Page 1

PAMS Technical Documentation

NSM–4 Series Transceivers

Disassembly &

Troubleshooting

Instructions

Issue 1 01/2002 Nokia Corporation

Page 2

NSM–4

Disassembly & Troubleshooting Instructions

PAMS Technical Documentation

CONTENTS

Disassembly of NSM–4 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transceiver Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWB Test Points 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Clock 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sleep Clock 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supplies 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone is totally dead 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash programming fails 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power doesn’t stay on or phone is jammed 19. . . . . . . . . . . .

Contact Service on the phone display 19. . . . . . . . . . . . . . . . .

SIM related faults 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio faults 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging fault 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Troubleshooting 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Nokia Corporation

Issue 1 01/2002

Page 3

PAMS Technical Documentation

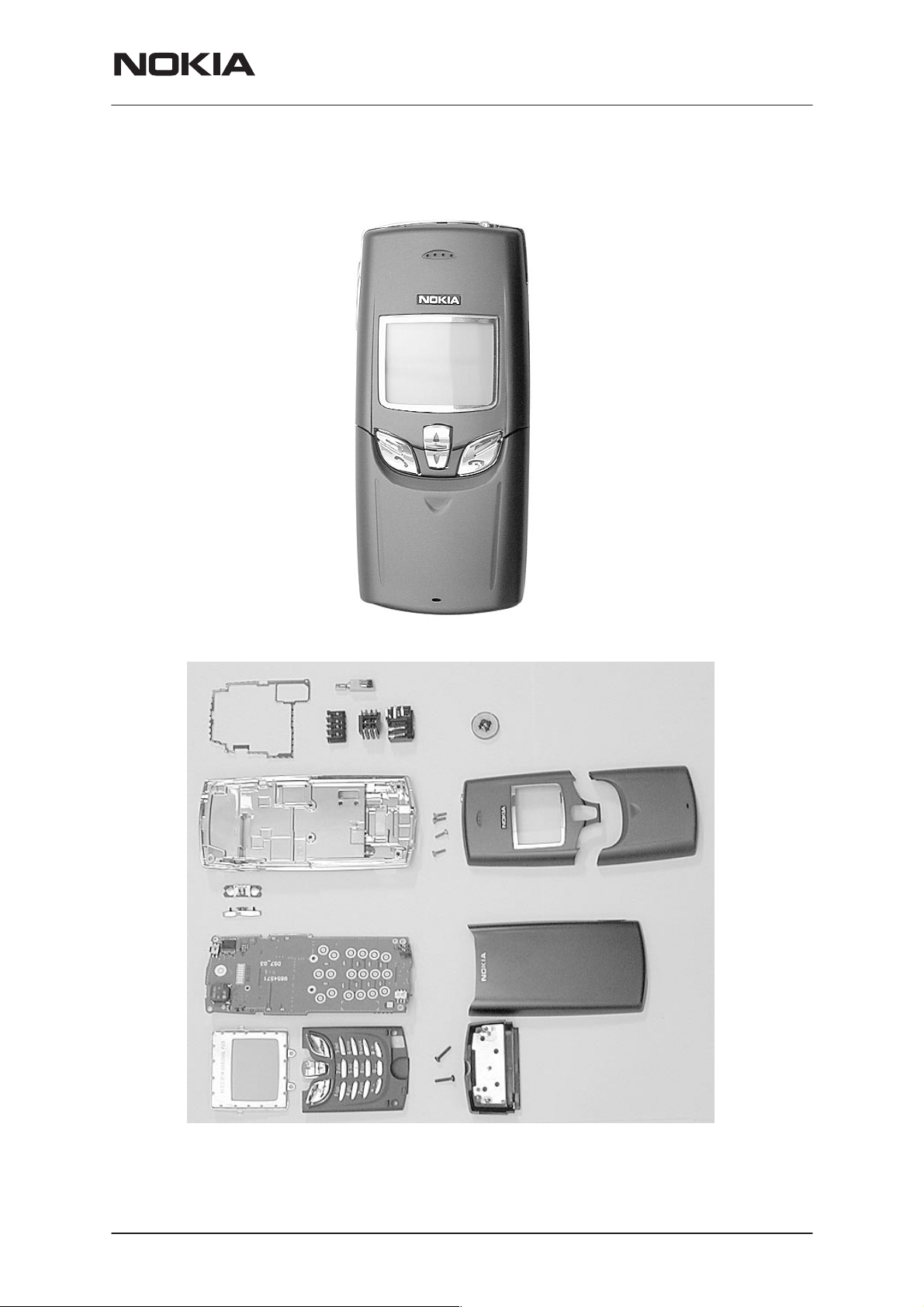

Disassembly of NSM–4

NSM–4

Disassembly & Troubleshooting Instructions

Issue 1 01/2002

NSM–4 phone disassembled.

