PROGRAMMING MANUAL

For SCA-3!!-4 models with HART

1st edition

Manufacturer:

NIVELCO Process Control Co.

H-1043 Budapest, Dugonics u. 11.

Tel.: (36-1)-369-7575 Fax: (36-1)-369-8585

E-mail:sales@nivelco.hu http://www.nivelco.hu

Basic conception and elements of the ultrasonic measurement

LEV= level (calculated: H-DIST)

VOL= volume (calculated from LEV)

DIST=distance measured

M

a

x

i

m

u

m

m

e

a

s

u

r

i

n

g

d

i

s

t

a

n

c

e

o

f

m

t

h

e

u

n

i

t

(

X

)

M

F

a

c

t

o

r

y

d

e

f

a

u

l

t

P

0

4

=

X

M

M

a

x

i

m

u

m

o

f

t

h

e

u

n

i

t

r

a

n

g

e

F

a

c

t

o

r

y

d

e

f

a

u

l

t

P

0

5

=

X

B

C

l

o

s

e

e

n

d

b

l

o

c

k

i

n

g

(

X

)

B

M

a

x

.

m

e

a

s

u

r

i

n

g

d

i

s

t

a

n

c

e

o

f

t

h

e

a

p

p

l

i

c

a

t

i

o

n

(

H

)

P

r

o

g

r

a

m

m

i

n

g

:

P

0

4

=

H

P

r

o

g

r

a

m

m

e

d

r

a

n

g

e

o

f

t

h

e

a

p

p

l

i

c

a

t

i

o

n

D

i

s

p

l

a

y

e

d

r

a

n

g

e

F

a

c

t

o

r

y

d

e

f

a

u

l

t

:

P

0

6

=

0

F

a

r

e

n

d

b

l

o

c

k

i

n

g

M

i

n

.

m

e

a

s

u

r

i

n

g

d

i

s

t

a

n

c

e

(

X

)

m

P

r

o

g

r

a

m

m

i

n

g

:

P

0

5

=

>

X

X

B

m

CONTENTS

1. PARAMETERS – DESCRIPTIONS AND PROGRAMMING..........................................................................................................2

1.1 Measurement Configuration .........................................................................................................................................................................2

1.2 Current Output ..............................................................................................................................................................................................8

1.3 Relay Output.................................................................................................................................................................................................9

1.4 Measurement Optimisation.........................................................................................................................................................................10

1.5 Volume Calculation.....................................................................................................................................................................................15

1.6 Volume Flow Measuring .............................................................................................................................................................................16

1.7 32-Point Linearisation Curve ......................................................................................................................................................................21

1.8 Service Parameters ....................................................................................................................................................................................21

1.9 Additional Parameters of Flow Metering.....................................................................................................................................................22

2. ERROR CODES ...........................................................................................................................................................................23

3. TABLE OF PARAMETERS

4. SOUND VELOCITIES IN DIFFERENT GASES ...........................................................................................................................26

2 EasyTREK Compact Ultrasonic Level Transmitters

Thank you for choosing a NIVELCO instrument.

We are sure that you will be satisfied throughout its use.

1. PARAMETERS – DESCRIPTIONS AND PROGRAMMING

1.1 Measurement Configuration

P00: - cba Application/Engineering Units

Programming of this parameter will result in loading the factory default with the corresponding

engineering units.

a Operating (measurement) mode

0 Liquid level measurement

b Engineering units (according to “c”)

Metric

ft

0 minch

1 cm inch

c Calculation system

0 Metric

1 US

FACTORY DEFAULT: 000

EasyTREK Compact Ultrasonic Level Transmitters 3

P01: - - ba Measurement Mode

Displayed value on the PC, current output and the switching points of the relays will be interpreted in the engineering units of the (measured or

calculated) process value corresponding to the programmed measurement mode. On the other hand the higher the “a” of the programmed

parameter value the more (measured or calculated) process values can be displayed on the PC by the EVIEW software. (e.g. if P01=b0 only the

Distance, if P01=b5 the Distance the Level, the Volume and the Flow can be displayed. Exception if P01=b2 or b4.)

a Measurement Mode Display symbol

0 Distance DIST

1 Level LEV

2 Level in percentage LEV%

3 Volume VOL

4 Volume in percentage VOL%

5 Flow FLOW

FACTORY DEFAULT: 11

P02: - cba Calculation units

a Temperature

0 °C

1 °F

This table is interpreted according to P00(c), P01(a) and P02(c) and is irrelevant in case of percentage measurement ( P01(a)= 2 or 4 )

b Volume Weight (set also P32) Volume flow

Metric US Metric US Metric US

0 m

3

ft

3

- lb (pound) m3/time ft3/time

1 liter gallons tons tons liter/time gallons/time

c Time

0 Sec

1 Min

2 Hour

3 Day FACTORY DEFAULT: 000

4 EasyTREK Compact Ultrasonic Level Transmitters

P03: - - - a Values Displayed-Rounding

It is important to keep in mind that the instrument is measuring distance as basic quantity.

