Page 1

SCt4812ET RF and Power Cabinet

Hardware Installation Manual

System Software Release 2.16.0

English

Apr 2001

68P09253A94–1

800/1700/1900 MHz

CDMA

DRAFT

Page 2

SCt4812ET RF and Power Cabinet Hardware

Installation Manual

800/1700/1900 MHz

CDMA

English

Apr 2001

68P09253A94–1

Page 3

SCt4812ET RF and Power Cabinet

Hardware Install ation Manual

System Software Release 2.16.0

English

Apr 2001

68P09253A94–1

800/1700/1900 MHz

CDMA

DRAFT

Page 4

Notice

While reasonable efforts have been made to assure the accuracy of this document, Motorola, Inc. assumes no liability resulting from any

inaccuracies or omissions in this document, or from use of the information obtained herein. The information in this document has been

carefully checked and is believed to be entirely reliable. However, no responsibility is assumed for inaccuracies or omissions. Motorola,

Inc. reserves the right to make changes to any products described herein and reserves the right to revise this document and to make

changes from time to time in content hereof with no obligation to notify any person of revisions or changes. Motorola, Inc. does not

assume any liability arising out of the application or use of any product, software, or circuit described herein; neither does it convey

license under its patent rights or the rights of others.

It is possible that this publication may contain references to, or information about Motorola products (machines and programs),

programming, or services that are not announced in your country. Such references or information must not be construed to mean

that Motorola intends to announce such Motorola products, programming, or services in your country.

Copyrights

This instruction manual, and the Motorola products described in this instruction manual may be, include or describe copyrighted

Motorola material, such as computer programs stored in semiconductor memories or other media. Laws in the United States and

other countries preserve for Motorola certain exclusive rights for copyrighted material, including the exclusive right to copy,

reproduce in any form, distribute and make derivative works of the copyrighted material. Accordingly, any copyrighted Motorola

material contained herein or in the Motorola products described in this instruction manual may not be copied, reproduced,

distributed, merged or modified in any manner without the express written permission of Motorola. Furthermore, the purchase of

Motorola products shall not be deemed to grant either directly or by implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Motorola, as arises by operation of law in the sale of a product.

Usage and Disclosure Restrictions

License Agreement

The software described in this document is the property of Motorola, Inc. It is furnished by express license agreement only and may

be used only in accordance with the terms of such an agreement.

Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is prohibited by law. No part of the software or

documentation may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, without prior written permission of Motorola, Inc.

High Risk Activities

Components, units, or third–party products used in the product described herein are NOT fault–tolerant and are NOT designed,

manufactured, or intended for use as on–line control equipment in the following hazardous environments requiring fail–safe

controls: the operation of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems, Air Traffic Control, Life

Support, or W eapons Systems (“High Risk Activities”). Motorola and its supplier(s) specifically disclaim any expressed or implied

warranty of fitness for such High Risk Activities.

Trademarks

and Motorola are registered trademarks of Motorola, Inc.

Product and service names profiled herein are trademarks of Motorola, Inc. Other manufacturers’ products or services profiled

herein may be referred to by trademarks of their respective companies.

Copyright

Copyright 2000 Motorola, Inc.

All Rights Reserved

Printed on

Recyclable Paper

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

REV010598

Page 5

TM

4812ET RF and Power Cabinet Hardware Installation Manual

SC

This manual includes...

Chapter Version Description Page

Front

1

2

3

4

5

6

A

B

C

D

E

F

G

H

I

V00.04

V01.03

V02.03

V03.03

V04.03

V05.03

V06.03

V0A.03

VOB.03

VOC.03

VOD.03

V0F.02

V0F.02

VOG.01

VOH.01

VOI.01

Table of Contents

Release 2.16.0

Foreword, General Safety, Revision History, Patent

Notification

Introduction 13

Site Preparation 33

How to Unpack the SC 4812ET BTS 59

Cabinet Mounting 67

Cabinet Cabling 81

What’s Next and Cleanup 119

Installing RGPS 123

Cabinet Specifications 127

Hardware Installation Quickstart 137

SC 4812ET/SC 614 BTS Power Sharing 145

SC 4812ET – SC 614/SC 614T Companion Frame

Installation

SC 4812ET to SC 4812ET Power Sharing 169

SC 4812ET – SC 4812ET Companion Frame

Installation

Installing RF GPS 181

Minimum Requirements for CSU 185

3

157

185

Apr 2001

V00.04

Index 189

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

5

Page 6

Foreword

Scope of manual

Text conventions

This manual is intended for use by cellular telephone system

craftspersons in the day-to-day operation of Motorola cellular system

equipment and ancillary devices. It is assumed that the user of this

information has a general understanding of telephony, as used in the

operation of the Public Switched Telephone Network (PSTN), and is

familiar with these concepts as they are applied in the cellular

mobile/portable radiotelephone environment. The user, however, is not

expected to have any detailed technical knowledge of the internal

operation of the equipment.

This manual is not intended to replace the system and equipment

training offered by Motorola, although it can be used to supplement or

enhance the knowledge gained through such training.

The following special paragraphs are used in this manual to point out

information that must be read. This information may be set-off from the

surrounding text, but is always preceded by a bold title in capital letters.

The four categories of these special paragraphs are:

*

NOTE

Presents additional, helpful, non-critical information that

you can use.

IMPORTANT

Presents information to help you avoid an undesirable

situation or provides additional information to help you

understand a topic or concept.

CAUTION

Presents information to identify a situation in which

equipment damage could occur, thus avoiding damage to

equipment.

WARNING

Presents information to warn you of a potentially

hazardous situation in which there is a possibility of

personal injury.

. . . continued on next page

6

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V00.04

Page 7

Changes to manual

Foreword

– continued

The following typographical conventions are used for the presentation of

software information:

S In text, sans serif BOLDFACE CAPITAL characters (a type style

without angular strokes: i.e., SERIF versus SANS SERIF) are used to

name a command.

S In text, typewriter style characters represent prompts and the

system output as displayed on an operator terminal or printer.

S In command definitions, sans serif boldface characters represent those

parts of the command string that must be entered exactly as shown and

typewriter style characters represent command output responses

as displayed on an operator terminal or printer.

S In the command format of the command definition, typewriter

style characters represent the command parameters.

Changes that occur after the printing date are incorporated into your

manual by Cellular Manual Revisions (CMRs). The information in this

manual is updated, as required, by a CMR when new options and

procedures become available for general use or when engineering

changes occur. The cover sheet(s) that accompany each CMR should be

retained for future reference. Refer to the Revision History page for a list

of all applicable CMRs contained in this manual.

Receiving updates

Technical Education & Documentation (TED) maintains a customer

database that reflects the type and number of manuals ordered or shipped

since the original delivery of your Motorola equipment. Also identified

in this database is a “key” individual (such as Documentation

Coordinator or Facility Librarian) designated to receive manual updates

from TED as they are released.

To ensure that your facility receives updates to your manuals, it is

important that the information in our database is correct and up-to-date.

Therefore, if you have corrections or wish to make changes to the

information in our database (i.e., to assign a new “key” individual),

please contact Technical Education & Documentation at:

MOTOROLA, INC.

Technical Education & Documentation

1 Nelson C. White Parkway

Mundelein, Illinois 60060

U.S.A.

Phone:

Within U.S.A. and Canada 800-872-8225. . . . .

Outside of U.S.A. and Canada +1-847-435–5700. .

FAX: +1-847-435–5541. . . . . . . . . . . . . . . . . . . . . .

. . . continued on next page

Apr 2001

V00.04

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

7

Page 8

Foreword

– continued

Reporting manual errors

24-hour support service

In the event that you locate an error or identify a deficiency in your

manual, please take time to write to us at the address above. Be sure to

include your name and address, the complete manual title and part

number (located on the manual spine, cover, or title page), the page

number (found at the bottom of each page) where the error is located,

and any comments you may have regarding what you have found. We

appreciate any comments from the users of our manuals.

If you have any questions or concerns regarding the operation of your

equipment, please contact the Customer Network Resolution Center for

immediate assistance. The 24 hour telephone numbers are:

Arlington Heights, IL 800–433–5202. . . . . . . . .

Arlington Heights, International +1–847–632–5390.

Cork, Ireland 44–1793–565444. . . . . . . . . . . . . . . .

Swindon, England 44–1793–565444. . . . . . . . . . . . .

8

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V00.04

Page 9

Remember! . . . Safety

depends on you!!

Ground the instrument

General Safety

The following general safety precautions must be observed during all

phases of operation, service, and repair of the equipment described in

this manual. Failure to comply with these precautions or with specific

warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the equipment. Motorola, Inc. assumes

no liability for the customer’s failure to comply with these requirements.

The safety precautions listed below represent warnings of certain dangers

of which we are aware. You, as the user of this product, should follow

these warnings and all other safety precautions necessary for the safe

operation of the equipment in your operating environment.

To minimize shock hazard, the equipment chassis and enclosure must be

connected to an electrical ground. The BTS must be connected to a

permanent terminal, and not via a plug to ensure a firm ground at all

times.

Do not operate in an explosive

atmosphere

Keep away from live circuits

Do not service or adjust alone

Do not operate the equipment in the presence of flammable gases or

fumes. Operation of any electrical equipment in such an environment

constitutes a definite safety hazard.

Operating personnel must:

S not remove equipment covers. Only Factory Authorized Service

Personnel or other qualified maintenance personnel may remove

equipment covers for internal subassembly, or component

replacement, or any internal adjustment.

S not replace components with power cable connected. Under certain

conditions, dangerous voltages may exist even with the power cable

removed.

S always disconnect power and discharge circuits before touching them.

Do not attempt internal service or adjustment, unless another person,

capable of rendering first aid and resuscitation, is present.

Do not substitute parts or

modify equipment

Apr 2001

V00.04

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

Because of the danger of introducing additional hazards, do not install

substitute parts or perform any unauthorized modification of equipment.

Contact Motorola Warranty and Repair for service and repair to ensure

that safety features are maintained.

9

DRAFT

Page 10

General Safety

– continued

Dangerous procedure

warnings

Warnings, such as the example below, precede potentially dangerous

procedures throughout this manual. Instructions contained in the

warnings must be followed. You should also employ all other safety

precautions that you deem necessary for the operation of the equipment

in your operating environment.

WARNING

Dangerous voltages, capable of causing death, are present in this

equipment. Use extreme caution when handling, testing, and

adjusting.