Nokia Corporation

Page 3

Page 4

NSM–4

Disassembly & Troubleshooting Instructions

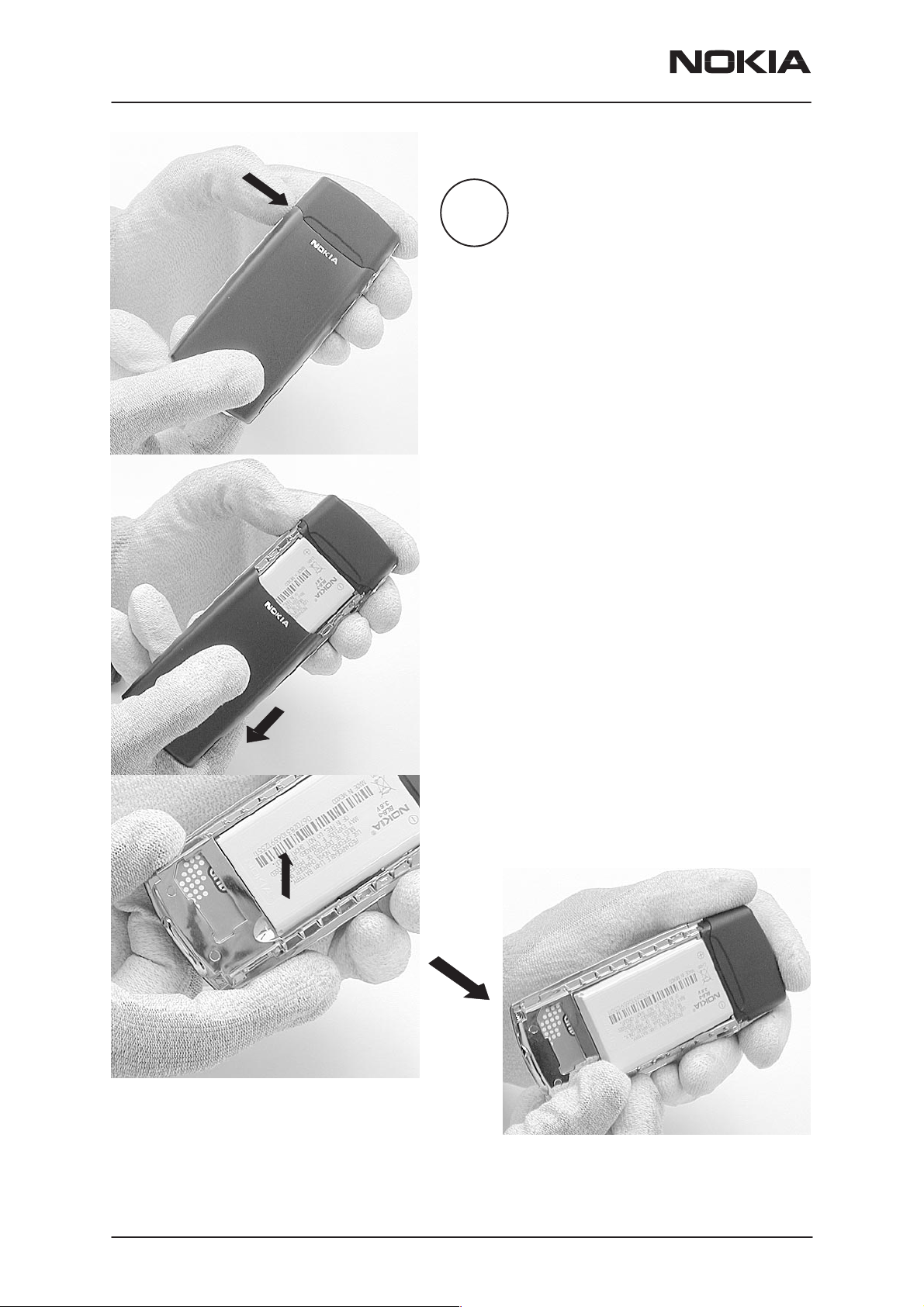

1.

PAMS Technical Documentation

1.

Step 1. Press the button on the side.

Step 2. Slide the cover downwards and

it will be released.

Remove battery.

3.

2.

Step 3. Lift the battery first from the

lower end. Remove the battery.

