Page 1

Chapter 6: Installing the Unit and Installation Check Off List

T able of Contents

Unit Installation Overview 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Installation Procedure Order 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector Locations 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector Locations 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attaching Back Fin Cover to Unit 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When to Use the Fin Covers 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attaching Optional Installation Handles to the Unit 6-6. . . . . . . . . . . . . . . . . . . . .

Objective 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Tools and Materials 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Attach the Installation Handles to the Unit 6-6. . . . . . . . . . .

Attaching Unit to Mounting Bracket 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools and Materials 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Attach the Unit to the Mounting Bracket 6-9. . . . . . . . . . . . .

Earth Ground Cabling 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other Grounding Considerations 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Description 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools and Materials 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attaching Front Fin Cover to Unit 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When to Use the Fin Covers 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attaching the Site I/O Junction Box to the Unit 6-15. . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Tools and Materials 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Attach the Site I/O Junction Box to the Unit 6-15. . . . . . . . . .

Procedure to Attach a Site I/O Cap to the Unit (optional) 6-16. . . . . . . . . .

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

Page 2

Table of Contents – continued

Attaching the Short Duration Battery to the Unit (optional) 6-17. . . . . . . . . . . . . . .

Objective 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Tools and Materials 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Attach the Battery to the Unit 6-17. . . . . . . . . . . . . . . . . . . . .

Short Duration Battery Cabling 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Cable 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Cabling 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Description 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cable and Connector Signal Information 6-21. . . . . . . . . . . . . . . . . .

Procedure 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Cabling 6-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Decription 6-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cable and Connector Signal Information 6-23. . . . . . . . . . . . . . . . . .

Procedure 6-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Antenna Cabling for Sites Equipped With

Customer–Supplied Site I/O Interface 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Descriptions 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Antenna Cabling for Sites Equipped with Optional Primary Surge Suppressor 6-30

MIB Cabling for Multi–Unit Configurations 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . .

SU Cabling 6-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Descriptions 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools and Equipment 6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 6-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 6-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools and Equipment 6-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Install SU Cabling for Single Unit 6-47. . . . . . . . . . . . . . . . . .

SU Cabling for Multi–Unit Configurations 6-48. . . . . . . . . . . . . . . . . . . . . .

Terminating Unused Connections 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination List (MicroCell) 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination List (PicoCell) 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 3

Table of Contents – continued

Powering on Unit and Mounting the Solar Cover 6-52. . . . . . . . . . . . . . . . . . . . . . .

Objective 6-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

You May Want to Wait 6-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 6-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure to Power On Unit and Mount Solar Cover 6-52. . . . . . . . . . . . . .

Procedure to Power On Surge Suppressor, Unit and Mount Solar Cover 6-52

Site Cleanup 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove protective covering 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lighting fixtures 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Materials 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove debris 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Completion Checklist 6-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Directions 6-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation completion checklist 6-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

Page 4

Table of Contents – continued

Notes

6

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 5

Unit Installation Overview

Overview

Unit Installation Procedure

Order

This chapter provides the procedures for unit installation and cabling.

The site cabling has been installed and routed to the location of the BTS.

In this chapter, the cables will be attached to the unit(s). Cabling

installation will be repeated as necessary for each unit at the BTS.

This chapter provides the information and procedures to:

S Attach the unit to the mounting bracket

S Attach cables to the unit

S Power on the unit

S Mount the solar covers

S Complete the installation completion checklist

The process of installing the unit requires that the following procedures

be completed in the order shown:

1. Attaching fin covers to the unit – optional

2. Attaching the installation handles to the unit

3. Attaching the unit to the mounting bracket and removing the

installation handles

4. Attaching earth ground cable and optional master ground cable.

5. Attaching the Site I/O junction box to the unit

6. Attaching the short duration battery (optional)

7. Attaching the AC input power or DC input power cable

8. Attaching antenna cable(s)

9. Attaching the MIB cables (optional)

10. Attaching the SU cables (optional)

11. Terminating unused connectors

12. Powering on the unit

13. Mounting solar cover

14. Cleaning up site

15. Filling out the installation completion checklist

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-1

Page 6

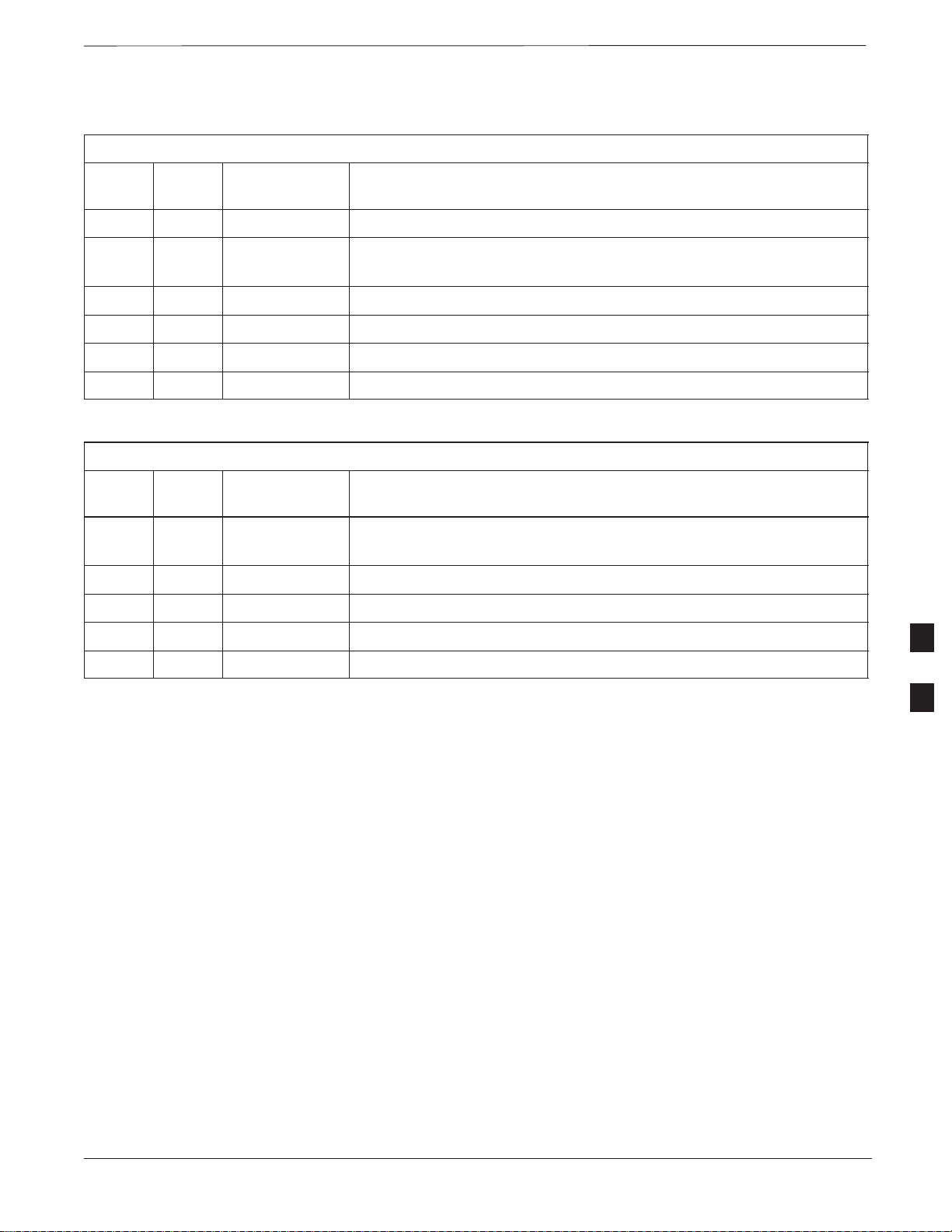

Connector Locations

Connector Locations

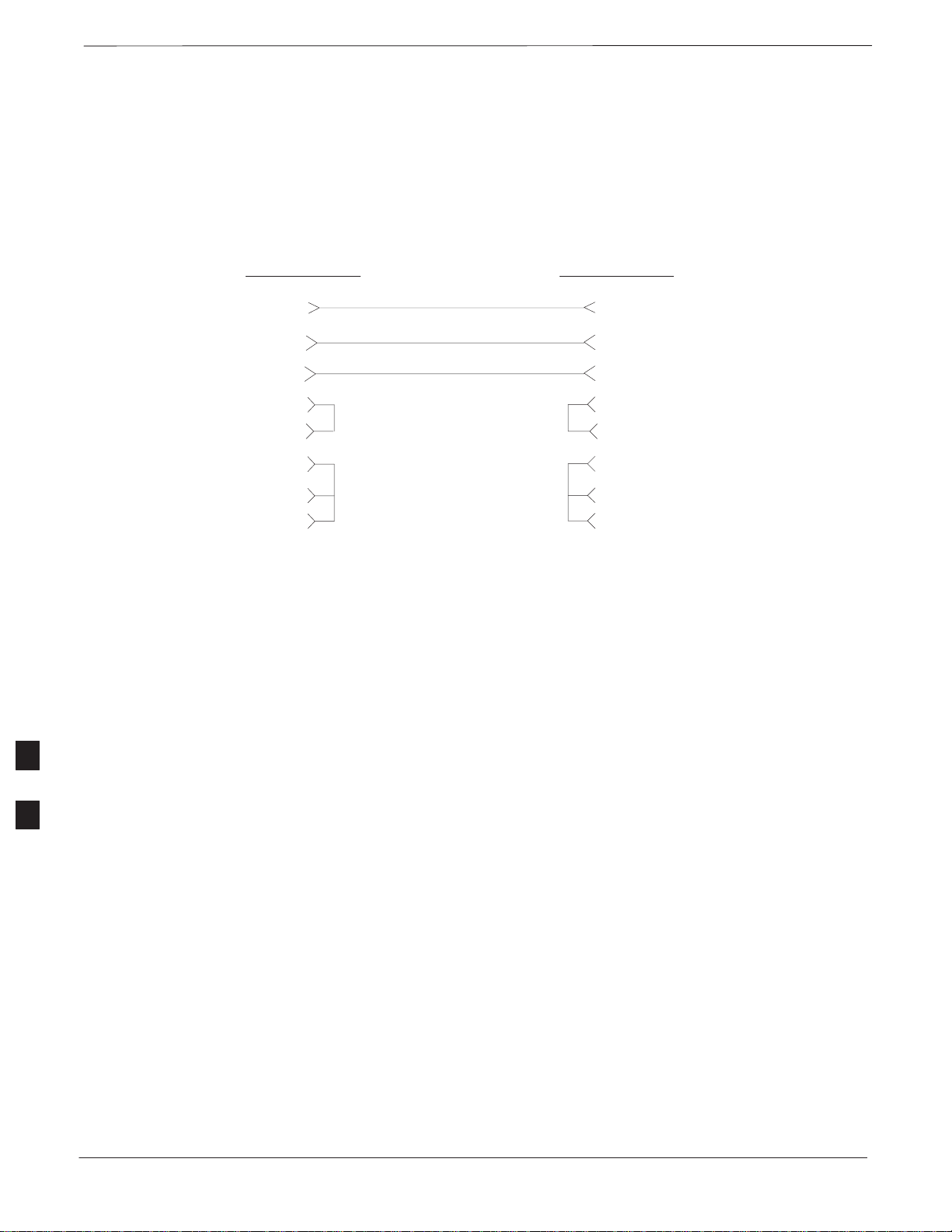

Figure 6-1, Figure 6-2, and Figure 6-3 show the location of the cable

connectors on the Microcell, Picocell, and Primary Surge Suppressor.

