Page 1

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

nokia

PAGE 1 (23) Approved 4.0

MGR

5140/5140i

NPL-5/RM-104

Transceiver characteristics:

• Xpress-on™ shells provide protection against splashes

and dust

• Push to talk

• Passive matrix color display 128 x 128 pixels -

5140i: 65536 colors

5140: 4096 colors

• Integrated VGA camera

• Stereo FM radio

• Flashlight

• Thermometer

• Decibel meter

• Infrared

• Polyphonic tones

• EGSM 900, GSM 1800, and GSM 1900 networks

• WIM (Wireless Identity Module)

• Pop-Port™ interface

• OMA Super Distribution over infrared and MMS

• EDGE Class 6 (3+1, 2+2)

• GPRS (General Packet Radio Service)

• HSCSD (High-Speed Circuit-Switched Data)

Transceiver with BL-5B 760mAh Li-Ion battery pack

Talk time Standby Note

2 h –5 h 150 h –300 h

Environmental characteristics:

• Lead-free soldered

Depends on

network

parameters

SERVICE MANUAL

Service Level 1&2

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 2

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

TABLE OF CONTENT

1. INTRODUCTION...................................................................................................................................................................................3

2. GENERAL REPAIR INFORMATION .....................................................................................................................................................4

3. PATHFINDER FOR WORKSHOP STAFF.............................................................................................................................................5

4. EXPLODED VIEW AND COMPONENT DISPOSAL .............................................................................................................................6

5. SPARE PARTS OVERVIEW ..................................................................................................................................................................7

6. SPARE PARTS LIST..............................................................................................................................................................................8

7. SERVICE TOOLS....................................................................................................................................................................................9

8. SW-UPDATE...................................................................................................................................................................................... 11

PAGE 2 (23) Approved 4.0

MGR

Page

9. DISASSEMBLY INSTRUCTIONS....................................................................................................................................................... 12

10. EXCHANGE OF SYSTEM CONNECTOR........................................................................................................................................ 14

11. LEGEND FOR QUICK TROUBLE SHOOTER................................................................................................................................. 15

12. QUICK TROUBLE SHOOTER PART 1.......................................................................................................................................... 16

13. QUICK TROUBLE SHOOTER PART 2.......................................................................................................................................... 17

14. QUICK TROUBLE SHOOTER PART 3.......................................................................................................................................... 18

15. CAMERA GONOGO TEST ............................................................................................................................................................. 19

16. INFRARED TEST........................................................................................................................................................................... 20

17. GONOGO TEST ............................................................................................................................................................................. 21

18. BATTERY TEST............................................................................................................................................................................. 21

19. FORWARDING OF REPAIRS ....................................................................................................................................................... 22

20. ESD PROTECTION REQUIREMENTS........................................................................................................................................... 23

CHANGE HISTORY

Status Version No. Date Comments

Draft 0.1 05.04.2004 Initial draft

Approved 1.0 11.05.2004 Approval

Approved 2.0 30.03.2005 5140i implemented

Approved 3.0 30.03.2005 Exploded view/ Spare Parts overview corrected

Approved 4.0 14.06.2005 Exploded view/ Spare Parts overview corrected

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 3

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

1. INTRODUCTION

The purpose of this document is to help NOKIA service levels 1 and 2 workshop technicians to carry out service to

NOKIA products. This Service Manual is to be used only by authorized NOKIA service suppliers, and the content of it

is confidential. Please note that NOKIA provides also other guidance documents (e.g. Service Bulletins) for service

suppliers, follow these regularly and comply with the given instructions.

While every endeavor has been made to ensure the accuracy of this document, some errors may exist.

If you find any errors or if you have further suggestions, please notify NOKIA using the address below:

mailto:cc-ts-rc.documentation@NOKIA.com

Please keep in mind also that this documentation is continuously being updated and modified, so watch always

out for the newest version.

Warnings and Cautions

Please refer to the phone’s user guide for instructions relating to operation, care and maintenance including

important safety information. Note also the following:

Warnings:

CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH ELECTRONIC ENGINE

1.

MANAGEMENT SYSTEMS AND ANTI–SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT CONDITIONS, EMITTED RF

ENERGY CAN AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/MANUFACTURER TO

DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC SYSTEMS TO RF ENERGY.

THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY TO CONTAIN

2.

POTENTIALLY EXPLOSIVE ATMOSPHERES EG PETROL STATIONS (SERVICE STATIONS), BLASTING AREAS ETC.

OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLULAR TELEPHONES, MAY INTERFERE

3.

WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR THE

MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY

ALSO BE SUBJECT TO INTERFERENCE.

PAGE 3 (23) Approved 4.0

MGR

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti–static workstation and that an anti–static wrist strap is worn.

3. Use only approved components as specified in the parts list.

4. Ensure all components, modules screws and insulators are correctly re–fitted after servicing and alignment.

5. Ensure all cables and wires are repositioned correctly.

Electrostatic discharge can easily damage the sensitive components of electronic products.

Therefore every Service Supplier has to take care of all precautions, which are mentioned in

the service level related “Service Partner Requirements”, available on NOKIA Online. Also see

ESD Protection Requirements in this Service Manual.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 4

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

2. GENERAL REPAIR INFORMATION

In this section the technician will get some general hints how to carry out repairs:

o

To familiarize oneself with NOKIA product read the tutorials or user guide on www.NOKIA.com -->Support-->

Phones, by selecting the Phone Model.

o

Before starting the repair you must take care of ESD precautions like being in your ESD Protected Area and

connecting your wristband.

o

Use gloves to avoid corrosion and fingerprints.

o Protect windows and displays with a film to avoid dust and scratches.

o When cleaning the LCD Module any lint-free cloth can be used (e.g. Micro-Fibre cloth).

o When cleaning the pads you have to use a soft cloth/ESD brush and Isopropanol. It is not allowed to use a

glass fiber pencil because it scratches the surface and will lead later on to corrosion.

o Mechanical parts (except shielding lids and bent parts), which didn’t repair the failure, can be reused, if they

are not soldered.

o When removing the shielding lids make sure to replace them with new ones, otherwise the high-frequency

leakage can have an influence on the device.

o Always use original NOKIA spare parts.

o Check the soldering joints of the parts, which are concerned regarding the indicated error (e.g. soldered

connectors or switches) and resolder them if necessary (Level 2 only).

o Remove redundant soldering flux after repair.

o Meet the torque requirements when assembling the unit (see also the document “torques for transceiver

assembly” on NOKIA Partner Web Site/NOKIA Online).

o Always use your own equipment for testing where you are sure that it works. E.g. if the customer complains

about charger function, please test the phone with your own charger to be sure if phone or charger causes the

malfunction.

o A SIM card is needed for all GoNoGo tests.

o When doing the fault log entries, always note the Item code, which caused the malfunction. Also, fill in the

appropriate part code from the assembly, if needed.

o Please be aware that some malfunctions could be software related and solved by an update.

o There are several documents available on NOL, which have to be followed:

o First, take care for the latest content pages of Service Bulletins, which are always available for each folder on

NOKIA Online. This is also important to recognize, if existing documents have become invalid.

o The service level indicator at the bottom of each document tells the appropriate destination.

Downloads > Support Library >

1. Instructions

2. General Service Bulletins

3. Product related documents

4. Spare Part Service Bulletins

5. Service Tools Service Bulletins

6. Common Software Service Bulletins

etc,…

Use General SB-217 as a reference or overview.

Please also check NOKIA Online (NOL) for latest news and files on a regular basis.