Page 4

Nokia Corporation

Issue 1 01/2002

Page 5

PAMS Technical Documentation

NSM–4

Disassembly & Troubleshooting Instructions

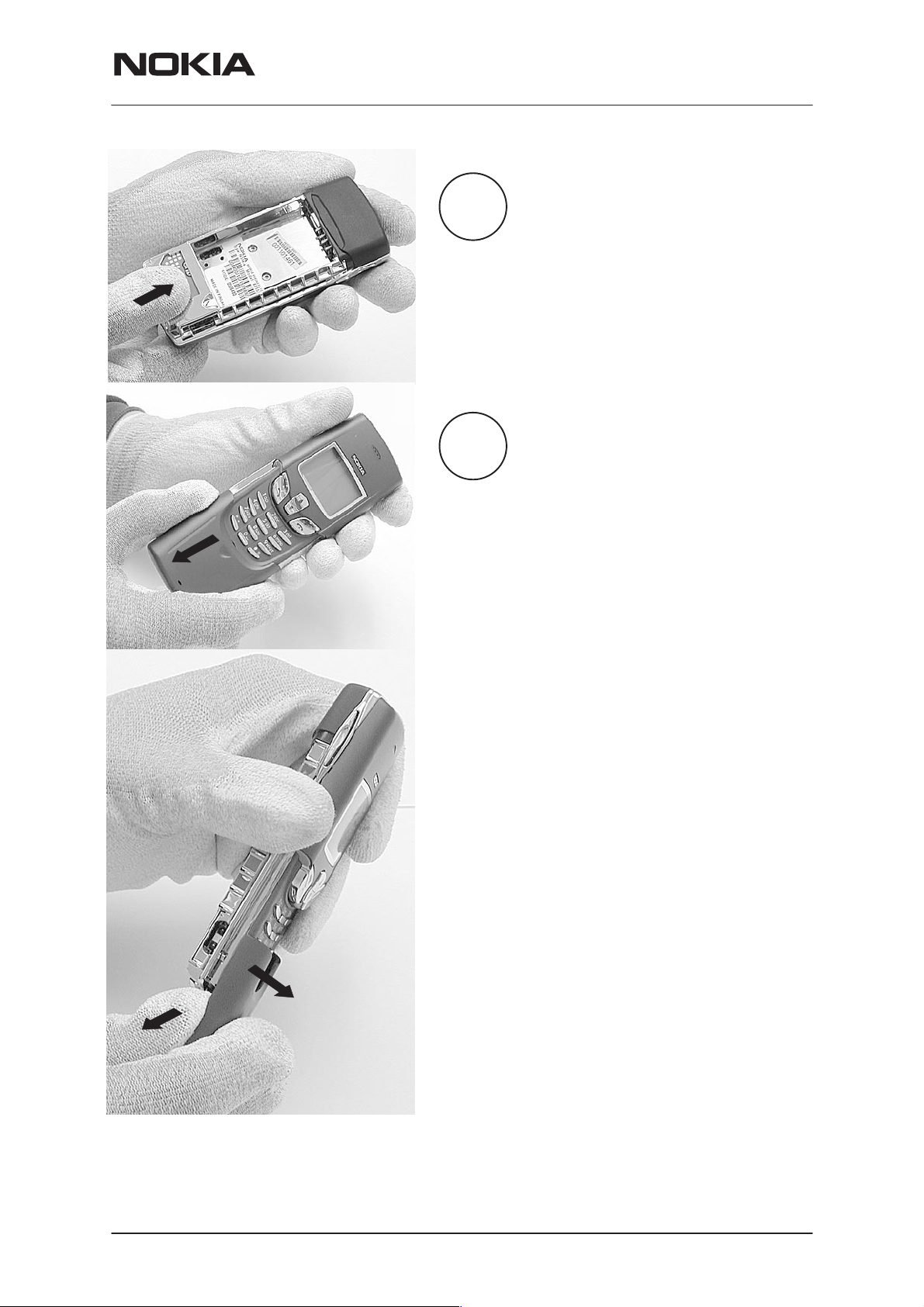

1.

2.

3.

Step 1. Open the slide cover.

Remove the SIM card from its location.

Remove the slide cover.

2.

Issue 1 01/2002

3.

Nokia Corporation

Step 2. Push the slide edge outwards.

NOTE: Use only numbered side 2 to release

the slide.

Step 3. Lift the slide up simultaneously and

the slide will be released.

