Page 1

SCt4812ET Optimization/ATP

Manual

Software Release R16.1.x.x

English

Aug 2002

68P09255A57-2

800 and 1900 MHz

CDMA

PRELIMINARY

Page 2

Notice

While reasonable efforts have been made to assure the accuracy of this document, Motorola, Inc. assumes no liability resulting

from any inaccuracies or omissions in this document, or from use of the information obtained herein. The information in this

document has been carefully checked and is believed to be entirely reliable. However, no responsibility is assumed for

inaccuracies or omissions. Motorola, Inc. reserves the right to make changes to any products described herein and reserves the

right to revise this document and to make changes from time to time in content hereof with no obligation to notify any person

of revisions or changes. Motorola, Inc. does not assume any liability arising out of the application or use of any product,

software, or circuit described herein; neither does it convey license under its patent rights or the rights of others.

It is possible that this publication may contain references to, or information about Motorola products (machines and

programs), programming, or services that are not announced in your country. Such references or information must not be

construed to mean that Motorola intends to announce such Motorola products, programming, or services in your country.

Copyrights

This instruction manual, and the Motorola products described in this instruction manual may be, include or describe

copyrighted Motorola material, such as computer programs stored in semiconductor memories or other media. Laws in

the United States and other countries preserve for Motorola certain exclusive rights for copyrighted material, including

the exclusive right to copy, reproduce in any form, distribute and make derivative works of the copyrighted material.

Accordingly, any copyrighted Motorola material contained herein or in the Motorola products described in this

instruction manual may not be copied, reproduced, distributed, merged or modified in any manner without the express

written permission of Motorola. Furthermore, the purchase of Motorola products shall not be deemed to grant either

directly or by implication, estoppel, or otherwise, any license under the copyrights, patents or patent applications of

Motorola, as arises by operation of law in the sale of a product.

Usage and Disclosure Restrictions

License Agreement

The software described in this document is the property of Motorola, Inc. It is furnished by express license agreement

only and may be used only in accordance with the terms of such an agreement.

Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is prohibited by law. No part of the

software or documentation may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language or computer language, in any form or by any means, without prior written permission of Motorola, Inc.

High Risk Activities

Components, units, or third-party products used in the product described herein are NOT fault-tolerant and are NOT

designed, manufactured, or intended for use as on-line control equipment in the following hazardous environments

requiring fail-safe controls: the operation of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems,

Air Traffic Control, Life Support, or Weapons Systems (“High Risk Activities”). Motorola and its supplier(s) specifically

disclaim any expressed or implied warranty of fitness for such High Risk Activities.

Trademarks

and Motorola are registered trademarks of Motorola, Inc.

Product and service names profiled herein are trademarks of Motorola, Inc. Other manufacturers’ products or services

profiled herein may be referred to by trademarks of their respective companies.

Copyright

Copyright 2002 Motorola, Inc.

All Rights Reserved

Printed on

Recyclable Paper

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

REV012501

Page 3

SCt4812ET Optimization/ATP

Manual

Table of Contents

.

.

.

Aug 2002

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

i

Page 4

Table of Contents

68P09255A57-2

Contents

FCC Requirements xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Content xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Part 15 Requirements xviii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Part 68 Requirements xix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foreword xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Safety xxii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History xxiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of This Document 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Document Composition 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA LMF Product Description 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Online Help 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Why Optimize? 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Is Optimization? 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When to Optimize 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Documentation 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Documents 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Documentation 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMF Hardware Requirements 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Guidelines 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Calibration 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Cable Calibration 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Warm-up 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment List 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Equipment 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations and Acronyms 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Overview 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Major Components 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Cabinet Internal FRUs 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

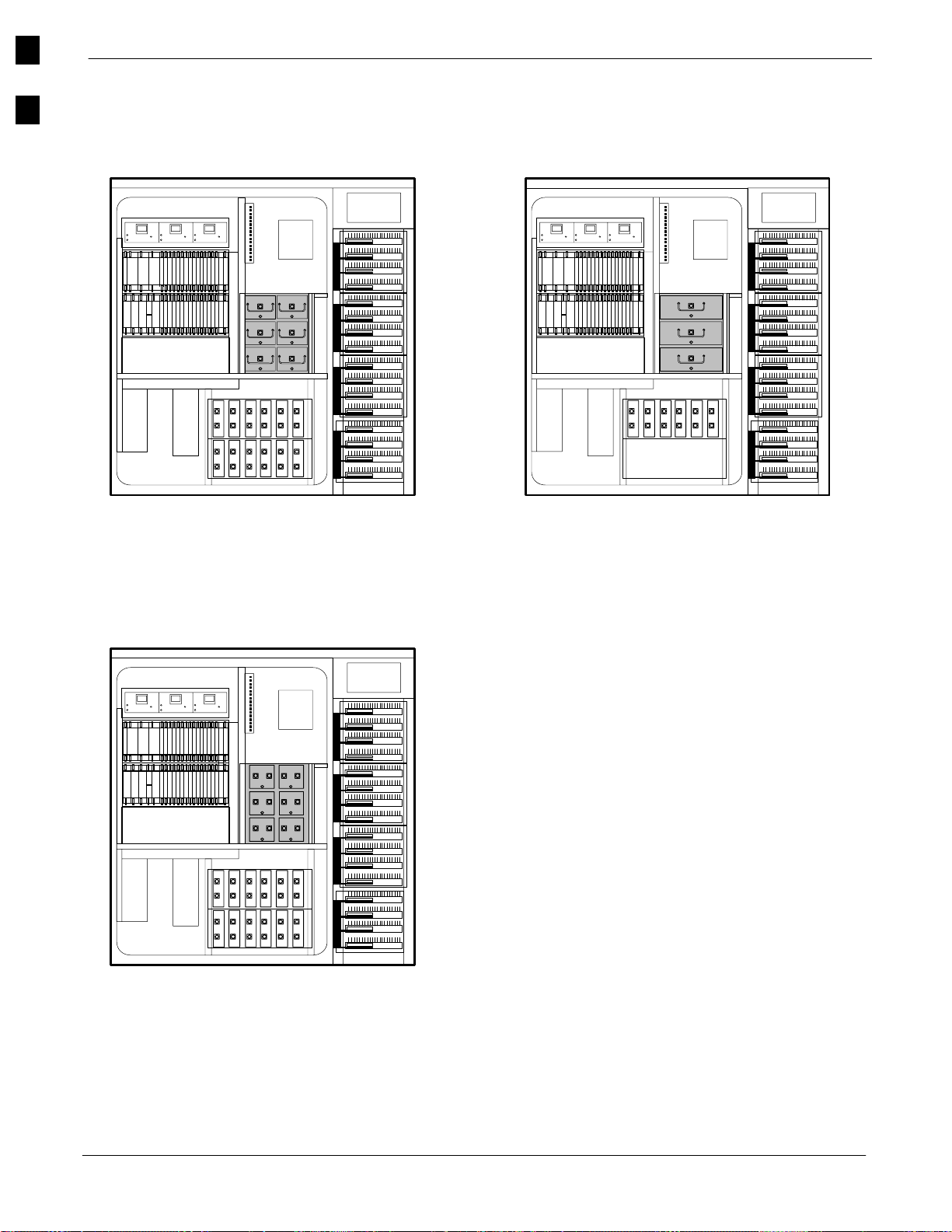

Sector Configuration 1-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

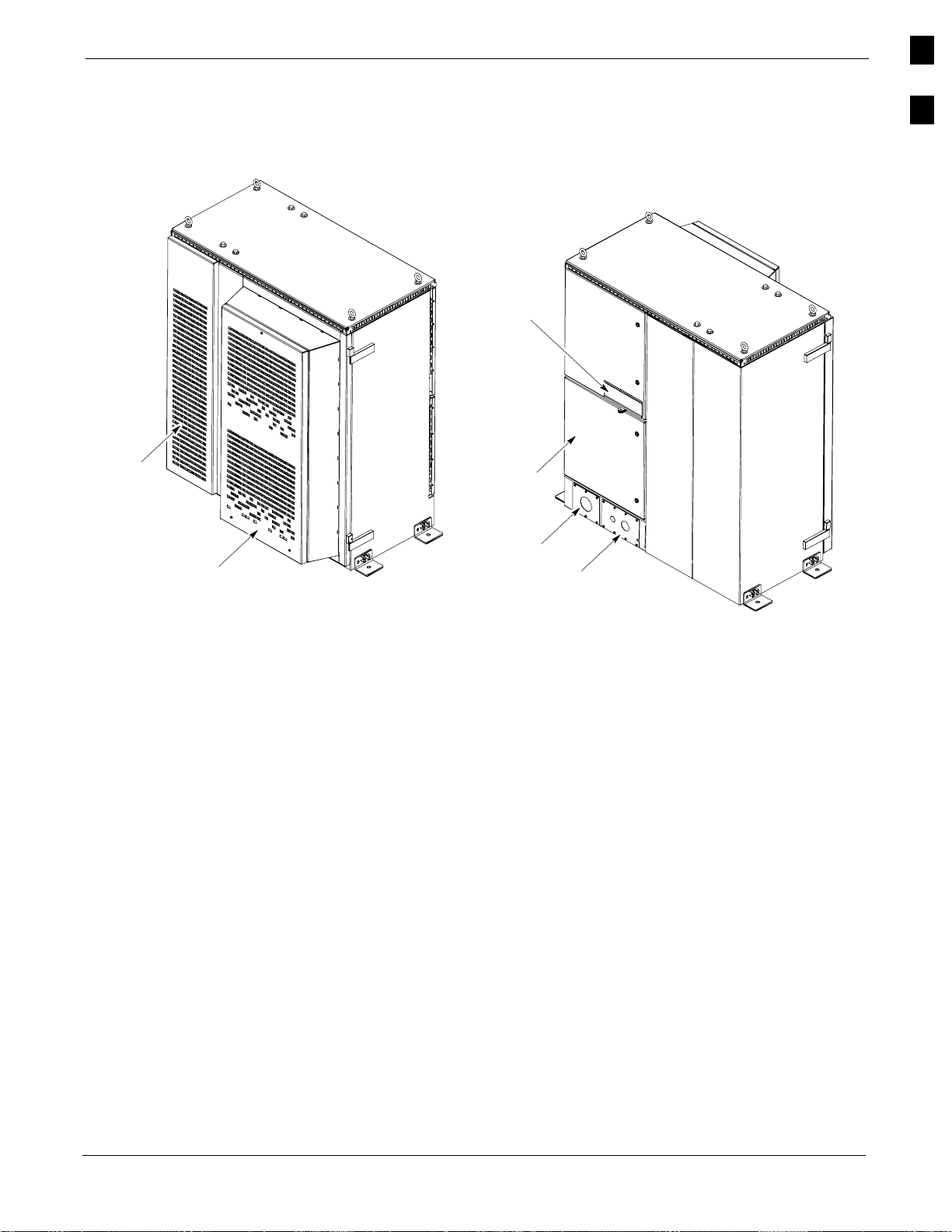

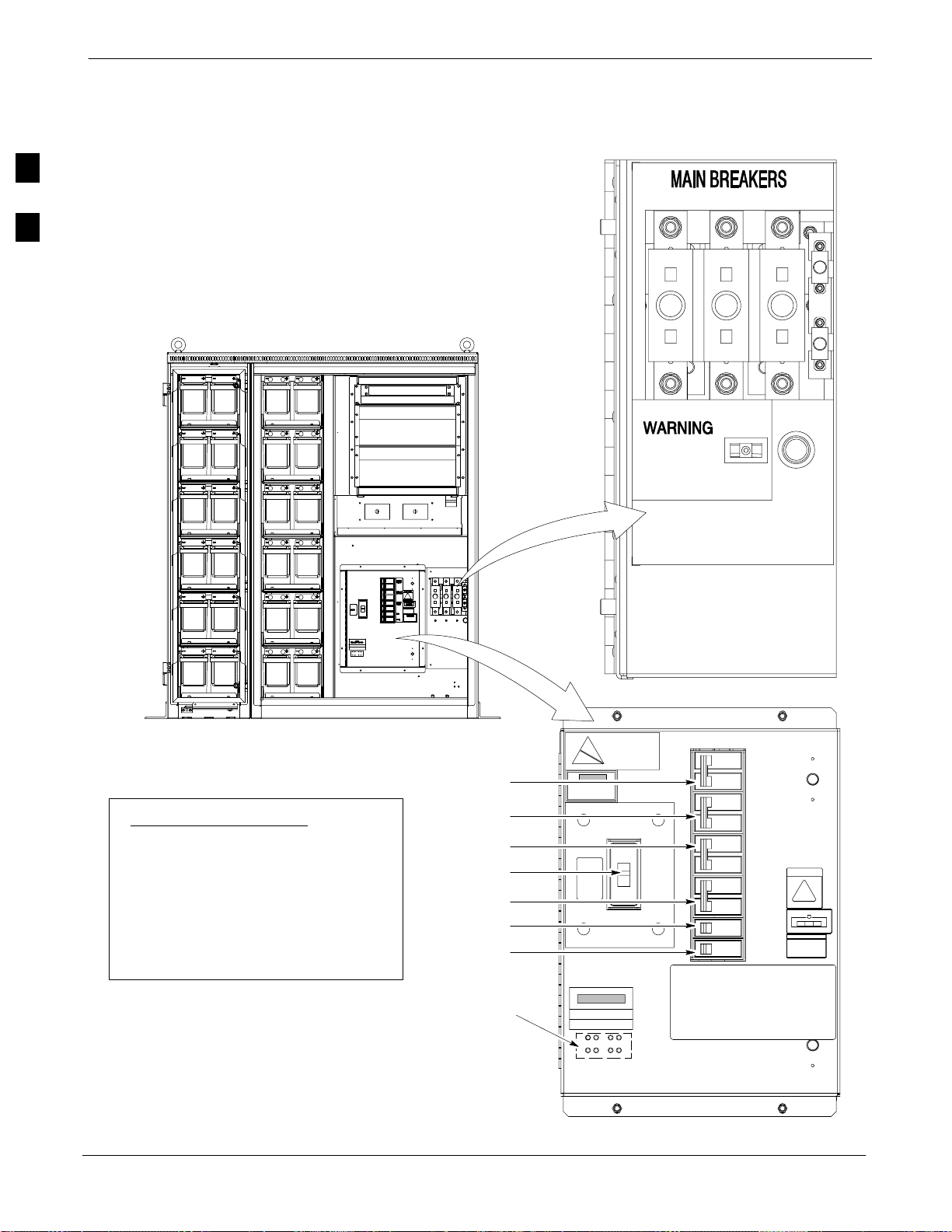

Power Cabinet 1-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal FRUs 1-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Power Up Procedures 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prepower-up 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cellsite Types 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDF 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Equipage Verification 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Installation of Boards/Modules 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Frame C-CCP Shelf Configuration Switch 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking for shorts 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Inspection 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Inspection and Setup 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Check 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