PAGE 4 (23) Approved 4.0

MGR

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 5

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

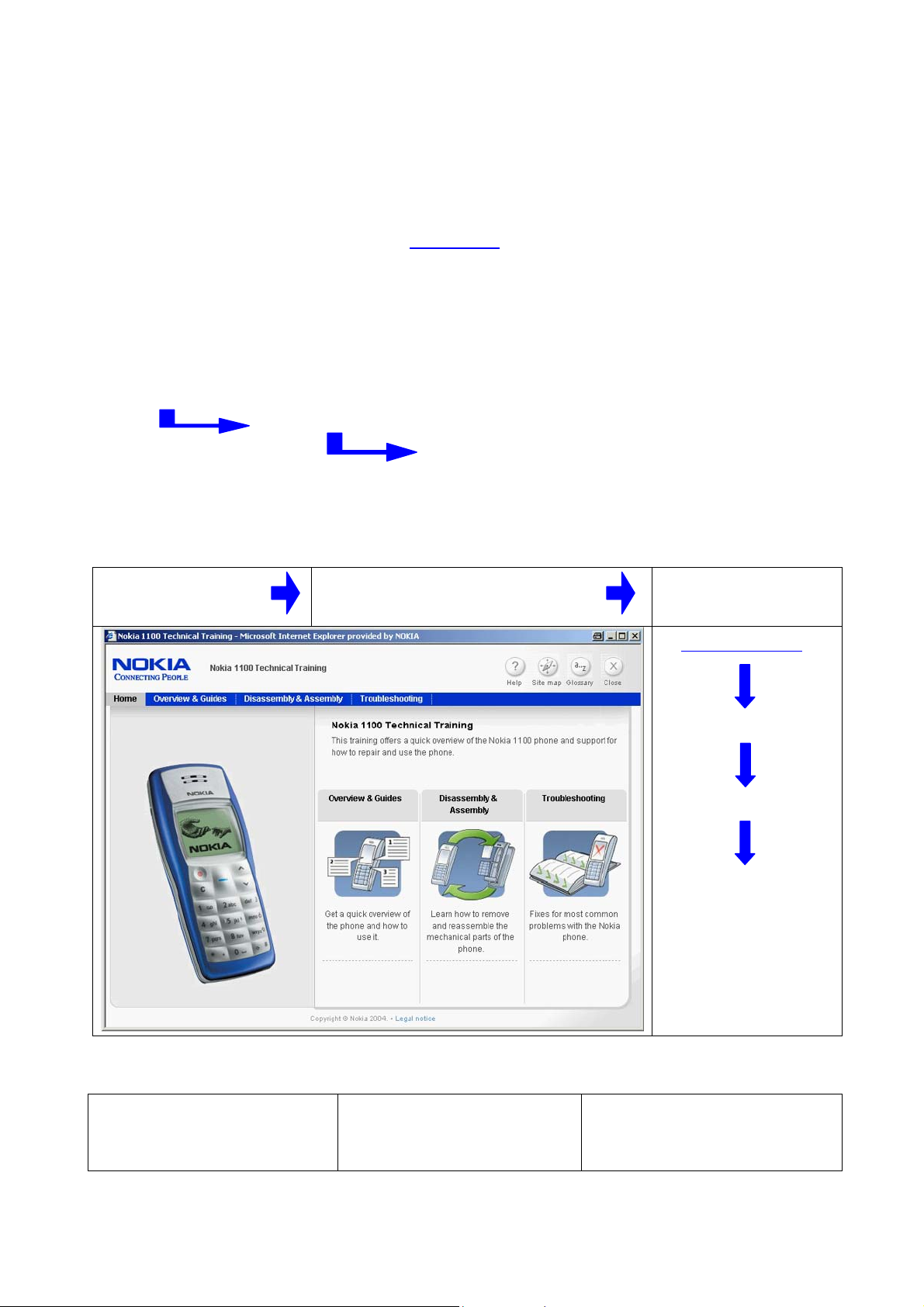

3. PATHFINDER FOR WORKSHOP STAFF

In addition to the information in this Service Manual, there are several instructions and information, which have to

be followed. Main documentation database is

content, like video clips or interactive tutorials.

It is mandatory to watch for newest technical and organizational information on a daily basis to be updated as

required (see “Latest files in Support Library”). Every new information has to be processed and implemented as

soon as possible.

When logged into NOL you can also find needed information in different folder like:

Support Library

Phones

Level 1&2 e-learning (former NOKIA CarePoint) on NOKIA Online

Former NOKIA CarePoint

content, such as

• Online Troubleshooting

• Product informations

• Videos – Disassembly/Assembly

PAGE 5 (23) Approved 4.0

NOKIA Online with the purpose of serving different multimedia

Service Manuals

Service Bulletins

Software

Repair Information

can be found on

NOKIA Online

MGR

NOKIA Online

Care Services

Training

Phone Models

Level 1&2 e-learning courses offer a quick overview of the NOKIA phone and support for how to repair and use the

phone:

Overview & Guides

Basic information about the

phone, features and technologies

To reduce the server traffic it is recommended to download newest version of huge files like videos, Phoenix

packages or Service Manuals only once and distribute it internally for further use.

