Page 1

Lucent CDMA 3G 1xEV

Powered by Bell Labs™

EXHIBIT 4: Installation Manual

The Installation manual is provided.

Applicant: Lucent Technologies FCC ID: AS5ONEBTS-11

Page 1 of 1

Page 2

Flexent Modular Cell 4.0B

Outdoor Cabinet Installation Manual

Lucent Technologies - Proprietary

This document contains proprietary information

of Lucent Technologies and is not to be disclosed or used

except in accordance with applicable agreements

401-703-454

FOA Draft Issue 1

February, 2006

Copyright 2006 Lucent Technologies

Unpublished and Not for Public atio n

All Rights Reserved

Page 3

Copyright 2006 Lucent Technologies. All Rights Reserved.

This material is protec ted by the copyrig ht and trade secre t laws of the United States and

other countries. It may not be reproduced, distributed or altered in any fashion by any

entity, (either internal or external to Lucent Technologies) except in accordance with

applicable agreements, contracts or licensi ng, wi tho ut the exp r es se d wri tten cons ent of

the Information Products and Training organization and the business management

owner of the material.

Notice

Every effort w as made to en sure t hat the inform ation in th is In formati on Prod uct (IP) was

complete and accura te at the time of printi ng. However, information is su bje ct to change.

Trademarks

All trademarks and service marks specified herein are owned by their respective

companies.

Ordering Informati on

The ordering number for this IP is 401 -703-414 . To order this IP, use one of the following

numbers to call the Lucent Technologies Customer Information Center in Indianapolis,

Indiana.

Within the United States: 1-888-LUCENT8 (1-888-582-3688; fax 1-800-566-9568)

From Canada: 1-317-322-6615 (fax 1-317-322-6699)

From all other countries: 1-317-322-6416 (fax 1-317-322-6699)

Technical Support

For technical support, see “To obtain documentation, training, and technical

support, or submit feedback” on the 401-010-001 Flexent

Networks System Documentation CD-ROM or the documentation web site at

https://wireless.support.lucent.com/amps/rls_info/rls_doc/cd_docs/customer.support/

customer.support_toc.pdf.wen

AUTOPLEXWireless

Technical Support Telephone Numbers

Lucent Technologies provides technical assi stanc e support for it s wirel ess product s. The

support numbers are:

Support via Customer Technical Support (CTS) in the United States:

1-866-LUCENT8 (1-866-582-3688)

From all other countries: 1-630-224-4672

Alternate: 1-800-CAL-4NSC (1-800-225-4672)

