User manual

NivuLog Easy

User Manual for the GPRS Data Logger NivuLog

Easy

(Original Instruction Manual - German)

Rev. 05 valid from:

l Firmware version: 02v003

l Modem version: 02v003 and 3v002

l Hardware version: 2.1

NIVUS GmbH

Im Taele 2

75031 Eppingen, Germany

Phone: +49 (0)7262 9191-0

Fax: +49 (0)7262 9191-999

E-mail: info@nivus.com

Internet: www.nivus.de

NivuLog Easy - Rev. 05 as of 02.07.2012 1 of 73

Chapter 1 Table of contents

Chapter 1 Table of contents

User Manual for the GPRS Data Logger NivuLog Easy 1

Chapter 1 Table of contents 3

Chapter 2 Declaration of conformity 7

Chapter 3 Specifications 9

Chapter 4 General specifications 11

4.1 Translation 11

4.2 Copyright 11

4.3 General descriptive names 11

4.4 Safety instructions 11

4.4.1 Use of the hazard warnings 12

4.4.2 Safety and preventative measures for handling GSM/GPRS modems 12

4.4.2.1 Safety and precautionarymeasures for the GSM/GPRS modem installation 12

4.4.2.2 Safety measuresfor installing the antenna 13

4.5 Overview 13

4.6 Intended use 14

4.7 General product information 14

4.8 Device labelling 15

4.9 Installation of replacement and wear parts 16

4.10 Storage of the product 16

4.11 Obligation of the operator 16

Chapter 5 Functional Principle 17

5.1 ALOHA transmission mode 17

Chapter 6 Storage, delivery and transport 19

6.1 Inspection of incoming deliveries 19

6.2 Scope of delivery 19

6.3 Storage 19

6.4 Transportation 20

6.5 Return 20

Chapter 7 Installation 21

7.1 Dimensions 21

7.2 Installing the NivuLog Easy 21

NivuLog Easy - Rev. 05 as of 02.07.2012 3 of 73

7.2.1 Wall mounting 22

7.3 Safety instructions for the cabling 23

7.4 Electrical installation 24

7.4.1 Connecting the sensors, actuators and supply 24

7.4.2 Connecting the GSM antenna 27

7.4.3 Technical details regarding the universal inputs 28

7.4.3.1 0/4 to 20mA mode 28

7.4.3.2 0 to 2V mode 28

7.4.3.3 0 to 10V mode 28

7.4.3.4 Standard digital modes(PWM, frequency, digital, day counter, impulse counter) 28

7.4.3.5 Low power digital mode (LP digital) 28

7.4.4 Technical details regarding the outputs 29

7.4.4.1 Output 1: Switchable sensor supply (Vout) 29

7.4.4.2 Output 2: Isolated switch contract (NO, CC) 29

7.4.4.3 Direct accu or battery voltage output (Vbatt) 29

7.4.5 Technical details regarding energy management 30

Chapter 8 Initial Start-Up 31

8.1 User information 31

8.2 General principles 31

8.3 Placing the system into operation 31

8.4 Testing the communication with the device 32

Chapter 9 User interfaces 35

9.1 User interface on the NivuLog Easy 35

9.1.1 Operating elements 35

9.1.1.1 Status LED 35

9.1.1.2 Buttons 36

9.1.1.3 Solenoid switch 37

9.2 User interface on the Device to Web-Server 37

9.2.1 Site configuration 37

9.2.1.1 Site 37

9.2.1.2 Comments 37

9.2.1.3 Measurement channels 37

9.2.1.3.1Basis 37

4 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 1 Table of contents

9.2.1.3.2Config 40

9.2.1.3.3Alarms 52

9.2.1.3.4Trigger 52

9.2.1.4 Calculated channels 53

9.2.1.4.1Basis 53

9.2.1.4.2Calculation 54

9.2.1.4.3Alarm 54

9.2.1.5 Output channels 54

9.2.1.5.1Basis 54

9.2.1.5.2Config 56

9.2.1.6 Internal channels 56

9.2.1.6.1Basis 56

9.2.1.6.2Alarms 56

9.2.1.6.3Trigger 57

9.2.1.7 Alarm settings 57

9.2.1.8 Basic settings 58

9.2.1.9 FTP export settings 59

9.2.2 Device configuration 59

9.2.2.1 Comments 60

9.2.2.2 Measurement instrument 60

9.2.2.3 Device-specific settings 62

9.2.2.4 GPRS 62

Chapter 10 Maintenance 63

10.1 General maintenance 63

10.2 Replacing the accu or battery pack 63

10.2.1 Charging the accu pack 65

10.3 Accu or battery pack 66

Chapter 11 Removal/disposal 67

Chapter 12 Troubleshooting and repair 69

12.1 General problems 69

12.2 Evaluating the device log 70

12.2.1 Evaluating the device log on the Device to Web server 70

12.2.2 Evaluating the device log using DeviceConfig 70

NivuLog Easy - Rev. 05 as of 02.07.2012 5 of 73

Chapter 13 Spare parts and accessories 71

13.1 Internal expansions 71

13.2 Assemblysets 71

13.3 Antennas 71

13.4 Accu and battery packs 71

13.5 Sensors 72

13.6 Other accessories 72

Chapter 14 Branch offices 73

6 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

DE / EN / FR

EU Konformitätserklärung

EU Declaration of Conformity

Déclaration de conformité UE

Für das folgend bezeichnete Erzeugnis:

For the following product:

Le produit désigné ci-dessous:

NIVUS GmbH

Im Täle 2

75031 Eppingen

Telefon: +49 07262 9191-0

Telefax: +49 07262 9191-999

E-Mail: info@nivus.com

Internet: www.nivus.de

Bezeichnung:

Description:

Désignation:

GPRS Datenlogger

GPRS Data logger

Enregistreur de données GPRS

Typ / Type: NivuLog 4, NivuLog PCM, NivuLog Easy

erklären wir in alleiniger Verantwortung, dass die auf dem Unionsmarkt ab dem Zeitpunkt der Unterzeichnung

bereitgestellten Geräte die folgenden einschlägigen Harmonisierungsvorschriften der Union erfüllen:

we declare under our sole responsibility that the equipment made available on the Union market as of the date of signature of

this document meets the standards of the following applicable Union harmonisation legislation:

nous déclarons, sous notre seule responsabilité, à la date de la présente signature, la conformité du produit pour le marché de

l’Union, aux directives d'harmonisation de la législation au sein de l’Union:

• 2014/30/EU • 2014/35/EU • 2015/53/EU • 2011/65/EU

Bei der Bewertung wurden folgende einschlägige harmonisierte Normen zugrunde gelegt bzw. wird die Konformität

erklärt in Bezug die nachfolgend genannten anderen technischen Spezifikationen:

The evaluation assessed the following applicable harmonised standards or the conformity is declared in relation to other

technical specifications listed below:

L’évaluation est effectuée à partir des normes harmonisées applicable ou la conformité est déclarée en relation aux autres

spécifications techniques désignées ci-dessous:

• EN 61326-1:2013 • EN 61010-1:2010 • EN 301489-1 V1.9.2:2011

• EN 301489-7 V1.3.1:2005 • EN 301511 V9.0.2:2003

Diese Erklärung wird verantwortlich für den Hersteller:

This declaration is submitted on behalf of the manufacturer:

Le fabricant assume la responsabilité de cette déclaration:

NIVUS GmbH

Im Taele 2

75031 Eppingen

Allemagne

abgegeben durch / represented by / faite par:

Marcus Fischer (Geschäftsführer / Managing Director / Directeur général)

Eppingen, den 20.04.2016

Gez. Marcus Fischer

Chapter 3 Specifications

Chapter 3 Specifications

Voltage supply Battery pack BP434R: 2 x Li-SOCl2-Cells fullyfabricated with 26Ah

Accu pack AP413D+: 2 x Li-ion - Accu cell fully fabricated with 13,6Ah

Charging voltage

7...30VDC (typically 170mA@12V)

(only when using an

accu pack)

Housing Material: Luran

Weight: 400g (without accu or battery)

Protection class: IP66

Dimensions (WHD): 86 x 165 x 64mm (without antenna)

Operating

-20...+60°C, 15...90%rH non-condensing

temperature

Storage

-30...+85°C

temperature

Display LED for indicating the operating mode and error code. (Only visible when the housing

cover is open)

Operation Button (with the housing cover open) or solenoidswitch (with the housingcover

closed) to initiate the ALOHA transmission mode

Antenna connection FME

Universalinputs 4 x analogue or digital

Modes:

l 0 to 20mA: Resolution 6µA, max. 22,5mA, load 100Ω

l 4 to 20mA: Resolution 6µA, max. 22,5mA, load 100Ω

l 0 to 2V: Resolution 610µV, max. 2,5V, load 220k1

l 0 to 10V: Resolution 8,3mV, max. 32V, load 8k9

l PWM: 1...99%, max. 100Hz, min. impulse length 1ms, load 8k9

l Frequency: 1...1000Hz, 8k9

l Digital: max. 32V, low <1,36V, high >2,73V, load 8k9

l Digital LP: max. V

l Day counter: min. impulse length 20ms, load 8k9

l Intervalcounter: min. impulse length 20ms, load 8k9

, low <100mV, high >200mV, load 220k1

Batt

Additional information is providedin "Technical detailsregarding the universal inputs"

on page 28.

External

1 x Cable temperature sensor 3m(todo) (Optional equipment)

temperature sensor

NivuLog Easy - Rev. 05 as of 02.07.2012 9 of 73

Outputs 1 x switchable sensor supply

l Standard: 15...19,5VDC, max. 66mA

l Order option: 24...31VDC, max. 41mA

1 x isolated switch contact

l I

l U

l R

l f

max

max

on

max

: 130mA

: 32V

: 35Ω

: 500Hz

Additional information is providedin "Technical detailsregarding the outputs " on page

29.

Data memory Internal flash memoryfor up to 25.580 measurement cycles

Data type f32 (32 Bit floating point)

Data transmission By means of GSM/GPRS quad-band modem to the relevant Device to Web server

SIM The NivuLog Easy is equipped with an integrated SIM chip.

Monthly data volume <4MB for two minute measurement cycle and 120 minute transmission cycle

10 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 4 General specifications

Chapter 4 General specifications

The information in this manual has been compiled with great care and to the best of our knowledge. The manufacturer, however, assumes no liability for any incorrect specifications that may possibly occur in this manual

The manufacturer is not responsible for direct, indirect, accidental or consequential damages which arise

from errors or omissions in this manual even if advised of the possibility of such damages. In the process of

continuous product development, the manufacturer reserves the right to make improvements to this manual

and the products describedin it at any time and without prior notification or obligation.

Note: The specifications of this manual are valid as of the versions listed on the title page. Revised specifications of this manual, as well as software and driver updates are available in the service area of the Device

to Web-Server.

4.1 Translation

For deliveries in the countries of the European Economic Area, the manual is to be translated into the respective language of the country of the user. Should discrepancies occur in the translated text, the original manual

(German) is to be referred to for clarification or the manufacturer is to be contacted.

4.2 Copyright

The copying, distribution and utilisation of this document as well as the communication of its contents to

others without expressed authorisation is prohibited. Contraventions are liable to compensation. All rights

reserved.

4.3 General descriptive names

The use of general descriptive names, trade names, trademarksand the like in this manualdoes not entitle

the reader to assume they may be used freely by everyone. They are often protected registered trademarks

even if not marked as such.

4.4 Safety instructions

For the connection, commissioning and operation of the NivuLog Easy , the following information and higher

legal regulations of the country (e.g. ÖVE), such as valid EX regulations as well as the applicable safety and

accident prevention regulations for the respective application case must be observed.

Please read this manual completely before unpacking, setting up or operating this device. Observe all hazard,

danger and warning information. Non-observance can lead to serious injuries to the operator and/or damage

to the device.

Ensure that the safety equipment of this measurement device is not impaired. Install and use the measuring

system only in the manner and methoddescribed in this manual.

NivuLog Easy - Rev. 05 as of 02.07.2012 11 of 73

Important note: The manufacturer's products that are designed for use outside have extensive protection against penetrating moisture and dirt. If these products are connected by cables with connectors rather than permanently installed cables to the power supply or sensors, the susceptibility of

the connector and socket to moisture and dirt penetration are significantly higher. The operator is

responsible for protecting the connector and socket against penetrating moisture and dirt in a suitable

way and complying with local safety regulations.

4.4.1 Use of the hazard warnings

DANGER:

Indicates a potential or threatening hazardous situation that will result in death or serious

injuries if not avoided.

WARNING:

Indicates a potential or threatening hazardous situation that can result in death or serious

injuries if not avoided.

CAUTION:

Indicates a potential hazardous situation that can result in minor or moderate injury.

Note: Indicates a situation that does not result in any injury to persons.

Important note: Indicates a situation that can result in damages to this instrument if it is not avoided.

Information that must be particularly emphasised.

Note: Information that supplements the specifications in the main text.

4.4.2 Safety and preventative measures for handling GSM/GPRS modems

Observe the following safety and preventative measures during all phases of installation, operation, maintenance or repair of a GSM/GPRS modem. The manufacturer shallnot be held liable if the customer disregards these preventative measures.

CAUTION:

The GSM/GPRS modem connection may not be used in hazardous environments.

No guarantee of any kind, whether implicit or explicit, is given by the manufacturer and its suppliers

for the use with high risk activities.

In addition to the following safety considerations, all directives of the country in which the device is installed

must be compliedwith.

Important note: No liability shall be assumed at any time and under no condition for the connection

via a GSM/GPRS modem for whose use radio signals and networks are utilized, The GSM/GPRS

modem must be switched on and be operated in an area where sufficient signal strength is present.

4.4.2.1 Safety and precautionary measures for the GSM/GPRS modem installation

l This device may onlybe installed by a trained technician who applies the recognised installation prac-

ticesfor a radio frequency transmitter including the of external antennas.

l The device may not be operated in hospitalsand/or near medical equipment such as heart pacemakers

or hearing aids.

l The device may not be operated in highly flammable areas such as petrol filling stations, fuel storage

sites, chemicalfactories and explosion sites.

l Do not operate the device in the vicinity of flammable gases, vapours or dusts.

12 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 4 General specifications

l Do not subject the device to strong vibrations or impacts.

l The GSM/GPRS modem can cause interference if it is located near television equipment, radios or

computers.

l Do not open the GSM/GPRS modem. Any modification to the equipment is prohibited and shalllead to

lossof the operating licence.

l The use of GSM services (SMS messages/data communication/GPRS etc.) may lead to additional

costs. The user alone is responsiblefor any damages and costs resulting through this.

l Do not install the device in any other manner than the one described in the operating instructions. An

improper use will invalidate the warranty.

4.4.2.2 Safety measures for installing the antenna

l Onlyuse antennas that are recommended or supplied by the manufacturer.

l The antenna must be installed at a distanceof at least 20 cm from individuals.

l The antenna must not be extended outside protected buildings and must be protected against lightning

strikes.

l The voltage supplymust be switched off before replacing the antenna.

4.5 Overview

Overview NivuLog Easy

NivuLog Easy - Rev. 05 as of 02.07.2012 13 of 73

1 Antenna connection 4 Pressure compensation

2 Housing cover 5 M20x1.5 cable screw connection (cable diameter

of 5 to 10mm)

3 M12x1.5 cable screw connection (cable diameter

of 3.5 to 7 mm)

4.6 Intended use

The portable measurement instrument is used to collect analogue and digital signals. The device can operate

without mains power. The measured and recorded data is stored in a non-volatile memory medium. This

stored data is sent to a central server for further processing via the mobile network. The device is equipped

with an integrated SIM chip for this purpose. The maximum permissible limit values set out in chapter "Specifications" on page 9 must be observed. The manufacturer shall not be liable for any operational casesthat

deviate from these limit values and have not been approved by the manufacturer in writing .

Note: This device is exclusively intended to be used for the purposes as described above. Any other

use or use beyond what is specified or a modification of the device shall be deemed to be not for the

intended purpose and is not permitted without the express written consent of the manufacturer. The

manufacturer shall not be held liable for any damages that may result from such unauthorised use or

modification. The operator alone bears the associated risk.

Note: The manufacturer is not liable for data loss of any kind if the device is damaged and data is not

able to be stored correctly.

Note: The integrated SIM chip provides a mobile communications connection to a variety of international service providers. In order to be able to utilise all functions of the device, you must ensure that

the device is located in the service area of one of these service providers. You can find a list of all supported countries and associated service providers under www.nivus.com. A Managed Service contract with NIVUS GmbH is required for use of the mobile data transmission (see www.nivus.com).

This includes the provisioning of the mobile communications connection via the network of the service

provider included in the above-mentioned list.

4.7 General product information

The device is a compact, portable instrument for recording and transmitting analogue and digital signals.

There are 4 universal inputs available, which can be operated in various analogue and digital modes. Additionally, an one wire bus is available for connecting an external temperature sensor. 2 output channelsare

also available. One of the two directlyswitches the sensor supply. The other is a galvanised isolated switch

contact. Both output channels can be configured independently so that they can each be switched by the

device prior to a measurement (to supply the sensor) or they can be switched wirelessly from a central location. All of the input measurement data is temporarily saved to an internal data memory along with the output

statuses and are then wirelessly transmitted to a centrallocation at freely selected intervals. The device is

also configured via this connection. The device is equipped with an integrated SIM chip. If the optional

SIM/USB option is available, the device can also be configured via the USB interface.

14 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 4 General specifications

4.8 Device labelling

The specifications in this manual applyexclusively to the device type NivuLog Easy . The type plate is located

on the right side of the device and includes the following specifications:

l Name and addressof manufacturer

l CE marking

l Protection class

l Environmental conditions during operation

l Electrical parameters for the installed switchable sensor supply

l Hardware revision

l Order number

l Serial number

The correct specification of the Order number and serialnumber is important for all queriesand spare part

orders. Only then can we process requestspromptly and properly.

NivuLog Easy type plate

Note: This symbol indicates that the NivuLog Easy is equipped with an integrated SIM chip.

Note: These operating instructions are part of the device and must be available for the user at all

times. The safety instructions included therein must be observed.

DANGER:

It is strictly prohibited to disable the safety equipment or modify its mode of operation.

NivuLog Easy - Rev. 05 as of 02.07.2012 15 of 73

4.9 Installation of replacement and wear parts

Please be advised that replacement and accessory parts that have not been supplied by the manufacturer

have also not been inspected or approved by it. Installing or using such products and similar can constructivelymodify the specified propertiesof the device in a negative way. The manufacturer shall not be liable

for any damages that arise from the use of non-original parts and non-original accessory parts.

4.10 Storage of the product

Ensure that all of the relevant data has been transmitted to the Device to Web server before storing the NivuLog Easy . If necessary initiate the ALOHA transmission mode using the magnetic contact (see "ALOHA

transmission mode" on page 17) and then check again that all relevant data has been transmitted. If you are

using an external charging voltage to charge the accu pack of the NivuLog Easy , disconnect this from the

device before removing the accuor battery pack. The remaining cables and antenna can then be removed.

Store the NivuLog Easy and accuor battery pack in the compartments provided in the original packaging.

The configuration and most recently determined data are retained. However, the systemclock will not continue to work without an energy supply. This means that following recommissioning, the time must be synchronised to ensure that measurement and log data timestamps are correct. This occurs automatically either

when the first connection is established with the Device to Web server or when the NivuLog Easy is connectedto the PC. For this purpose, the optional SIM/USB option and DeviceConfig configuration program

are required.

4.11 Obligation of the operator

WARNING:

In the EEA (European Economic Area), the national implementation of the framework direc-

tive (89/391/EEC) as well as the associated specific directives and from these in particular,

the directive (89/655/EEC) about the minimum safety and health requirements for use of

work equipment by workers at work, each in their respective version are to be complied

with.

The operator must obtainthe local operating licence and the associated documents.

In addition, the operator must comply with the local legal requirements for

l the safety of the personnel(accident prevention measures)

l the safety of the equipment (protective equipment and maintenance)

l the product disposal (waste disposal law)

l the material disposal (waste disposal law)

l the cleaning (cleaning agents and disposal)

l and the environmental protection amendments.

Before commissioning, the operator must ensure that the installation and commissioning – providedthese

were performed by the operator himself – are in compliance with the local regulations.

16 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 5 Functional Principle

Chapter 5 Functional Principle

5.1 ALOHA transmission mode

ALOHA transmission mode is a special connection mode whereby the NivuLog Easy creates a connection to

the Device to Web server for a period of time configured using the "Basic settings" configuration section (see

"Aloha/wake-up duration" in chapter "Basicsettings" on page 58).

There are two optionsfor initiating the ALOHA transmission mode:

l Directly on the device by meansof the solenoid switch (see "Solenoid switch" on page 37) or button

(see "Buttons" on page 36).

l Via the Device to Web sever if the "Interval & Wakeup" connection type has been selected (see "Basic

settings" on page 58).

A speech bubble in the measurement device list (see "Device to Web Server Manual " - upon request) with

the title "Aloha" indicates that a device is in ALOHA transmission mode.

Clicking on the speech bubble with the "Aloha" title opens the ALOHA data window (see "Device to Web

Server Manual " - upon request). It includes the internal"voltage", "GSM level"and "battery" measurement

values, as well as the measurement values of the 4 universal inputs. The measurement values for the last

thirty minutesare always shown in the ALOHA data window, this can mean that data from a previous ALOHA

transmission is included. The ALOHA data is generated every three seconds independentlyof the normal

measurement valuesthat are generated and is thus not saved with the standard measurement data.

If a measurement dataset is recorded during ALOHA transmission mode, it is immediately transmittedto the

Device to Web server and saved in the standard measurement data.

NivuLog Easy - Rev. 05 as of 02.07.2012 17 of 73

Chapter 6 Storage, delivery and transport

Chapter 6 Storage, delivery and transport

6.1 Inspection of incoming deliveries

Please check the shipment immediately after receiving for completeness and intactness. Immediately report

any discovered transport damagesto the delivering carrier. Also notify the manufacturer in writing about this

without delay. Report any incompleteness in the delivery to the responsible representative or directly to the

company headquarters of the manufacturer within 2 weeks (see "Branch offices " on page 73).

Note: Any claims received thereafter will not be acknowledged!

6.2 Scope of delivery

Note: The accu or battery pack required for operation, (see "Accu and battery packs" on page 71) is

not part of the standard scope of delivery and must be ordered separately.

The standard scope of delivery of the NivuLog Easy (206.210) includes:

l NivuLog Easy

l Tool Pen (NLM0TOOLPEN)

l 10-pole connector plug

l Magnet for device activation (NLM5MAGNET)

l Quick guide

Additional equipment suchas internal extensions, assemblysets, antennas, accu or battery pack, sensors,

power supply, charger, etc., depending on the order. Please check this against the delivery slip.

6.3 Storage

The following storage conditions must be observed:

NivuLog Easy Storage temperature -30...+85°C

Humidity 15...90%rH

BP434R Operating temperature -20...+50°C

Storage temperature 0...+35°C

AP413D+ Operating temperature -50...+60°C

Charging temperature -20...+60°C

Storage temperature 0... +30°C

Note: The table above only includes the storage conditions for the two energy sources used most frequently for

the NivuLog Easy . Please consult the appropriate factsheet for information about the storage conditions of

other accu or battery packs.

Important note: Remove the accu or battery pack from the NivuLog Easy prior to storage.

Store the measurement technology so that it is protected against corrosive or organic solvent vapours, radioactive emissions and strong electromagnetic radiation.

NivuLog Easy - Rev. 05 as of 02.07.2012 19 of 73

6.4 Transportation

The NivuLog Easy is designed for rough industrial applications. Nevertheless, it should not be subjected to

heavyshocks, bumps, impacts or vibrations. The original packaging must always be used for transport.

6.5 Return

Every return must be accompanied by a fully field-out return form. This return form is available in the service

area of the Device to Web-Server. An RMA number is mandatory for any returns and can be obtained from

the Support & Service Centre (see "Branch offices " on page 73). The return shipment of the NivuLog Easy

must occur in the original packaging and with freight and insurance paid to NIVUS GmbH (see "Branch

offices " on page 73). Insufficiently cleared return shipments will otherwise not be accepted!

20 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 7 Installation

Important note: The work described in this section of these instructions must only be performed by

qualified personnel to prevent any damage to the device.

7.1 Dimensions

Chapter 7 Installation

Dimensions: Width and height Dimensions: Depth

7.2 Installing the NivuLog Easy

Important note:

l Ensure the installation is completed properly.

l Comply with the existing legal and/or operational directives.

l Improper handling can cause injuries and/or damage to the devices.

NivuLog Easy - Rev. 05 as of 02.07.2012 21 of 73

The installation site must be selected according to specific criteria. The following conditions must be avoided

in any case:

l Direct sunlight

l Objects that radiate intense heat (maximum ambient temperature: -20...+60°C)

l Objects with a strong electromagnetic field (frequency converter or similar)

l Corrosive chemicals or gases

l Mechanicalimpacts

l Direct installation on foot or road ways

l Vibrations

l Radioactive emissions

Note: Leave sufficient space at the upper end to mount the antenna. The space required depends on the

antenna used. Approx. 15 cm of space must be left beneath the device for the cable connections. Further

information about the installation dimensions can be found in the relevant sub-chapter.

7.2.1 Wall mounting

For wall mounting the optional "Universal bracket for housing NivuLog Easy 86x126(NLM0HALEASY)"

equipment is required.

Step 1 of the wall mounting Step 2 of the wall mounting

1 NivuLog Easy 3 Assembly loop (included in the delivery scope of

NLM0HALEASY)

2 Delta PT M3.5x8 Torx 15 (included in the delivery

scope of NLM0HALEASY)

4 Raised head tapping screw 3.5x32 (included in

the delivery scope of NLM0HALEASY)

1. First attach the assembly loop (3) using the screws (2) included in the "Universalbracket for housing

NivuLog Easy 86x126 (NLM0HALEASY)" equipment set to the NivuLog Easy (see "Step 1 of the wall

mounting" on page 22).

22 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

2. Drilling the holes for mounting:

If you want to use the tapping screws (4) included in the equipment set to secure the assembly loop

(3) to the wall, drill four 6-mm holes in the wall using the drill template as a guide in accordance with

the dimensions in the diagram "Step 2 of the wall mounting" on page 22.

If you want to use your own fastening screws you can use the drill guide provided in the equipment

set to determine the position of the holes. The diameters are then determined by the screws that are

being used and any wall plugs that may be required.

3. Securing the NivuLog Easy to the wall:

If you want to use the tapping screws (4) included in the equipment set, first of all insert the supplied

wall plugs into each of the four drill holes before screwing the NivuLog Easy with the attached

assembly loop (3) to the wall (see "Step 2 of the wall mounting" on page 22).

If you are using your own screws, you must also insert the wall plugs into the holes before mounting

the NivuLog Easy with the attached assembly loop (3) to the wall (see "Step 2 of the wall mounting"

on page 22).

7.3 Safety instructions for the cabling

Chapter 7 Installation

Important note: To avoid any damage, always switch off the voltage supply to the device when

performing electrical connections.

When connections are made to the NivuLog Easy , the following warningsand information must be observed,

in addition to the warnings and information found in the individual chapters on the installation. Further safety

information is included in "Safety instructions" on page 11.

If present, disconnect the external charging voltage from the device and removethe accu or battery pack

before completing any wiring work.

Removing the accu or battery pack

NivuLog Easy - Rev. 05 as of 02.07.2012 23 of 73

1 Housing cover 3 Accu or battery pack

2 Supplyconnector

7.4 Electrical installation

Important note: Only qualified personnel should undertake the installation described in this chapter

of the operating instructions to avoid any damage to the device.

7.4.1 Connecting the sensors, actuators and supply

Important note:

l All cabling work must be performed in the de-energised state.

l Ensure a proper installation.

l Comply with the existing legal and/or operational directives.

l Improper handling can cause injuries and/or damage to the devices.

l Run all data and power cables so that they do not pose a stumbling risk and ensure that the

cables do not have any sharp bends.

l The NivuLog Easy must not be operated in the field with the lid open.

l The NivuLog Easy cannot be operated without an internal power supply (accu or battery pack).

l Ensure the polarity of the connector is correct when replacing the accu or battery pack.

l An external charging (V

is used.

l To ensure the housing is properly sealed, each of the two cable screw connections must only

hold a single cable.

) voltage must not be connected to the NivuLog Easy if a battery pack

in

24 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 7 Installation

Connection of the sensors and supply

1 Housing cover 7 Pressure compensation

2 Supplyconnector 8 M16x1.5 cable screw connection (cable diameter

of 4.5 to 10 mm)

3 Accu or battery pack 9 Main terminal blockX12

4 Antenna connection 10 Mounting for the accu or battery pack

5 connector X4 for the external temperature sensor 11 Status LED

6 M12x1.5 cable screw connection (cable diameter

12 Button

of 3.5 to 7 mm)

NivuLog Easy - Rev. 05 as of 02.07.2012 25 of 73

Allocation of the main terminal block X12

1 V

in

External charging voltage

2 GND Earthing

3 V

out

Output 1: Switchable sensor

supply

4 V

batt

Direct accu or battery voltage

output

5 Input 1 Universalinput 1

6 Input 2 Universalinput 2

7 Input 3 Universalinput 3

8 Input 4 Universalinput 4

9 NO Output 2: Isolated switch contact

10 CC

1. Remove the four screws that secure the housing cover. Then open the NivuLog Easy .

Important note: In the event of adverse weather conditions including rain or in a location

where water can penetrate from above, suitable measures must be implemented to protect the

device from penetrating moisture when the housing cover is open.

2. Connection of the external temperature sensor:

If the external temperature sensor was ordered at the same time as the NivuLog Easy , it should

alreadybe connected correctly.

If you ordered an external temperature sensor at a later date as an accessory, the following steps

must be completed:

Important note: Please note that not every type of external temperature sensor can be

installed by the customer (see "Sensors" on page 72).

1. Remove the main terminal block. Ensure that the external charging voltage is switched off if it is

alreadyconnected to the main terminal block.

2. Remove the accu or battery pack.

3. Thread the sensor and its cable internally through the M12 cable screw connection.

4. Connect the connector of the externaltemperature sensor to the connector X4 for the external

temperature sensor .

5. Tighten the M12 cable screw connection to secure the sensor cable.

6. Install the accu or battery pack before fitting the main terminal block.

3. Then connect your sensors and actuators with the universal inputs and outputs. If you are using an

accu packto supply the NivuLog Easy , connect the external charging voltage to Vinand the GND.

Ensure that no current is present!

Important note: Only a single cable must be threaded through the cable screw connections to

ensure the seal of the housing is not damaged.

4. Tighten the cable screw connections to secure the cables.

26 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 7 Installation

5. Affix blind plugs to all of the cable screw connectionsthat are not required.

Important note: All unused cable screw connections on the NivuLog Easy must be sealed

watertightly using the blind plugs supplied. Otherwise the degree of protection for the entire

device is not guaranteed and the manufacturer's warranty is void.

6. Insert the accu or battery pack into the NivuLog Easy and secure it with the appropriate mounting.

7. Connect the antenna (see "Connecting the GSM antenna" on page 27). The antenna is not included in

the scope of delivery and must be ordered separately.

8. Connect the accu or battery pack to the supply connector. The status LED should then start to flicker

(see "Status LED" on page 35), indicating that a connection is being established.

The following step is not mandatory.

9. Check whether the connection to the Device to Web has functioned correctly (see "Testing the

communication with the device" on page 32).

10. Close the housing cover. The best option is to tighten all four of the screws crosswise so that the

housing cover is positioned evenly.

Important note: Ensure that the seals are clean and intact before closing the housing cover.

Remove any foreign bodies and/or dirt. The manufacturer will not be liable for any damage to

the device caused by leaky or faulty seals.

The following step is onlynecessary if you are using an external charging voltage for the accu pack:

11. Now switch on the external charging voltage.

7.4.2 Connecting the GSM antenna

Important note: To ensure the correct functionality, only use antennas that are supplied by the

manufacturer.

The standard antenna is directly attached to the antenna connector (see "Overview" on page 13) of the

NivuLog Easy . In the event of a low radio signal strength, you can use the Flat antenna Smart Disc FME-F ( upon request).

If the distance between the antenna position and the NivuLog Easy is too great, you can use a 5 m Extension

for ANT900 FME (NLM0ANTVER05).

1. Ensure that the NivuLog Easy is de-energised.

2. If you need an antenna extension, connect this to the antenna first.

3. Connect the antenna extension or antenna directly to the antenna connection of the NivuLogEasy (see

"Overview" on page 13)

Important note: Do not apply too much force when tightening the antenna. Do not use any

tools to tighten the antenna or antenna extension; only tighten it manually.

4. Switch the power supply of the NivuLog Easy back on.

The following step is not mandatory.

5. Check whether the connection to the Device to Web has functioned correctly (see "Testing the

communication with the device" on page 32).

NivuLog Easy - Rev. 05 as of 02.07.2012 27 of 73

7.4.3 Technical details regarding the universal inputs

7.4.3.1 0/4 to 20mA mode

Note: Above 22,5mA, the affected input becomes highly resistive (safety shutdown to prevent damage to the

universal input).

Resolution 6µA

I

max

22,5mA

Load 100Ω

7.4.3.2 0 to 2V mode

Resolution 610µV

U

max

2,5V

Load 220k1

7.4.3.3 0 to 10V mode

Resolution 8,3mV

U

max

32V

Load 8k9

7.4.3.4 Standard digital modes (PWM, frequency, digital, day counter, impulse counter)

General U

max

32V

Low <1,36V

High >2,73V

Load 8k9

PWM Measurement

1...99%

range

f

max

Minimum pulse

100Hz

1ms

length

Frequency Measurement

1...1000Hz

range

Day and pulse

counter

Minimum pulse

length

20ms

7.4.3.5 Low power digital mode (LP digital)

Important note: If a universal input is in "LP digital", a switch contact must onlybe supplied by V

batt

.

Attaching an external voltage will cause damage to the universal input. In comparison to "digital" mode, the

energy consumption during "LP digital" mode with a closed switch contact is thus reduced by a factor of 13.

28 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 7 Installation

U

max

V

batt

Low <100mV

High >200mV

Load 220k1

7.4.4 Technical details regarding the outputs

7.4.4.1 Output 1: Switchable sensor supply (V

Note: The switchable sensor supply output is short-circuit-proof.

P

I

max

max

1W

66mA

@15V

41mA

@24V

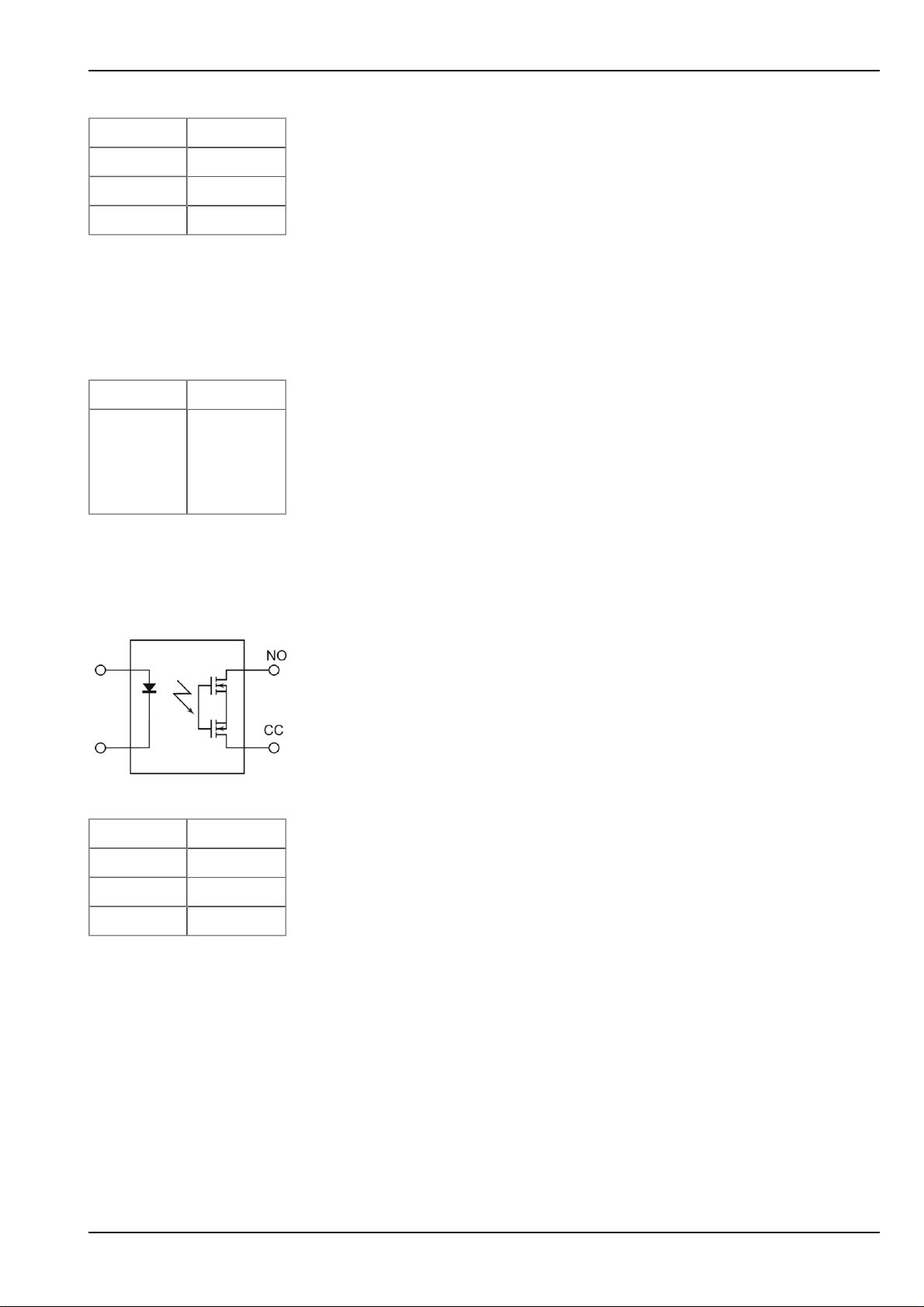

7.4.4.2 Output 2: Isolated switch contract (NO, CC)

out

)

Important note: The user must ensure that the current does not exceed 130mA via the isolated

switch contact.

Replacement circuit diagram for the isolated switch contact

I

max

U

max

R

on

f

max

7.4.4.3 Direct accu or battery voltage output (V

The accu or battery voltage is supplied directly to the voltage output V

130mA

32V

35Ω

500Hz

batt

)

protected by a PTC (I

batt

max

200mA).

The voltage available at this output is therefore directly dependent on the charging condition of the accu or

battery pack.

NivuLog Easy - Rev. 05 as of 02.07.2012 29 of 73

7.4.5 Technical details regarding energy management

The device will work until 3,1V, if the NivuLog Easy is operated without an external charging voltage (Vin). It

then switches to energy-saving mode in which only the charge controller is active. If an external charging

voltage (Vin) is supplied in this mode, the accu pack can be charged up again. Otherwise the NivuLog Easy

remainsin energy-saving mode until the accu pack is completely discharged.

When an externalcharging voltage (Vin) is used, the charge controller ensures that the accu pack is charged.

It is therefore necessary to select the type of accu used in the input screen of the device configuration (see

"Device-specific settings" on page 62). If a type of accu packis selected that is also assigned the title "solar",

the accu pack is constantly charged (recommended if a solar field is used to charge the accu pack). For all of

the other accu pack type settings, the accu pack is always charged to the maximum voltage, after which

charging is switched off and only reactivated when V

reached (used to optimise the service life of the accu pack).

All types of accu packs are only recharged if the ambient temperature does not have an impact on the

permissible range of the charging temperature. The permissible charging temperature is specified in the

factsheet for the relevant accu pack. Chapter "Accu and battery packs" on page 71 contains an overview of

the temperature ranges for several accu packs.

Note: Please be aware that some of the compatible accu packs cannot be charged at sub-zero temperatures.

Select an appropriate accu pack if you are expecting low temperatures during operation.

(see "Device-specific settings" on page 62) is

low

30 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 8 Initial Start-Up

Chapter 8 Initial Start-Up

8.1 User information

Before you connect the NivuLog Easy and place it into operation, you must observe and complywith the following user information!

This manual contains all information that is required for using the device.

Is intended for technically qualified personnel who have the relevant knowledge and experience in the area of

measurement technology.

Read this manual carefully and completely in order to ensure the proper functioning of the NivuLog Easy .

Please contact our technical department if anything is unclear or if you encounter difficulties with regard to

installation, connection or configuration (see "Branch offices " on page 73).

If necessary, please also refer to the manuals of the accessory parts when commissioning the complete system. These manuals are includedin the scope of delivery of the accessory parts.

8.2 General principles

The entire measurement system may only be placed into operation after completion and inspection of the

installation. Study the manual thoroughlybefore placing into operation to prevent faulty or incorrect configuration.

Utilise the manual to familiariseyourself with the operation of the NivuLog Easy and the input screens of the

Device to Web-Server before you begin with the configuration.

8.3 Placing the system into operation

Note: It is recommended that the NivuLog Easy is first placed into operation in the office before permanently

mounting the device at the place of use. In doing so you should set a site for the later operation on the Device to

Web server (see "Device to Web Server Manual " - upon request) and determine a site configuration (see "Site

configuration" on page 37). Take the opportunity to get to know the functions of the device in a stable environment. You can also use suitable test signals to simulate the sensors to establish the optimum configuration

of the NivuLog Easy prior to its actual first use. This will reduce the time needed for on-site installation to a minimum.

1. Once you have completed all of the steps described in the section "Connecting the sensors, actuators

and supply" on page 24, the NivuLog Easy is ready for operation and should have already made its first

connection to the Device to Web server.

2. Create a site for the operation on the Device to Web server (see "Device to Web Server Manual " upon request).

3. Configure the created site accordingto your requirements (see "Site configuration" on page 37).

4. Linkthe NivuLog Easy with the createdsite (see "Site" on page 37).

5. Check whether the type of accu packset in the device configuration (see "Device-specific settings" on

page 62) matches the accu or battery pack that is being used.

NivuLog Easy - Rev. 05 as of 02.07.2012 31 of 73

Important note: The accu pack type must be configured correctly, otherwise the charging

curve will not be correct.

6. Activate the ALOHA transmissionmode (see "ALOHA transmission mode" on page 17) so that the site

configuration is transmitted to the NivuLog Easy .

8.4 Testing the communication with the device

1. Create a site for the operation on the Device to Web server (see "Device to Web Server Manual " upon request).

2. Configure the created site accordingto your requirements (see "Site configuration" on page 37).

3. Linkthe NivuLog Easy with the createdsite (see "Site" on page 37).

4. Initiate the ALOHA transmission mode (see "ALOHA transmission mode" on page 17) so that the configuration of the site is transmitted to the NivuLog Easy .

5. Wait until the list of measurement instrumentsindicates that the unit is in ALOHA transmission mode.

This is indicated by a speech bubble with the "Aloha" inscription.

The following steps are only required if you also want to test the measurement value acquisition and data

transmission.

6. Terminate the ALOHA transmission mode by clicking the crossin the speech bubble with the "Aloha"

inscription or wait for the duration of the ALOHA transmission mode. This period can be determined in

the basic settings (see "Basicsettings" on page 58) of the site configuration. The default setting is ten

minutes.

7. Then wire up the sensors (see "Connecting the sensors, actuators and supply"on page 24) and restart

the ALOHA transmission mode

Important note: All wiring work must be performed in the de-energised state.

8. Check the incoming data in ALOHA data window of the Device to Web server, which can be accessed

by clicking on the speech bubble with the "Aloha" inscription (see "Device to Web Server Manual " upon request). Particular attentionmust be paid to the internal "GSM level" and "battery" measurement

values.

32 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Note: Additional explanation about evaluating the "GSM level":

"GSM level"

>-64dBm

-64 to -73dBm

-74 to -83dBm

-84 to -93dBm

-94 to -107dBm

<= -108dBm

Note: Additional explanation about evaluating the "battery":

"Battery"

> 3.81V

Chapter 8 Initial Start-Up

3,81V...3,70V

3,71V...3,63V

3,64V...3,59V

3,6V...3,19V

<= 3.2 V or invalid value

NivuLog Easy - Rev. 05 as of 02.07.2012 33 of 73

Chapter 9 User interfaces

Chapter 9 User interfaces

The configuration of the NivuLog Easy is carried out via the web interface on the Device to Web server (see

"User interface on the Device to Web-Server" on page 37), which your responsible sales partner will provide

to you.

9.1 User interface on the NivuLog Easy

9.1.1 Operating elements

A differentiation must be made between the operating elements of the NivuLog Easy that are only accessible

when the housing cover is open, and those that are also accessible when the housing is closed.

Operating elements that areaccessible when the housing

cover is open

1 Status LED 3 Solenoid switch

2 Buttons

9.1.1.1 Status LED

The status LED is used both to display the error/status codes and to indicate the current operating status. If

the ALOHA transmission mode was activated or the accu or battery pack was connected (PowerOn), the

statusLED shows the current operating status for 10 minutes. During these ten minutes, the error/status

codesare transmitted every three seconds.

Operating elements that areaccessible when the housing is

closed

NivuLog Easy - Rev. 05 as of 02.07.2012 35 of 73

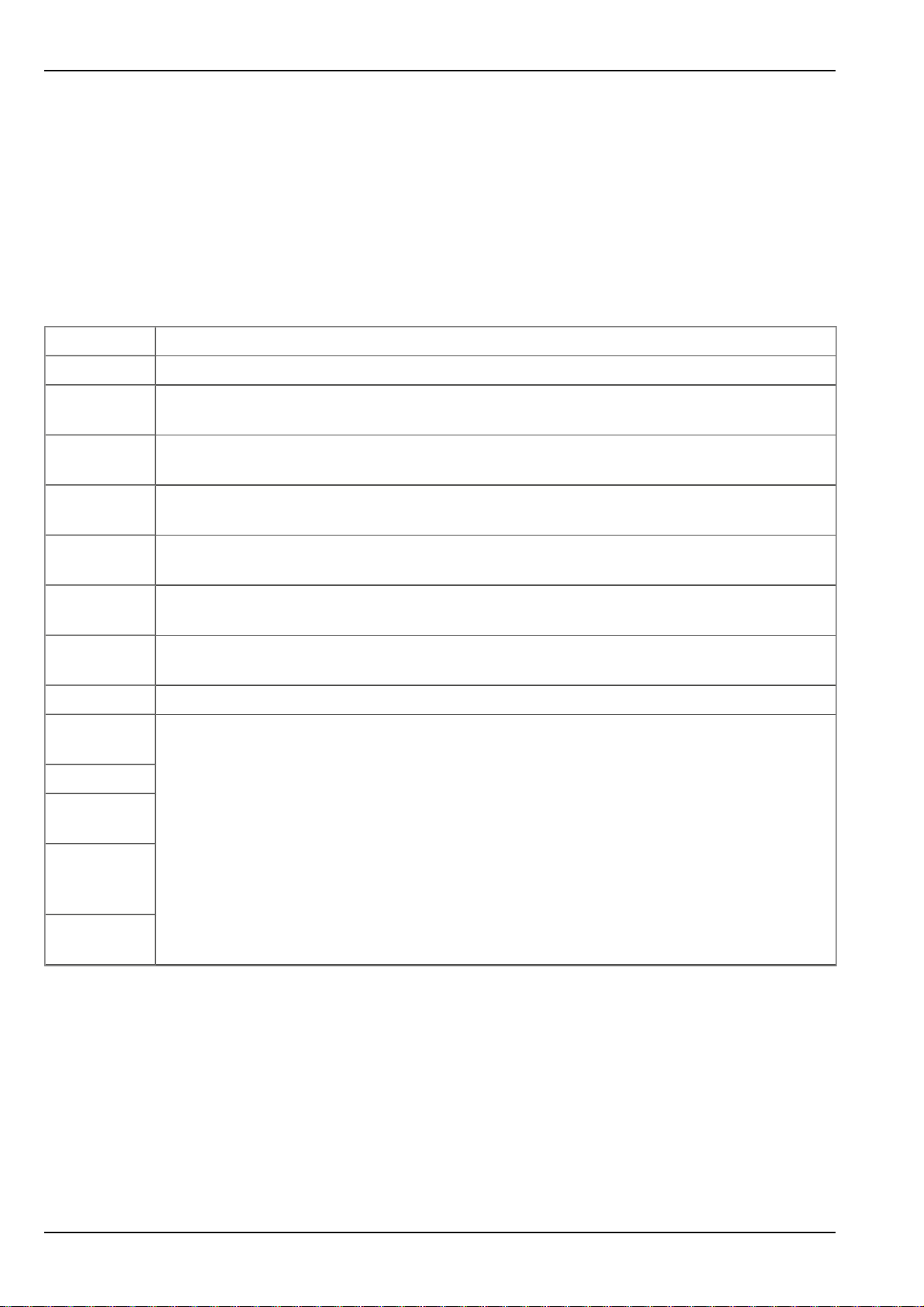

Error/status codes

Blink code Description Solution/cause

0x Transport lock (GPRS OFF, measurement

OFF)

If the ALOHA transmission mode is initiatedby

the button or solenoid switch, the NivuLog

Easy switches back into "RUN" mode (GPRS

ON, measurement ON).

1x Last connection OK

2x Last transmission faulty Try again later

4x Standby (GPRS ON, measurement OFF) See "transport lock"

6x Offline (GPRS OFF, measurement ON) See "transport lock"

7x Network block/no matching provider l Improve position of the antenna

l Check whether the device is located in

the coverage area of a service provider

that is supported by the integrated SIM

chip (www.nivus.com)

l Lift the network block (see

"DeviceConfig Manual" - upon request)

8x No GSM network l Try again later

l Improve position of the antenna

10x No GPRS connection Improve position of the antenna

11x No myDatanet server accessible l Check whether port 51241 is enabled on

the Device to Web server

l Try again later

12x Faulty SIM chip Contact support

Operating statuses

Status

LED

Description

Flickering Establishing connection

Lightsup GPRS connection established or button/solenoid switch actuates

Off Normal measuring operation according to configuration until the next transmission

9.1.1.2 Buttons

The button can also be used to initiate the ALOHA transmission mode or to instruct the NivuLog Easy to

immediatelygive out the error/status code.

User action Device response Operation after releasing the button

Press briefly for

approx. one second

Status LED illuminates Error/status code is displayed (see "Status

LED" on page 35)

Press and hold for

five seconds

Status LED flashes three times and then

remainson

ALOHA transmission mode

36 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

9.1.1.3 Solenoid switch

The solenoid switch initiates the same actions as the button. However, it can also be used with the housing

closed thanks to the Magnet for device activation (NLM5MAGNET) included in the scope of delivery.

9.2 User interface on the Device to Web-Server

9.2.1 Site configuration

Note: Several of the configuration fields in the following sub chapters may possibly be hidden depending on the

respective user level. In this case, please contact the Device to Web-Server administrator.

Click on the name of the site in the list of sitesto get to the input screen for configuring the site (see "Device to

Web Server Manual " - upon request).

9.2.1.1 Site

Customer

Specifies to which customer the site is assigned.

icon

Assign site to another customer

Name

Site designation (not relevant for the device or data assignment)

Instrument S/N

Serial number of the device that is linked to the site (device assignment!)

9.2.1.2 Comments

Comments

Empty comment field (is also displayed below the device type in the site list)

9.2.1.3 Measurement channels

9.2.1.3.1 Basis

Title 1-4

Freely selectable channel title for the universal inputs

Title 1Wire

Freely selectable channel title for the external temperature sensor

NivuLog Easy - Rev. 05 as of 02.07.2012 37 of 73

Mode

Basic settings for the measurement channel

Universal inputs

Off --- Measurement channel deactivated

(digital modes)

Digital Invert Inverts the input signal

Digital LP Invert Inverts the input signal

Cnt.Day Impulse Count value of an impulse in the measuring unit

Max Defines the upper scale end of the pointer instruments

Unit String, which is used as the measurement unit by all of the

server display elements

Decimal

places

Cnt.Intervl. Impulse Count value of an impulse in the measuring unit

Max Defines the upper scale end of the pointer instruments

Unit String, which is used as the measurement unit by all of the

Decimal

places

Freq Factor Factor by which the input signal is multiplied

Min Defines the lower scale end of the pointer instruments

Max Defines the upper scale end of the pointer instruments

Number of decimal places that are used by all of the server

display elements

server display elements

Number of decimal places that are used by all of the server

display elements

Unit String, which is used as the measurement unit by all of the

server display elements

Decimal

places

PWM 0% Start of measurement range in the measurement unit

100% End of measurement range in the measurement unit

Unit String, which is used as the measurement unit by all of the

Decimal

places

Number of decimal places that are used by all of the server

display elements

server display elements

Number of decimal places that are used by all of the server

display elements

38 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

Universal inputs

(analogue

modes)

0-20mA 0% Start of measurement range in the measurement unit

100% End of measurement range in the measurement unit

Unit String, which is used as the measurement unit by all of the

server display elements

Decimal

places

Number of decimal places that are used by all of the server

display elements

4-20mA 0% Start of measurement range in the measurement unit

100% End of measurement range in the measurement unit

Unit String, which is used as the measurement unit by all of the

server display elements

Decimal

places

Number of decimal places that are used by all of the server

display elements

0-2V 0% Start of measurement range in the measurement unit

100% End of measurement range in the measurement unit

Unit String, which is used as the measurement unit by all of the

server display elements

Decimal

places

Number of decimal places that are used by all of the server

display elements

Ext. temperature

sensor

0-10V 0% Start of measurement range in the measurement unit

100% End of measurement range in the measurement unit

Unit String, which is used as the measurement unit by all of the

server display elements

Decimal

places

Number of decimal places that are used by all of the server

display elements

Off --- Measurement channel deactivated

On Min Defines the lower scale end of the pointer instruments

Max Defines the upper scale end of the pointer instruments

Unit Selection of the temperature unit that is used by all of the

server display elements

Decimal

places

Number of decimal places that are used by all of the server

display elements

NivuLog Easy - Rev. 05 as of 02.07.2012 39 of 73

9.2.1.3.2 Config

Universalinputs

(digital modes)

Off --- --Digital Filter time Minimum signal length for signal detection

Decay Temporalfunction in the measurement cycle

Up Minimum signal length for x seconds on rising

edge

Down Minimumsignal length for x seconds on

falling edge

Up & down Minimum signal length for x seconds on both

edges

Time Time x, for which the decay modes "up" "down", and "up &

down" are used

Digital LP Filter time Minimum signallength for signal detection

Decay Temporalfunction in the measurement cycle

Up Minimum signal length for x seconds on rising

edge

Down Minimumsignal length for x seconds on

falling edge

Up & down Minimum signal length for x seconds on both

edges

Time Time x, for which the decay modes "up" "down", and "up &

down" are used

40 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

Universalinputs

(Counter modes)

Cnt.Day Filter time Minimum signal length for signal detection

Reset at Reset time of the day counter

Cnt.Intervl. Filter time Minimum signal length for signaldetection

Decay Temporalfunction in the measurement cycle

Off Decay deactivated

Min The minimum of the last x measurement

values is recorded.

Max The maximum of the last x measurement

values is recorded.

Avg The arithmetic mean of the last x

measurement valuesis recorded.

Med The median of the last x measurement

values is recorded.

Rms The root mean square of the last x

measurement valuesis recorded.

Time Time window for the decay. Up to max. 60 measurement

values can be used for the calculation (e.g. 1 channel: 60

measurement values; 4 channels: per 15 measurement

values). To calculate the number of considered

measurement valuessee "Example for explaining the

recording, measuring and burst cycles (in conjunction with

the decay)" on page 59.

NivuLog Easy - Rev. 05 as of 02.07.2012 41 of 73

Universalinputs

Freq

Filter time Minimum signal length for signal detection

(Frequencymode

1/2)

(1/2)

Decay Temporalfunction in the measurement cycle

Off Decay deactivated

Min The minimum of the last x measurement

values is recorded.

Max The maximum of the last x measurement

values is recorded.

Avg The arithmetic mean of the last x

measurement valuesis recorded.

Med The median of the last x measurement

values is recorded.

Rms The root mean square of the last x

measurement valuesis recorded.

Time Time window for the decay. Up to max. 60 measurement

values can be used for the calculation (e.g. 1 channel: 60

measurement values; 4 channels: per 15 measurement

values). To calculate the number of considered

measurement valuessee "Example for explaining the

recording, measuring and burst cycles (in conjunction with

the decay)" on page 59.

Hold Maintain the last valid measurement value for x

measurement cycles

Off Function deactivated

1-5 Number of measurement cyclesfor which

the measured value is maintained until the

error value is issued

On In the event of an error, the last valid

measurement value is maintained until a new

valid measurement value is present.

42 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

Universalinputs

(Frequencymode

2/2)

Freq

(2/2)

Overflow Handling measurement range violations

Ignore The measured value is calculated beyond the

range limits.

Silent cutoff The measured value is cutoff at the range

limits.

Overflow l If the measurement value is below the

lower limit, the error value "UF"

(underflow) is issued.

l If the measurement value is above the

upper limit, the error value "OF"

(overflow) is issued.

NAMUR

borders

l If the measurement value is below the

lower limit, the error value "UF"

(underflow) is issued.

l If the measurement value is above the

upper limit, the error value "OF"

(overflow) is issued.

NivuLog Easy - Rev. 05 as of 02.07.2012 43 of 73

Universalinputs

PWM

Filter time Minimum signal length for signal detection

(PWM mode 1/2)

(1/2)

Decay Temporalfunction in the measurement cycle

Off Decay deactivated

Min The minimum of the last x measurement

values is recorded.

Max The maximum of the last x measurement

values is recorded.

Avg The arithmetic mean of the last x

measurement valuesis recorded.

Med The median of the last x measurement

values is recorded.

Rms The root mean square of the last x

measurement valuesis recorded.

Time Time window for the decay. Up to max. 60 measurement

values can be used for the calculation (e.g. 1 channel: 60

measurement values; 4 channels: per 15 measurement

values). To calculate the number of considered

measurement valuessee "Example for explaining the

recording, measuring and burst cycles (in conjunction with

the decay)" on page 59.

Hold Maintain the last valid measurement value for x

measurement cycles

Off Function deactivated

1-5 Number of measurement cyclesfor which

the measured value is maintained until the

error value is issued

On In the event of an error, the last valid

measurement value is maintained until a new

valid measurement value is present.

44 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

Universalinputs

(PWM mode 2/2)

PWM

(2/2)

Overflow Handling

measurement

range

violations

Ignore

Silent cutoff The measured value is cutoff at the range

Overflow l If the measurement value is below the

NAMUR

borders

The measured value is calculated beyond the

range limits.

limits.

lower limit, the error value "UF"

(underflow) is issued.

l If the measurement value is above the

upper limit, the error value "OF"

(overflow) is issued.

l If the measurement value is below the

lower limit, the error value "UF"

(underflow) is issued.

l If the measurement value is above the

upper limit, the error value "OF"

(overflow) is issued.

NivuLog Easy - Rev. 05 as of 02.07.2012 45 of 73

Universalinputs

0-20mA

Filter time Temporal averaging for signal smoothing

(0-20mA mode 1/2)

(1/2)

Decay Temporalfunction in the measurement cycle

Off Decay deactivated

Min The minimum of the last x measurement

values is recorded.

Max The maximum of the last x measurement

values is recorded.

Avg The arithmetic mean of the last x

measurement valuesis recorded.

Med The median of the last x measurement

values is recorded.

Rms The root mean square of the last x

measurement valuesis recorded.

Time Time window for the decay. Up to max. 60 measurement

values can be used for the calculation (e.g. 1 channel: 60

measurement values; 4 channels: per 15 measurement

values). To calculate the number of considered

measurement valuessee "Example for explaining the

recording, measuring and burst cycles (in conjunction with

the decay)" on page 59.

Hold Maintain the last valid measurement value for x

measurement cycles

Off Function deactivated

1-5 Number of measurement cyclesfor which

the measured value is maintained until the

error value is issued

On In the event of an error, the last valid

measurement value is maintained until a new

valid measurement value is present.

46 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

Universalinputs

(0-20mA mode 2/2)

0-20mA

(2/2)

Overflow Handling

measurement

range

violations

Ignore

Silent cutoff The measured value is cutoff at the range

Overflow l If the measured value is above

NAMUR

borders

The measured value is calculated beyond the

range limits.

limits.

20.1mA, the error value "SC" (short

cut) is issued.

l If the measuredvalue is above

20.1mA, the error value "OF"

(overflow) is issued.

l If the measuredvalue is above 21mA,

the error value "SC" (short cut) is

issued.

NivuLog Easy - Rev. 05 as of 02.07.2012 47 of 73

Universalinputs

4-20mA

Filter time Temporal averaging for signal smoothing

(4-20mA mode 1/2)

(1/2)

Decay Temporalfunction in the measurement cycle

Off Decay deactivated

Min The minimum of the last x measurement

values is recorded.

Max The maximum of the last x measurement

values is recorded.

Avg The arithmetic mean of the last x

measurement valuesis recorded.

Med The median of the last x measurement

values is recorded.

Rms The root mean square of the last x

measurement valuesis recorded.

Time Time window for the decay. Up to max. 60 measurement

values can be used for the calculation (e.g. 1 channel: 60

measurement values; 4 channels: per 15 measurement

values). To calculate the number of considered

measurement valuessee "Example for explaining the

recording, measuring and burst cycles (in conjunction with

the decay)" on page 59.

Hold Maintain the last valid measurement value for x

measurement cycles

Off Function deactivated

1-5 Number of measurement cyclesfor which

the measured value is maintained until the

error value is issued

On In the event of an error, the last valid

measurement value is maintained until a new

valid measurement value is present.

48 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

Universalinputs

(4-20mA mode 2/2)

4-20mA

(2/2)

Overflow Handling

measurement

range

violations

Ignore

Silent cutoff The measured value is cutoff at the range

Overflow l If the measured value is below 3.9mA,

NAMUR

borders

The measured value is calculated beyond the

range limits.

limits.

the error value "OL" (open loop) is

issued.

l If the measuredvalue is above

20.1mA, the error value "SC" (short

cut) is issued.

l If the measuredvalue is below 3.6mA,

the error value "OL" (open loop) is

issued.

l If the measuredvalue is below 3.9mA,

the error value "UF" (under flow) is

issued.

l If the measuredvalue is above

20.1mA, the error value "OF"

(overflow) is issued.

l If the measuredvalue is above 21mA,

the error value "SC" (short cut) is

issued.

NivuLog Easy - Rev. 05 as of 02.07.2012 49 of 73

Universalinputs

0-2V

Filter time Temporal averaging for signal smoothing

(0-2V mode 1/2)

(1/2)

Decay Temporalfunction in the measurement cycle

Off Decay deactivated

Min The minimum of the last x measurement

values is recorded.

Max The maximum of the last x measurement

values is recorded.

Avg The arithmetic mean of the last x

measurement valuesis recorded.

Med The median of the last x measurement

values is recorded.

Rms The root mean square of the last x

measurement valuesis recorded.

Time Time window for the decay. Up to max. 60 measurement

values can be used for the calculation (e.g. 1 channel: 60

measurement values; 4 channels: per 15 measurement

values). To calculate the number of considered

measurement valuessee "Example for explaining the

recording, measuring and burst cycles (in conjunction with

the decay)" on page 59.

Universalinputs

(0-2V mode 2/2)

0-2V

(2/2)

Hold Maintain the last valid measurement value for x

measurement cycles

Off Function deactivated

1-5 Number of measurement cyclesfor which

the measured value is maintained until the

error value is issued

On In the event of an error, the last valid

measurement value is maintained until a new

valid measurement value is present.

Overflow Handling

measurement

range

violations

Ignore

The measured value is calculated beyond the

range limits.

Silent cutoff The measured value is cutoff at the range

limits.

Overflow If the measured value is above 2.01V, the

error value "OF" (overflow) is issued.

NAMUR

borders

If the measuredvalue is above 2.01V, the

error value "OF" (overflow) is issued.

50 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

Universalinputs

(0-10V mode 1/2)

0-10V

(1/2)

Filter time Temporal averaging for signal smoothing

Decay Temporalfunction in the measurement cycle

Off Decay deactivated

Min The minimum of the last x measurement

values is recorded.

Max The maximum of the last x measurement

values is recorded.

Avg The arithmetic mean of the last x

measurement valuesis recorded.

Med The median of the last x measurement

values is recorded.

Rms The root mean square of the last x

measurement valuesis recorded.

Time Time window for the decay. Up to max. 60 measurement

values can be used for the calculation (e.g. 1 channel: 60

measurement values; 4 channels: per 15 measurement

values). To calculate the number of considered

measurement valuessee "Example for explaining the

recording, measuring and burst cycles (in conjunction with

the decay)" on page 59.

Universalinputs

(0-10V mode 2/2)

0-10V

(2/2)

Hold Maintain the last valid measurement value for x

measurement cycles

Off Function deactivated

1-5 Number of measurement cyclesfor which

the measured value is maintained until the

error value is issued

On In the event of an error, the last valid

measurement value is maintained until a new

valid measurement value is present.

Overflow Handling

measurement

range

violations

Ignore

The measured value is calculated beyond the

range limits.

Silent cutoff The measured value is cutoff at the range

limits.

Overflow If the measured value is above 10.05V, the

error value "OF" (overflow) is issued.

NAMUR

borders

If the measuredvalue is above 10.05V, the

error value "OF" (overflow) is issued.

NivuLog Easy - Rev. 05 as of 02.07.2012 51 of 73

Ext. temperature

sensor

9.2.1.3.3 Alarms

Off --- Measurement channel deactivated

On Hold Maintain the last valid measurement value for x

measurement cycles

Off Function deactivated

1-5 Number of measurement cyclesfor which

the measured value is maintained until the

error value is issued

On In the event of an error, the last valid

measurement value is maintained until a new

valid measurement value is present.

"Digital" or "Digital LP"

mode

All other modes Warning

9.2.1.3.4 Trigger

"Digital" or "Digital LP"

mode

WA A "high" at the universal input initiates a "warning"

AL A "high"at the universal input initiates an "alarm"

SW A "high" at the universal input initiates a "fault warning"

SA A "high" at the universal input initiates a "fault alarm"

Alarm

Hyst % Hysteresis for all-clear (e.g. hyst = 5%, alarm or warning at 100 -> all-

QU Fastrecording (recording cycle = recording cycle / factor)

SL Slow recording (recording cycle = recording cycle * factor)

Value low A warning is initiated if the measurement value drops to or

below this value.

Value high A warning is initiated if the measurement value meets or

exceeds this value.

Value low An alarm is initiated if the measurement value drops to or

below this value.

Value high An alarm is initiated if the measurement value meets or

exceeds this value.

clear at 95)

MS Start measuring cycle immediately

XM Initiate transmission

ON Activate online mode

Edge Selection of the edge at which the trigger should be initiated

Rising Rising edge initiates trigger.

Falling Falling edge initiatestrigger.

Both Both edges initiatetrigger.

52 of 73 NivuLog Easy - Rev. 05 as of 02.07.2012

Chapter 9 User interfaces

All other modes QU Fastrecording (recording cycle = recording cycle / factor)

SL Slow recording (recording cycle = recording cycle * factor)

RO Switch on recording

RF Switch off recording

XM Initiate transmission

ON Activate online mode

Level Levels for initiating the trigger

Greater or

equal

Less or equal The measurement value must be less than or equal to

9.2.1.4 Calculated channels

Note: The values of the calculated channels are calculated directly for the data output (display on Device to

Web server or download from Device to Web server). They are not saved in the server database.

9.2.1.4.1 Basis

Title 1-5

Freely selectable channel title for the calculated channels

Mode

Possible calculation modes for the calculated channels

Off --- Calculated channel deactivated

Table Min Defines the lower scale end of the pointer instruments

Max Defines the upper scale end of the pointer instruments

The measurement value must be greater than or equal

to the levelto initiate the trigger.

the level to initiate the trigger.

Unit String, which is used as the measurement unit by all of the server display

elements

Decimal

places

Number of decimal places which are used by all of the server display

elements

Digital Invert Inverts the input signal

+, -, x, / Min Defines the lower scale end of the pointer instruments

Max Defines the upper scale end of the pointer instruments

Unit String, which is used as the measurement unit by all of the server display

elements

Decimal

places

Number of decimal places which are used by all of the server display

elements

Shifts element down

Shifts element up

NivuLog Easy - Rev. 05 as of 02.07.2012 53 of 73

9.2.1.4.2 Calculation

Off --- Calculated channel deactivated

Table

Source Selection of the channel from which the input data is used

Opensthe screen for entering the values table (between the table rows is

interpolated linearly, values outside of the defined table are extrapolated

linearly.)

Digital

Source Selection of the channel from which the input data is used

High level Signalrecognition level

+, -, x, /

Source Selection of the channel from which the input data is used

+, -, x, /

Source Selection of the channel from which the input data is used

9.2.1.4.3 Alarm

Note: The alarm levels for calculated channels can only be evaluated once the device has transmitted the

measurement data to the Device to Web server.

Alarm low An alarm is initiated if the measurement value drops to or below this value.

Alarm high An alarm is initiated if the measurement value meets or exceedsthis value.

Hyst % Hysteresis for all-clear (e.g. hyst = 5%, alarm or warning at 100 -> all-clear at 95)

9.2.1.5 Output channels

9.2.1.5.1 Basis