The system configuration determines which connectors are used.

Figure 6-1: Location of MicroCell Unit Connectors

SITE I/O

JUNCTION BOX

6

DC POWER BREAKER

DC INPUT

MIB C

MIB B

MIB A

ANTENNA A

TIE WRAP LOCATION

AC POWER BREAKER

AC INPUT

SU RF

SU 2

SU 1

ANTENNA B

0169–O_IL.doc

6-2

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 7

Connector Locations – continued

Figure 6-2: Location of PicoCell Unit Connectors

SITE I/O

JUNCTION BOX

DC POWER BREAKER

DC INPUT

MIB C

AC POWER BREAKER

AC INPUT

MIB B

MIB A

ANTENNA A

TIE WRAP LOCATION

SU RF

SU 2

SU 1

6

0170–O_IL.doc

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-3

Page 8

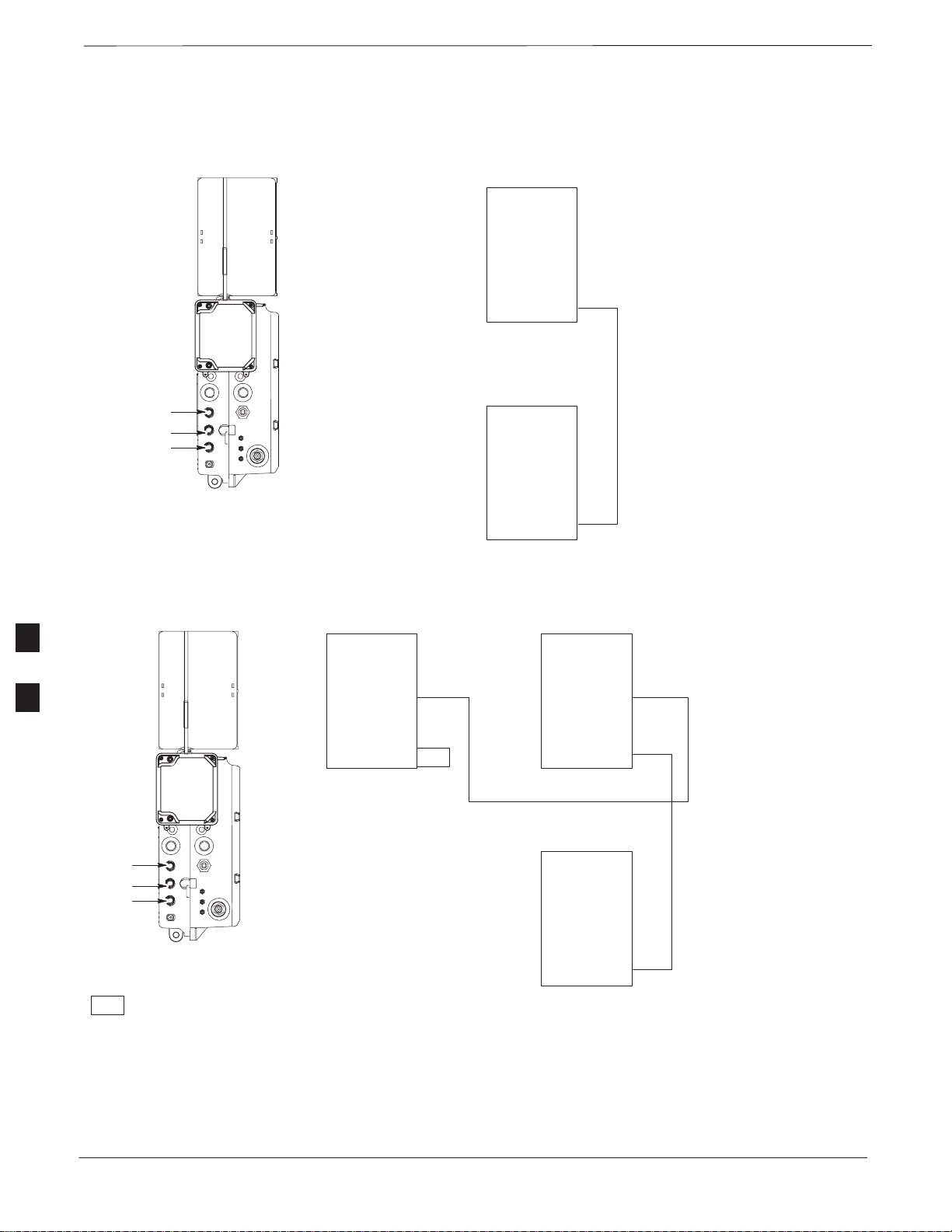

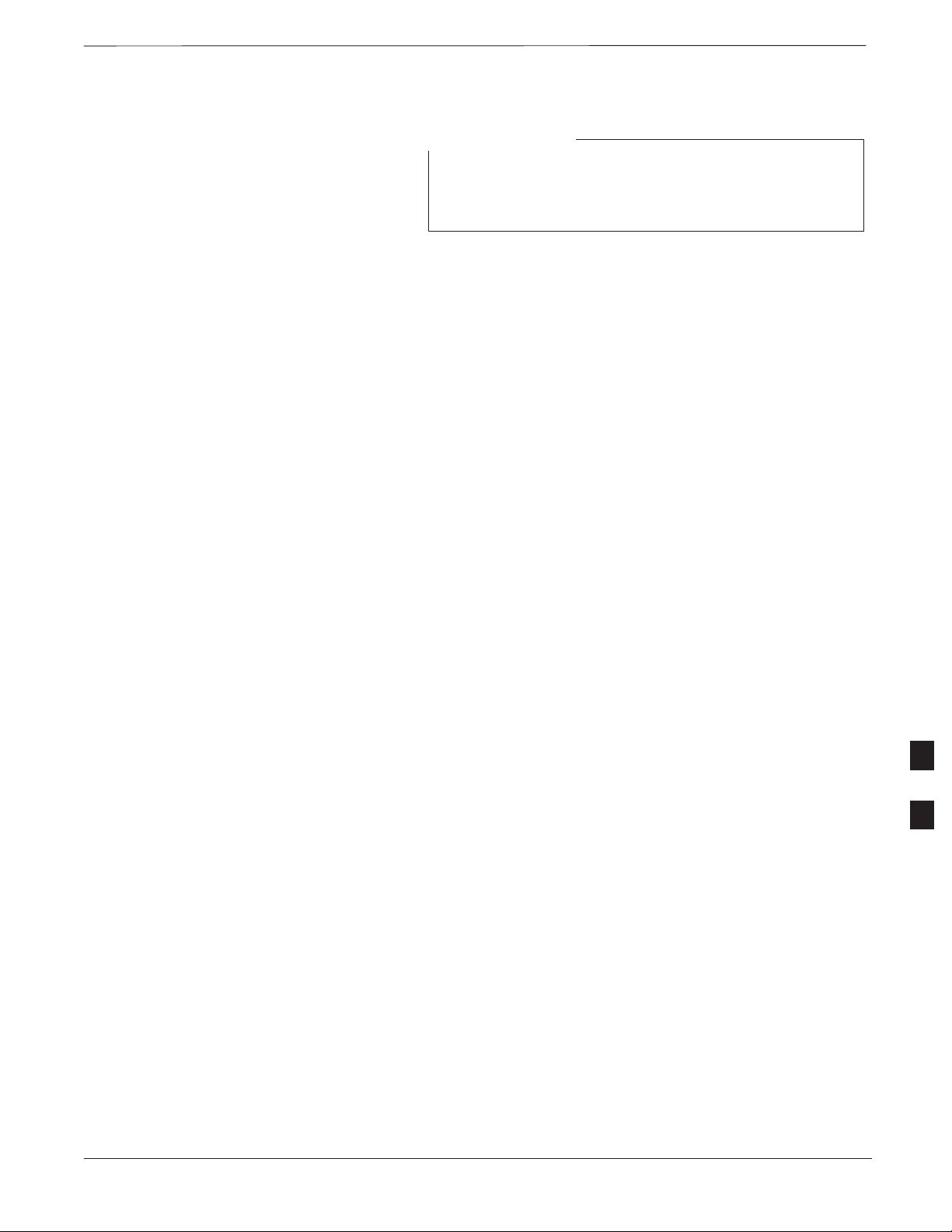

Connector Locations – continued

Figure 6-3: Location of Primary Surge Suppressor Connectors

LEFT SIDE

SITE I/O 2

SITE I/O INPUT

(Conduit Hole)

GROUND 4

GROUND 3

GROUND 2

AC POWER 2

AC POWER 3

AC POWER 4

ANTENNA PROTECTOR 1

ANTENNA PROTECTOR 6

(FOR FUTURE EXPANSION)

ANTENNA PROTECTOR 5

(FOR FUTURE EXPANSION)

6

ANTENNA PROTECTOR 4

(FOR FUTURE EXPANSION)

ANTENNA PROTECTOR 2

ANTENNA PROTECTOR 3

(FOR FUTURE EXPANSION)

RIGHT SIDE

SITE I/O 1

GROUND 1

EARTH

GROUND

AC POWER 1

AC INPUT

(Conduit Hole)

6-4

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 9

Attaching Back Fin Cover to Unit

Objective

The objective of this procedure is to attach the back fin cover to the

PicoCell and MicroCell units. The front fin cover is mounted to the unit

after the unit is mounted to the mounting bracket.

When to Use the Fin Covers

The fin covers should always be used in an indoor application.

Procedure

Attach the rear fin cover to the unit by following the procedures in

Table 6-1 and the information in Figure 6-4.

Step Action

1 Install back fin cover prior to placing unit on the mounting

Table 6-1: Procedure to Attach Rear Fin Cover to Units

bracket.

2 Center fin cover on the fins of the unit. See Figure 6-4 for

snap locations.

3 Align snap with center tab on fins.

4 Push fin cover into place.

Figure 6-4: Attaching Back Fin Cover to Unit (Picocell Shown)

LOCATION OF SNAPS T O ATTACH

FIN COVER TO UNIT

6

PICOCELL FINS

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-5

Page 10

Attaching Optional Installation Handles to the Unit

Objective

The objective of this procedure is to attach the optional installation

handles to the unit. The location for the handles is shown in Figure 6-5.

The handles should be used when lifting or carrying the unit.

