Page 1

Chapter 4: Acceptance Test Procedures

Table of Contents

Automated Acceptance Test Procedure 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reduced ATP 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Test Options 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Prerequisites 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX/RX Antenna Connections 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acceptance Tests – Test Set–up 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Test Equipment 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acceptance Test Equipment Set–up 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviated (All–inclusive) Acceptance Tests 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . .

All–inclusive Tests 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All TX/RX ATP Test 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All TX ATP Test 4-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All RX ATP Test 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Individual Acceptance Tests 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX and TX Testing 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Individual Tests 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Spectral Purity Transmit Mask Acceptance Test 4-13 . . . . . . . . . . . . . . . . . . . . .

Background 4-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spectral Purity TX Mask Acceptance Test 4-14 . . . . . . . . . . . . . . . . . . . . . .

TX Waveform Quality (Rho) Acceptance Test 4-16 . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 4-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Waveform Quality (Rho) Acceptance Test 4-16 . . . . . . . . . . . . . . . . . . . . . .

TX Pilot Time Offset Acceptance Test 4-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 4-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pilot Time Offset Acceptance Test 4-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Code Domain Power/Noise Floor Acceptance Test 4-20 . . . . . . . . . . . . . . . . . . .

Background 4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Code Domain Power/Noise Floor Test 4-21 . . . . . . . . . . . . . . . . . . . . . . . . .

RX FER Acceptance Test 4-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 4-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FER Acceptance Test 4-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generating an ATP Report 4-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 4-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Report 4-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP

PRELIMINARY

Page 2

Table of Contents – continued

Updating Calibration Data Files 4-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Release Caveats 4-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy and Load Cal File to the CBSC 4-26 . . . . . . . . . . . . . . . . . . . . . . . . . .

4

1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 3

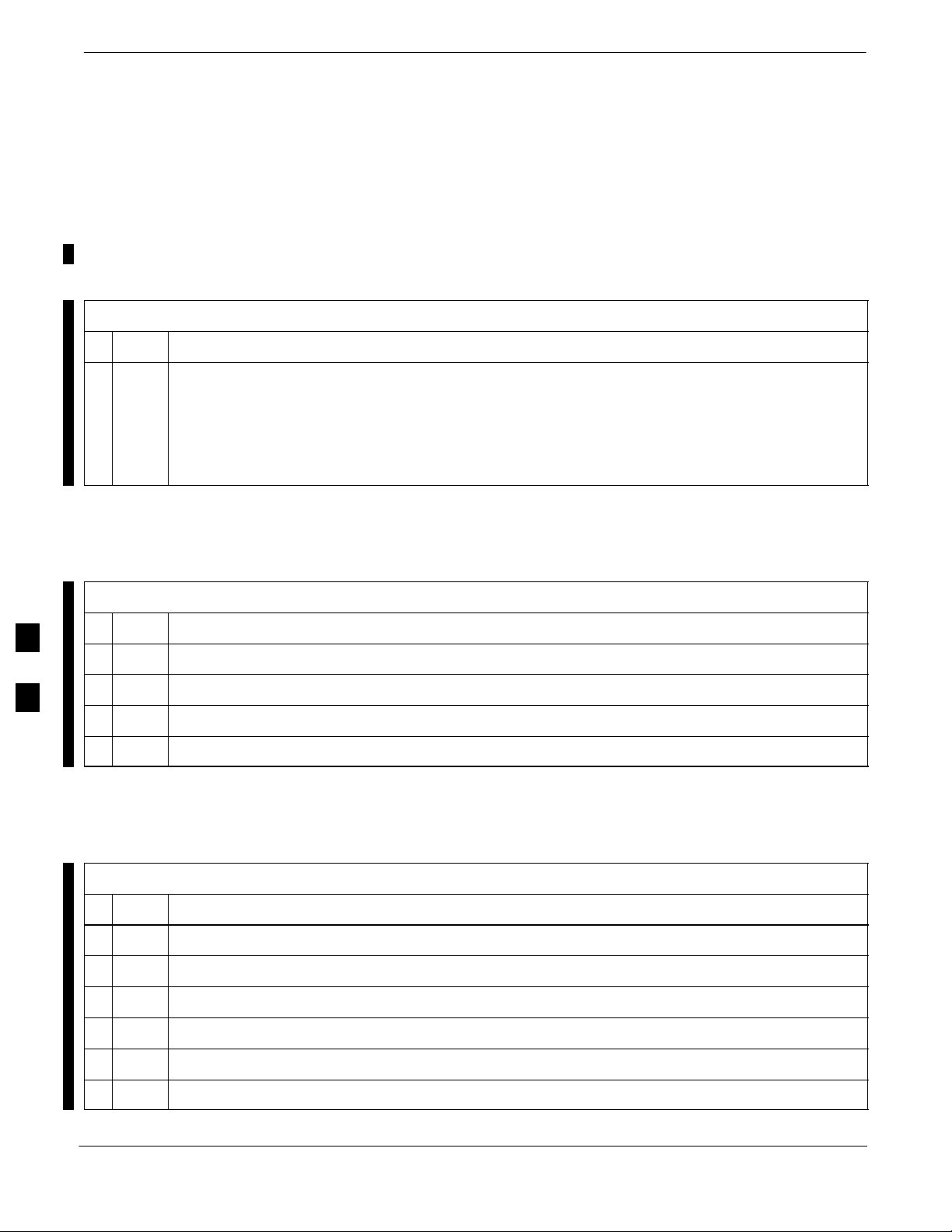

Automated Acceptance Test Procedure

Introduction

The Acceptance Test Procedures (ATP) allow Cellular Field Engineers

(CFEs) to run automated Acceptance Tests on all BTS Subsystem

Devices equipped in the CDF using the LMF and the Test Equipment it

supports.

The CFE can choose to save the results of ATP Tests to a report file from

which ATP Reports are generated for later printing. See the Generating

an ATP Report section in this chapter.

Because Test Equipment Functions during Acceptance Testing are

controlled by the LMF through the GPIB, only the Test Equipment

Models supported by the LMF can be used.

NOTE

– Before using the LMF, read the Release Notes

“Caveats” section in the WinLMF On-Line Help

SR2.16.x for any applicable information.

– The ATP Test is to be performed on out-of-service

sectors only.

– DO NOT substitute Test Equipment with other

models not supported by the LMF.

4

Reduced A TP

Refer to Chapter 3 for detailed interconnection information needed for

calibrating equipment, cables, and other Test Equipment Set

components.

NOTE

Equipment has been factory–tested for FCC Compliance.

If license–governing bodies require documentation

supporting BTS Site Compliance with regulations, a full

ATP may be necessary.

Perform the Reduced ATP only if reports for the specific

BTS Site are NOT required.

After downloading the proper operational software to the BTS, the CFE

must perform these procedures (minimum recommendation):

1. Verify that the TX/RX Paths by performing TX Calibration, TX

Audit, and FER Tests.

2. Retrieve Calibration Data required for normal site operation.

Should failures occur while performing the specified tests, refer to the

Basic Troubleshooting section of this manual for help in determining the

failure point. Once the point of failure has been identified and corrected,

refer to the BTS Optimization and ATP Test Matrix (Table C-1) to

determine the applicable test that must be performed.

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-1

PRELIMINARY

Page 4

Automated Acceptance Test Procedure – continued

In the unlikely event that the BTS passes these tests but has a Forward

Link problem during normal operation, the CFE should then perform the

additional TX Tests for troubleshooting: TX Spectral Mask, TX Rho,

and TX Code Domain.

ATP Test Options

ATP Tests can be run individually or as one of the following groups:

S All TX: TX Tests verify that the performance of the BTS Transmit

Elements. These include the GLI, MCC, BBX, Trunking Modules, the

LPA Modules, and passive components including Splitters,

Combiners, Bandpass Filter(s), and RF Cables.

S All RX: The RX Test verifies the performance of the BTS Receive

4

Elements. These include the MPC, EMPC (for Companion Frames),

BBX, MCC, GLI Cards, and the passive components including RX

Filters and RF Cables.

S All TX/RX: Executes all TX and RX Tests.

ATP Prerequisites

S Full Optimization: Executes the TX Calibration, downloads BLO,

and executes the TX Audit before running all TX and RX Tests.

Before attempting to run any ATP Tests, ensure that the following have

been completed:

S BTS has been optimized (BBX Cards calibrated and BLOs

downloaded) (Chapter 3)

S The carrier(s) and/or sector(s) to be tested have been taken out of

service at the CBSC.

S LMF is logged into the BTS.

S CSM Cards, GLI Cards, BBX Cards, MCC Cards and TSU (if the

RFDS is installed) have correct code and Data Loads.

S Primary CSM and GLI are INS_ACTIVE (bright green).

S MCC Cards are INS_ACTIVE (bright green).

S No BBX Cards are keyed (transmitting).

S BBX Cards are OOS_RAM (yellow).

S Test Cables are calibrated.

S Test Equipment has been selected, warmed–up 60 minutes, and

calibrated.

S GPIB is on.

S BTS Transmit Connectors are properly terminated for the test(s) to be

performed.

4-2 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 5

Automated Acceptance Test Procedure – continued

WARNING

1. All Transmit Connectors must be properly terminated

for all ATP Tests.

2. Before the FER is run, make sure that one of the

following is done:

– All transmitter Connectors are properly terminate

OR

– All LPA Modules are turned OFF (circuit breakers

pulled)

Failure to observe these warnings may result in bodily

injury or equipment damage.

