Page 1

Programmes After Market Services

Technical Documentation

[NMP Part No.0275454]

NSB-7 Cellular Phones

Issue 1 06/00

Copyrightã 2000 Nokia Mobile Phones. All Rights Reserved

Page 2

Programmes After Market Services

Technical Documentation

Amendment Record Sheet

Amendment No Date Inserted By Comments

Issue 1 06/00

Copyrightã 2000 Nokia Mobile Phones. All Rights Reserved

Page 3

Programmes After Market Services

Contents:

Technical Documentation

NSB-7 Overall Manual Contents

Section 1: Foreword

Section 2: General Information

Section 3: System Module

Section 4: UI Module

Section 5: Product Variants

Section 6: Service Software Instructions

Section 7: Service Tools

Section 8: Disassembly/Troubleshooting Instructions

Section 9: Non-serviceable Accessories

Section 10: Schematic Diagrams

Issue 1 06/00

Copyrightã 2000 Nokia Mobile Phones. All Rights Reserved

Page 4

Programmes After Market Services

This document is intended for use by qualified service personnel only.

Company Policy

Our policy is of continuous development; details of all technical modifications will be

included with service bulletins.

While every endeavour has been made to ensure the accuracy of this document, some

errors may exist. If any errors are found by the reader, NOKIA MOBILE PHONES Ltd.

should be notified in writing.

Please state:

Technical Documentation

IMPORTANT

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicable)

Page(s) and/or Figure(s) in error

Please send to: Nokia Mobile Phones Ltd.

PAMS Technical Documentation

PO Box 86

FIN-24101 SALO

Finland

Issue 1 06/00

Copyrightã 2000 Nokia Mobile Phones. All Rights Reserved

Page 5

Programmes After Market Services

Technical Documentation

Warnings and Cautions

Please refer to the phone's user guide for instructions relating to operation, care and

maintenance including important safety information. Note also the following:

Warnings:

1. CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND ANTI-SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT CONDITIONS, EMITTED RF ENERGY CAN

AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/

MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC

SYSTEMS TO RF ENERGY.

2. THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY

TO CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES EG PETROL STATIONS

(SERVICE STATIONS), BLASTING AREAS ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLU-

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and that an anti-

3. Ensure solder, wire, or foreign matter does not enter the telephone as dam-

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are correctly re-fit-

LAR TELEPHONES, MAY INTERFERE WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR THE

MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY QUESTIONS.

OTHER ELECTRONIC EQUIPMENT MAY ALSO BE SUBJECT TO INTERFERENCE.

static wrist strap is worn.

age may result.

ted after servicing and alignment. Ensure all cables and wires are repositioned correctly.

Issue 1 06/00

Copyrightã 2000 Nokia Mobile Phones. All Rights Reserved

Page 6

Programmes After Market Services

Technical Documentation

This Page Intentionally Blank

Issue 1 06/00

Copyrightã 2000 Nokia Mobile Phones. All Rights Reserved

Page 7

Programmes After Market Services

NSB-7 Series Transceivers

General Information

Issue 1 06/00 ãNokia Mobile Phones Ltd.

Page 8

NSB-7

General Information PAMS Technical Documentation

Table of Contents

Page No

General Information................................................................................................................1

Product Selection..................................................................................................................................... 4

Hand portables ...................................................................................................................................... 4

Desktop Option ...................................................................................................................................... 5

Express Car Kit (CARK-124) Option for Americas ....................................................................... 6

Product and Module List ....................................................................................................................... 7

Technical Specifications ........................................................................................................................ 8

General Specifications of Transceiver NSB-7 ............................................................................... 8

Page 2 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 9

NSB-7

PAMS Technical Documentation General Information

List of Figures

Page No

Fig 1 Hand portables..................................................................................................................................... 4

Fig 2 Desktop option ..................................................................................................................................... 5

Fig 3 Express Car Kit (CARK-124).............................................................................................................. 6

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 3

Page 10

NSB-7

General Information PAMS Technical Documentation

Product Selection

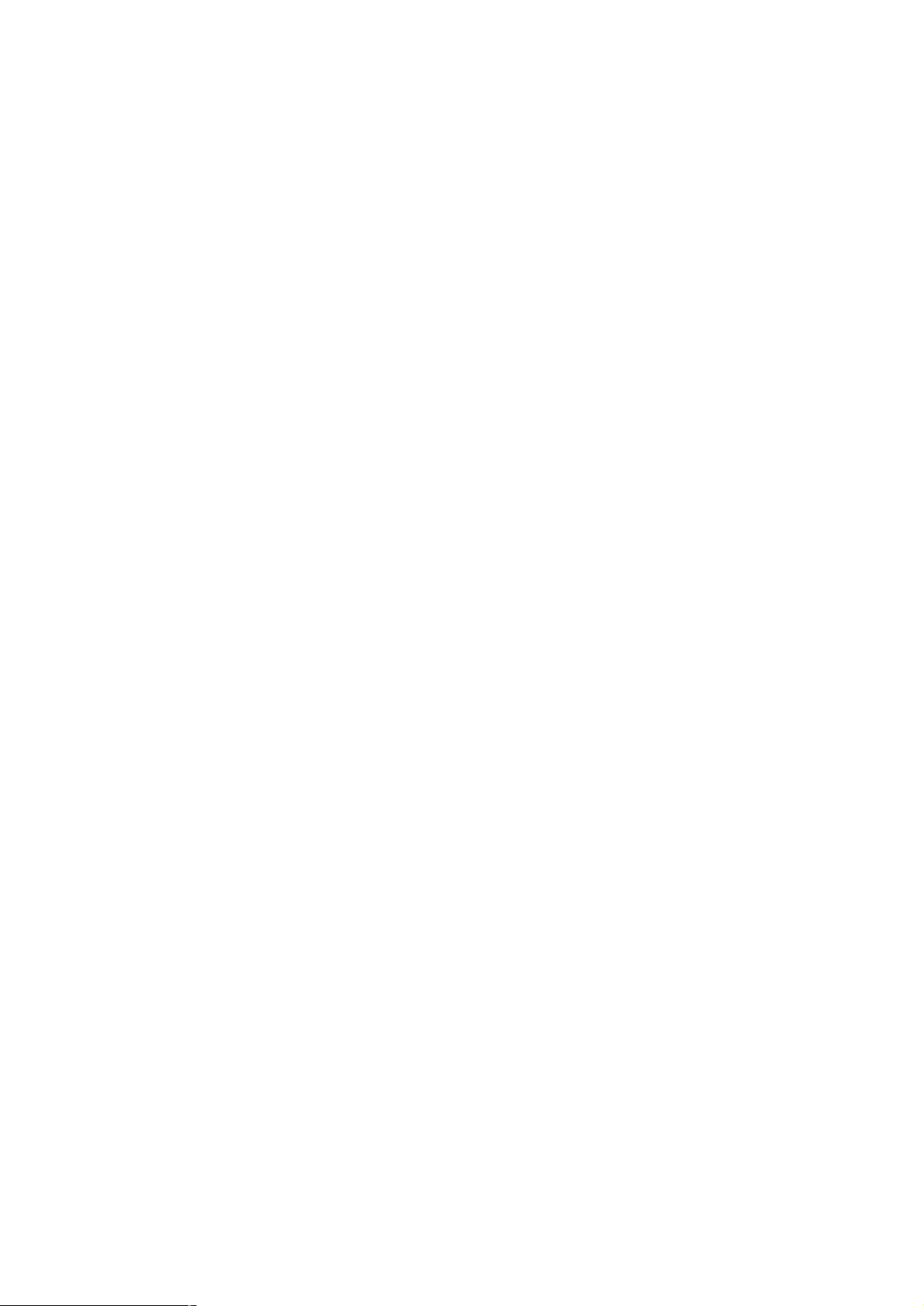

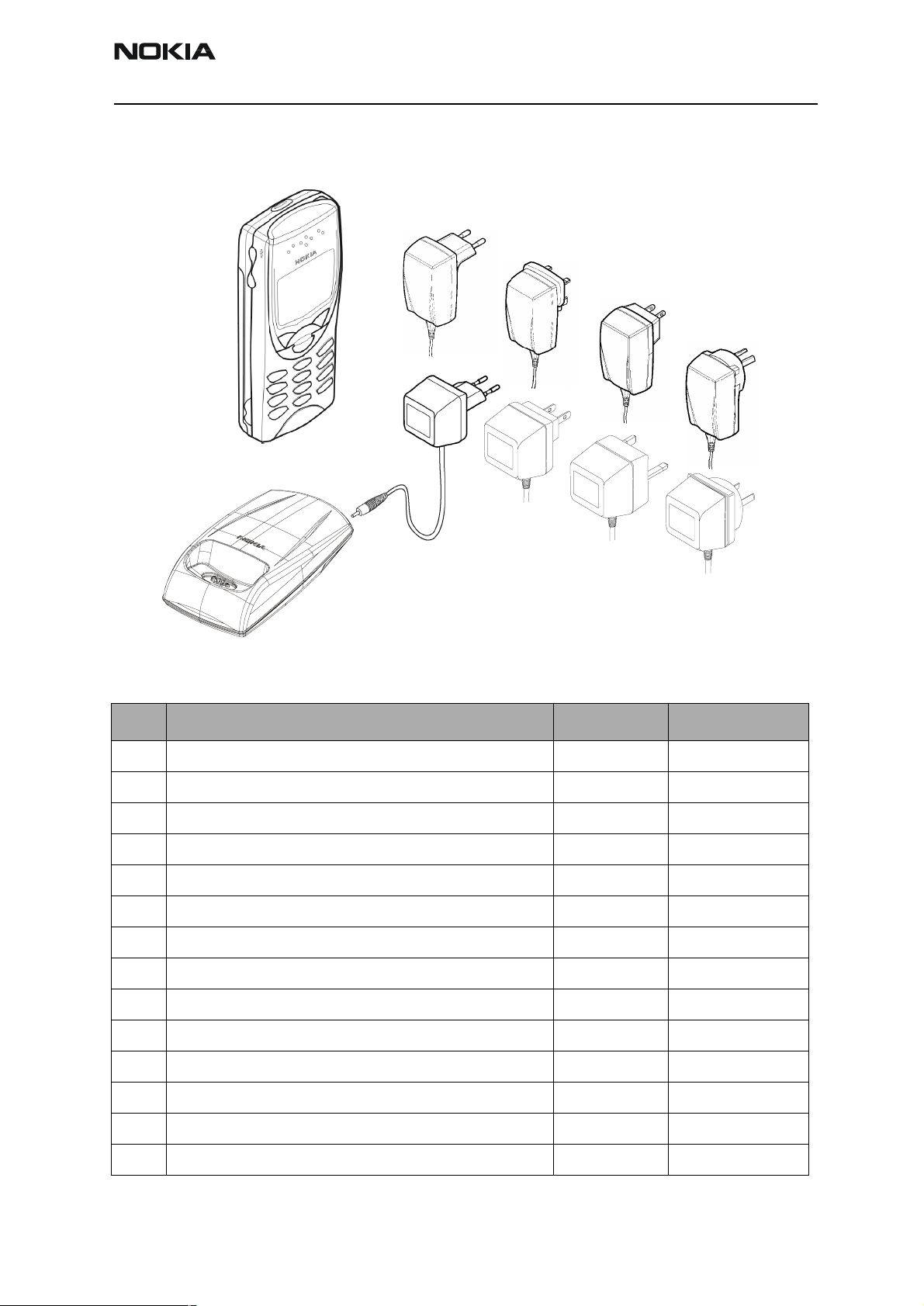

Hand portables

The NSB-7 is a single band hand portable mobile telephone for the GSM1900 networks

7.

3.

ACP-7E

ACP-8E

ACP-8K

4.

4.

ACP-7C

ACP-7U

ACP-8X

8.

ACP-8U

ACP-8C

9.

ACP-8A

10.

5.

ACP-7H

ACP-7X

6.

ACP-7A

1.

2.

2.

3.