10

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V00.04

Page 11

Manual Number

Manual Title

Version Information

Revision History

68P09253A94

TM

4812ET RF and Power Cabinet Hardware Installation Manual

SC

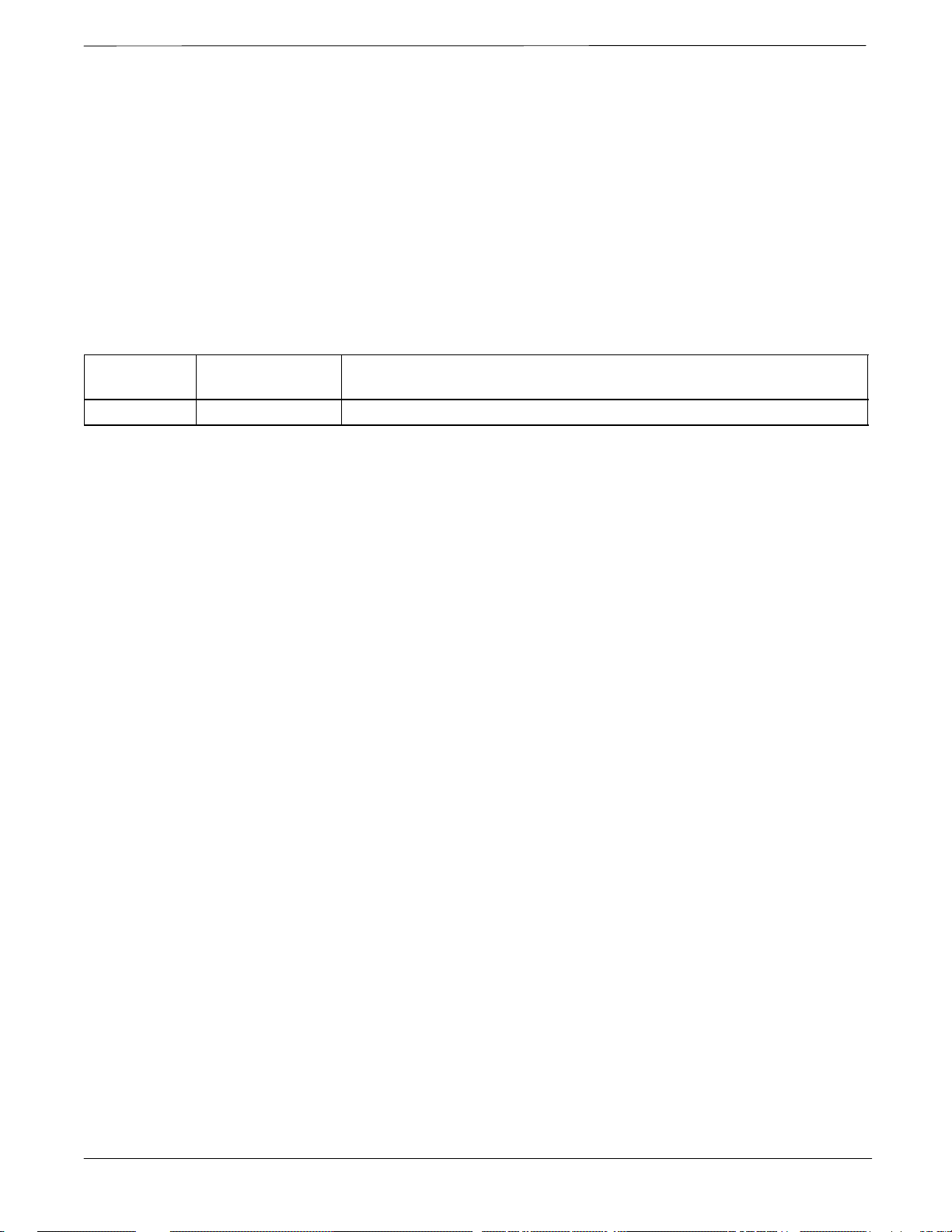

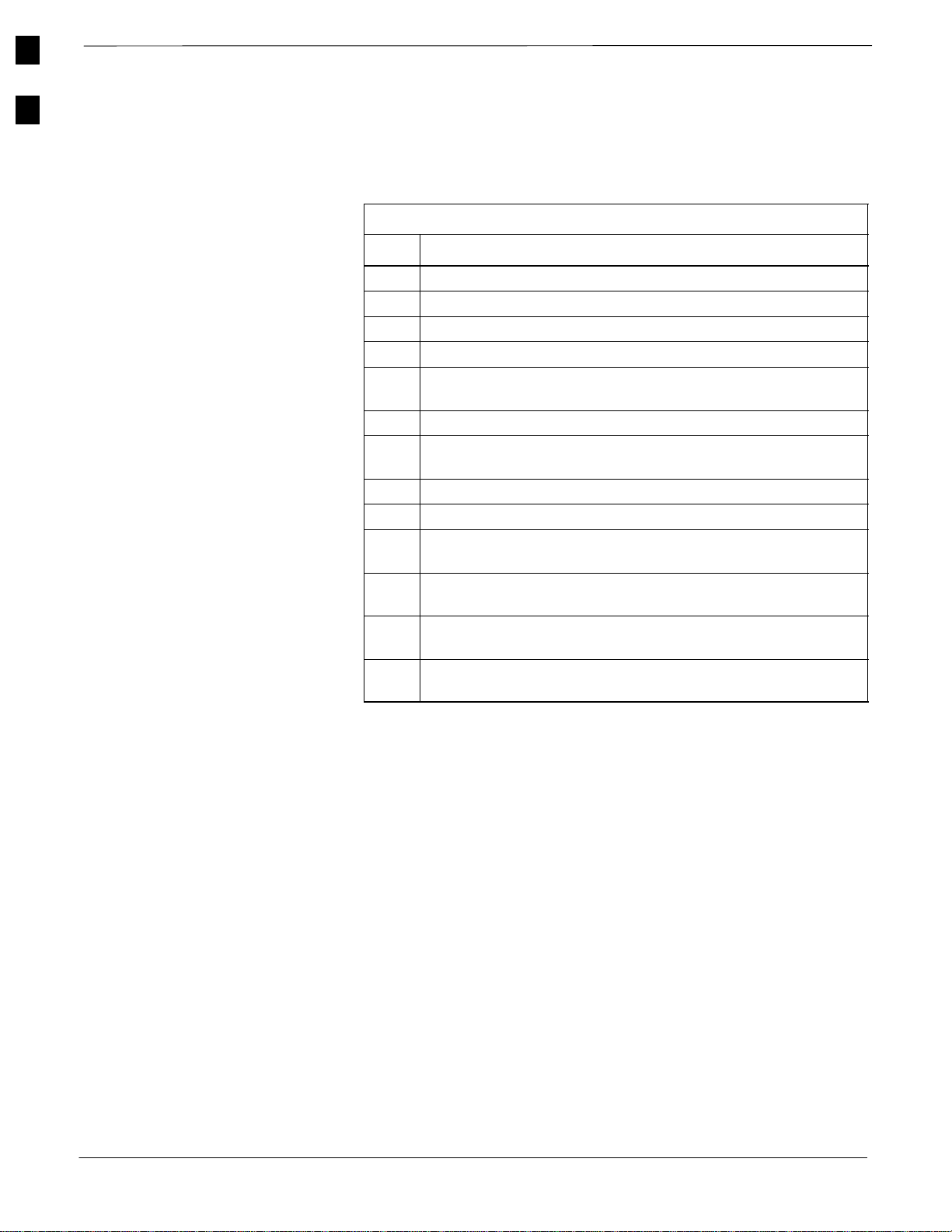

The following table lists the manual version, date of version, and

remarks on the version.

Version

Date of Issue Remarks

Level

1 Apr 2001 Original draft from engineering

Apr 2001

V00.04

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

11

Page 12

Patent Notification

Patent numbers

4128740 4661790 4860281 5036515 5119508 5204876 5247544 5301353

4193036 4667172 4866710 5036531 5121414 5204977 5251233 5301365

4237534 4672657 4870686 5038399 5123014 5207491 5255292 5303240

4268722 4694484 4872204 5040127 5127040 5210771 5257398 5303289

4282493 4696027 4873683 5041699 5127100 5212815 5259021 5303407

4301531 4704734 4876740 5047762 5128959 5212826 5261119 5305468

4302845 4709344 4881082 5048116 5130663 5214675 5263047 5307022

4312074 4710724 4885553 5055800 5133010 5214774 5263052 5307512

4350958 4726050 4887050 5055802 5140286 5216692 5263055 5309443

4354248 4729531 4887265 5058136 5142551 5218630 5265122 5309503

4367443 4737978 4893327 5060227 5142696 5220936 5268933 5311143

4369516 4742514 4896361 5060265 5144644 5222078 5271042 5311176

4369520 4751725 4910470 5065408 5146609 5222123 5274844 5311571

4369522 4754450 4914696 5067139 5146610 5222141 5274845 5313489

4375622 4764737 4918732 5068625 5152007 5222251 5276685 5319712

4485486 4764849 4941203 5070310 5155448 5224121 5276707 5321705

4491972 4775998 4945570 5073909 5157693 5224122 5276906 5321737

4517561 4775999 4956854 5073971 5159283 5226058 5276907 5323391

4519096 4797947 4970475 5075651 5159593 5228029 5276911 5325394

4549311 4799253 4972355 5077532 5159608 5230007 5276913 5327575

4550426 4802236 4972432 5077741 5170392 5233633 5276915 5329547

4564821 4803726 4979207 5077757 5170485 5235612 5278871 5329635

4573017 4811377 4984219 5081641 5170492 5235614 5280630 5339337

4581602 4811380 4984290 5083304 5182749 5239294 5285447 D337328

4590473 4811404 4992753 5090051 5184349 5239675 5287544 D342249

4591851 4817157 4998289 5093632 5185739 5241545 5287556 D342250

4616314 4827507 5020076 5095500 5187809 5241548 5289505 D347004

4636791 4829543 5021801 5105435 5187811 5241650 5291475 D349689

4644351 4833701 5022054 5111454 5193102 5241688 5295136 RE31814

4646038 4837800 5023900 5111478 5195108 5243653 5297161

4649543 4843633 5028885 5113400 5200655 5245611 5299228

4654655 4847869 5030793 5117441 5203010 5245629 5301056

4654867 4852090 5031193 5119040 5204874 5245634 5301188

This product is manufactured and/or operated under one or more of the

following patents and other patents pending:

12

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V00.04

Page 13

This section includes...

1

Chapter 1: Introduction

Product Description 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of this Document 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Overview 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Documents 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acronyms 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Hardware 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Tools 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Materials Available from Motorola 21. . . . . . . . . . . . . . . . . . . . . .

RF Cabinet External FRUs 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Cabinet Internal FRUs 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cabinet 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cabinet Internal FRUs 28. . . . . . . . . . . . . . . . . . . . . . . . . . .

Enclosure Dimensions 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enclosure Clearances 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables

Table 1-1: Acronyms 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-2: Installation Hardware Supplied with Cabinets 18. . . . .

Table 1-3: Recommended Tools 20. . . . . . . . . . . . . . . . . . . . . . . .

Table 1-4: Cables, Tools and Hardware 21. . . . . . . . . . . . . . . . . . .

Table 1-5: Cabinet Dimension 29. . . . . . . . . . . . . . . . . . . . . . . . . .

Figures

Figure 1-1: SC 4812ET Installation Hardware 19. . . . . . . . . . . . . .

Figure 1-2: SC 4812ET RF Cabinet 22. . . . . . . . . . . . . . . . . . . . .

Figure 1-3: RF Cabinet External FRUs 23. . . . . . . . . . . . . . . . . . .

Figure 1-4: SC 4812ET LPAs 23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-5: External Blower Assembly (EBA) 24. . . . . . . . . . . . .

Figure 1-6: RF Cabinet Internal FRUs 25. . . . . . . . . . . . . . . . . . .

Figure 1-7: Power Cabinet 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-8: Power Cabinet with Batteries Installed 28. . . . . . . . .

Figure 1-9: Minimum Cabinet Clearances 30. . . . . . . . . . . . . . . . .

Figure 1-10: Min. Site Clearances for SC 4812ET Cabinets 31. .

Apr 2001

V02.03

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

13

Page 14

1

Introduction

– continued

Product Description

The SC 4812ET BTS consists of an RF Cabinet that is an outdoor,

weatherized version of the SC 4812T. The RF cabinet is powered by 27

VDC and each cabinet has the capability to support up to 4 carriers (at 3

sector) or 2 carriers (at 6 sector). An optional outdoor, weatherized

Power Cabinet that provides AC/DC rectified power and battery back–up

is also available. An air to air heat exchanger is used for conditioning

each cabinet, except in the LPA area of the RF cabinet which uses

blower fans to draw outside air over the LPAs.

The SC 4812T utilizes a new RF “Trunking” technique that provides

shared power between sectors and increased RF output capability. The

SC 4812ET will support additional expansion cabinets to add more

carriers. Duplexer/Directional couplers will be standard equipment for

the SC 4812ET BTS.

The RF Cabinet houses the fan modules, Combined CDMA Channel

Processor shelf (C–CCP), Linear Power Amplifiers (LPA) modules, LPA

trunking backplane, Bandpass 2:1 & 4:1 Combiners, Duplexer/Receive

Filter/Directional Couplers (DRDC) and a DC Power distribution

assembly. The Power Cabinet (PC) provides +27 V DC distribution and

battery backup for the SC 4812ET. The Power Cabinet houses batteries,

battery heaters, rectifiers, an AC Load Center (ACLC), a power

distribution assembly, and two duplexed GFCI convenience outlets.

Scope of This

Document

Manual Overview

This document provides information pertaining to the installation of the

Motorola SC4812ET CDMA Base Transceiver Subsystem (BTS) and

optional equipment. The basic frame installation is described in the RF

and Power Cabinet mounting chapter. Expansion cabinet information

will be included in future manual revisions.

For detailed installation information of non–Motorola equipment, refer

to the vender manuals provided with such equipment.

Chapter 1 – “Introduction” – This chapter describes manual contents,

recommended documents, supplied and recommended tools and

hardware, and equipment identification.

Chapter 2 – “Site preparation” – This chapter details preparing the site

(concrete pad, rooftop, etc.) for RF and Power Cabinet installation,

location considerations, pad and roof mounting instructions, and ground

system information.

14

Chapter 3 – “How to Unpack the SC 4812ET BTS” – This chapter

contains information on how to unpack the RF and Power Cabinet and

how to inspect for damage.

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 15

Introduction

– continued

Chapter 4 – “Cabinet Mounting” – This chapter covers cabinet

preparation, rooftop (elevated) and concrete pad mounting, and battery

installation.

Chapter 5 – “Cabinet Cabling” – This chapter contains procedures for

cabling the RF and Power Cabinet. This includes earth ground, alarm &

span line, RGPS, RF GPS, LFR, RF, AC power, DC power, and other

cabling considerations.

Chapter 6 – “What’s Next and Cleanup” – This chapter includes site

cleanup and a pre–optimization checklist.

Appendix A – “Installing RGPS”— This appendix covers the mounting

and installation of the RGPS hardware.

Appendix B – “Cabinet Specifications”— This appendix covers the

basic specifications of the SC 4812ET RF Cabinet and Power Cabinet.

Appendix C – “Installation Quickstart” – A quick reference quide to the

installation of the SC 4812ET BTS.

1

Recommended

Documents

Appendix D – “SC 4812ET/SC 614 BTS DC Power Sharing” – This

appendix covers the instructions for powering both the SC 4812ET RF

Cabinet and the SC 614T BTS from one SC 4812ET Power Cabinet.

Appendix E – “SC 4812ET – SC 614/SC 614T Companion Frame

Installation” – This appendix covers the instructions for converting the

existing SC 614T site from a starter frame to an expansion frame.

Appendix F – “SC 4812ET to SC 4812ET DC Power Sharing” – This

appendix covers the instructions for cabling a SC 4812ET Power

Cabinet to two 4812ET RF Cabinets.

Appendix G – “SC 4812ET – SC 4812ET Companion Frame

Installation” – This appendix covers the instructions for connecting a

starter frame to an expansion frame.

Appendix H –“Installing RF GPS”

Appendix I – “Minimum Requirements for Customer purchased CSU”

Apr 2001

V02.03

The following documents are recommended to perform the installation

of the cell site equipment:

S SC 4812ET CDMA Optimization (Motorola part number

68P09253A74)

S SC 4812ET Field Replaceable Unit (FRU) Identification Guide

(Motorola part number 68P09253A48)

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

15

Page 16

1

Introduction

– continued

S Site Document (generated by Motorola Systems Engineering) which

includes:

– trial specific documentation

– channel allocation

– contact list (customer)

– ancillary/expendable equipment list

– site wiring lists

– card placement

– contact list (Motorola support)

– job box inventory

S Demarcation Document (Scope of Work agreement)

S Grounding Guidelines for Cellular Radio Installations (Motorola part

number 68P81150E62)

S Installation manuals for non-Motorola equipment (for reference

purposes only).

Acronyms

Table 1-1 defines the acronyms used in this manual.

Table 1-1: Acronyms

Acronym Definition

AMR Alarm Monitoring and Reporting Card

AWG American Wire Gauge

BBX–1X Broadband Transceiver Cards

BSS Base Station System

BTS Base Transceiver Subsystem

BSWG British Standard Wire Gauge

CBSC Centralized Base Station Controller

CCD CDMA Clock Distribution card

C–CCP Combined CDMA Channel Processor

CDMA Code Division Multiple Access

CHI Concentration Highway Interface

CIO Combiner Input/Output

CSM Clock Synchronization Manager

CSU Channel Service Unit

DRDC Duplexer/Receiver Filter/Directional Coupler

DS1 One Time Slot on T1 Span Line

EBA External Blower Assembly

EMX Electronic Mobile Exchange

EMPC Expansion Multicoupler Preselector Card

. . . continued on next page

16

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 17

Introduction

– continued

Table 1-1: Acronyms

Acronym Definition

EMPC6 Expansion Multicoupler Preselector Card (for 6–sector)

ETIB SC 4812ET Interface Board

FRU Field Replaceable Unit

GLI2 Group Line Interface 2

GPS Global Positioning Subsystem

GFCI Ground Fault Circuit Interrupter

HSO High Stability Oscillator

HSOX High Stability Oscillator Expansion Board

IIP3 Input Intercept Point

ISB Inter–shelf Bus

LAPD Link Access Protocol “D”

