Page 1

Chapter 7: Optimization and Optional Acceptance Test Procedures (ATP)

Table of Contents

ATP Overview 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Preparation 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Tools and Equipment 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Remove the Solar Cover 7-2. . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Power Up 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Remove Diagnostic Access Cover 7-4. . . . . . . . . . . . . . . . . .

Connect LMF to BTS 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMF to BTS Connection 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Connect LMF to BTS via Serial Port Connection 7-6. . . . . .

Procedure to Connect LMF to BTS via Ethernet Connection 7-7. . . . . . . .

Connect Test Equipment to BTS 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Connect Advantest R3465 to BTS 7-11. . . . . . . . . . . . . . . . .

Procedure to Connect Advantest R3267 to BTS 7-13. . . . . . . . . . . . . . . . . .

Procedure to Connect the Motorola CyberTest, HP 8935, and

HP 8921 to BTS 7-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Connect the Agilent E4406A/E4432B to BTS 7-16. . . . . . . . .

Connect Test Set and Power Meter to LMF 7-18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Connect the Communication Test Set and

Power Meter to the LMF 7-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS232 Cable Configuration 7-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Configuration 7-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Create a Named HyperTerminal Connection for MMI

Communication 7-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Establish an MMI Communication Session 7-22. . . . . . . . . . .

Procedure to Set IP Address 7-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Simulate an LMF Session 7-24. . . . . . . . . . . . . . . . . . . . . . . .

Updating Default Channel Setting to Customer Operating Channel 7-25. . .

Synchronization Background 7-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Verify and Change BTS Synchronization Mode 7-27. . . . . . .

Procedure to Verify DPLL Tracking (RGPS/HSO) 7-28. . . . . . . . . . . . . . . .

Procedure to Verify and Modify Default Location Coordinates 7-29. . . . . .

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

Page 2

Table of Contents – continued

Procedure to Set Frame ID for Multi–Unit Logical BTS Configuration 7-31

BTS Software 7-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the LMF Program and BTS Binaries 7-32. . . . . . . . . . . . . . . . . . . . .

Create a Site–Specific BTS Directory 7-32. . . . . . . . . . . . . . . . . . . . . . . . . .

Start the LMF and Login to the BTS 7-32. . . . . . . . . . . . . . . . . . . . . . . . . . .

Update BTS Specific CDF File Device Load Version 7-33. . . . . . . . . . . . .

Download/Enable MAWI 7-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Data File (CDF) 7-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Status LED States 7-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify and Set Span Line Settings 7-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span Line Settings 7-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Verify and Set Span Line Settings 7-37. . . . . . . . . . . . . . . . . .

SPAN_CONFIG Parameters 7-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Addresses 7-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 7-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify the Gigatronics 8541C Power Meter GPIB Address 7-40. . . . . . . . .

Verify and Set Motorola CyberTest GPIB Address 7-41. . . . . . . . . . . . . . . .

Verify and Set HP8935 Test Set GPIB Address 7-42. . . . . . . . . . . . . . . . . .

Verify and Set the HP8921A and HP83236A/B GPIB Addresses 7-43. . . .

Verify and Set Advantest R3465 GPIB Address 7-44. . . . . . . . . . . . . . . . . .

RS232 GPIB Interface Box 7-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify and Set Advantest R3267 GPIB Address 7-45. . . . . . . . . . . . . . . . .

Verify and Set Advantest R3562 Signal Generator GPIB Address 7-47. . . .

Verify and Set Agilent E4406A Transmitter Tester GPIB Address 7-47. . . .

Verify and Set Agilent E4432B Signal Generator GPIB Address 7-49. . . . .

Test Equipment Calibration 7-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 7-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Test Equipment Selection 7-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Meter Calibration 7-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

Procedure to Calibrate Test Equipment 7-52. . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Without the LMF 7-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Calibrate R3465 Test Set 7-53. . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Calibrate R3267 Test Set 7-53. . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Calibrate Agilent E4406A 7-54. . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Setup Advantest R3465 Test Equipment 7-55. . . . . . . . . . . . .

Procedure to Setup Advantest R3267 Test Equipment 7-56. . . . . . . . . . . . .

Objective 7-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 7-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Select Test Equipment 7-57. . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Test Equipment Automatically or Manually 7-58. . . . . . . . . . . . .

Procedure to Manually Select Test Equipment in a

Serial Connection Tab 7-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Automatically Select Test Equipment in a

Serial Connection Tab 7-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

JAN 2002

DRAFT

Page 3

Table of Contents – continued

Objective 7-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 7-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Calibrate the Power Meter 7-60. . . . . . . . . . . . . . . . . . . . . . . .

Test Cable Calibration 7-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 7-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose of Cable Calibration 7-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to do an Automated Cable Calibration 7-62. . . . . . . . . . . . . . . . .

Create CAL File 7-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 7-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Create a CAL File 7-66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acceptance Tests 7-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 7-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Test Objective 7-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Tests 7-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Test Objective 7-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Tests 7-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subscriber Unit (SU) Test and Setup 7-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 7-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Test and Verify SU 7-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Program SU NAM Parameters 7-71. . . . . . . . . . . . . . . . . . . . .

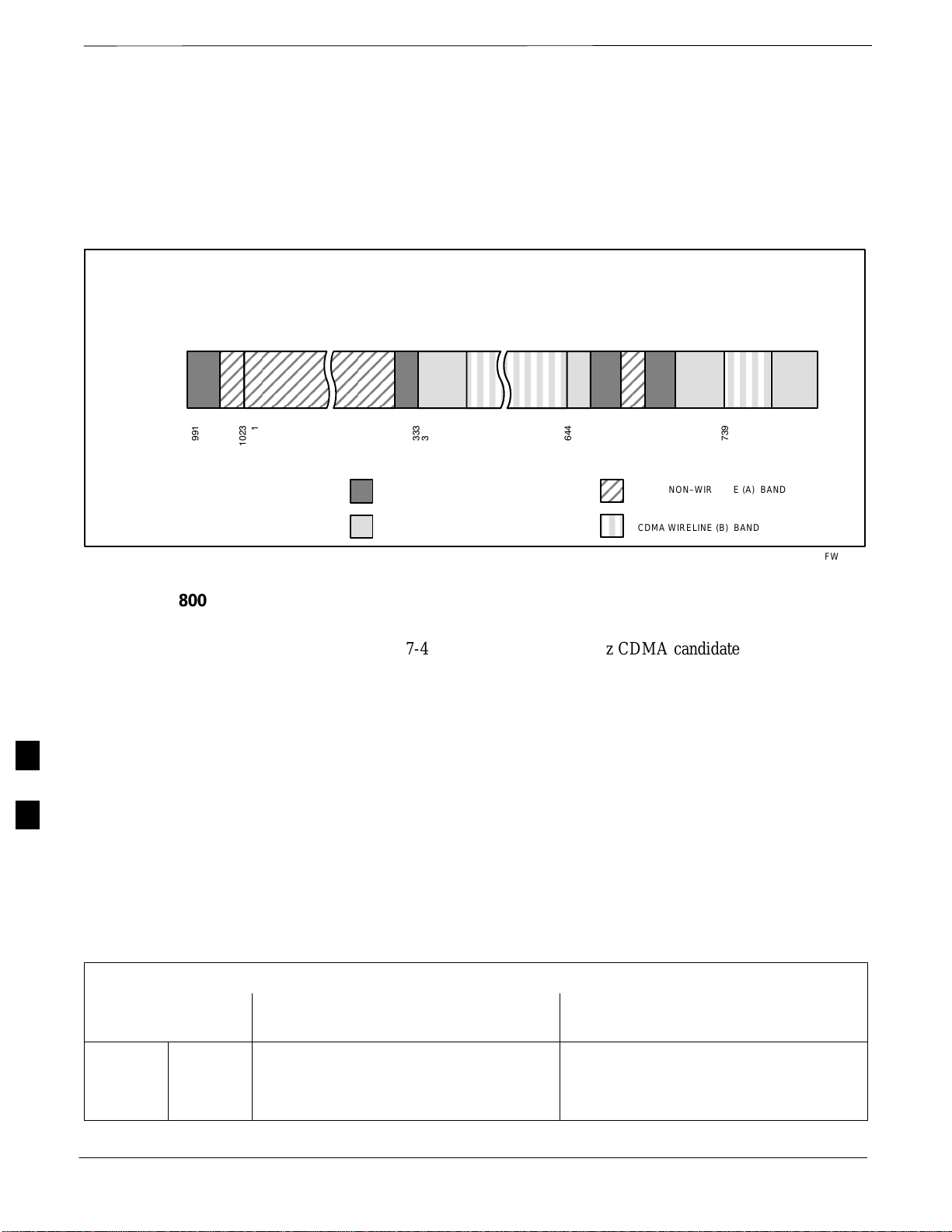

CDMA Operating Frequency Programming Information – North American

Cellular Bands 7-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1900 MHz PCS Channels 7-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculating 1900 MHz Center Frequencies 7-74. . . . . . . . . . . . . . . . . . . . . .

800 MHz CDMA Channels 7-76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculating 800 MHz Center Frequencies 7-76. . . . . . . . . . . . . . . . . . . . . . .

TX Acceptance Tests 7-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 7-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Run TX ATP Test 7-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Run TX Tests Using Backup Synchronization

(Sites Equipped With GPS) 7-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Acceptance Tests 7-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 7-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Run RX ATP Test 7-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

JAN 2002

Generate an ATP Report 7-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 7-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Report 7-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Run ATP Report 7-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy LMF CAL File to CBSC 7-89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 7-89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

Page 4

Table of Contents – continued

Background 7-89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Copy CAL Files from LMF to a Diskette 7-89. . . . . . . . . . . .

Procedure to Copy CAL Files from Diskette to the CBSC 7-90. . . . . . . . . .

Prepare to Leave the Site 7-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove External Test Equipment 7-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset and Initialize Site Remotely 7-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bring BTS into Service with the CDMA LMF 7-91. . . . . . . . . . . . . . . . . . .

Terminate LMF Session/Remove Terminal 7-92. . . . . . . . . . . . . . . . . . . . . .

Replace Diagnostic Access Cover 7-93. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replace Solar Cover 7-93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

JAN 2002

DRAFT

Page 5

ATP Overview

Overview

The purpose of this procedure is to outline the optimization and ATP

after a BTS installation. Calibration of the BTS is performed in the

factory and is not required. The ATP is also performed in the factory

and is optional.

All the procedures in this chapter are to be performed with the BTS out

of service or under LMF control. If necessary, refer to the “Shut Down

and Restoring BTS Signaling” procedure in Chapter 7.

For a complete listing of the required tools and equipment, refer to the

“ATP Tools and Equipment” list in Chapter 1.

IMPORTANT

*

You must run the ATP with LMF Software Release

2.15.0.1.10 or higher.

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-1

Page 6

BTS Preparation

Overview

Required T ools and Equipment

Procedure to Remove the Solar

Cover

The purpose of this procedure is to prepare the BTS for the ATP. This

procedure consists of:

1. Solar Cover Removal

2. BTS Power Up

3. Diagnostic Access Cover Removal

The following tools and materials are necessary to do this procedure:

Torque driver wrench, 1/4–in. hex female drive, 0–10 N–M

T20 Torx tamper bit

If you did not mount the solar cover during the unit installation, then this

procedure is not necessary.

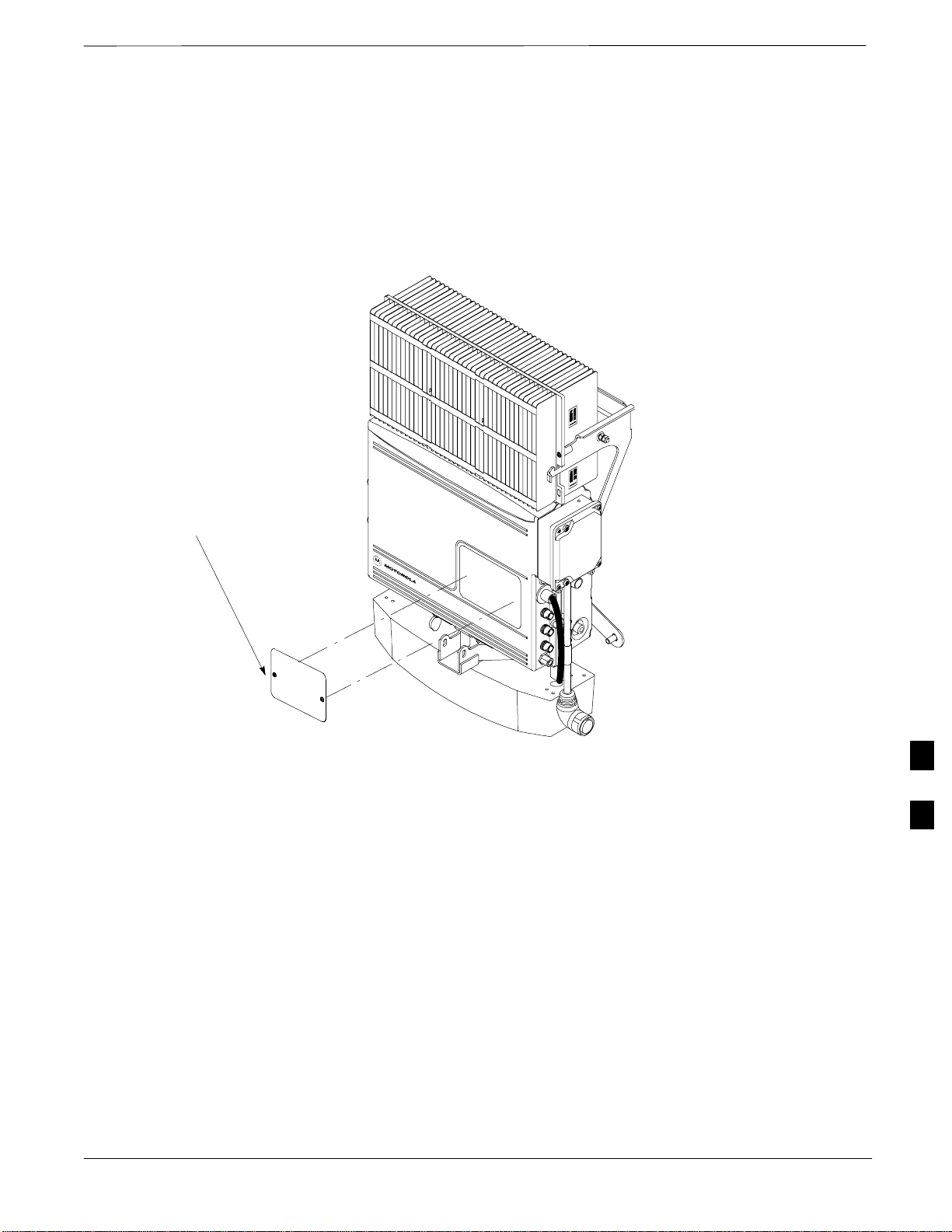

Remove the four captive screws (two on each side) that hold the front

solar cover. Refer to Figure 7-1.

Figure 7-1: Front Solar Cover

FRONT COVER

CAPTIVE SCREWS

7

CAPTIVE SCREWS

BTS Power Up

7-2

Figure 7-2 shows the location of the AC power breakers inside the

optional Primary Surge Suppressor. The AC breakers must be closed

before you power up the MicroCell unit.

Figure 7-3 shows the location of the AC and DC Power breakers on the

unit. Push both the AC and DC breakers in to power up the unit.

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 7

BTS Preparation – continued

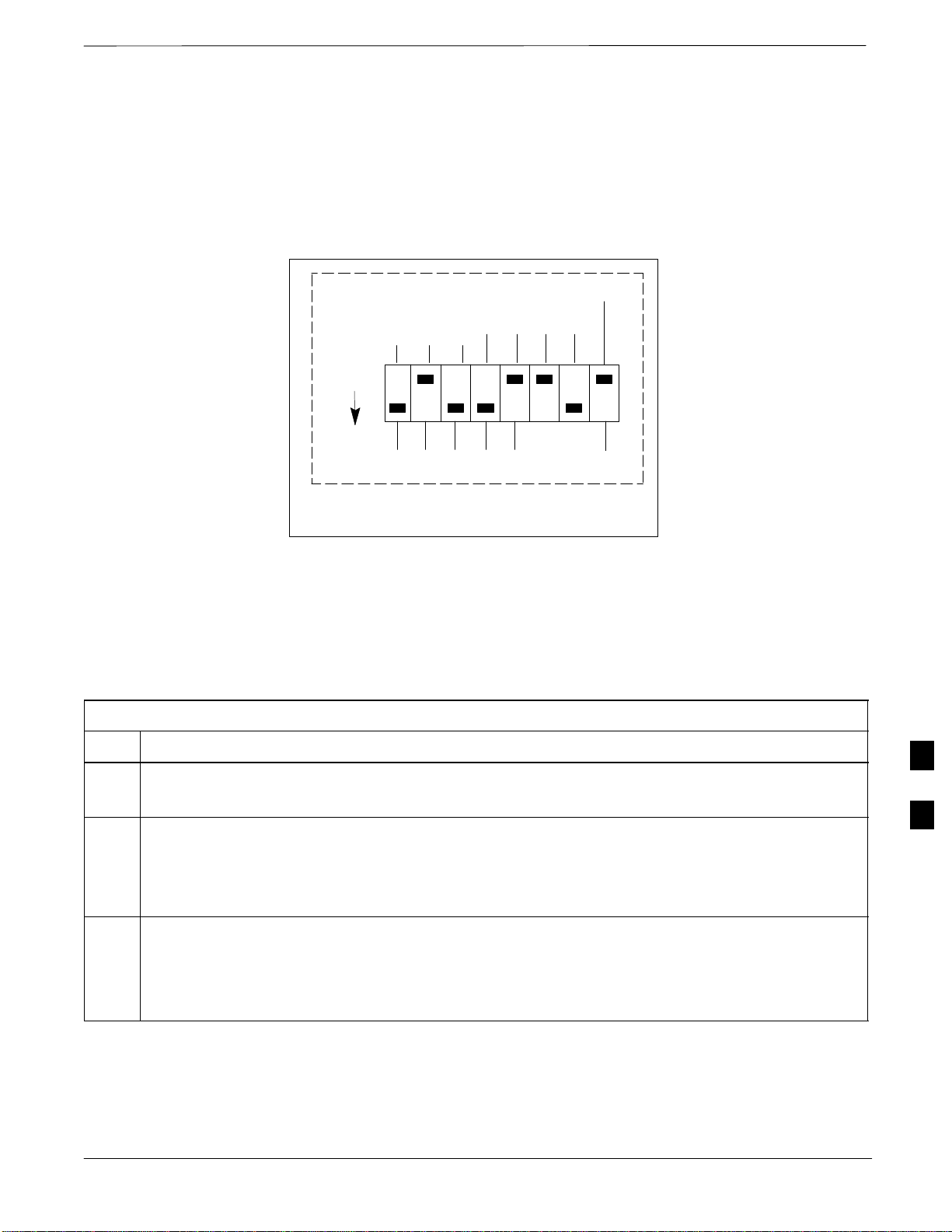

Figure 7-2: Location of AC Power Breakers Inside Primary Surge Suppressor

AC POWER BREAKER

CARRIER 2

AC POWER BREAKER

CARRIER 3

AC POWER BREAKER

CARRIER 4

Figure 7-3: Location of AC and DC Power Breakers

AC POWER BREAKER

CARRIER 1

MAIN INPUT BREAKER

JAN 2002

AC POWER BREAKER

DC POWER BREAKER

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7

7-3

Page 8

BTS Preparation – continued

Procedure to Remove

Diagnostic Access Cover

NOTE

The screws are captivated. Do not attempt to remove them

from the cover.