Developed by Lucent Technologies

Page 4

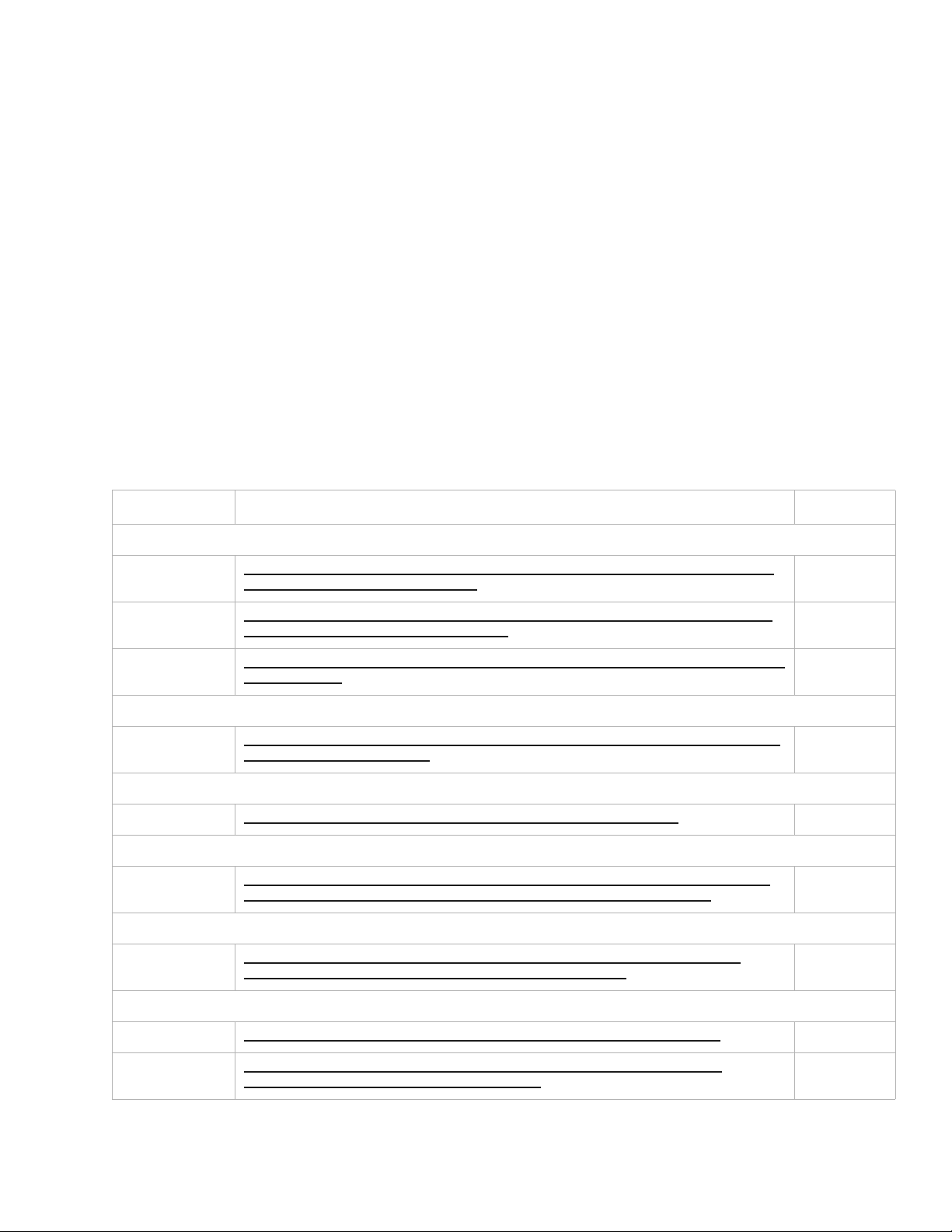

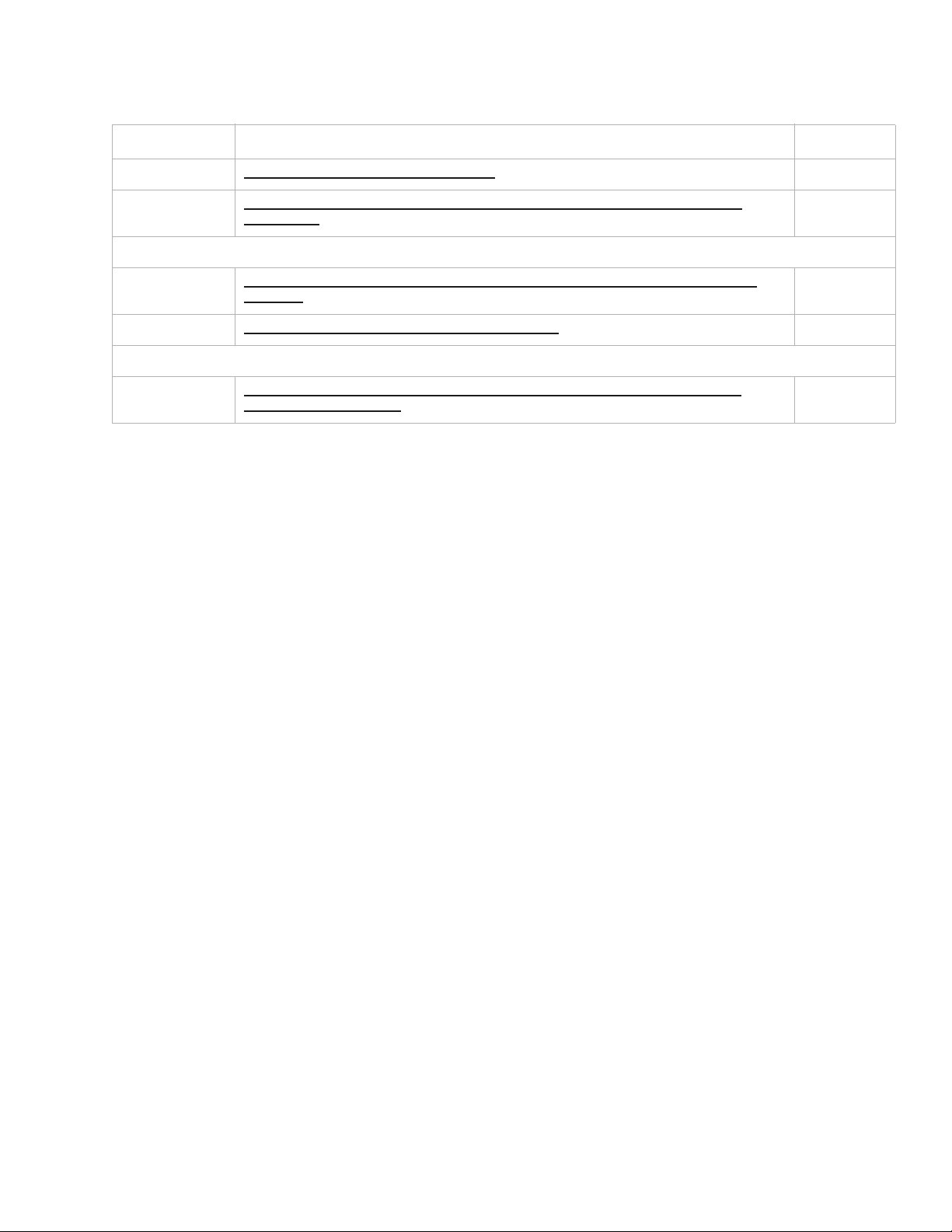

Contents

About this information productt

About this information product

Installation process

Physical installation process chart - xxii

Physical installation process table - xxii

Installation Procedure checkl is ts - xxiii

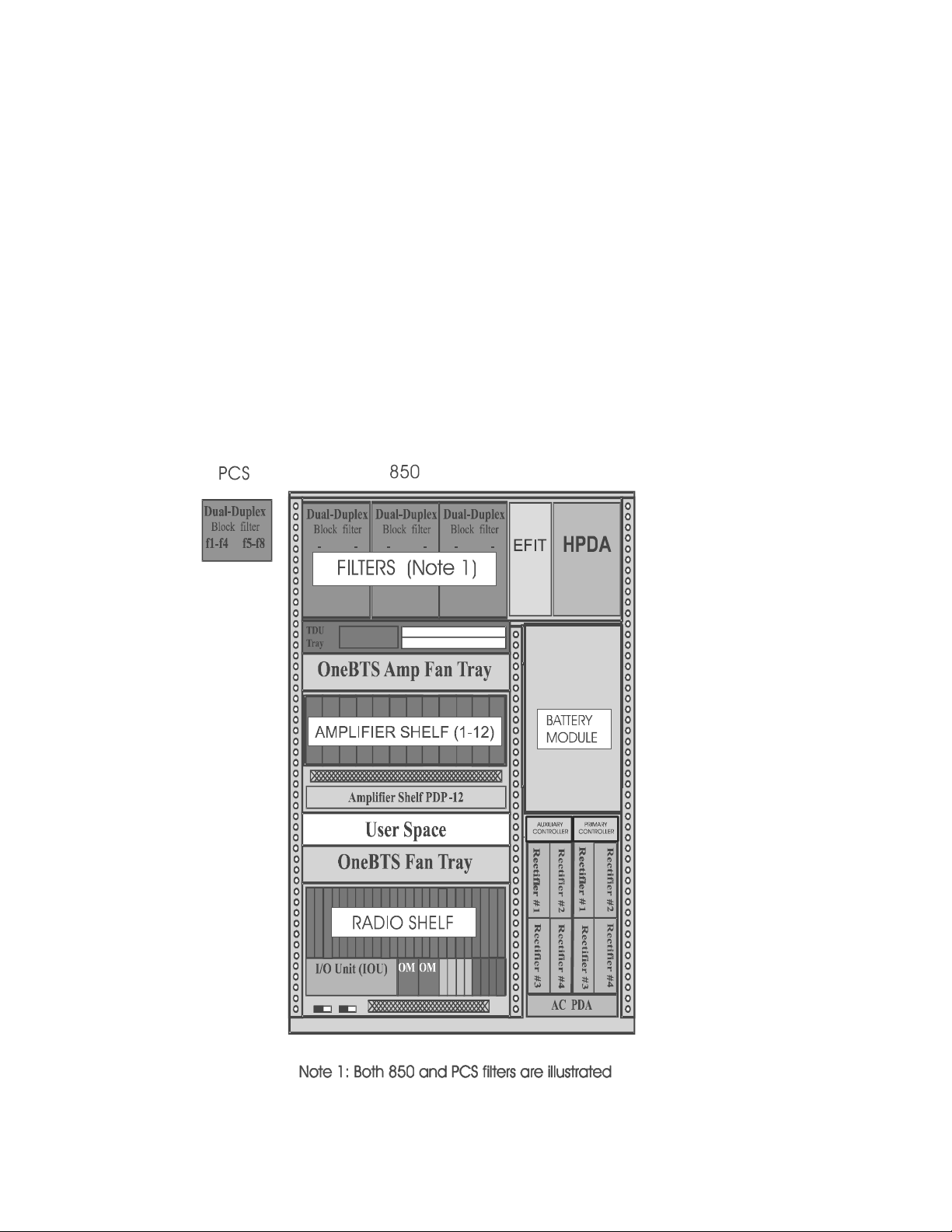

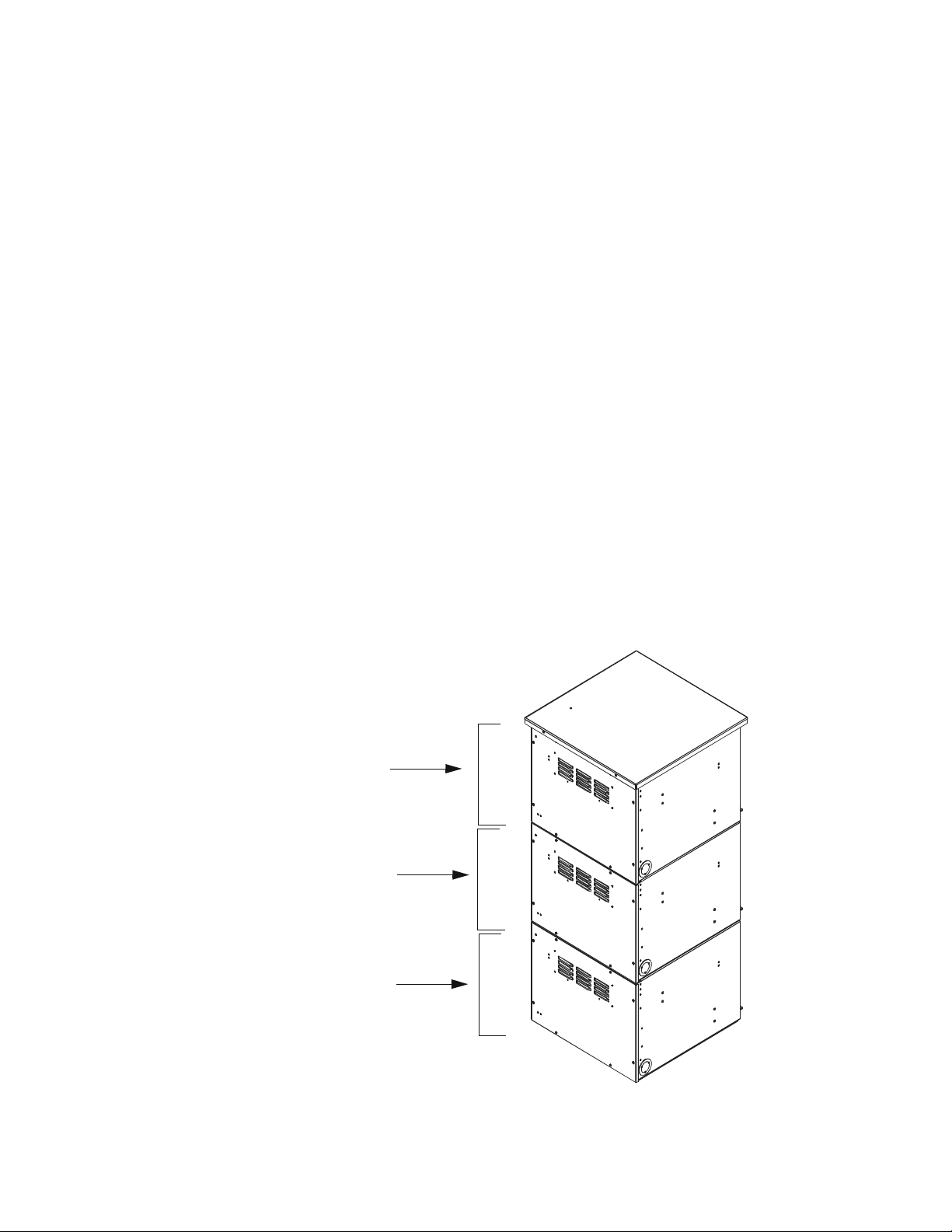

1 Overview of the Flexent Modular Cell4.0B cabinet installation

General information 1- 3

Modular Cell 4.0B cabinets 1- 2

Torque requirements 1- 29

Tools, supplies, and parts required (master list) 1- 31

Safety precautions 1- 34

Safety - General precautions for installation procedures 1- 35

Safety - Specific hazards 1- 37

v

Safety labels 1- 40

Product safety 1- 41

FCC statements 1- 42

Canadian standards 1- 45

Eco-environmental statements 1- 46

Packaging collection and recycling 1- 48

Minimum installation temperatures 1- 49

Network description 1- 51

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

Use pursuant to company instructions

CONTENTS

i

Page 5

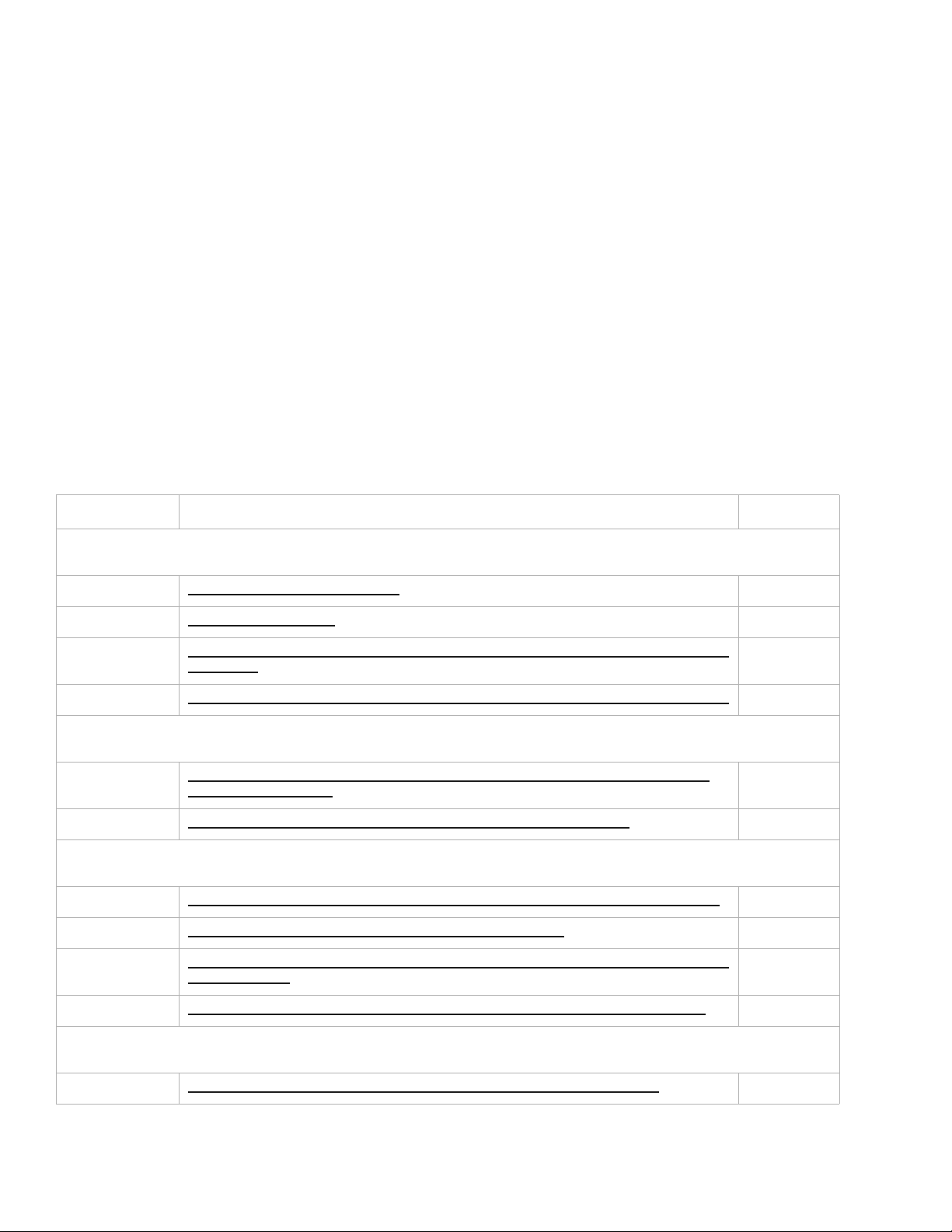

2 Modular Cell 4.0B and WNG24-BC cabinet handling, placement, anchoring and grounding

Installation of anchors and optional mounting bases, if applicable

Cabinet handling

Cabinet placement, anchoring and grounding

3 Cable connections in the Modular Cell 4.0B cabinets

Cable connection references 3- 2

Installation of the GPS antenna jumper cable for the 4.0B primary

cabinet

Connection of the conduit with T1/E1 lines and external user alarms

cables to a 4.0B primary cabinet

How to route the T1/E1 cable(s) to a Modular Cell 4.0B dual band

cabinet in a line-up that has a Modular Cell 3.0, 4.0, or 4.0B primary

cabinet with integrated power

How to route the T1/E1 cable(s) to a Modular Cell 4.0B dual band

cabinet in a line-up that has a Modular Cell 1.0, 2.0, 3.0, 4.0, or 4.0B

primary cabinet without integrated power

2- 2

2- 21

2- 28

3- 3

3- 13

3- 16

3- 18

Routing of T1/E1 and user alarm cables into a Modular Cell 4.0B

cabinet

Connection of T1/E1 Lines to the EFIM punchdowns in Modular Cell

4.0B cabinets

Connection of user alarms to the EFIM punchdown blocks in the

Modular Cell 4.0B primary cabinet

3- 27

3- 35

3- 48

............................................................................................................................................................................................................................................................