Required Tools and Materials

T ools

Attaching the installation handles to the unit requires:

S T30 Torx tamper bit

S Torque driver wrench, 1/4–in. hex female drive, 0–10 N–M

Motorola parts

Table 6-2 lists the parts necessary to do this procedure.

Table 6-2: Installation Handle Kit – SGLN5754

Quantity Part Number Description

4 387541C03 Screws M6x190

1 0787668C01 Left Handle

1 0787668C02 Right Handle

6

Procedure to Attach the

Installation Handles to the Unit

Use the procedure in Table 6-3 to attach the installation handles to the

unit. Refer to Figure 6-5.

Table 6-3: Procedure to Attach the Installation Handles to the Unit

Step Action

1 Hold the left handle in position and start the upper screw. The

handles are marked left and right. Refer to Figure 6-5.

2 Position and start the lower screw.

3 Use a T30 Torx tamper bit to torque both screws to 5.0 N–m.

4 Repeat steps 1–3 for the right handle.

6-6

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 11

Attaching Installation Handles to the Unit – continued

Figure 6-5: Attaching the Installation Handles to the Unit (Picocell Shown)

HOLES USED FOR

MOUNTING HANDLES

HOLES USED FOR

MOUNTING HANDLES

LEFT HANDLE

6

RIGHT HANDLE

M6X19 (4)

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

0164–O_IL.doc

6-7

Page 12

Attaching Unit to Mounting Bracket

Objective

The objective of this procedure is to attach the unit to the mounting

bracket. This procedure applies to mounting brackets that are attached to

a rack, wall, ceiling or pole. This procedure also applies to both the

MicroCell and PicoCell units.

Background

The unit attaches to the mounting bracket with two (2) M6 screws and

the provided pin or a customer–supplied padlock.

WARNING

For ceiling mount applications, two people must do this

procedure. One person must steady the unit while the

second person installs the unit.

NOTE

The handles should be mounted to the unit before

mounting the unit to the bracket. The handles should be

used to lift the unit onto the bracket. If the solar cover is to

be used, the back cover must be attached prior to mounting

the unit. Remove the handles once the unit has been

6

T ools and Materials

The following tools and materials are required to attach the unit to the

mounting bracket:

secured to the mounting bracket.

S Torque driver wrench, 1/4–in. hex female drive, 0–10 N–M

S T30 Torx tamper bit

S Two M6X19 screws (Motorola Part Number 0387541C03)

6-8

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 13

Attaching Unit to Mounting Bracket – continued

Procedure to Attach the Unit to

the Mounting Bracket

Follow the procedure in Table 6-4 to attach the unit to the mounting

bracket. Refer to Figure 6-6.

WARNING

For ceiling mount applications, two people must do this

procedure. One person must steady the unit while the

second person installs the unit.

CAUTION

Use caution when resting the MicroCell or PicoCell unit

on the hooks of the mounting bracket. Do not leave unit

supported by hooks only.

Table 6-4: Procedure to Attach the Unit to the Mounting Bracket

Step Action

1 Lift the unit using the installation handles and place it on the

mounting bracket by aligning the bracket’s upper arms into

the rectangular cutouts in the heatsink. The unit will need to

be raised up slightly so that the lower bracket flange does not

contact the unit’s lower surface. For a ceiling application, use

caution when resting the PicoCell on the hooks on the

mounting bracket.

2 Use a T30 Torx tamper bit to start, but not tighten, both

screws in the location shown in Figure 6-6.

3 At the bottom of the unit, align the hole in the mounting

bracket with the hole in the unit. Place the pin or

customer–supplied padlock through this hole. Screw pin

together and tighten firmly.

4 Use a T30 Torx tamper bit to torque the two mounting screws

to 5.0 N–M.

5 Use a T30 Torx tamper bit to remove the installation handles.

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-9

Page 14

Attaching Unit to Mounting Bracket – continued

Figure 6-6: Attaching the Unit to the Mounting Bracket

HOOKS

M6 SCREWS (2)

SLIDE PIN THROUGH HOLES IN

BRACKET AND SCREW TOGETHER

6

ATTACH THE HANDLES TO THE UNIT

BEFORE LIFTING

MOUNTING BRACKET

6-10

MOUNTING BRACKET

PIN (P/N 5587660C03)

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 15

Earth Ground Cabling

Objective

Other Grounding

Considerations

Cable Description

The objective of this procedure is to attach the earth ground cabling to

one or more MicroCell or PicoCell units. This procedure covers just the

grounding cables that attach to the MicroCell or PicoCell.

Grounding considerations beyond the ground cables that attach to the

MicroCell and PicoCell are summarized in Appendix A. Refer to

Appendix A and the site documentation for other grounding

considerations.

If your site is equipped with the optional Primary Surge Suppressor,

refer to the “Power, Earth Ground, and Battery Cabling” Procedure in

chapter 4 for information about installing the Master Ground cable.

The following cables in Table 6-5 are necessary to do this procedure.

Table 6-5: Ground Cable Description and Part Number

Cable Qty. Part Number Description

A 1–4 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector. Used for Primary Surge Suppressor Installation.

B 1–4 3087701C01 Ground cable, Site I/O Junction Box to Bracket.

Y 1 Customer

Supplied

T ools and Materials

Master Ground Cable, 6 -AWG, insulated copper wire. Used for both

Primary Surge Suppressor and non–Primary Surge Suppressor

installations.

The following tools are required to attach ground cabling to the

MicroCell and PicoCell units.

S 13 mm torque wrench set to 5.0 N–M

S Flathead screwdriver bit

S T30 TORX bit

Procedure

Use the following procedure to attach the ground cables. Refer to

Table 6-6 and Figure 6-7.

Table 6-6: Procedure to Attach the Earth Ground Cables

6

DEC 2000

Step Action

1 Remove the hex nuts and lock washers from the ground stud

on the mounting bracket.

2 Attach ground cable (cable A or Y) to ground stud on

mounting bracket.

. . . continued on next page

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-11

Page 16

Earth Ground Cabling – continued

Step Action

3 Replace one lock washer and nut on the ground stud and

4 Attach the ground cable from the Site I/O junction box (cable

5 Replace the second lockwasher and hex nut to the ground stud

Figure 6-7: Detail Location of Ground Stud

Table 6-6: Procedure to Attach the Earth Ground Cables

tighten to 5 N–m.

B) to the ground stud on the mounting bracket.

on mounting bracket. Use a torque wrench and a 13mm

socket to tighten to 5.0 N–m.

GROUNDING STUD

CABLE A OR Y

B

TO CUSTOMER DEFINED MASTER

6

GROUND PLATE OR CARRIER

GROUND CONNECTOR ON PRIMARY

SURGE SUPPRESSOR

6-12

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 17

Earth Ground Cabling – continued

Figure 6-8: Grounding Stud on Mounting Bracket

LOCK WASHER

MOUNTING BRACKET

NUT

LOCK WASHER

NUT

GROUNDING STUD

CUSTOMER UNIT

GROUND LUG

SITE I/O

GROUND LUG

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-13

Page 18

Attaching Front Fin Cover to Unit

Objective

The objective of this procedure is to attach the front fin cover to the

PicoCell and MicroCell units.

When to Use the Fin Covers

Always use fin covers for an indoor application.

Procedure

Follow the procedure in Table 6-7 to attach the front fin cover to the

unit. Refer to Figure 6-9.

Step Action

1 Center fin cover on the fins of the unit. See Figure 6-9 for

Table 6-7: Procedure to Attach Front Fin Cover to Unit

snap locations.

2 Align snap with center tab on fins.

3 Push fin cover into place.

Figure 6-9: Attaching Front Fin Cover to Unit (Picocell Shown)

6

LOCATION OF SNAPS T O ATTACH

FIN COVER TO UNIT

PICOCELL FINS

6-14

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 19

Attaching the Site I/O Junction Box to the Unit

Objective

The objective of this procedure is to attach the Site I/O junction box to

the unit. The location for the Site I/O junction box is shown in

Figure 6-10.

If you do not mount a Site I/O Junction box to a unit, leave the installed

Site I/O caps on the Site I/O Junction box connectors.

Required Tools and Materials

The following tools and materials are necessary to do this procedure:

S Torque driver wrench, 1/4–in. hex female drive, 0–10 N–M

S T30 Torx tamper bit

S Site I/O Junction box

Procedure to Attach the Site

I/O Junction Box to the Unit

Follow the procedure below to attach the site I/O junction box to the

unit.

Table 6-8: Procedure to Attach the Site I/O Junction Box to the Unit

Step Action

1 Use a T30 TORX bit to remove Site I/O Cap from the Site

I/O connector .

NOTE

Save Site I/O Cap for future use.

2 Remove the Site I/O Plate from the Site I/O Junction Box.

3 Attach one end of the Site I/O Ground cable to the Site I/O

Junction Box. Use one M6x19 tamper–resistant screw.

Torque to 5.0 N–m.

4 The free end of the Site I/O junction box cable should be

connected to the customer–supplied Site I/O interface or to

the Primary Surge Suppressor.

5 Position the Site I/O junction box as shown in NO TAG.

6 Insert the Site I/O junction box on to the housing, using the

alignment feature on the housing.

6

DEC 2000

7 Use a T30 Torx tamper bit to tighten (but do not torque) the

upper tamper resistant screw.

8 Tighten but do not torque the lower tamper resistant screw.

9 Use a T30 Torx tamper bit to torque the upper and lower

screw to 5 N–m.

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-15

Page 20

Attaching the Site I/O Junction Box to the Unit – continued

Figure 6-10: Attaching the Site I/O Junction Box to the Unit

SITE I/O JUNCTION BOX

CAPTIVE SCREWS

6

Procedure to Attach a Site I/O

Cap to the Unit (optional)

Use the following procedure in Table 6-9 to attach a Site I/O Cap to the

unit.

Table 6-9: Procedure to Attach a Site I/O Cap to the Unit (optional)

Step Action

1 Position the Site I/O cap, Motorola Part Number

3888121C01, over the Site I/O socket.

2 Use a T30 Torx tamper bit to tighten (but do not torque) the

upper tamper resistant screw.

3 Tighten but do not torque the lower tamper resistant screw.

4 Use a T30 Torx tamper bit to torque the upper and lower

screw to 5 N–m.

6-16

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 21

Attaching the Short Duration Battery to the Unit (optional)

Objective

The objective of this procedure is to attach the short duration battery to

the unit.

Required Tools and Materials

Attaching the battery to the unit requires:

S T30 Torx tamper bit, 1/4–in. hex

S Torque driver wrench, 1/4–in. hex female drive, 0–10 N–M

S Two (2) Screws M6x19 (Motorola Part Number 0387541C03)

Procedure to Attach the

Battery to the Unit

Follow the procedure in Table 6-10 to attach the short duration battery to

the unit. Refer to Figure 6-11.