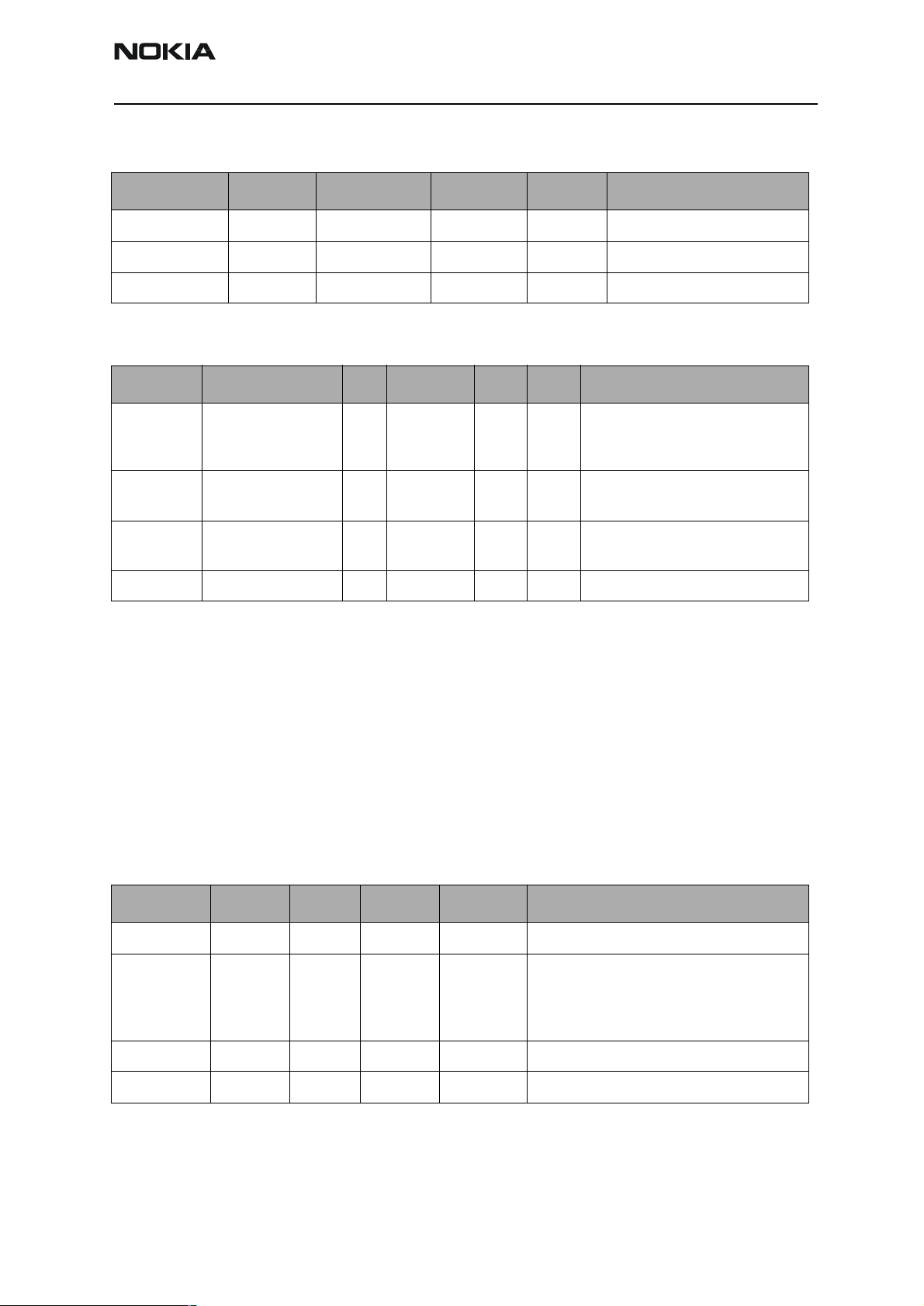

Figure 1: Hand portables

Item Name: Type Code: Material Code:

1. Transceiver See Product Variants

2. Standard Battery (Li-ion 650 mAh) BLB-2 0670246

Standard Battery (Li-ion 650 mAh) for Americas BLB-2 0670322

3. AC Travel Charger (Euro plug) 207-253 Vac ACP-7E 0675144

4. AC Travel Charger (US plug) 108-132 Vac ACP-7U 0675143

AC Travel Charger (US plug) 198-242 Vac ACP-7C 0675158

5. AC Travel Charger (UK plug) 207-253 Vac ACP-7X 0675145

AC Travel Charger (UK plug) 180-220 Vac ACP-7H 0675146

6. AC Travel Charger (Australia plug) 216-264 Vac ACP-7A 0675148

7. Performance Travel Charger Euro plug 90-264 Vac ACP-8E 0675195

Performance Travel Charger Korea plug 90-264 Vac ACP-8K 0675199

8. Performance Travel Charger UK plug 90-264 Vac ACP-8X 0675197

9. Performance Travel Charger US plug 90-264 Vac ACP-8U 0675196

Performance Travel Charger China plug 90-264 Vac ACP-8C 0675211

10. Performance Travel Charger Australia plug 90-264 Vac ACP-8A 0675214

Page 4 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 11

NSB-7

PAMS Technical Documentation General Information

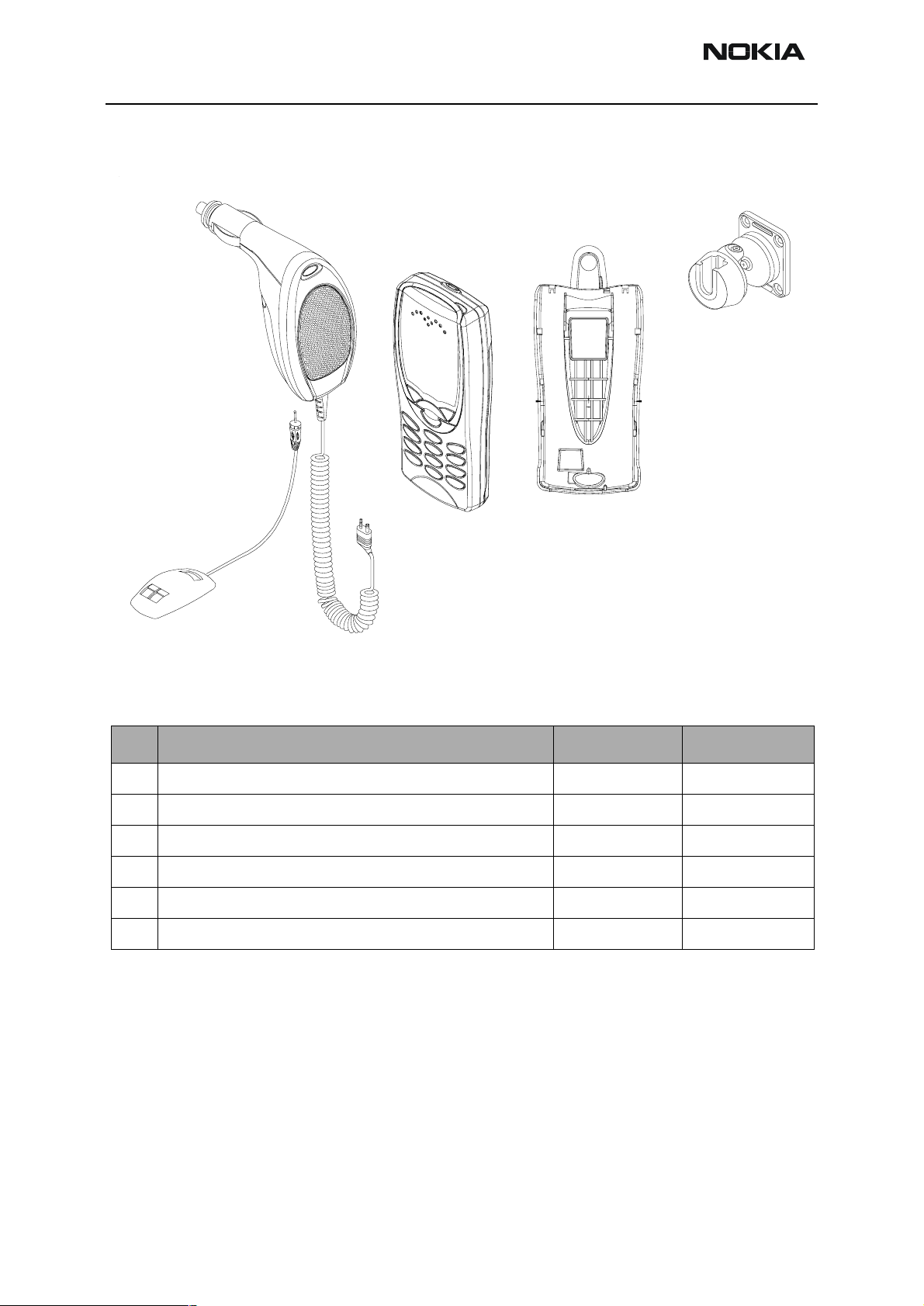

Desktop Option

The desktop option allows the user to charge the phone from the mains.

1.

3.

ACP-7E

2.

ACP-8E

ACP-8K

7.

ACP-8X

8.

ACP-8U

ACP-8C

9.

ACP-8A

10.

4.

ACP-7C

ACP-7U

5.

ACP-7H

ACP-7X

6.

ACP-7A

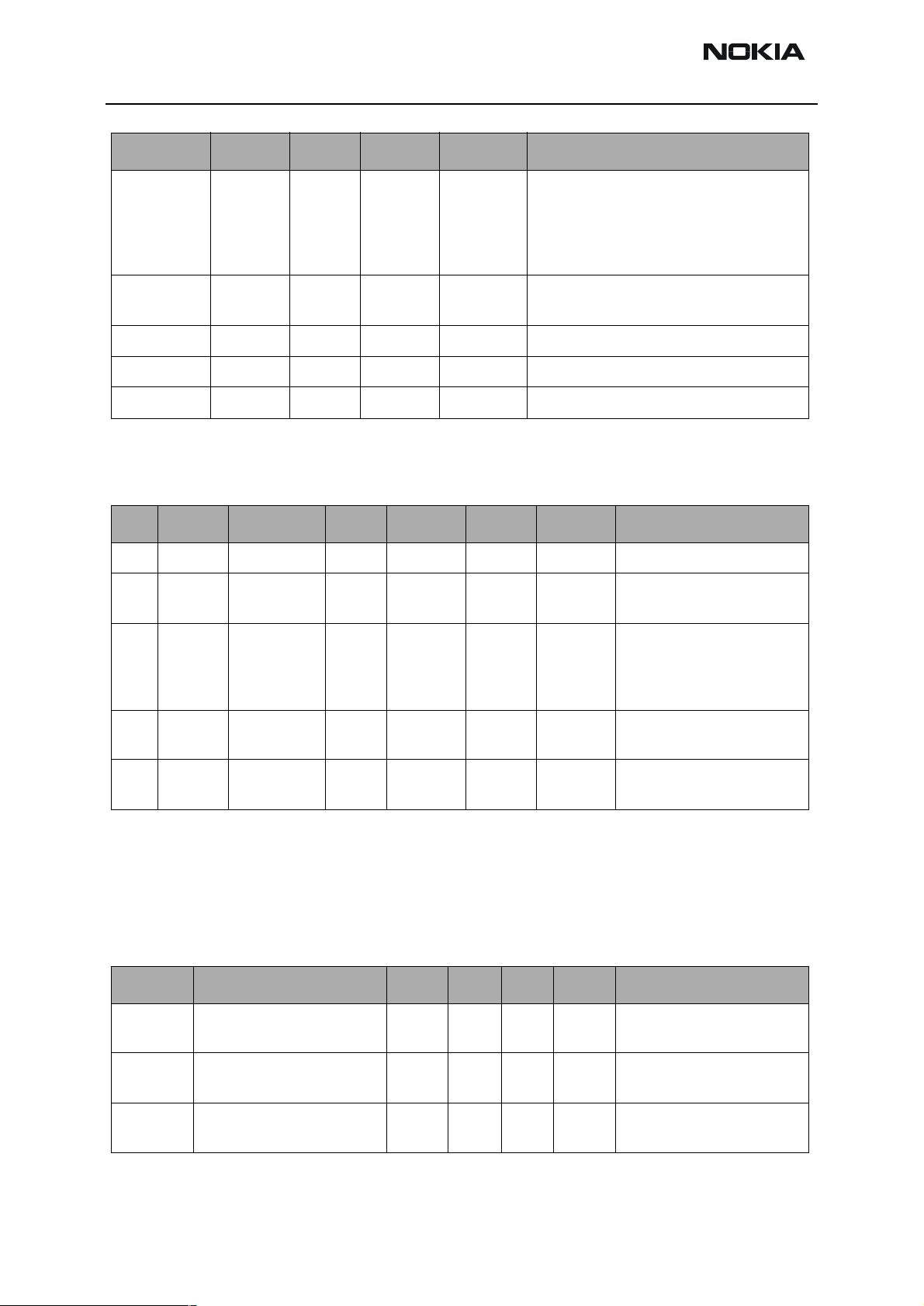

Figure 2: Desktop option

Item Name: Type Code: Material Code:

1. Transceiver See Product Variants

2 Desk stand DCV-1B 0675220

3. AC Travel Charger (Euro plug) 207-253 Vac ACP-7E 0675144

4. AC Travel Charger (US plug) 108-132 Vac ACP-7U 0675143

AC Travel Charger (US plug) 198-242 Vac ACP-7C 0675158

5. AC Travel Charger (UK plug) 207-253 Vac ACP-7X 0675145

AC Travel Charger (UK plug) 180-220 Vac ACP-7H 0675146

6. AC Travel Charger (Australia plug) 216-264 Vac ACP-7A 0675148

7. Performance Travel Charger Euro plug 90-264 Vac ACP-8E 0675195

Performance Travel Charger Korea plug 90-264 Vac ACP-8K 0675199

8. Performance Travel Charger UK plug 90-264 Vac ACP-8X 0675197

9. Performance Travel Charger US plug 90-264 Vac ACP-8U 0675196

Performance Travel Charger China plug 90-264 Vac ACP-8C 0675211

10. Performance Travel Charger Australia plug 90-264 Vac ACP-8A 0675214

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 5

Page 12

NSB-7

General Information PAMS Technical Documentation

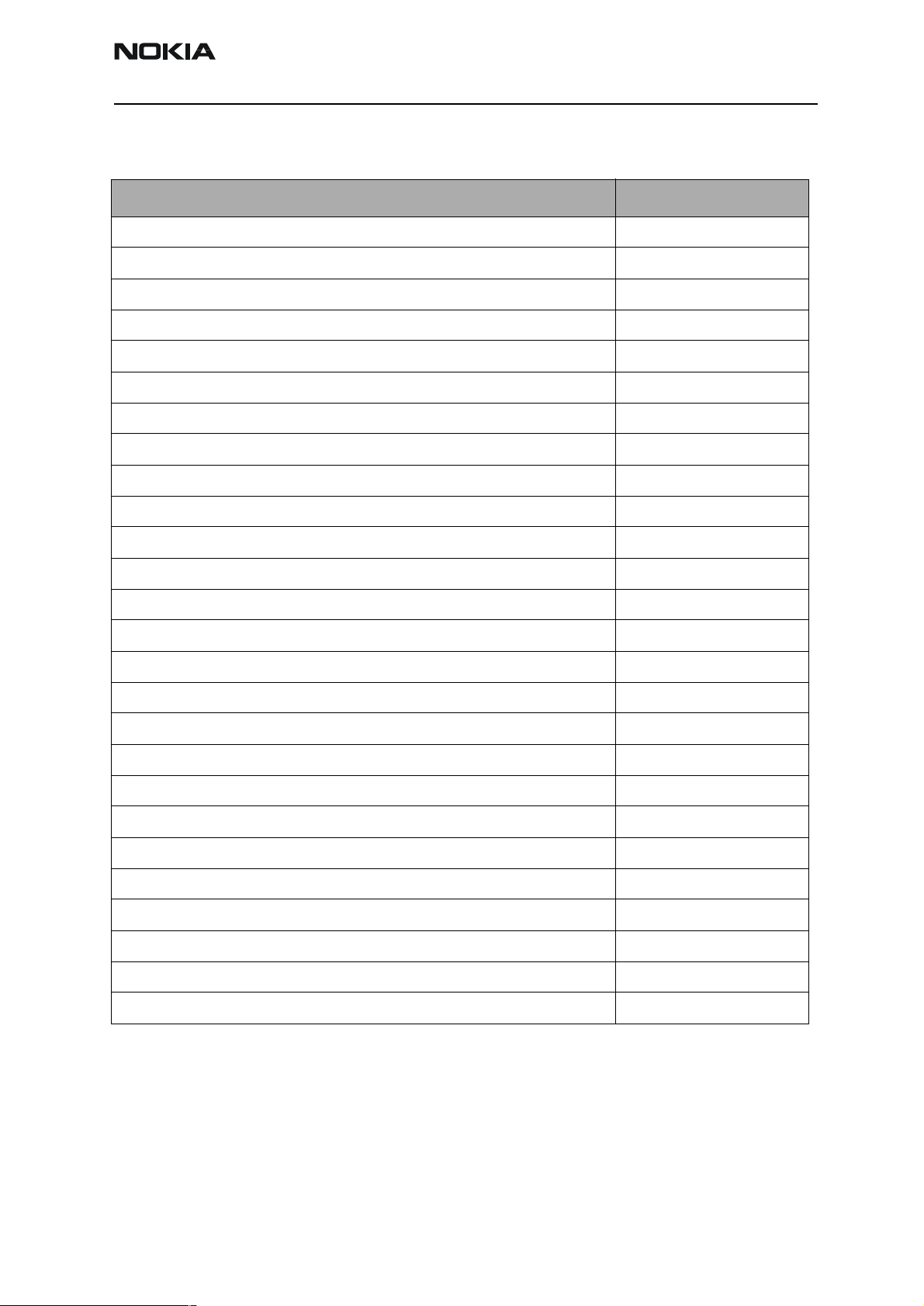

Express Car Kit (CARK-124) Option for Americas

5.

3.

1.

2.

4.

Figure 3: Express Car Kit (CARK-124)

Item Name: Type Code: Material Code:

Express Car Kit for Americas (Retail Pack) CARK-124 0080372

1. Transceiver (Not included, see Product Variants)

2. Pocket Clip SKB-2 0720218

3. Swivel Mount HHS-12 0620054

4. Hands Free Microphone HFM-8 0690016

5. Hands Free Cigarette Lighter Charger PPH-1 0675182

Page 6 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 13

NSB-7

PAMS Technical Documentation General Information

Product and Module List

Unit/Type: Product Code:

Transceiver NSB-7 See Product Variants

Standard Battery BLB-2 (Li-ion 650 mAh) 0670246

Standard Battery BLB-2 (Li-ion 650 mAh) for Americas 0670322

AC Travel Charger ACP-7E (EURO) 207-253 Vac 0675144

AC Travel Charger ACP-7U (US) 108-132 Vac 0675143

AC Travel Charger ACP-7C (US) 198-242 Vac 0675158

AC Travel Charger ACP-7X (UK) 207-253 Vac 0675145

AC Travel Charger ACP-7H (UK) 180-220 Vac 0675146

AC Travel Charger ACP-7A (AUS) 216-264 Vac 0675148

Performance Travel Charger ACP-8E (EURO) 90-264 Vac 0675195

Performance Travel Charger ACP-8K (KOREA) 90-264 Vac 0675199

Performance Travel Charger ACP-8X (UK) 90-264 Vac 0675197

Performance Travel Charger ACP-8U (US) 90-264 Vac 0675196

Performance Travel Charger ACP-8C (CHINA) 90-264 Vac 0675211

Performance Travel Charger ACP-8A (AUS) 90-264 Vac 0675214

Headset HDC-5 0694059

Loopset LPS-3 0630244

Pocket Clip SKB-2 0720218

Desk Stand DCV-1B 0675220

Swivel Mount HHS-12 0620054

HF Microphone HFM-8 0690016

Plug & Play HF Cigarette Lighter Charger PPH-1 0675182

Cigarette Lighter Charger LCH-8 0675231

Cigarette Lighter Charger LCH-9 0675120

Carrying Case CBK-3V 0272237

Carrying Case CBK-3H 0272236

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 7

Page 14

NSB-7

General Information PAMS Technical Documentation

Technical Specifications

General Specifications of Transceiver NSB-7

Parameter Unit

Cellular System GSM1900

RX frequency band 1930 ...1990 MHz

TX frequency band 1850 ...1910 MHz

Output power +0 ...+29 dBm / 1.0 mW ...1 W

Duplex spacing 80 MHz

Number of RF channels 299

Channel spacing 200 kHz

Number of TX power levels 16

Sensitivity, static channel -102 dBm

Frequency error, static channel < 0.1 ppm

RMS phase error < 5.0 ο

Peak phase error < 20.0 ο

Page 8 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 15

Programmes After Market Services

NSB-7 Series Transceivers

System Module

Issue 1 06/00 ãNokia Mobile Phones Ltd.

Page 16

NSB-7

System Module PAMS Technical Documentation

Table of Contents

Page No

System Module ........................................................................................................................1

Transceiver NSB-7 ................................................................................................................................... 6

Introduction ........................................................................................................................................... 6

Operational Modes ............................................................................................................................ 6

Interconnection Diagram ................................................................................................................... 7

System Module......................................................................................................................................... 8

Baseband Module ................................................................................................................................. 8

Block Diagram..................................................................................................................................... 8

Technical Summary ........................................................................................................................... 9

Technical Specifications ...................................................................................................................10

Absolute Maximum Ratings ........................................................................................................ 10

DC Characteristics .......................................................................................................................... 10

External and Internal Signals and Connections..................................................................... 10

DC (charger) connector ...............................................................................................................10

Service Connector .........................................................................................................................11

Battery connector .........................................................................................................................11

SIM card connector ......................................................................................................................12

RTC backup battery ......................................................................................................................12

Functional Description ......................................................................................................................13

Power Distribution.......................................................................................................................... 13

Battery Interface............................................................................................................................. 13

Battery charging ...........................................................................................................................14

Startup Charging ..........................................................................................................................14

Battery Overvoltage Protection ................................................................................................15

Battery Removal During Charging ...........................................................................................16

PWM .................................................................................................................................................16

Battery Identification ..................................................................................................................16

Battery Temperature ....................................................................................................................18

Supply Voltage Regulators .........................................................................................................19

Switched Mode Supply VSIM ....................................................................................................21

Power Up and Power Down ......................................................................................................... 22

Power up with charger ................................................................................................................22

Power Up with the Power Switch (PWRONX) ......................................................................23

Power Up by RTC ...........................................................................................................................24

Power Up by IBI .............................................................................................................................24

Power Down ...................................................................................................................................24

Modes of Operation ....................................................................................................................... 25

Acting Dead ....................................................................................................................................25

Active Mode ...................................................................................................................................25

Sleep Mode .....................................................................................................................................25

Charging ..........................................................................................................................................26

Watchdog .......................................................................................................................................26

Audio Control................................................................................................................................... 27

PCM serial interface ....................................................................................................................27

Digital Control ................................................................................................................................. 28

MAD2 WD1 .....................................................................................................................................28

Memories........................................................................................................................................... 37

Page 2 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 17

NSB-7

PAMS Technical Documentation System Module

MAD memory configuration ......................................................................................................37

Memory ...........................................................................................................................................37

Program and Data Memory .......................................................................................................37

Work Memory ................................................................................................................................37

MCU Memory Requirements .....................................................................................................37

MCU Memory Map .......................................................................................................................37

Flash Programming ......................................................................................................................38

COBBA GJP .....................................................................................................................................39

Real time clock ..............................................................................................................................40

RTC backup battery charging ....................................................................................................40

Security ............................................................................................................................................40

Baseband EMC Strategy .............................................................................................................40

Baseband Testing ..........................................................................................................................41

Alignments .....................................................................................................................................41

Baseband Startup for Testing ....................................................................................................42

RF Module............................................................................................................................................... 43

Shielding............................................................................................................................................ 43

Environmental Specifications .........................................................................................................43

Normal and Extreme voltages ...................................................................................................43

Temperature Conditions .............................................................................................................43

Humidity ..........................................................................................................................................43

Vibration ..........................................................................................................................................44

ESD Strength ..................................................................................................................................44

Main Technical Specifications ........................................................................................................44

Maximum Ratings .......................................................................................................................... 44

RF Frequency Plan ..............................................................................................................................45

DC Characteristics ..............................................................................................................................45

Regulators......................................................................................................................................... 45

Control Signals ................................................................................................................................ 46

Power Distribution Diagram ............................................................................................................47

RF Characteristics ...............................................................................................................................48

GSM1900 (PCS1900) ..................................................................................................................... 48

Transmitter Characteristics.......................................................................................................... 48

Output Power Requirements ....................................................................................................... 48

Output RF Spectrum due to modulation.................................................................................. 49

Spectrum due to switching transients...................................................................................... 49

Spurious Emissions (when allocated a channel).................................................................... 49

Spurious Emissions (idle mode) .................................................................................................. 50

Frequency Error and Phase Accuracy ........................................................................................ 50

Receiver Characteristics ...................................................................................................................50

Blocking Requirements ................................................................................................................. 51

AM Suppression Requirements ................................................................................................... 51

Sensitivity, Inter modulation, Spurious Rejection and Emissions..................................... 52

Reference Interference level........................................................................................................ 52

RF Block Diagram ...............................................................................................................................53

Frequency synthesizer .......................................................................................................................54

Receiver .................................................................................................................................................55

Transmitter ...........................................................................................................................................56

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 3

Page 18

NSB-7

System Module PAMS Technical Documentation

AGC strategy ........................................................................................................................................57

AFC function ........................................................................................................................................57

DC Compensation ...............................................................................................................................58

Parts List of RB9 (EDMS Issue 5.3) (Code: 0201512)................................................................ 59

Schematic Diagrams: RB9 (at the back of the binder)

Circuit Diagram of Power Supply (Version 05.21 Edit 64) for layout 5 ............................... A-1

Circuit Diagram of CPU Block (Version 05.21 Edit 45) for layout 5 ..................................... A-2

Connection between RF and Baseband modules (Version 05.21 Edit 37) for layout 5... A-3

Baseband Block Interconnections (Version 05.21 Edit 40) for layout 5 .............................. A-4

Circuit Diagram of MAD Block (Version 05.21 Edit 27) for layout 5 .................................... A-5

Circuit Diagram of RF Block (Version 05.21 Edit 132) for layout 5 ...................................... A-6

Circuit Diagram of UIF (Version 05.21 Edit 36) for layout 5................................................... A-7

Circuit Diagram of Audio and RFI (Version 05.21 Edit 72) for layout 5 .............................. A-8

Circuit Diagram of IR Module (Version 05.21 Edit 23) for layout 5 ..................................... A-9

Layout Diagram of RB9 -Top (Version 05.21)............................................................................A-10

Layout Diagram of RB9 - Bottom (Version 05.21)................................................................... A-10

Testpoints of RB9 - Top (Version 05.21) .....................................................................................A-11

Testpoints of RB9 - Bottom (Version 05.21)..............................................................................A-12

RF Testpoints for RB9 - Circuit Diagram (Version 05.21 Edit132 ) .....................................A-13

RF Testpoints of RB9 - Layout (Version 05.21) .........................................................................A-14

Page 4 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 19

NSB-7

PAMS Technical Documentation System Module

List of Figures

Page No

Fig 1 Block Diagram ...................................................................................................................................... 8

Fig 2 Block Diagram of Power Distribution ............................................................................................ 13

Fig 3 Charging Block Diagram.................................................................................................................... 14

Fig 4 Output Overvoltage Protection (in principle; not in time scale) ........................................... 15

Fig 5 Output Overvoltage Protection When Battery Removed (in principle)................................ 16

Fig 6 BSI connections for all battery types ............................................................................................ 17

Fig 7 SIMCardDetX Detection Levels........................................................................................................ 18

Fig 8 Standard Battery BTEMP connection ............................................................................................ 19

Fig 9 Principle of the SMR Power Functions.......................................................................................... 22

Fig 10 Power Up With Charger .................................................................................................................. 23

Fig 11 Power Up With Switch .................................................................................................................... 24

Fig 12 Flash Programming Sequence ....................................................................................................... 39

Fig 13 RF Frequency Plan............................................................................................................................. 45

Fig 14 Power Distribution Diagram .......................................................................................................... 47

Fig 15 RF Block Diagram.............................................................................................................................. 53

Fig 16 Phase Locked Loop............................................................................................................................ 55

Fig 17 Power Control Loop Diagram......................................................................................................... 57

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 5

Page 20

NSB-7

System Module PAMS Technical Documentation

Transceiver NSB-7

Introduction

The NSB-7 is a single band transceiver unit designed for the GSM1900 networks. It is

GSM1900 power class 1 (1W) transceiver.