CONTENTS

ii

Lucent Technologies – Proprietary

Use pursuant to compan y instructions

401-703-454

FOA Draft Issue 1

January, 2006

Page 6

4 Power and alarm connections in Modular Cell 4.0B cabinets with integrated power

Modular Cell 4.0B cabinets without integrated power that utilize non-

Lucent power (reference)

4- 2

Power and alarm wiring overview 4- 3

Safety precautions 4- 5

How to route and connect the AC utility wires at a Modular Cell 4.0B

primary or dual band cabinet

How to make the cable connections between the first WNG battery

cabinet and the 4.0B primary cabinet

How to make the cable connections between the second WNG battery

cabinet and the first WNG battery cabinet

How to install 60ECv2 battery cabinets with a 4.0B primary cabinet with

integrated power (reference)

5 Component installation in the Modular Cell 4.0B and the WNG24-BC battery cabinest

How to install components in Modular Cell 4.0B cabinets 5- 2

How to install batteries in a WNG24-BC battery cabinet

4- 6

4- 14

4- 44

4- 71

5- 10

How to route the thermal probe cable(s) and mount the therma l

probe(s) in the battery cabinets

How to make final DC connections after installation of a battery cabinet

6 RF cable connections between existing Modula r Cell cabinets and a 4.0B dua l band cabinet

Procedures for the use of this chapter

Routing and connection of RF inter-frame cables to a 4.0B Modular Cell

dual band cabinet

7 Finishing the installation

Finish the installation of the Modular Cell 4.0B ce ll site cab inets

5- 81

5- 84

6- 2

6- 8

7- 2

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

Use pursuant to company instructions

CONTENTS

iii

Page 7

Appendix A: EZBFo battery frame installation with Modular Cell 4.0B cabinets (with integrated power)

Appendiix B: Non-Lucent power ancillary hardware installation, cable routing and connection

Appendix C: Post-installation check lists by cabin et

Glossary

............................................................................................................................................................................................................................................................

CONTENTS

iv

Lucent Technologies – Proprietary

Use pursuant to compan y instructions

401-703-454

FOA Draft Issue 1

January, 2006

Page 8

About this information product

Purpose

This information product (IP) provides instructions for the physical

installation of the following:.

• Flexent Modular Cell 4.0B outdoor primary cabinets with

integrated power, and the associated WNG24-BC battery cabinets

or EZBFo battery frames

• Modular Cell 4.0B outdoor dual band cabinets with integrated

power, with various Legacy cabinets.

• Modular Cell 4.0B outdoor cabinets without integrated power, that

utilize customer power

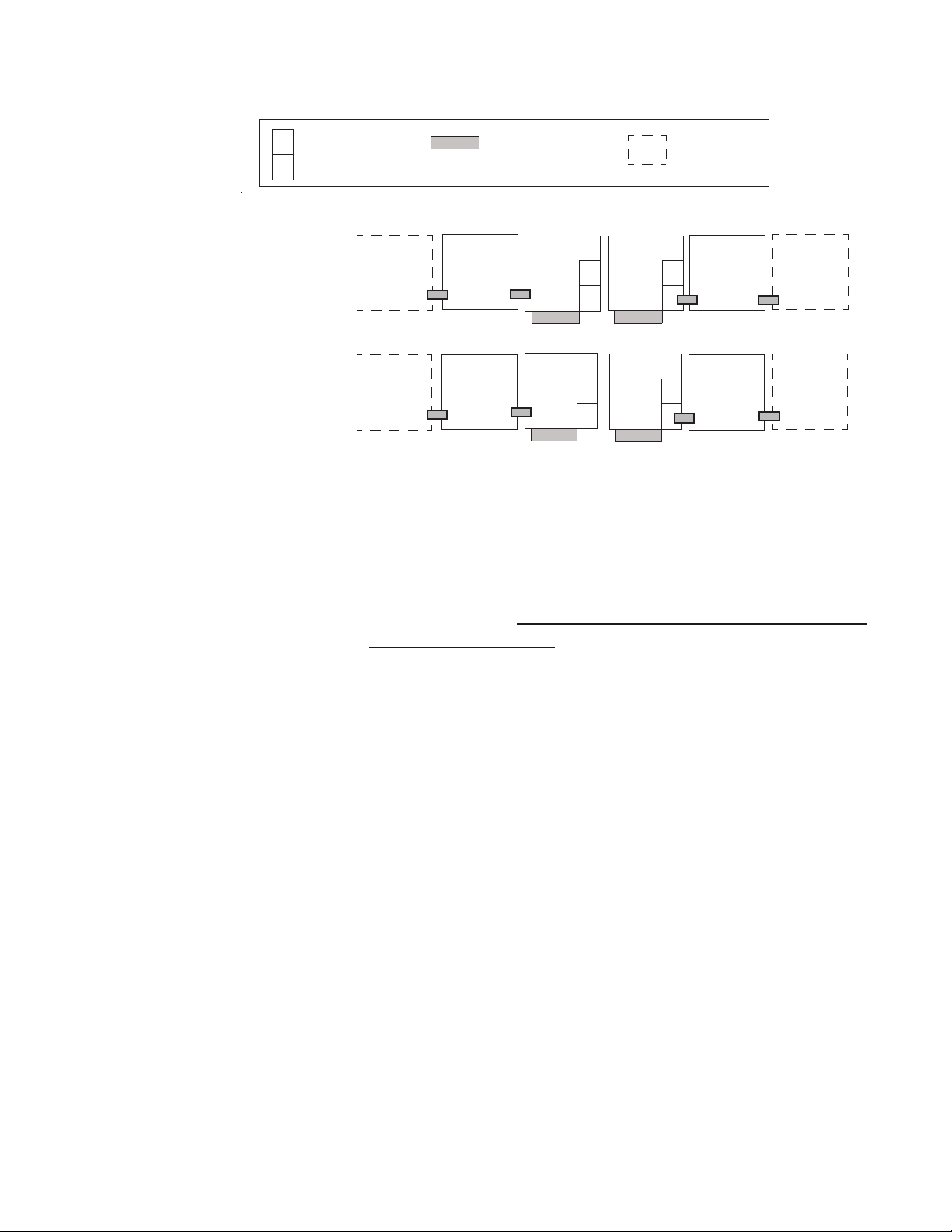

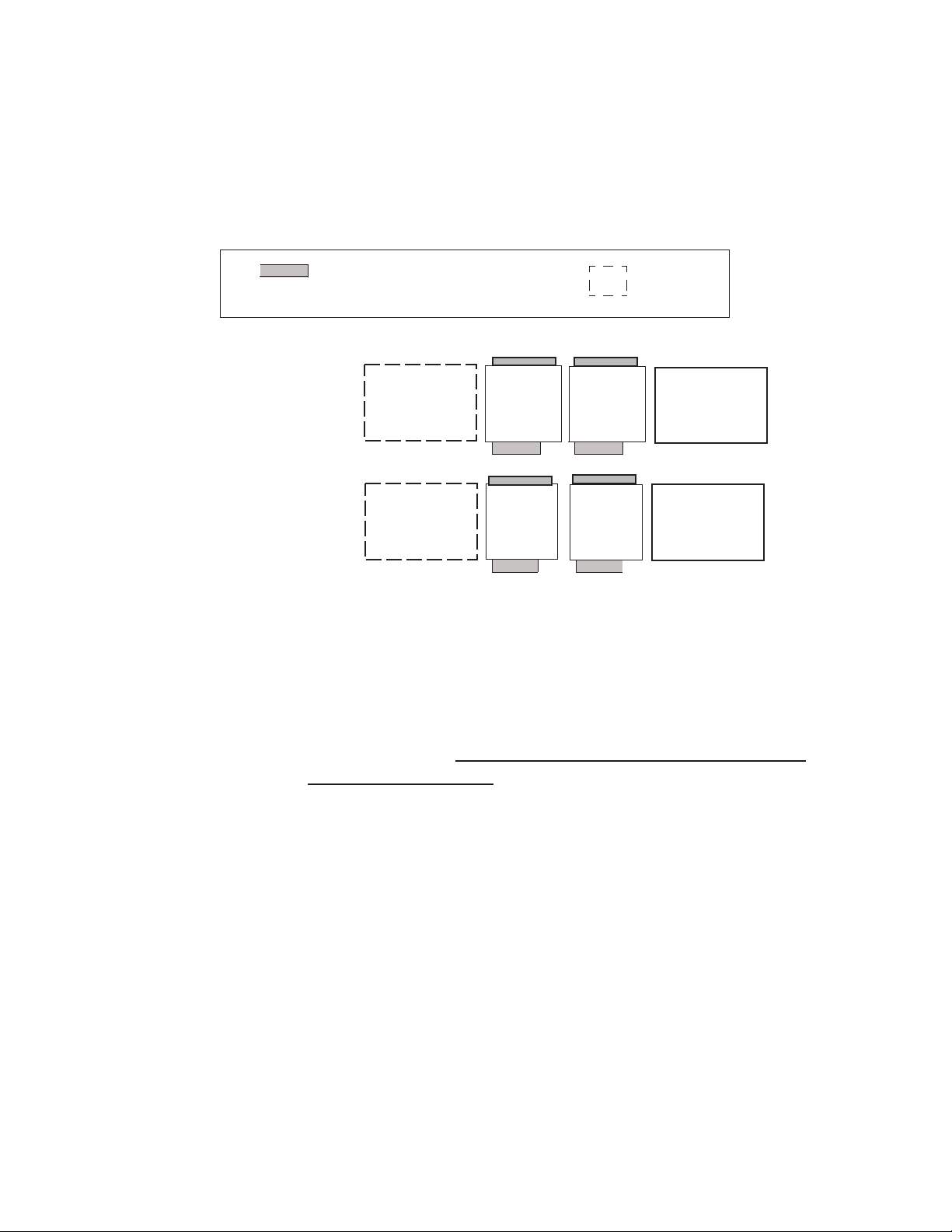

For 4.0B Dual Band cabinet installation, a PCS 4.0B dual band cabinet

may be installed with an 850 Cellular 4.0B primary cabinet. A PCS

4.0B dual band cabinet may be installed with an 850 Cellular 4.0B

primary cabinet. Also, a 4.0B PCS dual band cabinet with integrated

power may be installed with 850 Cellular 1.0/2.0/3.0/4.0 primary and/

or first growth cabinets in certain line-up configurations. Variations in

the RF cabling are specified in the text.

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

v

Page 9

When connecting 60ECv2 and WNG24-BC battery cabinets to

PowerHouse 24 and WNG24-K power cabinets, respectively, the

instructions are provided in Outdoor Flexent CDMA Modular Cell 1.0/

2.0 Cabinet Installation Manual, 401-710-123.

The tasks mentioned on the previous page are to be performed after

completion of all site preparation tasks, which are covered in Flexent

Modular Cell 4.0/4.0B Outdoor Site Preparation Guidelines, 401-703-

413.

Important! The procedures contained in this IP are based on

Lucent Technologies standard practices. Prior to beginning a

Modular Cell 4.0B cabinet, or battery cabinet installation,

installers should be familiar with these practices. If there is a

conflict, standard practices take precedence. However, this IP

takes precedence for identification of parts and materials specific

to a Modular Cell 4.0B cabinet, or battery cabinet installation.

Important! Following installation of the Modular Cell 4.0B

cabinet, the next step is to test and integrate it into the network.

Procedures for testing and integration may be found in Installation

Engineering Handbook 238.

...........................................................................................................................................................................................................................................................

vi

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 10

Reason for reissue

This is FOA Draft Issue 1 of the Flexent Modular Cell 4.0B Outdoor

Cabinet Installation Manual, document number 401-703-454. This

issue incorporates information that was formerly included in the

Flexent Modular Cell 4.0/4.0B Outdoor Cabinet Installation Manual,

document number 401-703-414. This issue also incorporates the

following new information available as of January, 2006:

• New 4.0B cabinet configurations:

• 4.0B PCS Dual Band G-2 cabinet installation with existing

primary and G1 Legacy cabinets

• 4.0B PCS Dual Band G-3 cabinet installation with existing

primary, G1 and G2 Legacy cabinets

• 4.0B PCS cabinet, four to six sectors added

• Increase in PCS carriers available in a 4.0B dual band cabinet to

eleven total.