Table 6-10: Procedure to Attach the Short Duration Battery to the Unit

Step Action

1 Hold the battery in the position shown in Figure 6-11.

2 The two holes at the end of the battery should align with the

mounting holes on the unit. See Figure 6-11.

3 Start but do not tighten the M6x19 screws.

4 Using a T30 Torx tamper bit wrench, 1/4–in. hex female

drive, 0–10 N–M, torque the screws to 5 N–M.

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-17

Page 22

Attaching the Short Duration Battery to the Unit (optional) – continued

Figure 6-11: Attaching the Short Duration Battery to the Unit

M6X19 SCREWS (2)

CONNECT TO DC INPUT CONNECTOR

WHEN BATTERY HAS BEEN SECURED

6

SHORT DURA TION

BATTERY

6-18

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 23

Short Duration Battery Cabling

Objective

The objective of this procedure is to attach the short duration battery

cable.

Battery Cable

The battery cable is part of the battery assembly. The same type

connector is used for the short duration battery and DC input cables.

Procedure

Use the following procedure in Table 6-11 to attach the short duration

battery (DC input) cable to the DC input connector. Refer to

Figure 6-12. The cable should be connected before the solar cover is

attached.

The short duration battery should not be opened under any

circumstances. No wire termination is required by the user except

connection to the BTS, with the provided connector.

Table 6-11: Procedure to Connect the Short Duration Battery Cable to

Unit

Step Action

1 Ensure that the ground wire has a connection to unit and the

Master Ground Bus (also called Master Ground Plate).

2 Verify that the DC power breaker is open. The white collar on

the breaker is visible when it is open.

3 Place the round, black connector of the DC input cable onto

the DC input connector on the BTS. Refer to Figure 6-12.

Turn the cable connector to align its key.

4 Hand tighten the connector (a clicking sound is heard, this is

normal). When the red line on the connector on the unit is

covered, connection is complete.

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-19

Page 24

Short Duration Battery Cabling – continued

Figure 6-12: Battery Cable Installation

DC INPUT CONNECTOR

BATTERY CABLE IS PART

OF BATTERY ASSEMBLY

6

6-20

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 25

AC Power Cabling

Objective

Cable Description

The objective of this procedure is to attach the AC input power cable to

the unit. Use this procedure only when AC power is used to power the

unit.

If the Primary Surge Suppressor is not used, the AC Installation Box is

required for all outdoor mounting applications.

WARNING

This equipment uses dangerous voltages and is capable of

causing death. Use extreme caution when handling and

testing this equipment.

The following cables in Table 6-5 are necesary to do this procedure:

Table 6-12: AC Input Cable Description and Part Number

Cable Qty. Part Number Description

S 1–4 3087854C02 AC input cable, 18 AWG, 5 m, is designed for 120–240 VAC power

input. Cable has Deutsch connector on both ends.

Power Cable and Connector

Signal Information

The AC input connector is located on the side of the unit as shown in

Figure 6-13. The unit is designed for 88–260 VAC power input.

Procedure

Use the following procedure in Table 6-13 to connect the AC input cable

to the unit. The AC input cable should be connected before the solar

cover is attached.

Table 6-13: Procedure to Connect AC Power to the Unit

Step Action

1 Ensure that the ground wire has a connection to the Master

Ground Bus (also called Master Ground Plate).

2 Verify that the AC power breaker is open. The white collar on

the breaker is visible when it is open.

6

DEC 2000

3 Place the round, black connector on the AC input cable (cable

S) onto the AC input connector. See Figure 6-13. Turn the

cable connector to align its key.

4 Hand tighten the connector (a clicking sound is heard, this is

normal). When the red line on the connector on the unit is

covered, connection is complete.

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-21

Page 26

AC Power Cabling – continued

Figure 6-13: AC Power Cabling Details

AC POWER

BREAKER

AC INPUT

CONNECTOR

AC INSTALL BOX

S

OR AC POWER

SOURCE OR

OPTIONAL

PRIMARY SURGE

SUPPRESSOR

AC CONDUIT

6

6-22

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 27

DC Power Cabling

Objective

Cable Decription

The objective of this procedure is to attach the DC input cable to the

unit. Use this procedure only when DC power is used to power the unit.

WARNING

This equipment uses dangerous voltages and is capable of

causing death. Use extreme caution when handling and

testing this equipment.

The following cables in Table 6-14 are necessary to do this procedure.

Table 6-14: DC Input Cable Description and Part Number

Cable Qty. Part Number Description

U 1 3087854C04 DC input cable, 18 AWG, 5 m, is designed for 20 to 30 VDC power

input.

Power Cable and Connector

Signal Information

The DC input connector is located on the side of the unit. The unit is

designed for 40 to 60 VDC.

Procedure

Use the following procedure in Table 6-15 to connect the DC input cable

to the unit. Refer to Figure 6-14. The DC input cable should be

connected before the solar cover is attached.

Table 6-15: Procedure to Connect DC Power to the Unit

Step Action

1 Ensure that the ground wire has a connection to the Master

Ground Bus (also called Master Ground Plate).

2 Verify that the DC power breaker is open. The white collar on

the breaker is visible when it is open.

6

DEC 2000

3 Place the round, black connector of the DC input cable onto

the DC input connector. See Figure 6-14. Turn the cable

connector to align its key.

4 Hand tighten the connector (a clicking sound is heard, this is

normal). When the red line on the connector on the unit is

covered, connection is complete.

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-23

Page 28

DC Power Cabling – continued

Figure 6-14: DC Power Cabling Details

DC POWER BREAKER

DC INPUT

CONNECTOR

DC POWER

SOURCE

U

0178–O_IL.doc

6

6-24

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 29

Antenna Cabling for Sites Equipped With Customer–Supplied Site I/O

Interface

Objective

The objective of this procedure is to attach the antenna cabling for one or

more units.

If your BTS is equipped with the optional Primary Surge Suppressor,

then proceed to the “Antenna Cabling for Sites Equipped with the

Optional Primary Surge Suppressor” procedure in Chapter 6.

Cable Labels

The cable designations are referenced to Table 6-16 in the “Cable

Description” area of Chapter 4.

Cable Descriptions

The following cables in Table 6-16 are necessary to do this procedure.

Table 6-16: Cable Descriptions and Part Numbers

Cable Qty. Part Number Description

C 1–8 Customer

Supplied

Procedure

Antenna cable, 50–Ohm coaxial terminated with at least one male,

N–type connector.

The cabling is installed between the unit(s) and the external lightning

arrestors. If lightning arrestors are not present, it connects to the

antenna.

If your BTS has one unit, cable the unit as shown in Figure 6-15.

Torque the connectors to 4.3 N–M.

If your BTS has more than one unit, cable the unit as shown in

Figure 6-18, Figure 6-17, Figure 6-16, Figure 6-21, Figure 6-20, or

Figure 6-19.

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-25

Page 30

Antenna Cabling for Sites Equipped With Customer–Supplied Site I/O

Interface

Figure 6-15: Antenna Cabling Details for MicroCell and PicoCell Unit

– continued

MICROCELL UNIT

PICOCELL UNIT

ANTENNA A

6

C

LIGHTNING

ARRESTOR

C

RX

ANTENNA

C

LIGHTNING

ARRESTOR

C

TX/RX

ANTENNA

ANTENNA B

ANTENNA A

C

LIGHTNING

ARRESTOR

C

TX/RX

ANTENNA

6-26

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 31

Antenna Cabling for Sites Equipped With Customer–Supplied Site I/O

Interface

Figure 6-16: Antenna Cabling for Two Microcells

ANTENNA A

ANTENNA B

– continued

MICROCELL UNIT

KEY

= LIGHTNING ARRESTOR

LA

RFT

= 50 OHM RF TERMINAT OR

MICROCELL 1

ANT A

ANT B

MICROCELL 2

ANT A

ANT B

RFT

RFT

C

LA

C

LA

ANTENNA 1

TX/RX

ANTENNA 2

TX/RX

Figure 6-17: Antenna Cabling for Three Microcells

MICROCELL UNIT

ANT A

ANT B

ANTENNA A

ANTENNA B

KEY

= LIGHTNING ARRESTOR

LA

RFT

= 50 OHM RF TERMINAT OR

6

MICROCELL 1MICROCELL 3

ANT A

RFT

ANT B

C

MICROCELL 2

ANT A

RFT

ANT B

C

LA

C

LA

LA

C

LA

ANTENNA 1

TX/RX

ANTENNA 3

TX/RX

ANTENNA 2

TX/RX

ANTENNA 4

RX

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-27

Page 32

Antenna Cabling for Sites Equipped With Customer–Supplied Site I/O

Interface

Figure 6-18: Antenna Cabling for Four Microcells

– continued

MICROCELL UNIT

MICROCELL 1MICROCELL 3

ANTENNA A

ANTENNA B

RFT

KEY

= LIGHTNING ARRESTOR

LA

= 50 OHM RF TERMINAT OR

ANT A

ANT B

ANT A

ANT B

RFT

C

RFT

C

ANT A

RFT

ANT B

MICROCELL 2MICROCELL 4

ANT A

RFT

ANT B

LA

C

LA

LA

C

LA

ANTENNA 1

TX/RX

ANTENNA 3

TX/RX

ANTENNA 2

TX/RX

ANTENNA 4

TX/RX

6

Figure 6-19: Antenna Cabling for Two Picocells

PICOCELL UNIT

PICOCELL 1

ANTENNA A

6-28

KEY

= LIGHTNING ARRESTOR

LA

SCt300 BTS Hardware Installation, ATP and FRU Procedures

ANT A

PICOCELL 2

ANT A

C

LA

C

LA

ANTENNA 1

TX/RX

ANTENNA 2

TX/RX

DEC 2000

PRELIMINARY

Page 33

Antenna Cabling for Sites Equipped With Customer–Supplied Site I/O

Interface

Figure 6-20: Antenna Cabling for Three Picocells

– continued

ANTENNA A

LA

PICOCELL UNIT

KEY

= LIGHTNING ARRESTOR

ANT A

PICOCELL 1PICOCELL 3

ANT A

C

PICOCELL 2

ANT A

C

LA

LA

C

LA

ANTENNA 1

TX/RX

ANTENNA 3

TX/RX

ANTENNA 2

TX/RX

Figure 6-21: Antenna Cabling for Four Picocells

PICOCELL UNIT

ANT A

ANTENNA A

KEY

= LIGHTNING ARRESTOR

LA

ANT A

6

PICOCELL 1PICOCELL 3

ANT A

C

PICOCELL 2PICOCELL 4

ANT A

C

C

LA

LA

C

LA

LA

ANTENNA 1

TX/RX

ANTENNA 3

TX/RX

ANTENNA 2

TX/RX

ANTENNA 4

TX/RX

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-29

Page 34

Antenna Cabling for Sites Equipped with Optional Primary Surge

Suppressor

Objective

The objective of this procedure is to attach the antenna cabling for one or

more units at a site equipped with the optional Primary Surge

Suppressor.

