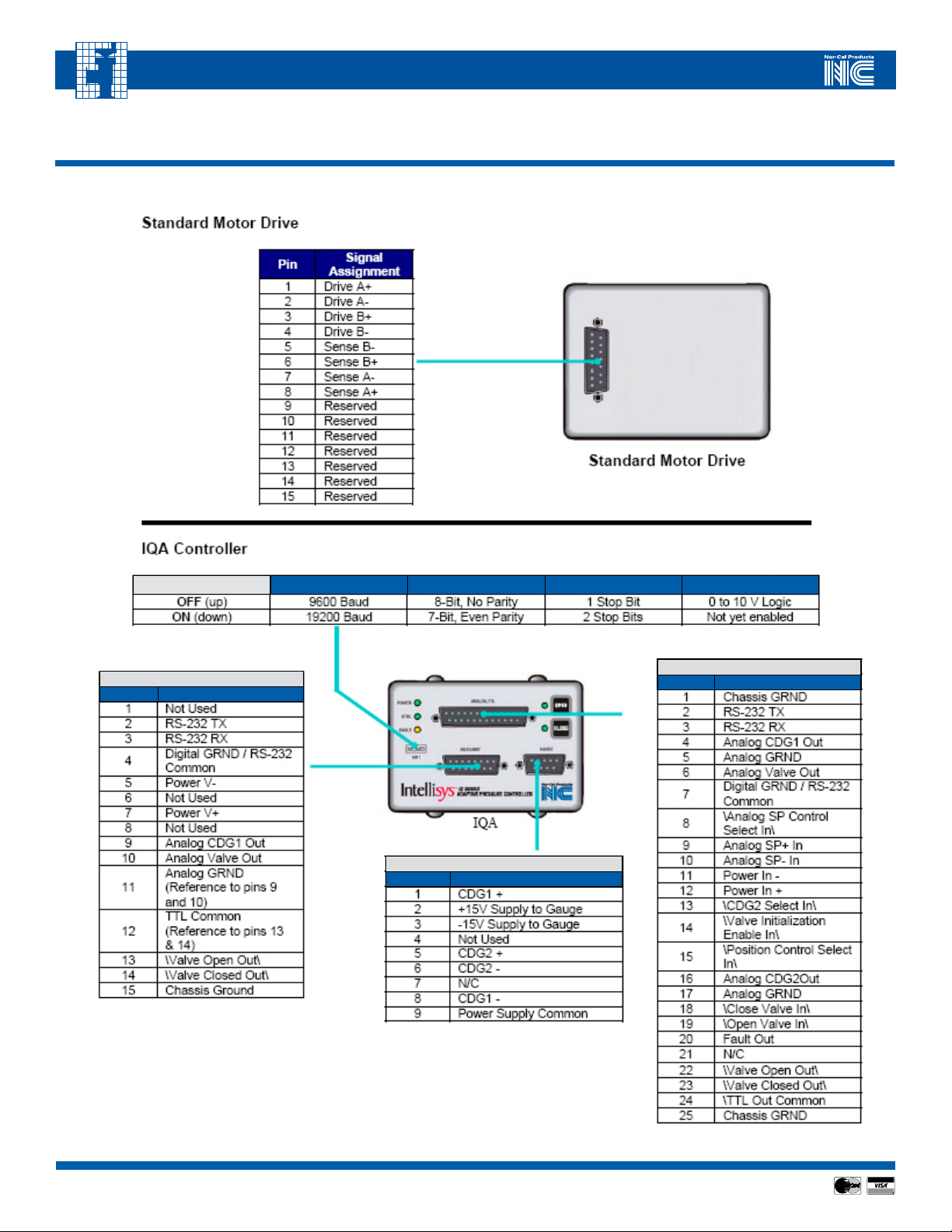

APPENDIX I - Summary Valve and Controller Connection Information

Controller Connection Diagrams Figures A-1

CAUTION: Do not connect cables to the valve when the controller is under power.

Motor Drive

For valves fitted with a motor-drive unit, connect a Nor-Cal TBV-CRD series valve cable between the motor drive and the buried-box controller.

IQA

For valves fitted with IQA controllers, first confirm that the DIPswitch settings are correct for your serial communications1, and then connect the

appropriate cables for Gauges, Auxiliary, and Analog/TTL

2

.

IQD

For valves fitted with IQD controllers, first confirm that the rotary DIPswitch settings are correct for your DeviceNet settings1, and then connect

the appropriate cables for Gauges, Auxiliary, Analog/TTL and/or a DeviceNet cable

1

IQ series DIPswitches are factory-set to default positions. Consult the IQ manual for detailed information on these settings.

2

Refer to the following section for detailed information on cabling requirements and pin-outs for IQ series accessory ports.

1313

2

.

Visit our Web Site www.n-c.com

TSS-OP-LIT 08/11

Page 14

IntellIsys softshutTM Gate ValVe Models

APPENDIX I - Summary Valve and Controller Connection Information, Conti.