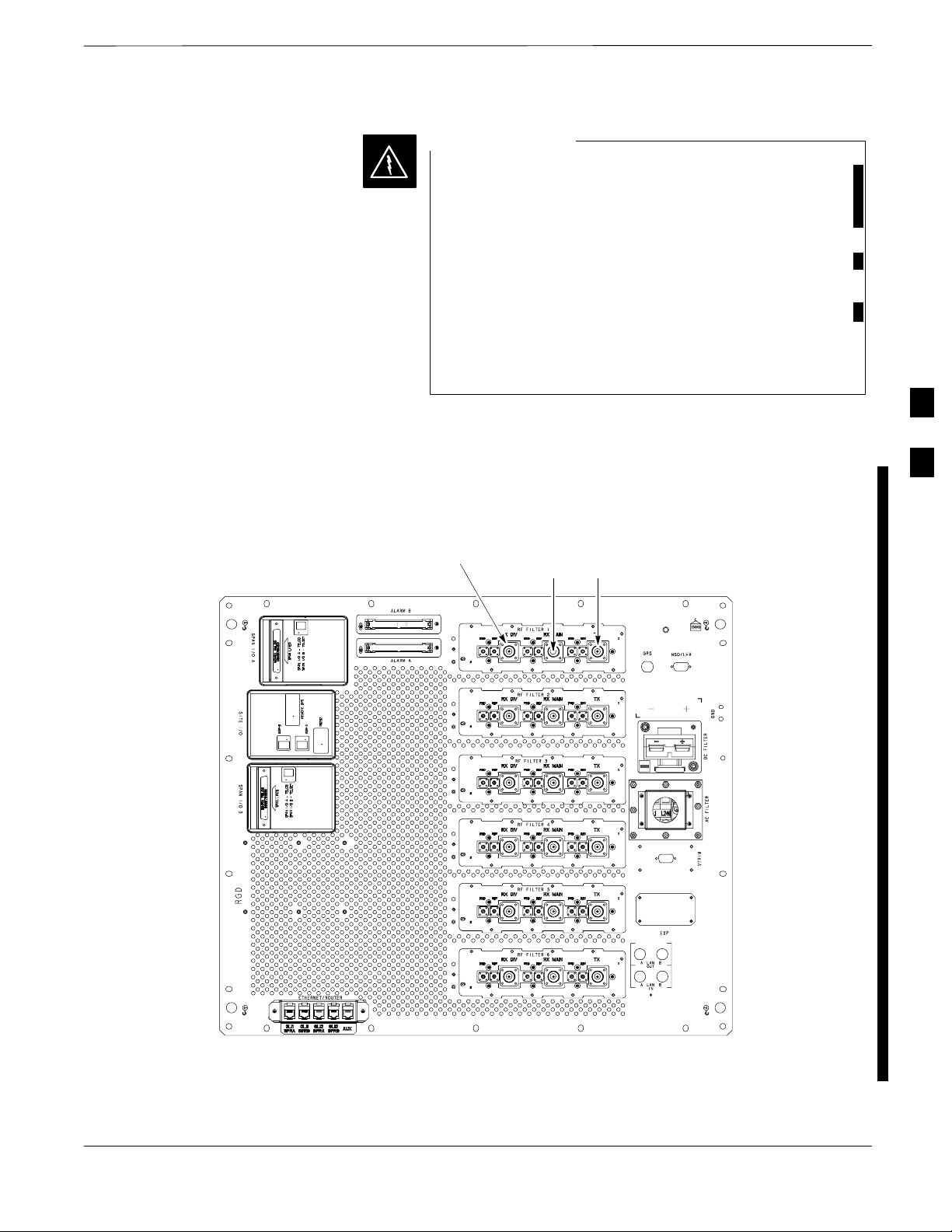

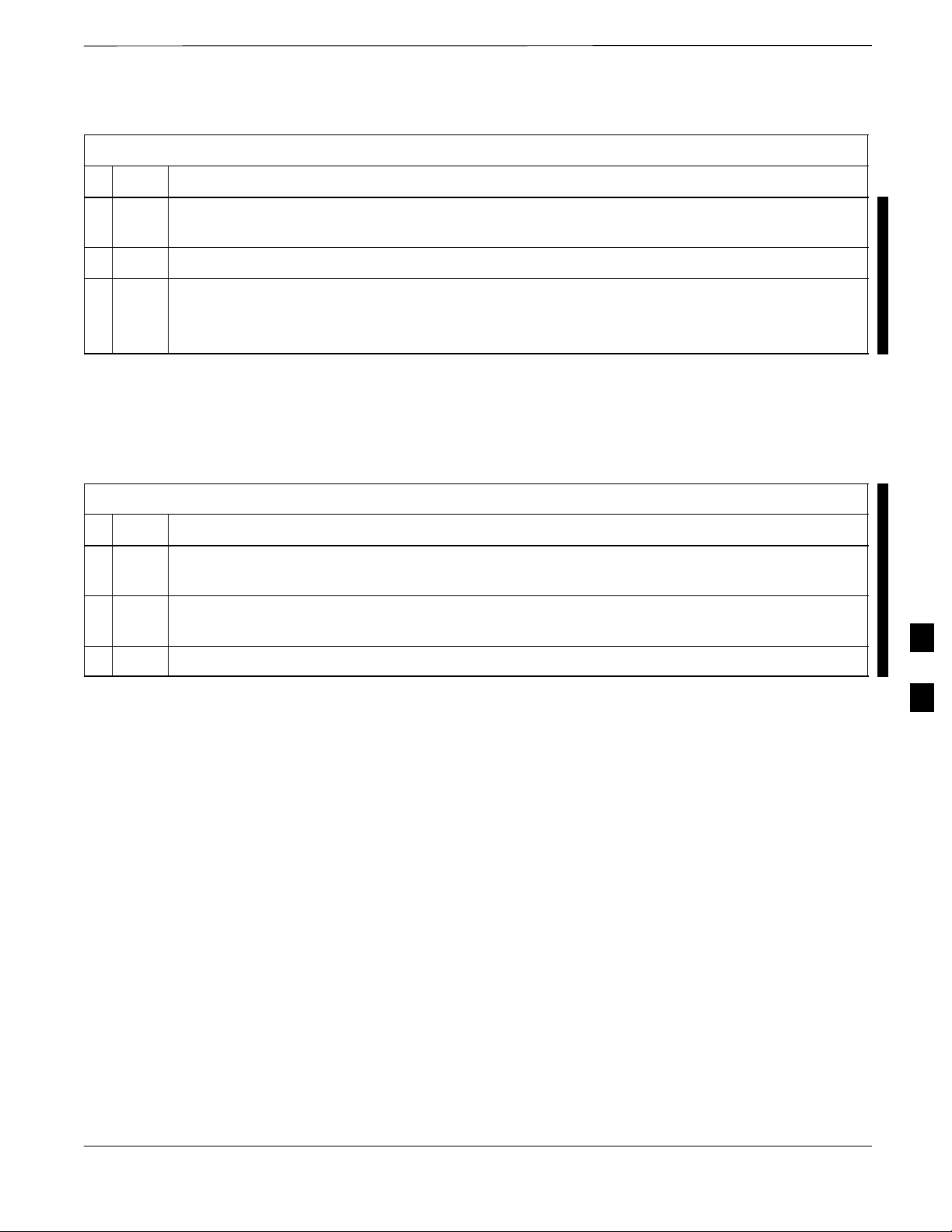

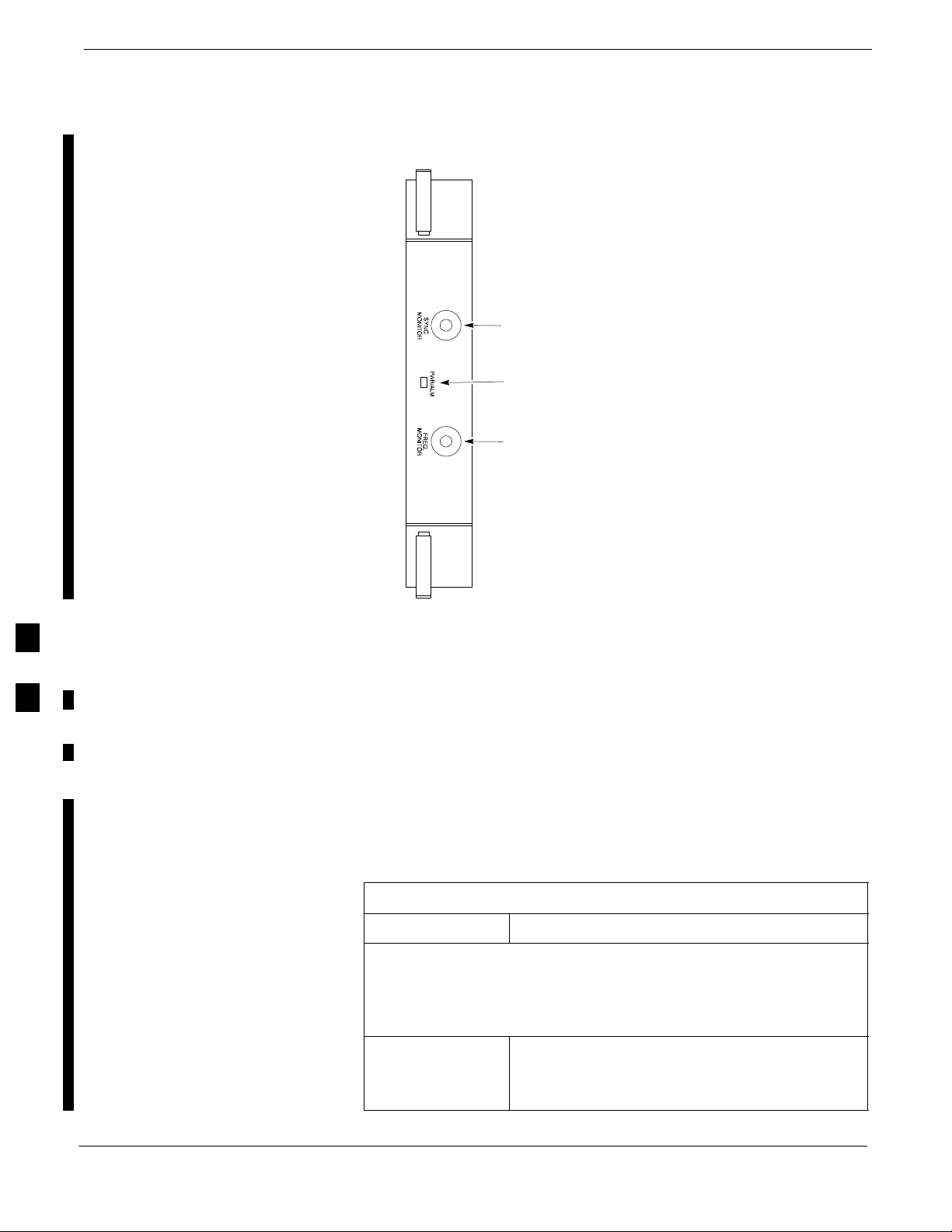

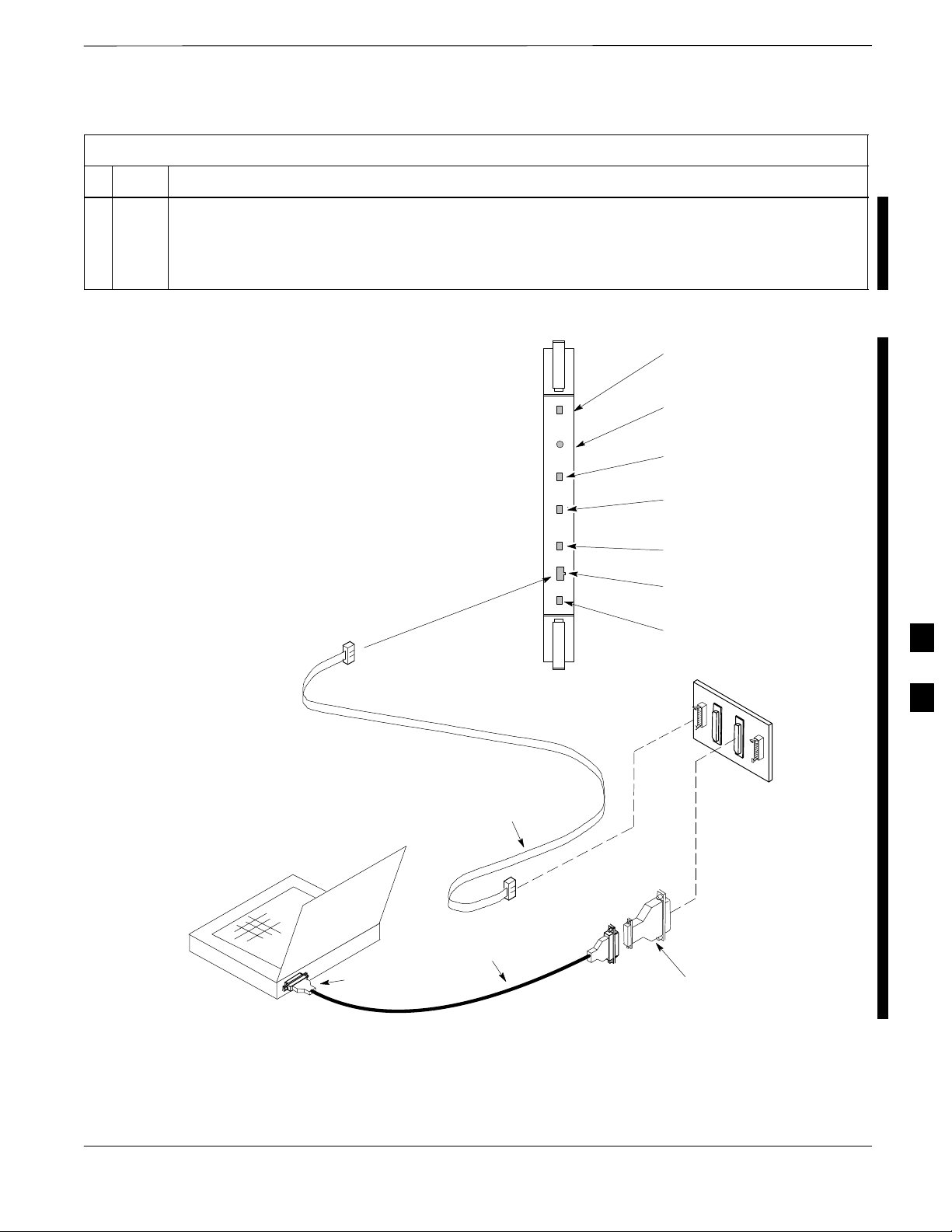

TX/RX Antenna Connections

Figure 4-1 identifies the Frame Transmit and Receive Antenna

Connections where measurements are to be taken.

Figure 4-1: TX and RX Antenna Connections on I/O Panel

RX DIV RX MAIN on TRF

REAR

Not Used on DRF

4

TX on TRF or

TX/RX MAIN on DRF

FRONT

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-3

ti-CDMA-WP-00214-v01-ildoc-ftw REF

PRELIMINARY

Page 6

Acceptance Tests – Test Set–up

Required T est Equipment

The following Test Equipment is required:

S LMF

S Power Meter (used with HP 8921A/600 and Advantest R3465)

S Communications System Analyzer

S Signal Generator for FER Testing (required for all Communications

System Analyzers for 1X FER)

WARNING

– Before installing any Test Equipment directly to any

BTS TX OUT Connector, verify that there are no

4

CDMA Channels keyed.

– At active sites, have the OMC–R/CBSC place the

carrier assigned to the LPA Modules under test OOS.

Failure to do so can result in serious personal injury

and/or equipment damage.

Acceptance T est Equipment

Set–up

NOTE

The Test Equipment must be re–calibrated before using it

to perform the TX Acceptance Tests.

All ATP Testing

Perform the procedure in Table 4-1 to Set–up Test Equipment for all

tests..

4-4 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 7

Acceptance Tests – Test Set–up – continued

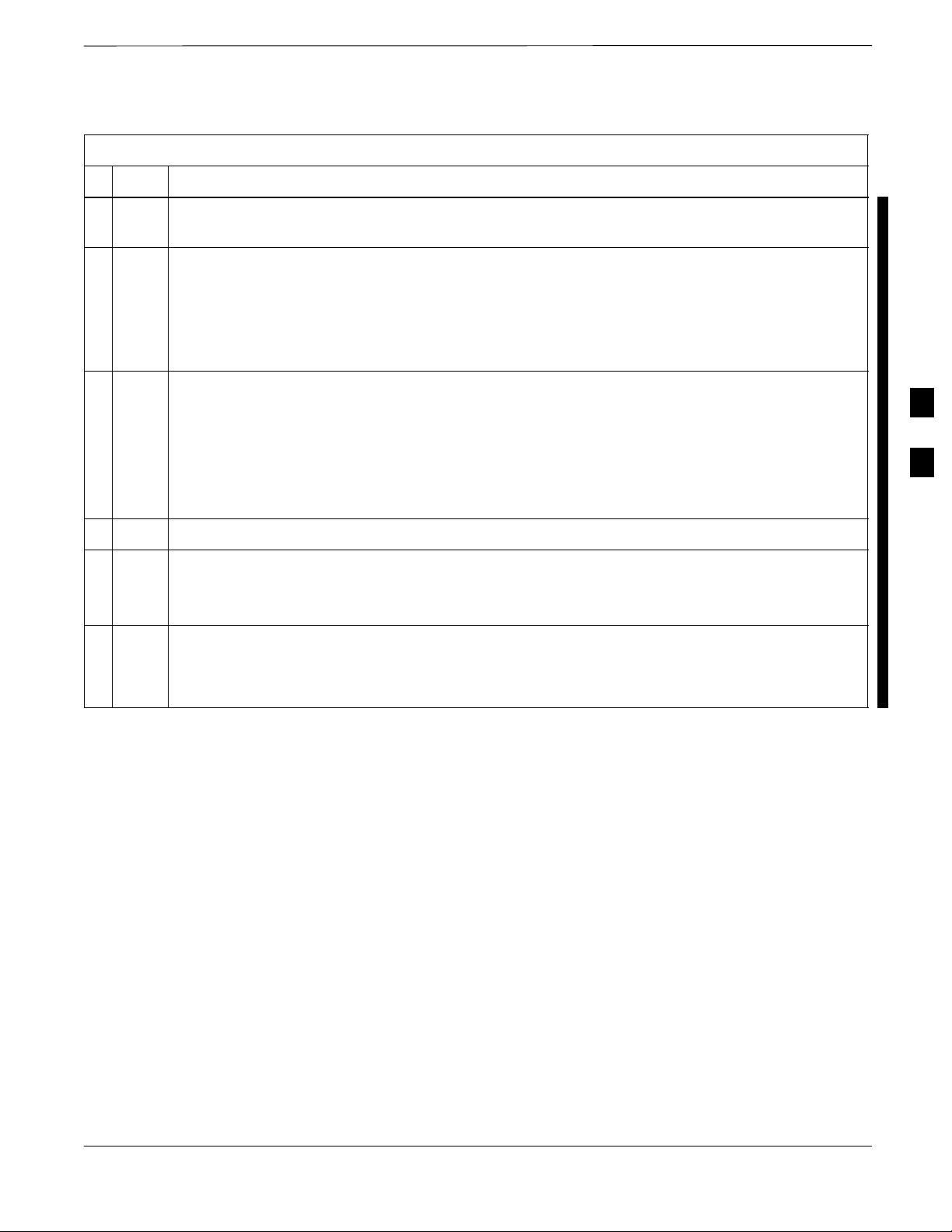

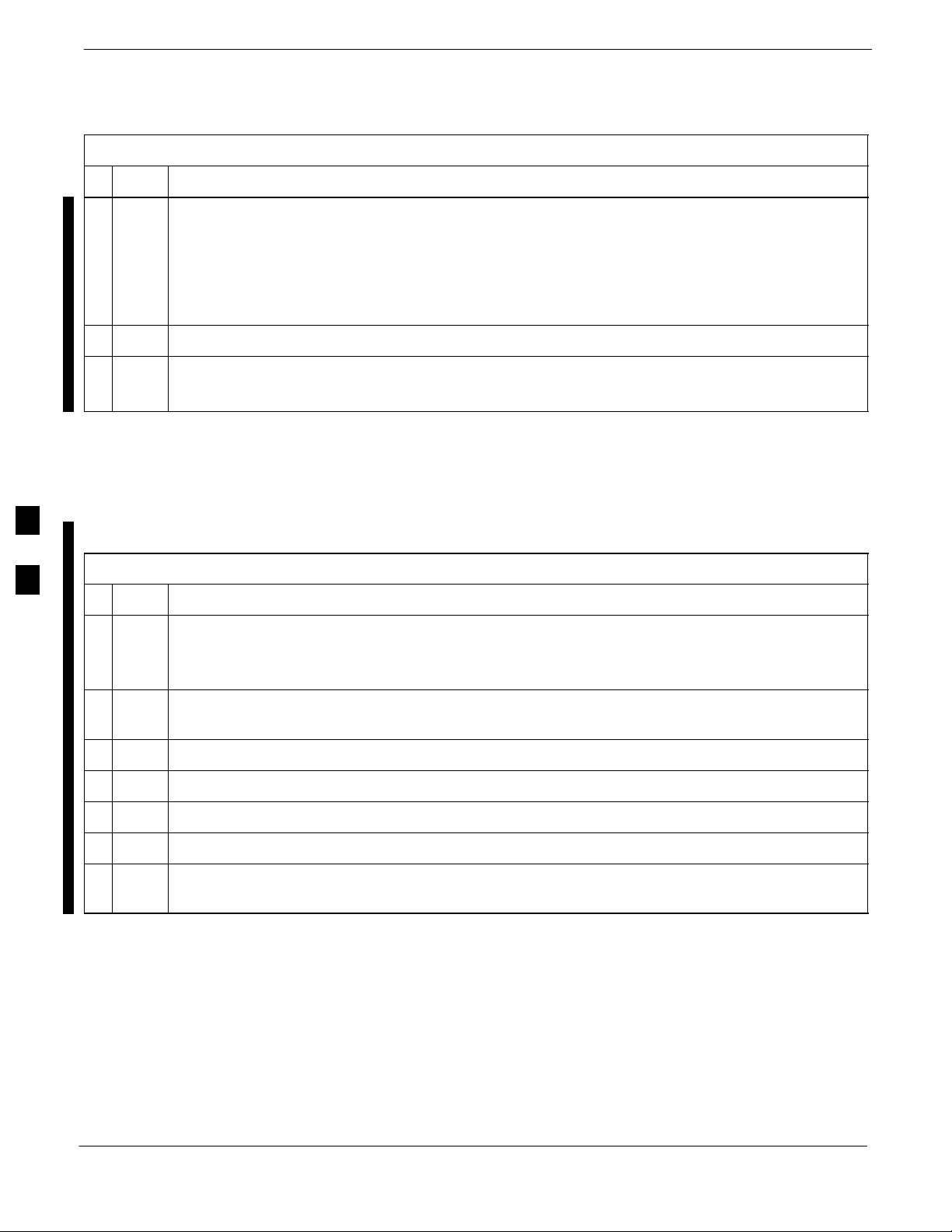

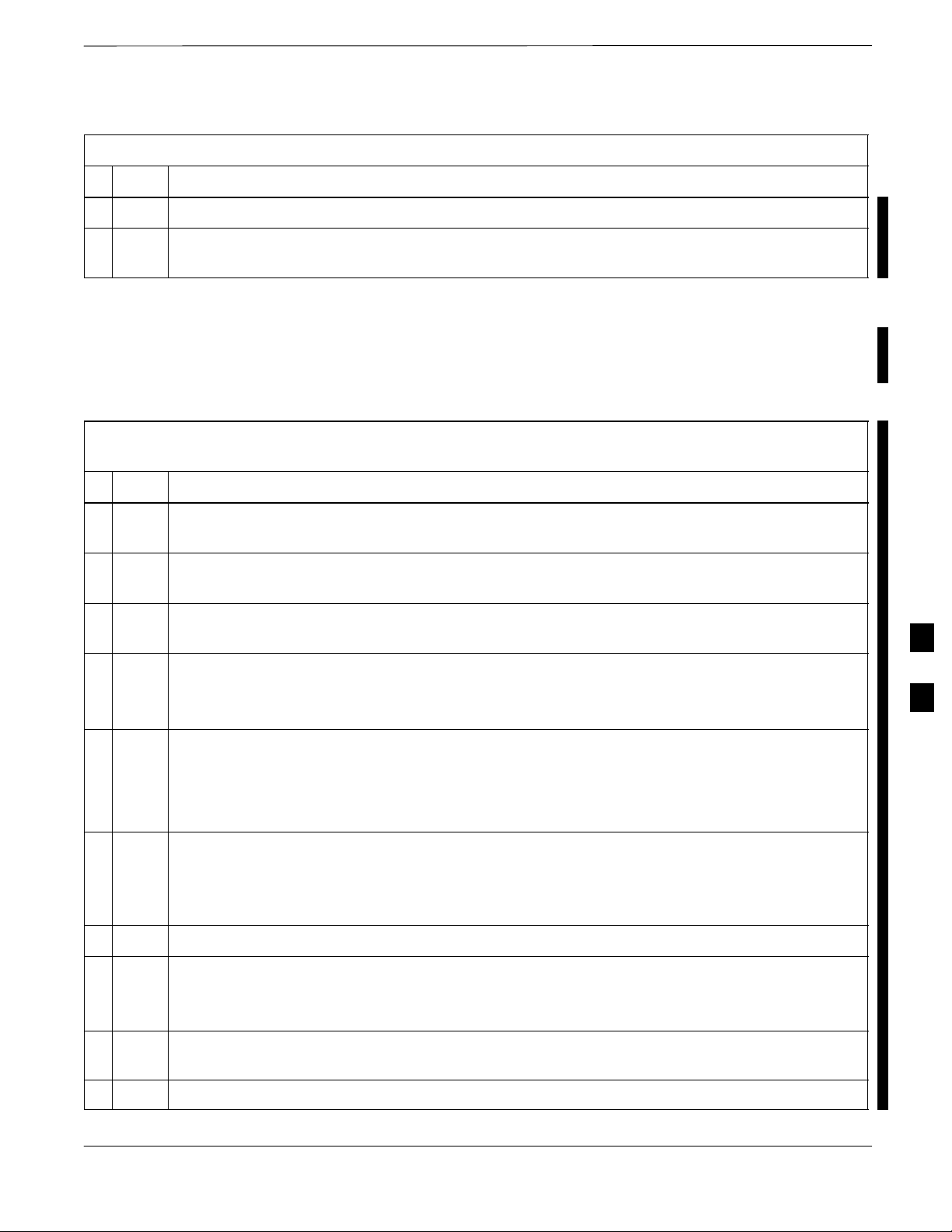

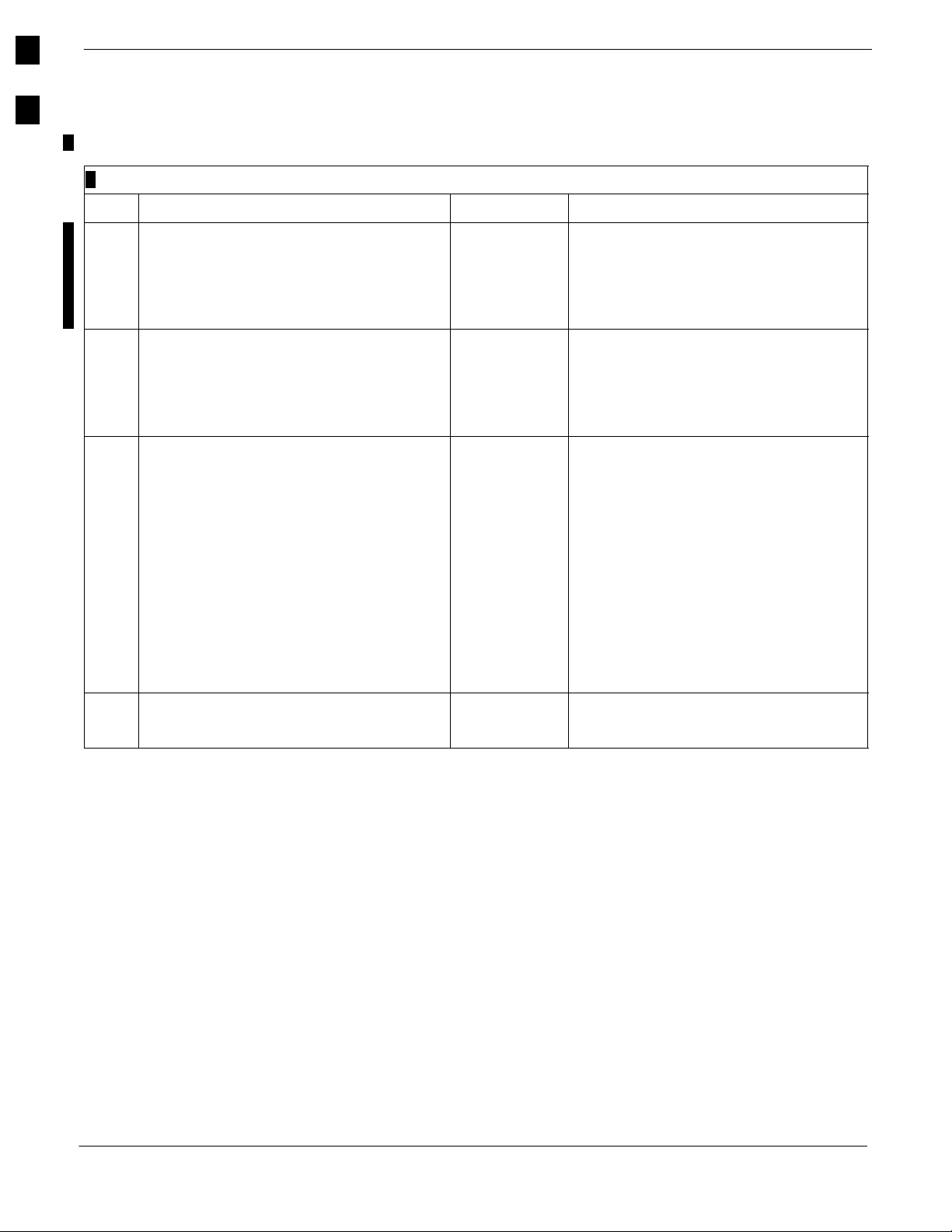

Table 4-1: Set–up Test Equipment – TX Output Verify/Control Tests Procedure

n Step Action

1 If it has not already been done, interface the LMF Computer to the BTS.

– Refer to Table 3-6 and Figure 3-3.