Measured distance Resolution

X

min

– 2m

1mm

2m – 5m 2mm

5m – 10m 5mm

The resolution depending on the distance can be considered as

a kind of rounding that will be contained in all further value (of

level, volume or volume flow) calculated. Therefore if

programmed for DIST or LEV measurement the setting of P03

is irrelevant.

Displayed VOL or FLOW

Displayed value Displayed form

0.000 – 9.999 x.xxx

10.000 – 99.999 xx.xx

100.000 – 999.999 xxxx.

1000.000 – 9999.999 xxxxx.

100000.000 – 99999.999 xxxxxx.

1 million – 9.99999*10

9

x.xxxx : e

(exponential form)

over 1*10

10

(overflow) Err4

Obviously the decimal position will be shifted with increasing

value displayed. (See table at the left).

Values over one million will be displayed in exponential format

whereas the value (e) represents the exponent. Over the value

of 1x10

10

Err4 (overflow) will be displayed.

Rounding

Parameter value “a”

Steps in the displayed

value

0 1 no rounding

1 2

2 5

3 10

4 20

5 50

A couple of millimetres of fluctuation of the basic DIST value (e.g. due to waves)

will be enlarged by the mathematical operations. This enlarged fluctuation in

displaying VOL or FLOW can (if disturbing) be avoided by rounding to be set in

P03. Rounding value 2, 5, 10 etc represents the steps by which the calculated

value will be changed in its (one or two) last digit(s).

Examples:

P03=1 steps by 2: 1,000; 1,002; 1,004

P03=5 steps by 50: 1,000; 1,050; 1,100 or 10,00; 10,05(0); 10,10(0); 10,15(0)

(the 0 from the steps 50, 100, 150 etc will not be displayed)

FACTORY DEFAULT: 0

EasyTREK Compact Ultrasonic Level Transmitters 5

P04: Maximum measuring distance (H)

The maximum measuring distance is the only one parameter that has to be programmed for each application other than distance

measurement mode. The DEFAULT value of P04 see table below:

EasyTREK Maximum measuring distance (XM)

Level transmitters (m/ft)

SCA-38_ 6 / 20

SCA-36_ 10 / 33

Keep in mind that

LEVEL

(as the result of the measurement) = P04 (H value, programmed) – DISTANCE (measured by the device)

Since the accuracy of level (and all further calculated) value depends on the accuracy of the max measuring distance of the application which is

the distance between the sensor face and the tank / silo bottom.

To obtain the best accuracy for a liquid level measurement, measure this distance in the empty tank with the EasyTREK.

FACTORY DEFAULT: according to the table

6 EasyTREK Compact Ultrasonic Level Transmitters

P05: Minimum measuring distance (Close-end blocking)

The EasyTREK will not accept any echo within the

blocking distance set here.

Automatic Close-end-blocking (Automatic Dead Band control) (P05= X

m

)

By using the factory default value, the unit will automatically set the smallest possible close-end-blocking distance i.e. the dead band.

Manual close-end-blocking (P05> X

m

)

Manual close-end-blocking would be used for example to block out the echo originating from the bottom rim of a stand-off pipe or from any object

protruding into the ultrasonic cone near to the transmitter.

By entering a value, higher than the factory default, the minimum measuring range will be extended and fixed to the specified value.

EasyTREK Minimum measuring distance (dead band)

Level transmitters (m/ft)

SCA-38_ 0,25 / 0,82

SCA-36_ 0,35 / 1,2

FACTORY DEFAULT: automatic dead band control

EasyTREK Compact Ultrasonic Level Transmitters 7

P06: Far-end blocking

A). Level measurement

Far end blocking is used to neglect incorrect

level/volume readings and output actions below a preset level. In the far-end of the measuring range, for

example tanks with heaters or other interfering objects

(sludge, cone of silo etc.) may cause faulty readings.

