SuperK COMPACT

Instruction Manual

This product is protected by intellectual property rights including one or more of the following granted or pending patents:

US 6611643; US 6796699; US 6888674; US 6898367; US 7123408; US 7466885; US 7679822; US 7787503; DE 10313987; DE 10331906; CN 101430476;

AU 2004304019; EP 1164400; EP 1184701; EP 1706788; EP 2045643;EP 1164406; EP 1164406; JP 2002098896; US 2002006264; JP 2002082286; EP

1184701; EP 1184701; DE 20122782; US 2002009260; US 2002028044; DE 10331906; WO 2005006042; US 2006165359; JP 2009513994; EP 1644765;

US 2009074023; WO 2005062113; NO 20063369; JP 2007515680; HK 1102937; EP 1697793; CN 101430476; CN 1898597; CN 100445858; CA 2544871;

AU 2004304019; EP 1706788; WO 2005071483; US 2008226242; AT 445175; DE 10115488; DE 10115589; US 2009086315; JP 2010102345; EP 2045643;

EP 2045642; EP 2045641; EP 2045641; DK 1184701; DE 10115590; DE 10115577; DE 10115509; DE 10115487; DE 10115486; AT 407381; EP 1164400; JP

2002055284; DE 20122783; US 2005122580; DE 10313987; WO 2005024482; US 2007025662; JP 2007504499; EP 1714187; DE 10340964; US

2010040335; WO 2008083686; EP 2111564; CN 101681079; CA 2675234; EP 2332892; WO 2010003422; US 2011116283; EP 2307915; US 2011019701;

WO 2009095022; EP 2238655; US 2010296529; WO 2009076967; EP 2223396; WO 2009095023; US 2010329292; WO 2010115432; US 2008226242; WO

2005071483; EP 1706788; AT 445175; WO 2009024490; DE 102007039498; EP 2181350;

GB 2380812; US 6792188; US 6972894; GB 238423; US 6856742; US 6892018; GB 2394712; US 7155097; AU 2002338639; CN 1535389; JP 4203320;

US 7174078; GB 2397135; US 7349611; AU 2002336075; EP1421420; FR1421420; DE 602 17 684.0-08; UK 1421420; AU 2002350398; US7327922; US

7221840; US 7266275; US 7289709; AU 755223; GB 1086393; US 6845204; US 6542681; AU755547; GB1086391; US6539155; US 7321712; US

7305164; US 7366388; US 7245807; AU 771646; AU 2004202828; CA 2362997; CN ZL00803964X; CN ZL 200410088155; DK 1153325; DK 1340725;

EP 1340725; FR 1153325; FR 1340725; DE 1153325; DE 60025766.5-08; IN 211164; KR 637542; SE 1340725; GB 1153325; GB 1340725; US 6954574;

US 6888992; AU 767773; CNZL 00803960; DK 1153324; FR 1153324; DE 1153324; IN 211165; KR 647378; GB 1153324; US 6631234; US 6990282; US

6853786; GB 2380811; DK 1388018; FI 1388018; FR 1388018; DE 602 22 111.0; IT 1388018; GB 1388018; US 7116875; US 7106932; GB 238435; GB

2403219; US 7346249; GB 2407390; US 7224873; CN 1143147; DE 0991967; GB 0991967; GB 2341457; KR 509720; US 6334019; US 6603912; US

6301420; AU 763796; CNZL 00808310X; GB2 350 904; RU 2226705; SG 83969; US 09/937715; EP 1153325; US 2004/0105641; EP 1340725; EP

1385028; AU 767773; US 6631324; EP 1236063; US 2003/0077058; EP 1236059; US 2003/0059185; EP1388018; EP 1385796; WO 2004/027475; WO

03/062160; WO 03/058308; WO 03/058310; GB 2389915; WO 03/058309; WO 03/093884; WO 03/080524; WO 2004/001461; WO 2004/001465; WO

2004/057393; WO 2004/057392; US 2004/0028356; WO 2004/057391; WO 2004/057394; PCT/GB98/01782; WO 0060388; AU 763796; AU 0038274; CA

2368778; CN 1353824; HK 02107625.6; IN/PCT/200101191/MUM; JP 2000-609822; KO 10-2001-7012566; NO 20014740; PL 0350990; RU 2226705; SG

83969; JP 2002541507; EP 1166160; US 6792188; US 6542681; EP 1460460; EP 1442323; GB 2397135; DE 69917776; WO 04053550; AT 0268482; WO

04049025; DE 69917022; EP 1086393; EP 1421420; AT 0266214; WO 0241050; EP 1086391; GB 2394712; WO 03078338; WO 04019092; GB 0329442;

EP 1381894; WO 03100488; GB 0320733; WO 03079077; WO 03079074; WO 03078338; GB 2384323; GB 2384323; GB 0310466; GB 0310466; WO

03032039; CA 2445487; GB 2380812; GB 2380812; GB 0302866; GB 0302866; WO 03019257; CA2445280; WO 02101429; WO 02101429; CN 1385399;

AU 0755547; AU 0755223; WO 02088801; WO 02084350; CA 2443037; WO 02072489; AU 0223515; WO 0241050; WO 0241050; AU 0214944; WO

0239159; EP 1181595; AU 0179603; WO 0214944; AU 0181741; WO 0212931; WO 0212931; EP 1086393; EP 1086391; AU 0035509; WO 0060390; CA

2368789; CA 2334554; CA 2334510; US 7305164.

Issue: 1.5

Published: May 2018

Copyright © 2018 by NKT Photonics A/S. All rights reserved. Reproduction or

translations of any part of this work is prohibited.

P a g e | 1

Table of

Contents

Table of

Contents ................................................................................................................................................. 1

Section 1: General ........................................................................................................................................... 2

Section

2: Laser Safety .................................................................................................................................... 3

2.1 General information and designated use .............................................................................. 3

2.2 Labels used on the SuperK COMPACT .................................................................................... 3

2.3 Safety hazards ........................................................................................................................ 5

2.4 Laser safety goggles ............................................................................................................... 5

2.5 Laser safety compliance list ................................................................................................... 6

2.6 Supply power .......................................................................................................................... 6

2.7 Key Switch ............................................................................................................................... 7

2.8 Remote Interlock .................................................................................................................... 7

Section

3:

Equipment

description and installation ....................................................................................... 10

3.1 Installation ............................................................................................................................ 10

3.2 Operating conditions ............................................................................................................ 10

3.3 Front Panel ........................................................................................................................... 11

3.4 Rear

Panel

........................................................................................................................... 12

Section

4: Operation and System Menu ....................................................................................................... 13

4.1 Precautions ........................................................................................................................... 13

4.2 Laser operation .................................................................................................................... 13

4.3 SuperK COMPACT with FC output connector ...................................................................... 17

4.4 SuperK COMPACT with collimated output ........................................................................... 17

Section

5:

Display

messages ........................................................................................................................... 19

5.1 Warning and error messages ............................................................................................... 19

Section

6:

Trigger input and remote connection

............................................................................................... 20

6.1 Trigger operating modes ...................................................................................................... 20

6.2 Remote interface connection ............................................................................................... 21

6.3 External Trigger input ........................................................................................................... 21

6.4 Coax trigger input ................................................................................................................. 21

6.5 Industrial trigger input ......................................................................................................... 22

6.6 Logic and analogue pulse output ......................................................................................... 22

Section

7: Service & Support ........................................................................................................................ 23

7.1

Service and storage

............................................................................................................. 23

7.2 Fiber tip cleaning .................................................................................................................. 23

7.3 Technical s

upport

................................................................................................................ 24

Section 8: Specifications

of the

SuperK

COMPACT ........................................................................................ 25

8.1 Electro-mechanical Specifications ........................................................................................ 25

8.2 Optical Specifications ........................................................................................................... 25

8.3 System dimensions ............................................................................................................... 26

Section 9: Accessories for the SuperK COMPACT ......................................................................................... 27

User Notes 28

P a g e | 2

Section 1: General

Introduction Please take the necessary time to read this instruction manual, which contains

important information on safety issues concerning the usage of this equipment.

The safety might be seriously impaired if the instruction manual is not followed

carefully.

Also, make sure to follow the instructions on how to unpack the SuperK COMPACT

from the shipping box if this is not already done.

The equipment comprises a laser Class 3B. It is recommended, that only

persons familiar with laser safety regulations and coherent light should operate

this equipment.

Do you have any questions concerning this product, please do not hesitate to

contact us.

This manual covers the SuperK COMPACT with the following model numbers:

SuperK COMPACT, model# S024-010-000 (FC/PC output connector)

SuperK COMPACT, model# S024-010-010 (FC/APC output connector)

SuperK COMPACT, model# S024-010-020 (Collimator output connector)

Performance The SuperK COMPACT has a broad spectrum ranging from app. 450 nm up to

above 2400 nm. The spectral power density is divided between >20% power in

the visible part of the spectrum and <80% power in the IR spectrum. A typical

output spectrum (limited to 2400nm by the measurement equipment) is

presented in figure 1.1.

Figure 1.1: Typical spectral performance of the SuperK COMPACT.

As performance may vary between individual laser units, please refer to the

SuperK COMPACT test reports for specific information on laser output

performance.

It is recommended to keep this manual in connection with the SuperK COMPACT

unit for operator reference.

P a g e | 3

Section

2: Laser Safety

Introduction Never attempt to switch on or operate the SuperK COMPACT before reading,

understanding and fully familiarizing yourself with the contents of this chapter.

2.1 General information and designated use

General The NKT Photonics SuperK COMPACT™ is classified as a Class 3B

laser product as

per the IEC/EN 60825-1:2014 laser safety standard and complies with FDA

21CFR 1040.10 and 1040.11 except for deviations provided in laser notice 50

(June 2007).

Intended usage

The SuperK COMPACT has been designed for general laboratory use and is as

such not approved nor tested for use in treatment or diagnostics of human or

animals and does not comply with European, US or rest of the World

requirements for medical device lasers. Neither is the system appropriate for

outdoor use or use in extreme conditions such as elevated/lowered

temperatures, particle/chemical contaminated environment or vacuum

conditions.

Laser Safety Officer

The SuperK COMPACT should only be used by staff familiar with laser safety

procedures and in facilities appropriate for laser operation. NKTP recommends

appointing a Laser Safety Officer (LSO) in accordance with valid local and

national safety regulations. The LSO should ensure that every user of the

system is familiar with the safety aspects of the laser unit and that the manual

should be clear and present to operators of the laser. Furthermore, any other

staff in close proximity of the SuperK COMPACT should be aware of any risk in

connection with usage of the unit.

2.2 Labels used on the SuperK COMPACT

Label type The SuperK COMPACT is equipped with a range of labels with dedicated

information regarding safety and product information. Please take time to identify

each label on the SuperK COMPACT before using it for the first time.

Figure 2.1: The side of the SuperK is labeled with laser warning label and explanatory label

P a g e | 4

Warning Labels The warning label pl a c e d on t h e si d e of t h e l ase r alerts the

user:

This product is a Class 3B laser.

The unit emits visible and invisible laser radiation from the optical output,

marked on the front panel.

Avoid direct exposure to the beam.

Figure 2.2: The output fiber contains a warning label placed 10 cm from the output

connector

The warning label placed on the armored output fiber alerts the user of the laser

aperture at the end of the output fiber.

Figure 2.3: The output collimator contains a warning label.

The warning label placed on the output collimator alerts the user of emission of

radiation from the output end of the collimator.

Avoid eye or skin exposure to direct or scattered

radiation.

Always wear

safety goggles matched for the

wavelength

spectrum while

operating

the

laser. Make sure that there

are

no reflective materials in the path of the

beam.

Warranty labels

There are 2 warranty labels. One is placed on the cover and the other on

the collimator. If any of the seals are broken, removed or otherwise

damaged, warranty on the SuperK COMPACT will be void. For service or

support on the system, please refer to section 7.3: Technical support.

Figure 2.4: Warranty void label placed on the cover of the SuperK COMPACT.

P a g e | 5

Serial number

A label identifying the part number and serial number of the SuperK

COMPACT is placed on the side of the top cover. Please refer to this label

whenever contacting NKTP for service or support.

Figure 2.5: Serial number identification label

The label contains the following information:

Manufacture of the system

Product description

Product number

Product serial number

Manufacturing date

Regulatory compliance

2.3 Safety hazards

Hazards The output laser beam from the SuperK COMPACT can cause a number of hazards

if not handled correctly. The following potential hazards should be considered:

Fire hazard

Skin burn

Eye injury

Care should especially be taken when using a SuperK COMPACT with collimated

output beam as the beam will pose a potential fire and skin/eye hazard over a

larger distance than when using a COMPACT unit with FC connector output.

Fire Hazard The laser beam can cause fire if the full beam or even just parts of the beam is

obstructed or guided towards flammable materials such as paper, solvents or other

similar combustible material. Keep the beam path free from any such parts and

keep a fire extinguisher in close range of the operation area of the SuperK

COMPACT.

Skin burn Even though the SuperK COMPACT is only a Class 3B laser unit, focused IR light

from the unit could cause potential skin burn. Avoid any contact between laser

beam and skin or wear appropriate skin protection if operation close to the beam is

required.

2.4 Laser safety goggles

Eye safety Due to the broad band nature of the SuperK source it is not possible to achieve full

protection from the output laser light using laser safety goggles. However, a

significant level of protection can be achieved by choosing appropriate type of laser

goggle and follow some simple rules of laser safety:

Always wear laser goggles when operating the output beam in free space

(e.g. using free space optics like mirrors and beam splitters/filters).

Always have a controlled beam path and investigate any possible

reflections/stray light.

P a g e | 6

Always ensure secure positioning of the output connector (PC or

collimator connector).

Avoid any reflecting parts close to the beam path which is not a part of a

specific setup.

Avoid any easily flammable parts close to the beam path (e.g. lens tissue

and solvents).

NKT Photonics recommend using a combination of several different filtertechnologies (absorption and interference). Absorption filters can be edge filters

as well as band pass filters. Only the combination of these filters makes it possible

to solve complex requirements for broadband light source laser applications. The

IR5D filter from NoIR Laser Company, LLC is among the most suitable product

available. Full protection is not achieved, but many alternatives are significantly

worse.

Figure 2.6 depicts the optical density of the IRD5 filter indicating the transmission

of visible green light.

Figure 2.6: Optical density as function of wavelength for the IRD5 filter

2.5 Laser safety compliance list

CE approval The SuperK COMPACT is CE-marked and has been tested for FCC and VCCI

compliance as well.

FDA Compliance The SuperK COMPACT complies with FDA part 1040.10 and 1040.11 except for

deviations provided in laser notice 50 (June 2007).

UL and CSA The equipment is not UL- or CSA approved.

2.6 Supply power

The SuperK COMPACT must be supplied with 100 – 240 VAC through a standard

power cable with an IEC type C13 appliance plug, and must be connected to

protective earth through this cable. A cable is supplied with the SuperK COMPACT,

but it may be exchanged with a compatible type, compliant with the local

regulations.

Main Power Switch With the power cable inserted into the socket on the back panel the SuperK

COMPACT is turned ON by means of the main power switch on the front panel. A

green LED indicating “POWER ON” turns on as well as the display on the front

panel.

P a g e | 7

2.7 Key Switch

Key switch The SuperK COMPACT is equipped with a key switch on the front panel. The key

must be switched to the ON position before laser light can be emitted. Whenever

the unit is not in use, the key should be removed and kept in a safe place. The

laser unit cannot be operated when the key is in the OFF position and the key

cannot be removed whenever it is in the ON position.

2.8 Remote Interlock

Remote Interlock A remote interlock safety system is provided with the SuperK COMPACT to lower the

risk of accidental exposure from the laser. An interlock socket is located on the

reverse side of the SuperK module. The socket is to be used together with a

remote interlock system e.g. a door interlock or similar.

The principle connection diagram of the interlock is shown in Figure 2.9.

SuperK Accessory The external bus socket also placed on the back panel can be used to connect

accessories to the module. External interlocks placed on these accessories are

connected to the module through the external bus. If a SuperK Accessory is not

present, the laser cannot be operated unless the supplied interlock defeater for external

bus (External Bus Terminater) is inserted in the external bus port. See figure 2.7.

Figure 2.7: Interlock Defeater for External Bus (External Bus Terminater)

LEMO The SuperK COMPACT is delivered with a LEMO connector Type 0B to interface to

the interlock connection.

Figure 2.8: LEMO Type FGG.0B.302 connector for interlock socket.

Operation

Inserting the LEMO connector:

Push the connector into the socket until the locking mechanism ’clicks’. The red dot

on the connector and socket indicates the correct orientation.

Figure 2.10: Inserting the LEMO Connector

P a g e | 8

Disengaging the connector:

Grab the connector by the sliding release sleeve (the textured area) and pull it

away from the socket. The release sleeve will slide over the main body of the

connector and accordingly disengage the locking mechanism.

Figure 2.11: Removing the LEMO interlock connector

Warning The two leads of the LEMO connector must be closed through an external interlock.

Due to safety, if the interlock circuit is not closed the laser will not operate. If the

interlock connections are left open they will prevent the laser from operating.

It is not recommended to operate the laser without an appropriate

interlock connection to e.g. a door or enclosure around the system. If users

bypass this safety feature, NKT Photonics bears no responsibility on

damage, loss or harm caused by accidental laser exposure.

Safety interlock The remote interlock circuit operates on 5V D.C. The total resistance (including

cable and switch) should not exceed 40 Ω. Typical signal current in remote circuit is

43 mA.

Interlock circuit specifications:

Voltage range: Min. 0 V; max. 12 V

Voltage, operational (Norm): 5 V

Current, operational (Nom): 43 mA

Short circuit current (Max): 80 mA

Figure 2.9: Principle connection diagram for a remote interlock system in connection with a

SuperK COMPACT.

Figure 2.9 shows a diagram of a simple remote switch interlock system. When the

switch is open (A) the electrical circuit is open, and the laser emission is shut off.

A

B

P a g e | 9

When the switch is closed (B) the circuit is closed and it is possible to have laser

emission.

The remote switch interlock enhances safety, as it shuts off laser emission if the

door switch to the room or enclosure where the system is located is opened.

If the interlock circuit is opened during operation, the interlock circuit must be reset

before laser emission can be initiated again.

Cable

The Interlock cable can be up to 5 meters long and it can be a non-shielded type. If

a cable longer than 5 meters is required, we recommend using a shielded type of

cable.

P a g e | 10

Section

3:

Equipment

description and installation

3.1 Installation

Unpacking Upon unpacking the system, please allow time for the module to reach ambient

temperature conditions before installation as the module may have a temperature

outside the specified temperature range due to transportation.

Installation Install the SuperK COMPACT in a horizontal position resting on all four feet placed

underneath the unit. There should be at least 7.5 cm (or 3 inch) of free space in

front and behind the unit. This is to ensure access of cables and allow airflow for

cooling. Do not stack anything on top of the unit. Keep the unit away from warm

or cold sources.

Electrical connection The SuperK COMPACT requires access to a power socket and a power cable with

an IEC type C-13 plug. No other connections are required in order to operate the

SuperK COMPACT.

3.2 Operating conditions

The SuperK COMPACT is specified to operate in the range of 15-30°C in a non

condensing environment. The output fiber should not be coiled to less than 10 cm

diameter. Do not expose the units to vibrations or mechanical shock during

operation.

P a g e | 11

3.3 Front Panel

The SuperK COMPACT can be operated entirely via the front panel interface.

Figure 3.1: Front panel of the SuperK COMPACT system.

(A) On / Off SWITCH

Turns the electrical power on/off to the laser.

(B) KEY SWITCH

Enables/disables interlock or laser emission

from the SuperK COMPACT. The key must be

turned to “ON” for the SuperK COMPACT to be

able to emit light.

(C) SELECTION WHEEL

Used to navigate the control menus.

(D) CONTROL BUTTONS

Three control buttons are present on the front

panel. The Return button, the Emission

button, and the Enter button.

(E) INDICATOR LEDs

Three indicator LEDs are present on the front

panel. The green power LED will light when

power is supplied to the module; the red

emission LED will light when emission is on;

the yellow pulse overrun LED will light when

the current pulse width cannot support the set

frequency.

(F) DISPLAY UNIT

System information display. See Section 5 for

details.

(G) OUTPUT FIBER

The output fiber is a non-linear crystal fiber

with a 0.20 NA (@1060nm). The fiber is

terminated with either an FC/PC, FC/APC

connector, or a collimator unit. A black fiber

boot indicates an FC/PC connector and a green

fiber boot indicates an FC/APC connector. The

non-linear crystal fiber is placed in an armored

jacket in case of a collimated output.

F

E D C

B

A

G

P a g e | 12

3.4 Rear

Panel

The rear panel of the SuperK COMPACT contains access for communication, power,

interlock connection and trigger input/output.

Figure 3.2: Rear panel of the SuperK COMPACT system.

(A) Power socket

100V-240V/50Hz-60Hz

(B) Interlock socket

Connector for interlock cable (LEMO connector)

(C) USB

USB interface. See Section 6 for details

(D) External Bus

Sub D-15 connection to SuperK Accessories or

Interlock Defeater for External Bus (Bus

Terminater)

(E) Coax trig input

BNC connector for coaxial external trigger

(F) Industrial trig input

Input for isolated external trigger

(G) Logic pulse output

BNC output port for logic signal with the laser

frequency

(H) Analog pulse output

BNC analog output signal of pulse emission

signal

(I) RS-232

Port for communication via RS-232

I

H

G

A

B C D E F

P a g e | 13

Section

4: Operation and System Menu

4.1 Precautions

Warning Make sure at all times during system operation, that the beam path is known and

controlled. Wear suitable protection and ensure everyone in the laser area is

aware that the system is in operation. Ensure that remote interlock is in place.

The SuperK COMPACT is not equipped with a back reflection isolator. Make sure to

minimize external back reflections into the laser. External back reflections can

compromise performance and ultimately damage the laser.

4.2 Laser operation

Operating the

SuperK COMPACT Use the following procedure to turn on the SuperK COMPACT once it is installed

(see section 3.1):

1

The power switch and key switch are set to

“

OFF”.

2

Connect the interlock cable (LEMO connector) to

the socket labeled

“Interlock” on the back panel

as described in section 2.8.

3

Connect the power cable to the connector labeled

“100V - 240V, 50 Hz -60 Hz” on the rear panel.

4

Remove dust protection cap from the fiber

connector and be aware of the light path out from

it. Insert into appropriate connector fixture (FC

adaptor or Collimator receptacle).

5

Consider cleaning the fiber facet before operation

using appropriate fiber cleaning methods.

Please refer to section 8: Service.

6

Turn on the Power by means of the main power

switch on the front panel.

The LED for “POWER” will turn ON (green) and

the display will show the message: “Key switch

off”.

7

Turn the key switch clockwise.

The display will show the message :

“Reset interlock : []“

8

Press the Return button [].

The display will show the message : “Laser off”.

The laser is now ready for operation.

9

Turn on emission by pressing the emission button.

The emission LED will turn on (Red). Light is

emitted from the laser.

Table 4.1: Step-by-step procedure for turning on the system.

P a g e | 14

The SuperK COMPACT may be operated in different modes. Table 4.2; 4.3; 4.4 and

4.5 describes the operating procedures for the different operating modes.

The laser can run with internal trigger mode. The resolution of the different modes

is dependent on the maximum frequency available and the hardware. If a more

precise setting of frequency/repetition rate is wanted, the laser must be run in

external trigger mode. To operate the laser using the internal trigger mode use the

following procedure:

1

Follow steps 1-8 in table 4.1.

The laser emission is off and the

display shows the message ‘laser off’.

2

Press enter to enter the system menu,

then select “operating mode”.

3

From the operating mode menu select

“internal trigger”.

4

From the operating mode menu select

“frequency” and set the frequency

using the selection wheel and enter

button.

5 Leave the system menu by pressing

the Return button [].

6

Turn on emission by pressing the

emission button. The emission LED will

turn on (Red). Light is emitted from

the laser.

7

To turn off emission press the

emission button.

8

It is also possible to change the

repition rate during emission.

Table 4.2: Operating in internal trigger mode.

P a g e | 15

Use the following procedure to operate the SuperK COMPACT using the external

trigger:

1

Check that the external trigger source delivers a trigger signal

between 0-4 volt with a frequency less or equal to the

maximum laser frequency.

2

Connect the external trigger source to the “COAX TRIG INPUT”

(see figure 8).

3

Follow steps 1-8 in table 4.1. The laser emission is off and the

display shows the message ‘laser off’.

4

Press enter to enter the system menu, then select “operating

mode”.

5

From the operating mode menu select “external trigger”.

6

From the system menu select “Coax trig level” and set the

trigger level.

7

Leave the system menu by pressing the Return button [].

8

Turn on emission by pressing the emission button. The

emission LED will turn on (Red). Light is emitted from the

laser.

Table 4.3: Operating in external trigger mode.

Use the following procedure to operate the SuperK COMPACT using the external

trigger burst mode:

1

Check that the external trigger source delivers a trigger signal

between 0-4 volt.

2

Connect the external trigger source to the “COAX TRIG INPUT”

(see figure 3.2).

3

Follow steps 1-8 in table 4.1. The laser emission is off and the

display shows the message ‘laser off’.

4

Press enter to enter the system menu, then select “operating

mode”.

5

From the operating mode menu select “external trigged burst”.

6

From the system menu select “Coax trig level” and set the

trigger level.

7

From the system menu select “Burst pulses” and set the

number of pulses.

8

From the operating mode menu select “frequency” and set the

frequency using the selection wheel and enter button.

9

Leave the system menu by pressing the Return button [].

10

Turn on emission by pressing the emission button. The

emission LED will turn on (Red). Light is emitted from the laser

when a trigger is delivered by the external trigger source.

Table 4.4: Operating in external trigger burst mode.

P a g e | 16

Use the following procedure to operate the SuperK COMPACT using the external

gate mode:

1

Check that the external trigger source supplies a trigger signal

between 0-4 volt.

2

Connect the external trigger source to the “COAX TRIG INPUT”

(see figure 8).

3

Follow steps 1-8 in table 4.1. The laser emission is off and the

display shows the message ‘laser off’.

4

Press enter to enter the system menu, then select “operating

mode”.

5

From the operating mode menu select “external gate on” or

“external gate off”

6

From the system menu select “Coax trig level” and set the

trigger level.

7

From the operating mode menu select “frequency” and set the

frequency using the selection wheel and enter button.

8

Leave the system menu by pressing the Return button []. The

display will show the selected frequency and number of pulses

in the burst.

9

Turn on emission by pressing the EMISSION button. The

emission LED will turn on (Red). Light is emitted from the laser

when the trigger level is high (low).

Table 4.5: Operating in external gate mode.

Please refer to section 6.1 for further information on the different operating

trigger modes like software burst mode etc.

Warning When operating at low repetition rate changing to a higher repetition rate a “Pulse

Overrun” situation may occur. E.g. changing from 1 kHz to 20 kHz could

momentarily trigger a “Pulse Overrun” situation due to the sudden change in pulse

acquisition. If this is observed, it is recommended to increase the repetition rate in

smaller steps of e.g. 5 kHz. In generally if a “Pulse Overrun” situation is encountered

it is recommended to turn down the repetition rate until the “Pulse Overrun” warning

disappears.

This can also happen in some variation of burst mode settings. We recommend to

lower the number of pulses or lower the rep rate.

Continuously “Pulse Overrun” warning in internal trigger mode will require service

from NKTP HQ.

P a g e | 17

4.3 SuperK COMPACT with FC output connector

Connector Handling and connecting the fiber output connector (FC/PC or FC/APC).

The FC/(A)PC connector is provided as a convenient means of terminating the fiber

and allowing the use of standard receptacles or holders to launch the light via free

space into other optical components/equipment.

Warning It is emphasized that if the SuperK connectorized fiber is mated to

another connectorized component, then there is an increased risk of

damage to the connector. This is because the SuperK COMPACT will

deliver significant peak power from the fiber and any loss, dirt or stress in

the connector due to mating, can promote damage.

The exit fiber and the connector is NOT covered by the warranty.

It is not guaranteed that this damage can be avoided, if connector mating is used,

but one can reduce the risk by adhering to the following:

Cleaning facet Before connecting the output, please ensure that the fiber facet is clean and free

of dust particles. A dirty fiber facet, may result in severe damage to the fiber facet

resulting in a significantly distorted beam profile. Dust from the fiber facet may be

removed be a number of approved fiber cleaning methods. Lens cleaning tissue

(lint free wipes) or similar appropriate material may be applied.

4.4 SuperK COMPACT with collimated output

The SuperK COMPACT can also be supplied with an armored fiber delivery,

terminated by a collimator, see figure below. The collimator consists of two

parts:

Collimator housing: outer diameter 28 mm

Collimator tube: outer diameter 12 mm

Figure 4.3: The optical output with collimator.

Warning

Do not open the collimator. This might destroy the entire laser system.

The warranty is void if the collimator is opened.

Warranty Sign

The output collimator is equipped with a “Warranty Void if removed” sign (figure

4-4). The sign indicates that the collimator should under no circumstances be

attempted to be taken apart. There are no serviceable parts inside the collimator.

Figure 4.4: Warranty Void sign on collimator

P a g e | 18

Beam Properties

The output beam is collimated with an achromatic lens to maximize coupling of

light into a single mode fiber. However, with a single lens it is impossible to

simultaneously maximize the coupling at all wavelengths of the output spectrum.

Per default the coupling is optimized for maximum average coupling across the

visible spectrum. Consequently, the beam is slightly larger for the infrared than

for the visible wavelengths; see table below for details.

Wavelength

Beam size at

collimator

Distance from collimator to where

beam has expanded to 1 cm

600 nm

Approx. 1 mm

Approx. 4 m

1500 nm

Approx. 3 mm

Approx. 6 m

Table 4.6 : Beam size after collimator for two wavelengths

Fixation of

collimator

During operation the collimator must be fixed for safety. For best performance,

we recommend the SuperK collimator holder (part no. A000-000-002) shown

below. If using other holders, we recommend gentle fixation on the collimator

tube using plastic screws instead of metal screws to minimize risk of scratches on

the collimator.

Figure 4.5: NKT Photonics collimator holder, part no. A000-000-002

Warnings

If the collimator is scratched it might not fit into the collimator input in

the SuperK accessories.

A small fraction of the beam power is absorbed in the collimator by stray light. If

the thermal contact between the collimator and the surroundings is poor, the

collimator can become significantly warmer than the surroundings. Thus, it is

recommended to enable firm thermal contact between the collimator and the

surroundings.

P a g e | 19

Section

5:

Display

messages

5.1 Warning and error messages

Before and during operation, the SuperK COMPACT laser will show various

messages in the display. Some of these indicate errors or other circumstances

that prevent the unit from functioning - others are merely information to the

operator. The warnings, alarms and messages are explained below.

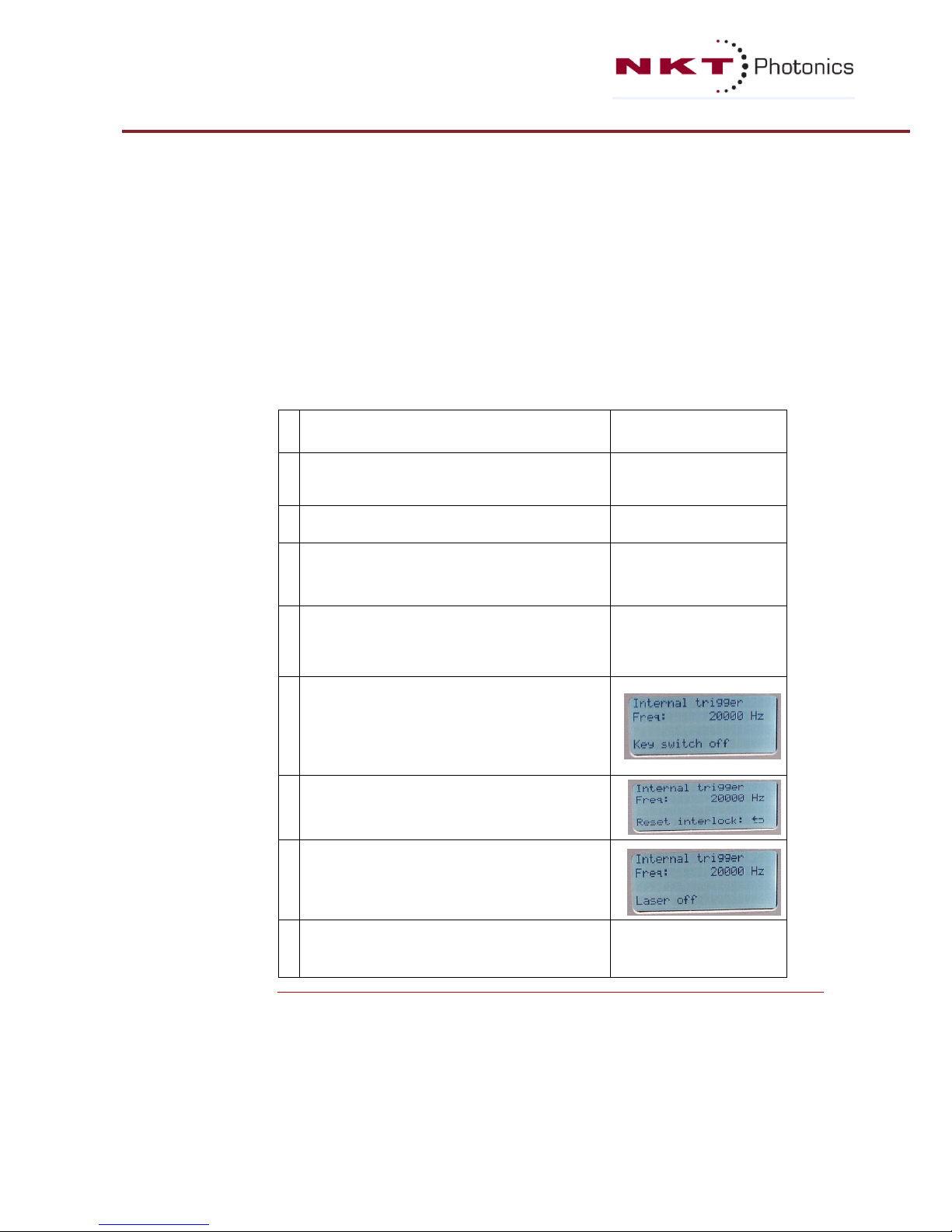

Messages

Message

Description

Emission

Emission is on. Emission LED activated (red).

Laser off

Emission is off. Emission LED off.

Door interlock

Emission is not possible, because the

external interlock loop is open. Check the

external interlock loop connected by the

LEMO connector at the interlock socket (see

Figure 3.2).

External interlock

Emission is not possible, because the

external interlock loop through the external

bus port is open.

Check the Bus Termination.

If an Accessory is connected to the bus, it

can be an opening in the interlock circuit on

the Accessory.

Check the external bus interlock loop.

Key switch off

Emission is not possible, because the key

switch is set to ‘OFF’.

Interlock opened

while emission is on

Emission stopped, because the interlock

opened while emission is on. This can be

caused be either of the above.

Table 5.1: List of common display messages

P a g e | 20

Section

6:

Trigger input and remote connection

6.1 Trigger operating modes

The selected operating mode determines when and how often the light source

generates an optical pulse. The operating mode can be selected in the front panel

menu or via the USB/RS-232 port.

Most operating modes use some additional settings: Frequency (repetition rate)

and/or Burst count. These can be altered in the front panel menu or via the

USB/RS-232 interface.

Internal trigger

The light source emits pulses at the user selected repetition rate. The resolution of

the different modes is dependent on the maximum frequency available and the

hardware. Trigger inputs are not used.

External trigger

One of the trigger inputs are used for triggering optical pulses. One optical pulse

is generated for each electrical trig pulse.

Software burst

The light source emits a specified number of pulses (Burst count) at the specified

repetition rate only when ordered to do so by an external host via the USB or RS232 interface.

Externally trigged burst

When the light source senses a positive edge on one of the trig inputs, the light

source emits a specified number of pulses (Burst count) at the specified repetition

rate.

External gate on

When one of the trig inputs receives a logic "high" signal, the light source emits

pulses continuously at the specified repetition rate, until the trig signal goes low.

The light source may emit one extra pulse after the trig signal has gone low.

External gate off

When both of the trigger inputs receives a logic "low" signal, the light source

emits pulses continuously at the specified repetition rate, until one trigger signal

goes high. The light source may emit one extra pulse after the trig signal has

gone high.

Note:

Although most of the operating modes can be used to keep pulses from being

generated, the light source must still be regarded as having emission on. Stopping

pulses by using the trig signals in a certain way, is not considered a safe way to keep

emission off.

P a g e | 21

6.2 Remote interface connection

Remote connection A USB and an RS-232 interface is located on the backside of the SuperK

COMPACT unit for communication with the unit through a computer.

The serial communications port on the SuperK COMPACT is a standard USB port,

designed for connecting to a standard PC USB-port. In order to connect the

SuperK COMPACT to a computer for remote operation please use a standard USB

cable with A to B connectors as indicated in figure 6.1. For RS-232 operation use

a D-Sub9 connector with standard RS232 pin out.

Figure 6.1: USB Cable A to B

SuperK CONTROL If you are interested in communicating with the laser system using as computer,

we recommend the NKT Photonics CONTROL software. CONTROL is compatible

with all latest generation NKT Photonics lasers and accessories. The software can

be located on our webpage for download.

SDK If you are interested in communicating with the laser system using the remote

interface, a special software development kit (SDK) is available. The software can

be located on our webpage for download.

6.3 External Trigger input

External trigger The trigger inputs are used for all modes except the Internal Trigger and Software

Burst modes. The function of the trigger signal depends on the mode that is used.

In order to accommodate most applications, there are two different kinds of

inputs. The operator selects which input to use by applying a trig signal to one

input, and nothing to the other. Signal is trigged on rising edge.

Warning Do not attempt to trigger with a signal above 200 kHz as this may slow down

performance of the SuperK COMPACT due to firmware limitations. The output

repetition rate will also be limited by the maximum repetition rate of the system.

6.4 Coax trigger input

Analogue input The coax trig input is a logic input with a 50 Ω impedance. The actual trig level

(the voltage level at which the light source is trigged) is adjustable from the front

panel menu (or the SuperK CONTROL), from 0 to +4 V. There is a hysteresis of

approximately 1 %, to reduce noise sensitivity.

Input impedance: Nom. 50 Ω

Input voltage (peak): Min. −7 V; max. 7 V

Input power (RMS): Max. 0.8 W / 29 dBm

P a g e | 22

Pulse width: Min. 200 ns

Trig level (adjustable): Min. 0 V; max. 4 V

Hysteresis: Approx. 1 %

Connector type: BNC

Max trigger frequency: 200 kHz

6.5 Industrial trigger input

This input is isolated electrically from the light source, which allows the operator

to connect the input to a wide variety of equipment. The input voltage range is

high, and the input impedance is considerably higher than the coax trig input

impedance. However, this input is not as fast as the coax trig input. The trig

voltage level is fixed (not adjustable).

Minimum pulse width: 5 µs

Max. input voltage (RMS): ± 30 V

"On" signal threshold (max): + 3.9 V

"Off" signal threshold (min): + 1.18 V

Input impedance @ 5 V: ≈ 1.7 kΩ

Input impedance @ 24 V: ≈ 1.45 kΩ

Isolation voltage: 350 V

Connector type: 5.08 mm terminal connector

6.6 Logic and analogue pulse output

Two types of output trigger are available: an analogue trigger output signal and a

logic trigger output signal.

Analogue output The analog pulse output is an amplified representation of the optical signal, while

the logic pulse is a digital representation of the analogue signal generated

subsequently. This may be used for detection of optical pulses, with minimum

timing jitter, i.e. for timing critical purposes.

Pulse width: ≈ 10 ns

Pulse voltage: System dependant (max. 2 V)

Output impedance: 50 Ω

Connector type: BNC

Logic output The logic pulse output generates a positive logic signal whenever the light source

emits an optical pulse. This can be used for triggering and pulse counting.

Pulse width (min): 1 µs

Pulse voltage (nom): ≈ 2.5 V @ 50 Ω load

Low-level output voltage (nom): 0 V

Output impedance: 50 Ω

Connector type: BNC

P a g e | 23

Section

7: Service & Support

7.1

Service and storage

General service There are no user serviceable components inside the SuperK. In case of malfunction,

NKT Photonics should be consulted.

The unit is sealed with a label “WARRANTY VOID IF

REMOVED”. There is a

potential risk of damage to the unit and/or personnel if this is compromised. It is

therefore strictly prohibited to remove the chassis cover.

A SuperK COMPACT should be returned to NKTP for service in its original casing

or similar. When in doubt, contact Technical Support prior to packaging.

Cleaning of t h e

Chassis

If cleaning of the SuperK unit is required the chassis may be cleaned with a damp

cloth. Do not use solvents for cleaning the chassis.

Storage If required the SuperK COMPACT should be stored in a dry and cool place. The

optical output should be protected using supplied caps. Avoid exposing the unit

to any vibrations or mechanical shocks.

7.2 Fiber tip cleaning

Fiber tip

cleaning

Only use cleaning tools that are specifically designed to be used with optical fibers.

Always use extreme caution when cleaning fibers.

Examples of appropriate cleaning tools are lens cleaning tissue (lint free wipes) as

shown in figure 7.1 or an Optical Fiber Cleaning Tool as shown in figure 7.2.

Figure 7.1: Lens cleaning tissue (lint free wipes).

Figure 7.2: Example of an Optical Fiber Cleaning Tool.

Signs of damage Signs of a damaged fiber facet may be one of the following:

Power suddenly decreases (from e.g. 100 mW to 60-70 mW)

The spectrum (as recorded from an Optical Spectrum Analyzer) is

P a g e | 24

significantly degraded compared to the original spectrum found in the

measurement report.

Light from the facet is not emitted in the usually hexagonal pattern but

rather in a random pattern with a large variation in colors (see Figure

7.3).

Figure 7.3: Left: Correct beam profile. The emitted beam has a noticeable hexagonal shape.

Right: Incorrect beam profile as a result of a damaged fiber facet. Emitted beam is random

in direction and colors.

If the fiber facet is damaged the connector must be re-polished before operation of

the SuperK COMPACT can continue. Failing to do so could result in incorrect

measurements/usage or even damage to the laser unit itself.

Warning Please note that the fiber from the SuperK COMPACT is a Photonic

Crystal Fiber

(PCF). Thus the connector should NOT be removed, as

special equipment and procedures are required to mount a new

connector onto the fiber.

Polishing The end of the fiber is collapsed at a length of 150-200 micron. Thus, there is

room to polish the fiber end, but one has to be careful not to over polish and we

recommend to send the unit for repair to do this. The procedure is:

1) Clean the connector and carefully polish the connector end shortly.

2) Clean the connector and then switch the source on. Observe the exit beam on a

screen. If it is not a nice single mode emission, re-polish another short time.

3) Continue this "quick polish, check beam" process until a nice beam is

obtained.

If one does not obtain a nice beam regardless, then the connector might be

damaged. In this case, the unit should be returned to NKT Photonics for repair.

Please note that this type of repair is not covered by warranty.

7.3 Technical s

upport

NKT Photonics can be contacted for technical information regarding issues with use

of the SuperK COMPACT or associated accessories.

Contact information:

NKT Photonics A/S

Blokken 84

DK-3460 Birkerød, Denmark

Phone (general): +45 4348 3900

Fax (general): +45 4348 3901

E-mail: mailto:support@nktphotonics.com

P a g e | 25

Section 8

:

Specifications

of the

SuperK

COMPACT

8.1 Electro-mechanical Specifications

Environmental

Temperature, operating

15-30 °C

Temperature, storage, non condensing

5-50 °C

Humidity, non condensing

20-80 % RH

Power

Power consumption, nominal with no accessories

connected

40 W

Power consumption, maximum

150 W

Line

100 – 240 VAC

Frequency

50-60 Hz

Fuses (5 × 20 mm)

Type: T 2A, 250 V

Weight

3,5 kg

Table 8.1: Electro-mechanical specifications

8.2 Optical Specifications

Min. Total Output Power

> 110 mW

Min. Visible Output Power (450-850 nm)

> 25 mW

Wavelength range

450 – 2400 nm

Spectral Stability (600-1040 nm)

< 0.12 db/hr

Spectral Stability (1100-1500 nm)

< 0.14 dB/hr

Max. Repetition rate

> 20 kHz

Output Pulse Length

< 2 ns

Length of out fiber cable

1.6 ± 0.1 m

Table 8.2: Optical specifications

P a g e | 26

8.3 System dimensions

Dimensions: All dimensions in mm

Section 9: Accessories for the SuperK COMPACT

SuperK SPLIT allows the SuperK spectrum to be divided into two spectral outputs.

In its standard form, the SuperK SPLIT provides two outputs: Visible and nIR.

However, the choice of the split in the spectrum can be user-defined to be

anywhere in the SuperK spectrum. Additionally, standard mounts within the SPLIT

allow the insertion of narrow band filters, polarisers or attenuators at each output

exit for further flexibility.

SuperK CONNECT is a high performance fiber delivery system complete with

broadband fibers and a range of termination options such as FC/PC connectors or

collimators. Interfacing is handled by the CONNECT fiber coupling unit that ensure

easy and stable single-mode coupling that can be disconnected and reconnected

without alignment.

SuperK VARIA is a cost effective and flexible alternative to a monochromator,

effectively turning the SuperK into a powerful single-line laser with a 440 nm

tuning range and variable bandwidth. The center wavelength of the pass band can

be tuned between 400 and 840 nm and the bandwidth is variable between 10 and

100 nm, making the VARIA the most flexible filter solution on the market.

Increasing the bandwidth of the filter increases power throughput and reduces

speckle in imaging applications. Moreover, a high out-of-band suppression of 50dB

makes the SuperK VARIA ideal for FLIM and other applications using high

sensitivity detectors.

SuperK SELECT is a tunable wavelength filter based on acusto-optic tunable filter

technology (AOTF). AOTFs tune over one octave of optical frequency and the

SuperK SELECT allows the integration of two AOTF crystals to provide wide

spectral coverage. Together with a range of unique features, the SuperK SELECT

provides an easy to use, flexible and accurate tuning accessory to access any

wavelength in the SuperK spectrum.

LLTF Tunable High Contrast Filter is a continuously tunable high-resolution

bandpass filter that effectively converts a NKT Photonics’s supercontinuum source

into a widely tunable picosecond laser. The filter transmits, with high efficiency, a

single laser line while blocking unwanted lines with excellent out-of-band

suppression.

The SuperK EXTEND-UV is a deep-UV supercontinuum spectral extension unit for

our SuperK EXTREME and COMPACT supercontinuum lasers. Get tunable UV light

from a robust fiber laser source with 270-480 nm range and 2-80 µW output

power.

P a g e | 28

User Notes

NKT Photonics

Blokken 84

3460 Birkerød

Denmark

Phone: +45 43483900

Fax: +45 43483901

www.nktphotonics.com

Loading...

Loading...