The transceiver consists of System/RF module (RB9), Display module (UX7) and assembly

parts.

The transceiver has a full graphic display and the user interface is based on a jack style

UI with two soft keys.

A back mounted antenna is used, there is no connection to an external antenna.

The transceiver has a low leakage tolerant earpiece and an omnidirectional microphone,

providing excellent audio quality. The transceiver supports full rate, an enhanced full rate

and a half rate speech decoding.

An integrated IR link provides a connection between two NSB-7 transceivers or a transceiver and a PC (internal data), or a transceiver and a printer.

The small SIM (Subscriber Identity Module) card is located under the back cover of the

phone.

Operational Modes

There are five different operational modes:

• power off mode

•idle mode

• active mode

• charge mode

• local mode

In the power off mode only the circuits needed for power up are supplied.

In the idle mode circuits are powered down and only the sleep clock is running.

In the active mode all the circuits are supplied with power although some parts might be

in idle state part of the time.

The charge mode is effective in parallel with all previous modes. The charge mode itself

consists of two different states, i.e. the fast charge and the maintenance mode.

Page 6 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 21

NSB-7

PAMS Technical Documentation System Module

The local mode is used for alignment and testing.

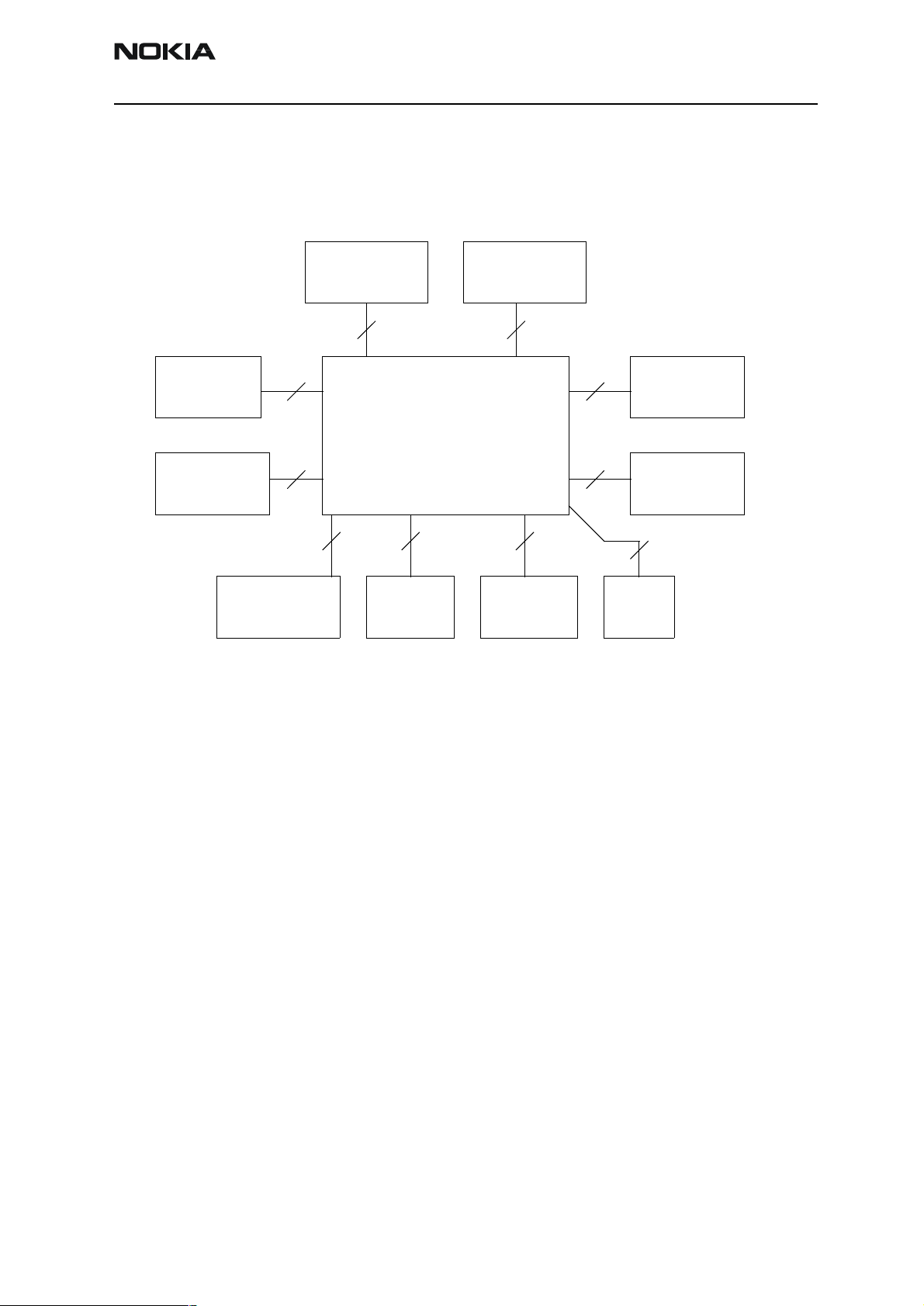

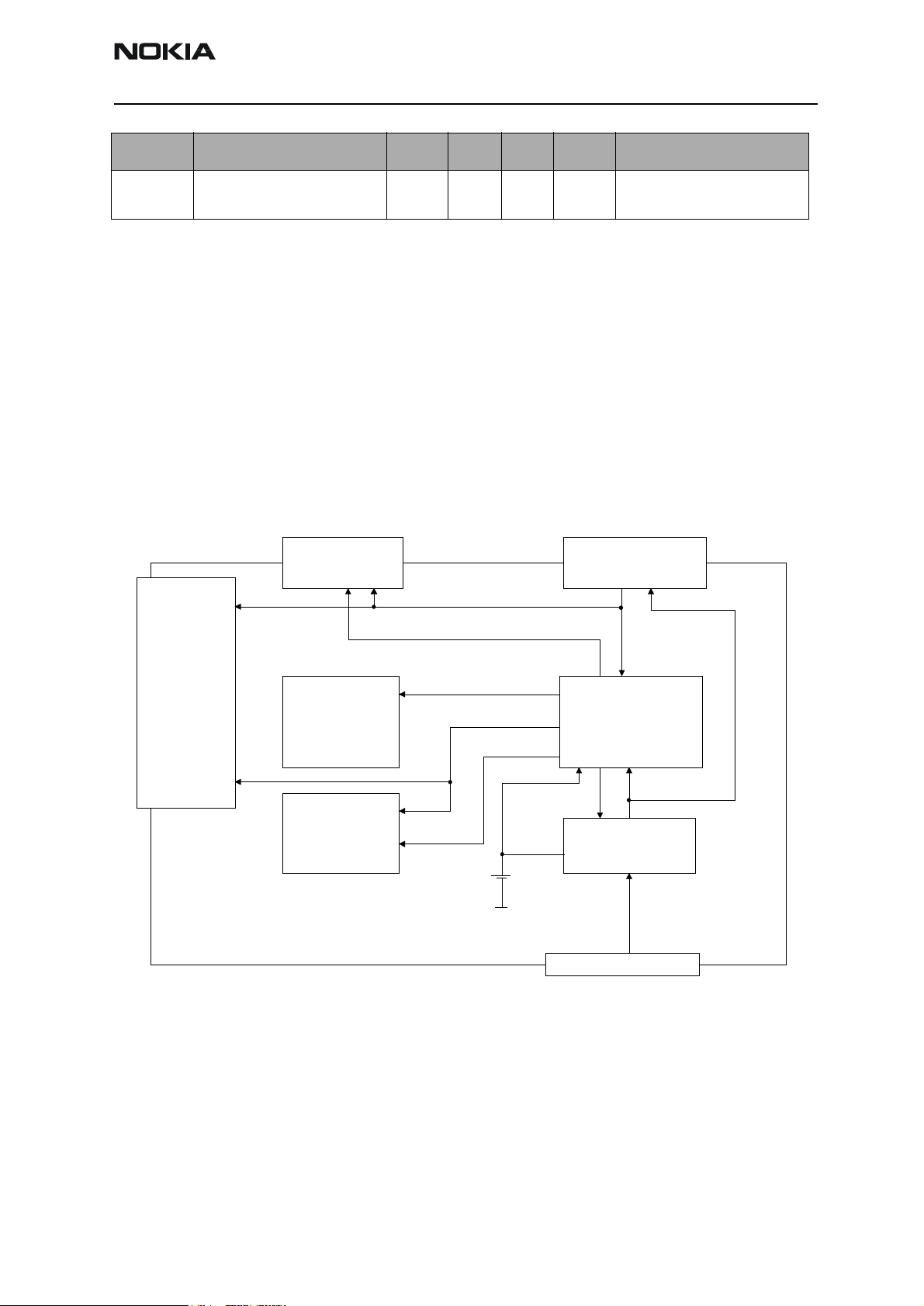

Interconnection Diagram

Keyboard LCD module

14 9

SIM

Antenna

Microphone IR Link Earpiece HF/HS

6

4

Battery

Radio

Module

2

RB9

2+2

Charger

2824

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 7

Page 22

NSB-7

System Module PAMS Technical Documentation

System Module

Baseband Module

The ASICs are in the uBGA package. Flash and SRAM chips are inside the same package.

EEPROM is software emulated with Flash. These changes have decreased the number of

I/O between the ICs. Smaller I/O count has made using smaller packages possible

The baseband architecture supports a power saving function called ”sleep mode”. This

sleep mode shuts off the VCTCXO, which is used as system clock source for both RF and

baseband. During the sleep mode the system runs from a 32 kHz crystal. The phone is

waken up by a timer running from this 32 kHz clock supply. The sleeping time is determined by some network parameters. The sleep mode is entered when both the MCU and

the DSP are in stand-by mode and the normal VCTCXO clock has been switched off.

The battery charging is controlled by a PWM signal from the CCONT. The PWM duty cycle

is determined by a charging software and is fed to the CHAPS charging switch.

Two types of chargers can be connected to the phone. Standard chargers (two wires)

provide a coarse supply power, which is switched by the CHAPS for suitable charging

voltage and current. Advanced chargers (three wires) are equipped with a control input.

Three wire chargers are treated like two wire ones.

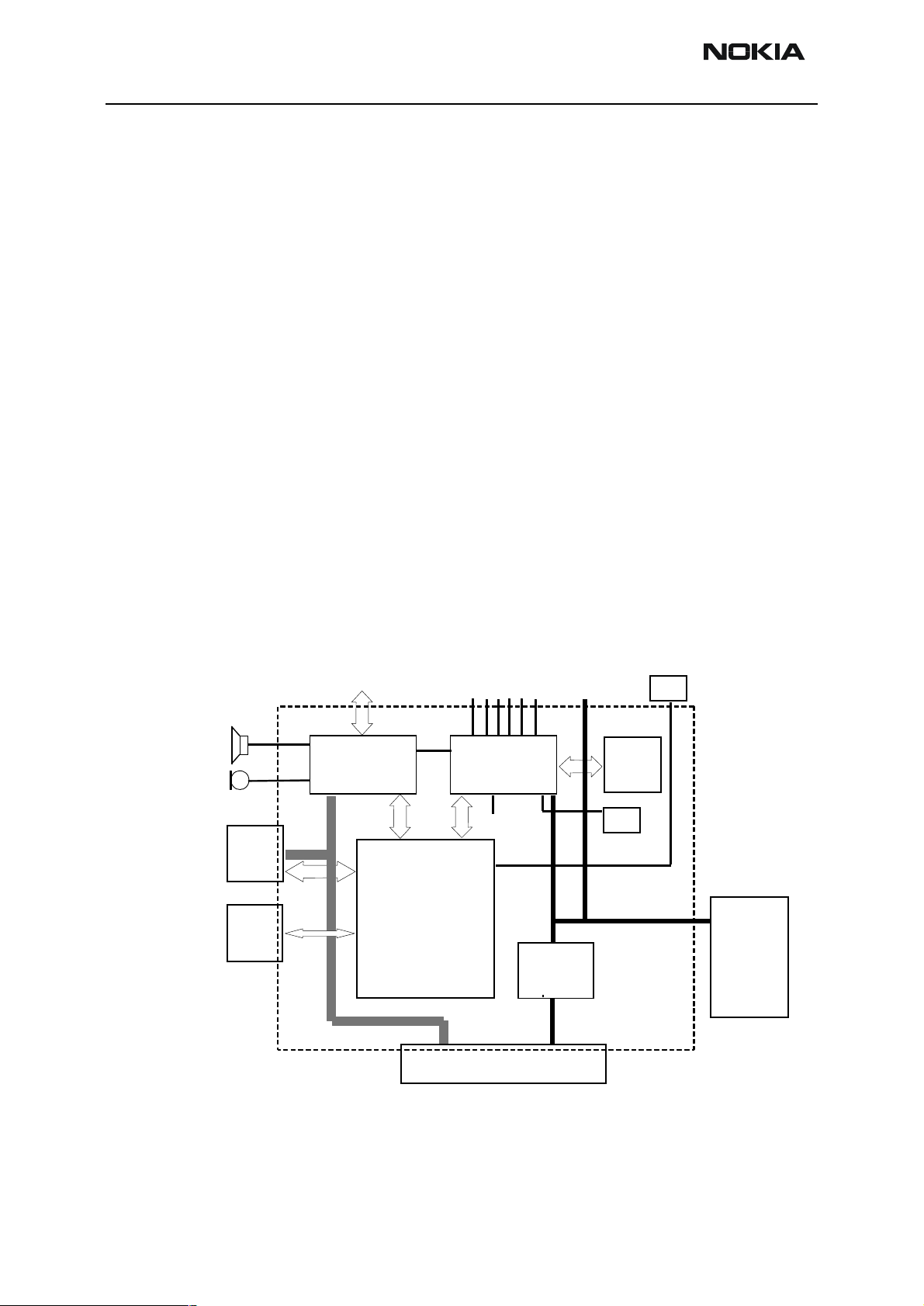

Block Diagram

TX/RX SIGNALS

COBBA SUPPLY

COBBA

UI

MAD

IR

+

MEMORIES

RF SUPPLIES

CCONT

BB SUPPLY

CHAPS

PA SUPPLY

SLEEP CLOCK

32kHz

CLK

VBAT

SIM

13MHz

CLK

SYSTEM CLOCK

BATTERY

BASEBAND

EXT. AUDIO

HS-connector

Charger

connector

Figure 1: Block Diagram

Page 8 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 23

NSB-7

PAMS Technical Documentation System Module

Technical Summary

The baseband module consists of four ASICs; CHAPS, CCONT, COBBA-GJP and

MAD2WD1, which take care of the baseband functions of the engine.