2 If it has not already been done, start a GUI LMF Session and log into the BTS.

– Refer to Table 3-10.

3 If it has not already been done, connect Test Equipment for Acceptance Testing.

– Refer to Figure 3-20, Figure 3-21, Figure 3-22, Figure 3-23, Figure 3-24, or Figure 3-25, as

applicable, for the Test Equipment and Antenna Duplexing being used.

* IMPORTANT

LMF–based Measurements factor into TX Test Test Cable Insertion Loss between the RF Modem

Frame and Test Equipment.

If additional attenuation, such as external TX Combiners, is inserted in the path, it must be

identified to the LMF by including it in the TX Test Cable Calibration.

– If this is not possible, include the attenuation in the TX Path by editing Test Cable Insertion

Loss Values (refer to Table 3-35).

– Failure to do this will result in test inaccuracies and potential for erroneous ATP failures

because the additional losses would not be compensated for in the test measurements.

4

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-5

PRELIMINARY

Page 8

Abbreviated (All–inclusive) Acceptance Tests

All–inclusive Tests

General

The all–inclusive Acceptance Tests are performed from the LMF GUI

Environment. These all–inclusive tests are called abbreviated ATPs

because they execute various combinations of individual Acceptance

Tests with a single command. This allows verification of multiple

aspects of BTS performance while minimizing time needed for

individual Test Set–up and initiation.

Abbreviated ATP Options

There are three abbreviated Acceptance Tests that evaluate different

performance aspects of the BTS. This allows the CFE to select testing to

4

meet the specific requirements for individual Maintenance and

Performance Verification situations. The following items summarize the

coverage of each Abbreviated Test.:

S All TX/RX: Performs all transmit and receive ATPs on the selected

MCC Cards and BBX Cards.

S All TX: Performs complete set of transmit ATPs on the selected MCC

Cards and BBX Cards. Testing is the equivalent of performing all of

the following individual tests:

– TX Mask Test

– Rho Test

– Pilot Time Offset Test

– Code Domain Power Test

S All RX: Performs complete Receive ATP on the selected MCC Cards

and BBX Cards. Testing is the equivalent of performing the FER Test.

Abbreviated Acceptance Test Procedures

Procedures to accomplish each type of Abbreviated ATP are included in

the following subsections..

All TX/RX A TP Test

Perform the procedure in Table 4-2 to perform the Abbreviated,

All–inclusive Transmit And Receive Test.

Table 4-2: All TX/RX Acceptance Test Procedure

n Step Action

1 Set–up the Test Equipment initially for Abbreviated Tests as described in Table 4-1.

NOTE

If the LMF has been logged into the BTS with a different Multi–Channel Preselector setting than

the one to be used for this test, the LMF must be logged out of the BTS and logged in again with

the new Multi–Channel Preselector setting.

– Using the wrong MPC Setting can cause a false test failure.

table continued on next page

4-6 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 9

Abbreviated (All–inclusive) Acceptance Tests – continued

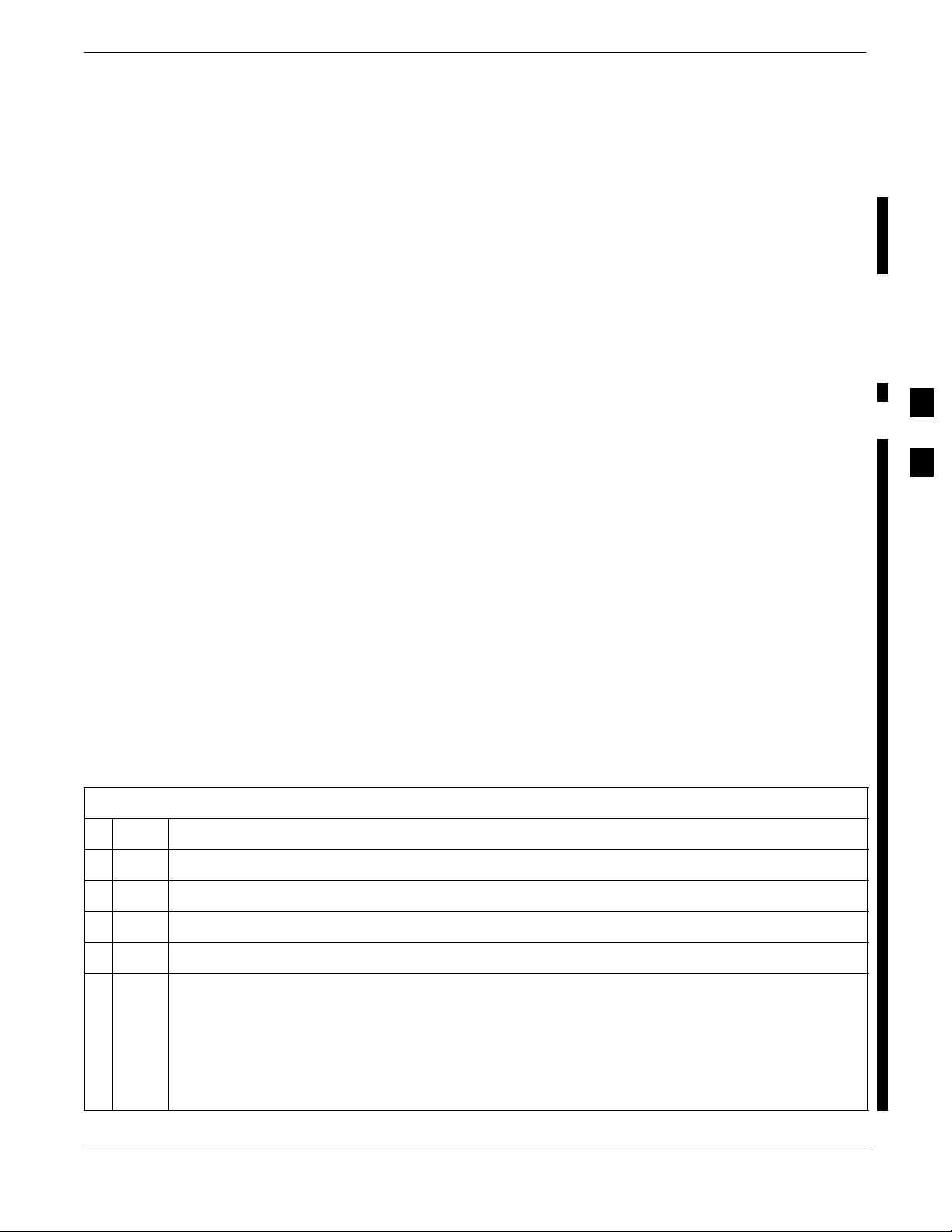

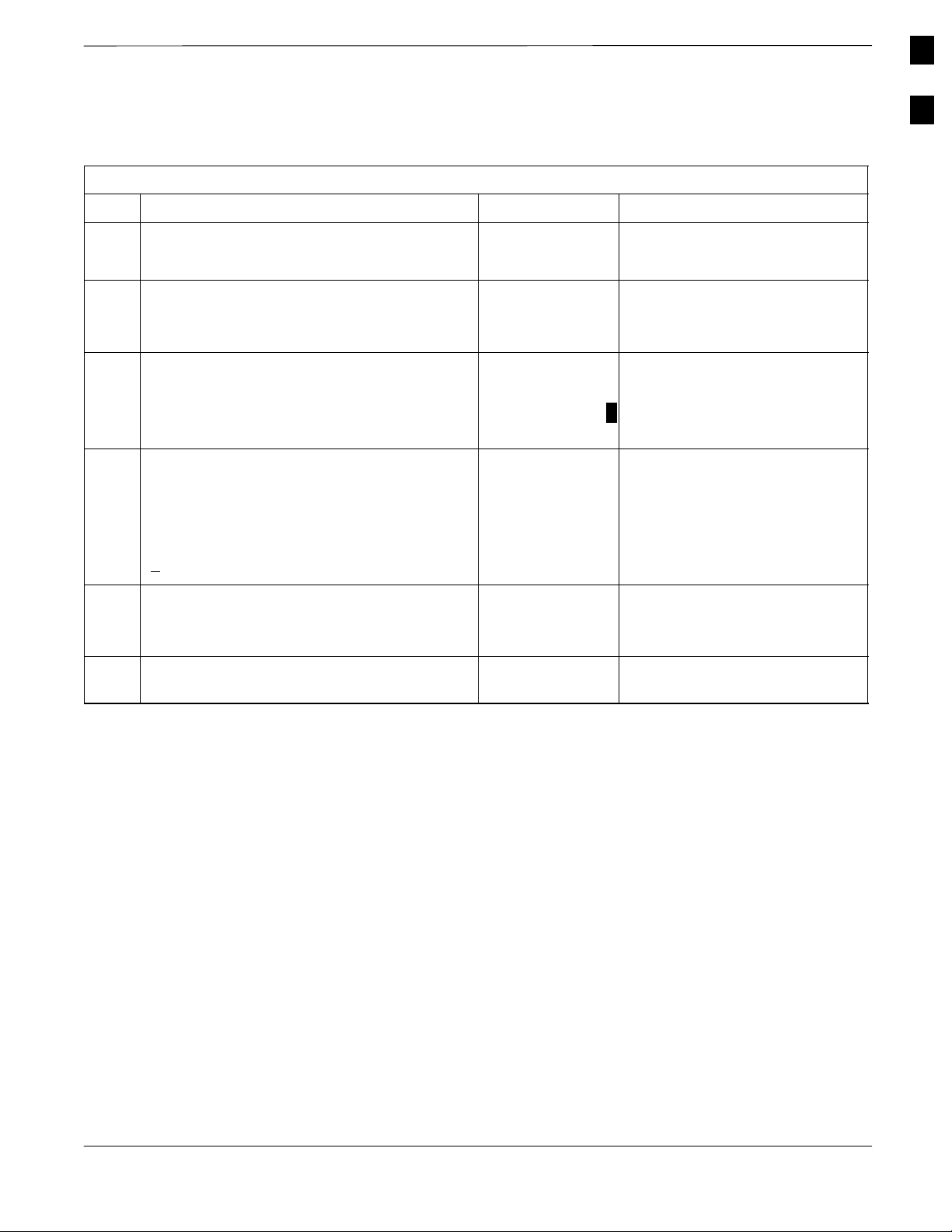

Table 4-2: All TX/RX Acceptance Test Procedure

n ActionStep

2 Select the BBX Cards and MCC Cards to be tested.

3 Click on Tests in the BTS Menu Bar, and select All TX/RX ATP... from the Pull–down Menu.

4 Select the appropriate carrier(s) and sector(s) (carrier-bts#-sector#-carrier#) from those displayed

in the Channels/Carrier Pick List.

NOTE

To select multiple items, hold down the Shift or Ctrl Key while clicking on Pick List Items to

select multiple carrier(s)–sector(s).

5 Verify that the correct Channel Number for the selected carrier is shown in the Carrier #

Channels Box.

– If it is not, obtain the latest bts–#.cdf (or bts–#.necf) and cbsc–#.CDF Files from the CBSC.

NOTE

If necessary, the correct Channel Number may be manually entered into the Carrier # Channels

Box.

4

6 Select the appropriate RX Branch (BOTH, MAIN, or DIVersity) in the Pull–down Menu.

* IMPORTANT

The RX Main and Diversity Paths must be tested separately for this configuration because each

requires a different Multi–Coupler Preselector type to provide the proper Test Signal Gain.

NOTE

If a Companion Frame with the Inter–frame Diversity RX Cabling disconnected is being tested do

not select BOTH in this step.

7 In the Rate Set Box, select the appropriate Data Rate (1=9600 3=9600 1X) from the Pull–down

Menu.

NOTE

The Rate Set selection of 3 is only available if 1X Cards are selected for the test.

8 Enter the Channel Elements to be tested for the RX ATP in the Channel Element(s) Box.

– By default, all Channel Elements are specified.

– The Channel Element Numbers are 0.based; therefore, the first Channel Element is 0.

NOTE

Use one of the following methods to enter more than one Channel Element:

– Enter non–sequential Channel Elements separated by a comma and no spaces (for example;

0,5,15).

– Enter a range of sequential Channel Elements by typing the first and last Channel Elements

separated by two periods (for example; 0..15).

table continued on next page

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-7

PRELIMINARY

Page 10

Abbreviated (All–inclusive) Acceptance Tests – continued

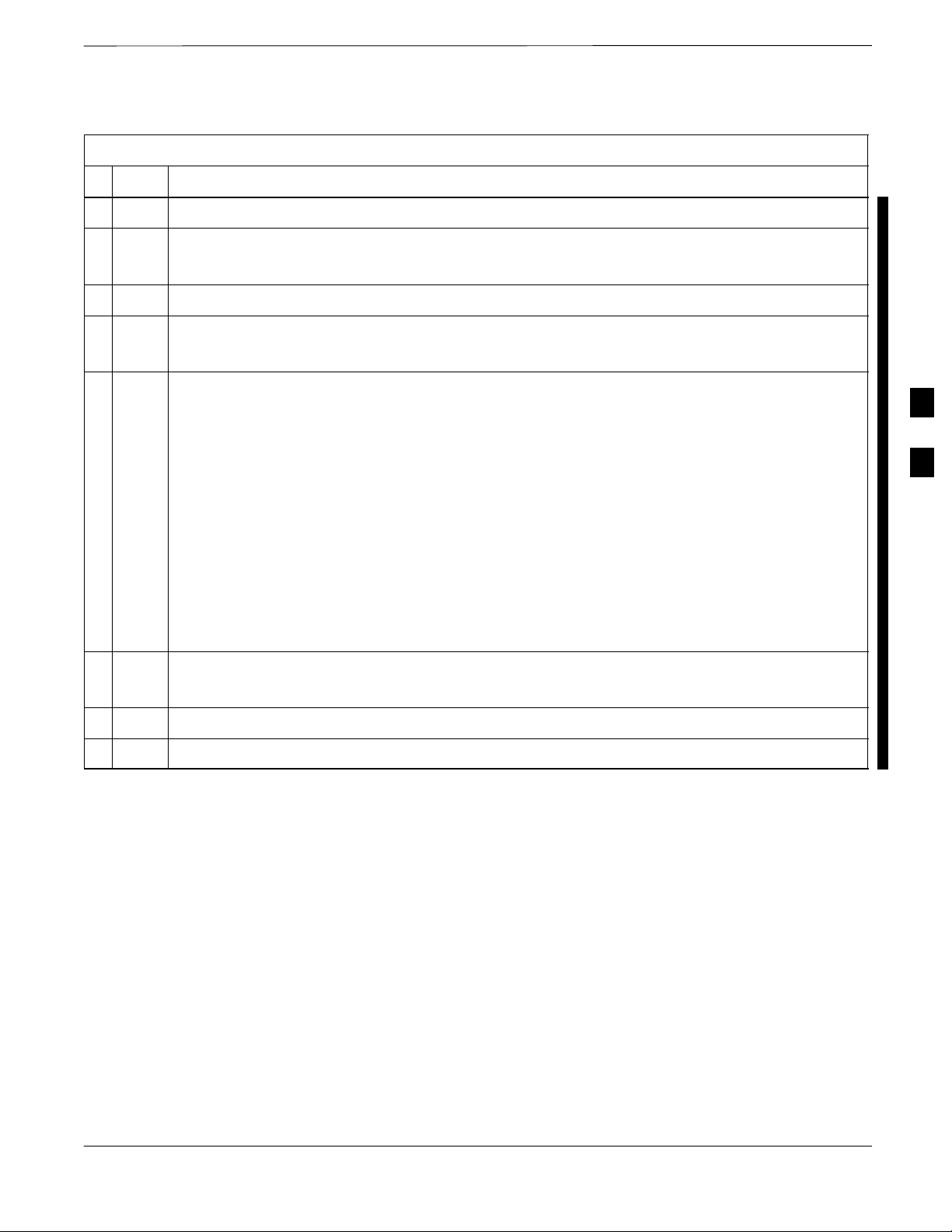

Table 4-2: All TX/RX Acceptance Test Procedure

n ActionStep

9 In the Test Pattern Box, select the Test Pattern to use for the Acceptance Tests from the

Pull–down Menu.

– Refer to “Test Pattern Drop–down Pick List” under “TX Calibration and the LMF” in the Bay

Level Offset Calibration section of Chapter 3.

10 Click OK to display a Status Bar followed by a Directions Pop–up Window.

11 Execute the Cable Connection Directions as they are displayed, and click the Continue Button to

begin testing.

– As the ATP Process is completed, results will be displayed in the Status Report Window.

12 Click either the Save Results Button or the Dismiss Button.

4

* IMPORTANT

If Dismiss is used, the test results will not be saved in the Test Report File.

All TX ATP Test

Perform the procedures in Table 4-3 to perform the Abbreviated,

All–inclusive Transmit Test.