LAN Local Area Network

LPA Linear Power Amplifier

LPAC LPA Control Board

LFR Low Frequency Receiver

LMF Local Maintenance Facility

MCC–1X Multi–channel CDMA Card

MMI Man–Machine Interface

MPC Multicoupler/Preselector Card

MGB Main Ground Bar

OSP Outside plant

PB Punch Block

PCSC Personal Communications Switching Center

PSTN Public Switched Telephone Network

PN Pseudo–Random Noise

POTS Plain Old Telephone System

PS Power Supply

RGD Remote GPS Distribution

RGPS Remote Global Positioning System (GPS) Receiver

RFDS Radio Frequency Diagnostic Subsystem

RX Receive

SS Stainless Steel

SAPB Stand Alone Pilot Beacon

STLPA Single Tone Linear Power Amplifier

STRAU SuperCell Transcoder Rate Adaption Unit

TCH Traffic Channel

1

Apr 2001

V02.03

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

17

Page 18

1

Introduction

– continued

Installation Hardware

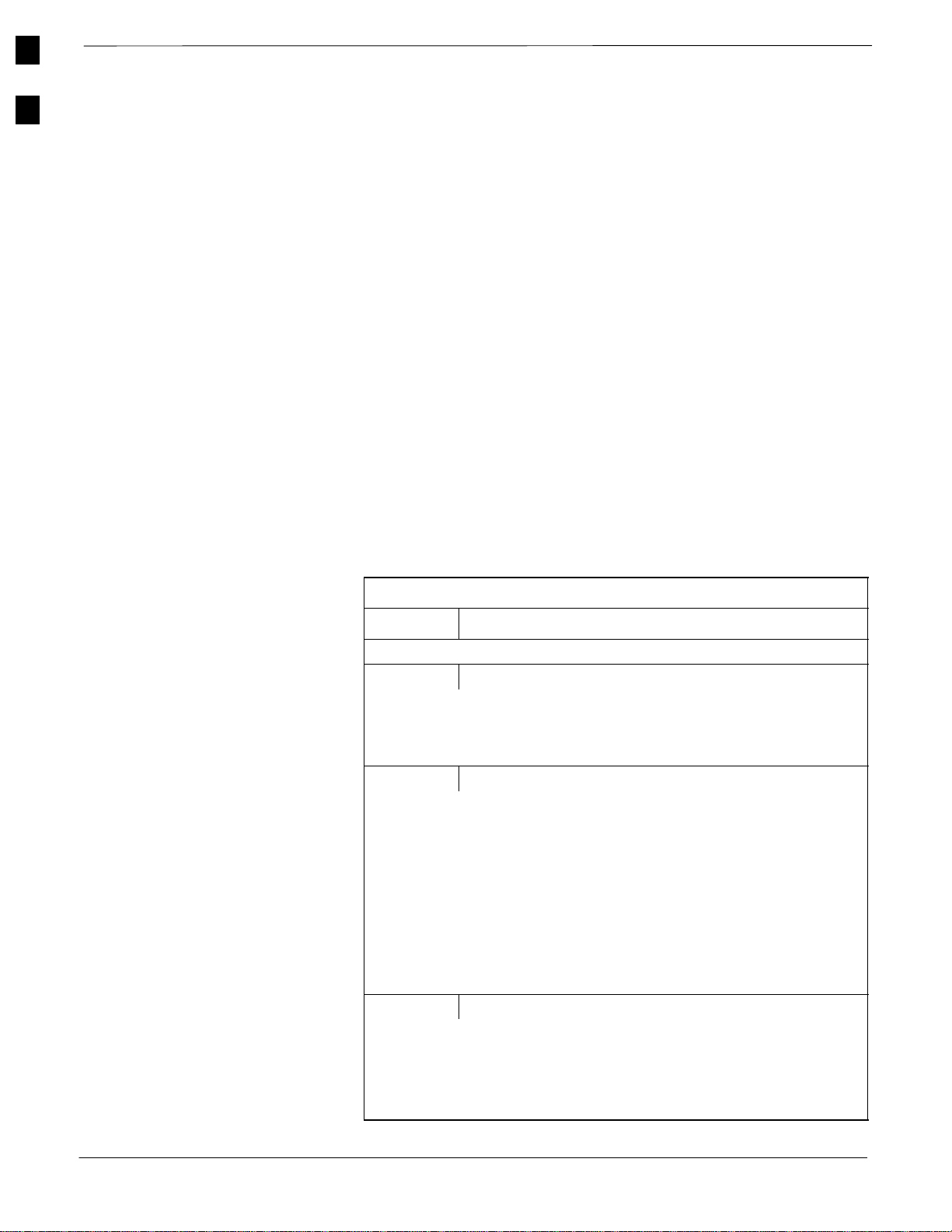

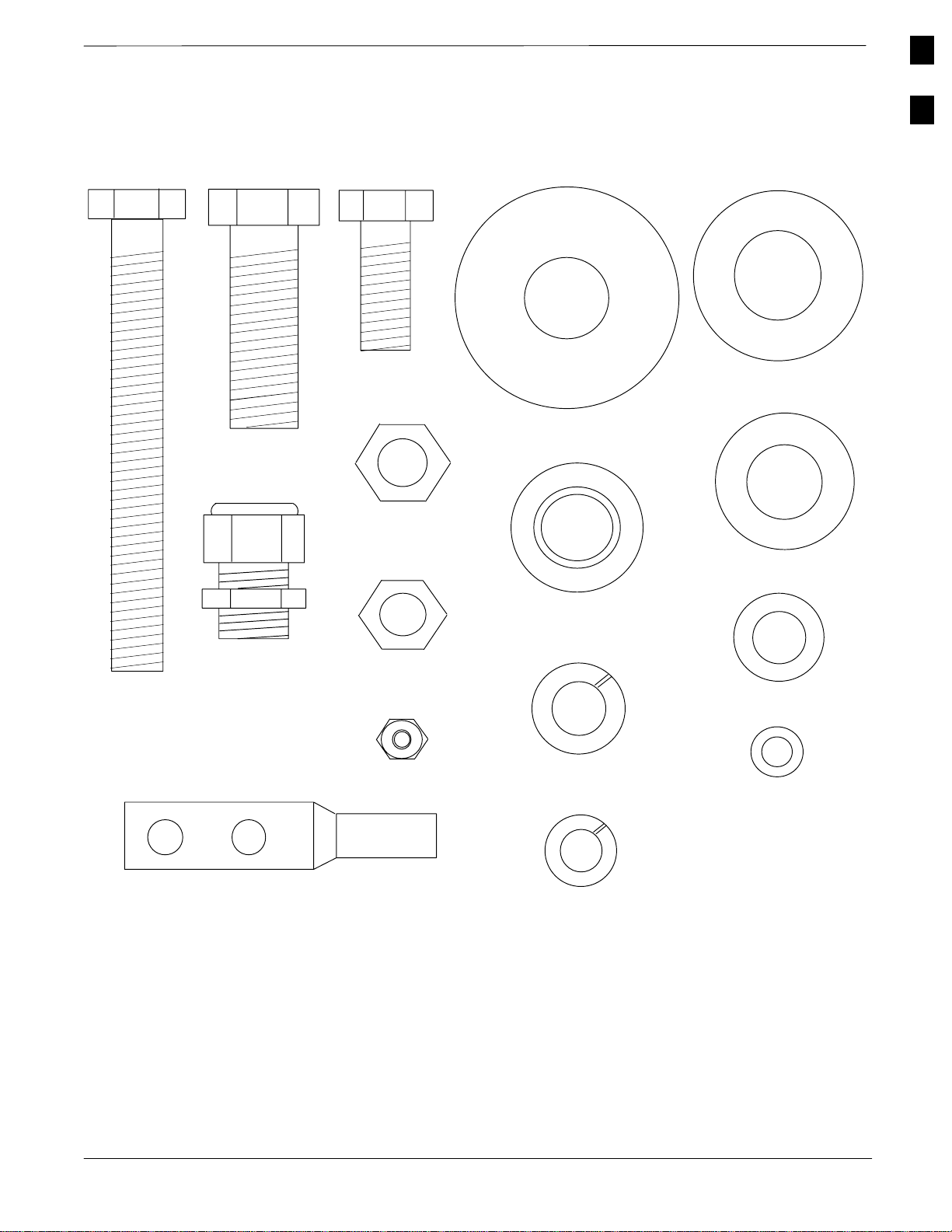

Table 1-2 shows the quantity and description of the installation hardware

that is shipped with the RF Cabinet and with the Power Cabinet.

Figure 1-1 is a template guide for identifying the parts.

Table 1-2: Installation Hardware Supplied with Cabinets

RF Power Description

1 1 7/16” Hex Tool

1 1 ESD Wrist Strap

4 4 Cabinet Mounting Brackets

8 8 M12 x 30 Bolts (for Mounting Brackets)

4 4 Insulating Shoulder Washer (for Mounting Bolts)

4 4 5/8” Bolts (to replace eye bolts)

1 1 Compression Lug (for #2 AWG Ground Wire)

2 2 M6 Stainless Steel Locking Hex Nuts (for Ground Lug)

4 4 M12 x 100 Bolt

4 16 M12 Flat Washer

4 4 M12 Lock Washer

4 4 M12 Nut

1 1 Motorola Ivory Touch–Up Paint

2 2 M6 Flat Washer

6 6 M10 Nut

6 6 M10 Flat Washer

6 6 M10 Lock Washer

4 4 5/8” Flat Washer

4 4 Large Flat Washer

1 – Weatherseal Bushing and Nut for RGPS Cable

1 – MMI Cable

– 12 Battery Terminal Straps

– 3 #2/0 AWG INS WELD Cable (Red)

– 3 #2/0 AWG INS WELD Cable (Black)

– 12 90° Compression Lug (for #2/0 AWG DC Cable)

– 1 Twisted Pair Cable (for Power Cabinet Alarms to RF Cabinet)

18

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 19

Figure 1-1: SC 4812ET Installation Hardware

Introduction

– continued

1

M12 X 100

5/8” BOLT

WEATHERSEAL

BUSHING & NUT

M12 X 30 BOLT

M12 NUT

M10 NUT

M6 NYLON

LOCKING NUT

LARGE FLAT

WASHER

INSULATION SHOULDER

WASHER

M12 LOCK

WASHER

5/8” FLAT

WASHER

M12 FLAT

WASHER

M10 FLAT

WASHER

M6 FLAT WASHER

Apr 2001

V02.03

COMPRESSION LUG (FOR

#2 AWG GROUND WIRE)

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

FW00468

M10 LOCK

WASHER

19

DRAFT

Page 20

1

Introduction

– continued

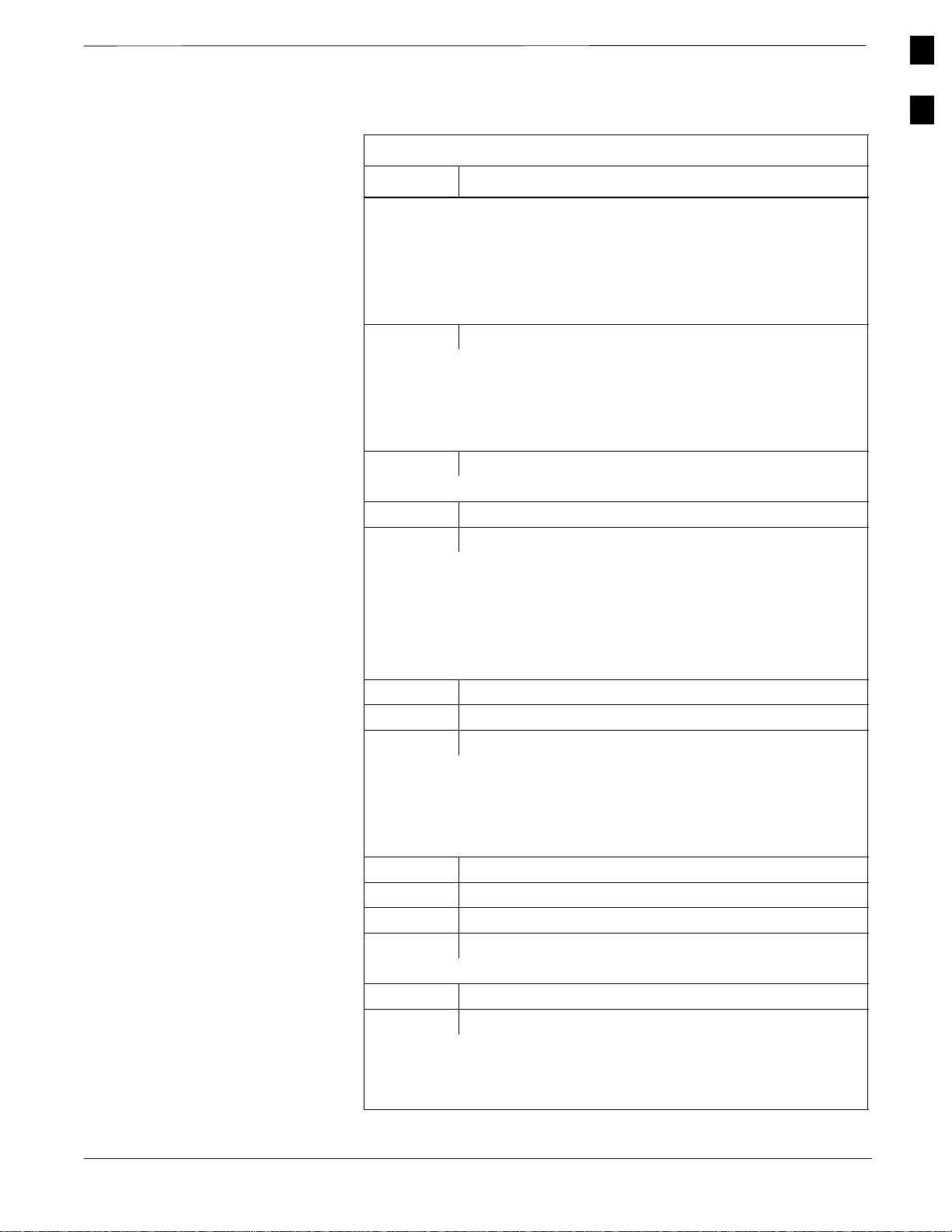

Recommended Tools

Table 1-3 lists tools recommended for installing RF and Power Cabinets.

Table 1-3: Recommended Tools

Item Tool Description

1 Tin Snips

2 Wire Brush

3 Knife or Scissors

4 10 mm Nut Driver

5 19 mm (3/4”) Open ended Torque Wrench (for N–type

connector)

6 110 Style Punch Block Termination Tool

7 Thomas & Betts TBM14 Hydraulic crimping tool with color

keyed crimp die set (or equivalent)

8 Drill Motor

9 18 mm (11/16”) Masonry Drill Bit

10 Ratchet Handle with 19 mm (3/4”) Socket (Deep Socket or

Ratchet Extension required).

11 Torque Driver (Torque Range: 5–135 N–m [4–100 ft–lbs])

with 19 mm (3/4”) and 10 mm Socket

12 Torque wrench for SMA’s Mountz Inc. MTBN2 (Part number

020314) with 5/16” open end head (Part number 020402).

13 Copper–based Conductive Grease (Berndy “Penetrox” or

equivalent).

20

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 21

Materials Available from Motorola

Introduction

– continued

Table 1-4 lists tools and materials available from Motorola. The items

are identified by the Motorola assigned part number and include a brief

description. These items can be ordered from your sales account team.