Aug 2002

PRELIMINARY

Page 5

68P09255A57-2

AC Power Up Sequence 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applying AC Power 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cabinet Power Tests 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Pre-test 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Checks 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Cabinet Power Up 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Test 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charge Test (Connected Batteries) 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discharge Test 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

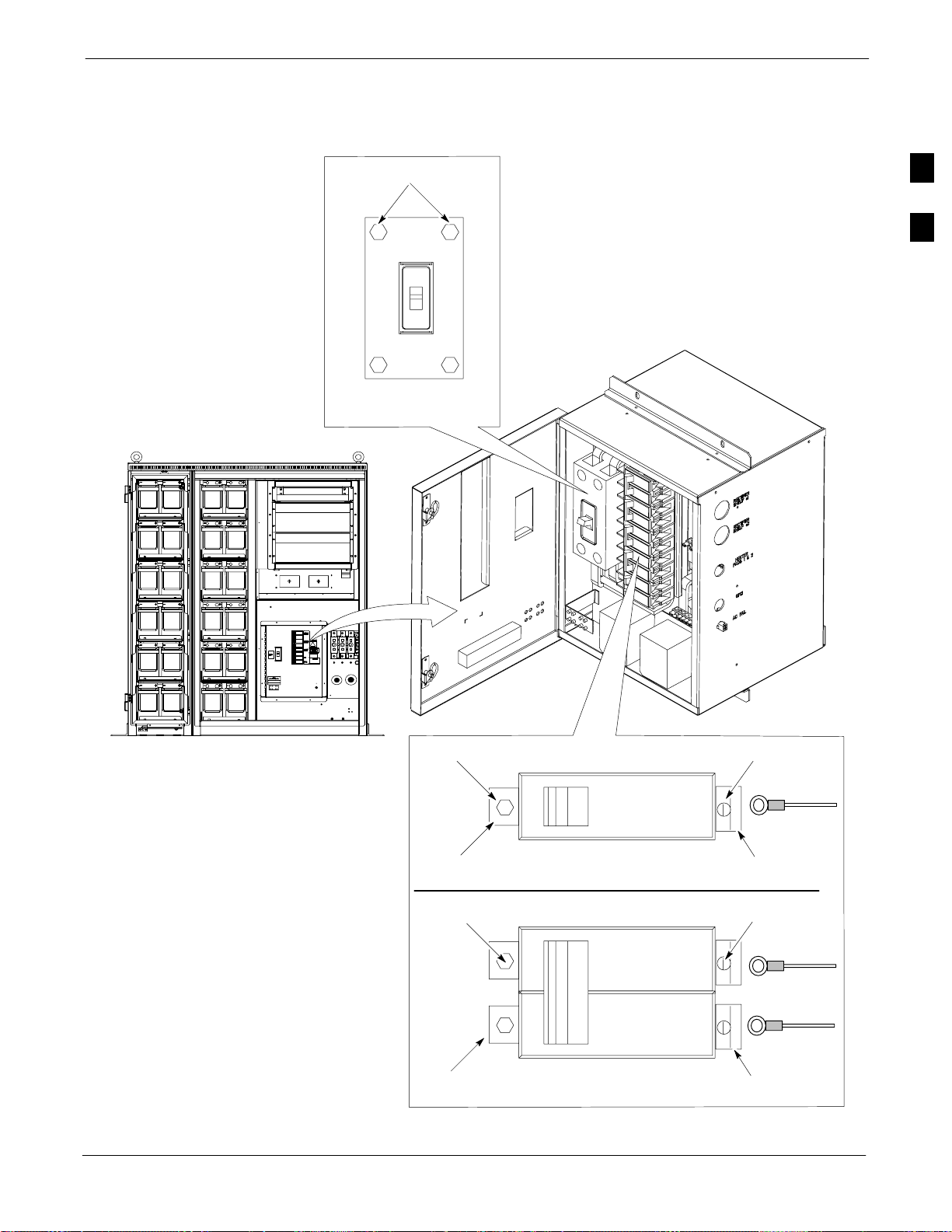

Heat Exchanger Power Up 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Chapter 3 Optimization/ATP 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Optimization 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optimization Process 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cell-site Types 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cell-site Data File 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS System Software Download 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Equipage Verification 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolate BTS from T1/E1 Spans 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Channel Service Unit 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm and Span Line Cable Pin/Signal Information 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm and Span Line Cable Pin/Signal Information 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T1/E1 Span Isolation 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolate BTS from T1/E1 Spans 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMF Operation 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the LMF 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMF Operating System Installation 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA LMF Home Directory 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy CBSC CDF Files to the LMF Computer 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Named HyperTerminal Connection for MMI Connection 3-16. . . . . . . . . . . . . . . . . . . . . . . . . .

Folder Structure Overview 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

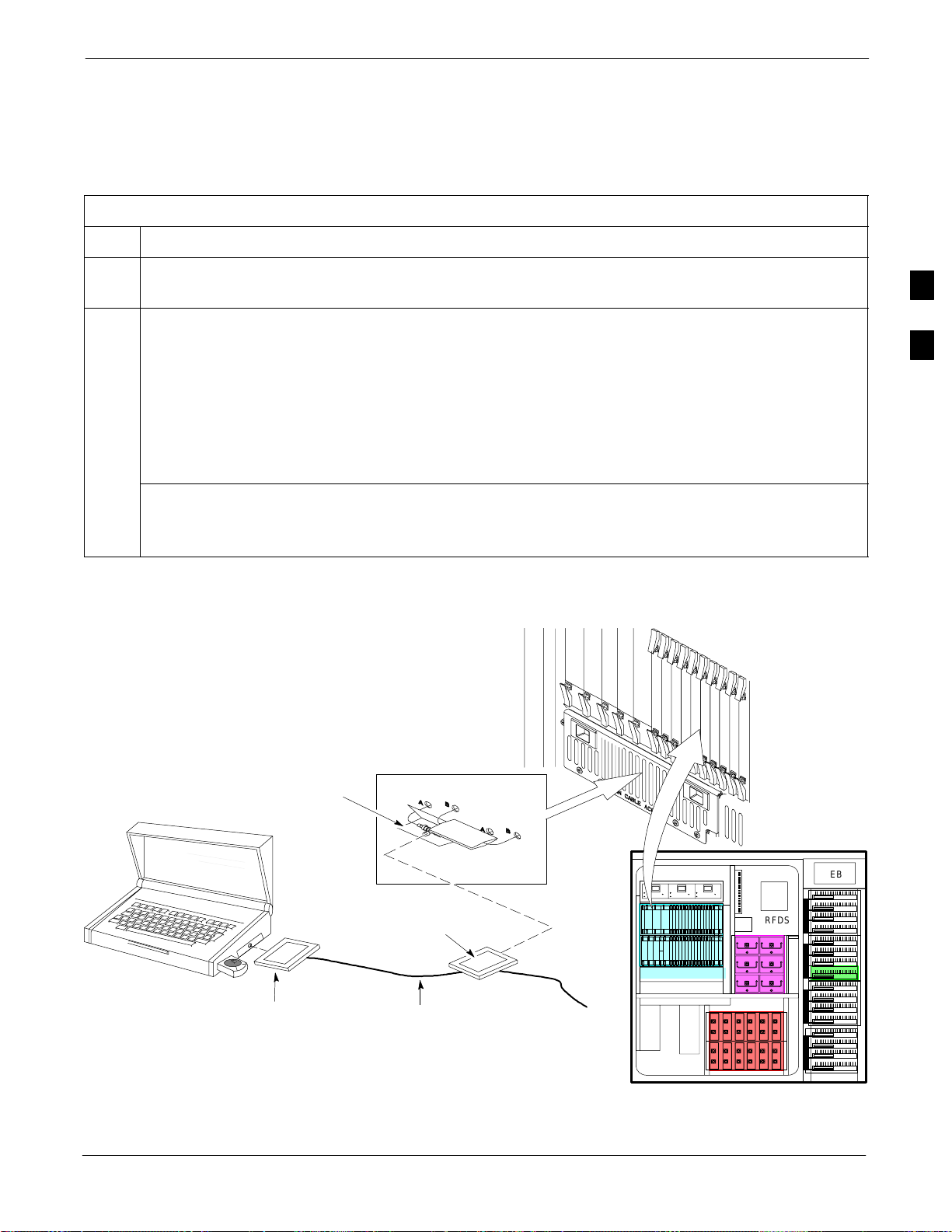

LMF to BTS Connection 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinging the Processors 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Log into and out of the BTS 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download Files to the LMF - Site Specific BTS Files 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download Files to the LMF - Master-bts-cdma Files 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create BTS Specific CDF File 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Update BTS Specific CDF File Device Load Version and Site Type 3-25. . . . . . . . . . . . . . . . . . . . . . . . . .

Update Antenna Mapping Files 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the LMF 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Operation 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logging into a BTS 3-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logging Out 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Establishing an MMI Communication Session 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Download Overview 3-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify GLI ROM Code Loads 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download RAM Code and Data to MGLI and GLI 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download RAM Code and Data to Non-GLI Devices 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Tests 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aug 2002

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

iii

Page 6

Table of Contents

Select CSM Clock Source 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable CSMs 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable MCCs 3-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Synchronization Manager System Time 3-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LFR/HSO 3-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSM Frequency Verification 3-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Setup

(GPS & LFR/HSO Verification) 3-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPS Initialization/Verification 3-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LORAN-C Initialization/Verification 3-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration and Test Equipment 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Test Equipment to the BTS 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment GPIB Address Settings 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported Test Sets 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Preparation 3-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Connection Charts 3-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Warm-up 3-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Cable Calibration Set-up 3-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Cable Calibration 3-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set-up for TX Calibration 3-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set-up for Optimization/ATP 3-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX ATP Setup 3-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68P09255A57-2

Loss/Gain Offset 3-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 3-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose 3-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Addresses 3-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Test Equipment 3-67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manually Selecting Test Equipment in a Serial Connection Tab 3-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatically Selecting Test Equipment in a Serial Connection Tab 3-69. . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating Test Equipment 3-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating Cables 3-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating Cables with a CDMA Analyzer 3-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating TX Cables Using a Signal Generator and Spectrum Analyzer 3-71. . . . . . . . . . . . . . . . . . . .

Calibrating RX Cables Using a Signal Generator and Spectrum Analyzer 3-73. . . . . . . . . . . . . . . . . . . .

Setting Cable Loss Values 3-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Coupler Loss Value 3-74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting for loss 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Path Bay Level Offset Calibration 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When to Calibrate BLOs 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Path Calibration 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLO Calibration Data File 3-76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Setup: RF Path Calibration 3-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmit (TX) Path Calibration 3-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download BLO Procedure 3-81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Audit Introduction 3-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmit (TX) Path Audit 3-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Audit Test 3-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All Cal/Audit Test 3-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create CAL File 3-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS Description 3-86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS Parameters 3-86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking and Setting RFDS Parameters 3-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

Aug 2002

PRELIMINARY

Page 7

68P09255A57-2

RFDS TSU NAM Programming 3-89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Explanation of Parameters Used When Programming the TSU NAM 3-89. . . . . . . . . . . . . . . . . . . . . . . .

Valid NAM Ranges 3-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Antenna Map Data 3-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set RFDS Configuration Data 3-91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS Calibration 3-92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS Calibration Procedure 3-93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program TSU NAM 3-94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarms 3-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Reporting Display 3-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat Exchanger Alarm Test 3-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Alarm 3-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Fail Alarm 3-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Minor Alarm 3-97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rectifier Alarms 3-98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Rectifier Failure (Three Rectifier System) 3-98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Rectifier Failure 3-98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Rectifier Failure

(Six Rectifier System) 3-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Rectifier Failure (Six Rectifier System) 3-99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Over Temperature Alarm (Optional) 3-100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rectifier Over Temperature Alarm 3-102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Leaving the site 3-103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Chapter 4 Automated Test Procedures (ATP) 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Tests 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reduced ATP 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Test Prerequisites 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX/RX OUT Connections 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Test Procedure 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA 2000 Testing 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Individual Acceptance Tests 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Test Procedure 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background: Tx Mask Test 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background: Rho Test 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background: Pilot Offset Acceptance Test 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background: Code Domain Power Test 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background: FER Test 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Report 4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Prepare to Leave the Site 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initializing Active Service 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Test Equipment Removal 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset All Devices 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Updating BTS CAL LMF Files in the CBSC 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Site Span Configuration Verification 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set BTS Site Span Configuration 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-connect BTS T1 Spans and Integrated Frame Modem 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMF Removal 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reestablish OMC-R Control/ Verifying T1/E1 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Troubleshooting 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aug 2002

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

v

Page 8

Table of Contents

Overview 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Log into Cell-Site 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Communicate to Power Meter 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Communicate to Communications Analyzer 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Code Download Failure 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Download DATA to Any Device (Card) 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot ENABLE Device 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPA Errors 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bay Level Offset Calibration Failure 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Audit Failure 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Forward link problem 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Perform Txmask Measurement 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Perform Rho or Pilot Time Offset Measurement 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Perform Code Domain Power and Noise Floor Measurement 6-7. . . . . . . . . . . . . . . . . . . . . . . .

Cannot Perform Carrier Measurement 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi-FER Test Failure 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problem Description 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intermittent 19.6608 MHz Reference Clock/GPS Receiver Operation 6-8. . . . . . . . . . . . . . . . . . . . . . . .