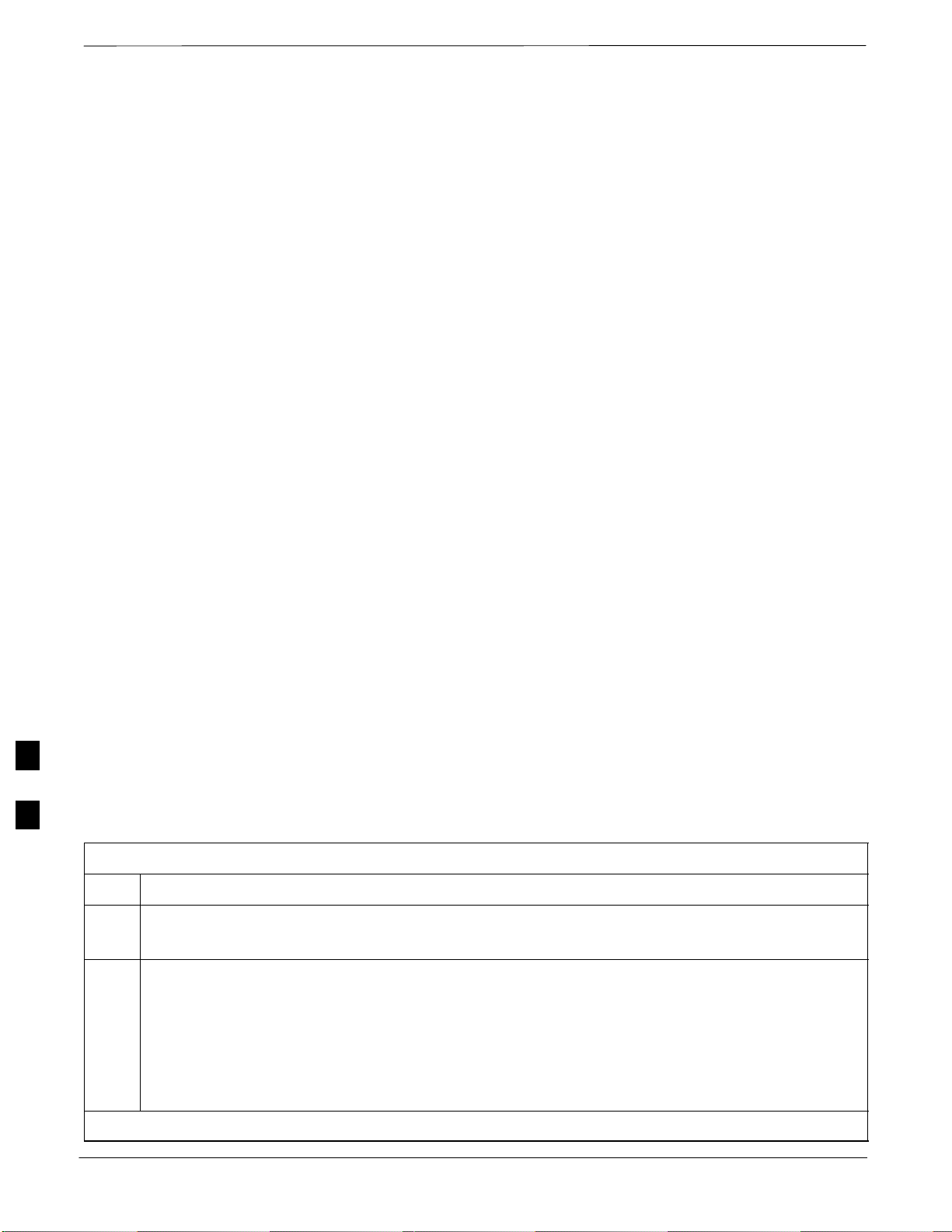

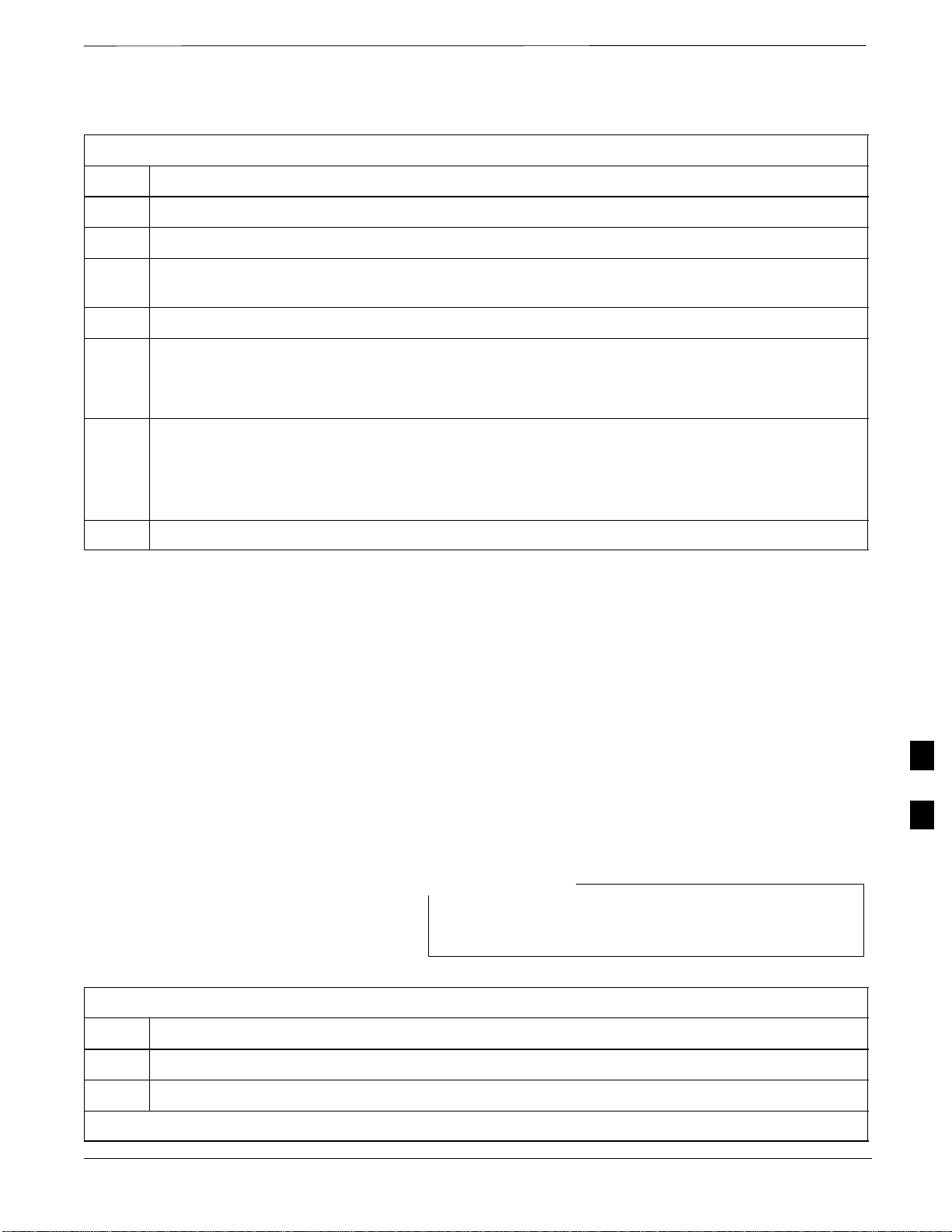

Table 7-1: Procedure for Removing Diagnostic Access Cover

Step Action

1 Using a T20 Torx tamper bit, loosen the two tamper resistant M4 screws holding the cover. See

Figure 7-4.

2 Gently tap the cover to loosen if required.

3 Remove the cover and set inside a secure place.

NOTE

The 19 MHz and 2 SEC connectors should not be terminated with a 50 ohm terminator.

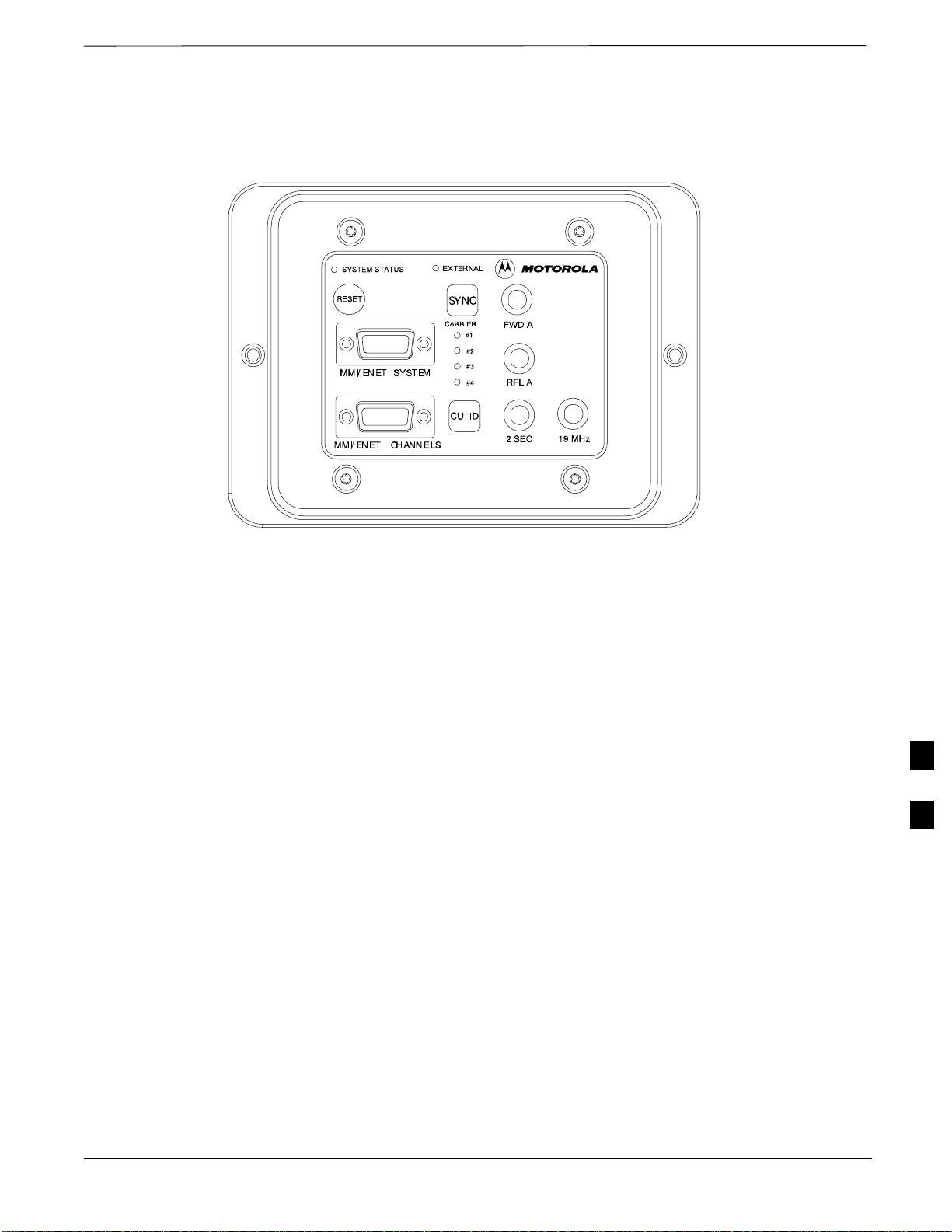

Figure 7-4: How To Remove The Diagnostic Access Cover

7

SCREWS IN DIAGNOSTIC

ACCESS COVER ARE CAPTIVE

7-4

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 9

BTS Preparation – continued

Figure 7-5: Detail Location of the Diagnostic Access Area

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7

7-5

Page 10

Connect LMF to BTS

Overview

LMF to BTS Connection

Procedure to Connect LMF to

BTS via Serial Port Connection

This procedure gives instructions to connect the LMF to the BTS.

The LMF is connected to the MMI/LMF connector on the diagnostic

access area.

The LMF serial port, or PCMCIA (Personal Computer Memory Card

International Association) Serial Adapter provides the connection

between the LMF and the MMI/LMF connector located on the

diagnostic access area.

There are three different methods to connect the LMF to the BTS: serial

port to DB9, Ethernet via Ethernet hub, and Ethernet via crossover

connection.

Connect the LMF to the BTS. Refer to Figure 7-6, Figure 7-10, and

Table 7-2.

Figure 7-6: Serial to DB9 BTS to LMF connection

7

CONNECT TO

LMF

PCMCIA SERIAL I/O

OR SERIAL I/O PORT

DB9 TO DB9 CABLE

CONNECT 15 TO 9–PIN MMI TO SERIAL

CONNECTOR TO MMI/ENET SYSTEM PORT

7-6

DB9

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DB9

DRAFT

JAN 2002

Page 11

Connect LMF to BTS – continued

Procedure to Connect LMF to

BTS via Ethernet Connection

You can connect the LMF to the BTS via an Ethernet connection.

Depending upon site configuration, you can use an Ethernet connection

with or without an Ethernet hub. For example, if your BTS is mounted

on a pole and there is no power connection available for the Ethernet

hub, then you can connect to the BTS via a RJ45 crossover cable or a

MMI to LAN crossover adapter. In either case, you must configure

either the RJ45 cable or the adapter to a crossover configuration.

Ethernet connection via Ethernet hub

To connect the LMF to the BTS via an Ethernet connection using an

Ethernet hub, refer to Figure 7-7, Figure 7-10, and Table 7-2.

Figure 7-7: Ethernet BTS to LMF Connection Using an Ethernet Hub

JAN 2002

CONNECT PCMCIA

LAN CARD TO

LMF

ETHERNET HUB

4–PORT 10 BASE T

ETHERNET HUB

RJ45 ETHERNET CABLE

Ethernet connection via crossover cable

To connect the LMF to the BTS via an Ethernet connection using a

crossover cable or adapter, you must configure the RJ45 cable or the

MMI to LAN adapter as a crossover. Refer to Figure 7-8 for information

on how to configure the cable or adapter. Refer to Figure 7-9,

Figure 7-10, and Table 7-2 to connect the LMF to the BTS.

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

7

RJ45 ETHERNET TO

15–PIN MMI TO LAN

ADAPTER

7-7

DRAFT

Page 12

Connect LMF to BTS – continued

Figure 7-8: Ethernet Crossover Cable and Adapter Wiring

RJ45 ETHERNET CABLE CROSSOVER CONFIGURATION

TX+

1

TX–

2

RX+

3

RX–

6

BLUE

ORANGE

BLACK

YELLOW

RED

GREEN

BROWN

GRAY

1

2

3

6

4

5

7

8

MMI/LAN ADAPTER CROSSOVER CONFIGURATION

15–PIN D–SUB

TX+

4

TX–

5

RX+

15

RX–

12

Figure 7-9: Ethernet BTS to LMF Connection Using Crossover Cable or Adapter

RJ–45

BLUE

ORANGE

BLACK

YELLOW

RED

GREEN

BROWN

GRAY

1

2

3

6

4

5

7

8

NOTE: YOU MUST CONFIGURE EITHER THE RJ45

CABLE OR THE MMI TO LAN ADAPTER AS A

CROSSOVER TO CONNECT THE LMF TO THE BTS IN

THIS FASHION.

7

CONNECT PCMCIA

LAN CARD TO

LMF

ETHERNET HUB

RJ45 ETHERNET TO

15–PIN MMI TO LAN

ADAPTER

(SEE NOTE)

RJ45 ETHERNET CABLE

(SEE NOTE)

7-8

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 13

Connect LMF to BTS – continued

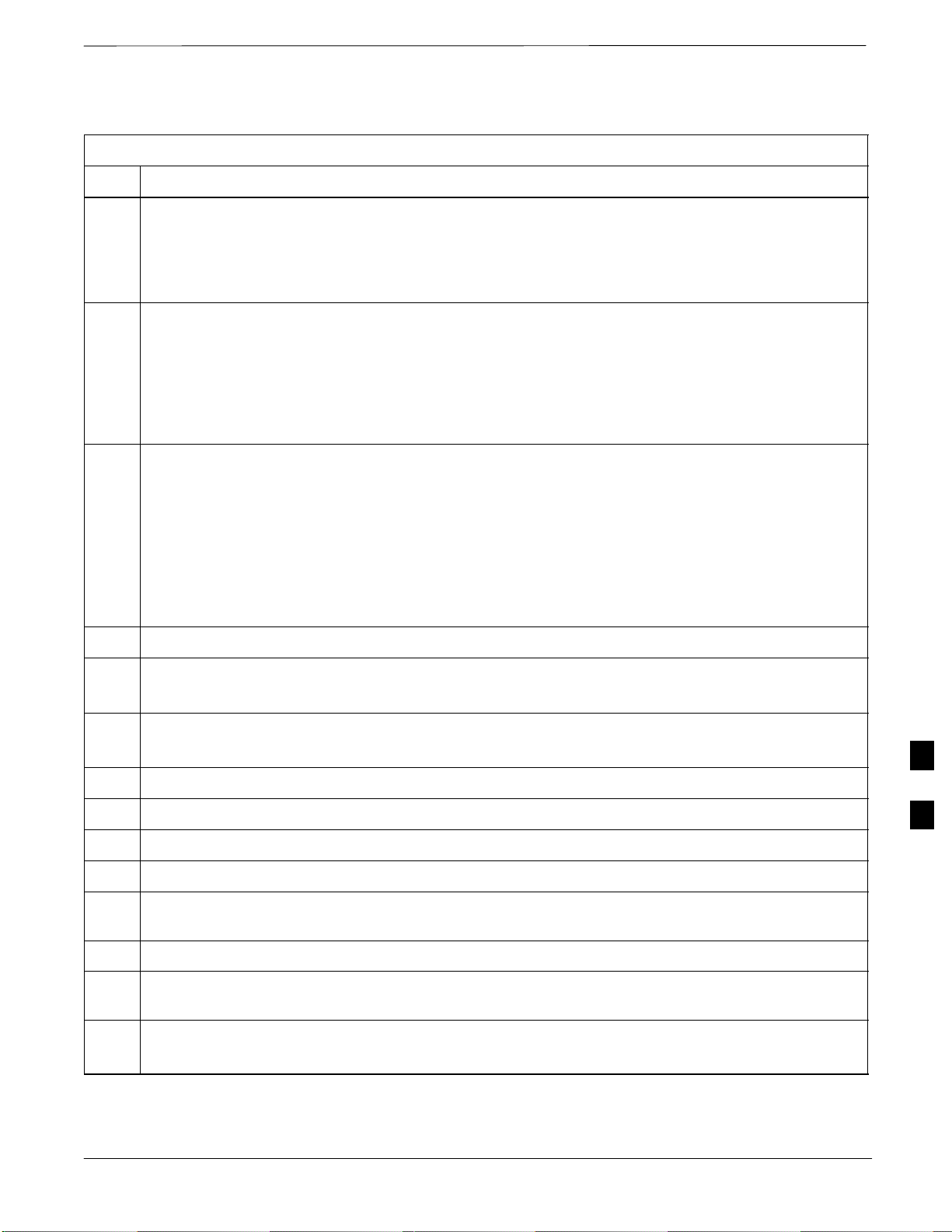

MMI/LMF serial connector information

Refer to Figure 7-10 and Table 7-2 for information for the 15–pin

MMI/LMF connector.

Figure 7-10: 15–Pin MMI/LMF Serial Connector

11 12 13 14 15

678910

12345

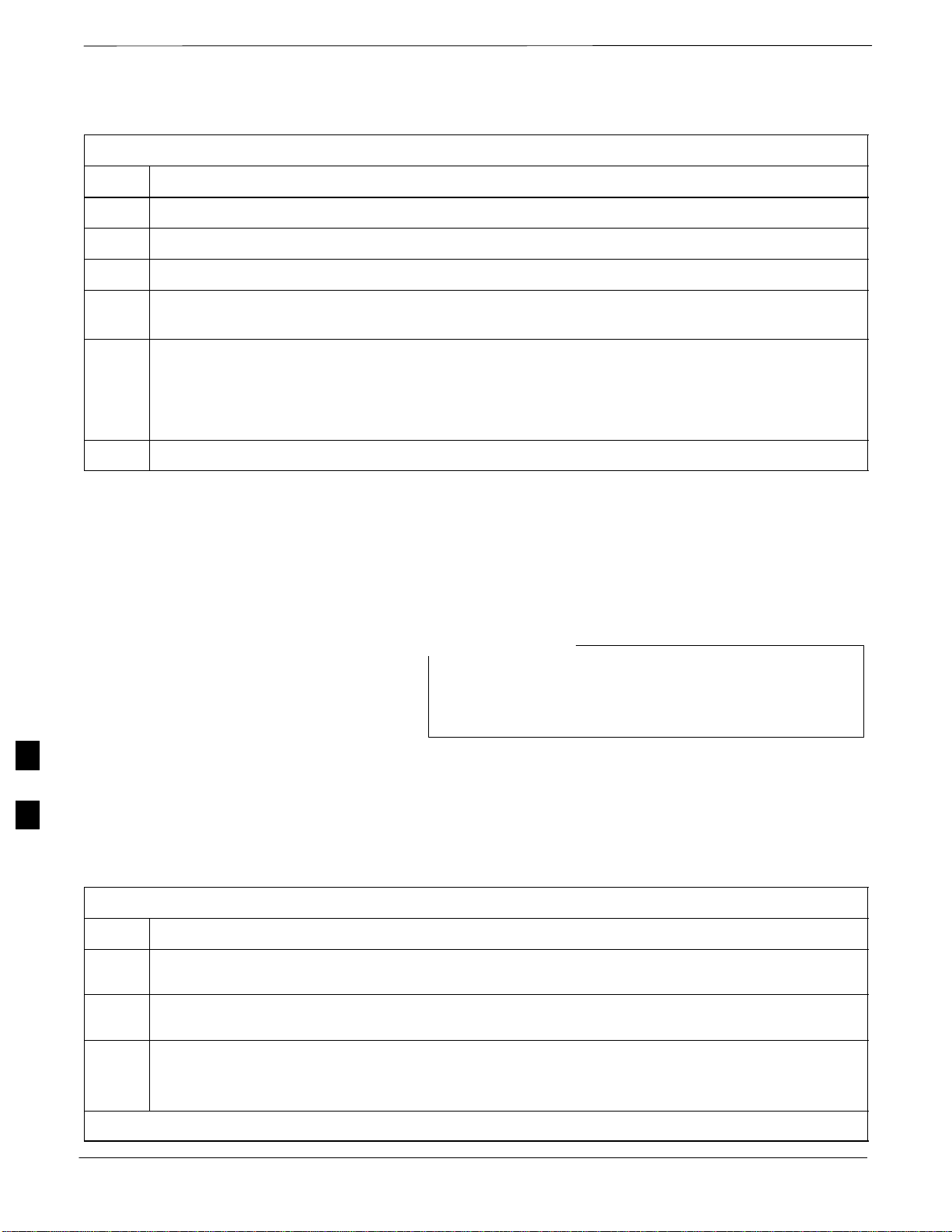

Pin# Abbreviation Description

1 RTS Request to Send

2 TXD Transmit Data

Table 7-2: 15–Pin MMI/LMF Serial Cable Information

3 RXD Receive Data

4 TX+ Ethernet Transmit +

5 TX– Ethernet Transmit –

6 CTS Clear to Send

7 CTS Clear to Send

8 CTS Clear to Send

9 – Open

10 RI Ring Indicator

11 RI Ring Indicator

12 RX+ Ethernet Receive +

13 CTS Clear to Send

14 GND Ground

15 RX– Ethernet Receive –

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-9

Page 14

Connect Test Equipment to BTS

Overview

The following test equipment setup applies to the BTS Acceptance Test

Procedure (ATP).

The SC300 BTS supports the following test sets for IS95 A/B testing:

1. Advantest R3465 with R3561 Signal Generator.

2. Motorola CyberTest

3. HP 8921A (for 800 MHz testing only)

4. Aglient 8935 Series E6380A (formally HP8935)

The 1X SC300 BTS supports the following test sets for CDMA2000

1X testing:

1. Advantest R3267 with R3562 Signal Generator

2. Agilent E4406A with E4432B Signal Generator

NOTE

If you are not going to perform the ATP, then proceed to

the “Creating a Named HyperTerminal Connection for

MMI Communication” procedure in this chapter.