If the level of the medium sinks below the blocked

out range:

- ”Sub 0” will be indicated for the level and volume

below 1/8 value of P06

-

- Distance value is not interpretable

- Current output will hold value corresponding to

the far end blocking level

4

m

A

m

A

2

0

m

A

P06

Far end blocking

Level

Volume

"SUB 0" indication

below this level

If the medium level is above the blocked out range:

The calculation of level and volume will be based on the programmed tank dimensions, therefore the measured or calculated process values

will not be influenced in any way, by the far end blocking value.

B). Open channel flow metering

Far end blocking will be used to neglect incorrect volume flow readings and output actions

below a pre-set level, where accurate volume flow calculation is not possible any more.

If the liquid level in the flume/weir falls below the blocked out range:

The EasyTREK will act as follows:

- Indicate ”No Flow” on the Display (Q=0)

- Hold current value corresponding to Q=0

If the level in the flume/weir is above the blocked out range:

The calculation of volume flow will be based on the programmed flume/weir data, therefore

the measurement values will not be influenced in any way, by the far end blocking value.

FACTORY DEFAULT: 0

P04

P46

h

P06

8 EasyTREK Compact Ultrasonic Level Transmitters

1.2 Current Output

P10: Value (of distance, level, volume or flow) assigned to 4 mA current output

P11: Value (of distance, level, volume or flow) assigned to 20 mA current output

Values are interpreted according to P01(a). Please note that in case of programming for (LEV or VOL) % measurement the min and max value

has to be entered in the relevant engineering units of LEV (m, ft) or VOL (m3, ft3).

Assignment can be made so that the proportion between the change of the (measured or calculated) process value and the change of the current

output be either direct or inverse. E.g. lev 1m assigned to 4mA and lev 10m assigned to 20mA represents direct proportion and lev 1m assigned

to 20mA and lev 10 m assigned to 4mA represents the inverse proportion.

FACTORY DEFAULT:

P10 (4mA); 0

P11 (20mA)

P12: - - - a Error indication by the current output

In case of error the EasyTREK will provide one of the current outputs below. (For errors and their indications see Chapter 7).

a Error indication (according to NAMUR)

0 Hold last value

1 3.6 mA

2 22 mA

FACTORY DEFAULT: 0

EasyTREK Compact Ultrasonic Level Transmitters 9

1.3 Relay Output

P13: - - - a Relay function

a Relay function Also set:

0 DIFFERENTIAL LEVEL CONTROL

(Hysteresis control)

Relay is energised if the measured or calculated

value exceeds the value set in P14

Relay is de-energised if the measured or calculated

value descends under the value set in P15

Relay

Level

P14

P15

Time

Energise d:

De-energised:

P14, P15

There is a need to set

(in level min 20mm)

hysteresis between

P14 and P15

1 Relay is energised in case of Echo Loss -

2 Relay is de-energised in case of Echo Loss -

3 COUNTER

Used for open channel flow metering.

A 140 msec pulse is generated every 1, 10, 100,

1.000 or 10.000 m

3

according to P16.

P16= 0: 1m

3

P16= 1: 10 m

3

P16= 2: 100 m

3

P16= 3: 1.000 m

3

P16= 4: 10.000 m

3

FACTORY DEFAULT: 2

P14: … Relay parameter – Setpoint value

P15: … Relay parameter – Setpoint value

P16: … Relay parameter – Pulse rate see P13(3)

FACTORY DEFAULT: P14=0, P15=0, P16=0

10 EasyTREK Compact Ultrasonic Level Transmitters

1.4 Measurement Optimisation

P20: - - - a Damping

Use this parameter to reduce unwanted fluctuation of the display and output.

LIQUIDSa Damping

time

(seconds)

None/moderate

fume or waves

Heavy/dense fume or

turbulent waves

0 no filter Recommended for testing only

1 3 applicable not recommended

2 6 recommended applicable

3 10 recommended recommended

4 30 recommended recommended

5 60 recommended recommended

6 100 applicable applicable

7 300 applicable applicable

8 600 not applicable not applicable

9 1000 not applicable not applicable

FACTORY DEFAULT: 60 sec

P22: - - - a Dome top tank compensation

To reduce disturbing effect of possible multiple echos.

a Compensation Applied

0 OFF In case the EasyTREK is mounted not in the centre of the top and the top is flat.

1 ON In case the EasyTREK is mounted in the centre of a tank with dome-shaped top

FACTORY DEFAULT: 0

EasyTREK Compact Ultrasonic Level Transmitters 11

P23: - - - a Angle of repose (repose formation) Will not be used

P24: - - - a Target tracking speed

a Tracking speed Remark

0 Standard For most applications

1 Fast For fast changing level

2 Special Only for special applications

(measuring range is reduced to 50% of the nominal value)

The measuring window (P25) is inactive and the EasyTREK will respond practically instantly to any

target. Recommended to fast target tracking, but usually not applicable for level metering.