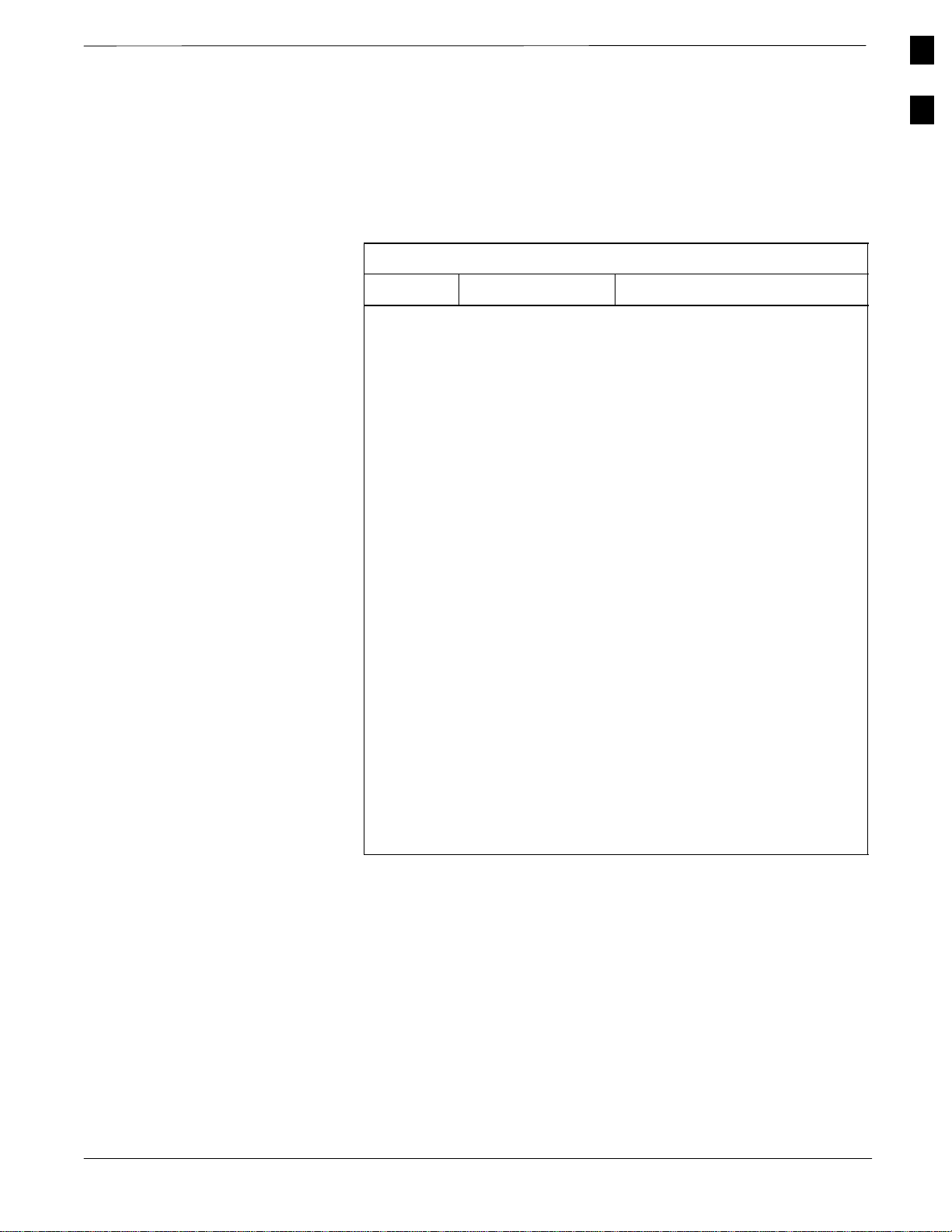

Table 1-4: Cables, Tools, and Hardware

Material Part Number Description

CGDSRG142BU RG – 142 COAX by the foot

SGDN4232A 1/2” LDF Heliax by the foot

SGDN4234A 7/8” LDF Heliax by the foot

SGDN4235A 1–1/4” LDF Heliax by the foot

SGDN4233A 1–5/8” LDF Heliax by the foot

CGDSFSJ450B 1/2” Superflex Heliax by the foot

CGDSFSJ150A 1/4” Superflex Heliax by the foot

Cables

Tools

Hardware

CGTDN7023A Transmission Line Kit for 1/2”

LDF Heliax

CGTDN7025A Transmission Line Kit for 7/8”

LDF Heliax

CGTDN7027A Transmission Line Kit for 1–5/8”

LDF Heliax

CGDS241148 1/2” Superflex Jumper – 30 ft. (1

N Male terminated, 1 N Male

non–terminated)

CGDSICPVC25FT 25 Twisted pair cable – 24 AWG

CGDS237776 110 Punchdown Tool (Handle

only)

CGDS237176 Replacement Blade for use with

110 Punchdown Tool

CGDSTBM25S Crimp Tool for Compression Lug

CGDS97400036 Earthquake Expansion type An-

chor Bolt

1

Apr 2001

V02.03

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

21

Page 22

1

Introduction

– continued

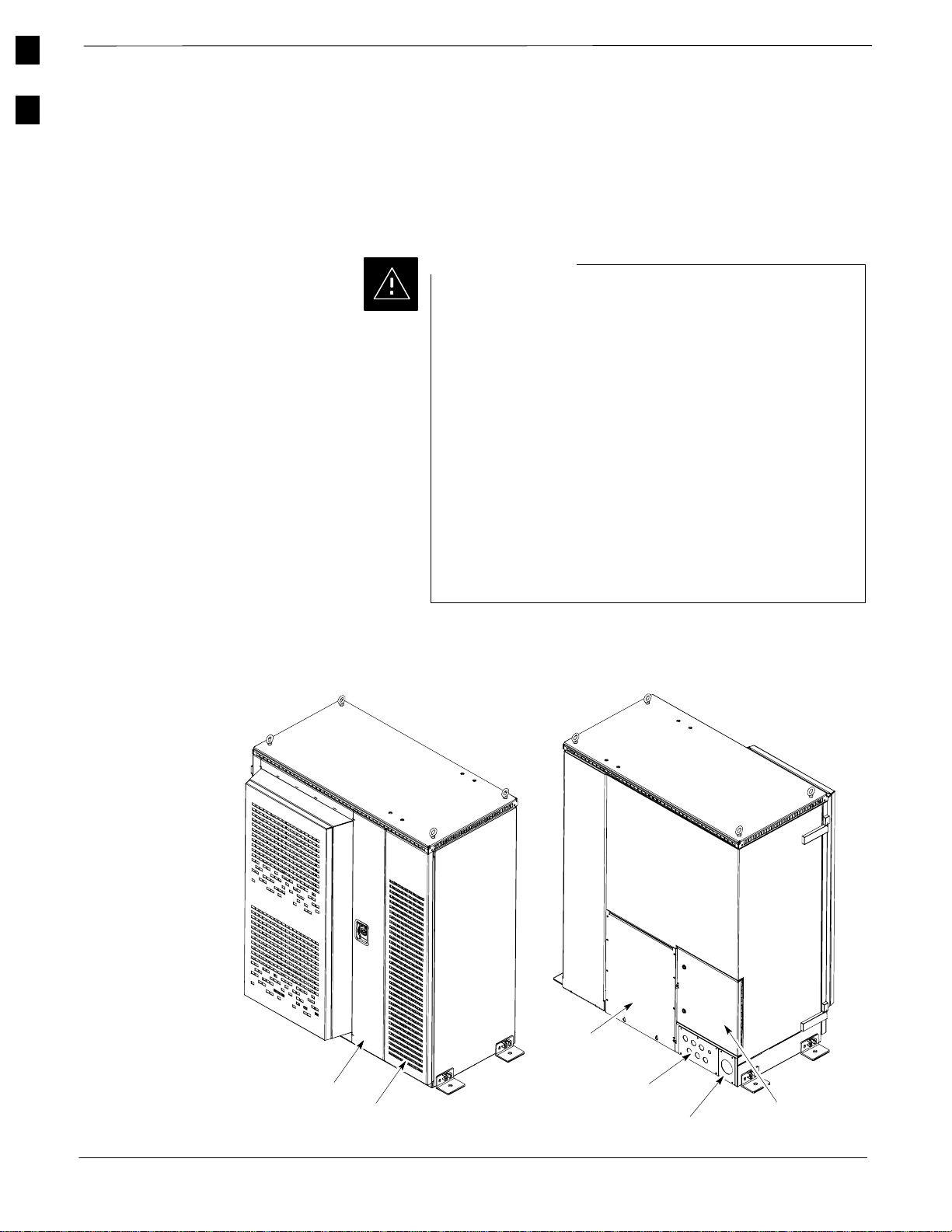

Overview

The major components which make up the Motorola SC 4812ET RF

Cabinet (see Figure 1-2) and Power Cabinet (see Figure 1-7) system are

illustrated in this section.

CAUTION

A service tent [reference: Pelsue Cabinet Mounted Service

Tent; Pelsue (800–525–8460) P/N CM564866M] must be

in place prior to opening the main doors of the SC 4812ET

RF or Power Cabinet during times of inclement weather

(rain, snow, sleet, or hail). This will prevent moisture from

being drawn into the electronics by internal fans and

damaging the equipment.

A service tent [reference: Pelsue Cabinet Mounted Service

Tent; Pelsue (800–525–8460) P/N CM564866M] with a

heater is required to service the SC 4812ET RF Cabinet

when temperatures are below –10 degrees C (14 degrees

F). Temperatures inside the tent should be above 0 degrees

C (32 degrees F) prior to opening the main cabinet door.

This will prevent a rapid temperature change to the

electronics which could result in site outage.

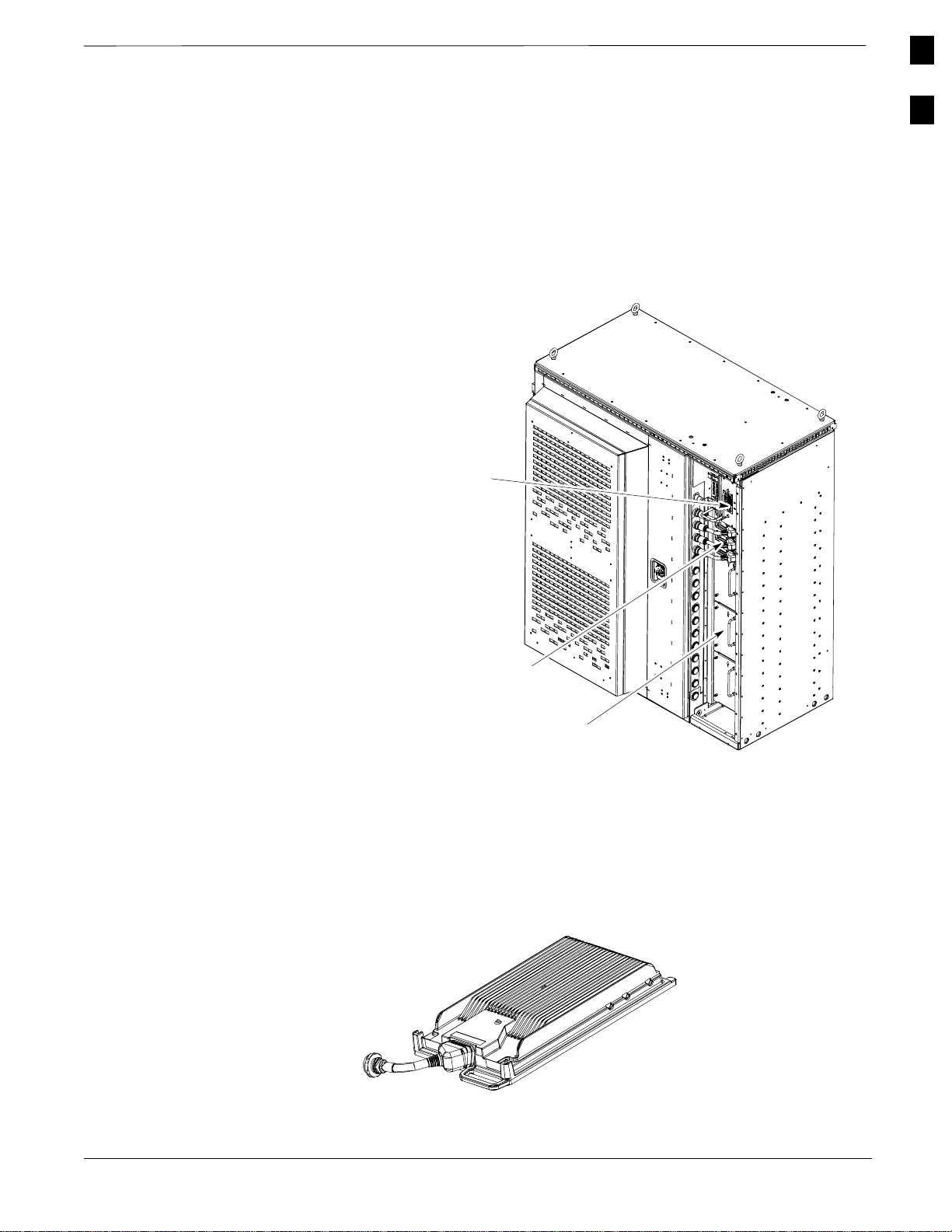

Figure 1-2: SC 4812ET RF Cabinet

Main Door

LPA Door

(Can only be opened after Main Door is open)

RF I/O

Area Cover Plate

Rear Conduit Panel

Rear DC Conduit Panel

Rear I/O Door

FW00189

22

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 23

RF Cabinet External

FRUs

Figure 1-3: RF Cabinet External FRUs

Introduction

– continued

Figure 1-3 shows the location of the External Field Replaceable Units in

the RF Cabinet. A brief description of each External FRU is found in the

following paragraphs.

External Blower

Assembly (EBA)

1

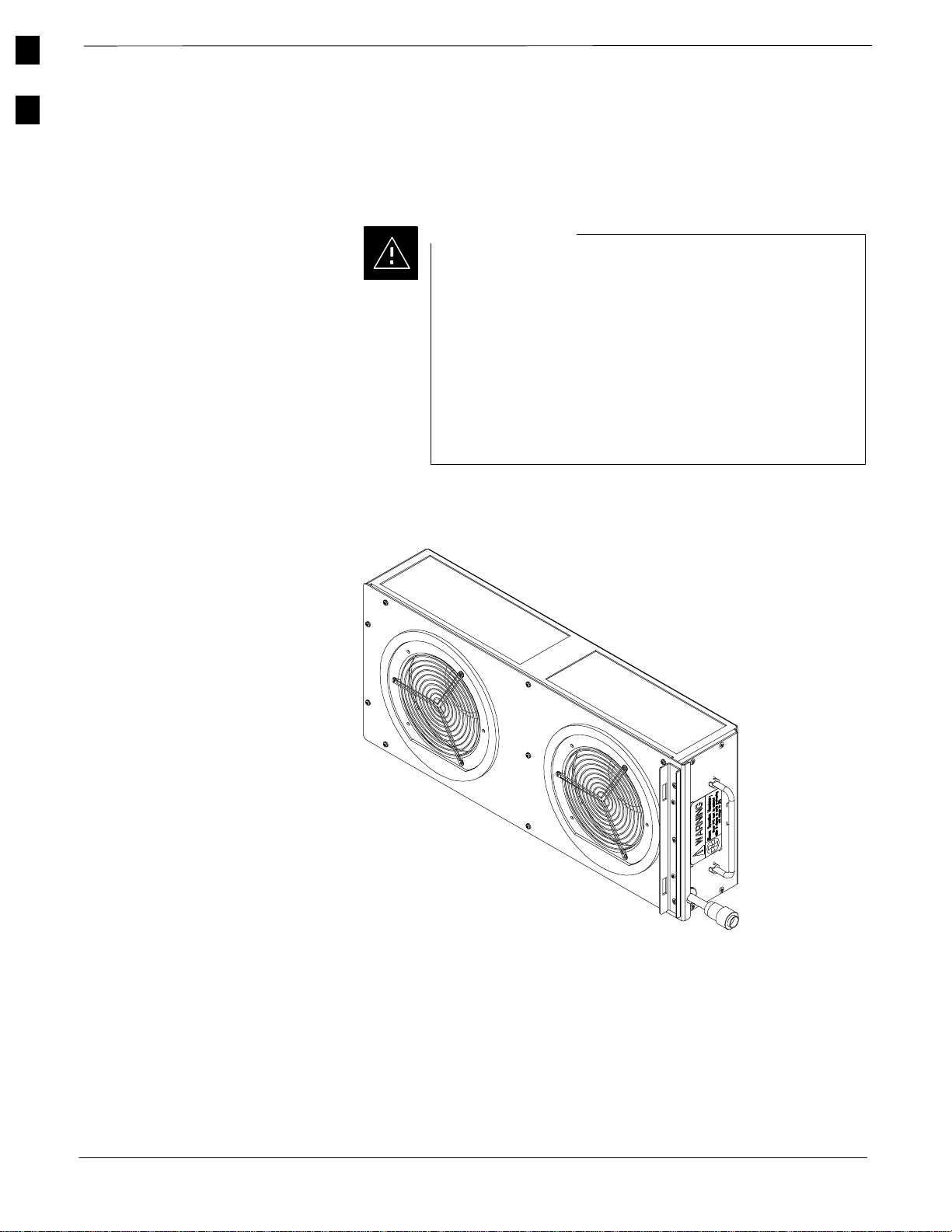

Figure 1-4: SC4812ET LPA

Note:

LPA Compartment

door not shown for

clarity

LPA

Unpopulated LPA

Shelf Cover

FW00190

Linear Power Amplifier (LPA)

The LPA (See Figure 1-4) amplifies RF signals for transmission via the

antenna. The SC 4812ET can accommodate up to 16 LPA’s. The actual

number of LPA’s present depends upon RF Cabinet configuration.