• Addition of installation instructions for the dual band integrated

power alarm cable

• 4.0B Heat exchanger and solar shield table revised

• RF cable routing and connection added between a 4.0B PCS Dual

Band G-2 or G-3 cabinet and existing Legacy cabinets

• Revisions to Appendix B to add an additional DC cable for

cabinets with an A6 shelf

The following significant changes have been made since the release of

Issue 8.0 of document 401-703-414:

Significant changes from last issue

• In Chapter 1:

• Miscellaneous line-up and carrier changes and clarifications

• New 4.0B line-up configurations added (see above list).

Refer to

Flexent Modular Cell 4.0B site descriptions (typical) on Page 1 -

Modular Cell 4.0B cabinets on Page 1 - 8 and Outdoor

15

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

vii

Page 11

• In Chapter 2:

• 4.0B heat exchanger and solar shield table revised. Refer to

Heat exchanger and solar shield configurations for Modular Cell

4.0B cabinets on Page 2 - 69.

• In Chapter 3:

• Addition of installation instructions for the dual band

integrated power alarm cable. Refer to Route and punch down

the dual band cabinet integrated power alarms on the EFIM in the

Modular Cell 4.0B primary cabinet, if applicable on Page 3 - 49

• In Chapter 4:

• AC junction box and conduit paragraph and figure added.

Refer to AC conduits on Page 4 - 3

• In Chapter 6:

• RF cable routing and connection added between a 4.0B PCS

Dual Band G-2 or G-3 cabinets and existing Legacy cabinets.

Refer to Routing and connection of RF inter-frame cables to a

4.0B Modular Cell dual band cabinet on Page 6 - 8

• In Appendix A:

• EZBFo footprint figure with Modular Cell 4.0B cabinets

added. Refer to EZBFo battery frame footprint with Modular Cell

4.0B primary and dual band cabinets on Page A - 5

• In Appendix B:

• Revisions to Appendix B to add an additional DC cable for

cabinets with an A6 shelf. Refer to

DC power cables to the Modular Cell 4.0B primary cabinet on

How to route and connect

Page B - 18, and How to route and connect DC power cables to a

Modular Cell 4.0B dual band cabinet on Page B - 54

• In "Installation Process":

• Revised installation process checklist references as a result of

changes made in the applicable chapters and appendices

...........................................................................................................................................................................................................................................................

viii

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 12

Safety labels

The safety alert symbol is used on product labels and in this IP to alert

the user to important safety instructions. The definitions of the three

types of safety labels are listed below, in order of severity.

DANGER

DANGER indicates the presence of a hazard that will cause

death or severe personal injury if the hazard is not avoided.

WARNING

WARNING indicates the presence of a hazard that can cause

death or severe personal injury if the hazard is not avoided.

CAUTION

CAUTION indicates the presence of a hazard that will cause

minor personal injury or property damage (to include loss of

software or interruption of servic e) if the hazar d i s not avoided.

Within this IP, the safety label typically includes addi tional information

such as the hazard type, a description of the damage that can be caused,

and the steps that should be taken to avoid the hazard.

Intended audience

This IP is intended for use by Lucent Technologies’ installation

technicians.

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

ix

Page 13

How to use this information

product

Since this IP contains instructions for the installation of all Modular

Cell 4.0B outdoor site cabinets (in all applications and configurations),

only certain pages are required for specific installations.

In order to isolate the pages required for your current installation, the

installer may use the "Installation Procedure Checklist", which list s a ll

installation procedures, by chapter, along with corresponding chapter

and page references where the actual instructions can be found. The

procedures required for a certain installation are separated by headings

which identify the installation activity.

This checklist may also be used by installers to record completion of

individual installation activities. The checklist contains a

"completed" column, and is printed on one side of the page only, in

order to facilitate copying.

For experienced installers, chapter and page references can be used in

the event a particular activity requires review.

The Installation Procedure Checklist is included in the "Installation

process" chapter, which immediately follows this chapter.

...........................................................................................................................................................................................................................................................

x

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 14

The following is a general overview of chapter and appendix usage.

Installation process Provides an explanation of the installation process,

and includes the "Installation Procedure Checklist".

After reading Chapter 1, the installer should use the following chapters

and appendices, as applicable. Note that a battery cabinet/frame(s) can

be installed simultaneously using the same chapter order. For the

installation of primary cabinets, use the following chapters and

appendices, as applicable

Primary 4.0B cabinet with integrated power: Initial installation

• Installation Process as a guide to installation steps

• Chapters 2 through 5, as applicable, and Chapter 7 to finish the

installation

Primary 4.0B cabinet without integrated power: Initial installation

• Installation Process as a guide to installation steps

• Chapters 2 and 3, Appendix B, and Chapter 7 to finish the

installation

4.0B dual band cabinet with integrated power: Initial installation

• Installation Process as a guide to installation steps

• Chapters 2 through 6, as applicable, and Chapter 7 to finish the

installation

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xi

Page 15

4.0B dual band cabinet without integrated power: Installation

• Installation Process as a guide to installation steps

• Chapters 2, 3, and 6, Appendix B, and Chapter 7 to finish the

installation

For the installation of power cabinets or frames, use the following

chapters and appendices, as applicable.

If a 4.0B dual band cabinet is installed with existing 1.0, 2.0, 3.0, or 4.0

cabinets that utilize a PowerHouse24 or WNG power cabinet, the total

load for all cabinets is limited to 17kW. The total number of carriers

possible in the 4.0B dual band cabinet will be limited. Use of a dual

band cabinet with Integrated Power is recommended to overcome this

limitation

For the installation of additional cabinets, use the following chapters

and appendices, as applicable.

EZBFo battery frame installation (first and/or second) with a Modular

Cell 4.0B primary or dual band cabinet, which has integrated power:

• Installation Process as a guide to installation steps

• Chapter 2 for handling, placement, anchoring and grounding

• Appendix A for installation instructions

Subjects covered in this manual are listed below.

Installation process Provides an explanation of the installation process,

and includes the "Installation Procedure Checklist".

Chapter 1 "Overview of the Flexent Modular Cell 4.0B cabinet

installation" provides the following information.

• An overview of the Flexent Modular Cell 4.0B cabinets

• A description of typical installation sites, as well as cabinets.

Chapter 2 "Modular Cell 4.0B and WNG24-BC cabinet handling,

placement, anchoring and grounding" provides the following

information.

• Procedures for anchor installation

• Instructions for installation of optional mounting bases

• Instructions for cabinet handling

...........................................................................................................................................................................................................................................................

xii

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 16

• Procedures for placement, anchoring and grounding of the

Modular Cell 4.0B primary cabinet, as well as the first and second

WNG battery cabinet

• Procedures for placement, anchoring and grounding of Modular

Cell 4.0B dual band cabinet.

Chapter 3 "Cable connections in the Modular Cell 4.0B cabinets"

provides procedures for connecting the following cables at the primary,

or dual band 4.0B Modular Cell cabinets, as applicable.

• GPS antenna (primary cabinet only)

• T1/E1.

• External user alarms (primary cabinet only)

Chapter 4 "Power and power alarm connections in Modular Cell 4.0B

cabinets with integrated power" provides the following procedures for

power and power alarm connections.

• Customer power references to other chapters and appendices, as

well as other documents

• AC Utility connection to the primary or dual band cabinet

• AC, DC, alarm and fan power cable connections between the first

battery cabinet and the primary Modular Cell 4.0B cabinet, as well

as between the second battery cabinet and the first battery cabinet

• Battery installation procedure revisions (for 66ECv2 battery

cabinet with 4.0B with integrated power)

Chapter 5 "Component installation in the Modular Cell 4.0B and

WNG24-BC battery cabinets" provides the following procedures for

the installation of power components.

• Rectifier and battery installation in the primary and dual band

cabinets (for reference only)

• Battery installation in the first and second WNG battery cabinets

• Final DC connections after installation of the first or second WNG

battery cabinet.

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xiii

Page 17

Chapter 6 "RF cable connections between existing Modular Cell

cabinets and a Modular Cell 4.0B dual band cabinet" provides the

following procedures for RF connections between cabinets.

• Procedures for the use of the chapter

• Routing and connection of RF cables between existing Modular

Cell cabinets and a Modular Cell 4.0B dual band cabinet

Chapter 7 "Finishing the installation" provides the following

procedures for finishing the installation of individual cabinets.

• RF antenna connections (Primary or dual band cabinets)

• Final connection of primary cabinet batteries

• Replacement of panels and closure of cabinet doors (all cabinets).

Appendix A "EZBFo Battery Frame Installation with Modular Cell

4.0B cabinets (with integrated power)" provides installation

procedures for the installation of the EZBFo battery frame as an

alternate to the WNG24-BC procedures presented in Chapters 4

and 5.

Appendix B "Non-Lucent power ancillary hardware installation, cable

routing and connection" provides instructions for the connection of

non-Lucent customer power at the 4.0B Modular Cell cabinets

Appendix C "Post-installation checklist by cabinet" provides

checklists to verify completion of required items.

Appendix D “Post-installation checklist by cabinet”

provides checklists

to verify completion of required items.

Glossary

...........................................................................................................................................................................................................................................................

xiv

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 18

Conventions used

The following conventions are used in this IP:

Illustrations

The illustrations shown in this IP are schematics. They do not contain

all details and exceptions, but are rather intended to highlight main

points. Dimensions are usually shown in millimeters, with inches in

parenthesis. As an example, 680.0 (26.77) equals 680 millimeters or

26.77 inches.

Naming conventions

The Flexent Modular Cell 4.0B cabinet will be referred to as the

Modular Cell 4.0B cabinet, or merely the 4.0B cabinet.

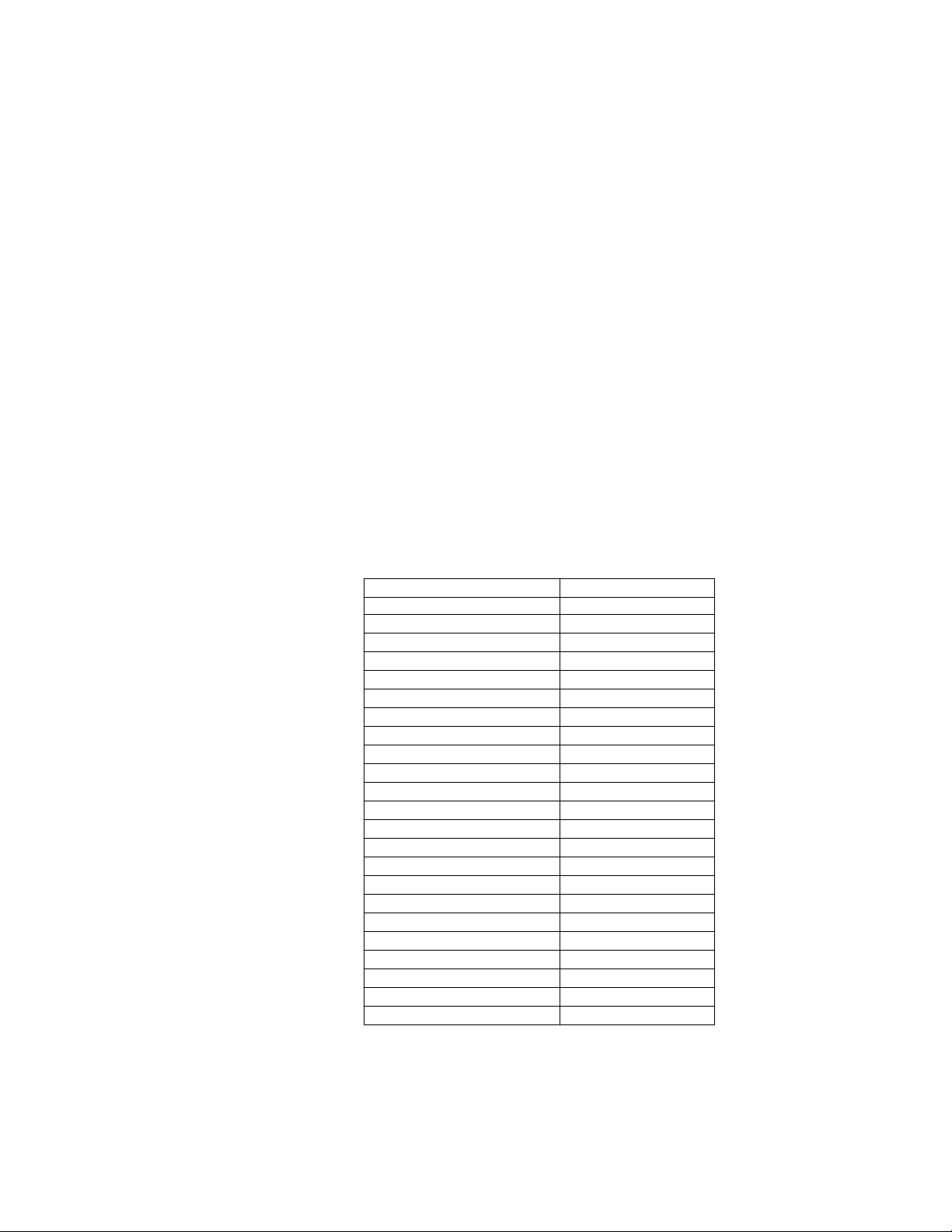

Standard cross-sections and wire diameters of round copper

conductors

The following table is from IEC standard 60947-1 (c) IEC:1996

+A1:1997+A2:1998.

