BKI 11 ATEX 0012 X le00100a0600p_05 1 / 60

AnaCONT

Manufacturer

Phone (36-1) (36-1)

E-mail: sales@nivelco.com www.nivelco.com

:

H-1043 Budapest, Dugonics u. 11.

: 889-0100 Fax: 889-0200

NIVELCO Process Control Co.

LE-100

LP-100

LG-100

Two-wire compact analytical transmitters

2 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

pH- and ORP- Dissolved oxygen

sensors and transmitters (compact type)

pH- and ORP- Dissolved oxygen

sensors and transmitters (integrated type)

BKI 11 ATEX 0012 X le00100a0600p_05 3 / 60

TABLE OF CONTENTS

1. INTRODUCTION.............................................................................................................................................................................................................................. 5

1.1. APPLICATION ............................................................................................................................................................................................................................ 5

1.2. OPERATION PRINCIPLE............................................................................................................................................................................................................... 5

1.2.1. Characteristics of an ideal pH electrode .......................................................................................................................................................................................................... 5

1.2.2. Characteristics of an ideal ORP electrode....................................................................................................................................................................................................... 6

1.2.3. Characteristics of an ideal DO sensor ............................................................................................................................................................................................................. 6

2. ORDER CODES............................................................................................................................................................................................................................... 7

2.1. CONFIGURATIONS.................................................................................................................................................................................................................... 11

3. TECHNICAL DATA........................................................................................................................................................................................................................ 16

3.1. TECHNICAL DATA OF THE PH ELECTRODES (INCLUDING EX VERSIONS) FOR LP-- INSTRUMENTS ................................................................................. 18

3.2. TECHNICAL DATA OF THE ORP ELECTRODES (INCLUDING EX VERSIONS) FOR LR-- INSTRUMENTS............................................................................. 20

3.3. TECHNICAL DATA OF THE DO SENSORS (INCLUDING EX VERSIONS) FOR LD-- INSTRUMENTS ..................................................................................... 22

3.4. ACCESSORIES......................................................................................................................................................................................................................... 22

4. MAINTENANCE AND REAPAIR................................................................................................................................................................................................... 23

4.1. STORAGE ............................................................................................................................................................................................................................... 23

4.2. PERIODIC SETTING, CALIBRATION AND VERIFICATION .................................................................................................................................................................. 23

4.2.1. Periodic calibration of the pH electrode ......................................................................................................................................................................................................... 24

4.2.2. Verification of the ORP electrode .................................................................................................................................................................................................................. 25

4.2.3. Periodic calibration of the DO sensor ............................................................................................................................................................................................................ 25

4.3. MAINTENANCE OF THE PH AND ORP ELECTRODES .................................................................................................................................................................... 27

4.4. MAINTENANCE OF THE DO SENSOR .......................................................................................................................................................................................... 29

4.5. SOFTWARE UPDATE................................................................................................................................................................................................................. 29

5. INSTALLATION............................................................................................................................................................................................................................. 30

5.1. MOUNTING.............................................................................................................................................................................................................................. 30

5.1.1. Installation of pH and ORP electrodes........................................................................................................................................................................................................... 30

5.1.2. Installation of DO sensor ............................................................................................................................................................................................................................... 31

5.1.3. Special application possibilities of the Integrated type instruments............................................................................................................................................................... 33

5.2. WIRING................................................................................................................................................................................................................................... 34

5.2.1. Wiring of Compact instruments...................................................................................................................................................................................................................... 34

5.2.2. Wiring of Integrated instruments.................................................................................................................................................................................................................... 35

5.3. LOOP CURRENT CHECKING WITH HAND INSTRUMENT.................................................................................................................................................................. 35

5.4. CONDITIONS OF EX APPLICATION .............................................................................................................................................................................................. 35

4 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

6. PROGRAMMING ........................................................................................................................................................................................................................... 36

6.1. THE SAP-300 DISPLAY UNIT.................................................................................................................................................................................................... 36

6.2. MEASURING WITH THE SAP-300 DISPLAY UNIT.......................................................................................................................................................................... 37

6.3. PROGRAMMING WITH THE SAP-300 DISPLAY MODULE ............................................................................................................................................................... 40

6.3.1. Components of the programming interface ....................................................................................................................................................................................................40

6.3.2. Menu structure................................................................................................................................................................................................................................................41

6.4. PROGRAMMABLE FEATURES DESCRIPTION................................................................................................................................................................................. 42

6.4.1. Basic measurement settings ..........................................................................................................................................................................................................................42

6.4.2. Analogue output .............................................................................................................................................................................................................................................44

6.4.3. Relay output ...................................................................................................................................................................................................................................................45

6.4.4. Digital output...................................................................................................................................................................................................................................................47

6.4.5. Service functions ............................................................................................................................................................................................................................................47

6.5. PH SENSOR CALIBRATION........................................................................................................................................................................................................ 53

6.5.1. Editing one item of the calibration table..........................................................................................................................................................................................................53

6.5.2. Adding an item to the calibration table ...........................................................................................................................................................................................................55

6.5.3. Deleting an element of the calibration table ...................................................................................................................................................................................................55

6.5.4. Reset the calibration table to default ..............................................................................................................................................................................................................55

6.5.5. Calibration procedure .....................................................................................................................................................................................................................................55

6.6. DO SENSOR CALIBRATION....................................................................................................................................................................................................... 56

6.6.1. Calibration of saturated value (100%) ............................................................................................................................................................................................................56

6.6.2. Calibration of Zero point (0%).........................................................................................................................................................................................................................57

6.6.3. Calibration with referential DO instrument......................................................................................................................................................................................................57

6.6.4. Reset the calibration table to default ..............................................................................................................................................................................................................57

6.6.5. Reset Timer....................................................................................................................................................................................................................................................57

6.7. ERROR CODES ........................................................................................................................................................................................................................ 58

BKI 11 ATEX 0012 X le00100a0600p_05 5 / 60

Thank you for choosing a NIVELCO instrument.

We are sure that you will be satisfied throughout its use!

1. INTRODUCTION

1.1. APPLICATION

The AnaCONT compact transmitters, liquid analytical instruments are suitable for high precision measurement and transmission of acidity or alkalinity - pH

(Hydrogen ion concentration) value -, reducing and oxidizing capability - ORP (Oxidation Reduction Potential) value -, or Dissolved Oxygen content of process

water, wastewater, surface water, ground water and drinking water. These measurements can be widely used in industrial practice and could be of great

relevance. In the field of environmental protection or sewage treatment, instruments like that are suitable for measuring the concentration of hazardous

substances (chromium, cyanide). In chemical- and pharmaceutical industry, high precision measurement has utmost importance in the aspect of the technology

(e.g. solvent feed), in many cases it is quality specification standard.

1.2. OPERATION PRINCIPLE

The intelligent signal processing of the electronics calculates the output signal from the voltage output values of the

electrode and the temperature probe, and compensates it to 25°C. This value composes the basis of all output

signals of the instrument.

1.2.1. Characteristics of an ideal pH electrode

he pH electrode immersed into the measured liquid measures a voltage value which is proportional to the hydrogen

ion concentration of the liquid.

0mV output at neutral pH value (pH=7.00)

Positive voltage output in acidic liquids (pH<7)

Negative voltage output in alkaline liquids (pH>7)

Total measuring range is 0-14pH

-59.16mV/pH (Nernst potential) slope at 25 °C

The temperature dependency of the Nernst potential is -0.001984 mV / °C.

600

500

400

300

200

100

0

100

200

300

400

500

600

100° C (74.04 mV/pH)

25° C (59.16 mV/pH)

0° C (54.20 mV/pH)

2 4 6 8 10 12 14

1 3 5 7 9 1 1 13

Because the pH electrodes in deed are not ideal (their properties depend on the design of the electrode, manufacturing tolerances and most of all the age of the

electrode) the parameters differ from the given values above. To achieve reliable pH measurement and accuracy these electrodes must be calibrated from time

to time. The time interval between two calibrations depends on the application conditions where the pH probes are used. Calibration of pH electrodes means

offsetting the displayed value (7.00pH) when gauging neutral buffer solution, and adjusting the slope (pH/mV) by measuring buffer solutions with other pH value

(usually with 4.00pH and 10.00pH value) by adjusting the displayed value to exact 4.00 and 10.00pH, respectively.

6 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

1.2.2. Characteristics of an ideal ORP electrode

Negative voltage output in liquids with reduction potential,

Positive voltage output in liquids with oxidation potential,

Output voltage is equal to the redox potential (according to the Nernst equation)

pH independent measurement with certain types

To achieve reliable measurement and accuracy, these electrodes have to be thoroughly checked before

installation and during usage from time to time. The time interval between two calibrations depends on the

application and conditions where the ORP probes are used.

1.2.3. Characteristics of an ideal DO sensor

The dissolved oxygen level indicates the amount (in mg/l or ppm) of physically dissolved gas-form oxygen in

liquid phase.

Oxygen-permeable membrane amperometric DC sensor wetted in the measurement medium gives output

urrent proportional to the dissolved oxygen concentration of the medium.

i

air

i

zero

O

utp

ut c

u

rre

n

t

of the DO sensor

Dissolved oxygen (DO), ppm

sat´n0

Slope =

/ppm oxygen

Output current of the

DO sensor

The ideal DO sensor has:

I

zero=0,

Temperature independent output current

Real DO sensor gives off a minimal I

zero

≠0ppm current in case of 0 ppm dissolved oxygen concentration and its oxygen-permeable capability is temperaturedependent. Oxygen-permeable capability of the membrane is increasing according to the increase of the temperature, at 25 °C it can be 4%/°C. Temperature

proportional correction is necessary for reliable measurement.

The DO sensors in deed are not ideal (their properties depend on the design of the electrode, manufacturing tolerances and most of all the age of the electrode),

so the parameters differ from the given values above. To give reliable DO measurement and accuracy these electrodes must be calibrated from time to time. In

case of DO sensors the calibration means that 0 ppm output value have to be set by offsetting in an oxygen-free solution. For DO measurement of other

mediums (for example dry air 20.95%@25°C or oxygen-saturated water) adjustment of slope (nA/ppm) has to done accurately according to the properties of

these mediums.

