Nobel AM, AM/T, AM/RT, AM/V, AM/RV Instruction Manual

...

AUTOMATIC SOFTENERS SERIES:

AM/T - AM/RT

AM/V - AM/RV

AM/METER - AM/R METER

INSTRUCTIONS MANUAL

WARNING!

The equipment must be used only for the utilization for which they have been

designed, as shown in the technical documentation.

Read carefully this leaflet until the end before starting any operation.

Proceed strictly according to all directions included in this manual.

Automatic softeners series AM are designed to treat raw water supplied from

municipalities or from well.

ANY OTHER APPLICATIONS OF THE EQUIPMENT DIFFERENT THAN THE MENTIONED

ONES IS MADE UNDER THE ONLY RESPONSIBILITY OF THE USER.

For any assistance concerning the installations, maintenance or utilization of the equipment

apply the NOBEL Service Center closest to you or directly:

NOBEL S.r.l.

e-mail: nobel@nobelitaly.it

tel. +39 02 2827968 fax +39 02 2610839

Page 1 of 15 am_tvm_mi-r1.doc

REL. 1

AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

INDEX

1. Safety........................................................................................................................................3

1.1. CE mark, declaration of conformity.....................................................................................3

1.2. How to displace the unit ......................................................................................................3

1.3. Hydraulics ...........................................................................................................................3

1.4. Electrical..............................................................................................................................3

1.5. How to store and delivery....................................................................................................3

2. Principles of working.................................................................................................................4

3. Technical characteristics ..........................................................................................................5

3.1. Assumed raw water characteristics.....................................................................................5

3.2. Technical characteristics (general) .....................................................................................5

3.3. Characteristics for each model............................................................................................5

3.4. Dimensions .........................................................................................................................6

3.5. Weight .................................................................................................................................6

4. Installation ................................................................................................................................6

4.1. Room conditions .................................................................................................................6

4.2. How to remove packaging...................................................................................................7

4.3. How to move and lift the unit...............................................................................................7

4.4. Placing & commissioning ....................................................................................................7

4.5. Hydraulic connections .........................................................................................................8

4.6. Electrical wiring connections ...............................................................................................8

5. End cycle and regeneration......................................................................................................9

5.1. End cycle.............................................................................................................................9

5.2. How to select the end-cycle ................................................................................................9

5.3. Regeneration.....................................................................................................................10

6. Starting-up ..............................................................................................................................11

7. Service & maintenance...........................................................................................................12

7.1. Disposal ............................................................................................................................12

8. Main components ...................................................................................................................13

8.1. Programmers ....................................................................................................................13

9. Trouble shooting guide ...........................................................................................................14

Annex:

• DRAWING 1: dimensions AM/T AM/V AM/METER AM/RT AM/RV AM/RMETER

• DRAWING 2: components AM/T AM/V AM/METER models 900÷2100

• DRAWING 3: components AM/RT AM/RV AM/RMETER models 900÷2100

• DRAWING 4: components AM/T AM/V AM/METER models 2700, 3300 e AM/RT AM/RV

AM/RMETER models 3600÷7200

• DRAWING 5: components AM/T AM/V AM/METER models 3600÷7200

• DRAWING 6: installation AM/T AM/V AM/METER models 900÷2100

• DRAWING 7: installation AM/RT AM/RV AM/RMETER models 900÷2100

• DRAWING 8: installation AM/T AM/V AM/METER models 2700, 3300 e AM/RT AM/RV

AM/RMETER models 3600÷7200

• DRAWING 9: installation AM/T AM/V AM/METER models 3600÷7200

• Membrane valves special instructions

• Programmer special instructions

• Declaration of conformity

s.r.l. - ITALY Page 2 of 15 am_tvm_mi-r1.doc - r.1

AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

1. Safety

1.1. CE mark, declaration of conformity

The equipment is designed to meet state-of-the-art safety requirements, has been tested and

left the factory in a condition in which it is safe to operate.

The equipment complies with the applicable standards and regulations as listed in the CE

declaration of conformity and thus complies with the statutory requirements of the CE

Directives.