The baseband is running from a 2.8V power rail, which is supplied by a power controlling

ASIC CCONT. MAD2WD1 supply voltages are VBB and VCORE (V2V), VBB feed I/O pins so

that MAD2WD1 is externally fully compatible with old versions. VCORE feed MAD2WD1

internal functions supply voltage; CPU, DSP and system logic. In the CCONT there are 6

individually controlled regulator outputs for RF-section and two outputs for the baseband. In addition there is one +5V power supply output (V5V). The CCONT contains also a

SIM interface, which supports both 3V and 5V SIM-cards. A real time clock function is

integrated into the CCONT, which utilizes the same 32kHz clock supply as the sleep

clock. A backup power supply is provided for the RTC, which keeps the real time clock

running when the main battery is removed. The backup power supply is a rechargable

battery. The backup time with the battery is ten minutes minimum.

The analog interface between the baseband and the RF section is handled by a COBBA

ASIC. COBBA provides A/D and D/A conversion of the in-phase and quadrature receive

and transmit signal paths and also A/D and D/A conversions of received and transmitted

audio signals to and from the user interface. The COBBA supplies the analog TXC and AFC

signals to RF section according to the MAD DSP digital control. Data transmission

between the COBBA and the MAD is implemented using serial bus for high speed signalling and for PCM coded audio signals. Digital speech processing is handled by the MAD

ASIC. COBBA is a dual voltage circuit, the digital parts are running from the baseband

supply VBB and the analog parts are running from the analog supply VCOBBA.

The baseband supports both internal and external microphone inputs and speaker outputs. Input and output signal source selection and gain control is done by the COBBA

according to control messages from the MAD. Keypad tones, DTMF and other audio tones

are generated and encoded by the MAD and transmitted to the COBBA for decoding. A

buzzer and an external vibra alert control signals are generated by the MAD with separate PWM outputs.

EMC shielding is implemented using a metallized plastic frame. On the other side the

engine is shielded with PCB grounding. Heat generated by the circuitry will be conducted

out via the PCB ground planes.

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 9

Page 24

NSB-7

System Module PAMS Technical Documentation

Technical Specifications

Absolute Maximum Ratings

Parameter Rating

Battery voltage -0.3... 5.3 V

Charger input voltage -5.0... 16V

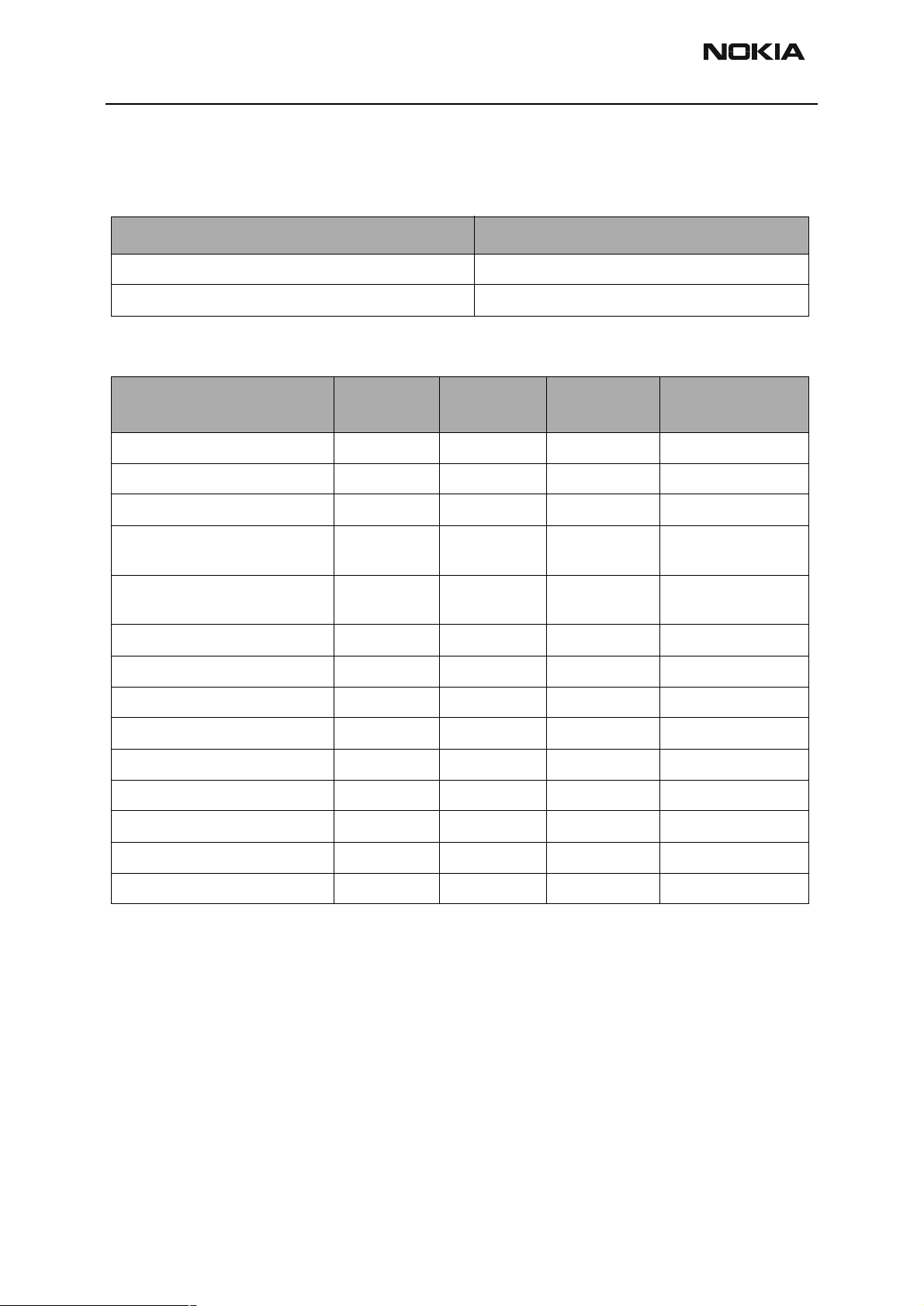

DC Characteristics

Line Symbol Minimum

Supply battery voltage 3.0 3.9 4.8 V

Battery powerup voltage (HW) 2.9 3.0 3.1 V

Battery cut off voltage (HW) 2.7 2.8 2.9 V (3.1 V SW cutoff)

Regulated baseband supply voltage

Regulated baseband supply current

COBBA analog supply voltage 2.7 2.8 2.85 V

COBBA analog supply current 5 20 100 mA

Regulated 5V supply voltage 4.8 5.0 5.2 V

Regulated 5V supply current 0 1 30 mA

Regulated 5V SIM supply voltage 4.8 5.0 5.2 V

Regulated 5V SIM supply current 3 10 30 mA

Regulated 3V SIM supply voltage 2.8 3.0 3.2 V

2.7 2.8 2.85 V

3 50 125 mA

Typical /

Nominal

Maximum Unit / Notes

Regulated 3V SIM supply current 1 6 30 mA

Voltage reference 1.4775 1.5 1.5225 V

External and Internal Signals and Connections

This section describes the external electrical connection and interface levels on the baseband. The electrical interface specifications are collected into tables that covers a connector or a defined interface.

DC (charger) connector

DC (charger) connector is physically integrated in the same component with the acces-

Page 10 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 25

NSB-7

PAMS Technical Documentation System Module

sory interface connector. DC connector has both jack and contact pads for desk stand.

Name Min Typ Max Unit Notes

VIN 0 12 V

0850mA

L_GND 0 0.3 V

Service Connector

Name Parameter Min Typ Max Unit Remark

MBUS Serial clock from

the Prommer

FBUS_RX Serial data from the

Prommer

FBUS_TX Data acknowledge

to the Prommer

GND GND 0 0 V Ground

0

2.0

0

2.0

0

2.0

logic low

logic low

logic low

logic high

logic low

logic high

0.8

2.85

0.8

2.85

0.5

2.85

V Prommer detection and Serial

Clock for synchronous communication

V Receive Data from Prommer to

Baseband

V Transmit Data from Baseband to

Prommer

The service connector is used as a flash programming interface for updating (i.e. re-programming) the flash program memory and an electrical access for services to the engine.

When the flash prommer is connected to the phone supply power is provided through the

battery contacts and the phone is powered up with a pulse given to the BTEMP line.

Battery connector

The BSI contact on the battery connector is used to detect when the battery is to be

removed to be able to shut down the operations of the SIM card before the power is lost

if the battery is removed with power on. The BSI contact disconnects earlier than the

supply power contacts to give enough time for the SIM and LCD shut down.

Name Min Typ Max Unit Notes

VBATT 3.0 3.9 4.2 V Battery voltage

BSI 0 2.85 V Battery size indication

Phone has 100kohm pull-up resistor.

SIM Card removal detection

(Threshold is 2.4V@VBB=2.8V)

68 kohm Battery indication resistor (BLB-2)

kohm Battery indication resistor (service battery)

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 11

Page 26

NSB-7

System Module PAMS Technical Documentation

Name Min Typ Max Unit Notes

BTEMP 0 1.4 V Battery temperature indication

Phone has a 100k (+/-5%) pull-up resistor,

Battery package has a NTC pull-down

resistor: 47k +/-5%@+25C, B=4050 +/3%

2.1

510330

0 1 kohm Local mode initialization (in production)

BGND 0 0 V Battery ground

V

ms

Phone power up by battery (input)

Power up pulse width

SIM card connector

The SIM card connector is located on the engine beside the battery pack.

Pin Name Parameter Min Typ Max Unit Notes

4GND GND 0 0 V Ground

3, 5 VSIM 5V SIM Card

3V SIM Card

6 DATA 5V Vin/Vout

3V Vin/Vout

2 SIMRST 5V SIM Card

3V SIM Card

4.8

2.8

4.0

0

2.8

0

4.0

2.8

5.0

3.0

“1”

“0”

“1”

“0”

“1”

“1”

5.2

3.2

VSIM

0.5

VSIM

0.5

VSIM

VSIM

V Supply voltage

VSIM data

Trise/Tfall max 1us

VSIM reset

1SIMCLKFrequency

Trise/Tfall

3.25

25

MHz

ns

SIM clock

RTC backup battery

The RTC block in CCONT needs a power backup to keep the clock running when the

phone battery is disconnected. The backup power is supplied from a rechargable Li-ion

battery that can keep the clock running ten minutes minimum. The backup battery is

charged from the main battery through CHAPS.

Signal Parameter Min Typ Max Unit Notes

VBACK Backup battery charging

from CHAPS

Backup battery charging

from CHAPS

VBACK Backup battery supply to

CCONT

3.02 3.15 3.28 V

100 200 500 uA Vout@VBAT-0.2V

23.28V

Page 12 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 27

NSB-7

PAMS Technical Documentation System Module

Signal Parameter Min Typ Max Unit Notes

Backup battery supply to

CCONT

Functional Description

Power Distribution

In normal operation the baseband is powered from the phone‘s battery. The battery consists of one Lithium-Ion cell. An external charger can be used for recharging the battery

and supplying power to the phone.

The baseband contains parts that control power distribution to whole phone excluding

those parts that use continuous battery supply. The battery feeds power directly to the

CCONT and UI (buzzer and display and keyboard lights).

The power management circuit CHAPS provides protection against over voltages, charger

failures and pirate chargers etc. that would otherwise cause damage to the phone.