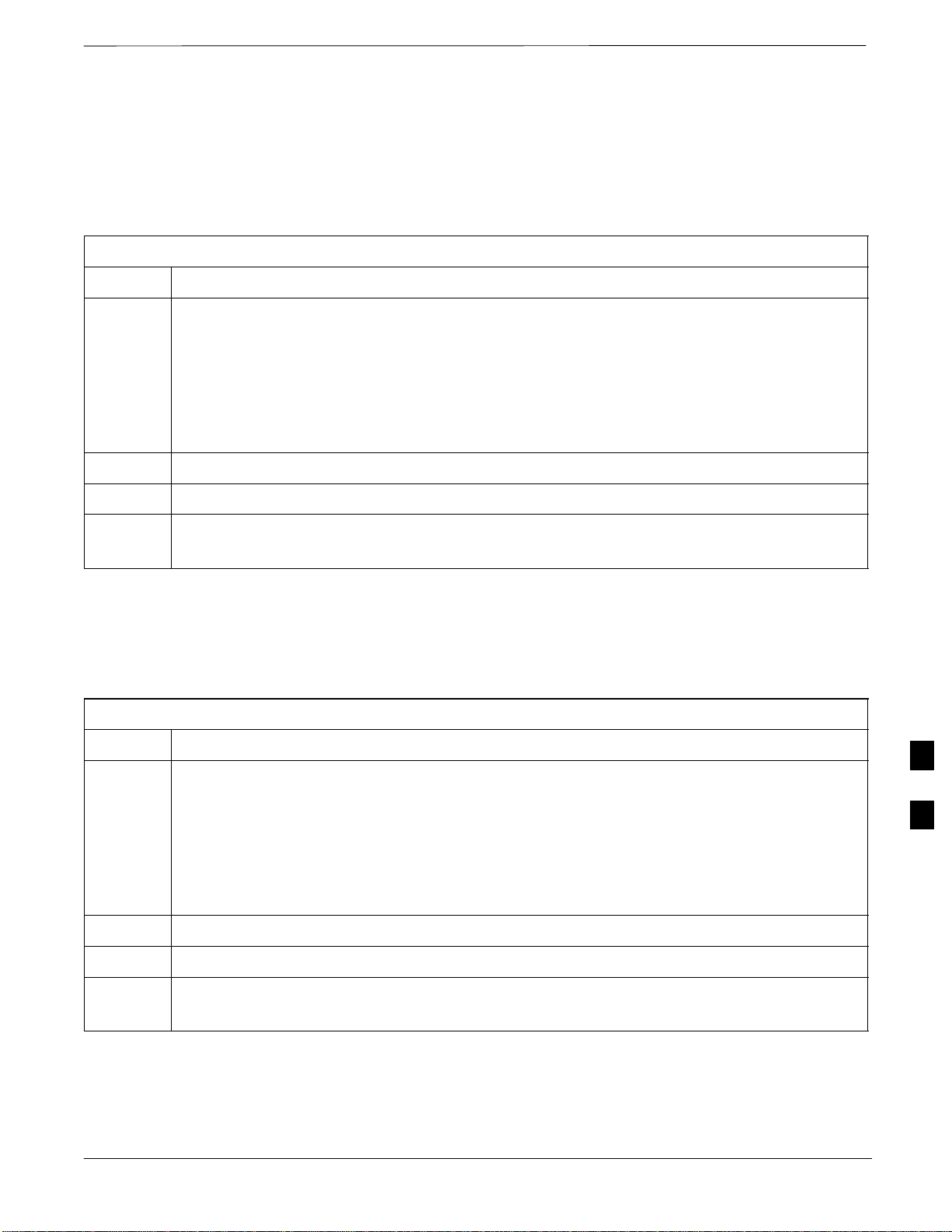

Equipment warm-up

IMPORTANT

*

7

*

Warm-up BTS equipment site for a minimum of 60

minutes prior to the BTS ATP. This assures BTS site

stability and contributes to test accuracy.

(Time spent running initial power–up, hardware/firmware

audit, and BTS download counts as warm–up time).

IMPORTANT

Warm-up test equipment for a minimum of 60 minutes

prior to their use in the BTS ATP. This assures maximum

equipment measurement accuracy and consistency during

testing.

7-10

All test equipment is controlled by the LMF via a Serial Cable/GPIB

bus. The LMF expects each piece of test equipment to have a factory-set

GPIB address. If there is a communications problem between the LMF

and any piece of test equipment, you should verify that the GPIB

addresses have been set correctly.

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 15

Connect Test Equipment to BTS – continued

NOTE

In the following procedure and illustrations, typical DIP

switch positions and/or configurations are shown. If

required, refer to the test equipment OEM user manuals for

additional information.

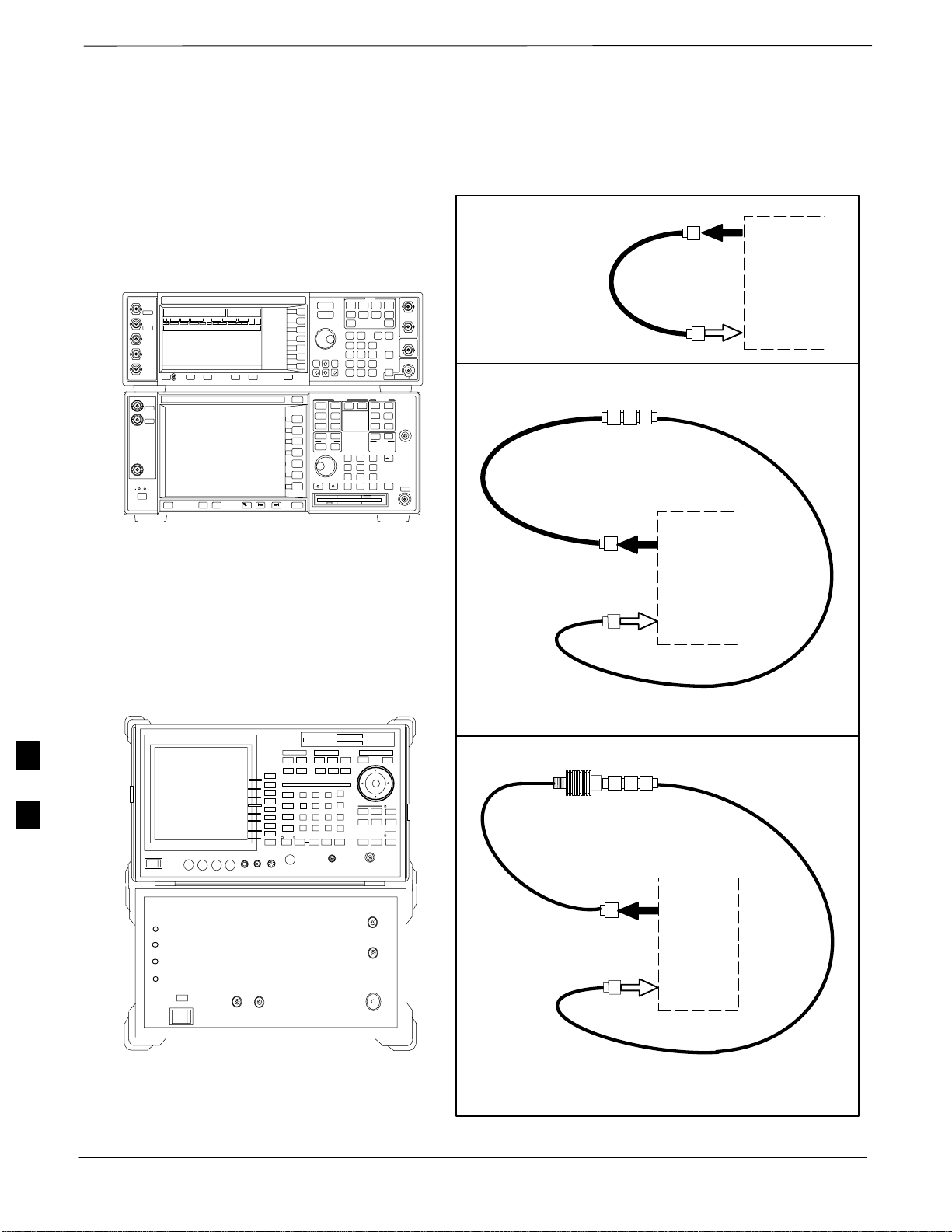

Procedure to Connect

Advantest R3465 to BTS

Follow the procedure in Table 7-3 to connect the Advantest R3465 to the

BTS. Refer to Figure 7-11.

Table 7-3: Connecting Advantest R3465 to the BTS

Step Action

1 Connect an SMA/BNC coax cable between the following points:

– BNC on the Advantest CDMA TIMEBASE IN port.

– SMA on the 19 MHz port on the diagnostic access area of the BTS.

2 Connect an SMA/BNC cable between the following points:

– BNC to one end of the BNC “T.”

– SMA on the 2 Sec port on the diagnostic access area of the BTS.

3 Connect a BNC/BNC cable between the following points:

– BNC to one end of the BNC “T.”

– BNC to the EXT TRIG port on the rear panel of the Advantest R3465.

4 Connect the BNC “T” to the EVEN SEC/SYNC IN port of the Advantest R356IL.

5 Verify the R3561 and R3465 rear panel connections are in place (These are common connections and

should already be installed):

– Serial cable between 3465A rear panel SERIAL I/O port and R3561 SERIAL I/O port.

– SMA cable between 3465A rear panel 1ST LO OUT port and R3561 LOCAL IN port.

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-11

Page 16

Connect Test Equipment to BTS – continued

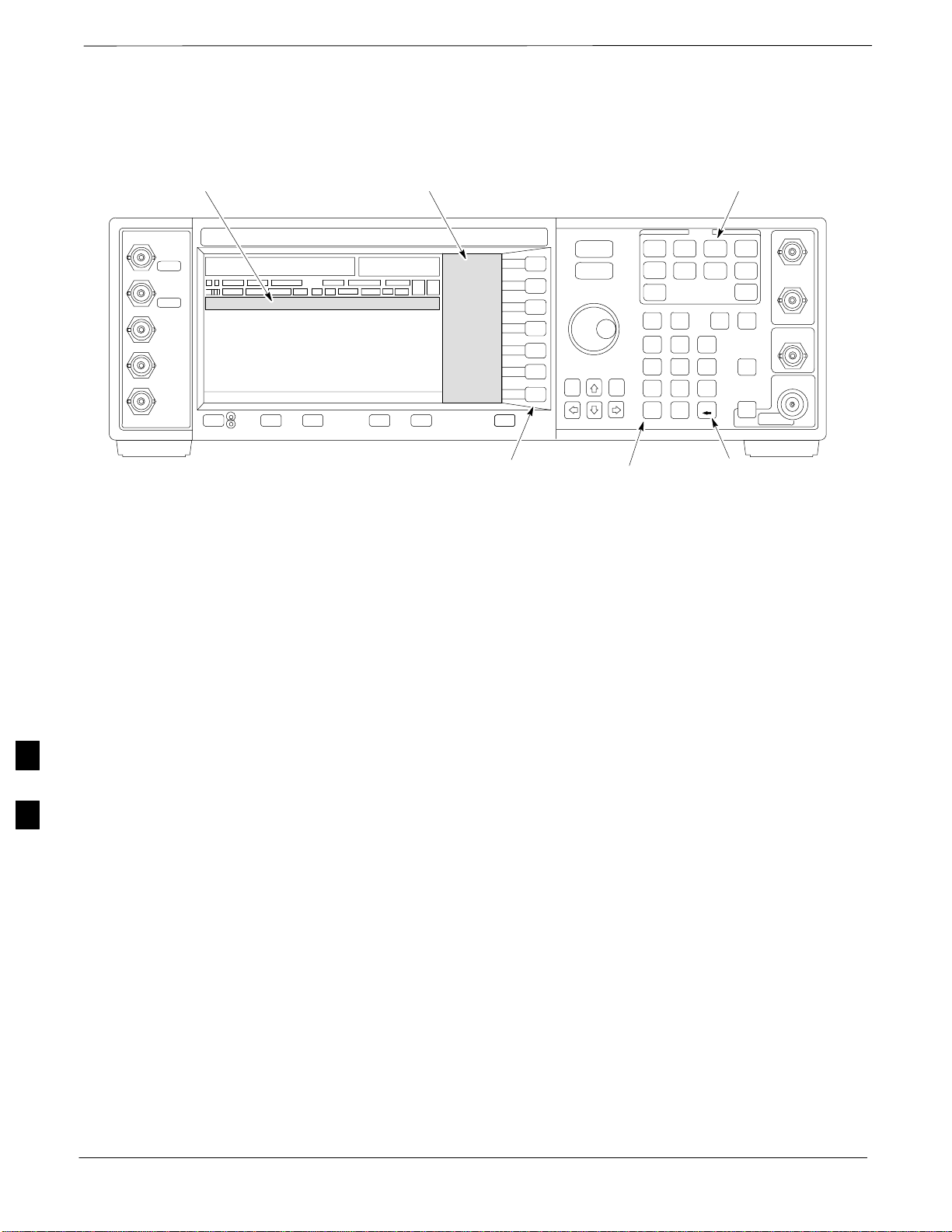

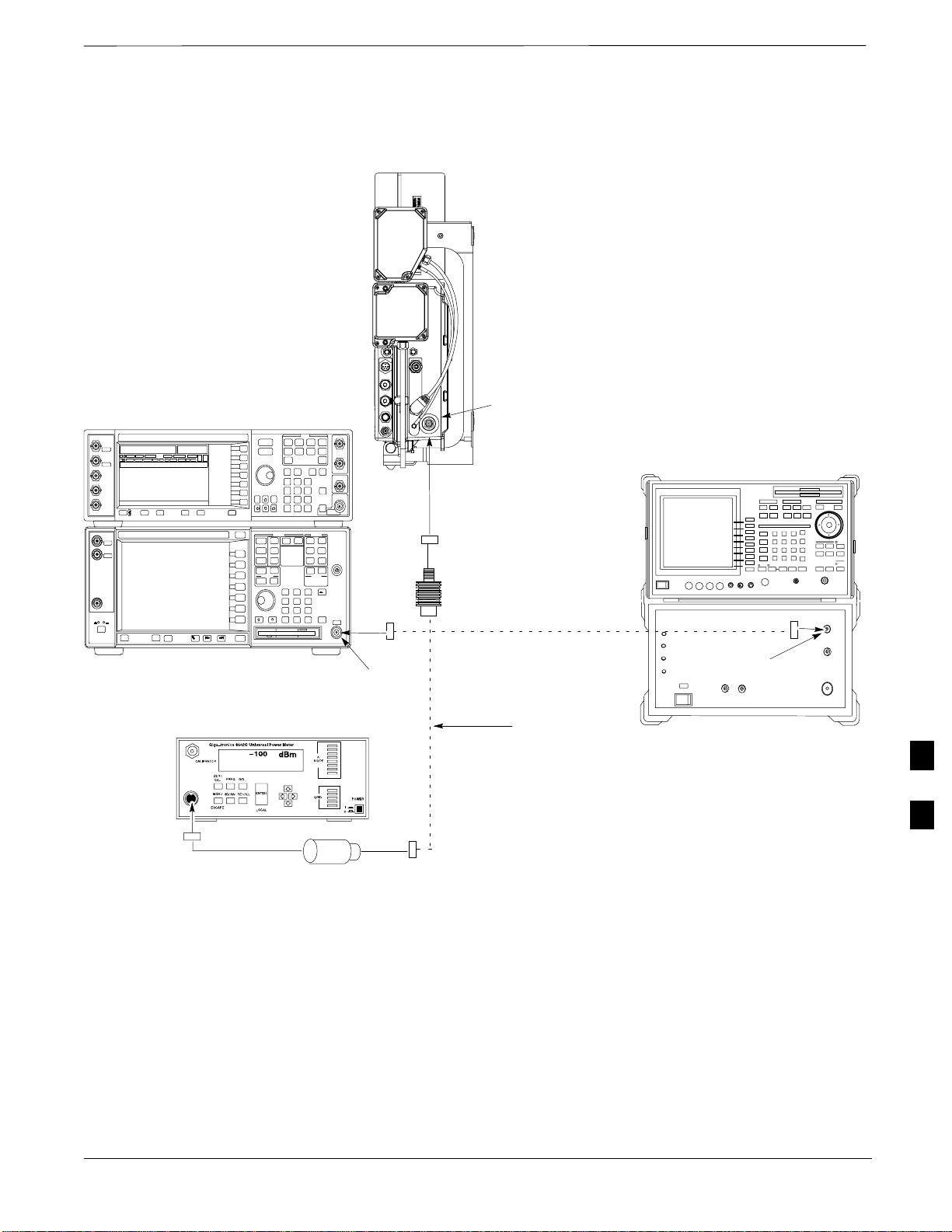

Figure 7-11: Communications Test Set Timing Signal Detail (Advantest R3465)

BTS DIAGNOSTIC ACCESS AREA

CONNECTIONS DEPICTED BY HEAVY BOLD LINES ARE

STATIONARY AND SHOULD REMAIN INSTALLED DURING

TEST EQUIPMENT TRANSPORT FROM SITE TO SITE.

2 SECOND REFERENCE

19.6608 MHZ REFERENCE

BNC

“T”

Advantest R3465

front panel

7

GPIB

CONNECTOR

FROM EVEN

SEC/SYNC IN

Advantest R3465

rear panel

7-12

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 17

Connect Test Equipment to BTS – continued

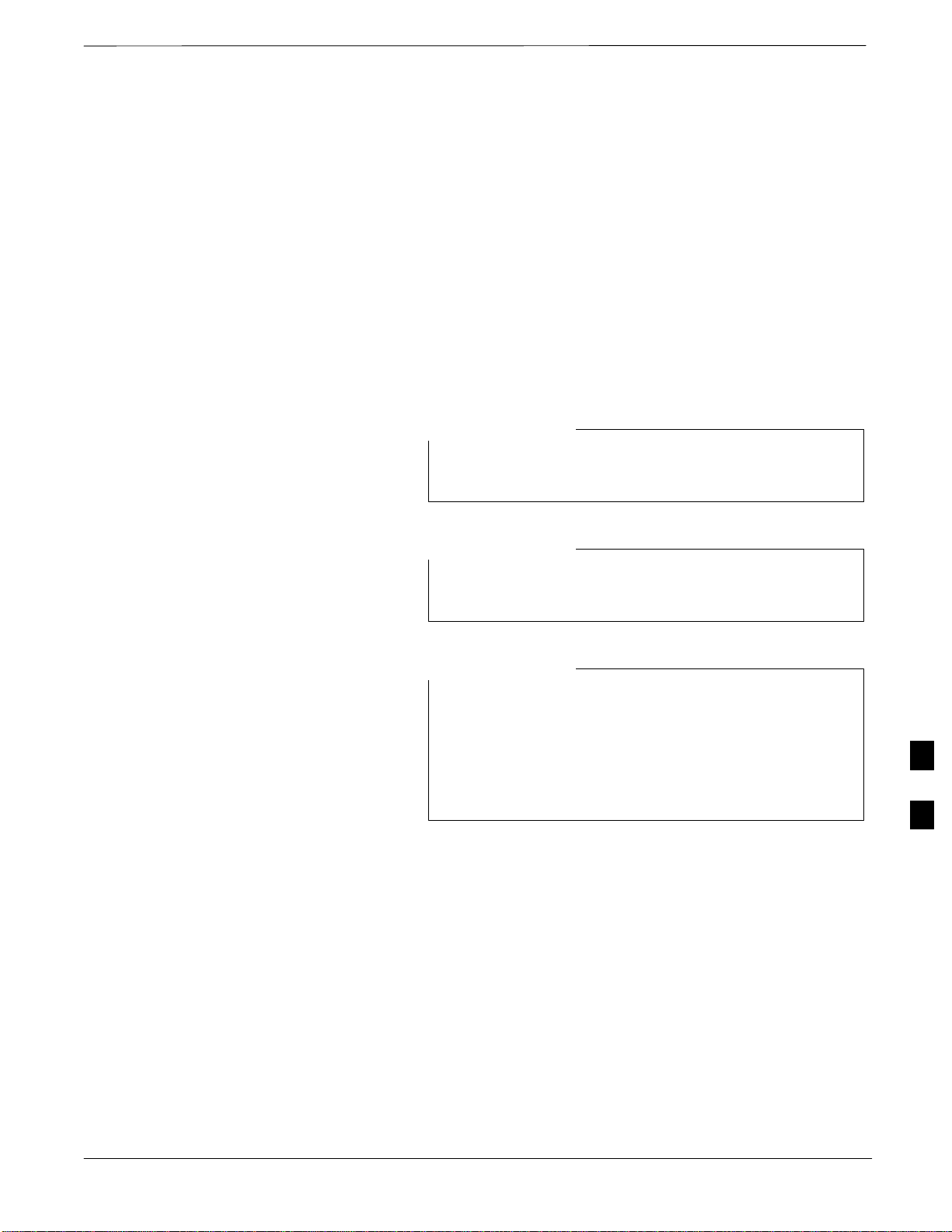

Procedure to Connect

Advantest R3267 to BTS

Use the procedures in Table 7-4 to connect the Advantest R3267 to the

BTS. Refer to Figure 7-12.

NOTE

The Advantest R3267 test set is used for 1X system

testing.

Table 7-4: Procedure to Connect Advantest R3267 to the BTS

Step Action

1 Connect an SMA/BNC coax cable between the following points:

– BNC on the MOD TIMEBASE IN port on the front panel of the Advantest R3562 Test

Source.

– SMA on the 19 MHz port on the diagnostic access area of the BTS.

2 Connect an SMA/BNC cable between the following points:

– SMA on the 2 Sec port on the diagnostic access area of the BTS.

– BNC to the EXT TRIG IN port on the front panel of the Advantest R3562 Test Source.

3 Verify the R3267 and R3562 rear panel connections are in place (These are common connections

and should already be installed):

– Serial cable between R3267 rear panel SERIAL I/O port and R3562 rear panel SERIAL I/O

port.