ISO CROSS SECTION (mm2)AWG

120 0000

95 000

70 00

50 0

35 2

25 4

16 6

10 8

610

412

2.5 14

1.5 16

116

0.75 18

0.5 20

0.5 22

0.2 24

DIAMETER (mm) AWG

0.81 20

0.65 22

0.51 24

0.4 26

0.32 28

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xv

Page 19

Related documentation

The following product-related documentation is available for the

Flexent Modular Cell 4.0B cabinet:

Lucent Technologies documents

• Flexent Modular Cell 4.0/4.0B Outdoor Site Preparation

Guidelines, 401-703-413*

• Outdoor Flexent Modular Cell 1.0/2.0 Cabinet Installation

Manual, 401-710-123*

• Grounding and Lightning Protection Guidelines for Lucent

Technologies Network Wireless System Cell Sites, 401-200-115*

• Base Station CDMA Reference Frequency Timing Generator and

GPS Antenna System Description, Operation, Installation and

Maintenance, 401-660-128*

• Lucent Technologies Installation Engineering Handbook 238*

• 12IR125 Series II Batteries KS-23997 Product Manual, Select

Code 157-622-025*

• Corner Mounted Rotating Derrick Equipped with Hydraulic

Digger - Description and Maintenance, 649-300-021*

• Slings, 649-310-115*

• B Connecting Links, 081-410-105*

* May be ordered by contacting Lucent’ s Customer Information Center

(CIC) at the telephone numbers on the following pages.

...........................................................................................................................................................................................................................................................

xvi

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 20

Related training

The following product-related training is available for the Flexent

Modular Cell cabinet:

Lucent Technologies training

Flexent Modular Cell 4.0 Installation Video Course,

CL 5494*

* May be ordered by contacting Lucent’ s Customer Information Center

(CIC) at the telephone numbers listed below.

Site preparation checklists

Information Product

Support

All site preparation activities, as well as adherence to the guidelines,

should be verified prior to the installation of the cell site equipment.

Various checklists and punchlist sheets have been provided in

Appendix A of the site preparation document (see Related

documentation) to aid customers and Lucent personnel during a base

station site Method of Procedure (MOP) walk-through prior to the

equipment installation. A general list is provided in Chapter 1.

Utilization of the checklists helps ensure a quality installation and

provides a base station site history file for later reference. The punchlist

is used to track completion of any outstanding site preparation items,

and to aid in the project management of installation resources.

For questions or concerns about this or any other Lucent Technologies

information products, please contact us at one of the following

numbers:

• 1 888 727 3615 (for the continental United States)

• 1 630 713 5000 (for all countries)

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xvii

Page 21

Technical Support

For technical support, contact your local customer support team. You

can reach them via the web at (https://support.lucent.com/) or at the

telephone number listed under the T echnical Assistance Center menu at

(http://www.lucent.com/contact/).

At the time of issue of this information product, the following

telephone numbers are supported, depending upon the region:

North America, Central and Latin America, and Asia Pacific Regions:

Customer Technical Assistance Management (CTAM) center: +1 630

713 0488

Europe, Middle East, and African regions:

International Customer Management Center (ICTM): +353 1692 4579

How to comment

Lucent Technologies makes every effort to ensure that all Flexent/

AUTOPLEX wireless documentation and training products meet your

needs. Lucent actively seeks feedback, comments, and suggestions

from customers to improve the quality and usability of documentation

and training. You may submit feedback about Flexent/AUTOPLEX

wireless networks documentation and training via the Internet or email.

To submit feedback via e-mail, send comments to:

ctiphotline@lucent.com

To submit feedback via the Internet, visit the Talk to Lucent web site

at:

http://www.lucent-info.com/comments

Follow the on-line instructions and submit your feedback to Lucent.

The result is that Lucent e-mails you a notice that they have received

your feedback, and will respond to it as soon as possible.

Lucent e-mails you a notice that they have received your feedback, and

will respond to it as soon as possible.

...........................................................................................................................................................................................................................................................

xviii

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 22

How to order this

information product

How to order

The ordering number for this IP is 401-703-414. If you order by mail,

address your request to:

Lucent Technologies Learning Organization

Attention: Order Entry Section

2855 N. Franklin Road

P.O. Box 19901

Indianapolis, IN 46219 USA

To order by phone, please contact the Lucent Technologies Customer

Information Center (CIC) at the following numbers:

• Within the United States:

Telephone: 1-888-LUCENT8 (1-888-582-3688)

Facsimile: 1-800-566-9568

• From Canada:

Telephone: 1-317-322-6615

Facsimile: 1-317-322-6699

• From all other countries:

Telephone: 1-317-322-6416

Facsimile: 1-317-322-6699

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xix

Page 23

...........................................................................................................................................................................................................................................................

xx

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 24

.............................................................................................................................................................................................................................................................

Overview

Installation process

Purpose

This section provides an outline for the physical installation process, as

well as installation procedure checklists to guide the installer through

specific installation procedures.

Physical installation process chart - xxii

Physical installation process table - xxii

Installation Procedure chec kli sts - xxiii

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxi

Page 25

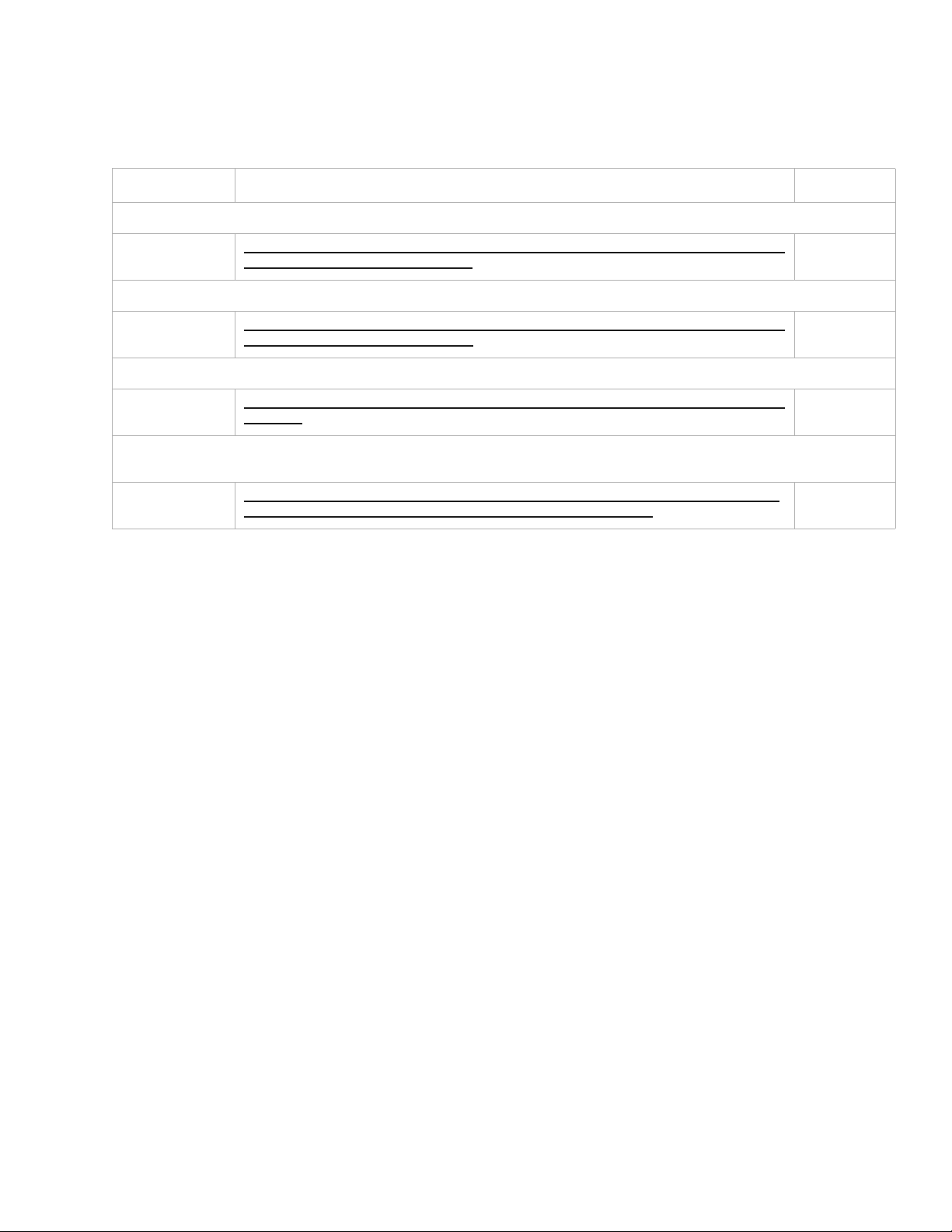

Installation process

INST ALLER ACTIVITY

2

5

6

Physical installation

process chart

ACTIVITY

NUMBER

ACTIVITY

NUMBER

Physical installation

process table

The chart shown below assigns the concurrent installa tion activit ies for

each of two installers. The specific activities are listed in the table that

follows.

INSTALLER 1

#1 #2 #3 #4 #6 #7 #8 #9 #10 #11 #12

INSTALLER 2

#2 #5

#7

#5 (CON’T )

This table represents the activities required to install a Modular Cell

4.0B primary cabinet with integrated power.

