Page 1

OPERATOR'S MA N U AL

© Nor-Cal Products, Inc., POPV-LIT 6/08

Air -to-Open Spring-to-Close Pneumatic

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Angle Valves

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ESVP-038 thru 200

CSVP-038 thru 200

AIVP-075 thru 200

CAIVP-075 thru 200

ILVP-038 thru 200

CILVP-038 thru 200

ESVP-038T thru 200T

CSVP-038T thru 200T

STVP-075

CSTVP-075

1

Nor-Cal Products, Inc. • 1967 S. Oregon St., Yreka, CA 96097 • 800-824-4166 or 530-842-4457 • FAX 530-842-9130 • ncsales@n-c.com • Web: www.n-c.com

Page 2

OPERATOR'S MA N U AL

© Nor-Cal Products, Inc., POPV-LIT 6/08

Air -to-Open Spring-to-Close Pneumatic Angle Valves

Unpacking

Inspect the shipping box before unpacking. Any damage

should be reported to the transportation company upon

receipt. Remove the valve from the box. Visually inspect the

valve, making sure that the flange faces are in good

condition. Apply 40-80 psig at the 1/8 inch NPT tapped hole

located on the black center plate of the valve to make sure the

valve operates smoothly before installation.

Installation Instructions

Determine that the valve and adjacent plumbing in the

vacuum system will be adequately supported when

installed. Make sure that the mating flanges are inline,

parallel and the correct distance apart to minimize straining

of the valve body. Remove the flange covers and wipe the

flanges and the gasket with a lint free wipe. With O-ring seal

flanges, apply a light film of vacuum grease to the O-ring

prior to installing in the flange groove. Proceed with the

installation while making sure that no foreign particles

enter the valve. Where applicable, lightly grease the flange

bolts with a high temperature anti-seize compound.

Carefully tighten around the flange in a 180º alternating

pattern until the flanges are in contact and the bolts are snug.

Valves will work equally well in any orientation. In addition,

vacuum can be on either side of the poppet and still maintain

a vacuum tight seal. However , it is recommended that valves

are installed with the poppet facing the process to prevent

contaminating the valve internals.

CAUTION: The air actuator sold under this agreement is spring

loaded. Any unauthorized disassembly of the air cylinder assembly will void the warranty, and any improper disassembly and maintenance is potentially dangerous. Do not dismantle the valve until

you shut off the air supply to the air solenoid and disconnect the

air supply line that is connected to the valve’s center plate (4).

Refer to the illustration and recommended service intervals

sections before installing a repair kit. Please contact Nor-Cal

to check on the warranty status prior to proceeding.

Viton® and Kalrez® are registered trademarks of DuPont Dow Elastomers.

®

Lubriplate

is a registered tracemark of Fiske Brothers Refining Company.