BKI 11 ATEX 0012 X le00100a0600p_05 7 / 60

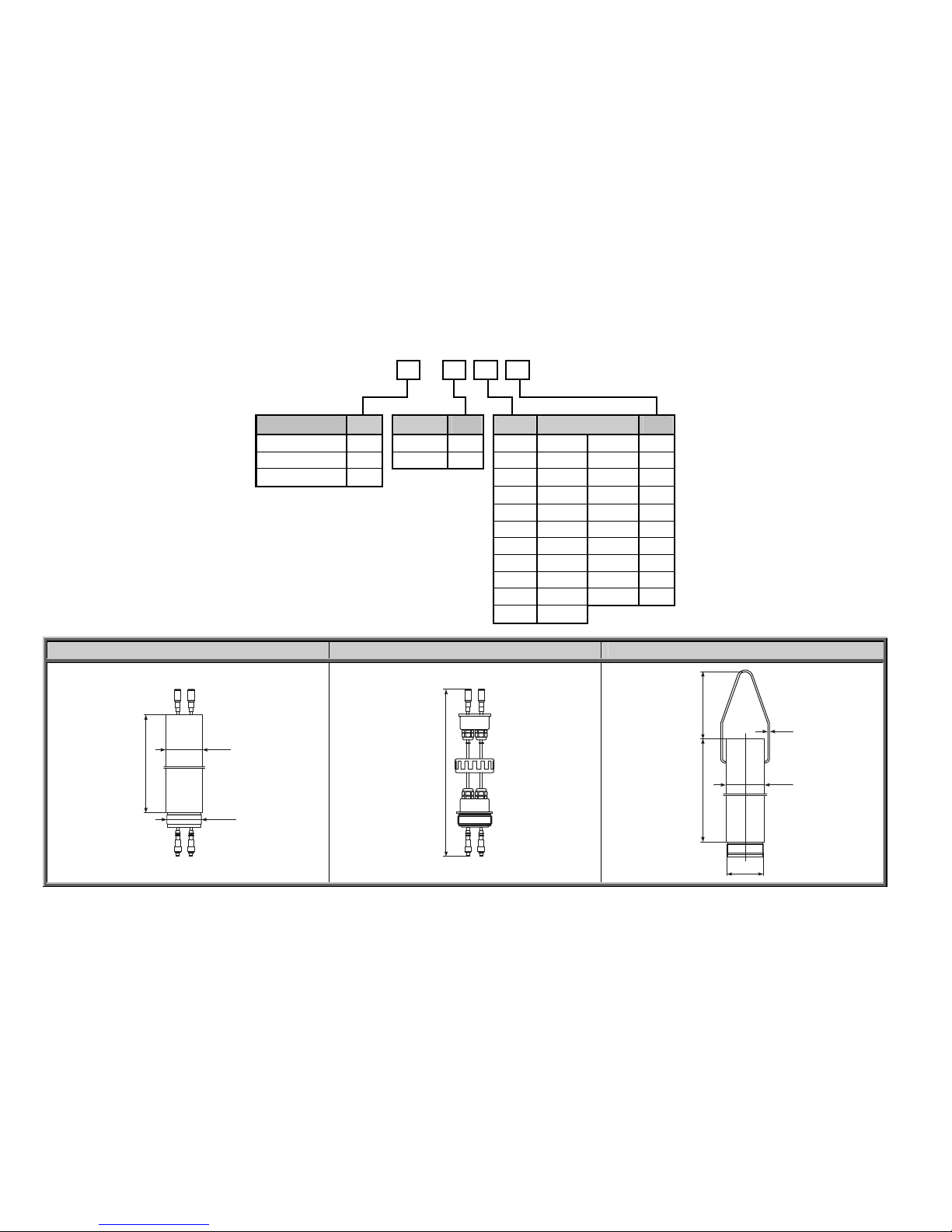

2. ORDER CODES

Not all combinations possible!

AnaCONT instruments:

AnaCONT L - -

*

TYPE CODE FUNCTION CODE HOUSING CODE PROBE**

PROC. CONN. /

MATERIAL

CODE OUTPUT CODE

Transmitter E pH P Plastic 1

BSP 1½ “ / PP 1 4 … 20 mA 2

Transmitter +

display

G ORP R Aluminium 2

BSP 1½ “ / PVDF 2 4 … 20 mA / HART 4

Integrated P DO D

NPT 1½ “ / PP 4 4 … 20 mA / Ex 6

NPT 1½ “ / PVDF 5 4 … 20 mA / HART / Ex 8

4 … 20 mA / Relay R

4 … 20 mA / HART / Realy H

PH PROBE CODE ORP PROBE CODE DO PROBE CODE

4xpher112seph 1

4xorrherpseor 1 4x085g0023ydo

/ 20ppm

1

4xphed112seph 2

4xorrhexpseor 2 4x085g0022ydo

/ 10ppm

2

4xphex112seph 3

4xorrheptseor 3

4xpheph314sph 4

4xorrhespseor 4

4xphe1120seph 5

4xorrheppseor 5

4xphes112seph 6

4xorrheklseor 6

4xphep112seph 7

4xphekl112seph 8

* The order code of an Ex version should end in “Ex”!

** Probe selection is detailed in 3rd chapter.

8 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

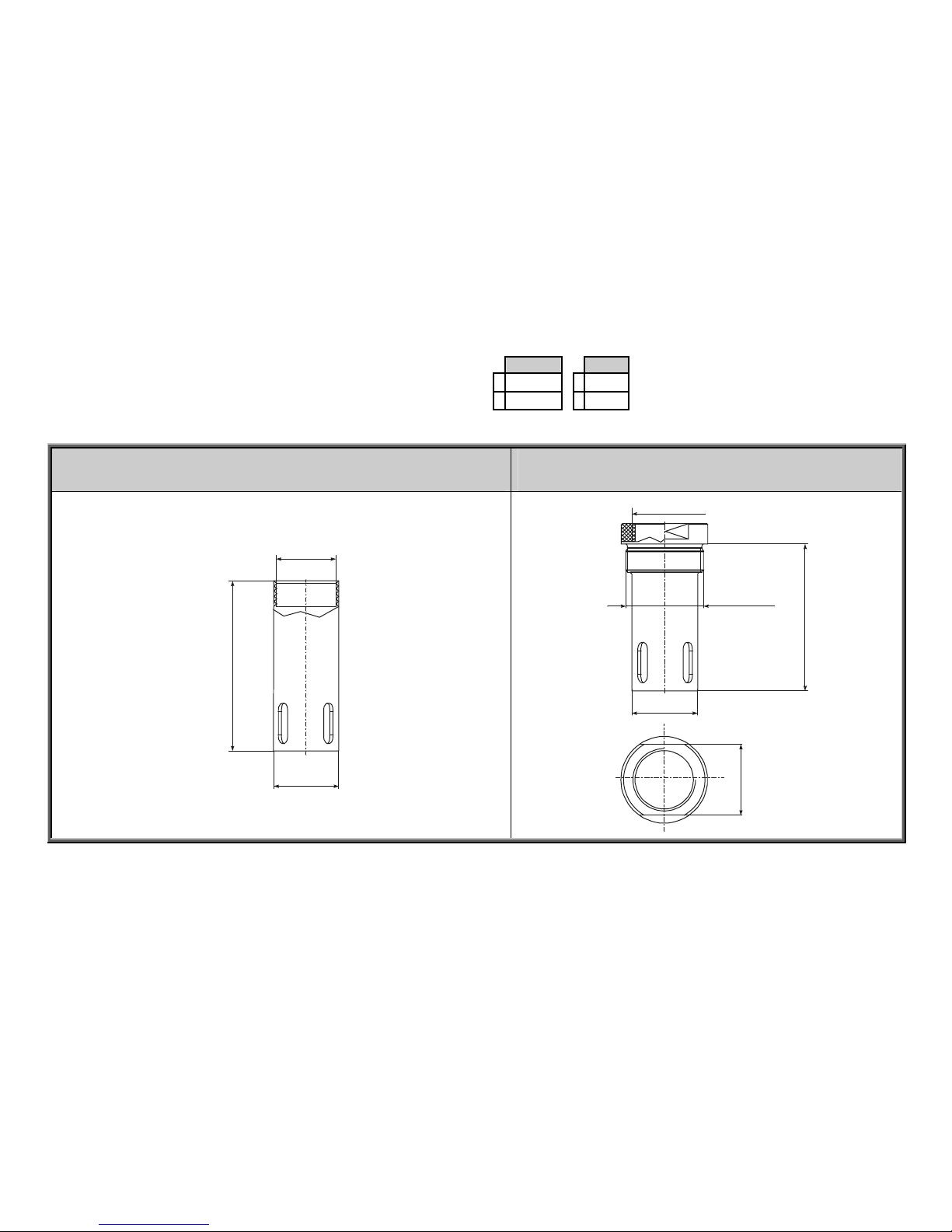

The extension unit, adjustment unit and the sensor housing can be ordered to every analytical device, apart from the type of the electrode, measurement

principal and measured quantity. Sensor protection tube is available only for LP--, or LR-- instruments.

EXTENSIONS L A – – 0

TYPE CODE MATERIAL CODE CODE LENGTH (L) CODE

Pipe R PP 1 0 0 m 0 m 0

Cable K PVDF 2 1 1 m 0.1 m 1

Suspended pipe F 2 2 m 0.2 m 2

3 3 m 0.3 m 3

4 4 m 0.4 m 4

5 5 m 0.5 m 5

6 6 m 0.6 m 6

7 7 m 0.7 m 7

8 8 m 0.8 m 8

9 9 m 09 m 9

A 10 m

PIPE EXTENSION: LAR--0 CABLE EXTENSION: LAK--0 SUSPENDED PIPE EXTENSION: LAF--0

L

=

0

,

2

-

3

m

BSP2"

Ø63

L

=

-

m

1

1

0

101

L = 0,2 - 3m

Ø3

Ø63

BSP2"

BKI 11 ATEX 0012 X le00100a0600p_05 9 / 60

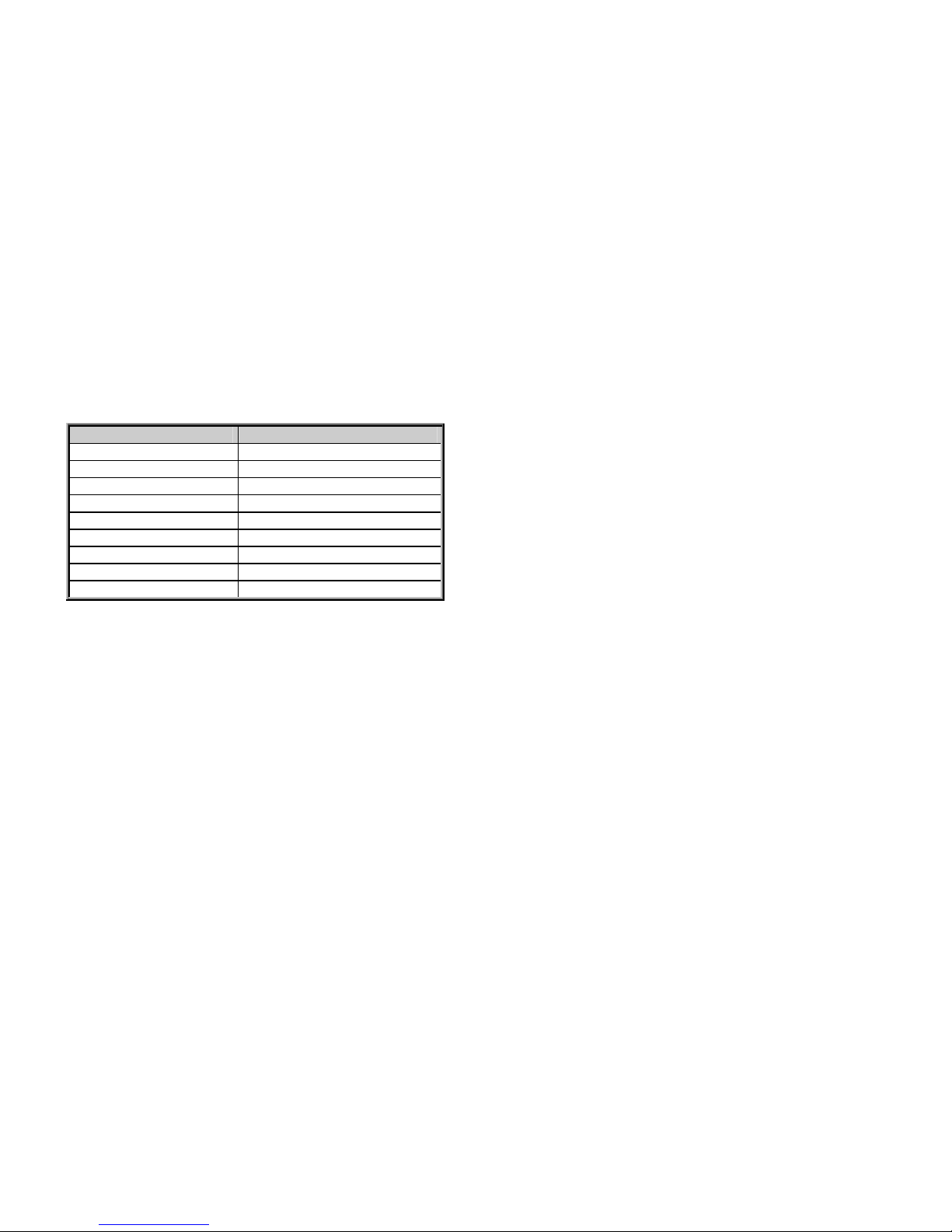

SLIDING SLEEVE: L A A – 1 0 – 0

CODE

DN80 PN16 / PP 2

DN100 PN16 / PP 3

DN125 PN16 / PP 4

DN150 PN16 / PP 5

DN200 PN16 / PP 6

Console mounting bracket, 200 mm K

Mounting bracket, 200 mm T

SLIDING SLEEVE WITH FLANGE: LAA-10-0

DN80 - DN200

63

DO

pH/ORP

CONSOLE MOUNTING BRACKET:

LAA-10K-0

MOUNTING BRACKET: LAA-10T-0

70

20 mm0

Ø

1

2

105

2

Ø

A

101

80

DO

pH/ORP

FOR EXTENSION TYPE

ØA

=63.5MM

FOR BASIC TYPE

ØA

=70.5MM

BKI 11 ATEX 0012 X le00100a0600p_05 10 / 60

MATERIAL

SIZE

SENSOR PROTECTION TUBE: L A P

–

1 PP 1 1½”

0–0

2 PVDF 2 2”

PROTECTION TUBE 1½”: LAP-10-0

FOR EXTENSION TYPE

PROTECTION TUBE 2”: LAP-20-0

FOR BASIC TYPE

BSP1 1/2"

130

Ø51

55

Ø51

BSP1 1/2"

112

BSP 2"

Sensor protection tube is available only for LP--, or LR-- instruments

BKI 11 ATEX 0012 X le00100a0600p_05 11 / 60

2.1. CONFIGURATIONS

COMPACT STANDARD TYPE: ANACONT LE--,

LG--

(+SENSOR PROTECTION TUBE: LAP-20-0)*

INTEGRATED STANDARD TYPE: ANACONT LP --

(+SENSOR PROTECTION TUBE: LAP-20-0)*

BSP1 1/2"

120 160

~90

120

~200

Ø95

BSP1 1/2"

*Further configuration drawings show only compact types, however many accessories are available to order with integrated types.