No GPS Reference Source 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checksum Failure 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPS Bad RX Message Type 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSM Reference Source Configuration Error 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Takes Too Long for CSM to Come INS 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-CCP Backplane 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector Functionality 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-CCP Backplane Troubleshooting Procedure 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Control Problems 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Power Problems 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All tests fail 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All RX and TX paths fail 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All tests fail on a single antenna 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Status Indicators 6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Status Combs All Modules (except GLI3, CSM, BBX2, MCC8/24E) 6-17. . . . . . . . . . . . . . . . . . . . .

DC/DC Converter LED Status Combinations 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSM LED Status Combinations 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLI3 LED Status Combinations 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLI3 Pushbuttons and Connectors 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BBX LED Status Combinations 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCC LED Status Combinations 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPA Shelf LED Status Combinations 6-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span Problems

(No Control Link) 6-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68P09255A57-2

Appendix A System Data A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Operation Verification A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verification of Test Equipment Used A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Checklist A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preliminary Operations A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-Power and Initial Power Tests A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Optimization Checklist A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPS Receiver Operation A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LFR Receiver Operation A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPA IM Reduction A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

Aug 2002

Page 9

68P09255A57-2

TX Bay Level Offset / Power Output Verification for 3-Sector Configurations A-10. . . . . . . . . . . . . . . . .

TX Bay Level Offset / Power Output Verification for 6-Sector Configurations A-15. . . . . . . . . . . . . . . . .

TX Antenna VSWR A-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Antenna VSWR A-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Verification A-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-CCP Shelf A-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPAs A-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Appendix B ATP Matrix Table B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-optimization B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Usage & Background B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detailed Optimization/ATP Test Matrix B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C BBX Gain C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BBX Gain Set Point C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Usage & Background C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D CDMA Operating Frequency Programming D-1. . . . . . . . . . . . . . . . . . . . . .

Channel Frequencies D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1900 MHz PCS Channels D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculating 1900 MHz Center Frequencies D-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

800 MHz CDMA Channels D-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculating 800 MHz Center Frequencies D-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E PN Offset E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PN Offset E-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background E-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Usage E-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix F Test Preparation F-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Setup F-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose F-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP8921A Test Equipment Connections F-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP8921A System Connectivity Test F-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting HP8921A and HP83236A/B GPIB Address F-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pretest Setup for HP8921A F-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pretest Setup for HP8935 F-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advantest R3465 Connection F-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

R3465 GPIB Address & Clock setup F-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pretest Setup for Advantest R3465 F-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Agilent E4406A/E4432B Test Equipment Interconnection F-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating Test Cable Setup

using HP PCS Interface (HP83236) F-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating Test Cable Setup using Advantest R3465 F-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating HP 437 Power Meter F-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating Gigatronics 8541C power meter F-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix G Power Calibration G-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating Output Power G-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Calibration G-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Warm up G-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aug 2002

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

vii

Page 10

Table of Contents

Power Delta Calibration Introduction G-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP8921A Power Delta Calibration G-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advantest R3465 Power Delta Calibration G-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP8935 Power Delta Calibration G-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Agilent E4406A Power Delta Calibration G-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In-Service Calibration G-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68P09255A57-2

Appendix H Cable Interconnection H-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intra-Cabinet Cabling H-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SC 4812ET Intra-Cabinet Cabling H-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-CCP Cables and Cable Connectors H-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Cabinet LPA Cables H-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPAC Cabling H-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ETIB Cables and Cable Connectors H-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPAN I/O Cable Connection Diagram H-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DRDC/TRDC Cables and Cable Connections H-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MPC Functional Description H-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS Cabling Details H-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50 Pair Punchblock H-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm and Span Line Cable Pin/Signal Information H-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Cabinet Parts Locator H-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix I GPIB Addressing I-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB I-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPIB Introduction I-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP437 Power Meter GPIB Address I-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gigatronics 8541C Power Meter GPIB Address I-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motorola CyberTest GPIB Address I-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP8935 Test Set GPIB Address I-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting HP8921A and HP83236A/B GPIB Address I-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advantest R3465 GPIB Address I-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS232 GPIB Interface Box I-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advantest R3267 Spectrum Analyzer GPIB Address I-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advantest R3562 Signal Generator GPIB Address I-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Agilent E4406A Transmitter Tester GPIB Address I-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Agilent E4432B Signal Generator GPIB Address I-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix J Downloading ROM J-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading ROM Code J-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exception Procedure - Downloading ROM Code J-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix K Companion Frame Optimization K-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optimizing the Companion Frame K-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optimizing the TX section K-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optimizing the RX section K-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

Aug 2002

Page 11

68P09255A57-2

Figure 1-1: Null Modem Cable Detail 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

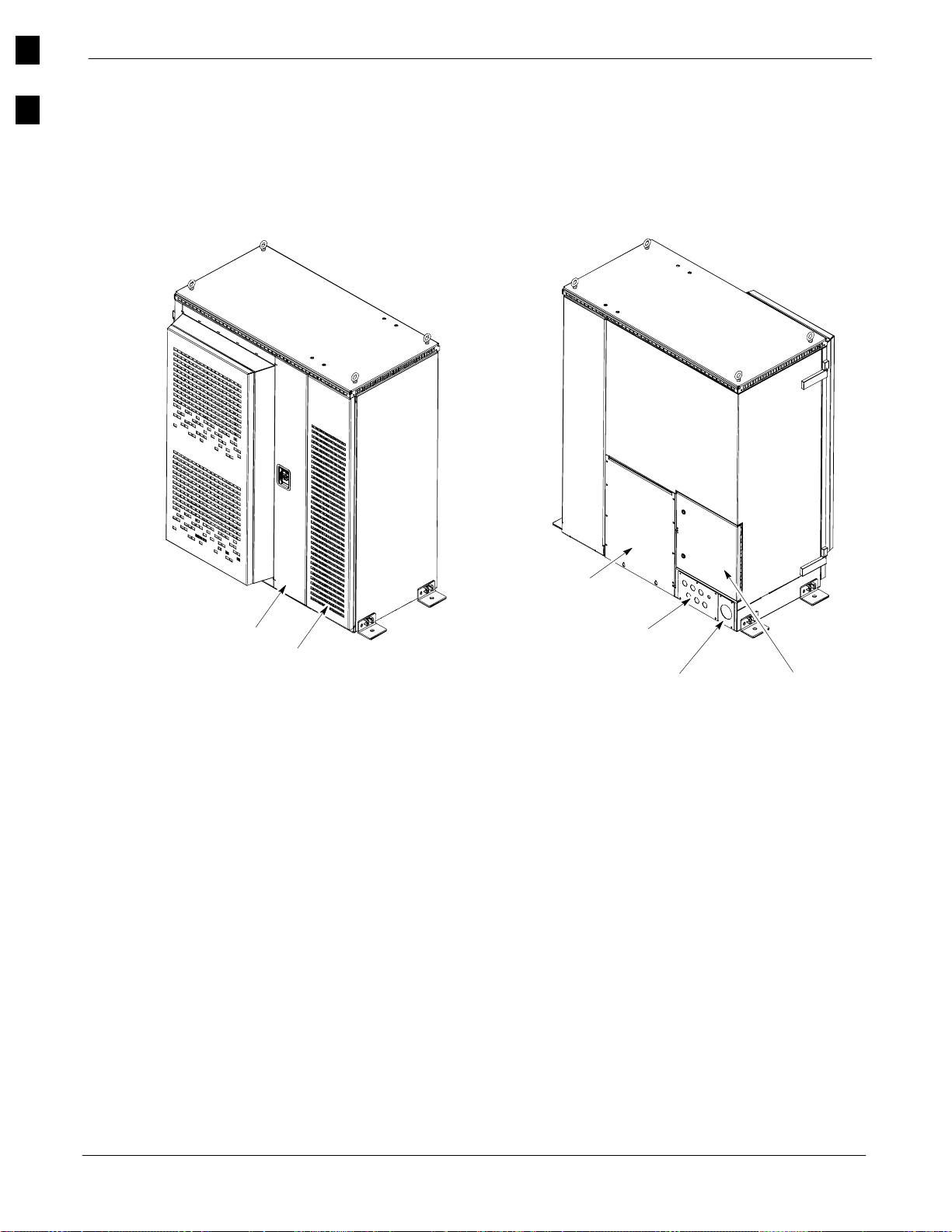

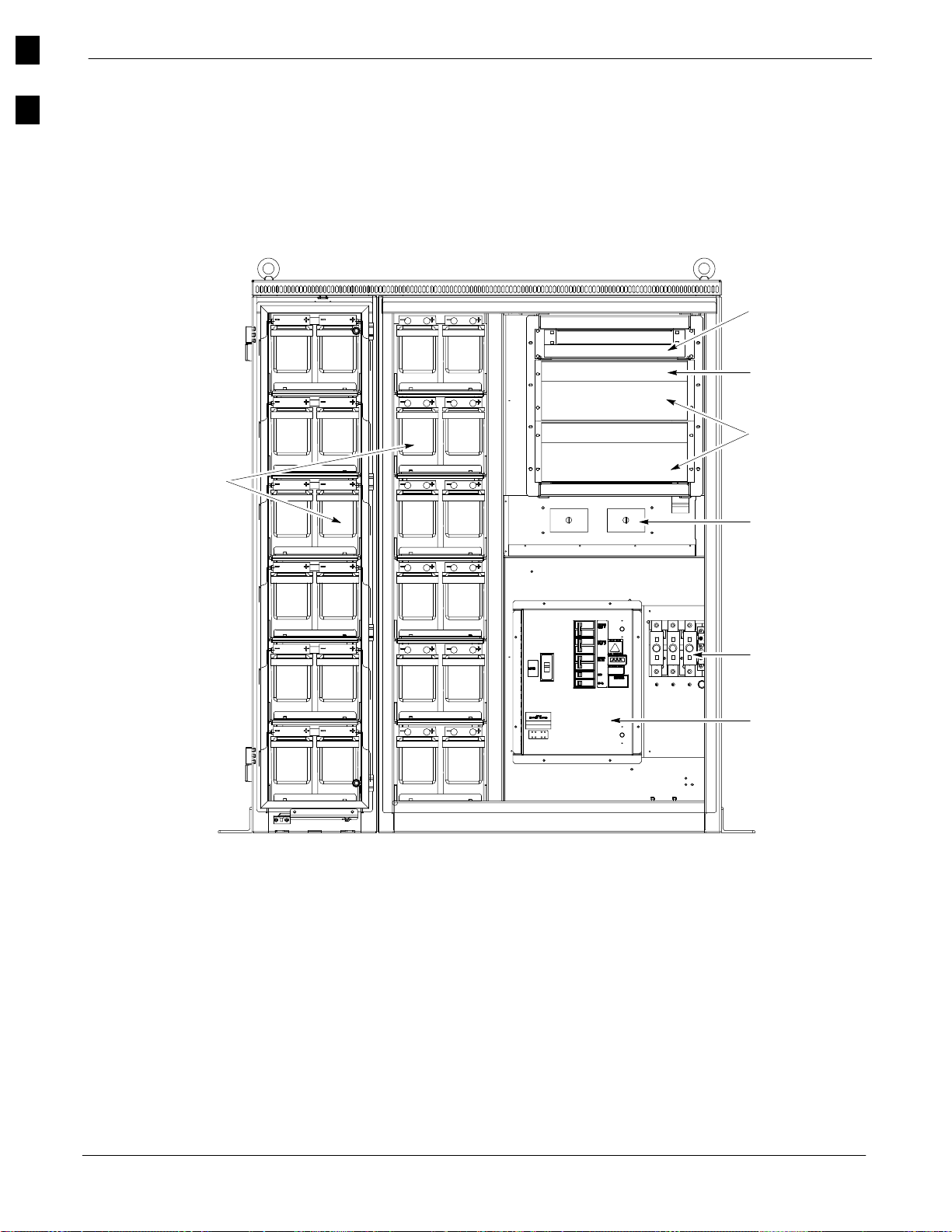

Figure 1-2: SC 4812ET RF Cabinet 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