Pin-Out Wiring Diagrams

Figure A-1.2

Figure A-1.3

IQA DIP Switches

IQA Auxiliary Connector

Pin Signal Assignment

Switch 1

Switch 2

IQA Gauge Connector

Pin Signal Assignment

Switch 3

Switch 4

IQA Analog/TTL Connector

Pin Signal Assignment

1414

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Page 15

IntellIsys softshutTM Gate ValVe Models

APPENDIX I - Summary Valve and Controller Connection Information, Conti.

IQD Controller

IQD DeviceNet Connector

Pin Signal Assignment

Pin Signal Assignment

Figure A-1.4

4

5

1

IQD Auxiliary Connector

3

2

IQD Gauge Connector

Pin Signal Assignment

1515

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Page 16

IntellIsys softshutTM Gate ValVe Models

APPENDIX II - Installation Hardware

1616

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Page 17

IntellIsys softshutTM Gate ValVe Models

APPENDIX II - Table Install Hardware

TABLE A-II.1 – INSTALLATION HARDWARE FOR ISO-FLANGED TSS VALVES MATING TO OF-TYPE FLANGE

1

Valve Type

TSS- (IQX)250-ISO-63

TSS- (IQX)300-ISO-80

TSS- (IQX)400-ISO-100

TSS- (IQX)600-ISO-160

TSS- (IQX)800-ISO-200

TSS- (IQX)1000-ISO-250

Attachment Hardware for

ISO-type valve w/OF-style

flanges (item “A”)

ISO-63-SCP-M 4 ISO-63-CR-SV, or ISO-63-CR-AV 1

ISO-80-SCP-M 8 ISO-80-CR-SV, or ISO-80-CR-AV 1

ISO-100-SCP-M 8 ISO-100-CR-SV, or ISO-100-CR-AV 1

ISO-160-SCP-M 8 ISO-160-CR-SV, or ISO-160-CR-AV 1

ISO-200-SCP-M 12 ISO-200-CR-SV, or ISO-200-CR-AV 1

ISO-250-SCP-M 12 ISO-200-CR-SV, or ISO-200-CR-AV 1

Required

Quantity

(per side)

Flange Viton O-ring

(item “B”)

Required

Quantity

(per side)

TABLE A-II.2 – INSTALLATION HARDWARE FOR ISO-FLANGED TSS VALVES MATING TO N-TYPE FLANGE

Valve Type

TSS- (IQX)250-ISO-63

TSS- (IQX)300-ISO-80

TSS- (IQX)400-ISO-100

TSS- (IQX)600-ISO-160

TSS- (IQX)800-ISO-200

TSS- (IQX)1000-ISO-250

TABLE A-II.3 – INSTALLATION HARDWARE FOR CF(M)-FLANGED TSS VALVES MATING TO CF-TYPE FLANGE

ValveType

TSS- (IQX)250-CF(M) -450

TSS- (IQX)400-CF(M)-600

TSS- (IQX)600-CF(M)-800

TSS- (IQX)800-CF(M)-1000

TSS- (IQX)1000-CF(M)-1200

Attachment Hardware for ISO-type

valve w/N-style flanges (item “C”)

M8 x 25mm bolt+ M8 flat washer 4 ISO-63-CR-SV, or ISO-63-CR-AV 1

M8 x 25mm bolt+ M8 flat washer 8 ISO-80-CR-SV, or ISO-80-CR-AV 1

M8 x 25mm bolt+ M8 flat washer 8 ISO-100-CR-SV, or ISO-100-CR-AV 1

M10 x 30mm bolt+ M10 flat washer 8 ISO-160-CR-SV, or ISO-160-CR-AV 1

M10 x 30mm bolt+ M10 flat washer 12 ISO-200-CR-SV, or ISO-200-CR-AV 1

M10 x 30mm bolt+ M10 flat washer 12 ISO-200-CR-SV, or ISO-200-CR-AV 1

AttachmentHardwareforCF-styleflanges

(item“E”)

B-450T (Imperial) or B-450T-M (metric):

set of 25

B-600T (Imperial) or B-600T-M (metric):

set of 25

B-800T (Imperial) or B-800T-M (metric):

set of 25

B-1000T (Imperial) or B-1000T-M (metric):

set of 25

B-1200T (Imperial) or B-1200T-M (metric):

set of 25

Required

Quantity

(per side)

Flange Viton O-ring

(item “B”)

Required

Quantity

(perside)

0.33 G-450-I 1

0.67 G-600-I 1

0.80 G-800-I 1

1.00 G-1000-I 1

1.30 G-1200 1

FlangeCopperGasket

1

(item“D”)

Required

Quantity

(per side)

Required

Quantity

(perside)

1717

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Page 18

IntellIsys softshutTM Gate ValVe Models

APPENDIX III - Valve, Accessories and Cable Assembly Ordering Information

Throttling Gate Valves with IQA or IQD Control Module

1

TSS- IQX

_ _ _

_ _ _ _

_ _ _

Size

Family

250 ISO 63 Viton (leave blank)

300 ISO 80 Perlast G74P (enter PP7)

400 ISO 100

600 ISO 160

800 ISO 200

1000 ISO 250

250 CF or CFM 450

400 CF or CFM 600

600 CF or CFM 800

800 CF or CFM 1000

1000 CF or CFM 1200

1

NOTE: “X” refers to the communications mode. D = DeviceNet, A = analog, etc…

Flange Type

Flange

Size

O-ring Option

Standard Throttling Gate Valves (to be operated by a stand-alone APC-series controller)