Page 5

Page 6

NSM–4

Disassembly & Troubleshooting Instructions

PAMS Technical Documentation

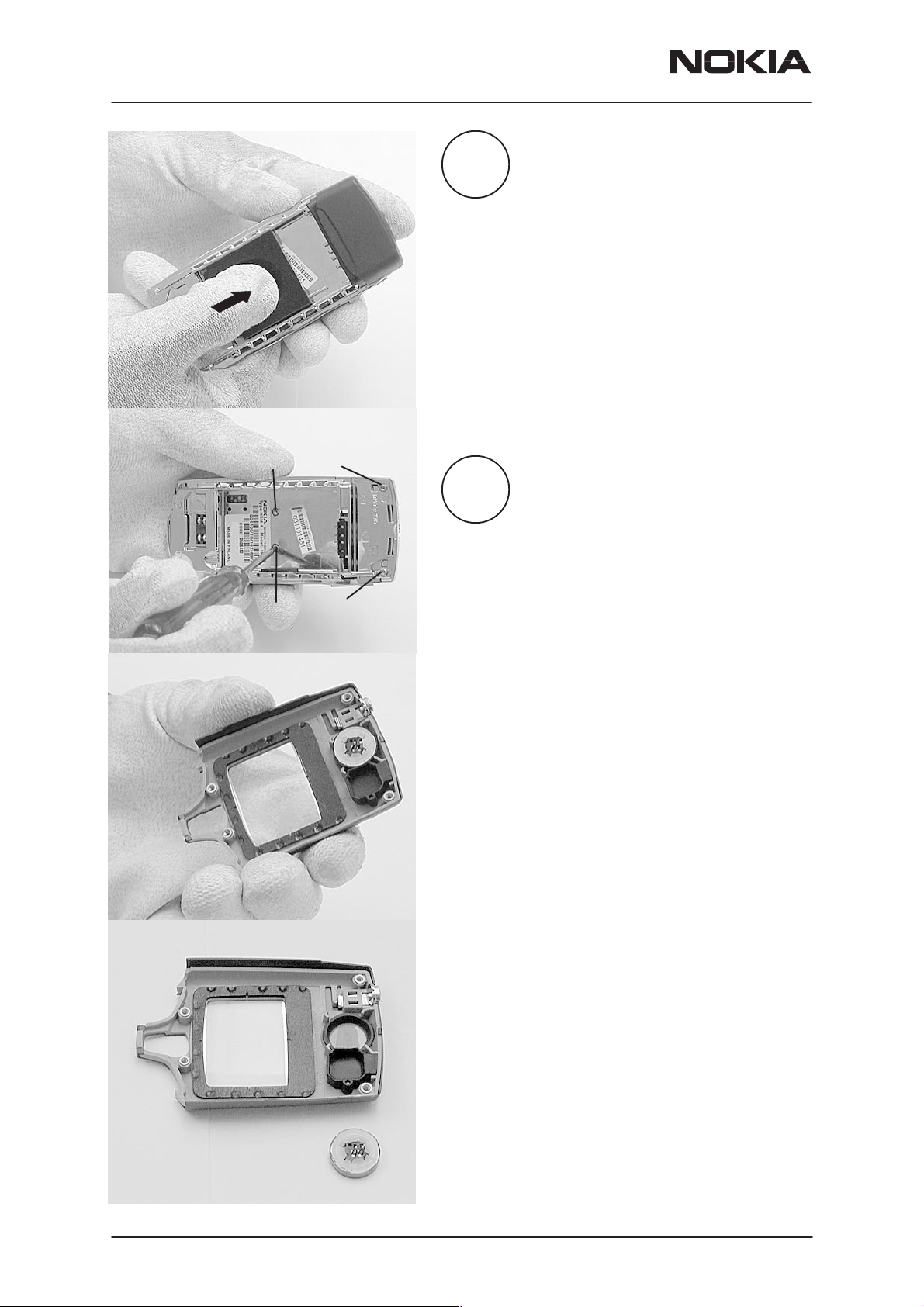

1.

4.

Step 1. To remove the antenna, push with the

thin spike of SRT–3 (Battery Connector Extractor Tool) forward to release the snaps and lift

up the antenna.

NOTE: Be careful not brake the middle frame.

1

3

5.

Remove the frame screws (4 pcs). Screws are

numbered according to the tightening order.

2

4

NOTE: When assembling the screws,

use 14 Ncm torque.

Remove the antenna.

Remove the A–cover.

A–cover can now be removed.

Remove speaker if needed.

Page 6

Nokia Corporation

Issue 1 01/2002

Page 7

PAMS Technical Documentation

NSM–4

Disassembly & Troubleshooting Instructions

6.

Remove keymat module screws (2 pcs).

NOTE: When assembling the

screws, use 17 Ncm torque.

Push SW/slide switch before removing

the keymat module. Now remove the

keymat module.

NOTE: Be careful not to damage the

slide switch on the PWB.

Keymat module removed.

Remove the keymat module.

7.

Push from the side to release the PWB.

To remove the display release the snap fixings in the display module.

Remove PWB and display.