Apr 2001

V02.03

FW00191

. . . continued on next page

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

23

Page 24

1

Introduction

– continued

External Blower Assembly (EBA)

The External Blower Assembly (see Figure 1-5) is a modular unit that

provides cooling to the LPA’s, two blowers are used in the RF Cabinet.

Figure 1-5: External Blower Assembly (EBA)

CAUTION

The EBA contains two blowers and provides cooling that

is VITAL to prevent service outage and possible damage

to the LPAs. Since the SC 4812ET can continue to operate

normally with one functional blower in the EBA, the EBA

should not be removed until the replacement EBA is

onsite. Then, the EBA is replaced as a unit while the RF

cabinet is running. The replacement must be done within 3

minutes to prevent damage to the LPAs. Refer to the SC

4812ET FRU Guide for details regarding FRU

replacement.

24

FW00192

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 25

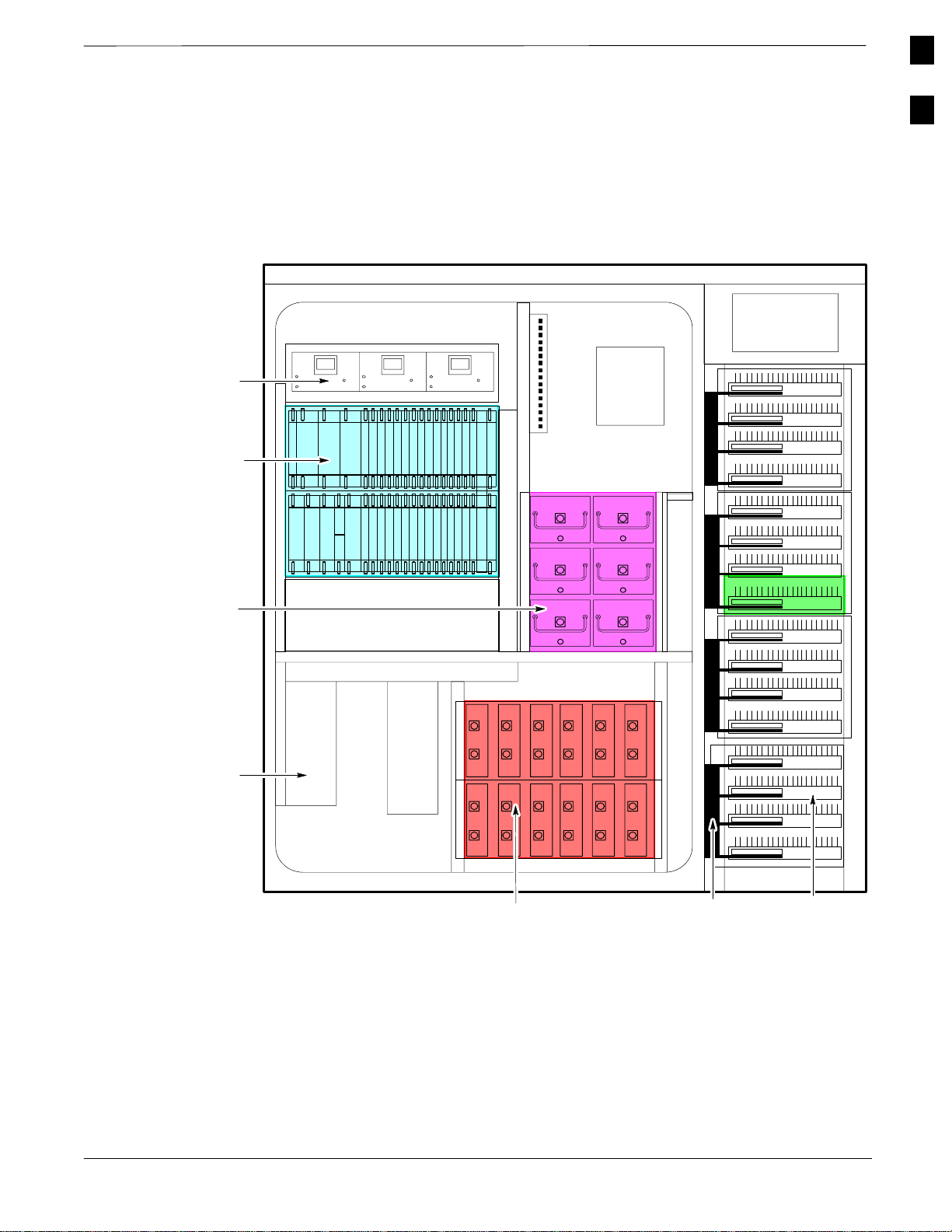

RF Cabinet Internal FRUs

Figure 1-6: RF Cabinet Internal FRUs

Introduction

– continued

Figure 1-6 shows the location of the Internal Field Replaceable Units. A

brief description of each Internal FRU is found in the following

paragraphs.

1

CCP Fans

C–CCP Shelf

Combiner

Cage

Circuit

Breaker Panel

DC

Power

Dist.

5 RU Rack Space

OPTIONAL AREA

Punch

Block

(back)

ETIB

EBA

RFDS

Apr 2001

V02.03

DRDC/TRDC

LPA Trunking

Backplane

Duplexer/Directional Coupler (DRDC)

The DRDC combines, in a single module, the functions of antenna

duplexing, receive band pass filtering, and surge protection.

TX Filter/RX Filter/Directional Coupler (TRDC)

The TRDC is the same as the DRDC but has a separate antenna

connector for TX and RX operation. The TRDC is not available in the

1.9 GHz band.

. . . continued on next page

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

LPA’s

FW00163

25

Page 26

1

Introduction

– continued

Combiner Cage (2:1, 4:1, or Band pass Filter)

The Combiner Cage holds the transmit band pass filters, 2:1 combiners,

or 4:1 combiners, depending on system configuration.

Combined CDMA Channel Processor (C–CCP) Shelf

The C–CCP shelf contains the following:

S High Stability Oscillator (HSO)/LFR (Optional) card

S Clock Synchronization Manager (CSM) on 2 cards (one with GPS

receiver if ordered).

S CDMA Clock Distribution (CCD) cards (2)

S Power Supply cards (2 minimum, 3 maximum)

S Multicoupler Preselector Cards (MPC) (2)

S Alarm Monitoring and Reporting (AMR) cards (2)

S Multi Channel CDMA [MCC–1X (8E or 24), MCC–1X (8E/24)]

cards (up to 12)

S Broadband Transceiver (BBX–1X) cards (up to 13)

S Combined Input/Output (CIO) (1)

S Group Line Interface (GLI2) cards (2)

S BBX2 Switch card (1)

S Modem (optional)

S Filler Panels

S Fan Module (3)

Punch Block

The Punch Block is the interface point of the RF Cabinet between the

T1/E1 span lines, the Customer I/O, alarms, multi–cabinet timing

(RGPS and RHSO), and Pilot Beacon control (optional).

Span I/O Board

The Span I/O Board provides the interface for the span lines from the

CSU to the C–CCP backplane.

RF Diagnostic Subsystem (RFDS)

The RFDS provides the capability for remotely monitoring the status of

the SC 4812ET RF Transmit and Receive paths.

SC 4812ET Interface Board (ETIB) & LPA Control Brd (LPAC)

The ETIB is an interconnect board showing status LEDs for the RF

Cabinet, as well as providing secondary surge protection. The LPAC

board provides the interface for the LPA connection.

SC 4812ET Trunking Backplane

The Trunking Backplane contains a complex passive RF network that

allows RF signals to share the resources of a bank of four LPAs. It also

provides DC Power and digital interconnect.

26

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 27

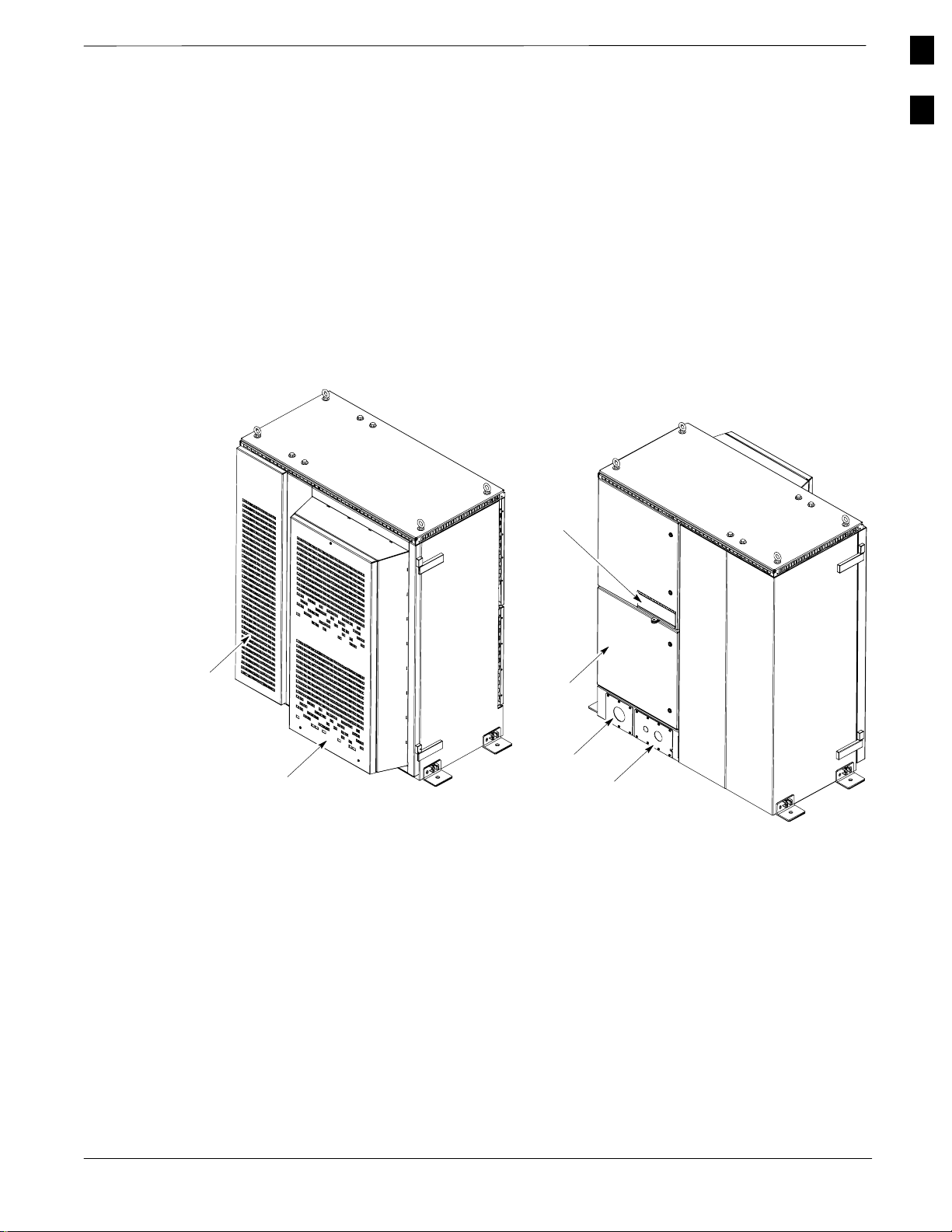

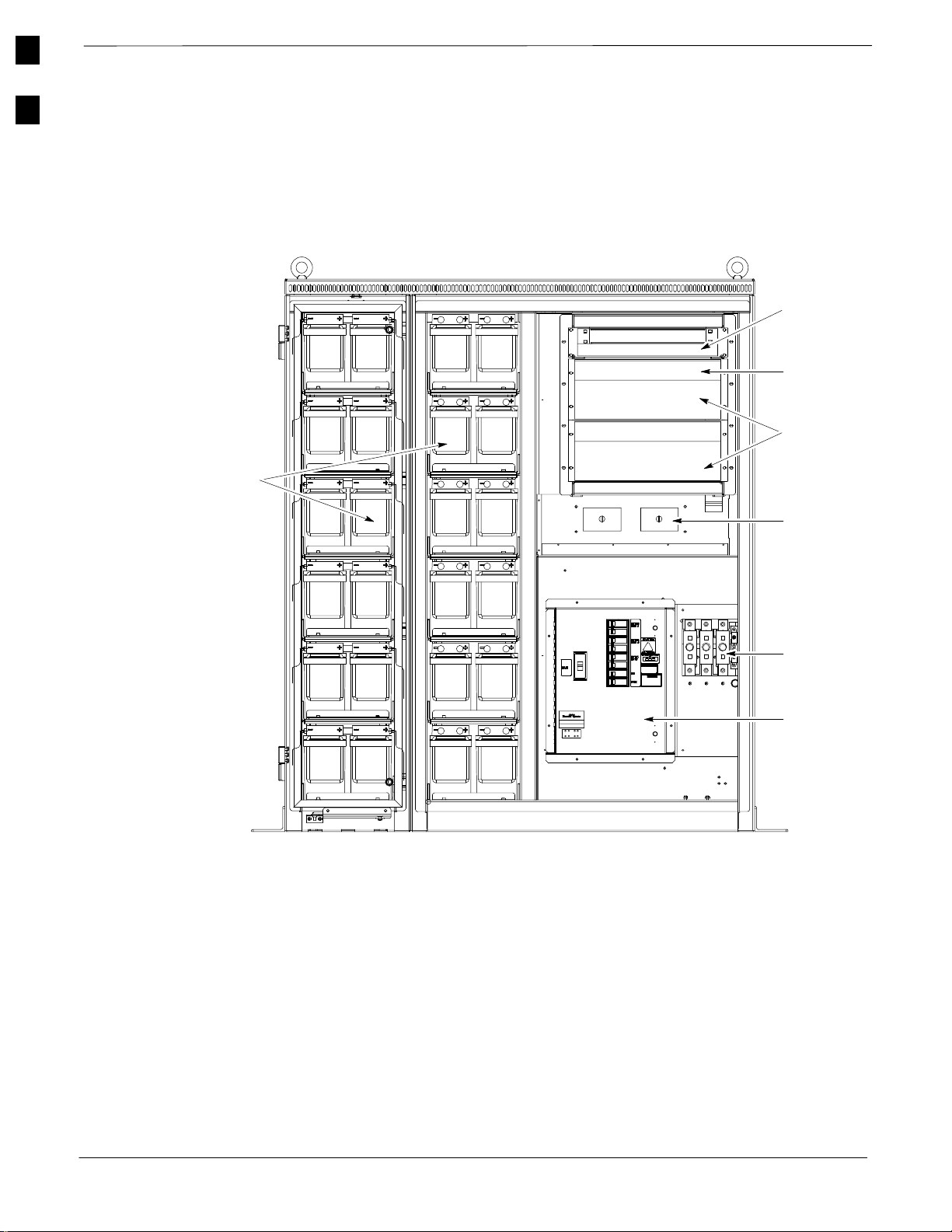

Power Cabinet

Figure 1-7: Power Cabinet

Introduction

– continued

Heat Exchanger

The Heat Exchanger provides cooling to the internal compartment of the

RF Cabinet. The fan speed of the heat exchangers adjusts automatically

with temperature. The Heat Exchanger is located in the primary front

door of the RF Cabinet.

