Page 1

Intellisys Isolation Pendulum Valve (IPV)

Quick-Start Guide

Body Engraving

Inspection Sticker

¼” 80 PSI CDA

Manual

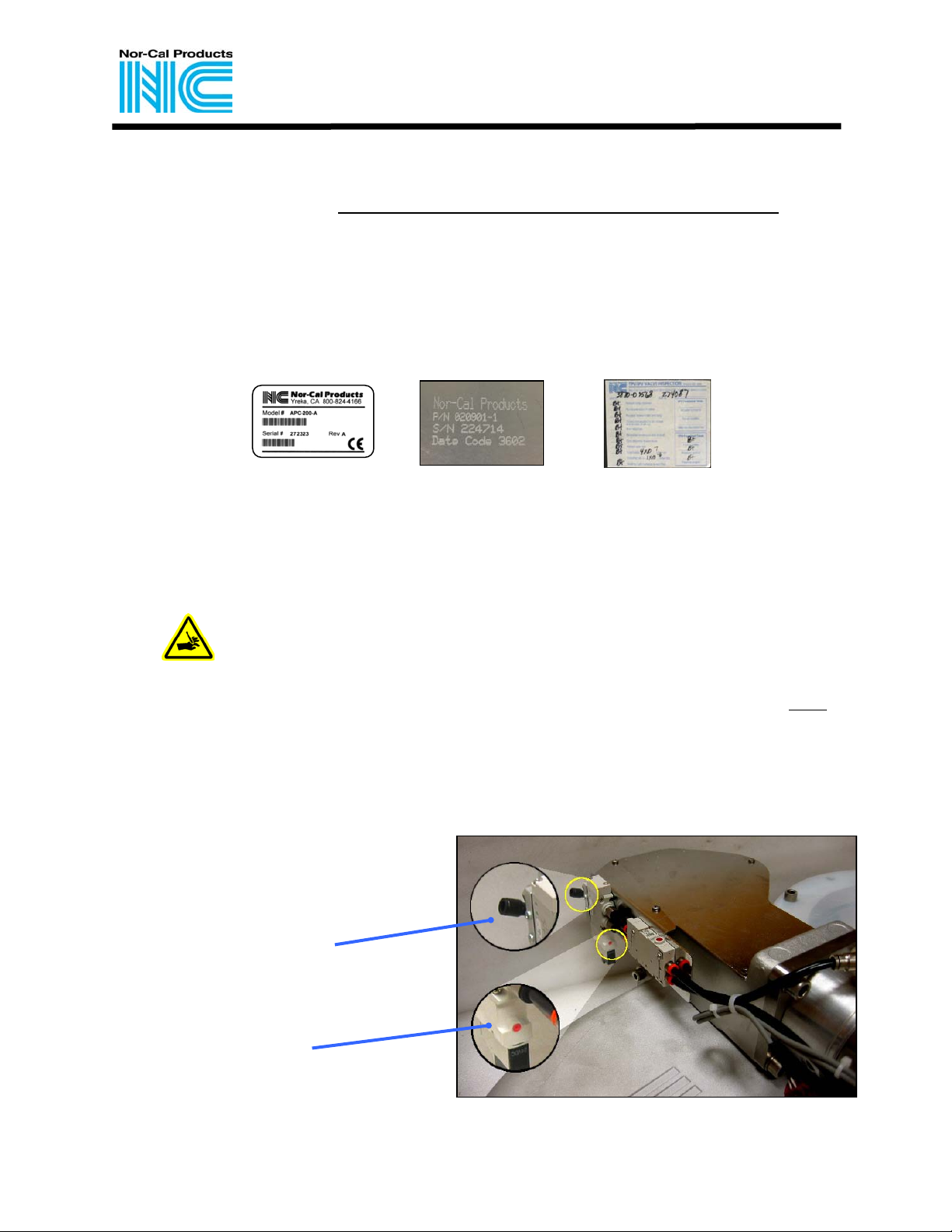

Location of Air Control Bracket

200mm, 250mm and 350mm Isolation Pendulum Gate Valves (IPV)

Unpacking & Handling

Use care when unpacking an Intellisys Pendulum Valve. Never lift by the Actuator or Motor, or set on edge.

Lift only on the body surfaces or lifting lugs. Aluminum surfaces scratch easily. A static-safe, particle-free

work surface is recommended. There is no need to remove parts during installation or inspection.