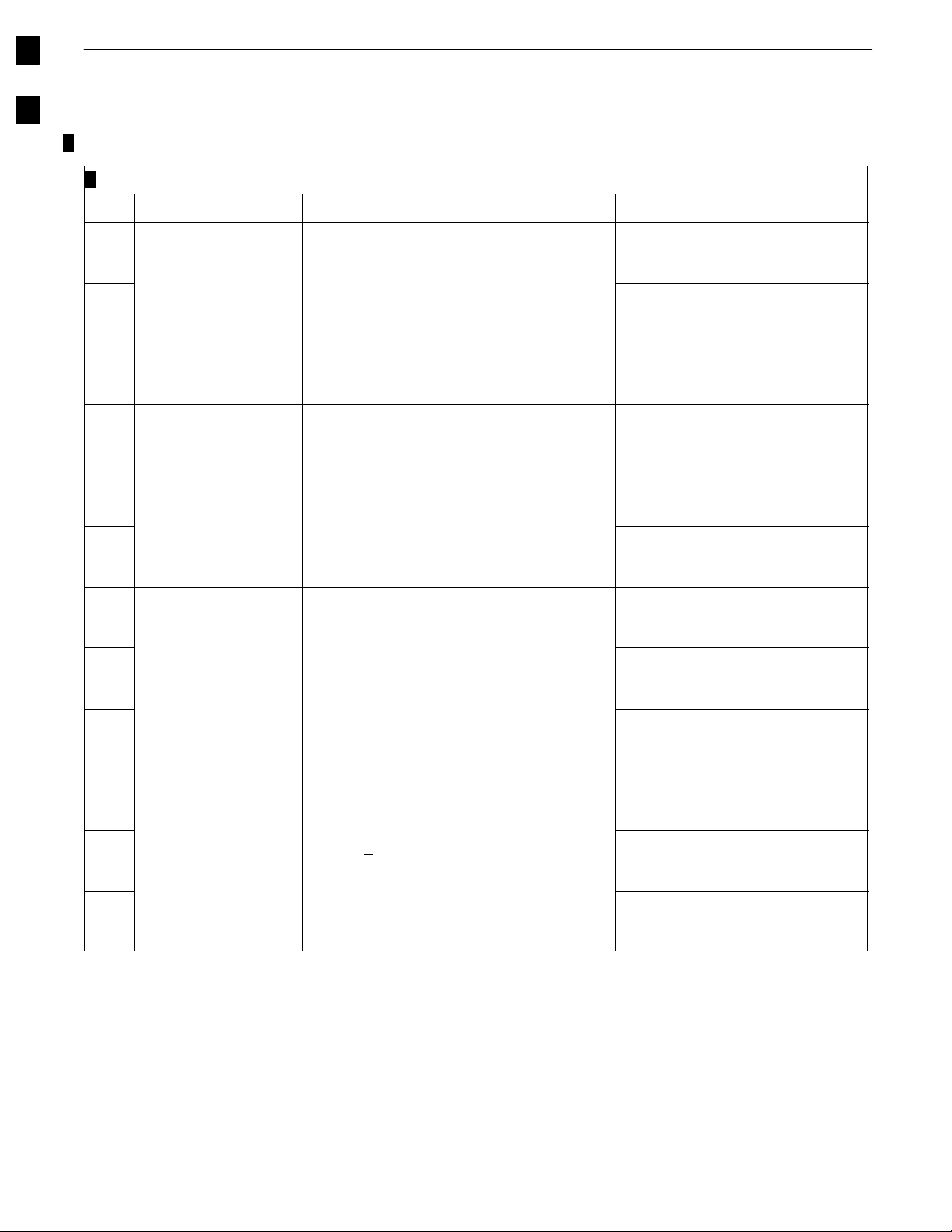

Table 4-3: All TX Acceptance Test Procedure

n Step Action

1 Set–up the Test Equipment for Abbreviated Tests per Table 4-1.

2 Select the BBX Cards and MCC Cards to be tested.

3 Click on Tests in the BTS Menu Bar, and select All TX ATP... from the Pull–down Menu.

4 Select the appropriate carrier(s) and sector(s) (carrier-bts#-sector#-carrier#) from those displayed

in the Channels/Carrier Pick List.

NOTE

To select multiple items, hold down the Shift or Ctrl Key while clicking on Pick List Items to

select multiple carrier(s)–sector(s).

5 Verify that the correct Channel Number for the selected carrier is shown in the Carrier #

Channels Box.

– If it is not, obtain the latest bts–#.cdf (or bts–#.necf) and cbsc–#.CDF Files from the CBSC.

NOTE

If necessary, the correct Channel Number may be manually entered into the Carrier # Channels

Box.

table continued on next page

4-8 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 11

Abbreviated (All–inclusive) Acceptance Tests – continued

Table 4-3: All TX Acceptance Test Procedure

n ActionStep

6 In the Rate Set Box, select the appropriate Transfer Rate (1 = 9600, 3 = 9600 1X) from the

Pull–down Menu.

NOTE

The Rate Set Selection of 3 is only available if 1X Cards are selected for the test.

7 In the Test Pattern Box, select the Test Pattern to use for the Acceptance Test from the Pull–down

Menu.

– Refer to “Test Pattern Drop–down Pick List” under “TX Calibration and the LMF” in the Bay

Level Offset Calibration section of Chapter 3.

8 Click OK to display a Status Bar followed by a Directions Pop–up Window.

9 Execute the Cable Connection Directions as they are displayed, and click the Continue Button to

begin testing.

– As the ATP Process is completed, results will be displayed in the Status Report Window.

10 Click either the Save Results Button or the Dismiss Button.

4

* IMPORTANT

If Dismiss is used, the test results will not be saved in the Test Report File.

All RX A TP Test

Perform the procedure in Table 4-4 to perform the Abbreviated,

All–inclusive Receive Test.

Table 4-4: All RX Acceptance Test Procedure

n Step Action

1 Set–up the Test Equipment for Abbreviated Tests per Table 4-1.

NOTE

If the LMF has been logged into the BTS with a different Multi–Channel Preselector setting than

the one to be used for this test, the LMF must be logged out of the BTS and logged in again with

the new Multi–Channel Preselector setting.

– Using the wrong MPC Setting can cause a false test failure.

2 Select the BBX Cards and MCC Cards to be tested.

3 Click on Tests in the BTS Menu Bar, and select All RX ATP... from the Pull–down Menu.

4 Select the appropriate carrier(s) and sector(s) (carrier-bts#-sector#-carrier#) from those displayed

in the Channels/Carrier Pick List.

NOTE

To select multiple items, hold down the Shift or Ctrl Key while clicking on Pick List Items to

select multiple carrier(s)–sector(s).

table continued on next page

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-9

PRELIMINARY

Page 12

Abbreviated (All–inclusive) Acceptance Tests – continued

Table 4-4: All RX Acceptance Test Procedure

n ActionStep

5 Verify that the correct Channel Number for the selected carrier is shown in the Carrier #

Channels Box.

– If it is not, obtain the latest bts–#.cdf (or bts–#.necf) and cbsc–#.CDF Files from the CBSC.

NOTE

If necessary, the correct Channel Number may be manually entered into the Carrier # Channels

Box.

6 Select the appropriate RX Branch (BOTH, MAIN, or DIVersity) in the Pull–down Menu.

7 In the Rate Set Box, select the appropriate Data Rate (1=9600, 2=14400, 3=9600 1X) from the

Pull–down Menu.

4

NOTE

The Rate Set Selection of 1 is only available if non–1X Cards are selected for the test.

The Rate Set Selection of 3 is only available if 1X Cards are selected for the test.

8 Enter the Channel Elements to be tested for the RX ATP in the Channel Element(s) Box.

– By default, all Channel Elements are specified.

– The Channel Element Numbers are 0.based; that is the first Channel Element is 0.

NOTE

Use one of the following methods to enter more than one Channel Element:

– Enter non–sequential Channel Elements separated by a comma and no spaces (for example;

0,5,15).

– Enter a range of sequential Channel Elements by typing the first and last Channel Elements

separated by two periods (for example; 0..15).

9 Click OK to display a Status Bar followed by a Directions Pop–up Window.

10 Follow Cable Connection Directions as they are displayed, and click the Continue Button to

begin testing.

– When the ATP Process is completed, results will be displayed in the Status Report Window.

11 Click either the Save Results Button or the Dismiss Button.

* IMPORTANT

If Dismiss is used, the test results will not be saved in the Test Report File.

4-10 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 13

Individual Acceptance Tests

RX and TX Testing

The following individual ATP Tests can be used to evaluate specific

aspects of BTS Operation against individual performance requirements.

All testing is performed using the LMF GUI Environment.

TX Testing

TX Tests verify any given Transmit Antenna Path and Output Power

Control. All tests are performed using the external, calibrated Test

Equipment. All measurements are made at the appropriate BTS TX

OUT Connector(s).

TX Tests verify TX Operation of the entire CDMA Forward Link using

selected BBX Cards assigned to respective Sector Antennas. Each BBX

is keyed–up to generate a CDMA Carrier (using both bbxlevel and

BLO) at the CDF File–specified Carrier Output Power Level.

RX Testing

RX Testing verifies Receive Antenna Paths for BBX Cards selected for

the test. All tests are performed using the external, calibrated Test

Equipment to inject a CDMA RF Carrier with all zero Longcode at the

specified RX Frequency at the appropriate BTS RX IN Connector(s).

RX Tests verify RX Operation of the entire CDMA Reverse Link using

all equipped MCC Cards assigned to all respective sector/antennas.

4

Individual Tests

Spectral Purity TX Mask

This test verifies that the transmitted CDMA Carrier Waveform

generated on each sector meets the transmit Spectral Mask Specification

(as defined in IS–97) with respect to the assigned CDF File Values.

Waveform Quality (Rho)

This test verifies that the transmitted Pilot Channel Element Digital

Waveform Quality (Rho) exceeds the minimum specified value in IS–97.

Rho represents the correlation between the actual and perfect CDMA

Modulation Spectrums. 1.0000 represents 100% (or perfect correlation).

Pilot Time Offset

The Pilot Time Offset is the difference between the Communications

System Test Set Measurement Interval (based on the BTS System Time

Reference) and the incoming block of transmitted data from the BTS

(Pilot only, Walsh Code 0).

Code Domain Power/Noise Floor

This test verifies the Code Domain Power Levels, that have been set for

all ODD numbered Walsh Channels, using the OCNS Command. This is

done by verifying that the ratio of PILOT divided by OCNS is equal to

2 dB, and, that the Noise Floor of all EVEN–numbered “OFF”

10.2 +

Walsh Channels measures < –27 dB for IS–95A/B and CDMA2000 1X

with respect to total CDMA Channel Power.

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-11

PRELIMINARY

Page 14

Individual Acceptance Tests – continued

BTS FER

This test verifies the BTS Receive FER on all Traffic Channel Elements

currently configured on all equipped MCC Cards (full rate at one percent

FER) at an RF Input Level of –119 dBm on the Main RX Antenna Paths

using operator–selected, CDF–equipped MCC Cards and BBX Cards at

the site. Diversity RX Antenna Paths are also tested using the lowest

equipped MCC Channel Element ONLY.

NOTE

There are no pass/fail criteria associated with FER

Readings taken at levels below –119 dBm, other than to

verify that the FER Measurement reflects changes in the

RX Iinput Signal Level.

4

4-12 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 15

TX Spectral Purity Transmit Mask Acceptance Test

Background

Overview

This test verifies the Spectral Purity of each operator–selected BBX

Carrier keyed–up at a specific frequency specified in the current CDF.

All tests are performed using the external, calibrated Test Equipment

controlled by the same command. All measurements are made at the

appropriate BTS TX Antenna Connector..

Test Patterns

There are four operator–selectable Test Patterns with which this

Acceptance Test can be performed. The patterns, along with the channels

tested and Gain Setting for each, are listed in Table 3-40. Refer to “TX

Calibration and the LMF” in the Bay Level Offset Calibration section of

Chapter 3 for more information on the Test Patterns..

Equipment Operation During Testing

At least one MCC must be selected to perform the Standard, CDF Pilot,

and CDF Test Patterns. For these Test Patterns, Forward Links are

enabled for Synch Channel (SCH), Paging Channel (PCH), and Traffic

Channel (TCH) Elements from the selected MCC(s), as shown in

Table 3-40.

Gain is set for the applicable channels on each antenna as shown in the

table. The operator–selected BBX Cards will be keyed using a

BLO–corrected bbxlvl Value to generate a CDMA Carrier. RF Output

Power, as measured at the appropriate Frame TX Antenna Connector,

will be set to one of the following depending on the Operating

Frequency Spectrum.:

S 800 MHz: 33.5 dBm

S 1.9 GHz: 31.0 dBm

4

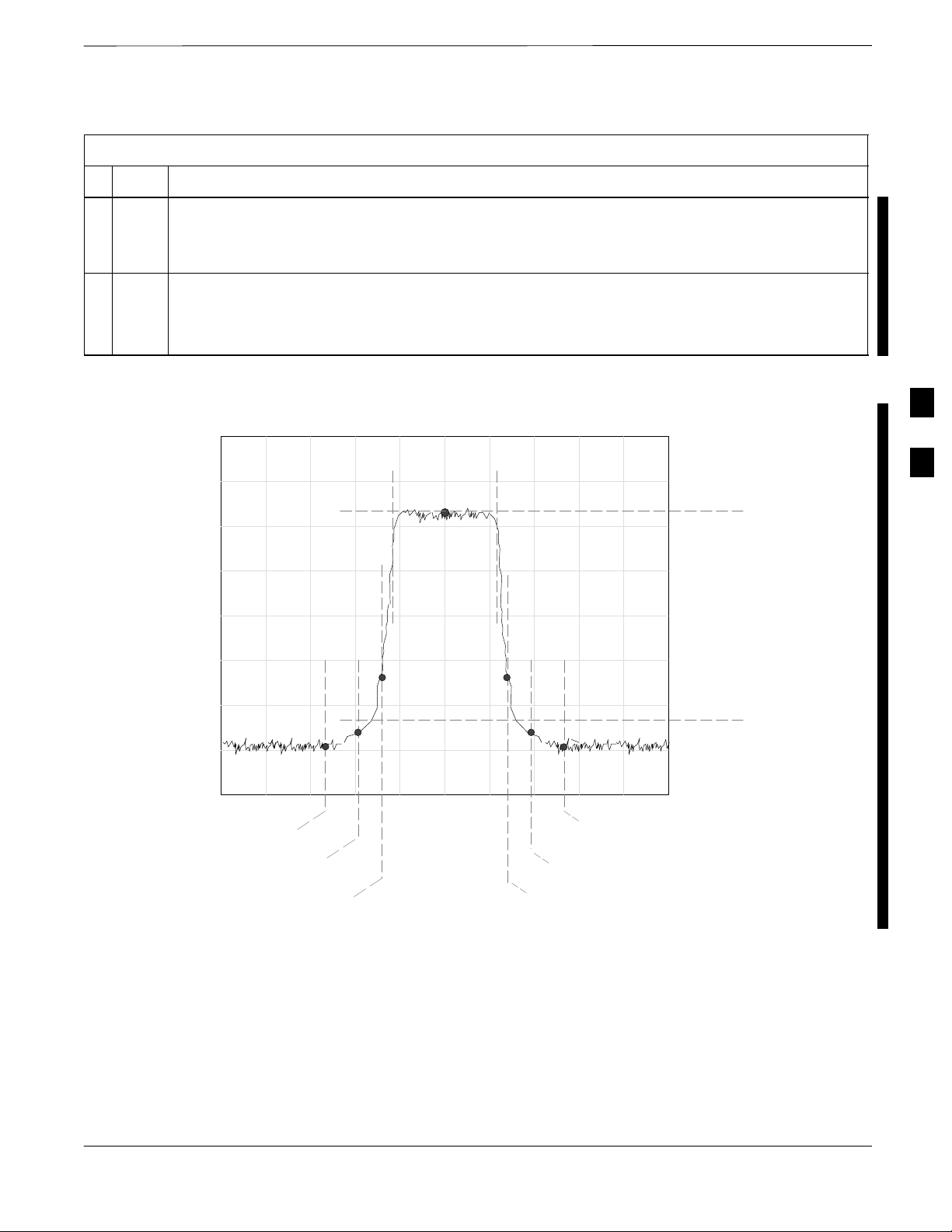

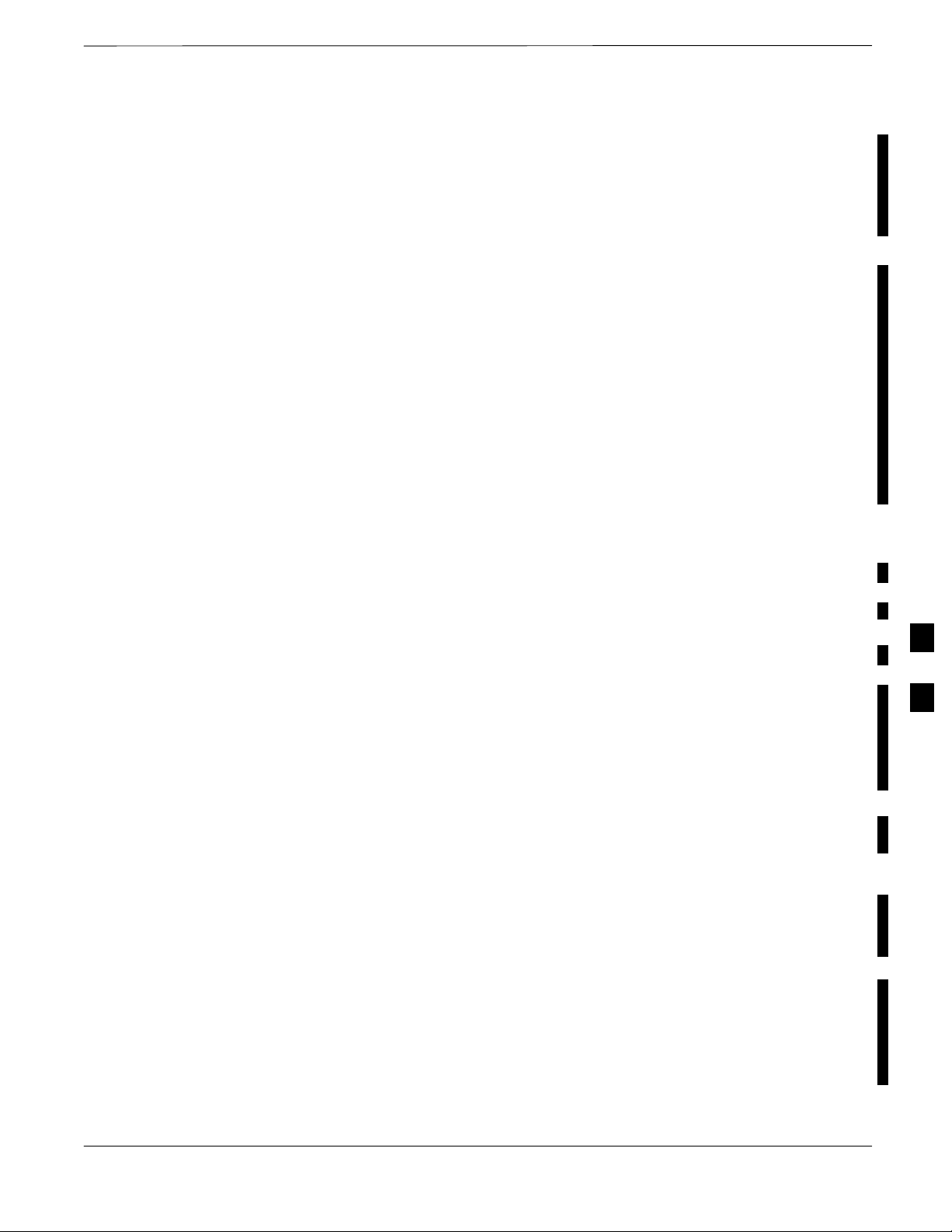

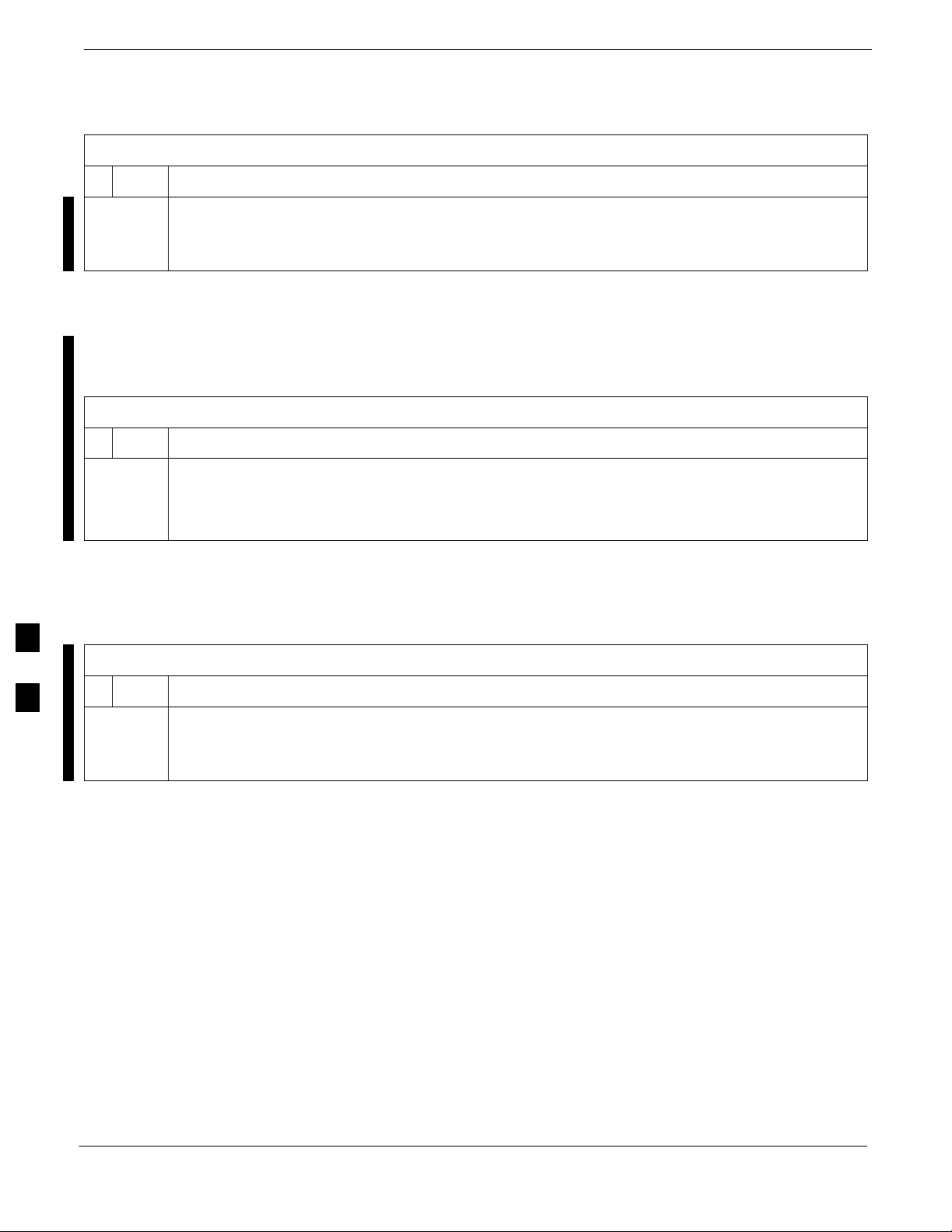

Test Measurements

The Test Equipment will measure and return the attenuation level in dB

of all spurious and IM products with respect to the Mean Power of the

CDMA Channel measured in a 1.23 MHz bandwidth, verifying that

results meet system tolerances at the following test points. Refer to also

Figure 4-2):

S For 800 MHz:

– At least –45 dB @ + 750 kHz from Center Frequency

– At least –45 dB @ – 750 kHz from Center Frequency

– At least –60 dB @ – 1980 kHz from Center Frequency

– At least –60 dB @ + 1980 kHz from Center Frequency

S For 1.9 GHz:

– At least –45 dB @ + 885 kHz from Center Frequency

– At least –45 dB @ – 885 kHz from Center Frequency

– At least –55 dB @ – 1980 kHz from Center Frequency

– At least –55 dB @ + 1980 kHz from Center Frequency

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-13

PRELIMINARY

Page 16

TX Spectral Purity Transmit Mask Acceptance Test – continued

Redundant BBX Testing

The BBX will then de–key, and if selected, the Redundant BBX will be

assigned to the current TX Antenna Path under test. The test will then be

repeated..

Spectral Purity TX Mask

Acceptance T est

Perform the procedure in Table 4-5 to verify that the Transmit Spectral

Mask Specification on the TX Antenna Paths for the selected BBX

Cards.

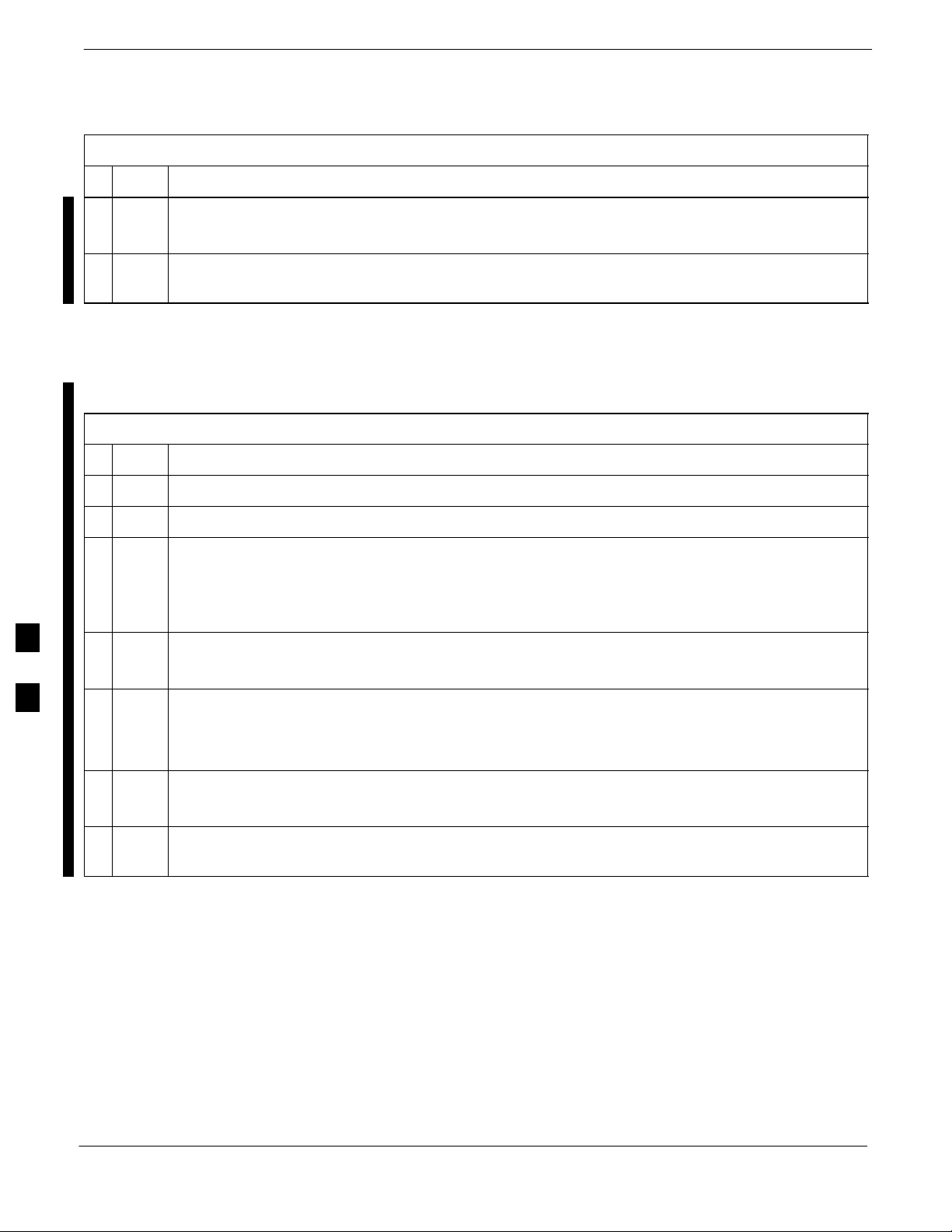

Table 4-5: Spectral Purity Transmit Mask Test Procedure

4

n Step Action

1 Set–up the Test Equipment for TX Acceptance Tests per Table 4-1.

2 Select the BBX Cards to be tested.

3 If the Test Pattern to be used is Standard, CDFPilot, or CDF; select at least one MCC.

– Refer to the “Test Pattern Drop–down Pick List” in the “BayLevel Offset Calibration” section

of Chapter 3.

4 Click on Tests in the BTS Menu Bar, and select TX > TX Mask... from the Pull–down Menus.

5 Select the appropriate carrier(s) and sector(s) (carrier-bts#-sector#-carrier#) from those displayed

in the Channels/Carrier Pick List.

NOTE

To select multiple items, hold down the Shift or Ctrl Key while clicking on Pick List Items to

select multiple carrier(s)–sector(s).

6 Verify that the correct Channel Number for the selected carrier is shown in the Carrier #

Channels Box.

– If it is not, obtain the latest bts–#.cdf (or bts–#.necf) and cbsc–#.CDF Files from the CBSC.

NOTE

If necessary, the correct Channel Number may be manually entered into the Carrier # Channels

Box.

7 If at least one MCC was selected in Step 3, select the appropriate Transfer Rate (1 = 9600, 3 =

9600 1X) from the Pull–down Menu in the Rate Set Box.

NOTE

The Rate Set Selection of 3 is only available if 1X Cards are selected for the test.

8 In the Test Pattern Box, select the Test Pattern to use for the Calibration from the Pull–down

Menu.

– Refer to the “Test Pattern Drop–down Pick List” under “TX Calibration and the LMF” in the

Bay Level Offset Calibration section of Chapter 3.

9 Click OK to display a Status Bar followed by a Directions Pop–up Window.

table continued on next page

4-14 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 17

TX Spectral Purity Transmit Mask Acceptance Test – continued

Table 4-5: Spectral Purity Transmit Mask Test Procedure

n ActionStep

10 Follow the Cable Connection Directions as they are displayed, and click the Continue Button to

begin testing.

– As the ATP Process is completed, results will be displayed in a Status Report Window.

11 Click either the Save Results Button or the Dismiss Button.

* IMPORTANT

If Dismiss is used, the test results will not be saved in the Test Report File.

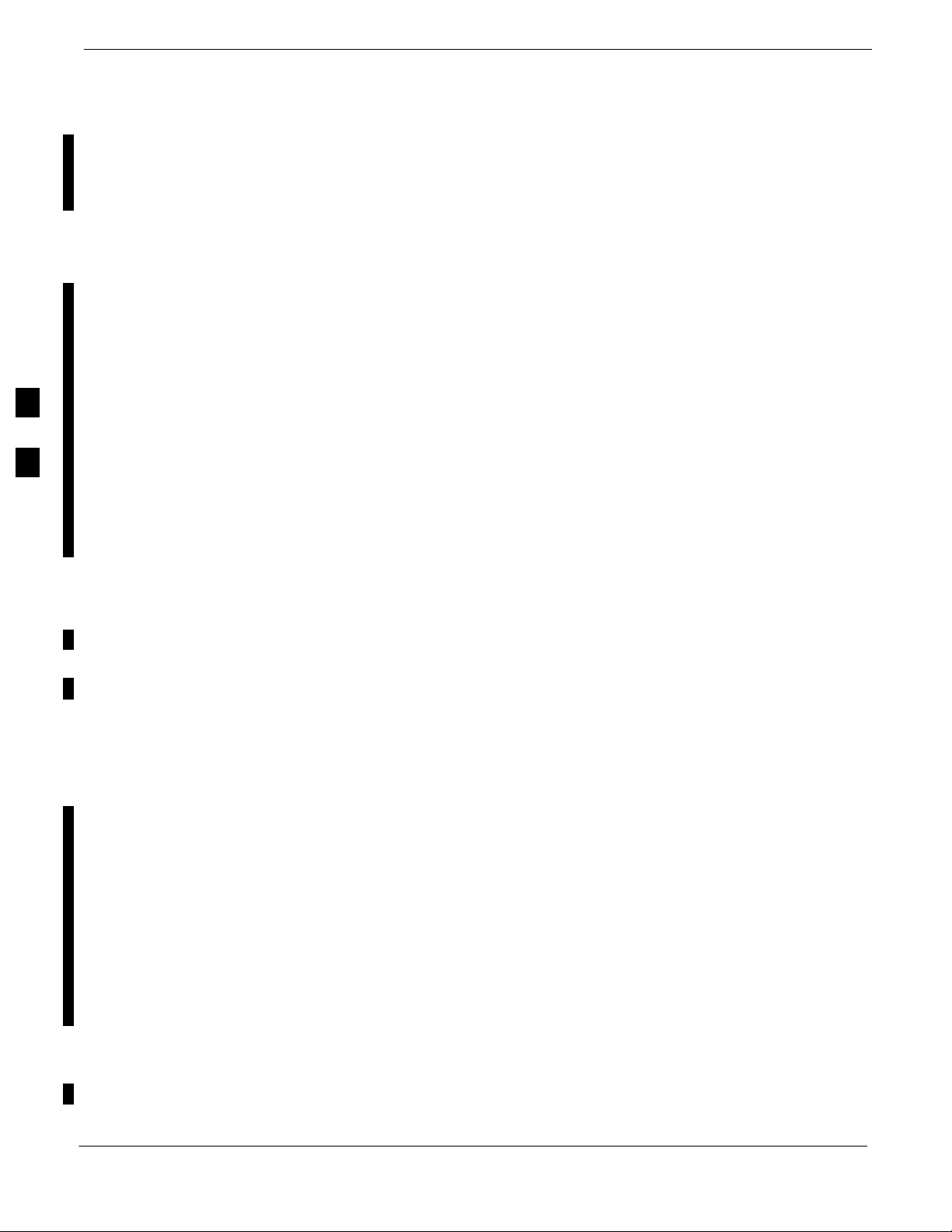

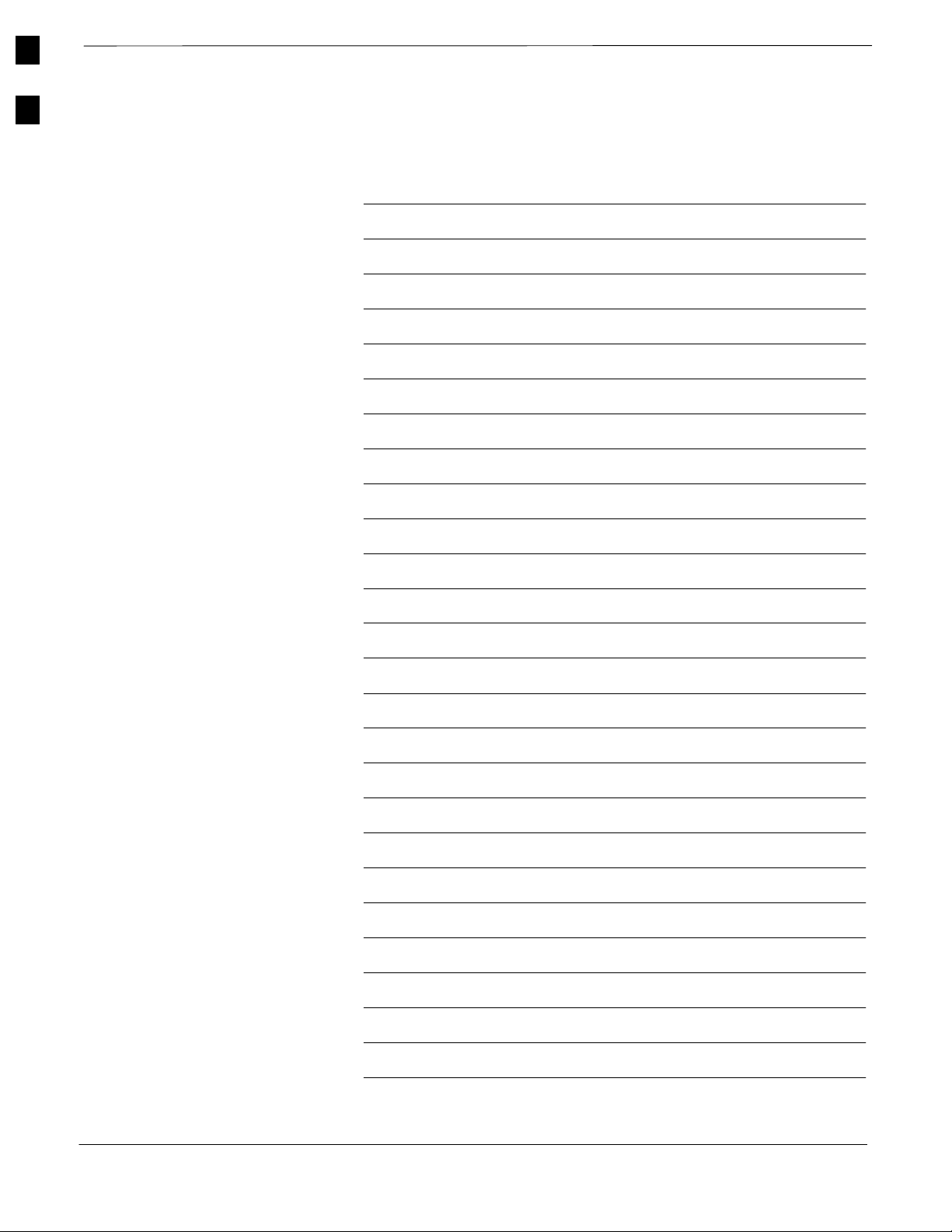

Figure 4-2: TX Mask Verification Spectrum Analyzer Display

.5 MHz Span/Div

Ampl 10 dB/Div

Mean CDMA Bandwidth

Power Reference

Center Frequency Reference

4

– 1980 kHz

– 885 kHz + 885 kHz

– 750 kHz

Attenuation level of all

spurious and IM products

with respect to the Mean

Power of the CDMA Channel

+ 1980 kHz

+750 kHz

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-15

PRELIMINARY

Page 18

TX Waveform Quality (Rho) Acceptance Test

Background

Overview

This test verifies the transmitted Pilot Channel Element Digital

Waveform Quality of each operator–selected BBX Carrier keyed–up at a

specific frequency specified in the current CDF. All tests are performed

using the external, calibrated Test Equipment controlled by the same

command. All measurements are made at the appropriate TX Antenna

Connector..

Equipment Operation During Testing

Pilot Gain will be set to 262 for each antenna, and all TCH Elements

from the MCC Cards will be forward–link disabled. The selected BBX

Cards will be keyed–up using both bbxlvl and BLO to generate a

4

CDMA Carrier (with Pilot Channel Element only, Walsh Code 0). RF

Output Power is set at 40 dBm as measured at the appropriate BTS TX

Antenna Connector..

Test Measurements

The Test Equipment will measure and return the Pilot Channel Element

Digital Waveform Quality (Rho) Percentage, verifying that the result

meets the following specification.:

Waveform Quality (Rho) should be > 0.912.

Redundant BBX Testing.

The BBX will then de–key, and if selected, the Redundant BBX will be

assigned to the current TX Antenna Path under test. The test will then be

repeated for the Redundant BBX..