– SMA cable between R3267 rear panel 10MHZ REF OUT port and R3562 rear panel

SYNTHE REF IN port.

– SMA cable between R3267 rear panel EXT TRIG port and R3562 rear panel CLOCK OUT

1 port.

– Parallel cable between R3267 rear panel GPIB port and R3562 GPIB port.

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-13

Page 18

Connect Test Equipment to BTS – continued

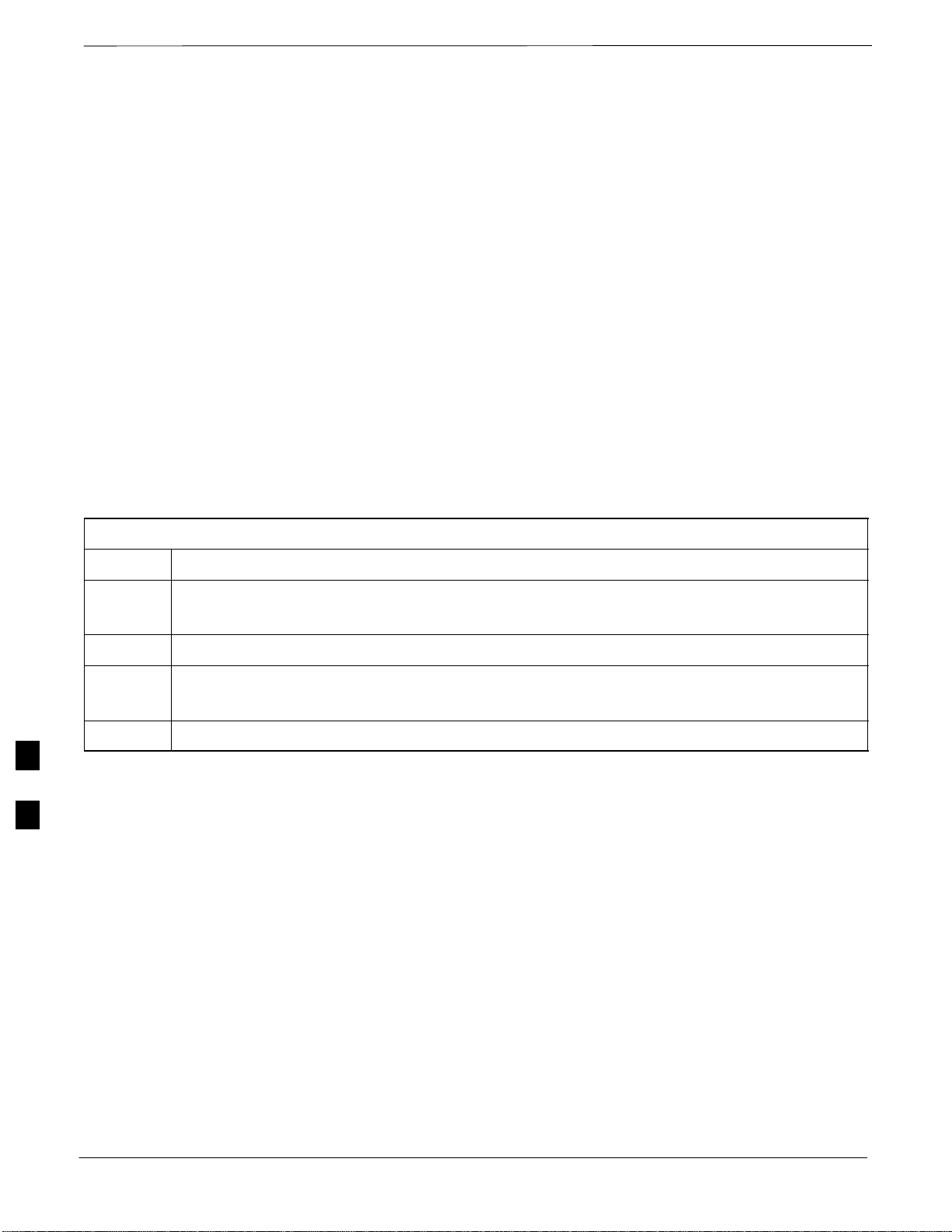

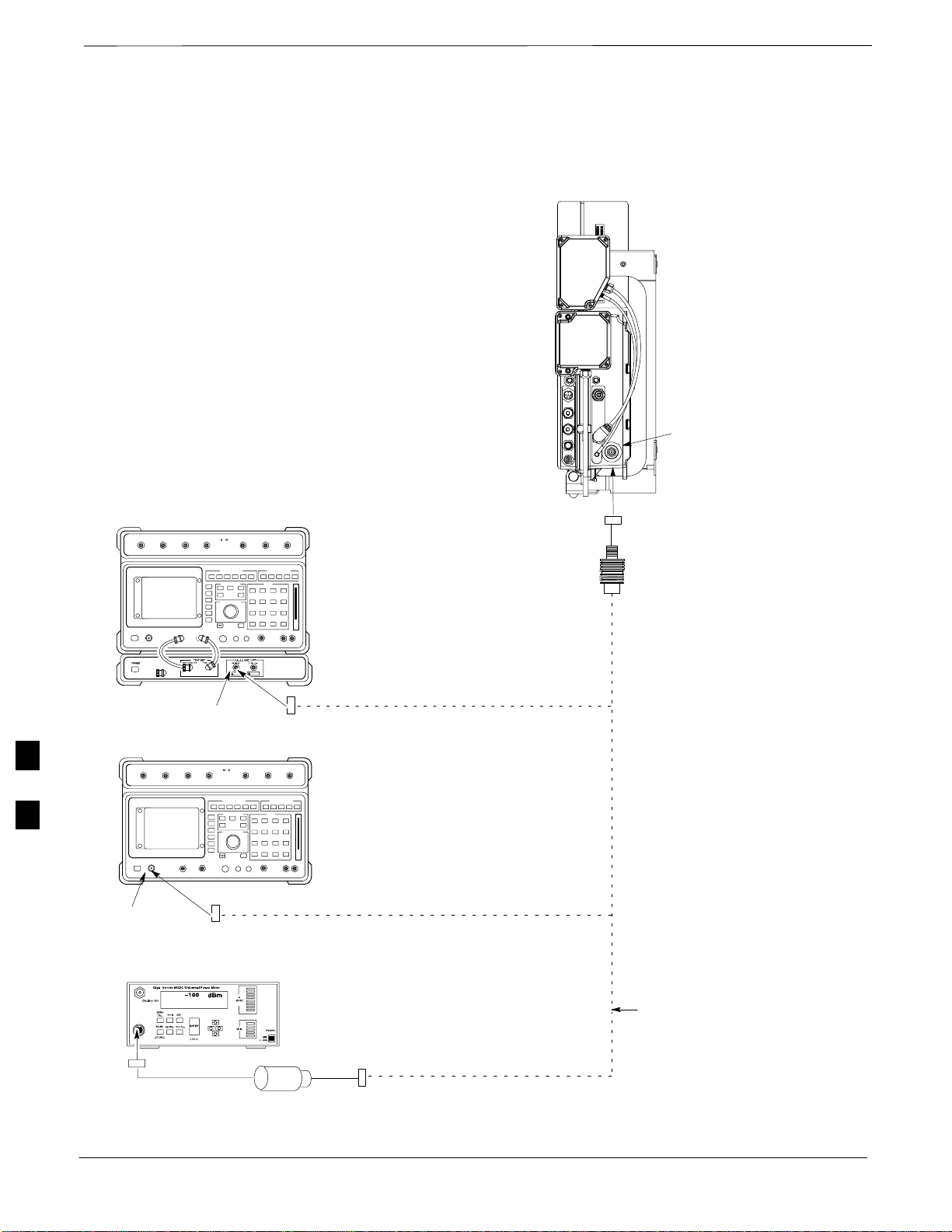

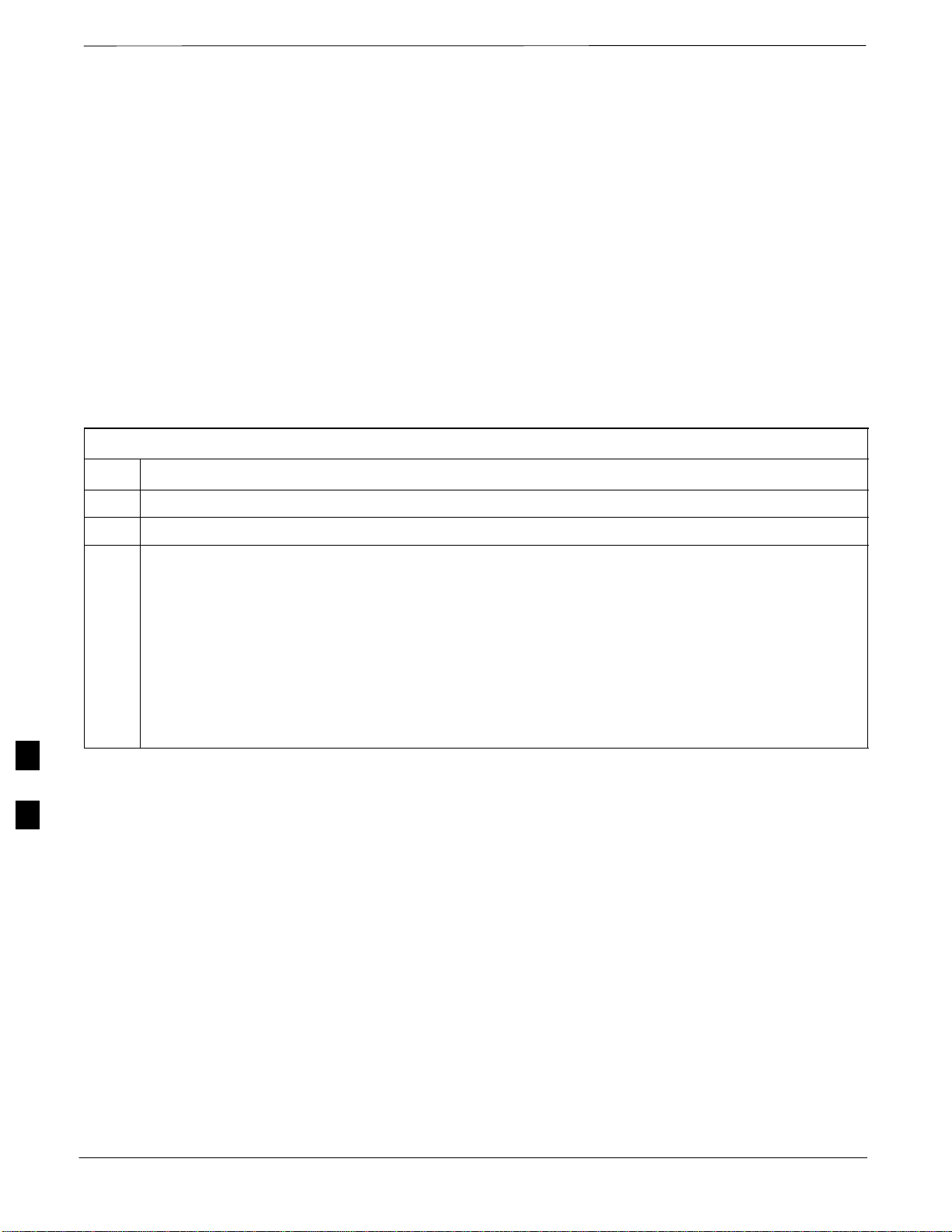

Figure 7-12: R3267 Communications Test Set Timing Signal Detail

CONNECTIONS DEPICTED BY HEAVY BOLD

LINES ARE STATIONARY AND SHOULD REMAIN

INSTALLED DURING TEST EQUIPMENT

TRANSPORT FROM SITE TO SITE.

2 SECOND REFERENCE

19.6608 MHZ REFERENCE

BTS DIAGNOSTIC ACCESS AREA

ADVANTEST R3267 FRONT PANEL ADVANTEST R3267 REAR PANEL

ADVANTEST R3267 SPECTRUM ANALYZER 100Hz –

8GHz

SERIAL I/O

EXT TRIG

7

10 MHZ

GPIB

!

RF OUT

ADVANTEST R3562 RECEIVER TEST SOURCE

EXT TRIG IN

MOD TIME BASE IN

SERIAL I/O

GPIB

SYNTHE

REF IN

!