TSS

_ _ _

_ _ _ _

_ _ _

2

1818

Size

Family

250 ISO 63 Viton (leave blank)

300 ISO 80 Perlast G74P (enter PP7)

400 ISO 100

600 ISO 160

800 ISO 200

1000 ISO 250

250 CF or CFM 450

400 CF or CFM 600

600 CF or CFM 800

800 CF or CFM 1000

1000 CF or CFM 1200

2

NOTE: Other O-ring materials are available. Call Nor-Cal Intellisys Customer Support for details

Flange Type

Flange

Size

O-ring Option

2

Visit our Web Site www.n-c.com

TSS-OP-LIT 08/11

Page 19

IntellIsys softshutTM Gate ValVe Models

APPENDIX III - Valve, Accessories and Cable Assembly Ordering Information

Cable Assemblies and Accessories

TABLE A-III.1 – TSS AND APC CABLE ASSEMBLIES AND ACCESSORIES

Description Nor-Cal Part Number

10’ (3 meter) APC controller-to-TSS valve cable TBV-CRD-10

10’ (3 meter) APC controller-to-15-pin CDG cable CDG-CRD-DB15-10

10’ (3 meter) APC controller-to-9-pin CDG cable CDG-CRD-DB9-10

10’ (3 meter) APC controller-to-flying lead CDG cable CDG-CRD-10

10’ (3 meter) APC controller-to-host RS-232 interface cable. DB-9 connector on host end APC-CRD-RS232-10

24 VDC, 3A power supply (100-240 VAC input) for IQ-series TSS. Includes AC power cord and 6’ (2 meter) DC cable with 15-pin

D-sub connector

10’ (3 meter) long IQD-to-host RS-232 interface cable. DB-9 connector on host end IQ-CRD-RS232-10

10’ (3 meter) long IQD-to-CDG interface cable. DB-15 connector on CDG end CDG-IQ-CRD-DB15-10

1’ (30 cm) long Y-cable used to interface two CDGs to IQD.* CDG-IQ-CRD-Y

RS-232 Service Software for Windows PC Call for details

APC-PSM-DB15

1919

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Page 20

IntellIsys softshutTM Gate ValVe Models

Appendix IV - Limited Warranty and Intellectual Property Coverage

Products manufactured by Nor-Cal Products, Inc. (hereinafter referred to as “Nor-Cal”) are warranted against defects in material and workmanship for a

period of twelve (12) months from the date of shipment from Nor-Cal to the buyer. Any modification to the product by the buyer or their agent voids this warranty. Liability under this warranty is expressly, limited to replacement or repair (at Nor-Cal ’s option) of defective parts. Nor-Cal may at any time discharge its

warranty as to any of it products by refunding the purchase price and taking back the products. This warranty applies only to parts manufactured, and labor

provided, by Nor-Cal under valid warranty claims received by Nor-Cal within the applicable warranty period and shall be subject to the terms and conditions

hereof. Expendable items such as tubes, heaters, sources, bellows, etc., by their nature may not function for one year; if such items fail to give reasonable service

for a reasonable period of time, as determined solely by Nor-Cal, they will be repaired or replaced by Nor-Cal at its election. All warranty replacement or repair

of parts shall be limited to equipment malfunctions which, in the sole opinion of Nor-Cal, are due or traceable to defects in original materials or workmanship.

Malfunctions caused by abuse or neglect of the equipment are expressly not covered by this warranty. Nor-Cal expressly disclaims responsibility for any loss or

damage caused by the use of its products other than in accordance with proper operating and safety procedures. Reasonable care must be taken by the user to

avoid hazards. In-warranty repaired or replacement parts are warranted only for the remaining unexpired portion of the original warranty period applicable to

the parts that have been repaired or replaced. After expiration of the applicable warranty period, the buyer shall be charged at Nor-Cal’s then current prices for

parts and labor plus transportation. Except as stated herein, Nor-Cal makes no warranty, expressed or implied (either in fact or by operation of law), statutory or

otherwise: and, except as stated herein, Nor-Cal shall have no liability for special or consequential damages of any kind or from any cause arising out of the sale,

installation, or use of any of its products. Statements made by any person, including representatives of Nor-Cal, which are inconsistent or in conflict with the

terms of this warranty shall not be binding upon Nor-Cal unless reduced to writing and approved by an officer of Nor-Cal. Merchandise may be returned at the

sole discretion of Nor-Cal Products, but not more than 60 days after shipment. A fee may be charged for restocking the item. An RMA number must be obtained

from Nor-Cal before returning any merchandise.

Intellectual Property Coverage

The products described in this manual are covered under U.S. Patent numbers 5,134,349; 5,202,613; 5,321,342; and 6,612,331. Additional patents are pending.

2020

TSS-OP-LIT 08/11

Visit our Web Site www.n-c.com

Loading...

Loading...