Figure 1-7 illustrates the Power Cabinet design.

GFCI Outlet

Cover

1

Battery Door

Main Door

Rear I/O

Door

Rear DC

Conduit Panel

Rear AC Conduit

Panel

FW00193

Apr 2001

V02.03

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

27

Page 28

1

Introduction

– continued

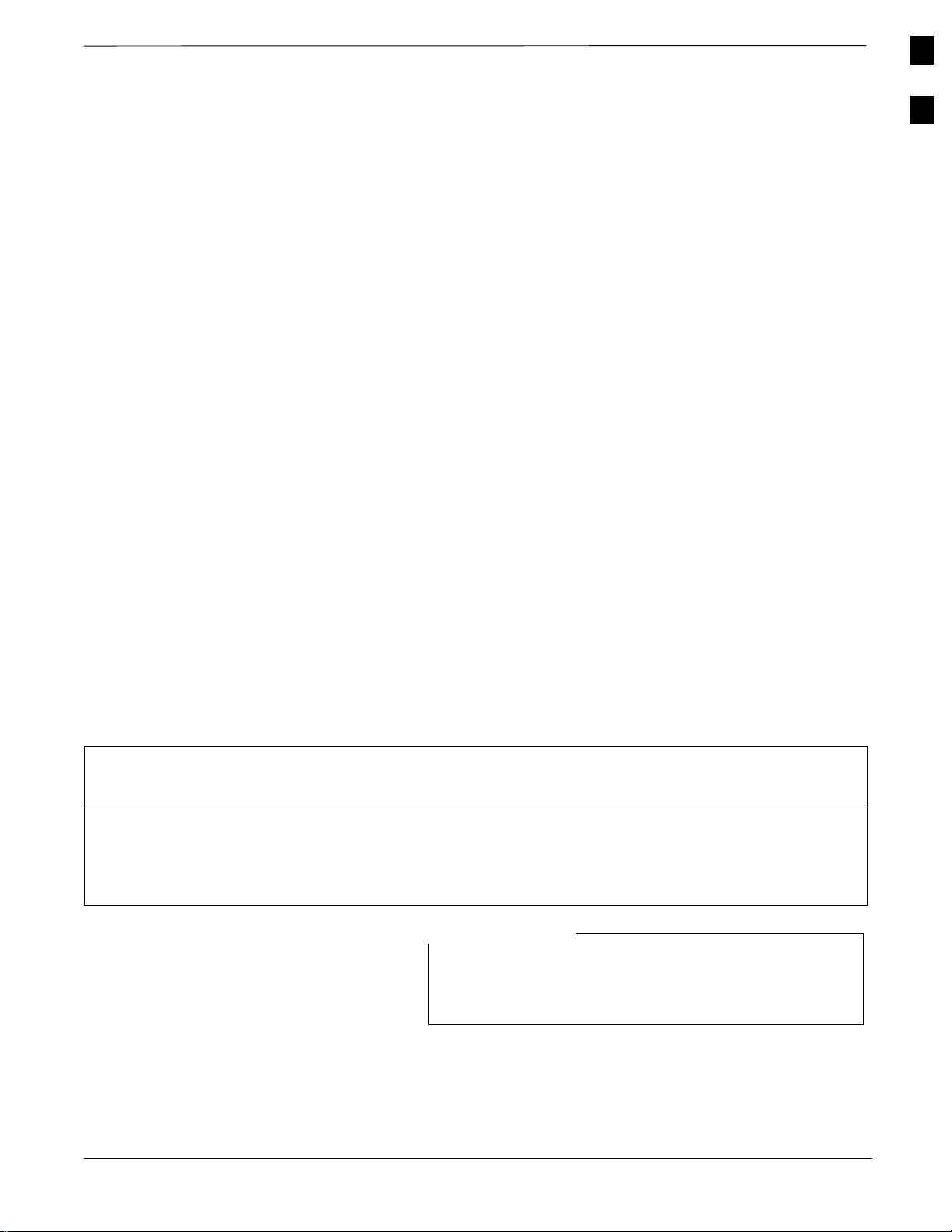

Power Cabinet Internal FRUs

Figure 1-8 shows the location of the Internal Field Replaceable Units.

The FRUs are described in the following paragraphs.

Figure 1-8: Power Cabinet with Batteries Installed (Doors Removed for Clarity)

Rectifier

Alarm

Module

Temperature

Control

Module

Rectifier

Batteries

(Battery

Heaters

located under

batteries)

Shelves

AC Outlet

Cover

NOTE

Punch Block

is not visible

in this view.

DC

Circuit

Breakers

AC

Load

Center

FRONT VIEW POWER CABINET

FW00164

Batteries

The batteries provide a +24V DC backup to the RF Cabinet should AC

Power be lost. The Power Cabinet can accommodate a total of 24 12V

batteries, configured in 12 strings of 2 batteries each. The time duration

of backup provided depends on system configuration.

Battery Heater

28

The battery heaters provide heating to the batteries in the Power Cabinet.

A separate heater is required for each string of batteries. The heater is a

pad the batteries sit on located top of each battery shelf. The number of

heaters is dependent on system configuration.

. . . continued on next page

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 29

Introduction

– continued

Battery Compartment Fan

The battery compartment fan provides air circulation for the two battery

compartments. It is located on the inside of the battery compartment

door.

Heat Exchanger

The Heat Exchanger provides cooling to the rectifier compartment of the

Power Cabinet. The Heat Exchanger is located in the primary front door

of the Power Cabinet.

Rectifiers

The +27V rectifiers convert the AC power supplied to the Power Cabinet

to +27V DC to power the RF Cabinet and maintain the charge of the

batteries.

AC Load Center (ACLC)

The ACLC is the point of entry for AC Power to the Power Cabinet. It

incorporates AC power distribution and surge protection.

1

Enclosure Dimensions

Height Width Item Depth Weight (Max)

1677 mm

(66”)

1677 mm

(66”)

1423 mm

(56”)

1423 mm

(56”)

Punch Block

The Punch Block is the interface for the alarm signalling between the

Power Cabinet and the RF Cabinet.

Table 1-5 show the dimensions for the SC 4812ET RF and Power

Cabinet enclosures.

Table 1-5: Cabinet Dimensions

SC4812ET RF Cabinet

Power Cabinet

NOTE

The primary front door of the RF Cabinet and both front

doors of the Power Cabinet are removable. The depth of

the cabinets with the door(s) removed is 711 mm (28”).

915 mm

(36”)

965 mm

(38”)

680 kg

(1500 lbs)

1590 kg

(3500 lbs)

Apr 2001

V02.03

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

29

Page 30

1

Introduction

– continued

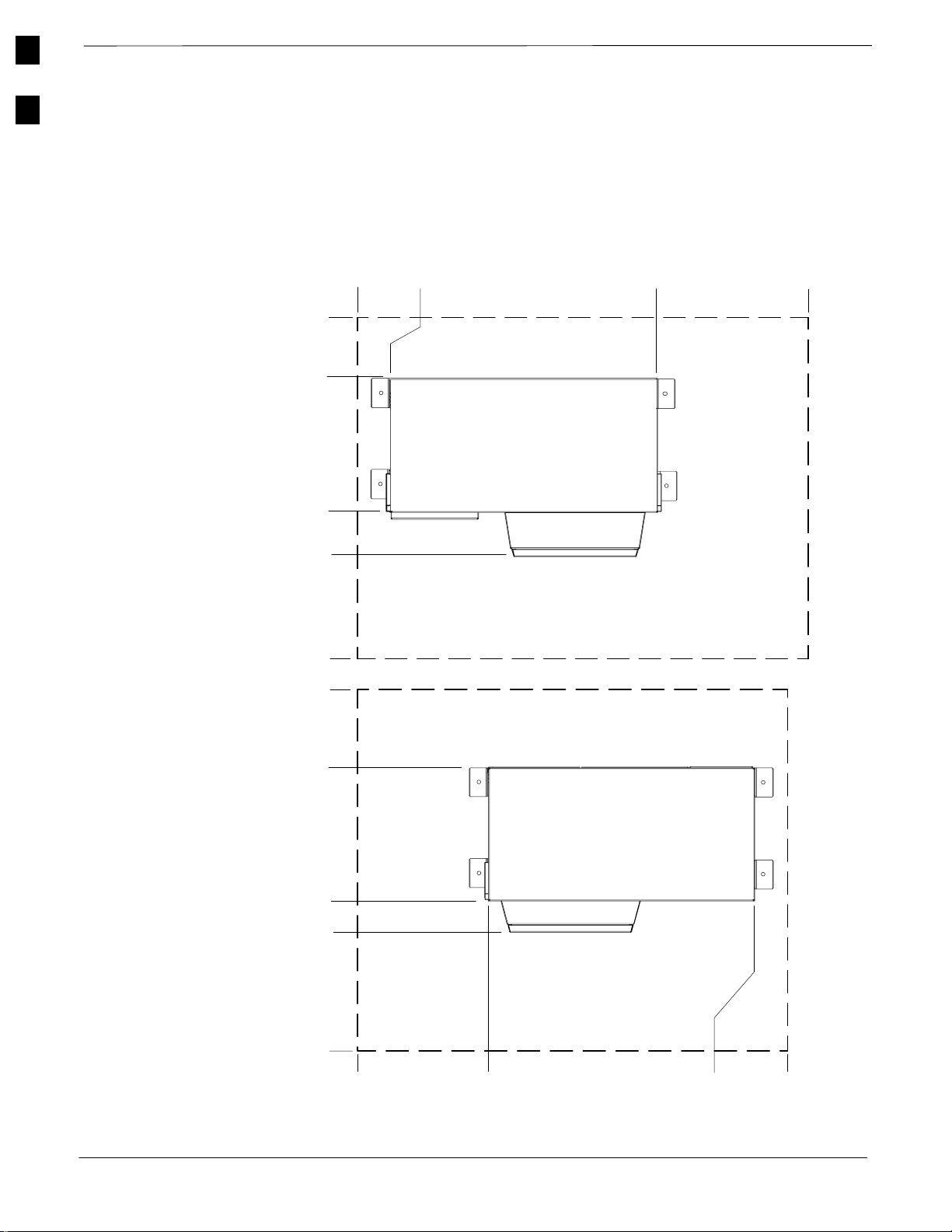

Enclosure Clearances

Figure 1-9 and Figure 1-10 show the clearances for the SC 4812ET RF

and Power Cabinet enclosures.

Figure 1-9: Minimum Cabinet Clearances for Door Openings and Mounting Brackets

0mm

(0I)

660mm

(26I)

1372mm

(54”)

1651mm

(65I)

2515mm

(99I)

0mm

(0I)

0mm

(0I)

130mm

(5I)

Power Cabinet

1550mm

(61I)

1880mm

(74I)

NOTE

Not To

Scale

30

510mm

(20I)

RF Cabinet

1220mm

(48”)

1421mm

(56I)

2363m

(93I)

0mm

(0I)

255mm

(10I)

1676mm

. . . continued on next page

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

(66I)

1803mm

(71I)

Apr 2001

FW00104

V02.03

Page 31

Figure 1-10: Minimum Site Clearances for SC 4812ET Cabinets

1143 mm

(45”)

130 mm

(5”)

Introduction

– continued

1

1143 mm

(45”)

Power

Cabinet

RF Cabinet

660 mm

(26”)

660 mm

(26”)

330 – 610 mm

(13” – 24”)

3430 – 3710 mm

(135 – 146”)

Apr 2001

V02.03

130 mm

2515 mm

(99”)

NOTE:

(1) 24” IS RECOMMENDED BETWEEN CABINETS TO ALLOW

SIMULTANEOUS OPENING OF CABINET DOORS

(2) BASED ON FIGURE 1–10 MOTOROLA RECOMMENDS A MINIMUM

PAD (OR PEDESTAL) SIZE OF 2515 MM (99”) BY 3710 MM (146”)

(5”)

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

FW00105

31

Page 32

1

Introduction

– continued

Notes

32

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 33

This section includes...

2

Chapter 2: Site Preparation

Overview 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indoor Location 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rooftop Location 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet Weight Table 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SC 4812ET RF Configuration 37. . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum Battery Count for Power Cabinet 42. . . . . . . . . . . . . . .

Outdoor Location 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Materials Needed 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Existing Concrete Pad Mounting 46. . . . . . . . . . . . . . . . . . . . . . . .

Drilling Introduction 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drilling Procedure 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rooftop 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rooftop (Elevated) 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New Concrete Pad 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection Materials 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Concrete Pad and Ground System Installation 51. . . . . . . . . . . . . .

RGPS Mounting Considerations 57. . . . . . . . . . . . . . . . . . . . . . . .

Apr 2001

V02.03

Tables

Table 2-1: DC Cabling Size – Maximum Cable Length 36. . . . . .

Table 2-2: Approximate Weight of SC 4812ET BTS 37. . . . . . . . .

Table 2-3: SC 4812ET FRU Configurations – Duplexed 38. . . . . .

Table 2-4: SC 4812ET FRU Configurations – Non–Duplexed 38.

Table 2-5: Min Battery Strings Required Sector–Carrier Configs 42

Table 2-6: Heliax Cable Loss and Minimum Bend Radii 44. . . . .

Table 2-7: Number of wires in Conduit 44. . . . . . . . . . . . . . . . . . .