CLOCK

ADVANTEST R3562 TEST SOURCE

FRONT PANEL

OUT 1

ADVANTEST R3562 TEST SOURCE

REAR PANEL

7-14

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 19

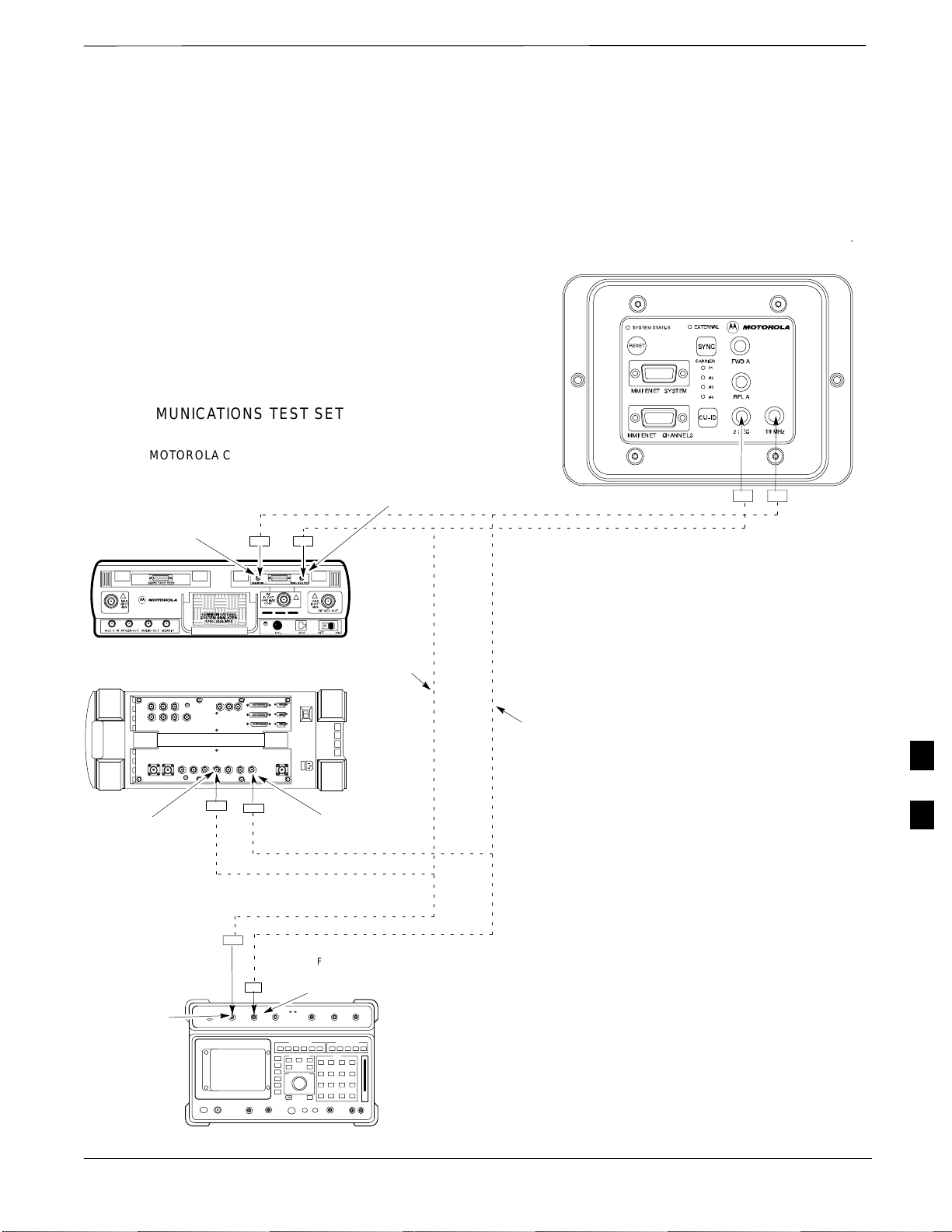

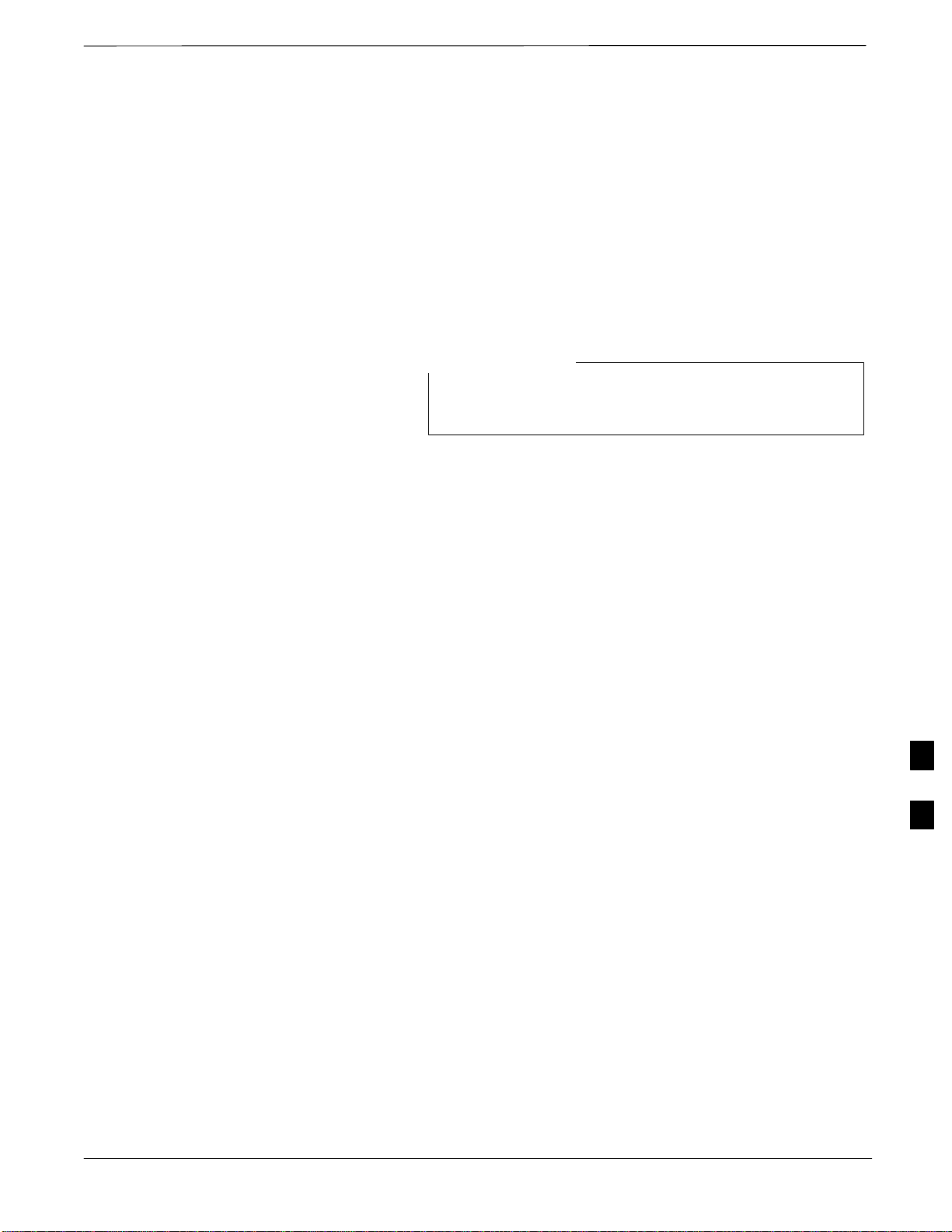

Connect Test Equipment to BTS – continued

Procedure to Connect the

Motorola CyberTest, HP 8935,

and HP 8921 to BTS

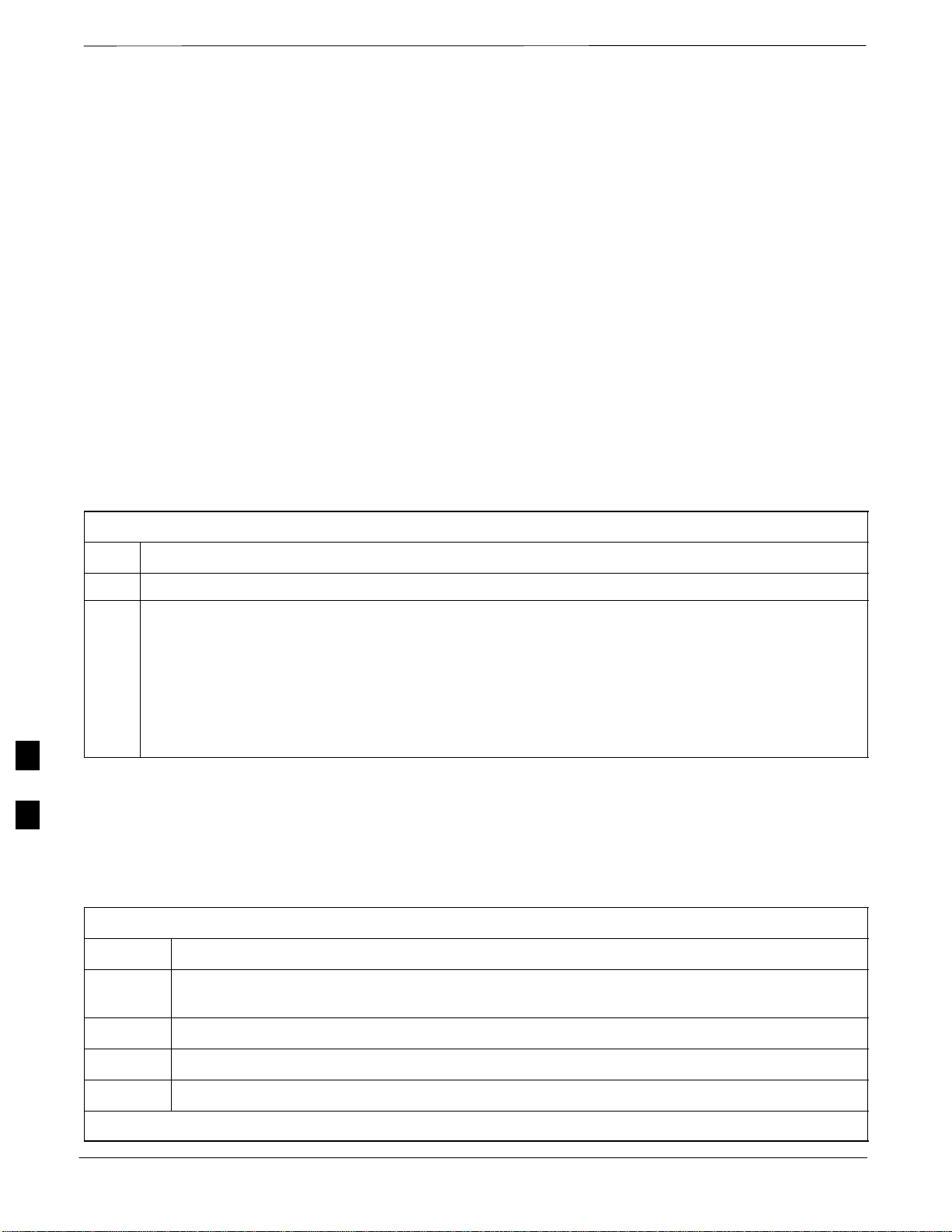

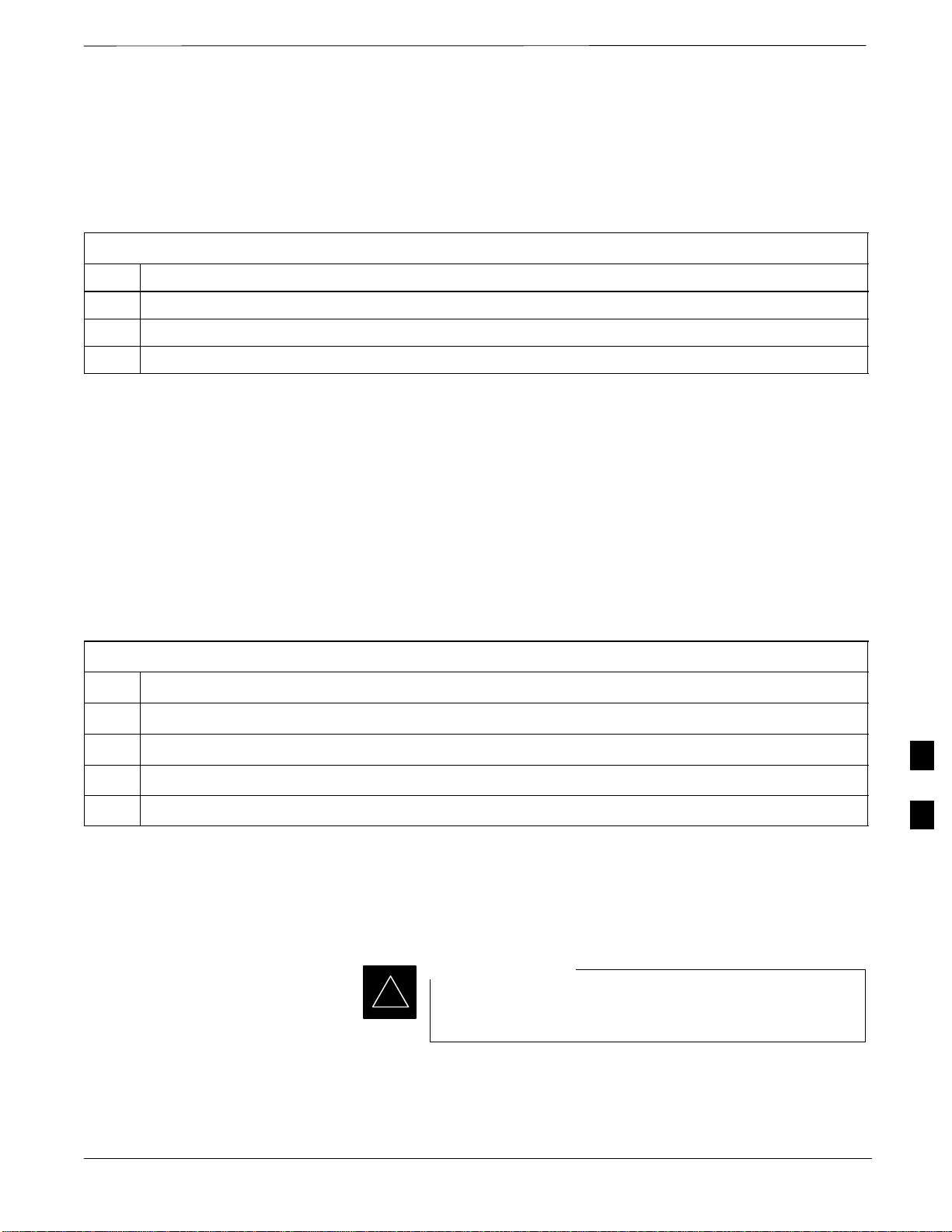

Figure 7-13: Communications Test Set Timing Signal Detail (CyberTest, HP 8935, and HP 8921)

BTS DIAGNOSTIC ACCESS AREA

COMMUNICATIONS TEST SET

MOTOROLA CYBERTEST

FREQ MONITOR 19.6608 MHZ CLOCK

REFERENCE FROM DIAGNOSTIC

SYNC MONITOR EVEN SEC TICK

PULSE REFERENCE FROM

DIAGNOSTIC ACCESS AREA

ACCESS AREA

AGILENT 8935 SERIES E6380A

(FORMALLY HP 8935)

SYNC MONITOR EVEN

SEC TICK PULSE

REFERENCE FROM

DIAGNOSTIC ACCESS

AREA

HP 8921

SYNC MONITOR

EVEN SEC TICK

PULSE REFERENCE

FROM DIAGNOSTIC

ACCESS AREA

2 SECOND REFERENCE

FREQ MONITOR 19.6608 MHZ CLOCK

REFERENCE FROM DIAGNOSTIC

ACCESS AREA

FREQ MONITOR 19.6608

MHZ CLOCK REFERENCE

FROM DIAGNOSTIC

ACCESS AREA

CONNECTIONS DEPICTED BY DOTTED LINES ARE

STATIONARY AND SHOULD REMAIN INSTALLED DURING

TEST EQUIPMENT TRANSPORT FROM SITE TO SITE.

19.6608 MHZ REFERENCE

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-15

Page 20

Connect Test Equipment to BTS – continued

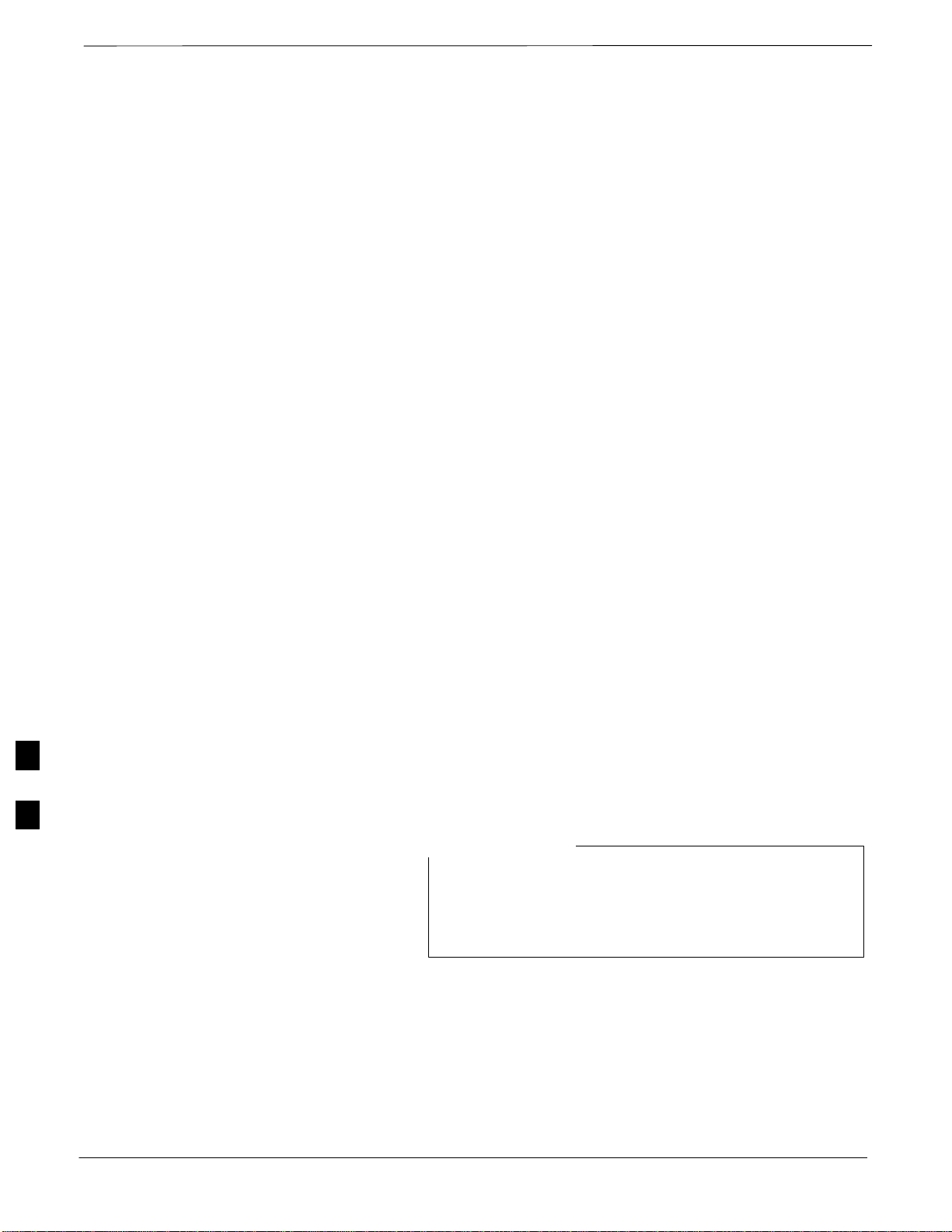

Procedure to Connect the

Agilent E4406A/E4432B to BTS

Agilent E4406A/E4432B test equipment interconnection

To provide proper operation during testing when both units are required,

the 10 MHz reference signal from the E4406A transmitter test set must

be provided to the E4432B signal generator. Connect a BNC (M)–BNC

(M) cable from the E4406A 10 MHz OUT (SWITCHED) connector to

the E4432B 10MHz IN connector as shown in Figure 7-14.

Figure 7-14: Agilent 10 MHz Reference Connections

E4432B

10 MHz IN

E4406A

10 MHz OUT

(SWITCHED)

TO GPIB BOX

7

7-16

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

JAN 2002

DRAFT

Page 21

Connect Test Equipment to BTS – continued

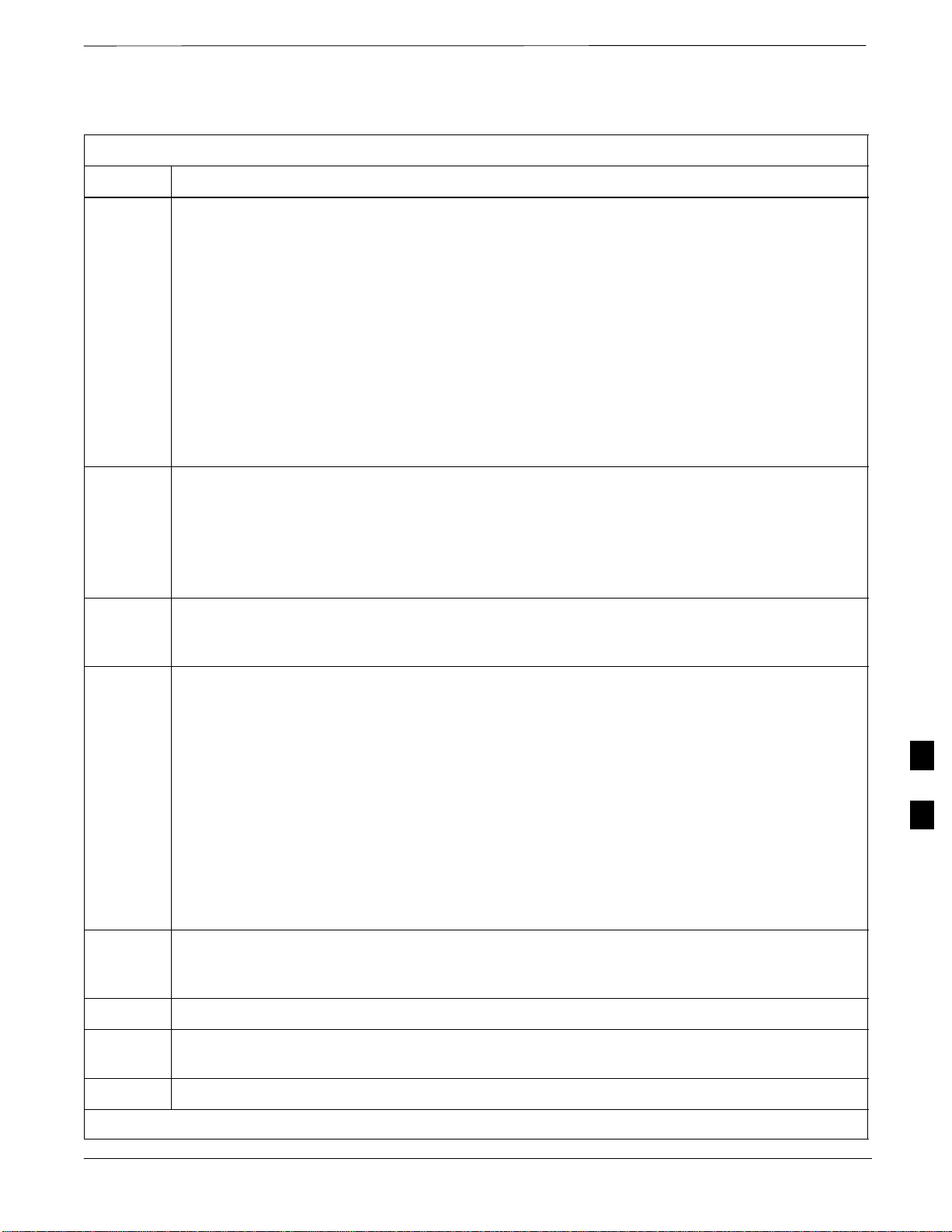

Figure 7-15: Agilent E4406A/E4432B Communications Test Set Timing Signal Detail

BTS DIAGNOSTIC ACCESS AREA

CONNECTIONS DEPICTED BY HEAVY BOLD

LINES ARE STATIONARY AND SHOULD REMAIN

INSTALLED DURING TEST EQUIPMENT

TRANSPORT FROM SITE TO SITE.

Agilent E4432B (Top) and E4406A (Bottom)

2 SECOND REFERENCE

19.6608 MHZ REFERENCE

TO TRIGGER IN

ON REAR OF

TRANSMITTER

TO PATTERN TRIG IN

ON REAR OF SIGNAL

GENERATOR

BNC

“T”

NOTE:

10 MHZ IN ON REAR OF SIGNAL GENERATOR IS CONNECTED TO

10 MHZ OUT (SWITCHED) ON REAR OF TRANSMITTER TESTER

(FIGURE 7-14).