Cable Labels

The cable designations are referenced to Table 6-17 in the “Cable

Description” area of Chapter 4.

Cable Descriptions

The following cables in Table 6-17 are necessary to do this procedure.

Table 6-17: Cable Descriptions and Part Numbers

Cable Qty. Part Number Description

C 1–8 Customer

Supplied

D 2–6 Customer

Supplied

Procedure

6

Antenna cable, 50–Ohm coaxial terminated with at least one male,

N–type connector.

Antenna cable, terminated with 2 male N–type connectors

Lightning arrestors are shipped/installed in the Primary Surge

Suppressor for one or two unit configurations. If you are expanding

from two to three or from three to four units, then you must install

lightning arrestors for units three and four. Refer to the procedure in

Table 6-18 to install antenna lightning arrestors.

If your BTS has one unit and is equipped with the Primary Surge

Suppressor, cable the unit as shown in Figure 6-23.

If your BTS has more than one unit and is equipped with the Primary

Surge Suppressor, cable the units as shown in Figure 6-24 through

Figure 6-29.

Table 6-18: Procedure to Install Antenna Lightning Arrestors

Step Action

1 Remove the 3/4–in. nut and lock washer from N–type

connector on antenna lightning arrestor. Refer to Figure 6-22.

6-30

2 Insert the antenna lightning arrestor through hole in mounting

flange.

NOTE

Antenna cable connectors may be connected to either side of

the antenna protectors on the Primary Surge Suppressor.

3 Install the lockwasher and 3/4–in. nut on the N–type

connector.

4 Use a 3/4–in. wrench to tighten to 20 N–m.

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 35

Antenna Cabling for Sites Equipped with Optional Primary Surge

Suppressor

Figure 6-22: Installation of Third and Fourth Antenna Lightning Arrestors

– continued

3/4–IN NUT

LOCKWASHER

ANTENNA LIGHTNING

ARRESTORS

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-31

Page 36

Antenna Cabling for Sites Equipped with Optional Primary Surge

Suppressor

Figure 6-23: Antenna Cabling Details for MicroCell and PicoCell Unit Equipped with Primary Surge

Suppressor

– continued

MICROCELL UNIT

PICOCELL UNIT

ANTENNA A

ANTENNA A

D

PRIMARY

SURGE

6

SUPPRESSOR

RX

ANTENNA

PRIMARY SURGE

SUPPRESSOR

(LEFT SIDE)

D

12

CC

TX/RX

ANTENNA

ANTENNA B

D

PRIMARY

SURGE

SUPPRESSOR

1

C

TX/RX

ANTENNA

PRIMARY SURGE

SUPPRESSOR

(RIGHT SIDE)

6-32

ANTENNA LIGHTNING

ARRESTOR 1

ANTENNA LIGHTNING

ARRESTOR 2

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 37

Antenna Cabling for Sites Equipped with Optional Primary Surge

Suppressor

Figure 6-24: Antenna Cabling for Two Microcells Equipped with Primary Surge Suppressor

MICROCELL UNIT

ANTENNA B

ANTENNA A

RFT

= 50 OHM RF TERMINAT OR

– continued

ANTENNA

PROTECTOR 1

KEY

PRIMARY SURGE

SUPPRESSOR

(RIGHT SIDE)

ANTENNA

PROTECTOR 2

MICROCELL 1

ANT A

ANT B

MICROCELL 2

ANT A

ANT B

RFT

D

1

2

PRIMARY

SURGE

SUPPRESSOR

RFT

D

ANTENNA 1

C

TX/RX

ANTENNA 2

C

TX/RX

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-33

Page 38

Antenna Cabling for Sites Equipped with Optional Primary Surge

Suppressor

Figure 6-25: Antenna Cabling for Three Microcells Equipped with Primary Surge Suppressor

– continued

MICROCELL 1MICROCELL 3

ANT A

ANT B

MICROCELL UNIT

D

D

ANT A

ANT B

MICROCELL 2

ANT A

ANT B

PRIMARY SURGE

SUPPRESSOR

(LEFT SIDE)

RFT

D

RFT

D

PRIMARY

SURGE

SUPPRESSOR

1

C

C

2

3

C

4

C

ANTENNA 1

TX/RX

ANTENNA 2

TX/RX

ANTENNA 3

TX/RX

ANTENNA 4

RX

PRIMARY SURGE

SUPPRESSOR

(RIGHT SIDE)

6

ANTENNA A

KEY

RFT

= 50 OHM RF TERMINAT OR

6-34

ANTENNA

PROTECTOR 1

PROTECTOR 2

ANTENNA B

ANTENNA

PROTECTOR 4

(SEE NOTE)

NOTE: YOU MUST INSTALL

ANTENNA PROTECTOR

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

ANTENNA

ANTENNA

PROTECTOR 3

(SEE NOTE)

DEC 2000

Page 39

Antenna Cabling for Sites Equipped with Optional Primary Surge

Suppressor

Figure 6-26: Antenna Cabling for Four Microcells Equipped with Primary Surge Suppressor

– continued

MICROCELL 4

ANT A

ANT B

RFT

MICROCELL 1MICROCELL 3

ANT A

RFT

D

ANT B

MICROCELL 2

D

PRIMARY

SURGE

SUPPRESSOR

1

C

2

C

3

C

4

C

ANTENNA 1

TX/RX

ANTENNA 2

TX/RX

ANTENNA 3

TX/RX

ANTENNA 4

TX/RX

KEY

RFT

= 50 OHM RF TERMINAT OR

MICROCELL UNIT

ANTENNA A

ANTENNA B

ANT A

ANT B

RFT

D

PRIMARY SURGE

SUPPRESSOR

(LEFT SIDE)

ANTENNA

PROTECTOR 4

(SEE NOTE)

NOTE: YOU MUST INSTALL

ANTENNA PROTECTOR

ANT A

ANT B

RFT

D

PRIMARY SURGE

ANTENNA

PROTECTOR 1

ANTENNA

PROTECTOR 2

SUPPRESSOR

(RIGHT SIDE)

6

ANTENNA

PROTECTOR 3

(SEE NOTE)

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-35

Page 40

Antenna Cabling for Sites Equipped with Optional Primary Surge

Suppressor

Figure 6-27: Antenna Cabling for Two Picocells Equipped with Primary Surge Suppressor

PICOCELL UNIT

– continued

PRIMARY SURGE

SUPPRESSOR

(RIGHT SIDE)

PICOCELL 1

ANT A

PICOCELL 2

ANTENNA

ANTENNA A

6

Figure 6-28: Antenna Cabling for Three Picocells Equipped with Primary Surge Suppressor

PICOCELL UNIT

PROTECTOR 1

ANTENNA

PROTECTOR 2

ANT A

PRIMARY SURGE

SUPPRESSOR

(RIGHT SIDE)

D

PRIMARY

SURGE

SUPPRESSOR

D

PICOCELL 1PICOCELL 3

1

2

ANTENNA 1

TX/RX

C

C

ANTENNA 2

TX/RX

ANTENNA

PROTECTOR 1

ANTENNA A

NOTE: YOU MUST INSTALL

ANTENNA PROTECTOR

ANTENNA

PROTECTOR 2

6-36

ANT A

ANTENNA

PROTECTOR 3

(SEE NOTE)

D

ANT A

D

PICOCELL 2

SUPPRESSOR

ANT A

D

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

PRIMARY

SURGE

1

C

2

C

C

3

ANTENNA 1

TX/RX

ANTENNA 2

TX/RX

ANTENNA 3

TX/RX

DEC 2000

Page 41

Antenna Cabling for Sites Equipped with Optional Primary Surge

Suppressor

Figure 6-29: Antenna Cabling for Four Picocells Equipped with Primary Surge Suppressor

– continued

ANT A ANT A

PICOCELL 4

PICOCELL 1PICOCELL 3

ANTENNA 1

1

C

D

PICOCELL 2

D

PRIMARY

SURGE

SUPPRESSOR

2

3

4

TX/RX

C

ANTENNA 2

TX/RX

C

ANTENNA 3

TX/RX

C

ANTENNA 4

TX/RX

PICOCELL UNIT

ANTENNA A

ANT A

D

PRIMARY SURGE

SUPPRESSOR

(LEFT SIDE)

ANTENNA

PROTECTOR 4

(SEE NOTE)

NOTE: YOU MUST INSTALL

ANTENNA PROTECTOR

ANT A

D

PRIMARY SURGE

SUPPRESSOR

(RIGHT SIDE)

6

ANTENNA

PROTECTOR 1

ANTENNA

PROTECTOR 2

ANTENNA

PROTECTOR 3

(SEE NOTE)

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-37

Page 42

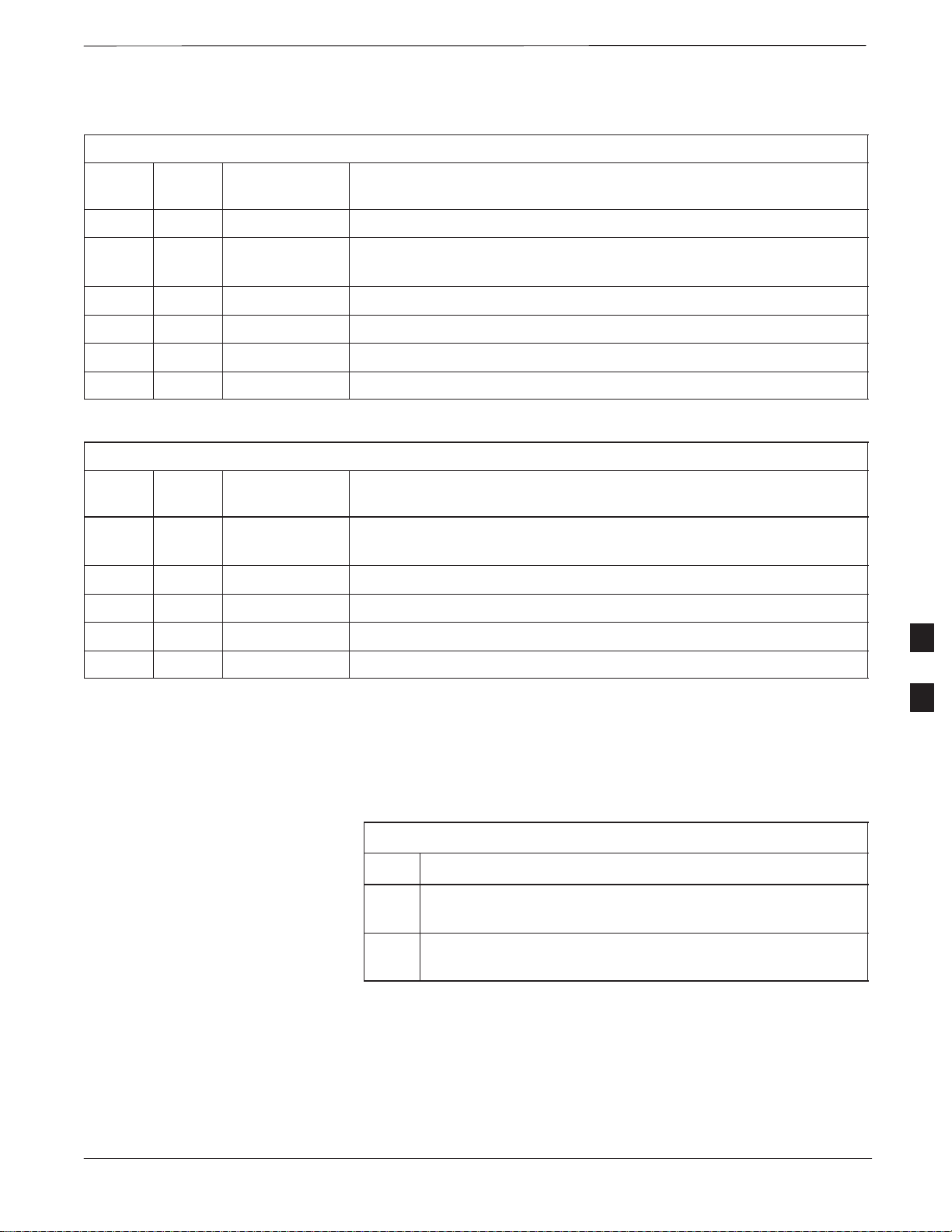

MIB Cabling for Multi–Unit Configurations

Overview

The objective of this procedure is to attach the MIB cabling for a

multi–BTS configuration.