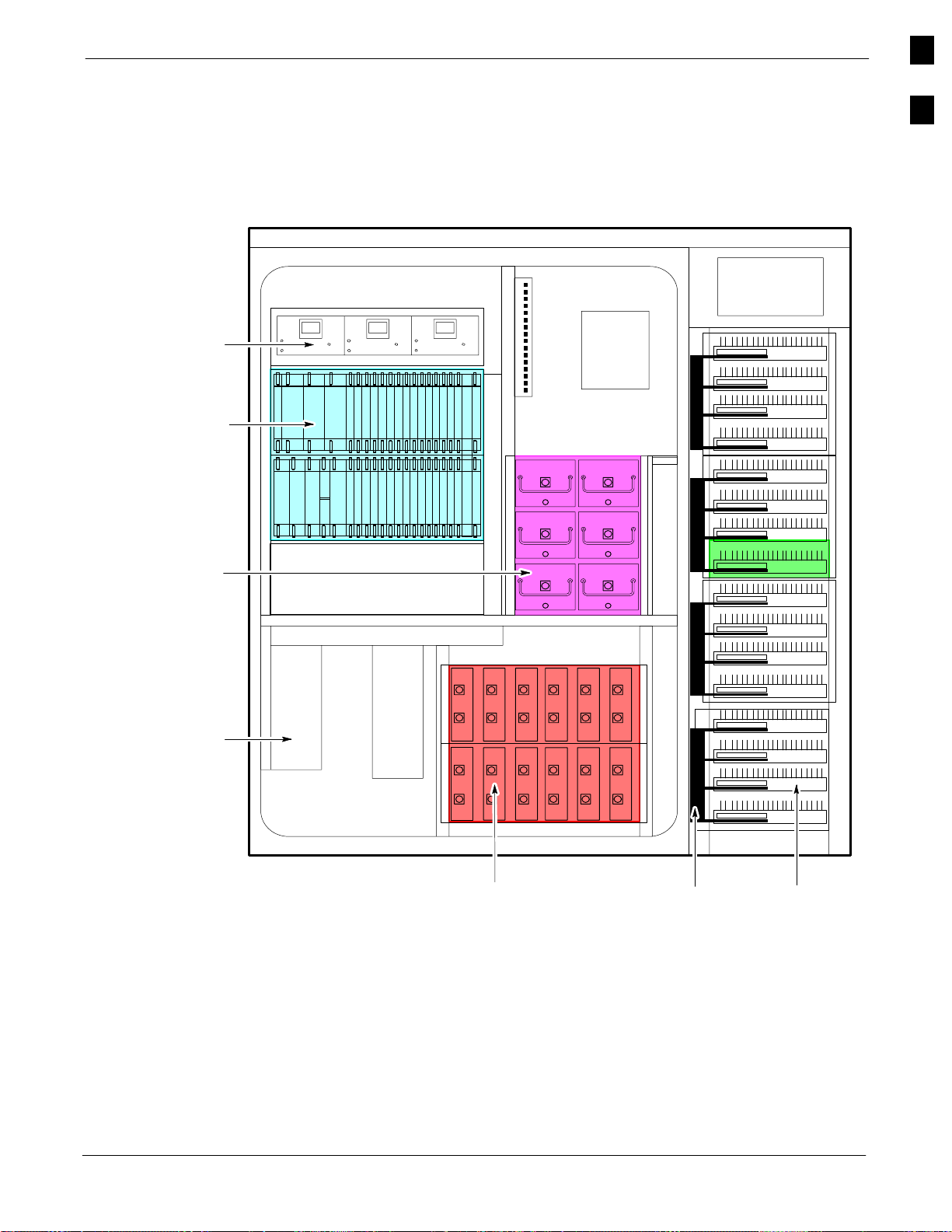

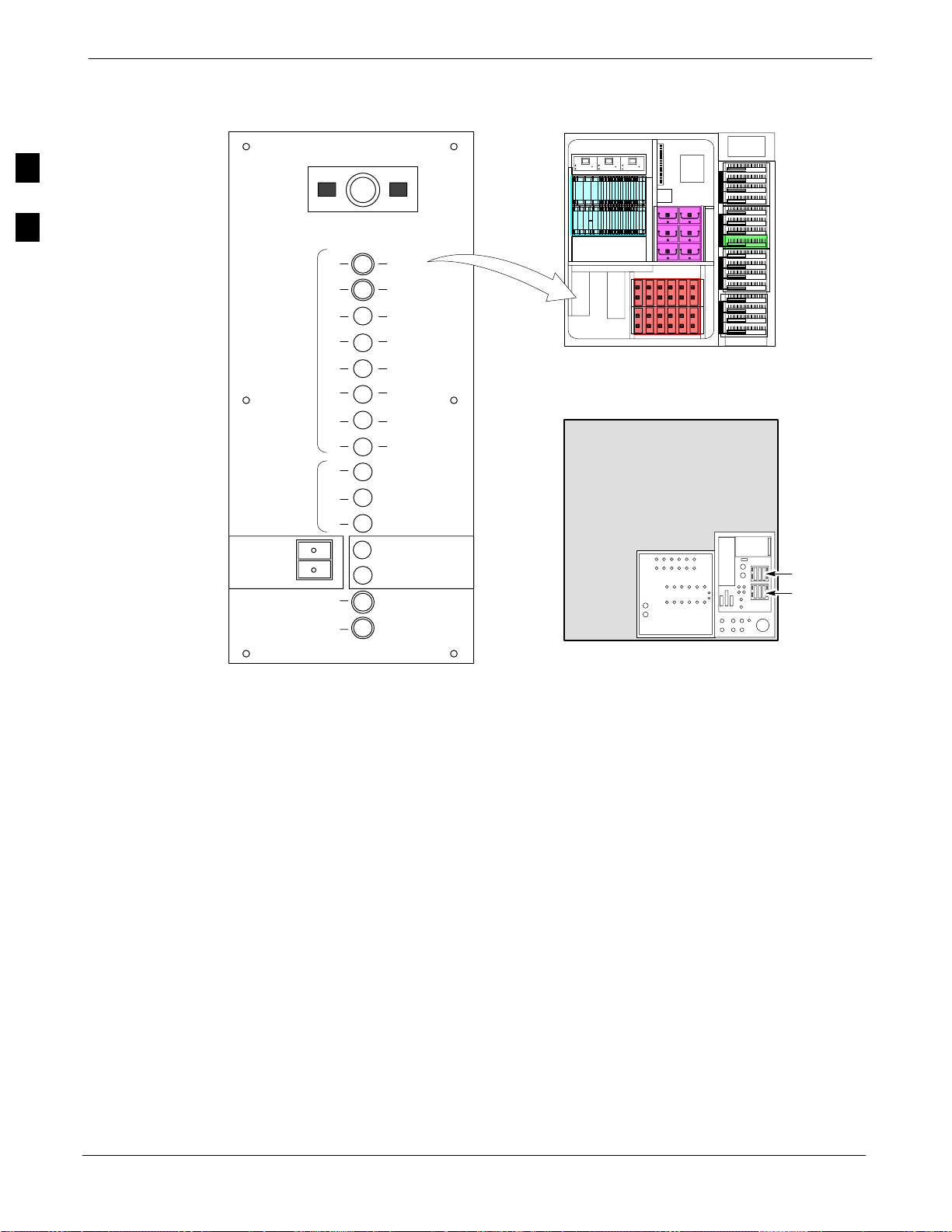

Figure 1-3: RF Cabinet Internal FRUs 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-4: SC 4812ET C-CCP Shelf 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-5: SC 4812ET Intercabinet I/O Detail (Rear View) 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-6: SC 4812ET I/O Plate Diagram 1-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-7: RFDS Location in an SC 4812ET RF Cabinet 1-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-8: SC4812ET LPA Configuration with Combiners/Filters 1-24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-9: Power Cabinet 1-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-10: Power Cabinet with Batteries Installed (Doors Removed for Clarity) 1-26. . . . . . . . . . . . . .

Figure 2-1: Backplane DIP Switch Settings 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-2: AC Load Center Wiring 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-3: Meter Alarm Panel 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-4: Temperature Compensation Panel 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

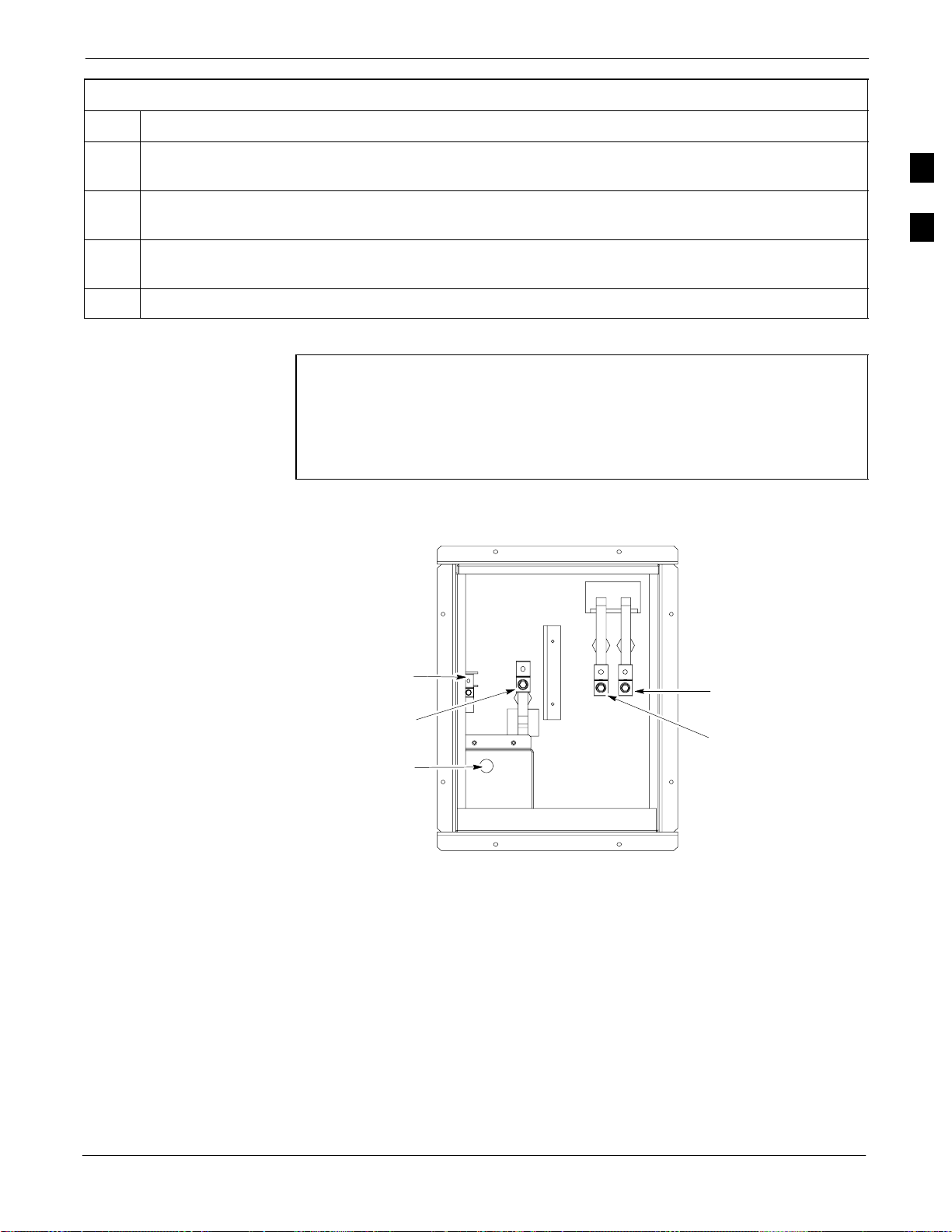

Figure 2-5: RF Cabinet Circuit Breaker Panel and 27Vdc Terminal Locations 2-10. . . . . . . . . . . . . . . . .

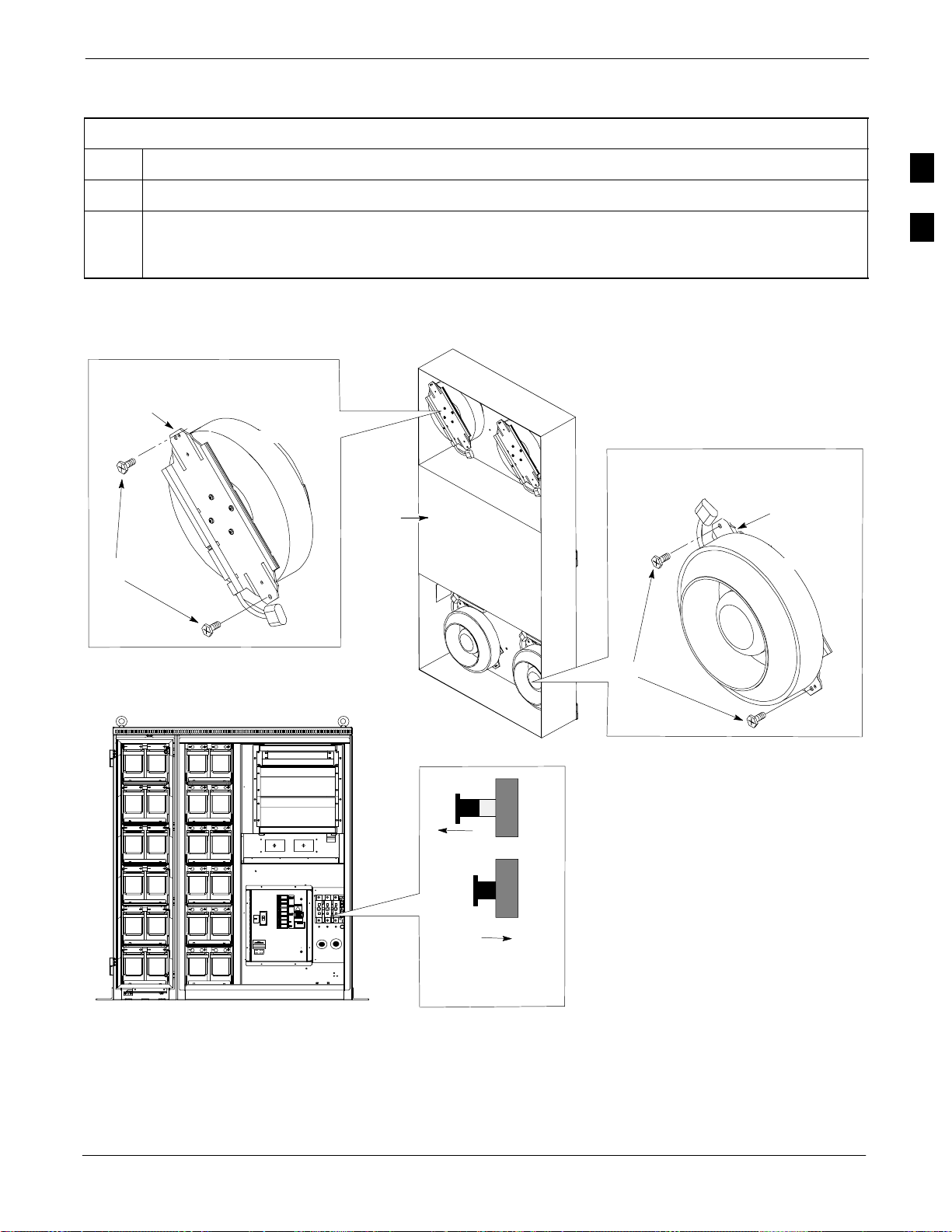

Figure 2-6: Heat Exchanger Blower Assembly 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