Waveform Quality (Rho)

Acceptance T est

Perform the procedure in Table 4-6 to verify that the Pilot Channel

Element Waveform Quality (Rho) on the TX Antenna Paths for the

selected BBX Cards.

Table 4-6: Waveform Quality (Rho) Test Procedure

n Step Action

1 Set–up the Test Equipment for TX Acceptance Tests per Table 4-1.

2 Select the BBX Cards to be tested.

3 Click on Tests in the BTS Menu Bar, and select TX > Rho... from the Pull–down Menus.

4 Select the appropriate carrier(s) and sector(s) (carrier-bts#-sector#-carrier#) from those displayed

in the Channels/Carrier Pick List.

NOTE

To select multiple items, hold down the Shift or Ctrl Key while clicking on Pick List Items to

select multiple carrier(s)–sector(s).

table continued on next page

4-16 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 19

TX Waveform Quality (Rho) Acceptance Test – continued

Table 4-6: Waveform Quality (Rho) Test Procedure

n ActionStep

5 Verify that the correct Channel Number for the selected carrier is shown in the Carrier #

Channels Box.

– If it is not, obtain the latest bts–#.cdf (or bts–#.necf) and cbsc–#.CDF Files from the CBSC.

NOTE

If necessary, the correct Channel Number may be manually entered into the Carrier # Channels

Box.

6 Click OK to display a Status Bar followed by a Directions Pop–up Window.

7 Follow the Cable Connection Directions as they are displayed, and click the Continue Button to

begin testing.

– As the ATP Process is completed, results will be displayed in a Status Report Window.

8 Click either the Save Results Button or the Dismiss Button.

* IMPORTANT

If Dismiss is used, the test results will not be saved in the Test Report File.

4

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-17

PRELIMINARY

Page 20

TX Pilot Time Offset Acceptance Test

Background

Overview

This test verifies the transmitted Pilot Channel Element Pilot Time

Offset of each operator–selected BBX Carrier keyed–up at a specific

frequency specified in the current CDF. All tests will be performed using

the external, calibrated Test Equipment controlled by the same

command. All measurements will be made at the BTS TX Antenna

Connector..

Equipment Operation During Testing

The Pilot Gain will be set to 262 for each antenna and all TCH

Elements from the MCC Cards will be forward–link disabled. The

4

selected BBX Cards will be keyed using both bbxlvl and BLO to

generate a CDMA Carrier (with Pilot Channel Element only, Walsh

Code 0). TX Power Output is set at 40 dBm as measured at the TX

Output..

Test Measurements

Pilot Time Offset Acceptance

Test

The Test Equipment will measure and return the Pilot Time Offset in ms,

verifying that results meet the following specification.:

Pilot Time Offset should be within 3 ms of the target PT Offset

(zeroms).

.Redundant BBX Testing –

The BBX will then de–key, and if selected, the Redundant BBX will be

assigned to the current TX Antenna Path under test. The test will then be

repeated for the Redundant BBX..

NOTE

This test also executes and returns the TX Frequency and

TX Waveform Quality (Rho) ATP Tests, however, only

Pilot Time Offset results are written to the ATP Test

Report.

Perform the procedure in Table 4-7 to verify that the Pilot Time Offset

on the TX Antenna Paths for the selected BBX Cards.

Table 4-7: Test Pilot Time Offset

n Step Action

1 Set–up the Test Equipment for TX Acceptance Tests per Table 4-1.

2 Select the BBX Cards to be tested.

table continued on next page

4-18 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 21

TX Pilot Time Offset Acceptance Test – continued

Table 4-7: Test Pilot Time Offset

n ActionStep

3 Click on Tests in the BTS Menu Bar, and select TX > Pilot Time Offset... from the Pull–down

Menus.

4 Select the appropriate carrier(s) and sector(s) (carrier-bts#-sector#-carrier#) from those displayed

in the Channels/Carrier Pick List.

NOTE

To select multiple items, hold down the Shift or Ctrl Key while clicking on Pick List Items to

select multiple carrier(s)–sector(s).

5 Verify that the correct Channel Number for the selected carrier is shown in the Carrier #

Channels Box.

– If it is not, obtain the latest bts–#.cdf (or bts–#.necf) and cbsc–#.CDF Files from the CBSC.

NOTE

If necessary, the correct Channel Number may be manually entered into the Carrier # Channels

Box.

4

6 Click OK to display a Status Bar followed by a Directions Pop–up Window.

7 Follow the Cable Connection Directions as they are displayed, and click the Continue Button to

begin testing.

– As the ATP Process is completed, results will be displayed in a Status Report Window.

8 Click either the Save Results Button or the Dismiss Button.

* IMPORTANT

If Dismiss is used, the test results will not be saved in the Test Report File.

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-19

PRELIMINARY

Page 22

TX Code Domain Power/Noise Floor Acceptance Test

Background

Overview

This test verifies the Code Domain Power and Noise Floor of each

operator–selected BBX Carrier keyed at a specific frequency specified in

the current CDF. All tests are performed using the external, calibrated

Test Equipment controlled by the same command. All measurements are

made at the appropriate BTS TX Antenna Connector..

CDMA Channel Test Set–up

Pilot Gain should be set to 262 for each antenna and the selected MCC

Cards should be configured to supply all odd–numbered Walsh Code

4

Traffic Channel Elements by enabling Orthogonal Channel Noise Source

(OCNS) on all odd MCC Channel Elements (maximum 32 Full Rate

Channels with an OCNS Gain of 81).

– All even–numbered Walsh Code Traffic Channel Elements should

have OCNS disabled, and are considered “OFF”.

– Selected MCC Cards should be Forward–Link Enabled for the

antenna (sector) under test..

Equipment Operation During Testing

The BBX should be keyed–up using a BLO–corrected

generate a CDMA Carrier consisting of Pilot and OCNS Channels. RF

Output Power, as measured at the appropriate Frame TX Antenna

Connector, is set at one of the following values depending on the

Operating Frequency Spectrum.:

– 800 MHz: 33.5 dBm

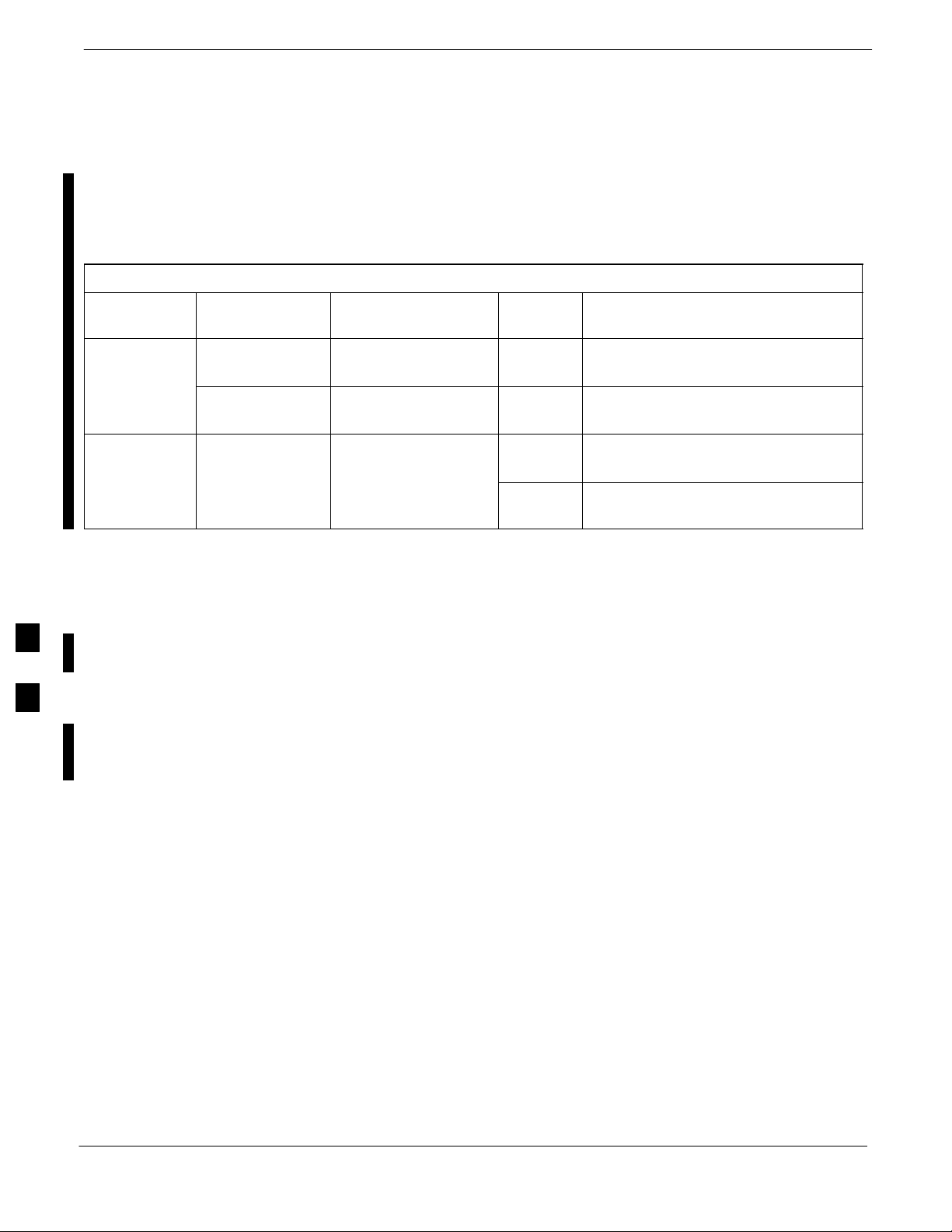

– 1.9 GHz: 31.0 dBm

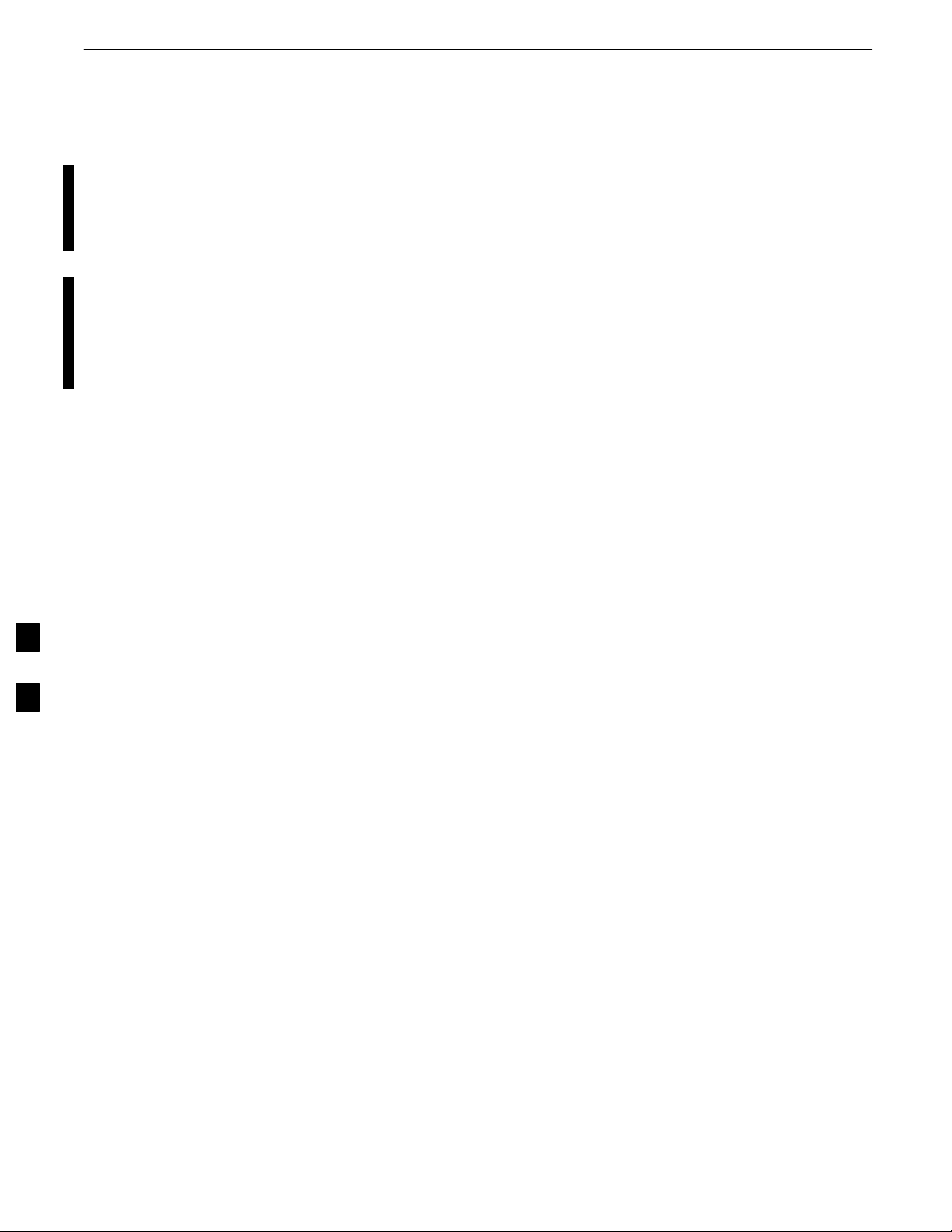

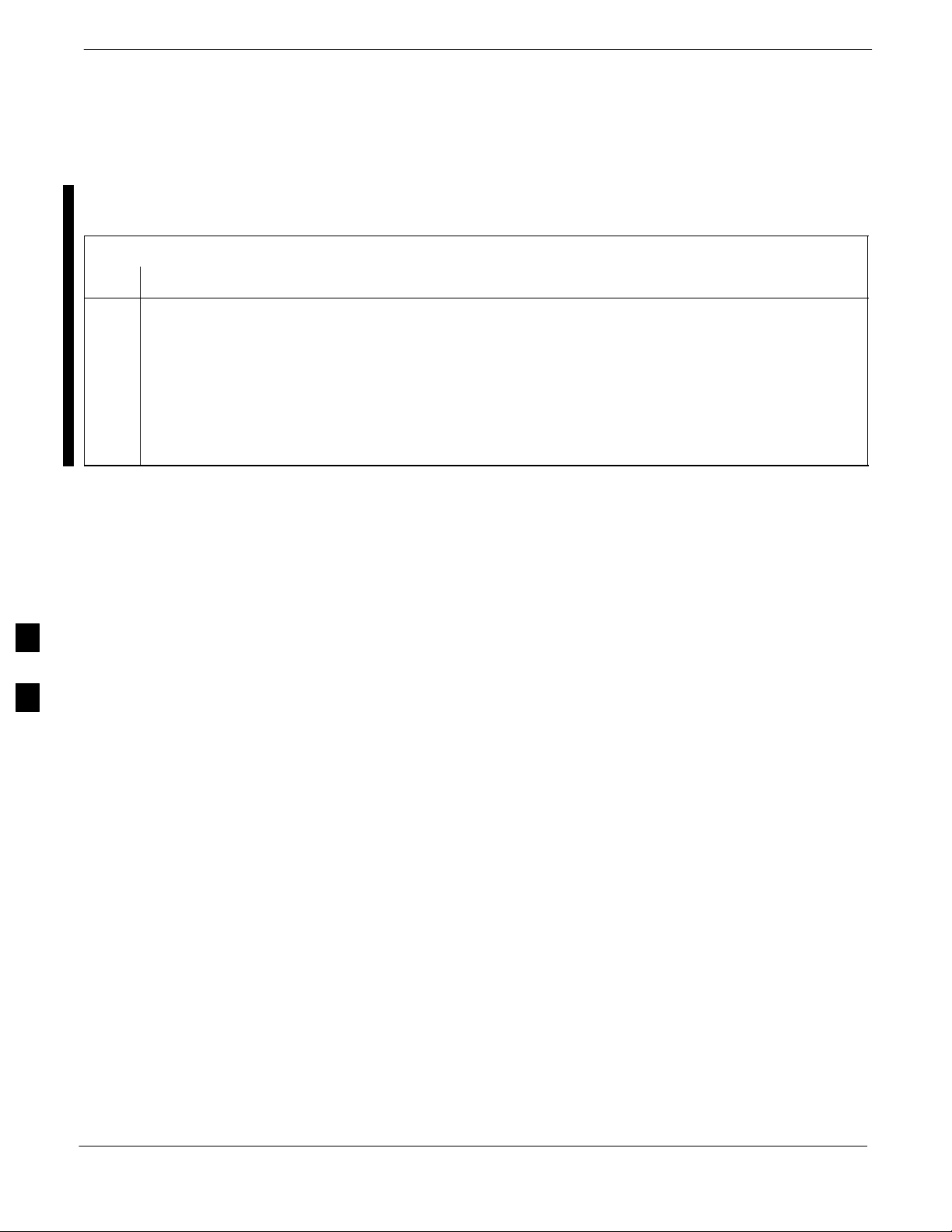

Test Measurements

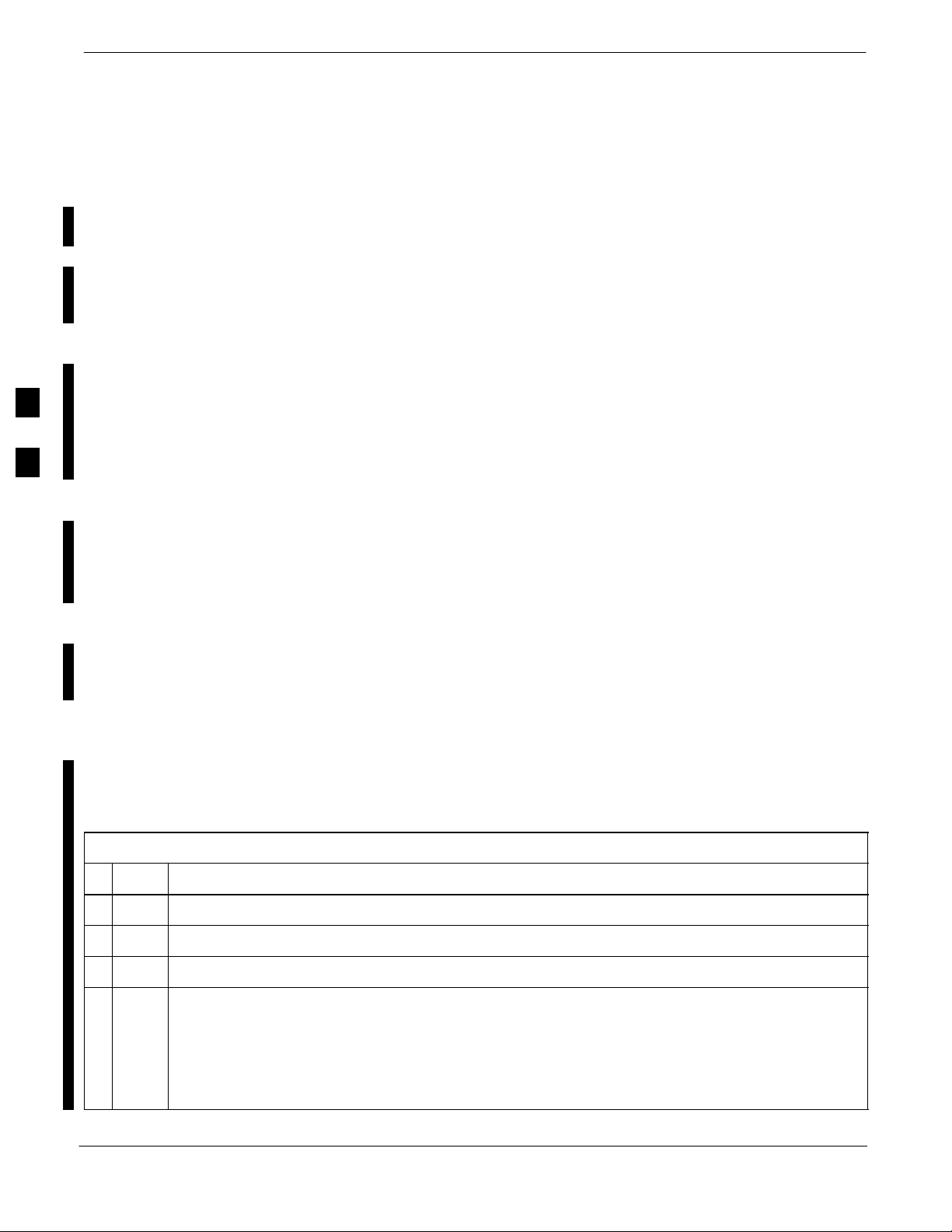

The Test Equipment will measure and return the Channel Element

Power in dB of all specified Walsh Channels within the CDMA

spectrum. Additional calculations will be performed to verify that the

following parameters are met.