Cable Labels

The cable designations are referenced in Table 4–1 in the “Cable

Descriptions” procedure in Chapter 4.

T ools and Equipment

Motorola parts

The following terminators in Table 6-19 are necessary to do this

procedure for a single–unit installation and are shipped with the unit:

Quantity Part Number Description

Table 6-19: MIB Terminators

3 3009865S04 Terminator, MIB (Picocell)

1 3009865S02 Terminator, MIB (Microcell)

2 3009865S04 Terminator, MIB (Microcell)

Motorola kits for multi–unit installations

6

Table 6-20: Microcell Expansion Kit for Units 1 to 2 Short MIB A (Cubicle) – T448AL

Cable Qty. Motorola Part

Number

n/a 2 5882106P01 50 Ohm Antenna Terminator

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

K 1 3087707C09 MIB A cable (short, 1m; micro)

Q 1 3088120C01 Long SU Cable

Table 6-20 through Table 6-29 give the Motorola kit numbers, cable

descriptions and part numbers for the Motorola kits required to perform

a multi–unit installation. Several kits are available depending upon the

carrier installation.

Description

connector.

6-38

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 43

MIB Cabling for Multi–Unit Configurations – continued

Table 6-21: Microcell Expansion Kit for Units 1 to 2 Long MIB A (Non–Cubicle) – T448AM

Cable Qty. Motorola Part

Number

n/a 2 5882106P01 50 Ohm Antenna Terminator

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

E 1 3087707C03 MIB A cable (current, 2m; micro)

Q 1 3088120C01 Long SU Cable

Table 6-22: Picocell Expansion Kit for Units 1 to 2 Short MIB A (Cubicle) – T448AN

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

L 1 3087707C10 MIB A cable (short 1m; pico)

Q 1 3088120C01 Long SU Cable

Description

Description

Table 6-23: Picocell Expansion Kit for Units 1 to 2 Long MIB A (Non–Cubicle) – T448AP

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

H 1 3087707C06 MIB A cable (long, 2m; pico)

Q 1 3088120C01 Long SU Cable

Table 6-24: Microcell/Picocell Expansion Kit for Units 2 to 3 Current 2m MIB B – T448AR

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

F 1 3087707C04 MIB B cable (current, 2m)

Q 2 3088120C01 Long SU Cable

R 2 3088120C02 Short SU RF Cable

n/a 2 5688123C01 SU Splitter

Description

Description

6

n/a 2 8009573X06 Lightning arrestor

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

6-39

PRELIMINARY

Page 44

MIB Cabling for Multi–Unit Configurations – continued

Table 6-25: Microcell/Picocell Expansion Kit for Units 2 to 3 Long 5m MIB B – T448AS

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

I 1 3087707C07 MIB B cable (long, 5m)

Q 2 3088120C01 Long SU RF Cable

R 2 3088120C02 Short SU RF Cable

n/a 2 5688123C01 SU Splitter

n/a 2 8009573X06 Lightning arrestor

Table 6-26: Microcell/Picocell Expansion Kit for Units 3 to 4 Current 2m MIBs B and C – T448AT

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

n/a 2 5882106P01 50 Ohm Antenna Terminator

E 1 3087707C03 MIB A cable (current, 2m; micro)

Description

Description

F 1 3087707C04 MIB B cable (current, 2m)

6

G 2 3087707C05 MIB C cable (current, 2m)

Q 1 3088120C01 Long SU RF Cable

Table 6-27: Microcell/Picocell Expansion Kit for Units 3 to 4 Longer 5M MIBs B and C – T448AU

Cable Qty. Motorola Part

Number

n/a 2 5882106P01 50 Ohm Antenna Terminator

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

E 1 3087707C03 MIB A cable (current, 2m; micro)

I 1 3087707C07 MIB B cable (long, 5m)

J 2 3087707C08 MIB C cable (long, 5m)

Q 1 3088120C01 Long SU RF Cable

Description

6-40

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 45

MIB Cabling for Multi–Unit Configurations – continued

Table 6-28: Picocell Expansion Kit for Units 3 to 4 Current 2M MIBs B and C – T448AV

Cable Qty. Motorola Part

Number

n/a 2 5882106P01 50 Ohm Antenna Terminator

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

E 1 3087707C03 MIB A cable (current, 2m; micro)

F 1 3087707C04 MIB B cable (long, 2m)

G 2 3087707C05 MIB C cable (long, 2m)

Q 1 3088120C01 Long SU RF Cable

Table 6-29: Picocell Expansion Kit for Units 3 to 4 Longer 5M MIBs B and C – T448AW

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

H 1 3087707C06 MIB A cable (long, 2m; pico)

I 1 3087707C07 MIB B cable (long, 5m)

Description

Description

J 2 3087707C08 MIB C cable (long, 5m)

Q 1 3088120C01 Long SU RF Cable

Procedure

Cable the units as shown in Figure 6-32, Figure 6-31 or Figure 6-30.

Make sure to terminate any unused connectors.

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-41

Page 46

MIB Cabling for Multi–Unit Configurations – continued

Figure 6-30: MIB Cabling for Two Units

MICROCELL SHOWN

UNIT 1

MIB C

MIB B

MIB A

E/1 MIB (MICROCELL)

H/1 MIB (PICOCELL)

K/1 MIB (MICROCELL/CUBICLE)

L/1 MIB (PICOCELL/CUBICLE)

MIB C

MIB B

MIB A

UNIT 2

MIB C

MIB B

MIB A

Figure 6-31: MIB Cabling for Three Units

MICROCELL SHOWN

MIB C

UNIT 1UNIT 3

MIB C

6

MIB B

MIB A

MT

F/1 MIB (MICRO/PICO)

I/1 MIB (MICRO/PICO)

MIB B

MIB A

MIB C

MIB B

MIB A

MT

= MIB TERMINAT OR

6-42

KEY

UNIT 2

E/1 MIB (MICROCELL)

H/1 MIB (PICOCELL)

K/1 MIB (MICROCELL/CUBICLE)

L/1 MIB (PICOCELL/CUBICLE)

NOTE 1: NO MIB

TERMINATORS ARE USED ON

PICOCELLS

NOTE 2: MIB TERMINAT OR

USED ON MICROCELL MIB A

CONNECTOR ONLY

MIB C

MIB B

MIB A

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 47

MIB Cabling for Multi–Unit Configurations – continued

Figure 6-32: MIB Cabling for Four Units

MICROCELL SHOWN

UNIT 1UNIT 3

G/1 MIB (MICROCELL/PICOCELL)

J/1 MIB (PICOCELL)

MIB C

MIB B

MIB A

NOTES:

1. NO MIB TERMINAT ORS ARE USED

ON PICOCELLS

2. MIB A BETWEEN UNITS 3 AND 4

DOES NOT EXIST ON PICOCELL

MIB C

MIB B

MIB A

MIB C

MIB B

MIB A

MIB C

MIB B

MIB A

F/1 MIB (MICRO/PICO)

I/1 MIB (MICRO/PICO)

UNIT 2UNIT 4

MIB C

MIB B

MIB A

E/1 MIB (MICROCELL)

H/1 MIB (PICOCELL)

K/1 MIB (MICROCELL/CUBICLE)

L/1 MIB (PICOCELL/CUBICLE)

(SEE NOTE 2)

E/1 MIB (MICROCELL)

H/1 MIB (PICOCELL)

K/1 MIB (MICROCELL/CUBICLE)

L/1 MIB (PICOCELL/CUBICLE)

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-43

Page 48

SU Cabling

Objective

Cable Labels

T ools and Equipment

The objective of this procedure is to install the SU cable on one or more

units.

The cable designations are referenced to Table 6-5 in the “Cable

Description” area of this chapter.

Required tools

A 5/16–in. breakaway torque wrench is required to do this procedure.

Motorola parts

SU Distribution Terminators, SMA (Motorola Part Number

0187683C02) are required to do this procedure.

Table 6-30 provides the quantitity and description of the SU cable used

for a single–unit installation.

Table 6-30: Cables Needed for SU Connections

Cable Qty. Part Number Description

P 1 3087416C19 SU cable, 105 mm

6

Q N/A* 3088120C01 SU RF cable, long (part of kits SGEN4062A, SGEN4061A,

SGEN4064A, SGEN4063A, SGEN4066A, SGEN4065A,

SGEN4068A, SGEN4067A, SGEN4070A and SGEN4069A).

R N/A* 3088120C02 SU RF cable, short (part of kits SGEN4066A and SGEN4065A)

*Quantity of cables depends upon system configuration. Refer to “Motorola Kits for Multi–Unit Installations”

for more information.

Motorola kits

Table 6-31 through Table 6-40 gives the Motorola Kit numbers, cable

descriptions and part numbers for the Motorola kits required to perform

the SU cabling on a multi–unit installation. Several kits are available

depending upon the carrier installation.