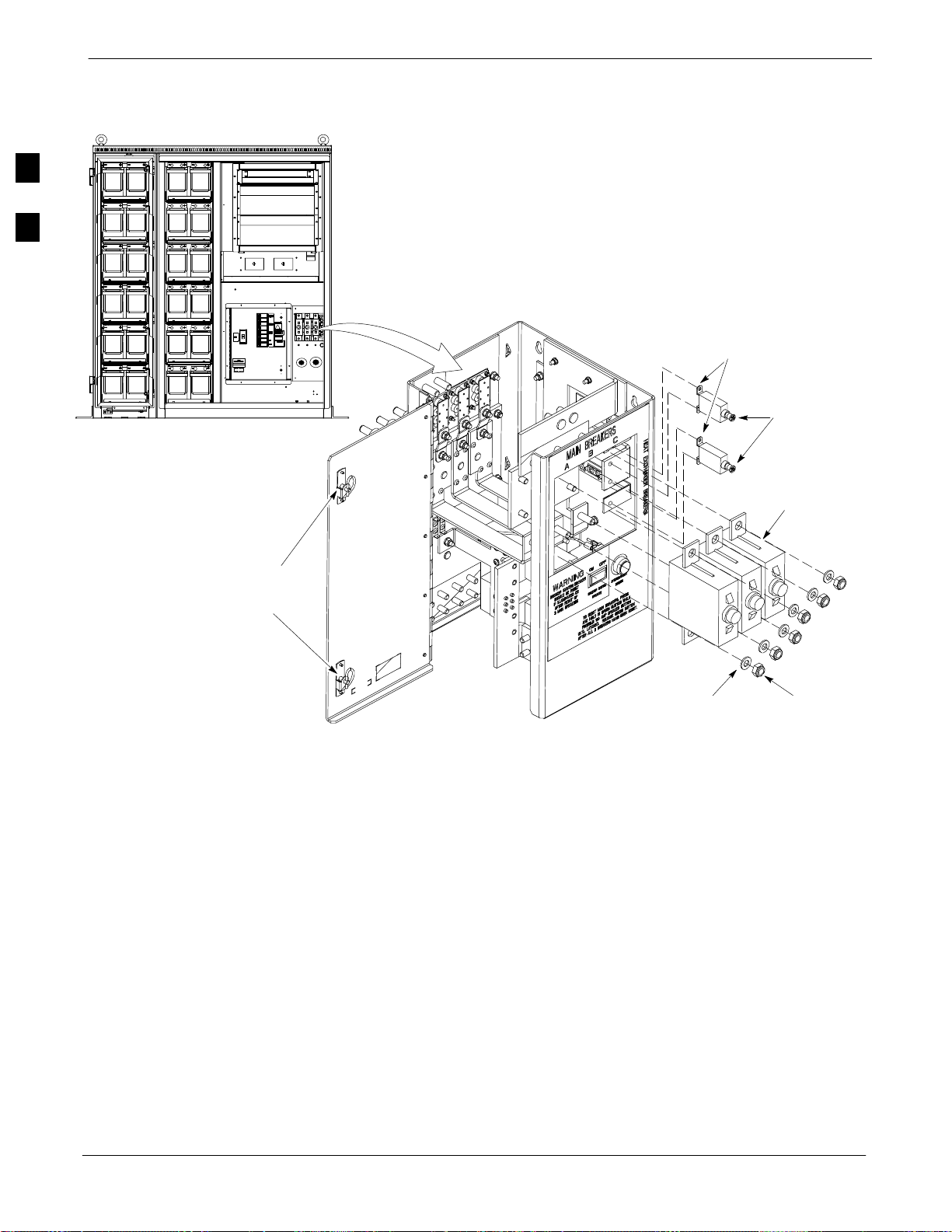

Figure 2-7: Power Cabinet Circuit Breaker Assemblies 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-8: Power Cabinet AC Circuit Breakers 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-9: Power Cabinet DC Circuit Breakers 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

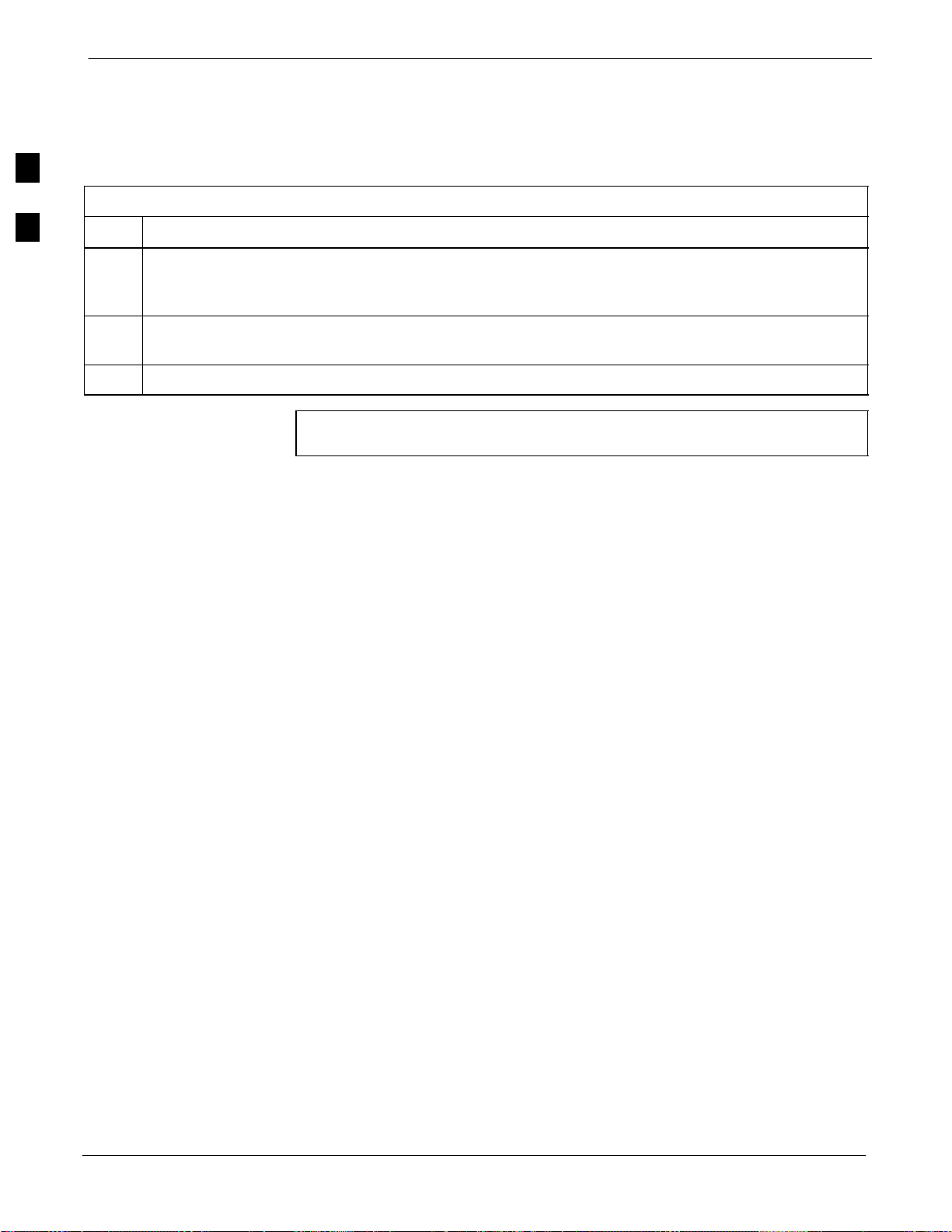

Figure 3-1: Back and Front View of the CSU 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-2: 50 Pair Punch Block 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-3: LMF Folder Structure 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-4: LMF Connection Detail 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-5: BTS Ethernet LAN Interconnect Diagram 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-6: CDMA LMF Computer Common MMI Connections 3-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-7: CSM MMI Terminal Connection 3-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-8: Cable Calibration Test Setup - CyberTest, Agilent 8935, Advantest R3465, and HP 8921A . . .

3-54

Figure 3-9: Cable Calibration Test Setup - Agilent E4406A/E4432B and Advantest R3267/R3562 3-55

Figure 3-10: TX Calibration Test Setup - CyberTest (IS-95A/B) and

Agilent 8935 (IS-95A/B and CDMA2000 1X) 3-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-11: TX Calibration Test Setup - Using Power Meter 3-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-12: TX Calibration Test Setup - Agilent E4406A and Advantest R3567

(IS-95A/B and CDMA2000 1X) 3-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-13: IS-95A/B Optimization/ATP Test Set-up, TRDC Shown - CyberTest and Advantest R3465 .

3-59

Figure 3-14: IS-95A/B Optimization/ATP Test Setup - HP 8921A 3-60. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-15: IS-95A/B and CDMA2000 1X Optimization/ATP Test Setup With DRDCs -

Agilent Test Equipment 3-61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-16: IS-95A/B and CDMA2000 1X Optimization/ATP Test Setup With DRDCs -

Advantest R3267/3562 Test Equipment 3-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-17: IS-95A/B and CDMA2000 1X Optimization/ATP Test Setup With TRDCs -

Agilent Test Equipment 3-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

List of Figures

Aug 2002

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

ix

Page 12

Table of Contents

Figure 3-18: IS-95A/B and CDMA2000 1X Optimization/ATP Test Setup With TRDCs -

Advantest R3267/3562 Test Equipment 3-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-19: Typical TX ATP Setup with Directional Coupler (shown with and without RFDS) 3-65. . .

Figure 3-20: Typical RX ATP Setup with Directional Coupler (shown with or without RFDS) 3-66. . . . .

Figure 3-21: Calibrating Test Equipment Setup for TX Cable Calibration

(Using Signal Generator and Spectrum Analyzer) 3-72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-22: Calibrating Test Equipment Setup for RX ATP Test

(Using Signal Generator and Spectrum Analyzer) 3-73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-23: Battery Over-temperature Sensor 3-101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-24: Location of Connector J8 on the Meter Alarm Panel 3-102. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-1: TX Mask Verification Spectrum Analyzer Display 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-2: Code Domain Power and Noise Floor Levels 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5-1: MGLI3/SGLI3 MMI Port Connection 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-1: CSM Front Panel Indicators & Monitor Ports 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-2: GLI3 Front Panel Operating Indicators 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-3: MCC24/8E Front Panel LEDs and LED Indicators 6-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure D-1: North America PCS Frequency Spectrum (CDMA Allocation) D-2. . . . . . . . . . . . . . . . . . . .

68P09255A57-2

Figure D-2: North American Cellular Telephone System Frequency Spectrum (CDMA Allocation). D-4

Figure F-1: HP8921A/600 Cables Connection for 10 MHz Signal and GPIB without Rubidium F-3. . .

Figure F-2: HP8921A Cables Connection for 10 MHz Signal and GPIB with Rubidium F-5. . . . . . . . .

Figure F-3: Cable Connections for Test Set without 10 MHz Rubidium Standard F-8. . . . . . . . . . . . . .

Figure F-4: Cable Connections for Test Set with 10 MHz Rubidium Standard F-9. . . . . . . . . . . . . . . . .

Figure F-5: Agilent 10 MHz Reference Connections F-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure F-6: Cable CalibrationUsing HP8921 with PCS Interface F-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure F-7: Cable Calibration using Advantest R3465 F-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure F-8: Power Meter Detail F-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure F-9: Gigatronics 8541C Power Meter Detail F-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-1: Delta Calibration Setup - HP8921A to HP437B G-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-2: Delta Calibration Setup - HP8921A to HP8921A G-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-3: Delta Calibration Setup - R3561L to HP437B G-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-4: Delta Calibration Setup - R3561L to R3465 G-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-5: Delta Calibration Setup - HP8935 to HP437B G-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-6: Delta Calibration Setup - HP8935 to HP8935 G-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-7: Delta Calibration Setup - Agilent E4432B to HP437 G-11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-8: Delta Calibration Setup - Agilent E4432B to Agilent E4406A G-11. . . . . . . . . . . . . . . . . . . .

Figure G-9: Optimization/ATP Test Setup Using RFDS G-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure G-10: IS-95 A/B/C Optimization/ATP Test Setup Using RFDS G-14. . . . . . . . . . . . . . . . . . . . . . . .

Figure H-1: 4812ET RF Cabinet Internal FRU Locations H-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-2: C-CCP Shelf Cable Numbers and Connectors H-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-3: C-CCP Backplane H-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-4: LPAs for the SC 4812ET H-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-5: BTS Combiner to LPA Backplane Cables H-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

Aug 2002

PRELIMINARY

Page 13

68P09255A57-2

Figure H-6: Combiner to LPA Backplane/LPA Backplane To CIO Board Cables H-10. . . . . . . . . . . . . . .

Figure H-7: Components Located on CIO Card H-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-8: LPAC Interface Board Connectors and Attaching Cable Numbers H-12. . . . . . . . . . . . . . . .

Figure H-9: ETIB I/O Connectors and Attaching Cable Numbers H-13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-10: SPAN I/O Cables and Connectors H-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-11: 3 Sector, 2 Carrier BTS Combiner DRDC/TRDC Cable Connection H-17. . . . . . . . . . . . . .

Figure H-12: BTS 2 to 1, 3 or 6 Sector Combiner DRDC/TRDC Cable Connection H-18. . . . . . . . . . . .

Figure H-13: BTS Combiner DRDC/TRDC Cable Connection H-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-14: SC 4812ET BTS Combiner DRDC/TRDC Cable Connection H-20. . . . . . . . . . . . . . . . . . . .

Figure H-15: DRDC To C-CCP Cage MPC Boards Cable Connections H-22. . . . . . . . . . . . . . . . . . . . . .

Figure H-16: RFDS Component Identification H-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-17: SC 4812ET BTS Combiner DRDC/TRDC RFDS Cable Connection H-25. . . . . . . . . . . . . .

Figure H-18: 50 Pair Punchblock H-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure H-19: SC 4812ET RF Cabinet Parts Locator H-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-1: HP437 Power Meter I-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-2: Gigatronics 8541C Power Meter Detail I-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Figure I-3: HP8935 Test Set I-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-4: HP8921A and HP83236A/B I-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-5: R3465 Communications Test Set I-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-6: RS232 GPIB Interface Box I-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-7: Setting Advantest R3267 GPIB Address I-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-8: Advantest R3562 GPIB Address Switch Setting I-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-9: Setting Agilent E4406A GPIB Address I-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure I-10: Setting Agilent E4432B GPIB Address I-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure K-1: Cabling of SC 4812ET Companion BTS to SC 4812ET Companion BTS (3 Sector) K-2.