Issue 1 01/2002

Nokia Corporation

Page 7

Page 8

NSM–4

Disassembly & Troubleshooting Instructions

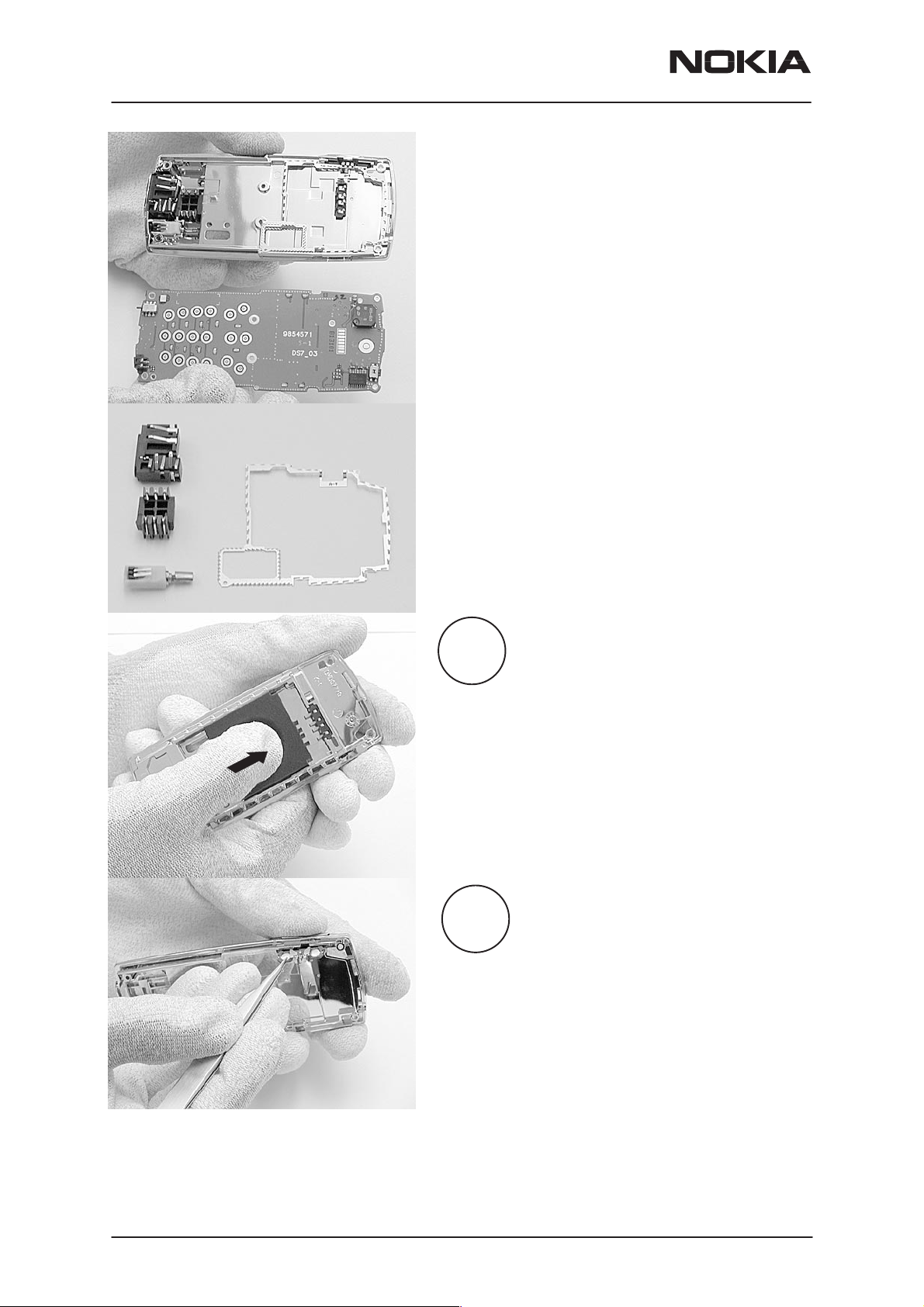

Main frame and PWB apart.

Following parts can be separated from the

main frame:

– bottom connector

– SIM connector

– vibra

– metal gasket

PAMS Technical Documentation

8.

Turn the phone around.

Press down battery connector springs

using SRT–3 (Battery Connector Extractor Tool). Battery connector will be

released.

9.

Remove first the volume switch.

Then remove the volume key.

Remove battery connector.

Remove volume switch and key.

Page 8

Nokia Corporation

Issue 1 01/2002

Page 9

PAMS Technical Documentation

NSM–4

Disassembly & Troubleshooting Instructions

10.

Parts separated from

the main frame.

Issue 1 01/2002

NSM–4 phone disassembled.

Nokia Corporation

Page 9

Page 10

NSM–4

Disassembly & Troubleshooting Instructions

Transceiver Troubleshooting

Baseband Troubleshooting

Because of the underfilling of the MAD and combo memory , it is impossible

to change those.

PWB Test Points

Reference Signal Note

C213 RFC MAIN CLOCK (13MHz)

J100* PWM CHARGE CURRENT CONTROL

J101 FBUSTX FBUS TRANSMITTED DA TA

PAMS Technical Documentation

HAGAR (N505) –> MAD (D200)

CCONT (N100) –> CHAPS (N101)

MAD (D200) –> SERVICE INTERFACE

J102 FBUSRX FBUS RECEIVED DA TA

SERVICE INTERFACE –> MAD (D200)

J103 MBUS ONE WIRE TWO DIRECTION SERIAL BUS

(9600 BIT/S)

MAD (D200) <–> SERVICE INTERFACE

J104 CCONT CSX CCONT (N100) CHIP SELECT

MAD (D200) –> CCONT (N100)

J223 CCONT INT CCONT (N100) INTERRUPT

MAD (D200) –> CCONT (N100)

J226 VCXOPWR 26MHz SYSTEM CLOCK CONTROL

MAD (D200) –> VCXO (G830)

J227 PURX POWER UP RESET

CCONT (N100) –> MAD (D200)

J228 SLEEPCLK SLEEP CLOCK (32kHz)

CCONT (N100) –> MAD (D200)

J230 GND GROUND

J234* HAGAR _RESET_X HAGAR (N505) RESET

MAD (D200) –> HAGAR (N505)

J235 ROM1SELX FLASH CHIP SELECT

MAD (D200) –> COMBO MEMORY (D210)

J236 RAMSELX RAM CHIP SELECT

MAD (D200) –> COMBO MEMORY (D210)

Page 10

J237 SYNTHDATA

(SDATA)

J239 DSPXF NOT CONNECTED

J240 MCURDX MCU READ

J241 MCUWRX MCU WRITE

J242 MCUAD1 MCU ADDRESS LINE 1

HAGAR (N505) SERIAL DA TA

MAD (D200) –> HAGAR (N505)

MAD (D200) –> COMBO MEMORY (D210)

MAD (D200) –> COMBO MEMORY (D210)

MAD (D200) –> COMBO MEMORY (D210)