Disassembly & Assembly

Instructions to disassemble and

assemble the phone

Step-by-step instructions on how to

locate and repair the most common

Troubleshooting

problems with the phone

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 6

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

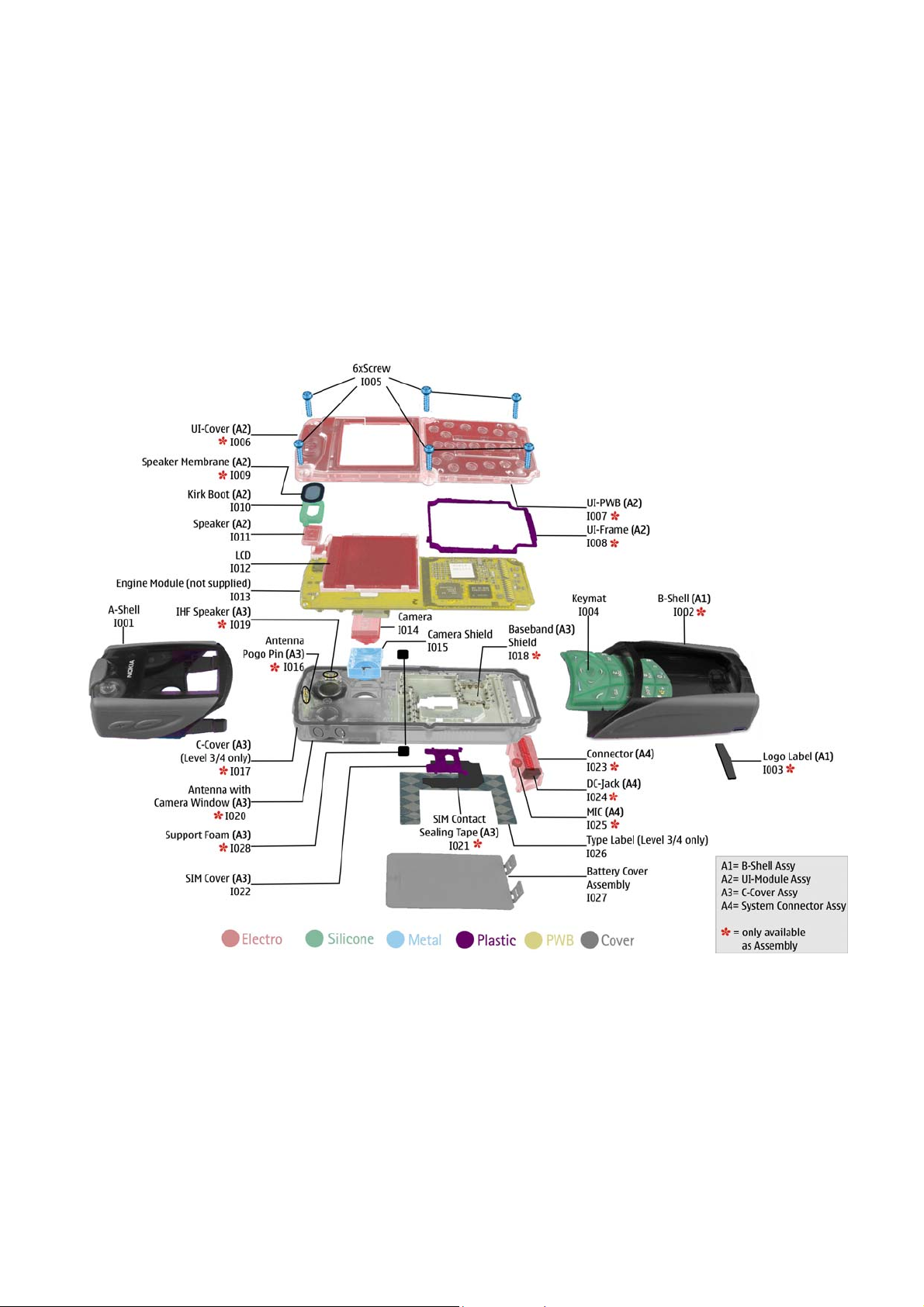

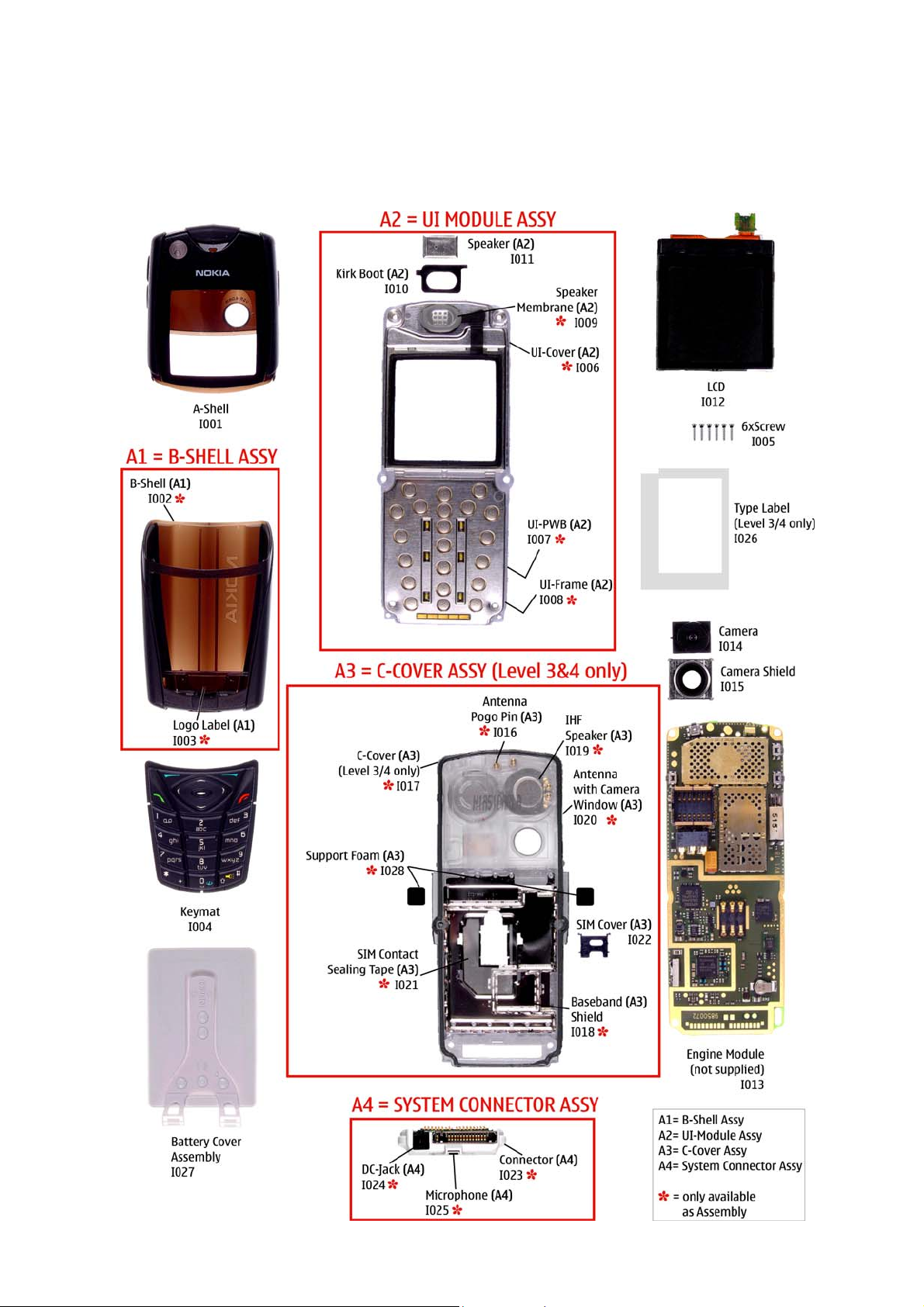

4. EXPLODED VIEW AND COMPONENT DISPOSAL

Recommendation for the ecologically friendly disposal of components. Colorized components show the different

categories. See corresponding ITEM/CIRCUIT REF in the Spare Parts Service Bulletins on NOL.

PAGE 6 (23) Approved 4.0

MGR

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 7

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

5. SPARE PARTS OVERVIEW

PAGE 7 (23) Approved 4.0

MGR

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 8

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

6. SPARE PARTS LIST

Please exchange this page (placeholder) with latest corresponding Service

Bulletins (spare parts, SWAP units and service tools) from NOL!

This will ensure, that you are using up-to-date order codes only.

Therefore Service Bulletins have to be checked from NOL on daily basis.

PAGE 8 (23) Approved 4.0

MGR

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 9

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

7. SERVICE TOOLS

PAGE 9 (23) Approved 4.0

FLS-4S incl. ACF-8, Driver and User Guide

Dongle and flash device incorporated into one package,

developed specifically for POS use.

MGR

ACF-8

Universal Power Supply is used to power FLS-4S.

Internal Battery BL-5B

Inserted under the back cover, this Li-Ion 760 mAh battery

provides power in a lightweight package.

Travel Charger ACP-12

Small and lightweight charger for fast charging of your phone

battery.

Headset HDS-3

Small and lightweight stereo headset for handsfree functionality

and listening to FM radio.

SRT-10

Camera removal tool. One side is for disassembly, the other side

for assembly

XCS-1

Service Cable is used to connect FLS-4S to SF-6 .