FACTORY DEFAULT: 0

P25: - - - a Selection of Echo within the measuring window

A so-called measuring window is formed around the echo signal. The position of this measuring window determines the flight time for calculation

of the distance of the target. (the picture below can be seen on the test oscilloscope)

Received

signal

amplitude

Echo 1.

t

"t" ultrasound flight time

Echo 2.

Some applications involve multiple (target + disturbing) echoes even within the measuring window. Basic echo selection will be done by the

Quest + software automatically. This parameter only influences the echo selection within the measuring window.

a Echo in the window to be selected Remark

0 With the highest amplitude For most applications (both with liquids)

1 First one For liquids applications with multiple echoes within the Measuring Window

2 Largest one Recommended if multiple echoes within the Measuring Window

FACTORY DEFAULT: 0

12 EasyTREK Compact Ultrasonic Level Transmitters

P26: (m/h) Level elevation rate (filling speed)

P27: (m/h) Level descent rate (emptying speed)

Use these parameters to provide additional protection against echo loss in applications with very heavy fuming.

These parameters must not be smaller than the fastest possible filling/emptying rate of the actual technology.

For all other applications, use the factory default setting.

FACTORY DEFAULT: 2000

EasyTREK Compact Ultrasonic Level Transmitters 13

P28 - - - a Echo-loss handling

a Echo-loss error

indication

Remark

0 Delayed During echo-loss, display and analogue output will hold last value.

If the echo-loss prevails for 10 sec plus the time period set in P20 (damping time), the reading on

the display will change to "no Echo" and the outputs will change according to the "Error Indication

Mode" preset in P12.

1 None For the time of echo-loss, display and analogue output will hold last value.

2 Advance to full During echo-loss in case of filling, the reading on the display and analogue output will shift towards

the "full" tank/silo state with a level elevation rate (filling speed) preset in P26

3 Immediate In case of echo-loss, the display will immediately change to “no Echo” and the outputs will change

according to the "Error Indication Mode" preset in P12.

4 No echo-loss indication in

case of empty tank/silo

Echo-loss may occur in completely empty tanks with a spherical bottom due to deflection of the

ultrasonic beam, or in case of silos with an open outlet.

If the echo is lost when the tank/silo is completely empty, the indication will correspond to empty

tank, in all other cases echo-loss indication will function according to the “Delayed”.

FACTORY DEFAULT: 0

P29 Blocking out of object #1

One fix object in the tank/silo that disturb the measurement can be blocked out.

Enter the distance of the object from the transducer. Use the Echo Map to read out the precise distance of disturbing objects.

FACTORY DEFAULT: 0

14 EasyTREK Compact Ultrasonic Level Transmitters

P31: Sound velocity at 20°C (m/sec or ft/sec depending on P00(c) )

Use this parameter if the sound velocity in the gases above the measured surface differs largely from that of in air.

Recommended for applications where the gas is more or less homogeneous. If it is not, the accuracy of the measurement can be improved using

the 32-point linearisation (P48, P49).

For sound velocities in various gases see section “Sound Velocities”.

FACTORY DEFAULT: Metric (P00: “EU”): 343.8 m/s, US (P00: “US”): 1128 ft/s

P32: Specific gravity

If you enter value (other than “0”) of specific gravity in this parameter, the weight will be displayed instead of VOL.

FACTORY DEFAULT: 0 [kg/dm3] or [lb/ft3] depending on P00(c)

EasyTREK Compact Ultrasonic Level Transmitters 15

1.5 Volume Calculation

P40: - - ba Tank/silo shape

ba Tank/silo shape Also to be set

b0 Standing cylindrical tank shape: value of “b” as below bottom P40(b), P41

01 Standing cylindrical tank/silo with conical bottom P41, P43, P44

02 Standing rectangular tank/silo (with chute) P41, P42, (P43, P44, P45)

b3 Lying cylindrical tank shape: value of “b” as bellow bottom P40(b), P41, P42

04 Spherical tank P41

FACTORY DEFAULT: 00

P41-45: Tank/silo dimensions

Standing cylindrical tank/silo

with hemispherical bottom

Standing cylindrical tank/silo

with conical bottom

Standing rectangular tank/silo

with or without chute

b=0

P40

b=1

b=2

b=3

If no chute

P43, P44 and P45=0

Lying cylindrical tank Spherical tank

b=0

b=1

b=2

b=3

P40

16 EasyTREK Compact Ultrasonic Level Transmitters

1.6 Volume Flow Measuring

P40: - - ba Appliances, formula, data

ba Appliances, formula, data Also to be set:

Type Calculation formula Qmin [l/s] Qmax [l/s] “P” [cm]

00 GPA-1P1 Q[l/s]= 60.87*h

1.552

0.26 5.38 30 P46

01 GPA-1P2 Q[l/s]= 119.7*h

1.553

0.52 13.3 34 P46

02 GPA-1P3 Q[l/s]= 178.4*h

1.555

0.78 49 39 P46

03 GPA-1P4 Q[l/s]= 353.9*h

1.558

1.52 164 53 P46

04 GPA-1P5 Q[l/s]= 521.4*h

1.558

2.25 360 75 P46

05 GPA-1P6 Q[l/s]= 674.6*h

1.556

2.91 570 120 P46

06 GPA-1P7 Q[l/s]= 1014.9*h

1.556

4.4 890 130 P46

07 GPA-1P8 Q[l/s]= 1368*h

1.5638

5.8 1208 135 P46

08

Nivelco Parshall flume

GPA-1P9 Q[l/s]= 2080.5*h

1.5689

8.7 1850 150 P46

09 General PARSHALL flume P46, P42

10 PALMER-BOWLUS (D/2) P46, P41

11 PALMER-BOWLUS (D/3) P46, P41

12 PALMER-BOWLUS (Rectangular) P46, P41, P42

13 Khafagi Venturi P46, P42

14 Bottom-step weir P46, P42

15 Suppressed rectangular or BAZIN weir P46, P41, P42

16 Trapezoidal weir P46, P41, P42

17 Special trapezoidal (4:1) weir P46, P42

18 V-notch weir P46, P42

19 THOMSON (90°-notch) weir P46

20 Circular weir P46, P41

21 General flow formula: Q[l/s]= 1000*P41*h

P42

, h [m] P46, P41, P42

EasyTREK Compact Ultrasonic Level Transmitters 17

P41-45: Flume/weir dimensions

See next pages.

FACTORY DEFAULT: 0

P46: Distance between transducer face and level of Q=0

P46 is always the distance between the transducer face and the level, where the volume flow is 0.

FACTORY DEFAULT:

0

Flume / Weir Dimensions

P40= 00

.

.

.

08

Nivelco Parshall flumes (GPA1P1 … GPA-1P9)

For further details see the Manual of the Parshall flume

Sensor

P46

Sensor

P40= 09 General Parshall flume

0.305 < P42(width) <2.44

0.026

Q[m3/s]= 0.372*P42*(h/0.305)

1.569*s

2.5 < P42

Q[m

3

/s]= K*P42*h

1.6

P= 2/3*A

A

h

P46

Sensor

Sensor

P42

P

s[m] K

3.05 2.450

4.57 2.400

6.10 2.370

7.62 2.350

9.14 2.340

15.24 2.320

18 EasyTREK Compact Ultrasonic Level Transmitters

P40= 10 Palmer-Bowlus (D/2) flume

Q[m3/s]= f(h1/P41)*P41

2.5

,

where h1[m]= h+(P41/10)

P04

P46

h

P41

D

D/10

P40= 11 Palmer-Bowlus (D/3) flume

Q[m3/s]= f(h1/P41)*P41

2.5

,

where h1[m]= h+(P41/10)

P04

P46

h

P41

D

D/10

P40= 12 Palmer-Bowlus (Rectangular) flume

Q[m3/s]= C*P42*h

1.5

,

where C= f(P41/P42)

D

P42

P46

P04

h

D/10

P41

EasyTREK Compact Ultrasonic Level Transmitters 19

P40= 13 Khafagi Venturi flume

Q[m3/s]= P42*1.744*h

1.5

+ 0.091*h

2.5

15cm

P46

Sensor

h

P42

Sensor

P40= 14 Bottom step weir

0.0005 < Q[m3/s] < 1

0.3 < P42[m] < 15

0.1 < h[m] < 10

Q[m

3

/s]= 5.073*P42*h

1.5

Accuracy: ±10%

P46

P42

h

P40= 15 Suppressed rectangular or BAZIN weir

0.001 < Q[m3/s] < 5

0.15 < P41[m] < 0.8

0.15 < P42[m] < 3

0.015 < h[m] < 0.8

Q[m

3

/s]= 1.7599*[1+(0.1534/P41)]*P42*(h+0.001)