RF

UI

(LCD,

backlights,

buzzer)

80 uA

RF supply voltages

VCobba

Vbb

Battery connector

VB

CCONTCOBBA GJP

Baseband

MAD2 +

MEMORY

CHRG_CTRL

VCORE

CHAPS

RTC backup

VChar

Charger & headset connector

Vbatt

Figure 2: Block Diagram of Power Distribution

Battery Interface

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 13

Page 28

NSB-7

System Module PAMS Technical Documentation

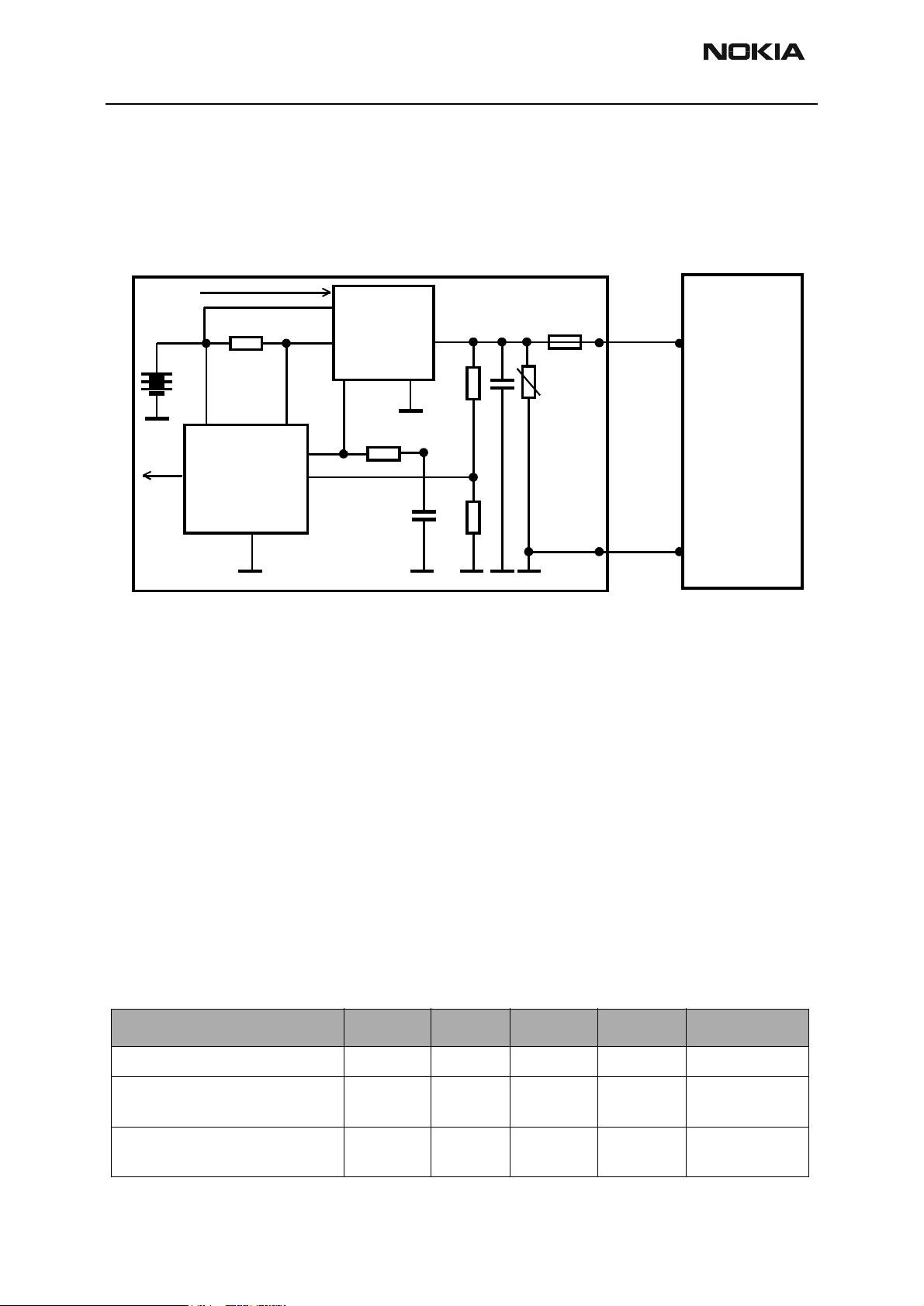

Battery charging

The electrical specifications give the idle voltages produced by the acceptable chargers

at the DC connector input. The absolute maximum input voltage is 30V due to the transient suppressor that is protecting the charger input. At phone end there is no difference

between a plug-in charger or a desktop charger. The DC-jack pins and bottom connector

charging pads are connected together inside the phone.

MAD

MAD

VBAT

CCONTINT

CCONT

0R22

GND

ICHAR

PWM_OUT

VCHAR

LIM

VOUT

CHAPS

RSENSE

PWM

VCH

GND

22k

TRANSCEIVER

1u

100k

1n

10k

Figure 3: Charging Block Diagram

30V

CHARGER

2A

VIN

L_GND

Startup Charging

When a charger is connected, the CHAPS is supplying a startup current minimum of

130mA to the phone. The startup current provides initial charging to a phone with an

empty battery. Startup circuit charges the battery until the battery voltage level is

reaches 3.0V (+/- 0.1V) and the CCONT releases the PURX reset signal and program execution starts. Charging mode is changed from startup charging to PWM charging that is

controlled by the MCU software. If the battery voltage reaches 3.55V (3.75V maximum)

before the program has taken control over the charging, the startup current is switched

off. For accessory detection, startup current is possible cut via CCUT line. The startup

current is switched on again when the battery voltage is sunken 100mV (nominal).

Parameter Symbol Min Typ Max Unit

VOUT Start-up mode cutoff limit Vstart 3.45 3.55 3.75 V

VOUT Start-up mode hysteresis

NOTE: Cout=4.7 uF

Start-up regulator output current

VOUT=0V....Vstart

Vstarthys 80 100 200 mV

Istart 130 165 200 mA

Page 14 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 29

NSB-7

PAMS Technical Documentation System Module

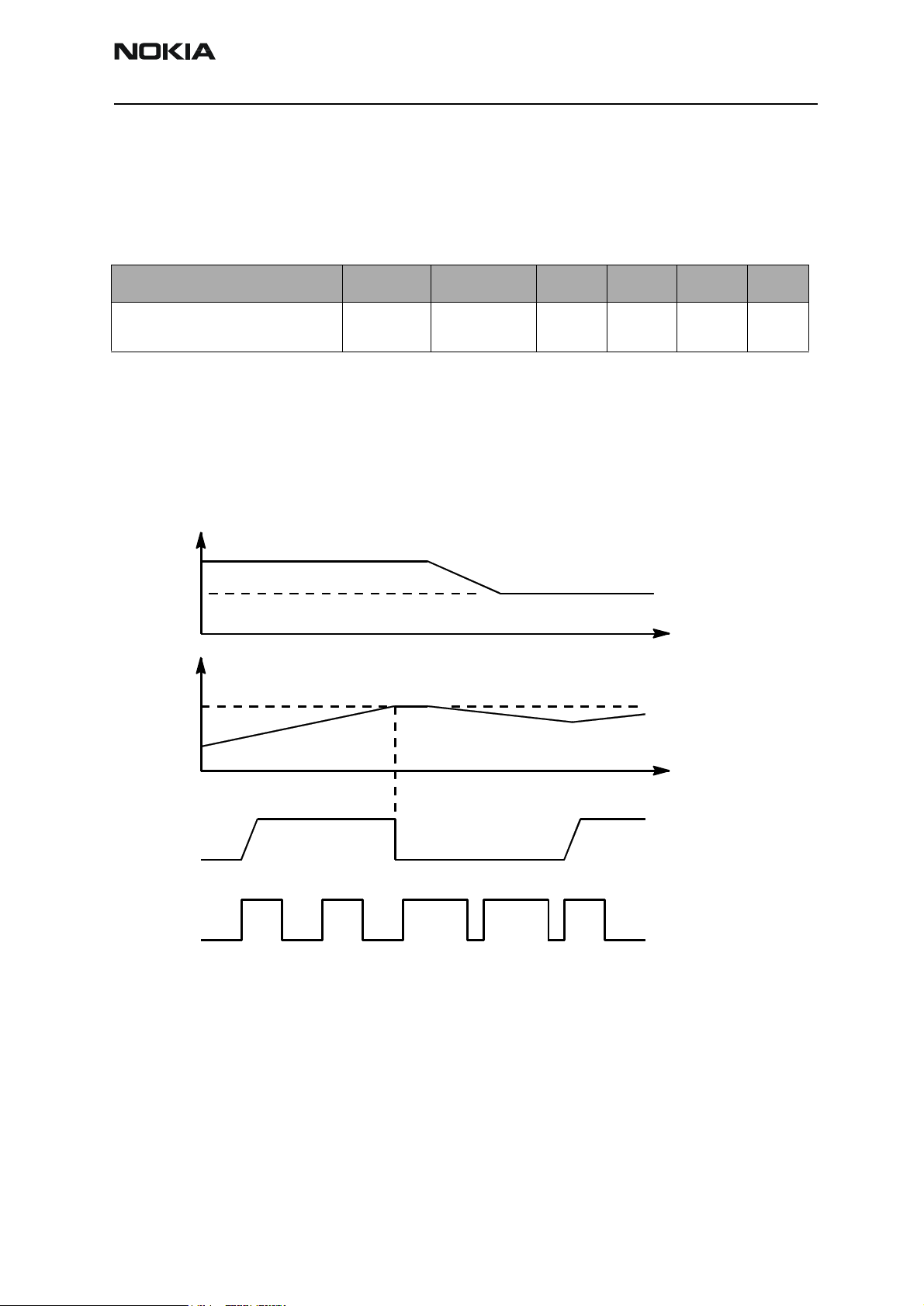

Battery Overvoltage Protection

Output overvoltage protection is used to protect phone from damage. This function is

also used to define the protection cutoff voltage for the Lithium-Ion battery. The power

switch is immediately turned OFF if the voltage in VOUT rises above the selected limit

VLIM.

Parameter Symbol LIM input Min Typ Max Unit

Output voltage cutoff limit (during transmission or Li-battery)

VLIM LOW 4.4 4.6 4.8 V

The voltage limit (VLIM1 or VLIM2) is selected by logic LOW or logic HIGH on the CHAPS

(N101) VLIM input pin.

When the switch in output overvoltage situation has once turned OFF, it stays OFF until

the battery voltage falls below VLIM and PWM = LOW is detected. The switch can be

turned on again by setting PWM = HIGH.

VCH

VCH<VOUT

t

VOUT

VLIM

SWITCH

PWM (32Hz)

t

ON OFF

Figure 4: Output Overvoltage Protection (in principle; not in time scale)

ON

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 15

Page 30

NSB-7

"1"

3

4

5

6

7

System Module PAMS Technical Documentation

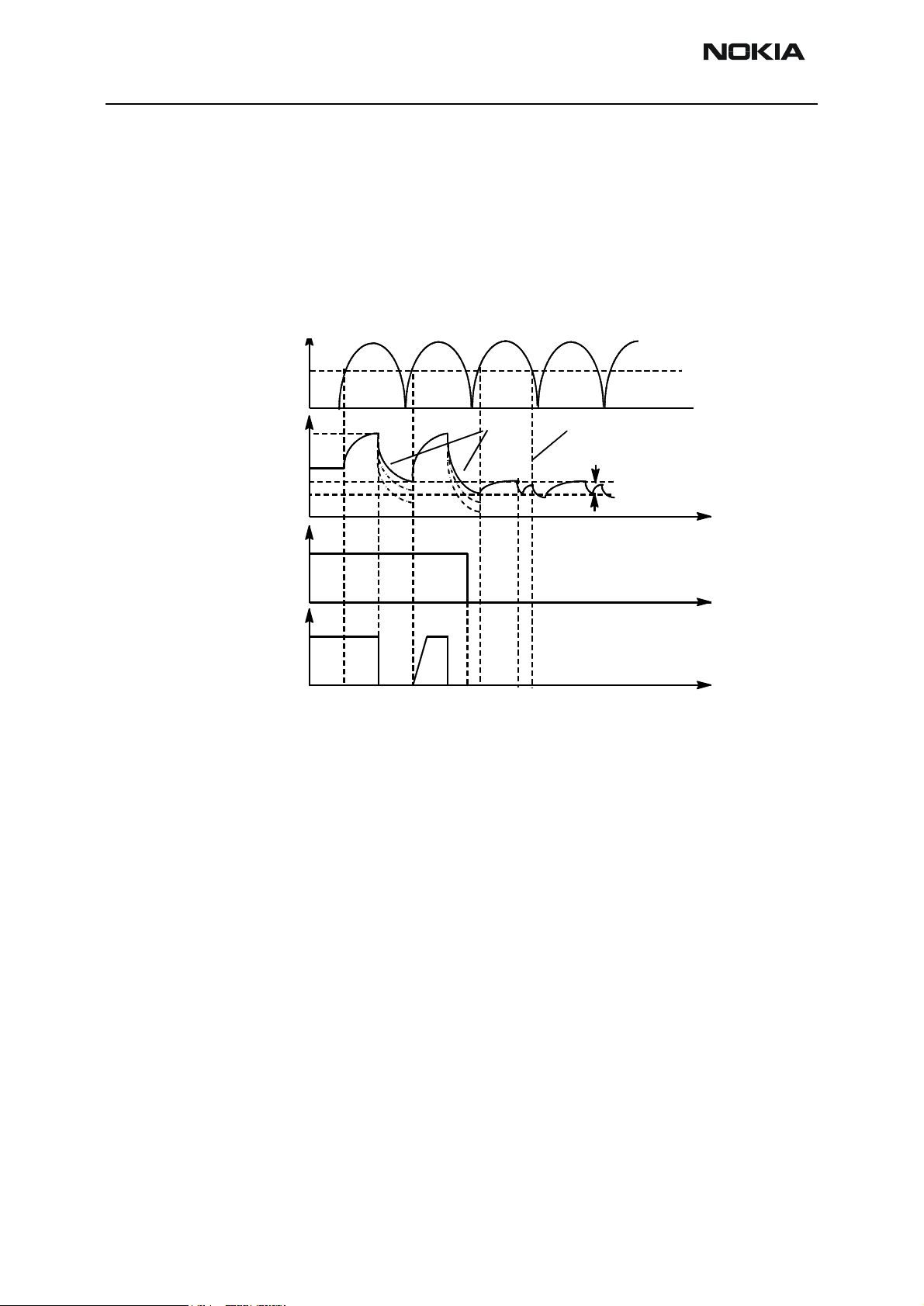

Battery Removal During Charging

Output overvoltage protection is also needed in case the main battery is removed when

charger connected or charger is connected before the battery is connected to the phone.

With a charger connected, if VOUT exceeds VLIM, CHAPS turns switch OFF until the

charger input has sunken below Vpor (nominal 3.0V, maximum 3.4V). MCU software will

stop the charging (turn off PWM) when it detects that battery has been removed. The

CHAPS remains in protection state as long as PWM stays HIGH after the output overvoltage situation has occured.