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 10

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

PAGE 10 (23) Approved 4.0

MGR

SF-6

POS Flash Adapter is used in POS (Point of Sales) environment for

software updating. It provides controlled supply voltage and

necessary connections between the phone and the Flash Device.

It substitutes for the phone’s standard battery during the

software update.

Test Pins

for Flash Adapter SF-6

RJ-8

Soldering Jig

Lead-free Solder Wire

Mandatory for lead-free products (Level 2 only).

0772040 NMP Standard Toolkit

NOKIA opening tool SRT-6 NOKIA No. 0770431

Tonichi torque driver NOKIA No. 6901525

Hoya micro fibre cloth MX304

Dastex gloves S, M, XL

Artilux goggles AH166

Wera bit T5 867/4TX 5x50

Wera 867/4 6IP; 50mm (Torx 6 PLUS®)

Wera bit T6 867/4TX 6x50

Wera 867/1 5IP; 25mm (Torx 5 PLUS®)

Wera bit T6 PLUS® 867/4TX 6IP

Facom side cutter 416E

Facom T5 driver SP.14032

Facom T6 driver SP.14033

Facom slot screwdriver AEF. 2x35.E

Wetec tweezers 7abb SA-ESD

Wetec tweezers 22 SA-ESD

Wetec tweezers 13 SA-SMD ESD

Wetec tweezers PSF SA-ESD

Wetec ESD brush E1211

Kaiser Fototechnik airbrush 6315

Wetec dental tool DEM83266/0

RS Components Scissors 323-5732

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 11

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

8. SW-UPDATE

To use FLS-4S Flash Dongle you have to follow the user guide inside the sales package. Please check always for the

latest version of flash software, which is available on

NOKIA Online.

Flash Concept – (Point of Sales)

It is very important to follow this insertion and removal procedure, otherwise the contact pins of Flash Adapter

will be damaged.

PAGE 11 (23) Approved 4.0

MGR

Insert the Flash Adapter SF-6 like a battery, start at the

Battery Connector side. Take care not damage the contact

pins of Flash Adapter and the spring contacts of SIM Card

reader

Remove SIM Card and close SIM Cover before inserting

the Flash Adapter!

Now, push down the bottom side of the phone, do not

use too much force.

When removing the phone, always start from the bottom

side of the unit.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Take away the unit now.

Page 12

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

9. DISASSEMBLY INSTRUCTIONS

Attention!

It is not allowed to open the unit more than once,

otherwise the unit is not splash proofed any more and

has to be sent to the appropriate

service supplier with higher service level. Always use

new screws for assembly.

PAGE 12 (23) Approved 4.0

1.) Press the grip markings on both sides of the B-Shell

and remove B-Shell.

MGR

2.) Remove the Keymat.

®

4.) Unscrew the four, Torx Plus

shown order. Always use new screws when re-

assembling! For assembly, reverse the order and use a

Torx Plus

32Ncm.

®

size 6 driver with a torque setting of

size 6 screws in the

3.) Remove the A-Shell.

5.) Take away the UI Module Assy with Engine Module.

6.) Separate the UI-Module Assy from Engine Module

carefully, because of the board-to board-connector.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

7.) Push out the LCD by using a clean cloth.

Page 13

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

PAGE 13 (23) Approved 4.0

MGR

8.). Protect the LCD with a film.

10.). Use tweezers to remove Speaker from Kirk Boot. 11.) Use a slotted screwdriver as a lever to open the

9.) Remove the Speaker with Kirk Boot. Note the

guiding when assembling.

Camera Shield.

12.) Camera Module is attached with four snaps into its

guidance. Place SRT-10 as shown in the picture and

unlock the snaps on both sides. Note releasing order.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

13.) Use tweezers to take away the Camera module.