ACTIVITIES

1. Check parts inventory

. Line up cabinet on the cabinet anch or ho les

3. Anchor the ca binet to the surface

4. Ground the cabinet

. Install six RF antenna cable jumpers and one GPS antenna

cable

. Install the conduit interface for the T1/E1 and user alarm

cables

7. Route the T1/E1 and user alarm cables into the cabinet X

8. Punch down the T1/E1 lines at the EFIM X

9. Install the conduit interface for the AC utility cable X

10. Route and connect the AC feed to the terminal block in the

power module

11. Turn on and check power X

12. Clean up X

ASSIGNMENT

INSTALLER 1 INSTALLER 2

X

XX

X

X

X

X

X

X

...........................................................................................................................................................................................................................................................

xxii

Lucent Technologies – Proprietary

See notice on first page

401-703-454

FOA Draft Issue 1

January, 2006

Page 26

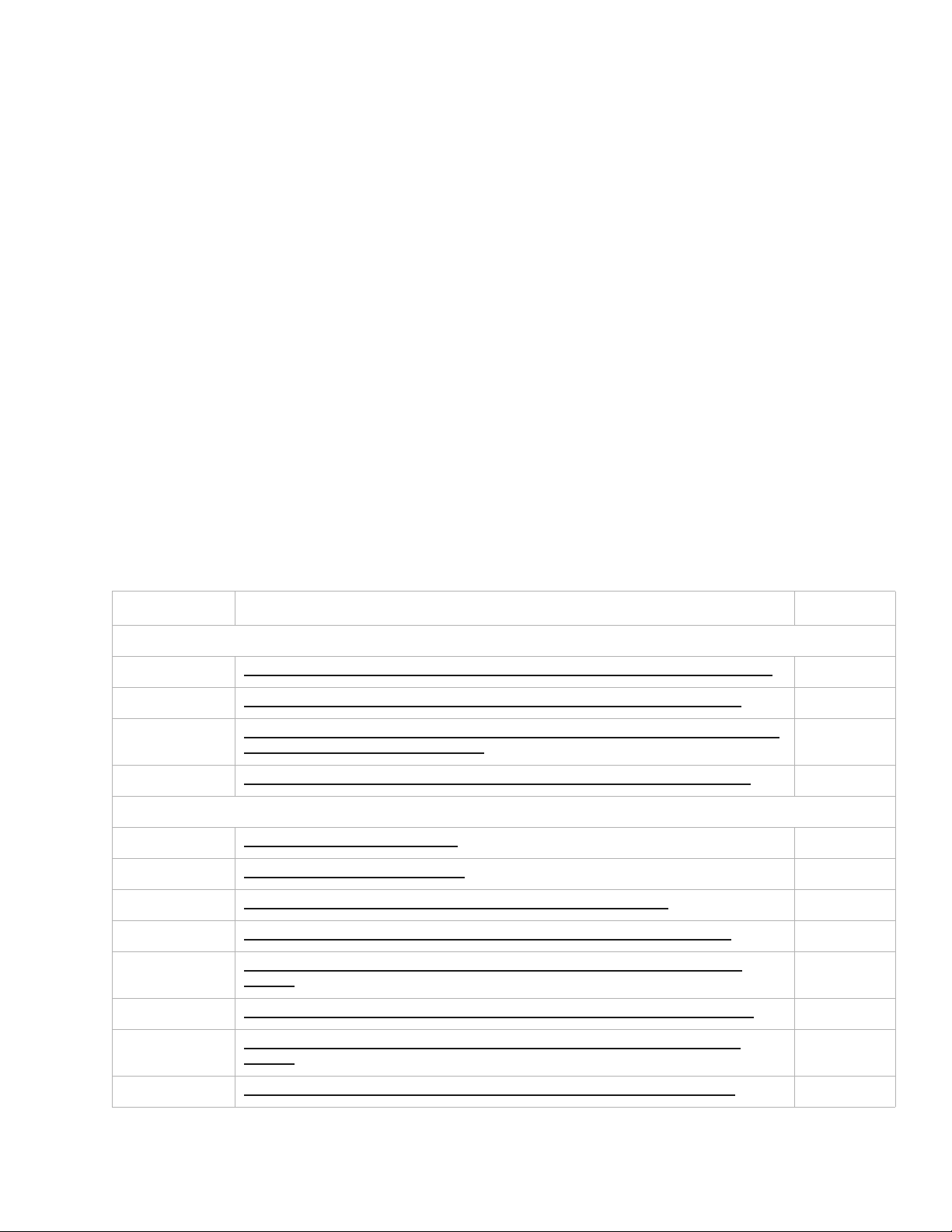

Installation Procedure checklists

.............................................................................................................................................................................................................................................................

Overview

Purpose

The following checklists may be used by all installers to record

completion of individual installation activities. The checklists are

particularly useful when used to determine the specific activity to be

performed. To use the checklists, make a copy of the pages. Since only

certain pages are required for specific installations, use only the pages

that apply to the specific equipment you are installing.

Page references are given for each activity. The checklists are therefore

useful to experienced installers, to use in place of the installation

manual itself. The page references can be used in the event that a

particular activity requires review.

This section contains installation checklists for the following chapters.

Chapter 2: Modular Cell 4.0B and WNG24-BC cabinet handling, placement,

anchoring and grounding

Chapter 3: Cable connections in the Modular Cell 4.0B cabinets -xxvi

Chapter 4: Power and power alarm connections in Modular Cell 4.0B cabinets

with integrated power

-xxiv

-xxviii

Chapter 5: Component installation in the Modula r Cell 4.0B and WNG2 4-BC

cabinets

Chapter 6: RF cable connections between existing Modular Cell cabinets and a

Modular Cell 4.0B dual band cabinet

Chapter 7: Finishing the installation -xxxiv

Appendix A: EZBFo battery frame installation with Modular Cell 4.0B cabinets

(with integrated power)

Appendix B: Non-Lucent power ancillary hardware installation, cable routing and

connection

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

-xxx

-xxxiii

-xxxv

-xl

xxiii

Page 27

Installation process

.............................................................................................................................................................................................................................................................

Chapter 2: Modular Cell 4.0B and WNG24-BC cabinet handling,

placement, anchoring and grounding

Overview

Table 1 lists the procedures covered in Chapter 2 for handling,

placement, anchoring and grounding of the 4.0B Modular Cell primary

and dual band cabinets, as well as the WNG24-BC battery cabinets.

Modular Cell 4.0B Primary Cabinet Serial Number:

_______________________________

Modular Cell 4.0B Dual Band Cabinet Serial Number:

_______________________________

WNG24-BC Battery Cabinet Serial Number:

_______________________________

Table 1

COMPLETED INSTALLATION STEP PAGE

rk and drill the anchor holes 2 - 5

Ma

Set the 1/2-inch drop-in anchor (if applicable) 2 - 7

PERFORM THE NEXT FIVE STEPS ONLY IF INSTALLING CABINETS ON MOUNTING BASES

Set the 12-mm expansion stud anchors for mounting bases 2 - 9

Chapter 2

Install the optional bases for the primary cabinet, and battery cabinets if

applicable, using zone 0, 1, and 2 type anchors

Install the optional mounting bases for the primary cabinet, and battery

cabinets if applicable, using zone 3 and 4 type anchors

Install the optional mounting bases for a dual band cabinet, using zone 0, 1,

and 2 type anchors

Install the optional mounting bases for a dual band cabinet using zone 3 and 4

type anchors

PERFORM THE NEXT FIVE STEPS IF APPLICABLE

Unpack the cabinet 2 - 24

Install the lifting eye bolts 2 - 24

Lift cabinet using boom tip winch 2 - 25

Transport cabinet 2 - 27

Remove cabinet from pallet 2 - 27

...........................................................................................................................................................................................................................................................

xxiv

Lucent Technologies – Proprietary

See notice on first page

2 - 11

2 - 13

2 - 17

2 - 19

401-703-454

FOA Draft Issue 1

January, 2006

Page 28

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT TWO STEPS ONLY IF INSTALLING A PRIMARY CABINET

Move/lift the primary cabinet into position 2 - 31

Install anchoring bolts or anchor assemblies and level the primary cabinet 2 - 32

PERFORM THE NEXT SEVEN STEPS ONLY IF INSTALLING A WNG2 4-BC BATTERY CABINET

Prepare the existing cabinet for attachment of an additional cabinet 2 - 35

Prepare the cabinet being installed for attachment to the existing cabinet 2 - 37

Partially install the AC cable guide in the cabinet being installed 2 - 39

Move/lift the cabinet being installed into position 2 - 40

Attach the cabinets together at the square cable support (with second battery

cabinet only)

Install anchoring bolts or anchor assemblies and level the battery cabinet(s) 2 - 45

Complete the installation of the AC feed-through coupling and tighten the

anchor bolts or nuts

PERFORM THE NEXT SEVEN STEPS ONLY IF INSTALLING A 4.0B DUAL BAND CABINET

Prepare the previous Modular Cell cabinet for connection of a 4.0B dual band

cabinet

Partially install the AC cable guide in the previous Modular Cell cabinet, if

applicable

Prepare the 4.0B dual band cabinet for connection to the previous Modular Cell

cabinet

Position the 4.0B dua l band Mod ula r Cel l cabinet 2 - 56

Install anchoring bolts or anchor assemblies and level the 4.0B dual band

cabinet

Finish the installation of the AC cable guide and tighten the anchor bolts 2 - 60

Attach the 4.0B dual band Modular Cell cabi net to the previous Modular Cell

cabinet at the RF cable guide

2 - 42

2 - 48

2 - 51

2 - 53

2 - 54

2 - 58

2 - 62

PERFORM THE NEXT FIVE STEPS FOR ALL CABIN ETS, IF APPLICABLE

Install the cabinet grounding cables 2 - 65

Remove the lifting eye bolts 2 - 67

Install the top solar shield 2 - 70

Install the right side solar shield on the primary cabinet (reference, if applicable) 2 - 75

Adjust the door roller bearing (if required) 2 - 76

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxv

Page 29

.............................................................................................................................................................................................................................................................

Chapter 3: Cable connections in the Modular Cell 4.0B cabinets

Overview

Table 2 lists the procedures covered in Chapter 3 for cable connections

in the 4.0B Modular Cell primary and dual band cabinets.

Modular Cell 4.0B Primary Cabinet Serial Number:

_______________________________

Modular Cell 4.0B Dual Band Cabinet Serial Number:

_______________________________

Table 2

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT THREE STEPS IF INSTALLING A 4.0B PRIMARY CABINET, IF APPLICABLE

Connect the unterminated end of the GPS jumper cables to the Modular Cell

4.0B primary cabinet, if applicable

Connect a terminated end of the GPS antenna jumper cables to the Modular

Cell 4.0B primary cabinet, if applicable

Connect the GPS antenna jumper cable to the GPS surge protector at the GPS

antenna cable

Chapter 3

3 - 4

3 - 8

3 - 11

PERFORM THE NEXT STEP TO INSTALL THE CONDUITS FOR TI/E! LINES AND EXTERNAL USER ALARMS

Connect the conduit between the metal conduits and the antenna cable cover

3 - 13

of the 4.0B primary cabinet

PERFORM THE NEXT STEP IF INSTALLING A DUAL BAND CABINET IN AN INTEGRATED POWER LINE-UP

Route T1/E1 cables to the Modular Cell 4.0B dual band cabinet 3 - 16

PERFORM THE NEXT STEP IF INSTALLING A DUAL BAND CABINET IN A LINE-UP WITH A POWERHOUSE 24 CABINET

Route the T1/E1 cable(s) to the Modular Cell 4.0B dual band cabinet (in line-

3 - 19

ups that utilize existing PowerHouse24 or customer supplied power)

PERFORM THE NEXT STEP IF INSTALLING A DUAL BAND CABINET IN A LINE-UP WITH A WNG POWER CABINET

Route the T1/E1 cable(s) to the Modular Cell 4.0B dual band cabinet (in

3 - 24

installations that utilize an existing WNG power cabinet)

PERFORM THE NEXT TWO STEPS IF INSTALLING T1/E1 AND/OR USER ALARM CABLES

Install the EMI / RFI cord grip seals with T1/E1 and user alarm cables 3 - 29

Prepare the T1/E1 and user alarm cables for punchdown and ground

3 - 33

connection at the facilities interface module

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxvi

Page 30

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT STEP IF INSTALLING T1/E1 CABLES WITH 4.0B CABINETS THAT HAVE A MAXIMUM OF 12 T1/E1 LINES

Punch down T1/E1 lines on the EFIM in Modular Cell 4.0B cabinets that accept

3 - 36

a maximum of twelve T1/E1 lines

PERFORM THE NEXT STEP IF INSTALLING T1/E1 CABLES WITH 4.0B CABINETS THAT HAVE A MAXIMUM OF 20 T1/E1 LINES

Punch down T1/E1 lines on the EFIM in Modular Cell 4.0B cabinets that accept

3 - 41

a maximum of twenty T1/E1 lines

PERFORM THE NEXT STEP TO INSTALLING EXTERNAL USER ALARM CABLES WITH 4.0B CABINETS

Punch down the external user alarms cables on the EFIM in Modular Cell 4.0B

3 - 48

cabinets

PERFORM THE NEXT STEP TO INSTALLING THE DUAL BAND CABINET INTEGRATED POWER ALARM CABLES TO THE 4.0B

PRIMARY CABINET

Route and punch down the dual band cabinet integrated power alarms on the

3 - 49

EFIM in the Modular Cell 4.0B primary cabinet, if applicable

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxvii

Page 31

Chapter 4: Power and power alarm connections in Modular Cell 4.0B

.............................................................................................................................................................................................................................................................

cabinets with integrated power

Overview

Table 3 lists the procedures covered in Chapter 4 for AC power

connections in the Modular Cell 4.0B integrated power primary and

dual band cabinets, as well as installation of the WNG24-BC battery

cabinets.