Table 2-8: Drilling Procedure 47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-9: Concrete Pad & Ground System Install Procedure 52. .

Figures

Figure 2-1: Drill Stabilization 48. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-2: Mounting Hole Drilling and Cleaning 49. . . . . . . . . . .

. . . continued on next page

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

33

Page 34

Site Preparation

– continued

Figure 2-3: Grounding Ring Detail 53. . . . . . . . . . . . . . . . . . . . . .

Figure 2-4: Conduit Stub Height Detail 53. . . . . . . . . . . . . . . . . . .

2

Overview

Figure 2-5: Cabinet Dimensions 54. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-6: Pad Forms and Conduit Layout 55. . . . . . . . . . . . . . . .

Figure 2-7: Mounting Hole Dimensions 55. . . . . . . . . . . . . . . . . . .

Figure 2-8: SC 4812ET RF Cabinet Conduit I/O 56. . . . . . . . . . . .

Figure 2-9: SC 4812ET Power Cabinet Conduit I/O 57. . . . . . . . .

This chapter covers the SC 4812ET BTS site preparation recommended

guidelines.

Installation sites can be classified into one of the three following

categories: Indoor, Rooftop or Outdoor.

All applications will have common requirements and considerations.

Differences between the location site requirements will be covered

throughout the installation section. The following information is meant

to serve as a guideline and can be impacted by site specific

considerations.

Indoor Location

WARNING

Every effort should be made to provide a safe working area

for all installation and service personnel.

CAUTION

The mounting surface must be flat. Door closure problems

may occur if the cabinets are not installed on a flat surface.

IMPORTANT

*

The following items should be considered when choosing an indoor

location for the SC 4812ET BTS:

– A permanent location is more desirable than a temporary one.

– The cabinets should be placed in a location with appropriate

Care should be taken to ensure that the AC power pedestal

does not interfere with the future addition of expansion or

optional equipment service area.

clearance from any obstructions. For minimum clearances see

Chapter 1.

. . . continued on next page

34

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

V02.03

Page 35

Site Preparation

– continued

– Adequate ventilation must be available to dissipate heat loads of

7,500 Watts (25,600 Btu / hr) for the RF Cabinet and 3,000 Watts

(10,300 Btu / hr) for the Power Cabinet (a total of 10,500 Watts;

35,900 Btu / hr), and maintain a maximum temperature of no

greater than 50 Deg C (122 Deg

– The AC meter and main disconnect should not be mounted to either

cabinet.

– Locations should be selected that will minimize accidental or

intentional vandalism. Do not select a location that is, or may be,

subject to submersion (i.e. diversion channels, sub–basements, etc).

While the RF and Power Cabinet are well insulated from the

environment, they will not tolerate submersion.

– There should be adequate clearance through doors and passageways

to allow movement of the cabinet from the delivery area to the

installation site.

– Verify, prior to final site selection, the availability and accessibility

to good grounding (ground system resistance must be less than 10

Ohms, with 5 Ohms or less being the goal; see ”Recommended

Documentation” for Grounding Guidelines), RF cabling, Telco

wiring, and 208–240 VAC power.

– There should be adequate space available for the future addition of

expansion or optional equipment.

– The location of an AC power pedestal to mount the AC meter, main

breaker, generator plug, etc. (if necessary), is at the installers option.

– Every effort should be made to minimize the separation distance

between the RF and Power Cabinet (see Table 2-1) for maximum

cable length between cabinets

F).

2

Table 2-1: DC Cabling Size – Maximum Cable Length

Cable Size Resistance per 1,000 ft @ 50Deg C

mW (THHN Cable)

2/0 AWG 96.8 (Superflex) 6.7 m (22 ft)

4/0 AWG 54 (Duraflex) 12.5 m (41 ft)

Maximum Cable Length

(Max Total Voltage Drop 0.4V,

assumes 90A per cable)

NOTE

– 3.65 m (12 ft.) is the length of the # 2/0 AWG DC Power Cable supplied with the Power Cabinet.

– If a custom cable is used, 610 mm (2 ft.) should be reserved at both ends to allow for the distance from the

edge of the cabinet to the power terminals.

Apr 2001

V02.03

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

35

Page 36

Site Preparation

– continued

Rooftop Location

In addition to the Indoor location considerations, the following

2

additional items should be considered when choosing a Rooftop

location:

WARNING

Roof load carrying limits must be reviewed and an

appropriate support structure must be installed to support

the cabinets as required.

CAUTION

The cabinets must be elevated sufficiently above the roof

surface to prevent water from puddling around its base.

Although the cabinets are well insulated from the

environment they will not tolerate submersion.

Loading Considerations (also see Table 2-2):

– A single SC 4812ET RF Cabinet can weigh up to 680 kg. (1500

lbs) and a single Power Cabinet enclosure can weigh up to 1590 kg.

(3500 lbs) with the batteries installed (batteries are shipped

separately). Expansion enclosures and optional equipment will add

weight (refer to the introduction section of this manual for obtaining

detailed information on the optional equipment).

NOTE

The Power Cabinet as shipped without batteries installed

can weigh up to 544 kg (1200 lbs.).

– When the cabinet is to be roof mounted, be sure to consider the rain

and/or snow loading of the region when determining whether the

roof can support the load.

Zoning requirements – that relate to building mounted equipment

should be checked for any restrictions that may affect cabinet or antenna

placement.

Adequate clearance through doors, passageways and stairwells to allow

movement of the cabinet from the delivery area to the installation site.

Cabinet Weight Table

36

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

Minimum separation distance – Every effort should be made to

minimize the separation distance between the RF and Power Cabinet

(see Table 2-1).

Table 2-2 lists the approximate weight of both the RF and Power

cabinets in various site configurations.

. . . continued on next page

Apr 2001

DRAFT

V02.03

Page 37

Table 2-2: Approximate Weight of SC 4812ET BTS

Site Preparation

– continued

# of Sectors

– Carriers

1

RF Cabinet

2

Power Cabinet

3

Total Weight Weight/Area Total Weight Weight/Area

3 570 kg (1260 lbs) 563 kg/m

6 610 kg (1340 lbs) 602 kg/m

9 644 kg (1420 lbs) 636 kg/m

12 680 kg (1500 lbs) 671 kg/m

2

(0.8 psi) 1015 kg (2240 lbs) 1002 kg/m

2

(0.85 psi) 1206 kg (2660 lbs) 1192 kg/m

2

(0.91 psi) 1400 kg (3080 lbs) 1383 kg/m

2

(0.95 psi) 1590 kg (3500 lbs) 1571 kg/m

2

2

2

2

NOTE

1

To obtain this number, multiply the number of sectors and the number of carriers present (i.e., 3 sector, 3

carrier is 9 sector–carriers)

2

Assumes 12 DRDCs present in cabinet

3

Assumes 4 hours of battery backup and maximum battery weight of 41 kg (90 lbs) each.

SC 4812ET RF FRU

Configuration

SC 4812ET FRU Configurations for Duplexed sites are described in

Table 2-3 (see page 38).

(1.84 psi)

(1.7 psi)

(2.0 psi)

(2.2 psi)

2

SC 4812ET FRU Configurations for Non–Duplexed sites are described

in Table 2-4 (see page 39).

Apr 2001

V02.03

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

37

Page 38

Site Preparation

– continued

Con–

3 Sector

6 Sector

Ttl #

fig

car

car

car

car

car

car

car

car

Sec

Car

1

2

3

4

5

6

7

8

VH

LPAs

3 4 1 3 3 opt 3 opt 6 6

6 8 2 3 3 opt 3 opt 6 6

9 12 3 3 3 3 opt 6 6

12 16 4 NA 6 3 opt 6 6

15 16 4 NA NA 3

18 16 4 NA NA 3

21 16 4 NA NA 3

24 16 4 NA NA 3

Trnk

Mod

Table 2-3: SC 4812ET FRU Configurations – Duplexed

BTS 1 – Starter BTS 2 – Expansion

4812

DBPF

4812

Cmbr

2:1

4812

4:1

Cmbr

DRDCs

6 (3

opt)

6 (3

opt)

6 (3

opt)

6 (3

opt)

Dplxd

AntsVHLPAs

3 4 1 3 3 opt 3 opt 3 3

3 8 2 NA 3 opt 3 opt 3 3

3 12 3 NA 3 3 3 3

3 16 4 NA 3 3 3 3

Trnk

Mod

4812

DBPF

Cmbr

4812

2:1

4812

4:1

Cmbr

DRDCs

Dplxd

Ants

Expansion Field Recabling

Add Tx cable trunking module

to DBPF/conbiner.

Add Tx cable trunking module

to DBPF/ combiner. Recable

Starter Tx to add combiners

Add Tx cable trunking module

to combiner. Recable Starter Tx

to add combiners

Recable Starter Tx to add

combiners, recable Starter Rx,

cable Rx exp. between frames,

& move 3 antennas to exp.

Add Tx cable trunking module

to DBPF/combiner. Recable

Exp Tx to add combiners

Add Tx cable trunking module

to combiner

Add Tx cable trunking module

to combiner

Expansion

Impact to

Service

None

Take down

ALL Tx

Take down

Carrier 3

Tx

Take down

diversity

Rx and

ALL Tx.

Take down

Carrier 5

Tx

Take down

Carriers 5

and 6 Tx

None

38

1

car

car

car

6 8 2 6 6–opt NA 12 12

2

12 16 4 6 6–opt NA 12 12

3

18 16 4 NA 6 NA

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

12(6–

opt)

6 8 2 6 6–opt NA 6 6

Add Tx cable trunking module

to DBPF/combiner

Recable Starter Tx to add

combiners, recable Starter Rx,

cable Rx exp between frames,

and move 6 antennas to exp.

. . . continued on next page

DRAFT

None

Take down

diversity

Rx and

ALL Tx

Page 39

Table 2-3: SC 4812ET FRU Configurations – Duplexed

Ttl #

Con–

Con–

Ttl #

Sec

Sec

fig

fig

Car

Car

8

car

4

car

NOTES: Tx combiners typicalln not used until system exceeds 2 carriers.

VH

LPAs

24 16 4 NA 6 NA

Duplexed diversity Rx antennas are routed to DRDCs in expansion frame and then diversity Rx expansion is routed back to starter frame.

Tx paths are NOT routed between expansion and starter frames (i.e. each frame must have its own Tx antennas which reduces loss).

When expansion frame is added, the unused DRDCs in the starter frame could be removed and replaced with cover plates, but it is not recommended due to the time involved.

Trnk

Mod

4812

DBPF

4812

Cmbr

2:1

4812

4:1

Cmbr

3NANA41624

DRDCs

6 (3

opt)

12(6–

opt)

Table 2-4: SC 4812ET FRU Configurations – Non–Duplexed

BTS 1 – Starter BTS 2 – Expansion

4812

DBPF

4812

Cmbr

2:1

4812

4:1

Cmbr

TRDCs

RX

Ant

Con–

fig

3 Sector

1

car

2

car

3

car

4

car

Ttl #

Sec

Car

VH

LPAs

3 4 1 3 3 opt 3 opt 6 6 3

6 8 2 3 3 opt 3 opt 6 6

9 12 3 NA 6 3 opt 6 6

12 16 4 NA 6 3 opt 6 6

Trnk

Mod

BTS 2 – ExpansionBTS 1 – Starter

2:1

4812

2:1

Cmbr

4812

4:1

Cmbr

4812

4:1

Cmbr

DRDCs

TRDCs

Dplxd

Ants

VH

LPAs

6 16 4 NA 6 NA 6 6

TX

AntVHLPAs

6 (3

opt)

6 (3

opt)

6 (3

opt)

Mod

DBPF

Trnk

Mod

4812

Trnk

4812

Cmbr

4812

DBPF

Dplxd

Ants

3333NA4163

RX

AntTXAnt

Site Preparation

Expansion Field Recabling

Expansion Field Recabling

Add Tx cable trunking module

to combiner

Add Tx cable trunking module

to combiner. Recable Exp Tx to

add combiners

Expansion Field

Recabling

Add Tx cable trunking

module to

DBPF/conbiner.

Add Tx cable trunking

module to DBPF/

combiner. Recable

Starter Tx to add

combiners

Add Tx cable trunking

module to combiner.

Recable Starter Tx to

add combiners

. . . continued on next page

– continued

Expansion

Expansion

Impact to

Impact to

Service

Service

None

Take

dowm

Carrier 3

Tx

Expansion

Impact to

Service

None

Take down

ALL Tx

Take down

Carrier 3

Tx

Apr 2001

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

39

DRAFT

Page 40

Site Preparation

– continued

Ttl #

Con–

Con–

6 Sector

Ttl #

Sec

Sec

fig

fig

Car

Car

LPAs

5

15 16 4 NA NA 3

car

6

18 16 4 NA NA 3

car

7

21 16 4 NA NA 3

car

8

24 16 4 NA NA 3

car

1

car

6 8 2 6 6 opt NA 12 12 6

VH

Trnk

Mod

4812

DBPF

4812

2:1

Cmbr

Table 2-4: SC 4812ET FRU Configurations – Non–Duplexed

BTS 2 – ExpansionBTS 1 – Starter

4812

4:1

Cmbr

TRDCs

6 (3

opt)

6 (3

opt)

6 (3

opt)

6 (3

opt)

RX

Ant

3

3

3

3

TX

Ant

3 (6

opt)

3 (6

opt)

3 (6

opt)

3 (6

opt)

VH

LPAs

4 1 3 3 opt 3 opt 3 3 3

8 2 NA 3 opt 3 opt 3 3 3

12 3 NA 3 3 3 3 3

16 4 NA 3 3 3 3 3

Mod

DBPF

4812

Trnk

4812

Cmbr

2:1

4812

4:1

Cmbr

TRDCs

RX

Ant

Expansion Field

TX

Ant

Expansion Field

Recabling

Recabling

Recable Starter Tx to

add combiners, recable

Starter Rx, cable Rx exp.

between frames, & move

3 antennas to exp.

Add Tx cable trunking

module to

DBPF/combiner. Recable

Exp Tx to add combiners

Add Tx cable trunking

module to combiner

Add Tx cable trunking

module to combiner

Expansion

Expansion

Impact to

Impact to

Service

Service

Take down

diversity

Rx and

ALL Tx.

Take down

Carrier 5

Tx

Take down

Carriers 5

and 6 Tx

None

40

2

12 16 4 6 opt 6 NA 12 126(12

car

3

18 16 4 NA 6 NA

car

4

24 16 4 NA 6 NA

car

12(6–

12(6–

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

opt)

opt)

opt)

6 6 8 2 6 opt 6 NA 6 6 6

6 6 16 4 NA 6 NA 6 6 6

DRAFT

Add Tx cable trunking

module to DBPF/

combiner. Recable

Starter Tx to add

combiners.

Recable Starter Tx to

add combiners, recable

Starter Rx, cable Rx exp

between frames, and

move 6 antennas to exp.

Add Tx cable trunking

module to combiner.