VCH

(Standard

Charger)

VOUT

PWM

SWITCH

Vpor

Droop depends on load

VLIM

4V

Vstart

0

ON

OFF

1

Battery removed, (standard) charger connected, VOUT rises (follows charger voltage)

2. VOUT exceedslimit VLIM(X),switch is turned immediatelyOFF

3

VOUT falls (because no battery) , also VCH<Vpor (standard chargers full-rectified

output).WhenVCH>VporandVOUT<VLIM(X)->switchturnedonagain(alsoPWM

is still HIGH) a nd VOUT again exceeds VLIM(X).

4. Software sets PWM = LOW -> CHAPS does n ot enter PWM mode

5. PWM low -> Startup mode, startup current flows until Vstart limit reached

6. VOUT exceeds limit Vstart, Istart is turned off

7. VCH falls below Vpor

2

1

& C in phone

Istart off due to VCH<Vpor

Vstarthys

t

t

t

Figure 5: Output Overvoltage Protection When Battery Removed (in principle; not in time scale)

PWM

When a charger is used, the power switch is turned ON and OFF by the PWM input. PWM

rate is 1Hz. When PWM is HIGH, the switch is ON and the output current Iout = charger

current - CHAPS supply current. When PWM is LOW, the switch is OFF and the output

current Iout = 0. To prevent the switching transients inducing noise in audio circuitry of

the phone soft switching is used.

Battery Identification

Different battery types are identified by a pulldown resistor inside the battery pack. The

BSI line inside transceiver has a 100k pull-up to VBB. The MCU can identify the battery

Page 16 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 31

NSB-7

PAMS Technical Documentation System Module

by reading the BSI line DC-voltage level with a CCONT (N100) A/D-converter.

Name Min Typ Max Unit Notes

BSI 0 2.8 V Battery size indication 100k pull-up resistor to

VBB in phone

SIM Card removal detection (Threshold is

2.4V@VBB=2.8V)

68 kohm Indication of a BLB-2 battery (600mAh Li-Ion)

22 kohm Indication resistor for a service battery

-5 5 % Indication resistor and pull-up resistor tolerance

VBATT

BATTERY

BTEMP

BSI

R

s

BGND

2.8V

10n

100k

10k

TRANSCEIVER

BSI

SIMCardDetX

CCONT

MAD

Figure 6: BSI connections for all battery types

The battery identification line is used also for battery removal detection. The BSI line is

connected to a SIMCardDetX line of MAD2. SIMCardDetX is a threshold detector with a

nominal input switching level 0.85xVcc for a rising edge and 0.55xVcc for a falling edge.

The battery removal detection is used as a trigger to power down the SIM card before the

power is lost. The BSI contact in the battery contact disconnects before the other con-

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 17

Page 32

NSB-7

System Module PAMS Technical Documentation

tacts so that there is a delay between battery removal detection and supply power off.

Vcc

0.85 _ 0.05 Vcc

0.55 _ 0.05 Vcc

SIMCARDDETX

GND

Figure 7: SIMCardDetX Detection Levels

SigOut

Battery Temperature

The battery temperature is measured with a NTC inside the battery pack. The BTEMP line

inside transceiver has a 100k pull-up to VREF. The MCU can calculate the battery temperature by reading the BTEMP line DC-voltage level with a CCONT (N100) A/D-converter.

Pin Name Min Typ Max Unit Notes

3 BTEMP 0 1.4 V Battery temperature indication 100k pull-up

resistor to VREF in phone

Battery package has NTC pull-down resistor: 47k

+/-5%@+25C, B=4050 +/-3%

2.1

510320

47 Kohm Service battery value

-5 5 % 100k pull-up resistor tolerance

V

ms

Phone power up by battery (input)

Power up pulse width

Page 18 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 33

NSB-7

PAMS Technical Documentation System Module

VBATT

BATTERY

R

NTC

BSI

BTEMP

T

BGND

TRANSCEIVER

VREF

100k

10k

BTEMP

CCONT

Based on 47 kohm ± 5 % NTC with B = 4090 ±1.5 %. Without any alignment, with that

and 1 % pull-up resistor, ± 2.5 _C accuracy is achieved between - 20 and +60 _C (± 3.5

_C @ -40 ... +85 _C).

Supply Voltage Regulators

The heart of the power distribution is the CCONT. It includes all the voltage regulators

and feeds the power to the whole system. The baseband digital parts are powered from

the VBB regulator which provides 2.8V baseband supply. The baseband regulator is active

always when the phone is powered on. The VBB baseband regulator feeds MAD and

memories, VCORE for MAD core, COBBA digital parts and the LCD driver in the UI section.

There is a separate regulator for a SIM card. The regulator is selectable between 3V and

5V and controlled by the SIMPwr line from MAD to CCONT. The COBBA analog parts are

powered from a dedicated 2.8V supply VCOBBA. The CCONT supplies also 5V for RF and

for flash VPP. The CCONT contains a real time clock function, which is powered from a

RTC backup when the main battery is disconnected. The RTC backup is rechargable polyacene battery. The battery is charged from the main battery voltage by the CHAPS when

the main battery voltage is over 3.2V.

Figure 8: Standard Battery BTEMP connection

Operating Mode Vref RF REG VCOBBA VBB VSIM SIMIF Vcore

Power off Off Off Off Off Off Pull-down Off

Power on On On/Off On On On On/Off On

Reset On Off

On On Off Pull-down On

VR1 On

Sleep On Off Off On On On/Off On

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 19

Page 34

NSB-7

System Module PAMS Technical Documentation

NOTE: COBBA regulator is off in SLEEP mode. Its output pin may be fed from VBB

in SLEEP mode by setting bit RFReg(5) to’1’ (default).

CCONT includes also five additional 2.8V regulators providing power to the RF section.

These regulators can be controlled either by the direct control signals from MAD or by

the RF regulator control register in CCONT which MAD can update. Below are the listed

the MAD control lines and the regulators they are controlling.

- TxPwr controls VTX regulator (VR5)

- RxPwr controls VRX regulator (VR2)

- SynthPwr controls all the rf regulators except VR1

- VCXOPwr controls VXO regulator (VR1)

CCONT generates also a 1.5 V reference voltage VREF to COBBA. The VREF voltage is also

used as a reference to some of the CCONT A/D converters.

In addition to the above mentioned signals MAD includes also TXP control signal which

goes to HAGAR power control block. The transmitter power control TXC is led from

COBBA to HAGAR.

Characteristics Condition Min Typ Max Unit

Output current VR1-VR6 Vout@2.8V 100 mA

Output current VR7

Depends on external BJT

Output current VR7BASE

Base current limit

Output current VBB On

Current limit 250mA

Output current VBB Sleep

Current limit 5mA

Output voltage VR1-VR7 over full temperature, input

Output voltage VBB over full temperature, input

Output voltage V2V

(VCORE)

Vout@2.8V 150 mA

Vout@2.8V -10 mA

Vout@2.8V

Vout@2.8V

voltage and load range

voltage and load range

Programmable:

Vout=1.3V+225mV*n

N = 0,1,2,3,4,5,6

2.7 2.8 2.85 V

2.7 2.8 2.85 V

1.30 2.65 V

125

1

mA

mA

Output voltage V2V

(VCORE) tolerance

Line regulation (not VBB) F v 10kHz, 2)

VBAT>3.15V

-5 +5 %

49 DB

Page 20 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 35

NSB-7

PAMS Technical Documentation System Module

Characteristics Condition Min Typ Max Unit

Line regulation (not VBB) F v 100kHz, 2)

VBAT>3.15v

Line regulation VBB, V2V

(VCORE)

Load regulation T = 25_C0.61mV/mA

Supply current (each regulator) VR1...VR7

Supply current VBB ON mode I

Supply current VBB SLEEP mode I

Output voltage V2V

(VCORE)

F v 100kHz 2) 30 DB

ON mode I

MAD2WD1 C10

MAD2WD1 C07

MAD2WD1 C05

40 DB

/

out

60+330

/60+

out

250

/60+

out

100

2.65

1.75

1.75

I

/

out

10+540

I

/10+

out

400

I

/10+

out

150

mA

mA

mA

V

NOTE 1: Characteristics above are NOT valid if Vbat < 3.0V.

NOTE 2: Line regulation is 20dB for f<100kHz when battery voltage is lower than 3.1V.

Switched Mode Supply VSIM

There is a switched mode supply for SIM-interface. SIM voltage is selected via serial IO.

The 5V SMR can be switched on independently of the SIM voltage selection, but can’t be

switched off when VSIM voltage value is set to 5V.

Characteristics Condition Min Typ Max Unit

Output voltage VSIM Over temperature

Over current

Output voltage V5V Over temp & current 4.8 5.0 5.2 V

Output voltage V5V_2 Over temperature 5.0 6.0 V

Output current VSIM Continuous DC 30 mA

Output current V5V Continuous DC 30 mA

Current consumption VSIM on

sleep

2.8

4.8

3.0

5.0

200

100

3.2

5.2

330

150

NOTE: VSIM and V5V can give together a total of 30mA.

V

uA

uA

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 21

Page 36

NSB-7

System Module PAMS Technical Documentation

In the next figure the principle of the SMR / VSIM-functions is shown.

CCONT External

VBAT

V5V_4

V5V_3

V5V_2

VSIM

Power Up and Power Down

The baseband is powered up by:

1 Pressing the power key, that generates a PWRONX interrupt signal from the

power key to the CCONT, which starts the power up procedure.

2 Connecting a charger to the phone. The CCONT recognizes the charger from the

VCHAR voltage and starts the power up procedure.

3 A RTC interrupt. If the real time clock is set to alarm and the phone is switched

off, the RTC generates an interrupt signal, when the alarm is gone off. The RTC interrupt

signal is connected to the PWRONX line to give a power on signal to the CCONT just like

the power key.

5V reg

V5V

Figure 9: Principle of the SMR Power Functions

5V

5/3V

4 A battery interrupt. Intelligent battery packs have a possibility to power up the

phone. When the battery gives a short (10ms) voltage pulse through the BTEMP pin, the

CCONT wakes up and starts the power on procedure.

Power up with charger

When the charger is connected CCONT will switch on the CCONT digital voltage as soon

as the battery voltage exceeds 3.0V. The reset for CCONT’s digital parts is released when

the operating voltage is stabilized (50 us from switching on the voltages). Operating

voltage for VCXO is also switched on. The counter in CCONT digital section will keep

MAD in reset for 62 ms (PURX) to make sure that the clock provided by VCXO is stable.

After this delay MAD reset is released, and VCXO -control (SLEEPX) is given to MAD. The

next diagram explains the power on procedure with charger (the picture assumes empty

Page 22 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 37

NSB-7

PAMS Technical Documentation System Module

battery, but the situation would be the same with full battery):

SLEEPX

PURX

CCPURX

Vbat

VR6

VR1

VBB (2.8V)

Vchar

Vref

12 3

1: Battery voltage over 3.0==>Digital voltages to CCONT (VBB)

2: CCONT digital reset released. VCXO turned on

3: 62ms delay before PURX released

Figure 10: Power Up With Charger

When the phone is powered up with an empty battery pack using the standard charger,

the charger may not supply enough current for standard powerup procedure and the

powerup must be delayed.

Power Up with the Power Switch (PWRONX)

When the power on switch is pressed the PWRONX signal will go low. CCONT will switch

on the CCONT digital section and VCXO as was the case with the charger driven power

up. If PWRONX is low when the 64 ms delay expires, PURX is released and SLEEPX control

goes to MAD. If PWRONX is not low when 64 ms expires, PURX will not be released, and

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 23

Page 38

NSB-7

System Module PAMS Technical Documentation

CCONT will go to power off (digital section will send power off signal to analog parts)

SLEEPX

PURX

CCPURX

PWRONX

VR1,VR6

VBB (2.8V)

Vchar

12 3

1:Power switch pressed ==> Digital voltages on in CCONT (VBB)

2: CCONT digital reset released. VCXO turned on

3: 62 ms delay to see if power switch is still pressed.

Power Up by RTC

RTC (internal in CCONT) can power the phone up by changing RTCPwr to logical 1.

Power Up by IBI

IBI can power CCONT up by giving a short pulse (10ms) through the BTEMP line. After

powerup BTEMP will act as any other input channel for ADC.

When the PURX reset is released, the MAD releases the system reset ExtSysResetX and

the internal MCUResetX signals and starts the boot program execution from MAD

bootrom if MAD GenSDIO pin is pulled low or from external memory if GenSDIO pin is

pulled high. In normal operation the program execution continues from the flash program memory. If the MBUS line is pulled low during the power up the bootrom starts a

flash programming sequence and waits for the prommer response through FBUS_RX line.

Power Down

The baseband is powered down by:

1 Pressing the power key, that is monitored by the MAD, which starts the power

down procedure.

Figure 11: Power Up With Switch

2 If the battery voltage is dropped below the operation limit, either by not charging

it or by removing the battery.

3 Letting the CCONT watchdog expire, which switches off all CCONT regulators and

Page 24 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 39

NSB-7

PAMS Technical Documentation System Module

the phone is powered down.

4 Setting the real time clock to power off the phone by a timer. The RTC generates

an interrupt signal, when the alarm is gone off. The RTC interrupt signal is connected to

the PWRONX line to give a power off signal to the CCONT just like the power key.

The power down is controlled by the MAD. When the power key has been pressed long

enough or the battery voltage is dropped below the limit the MCU initiates a power

down procedure and disconnects the SIM power. Then the MCU outputs a system reset

signal and resets the DSP. If there is no charger connected the MCU writes a short delay

to CCONT watchdog and resets itself. After the set delay the CCONT watchdog expires,

which activates the PURX and all regulators are switched off and the phone is powered

down by the CCONT.