Page 14

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

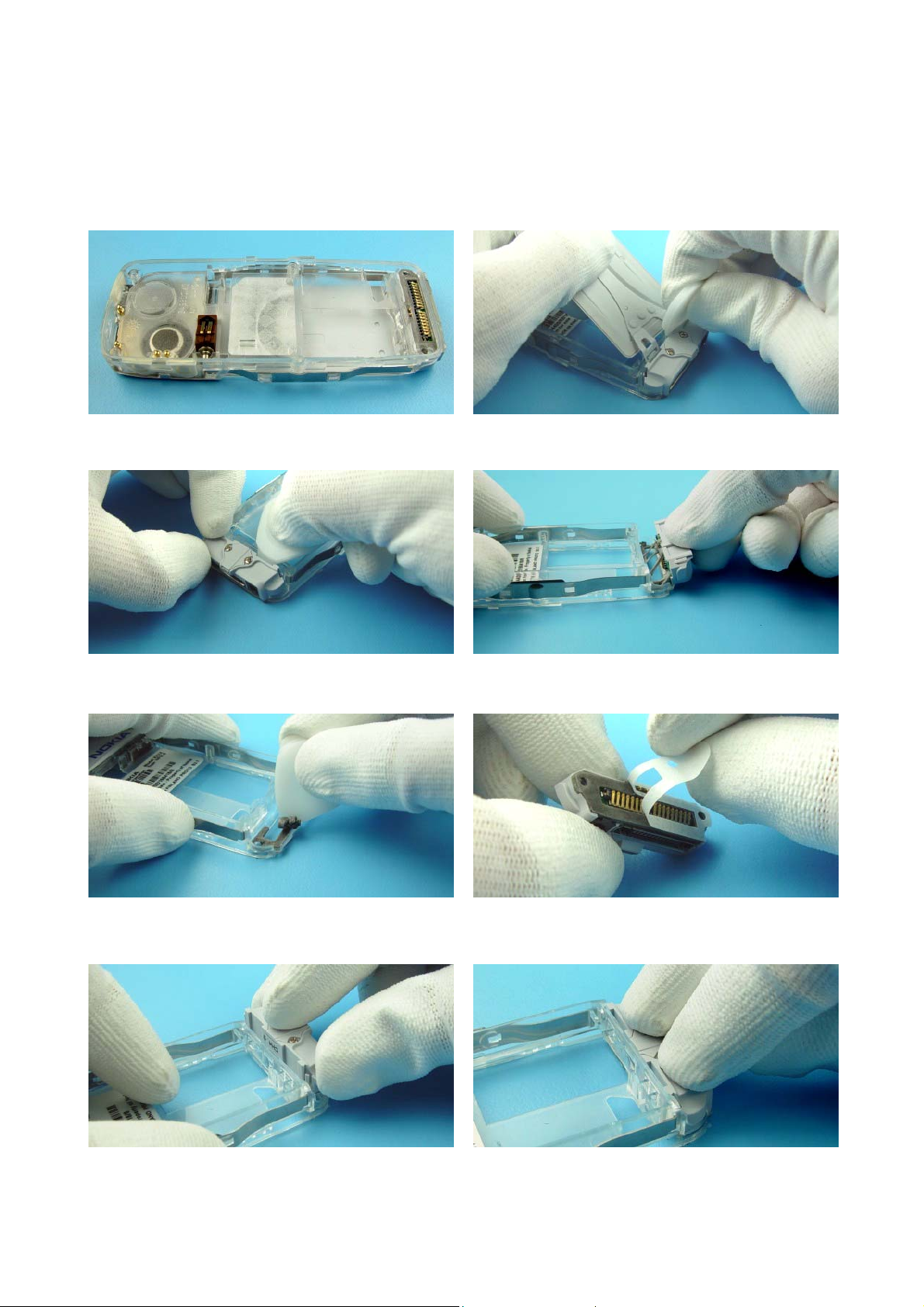

10. EXCHANGE OF SYSTEM CONNECTOR

(PICTURE EXAMPLES TAKEN FROM 5100)

PAGE 14 (23) Approved 4.0

MGR

1.) The System Connector Assy is attached with

double-sided adhesive gasket to C-Cover. Also note the

gasket on C-Cover.

3.) Press again SRT-6 between C-Cover and System

Connector Assy and remove the System Connector

Assy.

2.) Press SRT-6 between C-Cover and System

Connector Assy and remove the Battery Cover Assy.

4.) Remove the System Connector Assy.

5.) To remove the remaining adhesive gasket use SRT6 only.

Do not use sharp-edged tools for this procedure.

7.) Place the System Connector Assy to its guidance

exactly.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

6.) Remove protection foil from System Connector

Assy.

8.) Now press connector to C-Cover firmly, while

taking care not to slip C-Cover on your table.

Page 15

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

11. LEGEND FOR QUICK TROUBLE SHOOTER

This legend is valid for all parts of the Quick Trouble Shooter

Follow the steps until the problem is solved. If this doesn’t help, you are not authorized to go forward.

PAGE 15 (23) Approved 4.0

MGR

Only marked components ( e.g. I002

The start point of repair activities regarding the appeared fault symptoms.

Follow the arrows step by step

Pads or contacts: Check optical and mechanical condition particularly regarding

to corrosion. Clean if necessary.