Table 6-31: Microcell Expansion Kit for Units 1 to 2 Short MIB A (Cubicle) – T448AL

Cable Qty. Motorola Part

Number

n/a 2 5882106P01 50 Ohm Antenna Terminator

Description

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

K 1 3087707C09 MIB A cable (short, 1m; micro)

Q 1 3088120C01 Long SU Cable

6-44

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 49

SU Cabling – continued

Table 6-32: Microcell Expansion Kit for Units 1 to 2 Long MIB A (Non–Cubicle) – T448AM

Cable Qty. Motorola Part

Number

n/a 2 5882106P01 50 Ohm Antenna Terminator

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

E 1 3087707C03 MIB A cable (current, 2m; micro)

Q 1 3088120C01 Long SU Cable

Table 6-33: Picocell Expansion Kit for Units 1 to 2 Short MIB A (Cubicle) – T448AN

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

L 1 3087707C10 MIB A cable (short 1m; pico)

Q 1 3088120C01 Long SU Cable

Description

Description

Table 6-34: Picocell Expansion Kit for Units 1 to 2 Long MIB A (Non–Cubicle) – T448AP

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

H 1 3087707C06 MIB A cable (long, 2m; pico)

Q 1 3088120C01 Long SU Cable

Table 6-35: Microcell/Picocell Expansion Kit for Units 2 to 3 Current 2m MIB B – T448AR

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

F 1 3087707C04 MIB B cable (current, 2m)

Q 2 3088120C01 Long SU Cable

R 2 3088120C02 Short SU RF Cable

n/a 2 5688123C01 SU Splitter

Description

Description

6

n/a 2 8009573X06 Lightning arrestor

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

6-45

PRELIMINARY

Page 50

SU Cabling – continued

Table 6-36: Microcell/Picocell Expansion Kit for Units 2 to 3 Long 5m MIB B – T448AS

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

I 1 3087707C07 MIB B cable (long, 5m)

Q 2 3088120C01 Long SU RF Cable

R 2 3088120C02 Short SU RF Cable

n/a 2 5688123C01 SU Splitter

n/a 2 8009573X06 Lightning arrestor

Table 6-37: Microcell/Picocell Expansion Kit for Units 3 to 4 Current 2m MIBs B and C – T448AT

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

n/a 2 5882106P01 50 Ohm Antenna Terminator

E 1 3087707C03 MIB A cable (current, 2m; micro)

Description

Description

F 1 3087707C04 MIB B cable (current, 2m)

6

G 2 3087707C05 MIB C cable (current, 2m)

Q 1 3088120C01 Long SU RF Cable

Table 6-38: Microcell/Picocell Expansion Kit for Units 3 to 4 Longer 5M MIBs B and C – T448AU

Cable Qty. Motorola Part

Number

n/a 2 5882106P01 50 Ohm Antenna Terminator

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

E 1 3087707C03 MIB A cable (current, 2m; micro)

I 1 3087707C07 MIB B cable (long, 5m)

J 2 3087707C08 MIB C cable (long, 5m)

Q 1 3088120C01 Long SU RF Cable

Description

6-46

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 51

SU Cabling – continued

Table 6-39: Picocell Expansion Kit for Units 3 to 4 Current 2M MIBs B and C – T448AV

Cable Qty. Motorola Part

Number

n/a 2 5882106P01 50 Ohm Antenna Terminator

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

E 1 3087707C03 MIB A cable (current, 2m; micro)

F 1 3087707C04 MIB B cable (long, 2m)

G 2 3087707C05 MIB C cable (long, 2m)

Q 1 3088120C01 Long SU RF Cable

Table 6-40: Picocell Expansion Kit for Units 3 to 4 Longer 5M MIBs B and C – T448AW

Cable Qty. Motorola Part

Number

A 1 3087701C02 Ground cable, 8 -AWG, insulated copper wire. Requires one ring lug

connector.

H 1 3087707C06 MIB A cable (long, 2m; pico)

I 1 3087707C07 MIB B cable (long, 5m)

Description

Description

J 2 3087707C08 MIB C cable (long, 5m)

Q 1 3088120C01 Long SU RF Cable

Procedure to Install SU Cabling

for Single Unit

Table 6-41 gives the procedure to install the SU cable on one MicroCell

or Picocell. Figure 6-33 shows the location of the cable connectors on

the unit.

Table 6-41: Install the SU Cable on One MicroCell or PicoCell

Step Action

1 Connect cable P to the SU RF and the SU1 connectors of the

unit.

2 Torque the connectors at each end of the cable to 9 in–lb. Use

a 5/16–in. breakaway torque wrench.

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-47

Page 52

SU Cabling – continued

Figure 6-33: SU Cabling Details for Single MicroCell or Picocell

MICROCELL PICOCELL

H

SU RF

SU 2

SU 1

H

SU Cabling for Multi–Unit

Configurations

Table 6-42 gives the procedure to install the SU cabling for Multi–unit

configurations. Figure 6-34, Figure 6-35 and Figure 6-36 show the SU

cabling for multi–unit configurations.

6

Table 6-42: Install SU Cabling for Multi–BTS Configurations

Step Action

1 Connect cable H to the appropriate SU connectors as shown

in Figure 6-34, Figure 6-35 and Figure 6-36.

2 Torque the connectors at each end of the cable to 9 in–lb. Use

a 5/16–in. breakaway torque wrench.

3 Terminate all unused SU connectors.

6-48

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 53

SU Cabling – continued

Figure 6-34: SU Cabling Details for Two Units

MICROCELL

SHOWN

SU RF

SU(2)

SU(1)

KEY

RFT=50 OHM RF TERMINATION

UNIT 1

UNIT 2

SU RF

SU(2)

SU(1)

SU RF

SU(2)

SU(1)

H

H

RFT

RFT

Figure 6-35: SU Cabling Details for Three Units

MICROCELL

SHOWN

SU RF

SU(2)

SU(1)

KEY

RFT=50 OHM RF TERMINATION

2X =

SU SPLITTER

UNIT 1

UNIT 2

SU RF

SU(2)

SU(1)

SU RF

SU(2)

SU(1)

H

H

RFT

RFT

2X

2X

RFT

6

UNIT 3

SU RF

H

H

SU(2)

SU(1)

RFT

RFT

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-49

Page 54

SU Cabling – continued

Figure 6-36: SU Cabling Details for Four Units

MICROCELL

SHOWN

UNIT 1

SU RF

SU(2)

SU(1)

H

H

H

2X

H

2X

UNIT 3

SU RF

SU(2)

SU(1)

RFT

RFT

SU RF

SU(2)

SU(1)

KEY

RFT=50 OHM RF TERMINATION

2X = SU SPLITTER

UNIT 2

SU RF

SU(2)

SU(1)

H

RFT

RFT

H

UNIT 4

SU RF

SU(2)

SU(1)

RFT

RFT

6

6-50

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 55

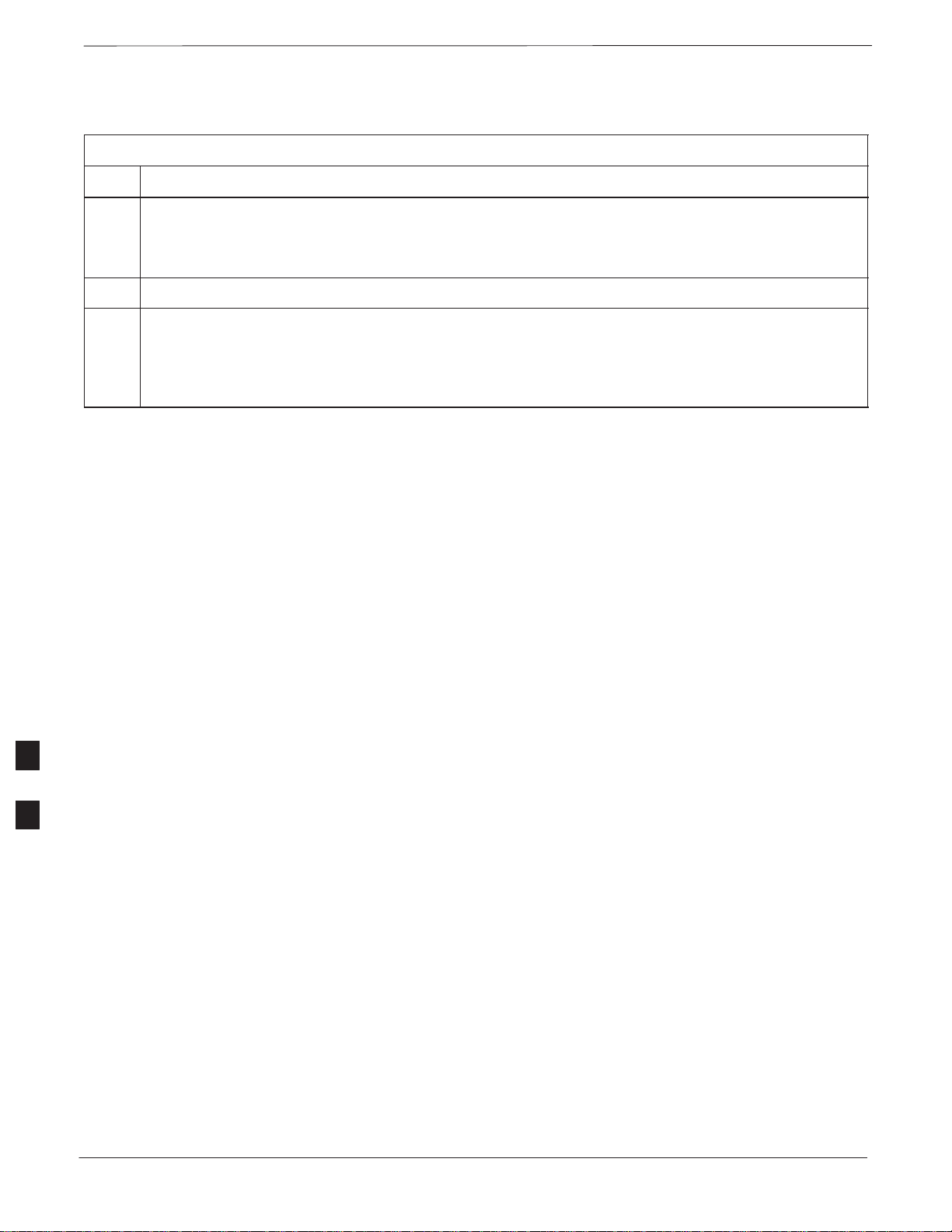

Terminating Unused Connections

Objective

The objective of this procedure is to terminate any unused connections.

IMPORTANT

T ermination List (MicroCell)

T ermination List (PicoCell)

*

Connector Motorola Part # Description

SU Distribution 0187683C02 Terminator, SMA

Connector Motorola Part # Description

Terminate all unused connections.

Table 6-43: Terminations of Unused Connectors

AC Input 5887659C02 Terminator, AC

DC Input 5887659C04 Terminator, DC

MIB A 3009865S02 Terminator, MIB

MIB B, C 3009865S04 Cap, MIB

Table 6-44: Terminations of Unused Connectors

AC Input 5887659C02 Terminator, AC

6

Procedure

DEC 2000

DC Input 5887659C04 Terminator, DC

MIB A, B, C 3009865S04 Cap, MIB

SU Distribution 0187683C01 Terminator, SMA

The unit is shipped with the above terminators. Verify that a terminator

is on each unused connector. Tighten the SMA terminators using a

5/16 Breakaway 9 in. lb. Hand tighten all other terminators.