TESTER

SYNC MONITOR

EVEN SEC TICK

PULSE REFERENCE

FROM CSM BOARD

TO EXT REF IN

ON REAR OF

TRANSMITTER

TESTER

FREQ MONITOR

19.6608 MHZ CLOCK

REFERENCE FROM

CSM BOARD

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-17

Page 22

Connect Test Set and Power Meter to LMF

Procedure to Connect the

Communication Test Set and

Power Meter to the LMF

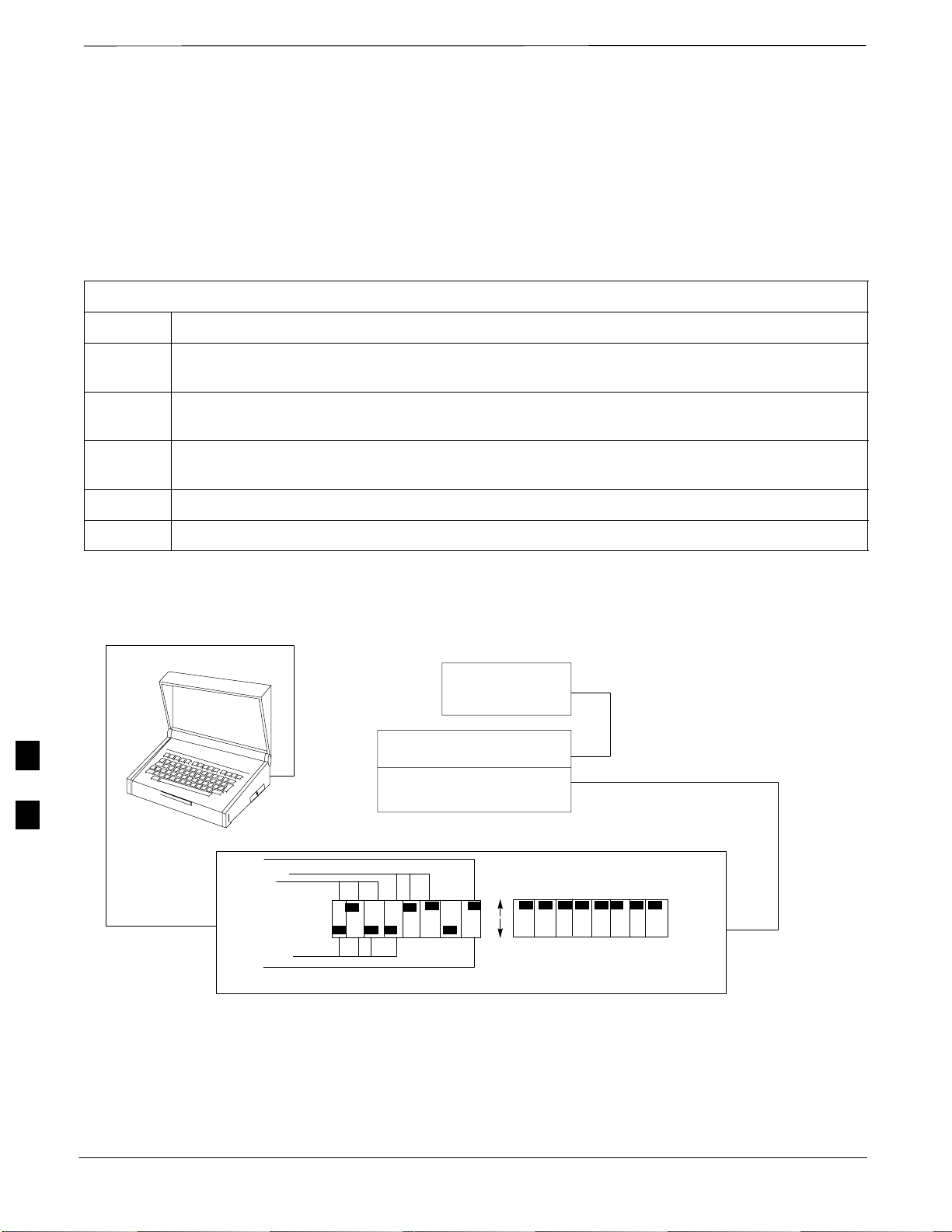

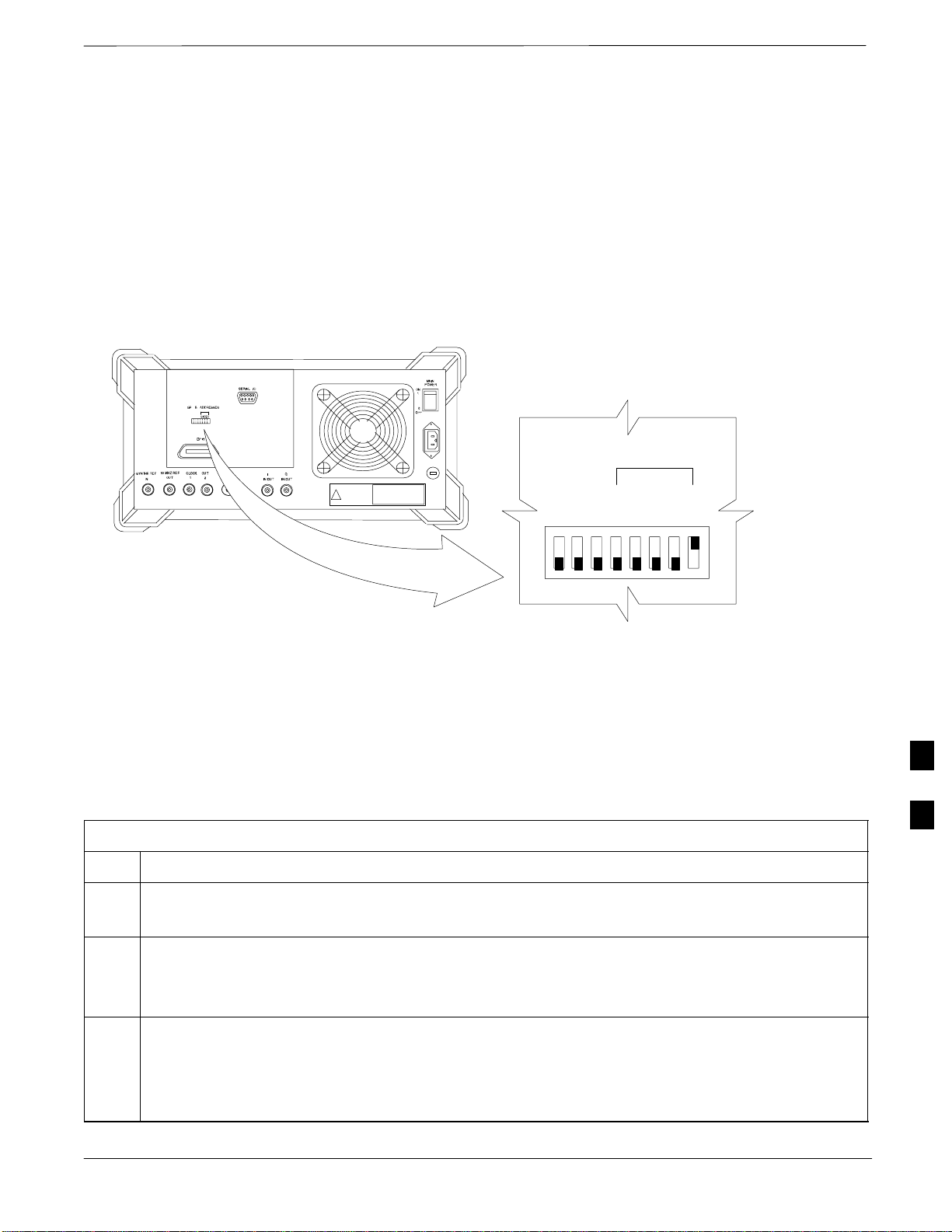

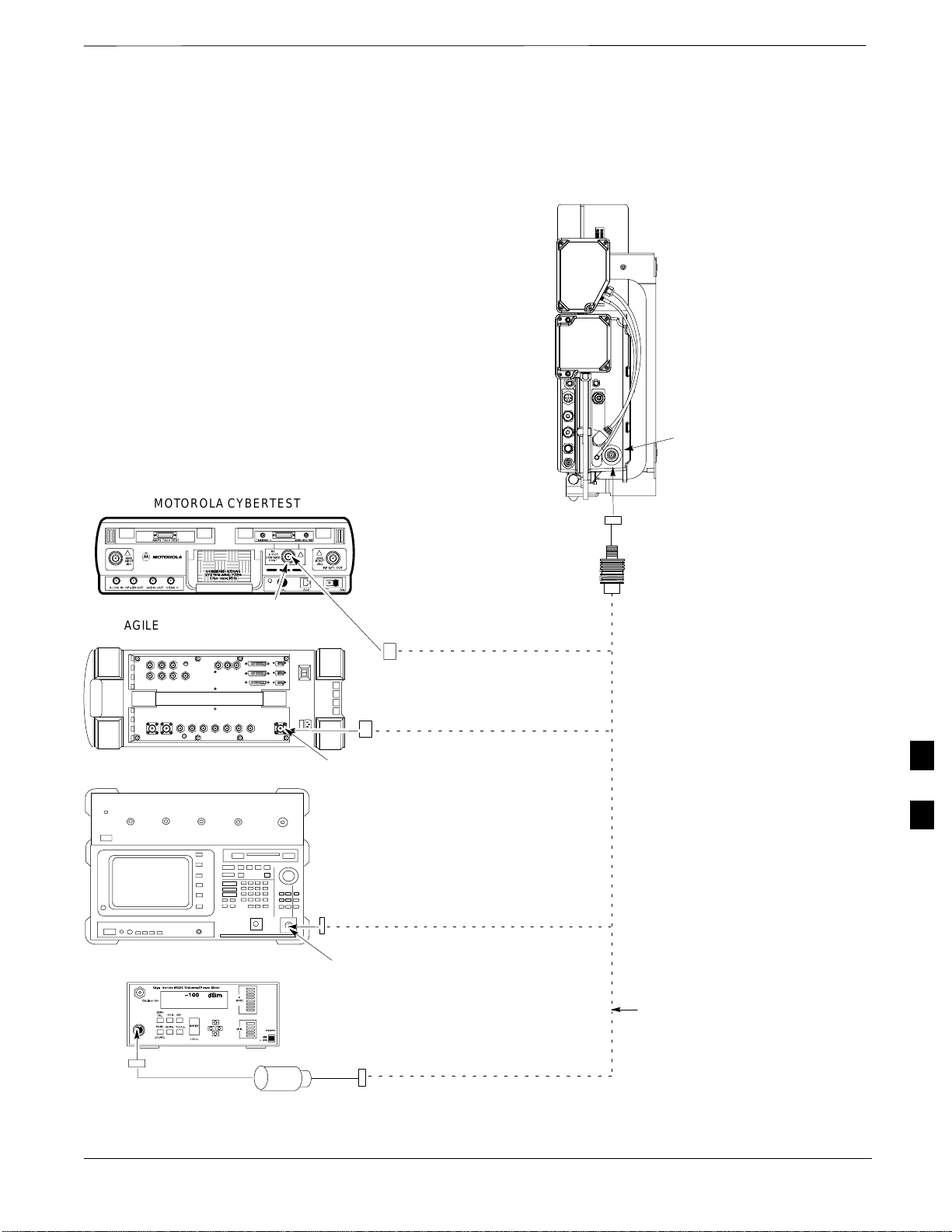

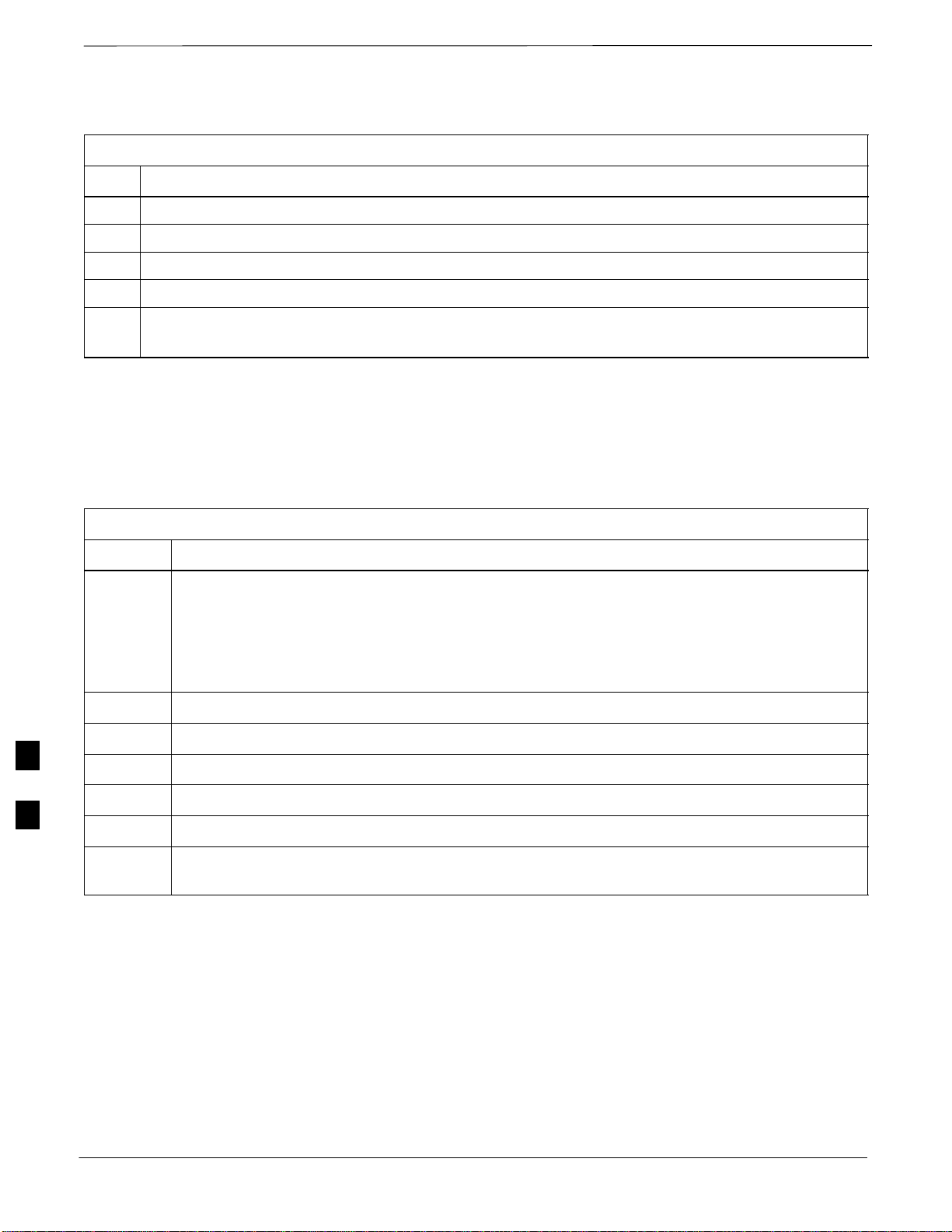

Use the following procedure in Table 7-5 to connect the communication

test set to the power meter and to the LMF. Refer to Figure 7-16.

Table 7-5: Procedure to Connect the Communication Test Set and Power Meter to the LMF

Step Action

1 Connect the RS232–IEEE488 converter serial cable between the COM1 port of the LMF and the

RS232 port of the RS232–IEEE488 converter.

2 Connect a GPIB cable between the RS232–IEEE488 converter and the GPIB port on the

communication test set.

3 Connect a GPIB cable between the GPIB port on the communication test set and the GPIB port of

the power meter.

4 Set the DIP switches on the RS232–IEEE488 converter as shown in Figure 7-16.

5 Power on the communication test set, power meter and RS232–IEEE488 converter.

Figure 7-16: LMF to Test Equipment Connection

RS–232 CABLE

TO COMM1 PORT ON CDMA

LMF NOTEBOOK

LMF

GIGATRONICS

POWER METER

SIGNAL GENERATOR

(IF EQUIPPED)

7

S MODE

DATA FORMAT

BAUD RATE

GPIB ADDRESS

G MODE

COMMUNICATION TEST SET

RS232–IEEE488 CONVERTER

OFF

ON

GPIB CABLE(S) TO GPIB

CONNECTOR ON TEST

EQUIPMENT

7-18

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 23

Connect Test Set and Power Meter to LMF – continued

RS232 Cable Configuration

One National Instruments GPIB–232–CT with Motorola

CGDSEDN04X RS232 serial cable or equivalent is used to interface the

LMF to the test equipment.

A Standard RS–232 cable can be used with the following modifications:

Pin 8 (CTS) does not have to be jumpered/shorted to the others as it is

a driver output. The DTR is already a driver output signal. The other

pins are to receivers. Short pins 7, 1, 4, 6 on each cable end:

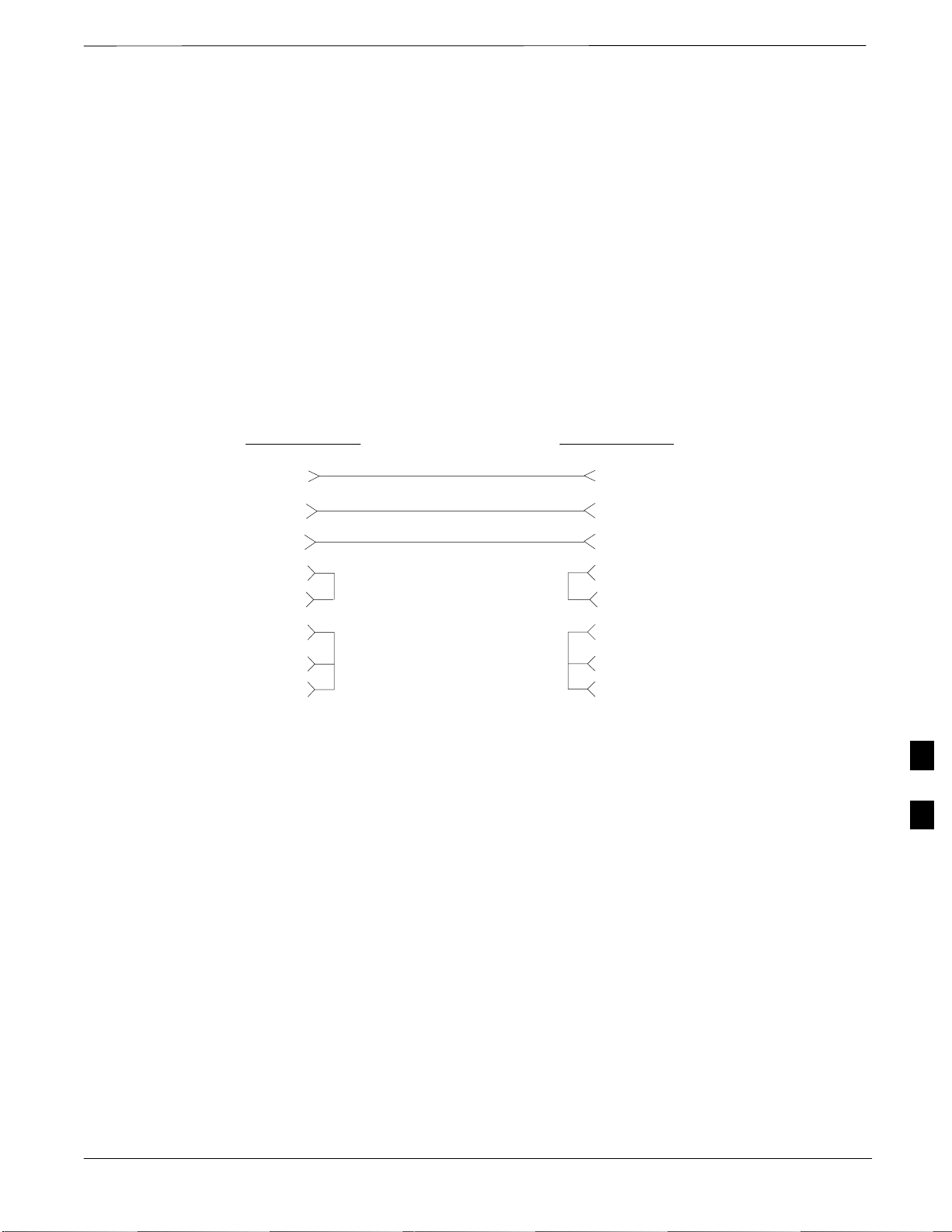

Figure 7-17 shows the cable configuration for the RS232–IEEE488

converter serial cable.

Figure 7-17: RS232–IEEE488 Converter Serial Cable Configuration

9–pin D (female) 9–pin D (female)

GND 5 5 GND

RX 3

RTS 7 7 RTS

CTS 8

RSD/DCD 1 1 RSD/DCD

DTR 4 4 DTR

DSR 6 6 DSR

ON BOTH CONNECTORS SHORT

PINS 7 AND 8;

SHORT PINS 1, 4 AND 6

2 TX

3 RXTX 2

8 CTS

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-19

Page 24

BTS Configuration

Objective

Procedure to Create a Named

HyperTerminal Connection for

MMI Communication

The objective of this procedure is to configure the BTS and establish

communication sessions between the LMF and BTS. This procedure

consists of:

1. Creating a named hyperterminal connection for MMI

communication

2. Establishing an MMI communication session

3. Verify and set IP address

4. Programming customer operating channel

5. Verifying BTS synchronization mode

6. Verifying DPLL tracking

7. Setting frame_id

Confirming or changing the configuration data of certain BTS Field

Replaceable Units (FRU) requires establishing an MMI communication

session between the CDMA LMF computer and the FRU. Using features

of the Windows operating system, the connection properties for an MMI

session can be saved on the CDMA LMF computer as a named Windows

HyperTerminal connection. This eliminates the need for setting up

connection parameters each time an MMI session is required to support

optimization.

Once the named connection is saved, a shortcut for it can be created on

the Windows desktop. Double–clicking the shortcut icon will start the

connection without the need to negotiate multiple menu levels.

7

Table 7-6: Procedure to Create a Named HyperTerminal Connection for MMI Communication

Step Action

1 From the Windows Start menu, select:

Programs > Accessories

2 Select Communications, double click the Hyperterminal folder, and then double click on the

Hypertrm.exe icon in the window which opens.

Follow the procedures in Table 7-6 to establish a named HyperTerminal

connection and create a Windows desktop shortcut for it.

7-20

NOTE

If a Location Information Window appears, enter the required information, then click on the

Close button. (This is required the first time, even if a modem is not to be used.)

If a You need to install a modem..... message appears, click on NO.

. . . continued on next page

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

JAN 2002

DRAFT

Page 25

BTS Configuration – continued

Table 7-6: Procedure to Create a Named HyperTerminal Connection for MMI Communication

Step Action

3 When the Connection Description box opens:

– Type a name for the connection being defined (e.g., MMI Session) in the Name: window,

– Highlight any icon preferred for the named connection in the Icon: chooser window, and

– Click OK.

NOTE

For CDMA LMF computer configurations where COM1 is used by another interface such as test

equipment and a physical port is available for COM2, select COM2 in the following step to prevent

conflicts.

4 From the Connect using: pick list in the Connect To box displayed, select Direct to Com 1 or

Direct to Com 2 for the RS–232 connection port, and click OK.

5 In the Port Settings tab of the COM# Properties window displayed, configure the RS–232 port

settings as follows:

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

6 Click OK.

7 Save the defined connection by selecting:

File > Save

8 Close the HyperTerminal window by selecting:

File > Exit

9 Click the Yes button to disconnect when prompted.

10 If the Hyperterminal folder window is still open, proceed to step 12.

11 Select Communications and double click the Hyperterminal folder.

12 Highlight the newly–created connection icon by clicking on it.

13 Right click and drag the highlighted connection icon to the Windows desktop and release the right

mouse button.

14 From the popup menu which appears, select Create Shortcut(s) Here.

7

15 If desired, reposition the shortcut icon for the new connection by dragging it to another location on the

Windows desktop.

16 Close the Hyperterminal folder window by selecting:

File > Close

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-21

Page 26

BTS Configuration – continued

Procedure to Establish an MMI

Communication Session

For those procedures which require MMI communication between the

CDMA LMF and the BTS, follow the procedures in Table 7-7 to initiate

the communication session.

NOTE

If an LMF session is in progress, logout of the LMF prior

to establishing an MMI communication session. Refer to

steps 1 and 2 of the “Remove LMF” procedure in

Table 7-54.

Table 7-7: Procedure to Establish an MMI Communication Session

Step Action

1 Connect the CDMA LMF computer to the BTS. Refer to the “Connecting the LMF to the BTS”

procedure in this chapter.

2 Start the named HyperTerminal connection for MMI sessions by double clicking on its Windows

desktop shortcut.

3

NOTE

If a Windows desktop shortcut was not created for the MMI connection, access the connection from

the Windows Start menu by selecting:

Programs > Accessories > Hyperterminal > HyperTerminal > <Named HyperTerminal

Connection (e.g., MMI Session)>

Once the connection window opens, establish MMI communication with the BTS FRU by pressing

the CDMA LMF computer Enter key until the prompt identified in the applicable procedure is

obtained.

Every command is entered at the SC300> prompt unless otherwise specified.

7

7-22

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 27

BTS Configuration – continued

Procedure to Set IP Address

You must set an IP address on the unit before you can begin an LMF

Ethernet (LAN) session. Follow the instructions in Table 7-8 to set the

IP address.

Table 7-8: Procedure to Set IP Address

Step Action

1 Enter the following command to check the ethernet IP address:

sc300>ether getip

Observe the following typical response (if the IP address was not set):

COMMAND ACCEPTED: ether getip

Current IP ADDRESS: 0.0.0.0

2 Enter the following command to check the ethernet gateway address:

sc300>ether getgw

Observe the following typical response (if the IP address was not set):

COMMAND ACCEPTED: ether getgw

GW address: 0.0.0.0

3 Enter the following command to check the ethernet netmask value:

sc300>ether getnm

Observe the following typical response (if the IP address was not set):

COMMAND ACCEPTED: ether getnm

NETMASK: 0.0.0.0

4 If the IP address is set, then you are finished with this procedure. If you must set the IP address,

then proceed with steps 5 through 7.

NOTE

The default LMF IP address is 128.0.0.2.

5 Enter the following command to set the IP address:

sc300>ether setip 128.0.0.2

The system will display the following output:

COMMAND ACCEPTED: ether setip 128.0.0.2

THESE ARE THE BYTES READ IN: 128.0.0.2

SETTING IP: 128.0.0.2

Completed flashing of IP address

CONFIRM NEW IP: 128.0.0.2

SETTING Ethernet Address: 8:0:80:0:0:2

Completed flashing of Ether address

CONFIRM NEW Ethernet Address: 8:0:80:0:0:2

7

JAN 2002

New parameters will take affect after next reset.

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

. . . continued on next page

7-23

DRAFT

Page 28

BTS Configuration – continued

Table 7-8: Procedure to Set IP Address

Step Action

6 Enter the following command at the sc300> prompt:

sc300>ether setgw 128.0.0.2

The system will display the following output:

COMMAND ACCEPTED: ether setgw 128.0.0.2

”128” ”0” ”0” ”2”

THESE ARE THE BYTES READ IN: 128.0.0.2

SETTING GW: 128.0.0.2

Completed flashing of Gateway address

CONFIRM NEW GW: 128.0.0.2

New parameters will take affect after next reset.

7 Enter the following command at the sc300> prompt:

sc300>ether setnm 255.255.255.255

The system will display the following output:

COMMAND ACCEPTED: ether setnm 255.255.255.255

”255” ”255” ”255” ”255”

THESE ARE THE BYTES READ IN: 255.255.255.255

SETTING NETMASK: 255.255.255.255

Completed flashing of SubnetMask address

CONFIRM NEW NETMASK: 255.255.255.255

New parameters will take affect after next reset.

8 Repeat steps 1 through 3 to verify your entries.

9 If your entries are correct, then press the red RESET button on the diagnostic access area to reset

the unit.

7

Procedure to Simulate an LMF

Session

You must start a simulated LMF session when you enter MMI

commands. Enter the following command at the MMI prompt to

simulate an LMF link:

sndtype 0xa178

You should enter this command at the beginning of every simulated

MMI Communication Session.