Nokia Corporation

Issue 1 01/2002

Page 11

PAMS Technical Documentation

J245* SCLK HAGAR (N505) SERIAL CLOCK

J250 COBBA CSX COBBA (N250) CHIP SELECT

J251 COBBA SDA COBBA (N250) SERIAL BUS DATA

J252 COBBA CLK COBBA (N250) SERIAL BUS CLOCK

J253 PCMRXDAT A AUDIO RECEIVED DA TA

J254 PCMDCLK AUDIO DATA CLOCK (512KHz)

J255 PCMSCLK AUDIO SYNC CLOCK (8kHz)

J255 ESYSRESETX COMPOMEMORY (D210) ENABLE

NSM–4

Disassembly & Troubleshooting Instructions

NoteSignalReference

MAD (D200) –> HAGAR (N505)

MAD (D200) –> COBBA (N250)

MAD (D200) <–> COBBA (N250)

MAD (D200) –> COBBA (N250)

COBBA (N250) –> MAD (D200)

MAD (D200) –> COBBA (N250)

MAD (D200) –> COBBA (N250)

MAD (D200) –> COMBO MEMORY (D210)

J256 PCMTXDATA AUDIO TRANSMITTED DA TA

MAD (D200) –> COBBA (N250)

J257 CCUT (MCUGE-

NIO0)

J258* BUTTON_CTRL

(MCUGENIO1)

J259 MCUGENIO2 NOT CONNECTED

J260 EXTMCUDA0 MCU DATA LINE 0

J299* TXP TRANSMITTER POWER CONTROL

L200 MIC MIC BIAS VOLTAGE, 2.1V IF NO MIC

N310 PIN 13 KBD LIGHT KEYP AD LED LIGHT CURRENT

N310 PIN 14 KBDLED_ADJ KEYPAD BACKLIGHT BRIGHTNESS AD-

N310 PIN 16 VIBRA_CTRL VIBRA DRIVE

CHARGE CUT

MAD (D200) –> CHAPS (N101)

HEADSET BUTTON DETECTION CONTROL

MAD (D200) –> XMICP

MAD (D200) <–> COMPOMEMORY (D210)

MAD (D200) –> RF

V250 –> MIC

UI–SWITCH (N310) –> KEYP AD BACKLIGHT LEDS

JUSTMENT

R311 –> UI–SWITCH (N310)

UI–SWITCH (N310) –> VIBRA (M300)

N310 PIN 19 VIBRA VIBRA CONTROL PWM

N310 PIN 3 BUZZER BUZZER CONTROL PWM

N310 PIN 6 BUZZER_CTRL BUZZER DRIVE

N310 PIN 7 KBLIGHTS KEYPAD AND DISPLAY BACKLIGHT CON-

Issue 1 01/2002

MAD (D200) –> UI–SWITCH (N310)

MAD (D200) –> UI–SWITCH (N310)

UI–SWITCH (N310) –> BUZZER (B301)

TROL

MAD (D200) –> UI–SWITCH (N310)

Nokia Corporation

Page 11

Page 12

NSM–4

Disassembly & Troubleshooting Instructions

N310 PIN 8 LCDLED_ADJ LCD BACKLIGHT BRIGHNESS ADJUST-

N310 PIN 9 LCD LIGHT LCD LED LIGHT CURRENT

N400 PIN 4 IRONX IRDA (N400) SHUTDOWN

N401 PIN 4 IRDA POWER 2.8V

R118 PWRONX POWER ON BUTTON

R206 SENA HAGAR (N505) CHIP SELECT

R211 VPP FLASH PROGRAMMING VOLTAGE

R277 EAD ACCESSORY DETECTION

PAMS Technical Documentation

NoteSignalReference

MENT

R310 –> UI–SWITCH (N310)

UI–SWITCH (N310) –> DISPLA Y BACKLIGHT LEDS

MAD (D200) –> IRDA (N400)

N401 –> IRDA (N400)

POWER BUTTON (S330) –> CCONT (N100)

MAD (D200) –> HAGAR (N505)

N220 –> COMPOMEMORY (D210)

XMICP –> CCONT (N100)

Testing

*Only in NSM–4..

The MCU software enters a local mode at start–up if suitable resistors are

connected to the BTEMP and BSI lines.

NOTE! Baseband doesn’t wake up automatically when the battery voltage

is connected. Power must be switched on by

pressing the Power key or

inserting a waking pulse BTEMP line or

connecting a charger

In the local mode the baseband can be controlled through MBUS or

FBUS connections by a PC–locals software. Baseband internal connections are tested with selftests if possible.

Parameters cannot be set accurate enough by design because of component tolerances. Due to use of 5% resistor values, the channels of the

CCONT A/D converters need to be aligned in the production phase. Within battery voltage tuning the MCU software reads the A/D reading from

CCONT at 4.1V and stores this reading to emulated EEPROM memory as

a reference point. Another reference point is created by assuming that

while the input voltage is zero, A/D reading is also zero. Now the slope is

known and A/D readings can be calibrated. Calibration is included in

VBATT A/D reading task.

Page 12

Nokia Corporation

Issue 1 01/2002

Page 13

PAMS Technical Documentation

Troubleshooting

Troubleshooting instructions are divided into following sections:

How to check/fix the system/sleep clock.

How to check/fix the power supplies.