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-51

Page 56

Powering on Unit and Mounting the Solar Cover

Objective

The objective of this procedure is to power on the unit and mount the

solar cover on the chassis.

Y ou May W ant to W ait

Do not mount the front solar cover on the unit if you wish to perform the

Acceptance Test Procedures (ATP). Otherwise, mount the front solar

cover until you perform the ATP.

T ools Required

The following tamper–resistant keys are required to do this procedure.

S Key for tamper–resistant stud (provided) for the solar cover.

S Key for tamper–resistant locks (provided) for the Primary Surge

Suppressor.

Procedure to Power On Unit

and Mount Solar Cover

Refer to the procedure in Table 6-45 to power on the unit and mount the

solar cover .

Table 6-45: Procedure to Power on the Unit and Mount the Solar

Cover

Step Action

6

1

n WARNING

Make sure the unit is properly grounded and that all

connections are connected before powering on unit.

If not applying AC power, go to step 2. If applying AC

power, push down on the AC power breaker until it clicks and

remains down. The white collar on the breaker is not visible

when the breaker is closed.

2 If not applying DC power or providing for battery backup, go

to step 3. If applying DC power or have short or long

duration batteries present, push down on the DC power

breaker until it clicks and remains down. The white collar on

the breaker is not visible when the breaker is closed.

3 Position the solar cover so the cooling vents are at the top and

place the solar cover on the unit. Use the key to tighten the

four tamper–resistant studs (two on each side). Refer to

Figure 6-37.

Procedure to Power On Surge

Suppressor, Unit and Mount

Solar Cover

6-52

SCt300 BTS Hardware Installation, ATP and FRU Procedures

If your BTS is equipped with the Primary Surge Suppressor, refer to the

procedure in Table 6-46 to power on the unit and mount the solar cover.

DEC 2000

PRELIMINARY

Page 57

Powering on Unit and Mounting the Solar Cover – continued

Table 6-46: Procedure to Power on the Surge Suppressor, the Unit, and

Mount the Solar Cover

Step Action

1 If closed, open the front cover of the Primary Surge

Suppressor. Use the tamper–resistant key and turn both the

locks counter–clockwise. Refer to Figure 6-37.

2 If not applying AC power, go to step 6. If applying AC

power, push the main AC power breaker on the Surge

Suppressor to the “On“ position. Refer to Figure 6-38.

3 Push the AC power breakers for each individual carrier to the

“On” position. All unused power breakers must be in the

“Off” position.

4 Close the Primary Surge Suppressor door. Use the

tamper–resistant key to turn the locks clockwise to the

“Locked” position.

5 Push down on the AC power breaker on the unit until it clicks

and remains down. The white collar on the breaker is not

visible when the breaker is closed.

6 If not applying DC power or providing for battery backup, go

to step 7. If applying DC power or have short or long

duration batteries present, push down on the DC power

breaker until it clicks and remains down. The white collar on

the breaker is not visible when the breaker is closed.

7 Position the solar cover so the cooling vents are at the top and

place the solar cover on the unit. Use the tamper–resistant

key to tighten the four screws (two on each side) to 2.2 N–M.

Refer to Figure 6-39.

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-53

Page 58

Powering on Unit and Mounting the Solar Cover – continued

Figure 6-37: Lock Positions on Primary Surge Suppressor

LATCHED POSITION

Figure 6-38: Location of AC Power Breakers on Primary Surge Suppressor

UNLA TCHED POSITION

NOTE: INTERNAL CABLING

NOT SHOWN FOR CLARITY

6

AC POWER BREAKER

CARRIER 2

AC POWER BREAKER

CARRIER 3

AC POWER BREAKER

CARRIER 4

AC POWER BREAKER

CARRIER 1

MAIN INPUT BREAKER

6-54

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 59

Powering on Unit and Mounting the Solar Cover – continued

Figure 6-39: Front Solar Cover

FRONT COVER

MOUNTING

SCREWS (4)

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-55

Page 60

Site Cleanup

Remove protective covering

Lighting fixtures

Tools

Materials

Remove debris

Remove any antistatic plastic or cloth sheeting that was used to cover the

equipment.

Remove the masking tape from the fluorescent light fixtures.

Place all hand and power tools in the installation tool kit or other

appropriate place. Note any tools that need replacement, cleaning, or

adjustment.

Place any leftover materials in a location specified by the site manager.

Remove any packing material.

Ensure that all scrap materials have been removed from any tables or

stands.

Clean/sweep the floor. Ensure that all alignment marks have been

removed.

6

Environment

Remove any temporary weather protection used for installation.

Check that all covers are in place.

Check that the power connections are tight.

Organize any items (manuals, materials, etc.) left on site and place them

in a location specified by the site manager.

Check that the unit lock is secure and key is removed.

Check that solar cover is secure.

Verify that cabling is properly secured between unit and enclosures.

6-56

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 61

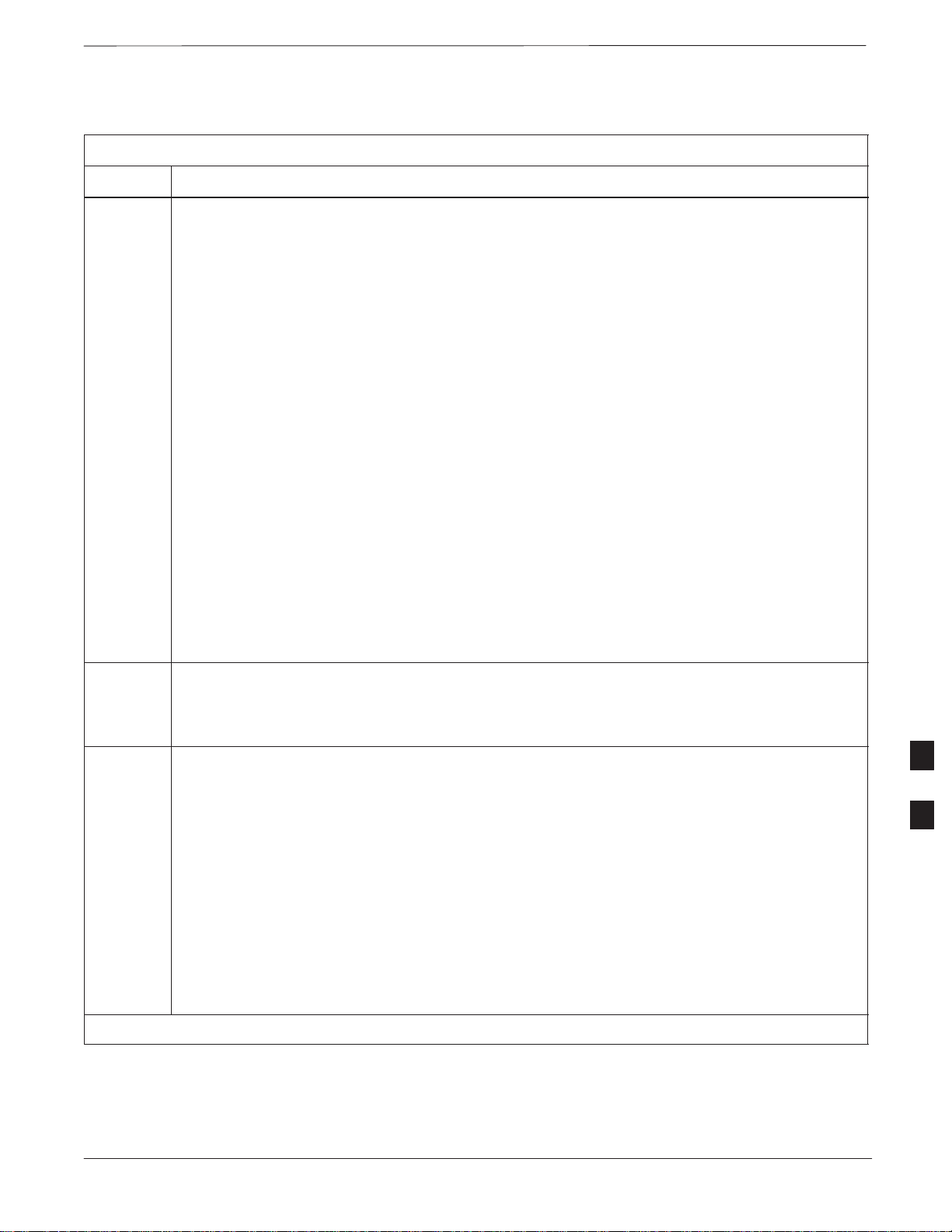

Installation Completion Checklist

Directions

Fill out the installation completion checklist and make any necessary

copies. You may copy this check sheet as needed.

6

DEC 2000

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

6-57

Page 62

Installation Completion Checklist – continued

Installation completion

checklist

Date Hardware Installation Completed: ________________________

Site:_______________________________________________________

Serial Number(s):__________________________

__________________________________________________________

Checklist Completed By:_____________________________________

Checklist Reviewed By:______________________________________

Table 6-47: Installation Completion Checklist

Status No. Item Notes

1 Air flow clearance requirements are met.

2 Equipment is not damaged.

3 Mounting bracket is level and secure.

4 Back solar cover (if applicable) is securely

attached to the mounting bracket.

5 RGPS head and mast are secure.

6 RGPS head has a clear view of the sky and is

not in a location which accumulates debris.

Make sure the RGPS is located away from

the BTS transmit antenna.

6

7 Mounting bracket is connected to the Master

ground.

8 The connection to the AC source is secure (if

applicable).

9 The AC source is protected by a lightning

arrestor (if applicable).

10 The connection to the DC source is secure (if

applicable).

11 The connection to the battery is secure (if

applicable).

12 The connection to the auxiliary device is

secure (if applicable).

13 The antenna connections are secure.

14 The antenna cables are protected by lightning

arrestors (if applicable).

6-58

15 Customer input alarm connections are

complete between the Site I/O cable and the

Site I/O interface(s).

16 RGPS connections are complete between the

Site I/O cable and the Site I/O interface(s).

SCt300 BTS Hardware Installation, ATP and FRU Procedures

PRELIMINARY

DEC 2000

Page 63

Installation Completion Checklist – continued

Table 6-47: Installation Completion Checklist

Status NotesItemNo.

17 Phone (modem) connections are complete

between the Site I/O cable and the Site I/O

interface(s).

18 Span connections are complete between the

Site I/O cable and the Site I/O interface(s).

19 Span, phone, and RGPS connections are

protected by lightning arrestors (if

applicable).

20 The RGPS/HSO cabling for multi–BTS

configurations is secure (if applicable).

21 The span line daisy chain cabling for

multi–BTS configurations is secure.

22 The RGPS ground lead is connected to the

BTS digital ground reference.

23 Fin covers are secure.

24 Installation hardware is removed.

25 The lock is in place and the key removed.

26 The site I/O junction box is secure.

27 The short–duration battery is secure (if

applicable).

28 The short–duration battery cable (DC input

cable) is secure (if applicable).