Figure K-2: WinLMF Display Screen K-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aug 2002

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

xi

Page 14

Table of Contents

FCC Part 68 Registered Devices xix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

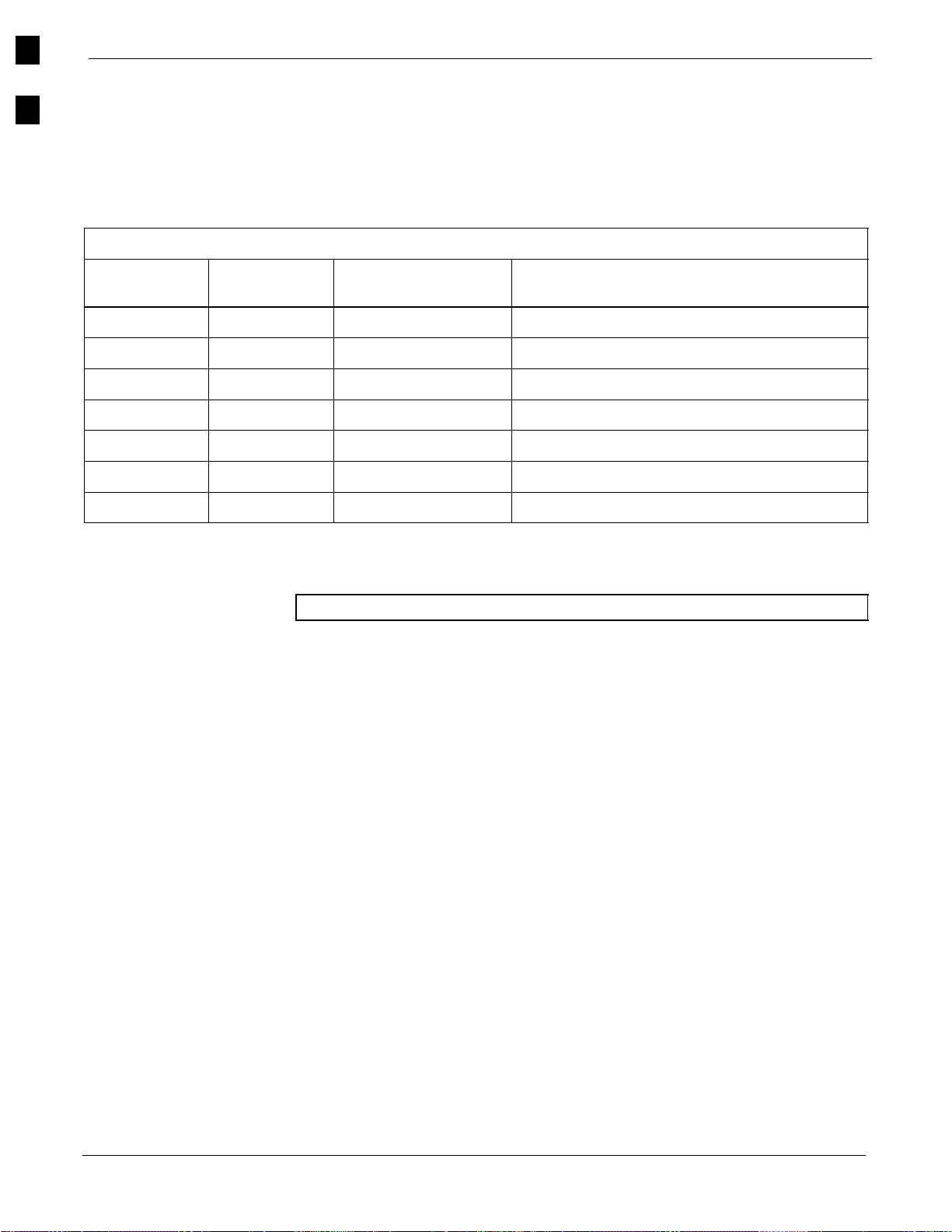

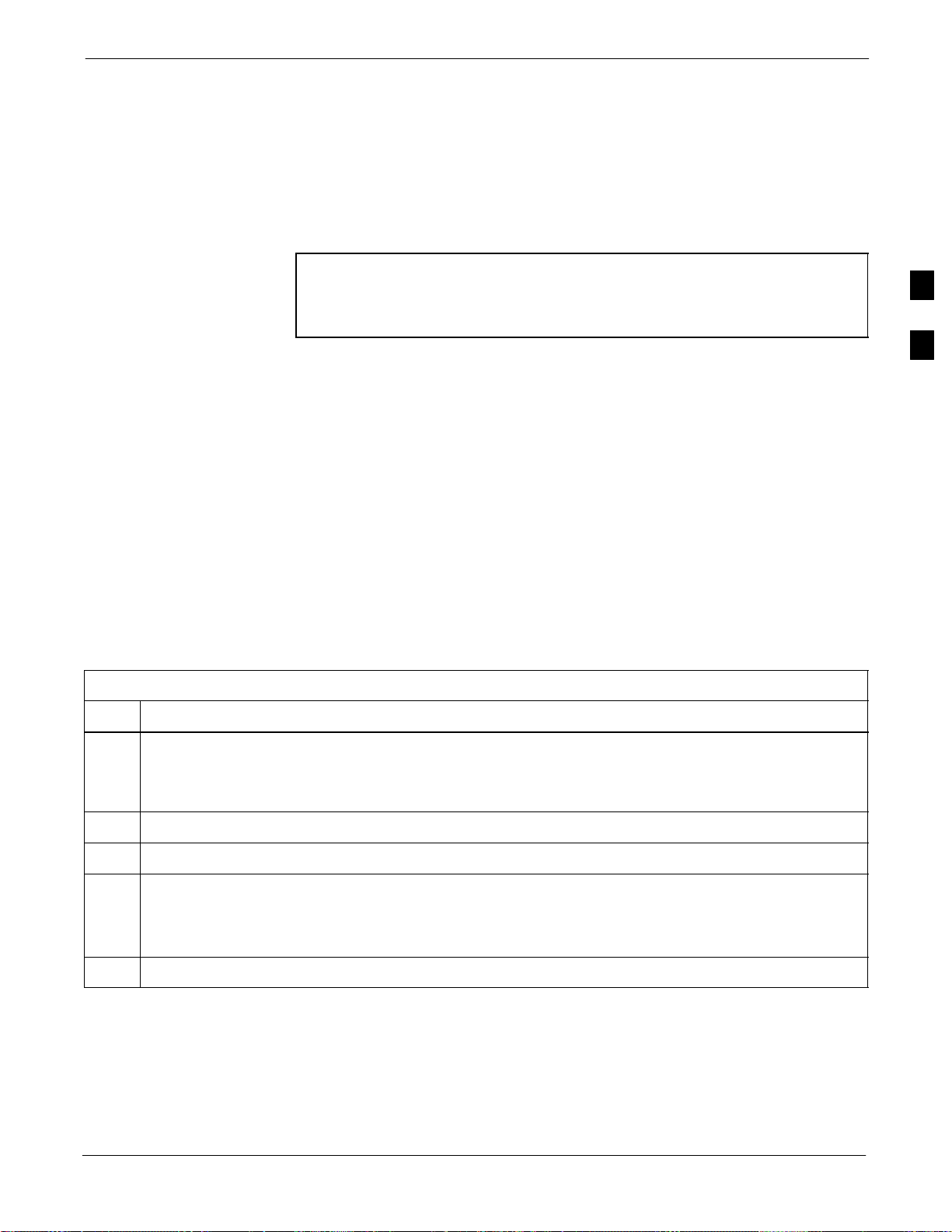

Table 1-1: CDMA LMF Test Equipment Support Table 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-2: Abbreviations and Acronyms 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