Recable Exp Tx to add

combiners

. . . continued on next page

None

Take down

diversity

Rx and

ALL Tx

Take

dowm

Carrier 3

Tx

Page 41

Table 2-4: SC 4812ET FRU Configurations – Non–Duplexed

Ttl #

Con–

Con–

Ttl #

Sec

Sec

fig

fig

Car

Car

8

car

NOTES: Tx combiners typically not used until system exceeds 2 carriers.

VH

LPAs

Duplexed diversity Rx antennas are routed to TRDCs in expansion frame and then diversity Rx expansion is routed back to starter frame.

Tx paths are NOT routed between expansion and starter frames (i.e. each frame must have its own Tx antennas which reduces loss).

When expansion frame is added, the unused TRDCs in the starter frame could be removed and replaced with cover plates, but it is not recommended due to the time involved.

Trnk

Mod

4812

DBPF

4812

Cmbr

2:1

4812

4:1

Cmbr

3NANA41624

TRDCs

6 (3

opt)

RX

Ant

Site Preparation

– continued

BTS 2 – ExpansionBTS 1 – Starter

Expansion Field

Expansion Field

Recabling

Recabling

Add Tx cable trunking

module to combiner

2:1

4812

4:1

Cmbr

TRDCs

RX

Ant

TX

Ant

33333NA416

TX

LPAs

Ant

3 (6

3

opt)

Mod

DBPF

4812

Trnk

VH

4812

Cmbr

Expansion

Expansion

Impact to

Impact to

Service

Service

None

Apr 2001

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

41

DRAFT

Page 42

Site Preparation

– continued

Minimum Battery Count for

2

Power Cabinet

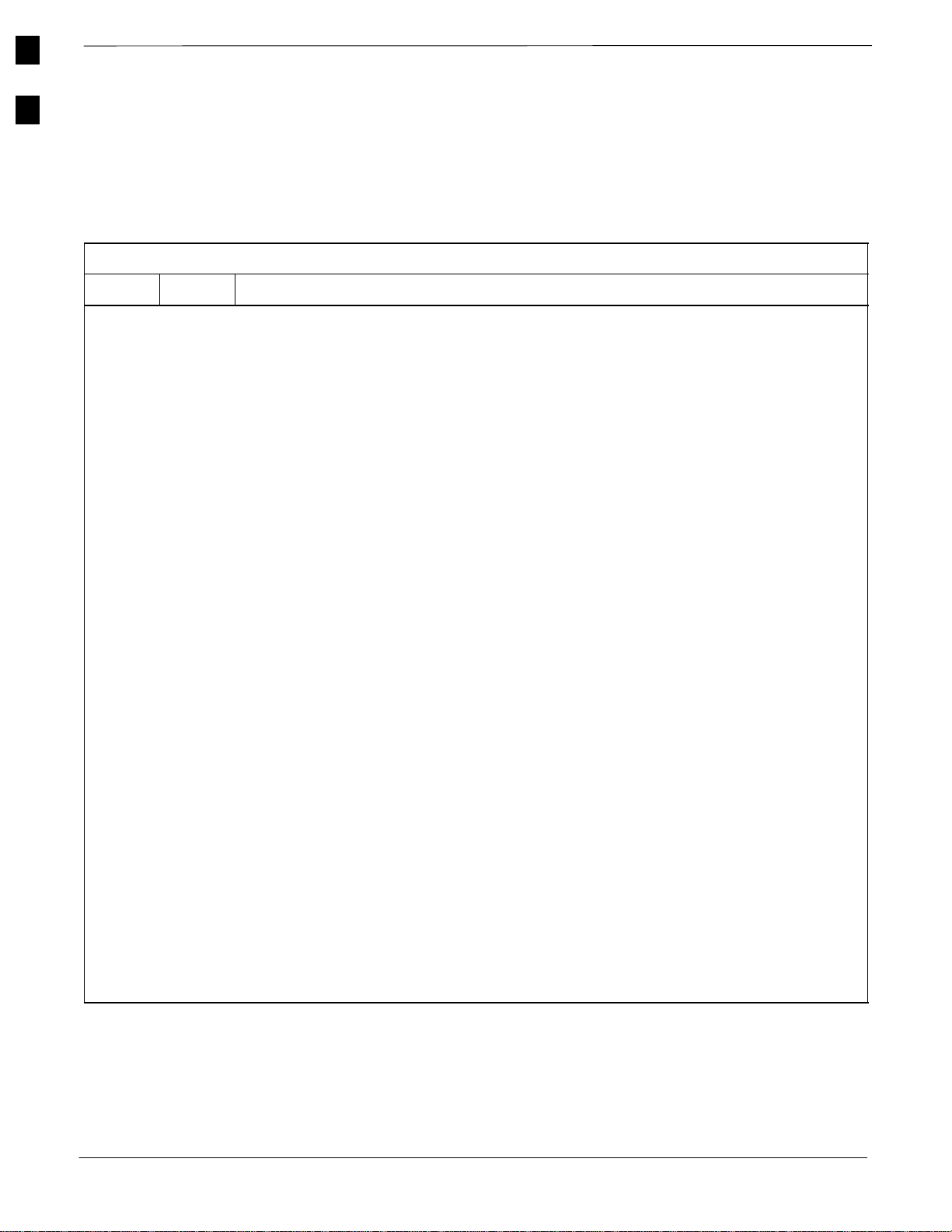

Table 2-5 lists the number of Battery strings required for the different

sector–carrier configurations and the backup power time provide by the

various combinations.

Table 2-5: Minimum Battery Strings Required for Sector–Carrier Configurations

# of

Battery

Strings

0 0 0 0 0

1

2

3

4

5

6 4.0 hrs

7 4.8 hrs 3.5 hrs

8 5.4 hrs 4.0 hrs

9 6.0 hrs 4.5 hrs 3.6 hrs

10 6.7 hrs 5.0 hrs 4.0 hrs 3.3 hrs

11 7.4 hrs 5.5 hrs 4.4 hrs 3.6 hrs

12 8.0 hrs 6.0 hrs 4.8 hrs 4.0 hrs

3 Rectifiers

(3 Sector–Carriers)

4 Rectifiers

(6 Sector–Carriers)

5 Rectifiers

(9 Sector–Carriers)

6 Rectifiers

(12 Sector–Carriers)

! CAUTION

The minimum number of battery strings presented in this table must be met or reduced backup time and

inadvertant tripping of the battery system breakers could result.

Outdoor Location

42

NOTE

The backup durations presented within this table is an

estimated time based on 25 Deg C (77Deg F) battery

temperature, actual backup duration may vary with system

configuration and loading.

CAUTION

Do not select a location that is, or may be subject to

submersion (i.e., floodplains, diversion channels, etc.).

While the cabinets are well insulated from the

environment, they will not tolerate submersion.

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

Page 43

Site Preparation – continued

In addition to the Indoor location considerations, the following

additional items should be considered when choosing an outdoor

location:

– The cabinet should be placed in a location with appropriate

clearance from any obstructions. For minimum clearances see

Chapter 1.

– It should be the practice of any installing company to acquire, in

advance of construction, the rights of way from landowners, and

permits or approvals from public authorities. It is recommended that

the BTSs be placed in servitudes, on dedicated (recorded)

easements, or on property owned by the company. Unrecorded

easements should be avoided.

– The cabinet should be easily accessible with adequate parking to

ensure craftsmen and vehicle safety. Also, place the cabinet where it

will not create a visual or physical obstruction to either vehicular or

pedestrian traffic.

– Locations should be selected that will minimize accidental or

intentional vandalism. The use of protective posts and/or fences

should be considered when located near parking areas where

vehicles may hit the cabinet.

– Every effort should be made to minimize the separation distance

between the RF and Power Cabinet (see Table 2-1).

2

Materials Needed

The following list of materials may vary depending on site specific

requirements. If in doubt contact Motorola Cellular Support Center. The

phone number is found in the Foreword of this manual.

Installation hardware is provided with the cabinets. (Refer to Chapter 1

for a description of this hardware).

Tools – Refer to Chapter 1 for a list of tools that will be helpful when

installing the SC4812ET BTS.

RF Transmission Lines

– Cables are 12.7 mm (1/2”), 22.2 mm (7/8”), 31.8 mm (1–1/4”) or

41.3 mm (1–5/8”) Foam

See Table 2-6 for dB Loss per foot and minimum bending radius.

– Either 102 mm (4”) or 152 mm (6”) conduit, depending on size of

Heliax (see Table 2-7), is recommended.

R

Heliax, depending on dB loss budget.

Apr 2001

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

43

Page 44

Site Preparation – continued

NOTE

It may not be necessary or desirable to run the transmission

2

Table 2-6: Heliax Cable Loss and Minimum Bend Radii

lines in any conduit at all. In this case the transmission

lines should be protected from falling objects (i.e., ice,

etc.) or from being stepped on.

Heliax Motorola Part

Heliax

Cable

RG 142 CGDSRG142BU .49 .66 .15 .20 10 mm .4”

3/8” LDF N/A .115 .167 .035 .051 95 mm 3–3/4”

1/2”LDF SGDN4232A .0768 .1132 .0234 .0345 125 mm 5”

1/2” FSJ4 N/A .119 .177 .0363 .0541 13.75 mm 1.25”

7/8”LDF SGDN4234A .0430 .0646 .0131 .0197 250 mm 10”

1–1/4”LDF SGDN4235A .0317 .0476 .00967 .0145 380 mm 15”

1–5/8”LDF SGDN4233A .0269 .0410 .00819 .0125 510 mm 20”

Motorola Part

No.

dB loss per meter dB loss per foot Min. bend radius

@ 1 GHz @ 2 GHz @ 1 GHz @ 2 GHz Metric U.S.

NOTE

As an additional rule of thumb, allow 0.1 dB additional loss for each connection point.

Table 2-7: Number of wires in Conduit

Conduit

Conduit

Trade Size

2” 5 2 1 – –

2–1/2” 7 3 1 – –

3” 11 5 3 – –

4” 19 9 5 1 1

6” 20 20 12 3 2

9.5 mm (3/8”) 12.7 mm (1/2”) 21.4 mm (7/8”) 31.8 mm (1–1/4”) 41.3 mm (1–5/8”)

Foam Heliax Trade Size (Cable Type LDF)

* IMPORTANT

The values listed above were calculated based on the percent of conduit cross–section filled and recommended

limits set forth by Andrew Corporation. These limits are based on common conditions or proper cabling and

alignment of conductors where the length of pull and the number of bends are within reasonable limits. It

should be recognized that for certain conditions a larger size conduit or a lessor fill should be considered.

Power Cabinet AC Power Connection

208–240 VAC – Flexible Liquid Tight Conduit is recommended.

44

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

Apr 2001

DRAFT

Page 45

Site Preparation – continued

IMPORTANT

*

The AC power pedestal or meter should be provided with a breaker to

protect the cable from the pedestal to the Power Cabinet. The Power

Cabinet rating is 130Amp. A 150–amp breaker is recommended, or as

appropriate for local electrical code.

The Power Cabinet is rated at 130 Amps (100 Amps

continuous / 130 Amps non–continuous, in the range of

208–240V AC, see Table 5-32 for details). Maximum

cable size that can be accommodated is 300 kc mil.

Cabling sizing should be determined by Local Electrical

Codes, using 90Deg C rated conductors, and derated for

50 Deg C operation. Motorola recommends not less than

#2/0 AWG (#1 BSWG; 50 mm

buried/raceway cables to the power pedestal, with an

associated power pedestal breaker size of 150 Amps for

one Power Cabinet.

NOTE

The knockout in the I/O plate of the Power Cabinet is the

proper size for a 2” Trade size conduit fitting.

2

) copper for

2

Ground Wire Connection (RF and Power Cabinet) – #3 B.S.W.G (#2

AWG; 35 mm

RF Cabinet Alarm Cable Connection

– Sixteen (16) twisted pair cable

– 25.4 mm (1”) conduit (maximum)

RF Cabinet Span and Modem Cable Connection

– Thirteen (13) twisted pair cable

– 25.4 mm (1”) conduit (maximum)

Main RF Cable – 50 Ohm Coaxial, male N–type connector on one end,

customer specific on other end.

RGPS Cable (if applicable) – See Table 5-1 for cable specifications

RF GPS Cable (if applicable) – See Table 5-1 for cable specifications

LFR Cable (if applicable) – See Table 5-1 for cable specifications

2

) solid–tinned copper wire or equivalent is recommended

. . . continued on next page

Apr 2001

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

45

Page 46

Site Preparation – continued

Power Cabinet Alarm Cable – A Twelve (12) wire, Six (6) twisted pair

cable [Cable supplied with the Power Cabinet is 4.5 m (15 ft) in length].

2

DC Power Interconnect

– #1 BSWG (#2/0 AWG; 50 mm2) insulated weld wire or equivalent

is recommended (supplied with the Power Cabinet)

– 51 mm (3”) conduit

Existing Concrete Pad

Mounting

NOTE

Custom cable lengths are available from Storm Products

(214–637–1381); 9215 Premier Row, Dallas, TX. 75247.

Part number “070197–6SA” for Non–Plenum rated cable.

NOTE

The DC Power Cabling and the Power Cabinet Alarm

Cable can be run in the same 3” Conduit from the RF

Cabinet to the Power Cabinet.

CAUTION

The mounting surface must be flat. Door closure problems

may occur if the BTS is not installed on a flat surface.

For an installation where the cabinet will mount flush to an existing

concrete floor, all of the connections to the cabinet will be made through

the rear I/O area of the cabinet. For this reason, the cabinet must be set

in place and bolted down prior to running any conduits or wiring.

Conduit/wire routing will be discussed in Chapter 5.

Lightning protection is provided with the cabinet. A good earth ground

(ground system resistance must be less than 10 Ohms, with 5 Ohms or

less being the goal), is required for the lightning protection equipment to

perform properly. Refer to Motorola’s guidelines (Motorola Publication

68P81150E62) for details on the design of a grounding system. Conform

to local electrical construction standards for conduit materials and sizing.

46

SCTM 4812ET RF and Power Cabinet Hardware Installation Manual

DRAFT

Apr 2001

Page 47

Site Preparation – continued

Drilling Introduction

The following includes steps that must be followed to safely drill the

mounting holes. Check the mounting hardware to be used to make sure

you use the correct drill bit sizes.

CAUTION

Motorola recommended anchor bolts (Motorola P/N

CGDS97400036) must be used to assure safety in the

event of an earthquake.

WARNING

Safety glasses, dust masks, and ear plugs must be worn by

all installation personnel, including those in the immediate

vicinity of personnel operating the drill equipment.

2

Drilling Procedure

Before beginning, read the following steps in their entirety to familiarize

yourself with the procedure.

Table 2-8: Drilling Procedure

Step Action

After the cabinet position has been established, the mounting hole location can be marked using the

1

dimensions supplied in Figure 2-5, by using the 1:1 installation template supplied in Appendix G, or

by placing the cabinet over the desired location and tracing the mounting hole locations.

NOTE

– Motorola recommended anchor bolts require 18 mm (11/16”) drill size.

n W ARNING

– Always wear safety glasses, dust masks, ear plugs, and proper attire when using power equipment.

Remove any loose jewelry and tuck shoe laces into work boots.

. . . continued on next page

Apr 2001