Essential dimension values are shown in the drawings of the standard types.

12 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

STANDARD TYPE: ANACONT L--

(+SENSOR PROTECTION TUBE: LAP-20-0)*

STANDARD TYPE: ANACONT L--

+ PIPE EXTENSION: LAR--0

(+SENSOR PROTECTION TUBE: LAP-10-0)*

~90

BSP1 1/2"

1

0

pH/ORP

112

BSP2"

BSP1 1/2"

DO

1

6

0

1

2

0

52

90

108

As per order

codes

BSP 1 ½"

120

pH/ORP

DO

10

Ø51

Ø63

* Sensor protection tube is available only for LP--, or LR-- instruments.

BKI 11 ATEX 0012 X le00100a0600p_05 13 / 60

STANDARD TYPE : ANACONT L--

+ PIPE EXTENSION : LAR--0

+ SLIDING SLEEVE WITH FLANGE: LAA-10-0

(+SENSOR PROTECTION TUBE: LAP-10-0)*

STANDARD TYPE: ANACONT L--

+ PIPE EXTENSION: LAR--0

+ CONSOLE MOUNTING BRACKET: LAA-10K-0

(+SENSOR PROTECTION TUBE: LAP-10-0)*

52

As per order codes

BSP 1 ½"

120

DO

Ø51

90

108

10

pH/ORP

52

90

108

As per order codes

BSP 1 ½"

120

pH/ORP

DO

10

Ø51

* Sensor protection tube is available only for LP--, or LR-- instruments.

14 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

STANDARD TYPE ANACONT L--

+ CABLE EXTENSION: LAK--0

(+SENSOR PROTECTION TUBE: LAP-20-0)*

STANDARD TYPE: ANACONT L--

+ CABLE EXTENSION: LAK--0

+ SUSPENDED PIPE EXTENSION: LAF--0

(+SENSOR PROTECTION TUBE: LAP-10-0)*

98

BSP 1 ½"

120

pH/ORP

DO

10

112

BSP2"

BSP1 1/2"

90

175

A

s per order

codes

120

DO

90

175

As per order

codes

As per order

codes

1 ½"

52

110

Ø63

10

Ø51

BSP1 ½"

pH/ORP

* Sensor protection tube is available only for LP--, or LR-- instruments.

BKI 11 ATEX 0012 X le00100a0600p_05 15 / 60

STANDARD TYPE: ANACONT L--

+ CABLE EXTENSION: LAK--0

+ SUSPENDED PIPE EXTENSION: LAF--0

+ SLIDING SLEEVE WITH FLANGE: LAA-10-0

(+SENSOR PROTECTION TUBE: LAP-10-0)*

STANDARD TYPE: ANACONT L--

+ CABLE EXTENSION: LAK--0

+ SUSPENDED PIPE EXTENSION: LAF--0

+ CONSOLE MOUNTING BRACKET: LAA-10K-0

(+SENSOR PROTECTION TUBE: LAP-10-0)*

52

As per order codes

BSP 1 ½"

120

pH/ORP

DO

10

90

175

A

s per order

codes

45

from

DN80

Ø51

BSP1 ½"

52

As per order codes

BSP 1 ½"

120

pH/ORP

DO

10

Ø51

BSP1 ½"

90

175

A

s per order

codes

* Sensor protection tube is available only for LP--, or LR-- instruments.

16 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

3. TECHNICAL DATA

GENERAL DATA

Material of sensor housing Polypropylene (PP), PVDF

Electrode As per order code

Housing material

Compact type: Plastic: Glass fibre plastic PBT Metal: Powder paint coated Aluminium

Integrated type: Same as the sensor housing

Medium temperature

(pressure dependent) *

PP sensor housing: –10 °C ... +90 °C,

PVDF sensor housing: -15 °C …. +100 °C

with DO probe: 0 °C ... +50 °C

Ambient temperature Metal housing: -30 °C …+70 °C, Plastic housing: -25 °C … +70 °C, both with display: -20 °C … +70 °C

Pressure (absolute)*

With pH and ORP probe: 0.05 … 1 MPa (0.5 … 10 bar) @25°C

With DO probe: 0,1…0,2 MPa (1…2 bar)@25°C

Sealing PP sensor housing: EPDM. all other sensor housing: FPM (Viton)

Ingress protection

Compact type: Sensor housing: IP 68, Housing: IP 67 (NEMA 6)

Integrated type: IP 68

Power supply / Consumption 12 … 36 V DC / 48 mW … 720 mW, galvanic isolation, protection against surge transients

Electrode input

With pH and ORP probe: Combined electrode, galvanic isolation, input impedance: >10

12

ohm, connection: SN6.

With DO probe: Galvanic isolated current input, 0.725V polarisation voltage, connection: SN6

Liquid potential (complementary) electrode** Stainless steel housing of the temperature sensor (1.4571) , connection: SN6

Temperature measuring

(semiconductive sensor)

Range: -50…130°C, Accuracy: ±0.5°C, Resolution: 0.1°C

Analogue: 4 … 20 mA, (3.9 … 20.5 mA), R

tmax

= 1200 Ώ ( [Ut – 12 V] / 0.022 A)

galvanic isolation, protection against surge transients

Relay: SPDT 30 V DC, 1A DC

Display: SAP-300 (128x64 pixels monochrome LCD, 41x24mm with effective display interface)

Outputs

Serial line: (optional) HART interface, terminal resistor 250 ohm

Electrical connections

Compact type: 2 x M20x1.5 metal cable gland, cable diameter: 7 … 13 mm, or 2 x M20x1.5 plastic cable gland, cable

diameter: 6 … 12 mm; connecting cable cross section: 0.5 ... 1.5 mm

2

(shielded cable is recommended) +

internal thread 2x NPT 1 / 2" cable protective pipe

Integrated type: 6x0.5mm

2

shielded cable 6 mm x 5 m (up to max. 30 m cable length)

Electrical protection Class III. electric shock protection, less than 24V voltage feed

* Depends on the selected electrode!

**In case of LP-- and LR-- instruments.

BKI 11 ATEX 0012 X le00100a0600p_05 17 / 60

M

EASUREMENT DATA

pH measurement

Range: 0…14pH, Reserve: ±2pH, Accuracy*: 0.1% of the measured value ±1 digit ±0.01% /°C,

Linearity: ±0.004pH, Resolution: 0.01pH, (internal resolution 0.004pH), Measuring cycle: 300msec, on display: 1 sec

ORP measurement

Range: ±1000mV, Reserve: ±200mV, Accuracy*: 0.1% of the measured value ±1 digit ±0.01% /°C,

Linearity: ±0.001%, Resolution: 0.1mV, Measuring cycle: 300msec, on display: 1sec

DO measurement

Range: 0…20ppm v. 0…10ppm, Reserve: 20%, Accuracy*: 0.5% of the measurement range ±1 digit ±0.01% /°C,

Linearity: ±0.05ppm, Resolution: 0.01ppm, (internal resolution 0.005ppm), Measuring cycle: 300msec, on display: 1sec

* Depends on the selected electrode / sensor!

S

PECIAL DATA FOR EX APPROVED MODELS

Ex marking

II1G Ex ia IIB T6 Ga

Intrinsically safe data

Ci ≤ 15 nF, Li ≤ 200

H, Ui ≤ 30 V, Ii ≤ 140 mA, Pi ≤ 1 W

For Ex transmitter only Ex ia power supply should be used

Ex power supply Uo < 30 V, Io < 140 mA, Po < 1 W, power supply voltage range 12 V … 30 V, Rt

max

= [Ut – 12 V] / 0.022 A

Medium temperature

With pH and ORP probe: for PP sensor housing: –10... +70 °C, PVDF sensor housing: –15... +80 °C

With DO probe: : 0… +50 °C

Ambient temperature Metal housing: -30 °C … +70 °C with display: -20 °C … +70 °C, Plastic housing : -20 °C … +70 °C

18 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

3.1. TECHNICAL DATA OF THE PH ELECTRODES (INCLUDING EX VERSIONS) FOR LP-- INSTRUMENTS

Type 4xpher112seph 4xphed112seph 4xphex112seph

Range [pH] 1...12 1...12 1...12

Process temperature °C 0…80 0…80 0…100

Max. process pressure [bar] 6 8 16 (<25°C), 6 (<100°C)

Min. conductivity µs/cm 50 150 500

Diaphragm (the conductive aperture of the reference

electrode)/electrolyte in closed glass-house

PTFE (Teflon) ring / 3 mol KCl 2 pcs ceramic rod / 3 mol KCl Concentrical gap/ 3 mol KCl

Connection / insertion length [mm] SN6 & PG13,5 / 120 SN6 & PG13,5 / 120 SN6 & PG13,5 / 120

Main application areas

Public and industrial

wastewater, process water,

drinking water, water in

chemical industry, water with

suspended solid particles.

Industrial water, drinking water,

slightly contaminated

wastewater, cooling tower

water, galvanic industry,

technologic water with Cr 6+,

CN

Wastewater, process water, water

in chemical industry, emulsions,

suspensions, mediums containing

proteins or sulphides, water with

high concentration of solid

particles.

Not applicable for

Steam sterilization, water with

low conductivity, sudden

temperature changes.

Steam sterilization, water with

low conductivity, sudden

temperature changes.

Steam sterilization, water with low

conductivity, sudden temperature

changes. Clear water!!

Type 4xpheph314sph 4xphe112seph 4xphes112seph

Range [pH] 3...14 1...12 1...12

Process temperature °C 0…100 0…60 0…60

Max. process pressure [bar] 6 (<25°C), 3 (<100°C) 0.5 3

Min. conductivity µs/cm 150 150 150

Diaphragm (the conductive aperture of the reference

electrode)/electrolyte in closed glass-house

Ceramic / 3 mol KCl Ceramic / 3 mol KCl Ceramic / 3 mol KCl

Connection / insertion length [mm] SN6 & PG13.5 / 120 SN6 & PG13,5 / 120 SN6 & PG13,5 / 120

Main application areas

Monitoring or controlling of

chemical processes of

mediums from neutral to very

alkaline.

Swimming pools, applications

in atmospheric pressure,

drinking water, slightly

contaminated wastewater.

Swimming pools, applications

under pressure, drinking water,

slightly contaminated industrial

and wastewater.

Not applicable for

Steam sterilization, water with

low conductivity, sudden

temperature changes.

Steam sterilization, water with

low conductivity, sudden

temperature changes, above

atmospheric pressure.