Operating Instructions

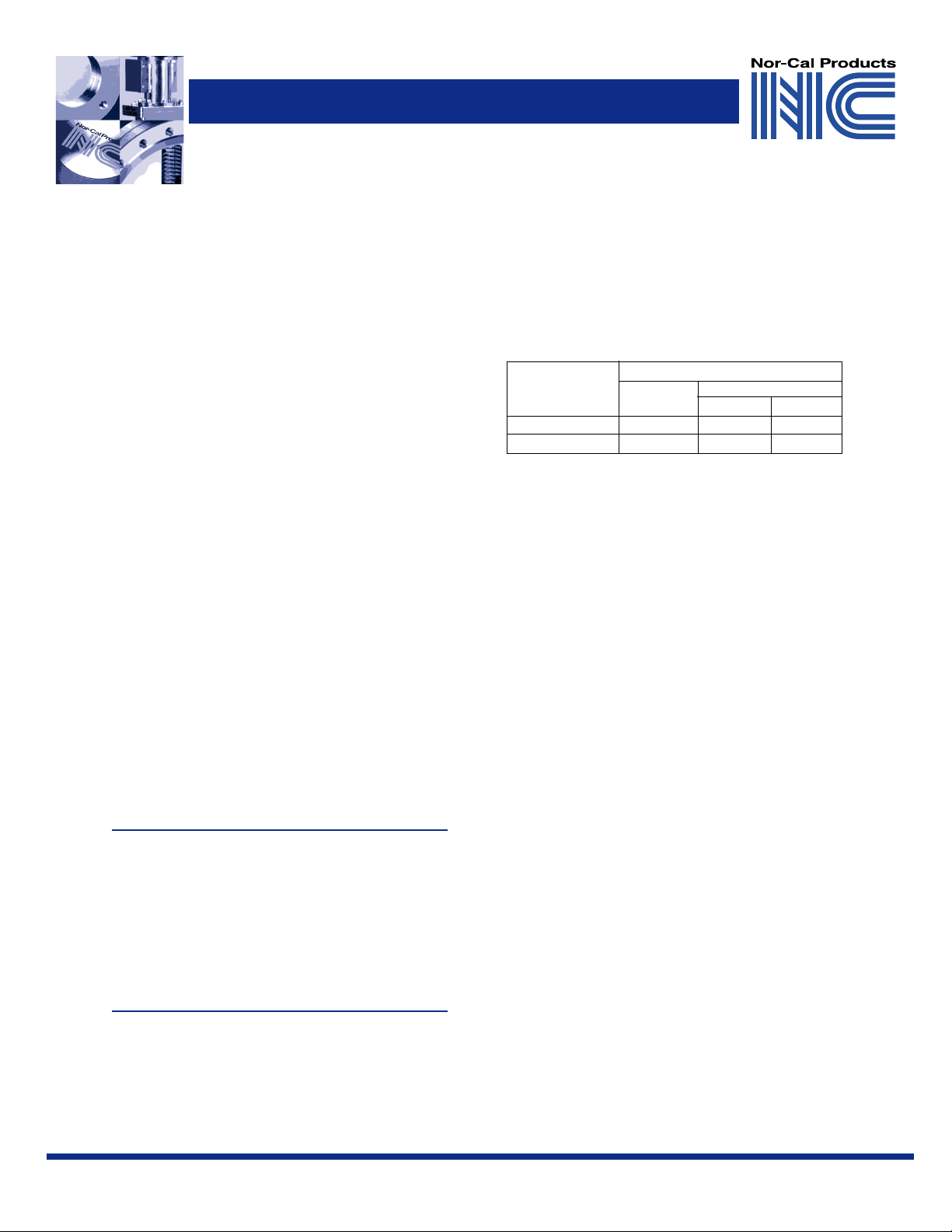

To ensure trouble free use, keep the valve clean and free

from contaminants. The air supply pressure should not exceed 80 psig. The bakeout temperature of the valve should

not exceed that of the elastomer that is used in it. See table

below for maximum recommended bakeout temperatures.

Valve Position

Closed

Pneumatic

120ºC

220ºC

Manual

ºC

100

150ºC

Viton

Kalrez

®

O-rings

®

O-rings

Open

150

280

ºC

ºC

Pneumatic Hook-up

Air-to-open, spring-to-close, pneumatic valves are to be

used with 3-way air solenoid valves. The air solenoid can be

purchased separately as a kit with installation instructions

and hardware. As an option, Nor-Cal can provide a pneumatic valve with the appropriate air solenoid in various

voltages pre-installed. Or, the valve may be connected

by an air line to an air solenoid in a remote location. The

instructions below are for the hook-up of a valve with a

pre-installed air solenoid. If the valve is connected to a

remote air solenoid, simply connect the air line from the

OUT port of the air solenoid to the 1/8 inch NPT hole on the

black valve centerplate using an appropriate fitting.

1. Connect a 60-80 psig air supply to the IN port

of theair solenoid using Teflon tape on all fittings to

ensure a leak-tight connection. For continued trouble

free operation, it is recommended that an air filter and

lubricator be used in the air line system.

2. Check the air solenoid name plate to confirm its

electrical specifications. Attach the appropriate

power source to the air solenoid.

3. Energizing the air solenoid will cause the valve

to open, de-energizing the air solenoid will cause

the valve to close.

Recommended Service Intervals

Service intervals are based on the number of cycles (openclose-open) a valve can be safely operated under clean

conditions without any maintenance. Nor-Cal recommends

that these valves be inspected for wear, and O-rings and

bellows be replaced as necessary after 250,000 cycles.