NOBEL confirms the successful testing of the equipment by sticking to it the CE mark.

1.2. How to displace the unit

Particular care and attention should be put in during moving and displacing of heavy items, in

order to avoid injuries to persons or damage properties. (see § 3.5 page 6). The heavy parts

must be lifted and displaced always hooking and lifting them by the points shown on the

drawings (see fig. 1) and using only suitable ropes, hooks and/or chains, according to the

weight (see weight table).

1.3. Hydraulics

All operations must be performed by and/or under direct supervision of skilled and authorized

operators, using proper tools and personal protection devices if required (CE marked).

Before any operation of taking out pipes or part of hydraulic system, it is required to release

the pressure inside and empty the part of the system.

1.4. Electrical

Before starting any operation on electrical devices, be sure that main power supply is OFF.

All operations must be performed by skilled and authorized operators.

In case of liquid leakage, switch off the main power supply before operate. Before the

switching ON, be sure all the parts of the system are perfectly dry. Check that the available

electrical power is correct, (see § 3.2 page 5) before connection. Do not make preliminary wiring

connections.

1.5. How to store and delivery

• closed rooms

• open space

• transport

= ºC

5÷45 41÷113 5÷95%

5÷45 41÷113 5÷95%

5÷45 41÷113 5÷95%

= ºF humidity rel. notes

without condensate

without condensate

without condensate

protect from sun-light and rain.

protect from sun-light and rain.

s.r.l. - ITALY Page 3 of 15 am_tvm_mi-r1.doc - r.1

AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

2. Principles of working

Softening is the process that allows to remove calcium and magnesium from water. These

two elements, together with bicarbonate, are the main cause of the scale inside thermal plant

and domestic appliances (heating system, laundry machines, etc.). They also can cause big

trouble in many industrial process.

The process of softening is featured by ion exchange. The resins contained in the column

exchange the ions calcium and magnesium (Ca

they are charged. When the resins are exhausted, they are fully charged of calcium and

magnesium (Ca

++

e Mg++) while they do not have any more sodium ions (Na+) available for

exchanging and they need to be regenerated.

Regeneration means re-built the charge of sodium ions (Na

(NaCl), common salt used in kitchen. During regeneration, an exchanging back is performed of

sodium ions (Na

+

) against ions calcium and magnesium (Ca++ e Mg++) which are carried away

to drain. The equipment prepares automatically the brine from the salt (NaCl) in grain or tablets.

AM series softeners are used for water treatment for residential and industrial applications as

well. All the materials, resins included, are food grade and approved for drinking water.

The range of models includes systems with capacity from 5 up to 60 m³/h and capacity from

900 up to 7200 m³ x ºF.

The working of the system is controlled by an automatic programmer, allowing to schedule

the frequency and the hour for the regeneration. Then the system automatically starts the

regeneration that proceed automatically. During regeneration, (except for "fast rinse" phase) the

system supplies non softened water thanks to a by-pass inside the automatic valve; for

AM/METER models, water supply during regeneration is completely inhibited by means of a

membrane valve mounted on the outlet.

These system can be equipped with automatic sterilizing device (Nobel CL 90 or CL 180),

according to the local laws of some countries for the treatment of drinking water.

++

and Mg++) against sodium ions (Na+), of which

+

) available from sodium chloride

s.r.l. - ITALY Page 4 of 15 am_tvm_mi-r1.doc - r.1

3. Technical characteristics

3.1. Assumed raw water characteristics

AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

• organics

• water temperature (min÷max)

• water pressure (min÷max)

NIL

ºC (ºF) 5÷40 (41÷104)

bar (kPa) 2÷6 (200÷600)

3.2. Technical characteristics (general)

• hardness of treated water (with raw water up to 30°Fr)