– Refer to Figure 4-3 for graphic representations.:

bbxlvl Value to

S Traffic Channel Element Power Level will be verified by calculating

the ratio of Pilot Power to OCNS Gain of all Traffic Channels [Root

Sum of the Square (RSS) of each OCNS Gain divided by the Pilot

Power].

– This value should be 10.2 dB + 2.0 dB.

S Noise Floor (unassigned “OFF” even–numbered Walsh Channels) is

verified to be < –27 dB for IS–95A/B and CDMA2000 1X with

respect to total CDMA Channel Power

4-20 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

.

PRELIMINARY

Page 23

TX Code Domain Power/Noise Floor Acceptance Test – continued

NOTE

When performing this test using the LMF and the MCC is

an MCC8E or MCC24E, the Redundant BBX may fail or

show marginal performance. This is due to a Timing

Mismatch that the LMF does not address. Performing this

test from the CBSC will not have this timing problem.

Redundant BBX Testing

The BBX will then de–key, and if selected, the Redundant BBX will be

assigned to the current TX Antenna Path under test. The test will then be

repeated for the Redundant BBX. Upon completion of the test, OCNS

Channels will be disabled on the specified MCC Channel Elements..

Code Domain Power/Noise

Floor T est

Perform the procedure in Table 4-8 to verify the Code Domain

Power/Noise Floor of each selected BBX Carrier keyed–up at a specific

frequency.

Table 4-8: Code Domain Power/Noise Floor Test Procedure

n Step Action

1 Set–up the Test Equipment for TX Acceptance Tests per Table 4-1.

2 Select the BBX Cards and MCC Cards to be tested.

3 Click on Tests in the BTS Menu Bar, and select TX > Code Domain Power... from the

Pull–down Menus.

4 Select the appropriate carrier(s) and sector(s) (carrier-bts#-sector#-carrier#) from those displayed

in the Channels/Carrier Pick List.

NOTE

To select multiple items, hold down the Shift or Ctrl Key while clicking on Pick List Items to

select multiple carrier(s)–sector(s).

5 Verify that the correct Channel Number for the selected carrier is shown in the Carrier #

Channels Box.

– If it is not, obtain the latest bts–#.cdf (or bts–#.necf) and cbsc–#.CDF Files from the CBSC.

4

NOTE

If necessary, the correct Channel Number may be manually entered into the Carrier # Channels

Box.

6 If at least one MCC was selected in Step 3, select the appropriate Transfer Rate (1 = 9600, 3 =

9600 1X) from the Pull–down Menu in the Rate Set Box.

NOTE

The Rate Set selection of 3 is only available if 1X Cards are selected for the test.

table continued on next page

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-21

PRELIMINARY

Page 24

TX Code Domain Power/Noise Floor Acceptance Test – continued

Table 4-8: Code Domain Power/Noise Floor Test Procedure

n ActionStep

7 Click OK to display a Status Bar followed by a Directions Pop–up Window.

8 Follow the Cable Connection Directions as they are displayed, and click the Continue Button to

begin testing.

– As the ATP Process is completed, results will be displayed in a Status Report Window.

9 Click either the Save Results Button or the Dismiss Button.

* IMPORTANT

If Dismiss is used, the test results will not be saved in the Test Report File.

4

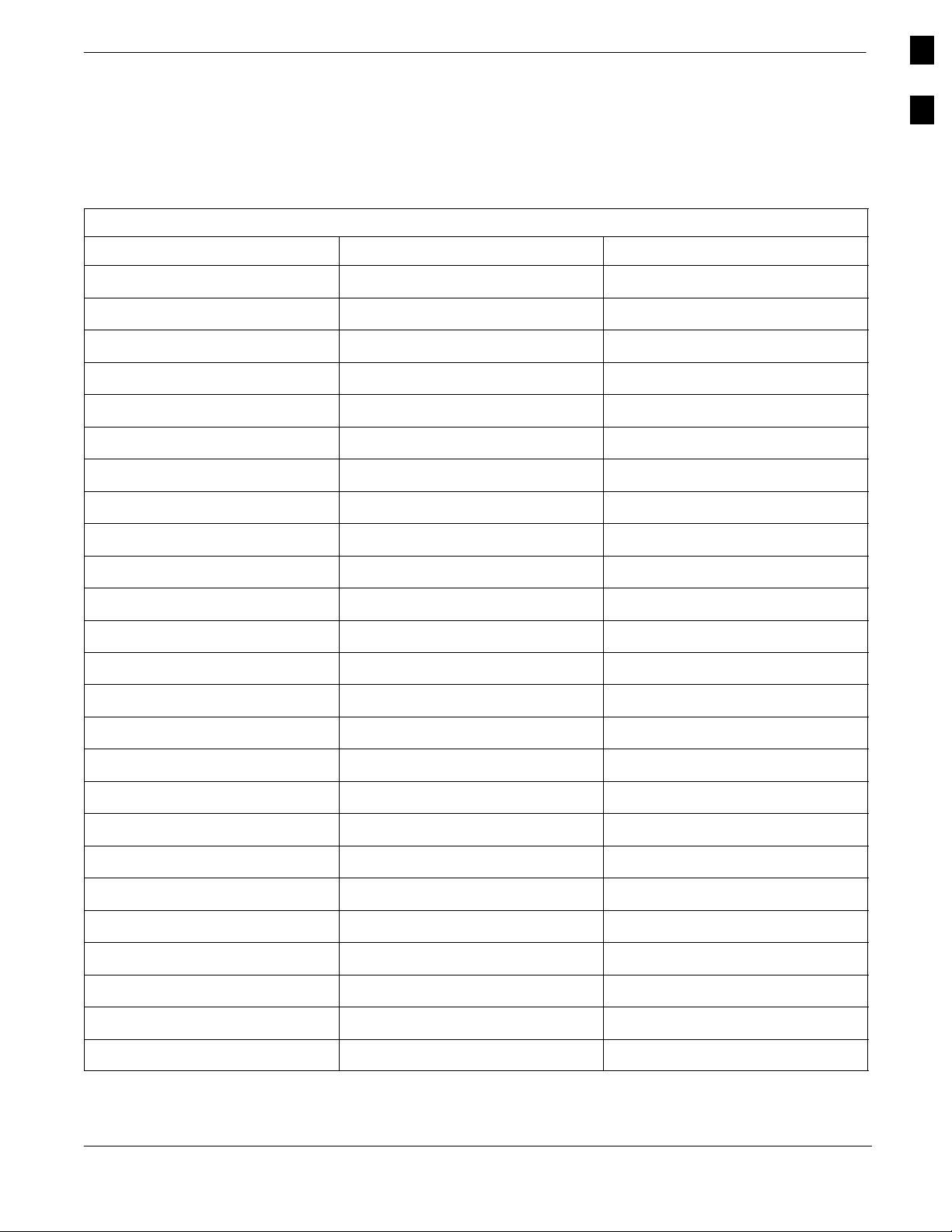

Figure 4-3: Code Domain Analyzer CD Power/Noise Floor Display Examples

Pilot Channel

MAX OCNS

CHANNEL

Active channels

MIN OCNS

CHANNEL

MAX NOISE

FLOOR

Walsh 0 1 2 3 4 5 6 7 ... 63

8.2 dB 12.2 dB

Inactive channels

Code Domain Power/Noise Floor (OCNS Pass) Example

Pilot Channel

FAILURE – EXCEEDS

MAX OCNS SPEC.

Active channels

8.2 dB 12.2 dB

PILOT LEVEL

MAX OCNS SPEC.

MIN OCNS SPEC.

MAXIMUM NOISE FLOOR:

< –27 dB FOR IS–95A/B AND

CDMA2000 1X

PILOT LEVEL

MAX OCNS SPEC.

MIN OCNS SPEC.

FAILURE – DOES NOT

MEET MIN OCNS SPEC.

Walsh 0 1 2 3 4 5 6 7 ... 63

FAILURE – EXCEEDS MAX

NOISE FLOOR SPEC.

MAXIMUM NOISE FLOOR:

< –27 dB FOR IS–95A/B AND

CDMA2000 1X

Inactive channels

Code Domain Power/Noise Floor (OCNS Failure) Example

4-22 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 25

RX FER Acceptance Test

Background

Overview

This test verifies the BTS Frame Erasure Rate (FER) on all TCHs

currently configured on operator–selected MCC Cards (full rate at 1%

FER) at –119 dBm. All tests are performed using the external, calibrated

Test Equipment as the Signal Source controlled by the same command.

Measurements are made at the specified BTS RX Antenna Connection..

Equipment Operation During Testing

The Pilot Gain on each MCC will be set to 262 for each TX Antenna,

and the Forward Link for all TCH Elements from the MCC Cards will

be enabled. Appropriate BBX(s) must be keyed in order to enable the

RX Receive Circuitry. Operator–selected BBX Cards will be keyed

using only bbxlvl, to generate a CDMA Carrier with Pilot Channel

Element only.

4

Transmit Power Output is set at –40 dBm. Test Equipment Output Power

is set so that the received power at the BBX is –119 dBm. The Final

Output Power Setting of the Test Equipment takes into account the MPC

type, BTS RF Path Losses, and test Test Cable Insertion Losses. If

selected, the Redundant BBX will be assigned to the current RX

Antenna Paths under test..

Test Measurements

The LMF will prompt the MCC Channel Element under test to measure

all–zero Longcode and provide the FER report on the selected active

MCC on the Reverse Link for the Main and, if selected, Diversity RX

Antenna Paths. Results are evaluated to ensure they meet the following

specification.:

FER returned less than 1% and Total Frames measured is 1500

Redundant BBX Testing

After the test, the BBX and the Test Equipment will be de–keyed to shut

down the Pilot Signal and the active Channel Element, respectively. If

the Redundant BBX was tested, BBXR assignment to an active sector

will also be reset..

FER Acceptance T est

Perform the procedure in Table 4-9 to verify the FER on RX Antenna

Paths using selected MCC Cards and BBX Cards.

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-23

PRELIMINARY

Page 26

RX FER Acceptance Test – continued

Table 4-9: FER Test Procedure

n Step Action

1 Set–up the Test Equipment for RX Acceptance Tests per Table 4-1.

2 If the LMF has been logged into the BTS with a different Multi–Channel Preselector setting than

the one to be used for this test, the LMF must be logged out of the BTS and logged in again with

the new Multi–Channel Preselector Setting.

* IMPORTANT

Using the wrong MPC Setting can cause a false test failure.

3 Select the BBX Cards and MCC Cards to be tested.

4 Click on Tests in the BTS Menu Bar, and select RX > FER... from the Pull–down Menu.

4

5 Select the appropriate carrier(s) and sector(s) (carrier-bts#-sector#-carrier#) from those displayed

in the Channels/Carrier Pick List.

NOTE

To select multiple items, hold down the Shift or Ctrl Key while clicking on Pick List Items to

select multiple carrier(s)–sector(s).

6 Verify that the correct Channel Number for the selected carrier is shown in the Carrier #

Channels Box.

– If it is not, obtain the latest bts–#.cdf (or bts–#.necf) and cbsc–#.CDF Files from the CBSC.

NOTE

If necessary, the correct Channel Number may be manually entered into the Carrier # Channels

Box.

7 Select the appropriate RX Branch (Both, Main, or Diversity) in the Pull–down Menu.

8 In the Rate Set Box, select the appropriate Data Rate (1=9600, 2=14400, 3=9600 1X) from the

Pull–down Menu.

NOTE

The Rate Set selection of 2 is only available if non–1X Cards are selected for the test.

The Rate Set selection of 3 is only available if 1X Cards are selected for the test.

9 Click OK to display a Status Bar followed by a Directions Pop–up Window.

10 Follow Cable Connection Directions as they are displayed, and click the Continue Button to

begin testing.

– As the ATP Process is completed, results will be displayed in the Status Report Window.

11 Click either the Save Results Button or the Dismiss Button.

* IMPORTANT

If Dismiss is used, the test results will not be saved in the Test Report File.

4-24 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 27

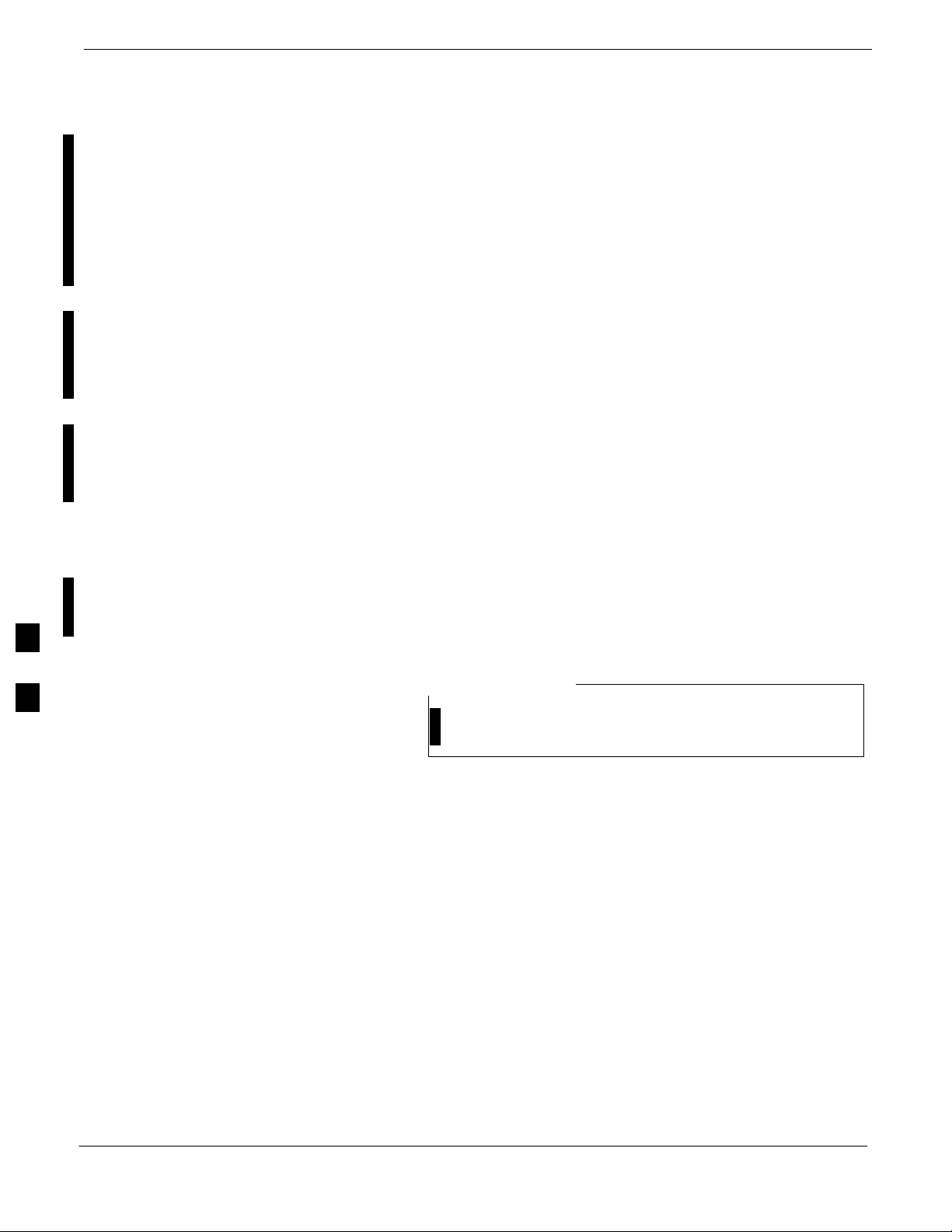

Generating an ATP Report

Background

ATP Report

Each time an ATP Test is run, ATP Data is updated and must be saved to

an ATP Report File using the Save Results Button to close the Status

Report Window. The ATP Report File will not be updated if the Status

Report Window is closed using the Dismiss Button.

A separate report is created for each BTS and includes the following for

each test:

S Test Name

S PASS or FAIL

S Description Information (if applicable)

S BBX Number

S Channel Number

S Carrier Number

S Sector Number

S Upper Test Limit

S Lower Test Limit

S Test Result

S Time Stamp

S Details/Warning Information (if applicable)

Perform the procedures in the Table 4-10 to view and create a printable

file for the ATP Report.

Table 4-10: ATP Report Generation Procedure

n Step Action

1 Click on the Login Tab (if not in the forefront).

4

2 Click on the desired BTS in the Available Base Stations Pick List to select it.

3 Click on the Report Button.

4 If a printable file is not needed, click on the Dismiss Button.

5 If a printable file is required, perform the following actions.

5a Select the desired file type (text, comma–delimited, HTML) for the report file from the Pull–down

Menu at the bottom of the screen.

5b Click the Save Button to save the file.

– The file will be saved in the selected format in the bts–# folder for the BTS selected.

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-25

PRELIMINARY

Page 28

Updating Calibration Data Files

Software Release Caveats

Software Release R2.16.5.x allows the user to load the Calibration File

from the LMF directly onto the MGLI. The MGLI will then FTP the

new Calibration File to the OMC–R, thereby eliminating the need for the

user to place the Calibration File at the OMC–R.

Copy and Load Cal File to the

CBSC

After completing the TX Calibration and audit, updated CAL File

information must be moved from the LMF Windows environment back

to the CBSC, a UNIX environment. The following procedures detail

moving files from one environment to the other.

Copying CAL Files from LMF to a Diskette

4

Table 4-11: Copy CAL Files to a Diskette Procedure

Perform the procedures in Table 4-11 to copy the CAL Files from an

LMF Computer to a 3.5 diskette.

n Step Action

1 With Windows running on the LMF Computer, insert a disk into Drive A:\.

2 Launch the Windows Explorer Application Program from the Start > Programs Menu List.

3 Select the applicable <x>:\<lmf home directory/cdma/bts–# Folder.

4 Drag the bts–#.cal file to Drive A.

5 Repeat Steps 3 and 4, as required, for other bts–# Folders.

Copying CAL Files from Diskette to the CBSC

Perform the procedures in Table 4-12 to copy CAL Files from a diskette

to the CBSC.