7-24

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 29

BTS Configuration – continued

Updating Default Channel

Setting to Customer Operating

Channel

A non–volatile database containing the default channel and default

power level of the site must be programmed. The default channel is the

customer operating channel for this site. The default power level must

be set to –50 dBm which will be overwritten by the MM/OMCR when

the site comes on–line.

It is imperative that the customer frequency be programmed into this

database. Failure to do so may result in the RF interference to other

RF–emitting devices in the local area whenever the site is powered up.

Table 7-9: Procedure to Update Default Channel Setting to Customer Operating Channel

Step Action

1 Connect the LMF computer terminal to the MMI/LMF connector. Refer to Figure 7-6.

2 If you have not already done so, logout of the BTS and exit the LMF. Wait 10 seconds before

proceeding.

3 Establish an MMI connection session with the BTS. Refer to Table 7-7.

4 Simulate an LMF connection by issuing the sndtype 0xa178 command.

5 Verify that the BTS is in OOS_RAM status by issuing the status command.

6 Enter the op_param –w –50 chan# command. The command parameters are as follows:

–w instructs the BTS to write the values into non–volatile memory.

–50 defaults the power to –50dBm

chan# the customer operating channel (refer to Table 7-43 for 1.9 GHz systems and

Table 7-44 for 800 MHz systems).

If the command is successful, the following response will display:

PASSED: TRX EEPROM updated for power level = –50 (dBm) and channel =

chan#

7 If no additional MMI sessions are required at this time, exit the MMI session and HyperTerminal

connection by selecting File>Exit.

If you are continuing the MMI session, proceed to Table 7-10.

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-25

Page 30

BTS Configuration – continued

Synchronization Background

GPS

GPS is typically used as the primary timing reference for CDMA BTSs.

In applications where RGPS is used, the BTS is said to be synchronous

with CDMA system time. The RGPS provides a 1 Pulse Per Second

timing reference and Time Of Day information to allow the BTS to

synchronize to CDMA system time.

HSO

A High Stability Oscillator (HSO) within the BTS provides a backup

timing reference in the event of a GPS outage. Using only the HSO, the

BTS can maintain CDMA system time for up to 24 hours. The BTS can

also use the HSO as the primary timing reference (non–synchronous

operation). However, synchronization to CDMA system time is not

possible. The HSO provides a 1 Pulse Per Second timing reference to

allow the BTS to remain synchronized to CDMA system time in the

event of a GPS outage (synchronous operation) or to provide a stable

frequency reference (non–synchronous operation).

NOTE

The HSO must be installed with GPS tracking for at least

24 hours before the HSO can provide 24 hours of backup

for CDMA system time synchronization.

BTS

The BTS uses a Digital Phase Locked Loop (DPLL) to track the RGPS

and/or HSO and generate a 19.6608 MHz CDMA timing reference. This

7

timing reference, in conjunction with Time Of Day information provided

by the RGPS, allows the BTS to synchronize to CDMA system time. A

2 Second reference is also generated by the BTS to allow alignment of

Pilot offsets for the BTS and external test equipment. Both the 19.6608

MHz (19 MHz) and 2 Second (2 Sec) references are available via SMA

connectors located in the Diagnostic Access Area.

In order for the DPLL to begin the RGPS tracking process, the RGPS

must be tracking GPS satellites. In order for the DPLL to begin the

HSO tracking process, the BTS must be powered up (warmed) for at

least 15 minutes.

The DPLL status is defined as being in one of five states: Init, Warm,

A1, A2 and TK.

7-26

The Init state is the starting state of the DPLL.

The Warm state is the condition during the 15 minute BTS warm up

time.

The A1 and A2 states are acquisition states when the DPLL is

adjusting the 19.6608 MHz frequency based on the available reference

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 31

BTS Configuration – continued

Procedure to Verify and

Change BTS Synchronization

Mode

Table 7-10: Procedure to Verify and Change BTS Sync Mode

sources (RGPS or HSO). Under normal operating conditions, the

acquisition states last about 5 minutes.

The TK state is the DPLL tracking state and is entered at the end of

the acquisition states. The TK state is required for performing ATP.

The Sync button in the Diagnostic Access Area is used to toggle the

RGPS or HSO as the primary timing reference for the BTS. If the

External indicator in the Diagnostic Access Area is illuminated, the BTS

expects an RGPS to be present for use as the primary timing reference.

If the External indicator is not illuminated, the BTS will use the internal

HSO as the primary timing reference.

Use the procedure in Table 7-10 to verify and, if necessary change the

BTS Sync mode.

Step Action

1 If an MMI session was established, proceed to step 7. If no MMI session is running, proceed to

step 2.

2 Connect the MMI/LMF.

3 Open an MMI Communication session.

4 Simulate an LMF connection by issuing the sndtype 0xa178 command.

5 Verify that the BTS is in OOS_RAM status by issuing the status command.

6 Enter the sndtype 0x4003 command to change the state to OOS_RAM.

7 Observe the condition of the External indicator.

8 No further action is required if the BTS is in the desired Sync mode. Continue with Step 9 if the

Sync mode needs to be altered.

9 Push the Sync button to change the BTS Sync mode.

10 Reset the BTS using the Reset button in the Diagnostic Access Area.

11 If no additional MMI sessions are required at this time, exit the MMI session and HyperTerminal

connection by selecting File>Exit.

If you are continuing the MMI session, proceed to Table 7-11.

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-27

Page 32

BTS Configuration – continued

Procedure to Verify DPLL

Tracking (RGPS/HSO)

The DPLL within the BTS must be tracking either RGPS or HSO in

order to perform ATP. Use the procedure in Table 7-11 to verify DPLL

tracking.

Table 7-11: Procedure to Verify DPLL Tracking

Step Action

1 If an MMI session was established, proceed to step 6. If no MMI session is running, proceed to

step 2.

2 Connect the MMI/LMF.

3 Open an MMI Communication session.

4 Simulate an LMF connection by issuing the sndtype 0xa178 command.

5 Verify that the BTS is in OOS_RAM status by issuing the status command.

6 If an RGPS is not present, go to Step 9.

7 Enter the gps_status command to display the current state of the RGPS. Observe the following

typical response:

gps_status

GPS Receiver Identification:

Current GPS Time :8 03 1999 23:01:12

Current GPS Receiver Status :8

Number of Satellites Currently visible :11

Number of Satellites Currently received :5

Number of Satellites Currently tracked :5

GPS Receiver Type :UT

7

Current GPS Task State :GPS_TRACK

Current Dilution of Precision (HDOP (2D)/antenna ok [0x01]): 0

Chan: 0, SVID: 9, Mode: 8, RSSI: 44, Status: 0xaa

Chan: 1, SVID: 4, Mode: 8, RSSI: 46, Status: 0xaa

Chan: 2, SVID: 10, Mode: 8, RSSI: 44, Status: 0xaa

Chan: 3, SVID: 6, Mode: 8, RSSI: 41, Status: 0xaa

Chan: 4, SVID: 7, Mode: 8, RSSI: 43, Status: 0xaa

Chan: 5, SVID: 24, Mode: 8, RSSI: 47, Status: 0xaa

Chan: 6, SVID: 30, Mode: 8, RSSI: 45, Status: 0xaa

Chan: 7, SVID: 5, Mode: 8, RSSI: 48, Status: 0xaa

Current Longitude: –350250952

Current Latitude: 118244730

Current Height: 24019

8 The RGPS must have a Current GPS Task State of GPS_TRACK to proceed.

NOTE

GPS tracking times vary depending on location and installation.

. . . continued on next page

7-28

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 33

BTS Configuration – continued

Table 7-11: Procedure to Verify DPLL Tracking

Step Action

9 Issue the dpll_status command to display the current state of the DPLL. Observe the following

typical response:

Current source set to: GPS reference

DPLL control task state: DPLL track.

DPLL status (not valid if using even sec src):

c:0000 off: –8639450,6736579,7204904 TK

(Note: This must say TK. A1 and A2 states will have preceded it)

Mode cntr: 120

ip: 9, iq: 4

aip1: 9, aiq1: 4

aip2: 6, aiq2: –2

tip: 3, tiq: –9

integrator: 4096

10 Verify that the DPLL is “tracking” either the RGPS or HSO. The DPLL must have a Current

source set to of GPS reference or HSO reference. The DPLL must also have a

DPLL control task state of DPLL track.

11 If no additional MMI sessions are required at this time, exit the MMI session and HyperTerminal

connection by selecting File>Exit.

If you are continuing the MMI session, proceed to Table 7-12.

Procedure to Verify and Modify

Default Location Coordinates

The BTS supplies the RGPS with default startup coordinates (latitude

and longitude) in order to assist the RGPS in tracking satellites. The

default startup coordinates can be modified and saved into non–volatile

memory to speed the tracking of satellites.

Use the procedure in Table 7-12 to verify and, if necessary, modify the

default startup coordinates. The procedure in Table 7-12 is only

applicable to sites equipped with an RGPS.

Table 7-12: Procedure to Verify Default Startup Coordinates

Step Action

1 If an MMI session was established, proceed to step 6. If no MMI session is running, proceed to

step 2.

7

2 Connect the LMF/MMI.

3 Open an MMI Communication session.

4 Simulate an LMF connection by issuing the sndtype 0xa178 command.

5 Verify that the BTS is in OOS_RAM status by issuing the status command.

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

. . . continued on next page

7-29

DRAFT

Page 34

BTS Configuration – continued

height

19740 centi–meters

Table 7-12: Procedure to Verify Default Startup Coordinates

Step Action

6 Issue the dpll_status command to display the current state of the DPLL. Verify that the DPLL

has a ”Current source set to” of GPS reference and a ”DPLL control task state” of DPLL

track. The DPLL must be tracking GPS in order to complete this procedure.

7

* IMPORTANT

The values for longitude and latitude in response to the gps_status command are given in units

of milli–arcseconds. Be careful to record the values accurately including any leading negative (–)

signs. The value of Current Height is given in units of centimeters.

Enter the gps_status command.

8 Record the values displayed for Current Longitude, Current Latitude and

Current Height.

9

* IMPORTANT

The gps_config command displays the default startup coordinates for the BTS. Note that

latitude is displayed first, followed by longitude. This is in reverse order compared to

the response of the gps_status command. The values for latitude and longitude are given in

units of milli–arcseconds. The value of Current Height is given in units of centimeters.

Enter the gps_config command to display the default startup coordinates for the BTS. Observe

the following typical response:

GPS Configuration data:

latitude: 151679715 msec

longitude: –316791269 msec

height_type: 0

cable_delay: 0 nsec

accuracy: 0

:

–

If the default startup coordinates need to be modified, the gps_config command can be issued

with additional parameters. Using the Current Longitude, Current Latitude and

Current Height values recorded in step 8, issue the following command:

7

gps_config <latitude> <longitude> <height> 0 0 0

Be careful to input the latitude and longitude in the proper order along with any leading negative

(–) signs.

The GPS Height Type Configuration should be set to “0.”

10 Issue the gps_config to verify that the coordinates are set.

11 Reset the BTS to save the new coordinates.

12 Repeat the steps in Table 7-11 to verify the DPLL status prior to performing ATP.

13 If no additional MMI sessions are required at this time, exit the MMI session and HyperTerminal

7-30

connection by selecting File>Exit.

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 35

BTS Configuration – continued

Procedure to Set Frame ID for

Multi–Unit Logical BTS

Configuration

Do the following procedure in Table 7-13 to setup the hardware for a

multi–unit logical BTS configuration.

Table 7-13: Procedure to Set Frame ID for Multi–Unit Logical BTS Configuration

Step Action

1 Establish an MMI session with the BTS. Refer to Table 7-7.

2 Enter the following command at the SC300> prompt to set the frame ID to “1” on the first frame:

frame_id 1

You can also set the frame_id to 1 by pressing the CU–ID button on the diagnostic access area to

the “CARRIER #1” state.

3 Enter the following command at the SC300> prompt to set the frame ID to “2” on the second

frame:

frame_id 2

You can also set the frame_id to 2 by pressing the CU–ID button on the diagnostic access area to

the “CARRIER #2” state.

4 If you have three or more units, enter the following command at the SC300> prompt to set the

frame ID to “3” on the third frame:

frame_id 3

You can also set the frame_id to 3 by pressing the CU–ID button on the diagnostic access area to

the “CARRIER #3” state.

5 If you have four units, enter the following command at the SC300> prompt to set the frame ID to

“4” on the second frame:

frame_id 4

You can also set the frame_id to 4 by pressing the CU–ID button on the diagnostic access area to

the “CARRIER #4” state.

6 Press the SYNC button on the diagnostic access area on all of the units to switch them to the

“EXTERNAL” mode.

7 If the frame_id of unit #1 is already set to “1” prior to the setup of the BTS, then you do not need

to reset it.

If the frame_id is not “1,” then you must press the RESET button on the diagnostic access area to

reset unit #1.

8 Press the RESET buttons on the diagnostic access areas of units #2, #3 (if equipped), and #4 (if

equipped).

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-31

Page 36

BTS Software

Objective

Install the LMF Program and

BTS Binaries

Create a Site–Specific BTS

Directory

This objective of this procedure is to:

1. Install the LMF program.

2. Create a site specific BTS directory.

3. Start the LMF.

4. Login to the BTS

5. Update the BTS–specific CDF file.

6. Download and enable the MAWI

Install the LMF and BTS binaries on the PC to be used if they are not already

installed. Refer to the CDMA LMF Operator ’s Guide, 68P64114A78 for

the installation procedure.

Follow the steps in Table 7-14 to create a bts–bts# directory, to which

the bts–bts#.cdf, cbsc–1.cdf, and ATP report files will

reside.

Table 7-14: Procedure to Create Site–Specific BTS Directory

Step Action

1 Use MS Windows Explorer to create a bts–# folder under the wlmf\cdma folder (where # is

the BTS number).

2 Get the bts–#.cdf file and cbsc–#.cdf file from the CBSC and put a copy of the files in the

wlmf\cdma\bts–# folder. Refer to the LMF help screens or the CDMA LMF Operator’s Guide,

68P64114A21 for the copy file procedure.

7

Start the LMF and Login to the

BTS

Use the following procedure in Table 7-15 to start the LMF and login to

the BTS.

Prerequisites

1. A bts–# folder with a correct CDF and CBSC file exists.

2. The LMF notebook is correctly set up and connected to the BTS.

Refer to Figure 7-6.

7-32

NOTE

The Refresh button can be used to update the Available

Base Stations pick list to include any new bts–#

folders added/created after the LMF was started. To logout

of the BTS, click on Select>Logout. A confirm logout

pop–up message will appear.

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 37

BTS Software – continued

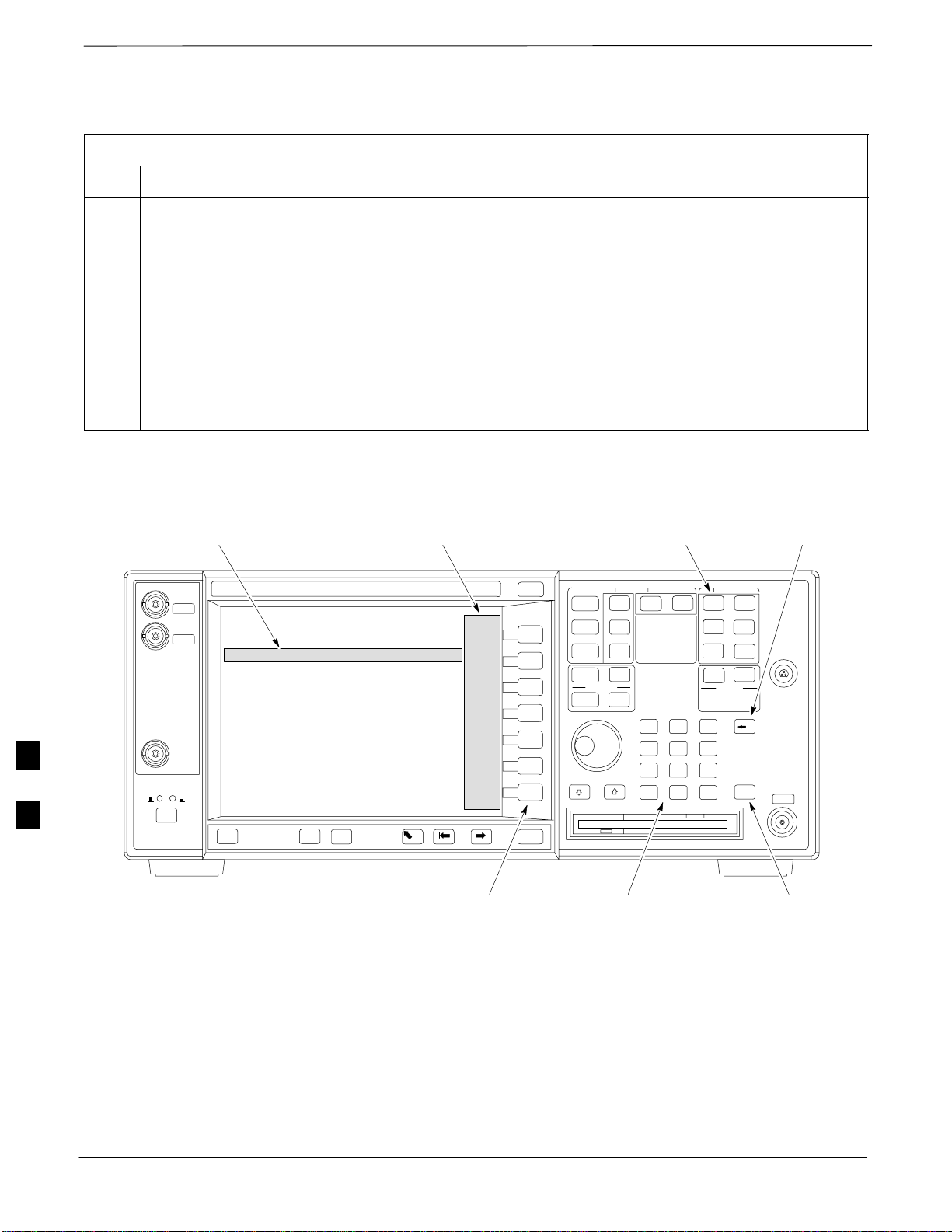

Table 7-15: Procedure to Start the LMF and Login to the BTS

Step Action

1 Click on the LMF desktop icon. The LMF window should appear.

2 Click on the Login tab if it is not already displayed.

3 Double–click on CDMA in the Available Base Stations pick list if the list of available BTSs is

not displayed.

4 Click on the desired BTS.

5 Is all of the information in the Serial Login tab and Equipage Information box list correct?

– If YES, go to step 7.

– If NO, go to step 6.

6 Click on the Serial Login tab if it is not in the forefront. Select the correct Comm Port (normally

COM2) and select the desired Baud Rate (normally 9600 for tests and 38400 for downloads).

NOTE

This step is not necessary if you are using the Ethernet LAN connection from the LMF to the BTS.

7 Click on the Login button. The system will display a graphic of the SC300 BTS.

Update BTS Specific CDF File

Device Load Version

Follow the steps in Table 7-16 to update the existing BTS specific CDF

file NextLoad parameter to reflect the current device load version to be

downloaded.

The NextLoad version parameter in the CDF file for a BTS can be

updated to one of the existing version numbers in the

wlmf>cdma>loads folder. When code is downloaded the code file

used is determined by the NextLoad parameter in the CDF file. If a

version number folder that has the same number as the NextLoad

parameter is not found when the download code function is used the

LMF will not automatically select the code and data files to be

downloaded.

NOTE

Device load version in the CDF file does not have to match

the current version loaded at the OMCR/CBSC.

7

Table 7-16: Procedure to Update BTS–Specific CDF File Device Load Version

Step Action

1 Click on the Tools menu item.

2 Select the Update NextLoad item.

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

. . . continued on next page

7-33

DRAFT

Page 38

BTS Software – continued

Table 7-16: Procedure to Update BTS–Specific CDF File Device Load Version

Step Action

3 Select CDMA.

4 Select the BTS number from the list of available base stations.

5 Select the radio button next to the desired version number.

6 Click on the Save button. A pop–up message will appear indicating that “This action may

take a few seconds.” Click on the OK button.

7 A pop–up message will appear indicating that the NextLoad file has been updated.

NOTENOTE

At this point, a backup copy of the original CDF is created with a _bak extension, (e.g.,

bts–812.cdf_bak).

8 Click on the OK button to dismiss the pop–up message.

Download/Enable MAWI

The objective of this procedure is to download and enable the BTS.

The BTS software platform is based on the Motorola Advanced

Wideband Interface (MAWI). The term MAWI is used to refer to the

MicroCell from the LMF’s point of view.

NOTE

The BTS is shipped from the factory with all the software

downloaded. Use the load procedure only when new

software is loaded.

7

Table 7-17: Procedure to Download/Enable MAWI

Step Action

1 If the ATP is going to be run, the MAWI has to have the same code load as the LMF CDF or the site

specific information cannot be loaded to MAWI (PN offset, etc.) for ATP to complete.

Follow the steps outlined in Table 7-17 to download the code and data to

enable the MAWI.

Before the download/enable process, use the status function and verify

the MAWI responds with status information. Use this information to get

the current code loaded in MAWI.

2 If downloading code, insure the LMF is logged into the BTS at 38400 Baud Rate for timely

download (20 minutes vs 2+ hours).

3 Click on the MAWI and select Device>Download>Code Manual.

A status report is displayed that confirms the change in device status. Click OK to close status

window.

. . . continued on next page

7-34

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 39

BTS Software – continued

Table 7-17: Procedure to Download/Enable MAWI

Step Action

4 Click on the MAWI and select Device>Download>Code Data. A status report is displayed that

confirms the change in device status. Click OK to close status window.

5 Click on the MAWI and select Device>Enable to enable the MAWI. The MAWI changes to green

(INS–ACT test mode).

NOTENOTE

The LMF may fail this step. After you enable the MAWI, verify that the LED on the SC300 changes

to a solid green, then click on the STOP radio button to halt the ENABLE command. Run the

STATUS MAWI command and the display will change to the INS_ACT (green) state.