If a charger is connected when the power key is pressed the phone enters into the acting

dead mode.

Modes of Operation

Acting Dead

If the phone is off when the charger is connected, the phone is powered on but enters a

state called ”acting dead”. To the user the phone acts as if it was switched off. A battery

charging alert is given and/or a battery charging indication on the display is shown to

acknowledge the user that the battery is being charged.

Active Mode

In the active mode the phone is in normal operation, scanning for channels, listening to

a base station, transmitting and processing information. All the CCONT regulators are

operating. There are several sub-states in the active mode depending on if the phone is

in burst reception, burst transmission, if DSP is working etc.

Sleep Mode

In the sleep mode all the regulators except the baseband VBB and the SIM card VSIM

regulators are off. Sleep mode is activated by the MAD after MCU and DSP clocks have

been switched off. The voltage regulators for the RF section are switched off and the

VCXO power control, VCXOPwr is set low. In this state only the 32 kHz sleep clock oscillator in CCONT is running. The flash memory power down input is connected to the ExtSysResetX signal, and the flash is deep powered down during the sleep mode.

The sleep mode is exited either by the expiration of a sleep clock counter in the MAD or

by some external interrupt, generated by a charger connection, key press, headset connection etc. The MAD starts the wake up sequence and sets the VCXOPwr and ExtSysResetX control high. After VCXO settling time other regulators and clocks are enabled for

active mode.

If the battery pack is disconnect during the sleep mode, the CCONT pulls the SIM interface lines low as there is no time to wake up the MCU.

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 25

Page 40

NSB-7

System Module PAMS Technical Documentation

Charging

Charging can be performed in any operating mode.The battery type/size is indicated by a

resistor inside the battery pack. The resistor value corresponds to a specific battery

capacity. This capacity value is related to the battery technology as different capacity

values are achieved by using different battery technology.

The battery voltage, temperature, size and current are measured by the CCONT controlled

by the charging software running in the MAD.

The power management circuitry controls the charging current delivered from the

charger to the battery. Charging is controlled with a PWM input signal, generated by the

CCONT. The PWM pulse width is controlled by the MAD and sent to the CCONT through a

serial data bus. The battery voltage rise is limited by turning the CHAPS switch off when

the battery voltage has reached 4.2 V. Charging current is monitored by measuring the

voltage drop across a 220 mohm resistor.

Watchdog

The Watchdog block inside CCONT contains a watchdog counter and some additional

logic which are used for controlling the power on and power off procedures of CCONT.

Watchdog output is disabled when WDDisX pin is tied low. The WD–counter runs during

that time, though. Watchdog counter is reset internally to 32 s at power up. Normally it

is reset by MAD writing a control word to the WDReg.

Page 26 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 41

NSB-7

PAMS Technical Documentation System Module

Audio Control

PCM serial interface

The interface consists of following signals: a PCM codec master clock (PCMDClk), a

frame synchronization signal to DSP (PCMSClk), a codec transmit data line (PCMTX) and

a codec receive data line (PCMRX). The COBBA-GJP generates the PCMDClk clock, which

is supplied to DSP SIO. The COBBA-GJP also generates the PCMSClk signal to DSP by

dividing the PCMDClk. The PCMDClk frequency is 512 kHz. PCMSClk frequency is 8.0 kHz.

PCMDClk

PCMSClk

PCMTxData

PCMRxData

sign extended

15 14 13 12 011 10

sign extended

MSB

MSB

LSB

LSB

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 27

Page 42

NSB-7

System Module PAMS Technical Documentation

Digital Control

The baseband functions are controlled by the MAD ASIC, which consists of a MCU, a system ASIC and a DSP. MAD with the GSM/PCN specific ASIC is named to MAD2.

MAD2 WD1

MAD2 WD1 contains following building blocks:

- ARM RISC processor with both 16-bit instruction set (THUMB mode) and 32-bit

instruction set (ARM mode)

- TI Lead DSP core with peripherals:

- API (Arm Port Interface memory) for MCU-DSP communication, DSP code

download, MCU interrupt handling vectors (in DSP RAM) and DSP booting.

- Serial port (connection to PCM)

-Timer

- DSP memory

- BUSC (BusController for controlling accesses from ARM to API, System Logic

and MCU external memories, both 8- and 16-bit memories)

- System Logic

- CTSI (Clock, Timing, Sleep and Interrupt control)

- MCUIF (Interface to ARM via BUSC). Contains MCU BootROM

- DSPIF (Interface to DSP)

- MFI (Interface to COBBA AD/DA Converters)

- CODER (Block encoding/decoding and A51&A52 ciphering)

- AccIF (Accessory Interface)

- SCU (Synthesizer Control Unit for controlling 2 separate synthesizer)

- UIF (Keyboard interface, serial control interface for COBBA PCM Codec, LCD

Driver and CCONT)

- SIMI (SimCard interface with enhanced features)

- PUP (Parallel IO, USART and PWM control unit for vibra and buzzer)

- Flexpool

Page 28 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 43

NSB-7

PAMS Technical Documentation System Module

The MAD2 operates from a 13 MHz system clock, which is generated from the 13Mhz

VCXO frequency. The MAD2 supplies a 6,5 MHz or a 13 MHz internal clock for the MCU

and system logic blocks and a 13 MHz clock for the DSP, where it is multiplied to 45.5

MHz DSP clock. The system clock can be stopped for a system sleep mode by disabling

the VCXO supply power from the CCONT regulator output. The CCONT provides a 32 kHz

sleep clock for internal use and to the MAD2, which is used for the sleep mode timing.

The sleep clock is active when there is a battery voltage available i.e. always when the

battery is connected.

MAD2WD1 supply voltages are VBB and VCORE (V2V), VBB feed I/O pins so that

MAD2WD1 is externally fully compatible with old versions. VCORE feed MAD2WD1

internal functions supply voltage; CPU, DSP and system logic.

Pin

No:

A1 MCUGemIO 0 O 2 0 MCU General pur-

C2 LEADGND Lead Ground

D2 Col4 I/O UIF 2 Input Programma-

D3 Col3 I/O UIF 2 Input Programma-

H11 MCUGenIO1 I/O 2 Input,

E4 GND Ground

D4 Col2 I/O UIF 2 Input Programma-

C4 Col1 I/O UIF 2 Input programma-

Pin Name

Pin

Type

Connecte

d to/

from

Drive

req. mA

Reset

State

pullup

Note Explanation

pose output port

I/O line for keyboard

ble pullup

PR0201

ble pullup

PR0201

Pullup

PR0201

ble pullup

PR0201

ble pullup

PR0201

column 4

I/O line for keyboard

column 3

General purpose I/O

port

I/O line for keyboard

column 2

I/O line for keyboard

column 1

C3 Col0 I/O UIF 2 Input programma-

ble pullup

PR0201

D1 LCDCSX I/O UIF 2 Input external pul-

lup/down

E1 LEADVCC Lead Power

F12 LoByteSelX NC

I/O line for keyboard

column 0

serial LCD driver chip

select, parallel LCD

driver enable

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 29

Page 44

NSB-7

System Module PAMS Technical Documentation

Pin

No:

E3 Row5LCDCD I/O UIF 2 Input,

N4 VCC_CORE Core VCC in

E2 Row4 I/O UIF 2 Input,

F4 Row3 I/O UIF 2 Input,

F3 Row2 I/O UIF 2 Input,

Pin Name

Pin

Type

Connecte

d to/

from

Drive

req. mA

Reset

State

pullup

pullup

pullup

pullup

Note Explanation

pullup

PR0201

3325c10

pullup

PR0201

pullup

PR0201

pullup

PR0201

Keyboard row5 data

I/O, serial LCD driver

command/data indi-

cator, parallel LCD

driver read/write

select

Power

I/O line for keyboard

row 4, parallel LCD

driver register selec-

tion control

I/O line for keyboard

row 3, parallel LCD

driver data

I/O line for keyboard

row 2, parallel LCD

driver data

F2 Row1 I/O UIF 2 Input,

pullup

F1 Row0 I/O UIF 2 Input,

pullup

L11 JTDO O 2 Tri-state JTAG data out

L5 GND Ground

N12 JTRst I Input,

pulldown

M12 JTClk I Input pulldown

N13 JTDI I Input,

pullup

M13 JTMS I Input,

pullup

G13 VCC_IO IO VCC in

L12 CoEmu0 I/O 2 Input,

pullup

pullup

PR0201

pullup

PR0201

pulldown

PD0201

PD0201

pullup

PR0201

pullup

PR0201

3325c10

pullup

PR0201

I/O line for keyboard

row 1, parallel LCD

driver data

I/O line for keyboard

row 0, parallel LCD

driver data

JTAG reset

JTAG Clock

JTAG data in

JTAG mode select

Power

DSP/MCU emulation

port 0

L13 CoEmu1 I/O 2 Input,

pullup

H4 LEADGND Lead Ground

pullup

PR0201

DSP/MCU emulation

port 1

Page 30 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 45

NSB-7

PAMS Technical Documentation System Module

Pin

No:

L1 ARMGND ARM Ground

N3 MCUAd0 O MCU

K4 ARMVCC ARM Power

N2 MCUAd1 O MCU

N1 MCUAd2 O MCU

M4 MCUAd3 O MCU

M3 MCUAd4 O MCU

M2 MCUAd5 O MCU

M1 MCUAd6 O MCU

Pin Name

Pin

Type

Connecte

d to/

from

MEMORY

MEMORY

MEMORY

MEMORY

MEMORY

MEMORY

MEMORY

Drive

req. mA

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

Reset

State

Note Explanation

H1 VCC_IO IO VCC in

3325c10

L4 MCUAd7 O MCU

MEMORY

L3 MCUAd8 O MCU

MEMORY

L2 MCUAd9 O MCU

MEMORY

K5 MCUAd10 O MCU

MEMORY

J4 GND Ground

K3 MCUAd11 O MCU

MEMORY

K2 MCUAd12 O MCU

MEMORY

K1 MCUAd13 O MCU

MEMORY

J3 MCUAd14 O MCU

MEMORY

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

Power

J2 MCUAd15 O MCU

MEMORY

2 0 MCU address bus

Issue 1 06/00 ãNokia Mobile Phones Ltd. Page 31

Page 46

NSB-7

System Module PAMS Technical Documentation

Pin

No:

J1 MCUAd16 O MCU

M10 VCC_CORE Core VCC in

H3 MCUAd17 O MCU

H2 MCUAd18 O MCU

G4 MCUAd19 O MCU

G3 MCUAd20 O MCU

G2 VCONT O

K6 ExtMCUDa0 I/O MCU

Pin Name

Pin

Type

Connecte

d to/

from

MEMORY

MEMORY

MEMORY

MEMORY

MEMORY

MEMORY

Drive

req. mA

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 0 MCU address bus

2 Input MCU data bus

Reset

State

Note Explanation

3325c10

Power

K9 GND Ground

L6 ExtMCUDa1 I/O MCU

MEMORY

M6 ExtMCUDa2 I/O MCU

MEMORY

N6 ExtMCUDa3 I/O MCU

MEMORY

L7 ExtMCUDa4 I/O MCU

MEMORY

M7 ExtMCUDa5 I/O MCU

MEMORY

N7 ExtMCUDa6 I/O MCU

MEMORY

N8 ExtMCUDa7 I/O MCU

MEMORY

M8 MCUGenIODa0I/O 2 Input MCU Data in

L8 MCUGenIODa1I/O 2 Input MCU Data in

2 Output MCU data bus

2 Output MCU data bus

2 Output MCU data bus

2 Output MCU data bus

2 Output MCU data bus

2 Output MCU data bus

2 Output MCU data bus

General purpose I/O

16-bit mode

16-bit mode

port

General purpose I/O

port

K8 MCUGenIODa2I/O 2 Input MCU Data in

16-bit mode

N9 MCUGenIODa3I/O 2 Input MCU Data in

16-bit mode

General purpose I/O

port

General purpose I/O

port

Page 32 ãNokia Mobile Phones Ltd. Issue 1 06/00

Page 47

NSB-7

PAMS Technical Documentation System Module

Pin

No:

E10 GND Ground

M9 MCUGenIODa4I/O 2 Input MCU Data in

L9 MCUGenIODa5I/O 2 Input MCU Data in

N10 MCUGenIODa6I/O 2 Input MCU Data in

L10 MCUGenIODa7I/O 2 Input MCU Data in

M5 MCURdX O MCU

G11 VCC_CORE Core VCC in

N5 MCUWrX O MCU

Pin Name

Pin

Type

Connecte

d to/

from

MEMORY

MEMORY

Drive

req. mA

2 1 MCU Read strobe

2 1 MCU write strobe

Reset

State

Note Explanation

General purpose I/O

16-bit mode

16-bit mode

16-bit mode

16-bit mode

3325c10

port

General purpose I/O

port

General purpose I/O

port

General purpose I/O

port

Power

N11 ROM1SelX O MCU

ROM

M11 RAMSelX O MCU

RAM

J11 IRON O IR Mod 2 1 IR control

A1 MCUGenIO1 I/O 2 Input,

D8 DSPXF O 2 1 External flag

K10 SCVCC Special cell Power

K11 RFClk I VCXO Input System clock from

K12 RFClkGnd Input System clock refer-

K13 SIMCardDetX I Input SIM card detection

J10 SCGND Special cell Ground

D9 BuzzPWM O BUZZER 2 0 Buzzer PWM control

D11 LEADVCC LEAD Power

2 1 ROM chip select

2 1 RAM chip select

pullup

pullup

PR0201

General purpose I/O

port

VCTCXO