Modular Cell 4.0B Primary Cabinet Serial Number:

_______________________________

Modular Cell 4.0B Dual Band Cabinet Serial Number:

_______________________________

WNG24-BC Battery Cabinet Serial Number:

_______________________________

Table 3

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT FOU R ST EP S IF INSTALLING A PRIMARY 4.0B CABINET WITH IN T EG R ATED POWER

Prepare the AC power module (ACPDA) for connection of the AC utility wires 4 - 7

Install a 2-inch flexible conduit fitting on the primary or dual band cabinet 4 - 9

Connect the flexible conduit between the existing metal conduit and the fitting

at the primary or dual band cabinet

Chapter 4

4 - 10

Route and connect the AC utility wires in the primary or dual band cabinet 4 - 12

PERFORM THE NEXT THIRTEEN STEPS IF INSTALLING A FIRST BATTERY CABINET

Install the cable interface panel 4 - 15

Determine the battery shelf type 4 - 19

Connect the DC cables in the first WNG24-BC battery cabinet 4 - 20

Identify the individual interface panel cables on the battery cabinet side 4 - 24

Route and connect the fan power/alarm cable in the WNG24-BC battery

cabinet

Route and connect the fuse alarm cable in the WNG24-BC battery cabinet 4 - 28

Route and connect the intrusion alarm cables in the WNG24-BC battery

cabinet

Identify the individual interface panel cables on the primary cabinet side 4 - 33

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

4 - 26

4 - 30

xxviii

Page 32

COMPLETED INSTALLATION STEP PAGE

Connect the fuse alarm and fan power/alarm cables in the Modular Cell 4.0B

primary cabinet

Connect the intrusion alarm cable in the Modular Cell 4.0B primary cabinet 4 - 36

Route and connect the thermal probe cable in the Modular Cell 4.0B primary

cabinet

Route the AC power cable into the Modular Cell 4.0B primary cabinet 4 - 40

Connect AC cable in the Modular Cell 4.0B primary cabinet 4 - 42

PERFORM THE NEXT SIXTEEN STEPS IF INS TALLING A SECOND BATTERY CABINET

Disconnect all battery connectors in the first battery cabinet 4 - 45

Disconnect first battery cabinet 24-VDC return wires in the Modular Cell 4.0B

primary cabinet

Prepare the first and second battery cabinets for connection of the DC cables 4 - 48

Connect the DC cables in the second battery cabinet 4 - 50

Connect the battery cabinet cables in the first battery cabinet 4 - 52

Identify and place the alarm and fan power/alarm cables between the two

battery cabinets

Route and connect the fan power/alarm cable in the second WNG24-BC

battery cabinet

4 - 34

4 - 38

4 - 47

4 - 54

4 - 56

Route and connect the fuse alarm cable in the second WNG24-BC battery

4 - 58

cabinet

Route and connect the intrusion alarm cables in the second WNG24-BC

4 - 60

battery cabinet

Route alarm and fan power/alarm cables in the first WNG24-BC battery cabinet 4 - 62

Connect alarm cables in the first WNG24-BC battery cabinet 4 - 64

Connect the fan power/alarm cable in the first WNG24-BC battery cabinet 4 - 65

Route the AC power cable into the first WNG24-BC battery cabinet 4 - 67

Connect AC cable in the first WNG24-BC battery cabinet 4 - 69

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxix

Page 33

Chapter 5: Component installation in the Modular Cell 4.0B and

.............................................................................................................................................................................................................................................................

WNG24-BC cabinets

Overview

Table 4 lists the procedures covered in Chapter 5 for installation of the

rectifiers and batteries in the 4.0B Modular Cell primary and dual band

cabinets with integrated power, as well as installation of batteries in the

WNG24-BC battery cabinets. Also listed are the procedures for final

connection of DC power after the installation of batteries in a WNG24BC battery cabinet.

Modular Cell 4.0B Primary Cabinet Serial Number:

_______________________________

Modular Cell 4.0B Dual Band Cabinet Serial Number:

_______________________________

WNG24-BC Battery Cabinet Serial Number:

_______________________________

Table 4

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT TWO STEPS IF MOVING OR INSTALLING A RECTIFIER OR BATTERIES IN A MODULAR CELL 4.0B CABINET

Install rectifiers in a Modular Cell 4.0B primary cabinet 5 - 3

Chapter 5

Install batteries in a Modular Cell 4.0B cabinet 5 - 5

PERFORM THE NEXT SEVEN STEPS IF INSTALLING L1, L2, OR 12IR125 BATTERIES IN A BATTERY CABINET THAT HAS TYPE 1

SHELVES (SPACING RODS)

Prepare the batteries for installation 5 - 16

Place the batteries on a shelf 5 - 18

Install the battery retaining bracket 5 - 21

Attach the two battery cable assemblies to the retaining bracket (L1,L2, and

12IR125 batteries only)

Connect positive battery cables to all battery strings 5 - 26

Attach interconnecting bus bars to all battery strings 5 - 28

Connect the negative battery cables to all battery strings 5 - 30

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

5 - 23

xxx

Page 34

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT NINE STEPS IF INSTALLING C-11 BATTERIES IN A BATTERY CABINET THAT HAS TYPE 1 SHELVES

(SPACING RODS)

Prepare the batteries for installation 5 - 32

Place the C-11 batteries on a shelf 5 - 35

Install the battery retaining bracket 5 - 37

Attach the two battery cable assemblies to the retaining bracket (C-1 1 batteries

5 - 39

only)

Place the battery negative and positive bus bars 5 - 40

Connect the positive battery cables to the batteries 5 - 42

Attach the interconnecting bus bars 5 - 44

Connect the negative battery cables to the batteries 5 - 46

Install the insulating battery terminal covers 5 - 48

PERFORM THE NEXT SIX STEPS IF INSTALLING 12IR125 BATTERIES IN A BATTERY CABINET THAT HAS TYPE 2 SHELVES (NO

SPACING RODS)

Prepare the 12IR125 batteries for installation 5 - 49

Place the 12IR125 batteries on a shelf 5 - 52

Adjust and secure the front battery retaining br ac ke ts 5 - 55

Connect positive battery cables to all battery strings 5 - 57

Attach interconnecting bus bars to all battery strings 5 - 59

Connect the negative battery cables to all battery strings 5 - 61

PERFORM THE NEXT EIGHT STEPS IF INSTALLING C-11 BATTERIES IN A BATTERY CABINET THAT HAS TYPE 2 SHELVES (NO

SPACING RODS)

Prepare the batteries for installation 5 - 64

Place the C-11 batteries on a shelf 5 - 67

Reinstall the battery retaining brackets 5 - 70

Place the battery negative and positive bus bars 5 - 72

Connect the positive battery cables to the batteries 5 - 74

Attach the interconnecting bus bars 5 - 76

Connect the negative battery cables to the batteries 5 - 78

Install the insulating battery terminal covers 5 - 80

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxxi

Page 35

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT STEP TO CONNECT THERMAL PROBES IN THE BATTERY CABINET

Route the thermal probe cable from the 4.0B primary cabinet and mount the

5 - 82

thermal probe in the battery cabinet

PERFORM THE NEXT THREE STEPS WHEN MAKING THE FINAL CABLE CONNECTIONS OF A FIRST OR SECOND BATTERY

CABINET, AS APPLICABLE

Connect the first battery cabinet +24-VDC cables at the HPDA in the Modular

5 - 85

Cell 4.0B primary cabinet

Connect the DC return cables from the battery cabinet to the return bus in the

5 - 87

primary cabinet

Connect the battery cables in the first and/or second WNG24-BC battery

5 - 88

cabinets

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxxii

Page 36

Chapter 6: RF cable connections between existing Modular Cell

.............................................................................................................................................................................................................................................................

cabinets and a Modular Cell 4.0B dual band cabinet

Overview

Table 5 lists the procedures covered in Chapter 6 for connection of

cables between Modular Cell 4.0B dual band cabinets and the existing

cabinet(s) in a line-up.

Modular Cell 4.0B Dual Band Cabinet Serial Number:

_______________________________

Table 5

COMPLETED INSTALLATION PROCEDURE PAGE

PERFORM THE NEXT THREE PROCEDURES BEFORE STARTING THE INSTALLATION OF CABLES BETWEEN MODULAR CELL

CABINETS

Read cabinet definitions 6 - 3

Identify your line-up configuration 6 - 4

Determine the prerequisite changes needed in the existing cabinet(s) in your

line-up configuration

PERFORM THE A NEXT TWO PROCEDURES TO ROUTE AND CONNECT RF CABLES BETWEEN MODULAR CELL CABINETS

Route and connect the 15-MHz cable(s) 6 - 9

Chapter 6

6 - 5

Route and connect the GPS cable 6 - 18

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxxiii

Page 37

.............................................................................................................................................................................................................................................................

Chapter 7: Finishing the installation

Overview

Table 6 lists the procedures covered in Chapter 7 for finishing the

installation of the Modular Cell 4.0B primary cabinet and dual band

cabinets, as well as the WNG24-BC battery cabinets.

Modular Cell 4.0B Primary Cabinet Serial Number:

_______________________________

Modular Cell 4.0B Dual Band Cabinet Serial Number:

_______________________________

WNG24-BC Battery Cabinet Serial Number:

_______________________________

Table 6

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT THREE STEPS TO VERIFY ANTENNA STATUS AND REFERENCE POWER UP AND SYSTEM TESTS

Verify GPS antenna connection 7 - 3

Verify RF antennas not connected 7 - 3

Perform power-up and system test 7 - 4

Chapter 7

PERFORM THE NEXT FIVE STEPS IF INSTALLING A 4.0B PRIMARY OR DUAL BAND CABINET

Test and connect the internal battery cables (if applicable) 7 - 5

Connect the unterminated end of the RF antenna jumper cables to the Modular

Cell 4.0B primary or 4.0B dual band cabinet

Connect a terminated end of the outdoor RF antenna jumper cables to the

Modular Cell 4.0B primary or 4.0B dual band cabinet

Connect RF antenna jumper cables to the antenna cables 7 - 15

Replace / close all access panels and doors 7 - 18

PERFORM THE NEXT STEP IF INSTALLING A FI RST OR SECOND BATTERY CABINET

Finish the installation of the first or second WNG24-BC battery cabinet 7 - 19

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

7 - 8

7 - 12

xxxiv

Page 38

Appendix A: EZBFo battery frame installation with Modular Cell

.............................................................................................................................................................................................................................................................