Table 4-12: Copy CAL Files from Diskette to the CBSC Procedure

n Step Action

1 Log into the CBSC on the OMC–R UNIX Workstation using your Account Name and Password.

2 Place the diskette containing the Calibration File(s) into the Workstation Diskette Drive.

3 Enter EJECT –q and press the Enter Key.

4 Enter mount and press the Enter Key.

NOTE

S Verify that the message “floppy/no_name” is displayed on the last line.

– If the EJECT Command was previously entered, floppy/no_name will be appended with a

number.

– Use the explicit floppy/no_name reference displayed.

table continued on next page

4-26 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 29

Updating Calibration Data Files – continued

Table 4-12: Copy CAL Files from Diskette to the CBSC Procedure

n ActionStep

5 Enter cd /floppy/no_name and press the Enter Key.

6 Enter ls –lia and press the Enter Key.

– Verify that the bts–#.cal file filename appears in the displayed Directory Listing.

7 Enter cd and press the Enter Key.

8 Enter pwd and press the Enter Key.

– Verify that the displayed response shows the correct Home Directory (/home/<user’s name>).

9 With Solaris versions of UNIX, create a UNIX–formatted version of the bts–#.cal file in the Home

Directory by performing the following actions.

9a Type the following command:

dos2unix /floppy/no_name/bts–#.cal bts–#.cal

Where: # = BTS Number for which the CAL File was created

9b Press the Enter Key.

NOTE

Other versions of UNIX do not support the dos2unix Command. In these cases, use the UNIX

cp (Copy) Command.

– The copied files contain DOS Line Feed Characters that must be edited out with a UNIX Text

Editor.

10 Enter ls –l *.cal and press the Enter Key. Verify that the CAL Files have been copied.

– Verify that all CAL Files to be transferred appear in the displayed listing.

11 Type EJECT, and press the Enter Key.

12 Remove the diskette from the workstation.

4

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 4-27

PRELIMINARY

Page 30

Updating Calibration Data Files – continued

Notes

4

4-28 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 31

Chapter 5: Prepare to Leave the Site

Table of Contents

Prepare to Leave the Site 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Test Equipment Removal 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bringing Modules into Service with the LMF 5-3 . . . . . . . . . . . . . . . . . . .

LMF Removal 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re–connect BTS T1/E1 Spans 5-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Checks Before Leaving Site 5-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset All Devices and Initialize Site Remotely 5-6 . . . . . . . . . . . . . . . . . . .

5

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP

PRELIMINARY

Page 32

Table of Contents – continued

Notes

5

1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 33

Prepare to Leave the Site

External T est Equipment

Removal

Perform the procedure in Table 5-1 to disconnect the Test Equipment and

configure the BTS for active service.

Table 5-1: External Test Equipment Removal Procedure

n Step Action

n W ARNING

Make sure that no BBX Cards are keyed before performing this procedure.

– Failure to do so can result in personal injury and damage to BTS LPA Modules.

1 At the rear of the frame, disconnect all external Test Equipment from all TX and RX Connectors.

2 Reconnect and visually inspect all TX and RX Antenna Feed Lines at the Frame RF Interface

Panel.

* IMPORTANT

Verify that all Sector Antenna Feed Lines are connected to the correct Antenna Connectors on the

frame. Crossed Antenna Cables will degrade Call Processing.

5

Bringing Modules into Service

with the LMF

NOTE

Whenever possible, have the CBSC/MM bring up the site

and enable all devices on the BTS.

If a Reason Code is present and/or data should/could not be loaded

remotely from the CBSC, follow the steps outlined in Table 5-2 as

required to bring BTS Processor Modules from an OOS State to an INS

State.

Table 5-2: Bring Modules into Service Procedure

n Step Action

1 In the LMF GUI Environment, select the device(s) to be enabled by clicking on each one.

* IMPORTANT

S The MGLI and CSM must be INS_ACTIVE (bright green) before an MCC can be enabled.

2 Enable the Processor Cards in the following order.

1. MGLI

2. CSM Cards

3. MCC Cards

table continued on next page

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 5-3

PRELIMINARY

Page 34

Prepare to Leave the Site – continued

Table 5-2: Bring Modules into Service Procedure

n ActionStep

3 Click on Device in the BTS Menu Bar, and select Enable from the Pull–down Menu.

– A Status Report Window is displayed.

* IMPORTANT

If a BBX is selected, a Transceiver Parameters Window is displayed to collect Keying

Information. Do not enable the BBX.

4 Click Cancel to close the Transceiver Parameters Window, if applicable.

5 Click OK to close the Status Report Window.

– Bright Green is the color of devices that successfully change to INS.

LMF Removal

Perform the procedure in Table 5-3 as required to terminate the LMF

GUI Session and remove the LMF Computer.

5

Table 5-3: Terminate the LMF Session and Remove the LMF Procedure

n Step Action

! CAUTION

Do not power down the LMF Computer without performing the procedure below; corrupted

and/or lost Data Files may result.

1 Log out of all BTS Sessions and exit the LMF by clicking on File in the LMF Window Menu Bar

and selecting Logout and Exit from the Pull–down Menu.

2 In the Windows Task Bar, click Start and select Shutdown.

3 Click Yes when the Shut Down Windows Message appears.

4 Wait for the system to shut down and the screen to go blank.

5 Disconnect the LMF Computer Ethernet Port from the BTS Frame.

6 Disconnect the LMF Computer Serial Port, the RS–232–to–GPIB Interface Box, and the GPIB

Cables as required for equipment transport.

5-4 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 35

Prepare to Leave the Site – continued

Re–connect BTS T1/E1 Spans

Before leaving the site, connect any T1 or E1 Span Connectors removed

previously to allow the LMF to control the BTS. Refer to Table 5-4 and

Figure 3-2.

Table 5-4: T1 or E1 Spans Re–connection Procedure

n Step Action

1 Re–connect any disconnected Span Connectors to the Span I/O A and B Boards.

2 If equipped, ensure that the CSU is powered ON.

3 Verify Span Status, ensuring that the OMC–R/CBSC can communicate with the BTS.

Final Checks Before Leaving

Site

Make sure all requirements listed in Table 5-5 are completed before

leaving the site.

Table 5-5: Check Before Leaving the Site Procedure

5

n Step Action

1 For AC Frame only:

Validate the Vtrim Signal Cabling.

2 Ensure that the Battery Voltage is 27 Volts at 25C.

– If external batteries are provided by the Customer, ensure that the Customer Circuit Breaker is

closed.

NOTE

A Low Voltage Disconnect must be in series with the external batteries.

3 Verify that no Alarm Conditions are being reported to the CBSC after all Cabinet Doors are

closed.

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 5-5

PRELIMINARY

Page 36

Prepare to Leave the Site – continued

Reset All Devices and Initialize

Site Remotely

Devices in the BTS should not be left with Data and Code Loaded from

the LMF. The Configuration Data and Code Loads used for normal

operation could be different from those stored in the LMF Files.

The following two procedure, one for Circuit Backhaul and the other for

Packet Backhaul, are provided to remotely reset the BTS Devices and

then initialize the BTS.

Circuit Backhaul Remote Reset and Initialization

Perform the procedure in Table 5-6 to remotely reset the BTS Devices in

a Circuit Backhaul BTS, and then remotely initialize the same BTS.

Table 5-6: Circuit Backhaul Remote Reset and Initialization Procedure

n Step Action

1 Terminate the LMF Session by performing the procedure in Table 5-3.

2 Reconnect the Spans by performing the procedure in Table 5-4.

5

3 From the BTS Site, contact the OMC–R and request the operator to perform a BTS Reset.

OR

At the BTS Site, perform the actions in Step 4 through Step 6.

4 Unseat one GLI Card and wait for 30 seconds.

5 Re–seat the GLI and wait for it to complete its Initialization Process (this takes about one minute).

6 Repeat Step 4 and Step 5 for the second GLI.

7 Depending on the number and configuration of installed operational GLI Cards, perform the

following actions.

S BTS with Redundant GLI Cards, proceed to Step 8.

S BTS with a non–Redundant GLI or a non–operational Redundant GLI, proceed to Step 9.

8 From the OMC–R, run the ACTIVATE Command on the BTS.

– After the ACTIVATE Command has been executed, proceed to Step 10.

9 From the OMC–R, perform the following actions.

9a ACTIVATE the GLI.

– This action sets the NextLoad Att ribute for the GLI to work wi th the current BSS Software

Version.

9b Disable the GLI.

9c Enable the GLI.

– This action allows the MM to load the software version specified by the NextLoad Attribute.

9d Once the GLI is INS_ACT, contact the OMC–R to again run the ACTIVATE Command on the

BTS.

table continued on next page

5-6 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 37

Prepare to Leave the Site – continued

Table 5-6: Circuit Backhaul Remote Reset and Initialization Procedure

n ActionStep

10 Once the GLI Cards are loaded with the specified Code Version, the active GLI will verify and

update, as required, its RAM.

– Also , i f necess ary, ROM Cod e Loads for the ins tal led CSM, M CC , a nd B BX Cards us in g th e

DLM.

11 After all activities at the site have been completed, contact the OMC–R to confirm that the BTS is

under OMC–R control.

Packet Backhaul Remote Reset and Initialization

Perform the procedure in Table 5-7 to remotely reset the BTS Devices in

a Packet Backhaul BTS, and then remotely initialize the same BTS.

Table 5-7: Packet Backhaul Remote Reset and Initialization Procedure

n Step Action

1 Terminate the LMF Session by performing the procedure in Table 5-3.

2 Reconnect the Spans by performing the procedure in Table 5-4.

3 Determine which of the two types of PREACTIVATE Load Processes is applicable to your

situation.

Rolling Upgrade: This Load Process is only available when the BTS Cards are populated for Full

Redundancy as applicable.

Quick Reboot: This Load Process is used when Redundancy for the BTS Cards is not available.

– The GLI3 disables and reboots to the new Load. This will cause all the other cards to go out

of service.

– Once it is rebooted, the GLI3 determines which cards require a new Load and then downloads

the cards in the order that they establish communication with the GLI3 following their reboot.

– The GLI3 can reload up to 16 devices simultaneously.

4 From the BTS Site, contact the OMC–R and request the operator to PREACTIVATE the BTS to

the required software version for the BSS.

5 After all activities at the site have been completed, contact the OMC–R to confirm that the BTS is

under OMC–R control.

5

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 5-7

PRELIMINARY

Page 38

Prepare to Leave the Site – continued

Notes

5

5-8 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 39

Chapter 6: Troubleshooting

Table of Contents

Basic Troubleshooting: Overview 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Installation 6-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Log into Cell-Site 6-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Force LAN A Active

(LMF Connection at I/O Panel LAN Connector) 6-3 . . . . . . . . . . . . . . . .

Force LAN A Active

(LMF Connection at Service Shelf LAN Connector) 6-4 . . . . . . . . . . . . .

Set the GLI IP Address 6-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Communicate with Power Meter 6-7 . . . . . . . . . . . . . . . . . . . . . . .

Cannot Communicate with Communications System Analyzer 6-7 . . . . . .

Cannot Communicate with Signal Generator 6-8 . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Download 6-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Download 6-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Download DATA to Any Device (Card) 6-10 . . . . . . . . . . . . . . . . . .

Cannot ENABLE Device 6-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPA Errors 6-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Calibration 6-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bay Level Offset Calibration Failure 6-12 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Audit Failure 6-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Basic Troubleshooting: RF Path Fault Isolation 6-14 . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 6-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If Every Test Fails 6-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify BLO Check Box 6-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single–Sided BLO Check Box 6-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

If Faults Are Isolated 6-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Isolation Flowchart 6-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flowchart Prerequisites 6-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Power Output Fault Isolation Flowchart 6-17 . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Transmit ATP 6-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Passed Reduced ATP Tests but Has Forward Link Problem in

Normal Operation 6-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Perform TX Mask Measurement 6-18 . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Perform Rho or Pilot Time Offset Measurement 6-18 . . . . . . . . . . .

Cannot Perform Code Domain Power and Noise Floor Measurement 6-19 .

Troubleshooting: Receive ATP 6-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi–FER Test Failure 6-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP

PRELIMINARY

Page 40

Table of Contents – continued

Troubleshooting: CSM Checklist 6-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problem Description 6-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intermittent 19.6608 MHz Reference Clock / GPS Receiver Operation 6-21

No GPS Reference Source 6-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checksum Failure 6-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPS Bad RX Message Type 6-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSM Reference Source Configuration Error 6-22 . . . . . . . . . . . . . . . . . . . . .

Takes Too Long for CSM to Come INS 6-22 . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: SCCP Backplane 6-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 6-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector Functionality 6-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCCP Backplane Troubleshooting Procedure 6-24 . . . . . . . . . . . . . . . . . . . .

Digital Control Problems 6-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Problems 6-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX and RX Signal Routing Problems 6-28 . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: RFDS 6-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 6-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All Tests Fail 6-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All RX and TX Paths Fail 6-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All Tests Fail on a Single Antenna 6-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Front Panel LED Indicators and Connectors 6-31 . . . . . . . . . . . . . . . . . . . . .

Module Status Indicators 6-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module LED Status (except GLI3, CSM, BBX, MCC) 6-31 . . . . . . . . . . . .

6

Troubleshooting: Span Control Link 6-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Module LED Status Combinations 6-31 . . . . . . . . . . . . . . . .

CSM LED Status Combinations 6-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLI3 LED Status Combinations 6-34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLI3 Pushbutton and Connectors 6-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BBX LED Status Combinations 6-37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCC LED Status Combinations 6-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLPA LED Status Combinations 6-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span Problems (No Control Link) 6-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set BTS Site Span Configuration 6-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 41

Basic Troubleshooting: Overview

Overview

The information in this chapter addresses some of the scenarios likely to

be encountered by Customer Field Engineering (CFE) Team Members

while performing BTS Optimization and Acceptance Testing. This

Troubleshooting Guide was created as an interim reference document for

use in the field. It provides “what to do if” basic troubleshooting

suggestions when the BTS Equipment does not perform according to the

procedures documented in the manual.

Comments are consolidated from inputs provided by CFEs and

information gained from experience in Motorola Labs and Classrooms.

6

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 6-1

PRELIMINARY

Page 42

Troubleshooting: Installation

Cannot Log into Cell-Site

Table 6-1: Login Failure Troubleshooting Procedures

n Step Action

1 If the LED on either GLI is solid RED, it implies a hardware failure.

Reset the GLI by re-seating it.

– If re–seating the MGLI does not fix the problem, proceed to Step 2.

2 Install a GLI Card in the Redundant GLI Slot and retry.

NOTE

A Red LED may also indicate no termination on an External LAN Connector (I/O Panel at the top

of the frame or at the top of a Logical BTS Frame).

3 Circuit BTS:

Verify that the Span Line is disconnected at the Span I/O Card.

Circuit or Packet BTS:

Verify that the OMC–R has disabled the BTS.

4 “Ping” the INS_ACTIVE GLI.

– Refer to Table 3-15.

5 Verify that the LMF is connected to the Primary LAN (LAN A) at one of the following locations.

6

6 If LAN A is not the active LAN, force a LAN Switch to LAN A by performing the procedure in

7 Verify that the LMF was configured properly.

8 If a Xircom Parallel BNC LAN Interface is being used, verify that the BTS-LMF Cable is RG-58

9 Verify that the External LAN Connectors are properly terminated at either of the following two

10 If the LMF is connected to the Primary LAN at the Service Shelf, verify that a T-Adapter is not

11 If the LMF is connected to the Primary LAN at the Service Shelf, try connecting to the Ethernet

– The Service Shelf below the SCCP Cage.

– The BTS I/O Panel at the top of the frame.

Table 6-2.

(flexible black cable, less than 2.5 feet in length).

locations.

– Service Shelf

– BTS I/O Panel at the top of the frame.

used on the LMF Computer or on the Ethernet Hub/Adapter Connector.

Out Port on the I/O Panel (top of frame) using the procedure in Table 3-7.

12 Re-boot the LMF and retry.

13 Re-seat the INS_ACTIVE GLI and retry.

table continued on next page

6-2 1X SC 4812T Lite BTS Optimization/ATP FEB 2005

PRELIMINARY

Page 43

Troubleshooting: Installation – continued

Table 6-1: Login Failure Troubleshooting Procedures

n ActionStep

14 Re-seat the INS_ACT GLI and retry.

15 Verify that the GLI IP Addresses are configured properly by performing the procedure in

Table 6-4.

Force LAN A Active (LMF

Connection at I/O Panel LAN

Connector)

Table 6-2: Procedure to Force Ethernet LAN A to Active State as Primary LAN

(LMF Connection at I/O Panel LAN Connector)

n Step Action

1 If LAN A is not the active LAN, make certain all External LAN Connectors are either terminated

with 50Ω Loads or cabled to another frame.

2 If it has not already been done, connect the LMF Computer to the Stand–alone or Starter Frame,

as applicable (Table 3-6).

3 If it has not already been done, start a GUI LMF Session and log into the BTS on the active LAN

(Table 3-10).

4 Remove the 50Ω Terminator from the LAN B IN Connector on the I/O Panel of the Stand–alone

or Starter Frame.

– The LMF Session will become inactive.

5 Log into the BTS with the LMF (Table 3-10).

– Forcing LAN A to the INS_ACTIVE State was successful if the LMF can log into the BTS

and status any card in the cage.

S If LAN A was successfully forced to an active state, skip to Step 12.

6 With the 50Ω Terminator still removed from the LAN B IN Connector, remove the 50Ω

Terminator from LAN B OUT Connector.

– If more than one frame is connected to the LAN, remove the Terminator from the last frame in

the chain.

7 Again attempt to log the LMF into the BTS Frame on LAN A.

8 If the LAN was successfully forced to an active state, proceed to Step 12.

– Forcing the LAN to the INS_ACTIVE State was successful if the LMF can log into the BTS

and status any card in the cage.

6

9 With the 50Ω Terminators still removed from LAN B, unseat each GLI Gard in each frame

connected to the LAN, until all are disconnected from the SCCP Backplanes.

10 Reseat each GLI Card until all are reconnected.

. . . continued on next page

FEB 2005 1X SC 4812T Lite BTS Optimization/ATP 6-3

PRELIMINARY

Page 44

Troubleshooting: Installation – continued

Table 6-2: Procedure to Force Ethernet LAN A to Active State as Primary LAN

(LMF Connection at I/O Panel LAN Connector)

n ActionStep

11 Allow the GLI Cards to power up, then attempt to select and status cards in the SCCP Cages.

S If LAN A is active, proceed toStep 12.

S If LAN A is still not active, troubleshoot or continue troubleshooting following the procedures

in Table 6-1.

Replace the 50Ω Terminators removed from the LAN B IN and OUT connectors.

12

NOTE

To ensure the INS_ACT GLI Card does not swap LANs after LMF login, the 50Ω Terminator may

be left off of the LAN B OUT connector until LMF operations are completed.

Force LAN A Active (LMF

Connection at Service Shelf

LAN Connector)

Table 6-3: Force Ethernet LAN A to Active State as Primary LAN,

LMF Connection at Service Shelf LAN Connector

n Step Action

6