1.5

Accuracy: ±1%

P04

P46

h

P42

P41

P40= 16 Trapezoidal weir

0.0032 < Q[m3/s] < 82

20 < P41[°] < 100

0.5 < P42[m] < 15

0.1 < h[m] < 2

Q[m

3

/s]= 1.772*P42*h

1.5

+1.320*tg(P41/2)*h

2.47

Accuracy: ±5%

P04

P46

h

P42

P41

20 EasyTREK Compact Ultrasonic Level Transmitters

P40= 17 Special Trapezoidal (4:1) weir

0.0018 < Q[m3/s] < 50

0.3 < P42[m] < 10

0.1 < h[m] < 2

Q[m

3

/s]= 1.866*P42*h

1.5

Accuracy: ±3%

1

4

P46

P04

h

P42

P40= 18 V-notch weir

0.0002 < Q[m3/s] < 1

20 < P42[°] < 100

0.05 < h[m] < 1

Q[m

3

/s]= 1.320*tg(P42/2)*h

2.47

Accuracy: ±3%

h

P46

P42

P04

P40= 19 THOMSON (90°-notch) weir

0.0002 < Q[m3/s] < 1

0.05 < h[m] < 1

Q[m3/s]= 1.320*h

2.47

Accuracy: ±3%

P46

P04

h

90

P40= 20 Circular weir

0.0003 < Q[m3/s] < 25

0.02 < h[m] < 2

Q[m

3

/s]= m*b*D

2.5

m= 0.555+0.418h/P41+(P41/(0.11*h))

Accuracy:

±5%

P46

P04

h

P41

P46: - - - - Distance between transducer face and level of Q=0

P46 is the distance between the transducer face and the liquid at which the flow starts (Q=0). (See figures)

During setting of P46 should be P06=0

FACTORY DEFAULT:

0

EasyTREK Compact Ultrasonic Level Transmitters 21

1.7 32-Point Linearisation Curve

P47: - - - a Linearisation

Linearisation is the method of assigning requested (calibrated or calculated) level, volume or flow to values measured by the transmitter.

It can be used for instance if the sound velocity is not known (LEVEL⇒LEVEL) or in the case of vertical cylindrical tank (LEVEL ⇒ VOLUME)

etc.

a Linearisation

0 OFF (FACTORY DEFAULT)

1 ON

1.8 Service Parameters

P60: (h) Overall operating hours of the unit

Indication varies according to the elapsed time:

Operating hours Indication form

0 to 999.9h xxx,x

1000 to 9999h xxxx

Over 9999h

X,xx: e meaning x,xx 10

e

P61: (h) Time elapsed after last switch-on

P62: (h) Operating hours of the relay

P63: Number of switching cycle of the relay

Indication same as in P60.

P64: (°C/°F) Actual temperature of the transducer

P65: (°C/°F) Maximum temperature of the transducer

P66: (°C/°F) Minimum temperature of the transducer

In case of a breaking in the temperature measuring Pt10 element „PtErr” will be displayed (See Chapter 7). The transmitter will perform

temperature correction corresponding to 20ºC.

22 EasyTREK Compact Ultrasonic Level Transmitters

P71: Distance of the of Measuring Window (read-out parameter)

P72 Amplitude of the Echo in the Measuring (read-out parameter)

P73:(msec) Echo Position (time) (read out parameter)

P74: Signal To Noise Ratio (read out parameter)

Ratio Measurement conditions

Over 70 Excellent

Between 70 and 30 Good

Under 30 Unreliable

P75: Blocking Distance

The actual close-end blocking distance is displayed. Provides useful information if automatic blocking was selected in P05.

1.9 Additional Parameter, of Open Channel Flow Metering

P76: (LEV) Head of flow

The Headwater value can be checked here. This is the “h” value in the formula for flow calculation.

P77: TOT1 volume flow totaliser (resetable)

P78: TOT2 volume flow totaliser (non-resetable)

EasyTREK Compact Ultrasonic Level Transmitters 23

2. ERROR CODES

Error

Code

Error description Causes and actions to be done

1 Memory error Contact local agent

No Echo

or

2

Echo loss No echo received (no reflection)

3 Hardware error Contact local agent

4 Overflow Check settings

5

Code referring to sensor error or improper

installation/mounting, level in the dead band

Verify sensor for correct operation and check for

correct mounting according to Users Manual

6 The measurement is at the reliability threshold Try to find a better location

7

No signal received within the measuring range

specified in P04 and P05.