Steam sterilization, water with low

conductivity, sudden temperature

changes

BKI 11 ATEX 0012 X le00100a0600p_05 19 / 60

TYPE 4xphep112seph 4xphekl112sph

Range [pH] 1...12

1...12

Process temperature °C 0…80

0…60

Max. process pressure [bar] 6

3

Min. conductivity µs/cm 150

150

Diaphragm (the conductive aperture of the reference

electrode)/electrolyte in closed glass-house

Ceramic / 3 mol KCl

Ceramic (polycarbonate)

Connection / insertion length [mm] SN6 & PG13,5 / 120

SN6 & PG13,5 / 120

Main application areas

Swimming pools, drinking water, process water,

slightly contaminated wastewater, electrolytic

metallization.

Swimming pools, drinking water, process water,

slightly contaminated wastewater.

Not applicable for

Steam sterilization, water with low conductivity,

sudden temperature changes.

Steam sterilization, water with low conductivity,

sudden temperature changes.

20 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

3.2. TECHNICAL DATA OF THE ORP ELECTRODES (INCLUDING EX VERSIONS)

FOR LR-- INSTRUMENTS

TYPE 4xorrherpseor 4xorrhexpseor 4xorrheptseor

Process temperature °C 0…80 0…100 0…60

Max. process pressure [bar] 6 16 (<25°C), 6 (<100°C) 1

Min. conductivity µs/cm 50 500 150

Diaphragm (the conductive aperture

of the reference electrode)/electrolyte

in closed glass-house

PTFE (teflon) ring / KCl Circular recess / solid electrolyte Ceramic

Connection / insertion length [mm] SN6 & PG13,5 / 120 SN6 & PG13,5 / 120 SN6 & PG13,5 / 120

Main application areas

public and industrial wastewater

process water

drinking water

water in chemical industry

water with suspended solid particles

polluted water

emulsions, mediums containing

sulphides

high pressure applications

drinking water

pools in atmospheric pressure

slightly polluted water

Not applicable for

steam sterilization

water with low conductivity

sudden temperature changes

steam sterilization

water with low conductivity

sudden temperature changes

clean water

steam sterilization

water with low conductivity

sudden temperature changes

BKI 11 ATEX 0012 X le00100a0600p_05 21 / 60

TYPE 4xorrhespseor 4xorrheppseor 4xorrheklseor

Process temperature [°C] 0…60 0…80 0…60

Max. process pressure [bar] 3 6 3

Min. conductivity [µs/cm] 150 150 150

Diaphragm / electrolyte Ceramic Ceramic Ceramic (polycarbonate housing)

Connection / insertion length [mm] SN6 & PG13,5 / 120 SN6 & PG13,5 / 120 SN6 & PG13,5 / 120

Main application areas

swimming pools

drinking water

slightly polluted water

slightly polluted water

drinking water

process water

swimming pools

metallization

chemical applications

swimming pools

drinking water

slightly polluted water

Not applicable for

steam sterilization

water with low conductivity

sudden temperature changes

steam sterilization

water with low conductivity

sudden temperature changes

above atmospheric pressure

mediums containing ozone

steam sterilization

water with low conductivity

sudden temperature changes

22 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

3.3. TECHNICAL DATA OF THE DO SENSORS (INCLUDING EX VERSIONS) FOR LD-- INSTRUMENTS

TYPE 4x085g0023ydo (20 ppm) 4x085g0022ydo (10 ppm)

DO range [ppm] 0...20 0...10

Process temperature [°C] 0…50 0…50

Max. process pressure [bar] 1 1

Min. speed of medium-flow [m/s] 0,05 0,05

Response time [sec] 110 22

Accuracy [%; ppm] ±0.5 ; 0.1 ±0.5 ; 0.05

Life-span [year] 2-3 2-3

Material/thickness of the membrane PTFE / 125µm PTFE / 50µm

Other materials

PBT/PC, gold, silver, silver-chloride, potassium-

chloride

PBT/PC, gold, silver, silver-chloride, potassium-

chloride

Application area

Fish- and crawfish farms, water conditioning of large

aquariums, Controlling of oxygen concentration in

water-plants, determination of biological condition in

surface water

Potable water production, river monitoring, water

treatment sites, controlling of dissolved oxygen

level in wastewater plants, determination of

biological condition in surface water.

SAP-300 DISPLAY UNIT

Display 128 x 64 pixels monochrome LCD, with 41x24mm effective display surface

Ambient temperature – 20°C…+70°C

Storage temperature – 30°C…+80°C

Housing material PBT fibre glass plastic

3.4. ACCESSORIES

Installation and programming manual,

Warranty Card

Declaration of Conformity,

2 pcs M20x1.5 cable glands,

pH/ORP electrode (as per order code, separately packed with user manual)

DO sensor (as per order code, separately packed with user manual)

SAP-300 display unit (optional)

CD (EViewLight, DataScope softwares)

BKI 11 ATEX 0012 X le00100a0600p_05 23 / 60

4. MAINTENANCE AND REAPAIR

The AnaCONT series do not require maintenance on a regular basis, but the electrode (depending on the application) may need to be checked, cleaned, calibrated

and replaced regularly.

Repairs during or after the warranty period are carried out exclusively at the Manufacturer’s. Equipments sent back for repairs should be cleaned or neutralised

(disinfected) by the User.

All sensors and electrodes including the NIVELCO recommended ones need proper storage, handling and calibration to have long life-time and give reliable

measurement. Improper handling and lack of calibration will lead to unreliable measurement

4.1. STORAGE

DO sensors can be stored (under normal storage conditions) for a period of 12 month without shortening its lifecycle. The lifetime of pH and ORP electrodes is

maximum one year (storage + usage). Prominent ships the electrodes hydrated in a well sealed container with a 3mol/l KCl solution in it. As a result, the membrane

remains wet and the electrode is in ready-to-use state. It is important to keep these containers as they are needed for storing the electrodes during calibration or in

case of transportation. If for any reason the electrodes are taken out of the process they must be put back into the storage containers containing storage liquid.

Notes: Never let the membrane and the diaphragm desiccated. Do not leave the electrode on open air longer than 10 minutes. If the electrode is warm it can

desiccate even within a shorter period of time!

4.2. PERIODIC SETTING, CALIBRATION AND VERIFICATION

The electrode is exposed to different stresses, dependent on the measured medium, its ORP and pH value and the medium temperature.

That is why the electrode needs to be recalibrated (its accuracy needs to be checked) between certain time intervals depending on the application utilizations. The

calibration intervals may vary from few days to several weeks (max. 8 weeks).

24 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

4.2.1. Periodic calibration of the pH electrode

The calibration has to be done minimum in two measuring points (using two different buffer solutions). The calibration points have to be selected so that the widest

measuring range is covered. The common calibration points are 4.00pH and 10.00pH, 4.00pH and 7.00pH, 7.00pH and 10.00pH, or even more points for example

4.00pH, 7.00pH and 10.00pH.

Recommended solutions:

ORDER CODE DENOMINATION

4vpuf4ph50mph Buffer solution pH4 / 50 ml

4vpuf4ph250ph Buffer solution pH4 / 250 ml

4vpuf4ph100ph Buffer solution pH4 / 1 l

4vpuf7ph50mph Buffer solution pH7 / 50 ml

4vpuf7ph250ph Buffer solution pH7 / 250 ml

4vpuf7ph100ph Buffer solution pH7 / 1 l

4vpuf10ph50ph Buffer solution pH10 / 50 ml

4vpuf10ph25ph Buffer solution pH10 / 250 ml

4vpuf10ph10ph Buffer solution pH10 / 1 l

4vtarkcI 350ph Storage solution KCl 3 mol / 50 ml

4vtarkcl 250ph Storage solution KCl 3 mol / 250 ml

4vtarkcl 310ph Storage solution KCl 3 mol / 1 l

4vtiszold 25ph Cleaning solution / 250 ml

The given pH values refer to 25°C. The temperature dependency is given by the manufacturer, usually in a table on the label of the bottle.

The calibration procedure is described in chapter 6.5

BKI 11 ATEX 0012 X le00100a0600p_05 25 / 60

4.2.2. Verification of the ORP electrode

The calibration can be done (for example) with a 465 mV buffer solution. After the electrode is rinsed with distilled water put the electrode into the buffer solution. The

electrode should reach the correct measurement value in 30 seconds. If the measured value is less with more than (the acceptable) 20mV the electrode should be

cleaned. If the electrode does not give the desired measurement after cleaning it has to be replaced

Recommended solutions:

ORDER CODE DENOMINATION

4vpuf22050mor Buffer solution ORP 220 mV / 50 ml

4vpuf220100or Buffer solution ORP 220 mV / 1 l

4vpuf46550mor Buffer solution ORP 465 mV / 50 ml

4vpuf465250or Buffer solution ORP 465 mV / 250 ml

4vpuf465100or Buffer solution ORP 465 mV / 1 l

4vtarkcI 350ph Storage solution KCl 3 mol / 50 ml

4vtarkcl 250ph Storage solution KCl 3 mol / 250 ml

4vtarkcl 310ph Storage solution KCl 3 mol / 1 l

4vtiszold 25ph Cleaning solution / 250 ml

The given (mV) values refer to 25°C. The temperature dependency is given by the manufacturer, usually in a table on the label of the bottle.

4.2.3. Periodic calibration of the DO sensor

The calibration has to be done minimum in two measuring points. Calibration points should be selected according to the required range to cover almost or fully.

In every case it is necessary for the calibration: one solution which does not contain any oxygen – may be a neutral gas – for the zero standard calibration, and an

other solution which has a known oxygen concentration for the full-scale standard calibration.

Zero calibration is necessary, because DO sensor gives output current when the measured medium does not contain any dissolved oxygen. This current is called

residual-current. The required zero-standard is an aqueous solution of sodium-sulphite (Na

2S03

) and cobalt(II)-chloride hexahydrate (CoCl2-6H2O) prepared

according to the followings. Oxygen-free nitrogen gas can be also used as zero-standard. The zero point calibration determines the offset of the calibration line.

Required items:

1 clean pot

1 mixer

1 dl distilled water

1g sodium-sulphite (Na

2S03

)

1mg cobalt(II)-chloride hexahydrate –Analytical Reagent– (CoCl

2

-6H2O)

26 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

Before the calibration pour the salts in the distilled water with continuous mixing.

For sensitivity calibration it is necessary a full-scale standard to determine the slope of the calibration line. Water solubility of oxygen at atmospheric pressure is well

known dependent on temperature and pressure, so air-saturated water is a natural choice for full-scale standard. The air-saturated water is difficult to prepare and

use. Usage of water-saturated air is a more general practice as a full-scale standard, because air-saturated water and water-saturated air are the same for the DO

sensor. These are same standards, because the sensor is actually measuring the chemical potential of the oxygen. This chemical potential is a force driving through

oxygen molecules from the sample through the membrane into the sensor. Output current of the sensor is proportional to the amount of oxygen driving through the

membrane, so this current is determined by the chemical potential of the oxygen in the sample. The amount of oxygen is the same in air-saturated water and watersaturated air, so the chemical potential of the oxygen are also the same in both phases. Consequently the output current of the sensor is also the same in both

cases.

Automatic calibration on air: The sensor should be simply hold in water-saturated air. The instrument measures the output current of the DO sensor, then store the

measured value if stabilized and measures the temperature of the sample. It determines the saturation vapor pressure of the water from the temperature. Then it

calculates the pressure of the dry air as the difference of atmospheric pressure and the saturation vapor pressure of the water. (Value of atmospheric pressure

should be entered in the menu of the instrument as a parameter, default value is 1013mbar=101,3kPa) Considering the fact, that oxygen concentration of dry air is

20.95%, it calculates the partial pressure of the oxygen. Knowing the partial pressure of the oxygen, it calculates the amount of atmospheric dissolved oxygen in

equilibrium at a current temperature using the Bunsen solubility coefficient. This calculated value is assigned to the stored output current of the sensor.

Usually it is has many difficulties to dismount the instrument or the sensor from the technologic process for the calibration. In case of this, the sensor can be

calibrated to a measurement value of a portable laboratory instrument in the same technologic process. Before this type of calibration, the laboratory instrument

(usually also using oxygen-permeable membrane amperometric sensor) should be calibrated in water-saturated air.