4.0B cabinets (with integrated power)

Overview

Table 7 lists the procedures covered in Appendix A for installation of

EZBFo battery modules with Modular Cell 4.0B primary or dual band

cabinets (with integrated power).

Modular Cell 4.0B Primary Cabinet Serial Number:

_______________________________

Modular Cell 4.0B Dual Band Cabinet Serial Number:

_______________________________

EZBFo Battery Frame serial number:

_______________________________

Table 7

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT FOU R ST EP S TO PLA C E AND ATTACH THE FIRST BATTERY BASE MODULE OUTER FRAME AND MARK,

DRILL, AND SET ANCHORS

Place and attach a battery base module to the Modular Cell cabinet or the first

battery base module using the applicable conduit

Remove the top and filter panels from the battery base module A - 14

Appendix A

A - 10

Mark and drill the anchor holes A - 16

Set the 1/2-inch diameter drop-in anchor A - 18

PERFORM THE NEXT FOUR STEPS TO INSTALL HEATER PADS IN THE BATTE RY MODULE INNER FRAMES

Remove the top and filter panels from the battery base module (Reference) A - 20

Remove the two piece battery retaining brackets, separating the two parts if

applicable

Install the internal AC wiring for the heater pads A - 21

Install the heater pads on each of the two battery shelves A - 24

PERFORM THE NEXT FOUR STEPS TO INSTALL THE INNER BATTERY FRAME AND LEVEL, ANCHOR, AND GROUND THE FIRST

OR SECOND BATTERY BASE MODULE

Remove the two piece battery retaining brackets, separating the two parts if

applicable (Reference)

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

A - 20

A - 27

xxxv

Page 39

COMPLETED INSTALLATION STEP PAGE

Prepare the battery module inner frame and place it inside the outer frame and

A - 28

attach the internal ground cable

Level and anchor the battery base module A - 32

Connect the battery base module grounding cables A - 34

PERFORM THE NEXT FO U R ST EPS TO IDENTIFY THE MOD UL A R CE LL 4.0B TO FIRST BATTERY BASE MODULES CABLES

Identify the first EZBFo battery base module alarm and fan power cable

A - 39

harness

Identify the first EZBFo battery base module thermal probe cable(s) and

A - 40

thermal probe(s)

Identify the first EZBFo battery base module 2 AWG DC cables A - 41

Identify the first EZBFo battery base module AC heater cable A - 39

PERFORM THE NEXT TWO STEPS TO IDENTIFY THE CONNECTORS AND ROUTE THE CABLES FROM THE MODULAR CELL 4.0B

TO THE FIRST BATTERY BASE MODULE

Identify the individual cable connectors and their terminations on each end A - 43

Route the cables through the conduit into the first battery base module A - 45

PERFORM THE NEXT STEP TO ROUTE AND CONNECT THE AC CABLE IN THE FIRST BATTERY BASE MODULE

Route and connect the AC cable from the Modular Cell cabinet to the AC block

A - 48

in the battery base module

PERFORM THE NEXT FIVE STEPS TO ROUTE AND CONNECT THE SIGNAL CABLES IN THE FIRST BATTERY BASE MODULE

Install the fuse, the fuse alarm actuator and the fuse alarm switch in the first

A - 52

battery base module

Route and attach the fuse alarm cable to the fuse alarm switch in the battery

A - 53

base module

Route and attach the fan power and alarm cable in the battery base module A - 54

Route and attach the intrusion alarm cable in the battery base module A - 55

Route the t her mal pr obe ca ble an d mou nt th e ther mal pr obe in the battery base

A - 56

module

PERFORM THE NEXT TWO STEPS TO ROUTE AND CONNECT THE DC CABLES IN THE FIRST BATTERY BASE MODULE

Route and connect the four +24V DC load cables in the battery base module A - 58

Route and connect the four 24V Return cables in the battery base module A - 60

PERFORM THE NEXT STEP TO SEAL THE CABLE CONDUIT IN THE FIRST BATTERY BASE MODULE

Seal both ends of the cable conduit inside of the first battery base module. A - 63

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxxvi

Page 40

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT SIX STEPS TO ROUTE AND CONNECT THE FIRST BATTERY BASE MODULE CABLES IN THE MODULAR

CELL 4.0B CABINET

Identify the individual cable connectors and their terminations on each end A - 66

Identify the HPDA in the 4.0B Modular Cell cabinet A - 67

Route and connect the fuse alarm and fan power/alarm cables in the Modular

A - 69

Cell 4.0B cabinet

Route and connect the intrusion alarm cable in the Modular Cell 4.0B cabinet A - 71

Route and connect the thermal probe cable in the Modular Cell 4.0B cabinet A - 73

Connect the heater pad kit AC cable in the Modular Cell cabinet A - 74

PERFORM THE NEXT FOUR STEPS TO PHYSICALLY ATTACH, PREWIRE, AND GROUND AN ADD-ON BATTER Y MODULE

Attach an add-on module to an existing battery module and attach the internal

A - 80

ground cable

Install the heater pads and outer frame wiring (Reference) A - 81

Install the battery module outer frame over the inner frame and attach the

A - 82

internal ground cables

Attach the internal ground cable between the add-on module and the module

A - 83

below it

PERFORM THE NEXT STEP TO ROUTE AND CONNECT THE AC CABLE FROM AN ADD-ON BATTERY MODULE TO THE MODULE

BELOW IT

Route and connect the AC cable from the add-on module to the next lower

A - 84

module

PERFORM THE NEXT TWO STEPS TO INSTALL THE INTRUS ION ALARM AND THERMAL PROBE CABLES IN AN ADD-ON MODULE

Route and connect the intrusion alarm cable from the existing battery module

A - 87

and connect it in the add-on module being installed

Move the thermal probe from the existing battery module and mount it in the

A - 92

add-on module being installed

PERFORM THE NEXT TWO STEPS TO INSTALL THE DC CABLES FROM AN ADD-ON BATTERY MODULE TO THE MODULE BELOW

IT

Identify the module to module DC cables and wiring A - 94

Route and connect the two +24V DC load and two 24V Return cables from the

A - 96

add-on module to the battery module below it

PERFORM THE NEXT STEP TO PLACE, ANCHOR, AND PREWIRE THE SECOND BATTERY BASE MODULE

Place, anchor and prewire the second battery base module (Reference) A - 104

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxxvii

Page 41

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT THREE STEPS TO ROUTE AND CONNECT THE SIGNAL CABLES FROM THE FIRST TO THE SECOND

BATTERY BASE MODULE

Route and connect the fan power and alarm cable between the first battery

A - 106

frame and the second battery base module

Route and connect the intrusion alarm cable between the first battery frame

A - 109

and the second battery base module

Relocate the thermal probe from the first batter y frame to the second battery

A - 112

base module

PERFORM THE NEXT STEP TO ROUTE AND CONNECT THE AC CABLE FROM THE FIRST TO THE SECOND BATTERY BASE

MODULE

Route and connect the AC cable from the first battery frame to the second

A - 114

battery base module

PERFORM THE NEXT STEP TO INSTALL THE RETURN BUS STRAP IN THE SECOND BA TTE RY BASE MODULE

Install the strap between the lower (RTN-1) and upper (RTN-2) 24V Return bus

A - 118

in the second battery base module

PERFORM THE NEXT STEP TO ROUTE AND CONNECT THE DC CABLES FROM THE FIRST TO THE SECOND BATTERY BASE

MODULE

Route and connect the four DC cables between the first and second battery

A - 119

base modules

PERFORM THE NEXT THREE STEPS TO INSTALL L1 BATTERIES IN A BATTERY MODULE

Place batteries on a shelf A - 128

Connect the battery cables to all batteries A - 130

Attach interconnecting bus bars to all battery strings A - 132

PERFORM THE NEXT THREE STEPS TO INSTALL 12IR125 BATTERIES IN A BATTERY MODULE

Separate and remove the two piece battery retaining brackets A - 135

Connect the battery cables to the batteries A - 136

Place the batteries on the shelves, and replace the retaining brackets A - 138

PERFORM THE NEXT TWO STEPS TO CONNECT (OR RECONNECT) THE FIRST BATTERY BASE MODULE DC CABLES IN THE

MODULAR CELL 4.0B CABINET

Connect the battery base module +24-VDC cables to the HPDA in the Modular

A - 143

Cell 4.0B cabinet

Connect (or reconnect) the 24V Return cables from the first battery base

A - 146

module to the return bus in the Modular Cell 4.0B cabinet

PERFORM THE NEXT THREE STEPS TO COMPLETE INSTALLATION OF L1 BATTERIES IN A BATTERY MODULE

Test and connect the L1 battery cables to the bus bars in the battery modules A - 149

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxxviii

Page 42

Installation process

COMPLETED INSTALLATION STEP PAGE

Complete the installation of batteries A - 153

Replace the battery module panels and close/secure the front door(s) (if

applicable)

PERFORM THE NEXT TWO STEPS TO COMPLETE INSTALLATION OF 12IR125 BATTERIES IN A BATTERY MODULE

Test and connect the 12IR125 battery cables to the bus bars in the battery

modules

Complete the installation of 12IR125 batteries A - 160

PERFORM THE TWO STEP TO COMPLETE THE INSTALLATION OF BATTERY MODULES

Replace the battery module panels and close/secure the front door(s), if

applicable (Reference)

A - 153

A - 157

A - 162

............................................................................................................................................................................................................................................................

401-703-454

FOA Draft Issue 1

January, 2006

Lucent Technologies – Proprietary

See notice on first page

xxxix

Page 43

Installation process

.............................................................................................................................................................................................................................................................

Appendix B: Non-Lucent power ancillary hardware installation, cable

routing and connection

Overview

Table 8 lists the procedures covered in Appendix B for Non-Lucent

power ancillary hardware installation, cable routing and connection to

Modular Cell 4.0B primary and dual band cabinets.

Modular Cell 4.0B Primary Cabinet Serial Number:

_______________________________

Modular Cell 4.0B Dual Band Cabinet Serial Number:

_______________________________

Table 8

COMPLETED INSTALLATION STEP PAGE

PERFORM THE NEXT FOUR STEPS TO INSTALL THE ANCILLIARY HARDWARE AND PHYSICALLY ATTACH THE NON LUCENT

POWER SOURCE

Install t he cable duct asse mbly B - 4

Install the AC conduit B - 6

Attach the non-Lucent power source directly to the cable duct (zero spacing), if

applicable

Appendix B

B - 11

Attach the non-Lucent power source to the cable duct assembly using conduits. B - 14

PERFORM THE NEXT TWO STEPS TO ROUTE AND CONNECT THE DC CABLES BETWEEN THE NON-LUCENT POWER SOURCE

AND THE MODULAR CELL 4.0B PRIMARY CABINET

Route the DC cables from the Modular Cell 4.0B primary cabinet to the nonLucent power source

Connect the DC cables at the Modular Cell 4.0B primary cabinet B - 24

PERFORM THE NEXT FOUR STEPS TO ROUTE AND CONNECT THE POWER ALARM CABLE BETWEEN THE NON-LUCENT POWER

SOURCE AND THE MODULAR CELL 4.0B PRIMARY CABINET

Route the power source alarm cable to the Modular Cell 4.0B primary cabinet B - 27

Install the EMI / RFI cord grip seal with the alarm cable B - 32

Prepare the alarm cable for punchdown and ground connection at the facilities

interface panel

Connect alarm cable to the EFIM punchdowns in Modular Cell 4.0B cabinet B - 37

PERFORM THE NEXT THREE STEPS TO ROUTE AND CONNECT THE AC CABLE(S) BETWEEN THE NON-LUCENT POWER

SOURCE AND THE MODULAR CELL 4.0B PRIMARY CABINET

Route the AC power cables to the Modular Cell 4.0B primary cabinet B - 42