Process induced contamination and bake-out temperatures above 150ºC may shorten service intervals significantly. After service is completed these valves can again be

operated for the specified number of cycles.

2

Nor-Cal Products, Inc. • 1967 S. Oregon St., Yreka, CA 96097 • 800-824-4166 or 530-842-4457 • FAX 530-842-9130 • ncsales@n-c.com • Web: www.n-c.com

Page 3

OPERATOR'S MA N U AL

© Nor-Cal Products, Inc., POPV-LIT 6/08

1

Repair Instructions

Tools Required

3

/8" to 1" • 7/16" open end wrench

• 7/16" Socket

• .050" ball driver

1 1/2" • 3/16" ball driver

• 9/16" socket

• 7/16" open end wrench

• .050" ball driver

2" • 5/32" ball driver

• 9/16" socket

• 7/16" open end wrench

• .050" ball driver

Procedure

Make sure that the valve internals that are

subject to vacuum remain clean. Use lint free wipes

as necessary and keep seals free of contaminants.

1. Shut off the air supply to the air solenoid.

2. Remove the air fitting at the center plate (4).

3. Remove the air cylinder (1), apply 30 to 40 lbs. of force

against the top of the air cylinder (1) to neutralize the

spring (9) while removing the bonnet screws (13).

4. Remove valve internals from the body (7) and inspect

body flange O-ring (15) and poppet O-ring (17) and

replace if necessary.

5. If the bellows assembly (16) requires replacement,

remove the jam nut (11) by first inserting a 7/16" open

end wrench in the stem shaft (5) to keep the bellows

assembly (16) from rotating while removing the

jam nut (11). Remove piston cup (12) and slide off

center plate (4). Remove set screw (6) and replace

the bellows assembly (16).

6. Replace all O-rings as necessary including the piston cup (12).

7. Apply a light film of high vacuum grease on the O-rings

prior to installing them.

8. Apply anti-seize or equivalent on set screw (6)

and on bonnet screws (13).

9. Apply Lubriplate® high temperature grease

#PTL0161-001 or equivalent on stem shaft (5).

10. Re-assemble the valve in the reverse order .

2*

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Diagram Key

1. Air Cylinder

2. Stem O-Ring

3. Retaining Plate

4. Center Plate

5. Stem Shaft

6. Set Screw

7. Body

8. Air Filter

9. Air Cylinder Spring

10. Spring Retainer

11. Jam Nut

12. Piston Cup

13. Bonnet Screws

14. Air Cylinder O-Ring

15. Body Flange O-Ring

16. Bellows Assembly

17. Poppet O-Ring

17

* 2" ID valves are

assembled with

two Stem O-Rings.

Warranty

Products manufactured by Nor-Cal Products Inc. (hereinafter referred

to as “Nor-Cal”) are warrantied against defects in material and workmanship for a period of twelve (12) months from the date of shipment

from Nor-Cal to the buyer . Any modification of the product by the buyer

or their agent voids this warranty. Liability under this warranty is expressly limited to replacement or repair (at Nor-Cal’s option) of defective parts. Nor-Cal may at any time discharge its warranty as to any of

its products by refunding the purchase price and taking back the products. This warranty applies only to parts manufactured, and labor provided by Nor-Cal within the applicable warranty period and shall be

subject to the terms and conditions hereof.

Items such as O-rings, bearings, pins, bellows, etc., by their nature,

may not function for one year due to process induced contamination

and/or continual cycling; if such items fail to give reasonable service

for a reasonable period of time, as determined solely by Nor-Cal, they

will be repaired or replaced by Nor-Cal at its election.

All warranty replacement or repair of parts shall be limited to equipment malfunctions which, in the sole opinion of Nor-Cal, are due or

traceable to defects in original materials or workmanship. Malfunctions caused by abuse or neglect of the equipment are expressly not

covered by this warranty. Nor-Cal expressly disclaims responsibility

for any loss or damage caused by the use of its products other than in

accordance with proper operating and safety procedures. Reasonable

care must be taken by the user to avoid hazards. In-warranty repaired or

replaced parts are warrantied only for the remainder unexpired portion

of the original warranty period applicable to the parts which have been

repaired or replaced.