Review programming, also look for installation

mistake

12

Linearisation table error: L(1) and L(2) are both zero

(no valid data-pairs)

See the Section ”Linearisation”

13

Linearisation table error: there are two same L(i) data in

the table

See the Section “Linearisation”

14 Linearisation table error: the r(i) values are not

monotone increasing

See the Section “Linearisation”

15 Linearisation table error: measured Level is higher than

the last Volume or Flow data-pair

See the Section “Linearisation”

16 The checksum of the program in the EEPROM is wrong Contact local agent

PtErr Break in the temperature sensor circuit Contact local agent

24 EasyTREK Compact Ultrasonic Level Transmitters

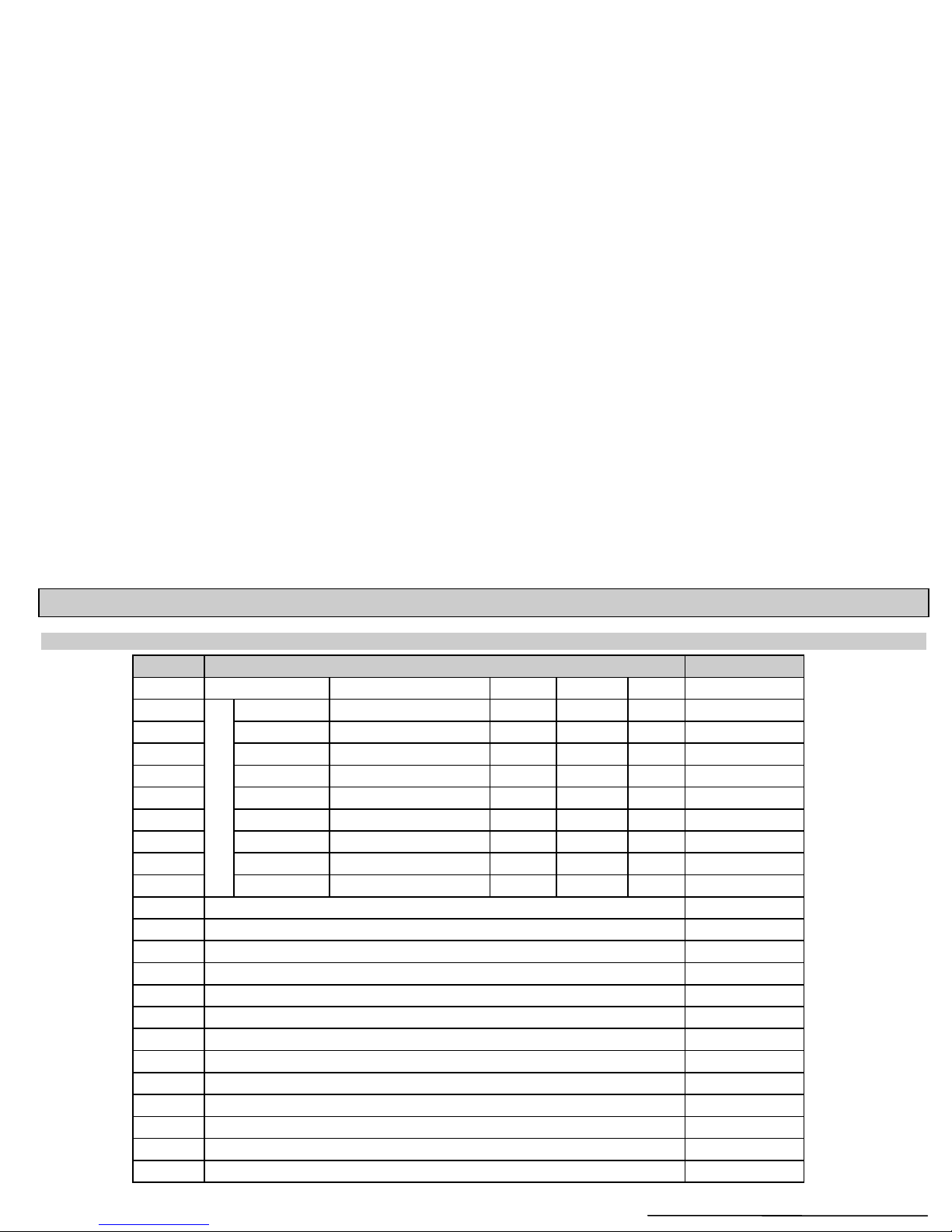

3. TABLE OF PARAMETERS

Par. Page Description Code Par. Page Description Code

dcba dcba

P00 2 Application/Engineering Units P28 13 Echo-loss handling

P01 3 Measurement Mode P29 13 Blocking sout of object #1

P02 4 Calculation units P30 - N.A.