Contact service case.

How to check/fix the SIM faults.

How to check/fix the Audio faults.

How to check/fix the charger faults.

The first thing to do is to carry out a thorough visual check of the module.

Make sure that:

– there are no mechanical damages

– solder joints are OK

Before changing anything ALL SUPPLY VOLTAGES AND SYSTEM

CLOCK / SLEEP CLOCK should be checked.

NSM–4

Disassembly & Troubleshooting Instructions

26MHz VCXO

G830

HAGAR

N505

/2

13MHz

Clock signal

buffer

V800++

MAD

C213

Issue 1 01/2002

Nokia Corporation

Page 13

Page 14

NSM–4

Disassembly & Troubleshooting Instructions

System Clock

Check the signal from the C213

Layout picture B signal RFC,

should be like in SYSTEM

CLOCK picture.

IF NOT

Check the signal from the RF side

buffer input C829. If there is signal,

check the R829,R834,R830,V800,

C834 and L800

IF THERE ISN’T

Check the signal from the RF side

oskilator VCXO G830 output from

C833. There should be 26MHz

signal.

PAMS Technical Documentation

IF IS

Change the Hagar

N505

IF THERE ISN’T

Change the VCXO

G830

Page 14

System clock picture.

Nokia Corporation

Issue 1 01/2002

Page 15

PAMS Technical Documentation

Sleep Clock

Check the signal from the J228

Layout picture B signal Clk 32kHz,

should be like in SLEEP CLOCK

picture.

IF NOT

Check R100, R154, R102,

C102, C101, C113 and B100

IF OK

Change the CCONT

N100

NSM–4

Disassembly & Troubleshooting Instructions

Sleep clock picture.

Issue 1 01/2002

Nokia Corporation

Page 15

Page 16

NSM–4

Disassembly & Troubleshooting Instructions

Power Supplies

Measure power supplies. Test points are shown in layout picture A.

PAMS Technical Documentation

A

Page 16

Nokia Corporation

Issue 1 01/2002

Page 17

PAMS Technical Documentation

Vbb = 2.7V – 2.87V

Vcore = 1.3V – 2.65V

Vcobba = 2,67V – 2.85V

Vref = 1.48V – 1.523V

Vbat = 3.11V – 4.2V

VXO = 2,67V – 2.85V

VRX = 2,67V – 2.85V

VTX = 2,67V – 2.85V

Vsyn1 = 2,67V – 2.85V

Vsyn2 = 2,67V – 2.85V

Power up sequence test:

Cconts digital parts keep MAD in reset by keeping PURX down for a

delay of 62ms.

NSM–4

Disassembly & Troubleshooting Instructions

Here is shown the start up sequence picture.

Ch1 = Vbb

Ch2 = VXO

Ch3 = SleepClk

Ch4 = PURX (see picture B)

Issue 1 01/2002

Nokia Corporation

Page 17

Page 18

NSM–4

Disassembly & Troubleshooting Instructions

B

PAMS Technical Documentation

Page 18

Nokia Corporation

Issue 1 01/2002

Page 19

PAMS Technical Documentation

Phone is totally dead

The phone doesn’t take current at all when the power switch is pressed or

when the watchdog disable pin (X001 pin 11) is grounded. Make sure that

the battery voltage you use is within the specification, i.e. 3.11 .. 4.2 V. If

the voltage is lower, hardware of CCONT (N100) prevents power on.

IF battery voltage is inside the specification Change the CCONT.

Flash programming fails

The flash programming can be done via panel connector X001 or via

dedicated PWB pads. In production, the first programming is done via

panel connector. After this, the panel connector is cut away, thus the programming must be done via PWB pads visible through the shield under

the battery. The main difference between these is that FLASH–programming voltage is produced differently. The fault finding diagrams for flash

programming is shown in the start up sequence picture.

In flash programming error cases the flash prommer can give some information about a fault. The fault information messages could be:

NSM–4

Disassembly & Troubleshooting Instructions

– MCU doesn’t boot

– Serial clock line failure

– Serial data line failure

– External RAM fault

– Algorithm file or alias ID not found

– MCU flash Vpp error

Power doesn’t stay on or phone is jammed

If this kind of fault has come after flash programming, there are most

probably open joints in ICs. Solder the joints of ICs. Normally the power

will be switched off by CCONT (N100) after 30 seconds if the watchdog of

the CCONT can not be served by software. This updating can be seen

with an oscilloscope at CCONTCSX (J104). In normal case there is a

short pulse from “1” to “0” every 8 seconds. The power off function can be

prevented by connecting WDDIS (R118 edge side head) to ground.

Because of the underfill, check the supply voltages, clock signals and

power up sequence. If power on sequence fails, there are some open

connections under MAD or compomemory. If all seems to be correct, it is

best way to erase the flash memory and try to put new software to phone.

Contact Service on the phone display

This fault means that software is able to run and thus the watchdog of

CCONT (N100) can be served. Selftest functions are run when power is

switched on and software is executed from flash. If any of the selftests

fails, a “contact service” text is shown on display.