3

Nor-Cal Products, Inc. • 1967 S. Oregon St., Yreka, CA 96097 • 800-824-4166 or 530-842-4457 • FAX 530-842-9130 • ncsales@n-c.com • Web: www.n-c.com

Page 4

OPERATOR'S MA N U AL

© Nor-Cal Products, Inc., POPV-LIT 6/08

Repair Kits

Nom

ID

3

/8" VSB ESVP-075-95 O-Ring Kit

1

/2" VSB ESVP-075-95 O-Ring and Gasket Kit

3

/4" VSB ESVP-075-95 O-Ring Kit ESVP-075, ESVP-075T, ILVP-075,

1" VSB ESVP-075-95 O-Ring Kit ESVP-100, ESVP-100T, ILVP-100

1 1/2" VSB ESVP-150-95 O-Ring Kit ESVP-150, ESVP-150T, ILVP-150

2" VSB ESVP-200-95 O-Ring Kit ESVP-200, ESVP-200T, ILVP-200

Bonnet

Type

CSB CSVP-075-95 O-Ring and Gasket Kit

CSB CSVP-075-95 O-Ring and Gasket Kit

CSB CSVP-075-95 O-Ring and Gasket Kit

CSB CSTVP-075-95 O-Ring and Gasket Kit

CSB CSVP-075-95 O-Ring and Gasket Kit

CSB CSTVP-075-95 O-Ring & Gasket Kit

CSB CSVP-150-95 O-Ring and Gasket Kit

CSB CSTVP-150-95 O-Ring and Gasket Kit

CSB CSVP-200-95 O-Ring and Gasket Kit

Kit

Part No.

ESV-075-16K Bellows Assembly ESVP-038, ESVP-038T and ILVP-038

ESVP-075-99 Complete Rebuild Kit

CSV-075-16K Bellows Assembly CSVP-038, CSVP-038T and CILVP-038

CSVP-075-99 Complete Rebuild Kit

ESV-075-16K Bellows Assembly ESVP-050, ESVP-050T and ILVP-050

ESVP-075-99 Complete Rebuild Kit

CSV-075-16K Bellows Assembly CSVP-050, CSVP-050T, and CILVP-050

CSVP-075-99 Complete Rebuild Kit

ESV-075-16K Bellows Assembly AIVP-075, and STVP-075

ESVP-075-99 Complete Rebuild Kit

CSV-075-16K Bellows Assembly CSVP-075, CSVP-075T, and CILVP-075

CSVP-075-99 Complete Rebuild Kit

CSV-075-16K Bellows Assembly CSTVP-075

CSTVP-075-99 Complete Rebuild Kit

ESV-075-16K Bellows Assembly and AIVP-100

ESVP-075-99 Complete Rebuild Kit

CSV-075-16K Bellows Assembly CSVP-100, CSVP-100T and CILVP-100

CSVP-075-99 Complete Rebuild Kit

CSV-075-16K Bellows Assembly CSTVP-100

CSTVP-075-99 Complete Rebuild Kit

ESV-150-16K Bellows Assembly and AIVP-150

ESVP-150-99 Complete Rebuild Kit

CSV-150-16K Bellows Assembly CSVP-150, CSVP-150T and CILVP-150

CSVP-150-99 Complete Rebuild Kit

CSTVP-150-16K Bellows Assembly CSTVP-150

CSTVP-150-99 Complete Rebuild Kit

ESV-200-16K Bellows Assembly and AIVP-200

ESVP-200-99 Complete Rebuild Kit

CSVP-200-16K Bellows Assembly CSVP-200, CSVP-200T and CILVP-200

CSVP-200-99 Complete Rebuild Kit

For Valve Model NumbersDescription

4

Nor-Cal Products, Inc. • 1967 S. Oregon St., Yreka, CA 96097 • 800-824-4166 or 530-842-4457 • FAX 530-842-9130 • ncsales@n-c.com • Web: www.n-c.com

Loading...

Loading...