The calibration procedure is described in 6.6.

BKI 11 ATEX 0012 X le00100a0600p_05 27 / 60

4.3. MAINTENANCE OF THE PH AND ORP ELECTRODES

In this chapter you can find some recommendations regarding re-hydration, chemical cleaning and reactivation of the electrodes.

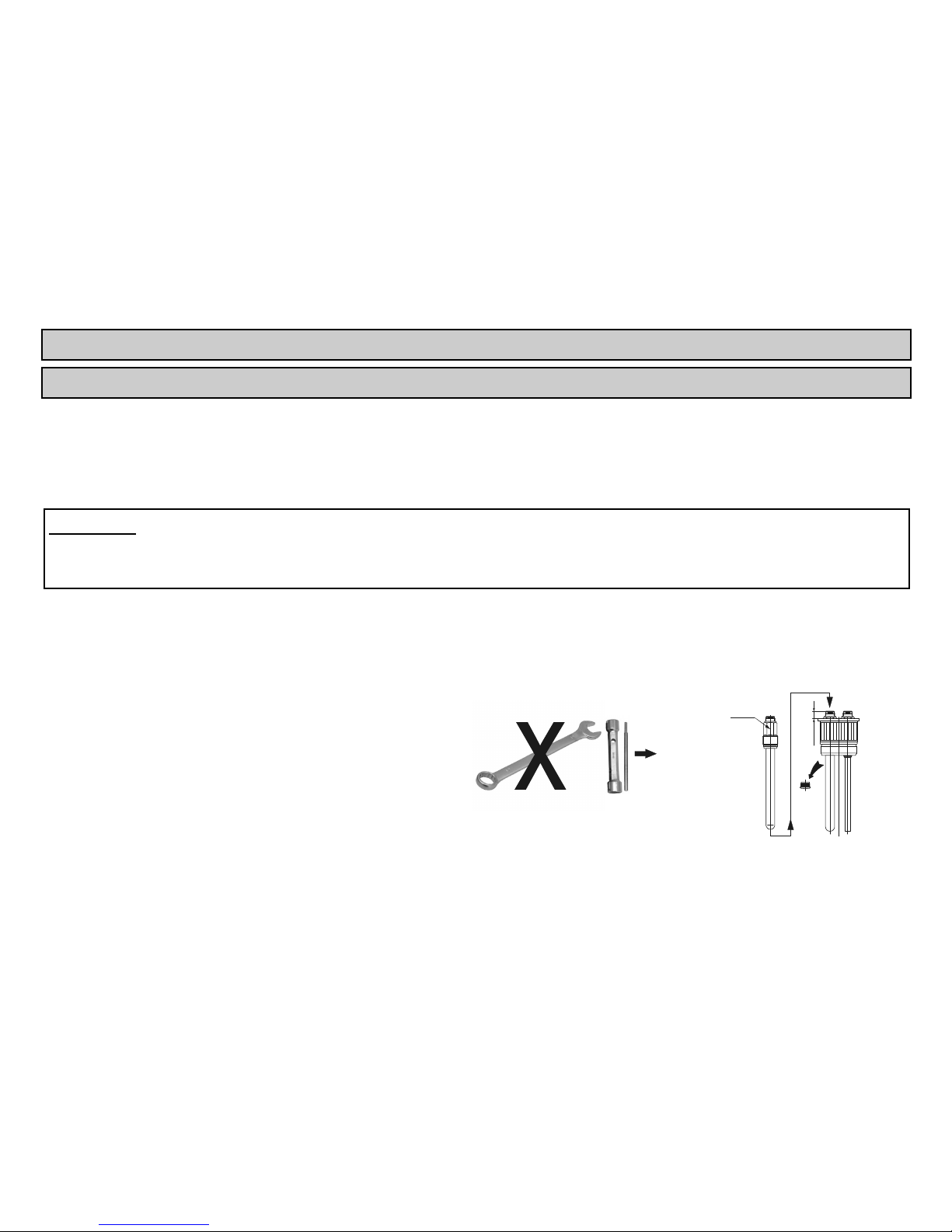

Disassembling the electrode

During this operation be careful not to expose the fragile electrode to mechanical (bending,

squeezing, tensile) forces!

Hold the electrode housing with one hand and the flare nut (right-threaded) with the other one

and loosen it completely.

Then detach carefully the electrode housing from the instrument housing.

Loosen the electrode carefully using a socket-wrench (size 17) and screw it off completely.

Don't use a pipe- or a double-end wrench!

Put the electrode into the storage solution or perform the following steps below.

size 17

Re-hydration

If the electrode was desiccated due to incorrect use or storage it needs to be re-hydrated. This has to be done by soaking the electrode in 3mol/l KCl storage solution

at 20°C for 24 hours. The process can be shortened to 6 hours if the KCl solution is at 60°C.

Note: long time desiccation or desiccation after measuring crystallizating mediums may have an irreversible effect on the electrode and thus the re-hydration may not

be successful.

Chemical cleaning

The deposits and obstructions on the surface of the electrode’s membrane and on the diaphragm have to be eliminated from time to time:

1. General deposits

Rinse the electrode with warm water then dry up gently using a soft rag!

Soak the electrode for 15 mins in 1.5mol/l (5%) hydrochloric acid (HCl)!

Rinse the electrode again with warm water then dry up gently using a soft swab!

Soak the electrode for 1 hour in 3mol/l KCl solution then perform the calibration procedure!

28 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

2. Non-organic deposits

Rinse the electrode with warm water then dry up gently using a soft rag!

Soak the electrode for 15 mins in 0.1 mol/l EDTA (ethylenediaminetetraacetic acid) solution!

Rinse the electrode again with warm water then dry up gently using a soft rag!

Soak the electrode for 1 hour in 3mol/l KCl solution then perform the calibration procedure!

3. Protein deposits

Rinse the electrode with warm water then dry up gently using a soft rag!

Soak the electrode for 15 mins in 0.5 mol/l hydrochloric acid (HCl) or in 0.1 mol/l HCl and 0.1% pepsin mixture!

Rinse the electrode again with warm water then dry up gently using a soft rag!

Soak the electrode for 1 hour in 3mol/l KCl solution then perform the calibration procedure!

4. Silver sulphide deposits

Rinse the electrode with warm water then dry up gently using a soft rag!

Soak the electrode for 15 mins in 0.1 mol/l thiourea and 1.5 mol/l (5 %) hydrochloric acid (HCl)!

Rinse the electrode again with warm water then dry up gently using a soft rag!

Soak the electrode for 1 hour in 3mol/l KCl solution then perform the calibration procedure!

Note: when deposits are hard to remove try using hydrogen peroxide or sodium hypochlorite solutions.

Reactivation

Regeneration of the glass membrane:

The physical or chemical damage of the glass membrane slows down the operation of the electrode. The reactivation of the membrane helps restoring the normal

operation of the electrode.

Immerse ONLY the spherical part of the glass electrode into ammonium bifluoride with 10% concentration for 60 seconds then immediately

into 50-50% mixture of undiluted HCl and water for 10 seconds. This will neutralize the strong base!

Soak the electrode for 12 hours in 3 mol/l hydrochloric acid (HCl)!

Rinse the electrode with water then dry up gently using a soft rag!

Soak the electrode for 1 hour in 3mol/l KCl solution then perform the calibration procedure!

BKI 11 ATEX 0012 X le00100a0600p_05 29 / 60

Reassembling the electrode

During this operation be careful not to expose the fragile electrode to mechanical (bending, squeezing, tensile) forces!

Insert the electrode to its place carefully, screw it in with your hand and then with a socket-wrench

(size 17) carefully, until it reaches the level of the connector of the temperature sensor

(

0

5.0

5.9

mm

,see figure). Don't use a pipe-wrench or a double-end wrench!

Assemble the instrument housing and the electrode housing then fasten the flare nut with your

hand. Pay attention to the encasement of the anti-rotation guides.

9.5

+ 0

- 0.5

s=17mm

4.4. MAINTENANCE OF THE DO SENSOR

During this operation be careful not to expose the fragile electrode to mechanical forces! Do not

scratch, finger or touch the membrane of the sensor!

Dismount the instrument from the technology process.

While holding the instrument in one hand rinse the membrane of the sensor with clean water.

If necessary some detergents could be used.

Dry up the sensor gently using a soft rag.

4.5. SOFTWARE UPDATE

Based on the observation and needs of our customers NIVELCO constantly improves the operating software of the device. The software can be upgraded with the

help of the ELink (USB) communication adapter plugged into the socket of the SAP-300 display. For software updates and for more information about software

updates please contact NIVELCO.

30 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

5. INSTALLATION

5.1. MOUNTING

When choosing the installation place please ensure proper space for later calibrations, verification or maintenance service. (see placement on page 32. )

Make sure that the transmitter is protected against overheating that can be caused by direct sunshine.

Assemble the electrode with the instrument prior to the installation.

It is advised to check the operation of the instrument prior to the installation in the control room.

If factory settings need to be modified do it according to the Programming Description.

The process connection should be selected according to the type to be installed.

ATTENTION!

When mounting or dismounting the instrument, avoid exposing the electrodes, DO sensors and temperature sensors to mechanical impacts because

these can cause malfunctioning of the unit. The unit should not be loosened if the process is under pressure, in this case user should take care of

depressurization first!

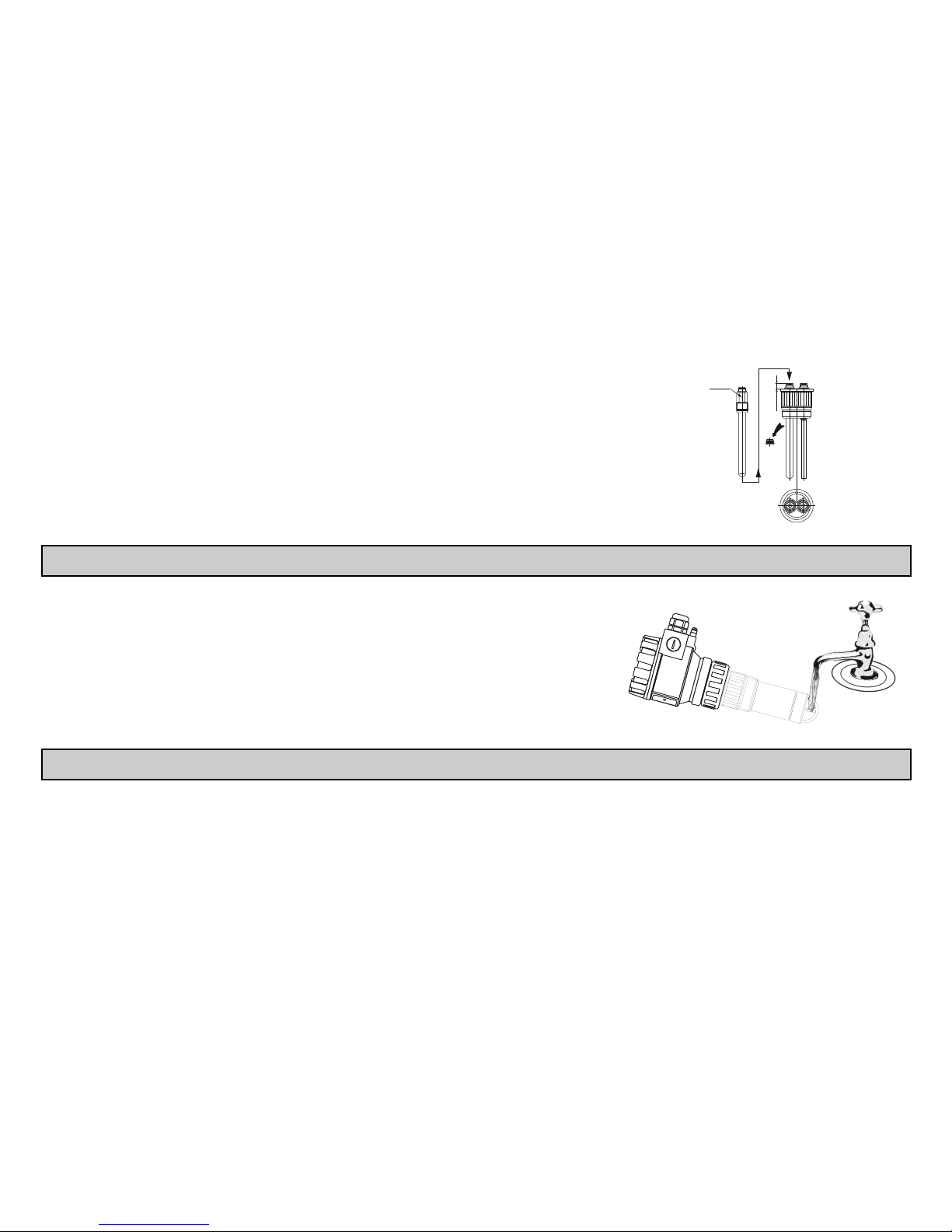

5.1.1. Installation of pH and ORP electrodes

Prior to mounting into the process the instrument should be put into operation-ready state. For this the user has to insert the electrode (packed separately) into

the instrument as described below:

During this operation be careful not to expose the fragile electrode to mechanical (bending, squeezing, tensile) forces!