Measure component for electrical functionality and change, if needed.

(Level 2 only)

Pads or contacts: Check optical and mechanical condition particularly regarding

to corrosion. Clean with ESD brush only, if necessary.

No more actions possible send product to the appropriate service supplier with

higher service level.

) can be changed.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 16

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

12. QUICK TROUBLE SHOOTER PART 1

PAGE 16 (23) Approved 4.0

MGR

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 17

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

13. QUICK TROUBLE SHOOTER PART 2

PAGE 17 (23) Approved 4.0

MGR

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 18

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

14. QUICK TROUBLE SHOOTER PART 3

PAGE 18 (23) Approved 4.0

MGR

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 19

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

15. CAMERA GONOGO TEST

Before starting the GoNoGo

test, check that camera

window is clean. If not, clean

the window with cloth.

PAGE 19 (23) Approved 4.0

MGR

• Press the red receiver button to reach the Home Menu

• From Home Menu, select the Menu key

• Press Capture to take a photo

This Image will be saved to Gallery into the Photos folder automatically.

Test was successful, if the Image appears on your Display. The camera is ok.

• Select Options

• Select Delete

• Select Yes

• Select Exit for Home Menu

If the test is failed see Quick Trouble Shooter.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 20

nokia

20 (23) Approved 4.0

EOPLE CONNECTING P

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

16. INFRARED TEST

Infrared test

You need another infrared device (e.g. 6230) to do a GoNoGo test. The infrared windows of the devices must be

directed to each other and should have a distance of approximate 15 cm. Make sure that infrared is activated in

receiver device.

Warning: Do not point the IR (infrared) beam at anyone’s eye or allow it to interfere with other IR devices. This

device is a Class 1 Laser product.

PAGE

MGR

Reference unit, Bluetooth /infrared activated Test unit

Settings on the test unit:

• Press the red End key to reach the Home Menu

• Select Names and select Search for an entry

If phone and SIM memory is empty, create one new entry.

• Select options

• Select Contact details

• Select Options

• Select Send business card

• Select Via infrared

If sending of business card fails, make sure again that infrared windows are directed to each other and

infrared is activated in reference device. Then try again sending.

Test was successful, if you get this message on receiver device.

You will

• Press the red End key to reach the Home Menu

not get a confirmation on sender device.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 21

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

17. GONOGO TEST

After the optical check, a GoNoGo test has to be carried out if the unit has been unscrewed to guarantee the

functionality of the phone.

Please refer to the actual information on NOKIA Online. When using delivered tester support files, take care of the

right setup according to the tester type and product type.

Please refer to “Recommended Service Equipment” on NOKIA Online.

PAGE 21 (23) Approved 4.0

MGR

Mobile Phone Tester

18. BATTERY TEST

A battery tester lets you test the capacity of NOKIA batteries.

Please refer to the actual information on NOKIA Online.

http://www.astratec.co.uk/

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

http://www.cadex.com/

Page 22

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

19. FORWARDING OF REPAIRS

When it is necessary to forward of repairs to appropriate service supplier with higher service level we recommend

using the offered swap phone cartons as described in Spare Parts SB-004.

Always Protect the window with a protection film.

PAGE 22 (23) Approved 4.0

Put the unit under the stretch film.

MGR

Add repair documentation e.g. filled-in service note into

the swap carton.

There are two different sizes of swap cartons for common mobile phones.

Fold the swap carton as shown in Spare Parts SB-004.

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Page 23

nokia

CONNECTING PEOPLE

CMO Operations & Logistics

WW Service Solutions & Development

Bochum / Germany CONFIDENTIAL 14.7.2005

20. ESD PROTECTION REQUIREMENTS

Please refer to the NOKIA Online document Service Supplier Requirements in folder General instructions.

PAGE 23 (23) Approved 4.0

MGR

USE Conductive bags and boxes

USE ESD compatible service tools

USE Conductive wastebaskets

USE ESD gloves when handling PWBs/PCBs

USE Cleaning material without changing el. Characteristics

USE Grounded service equipment, i.e. soldering station

USE ESD clothes such as coat or frock

The video covers general issues concerning Electro-Static Discharge (ESD)

NO Smoking

NO Drinking

NO Eating

NO Dust

NO Useless Items

NO Normal pressured air for cleaning

modules/displays

Service Manual 5140/5140i Level 1&2 Copyright © 2004-2005 NOKIA Corporation. All rights reserved.

Loading...

Loading...