Removing or disassembling parts without authorization from a Nor-Cal rep will void the warranty.

Check The Package Contents:

• Intellisys Isolation Pendulum Valve (IPV)

• This Quick-Start Guide

Serial Label

A Serial Label on the bag shows the mode l number and serial number of your product. Additionally, Model,

Serial and Date Codes are engraved, and an inspection sticker is affixed to the side of the valve.

Serial Label

Warranty

Nor-Cal Intellisys Controllers and valves are warranted against defects and material workmanship for a per iod of

15 months after the date of shipment to the buyer. For complete warranty and Intellectual Property details,

please refer to the full manual.

Pre-Installation Functionality Check

Refer to the photograph below for locations of the items that follow.

WARNING: The valve plate movement presents a severe pinching/crushi ng

hazard. Please keep fingers, hands and other objects away from the valve

opening and associated moving parts.

Connect the Pneumatic Line

For pneumatically driven IPV valves, connect an unpressurized CDA or N2 line to the input solenoid then slowly

bring up the pressure to 80PSI.

Open and Close Testing

To open the valve, manually depress and hold the small orange button on the solenoid near the CDA input.

Release the button to close the valve.

Connections & Interfaces

The IPV Pneumatic Air connector and

Manual Open/Close button are locate d

on the IPV Air Control Bracket, shown here:

or N2 input

(NOTE: 80-100 PSI is required

for proper valve sealing)

“Open” Button

Nor-Cal Products, Inc. 1967 South Oregon St., Yreka, CA 96097 USA

LIT-IPV-QSG, 05/2006

Page 2

Intellisys Isolation Pendulum Valve (IPV)

Quick-Start Guide

200mm, 250mm and 350mm Isolation Pendulum Gate Valves (IPV)

Basic Troubleshooting

Gate Seal does not pass Helium Leak Check

• Open the valve for approximately one hour to help r elieve o-ring compression set on t he gate seal.

• Wipe-down inner sealing flange and the gate o-ring with IPA and DI.

NOTE: Gray Aluminum Oxide residue on a cleanroom wipe is normal.

• Make sure 80-100 PSI CDA or N

• Check for cracked or broken air fittings. Listen for CDA leaks.

• Re-try the Helium leak test after the above steps have been taken

• If the valve still does not pass, record the areas where it fails, the leak rate, and the serial number,

then call a local Nor-Cal rep.

• Do not disassemble the valve without authorization from a Nor-Cal re p.

• Consult the specification for this seal to confirm there is a discrepancy.

Atmosphere seals (Bonnet, Shaft, Hard-stop) do not pass Helium Leak Check

• Record the area where the atmosphere seal leaks, the leak rate, and the serial number, then call a

Nor-Cal rep.

• Consult the specification for the seal to confirm there is a discrepancy.

is provided. Pressure <80 PSI can prevent complete sealing.

2

Bolts get stuck (galled) in the body or flange

• DO NOT force the bolts out! Irreparabl e damage can occur, or the bolts may break-off.

• Instead, use large amounts of DI or IPA to lubricate the bolts, slowly turning them back and forth in

small increments until the bolt has been removed.

NOTE: If the Helicoil backs out with the bolt, stop here, and then call a Nor-Cal Rep.

• Thoroughly clean and rinse the threads of both the bolt and the threaded hole.

• Inspect both for damage, and try hand-threading the bolt back into the hole.

• If there is resistance to hand-threadi ng, call a Nor-Cal rep.

Cosmetic discrepancies

• Some imperfections and discolor ation are normal. Consult the cosmet ic specification for the

particular location (casting, machined surface, paint, etc.) to be sure there is a discrepancy.

• Do not attempt to fix cosmetic scratches on machined or finished surfac es. If possible, photograph

the issue, and then email images to a Nor-Cal rep.

• Never use solvents or cleaners other than IPA or DI water to remove stain s or discoloration.

Contacting a Nor-Cal Representative

For a complete list of worldwide contacts, please visit the Nor-Cal website at

c.com/Worldmap.aspx.

Obtaining Complete Manuals

To download complete manuals for I ntellisys TBV Valves, please visit www.n-c.com. Click Support, choose

Product Documentation Downloads from the drop-down menu, and pick Downstream Pressure Control and

locate document under Manuals at the left.

http://www.n-

Nor-Cal Products, Inc. 1967 South Oregon St., Yreka, CA 96097 USA

LIT-IPV-QSG, 05/2006

Loading...

Loading...