P03 4 Values Displayed-Rounding P31 14

Sound velocity at 20°C

P04 5 Maximum measuring distance P32 14 Specific gravity

P05 6 Minimum measuring dist. (Close-end blocking) P33 -N.A.

P06 7 Far-end blocking P34 - N.A.

P07 - N.A. P35 - N.A.

P08 -N.A. P36 -N.A.

P09 - N.A. P37 - N.A.

P10 8 Value assigned to 4 mA current output P38 - N.A.

P11 8 Value to 20 mA current output P39 -N.A.

P12 8 Error indication by the current output P40 15 Tank/silo shape / Appliances, formula, data

P13 9 Relay function P41 15 Tank/silo dimensions / Flume/weir dimensions

P14 9 Relay parameter – Setpoint value P42 15 Tank/silo dimensions / Flume/weir dimensions

P15 9 Relay parameter – Setpoint value P43 15 Tank/silo dimensions / Flume/weir dimensions

P16 9 Relay parameter – Pulse rate P44 15 Tank/silo dimensions / Flume/weir dimensions

P17 - N.A. P45 15 Tank/silo dimensions / Flume/weir dimensions

P18 - N.A. P46 17 Dist. btw. transducer face and level of Q=0

P19 -N.A. P4721 Linearisation

P20 10 Damping P48 - N.A.

P21 - N.A. P49 - N.A.

P22 10 Dome top tank compensation P50 -N.A.

P23 - N.A. P51 - N.A.

P24 11 Target tracking speed P52 - N.A.

P25 11 Selection of Echo in the measuring window P53 -N.A.

P26 12 Level elevation rate (filling speed) P54 - N.A.

P27 12 Level elevation rate (emptying speed) P55 - N.A.

EasyTREK Compact Ultrasonic Level Transmitters 25

Par. Page Description Code Par. Page Description Code

dcba dcba

P56 -N.A. P7822 TOT2 volume flow totaliser (non-resetable)

P57 - N.A. P79 - N.A.

P58 -N.A. P80 -N.A.

P59 - N.A. P81 - N.A.

P60 21 Overall operating hours of the unit P82 - N.A.

P61 21 Time elapsed after last switch-on P83 -N.A.

P62 21 Operating hours of the relay P84 - N.A.

P63 21 Number of switching cycle of the relay P85 - N.A.

P64 21 Actual temperature of the transducer P86 -N.A.

P65 21 Maximum temperature of the transducer P87 - N.A.

P66 21 Minimum temperature of the transducer P88 - N.A.

P67 -N.A. P89 -N.A.

P68 - N.A. P90 - N.A.

P69 - N.A. P91 - N.A.

P70 -N.A. P92 -N.A.

P71 22

Distance of the of Measuring Window

P93

- N.A.

P72 22

Amplitude of the Echo in the Measuring window

P94

- N.A.

P73 22

Echo Position (time) (read out parameter)

P95

- N.A.

P74 22

Signal To Noise Ratio (read out parameter)

P96

- N.A.

P75 22 Blocking Distance P97 - N.A.

P76 22 Head of flow P98 - N.A.

P77 22

TOT1 volume flow totaliser (resetable)

P99

- N.A.

26 EasyTREK Compact Ultrasonic Level Transmitters

4. SOUND VELOCITIES IN DIFFERENT GASES

The following table contains the sound velocity of various gases measured on 20°C.

Gases Sound Velocity (m/s)

Acetaldehyde

C

2H4

O

252.8

Acetylene

C

2H2

340.8

Ammonia

NH

3

429.9

Argon Ar 319.1

Bensol

C

6H6

183.4

Carbon dioxide

CO

2

268.3

Carbon monoxide CO 349.2

Carbon tetrachloride

CCl

4

150.2

Chlorine

Cl

2

212.7

Dimethyl ether

CH

3

OCH

3

213.4

Ethane

C

2H6

327.4

Ethanol

C

2H3

OH

267.3

Ethylene

C

2H4

329.4

Helium He 994.5

Hydrogen sulphide

H

2

S

321.1

Methane

CH

4

445.5

Methanol

CH

3

OH

347

Neon Ne 449.6

Nitrogen

N

2

349.1

Nitrogen monoxide NO 346

Oxygen

O

2

328.6

Propane N.A.

C3H

8

246.5

Sulphur hexafluoride

SF

6

137.8

July, 2001

sca3802a0600p_01

Loading...

Loading...