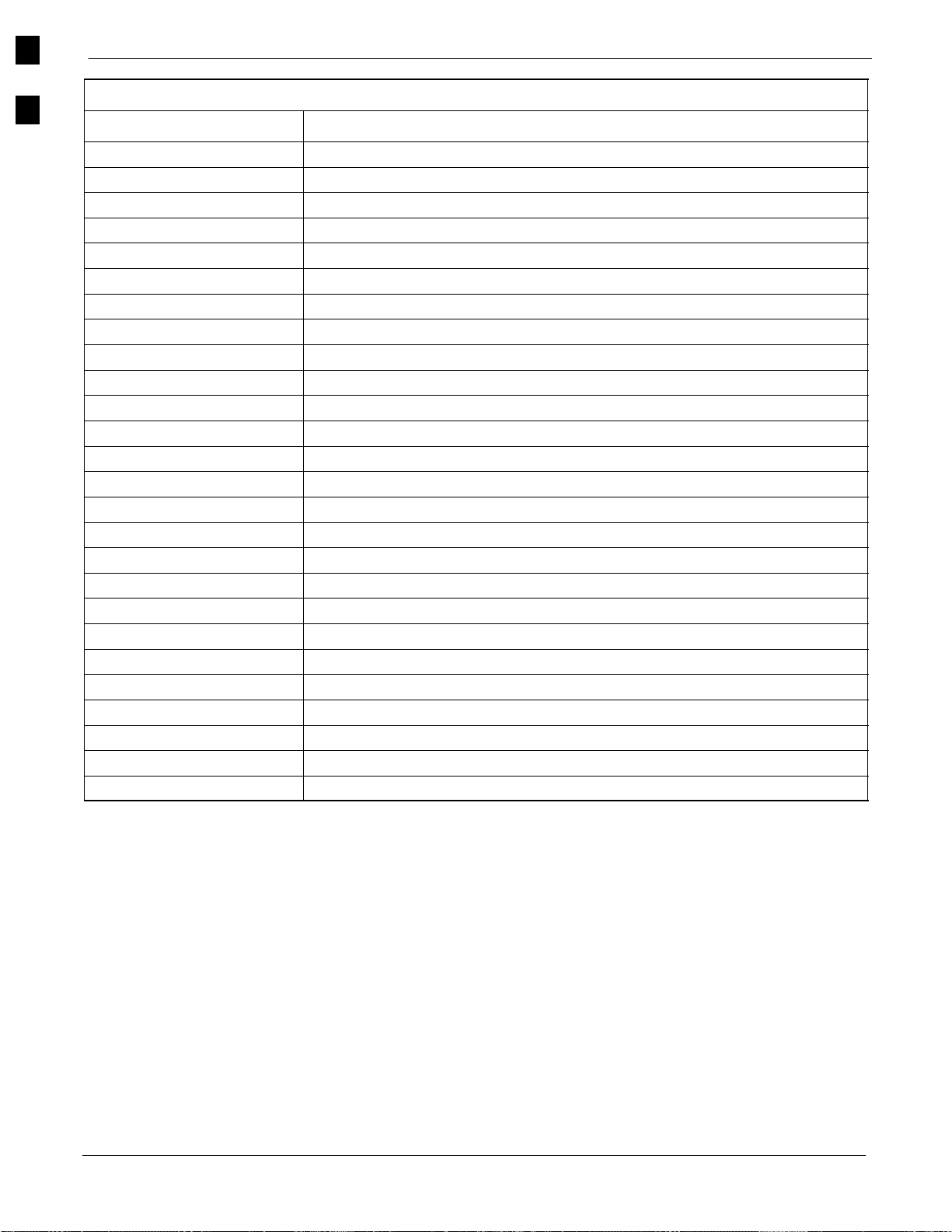

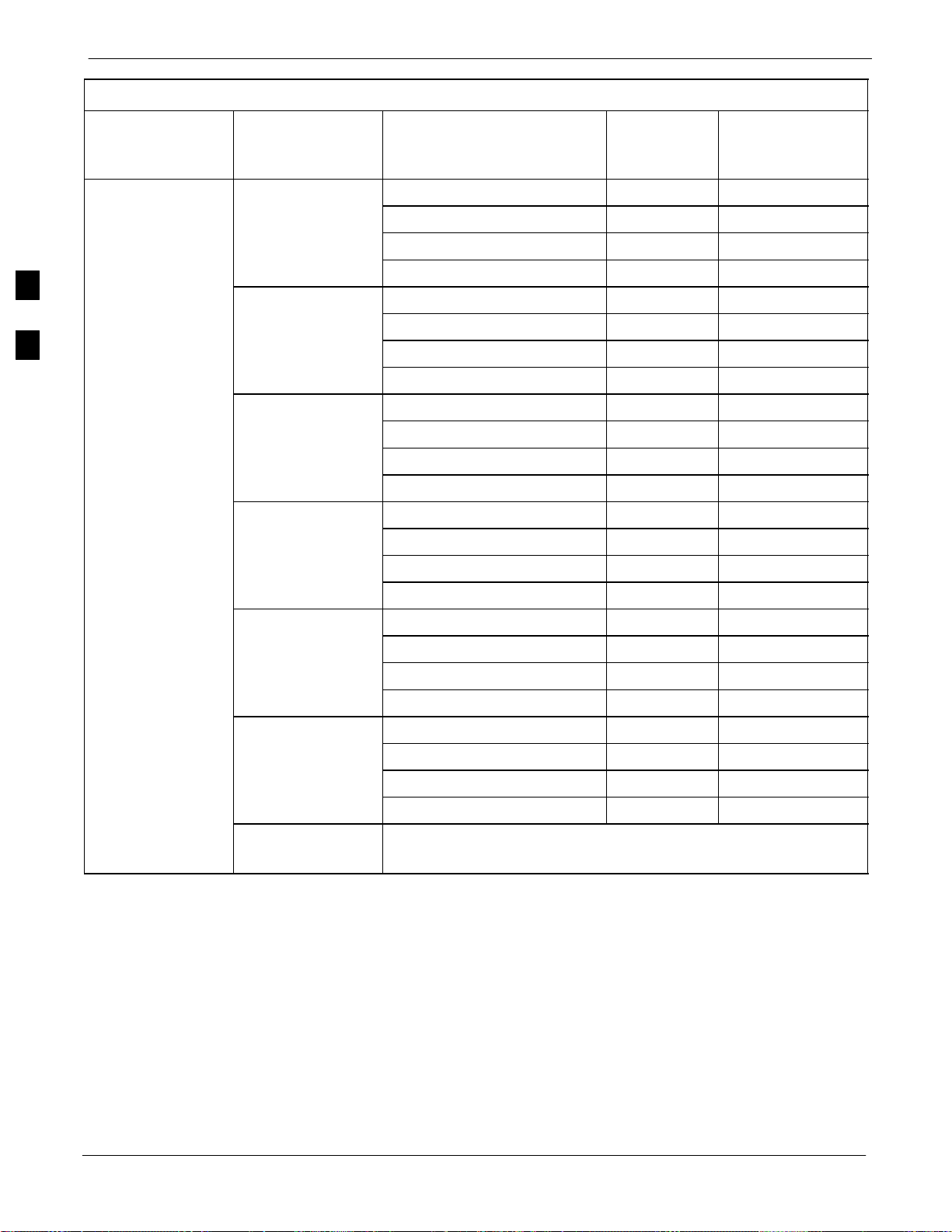

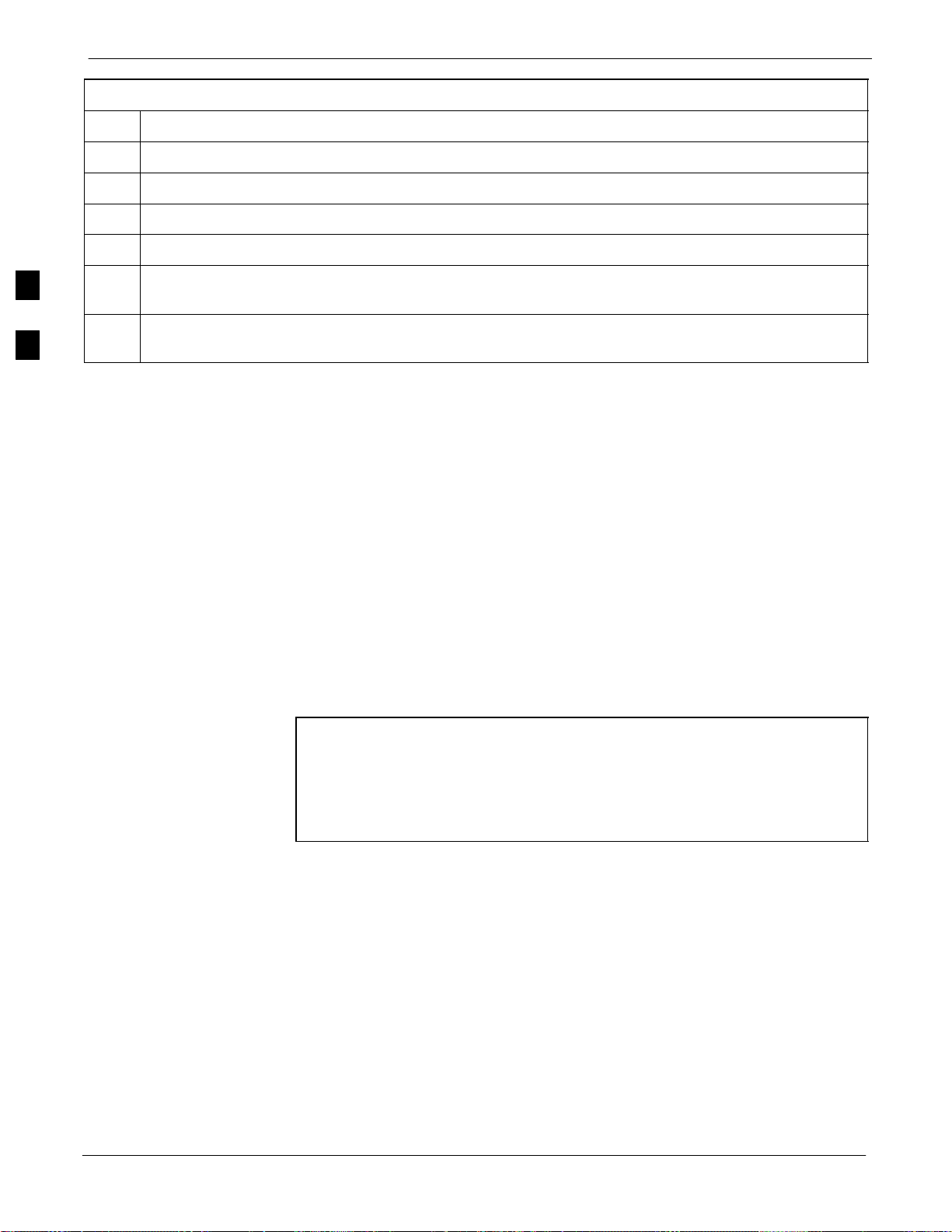

Table 1-3: C-CCP Shelf/Cage Card/Module Device ID Numbers (Top Shelf) 1-15. . . . . . . . . . . . . . . . . .

Table 1-4: C-CCP Shelf/Cage Card/Module Device ID Numbers (Bottom Shelf) 1-15. . . . . . . . . . . . . .