Configuration Data File (CDF)

The Configuration Data File (CDF) includes the CDMA channel element

allocation plan. This plan indicates how each CDMA carrier is

configured, and how the paging, sync, traffic, and access channel

elements (and associated gain values) are assigned.

The CDF file also contains a table for the Effective Rated Power (ERP)

for each transmit antenna. Motorola System Engineering specifies the

ERP of a transmit antenna based on site geography, antenna placement,

and government regulations. Working from this ERP requirement, the

antenna gain, (dependent on the units of measurement specified) and

antenna feed line loss can be combined to determine the required power

at the BTS TX output.

NOTE

Refer to the CDMA LMF Operators Guide; 68P64114A78

for additional information on the layout of the LMF

directory structure (including cdf file locations and

formats).

Site equipage verification

If you have not already done so, use an editor to view the CDF, and

review the site documentation. Verify the site engineering equipage data

in the CDF to the actual site hardware.

NOTE

If the current LMF or BTS binaries need to be installed on

the LMF PC, or for more information on viewing CDF

files, refer to the CDMA LMF Operators Guide;

68P64114A78.

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-35

Page 40

BTS Software – continued

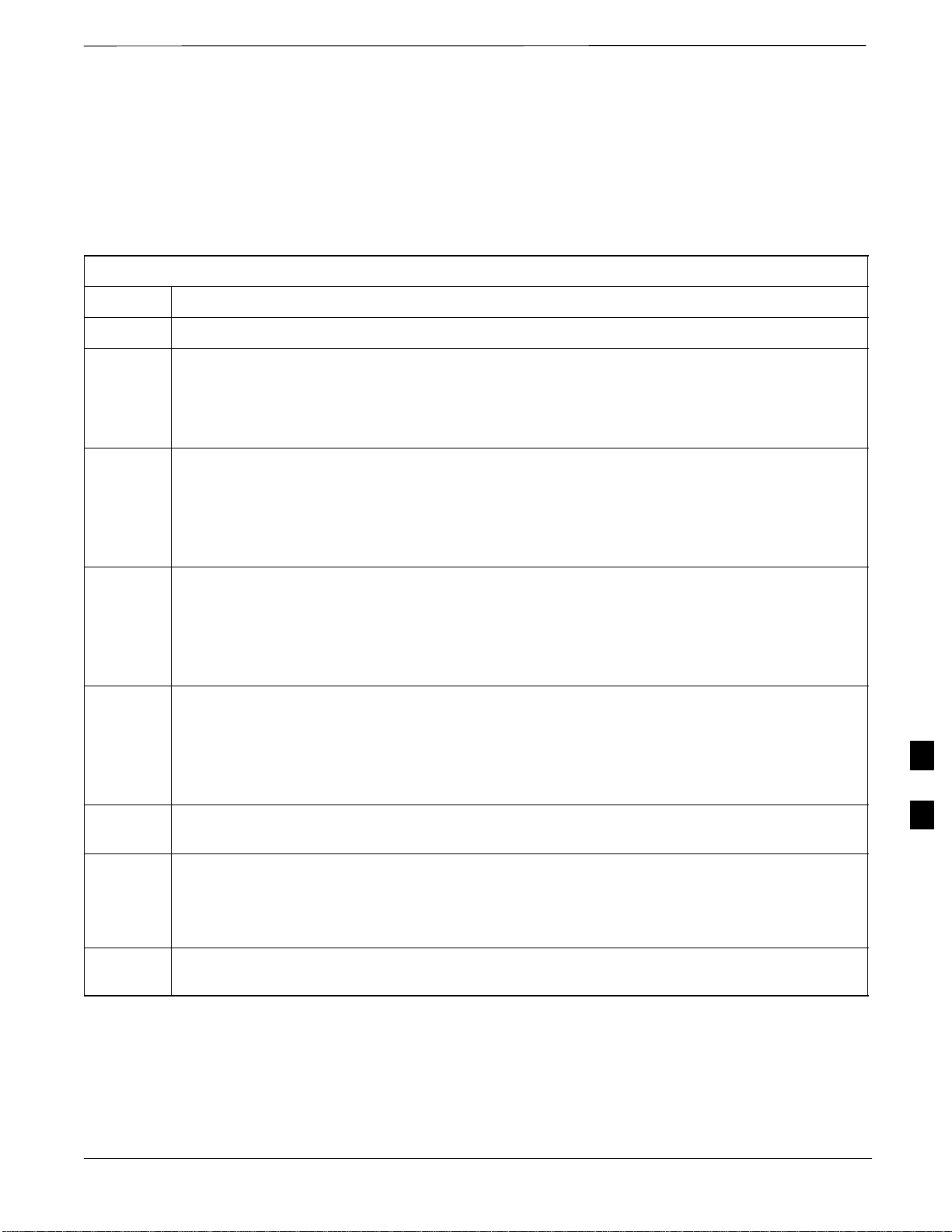

System Status LED States

Table 7-18 lists all of the possible system status LED states.

Table 7-18: System Status LED States

System Status LED Status Indication

Steady Green INS_ACT or INS_SBY, no alarms

Slow Flashing Red/Green

(0.2s Red, 1.4s Green)

Fast Flashing Green/Off

(0.2s Green, 0.2s Off)

Fast Flashing Red/Green

(0.2s Red, 0.2s Green)

Slow Flashing Green/Off

(0.2s Green, 1.4s Off)

Slow Flashing Green/Red

(0.2s Green, 1.4s Red)

Steady Red Critical hardware failure

Fast Flashing Red/Off

(0.25s Red/0.25s Off)

NOTE

The MAWI has powered up in boot code because

the ROM code is either corrupt or not present.

This condition may indicate a MAWI hardware

failure.

7

INS_ACT or INS_SBY w/alarms(s)

OOS_RAM with no alarms

OOS_RAM with alarms(s)

OOS_ROM with no alarms

OOS_ROM with alarm(s)

#1: RAM test failure

#2: FLASH 1 (512K) manufacture/device ID mismatch

#3: FLASH 2 (512K) manufacture/device ID mismatch

#4: FLASH 3 (512K) manufacture/device ID mismatch

#5: Modem present but untrained

#6: Unknown interrupt event

#7: Reset by hardware watchdog timeout

#8: Reset by software watchdog timeout

#9: Reset by double bus fault

#10: Reset by loss of clock

#11: Reset by RESET instruction

#12: Reset by soft reset pin

Off No DC Power applied to module

OOS_RAM refers to a MAWI that is loaded but not enabled

OOS_ROM refers to a MAWI that is not loaded.

INS_ACT refers to a MAWI that is in service and active.

INS_SBY refers to a MAWI that is in service but on standby.

The number of flashes equals the alarm #, with a three–second pause between flashes.

7-36

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 41

Verify and Set Span Line Settings

Objective

The following procedure is to verify and configure the BTS Span line

interface for T–1 or E–1 configurations.

Span Line Settings

The following are the span line settings for the BTS span line interface.

Span A: Primary span

Span B: Downstream span used for daisy–chaining.

Procedure to Verify and Set

Span Line Settings

Use the procedure in Table 7-19 to verify and set (if necessary) the span

line settings.

IMPORTANT

*

Table 7-19: Procedure to Verify and Set Span Line Settings

Step Action

1 If you have not already done so, connect the LMF computer terminal to the MMI/LMF connector.

Refer to Table 7-7.

2 Open an MMI communications session. Refer to Table 7-6.

3 Enter the following command at the SC300> prompt to verify the current span settings:

span_config a

The system will display the following output:

Span A data:

Span type: 5 – T1_2 (B8ZS, DS1 AT&T ESF 4 to 1 packing, 64K link)

Link Speed: 64K

Span EQ: 0 – T1_6 (T1, J1:longhaul, same as choice 10)

LAPD slot: 0

4 Enter the following command at the SC300> prompt to verify the current span settings:

span_config b

The system will display the following output:

Both spans A and B must be set to either T–1 or E–1. The

spans must match the parameters of the CBSC.

7

JAN 2002

Span B data:

Span type: 1 – E1_2 (HDB3)

Link Speed: 64K

Span EQ: 16 – E1 (Long haul: 120 Ohm)

LAPD slot: 1

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

. . . continued on next page

7-37

DRAFT

Page 42

Verify and Set Span Line Settings – continued

Table 7-19: Procedure to Verify and Set Span Line Settings

Step Action

5 If the span line settings are not the same for spans A and B, then enter the SPAN_CONFIG

command for span A. Refer to the SPAN_CONFIG parameters in Table 7-20.

SC300>span_config <span> <span type> <link speed> <span

equalization> <LAPD channel>

The SPAN_CONFIG parameters shown below are an example and may not be applicable to your

configuration.

SC300>span_config a 5 64 0 0

The system will return to the SC300> prompt:

6 Enter the SPAN_CONFIG command for span B. Use the same parameters that you used in step

5. Refer to the SPAN_CONFIG parameters in Table 7-20.

SC300>span_config <span> <span type> <link speed> <span

equalization> <LAPD channel>

The SPAN_CONFIG parameters shown below are an example and may not be applicable to your

configuration.

SC300>span_config b 5 64 0 0

The system will return to the SC300> prompt:

7 Enter the following command at the SC300> prompt to verify the changes to the span A settings:

SC300>span_config a

The system will display the following typical output.

Span A data:

Span type: 5 – T1_2 (B8ZS, DS1 AT&T ESF 4 to 1 packing, 64K link)

Link Speed: 64K

Span EQ: 0 – T1_6 (T1, J1:longhaul, same as choice 10)

LAPD slot: 0

8 Enter the following command at the SC300> prompt to verify the changes to the span B settings:

7

SC300>span_config b

The system will display the following typical output.

Span B data:

Span type: 5 – T1_2 (B8ZS, DS1 AT&T ESF 4 to 1 packing, 64K link)

Link Speed: 64K

Span EQ: 0 – T1_6 (T1, J1:longhaul, same as choice 10)

LAPD slot: 0

7-38

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 43

Verify and Set Span Line Settings – continued

SP AN_CONFIG Parameters

The following parameters in Table 7-20 are for the SPAN_CONFIG

command.

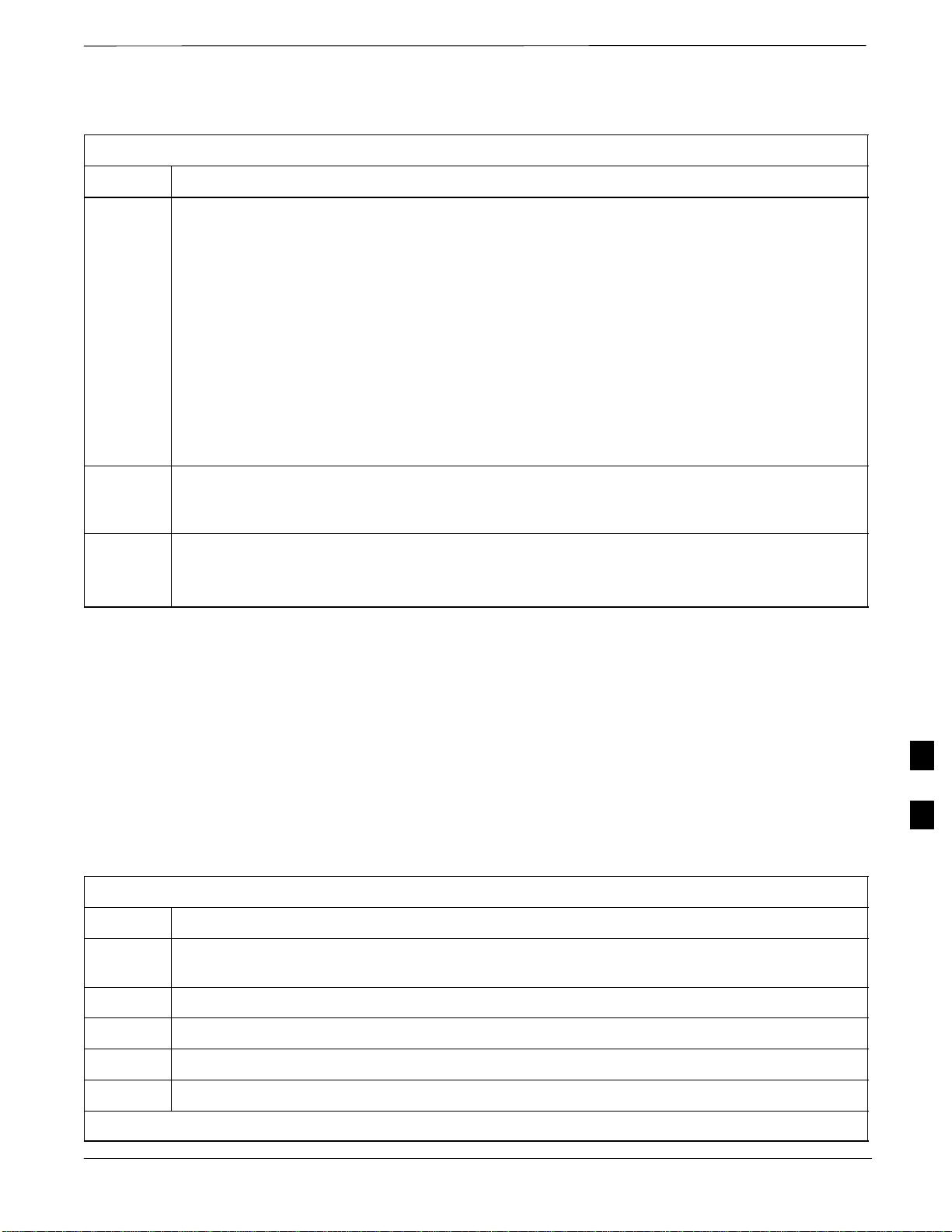

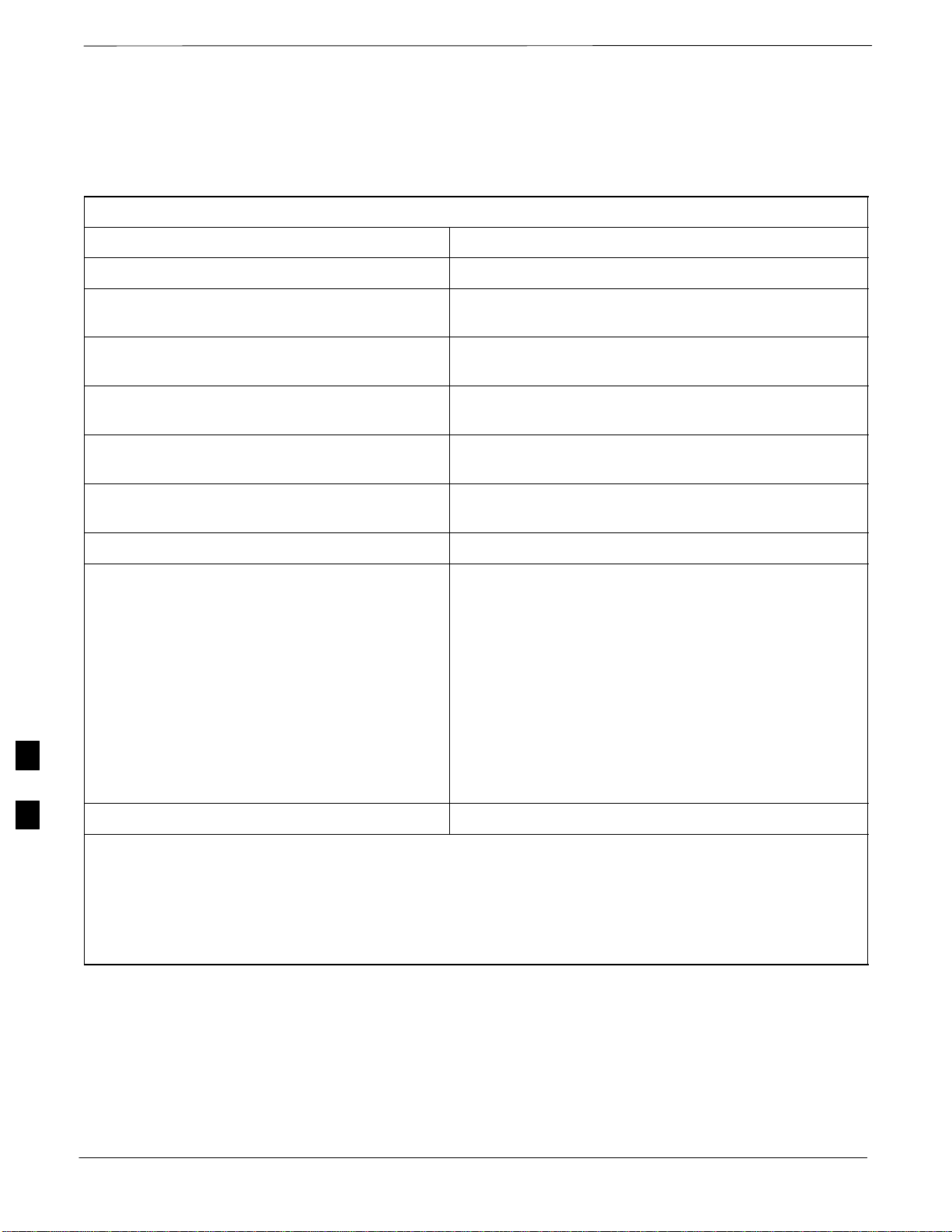

Table 7-20: SPAN_CONFIG Command Parameters

Parameter Values

<span> A or B

<span type> 0 = E1_1 (HDB3, CRC–4)

1 = E1_2 (HDB3)

2 = E1_3 (HDB3, CRC–4, TS16)

3 = E1_4 (HDB3, TS16)

4 = T1_1 (AMI, DS1 AT&T D4, Ext ZCS, 3 to 1 packing, Group 0 unusable)

5 = T1_2 (B8ZS, DS1 AT&T ESF 4 to 1 packing, 64K link)

6 = J1_1 (B8ZS, J1 AT&T ESF, Japan CRC6, 4 to 1 packing)

7 = J1_2 (B8ZS, J1 AT&T ESF, US CRC6, 4 to 1 packing)

8 = T1_3 (AMI, DS1vAT&T D4, Int ZCS, 3 to 1 packing, Group 0 unusable)

<link speed> 56 or 64

<span

equalization>

<LAPD

channel>

0 = T1_6 (T1,J1: long haul, same as choice 10)

1 = T1_4 (T1,J1:393–524 feet)

2 = T1_2 (T1,J1:131–262 feet)

3 = E1_75 (E1:120 Ohm / 75 Ohm coax)

4 = T1_1 (T1,J1:0–131 feet)

5 = T1_5 (T1,J1:524–655 feet)

6 = T1_3 (T1,J1:262–393 feet)

7 = E1_120 (E1:120 Ohm)

8 = T1 (T1,J1: long haul pulse 0 dB, gain 36 dB)

9 = T1 (T1,J1: long haul pulse –7.5 dB, gain 36 dB)

10 = T1 (T1,J1: long haul pulse –15 dB, gain 36 dB)

11 = T1 (T1,J1: long haul pulse –22 dB, gain 36 dB)

12 = T1 (T1,J1: long haul pulse 0 dB, gain 26 dB)

13 = T1 (T1,J1: long haul pulse –7.5 dB, gain 26 dB)

14 = T1 (T1,J1: long haul pulse –15 dB, gain 26 dB)

15 = T1 (T1,J1: long haul pulse –22 dB, gain 26 dB)

16 = E1 (Long haul: 120 Ohm)

17 = E1 (Long haul: 120 Ohm / 75 Ohm coax)

0–31

7

JAN 2002

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

7-39

Page 44

GPIB Addresses

Introduction

Verify the Gigatronics 8541C

Power Meter GPIB Address

Use the following procedures to verify and/or change the GPIB

addresses of the applicable test equipment.

GPIB addresses can range from 1 through 30. The LMF will accept any

address in that range, but the numbers in the GPIB address boxes must

match the addresses of the test equipment. Motorola recommends that

you use 1 for a CDMA signal generator, 13 for a power meter, and 18 for

a CDMA analyzer.

NOTE

The following procedures assume that the test equipment is

set up and ready for testing.

Follow the steps in Table 7-21 to verify and, if necessary, change the

Gigatronics 8541C power meter GPIB address.

Table 7-21: Verify and/or Change Gigatronics 8541C Power Meter GPIB Address

Step Action

1

! CAUTION

Do not connect/disconnect the power meter sensor cable with AC power applied to the meter.

Disconnection could result in destruction of the sensing element or miscalibration.

Press MENU (refer to Figure 7-18).

2 Use the arrow key to select CONFIG MENU and press ENTER.

7

3 Use the arrow key to select GPIB and press ENTER.

The system displays the current Mode and GPIB Address.

4 If the Mode is not set to 8541C, perform the following to change it:

– Use the arrow keys as required to select MODE.

– Use the arrow keys as required to set MODE to 8541C.

5 If the GPIB address is not set to 13, perform the following to change it:

– Use the arrow key to select ADDRESS.

– Use the arrow keys as required to set the GPIB address to 13.

6 Press ENTER to return to normal operation.

7-40

SC300 1X BTS Hardware Installation, ATP, and FRU Procedures

DRAFT

JAN 2002

Page 45

GPIB Addresses – continued

Figure 7-18: Gigatronics 8541C Power Meter Detail

1

MENU ENTER

ARROW

KEYS

Verify and Set Motorola

CyberTest GPIB Address

Follow the steps in Table 7-22 to verify and, if necessary, change the

GPIB address on the Motorola CyberTest. Changing the GPIB address

requires the following items:

Motorola CyberTest communications analyzer.

Computer running Windows 3.1/Windows 95.

Motorola CyberTAME software program “TAME”.

Parallel printer port cable (shipped with CyberTest).

Table 7-22: Verify and/or Change Motorola CyberTest GPIB Address

Step Action

1 On the LMF desktop, locate the CyberTAME icon. Double click on the icon to run the CyberTAME

application.