The housing of the instrument can be disassembled as described in chapter 4.3.

Remove the plug in the electrode housing from the connector

of the electrode.

Open the box and screw the electrode off the container.

Insert the electrode to its place carefully, screw in with your hand and

using a socket-wrench (size 17) until it reaches the level of the

connector of the temperature sensor (

0

5.0

5.9

mm

).

Don't use a pipe-wrench or a double-end wrench!

size 17

9.5

+ 0

- 0.5

s=17mm

Assemble the instrument as described in Chapter 4.3.

If the instrument is not installed immediately into the process the electrode should be put into storage solution to keep it wet.

BKI 11 ATEX 0012 X le00100a0600p_05 31 / 60

5.1.2. Installation of DO sensor

Prior to mounting into the process the instrument should be put into operation-ready state. For this the user has to insert the DO sensor (packed separately) into

the instrument as described below:

During this operation be careful not to expose the fragile DO sensor to mechanical (bending, squeezing, tensile) forces!

Remove the threaded protector- basket and the sponge-disc protector of the contacts.

Unpack the DO sensor and place it into a flat surface, downward with the plastic cap. Do not wipe the out the silione grease from the back of the

membrane! Silicone grease protect the contacts against short-circuit, even if water is infliltrated.

With one hand hold the instrument upwards with its sensor, with other hand remove the (right-threaded) protector- basket of the sensor.

Place the sensor into the instrument with its cap that the pins of the sensor-nest can fit into the holes in the rear side of the sensor.

Remove the cap from the sensor and replace the protector- basket of the sensor.

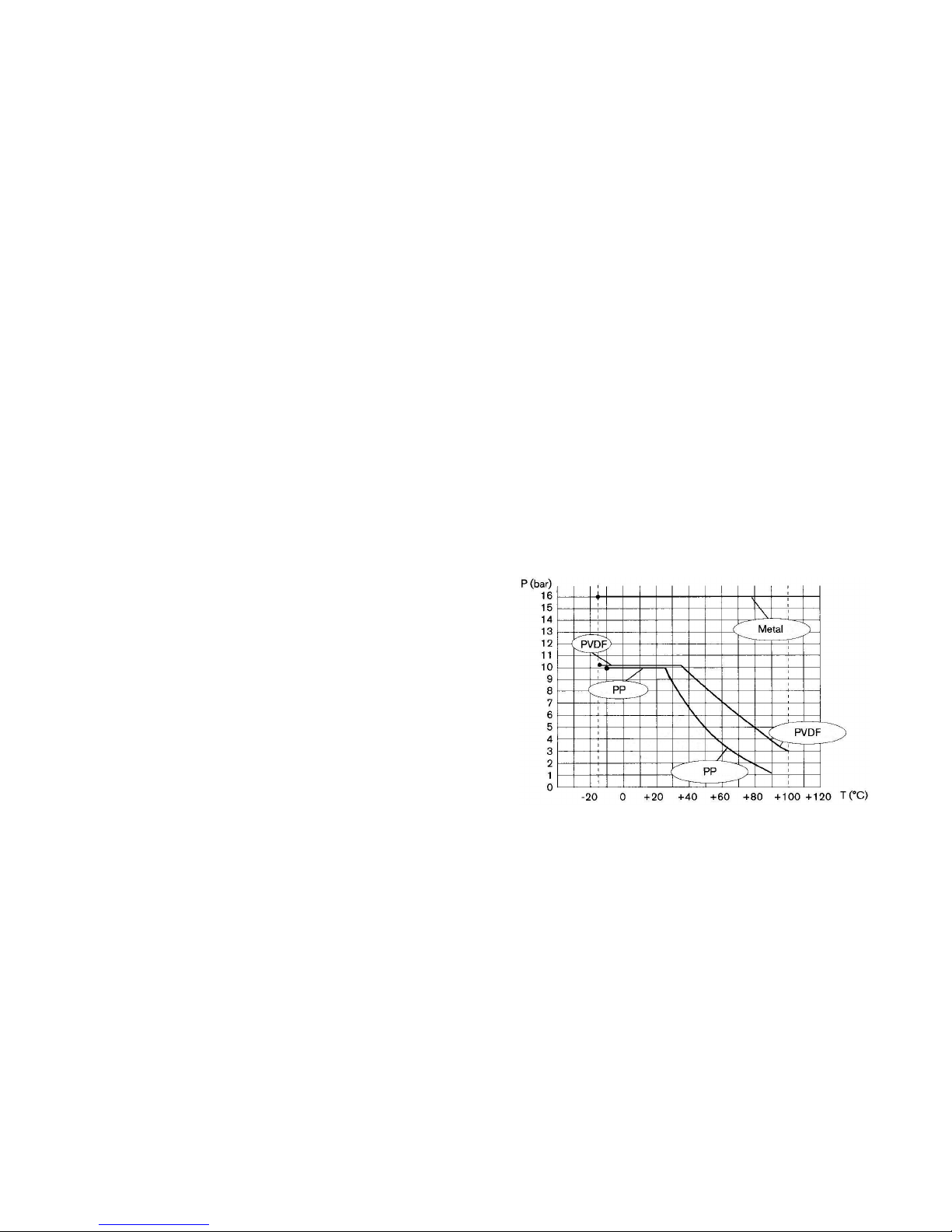

TEMPERATURE

As it is shown in the diagram below – there may be a drop in the pressure-resistance according to the changes of the medium temperature, - which, in any case,

should be considered, prior to the installation of the instrument into the technology process:

Depending on the location of the installation the instrument should be protected

against any heat source or direct sunlight to avoid higher temperatures than

specified!

32 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

PLACEMENT

The instrument should be mounted within a max. 45° angle, compared to vertical position.

Types mounted with 4xphekl112seph / 4xorrheklseor electrode may be positioned

horizontally as well!

If the unit is installed using a fitting piece the user has to assure that before and after the fitting piece

there is a straight pipe with the appropriate length to minimalize sedimentation and turbulency.

The influent section has to have min. 10xDN length while the effluent section has to have min. 3xDN

length.

It is advised to create a by-pass line so during the service of the instrument the electrode is kept wet

or a calibration can be done without stopping the process.

>10 DN

>3 DN

LIQUID CONTINUITY

Near the electrode (sensor), the pipeline should always be filled with liquid:

BKI 11 ATEX 0012 X le00100a0600p_05 33 / 60

BUBBLE, FOAM

Near the electrode (sensor), liquid in the pipeline should be free of bubbles or foam.

Installation of the threaded models

Screw the unit into its place and tighten by hand. Don’t use any tool!

After tightening, the enclosure can be rotated to the proper position. (Safety bolt prevents rotation more than 350°).

5.1.3. Special application possibilities of the Integrated type instruments

Integrated type instruments can be installed in the same place with the medium to be measured. In this case of application, the maximal process pressure can not

exceed 0.5 bar!

34 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

5.2. WIRING

The instrument operates from 12.5 … 36 V galvanic isolated and not grounded DC power supply in two wire system. (For Ex version: 12.5 … 30 V DC!)

Sum of the resistance of the equipped instruments, between the transmitter and the power supply, mainly depends on the supply voltage of power supply applied,

and the overall resistance value cannot exceed 1200 ohms. In case of using HART interface – to achieve proper communication between the transmitter’s interface

and the power-supply – a minimal 250 ohms resistance should be maintained within the network.

5.2.1. Wiring of Compact instruments

The instrument should be wired with shielded cable led through the cable gland. The wiring of

cables can be done after removing the cover of the instrument and the SAP display unit.

Make sure that the power supply is turned off at the source.

After removal of the cover of the housing and taking the display module (if any) out,

the wiring cables can be connected. (Recommended cable: shielded, two-wire, with

0.5 ... 1.5 mm2 cross section. Connect shielding to grounding by the inner or outer

grounding screw first.

Switch on the unit. After switching of the unit, necessary programming can be done.

After the wiring, adjustment and programming, check proper sealing and close the

cover carefully.

IMPORTANT: - The housing of the transmitter should be grounded to the EPH network.

Resistance of the EPH network should be R 2 ohm measured from the neutral. Shielding of

the cable should be grounded at the control room side to the EP network. To avoid disturbing

noises, keep away of closeness to high-voltage cables. Especially critical can be the inductive

couplings of harmonics (which are present at frequency converter control) because even cable

shielding does not supply effective protection against these cases.

RELAY

Display unit

connector

Loop current

measuring connect or

4...20 mA loop current

and supply (HART)

GND

1/2” NPT

1/2” NPT

M20x1,5

M20x1,5

I

23456

C2

5

4 6

C1

(Only normal

version)

2 3

1

2

U

1

!

The instrument may be damaged by electrostatic discharge (ESD) via its terminal, thus apply the precautions commonly used to avoid electrostatic

discharge e.g. by touching a properly grounded point before removing the cover of the enclosure.

BKI 11 ATEX 0012 X le00100a0600p_05 35 / 60

5.2.2. Wiring of Integrated instruments

The insrument can be connected directly to the suitable power suply unit. When extending the

cable, a junction box is needed to use for this purpouse. Shielding should be connected with

the shield of the extending cable and should be grounded at the signal processing device.

Make sure that the power supply is turned off at the source.

(Recommended cable: shielded cable with 6 x 0.5 mm

2

or greater cross section).

Turn on the power supply. After switching of the unit, necessary programming can be

done.

Colour codes of the wires:

Green – C1 relay output White – I One point (polarity-independent) of

loop current, power supply and HART

Yellow – CC relay output Brown – I Other point (polarity-independent) of

loop current, power supply and HART

Grey – C2 relay output Black – GND Grounding and shielding point

White

Green

Yel lo w

Grey

Braun

Black

Function box

Power

supply

Power supply

+HART

+Current output

HART modem

I

white (brown)

brown (white)

green

black

R

C1 C2

CC

yellow

grey

TRA NSM IT TER

mA

IMPORTANT: The shielding of the transmitter should be grounded at the control room side to the EPH network. Resistance of the EPH network should be R 2

ohm measured from the neutral. To avoid disturbing noises, keep away of closeness to high-voltage cables. Especially critical can be the inductive

couplings of harmonics (which are present at frequency converter control) because even cable shielding does not supply effective protection against

these cases.

5.3. LOOP CURRENT CHECKING WITH HAND INSTRUMENT

After removing the cover and lifting the Display Module, the actual loop current can be measured with an accuracy of ~ 5% by connecting a voltmeter (in the range of

200 mV) to the points indicated on the drawing above.

5.4. CONDITIONS OF EX APPLICATION

Intrinsically safe units with Ex ia IIB marking can only be used in certified intrinsically safe loops with the previously given technical data. (see values in special

data for Ex approved models under Point 3).

The size of the macrolon window of intrinsical safe equipment with metallic enclosure exceeds the limit, thus the devices must be protected against electrostatic

charges.