MCU self tests are devided to those executed while power up (start up

tests) and ones that can be executed with connected PC. The tests and

included items are as follows:

Issue 1 01/2002

Nokia Corporation

Page 19

Page 20

NSM–4

Disassembly & Troubleshooting Instructions

1. MCU ROM checksum

Calculates 16 bit checksum out of Flash code and compares it to one

found in Flash.

Items being checked are:

MAD2 <––> Flash data and address lines, CE0,CE1, WE, BYTE, Vcc,

GND, Flash internal functionality

2. MCU RAM interface

3. MCU RAM component

4. MCU EEPROM interface

5. MCU EEPROM component

6. RTC battery

7. CCONT interface

8. A/D converter

9. SW reset

A. Power off

B. Security data

C. EEPROM tune checksum

D. PPM checksum

E MCU download DSP

F. DSP alive

G. COBBA serial

H COBBA parallel

I. EEPROM checksum

K. PPM validity

PAMS Technical Documentation

Page 20

Nokia Corporation

Issue 1 01/2002

Page 21

PAMS Technical Documentation

SIM related faults

The hardware of the SIM interface from MAD2 (D200) to the SIM connector (X302) can be tested without a SIM card. When the power is

switched on and the BSI line is grounded by a resistor, all the used lines

(VSIM, RST, CLK, DATA) rise up to 5 V four times. Thus “Insert SIM card”

faults can be found without SIM card.

The fault information “Card rejected” indicates that ATR message (the first

message is always sent from card to the phone) is sent from card but the

message is somehow corrupted, data signal levels are wrong etc. or factory set values (stored to the emulated EEPROM) are not correct.

NSM–4

Disassembly & Troubleshooting Instructions

Check the Vsim. Is it 3V or 5V

Vsim (C128 bottom connector side

head )

IF NOT OK

Check the Vsrm (C131 RF side head)

V5V (C108 bottom connector side

head)

IF NOT OK

Check the regulator N600, V116, C132

and C131

OK

Check the V104. R128, R125, R124

and C128

OK

Change the CCONT N100

OK

Issue 1 01/2002

Nokia Corporation

Page 21

Page 22

NSM–4

Disassembly & Troubleshooting Instructions

Audio faults

earpiece doesn’t work

and there isn’t any

mechanical problem

Check C 292, C291, L272 and L271

OK

Change the COBBA N250

PAMS Technical Documentation

Microphone doesn’t work

and there isn’t any

mechanical problem

Check the voltage in resistor

R267 RF side head. Voltage should be

about 2.1V

OK

Check the R268,C 274,C263,C278

and C262

Check R266, C268, L287 and V250

OK

Change the COBBA N250

Page 22

Nokia Corporation

Issue 1 01/2002

Page 23

PAMS Technical Documentation

Headset earpiece doesn’t

work and there isn’t any

mechanical problem

Check R 257,R256, R270, L284, L283

C284, C283, C 296, C 297, C261and C255

OK

Change the COBBA N250

NSM–4

Disassembly & Troubleshooting Instructions

Headset earphone doesn’t

work and there isn’t any

mechanical problem

Check R 257,R256, R270, L284, L283

C284, C283, C 296, C 297, C261and C255

OK

Change the COBBA N250

Issue 1 01/2002

Nokia Corporation

Page 23

Page 24

NSM–4

Disassembly & Troubleshooting Instructions

Charging fault

Display ” not charging”

PAMS Technical Documentation

Check charge voltage with wintesla

OK

Check charge current with wintesla

IF NOT OK

Check V101 and R131

OK

Check F101, V100,R104 and

R103

Change the Chaps N101

Page 24

Nokia Corporation

Issue 1 01/2002

Page 25

NSM–4

Disassembly & Troubleshooting Instructions

VTXPON

RX IN

TX OUT

GSMTX

PCNTX

VTXGSM

GSM TX

OUT

VBATT

Vapc

VTXPCN

PCNRX

PCNTX

OUT

VTXGS

M

PCNRX

GSM RX

TXP

GSM RX

Vrxrf

TXC

Vchp

AFC

13MHz

Vtcxo

26MHz

TXQP/N

Vlna

RXQP/RXIP

RXREF

Vsynte

TXIP/N

Vref_2

Hagar_reset

OUT_CP

VCC

N702 Poweramplifier

Z670 Antenna switch

Z620 FirstRX SAW

Z600 Second RX SA W

G830 VCTCXO (26MHz)

N505 Hagar RF IC

G800 VCO (3.6GHz)

Z700 GSMTX SAW

T600 GSMRX Balun

T630 PCN RX Balun

T740 PCN TX Balun

T700 GSMTX Balun

T800 VCO Balun 3.6GHz

V903 PCN LNA

V904 GSMLNA

L553 Dual coupler

V730 Powerdetector

Page 25

Nokia Corporation

PAMS Technical Documentation

RF Troubleshooting

PCN/GSM

TX IN

TXBUFF

V800 VCTCXO Buffer

GSM TXPCNTX

VCO OUT

N600 Vcp regulator

Issue 1 01/2002

Page 26

NSM–4

Disassembly & Troubleshooting Instructions

PAMS Technical Documentation

This page intentionally left blank.

Page 26

Nokia Corporation

Issue 1 01/2002

Loading...

Loading...