• power supply

• regeneration time

ºFr < 0.5

V ph/Hz W 230 1/50 10

min. 40÷70

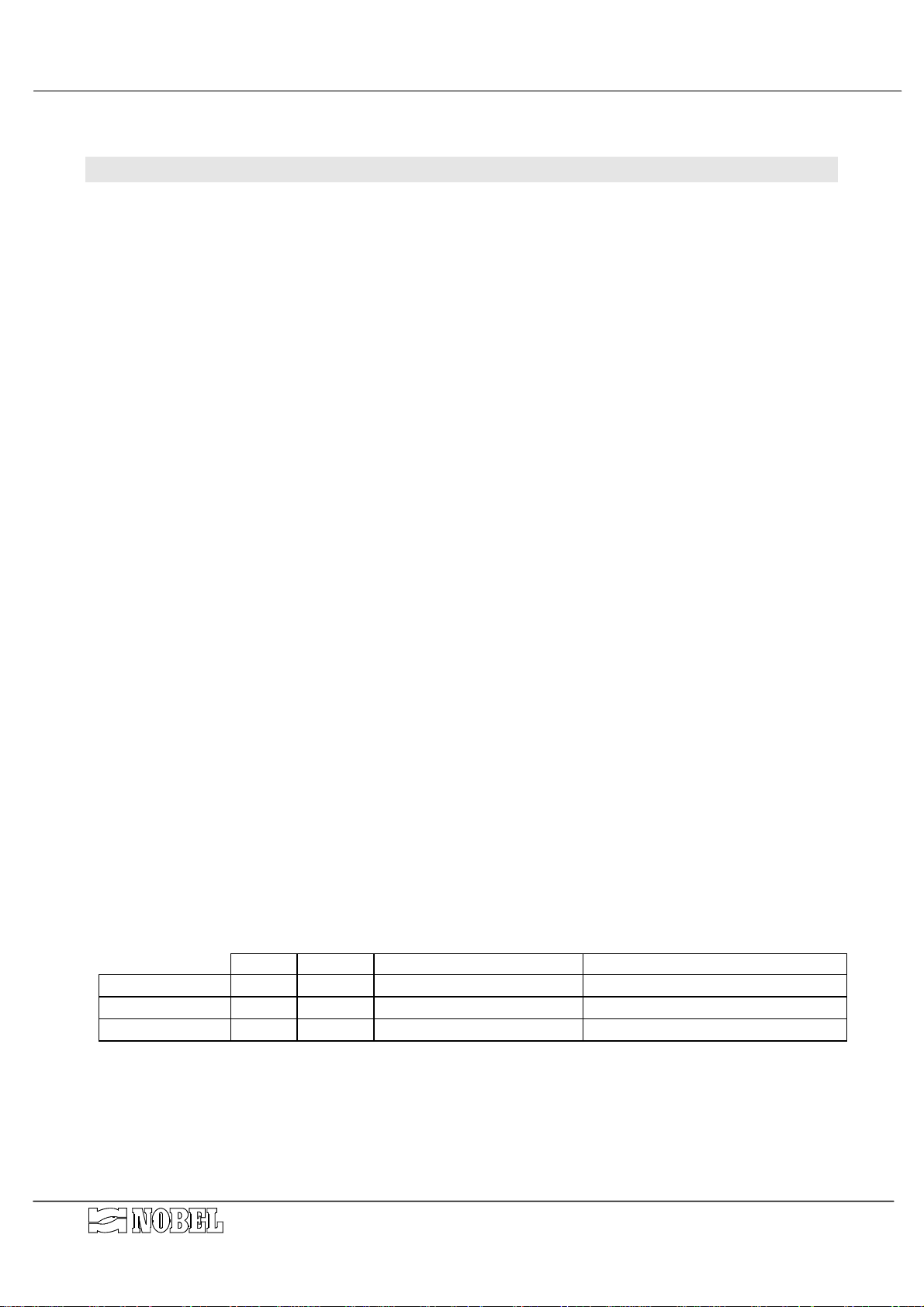

3.3. Characteristics for each model

MODEL

AM 900

AM 900

AM 1200

AM 1200

AM 1800

AM 1800

AM 2100

AM 2100

AM 2700

AM 3300

AM 3600

AM 3600

AM 4200

AM 4200

AM 4500

AM 4500

AM 5400

AM 5400

AM 6600

AM 6600

AM 7200

AM 7200

IN/OUT drain brine m³/h m³ x ºFr

/R

/R

/R

/R

R

/R

/R

/R

/R

DN80 1¼" ¾" 48.0 6600 1000 165 8800

/R

DN100 1¼" ¾" 60.0 7200 1000 180 9600

The above data are used also for series: AM/T, AM/RT, AM/V, AM/RV, AM/METER, AM/R METER

connections flow max cycle brine tank capacity consumption for

l tot ≅ kg sale

1¼" 1" 9.5

1½" 1" 9.5

1¼" 1" 9.5

2" 1" 9.5

1¼" 1" 9.5

2" 1" 9.5

1¼" 1" 9.5

2" 1" 9.5

2" 1¼" ¾" 18.0 2700 520 67.5 3600

2" 1¼" ¾" 22.0 3300 850 82.5 4400

2" 1¼" ¾" 22.0 3600 850 90 4800

3" 1¼" ¾" 28.0 3600 850 90 4800

2" 1¼" ¾" 22.0 4200 850 105 5600

3" 1¼" ¾" 28.0 4200 850 105 5600

2" 1¼" ¾" 22.0 4500 850 113 6000

3" 1¼" ¾" 32.0 4500 850 113 6000

2" 1¼" ¾" 22.0 5400 1000 135 7200

3" 1¼" ¾" 36.0 5400 1000 135 7200

2" 1¼" ¾" 22.0 6600 1000 165 8800

2" 1¼" ¾" 22.0 7200 1000 180 9600

mm 5,5 900 200 22.5 1200

mm 8,0 900 200 22.5 1200

mm 5,5 1200 300 30.0 1600

mm 10,5 1200 300 30.0 1600

mm 5,5 1800 300 45.0 2400

mm 14,5 1800 300 45.0 2400

mm 5,5 2100 520 52.5 2800

mm 14,5 2100 520 52.5 2800

regeneration

salt kg water l

s.r.l. - ITALY Page 5 of 15 am_tvm_mi-r1.doc - r.1

AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

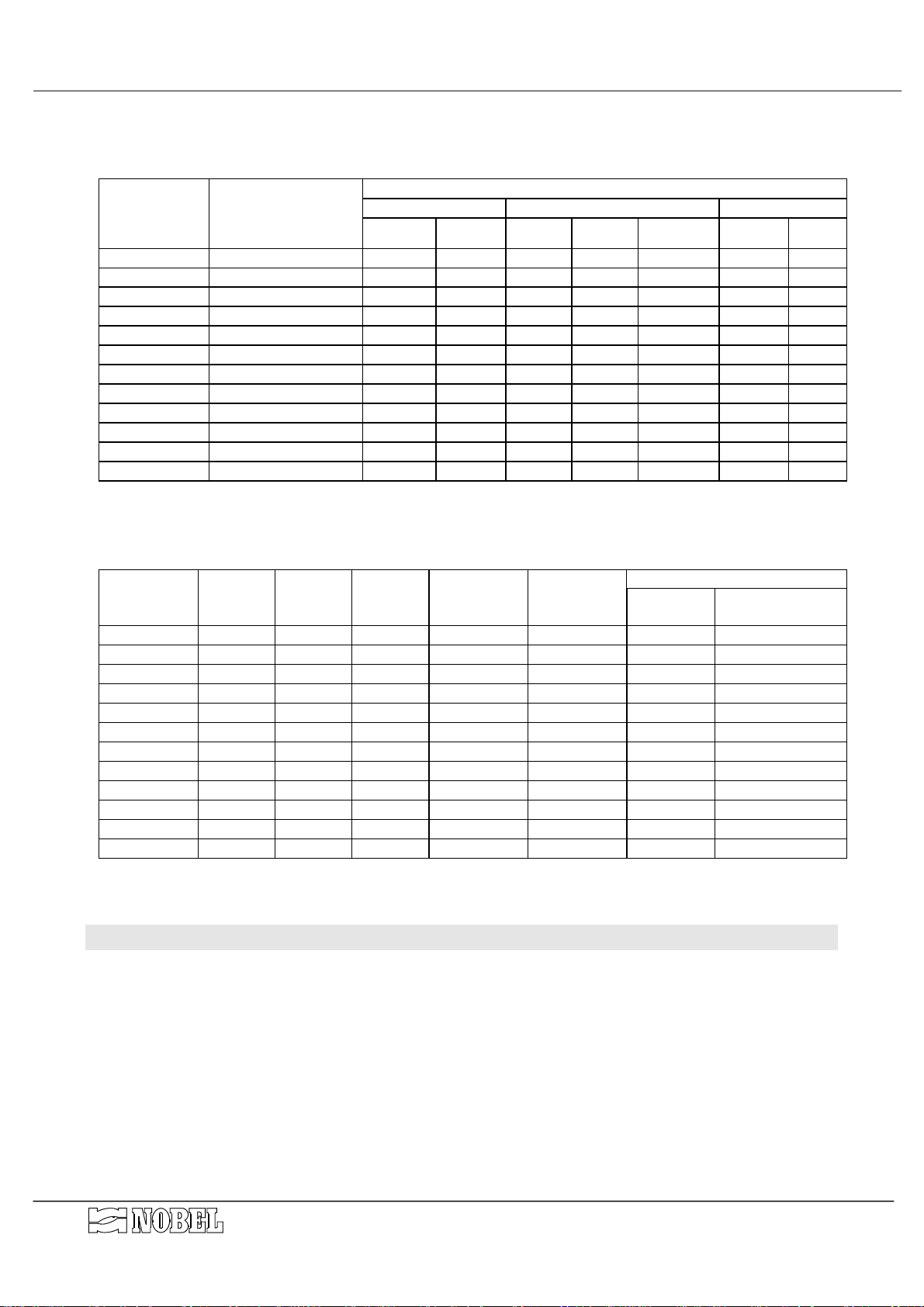

3.4. Dimensions

(See DRAWING 1 dimensions )

DIMENSIONS

MODEL overall vessels brine tank float valve

AM 900

AM 1200

AM 1800

AM 2100

AM 2700

AM 3300

AM 3600

AM 4200

AM 4500

AM 5400

AM 6600

AM 7200

l x p x h mm

1300x800x2100 2100 450 600 1100 420 3/8" 520

1450x900x2100 2100 500 700 1100 360 3/8" 460

1500x1100x2100 2100 600 700 1100 520 3/8" 620

1600x1100x2400 2400 600 800 1100 400 3/8" 500

1700x1050x2400 2400 700 800 1100 540 ¾" 640

1900x1050x2600 2600 700 1000 1100 410 ¾" 510

1950x1350x2400 2400 800 1000 1100 430 ¾" 530

1950x1350x2600 2600 800 1000 1100 490 ¾" 590

2050x1450x2400 2400 900 1000 1100 510 ¾" 610

2250x1550x2400 2400 1000 1100 1100 500 ¾" 600

2350x1700x2600 2600 1100 1100 1100 590 ¾" 690

2350x1750x2600 2600 1100 1100 1100 630 ¾" 730

h mm

Ø mm

Ø max

mm

h mm h plate mm type

The above data are used also for series AM/R

3.5. Weight

MODEL

AM 900

AM 1200

AM 1800

AM 2100

AM 2700

AM 3300

AM 3600

AM 4200

AM 4500

AM 5400

AM 6600

AM 7200

Vessel quartz-

sand

Kg kg

140 25 150 7 350 550 210

155 25 200 12 420 650 320

185 50 300 12 570 900 320

205 50 350 20 650 1050 550

305 50 450 20 850 1400 550

335 50 550 30 1000 1600 900

365 75 600 30 1100 1800 900

385 75 700 30 1200 2000 900

415 100 750 30 1300 2200 900

455 100 900 40 1500 2700 1050

625 100 1100 40 1900 3500 1050

625 100 1200 40 2000 3600 1050

resins brine tank total at

l (≅ kg)

The above data are used also for series AM/R

shipping

kg approx. kg approx. kg approx. kg

vessel fillled brine tank

on service

h mm

4. Installation

4.1. Room conditions

In cold countries, whether the room temperature is below 15 °C (59°F), the salt requires

longer time to be dissolved, even up to 10 hours; this feature must be considered in designing

and selecting the correct system. Apply Nobel Technical Dept. for further information.

• room temperature

• humidity rel.

• sun-light

• rain, snow etc.

s.r.l. - ITALY Page 6 of 15 am_tvm_mi-r1.doc - r.1

5÷45ºC (41÷113ºF)

5÷95 % without condensate

protection required

protection required

AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

4.2. How to remove packaging

The vessels are shipped wrapped in a plastic foil; remove it with care before starting-up. The

automatic valves and pulse sender water meter (if present) are packed in a wooden crate.

Withdraw carefully the components from the crate. The resins are shipped in bags of 25 l each,

and the quartz-sand in bag of 50 kg or fraction of it. Keep the cards and everything contained

inside the packaging.

4.3. How to move and lift the unit

The vessels can be displaced when they are empty, hooking and lifting by the special rings

mounted on the upper part of the vessels (see fig. 1). It is recommended to use proper sized

hooks and ropes, according to the weight. It is also possible to hook and lift the vessel by the

bearing legs.

GOLFARI

CAUTION : DO NOT LIFT OR MOVE THE UNIT HOOKING OR

CATCHING BY THE PRE-ASSEMBLED PARTS .

GAMBE DI SOSTEGNO

Figure A

4.4. Placing & commissioning

• Place the column of resins and the brine tank on a perfectly flat surface. Their mutual

position is shown on the installation drawing. The shown scheme is only suggested; the

column can be placed in different positions; according to the inlet/outlet connections on the

valve group.

• Load the supplied quartz-sand into the vessel, through the lower man-hole, until the sand

covers completely the filter-nozzles. Make a flat surface of the sand using a wooden tool, in

order to avoid any damage to the coating of the vessel. Close the man-hole tightening the

nuts.

• Load the supplied resins into the vessel, through the upper man-hole (or through the upper

head, see components drawing). The resins are shipped separately; check that the shipped

and available quantity complies exactly with the quantity listed in the Weight Table § 3.5

page 6).

• After completed the loading, close the upper man-hole (or upper head)

• Fix the group of the regeneration valve to the resins vessel. The valves group includes also

the programmer.

• For models AM/R METER, AM2700/METER and AM3300/METER : connect the pre-

assembled piece fitting/membrane valve on the outlet connection of the regeneration valve.

NB :

The fittings of control valve type S240 have to be inserted just pushing them inside the

connections of body valve and then fixed with proper pins. The fittings of valves type S360

are flanged type with 4 fixing bolts.

s.r.l. - ITALY Page 7 of 15 am_tvm_mi-r1.doc - r.1

AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

4.5. Hydraulic connections

(see installation and components drawings)

In order to avoid shut-off during maintenance operations, an emergency by-pass line

should be provided

• Connection of inlet fittings

For models AM/R, AM2700 and AM3300 only:

complete the line from the untreated water line

to the outlet fitting of the regeneration valve.

For all other AM models:

complete the line from the untreated water line to the outlet fitting of

the regeneration valve; connect also the inlet membrane valve V2 to the same water line.

• Connection of outlet fittings :

SERIES /T and /V, models AM/R, AM2700 and AM3300 only:

complete the line of the treated

water line to the inlet fitting of the regeneration valve.

SERIES /T and /V, all other AM models:

complete the line of the treated water line to the inlet

fitting of the regeneration valve; connect also the outlet membrane valve V1 to the same

water line.

SERIES METER:

For models AM/R, AM2700 and AM3300 only

complete the line of the treated water line to the outlet membrane valve V1.

the outlet membrane valve is installed

immediately downstream of the outlet fitting of the regeneration valve.

For all other AM models

the outlet membrane valve is plumbed at the bottom side of the resins

columns and the outlet fitting of regeneration line is plugged.

• Insert horizontally the pulse sender water meter downstream of outlet connections, (only for

series AM/V, AM/RV, AM/METER and AM/R METER).

• Connect the drain fitting placed on the side of the automatic valve to a floor drain. The gate

valve mounted on the drain fitting will be used to adjust the backwash flow rate.

A common flexible pipe made in plastic or rubber can be used for the drain line downstream

of the gate valve; its size must be equal or larger of the one mentioned on

“CHARACTERISTICS FOR EACH MODEL” table.

It is suggested that the drain line could be inspected in order to check quantity and quality of

drain water, as well as any leakage of resins from the unit.

CAUTION : Do not run the drain line together with overflow line of the brine tank; it will cause

the filling of the brine tank.

• Connect the over-flow fitting of the brine tank to a floor drain, with a line separated from the

drain lines of the vessels. Use proper sized flexible plastic or PVC pipe.

• Complete the line from the brine drawing fitting (on the side of the automatic valve) to the

float valve of the brine tank. For models up to AM 2100, use for the connection the supplied

plastic tubing ø 9.5 (mm); for models AM 2700 and over use ¾" galvanized pipe, or proper

sized PVC or plastic tubing, suitable to withstand the pressure and depressure (0.5 bar

negative).

• run the plastic tubes, already connected to the electronic programmer, to the fittings placed

on the control valves and on the diaphragm valves, according to the numbered sketch.

CAUTION : to avoid any damage of the plastic fittings and parts, it is required to hold all the

piping using adequately sized brackets.

4.6. Electrical wiring connections

• Connect the power feeder of the programmer to a power socket; check that the available

power is correct as listed in technical characteristics (see § 3.2 page 5).

• Connect the DIN plug from the water meter on the socket placed on the side of the

electronic programmer (only for series AM/V, AM/RV, AM/METER and AM/R METER).

s.r.l. - ITALY Page 8 of 15 am_tvm_mi-r1.doc - r.1

AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

f

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

5. End cycle and regeneration

5.1. End cycle

The softeners are equipped with an electronic programmer that allows to schedule the

automatic regeneration. The automatic start of regeneration depends on the type of

programmer that equips the unit, as follows :

• AM/T and AM/RT SERIES :

• AM/V and AM/RV SERIES :

• AM/METER and

AM/RMETER SERIES :

The end-cycle has to be adjusted according to the quality of available water and the

consumption of water.

The max. quantity of available soft water the equipment can supply between two following

regeneration is to be calculated as follows:

cycle of the softener (m³

=

total hardness o

raw water (°Fr)

∗

ºFr)

where 1°Fr = 10 ppm CaCO

The cycle of all NOBEL softeners are expressed by the number identifying the model (i.e.

AM 2700/D, the cycle is 2700 m

The regeneration can also be started manually at any time (see instruction of the

programmer).

electronic time programmer : selected time and day (24 h, 14

days, max 1 regeneration per day)

end-cycle by time/volume (pulse sender external to the

automatic valve); regeneration runs at selected time and day

(24 h, 14 gg, max 1 regeneration per day), or after the preset

volume of water has been supplied but only at a pre-set time.

end-cycle by volume; regeneration runs after the preset

volume of water has been supplied, with membrane valve to

shut off the flow during regeneration

m³ of available soft water per cycle

= 0.56° German

3

3

x °Fr)

5.2. How to select the end-cycle

The programmer installed on the AS/V and AS/METER series allows also working mode time

only, besides volume only and time/volume modes.

Whether it is desired to use the equipment with working mode different than the standard

one, it is possible to select an end-cycle mode different than the pre-set one; it is required to

select the new mode, according to the explanation in the special instruction of the programmer

(mod. AQUA TIMER).

s.r.l. - ITALY Page 9 of 15 am_tvm_mi-r1.doc - r.1

Loading...

Loading...