Equipment with plastic housing are susceptible to electrostatic charges, thus the deivces must be protected against electrostatic charges.

The aluminium content of equipment with metallic enclosure exceeds the limit, the devices must be protected against impact and friction effects.

Devices should be grounded by connecting their grounding screws to the equipotential system.

36 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

6. PROGRAMMING

The AnaCONT instruments can be programmed with the SAP-300 display unit.

Without SAP-300 the following LEDs can be seen:

RELAY Indicates the energised state of the relay (C2 closed, C1 open)

VALID Indicates the measuring capability of the unit. If lit, the input signal is stabilised.

If blinking,the input signal is changing.

COM Indicates digital (HART) communication. During Remote programming LEDs are

continuously illuminated.

When SAP-300 display is present, LEDs are not visible; functions are taken over by the display. In default state SAP

display shows the primary measured value (which the output current is calculated from). Programming is supported by

a text-based menu. Navigation is done by using the

E

/ / / buttons.

The instrument can operate without the SAP-300 module as well. Programming can be done only by using SAP-300

display module locally or by HART (REMOTE PROGRAMMING) communication system remotely.

6.1. THE SAP-300 DISPLAY UNIT

The SAP-300 is a 64x128 dot-matrix LCD display which can be plugged into the transmitter. (Universal – usable in

other NIVELCO devices as well – provided that the system software supports SAP-300.)

Warning!

The SAP-300 module is based on LCD technology, so please make sure it is not exposed to permanent heat or direct

sunlight, in order to avoid damage of the display unit. If the instrument cannot be protected against direct sunlight or

high temperature that is beyond the standard operating temperature range of the SAP-300, please do not leave the

SAP display in the instrument.

BKI 11 ATEX 0012 X le00100a0600p_05 37 / 60

6.2. MEASURING WITH THE SAP-300 DISPLAY UNIT

Elements of the display:

1. Primary value (PV), in a dimension depended on the type of the instrument

2. SENSOR VOLTAGE – informative data in case of pH measurement

3. Trend direction arrows. The empty triangle shows when the measured value is small, the filled triangle shows

large-scale change. If none of the arrows are shown the measured value is constant.

4. Measured value in relation to measurement range (Sensor range) in a bargraph.

5. Temperature is shown for temperature compensation (measured by internal sensor).

After the dimension, the temperature compensation mode is indicated by inverse inscription:

Any possible errors during measurement are shown in the lower part of the display.

Manual mode (see 6.4.1.3)

Temperature simulation active (see 6.4.5.8)

Temperature sensor error. In this case the instrument will compensate to 25 ºC.

6. Indication of primary value simulation. In this case the display and output will show the values of the simulation

and not the measured value.

7. Measured value normalized to 25˚C, 760Hgmm and Salinity=0 – informative data (only for DO transmitters)

8. Oxygen saturation (only for DO transmitters)

During active simulation the critical measurement errors will be displayed to give information to the user.

pH measurement

F

ORP measurement

DO measurement

38 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

A. Calculated value of the output current. After the dimension, the mode of current output is indicated by inverse

inscription:

Manual mode (see 6.4.2.1)

H

HART address is not 0, so output current has become overwritten to 4mA (see 6.4.2.1)

Analogue transmission reacts to a programmed failure condition if an upper or lower fault current is programmed.

(see 6.4.2.4)

B. Output range (4…20mA) indicated in a bargraph.

C. Relay state indication: if deenergized – C1 closed, C2 open, there is no indication. If RELAY message is visible, the relay is energised – C2 closed, C1 open.

D. Indication of Menu Lock:

If key symbol is visible, the unit is protected with a password. When entering the menu, the instrument asks for the correct password.

If REM message is visible, the instrument is in remote programming mode and the menu cannot be accessed.

Errors occurred during the measurement can be seen at the bottom line of the display.

BKI 11 ATEX 0012 X le00100a0600p_05 39 / 60

Information displays:

Press button to cycle between the information displays.

1. The general information display (DEV. INFO): overall

running time (OV. RUN TIME), run time after power on

(RUN TIME), type of interface (INTERFACE), relay

(RELAY) and logger (LOGGER) indication.

2. Sensor information: time passed after last sensor

change, slope and offset after sensor change, time

passed after last calibration, slope and offset at last

calibration, minimum / maximum temperature of the

sensor.

In case of DO measurement in addition to these:

atmospheric pressure (PRESSURE) and salinity

(SALINITY).

3. Relay information: number of switchings, total energised

time (C2 closed) (only if there is a relay in the unit).

The informative display switches back to main screen after 30

seconds.

By pressing the

button the user can get back to main screen at

any time.

Pressing the E button in any of the displays the user can enter to

menu. After exiting the menu always the main screen will be

shown.

Information display of pH

measurement

RUN TIME: 0.1h

OV. RUN TIME: 1.0h

RELAY: YES

INTERFACE: HART

- DEV. INFO ---0:1.00

LOGGER: NO

EN. TIME 15.2h

SW. COUNT 11

STATE: ON

--- RELAY INFO ------

T : 26.5°C

Io: 12.00mA

RELAY

0

F

700mV

S1: 00mV

RUN TIME: 42d

RUN TIME: 5d

-- LAST CALIBRATION -

--- SENSOR INFO -----

SC: 03mV

T: -5°C/ 70°C

Information display of ORP

measurement

Information display of DO

measurement

40 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

6.3. PROGRAMMING WITH THE SAP-300 DISPLAY MODULE

When entering the menu the instrument makes a copy of the actual parameters, all changes are done to this duplicated parameter set. During programming the

instrument keeps measuring and transmitting with the current (and intact) parameter set. After exiting the menu the instrument replaces the original parameters with

the new parameter set and will measure according the new parameters. This means that the change of the parameters does not become immediately effective when

pressing the E button!

Entering the menu can be done by pressing the E button while exiting the menu can be done by pressing the button.

If the instrument is left in programming mode after 30 mins it will automatically return to measuring mode. If the SAP display is removed during programming the

instrument immediately returns to measuring mode.

As programming with SAP-300 (manual programming) and HART (remote mode) programming is not possible at the same time use only one programming method

at a time. Measured values can be read out through HART at any time

6.3.1. Components of the programming interface

The parameters of the instrument are grouped according to their functions. The programming interface consists of lists, dialog windows, edit windows and report

windows.

Lists

Navigation between the lines of a list can be done by pressing / buttons. Pressing the E button

activates a list item. Selected list item is marked with inverse colour. Exit from a list by pressing the

button.

Menu list

Menu list is a specialized list. Its characteristic is that upon selecting a list item we directly get into another list,

and these lists are opening from each other in different levels.

The menu header (1) helps to navigate.

Entering the menu can be done by pressing the E button. Navigation between the menu items can be done

by pressing the

/ buttons. Enter to the selected menu by pressing the E button. The selected list item

is marked with inverse colour.

Exit from a submenu with

button. Pressing the button in the main menu will exit programming mode and

the instrument will return to measuring mode.

BKI 11 ATEX 0012 X le00100a0600p_05 41 / 60

Dialog window

The system sends messages or warnings using dialog windows. These usually can be acknowledged by

pressing the

button or the user can choose between two options (usually YES or NO) by pressing /

buttons. In some cases to correct an error one of the parameters has to be changed

WARNING

LOAD DEFAULT TO

PARAMETER TABLE!

ARE YOU SURE?

[YES] [NO]

Edit window

An edit window is used for modifying a numeric parameter value. The selected character can be changed

using the

/ buttons. The cursor can be moved to left, using the button.

The direction of the cursor movement through the digits is right to left. Changed value can be validated by

pressing the E button. The software checks if the entered value is appropriate, exiting the edit window is only

possible after entering a correct value. If the entered value is uninterpretable the software sends an error

message in the bottom line (1) of the display. The display gives the same error message, independently of the

measured value and the measurement principle.

PV: primary Value

Edit window – button combinations

In the edit window the following button combinations are available:

1. Recalling the parameters to the state before editing ( + , pressed for 3 secs);

2. Recalling default parameters (

+ , pressed for 3 secs);

3. Inserting (currently) measured value to the edit window (

+ , pressed for 3 secs)

Only for certain parameters!

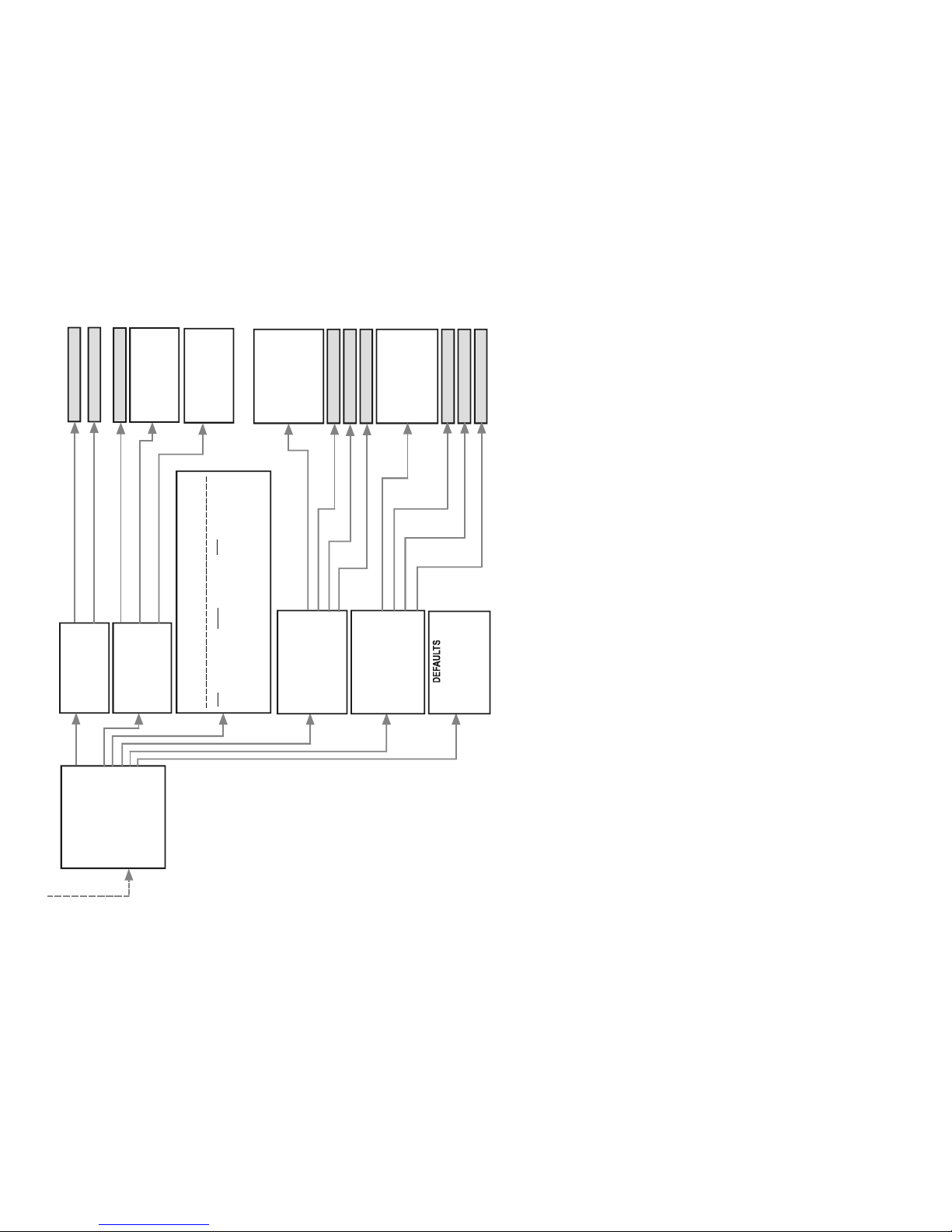

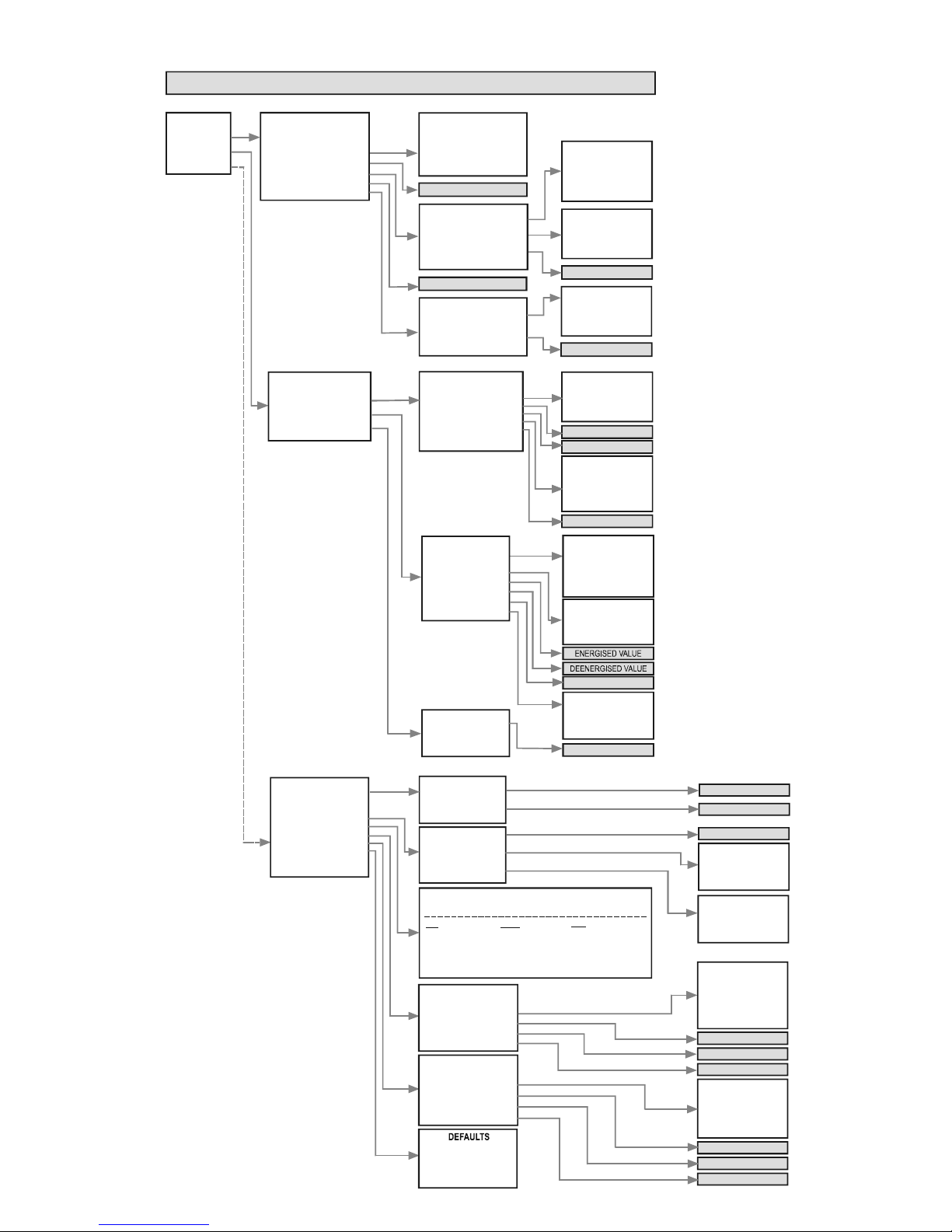

6.3.2. Menu structure

Main menu

BASIC SETUP Parameter group of the basic measurement parameters

OUTPUT SETUP Parameter group of the output parameters

SERVICE Service functions, calibration, test and simulation

42 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

6.4. PROGRAMMABLE FEATURES DESCRIPTION

6.4.1. Basic measurement settings

6.4.1.1 Measuring unit (Only for DO measurement)

Parameter: P02: b

Menu path: BASIC SETUP / MEASURING UNIT Default value:

Dimension of PV: primary value. ppm

ppm

mg/l

%sat

Description:

Primary values are the same in case of displaying ppm and mg/l, only

displayed and transmitted dimension changes. Large number on the screen

follows the dimension of ppm and mg/l in the setting of ppm and mg/l.

In case of choosing %sat, large numbered primary value indicates the oxygen

saturation.

6.4.1.2 Damping time

Parameter: P20

Menu path: BASIC SETUP / DAMPING TIME Default value:

pH

measurement

ORP

measurement

DO

measurement

Description: Damping time is used to damp the unwanted fluctuations of the output and

display.

If the measured value changes rapidly the new value will settle with 1%

accuracy after this set time

2 sec 2 sec 2 sec

6.4.1.3 Temperature compensation mode

Parameter: P06: a

Menu path: BASIC SETUP / TEMP. COMPENSATION / MODE Default value:

AUTO

Description: Mode of the temperature compensation

AUTO Compensation is done with the value measured by the temp. sensor.

MANUAL Compensation is done with a predefined temperature value

(see 6.4.1.5)

OFF No compensation

BKI 11 ATEX 0012 X le00100a0600p_05 43 / 60

6.4.1.4 Temperature compensation unit

Parameter: P02: a

Menu path: BASIC SETUP / TEMP. COMPENSATION / UNIT Default value:

Description: Dimension of the temperature measurement

ºC

ºF

ºC

6.4.1.5 Temperature compensation fixed value

Parameter: P07

Menu path: BASIC SETUP / TEMP. COMPENSATION / MANUAL VALUE Default value:

Description: Value of the manual temperature compensation (see 6.4.1.3)

25 ºC

6.4.1.6 Salinity correction value (Only for DO measurement)

Parameter: P23

Menu path: BASIC SETUP / SALTINITY CORRECTION / MANUAL VALUE Default value:

Description: Value of the salinity correction in ppt (parts per thousand)

0 ppt

6.4.1.7 Pressure correction unit (Only for DO measurement)

Parameter: P02: c

Menu path: BASIC SETUP / PRESSURE CORRECTION / UNIT Default value:

Hgmm

Description: Dimension of the atmospheric pressure correction

Hgmm Compensation is performed by the measured value of the

temperature sensor

bar Compensation is performed by a fix given temperature value.

kPa Compensation is off

Measurement unit is required to be selected first and value should be entered after this.

6.4.1.8 Pressure correction value (Only for DO measurement)

Parameter: P22

Menu path: BASIC SETUP / PRESSURE CORRECTION / MANUAL VALUE Default value:

Description: Value of the atmospheric pressure correction

Measurement unit is required to be selected first and value should be entered after this.

760 Hgmm

44 / 60 le00100a0600p_05 BKI 11 ATEX 0012 X

6.4.2. Analogue output

6.4.2.1 Output current mode

Parameter: P12: b

Menu path: OUTPUT SETUP / ANALOG OUTPUT / CURRENT MODE Default value:

AUTO

Description: Transmission mode of the current output [AUTO, MANUAL]

AUTO The output current is calculated from the measured value, output is

active.

MANUAL The output current is fixed at a constant (set) value (see 6.4.2.5). In

this mode the setting of the error current (see 6.4.2.4) is irrelevant.

The set (current) value overwrites the 4mA output of HART

multidrop mode!

6.4.2.2 Output current value 4mA

Parameter: P10

Menu path: OUTPUT SETUP / ANALOG OUTPUT / 4mA VALUE Default value:

pH measurement ORP measurement DO measurement

Description: Measured value assigned to 4mA

0 pH - 1000 mV 0 ppm

6.4.2.3 Output current value 20 mA

Parameter: P11

Menu path: OUTPUT SETUP / ANALOG OUTPUT / 20mA VALUE Default value:

pH measurement ORP measurement DO measurement

Description: Measured value assigned to 20mA

14 pH 1000 mV 8.24 ppm

6.4.2.4 Output current error mode

Parameter: P12: a

Menu path: OUTPUT SETUP / ANALOG OUTPUT / ERROR MODE Default value:

HOLD

Description: Error indication by the current output

HOLD Error indication has no effect on the output current.

3.8 mA Error indication: the output current gets 3.8mA.

22 mA Error indication: the output current gets 22mA

Attention! Also see chapter 6.4.2.1!

BKI 11 ATEX 0012 X le00100a0600p_05 45 / 60

6.4.2.5 Fixed output current

Parameter: P08

Menu path: OUTPUT SETUP / ANALOG OUTPUT / MANUAL VALUE Default value:

4 mA

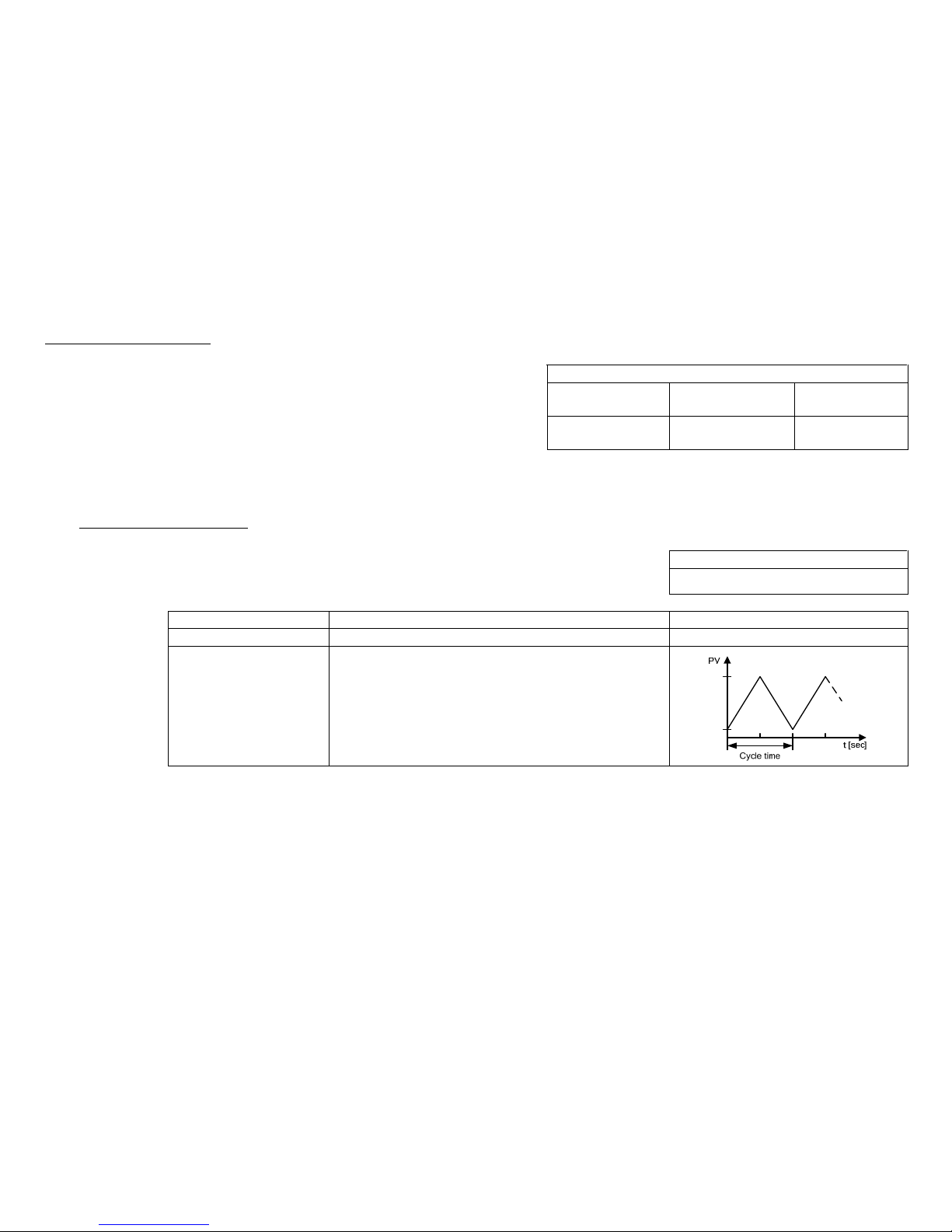

Description: Parameter for setting the fixed output current