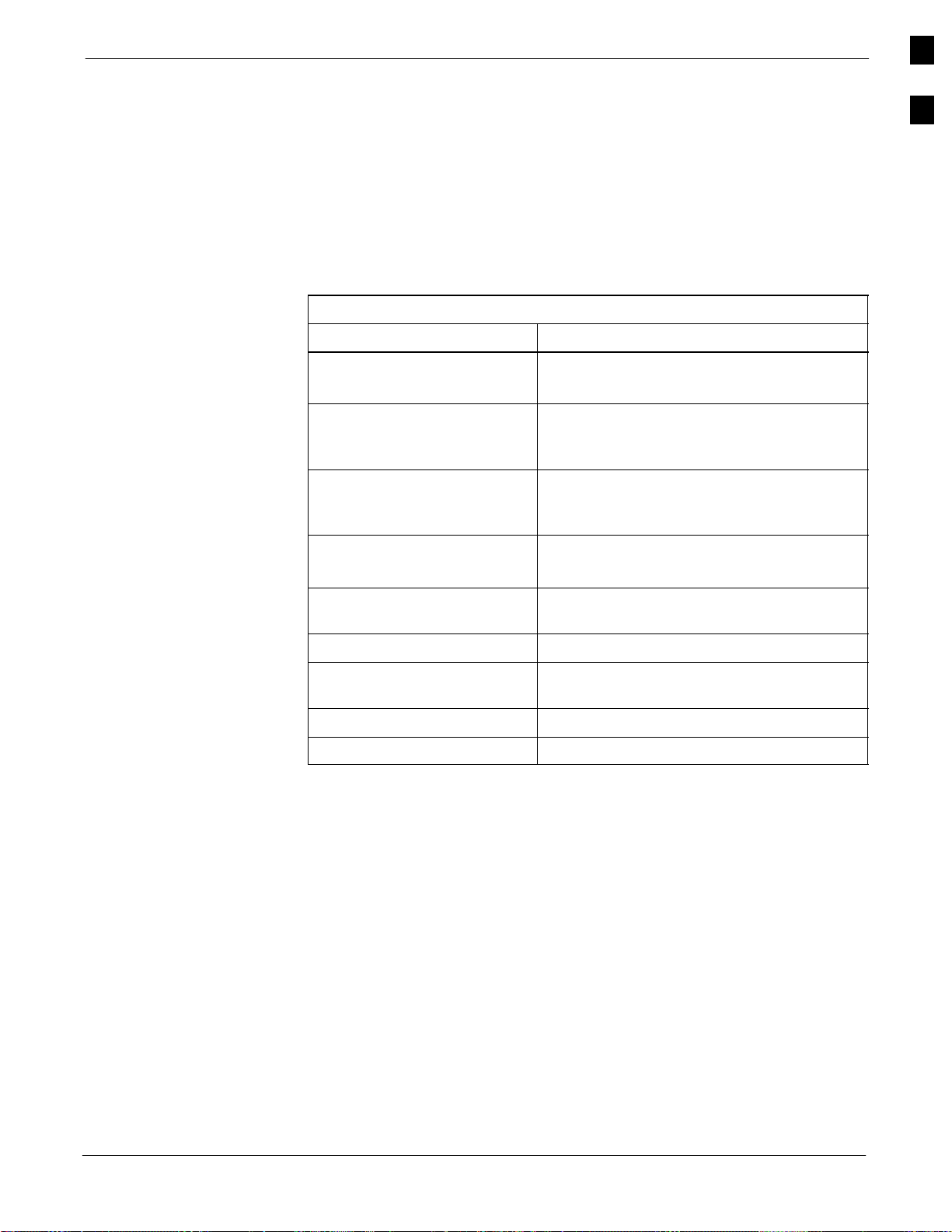

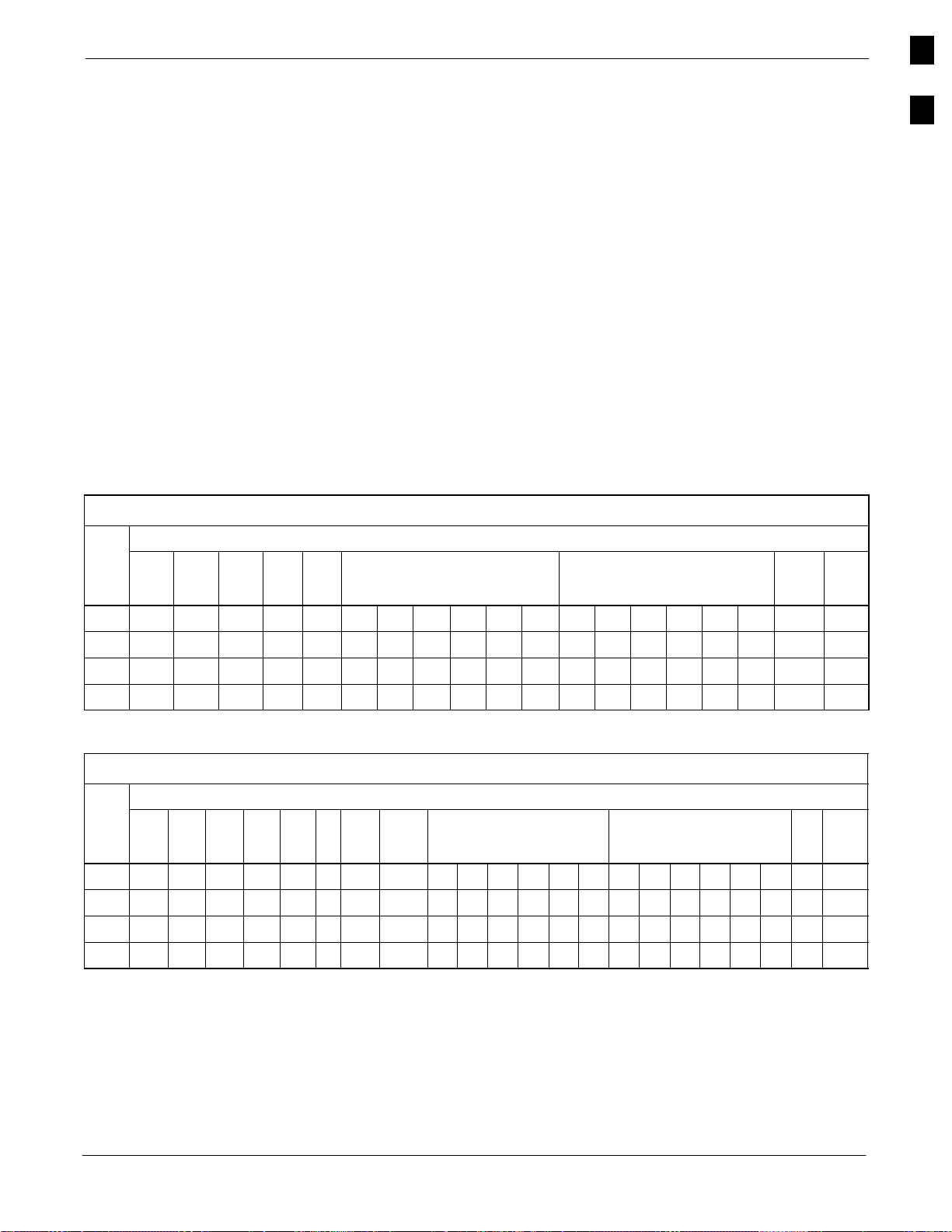

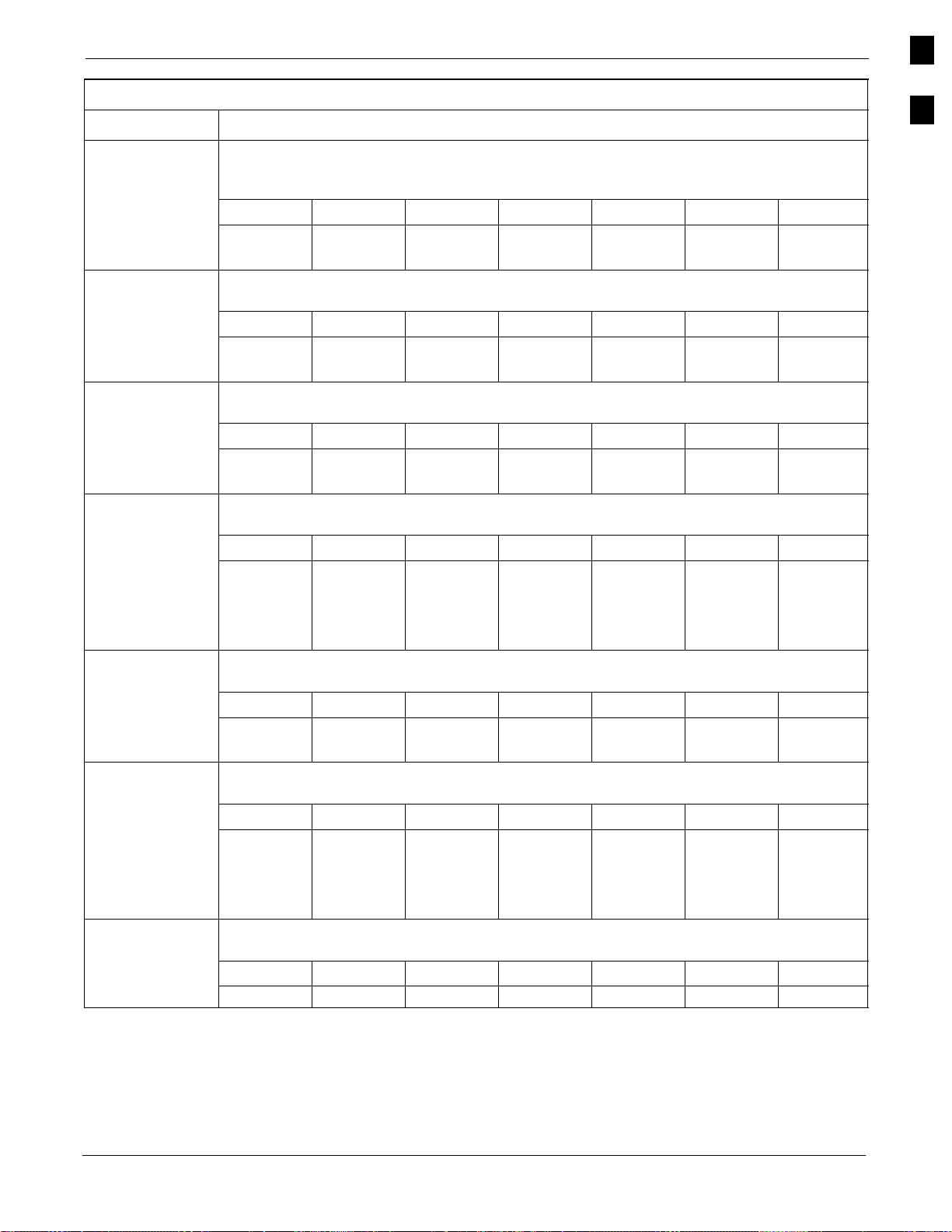

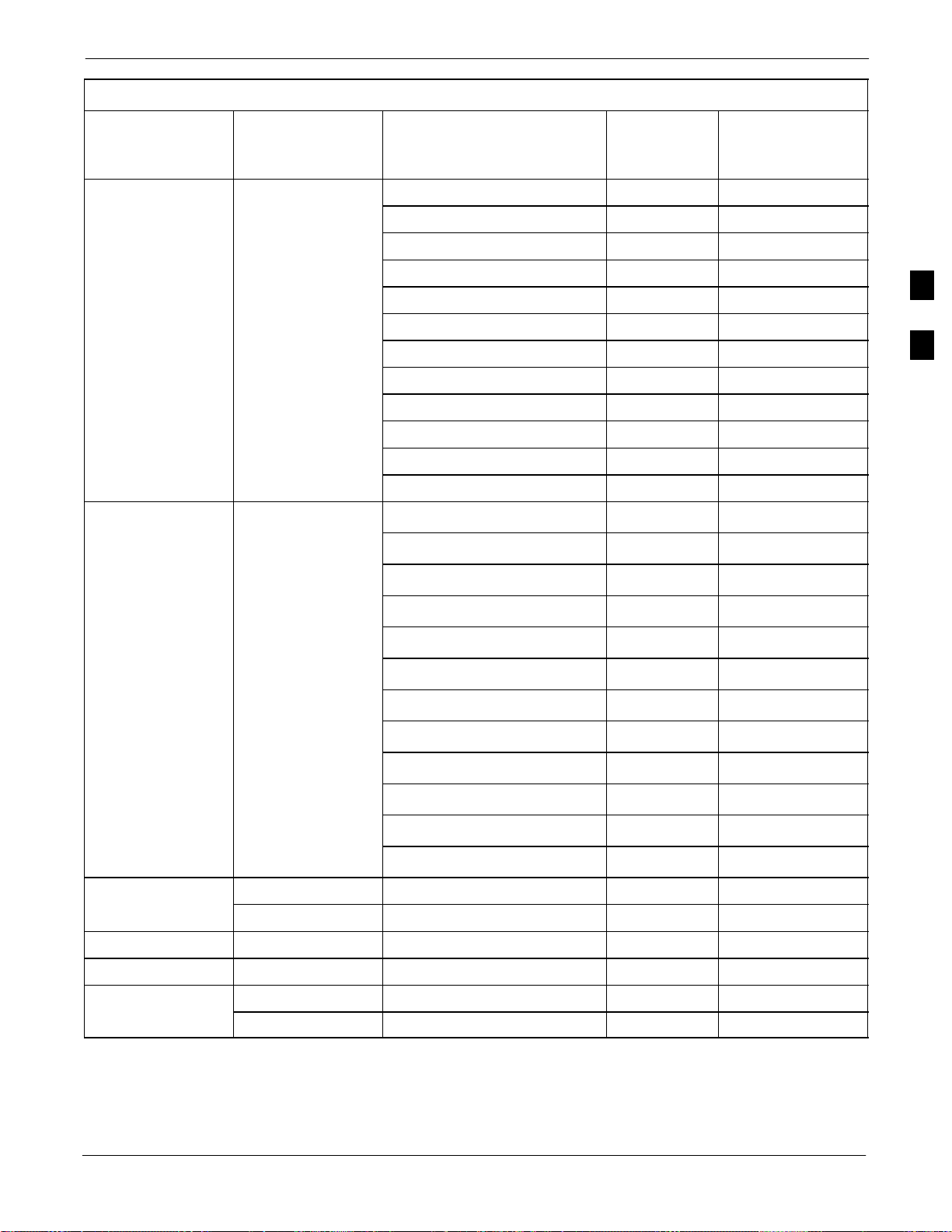

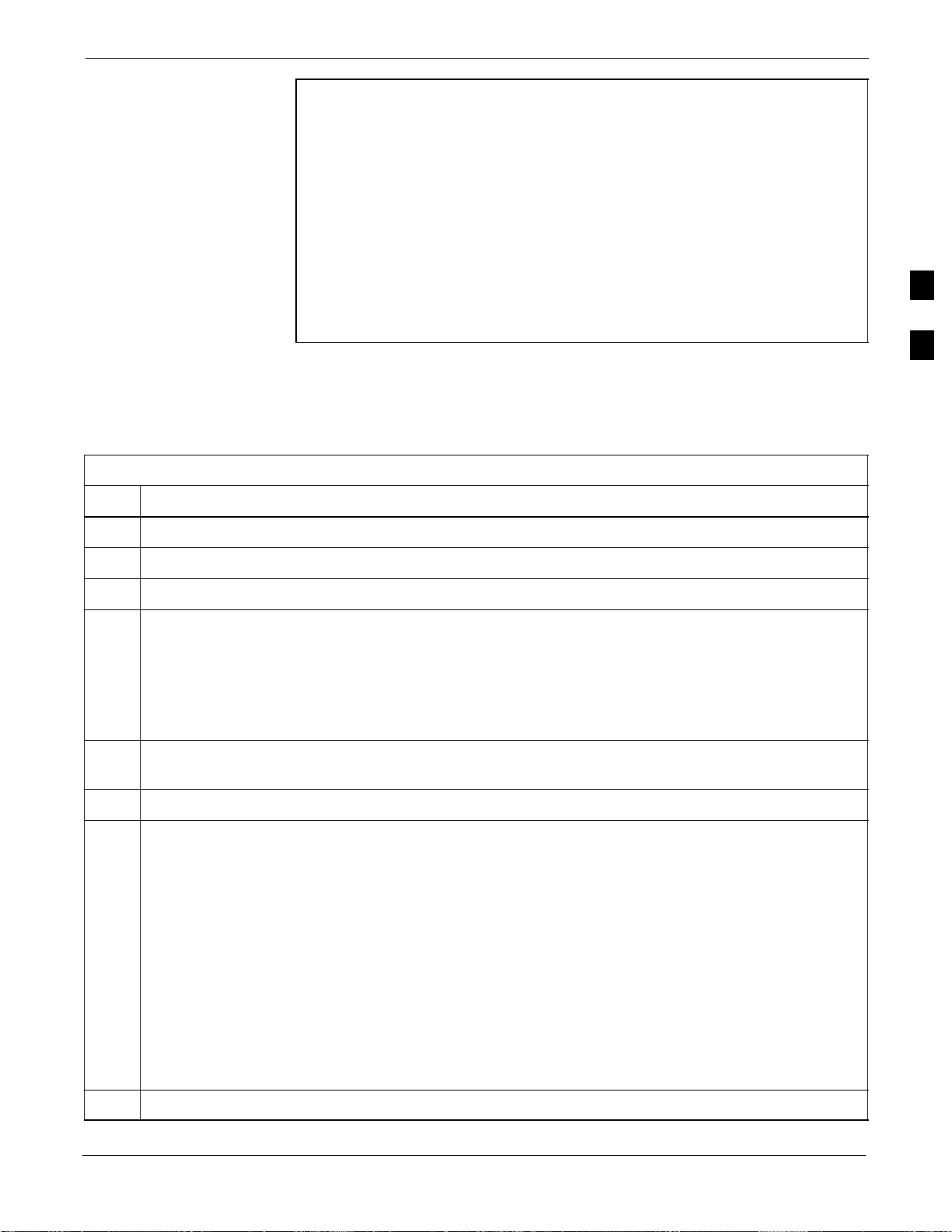

Table 1-5: BTS Sector Configuration 1-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-6: Sector Configurations 1-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-1: Initial Installation of Boards/Modules 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-2: Initial Inspection and Setup 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-3: AC Voltage Measurements 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-4: Applying AC Power 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-5: Power Cabinet Power Up Tests 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-6: DC Power Pre-test (BTS Frame) 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-7: RF Cabinet Power Up 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68P09255A57-2

List of Tables

Table 2-8: Battery Charge Test (Connected Batteries) 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-9: Battery Discharge Test 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-10: Heat Exchanger Power Up 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

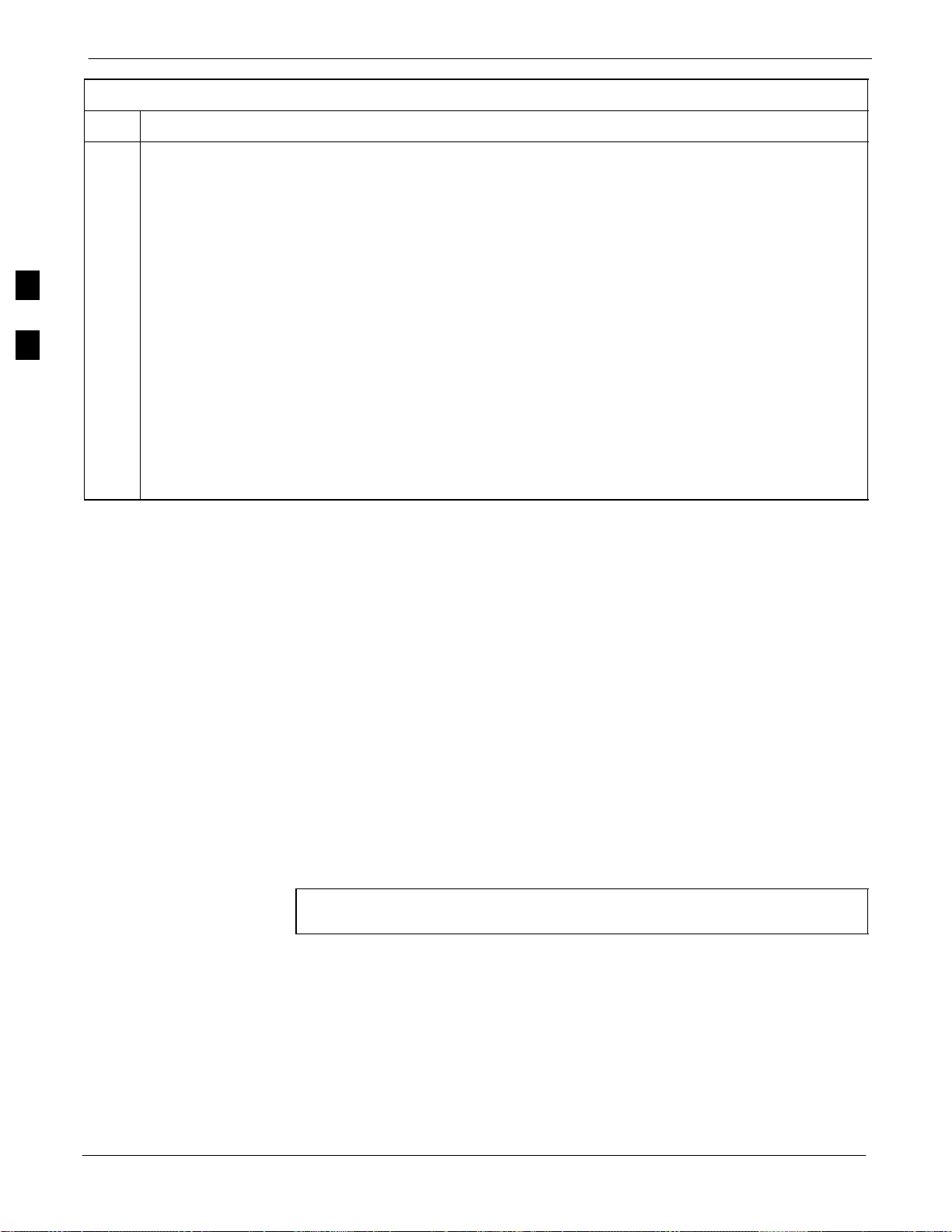

Table 3-1: Pin-Out for 50-Pair Punchblock 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-2: T1/E1 Span Isolation 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-3: LMF Operating System Installation 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-4: Copying CBSC CDF Files to the LMF 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-5: Creating a Named Hyperlink Connection for MMI Connection 3-17. . . . . . . . . . . . . . . . . . . . .

Table 3-6: LMF to BTS Connection 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-7: Pinging the Processors 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-8: Logging into the BTS 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-9: Downloading Site Specific BTS Files 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-10: Downloading and linking master-bts-cdma directory files for device loads 3-23. . . . . . . . .

Table 3-11: Create BTS Specific CDF File 3-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-12: Update BTS Specific CDF File Device Load Version 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-13: Update Antenna Mapping Files 3-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-14: BTS GUI Login Procedure 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-15: BTS CLI Login Procedure 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

Table 3-16: BTS GUI Logout Procedure 3-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-17: BTS CLI Logout Procedure 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-18: Establishing MMI Communications 3-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-19: Verify GLI ROM Code Loads 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-20: Download and Enable MGLI and GLI Devices 3-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-21: Download RAM Code and Data to Non-GLI Devices 3-36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-22: Select CSM Clock Source 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SC4812ET Optimization/ATP Manual Software Release R16.1.x.x

PRELIMINARY

Aug 2002

Page 15

68P09255A57-2

Table 3-23: Enable CSMs 3-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-24: Enable MCCs 3-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-25: Test Equipment Setup (GPS & LFR/HSO Verification) 3-41. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-26: GPS Initialization/Verification 3-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-27: LORAN-C Initialization/Verification 3-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-28: IS-95A/B-only Test Equipment Interconnection 3-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-29: CDMA2000 1X/IS-95A/B Test Equipment Interconnection 3-52. . . . . . . . . . . . . . . . . . . . . . .

Table 3-30: Selecting Test Equipment Manually in a Serial Connection Tab 3-68. . . . . . . . . . . . . . . . . . .

Table 3-31: Selecting Test Equipment Using Auto-Detect 3-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-32: Test Equipment Calibration 3-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-33: Cable Calibration 3-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .