INSTALLATION

and

PROGRAMMING MANUAL

1st edition

HiTECH/NIVELCO Process Control Co.

301Oxford Valley Road, Bldg 505, Yardley, PA 19067 Tel: (215) 321-6012 ♦ Fax: (215) 321-6067

E-mail:info@hitechtech.com ♦

www.hitechtech.com

scd3404a0600p_01 ♦ 1 / 36

scd3404a0600p_01 ♦ 2 / 36

PRINCIPLES OF ULTRASONIC LEVEL MEASUREMENT

m

)

m

m

>X

)

B

B

Min. meas. distance (X

DE FA U LT va lue of: P05=X

M

M

DEFAULT value of: P04=X

Max. measuring range of the dev ice

Max. measuring distance of the device (X )

Max. measuring distance of the

Close end blocking (X

Progr. value of: P05=X

T

S

I

D

Displa ya ble ran ge

application (H)

DEFAULT value of: P0 6=0

Far end blocki ng

Programmed value of: P04=H

Programmed measurement range

Angle of repose:

DIST=distance (measured)

LEV= level calculated H-D IST)(

VOL= volume (calculated f r om LEV)

scd3404a0600p_01 ♦ 3 / 36

CONTENTS

1. INTRODUCTION.............................................................................5

2. TECHNICAL DATA.........................................................................7

GENERAL DATA...........................................................................7

2.1.

SPECIAL DATA.............................................................................7

2.2.

ACCESSORIES.............................................................................8

2.3.

ORDER CODES............................................................................8

2.4.

DIMENSIONS...............................................................................9

2.5.

3. INSTALLATION.............................................................................10

4. WIRING..........................................................................................12

WIRING CONDITIONS..................................................................12

4.1.

CONNECTION CABLE EXTENSION ................................................12

4.2.

5. PUTTING INTO OPERATION, ADJUSTING, PROGRAMMING ..14

PUTTING INTO OPERATION .........................................................14

5.1.

5.1.1. Status indication signals in measuring mode..................15

SAFETY REGULATIONS OF THE EX APPROVED UNITS....................15

5.2.

PROGRAMMING.........................................................................15

5.3.

PARAMETERS – DESCRIPTION AND PROGRAMMING ......................16

5.4.

5.4.1. Measurement Configuration............................................16

5.4.2. Current value...................................................................21

5.4.3. Relay output....................................................................22

5.4.4. Measurement optimalization...........................................23

5.4.5. Volume measurement.....................................................28

5.4.6. Linearisation....................................................................29

5.4.7. Informational parameters................................................30

5.4.8. Test parameters..............................................................31

5.4.9. Error codes......................................................................32

6. MAINTENANCE, REPAIR............................................................ 33

7. STORAGE CONDITIONS.............................................................33

8. PARAMETER TABLE................................................................... 34

scd3404a0600p_01 ♦ 4 / 36

f

f

Thank you for choosing a HiTECH/ NIVELCO instrument.

We are sure that you will be satisfied throughout its use.

1. INTRODUCTION

APPLICATION

The EASYTREK SCD - 300 series compact ultrasonic transmitters from HiTECH/NIVELCO are designed to measure the level of free flowing solids, granules and

powders.

The unit does not touch the material to be measured and does not in clude any moving parts. Thus, it is not ex posed to mechanical loading, no abrasive effec t is

expected and regular maintenance is not required.

A Total beam angle of 5° at –3 dB is a feature of all HiTECH/NIVELCO’s ultrasonic sensors designed for the level measurement of free flowing solids.

This uniquely narrow beam angle ensures reliable measurement in narrow silos with uneven side walls or sometimes even in the presence of dusting.

Furthermore, as a result of the narrow beam angle – the emitted ultrasonic s ignals have an outstanding focusing – a sufficient signal penetration through dust is

ensured.

PRINCIPLE OF OPERATION

The ultrasonic level meter ing technology is based on the principle of measuring

the time required for the ultrasound pulses to make a round trip from the sensor to

the level to be measured and back.

The sensor emits an ultrason ic pulse trai n and receives the ec hoes refl ected. The

intelligent electronic device processes the received signals by selecting the

echoes reflected from the surface and calculates the distance from the time o

flight between the sensor and the surface of the medi um. This is the basis f or all

other output signals (level or volume) of the EasyTREK! For measuring the level o

the medium the greatest distance of the application (H) has to be programmed.

X

rr

D

XD

5 m 0,7 m

10 m 1,2 m

20 m 2 m

30 m 3 m

40 m 3,8 m

50 m 4,7 m

Diameters correspo nding to the

5° beam angle

X = 16,5 ft. D = 28.0”

X = 33.0 ft. D = 4.0 ft.

X = 65.0 ft. D = 7.0 ft.

X = 99.0 ft. D = 9.9 ft.

X = 131.0 ft. D = 13.0 ft.

X = 197.0 ft. D = 15.0 ft.

Minimum measu ring dist ance (Xm) is the construction defined smallest distance within w hich measuremen t is not possib le (Dead Band; see 5.3. Parameters P05).

In special applications this range should be extended with programming (close end blocking)

Maximum measuring distance (X

possible over this distance i.e. maximum distance of the application H must not be greater than X

): is the construction defined greatest distance, which can be measured by the unit under ideal conditions. No measurement is

M

. Under unfavourable circumstances such as bad reflection or heavy

M

dusting of the material the measuring capability may be reduced up to the half of the unit’s best performance.

scd3404a0600p_01 ♦ 5 / 36

THE FOLLOWING TYPES OF APPLICATIONS ARE POSSIBLE DEPENDING ON THE COMMUNICATION AND WHAT THE OUTPUT SIGNAL IS USED FOR:

1. Using the unit as a three - or four -wire current transmitter.

Normally, we use the analogue (4…20 mA) o utput signal of the EasyTREK. The application parameters of the device are set through HART communication at

installation (right after installation or in a laboratory, prior to installation). In this case the short address of the device should stay the factory default: P19 = 0.

2. Using both, current transmission and digital (HART) signal transfer in single transmitter systems.

Digital signal transfer is also used beside the standard utilis ation of the output current of the Eas yTREK. In this case, there can be one or more devices in the

current loop that use analogue

signals (with their total resistance being R

The short address of the EasyTREK should stay the factory default: P19 = 0. This application can be achieved w ith using a PE-10 or a PR-1 type

MultiCONT unit as the HART master which ensures the power supply of the EasyTREK too.

3. Simultaneous control of several EasyTREK transmitters with the help of a MultiCONT.

In this case all of the EasyTREK s keep the connection with the MultiCONT through HART communication only.

This means that the measurement values are collected in cycles, and that the modifications of the transmitter settings are arbitrary.

The short addresses of the units are P19 = 1 ... 15. All types of setting and programming tasks can be done through a MultiCONT.

= 250 … 600 Ω) and one HART master device.

t

scd3404a0600p_01 ♦ 6 / 36

2. TECHNICAL DATA

2.1. GENERAL DATA

Type

EasyTREK SCD– 3 - 4

EasyTREK SCD– 3 - 8 Ex*

Housing material PP+ Aluminium Aluminium

Total beam angle (-3dB) 5°

Process temperature -22ºF (–30°C) ... + 140ºF (60°C) - 4ºF (–20°C) ... +140ºF (60°C)

Process pressure (absolute) 0,07 ... 0,11 MPa (0,7 … 1,1 bar) 10 PSI – 16 PSI

Power supply / consumption 11,4 … 40 V DC / 3,6 W, 11,4 … 28 V AC / 4 VA

Output

Analogue 4 … 20 mA, R

Digital communication HART

= 600 ohm, Galvanic isolation; protection against surge transients

tmax

Relay SPST ; 48 V AC / 5A; A12

Accuracy

±( 0,2% of the measured distance + 0,1% of the range)

Resolution 0.39” (10 mm)

Damping 3 … 1000 s

Electric connection

6 x 2,5 mm

2

∅ 7,5 mm shielded cable ; standard length 9.8 ft (3 m) ; (to order up to 98 ft. (30m)

Electric protection Class III

Ingress protection IP65

Ex marking* n.a.

*Pending

ATEX II 1D IP 65 T 130 °C

2.2. SPECIAL DATA

Type

SCD-34 - 4

SCD-34 - 8 Ex*

Maximum measuring distance** (XM) 49 ft. (15 m) 98 FT. (30 m) 197’ (60 m)

Minimum measuring distance** (Xm) 1.6 ft. (0,5 m) 2 ft. (0,6 m) 3.28 FT. (1 m)

Ultrasound frequency 40 kHz 30 kHz 15 kHz

Sensor face PVC foam

Mass 7.7 lbs. (~ 3.5 kg) 7.7 lbs. (~ 3.5 kg) 14.0 lbs. (~ 6.5 kg)

SCD-33 - 4

SCD-33 - 8 Ex*

SCD-31 - 4

SCD-31 - 8 Ex*

*Under optimal circumstances of reflection and stabilised sensor temperature

scd3404a0600p_01 ♦ 7 / 36

2.3. ACCESSORIES

• Installation and Programming Manual

• Guaranty Certificate

• Manufacturer’s Declaration

• EView Light configuration software and description on CD

ACCESSORIES TO BE ORDERED

• Split flange (order code: SFA – 35)

• EView configuration software CD

• HART modem

2.4. ORDER CODES

Range Code

197 ft (60 m)

99 ft (30 m)

49 ft. (15 m)

scd3404a0600p_01 ♦ 8 / 36

EasyTREK

1

3

4

* The order code of an Ex version should end in “Ex”

S C D – 3 – *

Mounting Code

1" BSP 0

Aiming device J 4 … 20 mA+HART+Relay/Ex 8

Output / Ex Code

4 … 20 mA+HART+Relay 4

RS 485+ Relay B

RS 485+ Relay / Ex F

2.5. DIMENSIONS

SCD-310-_ SCD-310-_ Ex

SCD-330-_

SCD-340-_

SCD-330-_ Ex

SCD-340-_ Ex

Ball-joint Housing

(view from above)

SCD-31J-_ SCD-31J-_ Ex

SCD-33J-_ SCD-33J-_ Ex

SCD-34J-_ SCD-34J-_ Ex

scd3404a0600p_01 ♦ 9 / 36

3. INSTALLATION

POSITIONING

Selecting optimal location for the transmitter various considerations should be made.

If the measured material is granule (material s ize > 5 mm) and th e t ank roof is do me s haped or con ical, do n ot

install the transmitter in the centre of the tank/silo. In gen eral the transmitter can be installed on the radius

r= (0,3 … 0,5) R.

Avoid that the 5° conical beam angle of the transmitter contact the tank/silo wall. In case the transmitter is

mounted close to the wall, it should be tilted (S ee section “Aiming”). Protect the transmit ter electronics from

overheating due to direct sunshine. The same way no disturbing objects such as ladder, grid, thermometer, etc

should intrude into the beam cone. Heavy air movement can make measurement more difficult or even unable.

Device should be protected against direct sunshine no to let its temperature increase into excessive range.

GRAVITY FILLING

Select a location that is as

far away from the filling

point(s) as possible.

PNEUMATIC FILLING

Select a location where the speed of the in-fl owing

material is the smallest.

r

R

Suggest ed lo c ation (vie w from above)

40 m 3,8 m

50 m 4,7 m

MOUNTING (see illustration of mounting options on the next page)

The EasyTREK consists of a sensor that is attached to the aiming arm (a pipe with a ball-joint housing incor porating a ball joint) that is attached to the housing of the

electronics. It is recommended to mount the transmitter on the roof of the tank/silo using a flange (see drawing above). The Ball-joint housing has a screw-hole

diameter of 125 mm for fixing it. For easy installation we recommend using our special flange with a split insertion, available in four sizes of DN125/ 150/20 0/300 (to be

ordered separately). Removing the split insertion, the flange is to be put around the aiming arm and the ball-joint housing is to be fixed to the split flange. It is essentia l

to use the washers and the bolts (4 pcs each) deliv ered with the split flange. The ball-joint w ill be pressed to the housing by a spring allowi ng adjustment/aiming.

The 4 pcs of M12 bolts have to be tightened only after completing the adjustments/aiming.

scd3404a0600p_01 ♦ 10 / 36

When the entire tilting range of the aiming arm is required, the thickness of the roof can not exceed the values specified below.

The EasyTREK can also be mounted on existing (manhole) covers, access lids or for instance on a steel structure lowered into a larger ( ex.: 0.5 x 0.5 m) opening on

the roof. This solution is to be used with roofs thicker than 350 …380 mm.

Diameter of the

Opening

D

160 mm 110 mm

190 mm 150 mm

230 mm 200 mm

300 mm 280 mm

340 mm 300 mm

Maximum Thickness

of the Roof

V

Illustration of mounting

scd3404a0600p_01 ♦ 11 / 36

4. WIRING

4.1. WIRING CONDITIONS

• The transmitter is SELV supplied. In the case of DC supply the connection is

independent of polarity.

• Only SELV circuits can be switched on to the relay output.

• The house must be grounded to have noise protection; it should be

grounded to the equipotential bonding net.

• 3-wire DC powered devices can be created by connecting one of the power

supply wires to the white wire of the current output ( GND). In this case the

current output becomes galvanically non-isolated.

• The units and the cables should be arranged so that the fastening outside

the device relieves the end of the cable of any traction.

4.2. CONNECTION CABLE EXTENSION

Brown

Supply

Green

I

+ HART

OUT

Grey

White

Pink

Relay outpu t

Yellow

• It is advised to use a terminal box when cable extension is necessary.

The shielding should be connected to the shielding of the extension cable and

it should be grounded at the proces s ing unit.

Grounding

Colour codes of the outputs

Housing

scd3404a0600p_01 ♦ 12 / 36

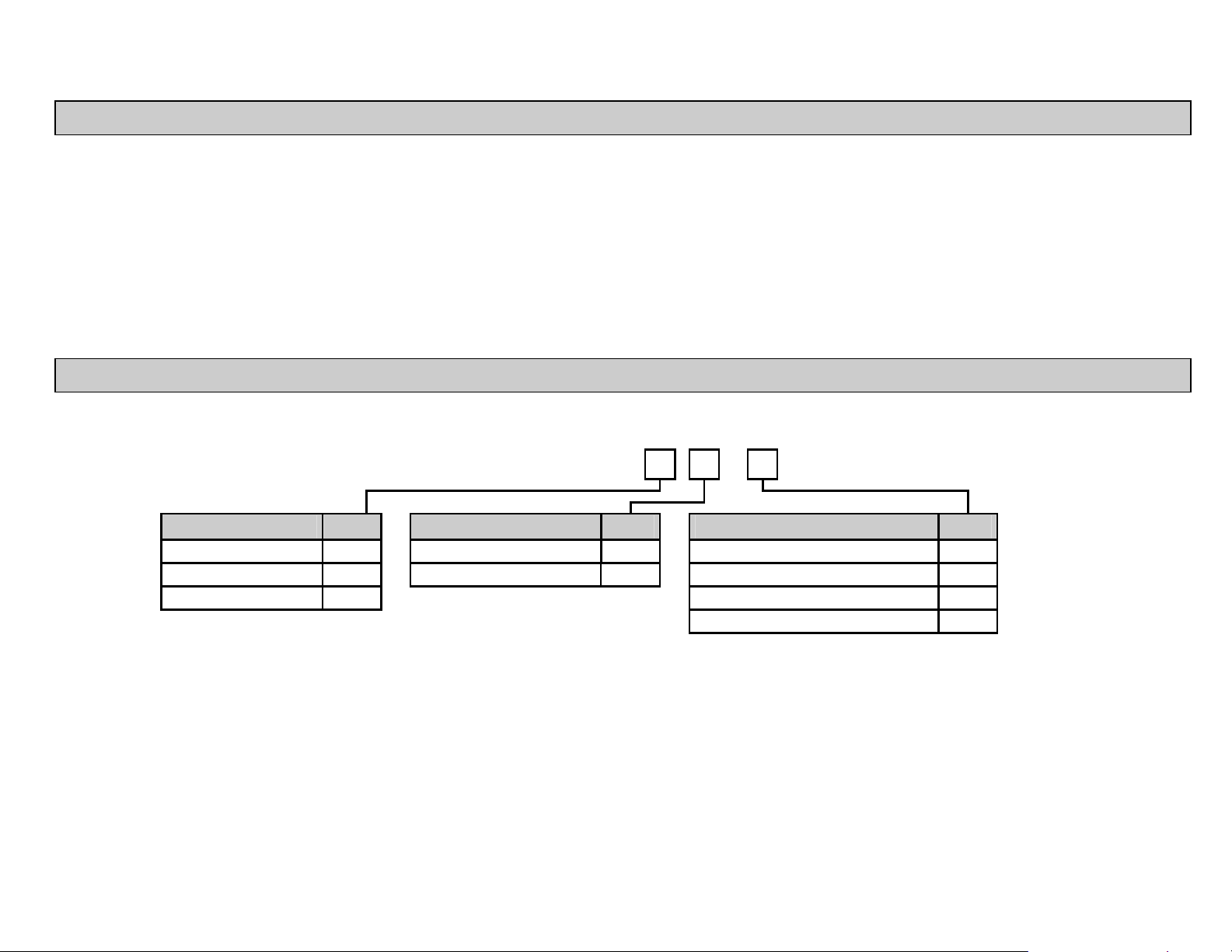

Multiple SCD-300 transmitters connected to a MultiCONT process control unit

Power is supplied from a common external source, the relays are not used.

DEVICES

MultiCONT

26 27 28

Shielding

Grey

Brown

24 V AC/DC

Green

White

Trial and laboratory programming of the SCD-300 transmitters

Output current test

mA

Grey

EasyTREK

White

SELV

supply

Brown

Green

HART communication and power supply of one SCD-300 transmitter from the

MultiCONT process control unit.

SCD-3_ _-4

SCD-3_ _-4

SCD-3_ _-4 SCD-3_ _-4

scd3404a0600p_01 ♦ 13 / 36

5. PUTTING INTO OPERATION, ADJUSTING, PROGRAMMING

5.1. PUTTING INTO OPERATION

After switching on the correc tly wired unit the transducer begins to click audibly. In about 20 … 50 s the ECHO LED goes on and a signal between 4 ... 20 mA

appears on the current output. When first powering the unit, it measures with the standard manufacturer’s settings (see some of the most important parameters

below).

Default parameters

All the transducers get the same factory default parameters that can also be reset later if needed. Some of the most important parameters of the EasyTREK

SCD-300 series can be found below.

⇒ Measurement mode: level (LEV),

⇒ 4 mA is assigned to the

⇒ 20 mA is assigned to the

⇒ Current output holds last value in case of error

⇒ Damping: 300 s

All the other measurement values are set to fit the values suitable for standard tasks. The functions used in special cases are switched off.

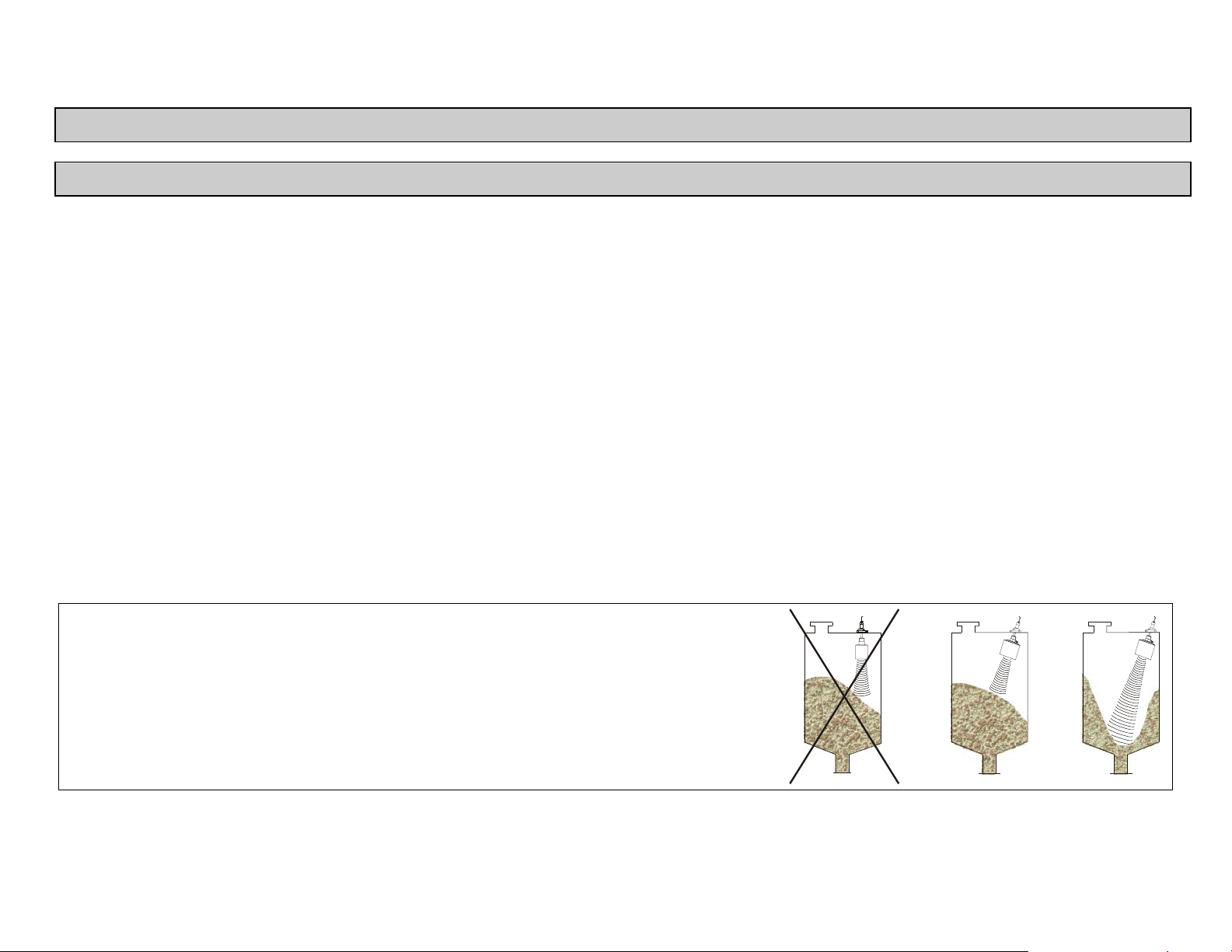

AIMING THE SENSORS

When the material to be measured i s being filled or empt ied, because o f the formation of an angle of repos e, the vertically installed transmitter will experience a weak

signal. This can be eliminated in most cases by tilting the unit, so the aiming device is a very important part of these transmitters. The proper aiming can be set and

checked while the transmitter is being used, desirably when the silo / t ank is almost empty . Usually it is best that the transmitter points to the middle of the bottom of

the silo/tank.

X

maximum measuring distance (minimum level)

M

X

minimum measuring distance (maximum level)

m

In cases when the silo is narrow, and the height / diameter value equals to or is more than 5, tilting is

usually not necessary. Aiming should also be checked when the silo / tank is full, because the echo can

be adversely weak even when c oming from a nearby surface. This us ually happens when the angle of

repose is big. In this case an optimal solution must be found in which the echo coming from any

distance is acceptable. The SERVICE PARAMETERS that can be reached dur ing progra mmin g provid e

help for set-up. That means that the aiming adjustment and the programming should be done at the

same time.

scd3404a0600p_01 ♦ 14 / 36

5.1.1. STATUS INDICATION SIGNALS IN MEASURING MODE

HART respond signals

The properly installed device with factory default settings gives the following

responses to the COM3 universal HART command:

primary value Level

secondary value Level

tertiary value Distance

quaternary value Temperature (See P01 programming).

5.2. SAFETY REGULATIONS OF THE EX APPROVED UNITS

Ex certified devices are approved for Zone 20 and Zone 21 areas.

Transmitters must not be installed in the dust path of the pneumatic filling!

Neither the device, nor a ny part of it should be used as a flame-proof barrier of a

Zone 20 area.

The cable outside the unit should be fixed so that it is tension-free.

The terminal box should be selected in accordance with the electrical class of the

area.

LED status signals on the unit

Green LED COM

Lights up during HART programming.

Red LED ECHO

Lights up when the device gets proper echoes.

5.3. PROGRAMMING

HART interface of the EasyTREK enables full access and programming of the complete parameter set.

Parameters can be accessed by two ways:

- with a HART modem and EView or Eview light configuration software run on a PC

- by the HiTECH/NIVELCO made MultiCONT multichannel controller

This instruction de scribes parameters and f eatures behind th em but does not deal with technical details for their selection and editing of their values. Compact Disk

attached to the transmitt er cont ains detailed i nformatio n on th e Eview co nfigurat ion s oftwar e (to install on PC ) and its descriptio n. Pro grammin g b y the MultiC ONT can

be taken from its Installation and Programming Manual.

Continuous measuring is going on during programming in accordance with the last programmed parameter set. This way the analog output signal

(4-20mA) continuously represents the actual value. The digital (HART) communication depends on the communication software. The new, modified

parameter set will be valid after returning to measurement mode. The device changes back to measurement mode automatically in 1 minute after

programming through HART communication has been finished or discontinued.

scd3404a0600p_01 ♦ 15 / 36

5.4. PARAMETERS – DESCRI PTIO N AND PRO G RAMMI NG

5.4.1. MEASUREMENT CONFIGURATION

P00: - c b a Application/Engineering Units

Programming of this parameter will result in loading the factory default with the corresponding engineering units.

a Operating (measurement) mode

1

b

0

1

c Calculation system

0

1

FACTORY DEFAULT: 001

DEVICE CAN BE OPERATED WITH TWO DIFFERENT ENGINEERING UNIT SYSTEMS, BUT FOR THE SAKE OF EASY OVERVIEW ONLY THE

METRIC SYSTEM WILL BE USED!

Free flowing solids level measurement

Engineering units (according to “c”)

Metric US

m ft

cm inch

ATTENTION!

( according to „c”)

Metric

US

scd3404a0600p_01 ♦ 16 / 36

V

VOLV

P01: - - b a Measurement Mode

Values transmitted by HART protocol, current output and the switching points of the relays will be interpreted into the engineering units of the

(measured or calculated) process value corresponding to the programmed measurement mode. On the other hand, the higher the “a” of the

programmed parameter value the more (measured or calculated) process values can be transmitted through HART (e.g. if P01=0 only the Distance, if

P01=4 Distance, Level and Volume; Exception: P01=2 or 4.)

a MEASUREMENT MODE

0

1

2

3

4

Distance Distance

Level

Level in percent

Volume

Volume in percent

TRANSMITTED

PROCESS VARIABLES

Level

Volume

LEV

Factory settings

PRIMARY VARIABLES

TRANSMITTED THROUGH

HART

DIST

LEV

LEV%

VOL

VOL%

LEV

OTHER VARIABLES TRANSMITTED

THROUGH HART

Secondary: LEV

Tertiary: DIST

Quaternary: Temp

Facto ry settings

Xm

DIST

H

P11

P10

P11

P10

LEV

LEV %

OL

OL %

0

100

[%]

0

scd3404a0600p_01 ♦ 17 / 36

100

[%]

P02: - c b a Calculation units

a Temperature

0

1

°C

°F

This table is interpreted according to P00(c), P01(a) and P02(c) and is irrelevant in case of percent age measurement ( P0 1( a)= 2 or 4 )

Volume Weight (set also P32

b

Metric US Metric US

3

m

0

1

ft3 tone lb (pound)

litre gallon tonne tonne

c

The value of character c has no significance at devices for solids

FACTORY DEFAULT: 000

P03: - - - a Values displayed – Rounding (Not used at EasyTREK)

P04: - - - - Maximum measuring distance (H and XM)

Maximum measuring distance is the greatest distance (H) between the sensor surface and the farthest surface to be measured in the application.

Factory default of this parameter is the m axi mum di stan ce (X

be set for the maximum distance (H) to be measured, whereas H ≤ X

EasyTREK

Level transmitters for liq uids

Maximum measuring distance

(XM) [m]

SD – 34 – 15

SD – 33 – 30

SD – 31 – 60

FACTORY DEFAULT: distance of XM as per table above

) that can be measured by the unit. (See table below) During pr ogra mming P04 should

M

.

M

Keep in mind that LEVEL

– DISTANCE

(measured by the device)

Since the accuracy of level

(as the result of the measurement) = P04 (programmed)

(and all further calculated) value depends on the

accuracy of the max measuring distance of the application which is the

distance between the sensor face and the tank / silo bottom.

To obtain the best accuracy for liquid level measurement, measure with

EasyTREK this distance in the empty tank.

scd3404a0600p_01 ♦ 18 / 36

P05: - - - - Minimum measurin g distance (Close-end blocking)

Basic feature of the ultrasound level meter s is their not bein g a ble to measure next to the sensor surface. Within this range the measurement can not be

interpreted, thus it should be avoided that material level get into this range. By en teri ng a v alue, hig her tha n the fact ory def ault , the m ini mu m mea surin g

range will be extended and fixed to that value. Manual close-end-blocking would be used for example to bl ock out the echo originatin g from the bott om

rim of a stand-off pipe or from any object protruding into the ultrasonic cone near to the transmitter.

Automatic Close-end-blocking (Automatic Dead Band control)

By using the factory default value, the unit will automatically be adjusted to the smallest possible dead band (X

in disadvantageous mountings greater than the dead band.

). In ideal cases this can be smaller and

m

Manual close-end-blocking P05 = X

Entering greater value in P05 than X

> Xm

B

will represent the extension of the close end blocking.

m

EASYTREK

Level transmitters

for liquids

Minimum measuring

distance

(Xm) [m]

SD – 34 – 0,5

SD – 33 – 0,6

SD – 31 – 1,0

FACTORY DEFAULT: automatic close end blocking (Xm as per the table)

scd3404a0600p_01 ♦ 19 / 36

P06: - - - - Far-end blocking

Far-end blocking is the range below the level

set in parameter P06. Far-end blocking can

be used to avoid disturbing effec ts of stirrers

or heaters at the bottom of the tanks.

When the unit detects ec hoes in this range it

gives special signals.

When level sinks below far-end bloc king:

- Message of "Sub 0" appears in EView (in

level and volume measurement mode)

- Current output holds value corresponding to

far-end blocking distance

When level rises above far- end blocking:

The calculation of level and volume will be bas ed on the programmed tank dimensions, th erefor e the me asured or calculated process values will not

be influenced in any way, by the value of far-end blocking.

FACTORY DEFAULT: 0

LEV

T

S

I

D

LEV=level

VOL=volume

0

4mA

20mA

I

out

DIST

H

“SUB 0” display

below this level

P06

Far-end blocking

scd3404a0600p_01 ♦ 20 / 36

5.4.2. CURRENT VALUE

P08: - - - - Fixed output current

With this step the output current can be s et as a fix value, selected between 3,8 mA and 20,5 mA. This function is not operational as per the factory

default: 0. Attention: fixing output current will make settings in P10, P11, P12 and P19 irrelevant.

FACTORY DEFAULT: 0

P10: - - - - Value (of distance, level o r volume) assigned to 4 mA current output

P11: - - - - Value (of distance, level o r volume) assigned to 20 mA current output

Values are interpreted according to P01(a). Please note that in case of programming for (LEV or VOL) % measurement the min and max value has to

be entered in the relevant engineering units of LEV (m, ft) or VOL (m

3

, ft3).

Assignments can be made so that the proportion between th e change of the (measured or calculated) process value and the change of the current

output be either direct or inverse. E.g. lev 1m assigned to 4mA and lev 10m assigned to 20mA represents direct proportion and lev 1m as signed to

20mA and lev 10 m assigned to 4mA represents inverse proportion.

Level dis pl ay

X

m

[m]

DIST

LEV

Level transmission

20,5 mA

Level % display

FACTORY DEFAULT: P10: 0, P11: X

P12: - - - a Erro r indication by the curren t output

In case of error the EasyTREK will provide one of the current outputs below for the time the failure prevails.

a Error indication (according to NAMUR)

0

HOLD last value

1

2

P11

P10

0

– Xm .(See P04 and P05)

M

3,8 mA

04 20

Factory settings Factory settings

I

out

[m ]A

0100

3,6 mA

22 mA FACTORY DEFAULT: 0

LEV %

[ ]

%

scd3404a0600p_01 ♦ 21 / 36

5.4.3. RELAY OUTPUT

P13: - - - - Relay functions

a Relay functions Also to set:

0

1

DIFFERENTIAL

LEVEL CONTROL

(Hysteresis control)

If the value selected for controlling the relay

increases over P14 : relay energises

decreases below P15 : rel a y de- energises

“no ECHO” indicated by energised relay —

ERROR INDICATION

2

“no ECHO” indicated by de-energised relay —

FACTORY DEFAULT: 2

P14: … Relay parameter – Setpoint value

FACTORY DEFAULT: 0

P15: - - - - Relay parameter – Setpoint value

Level

Relay

P14

P15

Energised:

De-energised:

Keep at least 2 cm

difference between

Time

P14, P15

P14 and P15

Relay set points are to be programmed for two-point control. Values should be set in the quantity selected for transmitting in parameter P01.

Keep at least 20 mm difference between P14 and P15

FACTORY DEFAULT: 0

P19: - - - - HART short add r ess

Short address is to enter here. The 00 short address is suitable for loop with one device only, when both analogue signal and HART is able to carry

information. For other settings see instruction in the manual for the configuration software EView supplied with the unit.

FACTORY DEFAULT: P19 = 00

scd3404a0600p_01 ♦ 22 / 36

5.4.4. MEASUREMENT OPTIMALIZATION

P20: - - - a Damping

This parameter can be used for reduction of unwanted fluctuation of the displayed value and the output.

a

0

1

2

3

4

5

6

7

8

9

Damping time [s]

None For test only

3 Not recommended Not recommended

6 Not recommended Not recommended

10 Not recommended Not recommended

30 Applicable Not recommended

60 Recommended Applicable

100 Recommended Recommended

300 Recommended Recommended

600 Recommended Recommended

1000 Applicable Applicable

FACTORY DEFAULT: 7 ( 300 s )

P23: - - - a Angle of repose (repose formation)

This parameter is important for the optimalisation of the of the QUEST+ software echo evaluation.

a Estimated angle of repose

0

1

2

No angle of repose α ≅ 0

α< 15°

α > 15°

The optimal setting of this parameter can be done with the help of checking the echo strength in

the read out parameter P72 indicating the echo amplitude in dB.

The ideal setting of P23 is at which the parameter value in P72 becomes the best (nearest “0”).

FACTORY DEFAULT: 0

Granules

particle size >2-3 mm

DUST

particle size < 1-2 mm

scd3404a0600p_01 ♦ 23 / 36

P24: - - - a Target tracking speed

g

With this parameter the evaluation can be sped up at the expense of the accuracy.

a Tracking speed Remark

0

1

2

Standard For most applications

Fast For fast changing level

Special

For very special cases only, as this reduces the maximum measuring range to 50% of the nominal value! The

measuring window (P25 and P33) is inactive and the EasyTREK will respond practically instantly to any target.

FACTORY DEFAULT: 0

P25: - - - a Selection of Echo within the measuring window

A so-called measuring window is formed around the echo signal. The position of this measuring window determines the flight time for calculation of the

distance of the target. (the picture below can be seen on the test oscilloscope)

Received

signal

amplitude

Some applications involve multiple (target + disturbing) echoes even within the measuring window. Basic echo selection will be done by the Quest +

software automatically. This parameter only influences the echo selection within the measuring window.

a Echo in the window to be select ed Remarks

0

1

2

With the highest amplitude For most applications (both liquids and solids)

First one For applications with multiple echoes within the Measuring Window

Largest one Recommended for applications with floating material in the air

FACTORY DEFAULT: 0

P26: - - - - Level elevation rate (filling speed) [m/h]

FACTORY DEFAULT: 500

Echo 1.

"t" ultrasound fli

ht time

Echo 2.

t

scd3404a0600p_01 ♦ 24 / 36

P27: - - - - Lev el wane rate (emptying speed) [m/h]

Use these parameters to provide additional protection against echo loss in applications involving dust during the filling process (powders, dusting

granules). Reliability of the measurement can be enhanced by the correct setting of this parameter.

These parameters must not be smaller than the fastest possible filling/emptying rate of the actual technology.

FACTORY DEFAULT: 500

P28 - - - a Echo-loss handling

a

0

1

2

3

Echo-loss error

indication

Delayed

None During an echo-loss the displayed value on the EView and the analogue output value will hold last value.

Advance to full

Immediate

No echo-loss

4

indication in case of

empty tank/silo

FACTORY DEFAULT: 0

Remark

During short periods of echo-loss, both Eview and the analogue output will hold last value. The current output

holds last value for twice as long as set in P20 before going to the "Error Indication Mode" set in P12.

HART

Holding value

Error Code 2

Echo loss

Echo LED goes out

2 * ”P20” time

Current 22 mA P12=2

Current output

Holding value

Holding last va lue P12=0

Current 3,6 mA P12=1

When echo-loss occurs during filling, the displayed value on the EView and the analogue output value shifts

towards the "full" tank/silo state with the level elevation rate (filling speed) set in P26

In case of an echo-loss, ‘no Echo’ will appear in EView and the outputs will change according to the "Error

Indication Mode" set in P12.

Echo-loss may occur in completely empty tanks with a spherical bottom due to deflection of the ultrasonic beam, or

in case of silos with an open outlet. If the echo is lost when the tank /silo is completely empty, the indication will

correspond to empty tank, in all other cases echo-loss indication will function according to the “Delayed”.

scd3404a0600p_01 ♦ 25 / 36

P29 Blocking out of object

One object in the tank/silo disturbing measurement can be blocked out.

Enter distance of the object from the transducer. Use the Echo Map (P70) to read out the precise distance of disturbing objects.

FACTORY DEFAULT: 0

P31: Sound velocity at 20 °C (m/sec or ft/sec depending on P00(c) )

Use this parameter if the sound velocity in the gases above the measured surface differs largely from that of in air.

Recommended for applications where the gas is more or less homogeneous. If it is not, the accuracy of the measurement can be improved using the

32-point linearization (P48, P49).

For sound velocities in various gases see s ect ion “ Sound Veloc it ies ” .

FACTORY DEFAULT: Metric (P00: “EU”): 343.8 m/s, US (P00: “US”): 1128 ft/s

P32: Specific gravity

If you enter value (other than “0”) of specific gravity in this parameter, the weight will be displayed in EView instead of VOL.

FACTORY DEFAULT:

0 [kg/dm

3

] or [lb/ft3] depending on P00(c)

P33: (m) Manual echo selection by moving the Measuring Window

A so-called measuring window is formed around the echo signal (See scheme on the next page.)

The distance of the target will be calculated from the flight ti me in acco rd anc e with th e posi t ion of the

measuring window.

Use this parameter if the EasyTREK unambiguously selects a wrong echo; for example the echo

reflected from the surface is muc h weaker than the interfering one(s) (see figure beside and on next

page).

Enter the distance of the correct echo and the software will move the measuring window and

calibrate itself to the echo found there.

To determine the distance of the corr ect echo, e ither use the Echo Map (to load-in a value from the

Echo Map, see paramet er P70), or measur e the dista nce with an appropriate d evice, and enter this

value in P33.

If this parameter has been used (P33 is not 0), its value will be continuously updated with the valid echo position.

This means, that in case of a power loss, the E asyTR EK will res tart the s ignal pr ocessing with the me asuring window at t he last updated

position. To switch-off this function, set P33= 0.

FACTORY DEFAULT: 0

scd3404a0600p_01 ♦ 26 / 36

1.

2.

MANUAL ECHO SELECTION

1.

Received

signal amplitude

Window

signal (comp.)

2.

Window

signal (comp.)

Weak echo

from the surface

Eg.: 3.85 m

1. 2.

measuring window

(locked on the disturbing echo)

Setting: P33=4.00 (results in shifting the measuring window to 4 m)

Disturbing echo

Eg.: 5.2 m

(flight time)

t

Transmitt ed DIST value

(of the disturbing echo)

5.2

t

3.

Window

signal (comp.)

t

Measuring Window finds the echo from the surface

t

Transmitt ed DIST value

(the value is correct)

3.85

scd3404a0600p_01 ♦ 27 / 36

5.4.5. VOLUME MEASUREMENT

P40: - - ba Tank / silo shape

ba Tank/silo shape

B0

01

02

B3

04

P41-45: - - - - Tank / silo dim ensions

Standing cylindrical tank shape: value of “b” as below bottom

Lying cylindrical tank shape: value of “b” as bellow bottom P40(b), P41, P42

Other parameters to be

set

P40(b), P41

Standing cylindrical tank/silo with conical bottom P41, P43, P44

Standing rectangular tank/silo (with ch ute

Spherical tank

) P41, P42, P43, P44, P45

P41

FACTORY DEFAULT: 00

Standing cylindrical tank/silo

with hemispherical bottom

b=0

b=1

b=3

b=2

P40

Lying cylindrical tank Spherical tank

b=3

P40

b=2

b=1

b=0

FACTORY DEFAULT: P41 ... P45 = 0

Standing cylindrical tank/silo

with conical bottom

Standing rectangular tank/silo

with or without chute

For flat bottom

P43, P44 and

P45 = 0

scd3404a0600p_01 ♦ 28 / 36

5.4.6. LINEARIZATION

P47: - - - a Linearization

Linearization is the method of assigning requested (calibrated or calculated) level, volume or flow to values measured by the transmitter.

It can be used for instance if the sound velocity is not known (LEVEL⇒LEVEL) or in the case of tank with other shape than under 5.4 . 5. (LEVEL ⇒

VOLUME).

a Linearization

0

1

Conditions of correct programming of the data pairs

The table must always start with: L(1)= 0 and r(1)= value (assigned to 0 level)

The table must be ended either with the 32

level value “0” e.g. L(j<32)= 0.

The EasyTREK will ignore data after recognising level value “0” with serial number other than “1”.

If the above conditions are not met, error codes will be sent (see chapter: Error Codes).

OFF (FACTORY DEFAULT)

ON

nd

data pair i.e. j=32 or if the linear isation t able c ontai ns less than 3 2 data-p airs j<32, i t must b e ende d with a

i

L (Left column)

Level values measured

1 0 r(1)

2 L(2) r(2)

L(i) r(i)

nn L(nn) r(nn)

nn+1 0

32

FACTORY DEFAULT: 0

P48: Number of linearization data pairs

Number of linearization data pairs entered in the table.

r (Right column)

Value assigned to transmit

scd3404a0600p_01 ♦ 29 / 36

5.4.7. INFORMATIONAL PARAMETERS

P60: - - - - Ove r a ll operating hours of the unit (h)

P61: - - - - Time elapsed si nce last switch-on (h)

P62: - - - - Operating hours of the relay (h)

P63: - - - - Numb e r o f switching cycles of the relay (h)

P64: - - - - Actual tem p er ature of the transdu cer ( °C/°F)

Broken loop of the thermometer will be indicated by Pt Error message that is initiated by a signal sent via HART. In this case the transmitter will per for m

temperature correction corresponding to 20ºC.

P65: - - - - Maximum temperature of the transducer (°C/°F)

P66: - - - - Minim um tem p erat ure of the transducer (°C/° F )

P70: - - - - Number of Echoes / Echo Map

Amplitude and position of the echoes can also be read out.

scd3404a0600p_01 ♦ 30 / 36

P71: - - - - Distance of the of Measu ring Window

P72 - - - - Amplitude of th e selected echo [dB] <0

P73: Position of the selected echo (time) : (ms)[ms]

P74: Signal to Noise Ratio

Ratio Measurement conditions

Over 70 Excellent

Between 70 and 50 Good

Under 50 Unreliable

P75: - - - - Blocking Distance

This parameter gives information about the actual close-end blocking distance (provided automatic blocking was selected in P05)

5.4.8.

TEST PARAMETERS

P96: - - - - Checksum

P97: - - - - Software code (Read only parameter)

P98: - - - - Hardware code (Read only parameter)

P99: dcba Access lock by secret code

The purpose of this feature is to provide protection ag ainst accidental pr ogramming of par ameters or by a pers on. not entitled. The secret c ode can be

any value other than 0000. Setting a secret code will automatically be activated w hen the E asyTREK is returned to the Me asurement Mode. In or der to

program locked device the secret code should be entered first in P99. Thus for entering a new code or erasing the old one the knowledge of the

previous code is necessary.

scd3404a0600p_01 ♦ 31 / 36

5.4.9. ERROR CODES

Error

Code

1

No Echo

or

Err2

Err3

Err4

Err5

Err6

Err7

Err12

Err13

Err14

Error description Causes and actions to be done

Memory error Contact local agent

Bad reflection from the surface, reflection not directed

Echo loss or echo too weak to evaluate

towards the sensor, due to dusting excessive sound

absorption. Check device selection and/or adjustme nt

Hardware error Contact local agent

Calculation overflow Check settings

Code referring to sensor error or improper

installation/mounting, level in the dead band

Verify sensor for correct operation and check for

correct mounting according to Users Manual

The measurement is at the reliability threshold Change aiming or try to find a better location

No signal received within the measuring range

specified in P04 and P05.

Linearization table error: L(1) and L(2) are both zero

(no valid data-pairs)

Linearization table error: there are two same L(i) data in

the table

Linearization table error: the r(i) values are not

monotone increasing

Review programming, also look for installation mistake

See the Section ”Linearization”

See the Section “Linearization”

See the Section “Linearization”

Err15

Err16

scd3404a0600p_01 ♦ 32 / 36

Linearization table error: measured Level is higher than

the last Volume or Flow data-pair

See the Section “Linearization”

The checksum of the program in the EEPROM is wrong Contact HiTECH at 888 NIVELCO

6. MAINTENANCE, REPAIR

The device does not require rout ine maintenance. In case dust adheres to the face of t he sensor despite the self-cleaning of the sensor face through r esonance,

(ex.: static build-up) it can be cleaned by pressurised air.

Equipment sent back for repai r shou l d b e cl eaned o r ster il i s ed by the User. T he User mu st decl ar e that t he above has been carr ied out.

Repairs during or beyond the guarantee period are carried out by HiTECH/NIVELCO.

7. STORAGE CONDITIONS

Environmental temperature range: - 22ºF (-30) ... 140ºF (+60°C)

Relative humidity: max. 98 %

scd3404a0600p_01 ♦ 33 / 36

8. Parameter TABLE

Par. Page Description Value Par. Page Description Value

d c b a d

P00 16 Application/Engineering Units P28 25 Echo loss indication

P01 17 Measurement Mode P29 26 Blocking out of disturbing object

P02 18 Calculation units P30 –

P03 - P31 26 Sound velocity in different gases

P04 18 Maximum Measuring Distance P32 26 Specific gravity

P05 19 Minimum Measuring Distance P33 –

P06 20 Far End Blocking P34 –

P07 – P35 –

P08 – P36 –

P09 – P37 –

P10 21 Transmitted value assigned to „4 mA” P38 –

P11 21 Transmitted value assigned to „20 mA” P39 –

P12 21 “Error” indication by the current output P40 28 Selection of tank shape/ open channel

P13 – P41 28 Dimensions of tank / Open Channel

P14 – P42 28 Dimensions of tank / Open Channel

P15 – P43 28 Dimensions of tank / Open Channel

P16 – P44 28 Dimensions of tank / Open Channel

P17 – P45 28 Dimensions of tank / Open Channel

P18 – P46 Level pertaining to flow Q= 0

P19 – P47 29 Linearization

P20 23 Damping P48 29 Linearization table

P21 – P49 –

P50 –

P23 – P51 –

P24 24 Target tracking speed P52 –

P25 24 Selection of Echo in the measuring window P53 –

P26 24 Level elevation rate P54 –

P27 25 Level descent rate P55 –

c b a

scd3404a0600p_01 ♦ 34 / 36

Par.

Page Description Value

Par.

Page

Description Value

d c b a d c b a

P56 – P78 34 TOT2 volume flow totalised

P57 – P79 –

P58 – P80 –

P59 – P81 –

P60 30

P61 30

Overall operating hours of the unit

Time elapsed after last switch-on

P82 –

P83 –

P62 – P84 –

P63 – P85 –

P64 30 Actual temperature of the transducer P86 –

P65 30 Maximum temperature of the transducer P87 –

P66 30 Minimum temperature of the transducer P88 –

P67 – P89 –

P68 – P90 –

P69 – P91 –

P70 30 Echo Map P92 –

P71 31 Position of the measuring window P93 –

P72 31 Amplitude of the selected echo P94 –

P73 31 Position of the selected echo P95 –

P74 31 Signal / noise ratio P96 34 Software code 1

P75 33 Blocking distance value P97 34 Software code 2

P76 34 Water head of the flow P98 34 Hardware code

P77 34 TOT1 volume flow totalised P99 34 Access lock by secret code

scd3404a0600p_01 ♦ 35 / 36

HiTECH/NIVELCO

scd3404a0600p_01.doc

May 2006

reserves the right to change technical specifications without notice.

scd3404a0600p_01 ♦ 36 / 36

Loading...

Loading...